Mitsubishi EVO X Repair Manual

GROUP 15

INTAKE AND

EXHAUST

CONTENTS

15-1

GENERAL INFORMATION . . . . . . . . 15-2

SERVICE SPECIFICATION . . . . . . . . 15-2

INTAKE AND EXHAUST DIAGNOSIS 15-2

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . 15-2

TROUBLESHOOTING STRATEGY . . . . . . 15-2

SYMPTOM CHART. . . . . . . . . . . . . . . . . . . 15-2

SYMPTOM PROCEDURES . . . . . . . . . . . . 15-3

SPECIAL TOOLS. . . . . . . . . . . . . . . . 15-4

TROUBLESHOOTING . . . . . . . . . . . . 15-4

ON-VEHICLE SERVICE. . . . . . . . . . . 15-5

MANIFOLD VACUUM CHECK . . . . . . . . . . 15-5

INTAKE CHARGE PRESSURE CHECK . . 15-5

TURBOCHARGER WASTEGATE ACTUATOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-6

INTAKE CHARGE PRESSURE CONTROL

SYSTEM CHECK . . . . . . . . . . . . . . . . . . . . 15-7

TURBOCHARGER WASTE GATE SOLENOID

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-8

TURBOCHARGER BYPASS VALVE

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-9

AIR CLEANER . . . . . . . . . . . . . . . . . . 15-10

REMOVAL AND INSTALLATION . . . . . . . . 15-10

INTAKE MANIFOLD . . . . . . . . . . . . . . 15-12

REMOVAL AND INSTALLATION . . . . . . . . 15-12

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 15-14

CHARGE AIR COOLER . . . . . . . . . . . 15-15

REMOVAL AND INSTALLATION . . . . . . . . 15-15

EXHAUST MANIFOLD AND

TURBOCHARGER . . . . . . . . . . . . . . . 15-16

REMOVAL AND INSTALLATION . . . . . . . . 15-16

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 15-23

EXHAUST PIPE AND MAIN

MUFFLER . . . . . . . . . . . . . . . . . . . . . . 15-24

REMOVAL AND INSTALLATION . . . . . . . . 15-24

15-2

INTAKE AND EXHAUST

GENERAL INFORMATION

GENERAL INFORMATION

The exhaust pipe is divided into three parts.

SERVICE SPECIFICATION

ITEM STANDARD VALUE LIMIT

Manifold distortion of the installation surface mm (in) 0.15 (0.006) or less 0.20 (0.008)

Intake charge pressure kPa (psi) 85 − 159 (12.4 − 23.0)

Turbocharger waste gate actuator pressure kPa (psi) 98 − 102 (14.3 − 14.7)

No. 1 Turbocharger waste gate solenoid terminal

resistance [at 20

No. 2 Turbocharger waste gate solenoid terminal

resistance [at 20

Exhaust manifold distortion of the installation surface

mm (in)

° C (68° F) ] Ω

° C (68° F) ] Ω

29 − 35

29 − 35

−

−

−

−

−

0.70 (0.028)

M1151000101041

M1151000301335

INTAKE AND EXHAUST DIAGNOSIS

INTRODUCTION

Intake leaks usually create driveability issues that

are not obviously related to the intake system.

Exhaust leaks or abnormal noise is caused by

cracks, gaskets and fittings, or by exhaust pipe or

muffler damage due to impacts during travel. The

exhaust leaks from these sections and causes the

exhaust noise to increase. There may be cases

when the system contacts the body and vibration

noise is generated.

TROUBLESHOOTING STRATEGY

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find an

intake or exhaust system fault.

