Page 1

Energy Measuring Unit Energy Measuring Standard Model

Energy Measuring Unit Energy Measuring High Performance Model

MODEL

EMU4-BM1-MB

EMU4-HM1-MB

User’s Manual (Details)

● Before operating the instrument, you should first read thoroughly this operation manual for

safe operation and optimized performance of the product.

Deliver this user’s manual to the end user.

Page 2

Safety precautions

This manual describes setup and usage for the Energy Measuring Unit. Before using the product, please read this manual

vehicles please refer to our sales representative.(For details, please see at the end of this manual.)

■ Notations in this manual

Use the following marks in this manual.

Mark

Meaning of the icons

Danger

Caution

Indicates that incorrect handling may result in injury or property damage, ignoring this marking.

Supplement

Indicates that the pages described that related matters.

■ Checking package contents

This following items for this device and included in package. Check that no items are missing.

Feature

This unit cannot be used for deal and proof of electric energy measurement stipulated in the

energy measurement stipulated.

Thank you for purchasing the Energy Measuring Unit (EcoMonitorPlus).

・

carefully to ensure correct use. Especially, in the case of where this unit is to be installed, please read “1. Precautions for Use” to

ensure correct use.

・ Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

・ Make sure to deliver this manual to the end-user.

・

If you are considering using this unit for special purpose such as nuclear power plants, aerospace, medical care or passenger

Indicates that incorrect handling may result in death or severe injury, ignoring this marking.

Indicates that precautions to avoid a malfunction and to work the unit properly.

or

Energy Measuring Unit x1

User’s Manual (Digest) x1

measurement law. Please use the certified watt-hour meter to be used for deal and proof of electric

This Energy Measuring unit can measure various types of electric quantity such as voltage, current, electric power and electric

energy.

The measured data can be sent to the high-end device, such as a monitoring device by MODBUS RTU communication function.

This Energy Measuring unit has one external input terminal, which can switch between pulse input and contact input.

Production quantity and water, gas, air (other than electricity) can be measured in the pulse input setting. (Model: EMU4-HM1-MB)

Monitoring of condition and alarm, measurement of operating time and electric energy during operation can be done in the contact

input setting.

Adding this unit enables measurement of multiple circuits.

For the single-phase 2-wire, this Energy Measuring Unit can measure two circuits of the system with the same voltage.

This Energy Measuring unit can measure energy without input voltage by use the simple measuring function.

MODBUS is a registered trademark of SCHNEIDER ELECTRIC USA, INC.

1

Page 3

Table of Content

Safety precautions ..................................................................................................................................................... 1

Feature ........................................................................................................................................................................ 1

Table of Content ......................................................................................................................................................... 2

1. Precautions for Use ............................................................................................................................................... 3

1.1 Precautions for Operating Environment and Conditions ........................................................................... 3

1.2 Matters concerning the precaution before use ........................................................................................... 3

1.3 Installation and Wiring Precautions ............................................................................................................ 3

1.4 Precautions for Use .................................................................................................................................... 4

1.5 Maintenance Precautions ........................................................................................................................... 4

1.6 Storage Precautions ................................................................................................................................... 4

1.7 Disposal Precautions .................................................................................................................................. 4

1.8 About packaging materials and this manual .............................................................................................. 5

2. Disclaimer ............................................................................................................................................................... 5

3. Name and function of each part .......................................................................................................................... 5

3.1 Name of each part ...................................................................................................................................... 5

3.2 Indication and function of LEDs .................................................................................................................. 6

3.3 2 circuits measuring in 1P2W ..................................................................................................................... 6

4. Attaching and removing the unit ......................................................................................................................... 7

4.1 Mounting on IEC rail ................................................................................................................................... 7

4.2 Mounting on JIS agreement type attachment ............................................................................................ 7

5. Procedure for wiring .............................................................................................................................................. 8

5.1 Wiring for EMU4-BM1-MB .......................................................................................................................... 8

5.2 Wiring for EMU4-HM1-MB ........................................................................................................................ 10

5.3 Precautions for the connection wire ......................................................................................................... 12

6. Setting ................................................................................................................................................................... 15

6.1 Setting data ............................................................................................................................................... 15

6.2 Initialization of related item by changing the setup .................................................................................. 20

7. Operation .............................................................................................................................................................. 22

7.1 Measurement ............................................................................................................................................ 22

7.2 Upper/lower limit monitoring function ....................................................................................................... 26

7.3 Simple measurement ................................................................................................................................ 29

8. Device operation .................................................................................................................................................. 33

8.1 Resolution of measuring data ................................................................................................................... 33

8.2 Restrictions of measured data ................................................................................................................. 34

9. Reference ............................................................................................................................................................ 35

9.1 In case you think the unit is in failure ........................................................................................................ 35

9.2 After-sales service ..................................................................................................................................... 36

9.3 Q&A ........................................................................................................................................................... 36

10. Requirement for the compliance with EMC Directives EMC ....................................................................... 39

11. Specifications ..................................................................................................................................................... 40

11.1 Common specifications ........................................................................................................................... 40

11.2 Specifications of MODBUS communications ......................................................................................... 42

12. Option devices ................................................................................................................................................... 43

12.1 About option devices .............................................................................................................................. 43

12.2 Specifications of option devices ............................................................................................................. 44

12.3 External dimensions of option devices ................................................................................................... 46

13. External dimensions ......................................................................................................................................... 54

14. Index .................................................................................................................................................................... 55

2

Page 4

1. Precautions for Use

1.1 Precautions for Operating Environment and Conditions

1.2 Matters concerning the precaution before use

1.3 Installation and Wiring Precautions

・Shut off the external power supply for the unit in all phases before installing or wiring. Failure to do so

・

shock, a failure of the unit, a fire etc.

Caution

<Precautions for Electric work>

Condition

Distance

Power line 600V or less

Other power line

300mm or longer

600mm or longer

Do not input voltage and current at NC terminals. Doing so can cause failure or malfunction of the unit.

This unit is premised on being used in pollution degree 2 (Note 1) environment. When used in higher pollution degree, protect this

unit from pollution on another device side to be incorporated.

Over voltage category of measuring circuit in this unit is CAT II (Note 1), and that of auxiliary power circuit (MA, MB) is CAT II (Note

1).

Do not use this product in the places listed below. Failure to follow the instruction may cause malfunctions and a life decrease of

product.

- Places the Ambient temperature exceeds the range -5 - +55°C.

- Places the average daily temperature exceeds 35°C.

- Places the Relative humidity exceeds the range 30-85% or places with dewfall.

- Vibration and impact exceed the specifications.

- Dust, corrosive gas, saline and oil smoke exist.

- Places exposed to direct sunlight.

- Places exposed to rain or water drop.

- Places in strong electromagnetic field or places large amounts of external noise exist.

- Places metal fragments or conductive substances are flying.

- Altitude exceeds 2000m.

Note 1: For the definition of the pollution degree and the over voltage category, refer to EN61010-1/2010.

Use the unit in the specified usage environment and conditions.

To set this unit, dedicated small-size display unit (EMU4-D65) is necessary. For the setting method, refer to User’s manual

(Details) of the display unit.

Danger

・ Any person who is involved in the installation and the wiring of this unit should be fully competent to do this work.

・ When tapping or wiring, take care not to entering any foreign objects such as chips and wire pieces into this unit.

・ Check the connection diagram when wiring. Wrong wiring may cause failure of the unit, a fire or electric shock.

・

For protection against noise, transmission lines and input/output lines shall not be placed close to or bound

together with the power lines and high-voltage lines.

・ The wires to be connected to this unit shall be placed in a duct or fixed together by cramping. If the electric wires are not

placed in the duct or cramped together, loosen wires or their movement or careless stretch may cause a breakage of

the unit or wire or a malfunction due to poor contact of electric wires.

・ If transmission lines and input/output lines are placed close to or bound together with the power lines and high-voltage

lines, keep distance as below between them.(Except for the input side of terminal block)

<Connection of terminal block>

・ Strip the wires with proper length. Overlong stripping length may cause short to next wire. Shorter stripping length may

cause contact failure.

・ Take care not to short to next terminal by a filament. (Do not plate the wires with solder.)

・ Do not connect three or more wires to one terminal of a terminal block for preventing loose contact and wires dropout.

・ Use appropriate size of electric wires. If inappropriate size of electric wire is used, it may cause a fire due to generated

heat.

・ Tighten the screw within the specified torque. Under tightening can cause drop of the screw, short circuit or malfunction.

Over tightening can damage the screw and/or unit, resulting in drop, short circuit or malfunction.

・ After tightening the screws, be sure to check all the screws tightened. Loose screw may cause malfunction of the unit,

a fire or electric shock.

・ Be sure to attach the terminal cover to prevent electric shock.

・ Use the crimp-type terminal appropriated for the size of electric wires. If inappropriate crimp-type terminal is used, a wire

breakage or a contact failure may occur, which may cause a device malfunction, a failure, a burnout or a fire.

・ Frame GND terminal must be grounded according to the D-type ground (ground resistance is not exceed 100Ω).

・ Do not directly touch any conductive part of the unit. Doing so can cause electric shock, failure or malfunction of the

unit.

・

may cause an electric shock or damage of this unit.

Work under the electric outage condition when installing and wiring. Failure to do so may cause electric

3

Page 5

<Connection with the current sensor>

・ When using this product, make sure to use it in combination with current sensor (EMU-CT**, EMU-CT**-A. EMU2-CT5

Cover the dangerous part of this unit.

1.4 Precautions for Use

Caution

Do not disassemble or modify this unit. It may cause failure, malfunction, injury or fire.

malfunction or failure of the Unit.

1.5 Maintenance Precautions

Do periodical maintenance under the electric outage condition. Failure to do so may cause

electric shock, failure of the unit or a fire. Tighten the terminal regularly to prevent a fire.

1.6 Storage Precautions

1.7 Disposal Precautions

and EMU2-CT5-4W). This product cannot connect with the secondary side (5A) of current transformer. Please not to

exceed the rating of this product for input of current sensor. For further details, please refer to current sensor manual to

maintain the functionality and the accuracy of this product.

・ The dedicated current sensor (EMU-CT**, EMU-CT**-A) is used only for low voltage circuit. It cannot be used for a high

voltage circuit. EMU2-CT5 and CT5-4W should be used with the secondary side (5A) of transformer transfixed. If it is

connected with a high-voltage circuit by mistake, it may cause a burnout of the device and a fire. It is critically dangerous.

For the allowable maximum voltage of current sensor, refer to “12. Option devices” in this manual.

・ The dedicated current sensor has a polarity (directionality). Be careful about it when installing the unit.

・ If the wires connected to this unit are strongly pulled off, it may cause a malfunction or a breakage to the unit or the wire.

<Connection of frame GND terminal>

・ Do not exceed the specified voltage when doing an insulation resistance test and a commercial frequency withstand

voltage test.

・ Frame FG terminal must be grounded according to the D-type ground.

・ To prevent persons with little knowledge about electric equipment from electric shock, panel must be taken either

following measure.

Lock the panel so that only those who get an education about electric equipment and have sufficient knowledge can

unlock, or shut off power supply automatically by opening the panel.

This unit cannot be used for deal and proof of electric energy measurement stipulated in the measurement law.

Before operating the product, check that active bare wire and so on does not exist around the product. If any bare wire exists,

stop the operation immediately, and take an appropriate action such as isolation protection.

In the event of a power outage during the setting by Display unit / Communication line, the Energy Measuring unit is not set

correctly. Please set again after power recovery.

Use this unit within the ratings specified in this manual. If it is used outside the ratings, it may cause not only

malfunction or failure but also fire burnout.

The secondary side of the models EMU2-CT5, EMU-CT50, EMU-CT100, EMU-CT250,EMU-CT50-A, EMU-CT100-A,

EMU-CT250-A, EMU-CT400-A, EMU-CT600-A is equipped with the protective circuit against opening of secondary

terminals. Opening them during the wiring work causes no problems. However, for safety, please do not continuously

energize the module with the terminals open.

The current sensors dedicated to this unit EMU-CT400/600 resemble the split current transformer for general gauges

CW-5SL closely in appearance. However, characteristics are completely different. Be sure to connect the dedicated

current sensor. Connecting CW-5SL to this unit directly may cause failure of the device, a burnout or a fire.

Push the RESET switch with an appropriate force (1.6N). The addition of force than necessary, it may cause a

Use a soft dry cloth to clean off dirt of the unit surface. Do not let a chemical cloth remain on the surface for an extended period

of time nor wipe the surface with thinner or benzene.

Check for the following items to use this unit properly for long time.

(1) Daily maintenance

(a) No damage on this unit

(b) No abnormality with LCD indicators

(c) No abnormal noise, smell or heat

(2) Periodical maintenance (Once every 6 months to 1 year)

- No looseness with installation and wire connection

Caution

To store this unit, turn off the power and remove wires, and put it in a plastic bag.

For long-time storage, avoid the following places. Failure to follow the instruction may cause a failure and reduced life of the unit.

- Places the Ambient temperature exceeds the range -10 - +60°C.

- Places the average daily temperature exceeds 35°C.

- Places the Relative humidity exceeds the range 30-85% or places with dewfall.

- Vibration and impact exceed the specifications.

- Dust, corrosive gas, saline and oil smoke exist.

- Places metal fragments or conductive substances are flying.

- Place where metallic particles or inductive substances are dispersed

When disposing of this unit, treat it as industrial waste.

