Page 1

Page 2

1. Safety precautions

► Observe these precautions carefully to ensure safety.

► After reading this manual, pass the manual on to the end user to retain for future

reference.

► The user should keep this manual for future reference and refer to it as necessary. This

manual should be made available to those who repair or relocate the units. Make sure

that the manual is passed on to any future air conditioning system user.

: indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

: indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

: addresses practices not related to personal injury, such as product

and/or property damage.

1-1. General precautions

Do not install the controller in areas where large amounts of oil, steam, organic solvents, or

corrosive gases (such as ammonia, sulfuric compounds, or acids), or areas where

acidic/alkaline solutions or special chemical sprays are used frequently. These substances

may significantly reduce the performance and corrode the internal parts, resulting in

electric shock, malfunction, smoke, or fire.

To reduce the risk of short circuits, current leak ag e, ele ct r ic shock, malfunction, smoke, or

fire, do not wash the controller with water or any other liquid.

To reduce the risk of electric shock, malfunction, smoke, or fire, do not touch the electrical

parts, USB memory, or touch panel with wet fingers.

To reduce the risk of injury or electric shock, before spraying a chemical aro un d the

controller, stop the operation and cover the controller.

To reduce the risk of injury, keep children away while installing, inspecting, or repairing the

controller.

If you notice any abnormality (e.g., burning smell), stop the operation, turn off the

controller, and consult your dealer. Continuing the operation may result in electric shock,

malfunction, or fire.

Properly install all required covers to keep moisture and dust out of the controller. Dust

accumulation and the presence of water may result in electric shock, smoke, or fire.

To reduce the risk of fire or explosion, do not place flammable materials or use flammable

sprays around the controller.

To reduce the risk of electric shock or malfunction, do not touch the touch panel, switches,

or buttons with a sharp object.

To avoid injury from broken glass, do not apply excessive force to the glass parts.

To reduce the risk of injury, electric shock, or malfunction, avoid contact with the sharp

edges of certain parts.

Page 3

Consult your dealer for the proper disposal of the controller. Improper disposal will pose a

risk of environmental pollution.

1-2. Precautions for relocating o r repairing the unit

The controller must be repaired or moved only by qualified personnel. Do not

disassemble or modify the controller. Improper installation or repair may result in injury,

electric shock, or fire.

1-3. Additional precautions

To avoid discoloration, do not use benzene, thinner, or chemical rag to clean the controller.

When the controller is heavily soiled, wipe the controller with a well-wrung cloth that has

been so aked in water with mild detergent, and then wipe off with a dry cloth.

This appliance is not intended f or use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety. Children should be supervised to ensure that they do not play

with the appliance.

Page 4

AE-200/AE-50/EW-50 Serv ice Handbook Contents

I About this manual

[1] About the information in this manual .................................... 2

II Be sure to read before performing service work

[1] Safety when performing service work .................................. 4

[2] Equipment and materials required for service work ............ 4

III System restrictions and notes

[1] System configuration restrictions .......................................... 6

[2] System Connection Examples ........................................... 10

[3] Restrictions and Notes on AC Power Supply Wiring......... 17

[4] Restrictions and Notes on Transmission Wiring ................ 17

[5] M-NET address settings ..................................................... 19

[6] Restrictions and notes on network wiring ........................... 20

[7] IP address settings .............................................................. 21

[8] Switch Settings .................................................................... 22

[9] Other points to note ............................................................. 23

IV Product specifications and functions

[1] Structure of AE-200/AE-50/EW-50 .................................... 25

1. External dimensions ....................................................... 25

2. Location of main parts .................................................... 27

3. Electrical wiring diagram ................................................. 30

4. How to remove and attach the cover ............................. 32

[2] Product specifications of AE-200/AE-50/EW-50 ............... 34

1. Product specifications ..................................................... 34

2. AE-200/AE-50/EW-50 unit functions and Web

browser functions ............................................................ 36

[3] PC operating environment .................................................. 40

[4] Various Functions ............................................................... 41

1. Functions and required equipment and materials ......... 41

2. Functions and licenses ................................................... 43

[5] How to check the version of AE-200/AE-50/EW-50 .......... 44

V Troubleshooting

[1] Before performing failure diagnosis .................................... 46

[2] Error code list ....................................................................... 46

1. List of error codes for errors detected by the

AE-200/AE-50/EW-50 .................................................... 46

2. Error and preliminary error code list ............................... 47

[3] Troubleshooting and solutions depending on the

equipment ........................................................................... 50

1. How to determine the cause and resolve trouble based

on the detected error display of the

AE-200/AE-50/EW-50 .................................................... 50

2. Error judgment based on the STATUS LED display of

the AE-200/AE-50/EW-50 .............................................. 59

3. Troubleshooting depending on the trouble symptoms

of the AE-200/AE-50/EW-50 and trouble examples ..... 60

[4] M-NET transmission waveform and noise check

procedure ............................................................................ 69

[5] LAN communication error check procedure ...................... 71

1. About the preliminary check items ................................. 71

2. About the check method using ping .............................. 74

[6] Peak cut troubleshooting .................................................... 79

[7] Energy management troubleshooting ................................ 80

VI Q & A

[1] About the entire system ...................................................... 82

[2] About Web browsers .......................................................... 82

[3] About the AE-200/AE-50/EW-50 Centralized Controller... 84

[4] About optional functions ...................................................... 86

[5] About models other than air-conditioning units .................. 87

[6] Other .................................................................................... 87

VII Test run check lists for initial work and expansion

work

[1] Setting check list .................................................................. 89

[2] Test run check list................................................................ 90

1. Test run check sheet ...................................................... 90

[3] Peak cut settings check list ................................................. 93

1. About the peak cut settings check list ............................ 93

2. About the peak cut operation check .............................. 94

[4] Apportioned electricity billing test run check list ................. 95

[5] Work procedure and check for system expansion work ... 95

1. Preparation ................................................................ 95

2. Notes about expansion................................................... 95

3. Work procedure .............................................................. 96

VIII Maintenance

[1] AE-200/AE-50/EW-50 update procedure .......................... 98

Page 5

[I About this manual]

1

I About this manual

[1] About the information in this manual ......................................................................................... 2

Page 6

[I About this manual]

2

[1] About the inf ormati on i n thi s manu al

This manual contains information regarding service work for the air conditioning control system centralized controller

AE-200/AE-50/EW-50.

Please note that the information about functions contained in this manual is as of May 2015 and so information about any

improvements made to functions after that is not included.

- Registered trademarks

・ Windows is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

・ Microsoft is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

・ Oracle and Java are trademarks or registered trademarks of Oracle Inc. in the United States and/or other countries.

・ Adobe Reader and Adobe Acrobat are registered trademarks of Adobe Systems Incorporated.

・ Other product names contained in this document may be trademarks or registered trademarks of their respective companies.

- Terms used in this manual

・ “Microsoft® Windows 7 Home Premium” is referred to as “Windows 7”, and “Microsoft® Windows 8.1” is referred to as “Windows

8.1”.

・ “Centralized Controller AE-200A/AE-200E” is referred to as “AE-200”.

・ “Centralized Controller AE-50A/AE-50E” is referred to as “AE-50”.

・ “Centralized Controller EW-50A/EW-50E” is referred to as “EW-50”.

・ “Advanced HVAC CONTROLLER” is referred to as “AHC”.

・ “DIDO controller (PAC-YG66DCA)” is referred to as “DIDO controller”.

・ “PI controller (PAC-YG60MCA)” is referred to as “PI controller”.

・ “AI controller (PAC-YG63MCA)” is referred to as “AI controller”.

・ “OA Processing unit (LOSSNAY with heater and humidifier)” is referred to as “OA Processing unit”.

・ Energy management and peak-cut control can be performed without a PI controller by directly inputting the pulse signals of a meter

to CN7 of the AE-200/AE-50/EW-50. In this manual, this method will be called pulse input (PI).

・ “Booster unit” and “Water HEX unit” are referred to as “Air To Water (PWFY) unit”.

・ “Hot Water Heat Pump unit” is referred to as “HWHP (CAHV, CRHV) unit”.

- About screen display

・ The screens displayed in this manual may differ from those of the latest version.

- About terms

SSL: Stands for Secure Sockets Layer, which is a protocol for securely exchanging data via the Internet.

PLC: Stands for programmable logic controller, which performs the operation of a sequencer.

In the AE-200/AE-50/EW-50 system, there are a total of three types: PLC for Electric Amount Count (PAC-YG11CDA), PLC for

Demand Input (PAC-YG41CDA), and PLC for General Equipment (PAC-YG21CDA) (TG-2000A is required).

Java®: A programming language that runs independent of a given computer architecture or platform.

OS: Stands for operating system. It is the basic software for running programs on a computer.

Page 7

[II Be sure to read before performing service work]

3

II Be sure to read before performing service work

[1] Safety when performing service work ........................................................................................ 4

[2] Equipment and materials required for service work .................................................................. 4

Page 8

[II Be sure to read before performing service work]

4

[1] Safety when performing service work

Be sure to carefully rea d "Safe ty Precaut ions" at t he beginn ing of this manual a nd perf orm service work while

paying att entio n to safe ty.

To ensure inspection and replacement work is performed safely, observe the following precautions when performing the work.

Before replacing parts, be sure to turn off the breaker in the control panel and the main breaker outside the

control panel to shut off the power supply to the AE-200/AE-50/EW-50.

If inspection work must be performed while the equipment is energized, do not touch live parts and take

sufficient precautions against electric shock.

Use appropriate tools for inspection and replacement work.

Using worn out tools may result in an accident due to inadequate tightening, contact failure, etc.

Be sure to ground the equipment. Furthermore, inspect the grounding state and perform the work again if

the grounding is inadequate.

After performing the inspection and replacement work, clean the equipment and the area around the

equipment and then notify the customer that the inspection and replacement work is complete.

[2] Equipment and materials required for service work

Prepare the following equipment and materials for the service work. (Note: Prepare the items that will be required for the particular

site.)

<Tools>

・ Screwdriver

・ Hex key Used to remove the front cover of the AE-200/AE-50.

Width across flats: 2.5 mm (0.1 in)

A hex key is included with the AE-200/AE-50.

<Measuring instruments>

・ Tester Used to check the wiring and voltage.

・ Oscilloscope Used to check the M-NET transmission waveform.

<Reference materials>

・ Diagram of air conditioning control system at the site

・ AE-200/AE-50 Installation and Instructions Manual

・ EW-50 Installation and Instructions Manual

・ AE-200/AE-50/EW-50 Web Browser Instruction Book (Administration and Initial Settings)

・ Instruction Manual and Installation Manual for each air-conditioning unit, controller, and power supply unit

・ Service Handbook (this manual)

・ Air-conditioning Unit Service Handbook

・ Air-conditioning Unit Service Parts Catalog

<Other items>

・ License numbers License numbers of AE-200/AE-50/EW-50 r equired for the functions to be used

(Required when new installation, replacement, etc.)

・ USB memory device Used to back up the initial settings data.

(Use a USB memory device specified in "III [9] (2) About USB memory devices.")

・ PC Used for various tools and Web display.

・ LAN cable 100BASE-TX compatible LAN cable (category 5 or better)

1. Turn off the

breakers

2. Take electrical

shock precautions

3. Use appropriate

tools

4. Ground

5. Clean

Page 9

[III System restrictions and notes]

5

III System restrictions and notes

[1] System configuration restrictions ............................................................................................... 6

[2] System Connection Examples ................................................................................................. 10

[3] Restrictions and Notes on AC Power Supply Wiring .............................................................. 17

[4] Restrictions and Notes on Transmission Wiring ..................................................................... 17

[5] M-NET address settings .......................................................................................................... 19

[6] Restrictions and notes on network wiring ................................................................................ 20

[7] IP address settings ................................................................................................................... 21

[8] Switch Settings ......................................................................................................................... 22

[9] Other points to note .................................................................................................................. 23

Page 10

[III System restrictions and notes]

