Page 1

GROUP 26

FRONT AXLE

CONTENTS

26-1

GENERAL INFORMATION . . . . . . . . 26-2

SERVICE SPECIFICATIONS. . . . . . . 26-3

LUBRICANTS . . . . . . . . . . . . . . . . . . 26-3

SPECIAL TOOLS. . . . . . . . . . . . . . . . 26-3

ON-VEHICLE SERVICE. . . . . . . . . . . 26-6

WHEEL BEARING AXIAL PLAY CHECK . . 26-6

HUB BOLT REPLACEMENT . . . . . . . . . . . 26-6

FRONT AXLE HUB ASSEMBLY . . . . 26-7

REMOVAL AND INSTALLATION . . . . . . . . 26-7

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-9

DISASSEMBLY AND REASSEMBLY . . . . . 26-10

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-10

DRIVE SHAFT ASSEMBLY . . . . . . . . 26-12

REMOVAL AND INSTALLATION . . . . . . . . 26-12

DISASSEMBLY AND REASSEMBLY . . . . . 26-15

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-18

EBJ BOOT (RESIN BOOT)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 26-18

Page 2

26-2

FRONT AXLE

GENERAL INFORMATION

GENERAL INFORMATION

M1261000100444

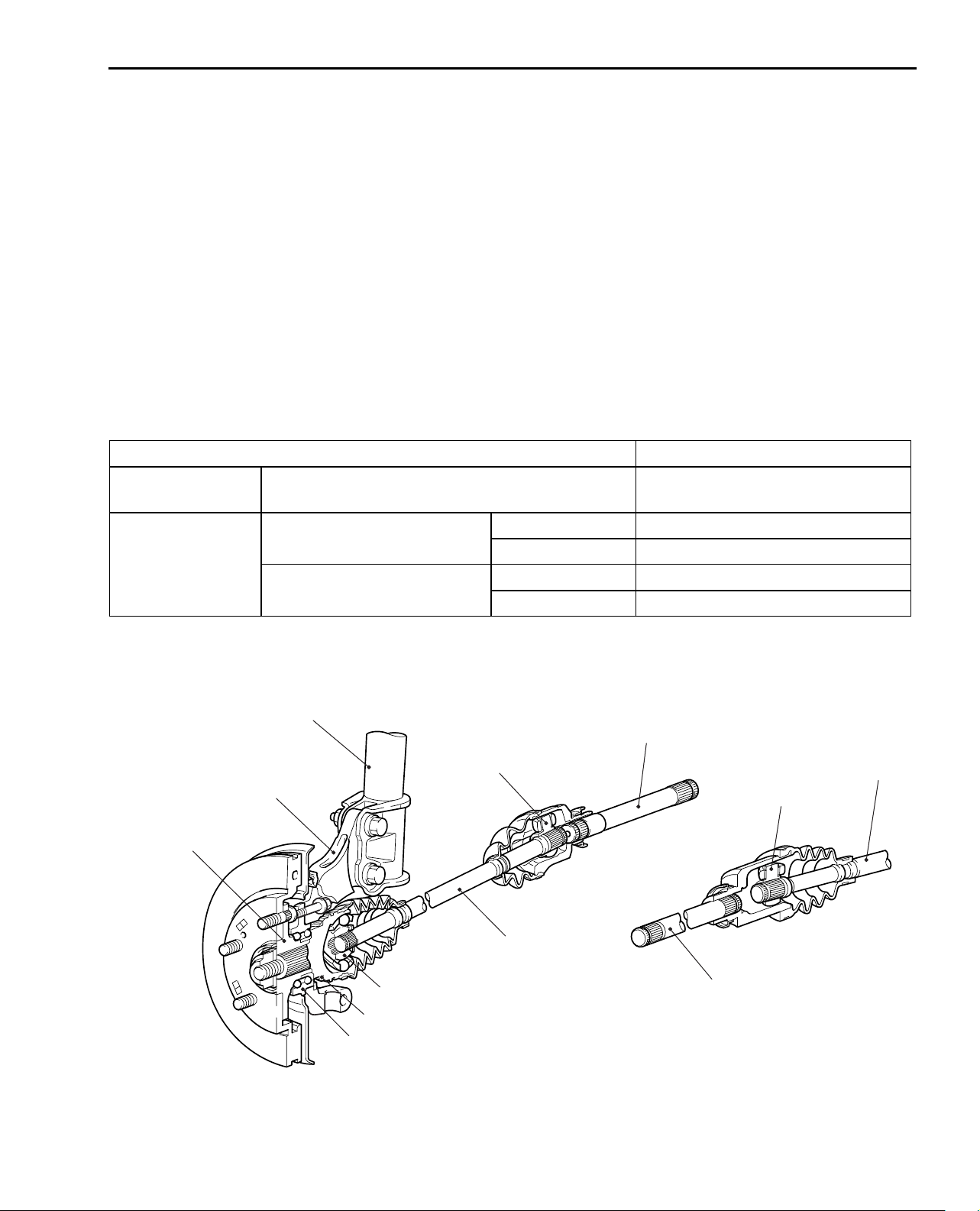

The front axle consists of front wheel hub assembly,

knuckles and drive shafts, and has the following

features:

• The wheel bearing incorporates a unit ball

bearing (double-row angular contact ball bearing)

for reduced friction.

• The front wheel hub assembly combines the hub,

wheel bearing, housing, and oil seal in a single

unit for fewer parts, better rigidity, improved

assembly precision, and better structural

organization.

• The drive shaft on wheel side incorporates an

EBJ type constant velocity joint.

SPECIFICATIONS

Item Specification

Wheel bearing Type Unit ball bearing (Double-row

• The drive shaft on the differential side

incorporates a TJ type constant velocity joint.

• ABS rotor for detecting the wheel speed is

press-fitted to the EBJ.

• For environmental protection, a lead-free grease

is used on the joints.

