Mitsubishi Electric EW-50A, EW-50E Installation And Instruction Manual

Air Conditioning Control System

Centralized Controller

EW-50A/EW-50E

Before installing the controller, please read this Installation Manual carefully to ensure proper operation.

Retain this manual for future reference.

Installation and Instructions Manual

Safety notes are marked with WARNING

or

CAUTION, depending on the severity

of possible consequences that may result

when the instructions are not followed

exactly as stated.

Proper installation is important for your

safety and proper functioning of the units.

Thoroughly read the following safety

precautions prior to installation.

Contents

1. Safety precautions .......................................................................2

1-1. General precautions ....................................................................................... 2

1-2. Precautions for unit installation ....................................................................... 3

1-3. Precautions for electrical wiring ...................................................................... 3

1-4. Precautions for relocating or repairing the unit ............................................... 4

1-5. Additional precautions .................................................................................... 4

2. Introduction ..................................................................................6

2-1. Part names ..................................................................................................... 6

3. Package contents .........................................................................8

4. Specifications ...............................................................................9

4-1. Product specifications ..................................................................................... 9

4-2. External dimensions ..................................................................................... 10

4-3. Product features ............................................................................................11

5. System configuration ..................................................................14

5-1. System restrictions ....................................................................................... 14

5-2. M-NET power feeding coefficient .................................................................. 15

5-3. System configuration example ..................................................................... 16

5-4. Number of connectable units ........................................................................ 20

5-5. Setting M-NET address for various devices ................................................. 21

6. Installation ..................................................................................23

6-1. Items not included ........................................................................................ 24

6-2. Items sold separately .................................................................................... 24

6-3. M-NET transmission cable length ................................................................. 25

6-4. Installation space .......................................................................................... 26

6-5. Installation procedures ................................................................................. 27

7. Wiring connections .....................................................................30

7-1. Removing/reinstalling the service cover ....................................................... 30

7-2. Connecting AC power cables and M-NET transmission cables.................... 32

7-3. Connecting the LAN cable ............................................................................ 34

7-4. Confirming the LAN transmission delay time ................................................ 34

8. Initial settings .............................................................................36

8-1. Logging in to the Web Browser for Initial Settings ........................................ 36

8-2. Initial settings on the Web browser ............................................................... 36

8-3. Quick IP address setting ............................................................................... 37

8-4. Network settings on the Web browser .......................................................... 38

9. Test run ......................................................................................39

9-1. Collective operation ON/OFF ....................................................................... 39

10. External input/output ..................................................................40

10-1. External signal input/output function ........................................................... 40

10-2. Pulse signal input function .......................................................................... 44

11. Maintenance ...............................................................................45

11-1. Inspection and maintenance ....................................................................... 45

11-2. Back up/import settings data.......................................................................46

11-3. Software update .......................................................................................... 48

11-4. Software information ................................................................................... 51

12. Error code list .............................................................................52

12-1. M-NET errors .............................................................................................. 52

12-2. Errors between AE-200 and AE-50 (EW-50) .............................................. 54

2

WT07417X01

1. Safety precautions

►Thoroughly read the following safety precautions prior to installation.

►Observe these precautions carefully to ensure safety.

►After reading this manual, pass the manual on to the end user to retain for future

reference.

►The user should keep this manual for future reference and refer to it as necessary. This

manual should be made available to those who repair or relocate the units. Make sure

that the manual is passed on to any future air conditioning system user.

►All electrical work must be performed by qualified personnel.

: indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

: indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

: addresses practices not related to personal injury, such as product

and/or property damage.

1-1. General precautions

Do not install the controller in areas where large amounts of oil, steam, organic solvents,

or corrosive gases (such as ammonia, sulfuric compounds, or acids), or areas where

acidic/alkaline solutions or special chemical sprays are used frequently. These substances

may significantly reduce the performance and corrode the internal parts, resulting in

electric shock, malfunction, smoke, or fire.

To reduce the risk of injury, electric shock, or fire, do not alter or modify the controller.

To reduce the risk of electric shock, malfunction, smoke, or fire, do not touch the electrical

parts or USB memory with wet fingers.

To reduce the risk of injury or electric shock, before spraying a chemical around the

controller, stop the operation and cover the controller.

To reduce the risk of burns, do not touch the electrical parts with bare hands during and

immediately after operation.

To reduce the risk of injury, keep children away while installing, inspecting, or repairing the

controller.

Test runs, inspection, and service must be performed by qualified personnel in accordance

with this manual. Incorrect use may result in injury, electric shock, malfunction, or fire.

If you notice any abnormality, stop the operation and turn off the controller. Continuing the

operation may result in electric shock, malfunction, or fire.

Properly install all required covers to keep moisture and dust out of the controller. Dust

accumulation and the presence of water may result in electric shock, smoke, or fire.

To reduce the risk of frostbite, burns, injury, or electric shock, keep the equipment out of

the reach of children.

3

WT07417X01

To reduce the risk of fire or explosion, do not place flammable materials or use flammable

sprays around the controller.

To reduce the risk of electric shock or malfunction, do not touch the switches or buttons

with a sharp object.

To reduce the risk of injury, electric shock, or malfunction, avoid contact with the sharp

edges of certain parts.

To reduce the risk of injury, wear protective gear when working on the controller.

Wear protective gear when working on the controller. High-voltage parts pose a risk of

electric shock, and high-temperature parts pose a risk of burns.

1-2. Precautions for unit installation

Do not install the controller where there is a risk of flammable gas leaks. If flammable gas

accumulates around the controller, it may ignite and cause a fire or explosion.

Properly dispose of the packing materials. Plastic bags pose a suffocation hazard to

children.

Take appropriate safety measures against earthquakes to prevent the controller from

causing injury.

To prevent injury, install the controller on a flat surface strong enough to support its

weight.

To reduce the risk of short circuits, current leakage, electric shock, malfunction, smoke, or

fire, do not install the controller in a place exposed to water or in a condensing

environment.

The controller must be installed by qualified personnel according to the instructions

detailed in this manual. Improper installation may result in electric shock or fire.

1-3. Precautions for electrical wiring

To reduce the risk of malfunction, smoke, fire, or damage to the controller, do not connect

the power cable to the signal terminal block.

To reduce the risk of malfunction, smoke, fire, or damage to the controller, do not apply a

power supply voltage in excess of that specified.

Properly secure the cables in place and provide adequate slack in the cables so as not to

stress the terminals. Improperly connected cables may break, overheat, and cause smoke

or fire.

To reduce the risk of injury or electric shock, switch off the main power before performing

electrical work.

4

WT07417X01

Electrical work must be performed by qualified personnel in accordance with local

regulations and the instructions provided in this manual. Only use specified cables and

dedicated circuits. Inadequate power source capacity or improper electrical work will

result in electric shock, malfunction, or fire.

To reduce the risk of electric shock, install an overcurrent breaker and an earth leakage

breaker on the power supply. To reduce the risk of electric shock, smoke, or fire, install an

overcurrent breaker for each controller.

Only use properly rated breakers (earth leakage breaker, local switch <switch + fuse that

meets local electrical codes>, moulded case circuit breaker, or overcurrent breaker). The

use of improperly rated breakers or the substitution of fuses with steel or copper wire may

result in electric shock, malfunction, smoke, or fire.

To reduce the risk of current leakage, overheating, smoke, or fire, use properly rated

cables with adequate current carrying capacity.

Proper grounding must be provided by qualified personnel. Do not connect the protective

ground wire to a gas pipe, water pipe, lightning rod, or telephone wire. Improper grounding

may result in electric shock, smoke, fire, or malfunction due to electrical noise

interference.

To reduce the risk of short circuits, electric shock, or malfunction, keep wire pieces and

sheath shavings out of the terminal block.

To reduce the risk of short circuits, current leakage, electric shock, or malfunction, keep

the cables out of contact with controller edges.

To reduce the risk of electric shock, malfunction, or fire, seal the gap between the cable

and the end of the conduit tube with putty.

To reduce the risk of injury, do not touch the burrs of the knockout holes.

1-4. Precautions for relocating or repairing the unit

The controller must be repaired or moved only by qualified personnel. Do not disassemble

or modify the controller. Improper installation or repair may result in injury, electric shock,

or fire.

To reduce the risk of short circuits, electric shock, malfunction, or fire, do not touch the

circuit board with tools or with your hands, and do not allow dust to accumulate on the

circuit board.