1. Gather information from the customer.

SYMPTOM CHART

Symptom Inspection procedure Reference page

Exhaust Leakage 1

Abnormal Noise 2

2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

P.15-3

P.15-3

M1151006900406

M1151007000398

M1151007100395

TSB Revision

INTAKE AND EXHAUST

INTAKE AND EXHAUST DIAGNOSIS

SYMPTOM PROCEDURES

Inspection Procedure 1: Exhaust Leakage

15-3

DIAGNOSIS

STEP 1. Start the engine. Have an assistant stay

in the driver’s seat. Raise the vehicle on a hoist.

Have the assistant rev the engine while

searching for exhaust leaks.

Q: Is the exhaust leaking?

YES : Go to Step 2.

NO : The procedure is complete.

Inspection Procedure 2: Abnormal Noise

DIAGNOSIS

STEP 1. Start the engine. Have an assistant stay

in the drivers seat. Raise the vehicle on a hoist.

Have the assistant rev the engine while

searching for exhaust leaks.

STEP 2. Check the gasket for cracks, damage.

Q: Is the gasket damaged?

YES : Replace the gasket, then go to Step 1.

NO : Go to Step 3.

STEP 3. Check for loosening in each coupling

section.

Q: Is there any loosening in any section?

YES : Tighten, then go to Step 1.

NO : There is no action to be taken.

STEP 4. Check for interference of the pipes and

muffler with the body.

Q: Are the pipes and muffler interfering with the

body?

YES : Repair, then go to Step 1.

NO : Go to Step 5.

Q: Is any abnormal noise generated?

YES : Go to Step 2.

NO : The procedure is complete.

STEP 2. Check for missing parts in the muffler.

Tap the muffler lightly to check for loose baffles,

etc.

Q: Are there any missing parts in the muffler?

YES : Replace, then go to Step 1.

NO : Go to Step 3.

STEP 3. Check the hanger for cracks.

Q: Is the hanger cracked?

YES : Replace, then go to Step 1.

NO : Go to Step 4.

STEP 5. Check the heat protectors.

Q: Are any heat protectors loose or damaged?

YES : Tighten or replace, then go to Step 1.

NO : Go to Step 6.

STEP 6. Check the pipes and muffler for damage.

Q: Are the pipes and muffler damaged?

YES : Replace, then go to Step 1.

NO : There is no action to be taken.