NOTE: .

• EBJ: Eight Ball Fixed Joint; The use of the

smaller-sized eight balls inside the joint achieves

weight saving and compact size compared with a

BJ (Birfield Joint).

• TJ: Tripod Joint

angular contact ball bearing)

Driveshaft Joint type Outer EBJ

Inner TJ

Length (joint to joint) ×

diameter mm

Left 352.5 × 26

Right 429.5 × 26

NOTE: The wheel bearing is part of the hub,

therefore its size is not listed here.

CONSTRUCTION DIAGRAM

Strut assembly

Output shaft

TJ (LH)

Knuckle

Front wheel

hub assembly

Drive shaft

(LH)

EBJ

Output shaft

TJ (RH)

Drive shaft

(RH)

ABS rotor

Wheel bearing

AC211166

AB

Page 3

FRONT AXLE

B990767

MB991618

AC106827

SERVICE SPECIFICATIONS

SERVICE SPECIFICATIONS

Item Standard value Limit

Wheel bearing axial play mm − 0.05

Wheel bearing rotation starting torque N⋅m − 1.03

Setting of TJ boot length mm 85 ± 3 −

26-3

M1261000300460

Opening dimension of the

special tool (MB991561) mm

Crimped width of the EBJ boot band mm 2.4 − 2.8 −

When the EBJ boot

band (small) is crimped

When the EBJ boot

band (large) is crimped

2.9 −

3.2 −

LUBRICANTS

Item Specified lubricant Quantity

TJ boot grease Repair kit grease 145 ± 10 g

EBJ boot grease Repair kit grease 100 ± 10 g

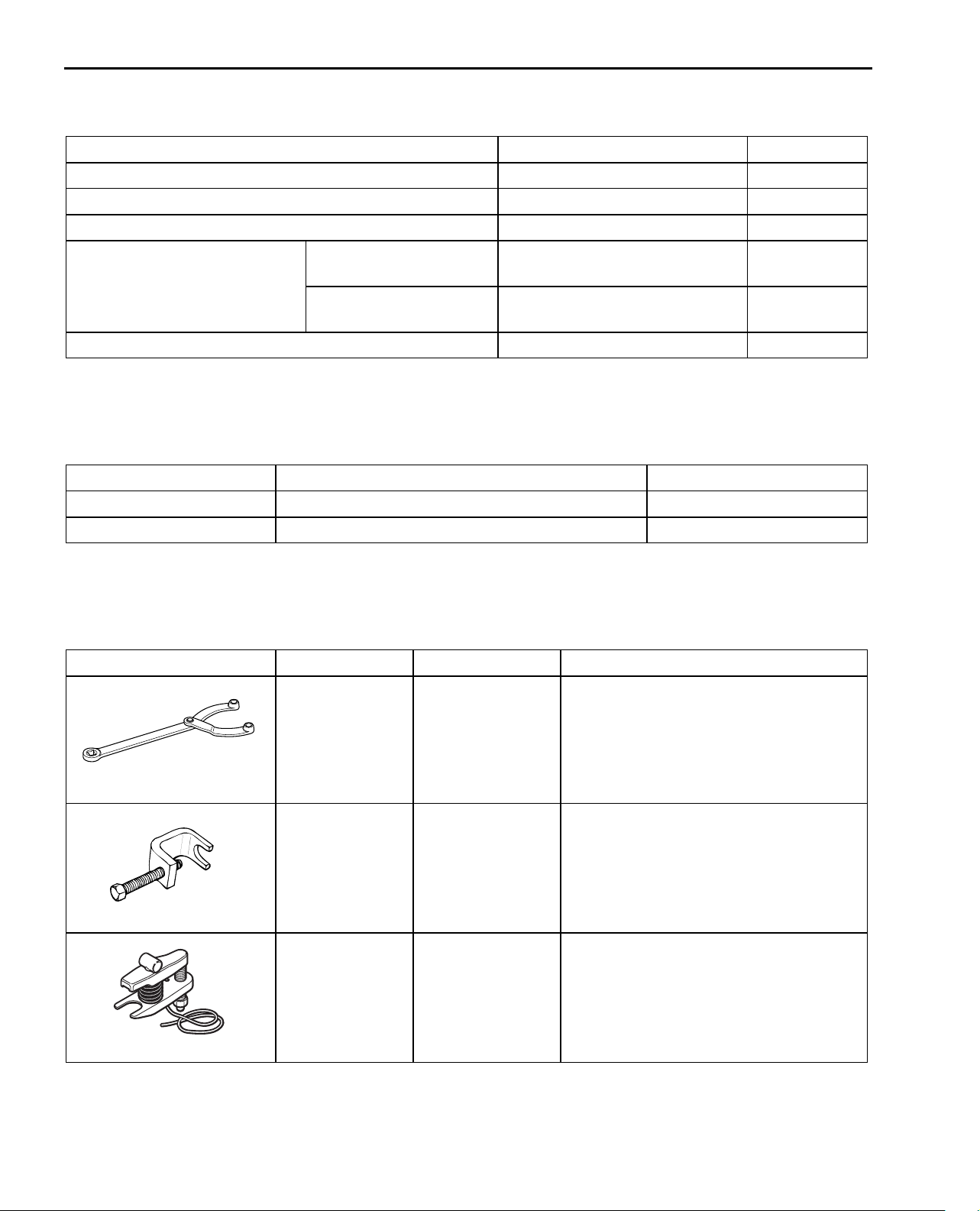

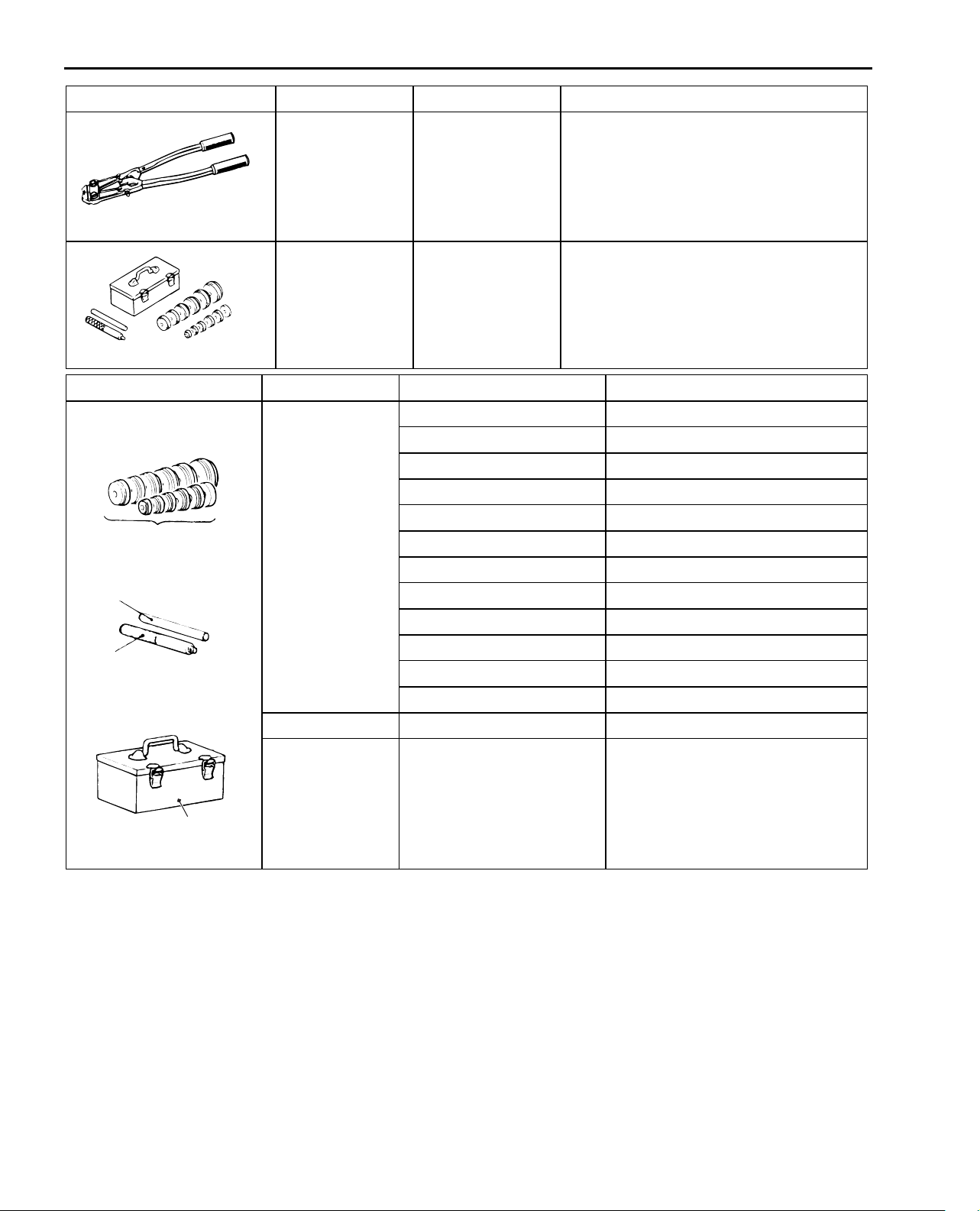

SPECIAL TOOLS

Tool Number Name Use

MB990767 End yoke holder Fixing of the hub

M1261000400490

M1261000600483

MB991618 Hub bolt remover Removal of the hub bolt

MB991897 Ball joint remover Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113)is also used

to disconnect knuckle and tie rod end

ball joint.