1-5. Additional precautions

To avoid damage to the controller, use appropriate tools to install, inspect, or repair the

controller.

To prevent unauthorized access, always use a security device such as a VPN router when

connecting to the Internet.

5

WT07417X01

Take appropriate measures against electrical noise interference when installing the

controller in hospitals or radio communication facilities. Inverter, high-frequency medical,

or wireless communication equipment as well as power generators may cause the air

conditioning system to malfunction. The air conditioning system may also adversely affect

the operation of these types of equipment by creating electrical noise.

To avoid malfunction, do not bundle power cables and signal cables together or place

them in the same metallic conduit.

To avoid damage to the controller, do not overtighten the screws.

To avoid deformation and malfunction, do not install the controller in direct sunlight or

where the ambient temperature may exceed 55°C (131°F) or drop below -10°C (14°F).

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety. Children should be supervised to ensure that they do not play

with the appliance.

6

WT07417X01

2. Introduction

EW-50A/EW-50E is a total management system.

Any connected air conditioning systems can be operated or monitored on the Web browser. EW-50A/EW-50E can

also be used as an expansion controller of AE-200A/AE-200E.

By connecting AE-200A/AE-200E, up to 200 indoor units and other equipment can be controlled.

Hereafter, AE-200A and AE-200E, unless otherwise specified, will be called “AE-200.”

Hereafter, AE-50A and AE-50E, unless otherwise specified, will be called “AE-50.”

Hereafter, EW-50A and EW-50E, unless otherwise specified, will be called “EW-50.”

Note: A PC is required to monitor and operate the air conditioning units.

Note: The required licenses vary, depending on the functions to be used. Consult your dealer.

Note: For how to use the Web browser, refer to the Web browser instruction books (separate volume).

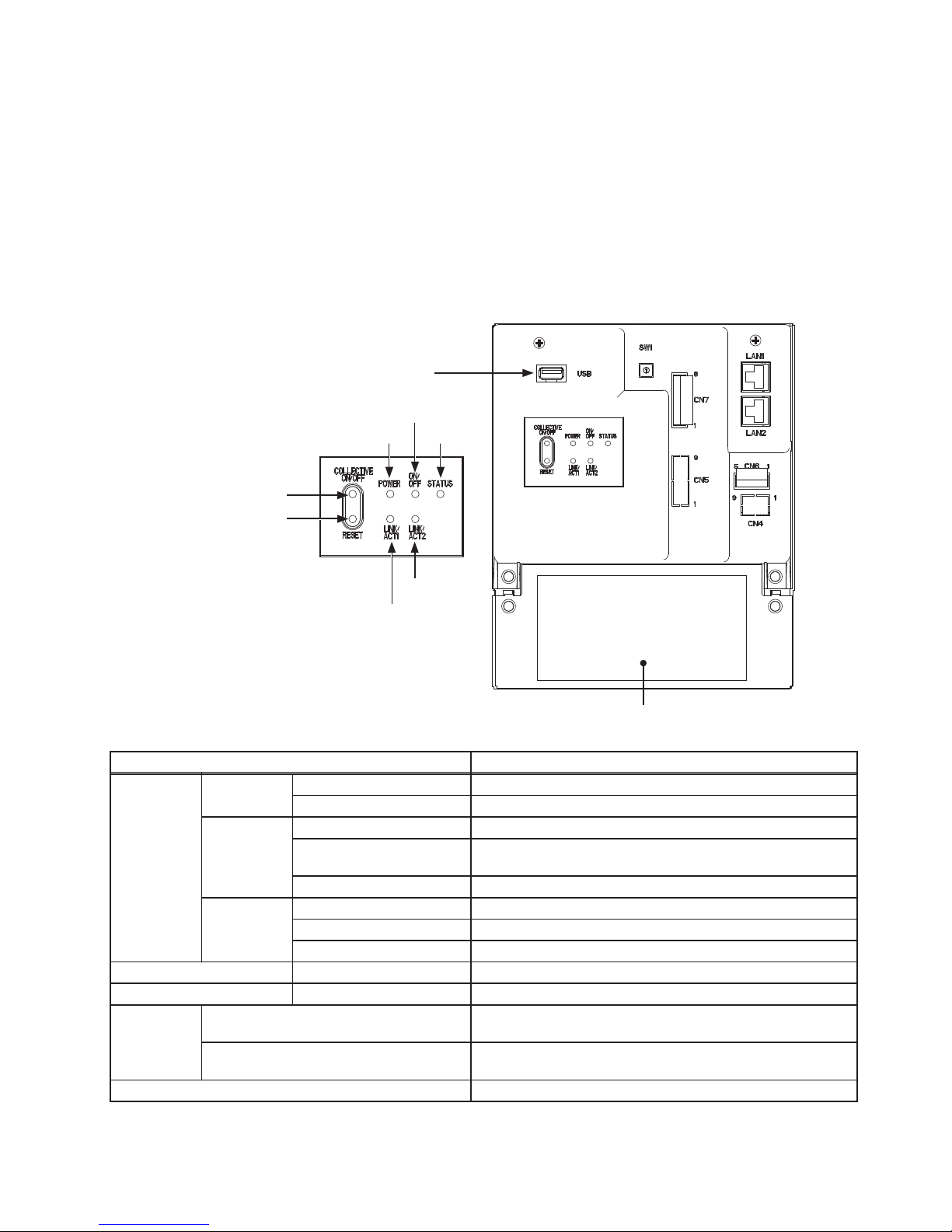

2-1. Part names

Item Description

LED

Power

Lit in green Power ON

Unlit Power OFF

ON/OFF

Lit in green One or more air conditioning units are ON.

*1

Blink in green

One or more air conditioning units or other related equipment

are in error.

Unlit All air conditioning units are OFF.

*1

Status

Blink in orange Startup error

Blink in blue Software update in progress

Blink in pink Software update failed

LINK/ACT1 Blink in orange Data transmission in progress (LAN1)

LINK/ACT2 – Unused

Push switch

ON/OFF

Used to turn the connected air conditioning units and the other

related equipment ON and OFF all at once.

Reset

Used to reboot the EW-50. (This will not affect the operation

status of the air conditioning units.)

USB port Unused

*1 The operation status of the other equipment are excluded.

USB port

(unused)