TSB Revision

15-4

INTAKE AND EXHAUST

SPECIAL TOOLS

SPECIAL TOOLS

Tool Tool number and name Supersession Application

MB992274

Palm socket

B992274

MB991614

Angle gauge

MB991614

MB991953

Oxygen sensor wrench

B991953

MB992188

Fuel injection pipe

wrench

- Removal and installation

of turbocharger

compressor bracket

General service tool Installation of

turbocharger assembly

coupling bolt and nut

MB991953-01 Removal and installation

of heated oxygen sensor

MB992188-01 Removal and installation

of No.2 air temperature

sensor

M1151000601024

TROUBLESHOOTING

Symptom Probable cause Remedy

Exhaust gas leakage Loose joints Retighten

Broken pipe or muffler Repair or replace

Abnormal noise Broken baffle in muffler Replace

Broken rubber hangers Replace

Interference of pipe or muffler with vehicle

body

Broken pipe or muffler Repair or replace

Correct

M1151010200035

TSB Revision

INTAKE AND EXHAUST

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

15-5

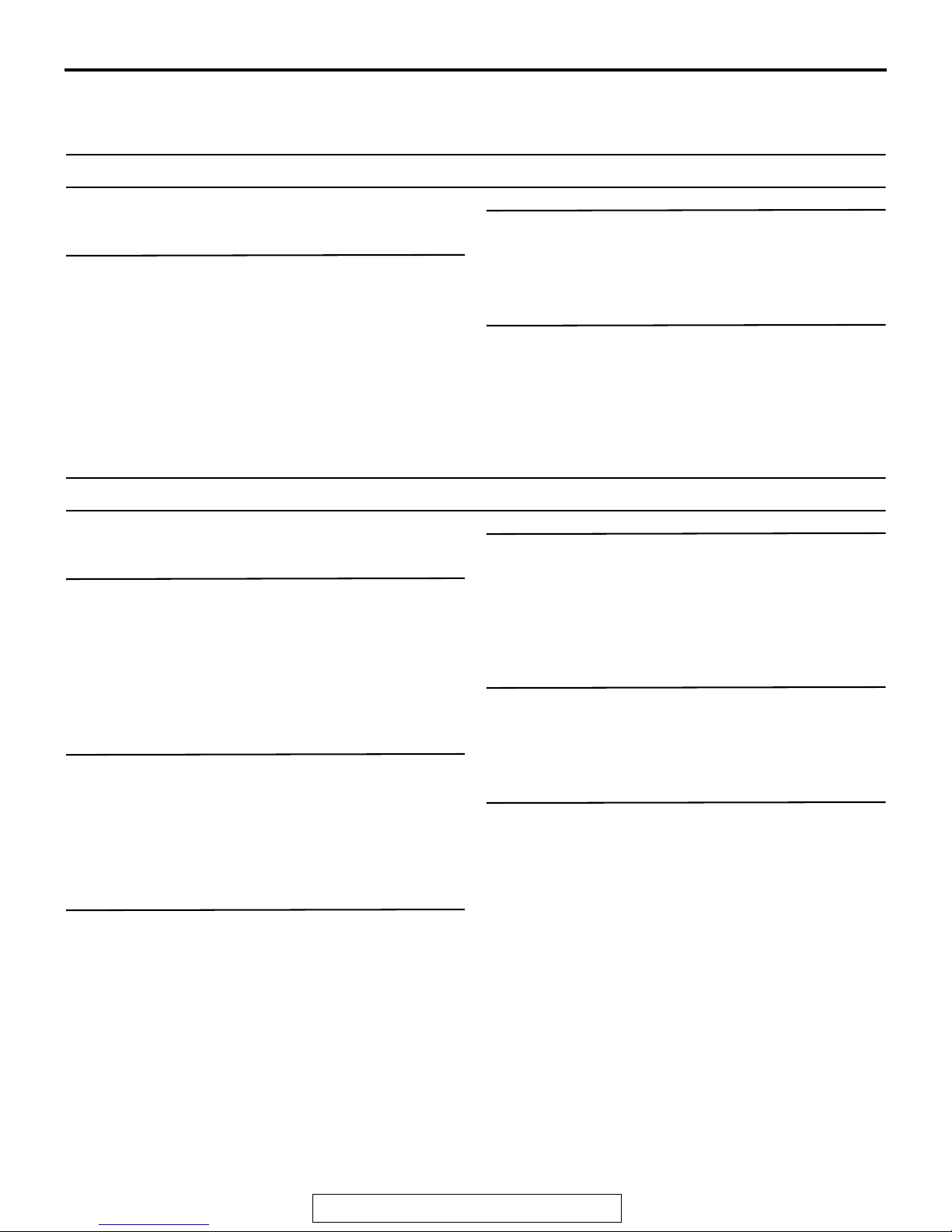

Cap

No. 1 turbocharger

wastegate solenoid

AK703282

AC

MANIFOLD VACUUM CHECK

M1151001800352

Refer to GROUP 11A, Engine Mechanical − On-vehicle Service

− Manifold Vacuum Check. P.11A-16

INTAKE CHARGE PRESSURE CHECK

M1151001000549

1. Removing the black hose from the No.1 turbocharger

wastegate solenoid or the brown connector, install the

pressure gauge to this hose. Cap the nipple of solenoid after

removing the black hose.

2. Disconnect the black connector of No.2 turbocharger

wastegate solenoid.

3. When the engine speed reaches approximately 3000r/min

or more with the throttle fully opened in the second gear,

measure the boost pressure.