6

[1] System configuration restrictions

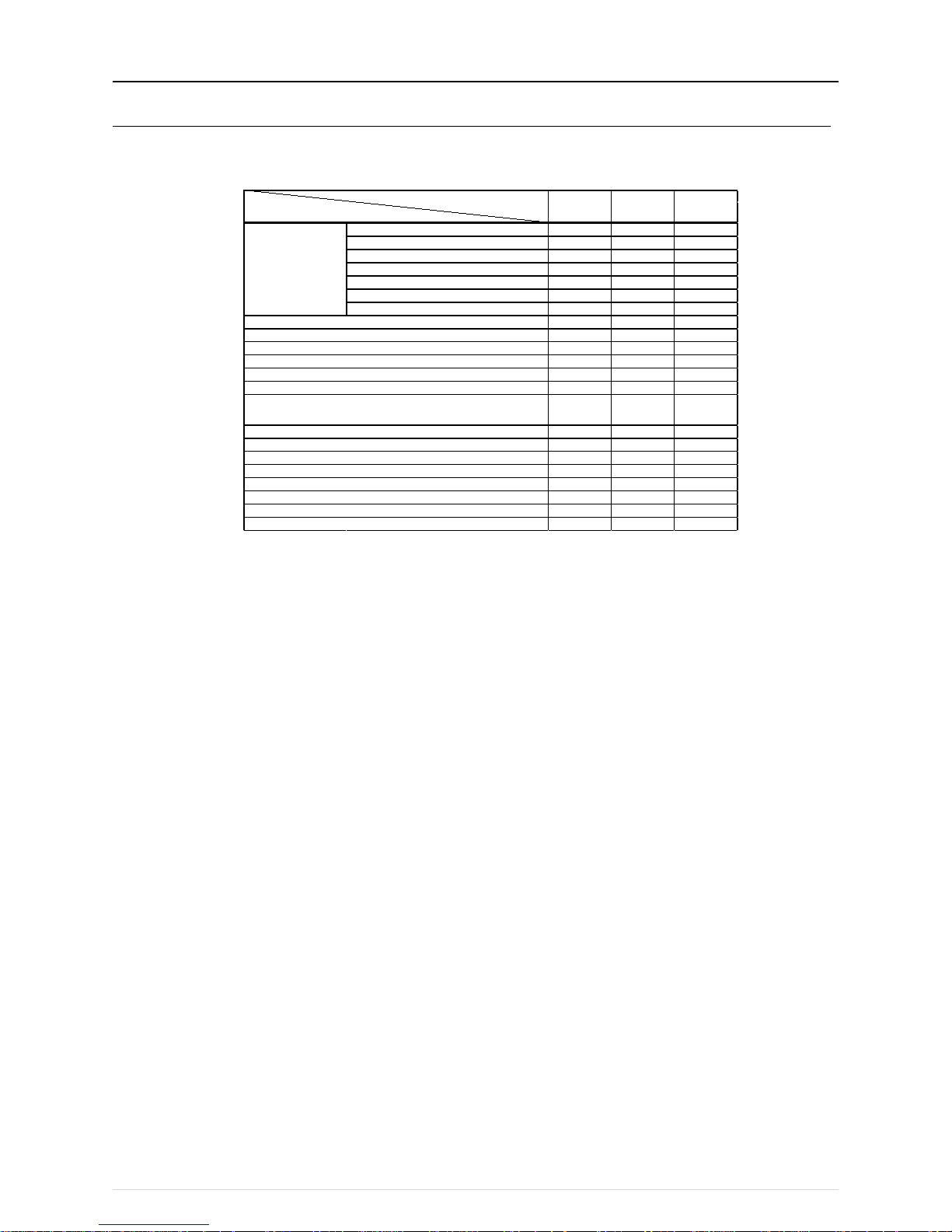

(1) Managed equipment

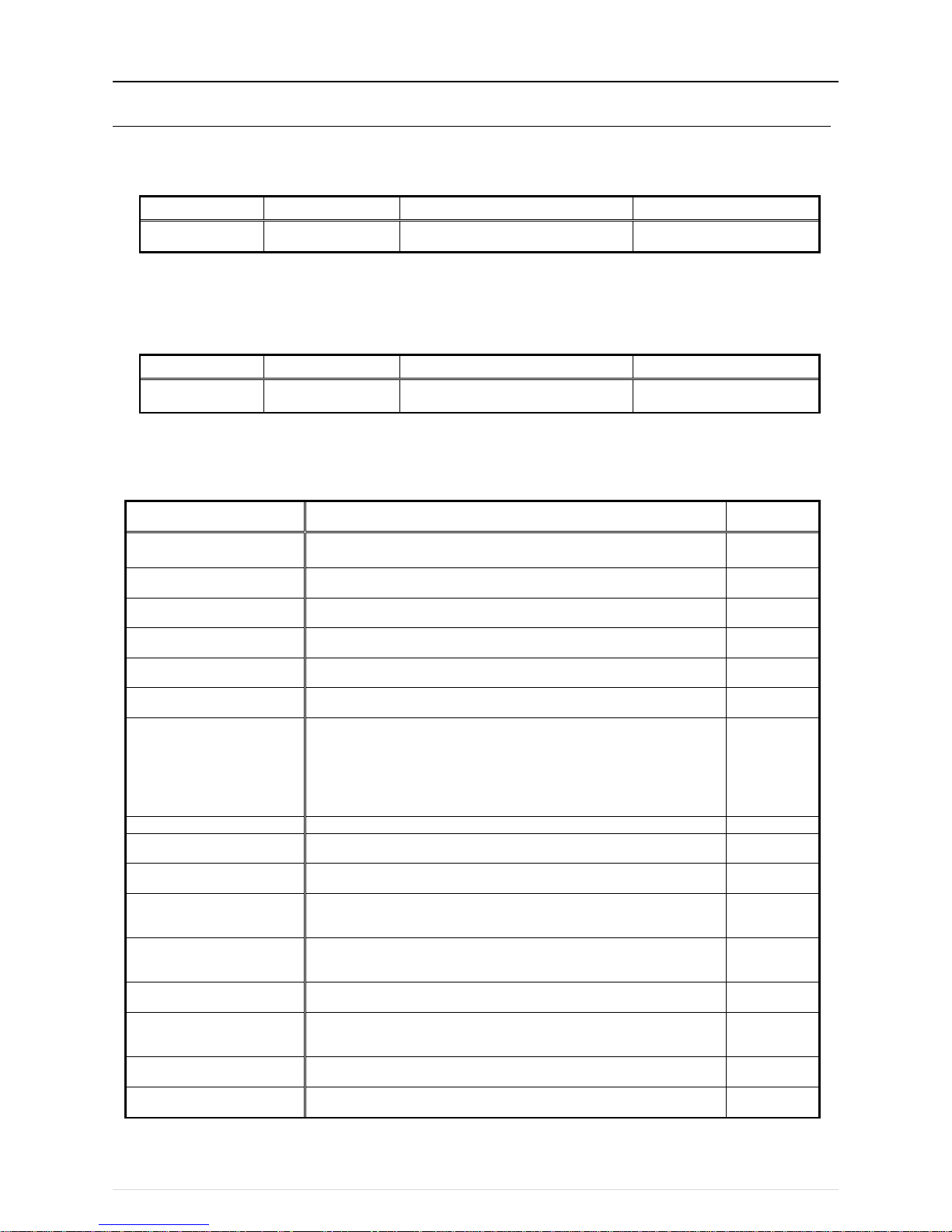

The devices that AE-200/AE-50/EW-50 can control are shown in the following table.

[Legend] ○: Use possible, ×: Use not possible

S series ○ ○ ○

Y seri es*1

○ ○ ○

HP series

○ ○ ○

R2 series*1

○ ○ ○

WY series

○ ○ ○

WR2 series

○ ○ ○

HVRF serie s

○ ○ ○

○ × ×

○ ○ ×

○*2 ○*3

×

○

○*3

×

× × ×

○*2 ○*3

×

○ × ○

○ ○ ×

○ ○ ×

○ ○ ×

○ × ×

○ × ×

○ × ×

○ × ×

○ × ×

Night mode

CITY MULTI

AHC

HWHP (CAHV/CRHV)

General equipment (DIDO controller connection)

General equipment (indoor unit fr ee contact connecti on)

Monitoring/o

peration

Peak cut

Air To Water (P WFY) Booster unit

Air To Water (P WFY) HEX unit

DOAS (Dedicated Outside Air System)

Commercial PAC (PFAV)

Commercial PAC (PEV/PFV)

Computer room PAC (PFD)*4

LOSSNAY

OA Processi ng unit

A-c ontrol unit (Mr. Slim)

AK-c ontrol unit (Mr. Slim)

K-c ontrol unit

Room air conditioner ( RAC)

Function

Model

*1 Also includes Replace Multi.

*2 A separate adapter is required.

A-control (Mr. Slim) model: M-NET connection adapter

Room air conditioner: M-NET control interface

*3 Only set temperature control or stop control can be performed for RAC and HAC.

*4 When the Computer room PAC is in maintenance mode, operation is not possible.

Page 11

[III System restrictions and notes]

7

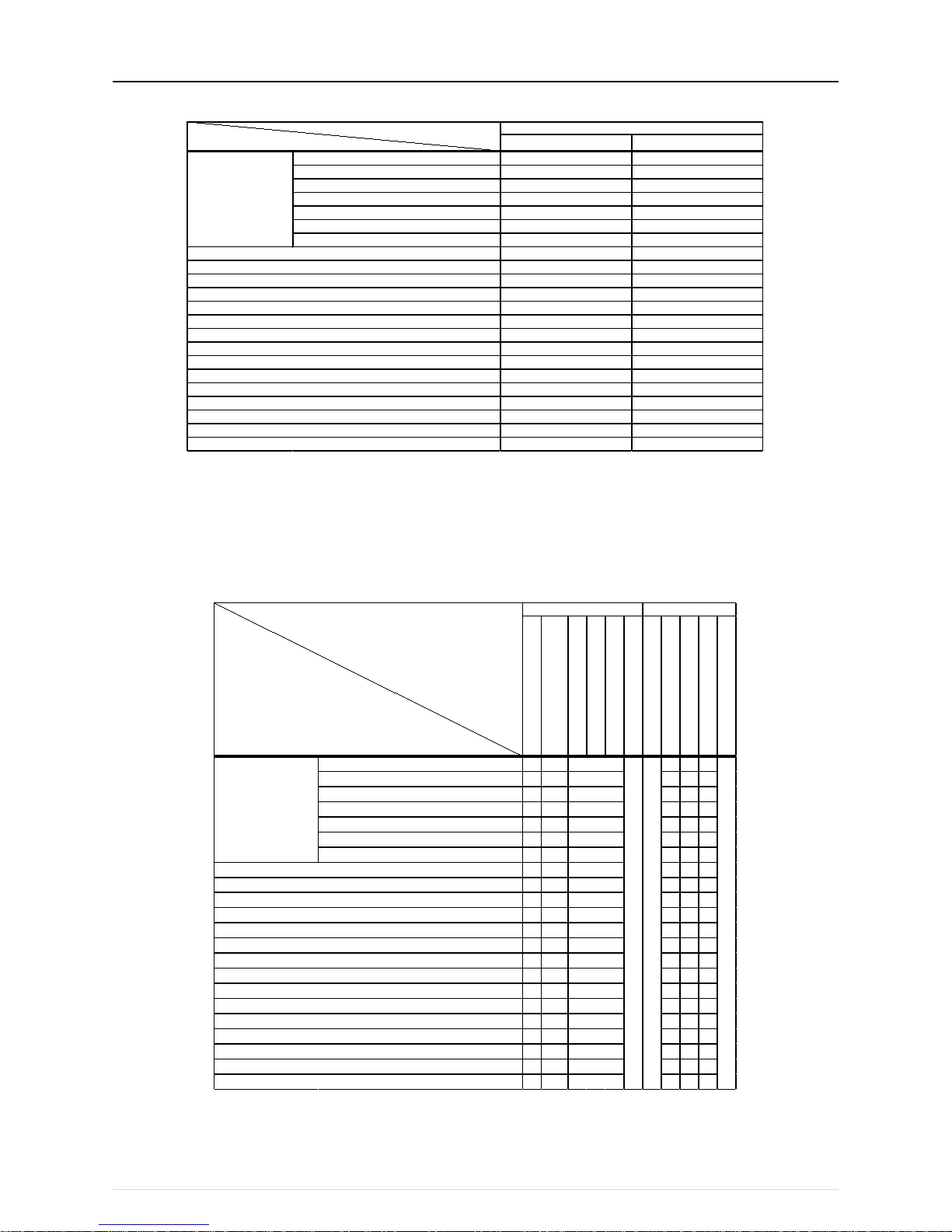

Apportioned electricity billing function [Legend] ○: Use possible, ×: Use not possible

Metering method

Manual input method

S series

○ ○

Y series

○

○

HP series

○ ○

R2 series

○

○

WY series

○ ○

WR2 series

○

○

HVRF series

×

×

○ ○

○

○

○ ○

× ×

×

×

○

*3

×

○ ○

×

×

○ ○

○

○

○

○

× ×

× ×

○

*3

×

○*3

×

Room air conditioner ( RAC)

Apportioned electricity billing f unction*2

CITY MULTI

AHC

LOSSNAY

OA Processi ng unit

A-c ontrol unit (Mr. Slim)* 1

AK-control unit ( Mr. Slim)*1

K-c ontrol unit

General equipment (DIDO controller connection)

General equipment (indoor unit free contact connecti on)

Air To Water ( PWFY) Booster uni t

DOAS (Dedicated Outside Air System)

Commercial PAC (PFAV)

Commercial PAC (PEV/PFV)

Computer room PAC (PFD )

HWHP (CAHV/C RHV)

Function

Model

*1 [Capacity save amount] can be selected in outdoor unit apportioned electricity mode only when the M-NET adapter is one of the

following models.

PAC-SJ19MA-E, PAC-SJ83MA-E

*2 Registration of the license is required for each AE-200/AE-50/EW-50.

*3 The apportioned electricity billing function can be used if an electricity meter is connected individually to each unit.

Bar graph and line graph for energy management (*1) [Legend] ○: Use possible, ×: Use not possible, -: No item

Electric energy amount

Fan operat ion time

Thermostat on (total)

Thermostat on (cool ing)

Thermostat on (heating)

Meter values

Outdoor air temperature

Set cooli ng temperature

Set heat ing tem perature

Indoor temper ature

Measured v alue

S series

○ ○ ○ ○ ○

Y series ○ ○ ○ ○

○

HP series

○ ○ ○ ○ ○

R2 series

○ ○ ○ ○ ○

WY series ○ ○ ○ ○

○

WR2 series

○ ○ ○ ○ ○

HVRF series ○ ○ ○ ○ ○

× ○

- - -

○ ○ ○ ○

○

○ ○ ○

○ ○

○ ○

○ ○ ○

×

× × × ×

○ ○

○ ○ ○

○

○*2

○ ○ ○

○ ○ ○ ○ ○

○ ○ ○ ○ ○

○ ○ ○ ○ ○

○ ○ ○ ○ ○

-

- - - -

- - -

- -

× ×

- - -

× ×

- - -

×

○

○

○

○

-

×

○

○

-

×

Bar gr aphs

Line graphs

Measurement val ues of P I c ontroller c an be display ed

Measurement val ues of A H C and A I contr oller can be dis play ed

Measurement val ues of A H C and A I contr oller can be dis play ed

○

○

○

○○○

○

×

○

○

○

Room air condi ti oner (RAC)

CITY MUL TI

AHC

LOSSNAY

OA Processi ng unit

A-control unit ( Mr. Slim)

AK-control unit ( Mr . Slim)

K-control unit

General equipment (DIDO controller connection)

General equipment (indoor unit fr ee contact connection)

Air To W ater (PWFY) Booster unit

DOAS (Dedicated Outside Air System)

Commercial PAC (PFAV)

Commercial PAC (PEV/PFV)

Computer room PAC (PFD )

HWHP (CAHV /CRHV )

Graph display details

Model

*1 Registration of the license is required for each AE-200/AE-50/EW-50.

*2 Becomes the cumulative operation time.

● The above functions are subject to change without notice for improvement.

Page 12

[III System restrictions and notes]

8

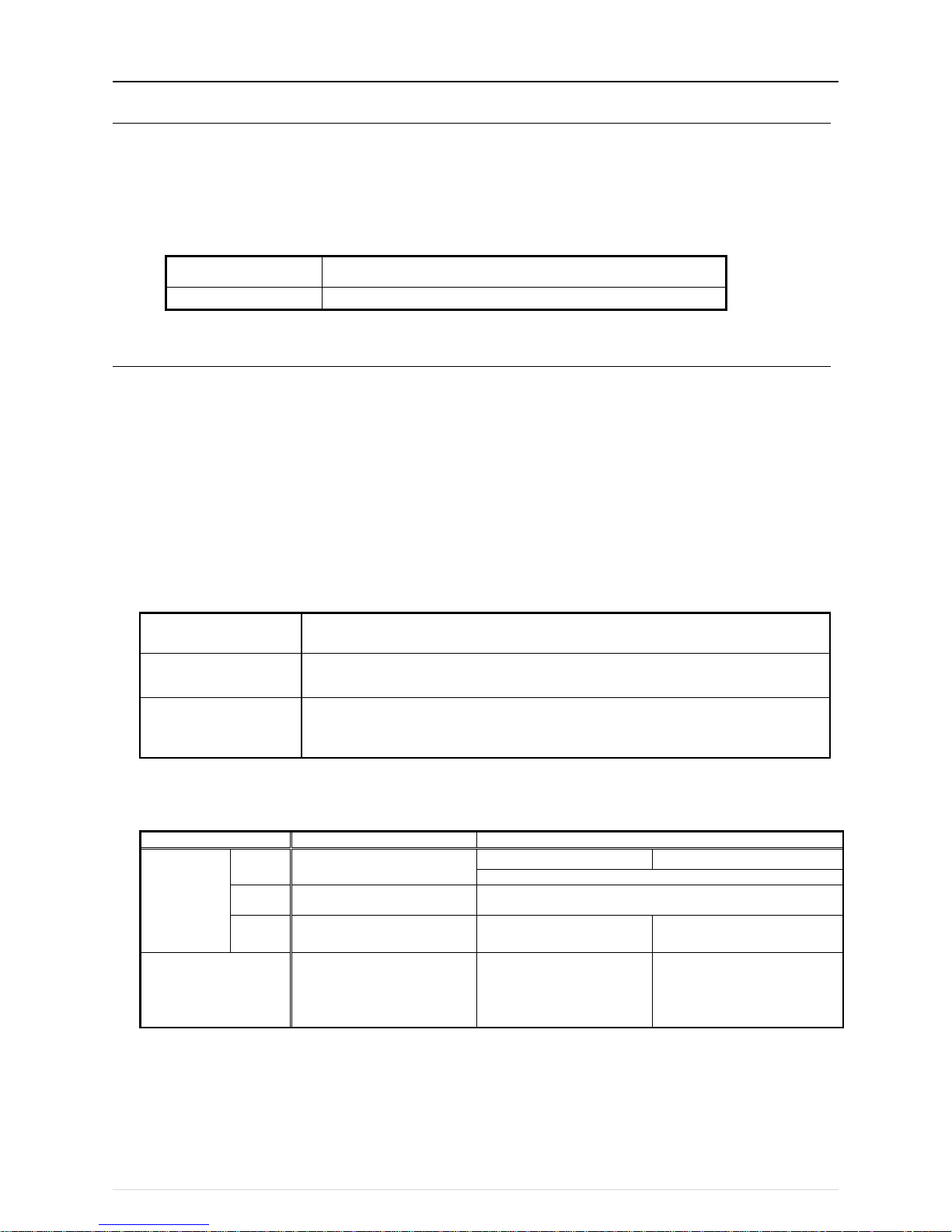

(2) Number of connectible/controllable units in a system

1. Number of controllable units for AE-200/AE-50/EW-50

Item

Description

Managed equipment

Number of controllable

indoor units

Max. 50 *1

IC, LC, FU, AIC, RAC, PWFY, HWHP,

AI controllers, PI controllers, DIDO controllers*2, AHC*3

[Code] IC: Indoor unit (OA Processing unit [without interlock control]), LC: Free-plan LOSSNAY,

FU: OA Processing unit (with interlock control), AIC: Mr. Slim air conditioner, RAC: Room air conditioner,

PWFY: Air To Water (PWFY), HWHP: HWHP (CAHV, CRHV)

*1 AE-50 cannot be operated individually.