Page 4

26-4

MB990241

AB

A

B

MB991354

MB990590

A

B

MB991721

AC100320AB

A

B

C

MB990326

FRONT AXLE

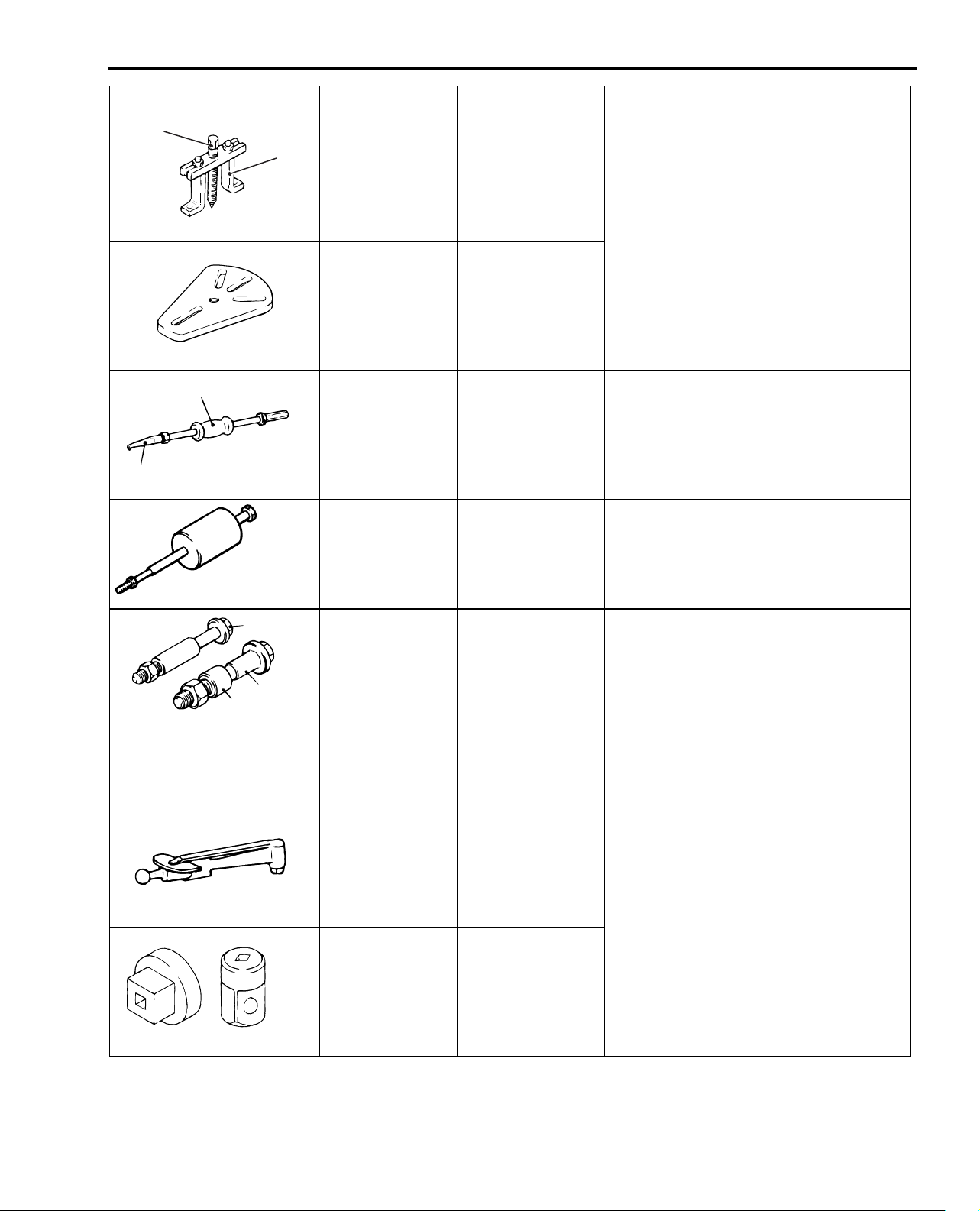

SPECIAL TOOLS

Tool Number Name Use

MB990241

A: MB990242

B: MB990244

Axle shaft puller

A: Puller shaft

B: Puller bar

Removal of the drive shaft

MB991354 Puller body

MB990590

A: MB990212

B: MB990211

Rear axle shaft oil

seal remover

A: Adapter

Removal of the front wheel hub

B: Slide hammer

MB991721 Slide hammer Removal of the output shaft

A: MB991017

B: MB990998

C: MB991000

A, B: Front hub

remover and

installer

C: Spacer

• Removal of the hub

• Provisional holding of the wheel

bearing

• Measurement of hub starting torque

• Measurement of wheel bearing axial

play

NOTE: MB991000, which belongs to

MB990998, should be used as a

spacer.

MB990685 Torque wrench Measurement of hub starting torque

MB990326 Preload socket

Page 5

FRONT AXLE

MB991561

MB990925

SPECIAL TOOLS

Tool Number Name Use

26-5

MB991561 Boot band

BJ boot (resin boot) band installation

crimping tool

MB990925 Bearing and oil

seal installer set

• Removal of the wheel bearing

• Removal and installation of the

centre bearing

• Press-fitting of the dust seal outer,

inner

Tool Type Tool number O D mm

MB990925

A MB990926 39.0

MB990927 45.0

MB990928 49.5

MB990929 51.0

MB990930 54.0

A

Installer adapter

MB990931 57.0

MB990932 61.0

C

Brass bar

MB990933 63.5

MB990934 67.5

B

Bar (snap-in type)

Tool box

ACX02372

MB990935 71.5

MB990936 75.5

MB990937 79.0

B MB990938 −

C MB990939 −

AC

Page 6

26-6

!

CAUTION

!

CAUTION

FRONT AXLE

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

WHEEL BEARING AXIAL PLAY CHECK

M1261000900268

During maintenance, take care not to contact the

parts or tools to the caliper because the paint of

caliper will be scratched.

1. Remove the caliper assembly and suspend it with

a wire.

2. Remove the brake disc from the front hub.

AC102438AD

3. Attach a dial gauge as shown in the illustration,

and then measure the axial play while moving the

hub in the axial direction.

Limit: 0.05 mm

4. If axial play exceeds the limit, disassemble the

front hub assembly and check the parts.

5. Install the brake disc, caliper assembly and

tighten the caliper assembly mounting bolts to the

specified torque 108 ± 10 N⋅m.

