Mitsubishi EHSD-VM2C.UK, EHSC-VM2EC.UK, EHSC-MEC.UK, EHSC-VM2C.UK, EHSC-VM6C.UK Service Manual

...Page 1

SERVICE MANUAL

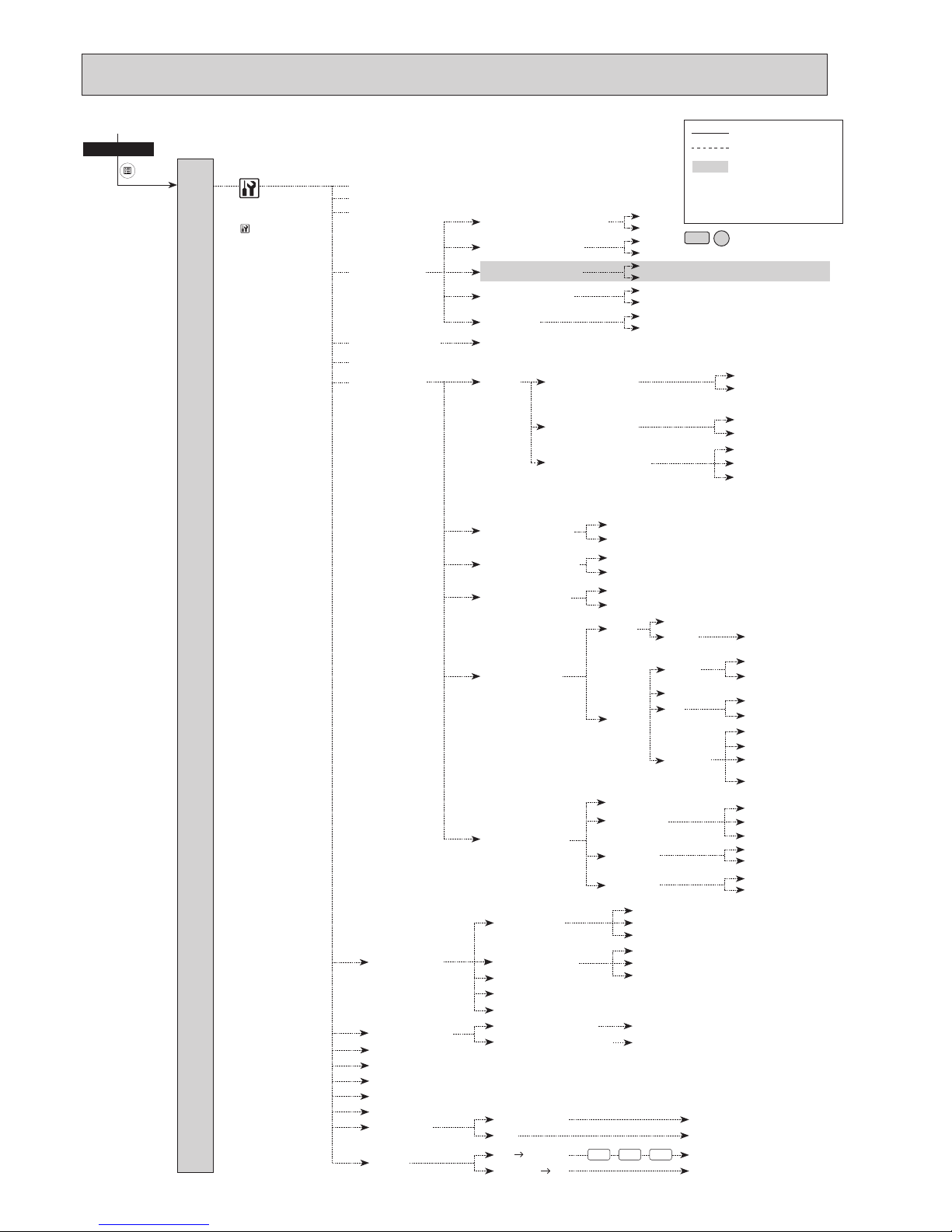

CONTENTS

1. REFERENCE MANUAL

...................................

2

2. SAFETY PRECAUTION

...................................

3

3. SPECIFICATIONS

............................................