*2 One contact is counted as one unit for a DIDO controller.

*3 Maximum number of connectible/controllable units in the case of AHC: Indoor units + AHC = 70 units.

2. Number of controllable units in an AE-200 + expansion controller (AE-50/EW-50) system

Item

Description

Managed equipment

Number of controllable

indoor units

Max. 200 (When using three

AE-50/EW-50)*1

IC, LC, FU, AIC, RAC, PWFY, HWHP, AI con trollers, PI

controllers, DIDO controllers*2, AHC*3

*1 When M-NET of AE-200 is not used or the apportioned electricity billing function of AE-200 is used, four AE-50/EW-50 units can

be connected. (Max. 200 indoor units)

*2 One contact is counted as one unit for a DIDO controller.

*3 Maximum number of connectible/controllable units in the case of AHC: Indoor units + AHC = 70 units.

(3) When performing integrated centralized control with the integrated centralized control software TG-2000A.

Use Ver.6.60 or later of TG-2000A.

(4) Number of connectable units

The table below summarizes the number of connectable units in an M-NET system.

Unit type

Number of connectable units

Indoor units, PWFY, HWHP, LOSSNAY, OA Processing unit, DIDO

controllers, PI controllers*1, and AI controllers per AE-200/AE-50/EW-50

Up to 50 units*2 (including the interlocked LOSSNAY units)

AHC per AE-200/AE-50/EW-50

Maximum of 70 indoor units for indoor units+AHC

Indoor units, PWFY, HWHP, LOSSNAY, OA Processing unit, and DIDO

controllers in one group

1–16 units*3*4

(Indoor units, PWFY, HWHP, LOSSNAY, OA Processing unit, and

DIDO controllers cannot be used together in the same group.)

AHC in a group

1 unit

(At least one indoor unit is required in the same group.)

Remote controllers in a group

0–2 units

System controllers in a group

(AE-200/AE-50/EW-50 included)

0–5 units

(Up to four remote and system controllers combined can be

assigned to each group.)

LOSSNAY unit that can be interlocked with each indoor unit

1 unit

Indoor units that can be interlocked with each LOSSNAY unit

1–16 units

*1 15 PI controllers can be connected to each AE-200/AE-50/EW-50 and a maximum of 20 can be connected within an AE-200 system.

A PI is counted as one unit.

*2 By connecting AE-50/EW-50 controllers to an AE-200, up to 200 units can be controlled.

*3 The maximum number of controllable units for DIDO controllers differs depending on the number of channels used.

*4 One contact of a DIDO controller is calculated as one unit.

Page 13

[III System restrictions and notes]

9

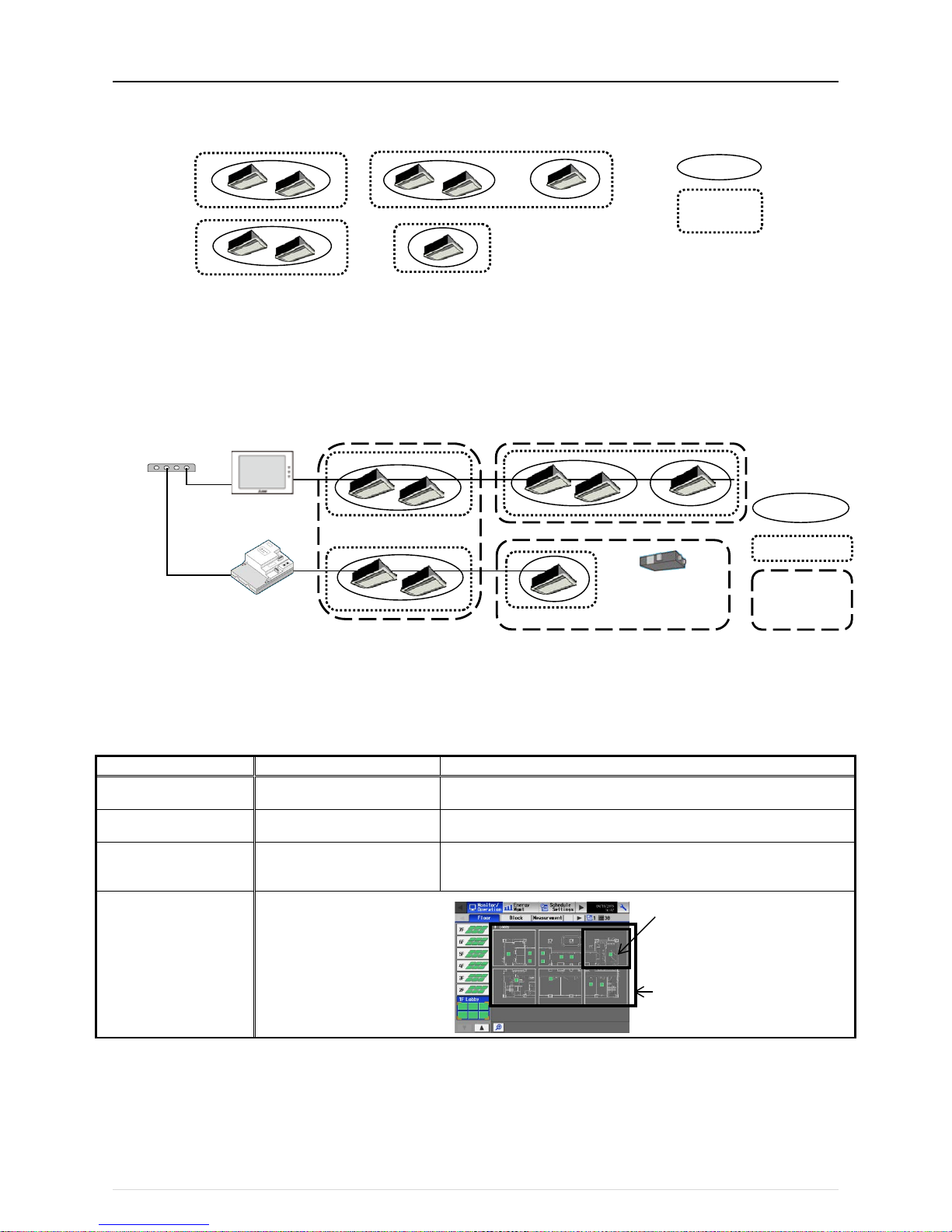

(5) Operation block setting restrictions

・ An operation block is a collection of groups, and groups of different models (air-conditioning units, LOSSNAY, general equipment,

etc.) can even be set in the same operation block.

・ An operation block that spans AE-200/AE-50/EW-50 systems cannot be set.

・ The operation items differ so we recommend setting operation blocks separately for each of the indoor units, LOSSNAY units,

and A-control models.

・ When peak-cut control is used, blocks become the setting target unit so be sure to set the operation blocks.

(6) Energy management block setting restrictions

・ An energy management block is a collection of operation blocks and OA Processing unit (with interlock control), and operation

blocks of different models (air-conditioning units, LOSSNAY, general equipment, etc.) can also be set in the same energy

management block.

・ An energy management block that spans multiple AE-50/EW-50 in an AE-200 system can be set, but an energy management

block cannot span multiple AE-200 systems.

・ When the apportioned electricity billing function is used, energy management blocks become the apportioning target unit so be

sure to set the energy management blocks.

(7) Group setting restrictions

Restrictions also apply to group settings.

Item

Description

Remark

Number of remote controllers

that can be connected

Up to two remote controllers in one

group

MA remote controllers do not need to be registered and set on this equipment.* 1

Number of indoor units that can

be connected in one group

1 to 16 IC, AIC, FU, and LC cannot be connected to the same group.

However, groups that span multiple AE-200/AE-50/EW-50 cannot be configured.* 2

Number of SC and RC units

that can be connected in one

group

Up to four units in one group

Number of groups per area

Number of groups per floor

Up to 30 groups per area

Up to 180 groups per floor

*1 An ME remote controller and MA remote controller cannot be used together in the same group.

*2 If a group is made up of indoor units with different functions, only the function of the indoor unit with the lowest address in the

group is operated and monitored.

Group

Operation

block

[Floor]

Up to 180 groups can be placed

[Area]

Up to 30 groups can be placed

Group

Operation block

Energy

management

block

OA Processing unit

(with interlock control)

AE-200

EW-50

HUB

LAN

LAN

Page 14

[III System restrictions and notes]

10

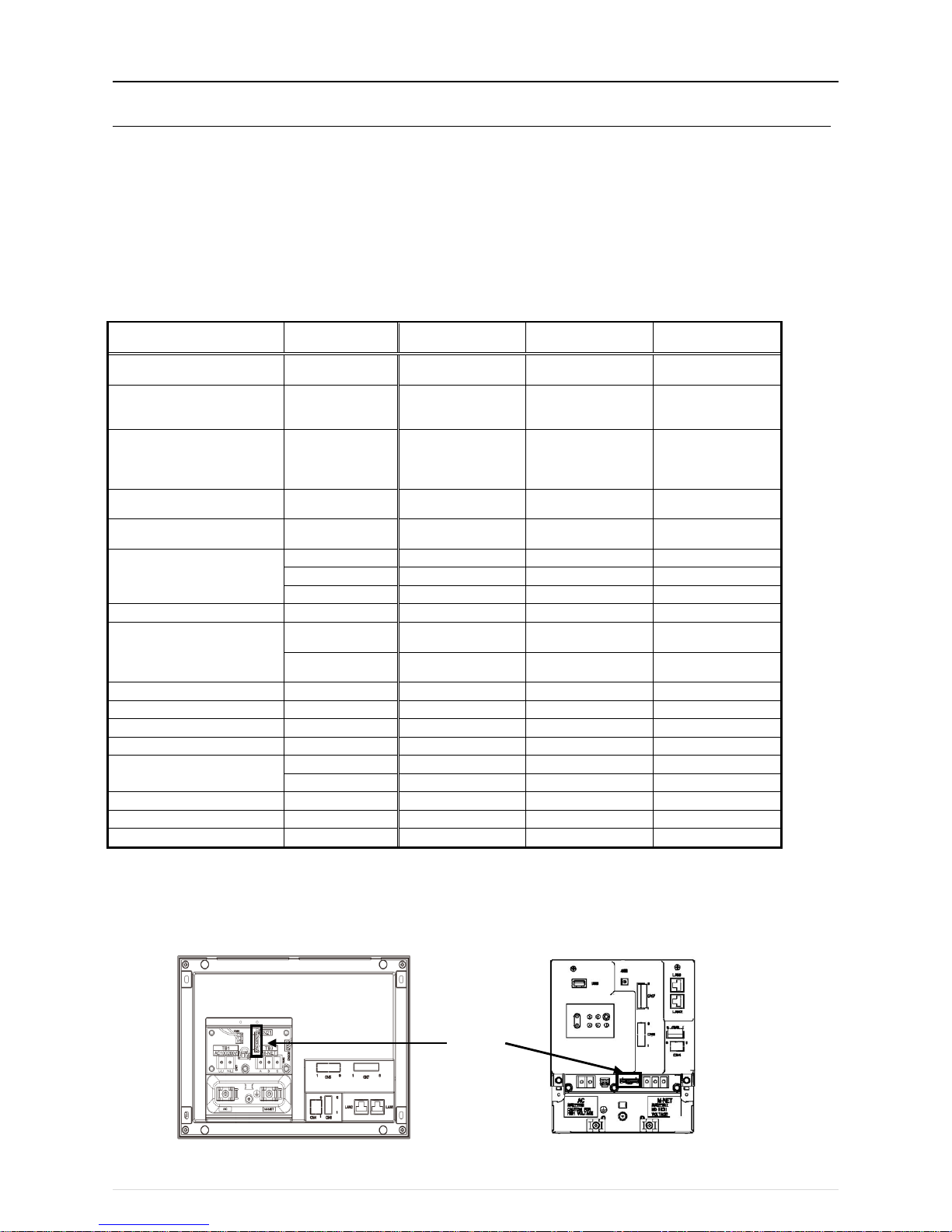

[2] System Connection Examples

The following shows the equivalent power supply of the AE-200/AE-50/EW-50 and transmission line power supply unit and the

equivalent power consumption and the equivalent number of units of the DIDO controller, PI controller, and AI controller.

Leave the power jumpers (CN41) of the outdoor units that are connected to M-NET centralized control transmission lines all

connected to the CN41 in the same way as they were connected at the time of shipment.

If the equivalent power supply is insufficient because system remote controllers and other equipment are connected to the M-NET

centralized control transmission lines, transmission line power supply units need to be added.

When connecting system remote controllers and other equipment to the M-NET centralized control transmission lines, make sure

that the equivalent number of units total will be 40 or less.

If the equivalent number of units will exceed 40, add transmission line power supply units so that the equivalent number of units will

be 40 or less.

To supply M-NET power from a transmission line power supply unit, disconnect the CN21 jumper from the AE-200/AE-50/EW-50.

NOTE:

○ If you remove the service cover from the back of the unit, you will find the power jumper (CN21) of the AE-200/AE-50 in the place

indicated in the figure below.

○ If you remove the service cover from the front of the unit, you will find the power jumper (CN21) of the EW-50 in the place indicated in

the figure below.