4

Page 6

1.8 About packaging materials and this manual

For reduction of environment load, packaging materials are produced with cardboard, and this manual is printed on recycled

2. Disclaimer

3. Name and function of each part

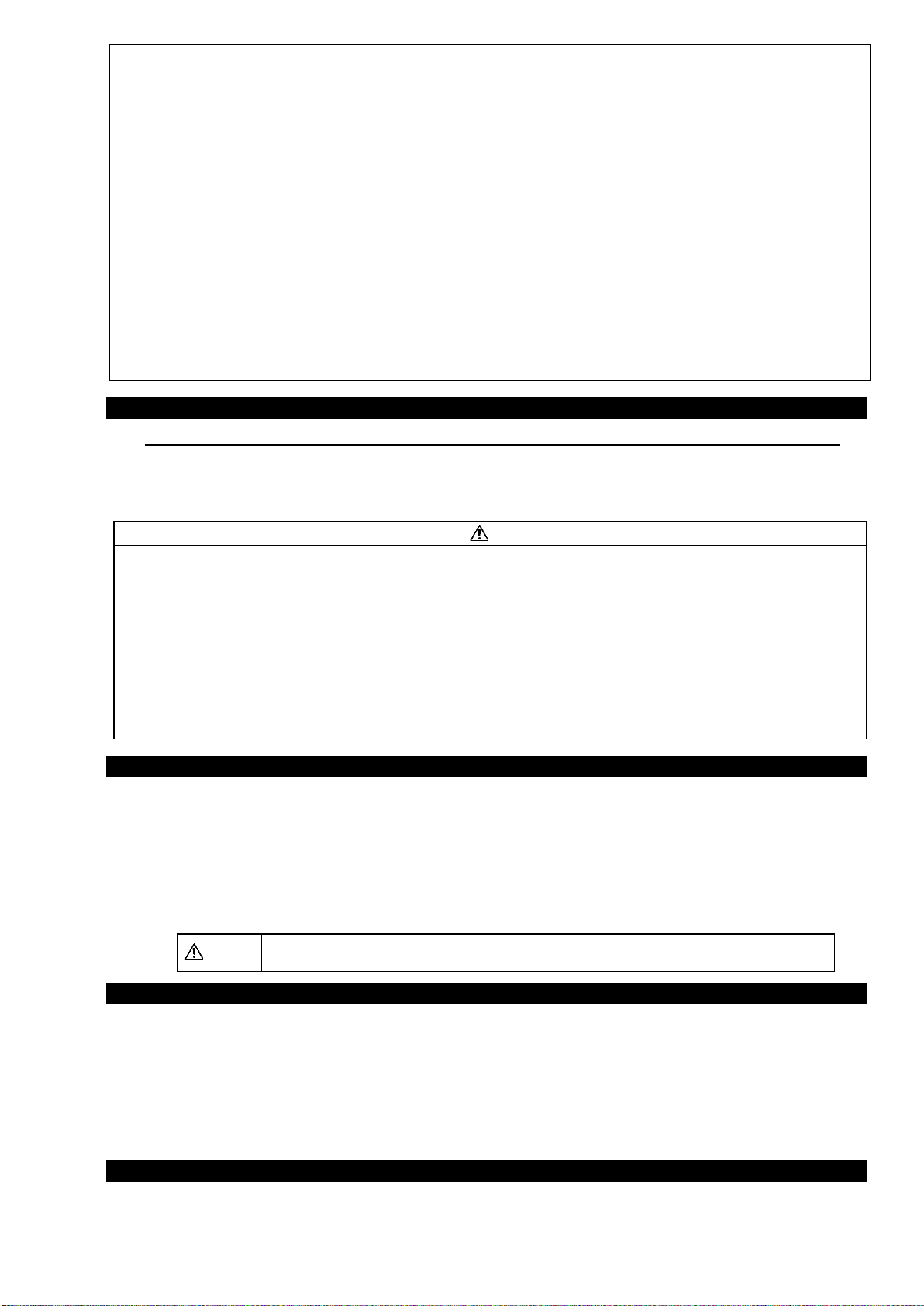

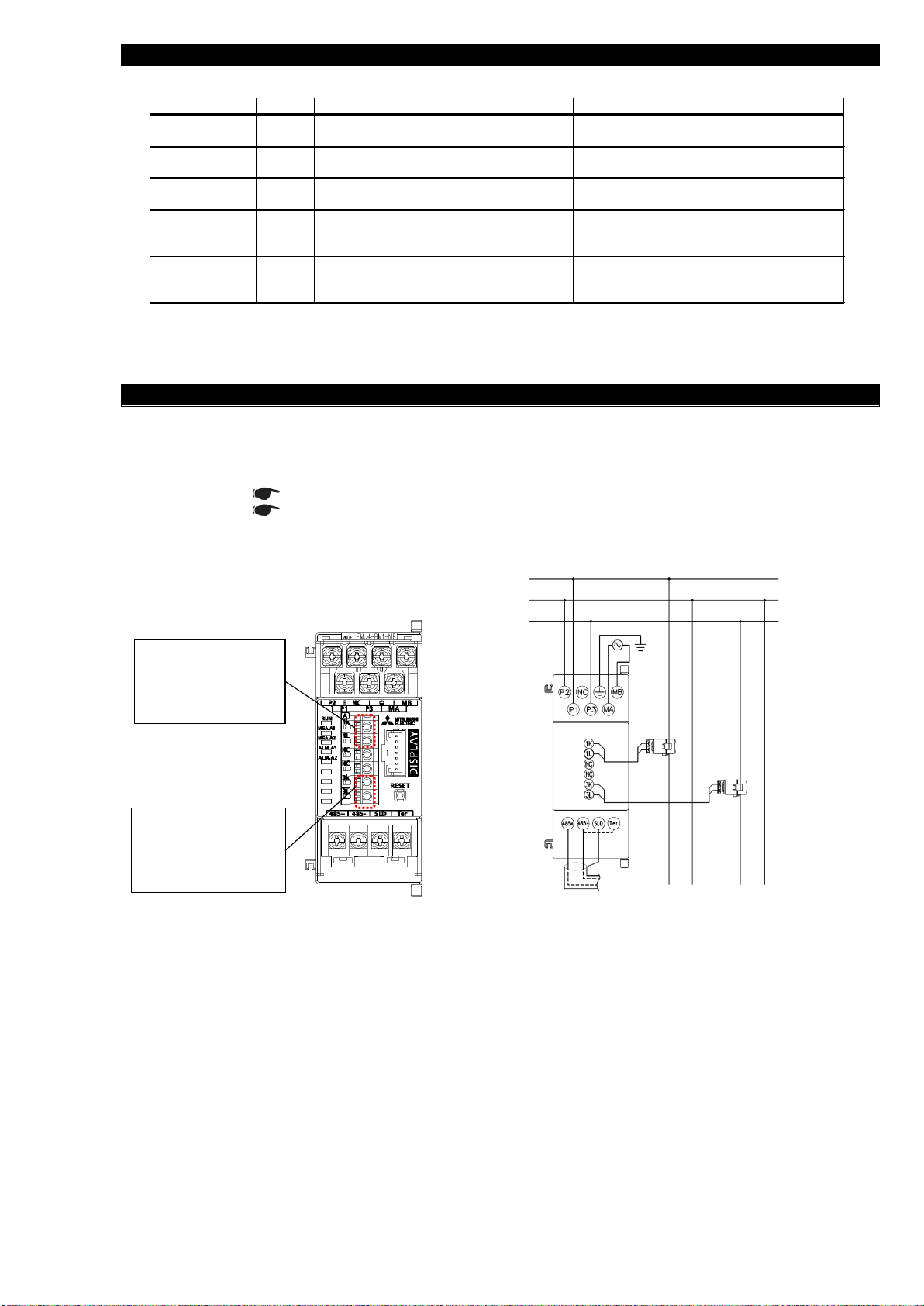

3.1 Name of each part

Connector(small-size display unit)

Connect the display unit.

Reset button

Reset main unit.

LED

Operation mode is

displayed.

( Please reference to 4.2

LED display and function)

Input current

(1K,1L,3K,3L)

Connect the secondary

output of the dedicated

current sensor connected to

the measurement circuit’s

current wire.

※Please setup input current

to 3K,3L

when measuring 2 circuits

by a terminal in 1P2W

(Please reference to the 6.1

Wiring)

Input voltage(P1,P2,P3)

Connect the voltage input wire

for the measuring circuit.

Auxiliary power(MA,MB)

Connect the auxiliary power supply.

MODBUS communication terminal(485+、

485-、SLD、Ter )

485+、485-:MODBUS connect the communication wire.

SLD:Connect to ground (D type ground).

Ter :Connect with “485- “terminal (the unit at end of the link)

Frame GND(FG)

Connect to ground (D type ground).

Connector

(small-size display unit

)

Connect the display unit.

Reset button

Reset main unit.

LED

Operation mode is

displayed.

(Please reference to 4.2 LED

display and function)

Input current

(1K, 1L, 2K, 2L, 3K, 3L)

Connect the secondary

output of the dedicated

current sensor connected to

the measurement circuit’s

current wire.

※Please setup input current

to 3K,3L

when measuring 2 circuits

by a terminal in 1P2W

(Please reference to the 6.1

Wiring)

MODBUS communication terminal(485+,485-,S LD、Ter)

485+、485-:MODBUS connect t he communication wire.

SLD:Connect to ground (D t ype ground).

Ter :Connect with “485- “terminal (the unit at end of the link)

Output terminal(X1,COMX1 )

Connect to pulse/contact

output.

Output terminal

(Y1,COMY1)

Connect to pulse/contact

output.

Input voltage

(P1/P1,P2/P0,P3/P3,NC/P2)

Connect the voltage input wire

for the measuring circuit.

Auxiliary power(MA,MB)

Connect the auxiliary power supply.

Frame GND(FG)

Connect to ground (D type ground).

Connector

(Extension)

Connect to

extension units.

IEC rail fixture

Connector

(Option devices)

Connect to option

Units.

Back view

Right side

Left side

Connection stop

This is used to connect the

extension unit to the Ener

gy

Measuring Unit.

Connection stop

This is used to connect the

option

unit to the Energy

Measuring Unit.

paper.

It is prohibited to reprint or copy all contents of this document in any form without our permission.

The contents of this document will be updated to follow revisions to software and hardware, however under unavoidable

circumstances it may not be synchronized.

(1)EMU4-BM1-MB (2)EMU4-HM1-MB

(3)Back view and side view

5

Page 7

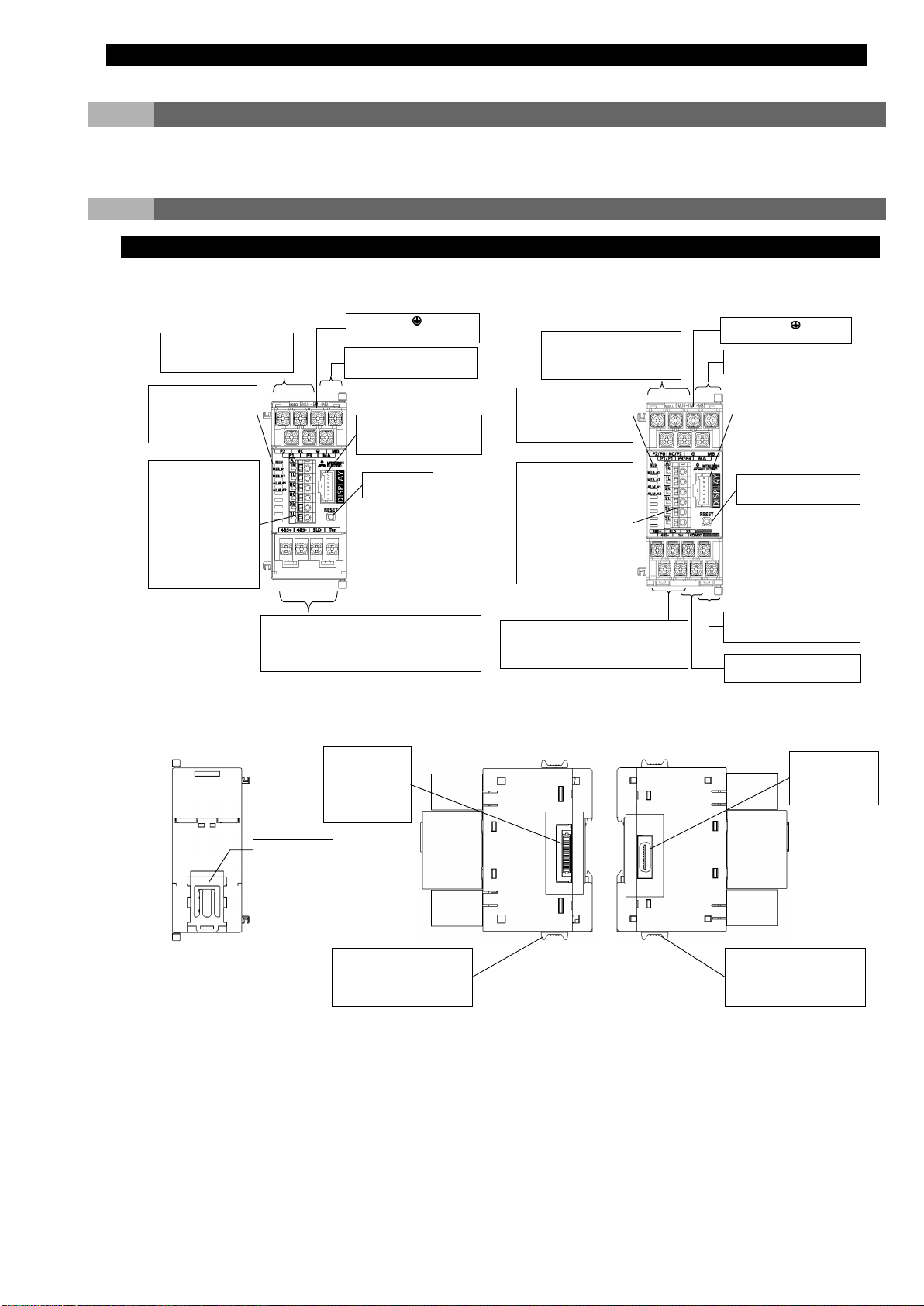

3.2 Indication and function of LEDs

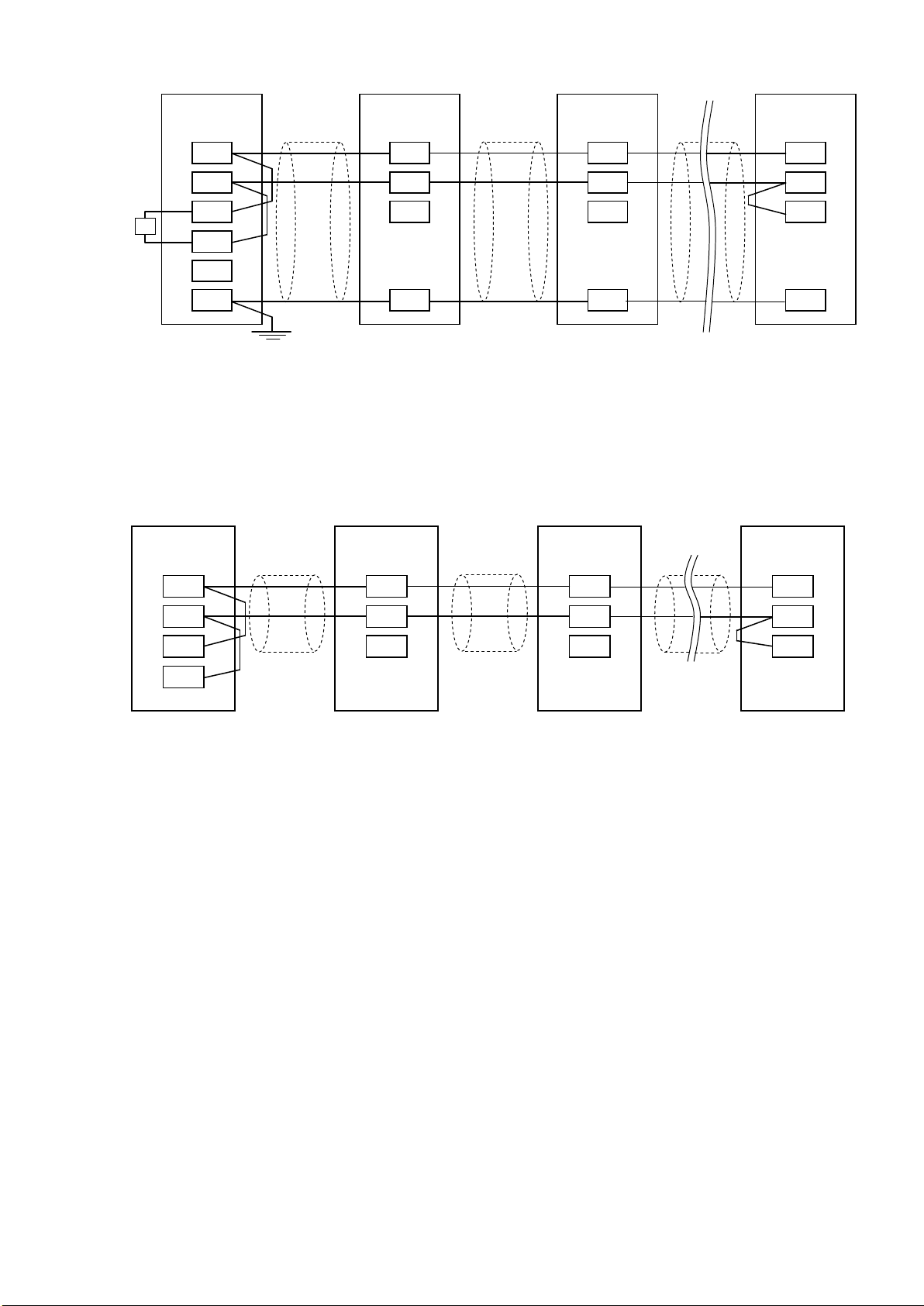

3.3 2 circuits measuring in 1P2W

Circuit A1

The circuit connected to

1K and 1L of SENSOR

A becomes circuit A1.