6

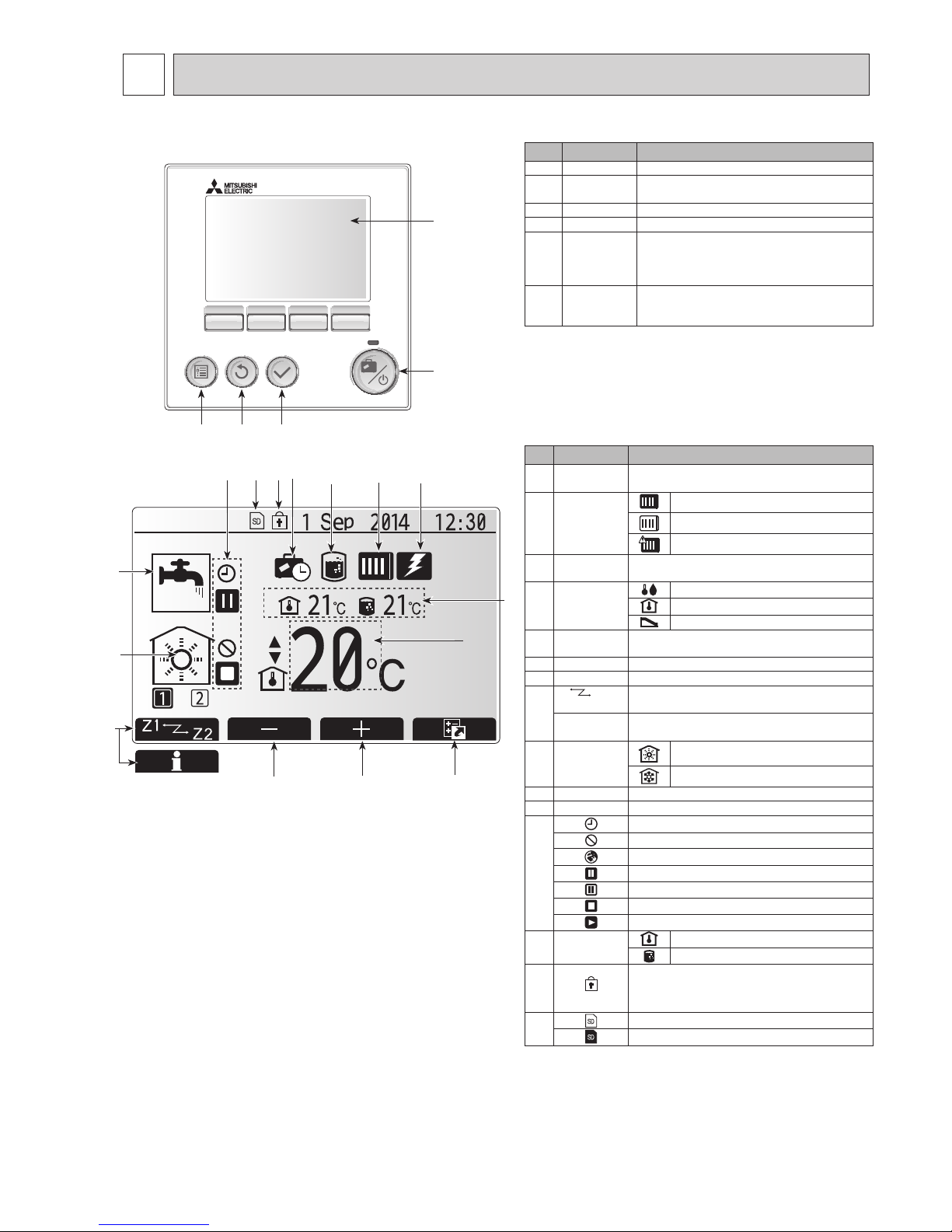

4. PART NAMES AND FUNCTIONS

..................

7

5. OUTLINES AND DIMENSIONS

.......................

8

6. WIRING DIAGRAM

........................................

10

7. FIELD WIRING

...............................................