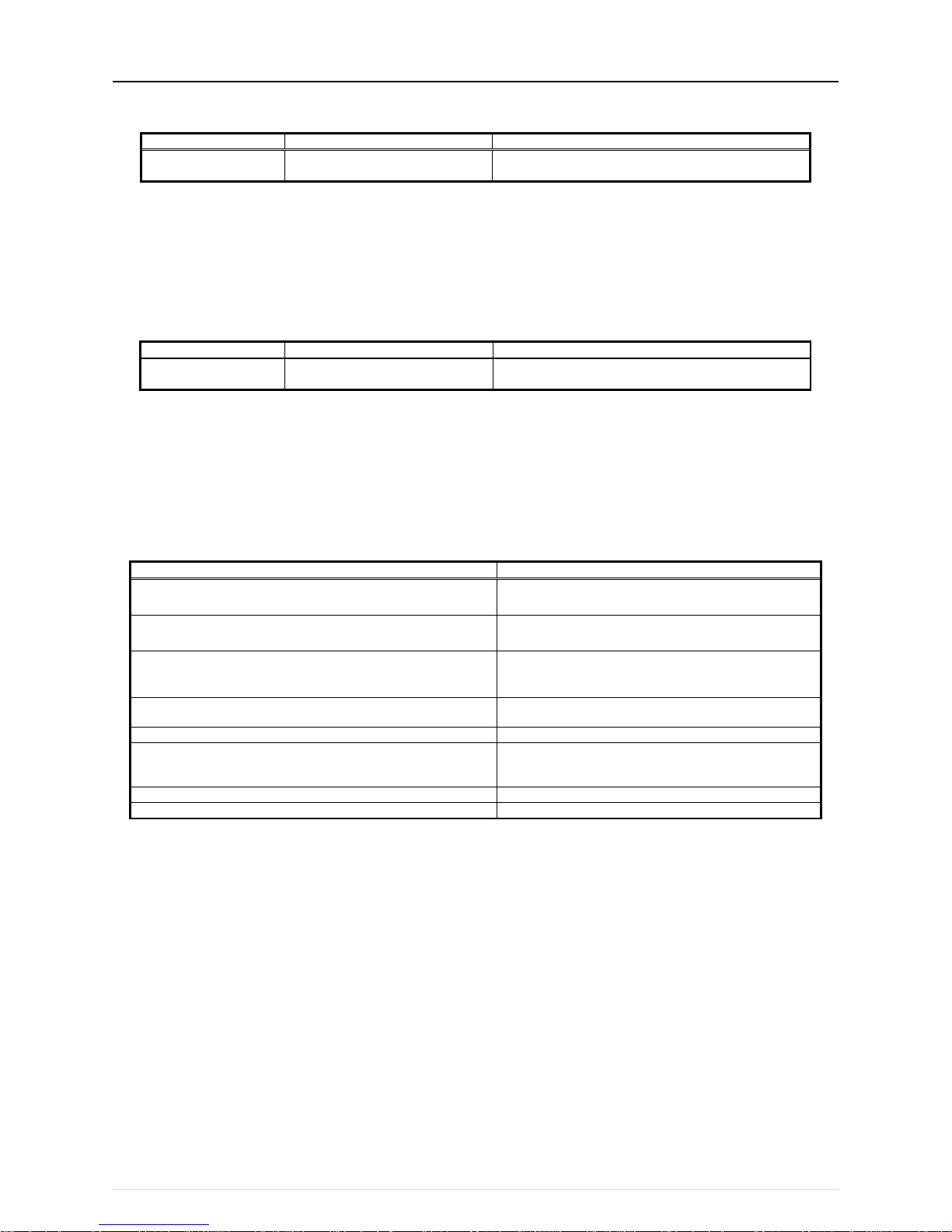

Product Model

The equivalent power

supply

The equivalent power

consumption

The equivalent

number of units

Air Conditioning Control System

Centralized Controller

AE-200 0 - -

Air Conditioning Control System

Centralized Controller

(Expansion controller)

AE-50 0 - -

Air Conditioning Control System

Centralized Controller

(Controller or Expansion Controller

without LCD)

EW-50 1.5 - -

Power Supply Unit for

Transmission Line

PAC-SC51KUA 5 - -

Power Supply Expansion Unit for

Transmission Line

PAC-SF46EPA 25 - -

System Remote Controller

AT-50B, TC-24B

-

1.5

5

AT-50A, TC-24A

-

1.5 5

PAC-SF44SRA - 1/2

1

ON/OFF Remote Controller PAC-YT40ANRA - 1 1

ME Remote Controller

PAR-U02MEDA,

PAR-U01MEDU

- 1/2 1

PAR-F27MEA,

PAR-F27MEA-US

- 1/4 1

AHC

PAC-IF01AHC-J

-

1/2

1

DIDO Controller PAC-YG66DCA - 1/4 1

PI Controller

PAC-YG60MCA

-

1/4

1

AI Controller PAC-YG63MCA - 1/4 1

MN Converter

CMS-MNG-E - 2

1

CMS-MNF

-

1/2 1

Simple ME Remote Controller

PAC-SE51CRA - 1/4

1

Group Remote Controller PAC-SC30GRA

-

1/2

1

Schedule Timer

PAC-YT34STA

-

1/2

1

AE-200/AE-50

CN21

EW-50

Page 15

[III System restrictions and notes]

11

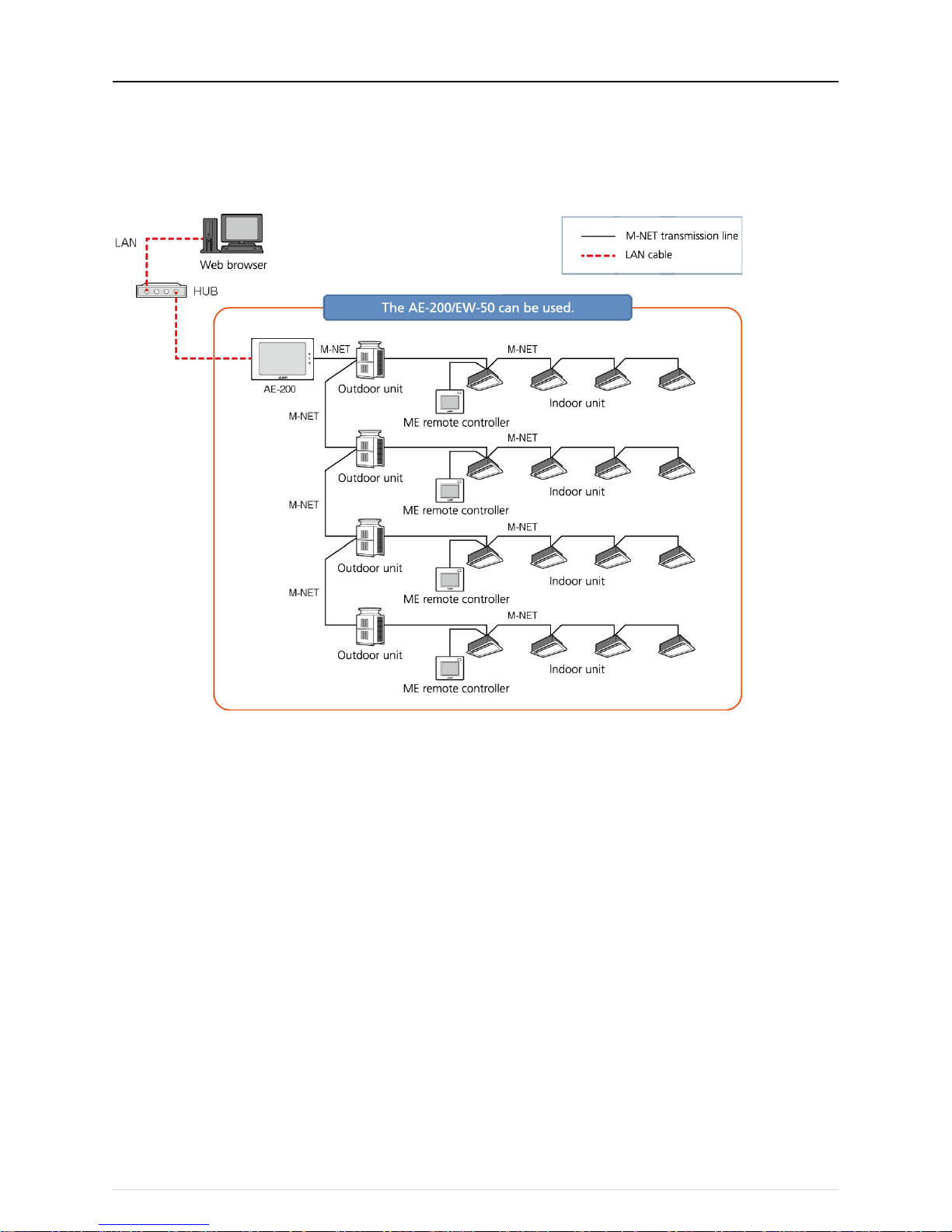

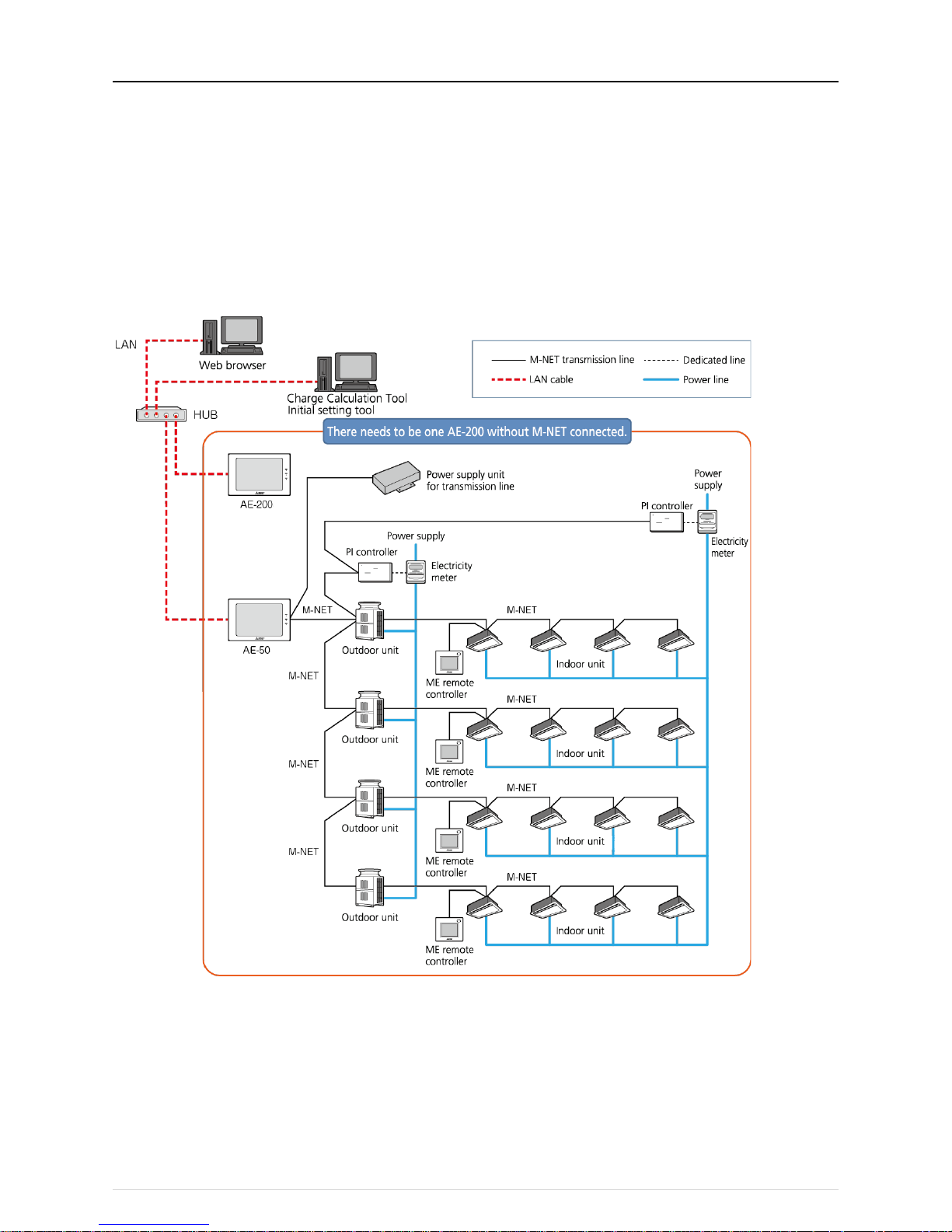

(1) When using the M-NET transmission line of the AE-200 and there are 50 or fewer air-conditioning units (apportioned electricity billing

function is not used)

With the AE200, up to 50 air-conditioning units can be monitored and operated from the unit LCD screen or a Web browser.

Also, if the EW-50 is connected instead of the AE-200, monitoring and operation from a Web browser are possible.

・ The AE-50 cannot be used on its own.

Page 16

[III System restrictions and notes]

12

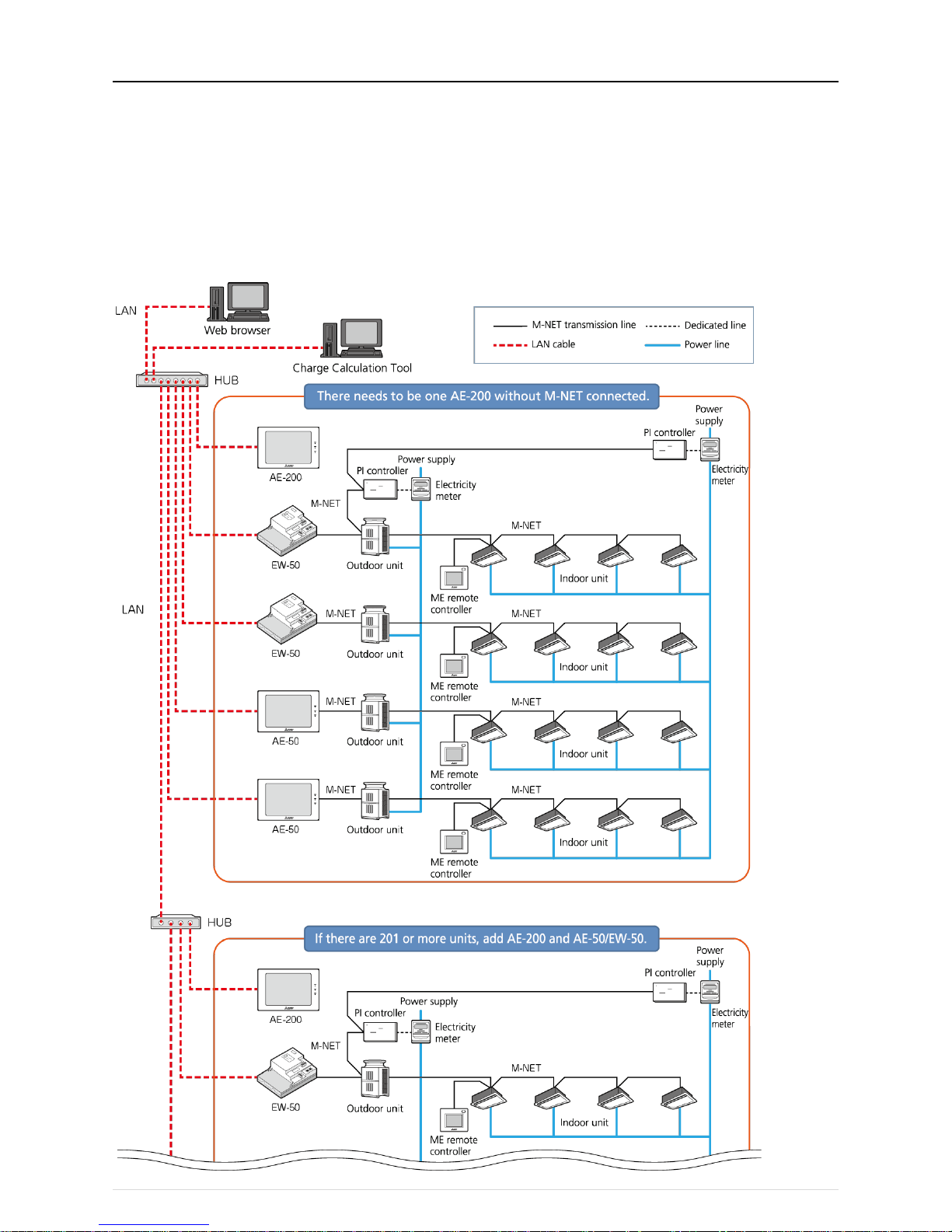

(2) When using the M-NET transmission line of the AE-200 and there are 51 or more air-conditioning units (apportioned electricity billing

function is not used)

Up to 200 air-conditioning units can be monitored and operated by using three AE-50/EW-50 expansion controllers.