Power

LINK/ACT1

ON/OFF

LINK/ACT2

Status

Push switch ON/OFF

Service cover

Push switch Reset

7

WT07417X01

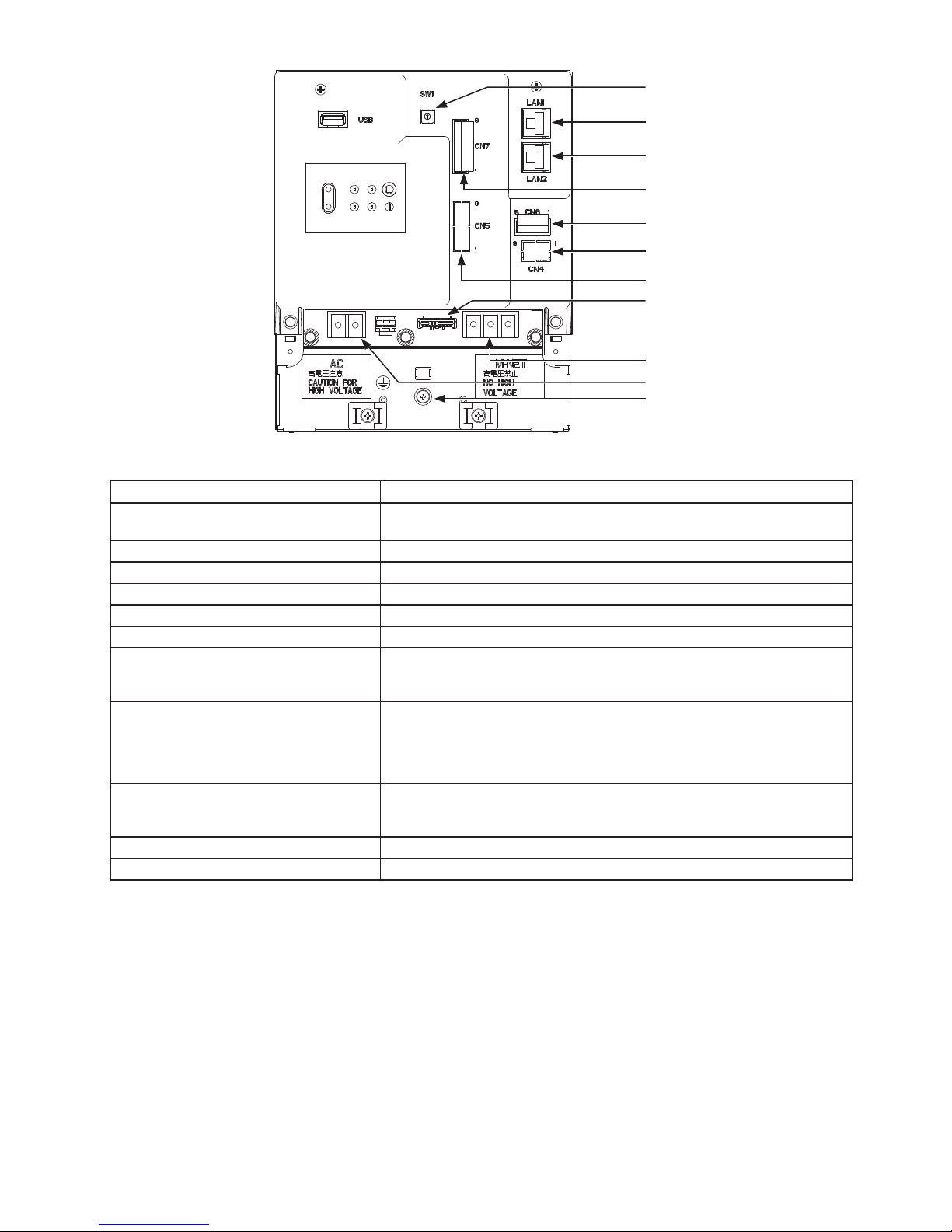

Item Description

SW1

IP addresses can be easily set with SW1. Refer to section 8-3 “Quick IP

address setting” for details.

LAN1 Connects to other units of equipment over the LAN via a HUB.

LAN2 Unused

CN7 (Pulse Input)

*1

Connects to metering devices using the supplied connector.

CN6 Unused

CN4 Unused

CN5 (External I/O)

*1

Connects to an external input/output adapter PAC-YG10HA-E.

(When connecting an external input/output adapter PAC-YG10HA-E, cut out

the knockout hole.)

CN21 (M-NET power jumper)

Connects to the M-NET power jumper to supply power (default).

* If another system controller is connected to the same M-NET system and the power

consumption coefficient is 1.5 or above, disconnect the M-NET power jumper to supply

power from the separately-sold power supply unit. (Refer to section 5-2 “M-NET power

feeding coefficient” for details.)

TB3 (M-NET A, B, S) (M3.5)

M-NET transmission terminal block

Connects to M-NET transmission cables from the outdoor unit.

(A, B: Non-polarized, S: Shield)

TB1 (Power source AC L/L1, N/L2) (M3.5) Connects to the power cable.

Ground (M4) Connects to the protective ground wire.

*1 Refer to chapter 10 “External input/output” for details.

* Back side with the service cover removed

LAN1

LAN2

(Unused)

CN7

CN6

(Unused)

CN4

(Unused)

CN5

TB3

Ground

CN21

TB1

SW1

8

WT07417X01

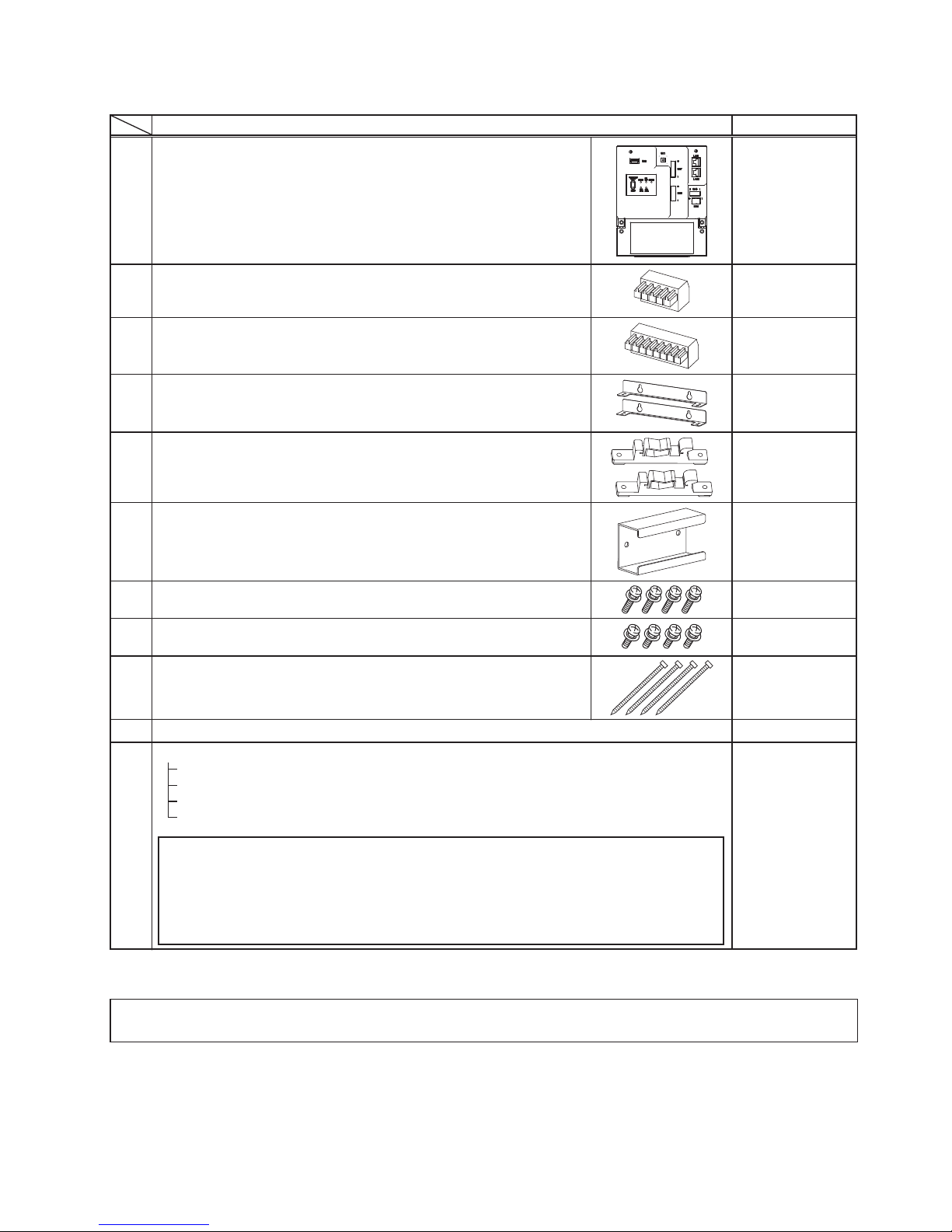

3. Package contents

The following items are included in the package.

Package contents Qty.

(1)

EW-50 1

(2)

Connector (CN6)

(Unused)

1

(3)

Connector (CN7)

(Used for pulse input)

1

(4)

L-fitting

2

(5)

DIN rail attachment

(for attaching DIN rail of 35 mm (1-7/16 in) width)

2

(6)

DIN rail auxiliary bracket 1

(7)

Roundhead screw (M3 × 12)

*1

(for fixing DIN rail attachment)

4

(8)

Roundhead screw (M3 × 6)

*1

(for fixing DIN rail auxiliary bracket or L-fitting)

4

(9)

Cable tie

4

(Two are spare.)

(10)

Installation and Instructions Manual (this manual)

*2

1

(11)

CD-ROM

*2

Installation and Instructions Manual (this manual)

Instruction Book (Web Browser for Initial Settings)

Instruction Book (Web Browser for System Maintenance Engineer)

Instruction Book (Web Browser for User)

Note

● The CD-ROM can only be played on a CD-drive or a DVD-drive. Do not attempt to play the

CD-ROM on an audio CD player as this may damage your ears and/or speakers.

● Each document is in PDF format. Viewing documents requires a computer with Adobe

®

Reader

®

or Adobe® Acrobat® installed. “Adobe® Reader®” and “Adobe® Acrobat®” are

registered trademarks of Adobe Systems Incorporated.

1

*1 ISO metric screw thread

*2 For details about the apportioned electricity billing function, refer to the Instruction Book that comes with the “Charge” license.