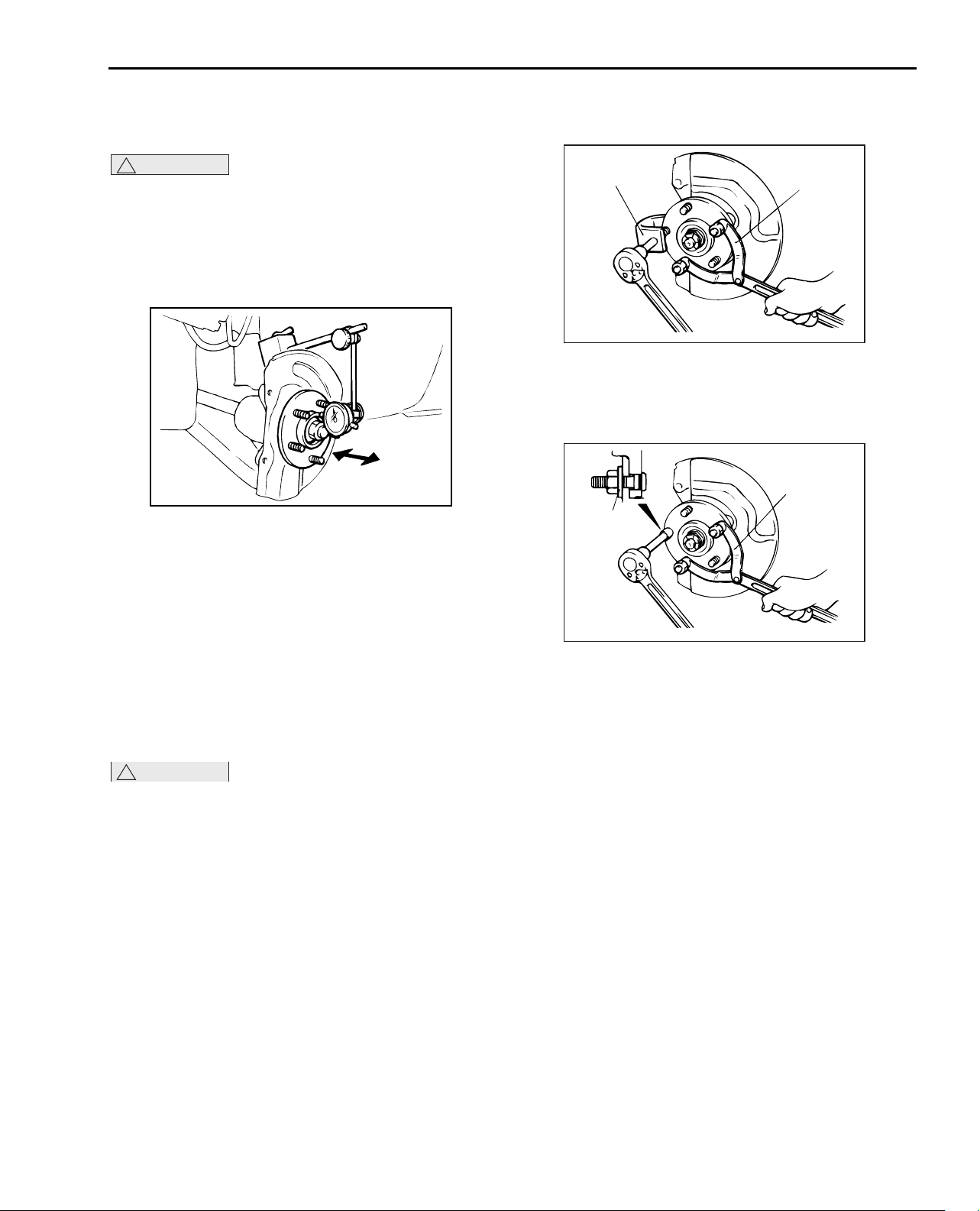

HUB BOLT REPLACEMENT

M1261001000332

2. Remove the brake disc.

MB991618

MB990767

AC102439AC

3. Use the following special tools to remove the hub

bolts.

• End yoke holder (MB990767)

• Hub bolt remover (MB991618)

MB990767

Plain

washer

AC102440

AC

4. Install the plain washer to the new hub bolt, and

install the bolt with a nut.

5. Install the brake disc, caliper assembly and

tighten the caliper assembly mounting bolts to the

specified torque 108 ± 10 N⋅m.

During maintenance, take care not to contact the

parts or tools to the caliper because the paint of

caliper will be scratched.

1. Remove the caliper assembly and suspend it with

wire so that it does not fall.

Page 7

FRONT AXLE

!

CAUTION

FRONT AXLE HUB ASSEMBLY

26-7

FRONT AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATION

M1261001700483

• Do not strike the ABS rotors installed to the EBJ outer race of drive shaft against other parts when

removing or installing the drive shaft. Otherwise the ABS rotors will be damaged.

• Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

• During maintenance, take care not to contact the parts or tools to the caliper because the paint of

caliper will be scratched. And if there is brake fluid on the caliper, wipe off quickly.

Pre-installation Operation

• Front Under Cover, Side Under Cover Removal

• Transmission Oil Draining (Refer to

GROUP22A, On-vehicle Service − Manual

Transmission Oil P.22A-149. )

• Transfer Oil Draining (Refer to GROUP22A,

On-vehicle Service −Transfer Oil P.22A-149. )

11

167 ± 9 N·m

12

10

108 ± 10 N·m

Post-installation Operation

• Check the dust cover for cracks or damage by

pushing it with your finger.

• Transfer Oil Filling (Refer to GROUP 22A,

On-vehicle Service−Transfer Oil P.22A-149. )

• Transmission Oil Filling (Refer to GROUP22A,

On-vehicle Service − Manual Transmission Oil

P.22A-149).

• Front Under Cover, Side Under Cover

Installation

25 ± 5 N·m

N

9

4

7

8.9 ± 1.9 N·m

6

<<A>> >>A<<

>>A<<

<<B>>

<<C>>

8

5

Removal steps

1. Split pin

2. Drive shaft nut

3. Washer

4. Front ABS sensor

5. Caliper assembly

6. Brake disc

7. Dust cover

108 ± 10 N·m

<<D>>

<<E>>

3

1

226 ± 19 N·m

Removal steps (Continued)

8. Connection for lower arm ball joint

9. Self-locking nut (tie rod end

connection)

10. Drive shaft

11. Nut (hub and knuckle to strut

connection)

12. Hub and knuckle assembly

2

AC211630

N

AC

Page 8

26-8

!

CAUTION

!

CAUTION

FRONT AXLE

FRONT AXLE HUB ASSEMBLY

REMOVAL SERVICE POINTS

<<A>> DRIVE SHAFT NUT REMOVAL

Do not apply pressure to wheel bearing by the

vehicle weight to avoid possible damage when

drive shaft nut is loosened.

MB990767

AC102462

AC

Use special tool end yoke holder (MB990767) to fix

the hub and remove the drive shaft nut.

<<B>> CALIPER ASSEMBLY REMOVAL

<<D>> SELF-LOCKING NUT (TIE ROD

END CONNECTION) REMOVAL

CAUTION

!

• Do not remove the nut from ball joint. Loosen

it and use the special tool to avoid possible

damage to ball joint threads.

• Hang the special tool with cord to prevent it

from falling.

Cord

Nut

Ball joint

1. Install special tool ball joint remover (MB991897)

as shown in the figure.