・ When using the Web browser function, access each AE-200/AE-50/EW-50 to perform monitoring and operation.

Page 17

[III System restrictions and notes]

13

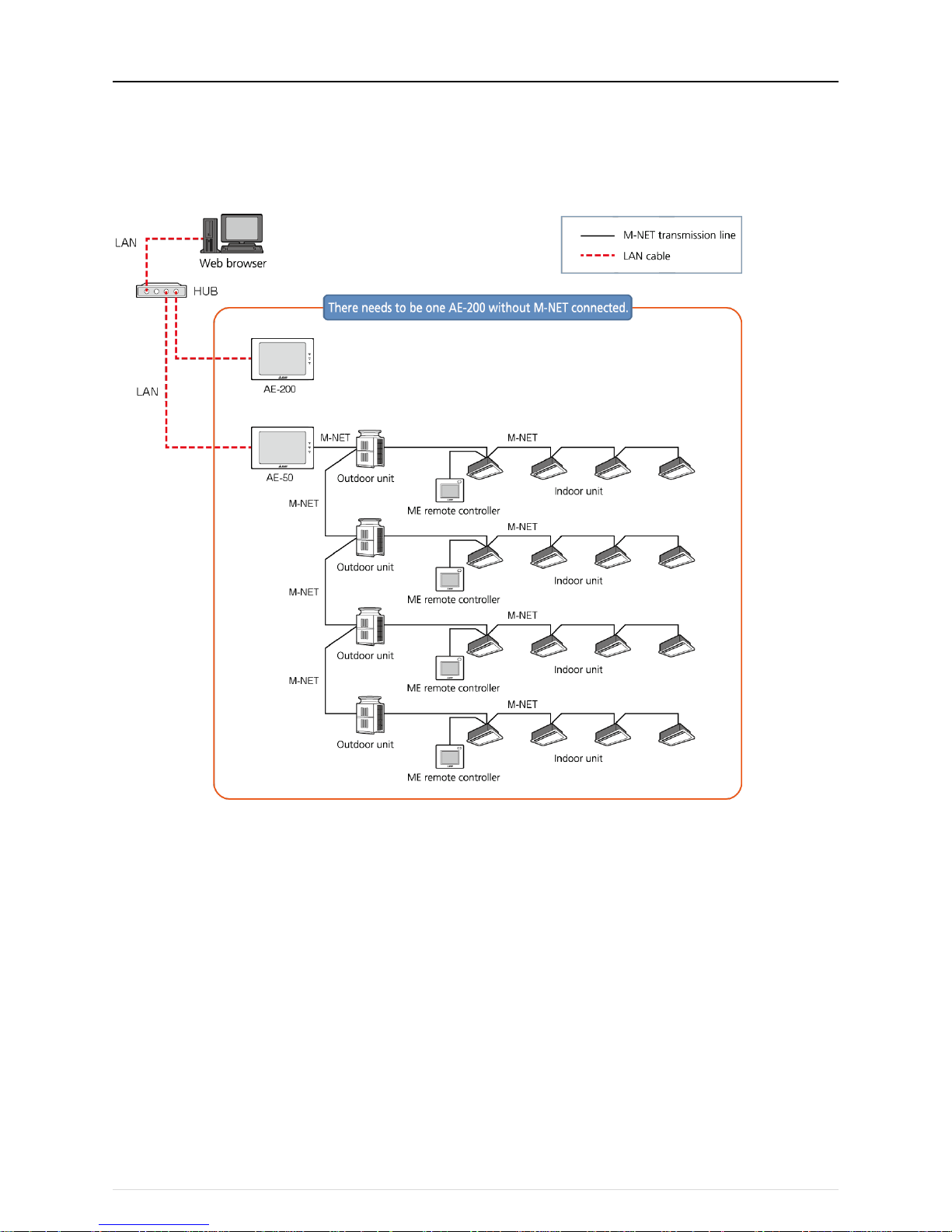

(3) When there are 50 or fewer air-conditioning units (apportioned electricity billing function is not used and M-NET transmission of the

AE-200 is not used)

When M-NET is connected to one AE-50 expansion controller, and AE-200 is used without using M-NET transmission line, up to 50

air-conditioning units can be monitored and operated from two AE-200/AE-50 locations.

Also, monitoring and operation from an AE-200 can be performed by connecting an EW-50 in the same way.

・ When using the Web browser function, access each AE-50/EW-50 t o perform monitoring and operation.

Page 18

[III System restrictions and notes]

14

(4) When there are 51 or more air-conditioning units (apportioned electricity billing function is not used and M-NET transmission of the

AE-200 is not used)

Up to 200 air-conditioning units can be monitored and operated by connecting an AE-200 and up to four AE-50/EW-50 expansion

controllers.

・ When using the Web browser function, access each AE-50/EW-50 t o perform monitoring and operation.

Page 19

[III System restrictions and notes]

15

(5) When using the apportioned electricity billing function and there are 50 or fewer air-conditioning units

Each AE-50/EW-50 expansion controller can monitor and operate up to a total of 50 air-conditioning units using the apportioned

electricity billing function.

・ When the apportioned electricity billing function is used, the combination of an AE-200 (without M-NET connection) and

AE-50/EW-50 expansion controller is required to obtain a backup of the data.

・ When the apportioned electricity billing function is used, the M-NET transmission line of the AE-200 cannot be used.

・ When using the Web browser function, access the AE-50/EW-50 to perform monitoring and operation.

・ Registration of the license is required for each centralized controller.

・ An electricity meter needs to be connected to each AE-200 system. Electricity meters connected to other AE-200 systems cannot

be set.

・ To set the apportioned electricity billing function, Initial Setting Tool is required.

・ To perform the charge calculation of the apportioned electricity billing function, Charge Calculation Tool is required.

・ When using the apportioned electricity billing function, use Ver.7.23 or later of AE-200/AE-50/EW-50.

Page 20

[III System restrictions and notes]

16

(6) When using the apportioned electricity billing function and there are 51 or more air-conditioning units

By using4 AE-50/EW-50 expansion controllers, up to a total of 200 air-conditioning units can be monitored and operated using the

apportioned electricity billing function.

・ When the apportioned electricity billing function is used, the M-NET transmission line of the AE-200 cannot be used.

・ When using the Web browser function, access the AE-50/EW-50 to perform monitoring and operation.

・ Registration of the license is required for each centralized controller.

・ An electricity meter needs to be connected to each AE-200 system. Electricity meters connected to other AE-200 systems cannot

be set.

・ To set the apportioned electricity billing function, Initial Setting Tool is required.

・ To perform the charge calculation of the apportioned electricity billing function, Charge Calculation Tool is required.

・ When using the apportioned electricity billing function, use Ver.7.23 or later of AE-200/AE-50/EW-50.

Page 21

[III System restrict i o ns and notes]

17

[3] Restrictions and Notes on AC Power Supply Wiring

(1) Notes

1. Perform electrical work in accordance with the instructions in the installation manual.

2. To prevent electrical noise from the power supply wiring affecting the wiring for transmission (control), lay the power supply wiring

at least 5 cm (2 in) apart if laying the wiring in parallel.

(Do not insert them in the same conduit.)

3. Be sure to connect the ground wire for protection.

4. Select electrical wiring that meets the requirements in the following table.

Recommended power

cable type

VCT, VVF, VVR, or its equivalent

Power cable size 0.75 to 2.00 mm2 (ø1.0 to ø1.6 mm)

[4] Restrictions and Notes on Transmission Wiring

(1) Notes

1. Perform electrical work in accordance with the instructions in the installation manual.

2. To prevent the wiring for transmission (control) from being affected by electrical noise from the power supply wiring, lay the wiring

for transmission (control) at least 5 cm (2 in) apart from the power supply wiring.

(Do not insert them in the same conduit.)

3. Never connect a 100 V or 200 V power supply to the terminal block for the transmission wiring. In the event that a power supply

is connected, the electrical components will burn out.

4. Use a 2-core shielded cable for the transmission wiring. Never use the same cable with multiple cores for wiring multiple systems

because the transmission signals will become unable to be sent and received normally, resulting in erroneous operation.

(2) M-NET transmission line

The type and tolerance of wiring differ depending on the system configuration. Furthermore, if the transmission line is long and there

is a noise source within the vicinity of a unit, move the noise source away from the unit to prevent noise interference.

Transmission line type*1

CPEVS ø1.2 to ø1.6 mm: PE insulated PVC jacketed shielded communication cable

CVVS, MVVS 1.25 to 2 mm

2

: PVC insulated PVC jacketed shielded control cable

Maximum length for

indoor/outdoor transmission

line

Max. 200 m (656 ft)

Farthest distance for

M-NET transmission line

(maximum length via an

outdoor unit)

Max. 500 m (1640 ft)

* The maximum wire length from the transmission line power supply unit installed for the

centralized control transmission line to each outdoor unit and system controller is 200 m (656 ft).

*1 PE: Polyethylene, PVC: Polyvinyl chloride

(3) Remote controller line

MA remote controller*1

M-NET remote controller*2

Wiring type

Type

VCTF, VCTFK , CVV , CVS ,

VVR, VVF, VCT

10 m (32 ft) or less

If 10 m (32 ft) is exceeded

Shielded wire CVVS,CPEVS,MVVS

Number

of wires

2-core cable

2-core cable

Wire

diameter

0.3 to 1.25 mm2*3*4

(0.75 to 1.25 mm2)*5

0.3 to 1.25 mm2*3*4

(0.75 to 1.25 mm2)*5

At least 1.25 mm

2

Total length

Max. 200 m (656 ft)*6

Max. 10 m (32 ft)

The portion that exceeds 10 m

(32 ft) must be included in the

calculation for the maximum

length of the indoor/outdoor

transmission line.

*1 MA remote controllers include simple MA remote controllers and wireless remote controllers.

*2 M-NET remote controllers refer to ME remote controllers and LOSSNAY remote controllers.

*3 A wire diameter of up to 0.75 mm

2

is recommended.

*4 When connecting an MA remote controller, use a 0.3 mm

2

cable with a sheath for the wiring.

*5 When connecting to the terminal block of a simple MA remote controller, use wire with a diameter within the parentheses.

*6 Maximum 100 m (328 ft) w hen connecting a pair of remote controllers including an MA remote controller.

Page 22

[III System restrictions and notes]

18

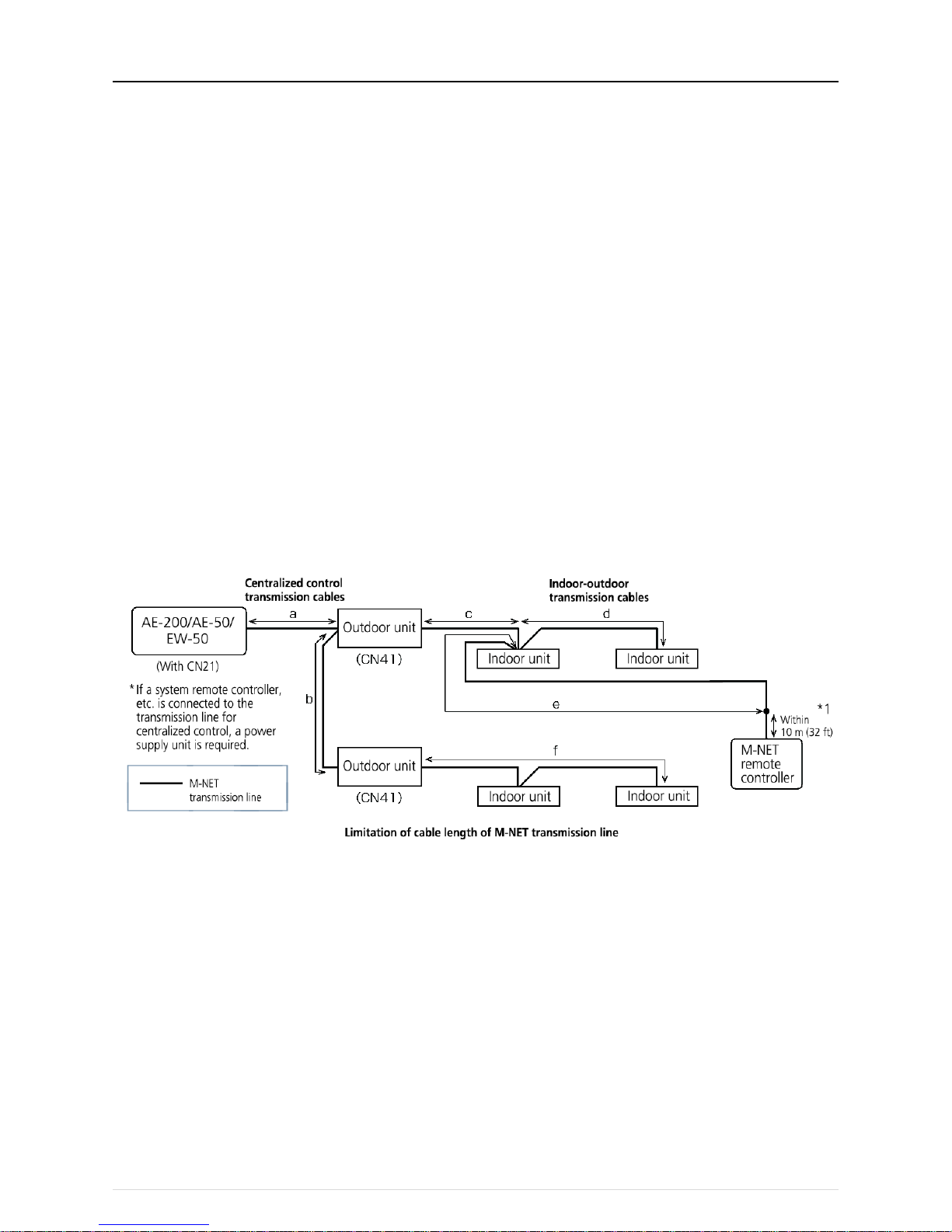

The following shows an example of a wiring diagram for the M-NET transmission line of CITY MULTI.