Standard value: 85 − 159kPa (12.4 − 23.0 psi)

No. 2 turbochager

wastegate solenoid

No. 2 turbochager

wastegate solenoid

AK703283

AK703283

AC

AC

4. If the boost pressure is lower than the standard, check the

following possible causes.

a. Turbocharger wastegate actuator malfunction

b. Boost pressure leakage

c. Turbocharger malfunction

5. If the boost pressure is higher than the standard, check on

the following areas because the boost pressure control

might be abnormal.

a. Turbocharger wastegate actuator malfunction

b. Wastegate regulating valve malfunction

c. Rubber hose of turbocharger wastegate actuator discon-

nected or cracked

6. Connect the black connector of No.2 turbocharger

wastegate solenoid.

TSB Revision

15-6

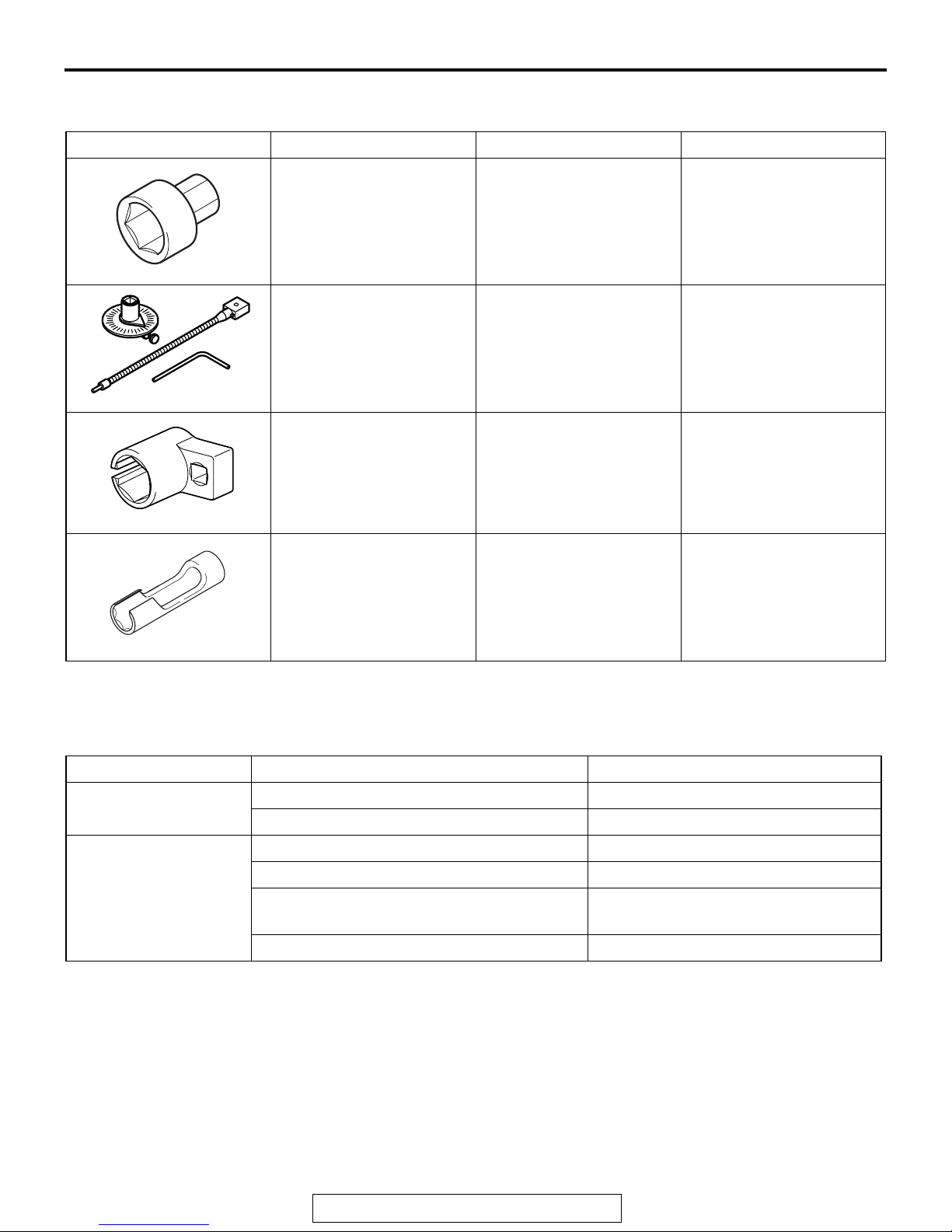

Data link connector

MB991910

MB991824

INTAKE AND EXHAUST

ON-VEHICLE SERVICE

7. If the diagnostic trouble code is stored during the check, use

scan tool MB991958 to eliminate the diagnosis code.