16

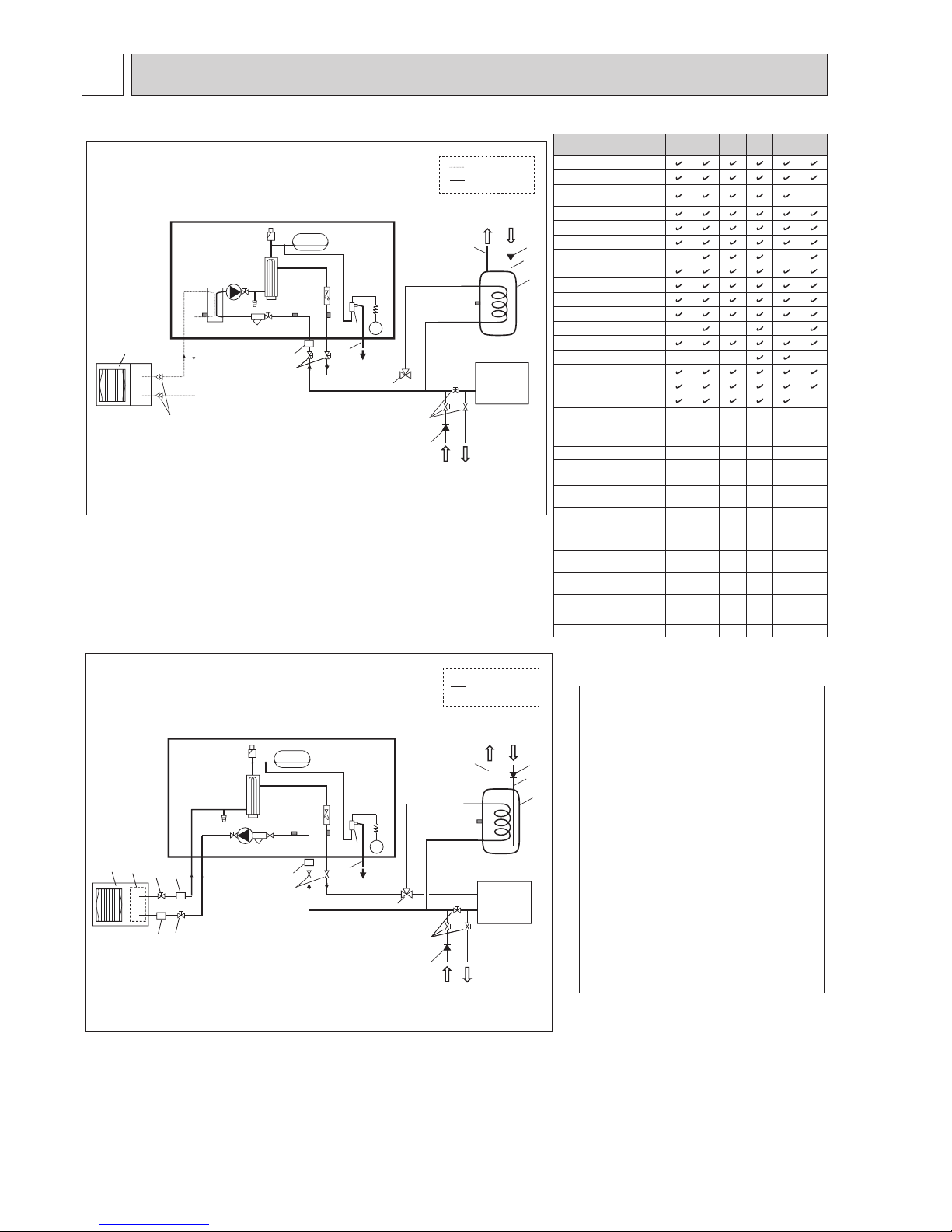

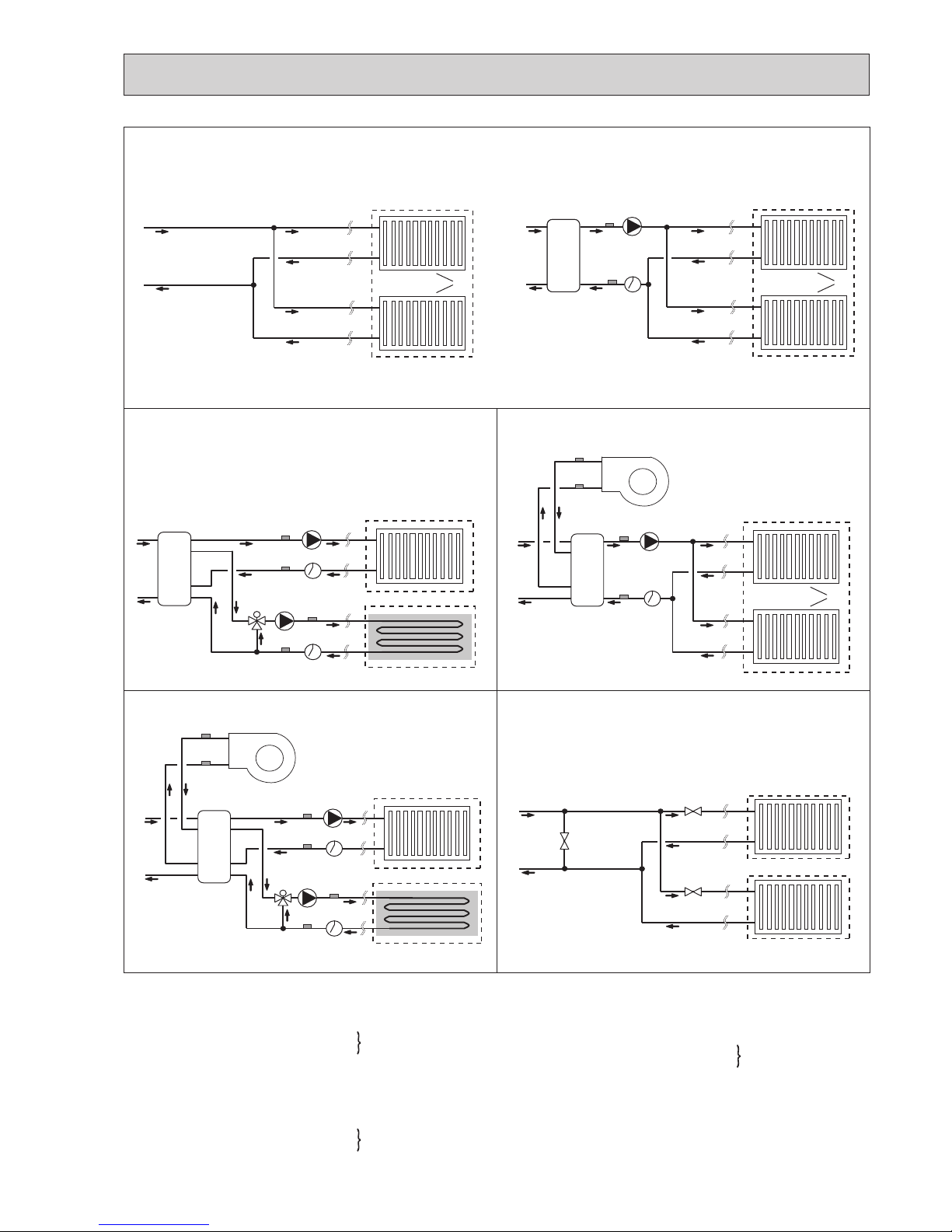

8. WATER SYSTEM DIAGRAM

.........................