Circuit A2

The circuit connected to

3K and 3L of SENSOR A

becomes circuit A2.

k l K

L k l K L

Load A1

Load A2

RS-485(MODBUS RTU)

K

1

N

3

Power

supply

side

Load

side

Name

Color

Function

Status

RUN LED

Red

Indicate operating status of this unit.

ON: Normal condition

OFF: Power off or hardware failure (Note 1)

MEA. A1 LED

Red

Indicate measuring status of the circuit

A1.

ON: In the middle of measuring

OFF: Halting measurement

MEA. A2 LED

(Note 2)

Red

Indicate measuring status of the circuit

A2.

ON: In the middle of measuring

OFF: Halting measurement

ALM. A1 LED

Red

Indicate occurrence status of upper/lower

limit alert of the circuit A1.

ON: An error occurs (Note 1)

Blink: Upper/lower limit alert is issued

OFF: No alert

ALM. A2 LED

(Note 2)

Red

Indicate occurrence status of upper/lower

limit alert of the circuit A2.

ON: An error occurs (Note 1)

Blink: Upper/lower limit alert is issued

OFF: No alert

The names and operations of LEDs are as follows.

(Note 1) For details, refer to Chapter 14 "Error codes" of “User’s Manual (Details)”.

(Note 2) Only in the case of single-phase 2-wire system, these indicate the status of the measured circuit of the current sensor in

No.1 side of the circuit A2. (See 3.3)

This unit can measure 2 circuits in the case wiring type 1P2W.

It is a function to measure the 1P2W of 1-N and 3-N branched from 1P3W. (Reference to Figure 3.3.2)

2 circuits measuring can be conducted when current sensor is connected to 1 side (1K, 1L) and 3 side (3K, 3L).

(Reference to Figure 3.3.1 and 3.3.2)

Please reference to 5 chapter about wiring.

Please reference to 6.1 section and EMU4-D65 User’s Manual (Details) when setup for measuring 2 circuits

You can only measure same primary current value in 1 side and 3 side when 2 circuit measuring mode.

Figre3.3.1 Figre3.3.2

6

Page 8

4. Attaching and removing the unit

Any person who is involved in the installation and the wiring of this unit should be fully competent to do this work.

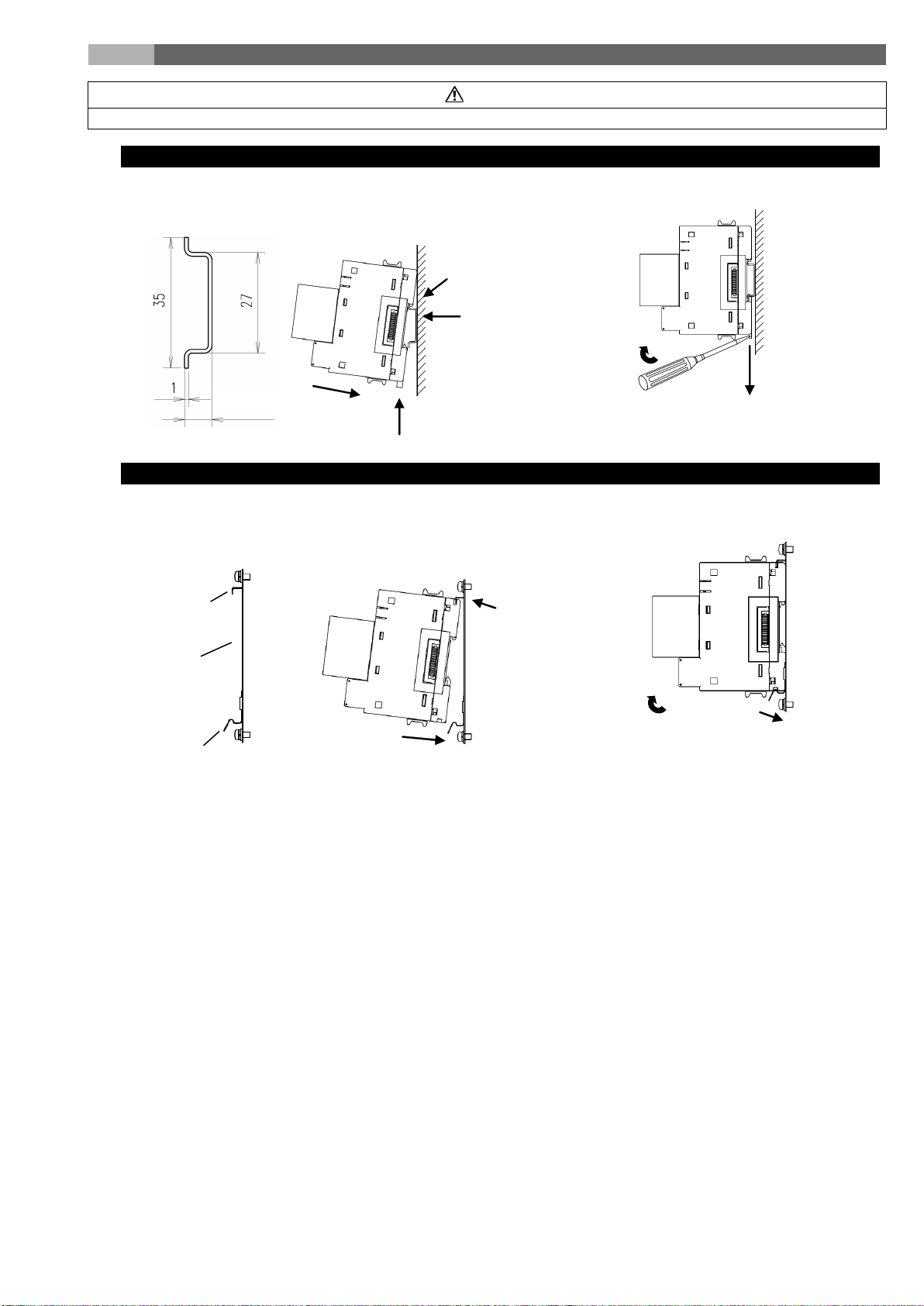

4.1 Mounting on IEC rail

4.2 Mounting on JIS agreement type attachment

•

Applicable IEC rail

(35mm)

•

Mounting

•

Removing

(1) Pull IEC rail fixture downward

(2) Pull the unit

(1) Hold the unit and pull IEC

rail fixture downward

IEC rail

(4) Push the IEC rail

fixture upward

(3) Push in

(2) Catch

7.3 or more

• Mounting

• JIS agreement type

attachment

• Removing

Spring fitting

Attachment

panel

Hook

(2) Hitch 3 chases at

upper part of the

module to the hook

on the attachment

plate

(3) Push the module down and fit in the

spring fitting in chases at the lower

part of the module.

(1) Push the stopper of the IEC rail

above

(1) Push down the

spring fitting

(2) Lift the lower part of

module slowly and

remove in reverse order

of Attaching.