MB991827

Turbochager wastegate actuator

AC608435

AK703279

AB

AC

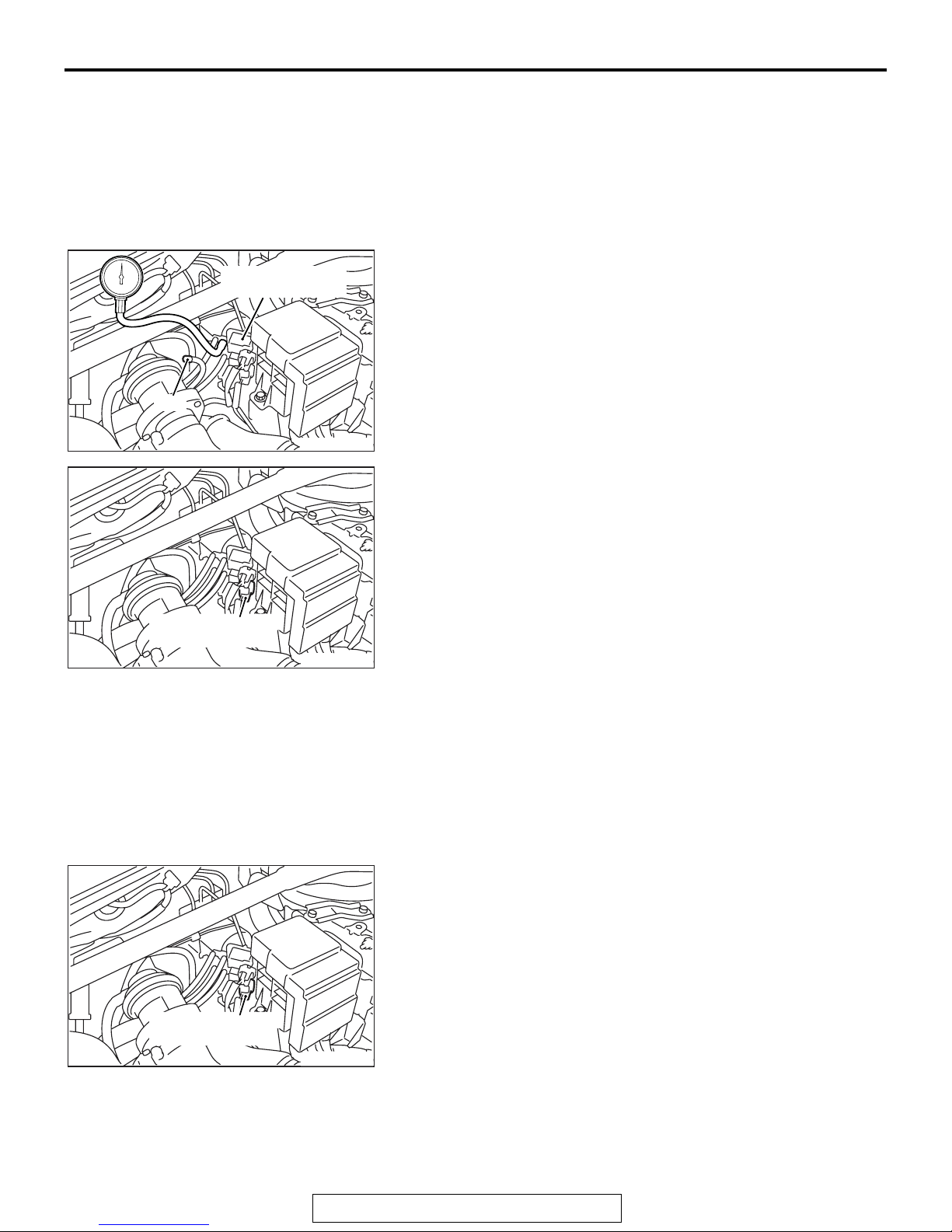

TURBOCHARGER WASTEGATE ACTUATOR

CHECK

1. Connect a hand vacuum pump (pressure-application type)

to nipple.

CAUTION

In order to abovid damage to the diaphragm, do not apply

a pressure of 117 kPa (17 psi) or higher.

2. While gradually applying pressure, check the pressure that

begins to activate (approximately 1 mm stroke) the

wastegate actuator rod.

Standard value: 98 − 102 kPa (14.3 − 14.7 psi)

3. If there is a significant deviation from the standard value,

check the actuator or the wastegate valve: replace if

necessary.