The example in the figure below shows the cable length limit of centralized control M-NET transmission line and indoor-outdoor M-NET

transmission line for each system.

1. Farthest distance for M-NET transmission line (limited by attenuation of the signal waveform)

・ Make the distance between the transmission source and transmission destination of signals no more than 500 m (1640 ft).

If this maximum distance is exceeded, communication will become impossible due to the attenuation of the waveform.

a+c+d ≤ 500 m (1640 ft), a+c+e ≤ 500 m (1640 ft), a+b+f ≤ 500 m (1640 ft), c+d+b+f ≤ 500 m (1640 ft), c+e+b+f ≤ 500 m

(1640 ft)

2. Maximum power supply distance for M-NET transmission line (limited by voltage drop)

(1) Maximum total length of power feed for the centralized control transmission lines

・ Make the distance between the supply source and supply destination of power no more than 200 m (656 ft).

If this maximum distance is exceeded, communication will become impossible due to the voltage drop.

a+c+d ≤ 200 m (656 ft), a+c+e ≤ 200 m (656 ft), a+b+f ≤ 200 m (656 ft)

* If a system remote controller, etc. is connected to the transmission line for centralized control, a power supply unit

(PAC-SC 51KUA) is required.

* There are cases where the supply source and supply destination of M-NET power differ depending on the setting of the

M-NET supply connector.

(2) Maximum total length of power feed for the indoor-outdoor transmission lines

・ Make the distance from an outdoor unit to the supply destination no more than 200 m (656 ft).

c+d ≤ 200 m (656 ft), c+e ≤ 200 m (656 ft)

*1 The wiring length of the M-NET remote controller must be 10 m (32 ft) or less. If 10 m (32 ft) is exceeded, the portion that

exceeds 10 m (32 ft) must be included in the calculations for the maximum total wiring length of the M-NET transmission line

(500 m (1640 ft)) and the maximum total power supply distance (200 m (656 ft)).

Page 23

[III System restrictions and notes]

19

[5] M-NET address settings

The setting range for the address setting differs depending on the device.

(1) AE-200

Use "0" (factory setting) for the address of the AE-200.

Change it to a value within the range of 201 to 250 only if it duplicates the address of another controller (BM adapter, etc.).

Address setting range Setting method When enabled

Unit address 0, 201–250

Any address within the address range on

the left.

Always*1

(Network setting screen)

*1 The setting is applied after a restart. (A restart is performed automatically after the setting is changed.)

The setting can be checked from the network setting screen of the LCD screen or a Web browser.

(2) AE-50/EW-50

Use "0" (factory setting) for the address of the AE-50/EW-50.

Change it to a value within the range of 201 to 250 only if it duplicates the address of another controller (BM adapter, etc.).

Address setting range Setting method When enabled

Unit address 0, 201–250

Any address within the address range on

the left.

Always*1

(Network setting screen)

*1 The setting is applied after a restart. (A restart is performed automatically after the setting is changed.)

The setting can be checked from the network setting screen of the LCD screen or a Web browser.

(3) Various M-NET devices

Designate the address for each M-NET device. The addresses cannot be overlapped within the same M-NET system.

Address setting method

M-NET

address

Indoor unit

Assign the lowest address to the main indoor unit in the group, and assign

sequential addresses to the rest of the indoor units in the same group.

1–50

Outdoor unit

Assign an address that equals the lowest indoor unit address in the same

refrigerant system plus 50.

51–100

Auxiliary outdoor unit

(BC controller etc.)

Assign an address that equals the address of the outdoor unit in the same

refrigerant system plus 1.

52–100

Interlocked OA Processing

unit/LOSSNAY

Assign an arbitrary but unused address to each of these units after assigning

an address to all indoor units.

1–50

A-control Mr. Slim outdoor unit

Make the settings in the same way as with the indoor units. Requires

PAC-SJ19MA-E/PAC-SJ83MA-E (sold separately).

1–50

Room air conditioner

Make the settings in the same way as with the indoor units. Requires

MAC-333IF (sold separately).

1–50

AHC

Assign an address that equals the address of the main indoor unit with the

lowest address in the group plus 200. If the address overlaps with the Sub

system controller’s address, assign an arbitrary but unused address between

201 and 250 to the Advanced HVAC CONTROLLER.

201–250

Air To Water (PWFY) unit

Make the settings in the same way as with the indoor units.

1–50

HWHP (CAHV, CRHV) unit

(Main Box)

Make the settings in the same way as with the indoor units.

1–50

HWHP (CAHV, CRHV) unit

(Sub Box)

Assign addresses that equal the addresses of the main and sub units in the

Main Box plus 50 to the units in the Sub Box.

51–100

M-NET remote controller

Assign an address that equals the address of the main indoor unit with the

lowest address in the group plus 100. Add 150 instead of 100 to set the

address for a sub remote controller.

101–200

MA remote controller

Address setting is not required.

Connection of two remote controllers requires the Main/Sub setting for each

controller to be made.

-

Sub System controller

Assign an address that equals the group number of the smallest controlled

group plus 200.

201–250

DIDO controller

Assign an arbitrary but unused address to the controller after completing the

address setting for the units with an address between 1 and 50. The number

of controllable units varies with the number of channels used.

1–50

PI controller

Assign an arbitrary but unused address to the controller after completing the

address setting for the units with an address between 1 and 50.

1–50

AI controller

Assign an arbitrary but unused address to the controller after completing the

address setting for the units with an address between 1 and 50.

1–50

* Some models cannot be controlled from the AE-200/AE-50/EW-50.

For details on the managed equipment, refer to "III [1] (1) Control target equipment."

Page 24

[III System restrictions and notes]

20

[6] Restrictions and notes on network wiring

NOTE:

When connecting the AE-200/AE-50/EW-50 to t he Internet, be sure to use a VPN router or other security device to prevent

unauthorized access.

(1) About LAN

We recommend using 100BASE-TX for the LAN.

Also, with regard to the category of LAN cables, use category 5 or better for reasons such as availability and connectivity with optical

cables (100BASE-FX).

The main cable type is shown in the following table.

LAN standard Cable specification

Maximum

wiring length

Communication

speed

100BASE-TX

Twisted pair cable (T)

100 m (328 ft)

100 Mbps

(2) About HUB

Use a switching HUB for the HUB.

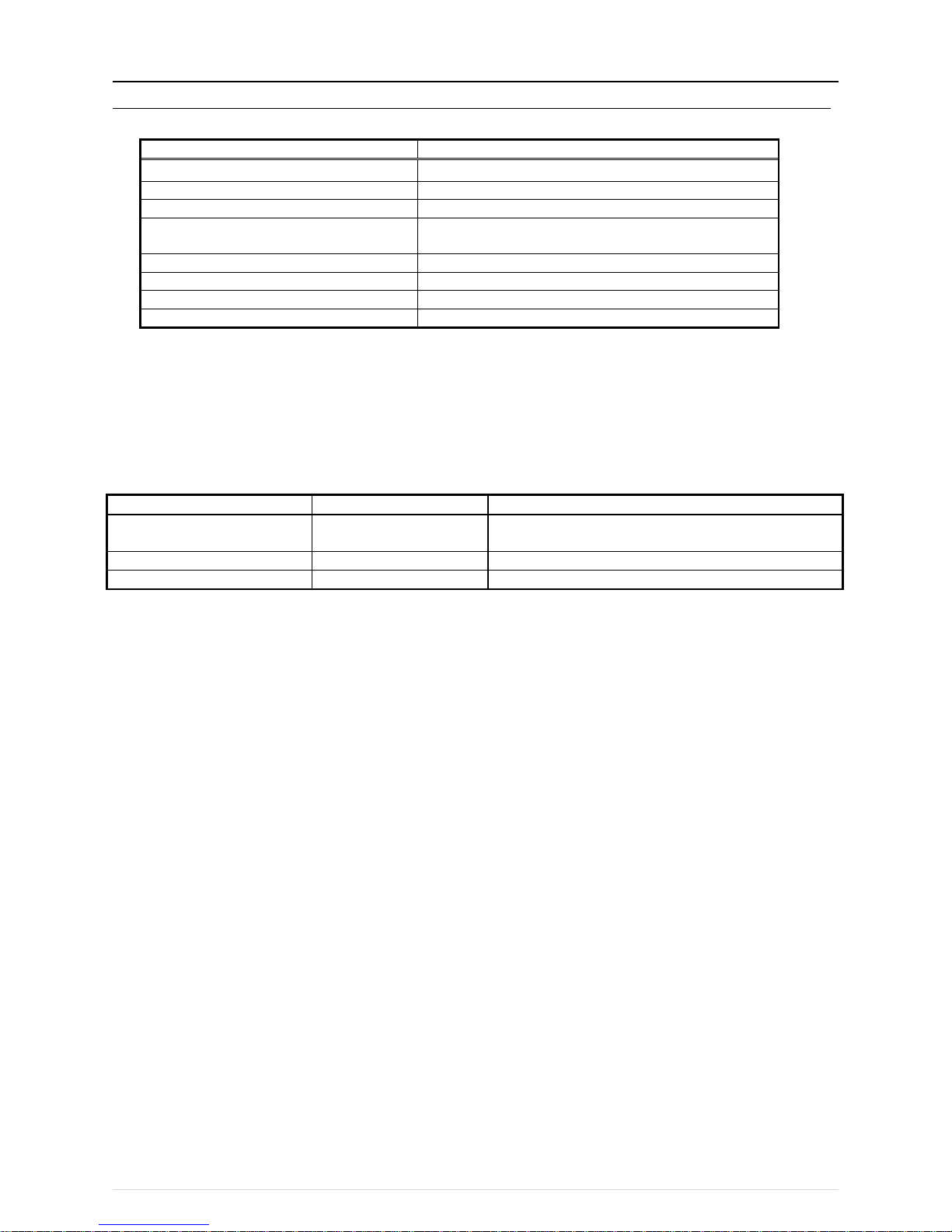

(3) LAN cable length

The maximum cable length for 100BASE-TX when connecting to the A E-200/AE-50/EW50 is 100 m (328 ft).

Therefore, if the LAN cable length exceeds 100 m (328 ft), you can increase the distance between the PC for state monitoring and

operation and the AE-200/AE-50/EW-50 by connecting via a switching HUB or other device.

NOTE:

For details on the switching HUB, refer the instruction manual supplied with the switching HUB.

There is no limit on the number of switching HUB connections, but if the load on the network becomes extremely high, delays will

occur and connecting normally with the network may not be possible.

The recommended number of devices, including a HUB, gateway, router, or layer 3 switch, to connect between the

AE-200/AE-50/EW-50 is four or less.

(The transmission delay time must be 4 seconds or less round trip. If the transmission delay time needs to be checked because, for

example, five or more devices are connected, refer to "V [5] 2. About the check method using ping.")

If a LAN communication error code appears, check the error as described in "V [5] LAN communication error check procedure."

NOTE:

○ Use commercially available LAN cables.

AE-200/AE-50/EW-50

100 m (328 ft)

PC for status

monitoring/operation

Switching HUB

100 m (328 ft)

Switching HUB

Switching HUB

Switching HUB

Page 25

[III System restrictions and notes]

21

[7] IP address settings

We recommend using the IP addresses in the following table for the AE-200/AE-50/EW-50, TG-2000A, and other equipment when

using a dedicated LAN.

Model

IP address range

AE-200/EW-50 unit *1

[192.168.1.1] to [192.168.1.40]

AE-50/EW-50 unit *1

[192.168.1.211] to [192.168.1.249]

PC for brow ser

[192.168.1.101] to [192.168.1.149]

PC for integrated centralized control software

TG-2000A

[192.168.1.150]

PLC for Electric Amount Count (PAC-YG11CDA)

[192.168.1.151] to [192.168.1.170]

PLC for General Equipment (PAC-YG21CDA)

[192.168.1.171] to [192.168.1.190]

PLC for Demand Input (PAC-YG41CDA)

[192.168.1.191] to [192.168.1.194]

Router

[192.168.1.254]

*1 Set an address within the range of [192.168.1.1] to [192.168.1.40] when using EW-50 individually and within the range of

[192.168.1.211] to [192.168.1.249] when using it as an expansion controller.

Unless otherwise specified, leave the subnet mask of the AE-200/AE-50/EW-50 set to the initial value of [255.255.255.0].

NOTE:

When connecting to an existing LAN, set the IP address and subnet mask specified by the LAN administrator.

The IP address range for various software of PLC differs depending on the model. We recommend using the IP address in the following

table.

Software name

Model name

IP addresses

Electric Amount Count PLC

Software

PAC-YG11CDA [192.168.1.151] to [192.168.1.155]

General Control PLC Software

PAC-YG21CDA

[192.168.1.171] to [192.168.1.190]

Demand Input PLC Software

PAC-YG41CDA

[192.168.1.191] to [192.168.1.194]

Page 26

[III System restrictions and notes]

22

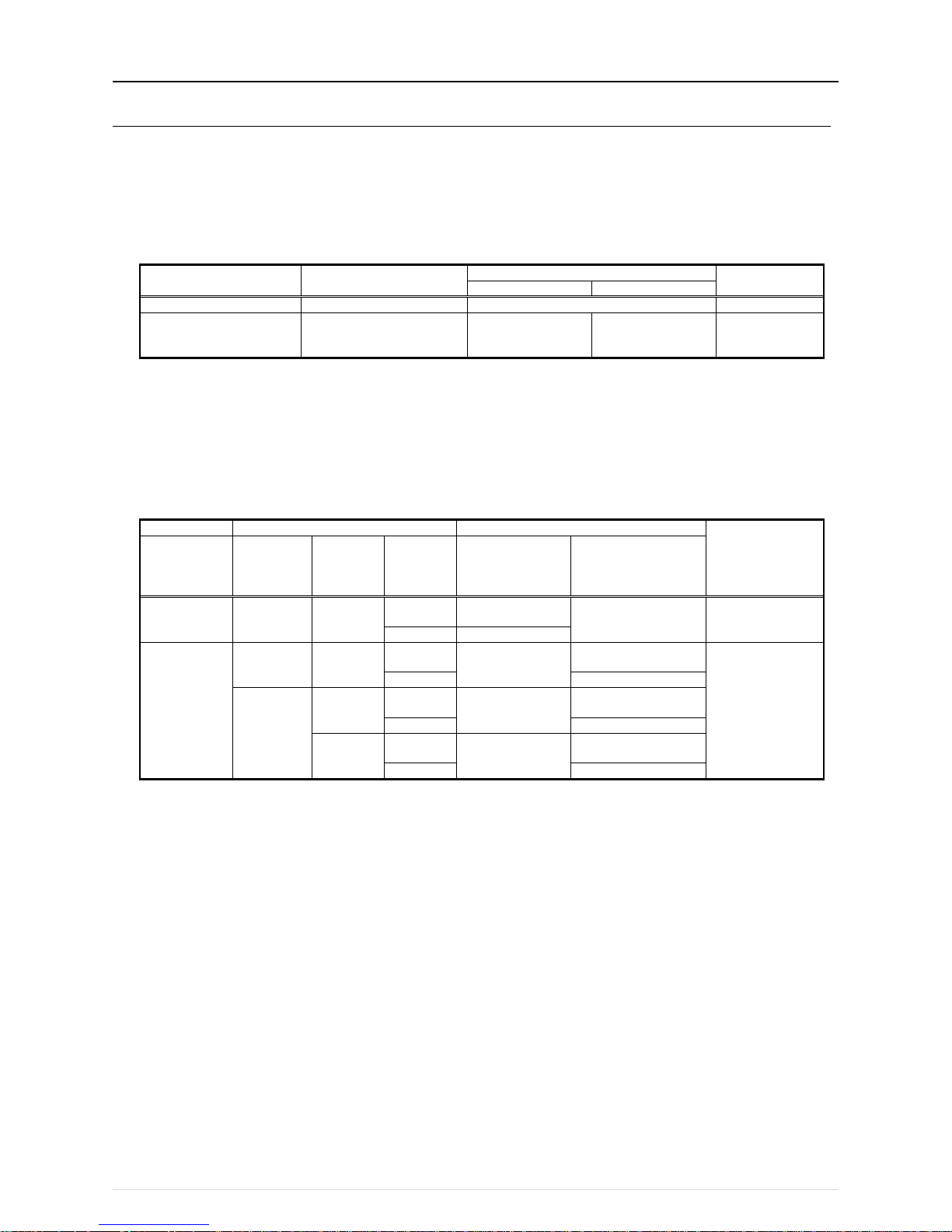

[8] Switch Settings

(1) AE-200/AE-50/EW-50 Switch Settings

The power jumper (CN21) needs to be set (disconnected/connected) depending on the system configuration.