Notes on the SD card installed on the EW-50

● Do not use the SD card installed on the EW-50 for any other equipment.

9

WT07417X01

4. Specifications

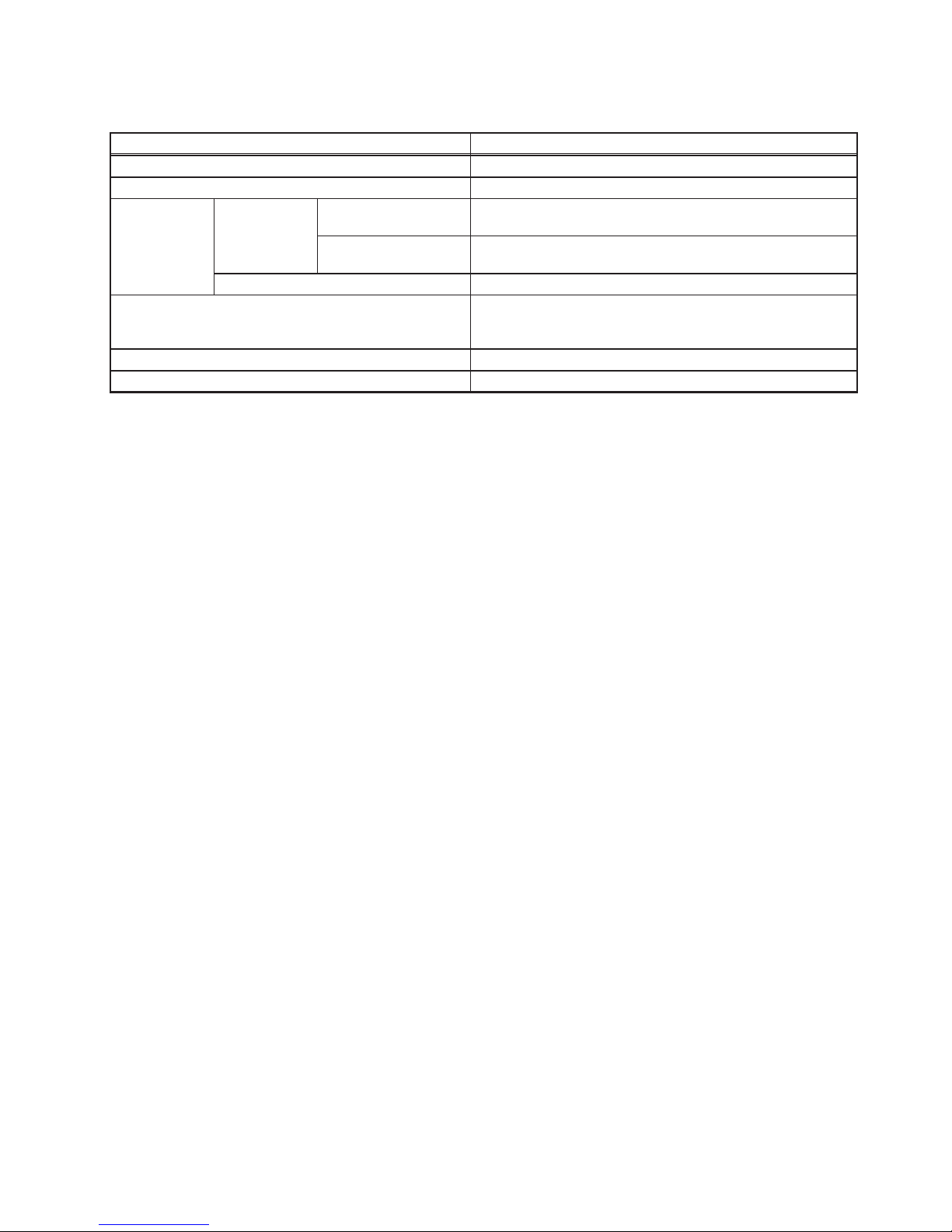

4-1. Product specifications

Item Specifications

Power supply 100–240 VAC ± 10%; 50/60 Hz Single-phase

M-NET power feeding coefficient 1.5

Ambient

conditions

Temperature

Operating temperature

range

-10°C – +55°C (+14°F – +131°F)

Storage temperature

range

-20°C – +60°C (-4°F – +140°F)

Humidity 30%–90% RH (Non-condensing)

Dimensions (W × H × D)

172 × 209 × 92 mm

(6-13/16 × 8-4/16 × 3-10/16 in)

* 253 × 172 × 92 mm (10 × 6-13/16 × 3-10/16 in) when using L-fittings

Weight 1.7 kg (4 lbs)

Installation conditions Only in a metal control box indoors

10

WT07417X01

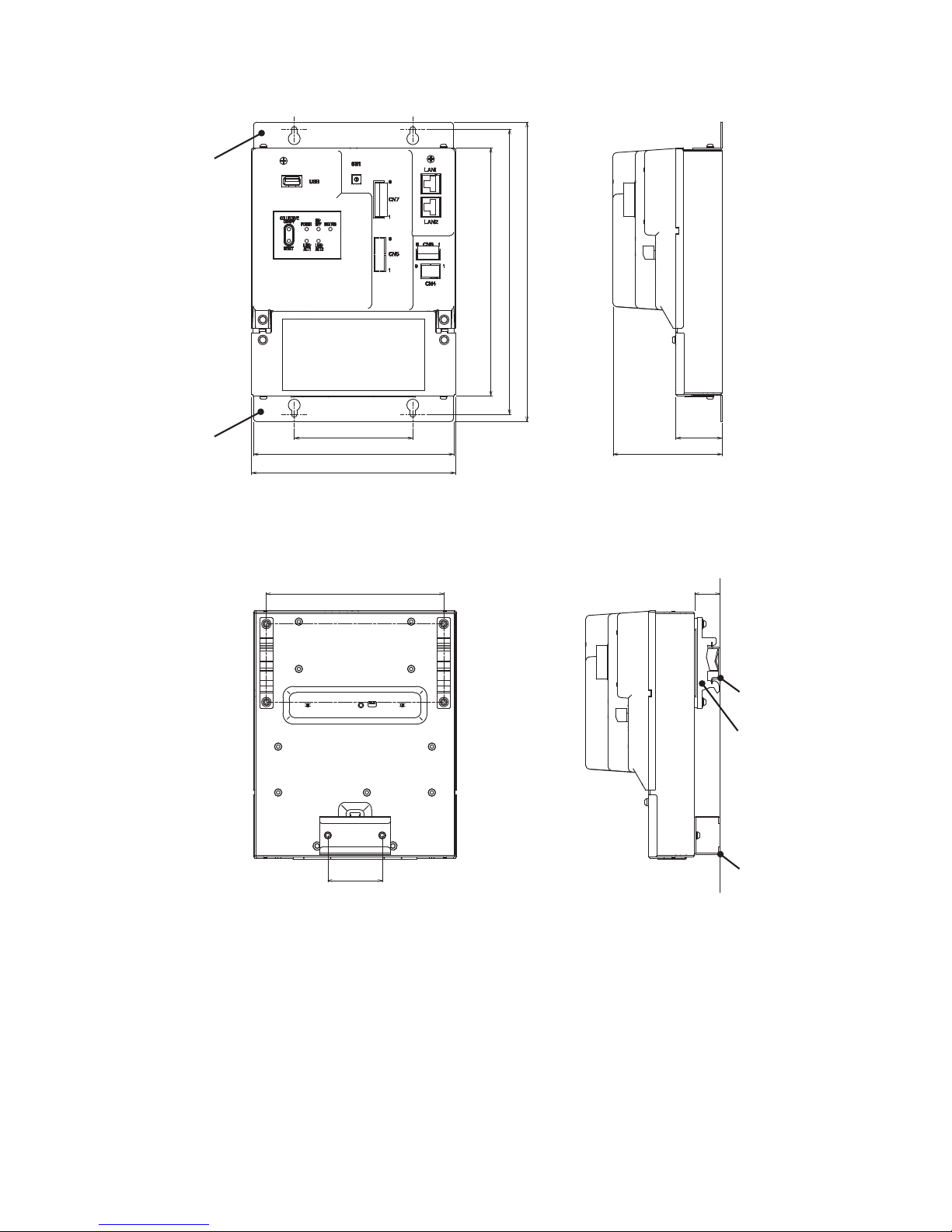

4-2. External dimensions

(1) When using L-fittings

(2) When using DIN rail

Unit: mm (in)