18

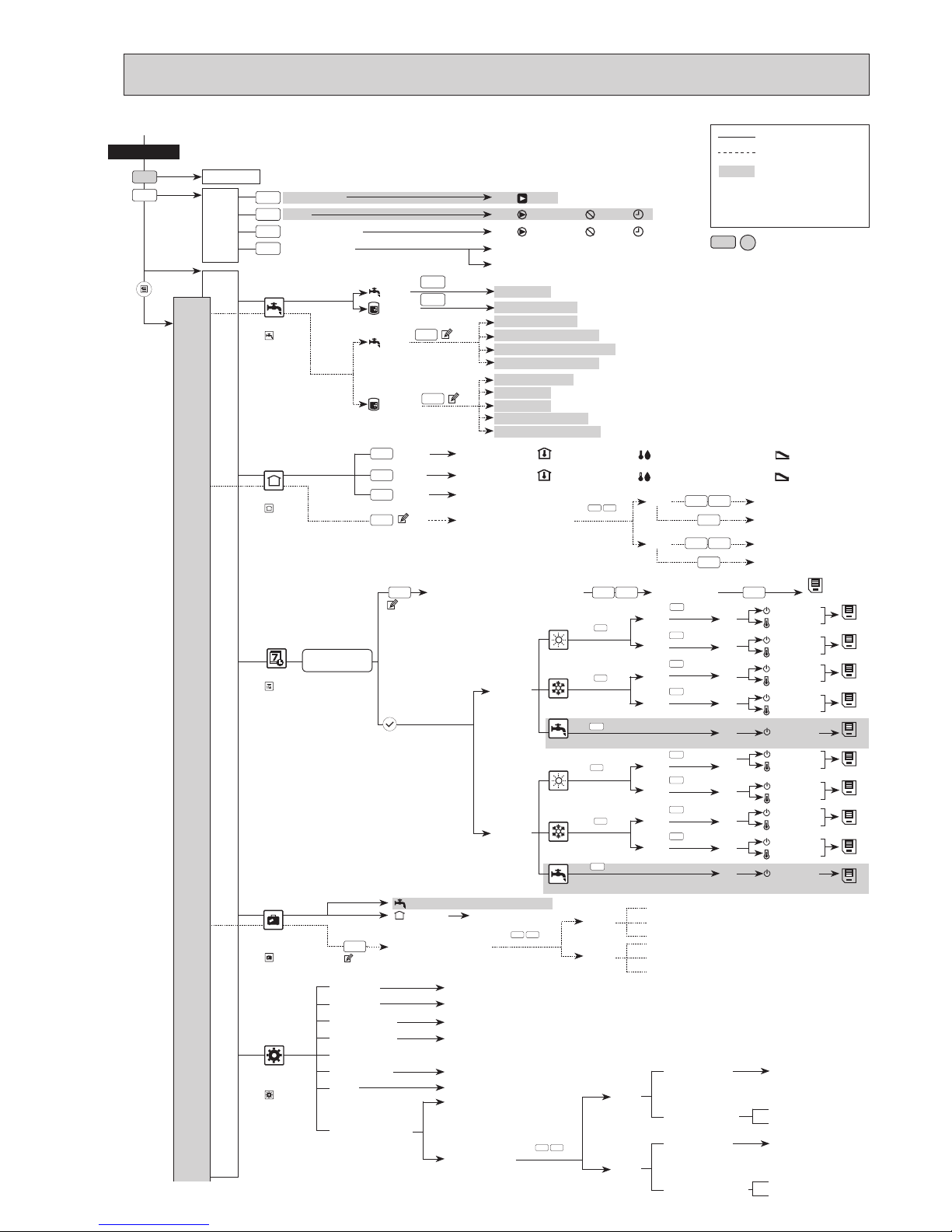

9. CONTROLS

...................................................

21

10. TROUBLESHOOTING

...................................

41

11. DISASSEMBLY PROCEDURE

......................

58

12. SUPPLEMENTARY INFORMATION

.............

79

13. SERVICE AND MAINTENANCE

...................

80

Note:

• This manual describes

only service data of

Hydrobox.

• RoHS compliant products

have <G> mark on the

spec name plate.

R410A

MAIN REMOTE

CONTROLLER

PARTS CATALOG (OCB571)

HYDROBOX

[Model name]

EHSD-MEC

EHSD-VM2C

EHSC-MEC

EHSC-VM2C

EHSC-VM2EC

EHSC-VM6C

EHSC-VM6EC

EHSC-YM9C

EHSC-YM9EC

EHSC-TM9C

ERSD-VM2C

ERSC-MEC

ERSC-VM2C

EHPX-VM2C

EHPX-YM9C

[Service Ref.]