MB991897

Bolt

AC208247

AD

During maintenance, take care not to contact the

parts or tools to the caliper because the paint of

caliper will be scratched.

Secure the removed caliper assembly with wire, etc.

<<C>> BRAKE DISC REMOVAL

Bolts

(M8×1.25)

AC205799

If the brake disc is seized, install a M8×1.25 mm

bolts as shown, and remove the disc by tightening

the bolts evenly and gradually.

AC

Bolt

Parallel

Knob

Correct

Wrong

AC106821

AD

2. Turn the bolt and knob as necessary to make the

jaws of special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the

figure.

3. Tighten the bolt with a wrench to disconnect the

tie rod end.

Page 9

FRONT AXLE

AC201827

MB991354

MB990244

(Three)

MB990242

MB990767

AE

AC102551

AC

Drive shaft

FRONT AXLE HUB ASSEMBLY

26-9

<<E>> DRIVE SHAFT REMOVAL

1. Use the following special tools to push out the

drive shaft from the hub and knuckle.

• Puller shaft (MB990242)

• Puller bar (MB990244)

• Puller body (MB991354)

• End yoke holder (MB990767)

INSTALLATION SERVICE POINT

>>A<< WASHER/ DRIVE SHAFT NUT

INSTALLATION

CAUTION

!

Before securely tightening the drive shaft nuts,

make sure there is no load on the wheel

bearings. Otherwise the wheel bearings will be

damaged.

Washer

MB990767

AC102465

1. Be sure to install the drive shaft washer in the

specified direction.

2. Using special tool end yoke holder (MB990767),

tighten the drive shaft nut to the specified torque.

Tightening torque: 226 ± 19 N⋅m

AD

2. Withdraw the drive shaft from the hub by pulling

the bottom of the hub and knuckle towards you.

3. Hang the drive shaft on the vehicle body with a

rope.

INSPECTION

M1261001800286

• Check the hub for cracks and spline for wear.

• Check the knuckle for cracks.

Page 10

26-10

FRONT AXLE

FRONT AXLE HUB ASSEMBLY

DISASSEMBLY AND REASSEMBLY

88 ± 10 N·m

Disassembly steps

1. Knuckle

<<A>>

2. Front wheel hub assembly

DISASSEMBLY SERVICE POINTS

1

2

INSPECTION

WHEEL BEARING ROTATION STARTING TORQUE AND AXIAL PLAY CHECK

M1261001900261

AC211631

M1261002000108

AC

<<A>> FRONT WHEEL HUB ASSEMBLY

REMOVAL

1. If the front wheel hub is seized, remove the

knuckle together with front wheel hub and fix them

with a vise.

MB990244

MB990211

MB991354

2. Use the following special tools to pull out the front

wheel hub from the knuckle.

• Puller bar (MB990244)

• Puller body (MB991354)

• Slide hammer (MB990211)

AC210309

AE

MB991017

MB991000

AC301927

AF

1. Tighten the following special tools to the specified

torque.

• Front hub remover and installer (MB991017)

• Spacer (MB991000)

Tightening torque: 226 ± 19 N⋅m

2. Hold the front wheel hub assembly in a vice with a

wooden block.

3. Rotate the hub in order to seat the bearing.

Page 11

FRONT AXLE

AC206090

AD

MB990326

Wooden

block

MB990685

Wooden

block

FRONT AXLE HUB ASSEMBLY

Wooden

block

MB991017

Wooden

block

AC206091

26-11

AG

4. Measure the wheel bearing rotation starting

torque by using the following special tools.

• Preload socket (MB990326)

• Torque wrench (MB990685)

Limit: 1.03 N⋅m

5. If the rotation starting torque is not within the limit

range while the nut is tightened to 226 ± 19 N⋅m,

replace the front wheel hub assembly. If there are

any signs of binding or tight spots when the wheel

bearing turns, replace it.

6. Measure to determine whether the wheel bearing

axial play is within the specified limit or not.

Limit: 0.05 mm

7. If the play is not within the limit range while the nut

is tightened to 226 ± 19 N⋅m, replace the front

wheel hub assembly.

Page 12

26-12

!

CAUTION

FRONT AXLE

DRIVE SHAFT ASSEMBLY

DRIVE SHAFT ASSEMBLY

REMOVAL AND INSTALLATION

M1261003500537

• Do not strike the ABS rotors installed to the EBJ outer race of drive shaft against other parts when

removing or installing the drive shaft. Otherwise the ABS rotors will be damaged.

• Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

• During maintenance, take care not to contact the parts or tools to the caliper because the paint of

caliper will be scratched. And if there is brake fluid on the caliper, wipe off quickly.

Pre-installation Operation

• Front under cover, side under cover removal

• Transmission Fluid Draining (Refer to GROUP

22A, On-vehicle service − Transmission oil

replacement P.22A-149).

• Transfer Oil Draining (Refer to GROUP 22A,

On-vehicle service − Transfer oil P.22A-149).

N

12

10

11

12

N

39 ± 5 N·m

Post-installation Operation

• Check the ball Joint dust cover for cracks or

damage by pushing it with your finger.

• Transfer Oil Filling (Refer to GROUP 22A,

On-vehicle service − Transfer oil P.22A-149).

• Transmission Fluid Filling (Refer to GROUP

22A, On-vehicle service − Transmission oil

replacement P.22A-149).

• Front Under cover, side under cover Installation

6

5

N

25 ± 5 N·m

9

4

3

1

2

7

N

<<A>> >>B<<

>>B<<

39 ± 5 N·m

8

Removal steps

1. Split pin

2. Drive shaft nut

3. Washer

4. Front ABS sensor

5. Front ABS sensor harness bracket

6. Brake hose bracket

7. Stabilizer bar link connection

108 ± 10 N·m

<<B>>

<<C>> >>A<<

<<D>> >>A<<

226 ± 29 N·m

AC211632

Removal steps (Continued)

8. Lower arm ball joint connection

9. Self-locking nut (tie rod end

connection)

10. Drive shaft

11. Output shaft

12. Circlip

AC

Page 13

DRIVE SHAFT ASSEMBLY

!