・

Caution

7

Page 9

5. Procedure for wiring

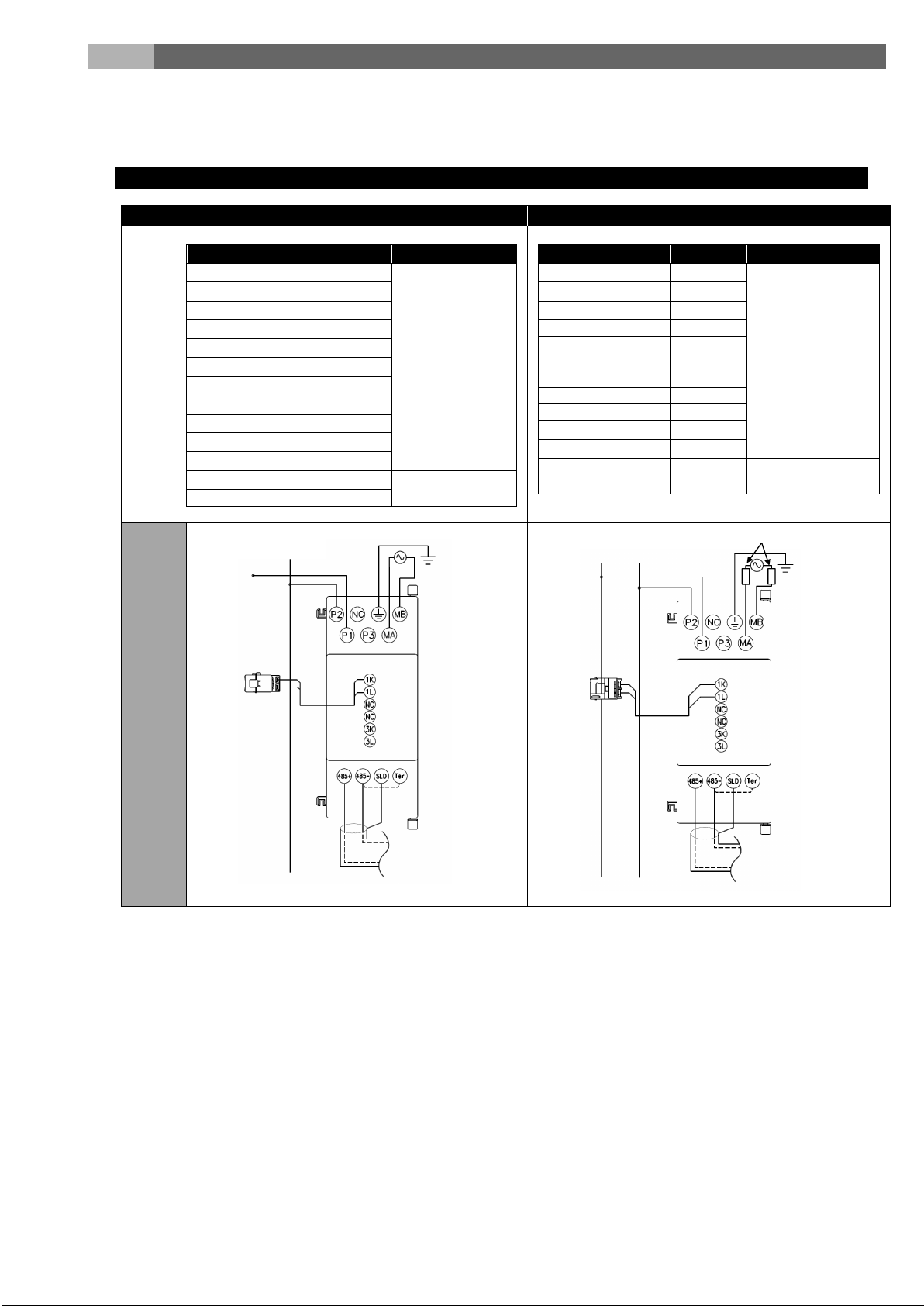

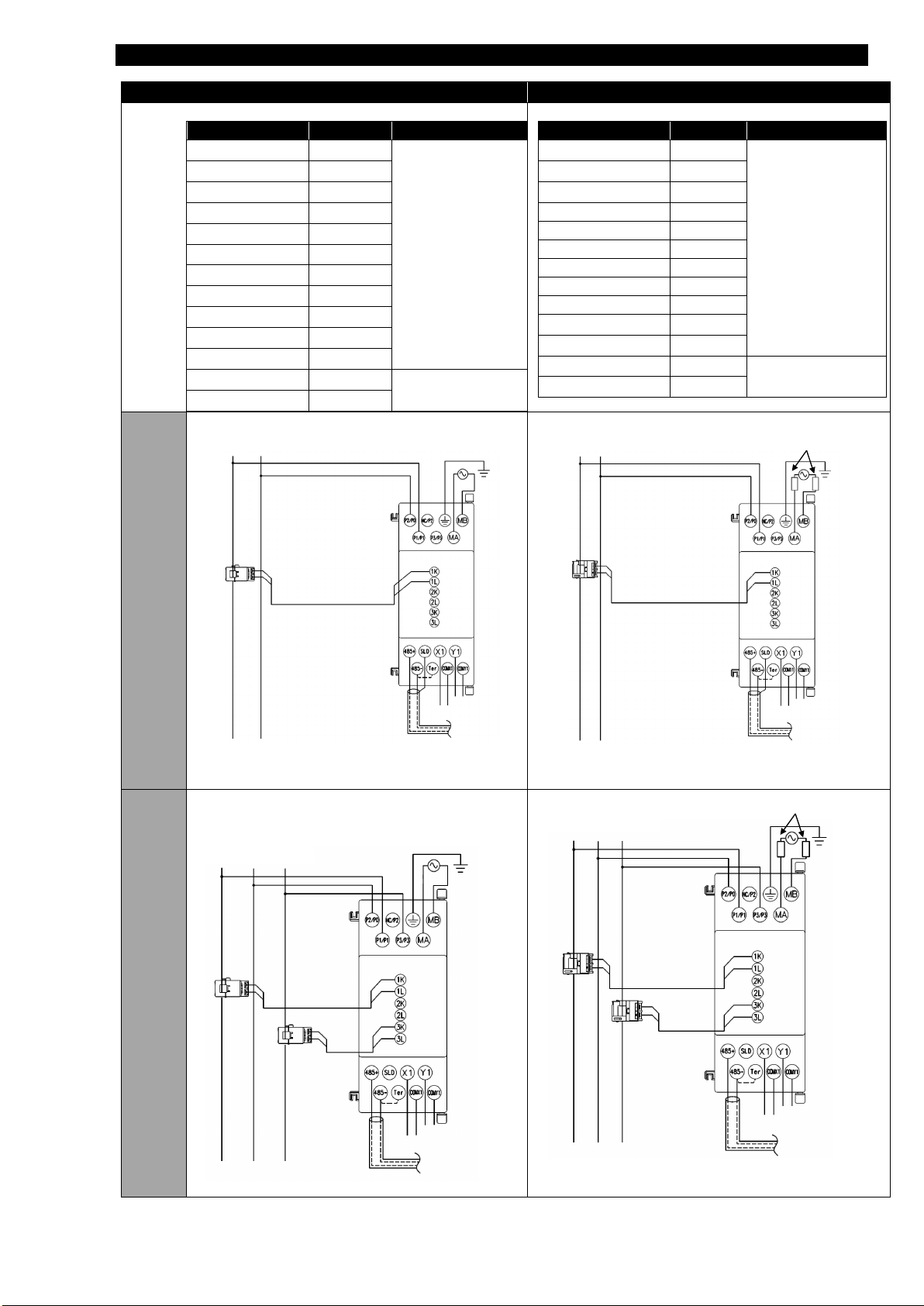

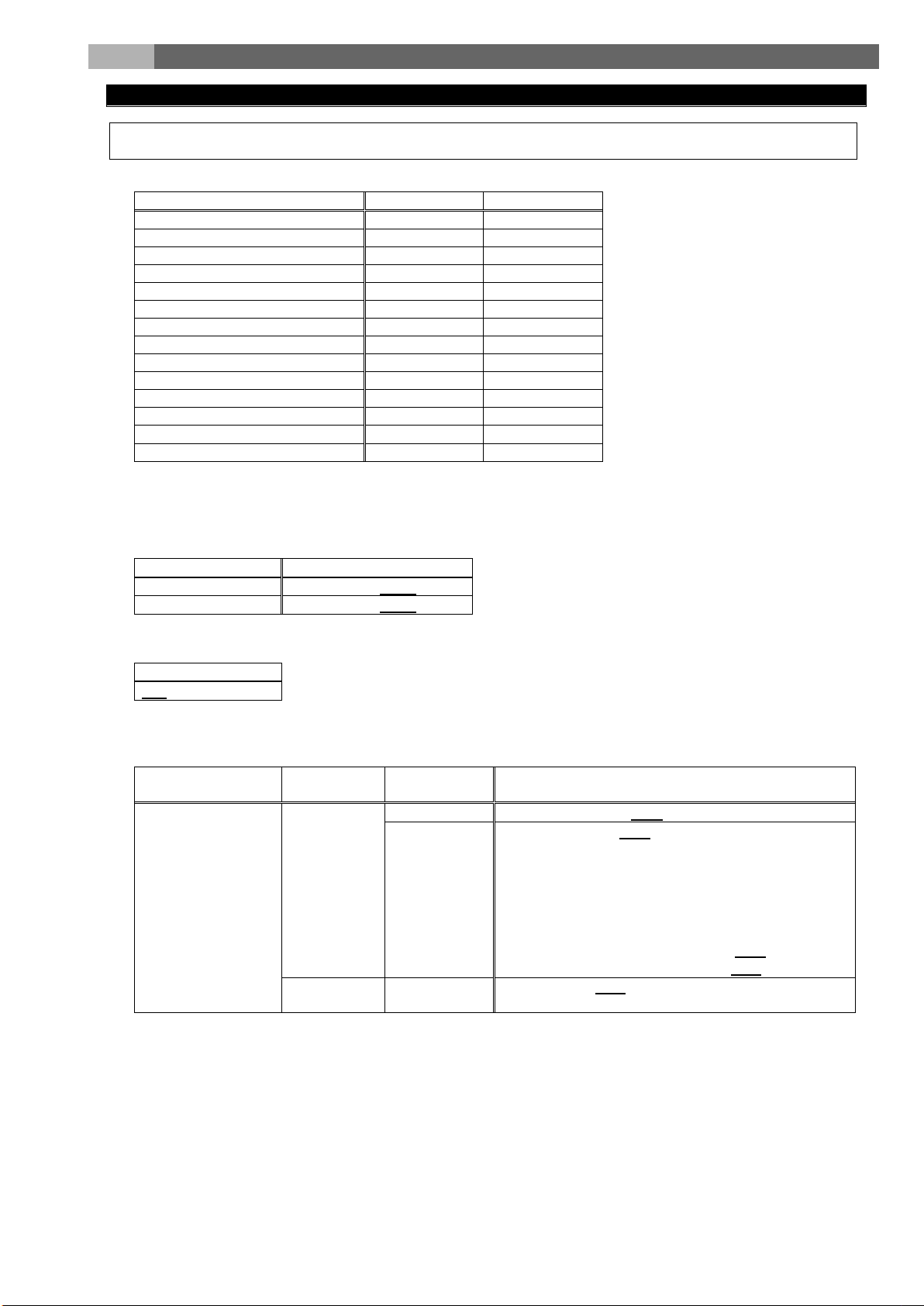

5.1 Wiring for EMU4-BM1-MB

When UL compliance is unnecessary

When UL compliance is necessary

Usable current sensor

Models

Support

remark

EMU-CT50

Connection with

EMU-CT100

EMU-CT250

EMU-CT400

EMU-CT600

EMU-CT5-A

EMU-CT50-A

EMU-CT100-A

EMU-CT250-A

EMU-CT400-A

EMU-CT600-A

EMU2-CT5

Connection with

EMU2-CT5-4W

×*1

*1: EMU2-CT5-4W is only used 3phase-4wire system.

Usable current sensor

Models

Support

remark

EMU-CT50

Connection with

EMU-CT100

EMU-CT250

EMU-CT400

×

EMU-CT600

×

EMU-CT5-A

×

EMU-CT50-A

×

EMU-CT100-A

×

EMU-CT250-A

×

EMU-CT400-A

EMU-CT600-A

EMU2-CT5

Connection with

EMU2-CT5-4W

×*1

Power supply side

Load side

K

L

RS485 (MODBUS RTU)

k

l 1 2

Power supply side

Load side

K

L

RS485 (MODBUS RTU)

k

l

Fuse 0.5A

1

2

Follow the wiring diagram for external connections of this unit.

To use this unit, Base unit (EMU4-BM1-MB、EMU4-HM1-MB、EMU4-LG1-MB) is necessary.

When using this unit, current sensor (EMU-CT***, EMU-CT***-A, EMU2-CT5 or EMU2-CT5-4W) is necessary

(Note) “***” indicates the rated current of the current sensor (50/100/250/400/600).

Please do not use EMU-CT*** type sensor and EMU-CT***-A type sensor with mixture.

1P2W

◯

◯

◯

◯

◯

◯

◯

◯

◯

◯

◯

◯

general wire

dedicated cable

◯

◯

general wire

◯

◯

◯

◯

dedicated cable

*1: EMU2-CT5-4W is only used 3phase-4wire system.

8

Page 10

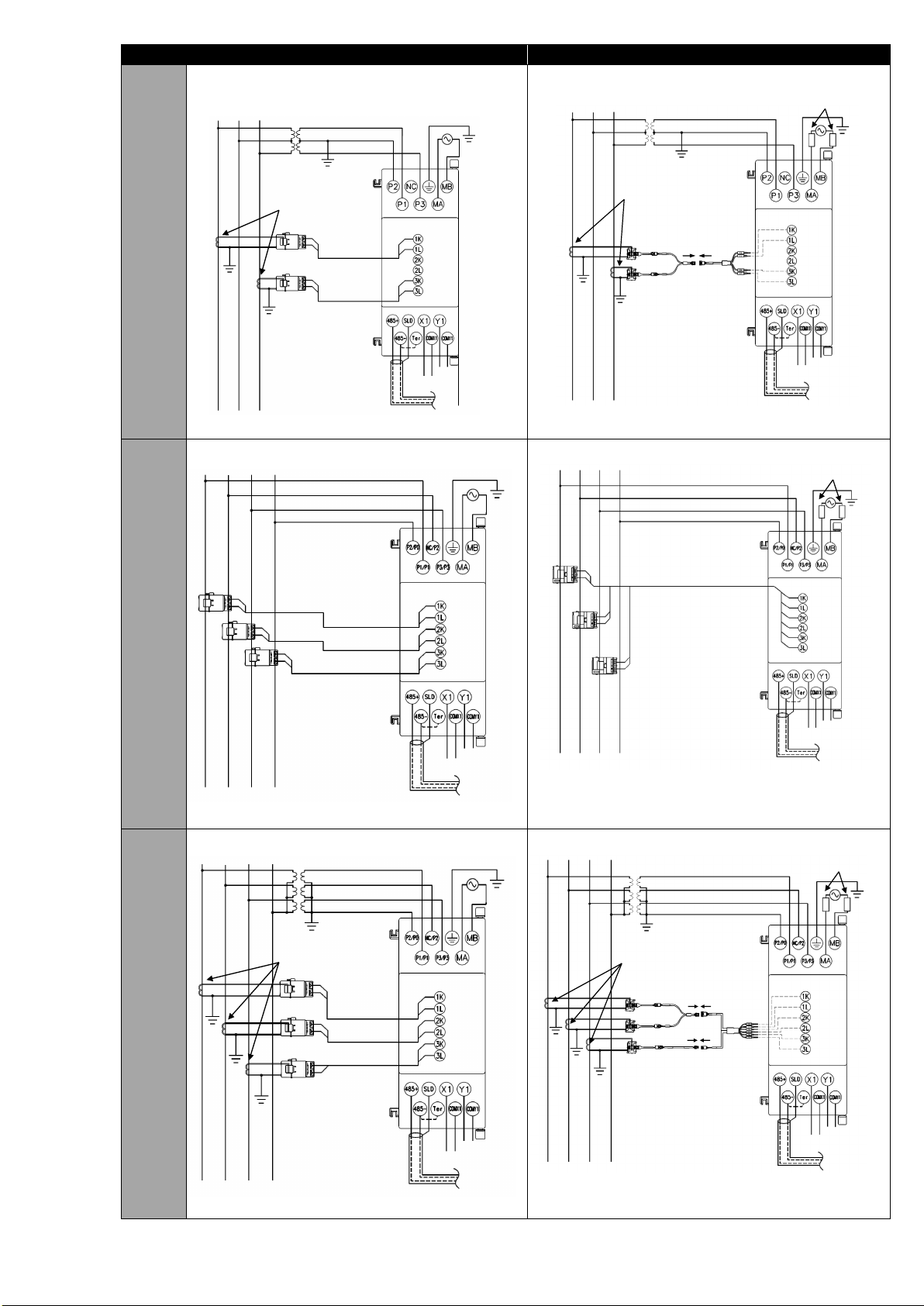

1P3W

Power supply side

Load side

K

L

RS-485 (MODBUS RTU)

k

l

K

L

k

l

1

2

3

1 N 3

Power supply side

Load side

K

L

RS485 (MODBUS RTU)

k

l

K L k

l

Fuse 0.5A

1 2 3

1 N 3

k l K

L

k l K

L

Load A1

Load A2

RS-485(MODBUS RTU)

K

1

N

3

Power

supply

side

Load

side

Load A1

RS-485(MODBUS RTU)

K

L k l

Load A2

K

L

k

l

Fuse 0.5A

1

N

3

Power

supply

side

Load

side

3P3W

1P2W

(2circuit

measurin

g)