100 (3-15/16)

169 (6-11/16)

172 (6-13/16)

209 (8-4/16)

240 (9-8/16)

252 (9-15/16)

92 (3-10/16)

38

(1-8/16)

L-fitting

(supplied)

L-fitting

(supplied)

DIN rail attachment

(supplied)

46 (1-13/16)

DIN rail auxiliary

bracket

(supplied)

DIN rail

23 (15/16)

150 (5-15/16)

11

WT07417X01

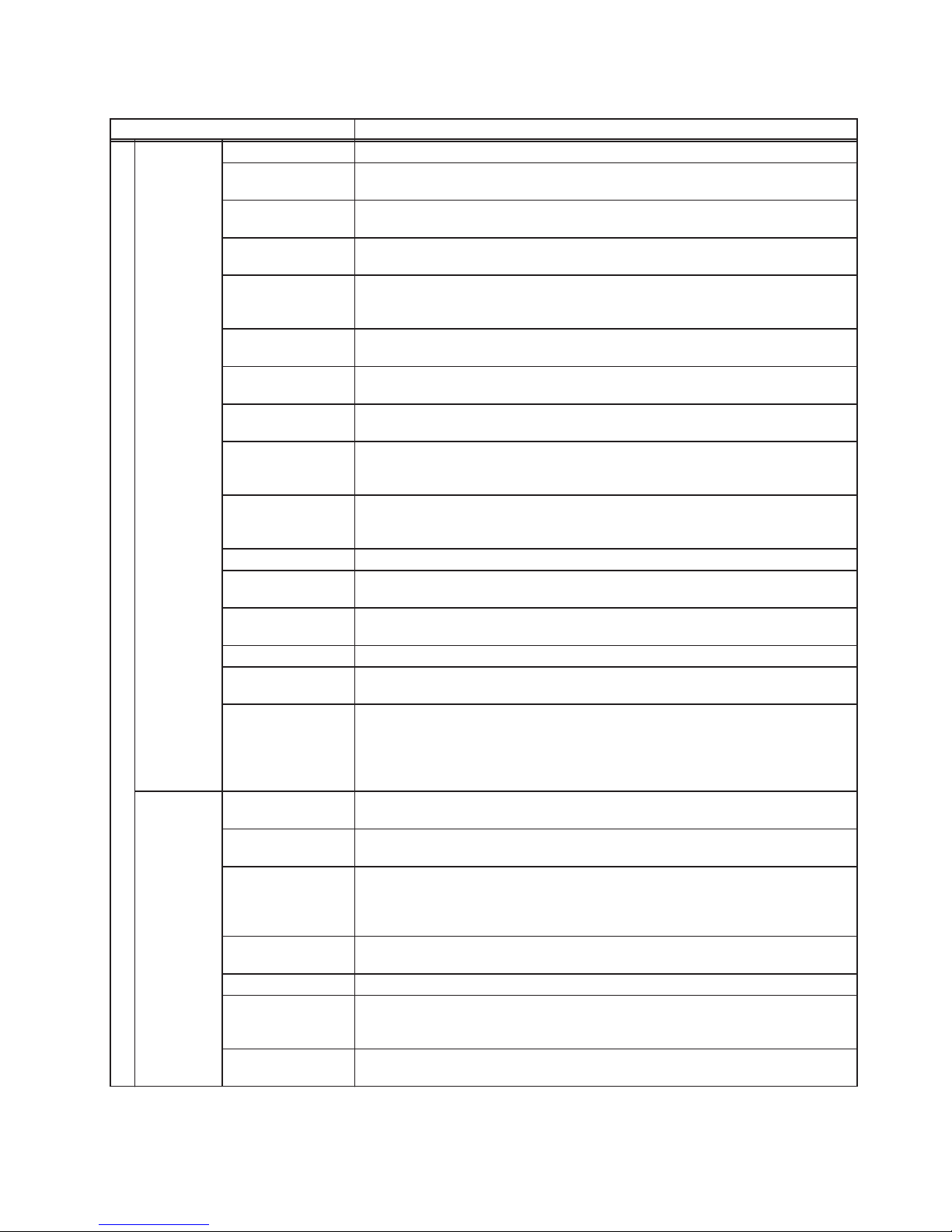

4-3. Product features

The table below summarizes the available functions and settings on the Web browser. Refer to the Web browser

instruction books (separate volume) for details.

Function Description

User's operation functions

Operation

*1

ON/OFF The ON/OFF operation can be performed collectively or for each group or block.

Operation mode

The operation mode can be switched collectively or for each group or block. (The

available operation modes depend on the unit model.)

Set temperature

The set temperature can be set collectively or for each group or block. (The

available set temperatures depend on the unit model.)

Air direction

The air direction can be changed collectively or for each group or block. (The

available air directions depend on the unit model.)

Fan speed

The fan speed can be changed collectively or for each group or block. (The number

of available fan speeds depend on the unit model.) Auto mode is available only on

the models that support Auto mode.

Fan speed

(LOSSNAY unit)

The fan speed (3 speeds and Auto) can be changed.

Fan mode (HWHP

unit)

The fan can be set to keep rotating even while the unit is stopped to avoid snow

accumulation on the fan guard during the winter.

Ventilation mode

(LOSSNAY unit)

The ventilation mode can be switched.

Interlocked ventilator

(LOSSNAY unit)

ON/OFF

Interlocked LOSSNAY units (if any) can be operated or stopped collectively or for

each group or block.

Prohibition of local

remote controller

operation

Some operations or settings from the local remote controllers can be prohibited

collectively or for each group or block.

Filter sign reset Filter sign can be reset collectively or for each group or block.

Schedule

Weekly, annual, and today’s schedules can be set collectively or for each group or

block.

Schedule (Available/

Not Avail.)

The scheduled operations can be enabled or disabled.

Malfunction reset Displayed errors can be reset.

Clear malfunction

log

Displayed unit errors and communication errors can be cleared.

External input

Using external contact signals, the following collective operations can be controlled:

Demand level, Emergency stop, ON/OFF operation, and Prohibit/Permit local

remote controller operation.

* A separately-sold external input/output adapter (PAC-YG10HA-E) is required.

* Connect the external input/output adapter to each AE-200/AE-50/EW-50.

Monitor

*1

Energy Use Status

Displays and compares the energy-control-related status, such as electric energy

consumption, operation time, and outdoor temperature, in a graph.

Ranking

Displays the rankings in electric energy consumption and the fan operation time of

given indoor units in a bar graph.

Target Value Setting

Sets the target electric energy consumption values for the entire system for the

current year, each month, each day of the week, and each block. The set values

will be displayed in the graph on the [Energy Use Status] screen and the [Ranking]

screen.

Peakcut Control

Status

Displays the average electric power consumption and the control level.

Condition List Displays the operation status of each group.

Prohibition of local

remote controller

operation

Displays the icon to indicate that the operation is prohibited by the EW-50.

Measurement List

Displays the readings of the temperature sensor, humidity sensor, and metering

device.