CAUTION

!

CAUTION

AC102462

AC

MB990767

AC208247

AD

Cord

Bolt

MB991897

Nut

Ball joint

REMOVAL SERVICE POINTS

FRONT AXLE

26-13

<<A>> DRIVE SHAFT NUT REMOVAL

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the drive shaft nut is loosened.

Use special tool end yoke holder (MB990767) to fix

the hub and remove the drive shaft nut.

<<B>> SELF-LOCKING NUT (TIE ROD

END CONNECTION) REMOVAL

Bolt

Parallel

Knob

Correct

Wrong

AC106821

AD

2. Turn the bolt and knob as necessary to make the

jaws of special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the

figure.

3. Tighten the bolt with a wrench to disconnect the

tie rod end.

<<C>> DRIVE SHAFT REMOVAL

• Do not remove the nut from ball joint. Loosen

it and use special tool to avoid possible

damage to ball joint threads.

• Hang special tool with cord to prevent it from

falling.

1. Install special tool ball joint remover (MB991897)

as shown in the figure.

MB990767

MB990244

(Three)

MB990242

MB991354

AC102550

AC

1. Use the following special tools to push out the

drive shaft from the hub.

• Puller shaft (MB990242)

• Puller bar (MB990244)

• Puller body (MB991354)

• End yoke holder (MB990767)

Drive shaft

AC102551

AC

2. Remove the drive shaft from the hub by pulling

the bottom of the brake disc towards you.

Page 14

26-14

!

CAUTION

!

CAUTION

• Do not pull on the drive shaft; doing so will

damage the TJ; be sure to use the pry bar.

• When pulling the drive shaft out from the

transmission, be careful that the spline part of

the drive shaft does not damage the oil seal.

FRONT AXLE

DRIVE SHAFT ASSEMBLY

<<D>>OUTPUT SHAFT REMOVAL

CAUTION

!

When pulling the output shaft out from the

tansaxle, be careful that the spline part of the

output shaft does not damage the oil seal.

Transmission

TJ assembly

Pry bar

AC100141

AG

3. Insert a pry bar between the transmission case

and the drive shaft, and then pry and remove the

drive shaft from the transmission.

MB991000

MB991017

AC210315

AF

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the drive shaft is removed. If, however,

vehicle weight must be applied to the bearing in

moving the vehicle, temporarily secure the wheel

bearing by using the following special tools.

• Spacer (MB991000)

• Front hub remover and installer (MB991017)

MB991721

Output shaft

AC102556

AC

Use special tool slide hammer (MB991721) to

remove the output shaft.

INSTALLATION SERVICE POINTS

>>A<< OUTPUT SHAFT/DRIVE SHAFT

INSTALLATION

CAUTION

!

When installing the output shaft or the drive

shaft, be careful that the spline part of the output

shaft or the drive shaft do not damage the oil

seal.

>>B<< WASHER/DRIVE SHAFT NUT

INSTALLATION

Washer

MB990767

AC102465

AD

1. Be sure to install the drive shaft washer in the

specified direction.

CAUTION

!

Before securely tightening the drive shaft nuts,

make sure there is no load on the wheel

bearings. Otherwise the wheel bearing will be

damaged.

2. Using special tool end yoke holder (MB990767),

tighten the drive shaft nut to the specified torque.

Tightening torque: 226 ± 29 N⋅m

Page 15

FRONT AXLE

!

CAUTION

DRIVE SHAFT ASSEMBLY

26-15

DISASSEMBLY AND REASSEMBLY

M1261003700586

• Be careful not to damage the ABS rotor, which is attached to the EBJ outer race during

disassembly and reassembly.

• Never disassemble the EBJ assembly except when replacing the EBJ boot.

3

4

N

5

6

N

2

N

1

3

4

5

6

1

2

TJ boot repair kit TJ repair kit

Disassembly steps

>>D<<

>>D<<

<<A>> >>C<<

<<A>> >>B<<

<<B>> >>A<<

1. TJ boot band (large)

2. TJ boot band (small)

3. TJ case

4. Snap ring

5. Spider assembly

6. TJ boot

7. EBJ assembly

9

7

8

10

6

4

1

Grease

for EBJ

Grease

for TJ

2

EBJ boot repair kit

8. EBJ boot band (small)

9. EBJ boot band (large)

10. EBJ boot

NOTE: .

• TJ: Tripod Joint

• EBJ: Eight Ball Fixed Joint

4

1

2

8

9

10

AC211633

Disassembly steps (Continued)

AC

Page 16

26-16

!

CAUTION

LUBRICATION POINTS

FRONT AXLE

DRIVE SHAFT ASSEMBLY

5

Grease: repair kit grease

Amount used: 145 ± 10 g

CAUTION

The drive shaft joint uses special

grease. Do not mix old and new or

different types of grease.

Grease: repair kit grease

Amount used: 100 ± 10 g

CAUTION

The drive shaft joint uses special

grease. Do not mix old and new or

different types of grease.

DISASSEMBLY SERVICE POINTS

<<A>> TJ CASE/SPIDER ASSEMBLY

REMOVAL

Do not disassemble the spider assembly.

AC211634

AC

1. Wipe off grease from the spider assembly and the

inside of the TJ case.

2. Always clean the spider assembly when the

grease contains water or foreign material.

Page 17

FRONT AXLE

!

CAUTION

AC102654AC

Chamfered

side

DRIVE SHAFT ASSEMBLY

26-17

<<B>> TJ BOOT REMOVAL

1. Wipe off grease from the shaft spline.

2. When reusing the TJ boot, wrap plastic tape

around the shaft spline to avoid damaging the

boot.