9

Page 11

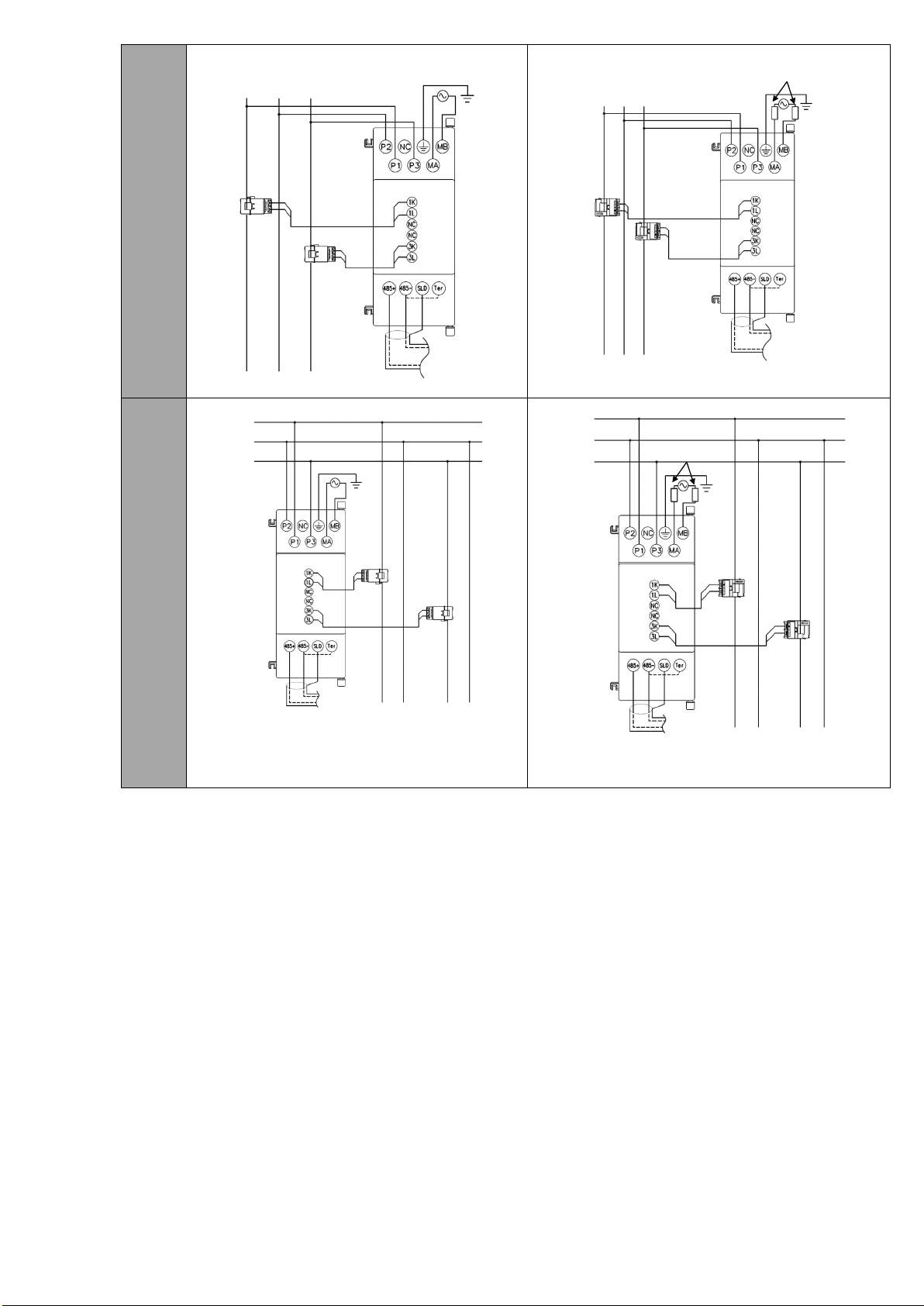

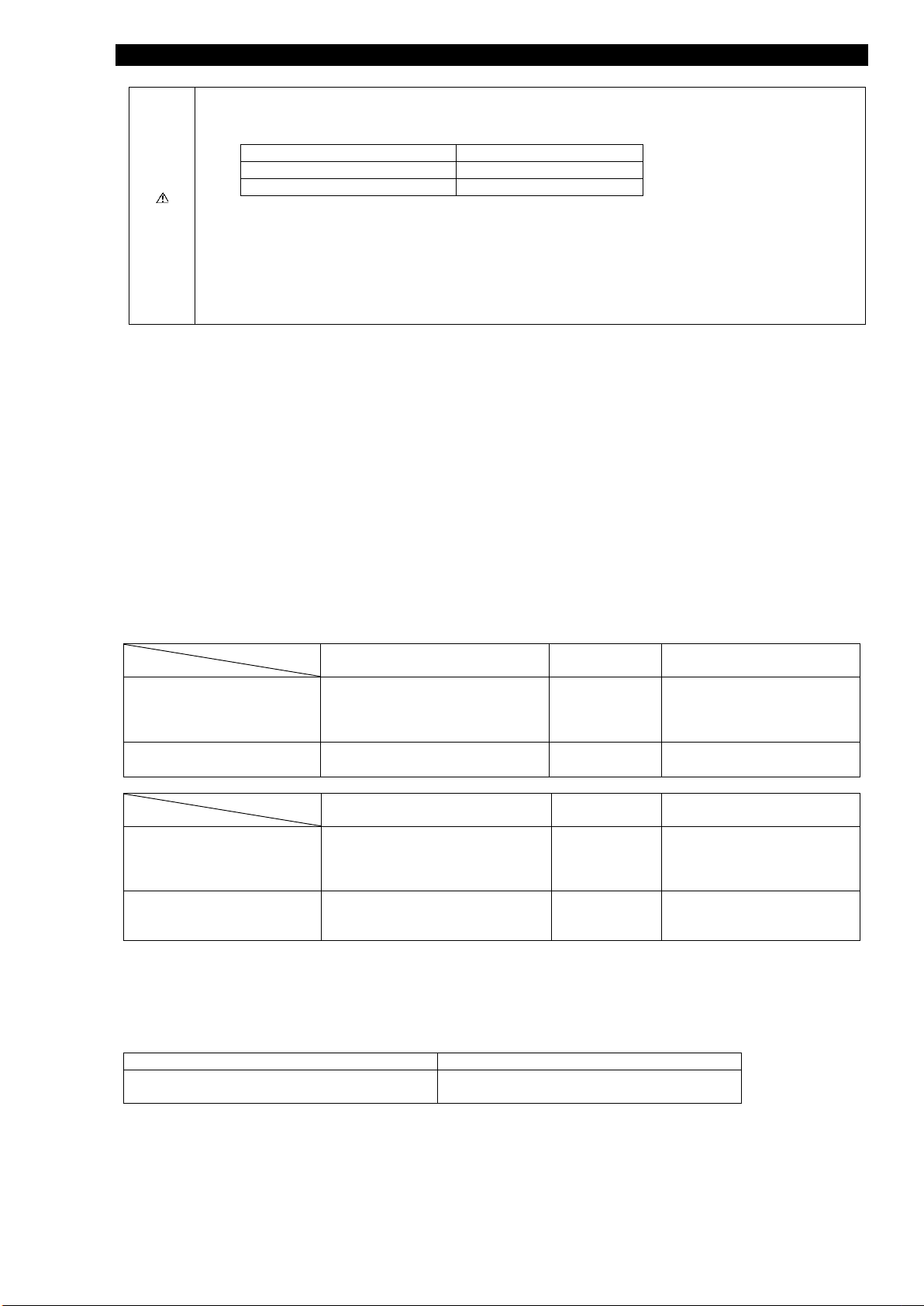

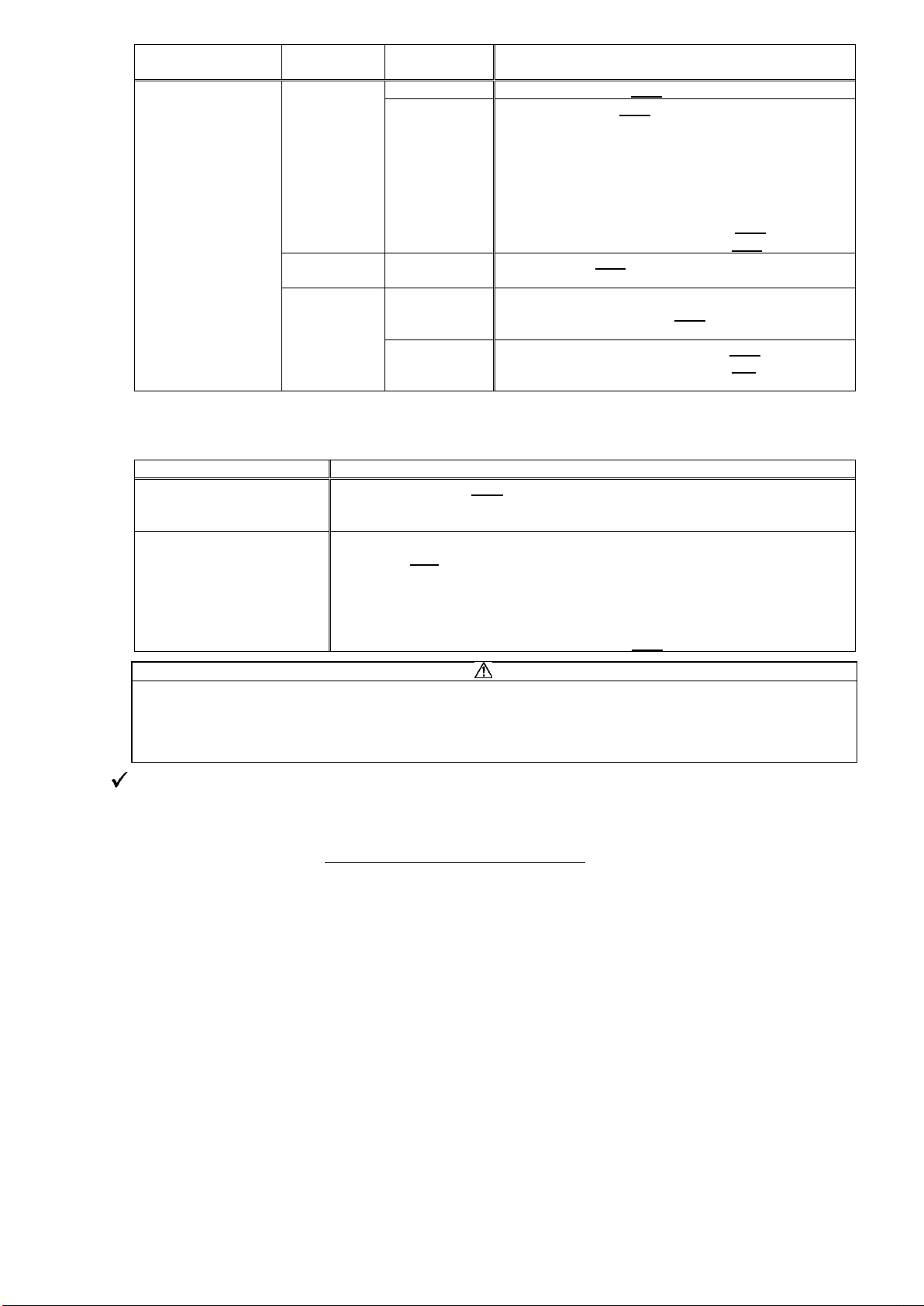

5.2 Wiring for EMU4-HM1-MB

When UL compliance is unnecessary

When UL compliance is necessary

Usable current sensor

Models

Support

remark

EMU-CT50

Connection with

EMU-CT100

EMU-CT250

EMU-CT400

EMU-CT600

EMU-CT5-A

EMU-CT50-A

EMU-CT100-A

EMU-CT250-A

EMU-CT400-A

EMU-CT600-A

EMU2-CT5

Connection with

EMU2-CT5-4W

Usable current sensor

Models

Support

remark

EMU-CT50

Connection with

EMU-CT100

EMU-CT250

EMU-CT400

×

EMU-CT600

×

EMU-CT5-A

×

EMU-CT50-A

×

EMU-CT100-A

×

EMU-CT250-A

×

EMU-CT400-A

EMU-CT600-A

EMU2-CT5

Connection with

EMU2-CT5-4W

Power supply side

Load side

RS-485(MODBUS RTU

)

K

L

k

l

1

2

Power supply side

Load side

RS-485(MODBUS RTU

)

l k K

L

Fuse

0.5A

1

2

Power supply side

Load side

RS-485(MODBUS RTU)

K

L

k

l

K

L

k

l

1 2 3

1 N 3

Power supply side

Load side

RS-485(MODBUS RTU)

l

k

K

L

l

k

K

L

Fuse 0.5A

1 2 3

1

N

3

◯

◯

◯

◯

◯

◯

◯

◯

◯

◯

◯

◯

◯

general wire

dedicated cable

◯

◯

◯

◯

◯

◯

◯

general wire

dedicated cable

1P2W

1P3W

3P3W

10

Page 12

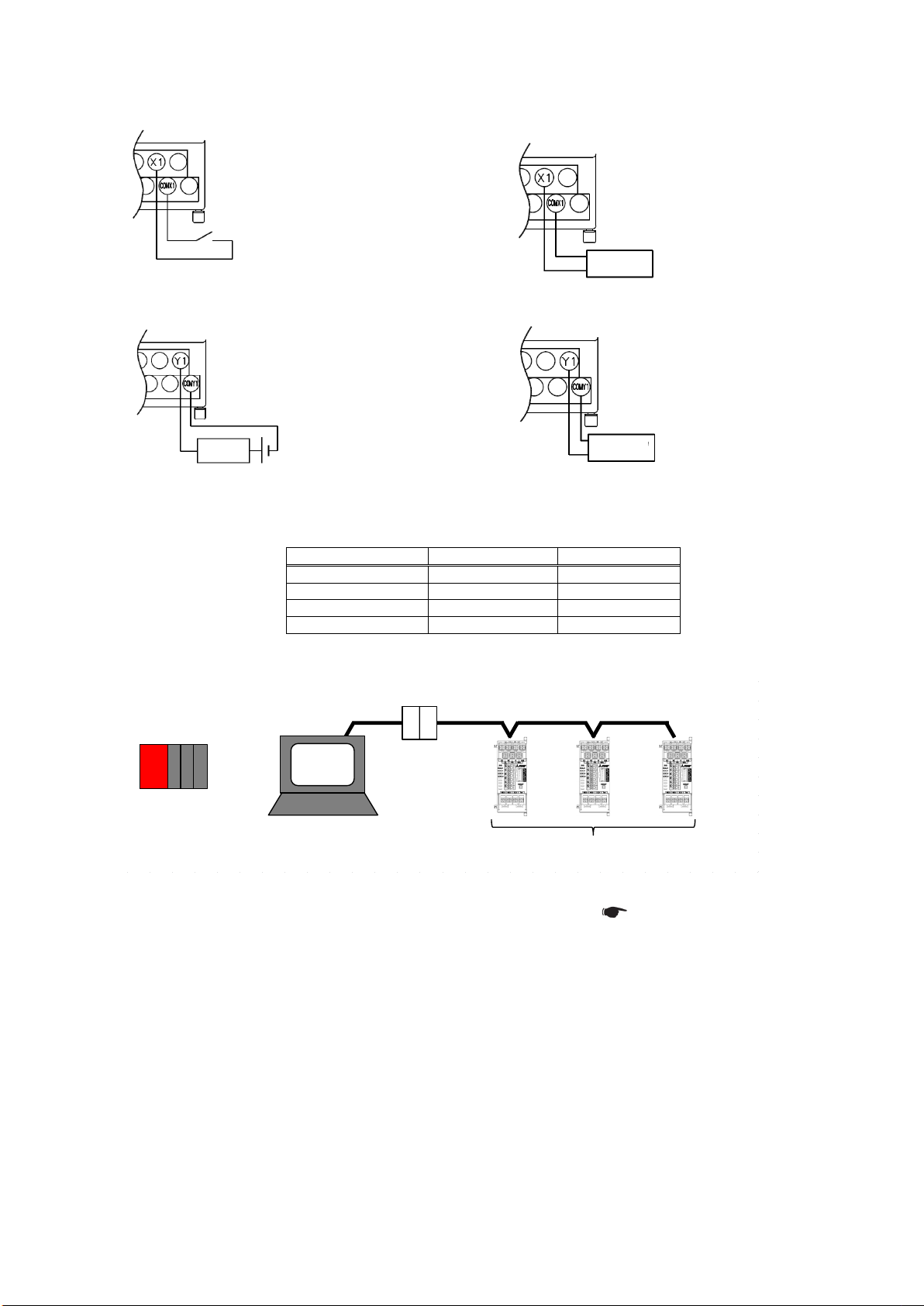

When UL compliance is unnecessary

When UL compliance is necessary

3P3W

Power supply side

Load side

RS-485(MODBUS RTU)

K

L

K

L

l

k

K

L

K

L

l

k

Current transformer

(Secondary current is 5A)

1 2 3

1 N 3

Power supply side

Load side

RS-485(MODBUS

RTU)

K

L

K

L

Current transformer

(Secondary current is 5A)

Fuse 0.5A

1 2 3

1 N 3

Power supply side

Load side

RS

-485(MODBUS RTU)

K

L

l

k

K

L

l

k K L

l

k

1 2 3

N

Power supply side

Load side

RS-485(MODBUS

RTU)

K L l

k

l

k

k

l

K

L

K

L

Fuse 0.5A

1 2 3

N

Power supply side

Load side

RS-485(MODBUS RTU

)

Current transformer

(Secondary current is 5A)

K

L

K

L

K

L

K

L K L

K

L

l k l

k

l

k 1 2 3 N

Current transformer

(Secondary current is 5A)

Load side

RS-485(MODBUS

RTU)

K

L

K

L

K

L

Power supply side

K

L

K

L

K

L

Fuse 0.5A

1 2 3

N

(High

voltage

circuit)

3P4W

3P4W

(Use

with

VT)

11

Page 13

5.3 Precautions for the connection wire

Applicable wire

Tightening

torque

Applicable crimp-type terminal

Power supply terminals,

Stranded wire: AWG26-14

(0.41 - 1.62mm)

0.8 - 1.0 N·m

For M3.5 screw of external

MODBUS communication

terminals

SPEV(SB)-MPC-0.2×1P

equivalent

0.5-0.6 N·m

For M3 screw of external

diameter below 6.1mm

Applicable wire

Tightening

torque

Applicable crimp-type terminal

Power supply terminals,

Stranded wire: AWG26-14

(0.41 - 1.62mm)

0.8 - 1.0N·m

For M3.5 screw of external

MODBUS communication

External input/output terminals

SPEV(SB)-MPC-0.2×1P

0.5-0.6 N·m

For M3 screw of external

Applicable wire

Applicable crimp-type terminal

stranded wire: AWG20-16 (0.5 - 1.3mm2)

single wire: AWG24-17 (0.5 - 1.2mm)

TGV TC-1.25-11T (by NICHIFU) equivalent

• For protection against noise, transmission lines and input/output lines shall not be placed close to or bound

Condition

Distance

High-voltage line 600V or less

300mm or more

Other high-voltage line

600mm or more

burnout or a fire.

together with the power lines and high-voltage lines. Keep distance as below between them. (except for the

terminal block)

Caution

• For the actual usage, connect the FG terminal to ground. (D-type ground: Type 3) Connect it directly to the

ground terminal.