12

WT07417X01

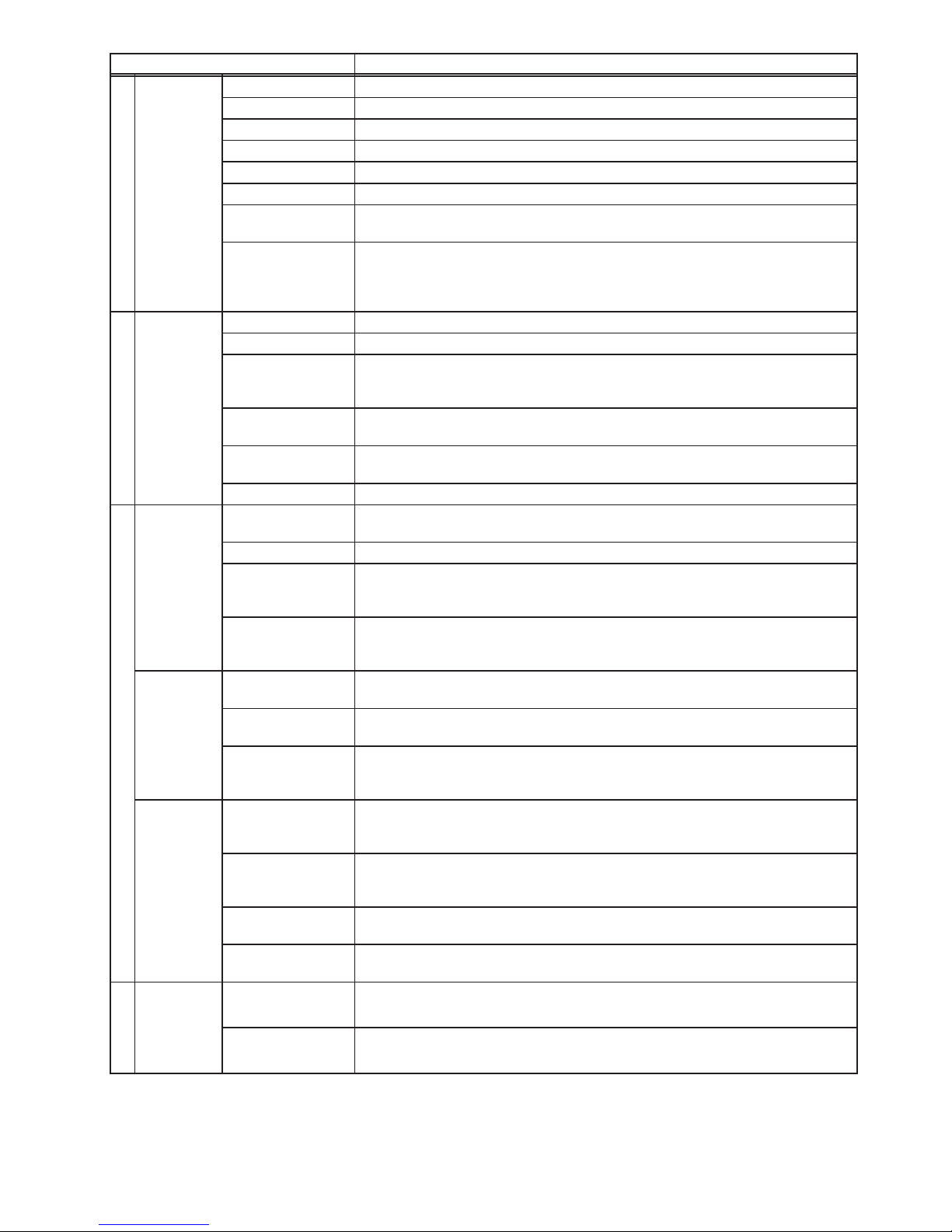

Function Description

User’s operation functions

Monitor

*1

Malfunction List Displays the address of the unit in error and error code.

Filter sign Indicates that the filter on the unit in a given group is due for cleaning.

AHC List Displays the input and output status of Advanced HVAC CONTROLLERs.

Free Contact List Displays the ON/OFF status of the indoor unit free contact.

Malfunction Log Displays unit errors and communication errors.

Send Mail Log Displays a list of error notification e-mail that have been sent.

Outdoor unit status

Displays outdoor unit capacity value, high pressure, and low pressure of each

outdoor unit.

External output

Outputs signals (ON/OFF, Error) to an external device.

* A separately-sold external input/output adapter (PAC-YG10HA-E) is required.

* The operation status of general equipment (via a DIDO controller (PAC-YG66DCA)) will not

be output.

Initial settings

Operation

*1

Date and time Sets the current date/time and daylight savings time.

License Registers license for optional functions.

Basic System

Sets unit name, unit ID, IP address, subnet mask, gateway, display format, M-NET

address, range of prohibited controllers, external input setting, and advanced

setting.

Groups

Registers air conditioning units, Air To Water (PWFY) units, LOSSNAY units, general

equipments, remote controllers, and sub system controllers to a group.

Interlocked

LOSSNAY

Interlocks the operation of indoor units and LOSSNAY units.

Blocks Registers groups to a block.

Function settings

Functions 1

*1

E-Mail

The e-mail server information, EW-50 e-mail information, and e-mail settings for the

error notification e-mail function and e-mail communication function can be set.

Peak Cut The Peak Cut method and control settings for outdoor and indoor units can be set.

Measurement

AI and PI controllers, temperature sensor, humidity sensor, and metering device can

be registered. The trend data format, error notification e-mail function settings, and

e-mail alarm function settings can be set.

Energy

Management

Settings

The settings related to energy-use-status display can be made.

Functions 2

*1

Set Temperature

Range Limit

The settable temperature range can be set.

Night Mode

Schedule

The start/end times for the Night mode (quiet operation) for outdoor units can be set.

System-changeover

This function switches the operation modes of the indoor units connected to the

same outdoor unit between cooling and heating based on the room temperature and

the set temperature. The target outdoor units and details for this function can be set.

Functions 3

*1

External

Temperature

Interlock

This function adjusts the set temperature based on the temperature difference

between the set temperature and the outdoor temperature. A maximum temperature

value to be added to the set temperature can be set for each group.

Night Setback

Control

This function performs cooling or heating operation when the room temperature

goes outside of the specified temperature range. The start/end times and

temperature range can be set for each group.

Interlock control

Interlock control between the connected devices can be performed by making

various settings. Up to 150 interlocking conditions can be set.

AHC Port Name

Settings

The names of the AHC analog/digital input/output ports can be set.

User settings

User settings

Maintenance user User name and password for maintenance users can be set.

Building manager User name, password, and available functions to building managers can be set.

13

WT07417X01

Function Description

Miscellaneous

Back up settings data Backed-up settings data can be restored from the PC.

Import settings data Backed-up settings data can be restored from a PC.

Group setting information/

Interlocked LOSSNAY information

The group setting information and interlocked LOSSNAY information are retained in

the hardware, even if power is turned off.

Malfunction log The malfunction log is retained in the hardware, even if power is turned off.

Scheduled operations

The scheduled operations set for each group are retained in the hardware, even if

power is turned off.

Current date and time

The current date and time are retained by the built-in capacitor when power is

turned off.

CSV output

The operation data, such as apportioning parameters and power consumption, can

be output.

Software Update

The software can be updated by inserting a CD or USB memory device in which the

update file is stored to a PC.

Time synchronization

Clocks on the controllers and the units that are under the control of the main system

controller are synchronized once a day (applicable only to the ones that support this

function).

*1 The item and range that can be operated or monitored depend on the unit model.

14

WT07417X01

5. System configuration

5-1. System restrictions

The software version of the AE-200, AE-50, and EW-50 units in a system must be the same. For details about how

to update the software, refer to section 11-3 “Software update”.

The restrictions vary, depending on the number of the controlled units, model of the connected units, and the

functions in use.