M1151001200413

TSB Revision

Three-way joint

INTAKE AND EXHAUST

ON-VEHICLE SERVICE

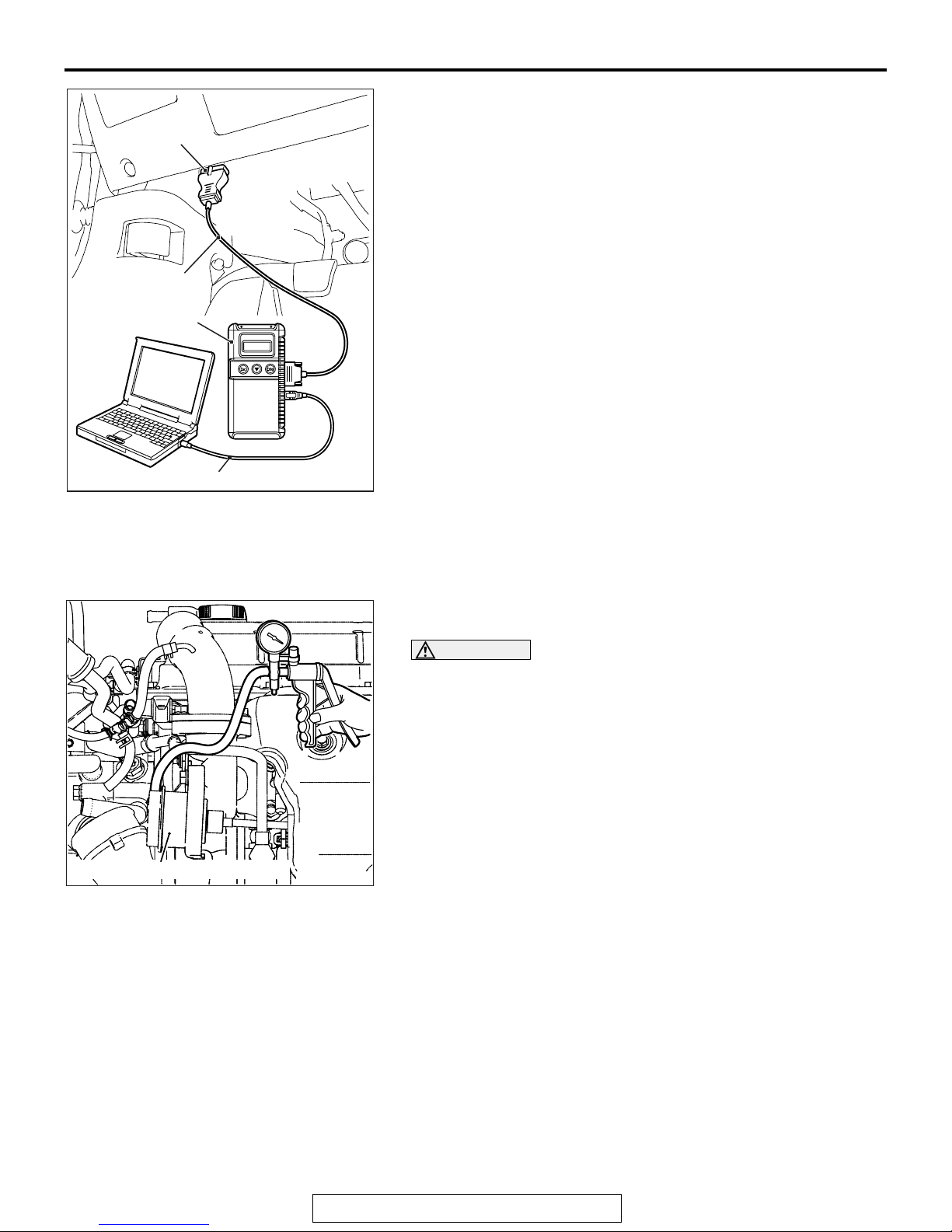

INTAKE CHARGE PRESSURE CONTROL SYSTEM

CHECK

1. Removing the black hose from the No.1 turbocharger

wastegate solenoid or the brown connector, connect

three-way joint between the hose and the solenoid.

2. Connect the pressurized type hand vacuum pump with the

three-way joint.

M1151001100342

15-7

Boost hose

Turbochager

wastegate actuator

AK703284

AK703105

No. 1 turbochager

wastegate solenoid valve

AC

AC

3. Use the turbocharger wastegate actuator control boost

nipple of air outlet fitting to remove the boost hose. Plug this

nipple.

CAUTION

Do not apply the pressure of 117kPA or more to prevent

the diaphragm damage.

4. Blocking or releasing the boost hose end, apply the

pressure. Check the pressurized state.

Engine state Boost hose end Normal state

Stopped: Ignition

switch in "ON"

position

Opened Pressure leaks

Closed Pressure

maintained

Rapid racing Pressure leaks

5. Put the ignition switch in "LOCK" (OFF) position.

6. Disconnect the connector of No.1 turbocharger wastegate

solenoid or the brown connector.

7. Blocking or releasing the boost hose end, apply the

pressure. Check the pressurized state. Plug the boost hose

end while driving.

AK703285

AC

NOTE: Unless the pressurized state is normal, the turbocharger wastegate actuator, turbocharger wastegate solenoid

or the hose might have a malfunction.

TSB Revision

Engine state Boost hose end Normal state

Stopped: Ignition

switch in "ON"