• Do not connect to FG terminal during the insulation resistance test and pressure test. Refer to “User’s manual

(Details)” Chapter 11 “Specifications” for the applying place.

• The current sensors dedicated to this unit EMU-CT400/600 resemble the split current transformer for general

gauges CW-5SL closely in appearance. However, characteristics are completely different. Be sure to connect

the dedicated current sensor. Connecting CW-5SL to this unit directly may cause failure of the device, a

• Maximum voltage of the circuit connected to EMU4-BM1-MB is 260V, EMU4-HM1-MB is 480 (In 3P4W wiring is 277 / 480V). For

the circuit over this voltage, use the transformer. Using the transformer, primary voltage is configurable up to 11000V. Secondary

voltage can be set up to220V.)

• Make sure that before connecting the cable, the orientation of the current sensor is correct for attachment. K to L is the correct

direction. K: power source side, L: load side

• EMU-CT*** and EMU-CT***-A are extendable up to 50m.

• EMU2-CT5 and EMU2-CT5-4W are extendable up to 11 m, using together with an extension cable. To extend the wire further, use

the current transformer CW-5S(L) for split-type instrument in combination, extending the secondary wiring on CW-5S(L) side.

• EMU-CT*** and EMU-CT***-A are used only for low voltage circuit. It cannot be used for a high voltage circuit. EMU2-CT5 and

EMU2-CT5-4W should be used with the secondary side (5A) of transformer transfixed. If they are used for the circuit directly, they

should be used under 200V.

• Do not ground the secondary side of the current sensor.

5.3.1 How to connect wire

<Voltage input terminals, External input/output terminals>

• Use appropriate crimp-type terminal. Applicable crimp-type terminal is shown in the tables below.

• Use electric wires as below, and tighten the terminal screws by the torque as below.

[EMU4-BM1-MB]

Voltage input terminals

[EMU4-HM1-MB]

Voltage input terminals

terminals,

<Current input terminals>

• Stripping length of the used wire in use has to be 10 to 11mm.

• In case using stranded wire, take measures so that the filament should not vary by using a bar terminal or by processing the point

twisted.

• When attaching and detaching cables to/from the terminal, use the push button. Check that the wire is securely inserted.

• Insert a wire to the terminal all the way until it touches the end.

• Use appropriate electric wires as shown below.

(0.13 - 2.0mm2)

Single wire: AWG26-14

(0.13 - 2.0mm2)

Single wire: AWG26-14

equivalent

diameter below 7.1mm

diameter below 7.1mm

diameter below 6.1mm

12

Page 14

5.3.2 Connection of external input / external output

Wire diameter [mm]

Resistivity[Ω/km]

Wiring length[m]

0.5

94

300

0.65

56.8

400

0.9

29.2

750

1.2

16.5

1000

Please connect GND side to

No-voltage a-contact

/ open collector

Voltage of the contact is 5V DC,

and current is 7mA, so use

something appropriate for the

switching condition.

Transmitter

No-voltage a-contact

/ open collector

Voltage of the contact is 5V

DC, and current is 7mA, so

use something appropriate

for the switching condition.

Counter

Relay

In case using external input and/or external output, refer to the following.

External input:For the case of contact input External input: For the case of pulse input

COMX1 when output of

transmitter is open collector pulse.

External output:For the case of contact output External output: For the case of pulse output

• Wiring length of pulse input (Reference value)

The wire length for each wire diameter is below. Please refer to wiring.

※Polyethylene insulating vinyl sheath cable FCPEV wire.

5.3.3 System configuration example of MODBUS communication

●Connection of MODBUS communication terminals:

1. Use the twisted shielded pair cable for transmission lines.(Recommended cable 11. 2 )

2. Connect the termination resistances (120Ω) to both ends of the devices connected the MODBUS transmission line.

Termination resistances of 120Ω can be used by short-circuiting “485-” and “Ter” terminals.

3. Connect to ground by using thick wires to decrease impedance.

4. MODBUS transmission lines shall not be placed close to or bound together with the high-voltage lines.

5. Ground the “SLD” terminal at one end.

13

Page 15

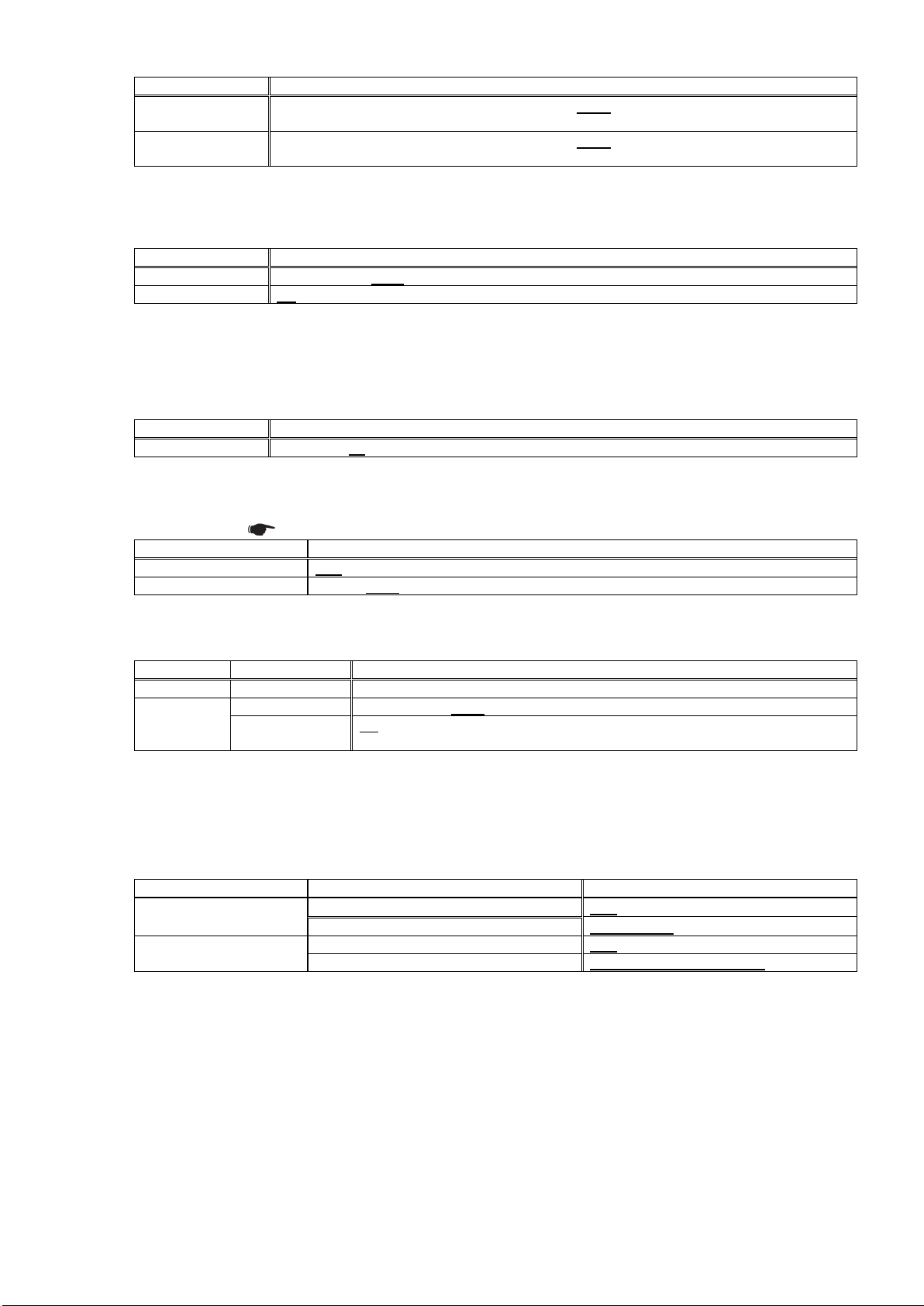

・Wiring for MODBUS module (QJ71MB91, QJ71C24N) and EcoMonitorPlus

Terminal

resistance

MODBUS

Module

(QJ71MB91)

SDA

SDB

RDA

RDB

SG

FG

R

EMU4-BM1-MB

or

EMU4-HM1-MB

485+

485-

Ter

SLD

EMU4-BM1-MB

or

EMU4-HM1-MB

485+

485-

Ter

SLD

EMU4

-BM1

-MB

or

EMU4-HM1-MB

485+

485

-

Ter

SLD

GOT1000

GOT2000

SDA

SDB

RDA

RDB

EMU4-BM1-MB

or

EMU4-HM1-MB

485+

485-

Ter

EMU4-BM1-MB

or

EMU4-HM1-MB

485+

485-

Ter

EMU4-BM1-MB

or

EMU4-HM1-MB

485+

485-

Ter

Note: The terminal resistance of the MODBUS module (QJ71MB91, QJ71C24N) side, please connect "110Ω".

For details, please refer to the instruction manual of the MODBUS module (QJ71MB91, QJ71C24N).

Instruction manual (QJ71MB91): MODBUS Interface Module User's Manual (Manual number: SH(NA)-080578ENG)

Instruction manual (QJ71C24N): Q Corresponding Serial Communication Module User's Manual (Basic) (Manual number:

SH(NA)-080006)

・Wiring for GOT (GOT1000, GOT2000) and EcoMonitorPlus

Note: Please set the terminal resistance of the GOT (GOT1000, GOT2000) "110 Ω".

For the setting procedure, please refer to the connection manual of GOT (GOT1000, GOT2000).

Connection manual (GOT1000): GOT1000 Series Connection Manual (Microcomputer, MODBUS Products, Peripherals)

for GT Works3 (Manual number: SH-080871ENG)

Connection manual (GOT2000): GOT2000 Series Connection Manual (Microcomputers, MODBUS Products,

Peripherals) For GT Works3 Version1 (Manual number: SH-081200ENG)

14

Page 16

6. Setting

6.1 Setting data

Items

EMU4-BM1-MB

EMU4-HM1-MB

Phase wire system

○

○

2 circuits measuring setting

○

○

Primary voltage

○

○

Primary current

○

○

Demand time

○

○

Electric energy converted value

×

○

Cut-off rate of current

○

○

Simple measurement

○

○

External input

×

○

Operating time

○

○

External output

×

○

MODBUS Communication setting

○

○

Setup for logging

○

1

○

1

Setup for upper and lower limit alarm

○

○

Model

Setting value

EMU4-BM1-MB

1P2W、1P3W、3P3W

EMU4-HM1-MB

1P2W、1P3W、3P3W、3P4W

2 circuits measuring

Use, Non-use

Model

Phase wire

system

Use or non-use

of VT

Setting value

EMU4-BM1-MB

1P2W/3P3W

Non-use of VT

[Direct voltage]:110V, 220V

Use of VT

[Primary voltage]:440V, 690V, 1100V, 2200V, 3300V,

1 to 220V(110V)

1P3W

Non-use of VT

(Hold)

[Direct voltage]:110V

To set this unit, dedicated small-size display unit (EMU4-D65) is necessary.

For the setting method, refer to User’s manual (Details) of the display unit.

Items can be setup by model is showed below table.

※

※

*: This items can be setup when using Logging Unit(EMU4-LM).

The data can be setup is showed below. Bold text is default setting value.

Phase wire system

6.1.1

Setup is showed in below table in each unit.

6.1.2

2 circuits measuring setting

Setup is showed in below table in phase wire system is 1P2W.

6.1.3

Primary voltage

Set the rated voltage of the measuring circuit. Please setup the primary voltage of VT when set “Use of VT”.

Primary voltage is set below value by use of VT or not, setup for wiring type and unit.

6600V,11000V, 13200V, 13800V, 15000V, 16500V,

22000V, 24000V, 33000V, 66000V, 77000V,

110000V, SP※

※This setting value can be set [Special primary voltage]

and [Special secondary voltage] when setting SP. Can be

set in the 1V step.

[Special primary voltage]:1 to 110000V(440V)

:

15

Page 17

Model

Phase wire

system

Use or non-use

of VT

Setting value

EMU4-HM1-MB

1P2W/3P3W

Non-use of VT

[Direct voltage]:110V, 220V, 440V

Use of VT

[Primary voltage]:440V, 690V, 1100V, 2200V, 3300V,

6600V,11000V, 13200V, 13800V, 15000V, 16500V,

can set [Special primary voltage] and

[Special secondary voltage]:1 to 220V(110V)

1P3W

Non-use of VT

(Hold)

[Direct voltage]:110V, 220V

3P4W

Non-use of VT

[Direct voltage]:63.5V, 100V, 105V, 110V, 115V, 120V,

250V, 254V, 265V, 277V

Use of VT

[Special primary voltage]:1 to 63500V(440V)

Can be set in the 1V step.

Sensor type

Setting value

Direct sensor

EMU-CT***-A)

[Primary current]:50A, 100A, 250A, 400A, 600A

5A Sensor

[Primary current]:5A, 6A, 7.5A, 8A, 10A, 12A, 15A, 20A, 25A, 30A, 40A, 50A, 60A, 75A, 80A,

[5A sensor special primary current]:5.0 to 30000A(100A)

Caution

EMU-CT*** and EMU-CT***-A are used only for low voltage circuit. It cannot be used for a high voltage circuit.

dangerous

α:1 Single-phase, 2-wire

3 Three-phase, 4-wire

22000V, 24000V, 33000V, 66000V, 77000V,

110000V, SP

※

※This setting

[Special secondary voltage] when setting S P. Can be set

in the 1V step.

[Special primary voltage]:1 to 110000V(440V)

127V, 200V, 220V, 230V, 240V, 242V,

[Special secondary voltage]:1 to 220V(64V)

6.1.4 Primary current

Set the rated current of the measuring circuit. Please select using sensor and setup primary current by sensor type.

Primary current is set below value by the sensor type. Value is common regardless of unit.

(Use of EMU-CT***,

(Use of EMU2-CT5,

EMU2-CT5-4W, EMU-CT5-A)

100A, 120A, 150A, 200A, 250A, 300A, 400A, 500A, 600A, 750A, 800A, 1000A,

1200A, 1250A, 1500A, 1600A, 2000A, 2500A, 3000A, 4000A, 5000A, 6000A,

7500A, 8000A, 10000A, 12000A, 20000A, 25000A, 30000A, SP

※Setup the [5A sensor special primary current] in SP setting. 10A less than, the upper

two digits. 10A or more is possible to set the upper three digits.