For details, refer to "III [2] System connection examples."

(2) Main board of outdoor units

The following shows the DIP switches to use for a system with the AE-200/AE-50/EW-50 connected.

When connecting the AE-200/AE-50/EW-50, set t he centralized control switch to ON.

Switches Function

Operations according to switch setting

Switch setting

timing

OFF

ON

SWU1, 2

Unit address setting

Set to 51 to 100 with the dial switch

Before power on

SW2–1

(SW 5–1 depending on the

model)

Centralized control switch

Without connection

to centralized

controller

With connection to

centralized controller

Before power on

Change the setting of the power jumper of the outdoor units in accordance with the system to be built.

For details, refer to the illustrations in "III [2] System connection examples."

(3) Indoor Units

The following shows the switch settings to change to the free contact mode that can generally use external inputs and outputs of an

indoor unit.

The free contact compatible models of indoor units are R410A compatible models and R407C compatible Ver.33 or later

*1

.

*1 The version can be verified in the indoor unit version display part in Maintenance Tool.

Function

Switch settings

Other functions

Remarks

Free contact SW1–10 SW1–9 SW1–5

Power ON/OFF

and power failure

automatic

recovery

Remote display

switching

Enabled ON ON

ON

Power failure auto

recovery

Disabled

Differs from switch

setting.

OFF

Disabled

Disabled

ON OFF

ON

Power ON/OFF

Thermostat ON signal

display

Depends on the

original switch

setting.

OFF

Fan output display

OFF

ON

ON

Power failure auto

recovery

Thermostat ON signal

display

OFF

Fan output display

OFF

ON

Disabled

Thermostat ON signal

display

OFF

Fan output display

(Reference) For a model prior to the free contact compatible models, SW1-5 is remote display switching, SW1-9 is power failure auto

recovery, and SW1-10 is power ON/OFF.

Page 27

[III System restrictions and notes]

23

[9] Other points to note

(1) About using General equipment

・ There may be cases when the general equipment cannot be monitored or operated due to, for example, a disconnection of the

wiring between the general equipment or a failure of the DIDO controller or PLC. In such a case, Mitsubishi Electric will not be held

liable in the event of any damages. We recommend providing a circuit that enables emergency remedial operation, etc. to be

performed when a failure occurs.

・ With the Ver.1 series of General Control PLC Software, the license number does not need to be registered to the

AE-200/AE-50/EW-50.

・ With the Ver.2 series of General Control PLC Software, General Control PLC Software License is not required to operate and

monitor general equipment and use the schedule functions, but TG-2000A is required.

To use interlock control, General Control PLC Software License is required for each AE-200/AE-50/EW-50.

General Control PLC Software License is required even for interlock control within the PLC.

・ A license number does not need to be registered to, for example, operate general equipment with a DIDO controller.

(2) About USB memory devices

● Select a USB memory device that meets the following conditions and verify operation several times before use.

* Reading and writing with a memory device for which operation has not been verified may cause an unexpected operation.

Therefore, verify operation of the memory device (during trial operation) before use.

Do not use a USB memory device for which a data writing error has occurred.

1. USB standard: Supports USB 2.0.

2. Formatted with FAT32 or FAT (FAT16)

3. Security function is not provided or not required to be set.

(Depending on the security function, there may also be some USB devices for which use is possible.)

In cases such as when data writing can still not be performed normally when a USB memory device has been replaced with

another one after a data error occurs, restart the AE-200/AE-50/EW-50 (turn the power off and then back on) and then perform

the check again with a USB memory device other than the one with which the error first occurred.

● Do not remove and insert a USB memory device during writing to a USB memory device.

A USB memory device may not be recognized if it is removed and inserted within a short period of time.

If that happens, the unit needs to be restarted (turn the power off and then back on).

Page 28

[IV Product specifications and function s ]

24

IV Product specifications and functions

[1] Structure of AE-200/AE-50/EW-50 .......................................................................................... 25

1. External dimensions ............................................................................................................ 25

2. Location of main parts ......................................................................................................... 27

3. Electrical wiring diagram ...................................................................................................... 30

4. How to remove and attach the cover .................................................................................. 32

[2] Product specifications of AE-200/AE-50/EW-50 ..................................................................... 34

1. Product specifications .......................................................................................................... 34

2. AE-200/AE-50/EW-50 unit functions and Web browser functions ..................................... 36

[3] PC operating environment ....................................................................................................... 40

[4] Various Functions..................................................................................................................... 41

1. Functions and required equipment and materials .............................................................. 41

2. Functions and licenses ........................................................................................................ 43

[5] How to check the version of AE-200/AE-50/EW-50 ................................................................ 44

Page 29

[IV Product specifications and function s ]

25

[1] Structure of AE-200/AE-50/EW-50

1. External dimens ions

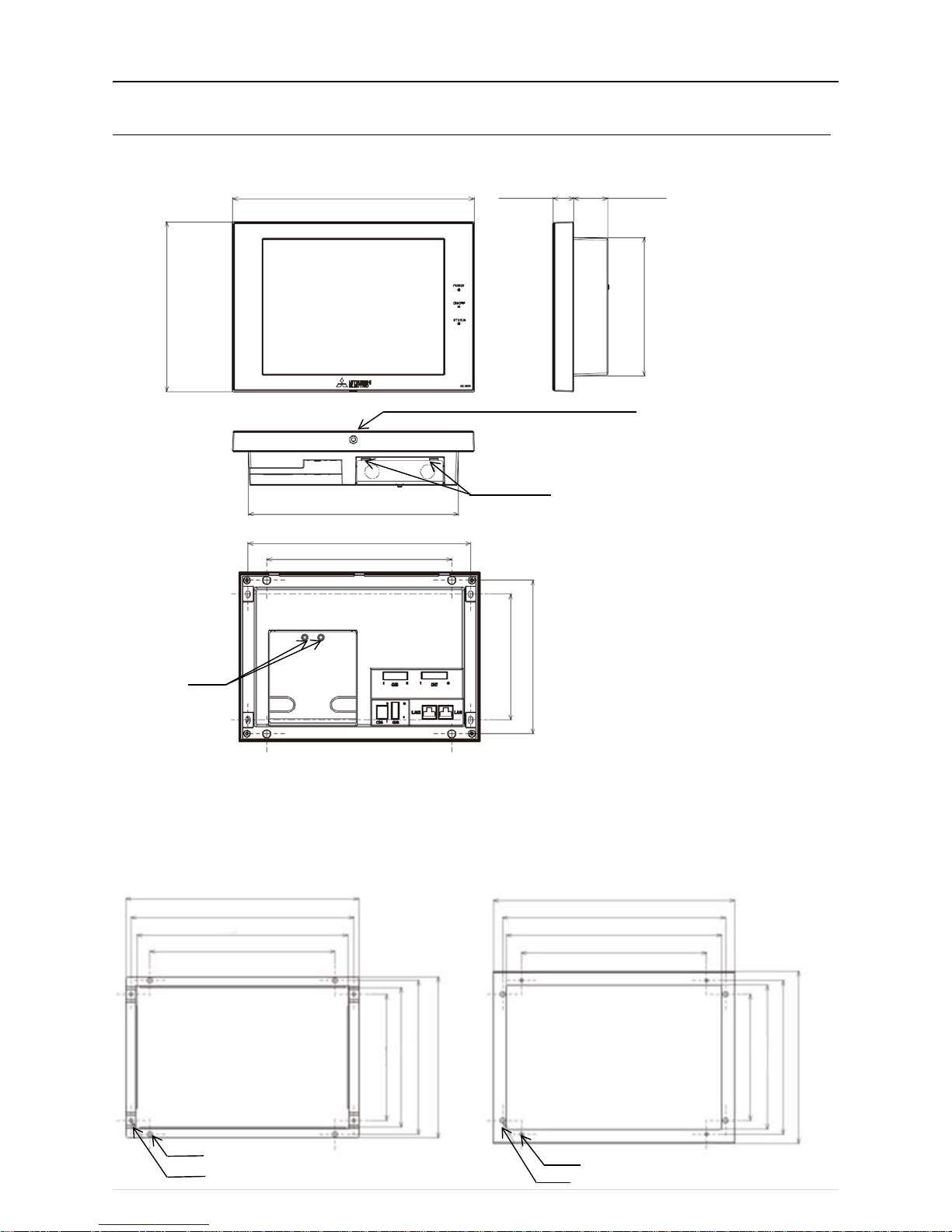

(1) AE-200/AE-50 *1

*1 The dimensions of the AE-200 and AE-50 are the same.

*2 The protrusion when the unit is mounted to a wall or metal control box is 25.0 mm.

*3 A hex key for removing the hex socket bolt is supplied with the AE-200/AE-50 unit.

For how to use it, refer to "IV [1] 4. How to remove and attach the cover."

Mounting plate (supplied)

Used when mounting to a wall or metal control box.

For the mounting procedure, refer to "4-1-2 Wall-embedded installation" in the AE-200/AE-50 Installation Manual.

M4 hex socket bolt (2.5 mm (0.1 in) across flats)*3

40 (1.6)

Bottom hooks

Mounting screws

284 (11)

163 (6.4)

Mounting plate A

Mounting plate B

164 (6.5)

180.4 (7.1)

188.9 (7.4)

148 (5.8)

169.2 (6.7)

180.4 (7.1)

202.1 (8)

217 (8.5)

247 (9.7)

261.2 (10.3)

272.7 (10.7)

282.7 (11.1)

261.2 (10.3)

252.2 (9.9)

217 (8.5)

φ6

φ4

φ6

Unit: mm (in)

25 (0.9)* 2

200 (7.8)

246 (9.6)

261.2 (10.2)

217 (8.5)

180.4 (7.1)

148 (5.8)

φ4

148 (5.8)

Page 30

[IV Product specifications and funct ion s]

26

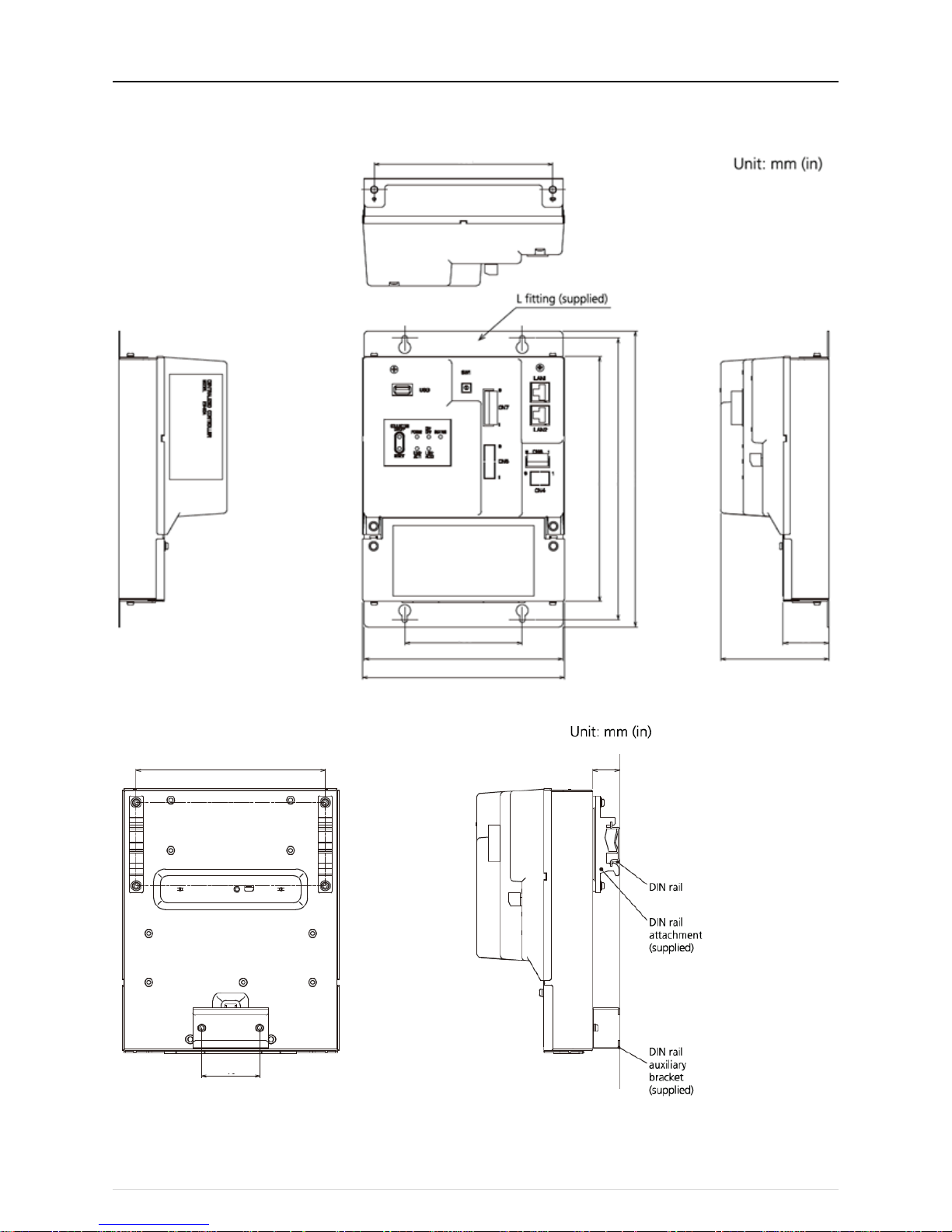

(2) EW-50

When attaching L-fittings

When mounting on DIN rails

* For the installation method, refer to "4. Installation" in the EW-50 Installation and Instructions Manual

152 (6)

100 (3.9)

169 (6.7)

172 (6.8)

209 (8.2)

240 (9.4)

253 (9.7)

38 (1.5)

92 (3.6)

46 (1.8)

150 (5.9)

23 (0.9)

Page 31

[IV Product specifications and function s ]

27

2. Location of main parts

(1) Front of AE-200/AE-50

LED

Description

Power

Lit in green

Power ON

Unlit

Power OF F

LAN1

Blink in orange

Data transmission in progress (LAN1)

LAN2

Planned to be used with BACnet

ON/OFF

Lit in green

One or more air conditioning units are ON.