position

4000r/min after

Opened Pressure leaks

Closed Pressure

maintained

Pressure leaks

warming up

engine

15-8

A

B

No. 1 turbochager

wastegate solenoid valve

AK703285

AC

INTAKE AND EXHAUST

ON-VEHICLE SERVICE

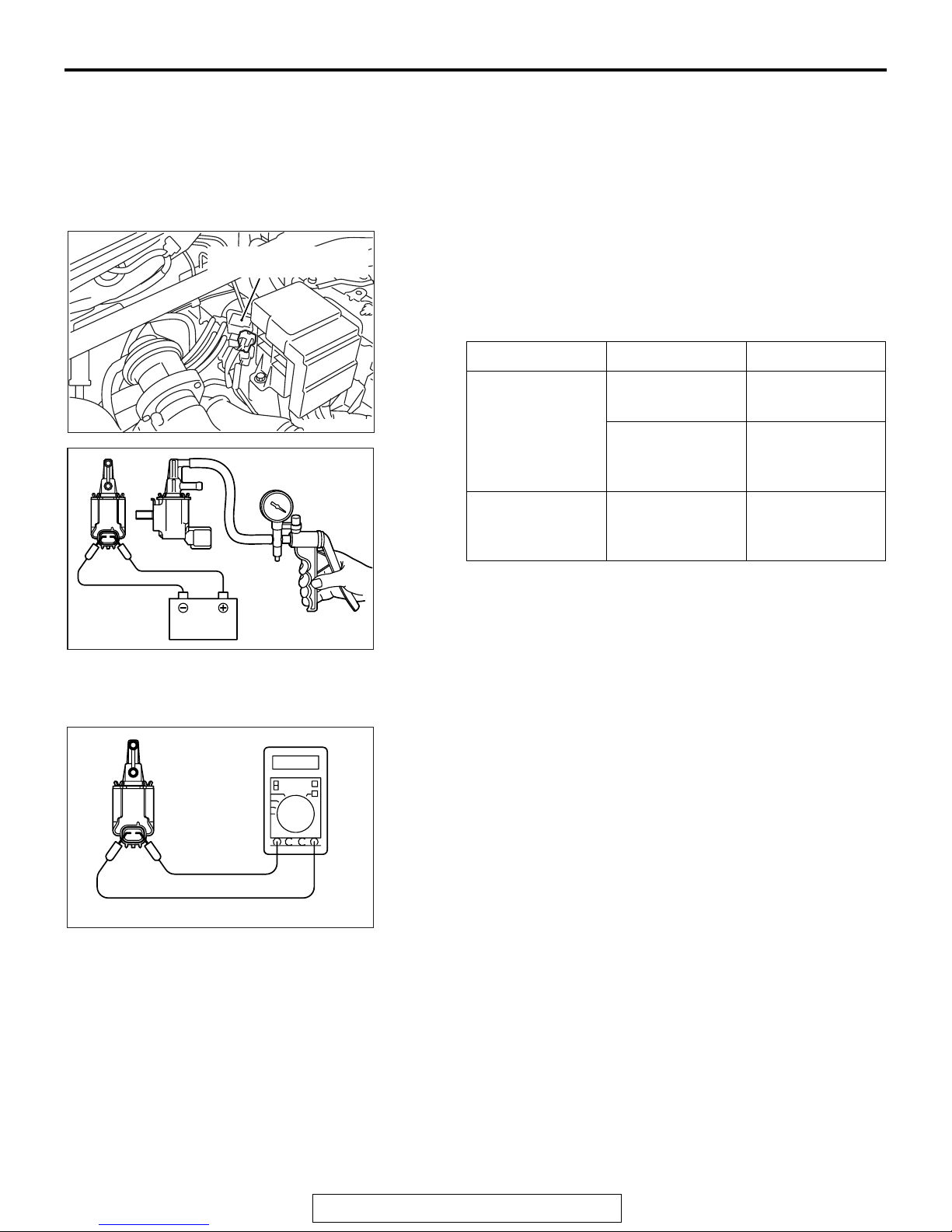

TURBOCHARGER WASTE GATE SOLENOID

CHECK

M1151001300272

No.1 turbocharger wastegate solenoid or brown

connector

.

A Operation check

1. Install the hand vacuum pump to the nipple "A" of solenoid.

2. Use the jumper wire to connect the solenoid terminal with

the battery terminal.

3. Disconnecting the jumper wire at the negative (-) battery

side, apply the vacuum pressure. Check the airtightness.

Jumper wire Nipple "B" state Normal state

Connected Opened Negative

pressure leaks

Closed Negative

pressure

maintained

Disconnected Opened Negative

pressure

maintained

BATTERY

AK200441

AK200442

AD

.

B Check of coil resistance

1. Measure the resistance between the solenoid terminals.

Standard value: 29 − 35 Ω at 20° C

TSB Revision

Loading...

Loading...