EMU2-CT5 and EMU2-CT5-4W should be used with the secondary side (5A) of transformer transfixed. If they are used

for the circuit directly, they should be used under 200V.

If it is connected with a high-voltage circuit by mistake, it may cause a burnout of the device and a fire. It is critically

Supplement ------------------------------------------------------------------------------------------------------------------------------------------

Please setup CT rating of primary side when use EMU2-CT5, EMU2-CT5-4W or EMU-CT5-A.

Full load power is calculated in below equation.

Full load power [kW] =

α × (VT primary voltage) × (CT primary current)

1000

2 Single-phase, 3-wire

√3 Three-phase, 3-wire

*1: VT primary voltage in single-phase 3-wire system is regarded as 110V.

*2: Using direct connection, replace VT primary voltage with direct voltage in calculation above.

*3: In three-phase 4-wire system, replace VT primary voltage or direct voltage with phase voltage in calculation above.

※

16

Page 18

6.1.5 Demand time

Setting item

Setting value

Current demand

time

0sec, 10 sec, 20 sec, 30 sec, 40 sec, 50 sec, 1min, 2 min, 3 min, 4min, 5 min, 6 min, 7 min, 8 min,

9 min, 10 min, 11 min, 12 min, 13 min, 14 min, 15 min, 20 min, 25 min, 30 min

Power demand time

0sec, 10 sec, 20 sec, 30 sec, 40 sec, 50 sec, 1min, 2 min, 3 min, 4min, 5 min, 6 min, 7 min, 8 min,

9 min, 10 min, 11 min, 12 min, 13 min, 14 min, 15 min, 20 min, 25 min, 30 min

Setting item

Setting value

Wh conversion rate

0.001 to 10000(1.000)

Unit

Off, Wh,

2

,

3

, L, kL, sec, min, hour, piece, unit, g, kg, t, ¥, $

Setting item

Setting value

Cut-off current

0.1 to 50.0% (0.5

Setting item

Setting value

Simple measurement

OFF, ON

Setup for power factor

-0.001~1.000~0.000

External input

Setting item

Setting value

Contact input

Reset method

Auto, Hold

Pulse input

Pulse converted

0.001 to 10000(1.000)

Unit

Off, Wh,

2

,

3

, L, kL, sec, min, hour, piece, unit, g, kg, t,

Model

Setting items

Setting value

EMU4-BM1-MB

Counting operating time

OFF, ON

Counting method of operating time

Current input

EMU4-HM1-MB

Counting operating time

OFF, ON

Counting method of operating time

Current input, Contact input

Current demand alarm, electric energy can be setup in each. It is common regardless the unit type.

Electric energy converted value

6.1.6

Setup the converted rate and conversion unit of electric converted value.

You can’t setup in EMU4-BM1-MB. Please setup electric energy conversion rate 1side and 3side in 2 circuits measuring in 1P2W.

Electric energy converted value = Electric energy × Wh conversion rate

kWh, MWh, J, m

m

6.1.7

Cut-off rate of current※

Set the cut-off value when measuring current. Measured current is 0 when measured current is lower than Cut-off current.

Cut-off current = Rated current ×Cut-off rate.

Setup is common regardless of unit type. Please setup cut-off rate of current rate 1side and 3side in 2 circuits measuring.

※The ratio of measured lower current limit (cut-off current) to primary current.

Primary current × cut-off rate = cut-off current

)

6.1.8

Simple measurement

Setup the whether to do simple measurement.

Setup is common regardless of unit type. Please setup power factor 1side and 3side in 2 circuits measuring.

Please reference to

for simple measurement

6.1.9

External input

Setup the measurement target of external input. You can’t setup in EMU4-BM1-MB.

kWh, MWh, J, m

m

¥, $

6.1.10 Operating time

Setup the whether to measure operating time. Setting value is showed below table.

Please setup operating time 1side and 3side in 2 circuits measuring in 1P2W.

Operating time is integration time while current measuring when select Current. Operating time is integration time while Contact

input is ON when Contact input.

17

Page 19

External output

method

Setting item

Setting value

Pulse output

The unit of pulse

Setting range is changed by the value of Full load power.

Total load power(kW)

Setting range

Less than 12

0.001, 0.01, 0.1, 1

12 or more

Less than 120

0.01, 0.1, 1, 10

120 or more

Less than 1200

0.1, 1, 10, 100

1200 or more

Less than 12000

1, 10, 100, 1000

12000 or more

Less than 120000

10, 100, 1000, 10000

120000 or more

100, 1000, 10000, 100000

Alarm output

The object of

1, 2

If the target of external output is 3K, 3L connection side circuit, Set [2].

Setting item

Setting value

MODBUS Address

001 to 255

MODBUS Baud rate

2400, 4800, 9600, 19200, 38400

MODBUS Parity

Non, Even, Odd

MODBUS Sop bit

1, 2

Setting item

Setting value

Logging ID

001~255

Confirmation of logging data

OK、Cancel

6.1.11 External output

Setup the output method of the contact output terminal. Please setup external output in which circuit 1 side circuit or 3 side circuit.

You can’t setup in EMU4-BM1-MB.

output

alarm output

*If the target of external output is 1K, 1L connection side circuit, Set [1].

6.1.12

MODBUS Communication setting

Setup the items for MODBUS communication.Setting values are showed below. This is common regardless of units.

6.1.13 Setup for logging

Setup the items for logging using EMU4-LM. Setting values are showed below. This is common regardless of units.

18

Page 20

6.1.14 Setup for upper and lower limit alarm

Setting item

Setting values

Upper and lower limit alarm existence

ON, OFF

Elements of upper and lower limit alarm

Current demand upper limit, current demand lower limit, line voltage upper

limit, current unbalance rate upper limit, current unbalance rate lower limit

Upper

Current demand upper limit

0~120% of primary current (100% of primary current)

Less than 40A

Step 0.01A

40A ~ 400A

Step 0.1A

400A ~ 4000A

Step 1A

4000A ~

Step 10A

Current demand lower limit

0~120% of primary current (0% of primary current)

Lower than 40A

Step 0.01A

40A ~ 400A

Step 0.1A

400A ~ 4000A

Step 1A

4000A ~

Step 10A

Line voltage upper limit

0~100%×15/11 of primary voltage (110% of primary voltage)

Less than 300V

Step 0.1V

300V ~ 3000V

Step 1V

3000V ~

Step 10V

Line voltage lower limit

0~100%×15/11 of primary voltage(0% of primary voltage)

Less than 300V

Step 0.1V

300V ~ 3000V

Step 1V

3000V ~

Step 10V

Electric power upper limit

-120~0~120% of full load(100% of full load)

Less than 12kW

Step 0. 001kW

12kW ~ 120kW

Step 0.01kW

120kW ~ 1200kW

Step 0.1kW

1200kW ~ 12000kW

Step 1kW

12000kW ~ 120000kW

Step 10kW

120000kW ~

Step 100kW

Electric power lower limit

-120~0~120% of full load(0% of full load)

Less than 12kW

Step 0. 001kW

12kW ~ 120kW

Step 0.01kW

120kW ~ 1200kW

Step 0.1kW

1200kW ~ 12000kW

Step 1kW

12000kW ~ 120000kW

Step 10kW

120000kW

Step 100kW

Power factor upper limit

-0.050, -0.100, …-0.950, 1.000, 0.950, …0.100, 0.050(-0.500)

Power factor lower limit

-0.050, -0.100, …-0.950, 1.000, 0.950, …0.100, 0.050(0.500)

Pulse converted upper limit

1 to 999999(100000)

Current unbalance rate

upper limit

0.01 to 999.99%(30.00%)

Voltage unbalance rate

upper limit

0.01 to 999.99%(3.00%)

Alarm delay time

0sec, 5sec, 10sec, 20sec, 30sec, 40sec, 50sec, 1min, 2min, 3min, 4min,

5min

Alarm reset method

Auto、Hold

Setup the whether to monitor upper and lower limit alarm.

Please refer to 7.2.2 Upper/lower limit monitoring function for more details.

Showed below table. Please setup upper and lower limit alarm of second circuit (3 side circuit) in 2 circuits measuring in 1P2W.

limit, line voltage lower limit, phase voltage upper limit, phase voltage lower

limit, electric power upper limit, electric power lower limit, power factor upper

limit, power factor lower limit, N phase demand current upper limit, N phase

demand current lower limit, pulse converted upper limit, pulse converted lower

and

lower limit

N phase current demand

upper limit

Phase voltage upper limit

Phase voltage lower limit

The minimum step of settable value is varies by primary current.

:

:

:

:

The minimum step of settable value is varies by primary current.

:

:

:

:

The minimum step of settable value is varies by primary voltage.

:

:

:

The minimum step of settable value is varies by primary voltage.

:

:

:

The minimum step of settable value is varies by full load.

:

:

:

:

:

:

The minimum step of settable value is varies by full load.

19

:

:

:

:

:

~

:

Page 21

6.2 Initialization of related item by changing the setup

●

●

●

●

●

●

●

●

●

● ●

○

○

○ ○ ○

○

○ ○

○ ○

○

○ ○

○

○ ○

Demand current alarm(3side)

○ ○

○ ○ ○ ○ ○ ○ ○ ○ ○ □ ○ △

○ ○ ○ ○ ○ ○ ○ ○ ○ □ ○ △

○ ○ ○ ○ ○ ○ ○ ○ ○ □ ○ △ ○

○ ○ ○ ○ ○ ○ ○ ○ ○ □ ○ △

○ ○ ○ ○ ○ ○ ○ ○ ○ □ ○ △

○ ○ ○ ○ ○ ○ ○ ○ ○ □ ○ △ ○

Initialize

Initialize bas ed on the wirinf type.

Initialize when puls e input is turned to be contact area input in the condition that upper/lower lim itof pulse convertion in.

Alarm mask time(3side)

Alarm reset mode(3side)

Logging ID

Additional element4

Contents

□

●

○

Mar k

Logging delete confirmation

Simple measuring s etup

Power factor s etup in simple measuring

Power factor s etup in simple measuring (3side)

Additional element1

Additional element2

Additional element3

Upper and lower limit alarm extence(3side)

Upper and lower limit alarm element(3side)

Upper and lower limit alarm value(3side)

Operating tim e

Operating tim e measuring items

Operating tim e(3side)

Operating tim e measuring items(3side)

Upper and lower limit alarm extence

Upper and lower limit alarm element

Cut-o ff setup

Cut-off s etup(3side)

Demand electric energy alarm (3side)

Modbus address

Modbus baurate

Modbus parity

Modbus stopbit

Upper and lower limit alarm value

Alarm mask time

Alarm reset mode

Electric energy convertion unit (3s ide)

Pulse convertion unit

Pulse convertion

Electric energy convertion(3side)

Electric energy convertion unit

Additional element4

Setup value (initialized)

Wiring type

VT use or non-use

Direct voltage

VT prim ary voltage

VT special primary voltage

Secondary voltage

Current sensor type

Primary current

Simple measuring setup

Power factor setup in simple measuring

Power factor setup in simple(3side)

Additional element1

Additional element2

Additional element3

Upper and lower limit alarm element(3side)

Upper and lower limit alarm value(3side)

External input setup

Contact point reset mode

External input setup

External input target circuit

Pulse output unit

Electric energy convertion

Demand electric energy alarm

Demand current alarm

Current sensor type(3side)

Primary current(3sid e)

Demand electric energy alarm

Demand current alarm

Current sensor type(3phase)

Primary current(3phase)

5A sensor primary special current(3side)

2 circuits measuri ng

2 circuits measuring

Logging delete confirmation

Upper limit alarm extence

Upper limit alarm element

Upper limit alarm value

Alarm mask time

Alarm reset mode

Upper and lower limit alarm extence(3side)

Alarm reset mode(3side)

5A sensor primary special current

Cut-off setup(3side)

Electric energy co nvertion

Electric energy convertion unit

Electric energy convertion(3side)

Electric energy convertion(3side)

Pulse convertion

Pulse convertion unit

Alarm mask time(3sid e)

Demand current alarm(3side)

Modbus address

Modbus baurate

Modbus parity

Operating time

Operating time measuring items

5A sensor prima ry special current

△

Initialize when upper puls e convertion is s etup in upper/lower lim it element.

Setup items

Setup value to be changed

Wiring type

VT use or non-use

Direct voltage

VT primary voltage

VT special prima ry voltage

Secondary voltage

Current sensor type

Modbus stopbit

External input setup

Contact point reset mode

External input setup

External input target circuit

Pulse output unit

5A sensor prima ry special(3side )

Demand electric energy(3side)

Operating time(3side)

Operating time measuring items(3side)

Cut-o ff setup

Primary current

Logging ID

Setup value and measured data is initialized after change the setting value according to table 6.2.1 and 6.2.2.

Please setup again.

Table 6.2.1 List of initialization when changing setup value (setup data)

20

Page 22

Table 6.2.2 List of initialization when changing setup value (Measured data and operating data)

Electric energy(consumption)

Regenerate electric energy

Reactive electric energy

Periodic electric energy

○

Electiric energy convertion

Electiric energy convertion (3phase)

Pulse count

○

Pulse convertion

○

Operating tim e

○

Electric energy (consumption) (3phase)

Regenerate electric energy (3phase)

Periodic electric energy (3phase)

CO2 convertion

Operating tim e (3phase)

○

Line voltage (all phas es)

○

○ ○ ○ ○ ○ ○

Line voltage (1-2)

○

○ ○ ○ ○ ○ ○

Line voltage (2-3)

○ ○ ○ ○ ○ ○ ○

Phase voltage (All phases )

○

○ ○ ○ ○ ○ ○

Powr factor (All phases)

○

○ ○ ○ ○ ○ ○ ○ ○ ○

Powr factor (1phase)

○

○ ○ ○ ○ ○ ○ ○ ○ ○

Powr factor (3phase)

○

○ ○ ○ ○ ○ ○ ○ ○ ○

Demand current (All phas es)

○

○ ○ ○ ○ ○

Demand current (1 phase)

○

○ ○ ○ ○ ○

Demand current (3 phase)

○ ○ ○ ○ ○ ○

Demand electric power (All phas es)

○

○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Demand electric power (1 phase)

○

○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Demand electric power (3 phase)

○

○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Current unbalance rate

○

○ ○ ○ ○

Voltage unbalance rate

○

○ ○ ○ ○ ○ ○

Line voltage (all phas es)

○ ○ ○ ○ ○ ○ ○

Line voltage (1-2)

○ ○ ○ ○ ○ ○ ○

Line voltage (2-3)

○ ○ ○ ○ ○ ○ ○

Phase voltage

○

○ ○ ○ ○ ○ ○

Powr factor (All phases)

○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Powr factor (1phase)

○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Powr factor (3phase)

○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Demand current (All phas es)

○ ○ ○ ○ ○ ○

Demand current (1 phase)

○ ○ ○ ○ ○ ○

Demand current (3 phase)

○ ○ ○ ○ ○ ○

Demand electric power (All phas es)

○

○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Demand electric power (1 phase)

○

○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Demand electric power (3 phase)

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○

Setup items

Setup value to be changed

Wiring type

VT use or non-use

Direct voltage

VT primary voltage

VT special prima ry voltage

Secondary voltage

Current sensor type

Primary current

Demand electric energy(3side)

Demand current alarm(3side)

Modbus address

Modbus baurate

Modbus parity

Modbus stopbit

5A sensor prima ry special current

Demand electric energy alarm

Demand current alarm

Current sensor type(3side)

Primary current(3sid e)

5A sensor prima ry special(3side )

Electric energy convertion unit

Electric energy convertion(3side)

Electric energy convertion(3side)

Pulse convertion

Pulse convertion unit

Operating time

External input setup

Contact point reset mode

External input setup

External input target circuit

Pulse output unit

Electric energy co nvertion

Upper and lower limit alarm element

Upper and lower limit alarm value

Alarm mask time

Alarm reset mode

Upper limit alarm extence(3side)

Upper limit alarm element(3side)

Operating time measuring items

Operating time(3side)

Operating time measuring items(3side)

Cut-o ff setup

Cut-off setup(3side)

Upper and lower limit alarm extence

2 circuits measuri ng

○

Initialize.■Initialize (Not initialize in 1P2W).