Blink in green One or more air conditioning units or other related equipment are

in error.

Unlit

All air conditioning units are OFF.

Status

Blink in orange

Error in SD card, or startup failed

Blink in blue

Software update in progress

Blink in pink

Software update failed Item

Description

Reset switch

Used to reboot the AE-200/AE-50.

Collective ON/OFF switch Collectively runs/stops air-conditioning units that have their own

M-NET connected.

The operation becomes the collective stop operation if even one

air-conditioning unit is operating, and the collective run operation if

they are all stopped.

USB port Used when updating the software version, backing up the setting

data, and acquiring billing data.

Model name

Collective ON/OFF switch

Power

LAN1

ON/OFF

Status

Reset switch

Display/touch panel

USB port

for USB

memory

device

LAN2

Decorative cover

* In the case of the AE-50, the model name at the bottom right is "AE-50."

* To remove the decorative cover, you need to remove the hex socket bolt at the bottom.

* If the separately sold cover with a USB door (PAC-YE72CWL) is used, a USB memory device can be connected without

removing the decorative cover.

Page 32

[IV Product specifications and function s ]

28

(2) Back of AE-200/AE-50

Item

Description

LAN1

Connect with other equipment over a LAN via a switching HUB.

LAN2

Planned to be used with BACnet

CN7

Pulse input

Connect the pulse detector of an electricity meter.

CN6

RS-422/485

Unused

CN4

RS-232C

Unused

CN5

External I/O

Cut out the knockout hole and then connect an external I/O adapter (PAC-YG10HA).

TB3 M-NET A, B, S

(M3.5)

M-NET transmission line terminal block

Connect with an outdoor unit using an M-NET transmission line.

(A, B: Non-polarized, S: Shielded)

Ground

(M4)

Connect a ground wire for protection.

CN21 M-NET power jumper Connect the power jumper to supply power to M-NET (default).

If another system controller is connected to the same M-NET, disconnect the power

jumper to supply power to the M-NET from the power supply unit.

TB1 AC power supply

L/L1, N/L2

(M3.5)

Connect an AC power supply cable.

Service cover

* To remove the service cover,

you need to remove the two

fixing screws from the back and

then unhook the hooks at the

bottom.

* When attaching the service

cover, be sure to hook the hooks

before securing the cover with

the two screw s.

Page 33

[IV Product specifications and function s ]

29

(3) Front of EW-50

LED

Description

Power

Lit in green

Power ON

Unlit

Power OF F

ON/OFF

Lit in green

One or more air conditioning units are ON.*1

Blink in green

One or more air conditioning units or other related equipment are in error.

Unlit

All air conditioning units are OFF.*1

Status

Blink in orange

Startup error

Blink in blue

Software update in progress

Blink in pink

Software update failed

LINK/ACT1

Blink in orange

Data transmission in progress (LAN1)

LINK/ACT2

Unused (planned to be used with BACnet)

*1 The statuses of other related equipment are not indicated.

Item

Description

Push switch ON/OFF Collectively runs/stops air-conditioning units that have their own M-NET

connected.

The operation becomes the collective stop operation if even one

air-conditioning unit is operating, and the collective run operation if they are all

stopped.

Reset Used to reboot the EW-50. (This will not affect the operation status of the air

conditioning units.)

USB port

Unused

SW1

Simple address setting

IP addresses can be easily set with SW1.

LAN1

LAN connection

Connects to other units of equipment over the LAN via a HUB.

LAN2

Planned to be used with BACnet

CN7

PI

Connects to metering devices using the supplied connector.

CN6 Unused

CN4 Unused

CN5 External I/O Connects to an external input/output adapter (PAC-YG10HA) by cutting out the

knockout hole.

CN21 M-NET power jumper Connects to the M-NET power jumper to supply power (default).

If another system controller is connected to the same M-NET system and the

equivalent power consumption is 6 or above, disconnect the M-NET pow er

jumper to supply power from the separately-sold power supply unit.

TB3 M-NET A,B,S (M3.5) M-NET transmission terminal block

Connects to M-NET transmission lines from the outdoor unit.

(A, B: Non-polarized, S: Shield)

TB1 Power source AC L/L1, L/L2

(M3.5)

Connects to the power cable.

Ground

(M4)

Connects to the protective ground wire.

Page 34

[IV Product specifications and function s ]

30

3. Electrical wiring diagram

(1) AE-200/AE-50

Board

Code

Name

Board

Code

Name

SUBPWR

TB1 Power terminal block

M-NET

CN5 Connector (external I/O)

TB3 M-NET transmission terminal block CN7 Connector (pulse input)

CN21 Jumper (power supply selector)

CONT

D651 LED (POWER)

F751 Fuse (250 VAC T6.3AH) D652 LED (ON/OFF)

F752 Fuse (250 VAC T2A) D653 LED (STATUS)

MAIN

CN4 Connector (RS-232C) D654 LED (LAN1 LINK/ACT)

CN6 Connector (RS-422/485) D655 LED (LAN2 LINK/ACT)

CN19 Connector (SD card) S651 Reset switch

LAN1 Connector (LAN1) S652 Collective ON/OFF switch

LAN2 Connector (LAN2) USB CN18 Connector (USB)

Page 35

[IV Product specifications and function s ]

31

(2) EW-50

Board

Code

Name

Board

Code

Name

SUBPWR

TB1 Power terminal block

M-NET

CN5 Connector (external I/O)

TB3 M-NET transmission terminal block CN7 Connector (pulse input)

CN21 Jumper (power supply selector) SW1 Switch (IP address setting)

F751 Fuse (250 VAC T6.3AH)

LED

D651 LED (POWER)

F752 Fuse (250 VAC T2A) D652 LED (ON/OFF)

CN4 Connector (RS-232C) D653 LED (STATUS)

MAIN

CN6 Connector (RS-422/485) D654 LED (LAN1 LINK/ACT)

CN19 Connector (SD card) D655 LED (LAN2 LINK/ACT)

LAN1 Connector (LAN1) S651 Reset switch

LAN2 Connector (LAN2) S652 Collective ON/OFF switch

USB CN25 Connector (USB)

Page 36

[IV Product specifications and function s ]

32

4. How to remove and attach the cover

(1) AE-200/AE-50

Item

Work procedure Illustrations

How to remove the

decorative cover

Use the supplied hex key to remove the hex socket bolt

from the bottom of the decorative cover.

How to attach the

decorative cover

Attach the decorative cover to the AE-200/AE-50 unit

and then use the supplied hex key to screw the hex

socket bolt into the bottom of the decorative cover.

How to remove the service cover

[Wiring at the back]

Remove the two fixing screw, lift up the service cover,

and remove the cables from the holes for wiring.

Unhook the bottom hooks from the AE-200/AE-50 unit.

[Wiring at the bottom]

Remove the two fixing screws and unhook the bottom

hooks from the AE-200/AE-50 unit.

・ How to remove the service cover

1. Remove the two fixing screws and lift up the cover.

(Do the same for the wiring at the bottom)

2. Remove the cables from the holes for wiring.

(Only for the wiring at the back)

3. Unhook the bottom hooks from the AE-200/AE-50 unit. (Do

the same for the wiring at the bottom)

How to attach the service cover

[Wiring at the back]

Insert the bottom hooks of the service cover into the

AE-200/AE-50 unit.

Close the cover so that the power supply cable and

M-NET transmission line pass through the holes for the

wiring of the service cover.

Secure the service cover with the two fixing screws.

[Wiring at the bottom]

Check that the power cable and M-NET transmission

line are routed through the knockout holes and

connected to the terminals.

Insert the bottom hooks of the service cover into the

AE-200/AE-50 unit and then secure cover the two fixing

screws.

(Supplied)

Page 37

[IV Product specifications and function s ]

33

(2) EW-50

Item

Work procedure

Illustrations

How to remove the service

cover

Remove the two fixing screw and lift up the service

cover.

How to attach the service cover

Hook the claws at the top of the service cover onto

the EW-50 unit and then secure the cover with the

fixing screws.

Note: When attaching the service cover, take care

that the power supply cable and transmission

line are not trapped between the EW-50 unit

and service cover.

Page 38

[IV Product specifications and function s ]

34

[2] Product specifications of AE-200/AE-50/EW-50

1. Product specifications

(1) Product specifications

The following shows the product specifications of the AE-200/AE-50.

Item

Specifications

Power supply (for

driving unit)

Rated input 100–240 VAC ± 10%; 50/60 Hz Single-phase

Power consumption

12 W

M-NET equivalent power supply No specifications

Only an MN converter can be connected.

Ambient conditions Operating temperature

range

0°C – +40°C (+32°F – +104°F)

Storage temperature

range

-20°C – +60°C (-4°F – +140°F)

Humidity

30%–90% RH (Non-condensing)

Weight

2.3 kg (5-5/64 lbs)

Dimensions (W × H × D) 284 × 200 × 65 mm (11-5/32 × 7-55/64 × 2-17/32 in)

* When installed, AE-200/AE-50 will protrude 25.0 mm (31/32 in) from the

wall or the metal control box.

Installation environment Indoor only

・ For an office environment, install inside a metal control box or similar

environment.

● The above specifications are subject to change without notice for improvement.

The following shows the product specifications of the EW-50.

Item

Specifications

Power supply (for

driving unit)

Rated input 100–240 VAC ± 10%; 50/60 Hz Single-phase

Power consumption

12 W

M-NET equivalent power supply

The equivalent power supply of 1.5

Ambient conditions Operating temperature

range

-10°C – +55°C (14°F – +131°F)

Storage temperature

range

-20°C – +60°C (-4°F – +140°F)

Humidity

30%–90% RH (Non-condensing)

Weight

1.7 kg (4 lbs)

Dimensions (W × H × D) 172 × 209 × 92 mm (6-13/16 × 8-4/16 × 3-10/16 in)

(172 × 253 × 92 mm (10 × 6-13/16 × 3-10/16 in) when using L-fittings)

Installation environment Only in a metal control box indoors

● The above specifications are subject to change without notice for improvement.

Page 39

[IV Product specifications and function s ]

35

(2) Default Settings

The following table lists the default settings of the AE-200/AE-50/EW-50.

Item

AE-200A/AE-50A/EW-50A

AE-200E/AE-50E/EW-50E

Common settings

Date and time settings

April 1, 2014

IP addresses

192.168.1.1

Subnet mask

255.255.255.0

Gateway address

Unset

M-NET address

0

Range of prohibited controllers

SC/RC

External input setting*1

Do not use

External output setting*1

ON/OFF and Error/Normal

Time master setting

Master

Schedule/Season setting

Enabled

Old model compatible mode

OFF

System expansion

Do not expand

AE-200 M-NET *1

Use

AE-200 apportioning *1

Do not use

Occupancy sensor display setting

Show occupancy mark

Brightness sensor display setting

Hide

Date format

dd/mm/yyyy

yyyy/dd/mm

Time format

AM/PM

24-hour display

Unit of temperature display

°F

°C

Room temperature display

*2

Unit of pressure display

PSI

MPa

Humidity display

Display

Maintenance user name

initial

Maintenance user password

init

Administrator user name

administrator

Administrator user password

admin

Unit screen settings

Sound

Level 1

Brightness

100%

Test run

Do not use

Screen lock

Do not use

Administrator user restriction functions

Unit information

Advanced settings

Network settings

Group settings (group configuration)

Interlock LOSSNAY settings

Block settings (block configuration)

Floor layout (floor configuration)

Energy management settings

Peak cut (system configuration)

Web browser settings

List screen group name display

ON

Filter sign display

ON

Administrator user restriction functions

Basic system

Group settings (group configuration)

Interlock LOSSNAY settings

Block settings (block configuration)

Peak cut (system configuration)

Measurement settings

*1 AE-200 only

*2 The settings differ between the LCD screen and the Web browser.

Page 40

[IV Product specifications and function s ]

36

2. AE-200/AE-50/EW-50 unit fu nctio ns and Web browse r func tions

The following table lists the AE-200/AE-50/EW-50 unit functions and Web browser functions.

○: Function available

Item Description

Unit

Web

browser

ON/OFF/Test run

The equipment can be turned on and off and operated per group, per block, or per floor, or

collectively. When the test run mode is selected, the test run operation can be performed. (Unit

screen only)

○ ○

Operation mode

The operation mode can be switched between Cool, Dry, Heat, Fan, and Auto per group, per block,

or per floor, or collectively.

○ ○

Set temperature

The indoor temperature can be set per group, per block, or per floor, or collectively. (0.5°C (1°F)

increments)

Setting temperature range Cool/Dry: 19°C to 35°C (66°F to 95°F) (14°C to 30°C (57°F to 86°F)

when mid temperature model connected)

Heat: 4.5°C – 28°C (40°F – 82°F)

Auto: 19°C to 28°C (66°F to 82°F) (17°C to 28°C (63°F to 82°F)

when mid temperature model connected)

Note: The settable temperature differs depending on the model.

Note: The set temperature may be in 1°C (2°F) increments depending on the model.

Note: The set temperature may be able to be registered for each of the cool and heat

modes depending on the model.

○ ○

Fan speed / Air flow

(LOSSNAY)

*1

The fan speed can be switched to any of four levels per group, per block, or per floor, or collectively.

(There may be no levels, 2 levels, 3 levels, or 4 levels depending on the model, and auto operation is

available for models with an auto function.)

(In the case of LOSSNAY, the fan speed can be switched to Very Low, Low, High, and Auto. The air

flow levels that can be selected differ depending on the model. However, there are the two levels of

Low and High in the case of an interlocked LOSSNAY.)

○ ○

Air flow direction

setting

The air direction setting can be switched to any of five vertical air flow directions, auto, and swing per

group, per block, or per floor, or collectively. (The air flow functions that can be selected differ

depending on the model.)

Operation with five air flow directions and auto is possible only for the models with those functions.

○ ○

Ventilation mode

(LOSSNAY)*1

The ventilation mode can be switched to any of Bypass, Heat Recovery, and Auto per group, per

block, or per floor, or collectively.

○ ○

ON/OFF of interlocked

LOSSNAY*1

When there are interlocked LOSSNAY, they can be switched ON (high/low) or OFF per group or per

block, or collectively.

○ ○

Monitoring of energy

use status*2

The electric energy consumption, outdoor temperature, operation time, and other information can be

displayed and compared in bar graphs and line graphs.

Note: A PI controller and electricity meter (pulse output type) need to be connected to display the

electric energy consumption.

The electric energy consumption cannot be displayed with a PLC for Electric Amount Count

connection.

An AI controller or AHC and a temperature sensor need to be connected for outdoor

temperature display.

○ ○

Ranking*2

The consumption and time can be displayed ranked in order of largest to smallest for electric energy

consumption and fan operation time.

Note: The ranking of electric energy consumption can only be displayed by block.