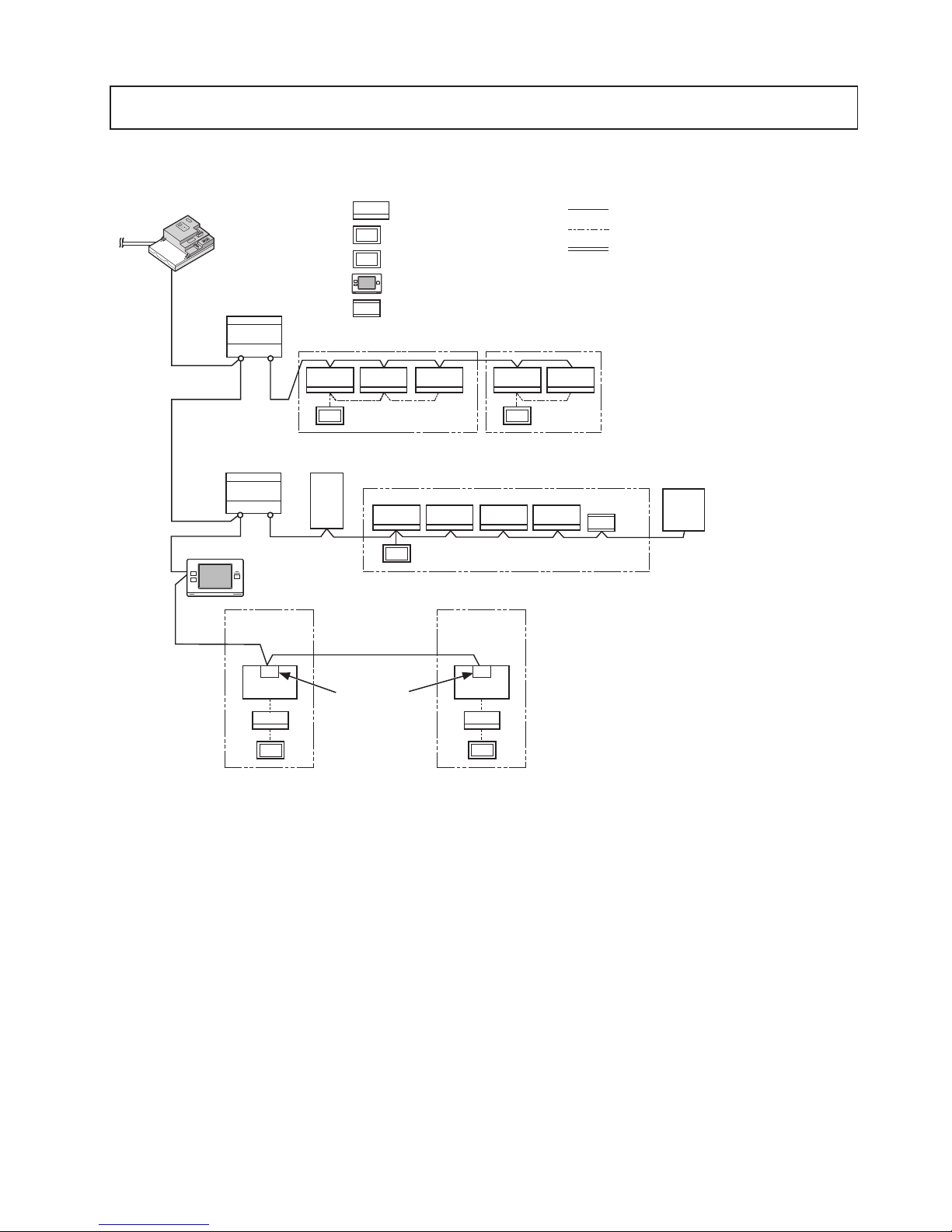

5-1-1. When not using an apportioned electricity billing function

Note: AE-200 is required when using AE-50.

(1) Controlling 50 or fewer units of equipment

1. AE-200

2. EW-50

M-NET

AE-200

M-NET

EW-50

(2) Controlling more than 50 units of equipment (with connection to an AE-200 controller)

M-NET

M-NET

M-NET

M-NET

AE-200

AE-50

EW-50

5-1-2. When using an apportioned electricity billing function

Note: AE-200 is required to use a billing function.

Note: AE-200 M-NET cannot be used when a billing function is used.

Note: “Charge” license is required to use a billing function.

M-NET

M-NET

M-NET

M-NET

M-NET

AE-200

AE-50

EW-50

Outdoor unit

Indoor unit

Remote controller

Outdoor unit

City Multi system

City Multi system

Remote controller

Indoor unit

Outdoor unit

Indoor unit

Remote controller

HUB

City Multi system

City Multi system

HUB

Remote controller

Outdoor unit

Indoor unit

15

WT07417X01

5-2. M-NET power feeding coefficient

The EW-50’s power feeding coefficient is 1.5.

A power supply unit is not required when the power consumption coefficient of the M-NET equipment (e.g. system

controller, PI controller) that will be connected to the centralized control transmission cables is 1.5 or below.

Power feeding coefficient

Product Power feeding coefficient

EW-50 1.5

Power supply unit (PAC-SC51KUA) 5

Power consumption coefficient

Product Power consumption coefficient

DIDO controller (PAC-YG66DCA) 1/4

PI controller (PAC-YG60MCA) 1/4

AI controller (PAC-YG63MCA) 1/4

System controller

(North America: TC-24B, Europe: AT-50B)

1.5

ON/OFF remote controller (PAC-YT40ANRA) 1

Use a power supply unit and connect the M-NET power jumper as shown in the table below, depending on the

system configuration and the power consumption coefficient of the M-NET equipment that will be connected to the

centralized control transmission cables.

Power supply unit M-NET power jumper (CN21)

System with connection to a

sub system controller or other

related equipment

Power consumption

coefficient ≤ 1.5

Not required

Connect

(Connected at factory shipment)

Power consumption

coefficient > 1.5

Required Disconnect

* Leave the M-NET power jumper connected to CN41 on all outdoor units.

* Provide a single point ground for the shield of the centralized control transmission cable. (Provide the appropriate grounding according to

local standards.) Refer to section 7-2-2 “M-NET transmission cables (Centralized control transmission cables)” for details.

* Set the centralized control switch (SW5-1 (or SW2-1, depending on the unit model)) on the outdoor unit connected to the M-NET

transmission cable to ON.

* Refer to section 2-1 “Part names” for the location of CN21.

16

WT07417X01

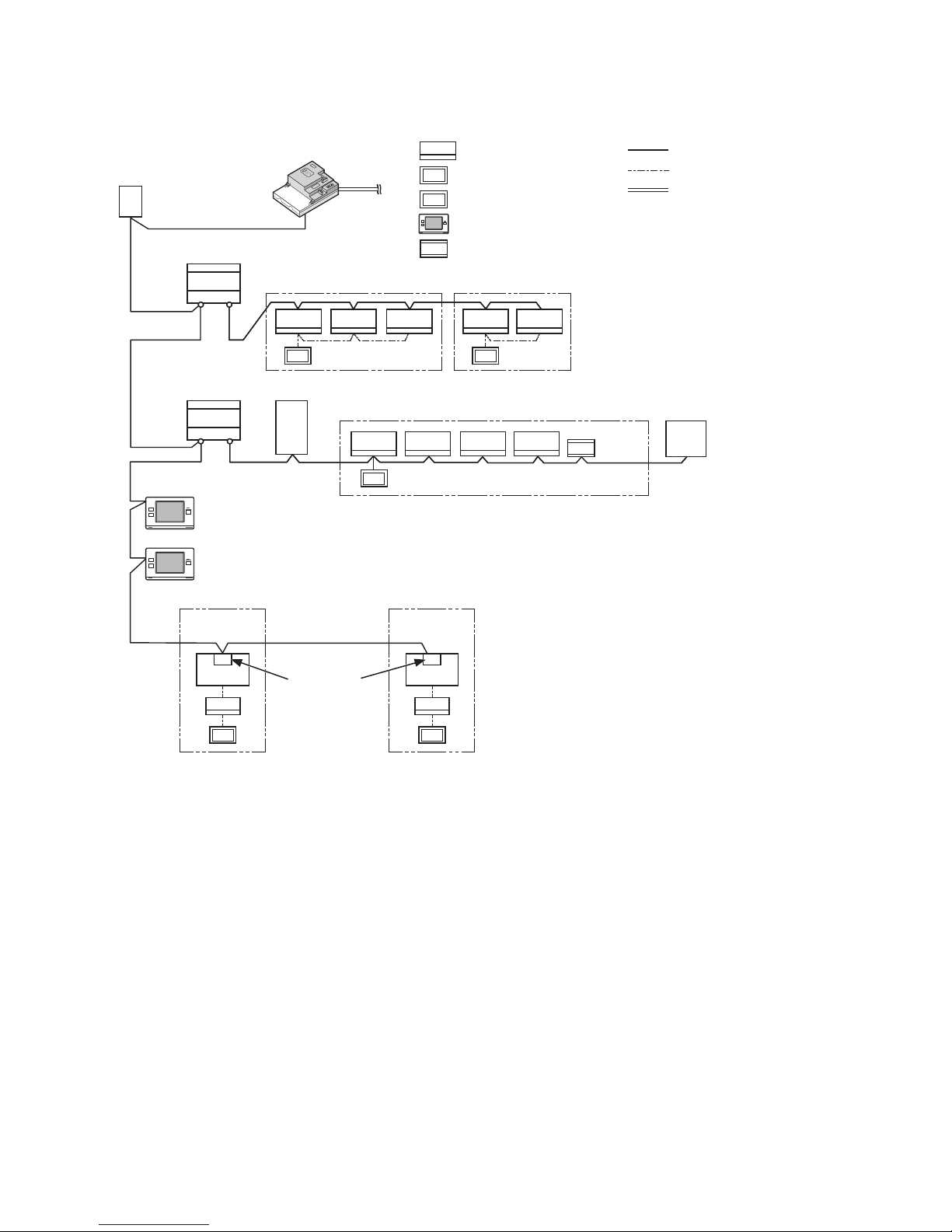

5-3. System configuration example

Note

● The figures in (1) through (3) below only show the transmission cable connections. Power cables are omitted.