REASSEMBLY SERVICE POINTS

>>A<< TJ BOOT INSTALLATION

Wrap plastic tape around the shaft spline, and then

install the TJ boot band (small) and TJ boot.

>>B<< SPIDER ASSEMBLY

INSTALLATION

• The drive shaft joint use special grease. Do

not mix old and new or different types of

grease.

• If the spider assembly has been cleaned, take

special care to apply the specified grease.

1. Apply the specified grease furnished in the repair

kit to the spider assembly between the spider axle

and the roller.

Specified grease: Repair kit grease

>>C<< TJ CASE INSTALLATION

CAUTION

!

The drive shaft joint uses special grease. Do not

mix old and new or different types of grease.

AC102656

AC

After applying the specified grease to the TJ case,

insert the drive shaft and apply grease one more

time.

Specified grease: Repair kit grease

Amount to use: 145 ± 10 g

NOTE: The grease in the repair kit should be divided

in half for use, respectively, at the joint and inside the

boot.

>>D<< TJ BOOT BAND (SMALL)/TJ BOOT

BAND (LARGE) INSTALLATION

2. Install the spider assembly to the shaft from the

direction of the spline chamfered side.

A

AC102657

AC

Set the TJ boot bands at the specified distance in

order to adjust the amount of air inside the TJ boot,

and then tighten the TJ boot band (small), TJ boot

band (large) securely.

Standard value (A): 85 ± 3 mm

Page 18

26-18

FRONT AXLE

DRIVE SHAFT ASSEMBLY

INSPECTION

M1261003800215

• Check the drive shaft for damage, bending or

corrosion.

• Check the drive shaft spline part for wear or

damage.

• Check the spider assembly for roller rotation,

wear or corrosion.

• Check the groove inside TJ case for wear or

corrosion.

• Check the boots for deterioration, damage or

cracking.

EBJ BOOT (RESIN BOOT) REPLACEMENT

M1261005200435

AC102658

1. Remove the boot bands (large and small).

NOTE: The boot bands cannot be re-used.

2. Remove the EBJ boot.

3. Wrap a plastic tape around the shaft spline, and

assemble the boot band and EBJ boot.

MB991561

Stopper

W

Adjusting bolt

AC102660

AC

5. Turn the adjusting bolt on special tool boot band

crimping tool (MB991561) so that the size of the

opening (W) is at the standard value.

Standard value (W): 2.9 mm

<If it is larger than 2.9 mm> Tighten the

adjusting bolt.

<If it is smaller than 2.9 mm> Loosen the

adjusting bolt.

NOTE: The value of W will change by

approximately 0.7 mm for each turn of the

adjusting bolt.

NOTE: The adjusting bolt should not be turned

more than once.

Boot

A

Boot band

(small)

B

AC102659

4. Align the centre groove on the EBJ boot small end

with the shaft groove.

Projection

AC102661AC

6. Position the EBJ boot band (small) so that there is

even clearance at either end (A and B).

Page 19

FRONT AXLE

!

CAUTION

AC102663AC

MB991561

AC102662

C

AD

DRIVE SHAFT ASSEMBLY

• Secure the drive shaft in an upright position

and clamp part of the boot band to be

crimped securely in the jaws of special tool.

• Crimp the boot band until special tool

touches the stopper.

7. Use the special tool to crimp the boot band

(small).

26-19

9. Check that the boot band is not sticking out past

the place where it has been installed. If the boot

band is sticking out, remove it and then repeat

steps 6 to 8, using a new boot band.

CAUTION

!

The drive shaft joint uses special grease. Do not

mix old and new or different types of grease.

10.Fill the inside of the boot with the specified

amount of the specified grease.

Specified grease: Repair kit grease

Amount to use: 100 ± 10 g

8. Check that the crimping amount (C) of the boot

band is at the standard value.

Standard value (C): 2.4 − 2.8 mm

<If the crimping amount is larger than 2.8 mm >

Readjust the value of (W) in step 5 according

to the following formula, and then repeat the

operation in step 7.

W = 5.5 mm − C

Example: If C = 2.9 mm, then W = 2.6 mm.

<If the crimping amount is smaller than 2.4

mm >

Remove the EBJ boot band, readjust the

value of (W) in step 5 according to the

following formula, and then repeat the

operations in steps 6 and 7 using a new EBJ

boot band.

W = 5.5 mm − C

Example: If C = 2.3 mm, then W = 3.2 mm.

AC102664

AC

11.Align the centre groove on the EBJ boot big end

with the EBJ case groove.

12.Follow the same procedure as in step 5 to adjust

the size of the opening (W) on the special tool so

that it is at the standard value.

Standard value (W): 3.2 mm

Projection

D

Boot band

(large)

Boot

E

AC102665

AC

13.Position the EBJ boot band (large) so that there is

even clearance at either end (D and E).

14.Use the special tool to crimp the EBJ boot band

(large) in the same way as in step 7.

Page 20

26-20

FRONT AXLE

DRIVE SHAFT ASSEMBLY

16.Check that the boot band is not sticking out past

the place where it has been installed. If the boot

band is sticking out, remove it and then repeat

steps 13 to 15, using a new boot band.

F

AC102666

AD

15.Check that the crimping amount (F) of the boot

band is at the standard value.

Standard value (F): 2.4 − 2.8 mm

<If the crimping amount is larger than 2.8 mm >

Readjust the value of (W) in step 12

according to the following formula, and then

repeat the operation in step 14.

W = 5.8 mm − F

Example: If F = 2.9 mm, then W = 2.9 mm.

<If the crimping amount is smaller than 2.4

mm >

Remove the EBJ boot band, readjust the

value of (W) in step 12 according to the

following formula, and then repeat the

operations in steps 13 and 14 using a new

EBJ boot band.

W = 5.8 mm − F

Example: If F = 2.3 mm, then W = 3.5 mm.

Loading...

Loading...