Measured value (initialized)

Integral value

Max

Min

Mark

Contents

Power factor setup in simple measuring

Power factor setup in simple measuring(3side)

Additional element1

Additional element2

Additional element3

Additional element4

Upper limit alarm value(3side)

Alarm mask time(3sid e)

Alarm reset mode(3side)

Logging ID

Logging delete confirmation

Simple measuring setup

21

Page 23

7. Operation

7.1 Measurement

Model

Display

mode

1P2W

1P2W

1P2W

Electric energy

Present value

● ● ● ● ● ● ● ● ●

Converted electric

energy

Periodic electric

energy

○ ○ ○

○ ○ ○ ○ ○ ○ ● ● ●

Regenerated electric

energy

Pulse count

Present value

Pulse converted value

Present value

Current

1,2,3,N,Total

1

1,2,3,N

1

Max, Min

1-2,2-3,3-1,1-N,

2-N,3-N,Total※2

Max, Min

Electric power

Present value

Electric power

demand

Present value

Max, Min

Reactive power

Present value

○ ○ ○ ○ ○ ○ ● ● ●

─ ─ ─ ─ ─

○

7

─ ─ ─

Present value

Max, Min

○ ○ ○ ○ ○ ○ ● ● ●

Harmonics total

RMS/Distortion ratio

Harmonics total

RMS/Distortion ratio

Harmonics current※9

RMS/Distortion ratio

Harmonics voltage※9

RMS/Distortion ratio

1-2,2-3,

1-N,2-N,3-N※4

Reactive energy

Present value

○ ― ○ ○ ― ○ ─ ─ ─

Current unbalance

rate

Present value

Max

Voltage unbalance

rate

Present value

Max

●

8

●

8

●

8

●

8

●

8

●

8

●

8

●

8

●

8

Error

─

● ● ● ● ● ● ● ● ●

Measurement elements are showed below table in each unit.

In the case displaying in Display unit.

● … Measured elements ○…Elements displayed when only setup and selected ─ … Not displayed elements

EMU4-BM1-MB EMU4-HM1-MB

Wh+A+4 elements Wh+A+4 elements Harmonics

Wiring type

Present value

Present value

Operating time Present value

Present value

Current demand

Voltage

Apparent power Present value

Power factor

Frequency Present value

※

※

1P3W

/3P3W

/3P4W

1 circuit

measuring

2 circuits

measuring

1 circuit

measuring

2 circuits

measuring

1P3W

/3P3W

1 circuit

measuring

2 circuits

measuring

─ ─ ─ ○ ○ ○ ● ● ●

─ ─ ─

● ● ●

○ ○ ○ ○ ○ ○ ● ● ●

─ ─ ─ ○ ○ ○ ● ● ●

● ● ● ● ● ● ● ● ●

○ ○ ○ ○ ○ ○ ● ● ●

○ ○ ○ ○ ○ ○ ● ● ●

※

○ ○ ○ ○ ○ ○ ● ● ●

1P3W

/3P3W

/3P4W

current

voltage

1,2,3,N※3

1-2,2-3,3-1,

1-N,2-N,3-N

1,2,3,N※3

─ ─ ─ ○ ○ ○

※4

─ ─ ─ ○ ○ ○

─ ─ ─ ─ ─ ─

─ ─ ─ ─ ─ ─

※

6

○

○

※

6

○

○

Time Present value

※1 2 and 3 phases is not displayed in wiring setting 1P2W. N phase is only displayed in 3P4W setting.

※2 Between 2 and 3 , 3 and 1 is not displayed in setting 1P2W1-N . Between 2 and N, 3 and N is displayed in 3P4W setting.

※3 If wiring setting is 1P2W, 3 phase is not displayed. 2 phase is only displayed in setting 3P4W.

※4 If wiring setting is 1P2W, between 2 and 3 is not displayed. Between 1 and N, 2 and N, 3 and N is only displayed.

※5 Either effective value and content rate ,distortion by the setting elements of HA and HV.

※6 Current unbalance rate, voltage unbalance rate is displayed 0% in 1P2W setting.

※7 Apparent power is only measured in 3P4W setting

※8 Present time is only displayed when connected EMU4-LM.

※9 3rd, 5th, 7th, 9th, 11th, 13th are displayed.

※

※

6

○

※

6

○

※

※

※

○

※

○

※

6

○

6

○

※

6

○ ─ ─ ○

※

6

○ ─ ─ ○

※

※

※

○

※

○

※

○

※

○

※

5

○

5

○

5

○

5

○

※

5

○

※

5

○

※

5

○

※

5

○

※

※

5

※

5

※

5

※

5

※

22

Page 24

In the case monitoring by MODBUS communication and CC-Link communication

Model

EMU4-BM1-MB

EMU4-HM1-MB

Electric energy

Present value

● ● ● ● ●

●

Electric energy(Extended)

Present value

● ● ● ● ●

●

Converted electric

energy

Periodic electric

energy

Operating time

Present value

● ● ● ● ●

●

Regenerated electric

energy

● ● ●

Pulse count

Present value

Pulse converted value

Present value

Current

1,2,3,N, Total

● ● ● ● ●

●

1,2,3,N ● ● ● ● ● ●

Max, Min ─ ─ ─ ─ ─ ─

1-2,2-3,3-1,1-N,

2-N,3-N, Total

Max, Min ─ ─ ─ ─ ─ ─

Electric power

Present value

● ● ● ● ●

●

Electric power

demand

Present value

● ● ● ● ●

●

Max, Min ─ ─ ─ ─ ─ ─

Reactive power

Present value

● ● ● ● ●

●

Reactive power

(Extended)

● ● ●

Apparent power

Present value

─ ─ ─ ─ ─

●

1

Present value

● ● ● ● ●

●

Max, Min ─ ─ ─ ─ ─ ─

Frequency

Present value

● ● ● ● ●

●

Harmonics total current

RMS/Distortion ratio

Harmonics total voltage

RMS/Distortion ratio

1-2,2-3,3-1,

1-N,2-N,3-N

Harmonics current

RMS/Distortion ratio

Harmonics voltage

RMS/Distortion ratio

1-2,2-3,

1-N,2-N,3-N

Reactive energy

Present value

● ● ● ● ●

●

Current unbalance

Rate*2

Present value

─ ─ ● ─ ─

●

Max, ─ ─ ─ ─ ─ ─

Voltage unbalance

rate*2

Present value

─ ─ ● ─ ─

●

Max ─ ─ ─ ─ ─ ─

Time

Present value

─ ─ ─ ─ ─

─

Error ─ ● ● ● ● ●

●

● … Data can monitoring ─ … Data cannot monitoring

Current demand

Voltage

Power factor

Wiring

type

1 circuit

measuring

1P2W

2 circuits

measuring

1P3W

/3P3W

measuring

1 circuit

1P2W

measuring

2 circuits

1P3W

/3P3W

/3P4W

Present value ─ ─ ─ ● ● ●

Present value ─ ─ ─ ● ● ●

Present value

● ● ●

─ ─ ─ ● ● ●

● ● ● ● ● ●

Present value

● ● ●

※

1,2,3,N ─ ─ ─ ● ● ●

─ ─ ─ ● ● ●

1,2,3,N ─ ─ ─ ● ● ●

─ ─ ─ ● ● ●

※1 Apparent power is only measured in 3P4W wiring.

※2 These values can be monitored only CC-Link Communication.

23

Page 25

In the case logging using EMU4-LM.

Model

EMU4-BM1-MB

EMU4-HM1-MB

1P2W

1P3W

3P3W

1P2W

1P3W

3P3W

3P4W

Current

Average

● ● ● ● ● ● ●

Phase 1

● ● ● ● ● ● ●

Phase 2

─ ● ● ─ ● ● ●

Phase 3

●*1 ● ●

●*1 ● ●

●

Phase N

─ ─ ─ ─ ─ ─ ●

Current

Phase 1

● ● ● ● ● ● ●

Phase 2

─ ● ● ─ ● ● ●

Phase 3

●*1 ● ●

●*1 ● ●

●

Phase N

─ ─ ─ ─ ─ ─ ●

Voltage

Phase 1-N

─ ─ ─ ─ ─ ─ ●

Phase 2-N

─ ─ ─ ─ ─ ─ ●

Phase 3-N

─ ─ ─ ─ ─ ─ ●

Average

● ● ● ● ● ● ●

1-2 ● ● ● ● ● ● ● 2-3

●*1 ● ●

●*1 ● ●

●

3-1 ─ ● ● ─ ● ●

●

Electric

[1]

※2

● ● ● ● ● ● ●

[2]

※2

● ― ― ● ― ― ―

[1]

※2

● ● ● ● ● ● ●

[2]

※2

● ― ― ● ― ― ―

power

[1]

※2

● ● ● ● ● ● ●

[2]

※2

● ― ― ● ― ― ―

Apparent power

─ ─ ─ ─ ─ ─ ●

[1]

● ● ● ● ● ● ●

[2]

※2

● ― ― ● ― ― ―

Frequency

● ● ● ● ● ● ●

Current unbalance rate

─ ● ● ─ ● ● ●

Voltage unbalance rate

─ ● ● ─ ● ● ●

Harmonics

RMS

Average

Phase 1

─ ─ ─ ● ● ● ●

Phase 2

─ ─ ─ ─ ─ ─ ●

Phase 3

─ ─ ─

●*1 ● ●

●

Phase N

─ ─ ─ ─ ─ ─ ●

Distortion

Average

Phase 1

─ ─ ─ ● ● ● ●

Phase 2

─ ─ ─ ─ ─ ─ ●

Phase 3

─ ─ ─

●*1 ● ●

●

Phase N

─ ─ ─ ─ ─ ─ ●

Harmonics

RMS Average

Phase 1-N

─ ─ ─ ● ● ● ●

Phase 2-N

─ ─ ─ ─ ─ ─ ●

Phase 3-N

─ ─ ─

●*1 ● ●

●

Phase N

─ ─ ─ ─ ─ ─ ●

1-2 ─ ─ ─ ● ● ●

─

2-3 ─ ─ ─ ●*1 ● ●

─

Distortion

Average

Phase 1-N

─ ─ ─ ─ ─ ─ ●

Phase 2-N

─ ─ ─ ─ ─ ─ ●

Phase 3-N

─ ─ ─ ─ ─ ─ ●

1-2 ─ ─ ─ ● ● ● ─ 2-3 ─ ─ ─ ●*1 ● ●

─

Electric

Consump

tion

[1]*2 ● ● ● ● ● ● ● [2]*2 ● ─ ─ ● ─ ─

─

Regener

ated

[1]*2 ● ● ● ● ● ●

●

[2]*2 ● ─ ─ ● ─ ─

─

Consumption(expanded)

─ ─ ─ ─ ─ ─ ─

Regenerated(expanded)

─ ─ ─ ─ ─ ─ ─

Reactive

Consumption delay

● ● ● ● ● ● ●

Consumption delay(expanded)

─ ─ ─ ─ ─ ─ ─

Electric energy conversion

─ ─ ─ ─ ─ ─ ─

Operating time

─ ─ ─ ─ ─ ─ ─

Periodic electric energy

─ ─ ─ ● ● ● ●

Pulse count

─ ─ ─ ● ● ● ●

Pulse conversion

─ ─ ─ ● ● ● ●

● … Data can logging ─ … Data cannot logging

Elements

demand

power

Electric power

demand

Reactive

Power factor

total

current

total

voltage

energy

ratio

ratio

※2

Basic

th

3~13

th

3~13

Basic

th

3~13

3~13th

energy

*1: Shows second circuit (3 side circuit) when setting 2 circuits measuring in 1P2W.

*2: [1] shows first circuit when setting 2 circuits measuring in 1P2W. It is displayed when not setting 2 circuits measuring

or 1P3W, 3P3W, 3P4W.[2] shows second circuit (3 side) when setting 2 circuits measuring in 1P2W.

24

Page 26

The details of measuerment items showed below table.

Item

Details

The sign of measured value is showed below figure.

Calculated depending on the phase-wire system.

Phase-wire system

Calculating formula

Single-phase 2-wire

phase 1 current

Single-phase 3-wire

Three-phase 3-wire

(phase 1 current + phase 3 current) / 2

Three-phase 4-wire

(phase 1 current + phase 2 current + phase 3 current) / 3

Calculated depending on the phase-wire system.

Phase-wire system

Calculating formula

Single-phase 2-wire

voltage V12

Single-phase 3-wire

Three-phase 3-wire

(voltage V12+ voltageV23) / 2

Three-phase 4-wire

(voltage V12 + voltage V23+ voltage V31) / 3

Calculated below equation.

Electric energy converted value:0.000~10000(Initial value:1.000)

Measuring the time during contact input is ON or measuring current.

Measurement range

Unit

0~999999

Time [hour]

Measure the input pulse. Measure the output pulse of equipment by connecting it.

Measurement range

Unit

0~999999

Pulse

Calculated below equation.

Pulse converted value:0.000~10000(Initial value:1.000)

90°

0°

270°

180°

+

-

Consumption

delay

Regeration

progress

Regeration

delay

+

-

Consumption

progress

Electric power

Reactive power

Power factor

RMS current value (Average)

RMS voltage value (Average)

Electric energy conversion

Electric energy×Electric energy converted value

※

Operating time

Periodic electric energy Measuring the electric energy (consumption) during contact input is ON.

Pulse count

Pulse conversion

Pulse count ×Pulse converted value

※

25

Page 27

7.2 Upper/lower limit monitoring function

Monitoring items

Display or not in each unit

EMU4-BM1-MB

EMU4-HM1-MB

Current demand upper limit alarm

●

●

Current demand lower limit alarm

●

●

Line voltage upper limit alarm

●

●

Line voltage lower limit alarm

●

●

Phase voltage upper limit alarm

―

●

1