(1) When the power consumption coefficient of the M-NET equipment that will be connected to the

centralized control transmission cables is 1.5 or below

TB7 TB3

TB7 TB3

MA

ME

MA

[051]

[056

]

[11] [12]

MA

M-NET

M-NET

EW-50

[000]

[057]

LOSSNAY

MA

[004] [005][001] [002] [003]

[006] [007] [008] [009] [010]

[106]

[201]

ME

MA

AHC

AHC

[201]

*1 Leave the M-NET power jumper connected to CN21 on the EW-50.

*2 Leave the M-NET power jumper connected to CN41 on all outdoor units.

*3 An M-NET adapter (sold separately) is required to connect the Mr. Slim model of units to the M-NET.

LAN

*1

Outdoor unit (Y)

*2

Group 1

Outdoor unit (R2)

*2

BC controller

Mr. Slim

outdoor unit

Group 2

Group 3

M-NET adapter

Indoor unit

Local remote controller (MA R/C type)

Local remote controller (ME R/C type)

M-NET transmission cable

MA remote controller cable

Numbers in parentheses indicate address

numbers.

Sub system controller

*3

LAN cable

Mr. Slim

outdoor unit

Group 4

*3

Group 5

Advanced HVAC CONTROLLER

17

WT07417X01

(2) When the power consumption coefficient of the M-NET equipment that will be connected to the

centralized control transmission cables is greater than 1.5

Example: When two system controllers (North America: TC-24B, Europe: AT-50B) (power consumption coefficient: 1.5

each) are connected, the power consumption coefficient is 3. In this case, use a power supply unit.

[201]

[202]

LAN

EW-50

[000]

LOSSNAY

TB7 TB3

TB7 TB3

M-NET

[051]

[056]

ME

[006] [007] [008] [009] [010]

[106]

MAMA

[004] [005][001] [002] [003]

[11]

MA

[057]

M-NET

M-NET

[12]

MA

ME

MA

AHC

AHC

[201]

*1 Disconnect the M-NET power jumper (CN21) from the EW-50.

*2 Leave the M-NET power jumper connected to CN41 on all outdoor units.

*3 An M-NET adapter (sold separately) is required to connect the Mr. Slim model of units to the M-NET.

*1

Outdoor unit (Y)

*2

Group 1

Outdoor unit (R2)

*2

BC controller

Mr. Slim

outdoor unit

Group 2

Group 3

M-NET adapter

Indoor unit

Local remote controller (MA R/C type)

Local remote controller (ME R/C type)

M-NET transmission cable

MA remote controller cable

Numbers in parentheses indicate address

numbers.

Sub system controller

*3

LAN cable

Mr. Slim

outdoor unit

Group 4

*3

Group 5

Power supply unit

PAC-SC51KUA

(sold separately)

Advanced HVAC CONTROLLER

18

WT07417X01

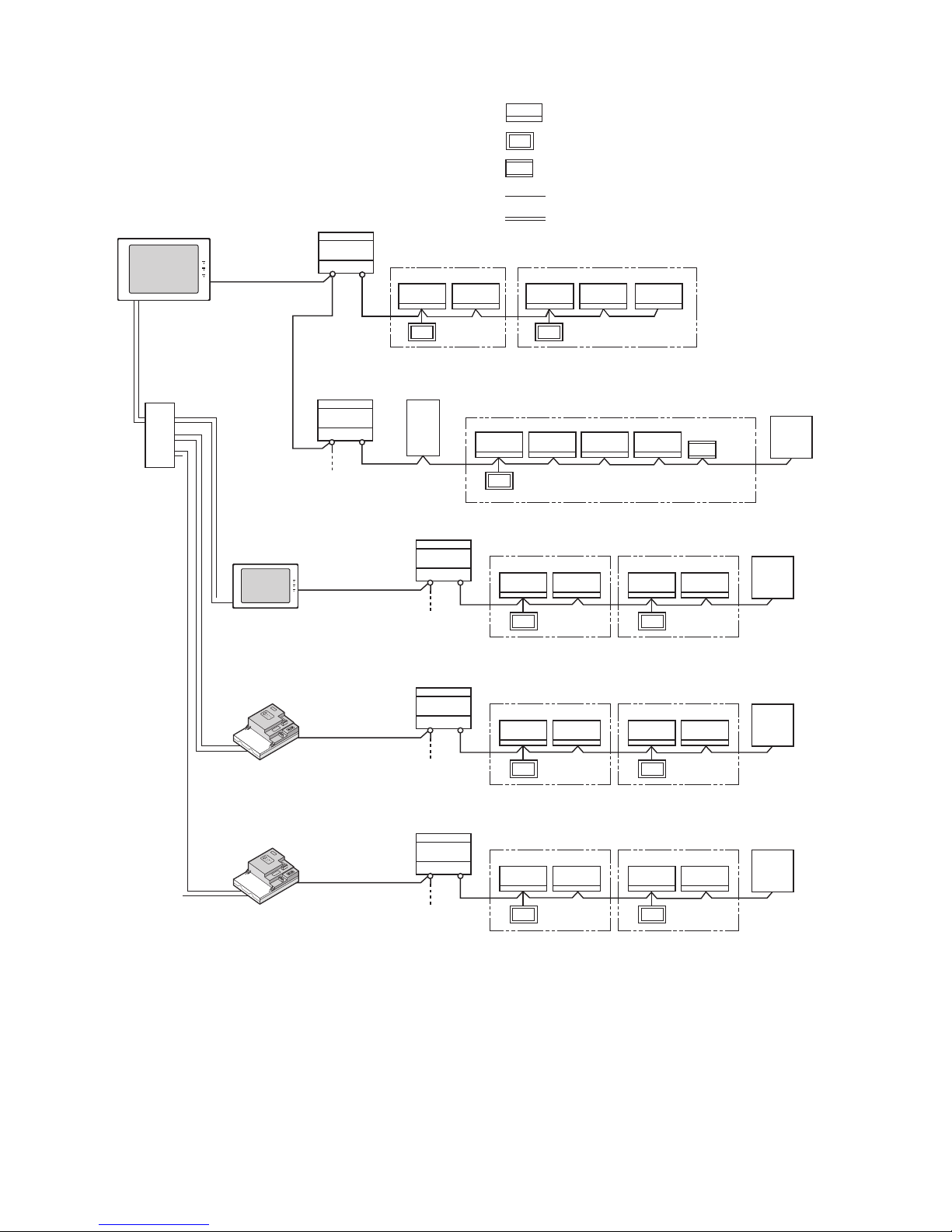

(3) When connecting AE-50/EW-50 controllers (up to four controllers) to an AE-200

1. When not using an apportioned electricity billing function

LOSSNAY

LOSSNAY

TB7 TB3

TB7 TB3

ME ME

ME

[051]

[056] [057]

[001] [002] [003] [004] [005]

[006] [007] [008] [009] [010]

[106]

M-NET

LAN

LAN

LAN

LAN

M-NET

M-NET

TB7 TB3

ME

[051]

[001] [002] [003] [004] [005]

[101]

TB7 TB3

ME

[051]

[001] [002] [003] [004] [005]

[101]

ME

[103]

[101] [103]

ME

[103]

LOSSNAY

M-NET

TB7 TB3

ME

[051]

[001] [002] [003] [004] [005]

[101]

ME

[103]

LOSSNAY

AE-200

[000]

AE-50

[000]

EW-50

[000]

EW-50

[000]

ME

AHC

AHC

[201]

*1 Leave the M-NET power jumper connected to CN21 on the AE-200 and EW-50.

*2 Leave the M-NET power jumper connected to CN41 on all outdoor units.

LAN1 IP: 192.168.1.001

*1

Switching

HUB

Outdoor unit (Y)

Outdoor unit (R2)

Group 1

LAN1 IP: 192.168.1.211

BC controller

Outdoor unit

Group 2

Group 3

Group 1

LAN1 IP: 192.168.1.212

Indoor unit

Local remote controller (ME R/C type)

M-NET transmission cable

Outdoor unit

Numbers in parentheses indicate address

numbers.

Group 2

Group 1

LAN1 IP: 192.168.1.213

Outdoor unit

Group 2

Group 1 Group 2

*1

LAN cable

*1

*1

*2

*2

*2

*2

Advanced HVAC CONTROLLER

*2

Loading...

Loading...