EHSD-MEC.UK

EHSD-VM2C.UK

EHSC-MEC.UK

EHSC-VM2C.UK

EHSC-VM2EC.UK

EHSC-VM6C.UK

EHSC-VM6EC.UK

EHSC-YM9C.UK

EHSC-YM9EC.UK

EHSC-TM9C.UK

ERSD-VM2C.UK

ERSC-MEC.UK

ERSC-VM2C.UK

EHPX-VM2C.UK

EHPX-YM9C.UK

October 2014

HYDROBOX

No. OCH571

Page 2

2

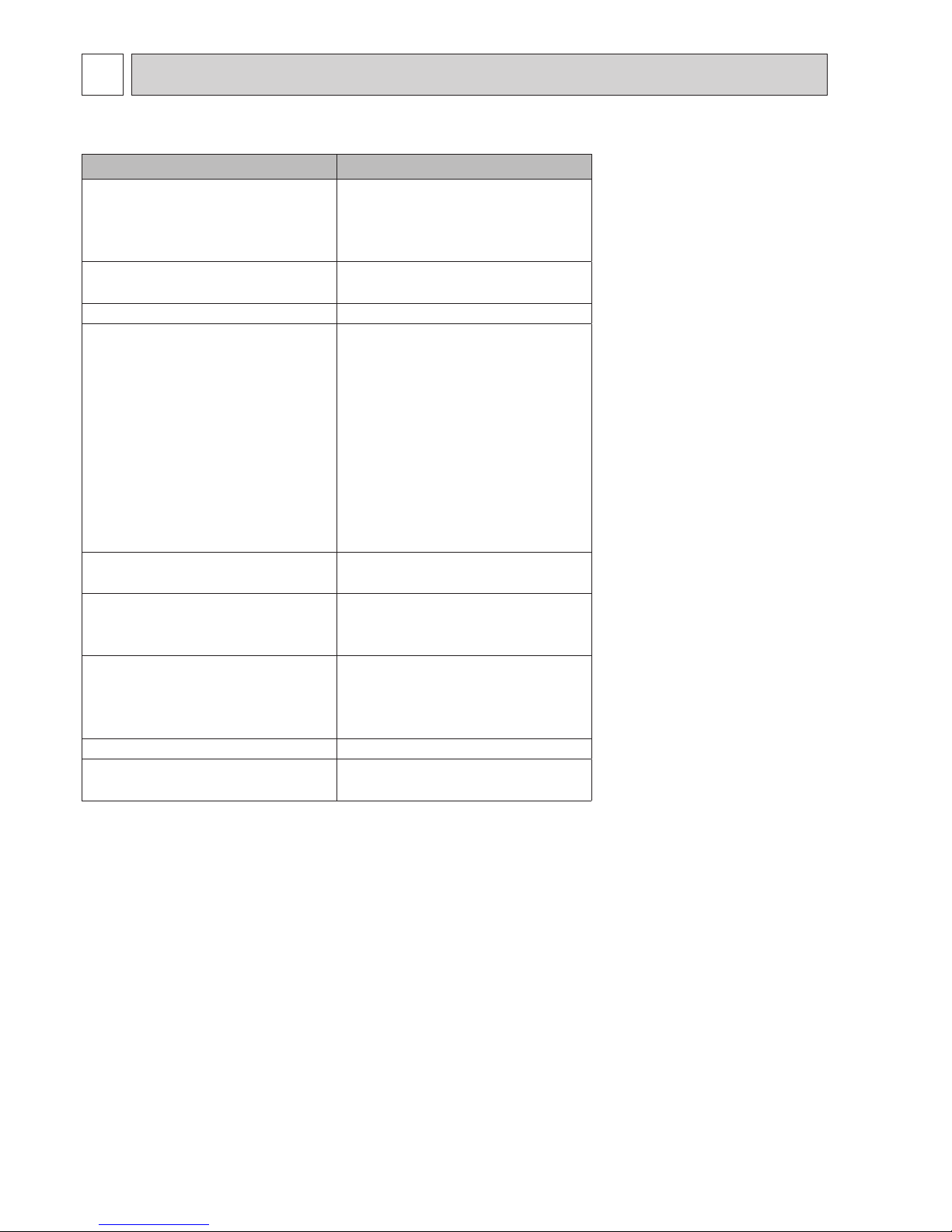

REFERENCE MANUAL

1

OUTDOOR UNIT'S SERVICE MANUAL

Service Ref. Service Manual No.

PUHZ-W50/85VHA(-BS)

OCH439

PUHZ-W50/85VHAR1(-BS)

PUHZ-W50VHAR2(-BS)

PUHZ-W50VHAR3(-BS)

PUHZ-W85VHA2-BS.UK

OCH465

PUHZ-W85VHA2(R1)-BS.UK

PUHZ-W112VHA(-BS) OCH562

PUHZ-HW112/140YHA(-BS)

OCH439

PUHZ-HW112/140YHA2(-BS)

PUHZ-HW112/140YHA2R1(-BS)

PUHZ-HW112/140YHA2R3(-BS)

PUHZ-HW112/140YHA2R4(-BS)

PUHZ-HW140VHA(-BS)

PUHZ-HW140VHA2(-BS)

PUHZ-HW140VHA2R1(-BS)

PUHZ-HW140VHA2R2-BS

PUHZ-HW140VHA2R3(-BS)

PUHZ-HW140VHA2R4(-BS)

PUHZ-SW40/50VHA(-BS)

OCH525

PUHZ-SW40/50VHAR1(-BS)

PUHZ-SW75/100/120VHA(-BS)

OCH533PUHZ-SW100/125YHA(-BS)

PUHZ-SW100/125YHAR1(-BS)

PUHZ-SHW80/112VHA

OCH526

PUHZ-SHW80/112VHAR2(-BS).UK

PUHZ-SWH112/140YHA(R1)

PUHZ-SWH112/140YHAR2(-BS).UK

PUHZ-FRP71VHA OCH544

SUHZ-SW45VA(H).TH

OCH557

SUHZ-SW45VA(H)R1.TH

OCH571

Page 3

3

SAFETY PRECAUTION

2

WARNING

Mechanical

The hydrobox and outdoor units must not be installed, disassembled, relocated, altered or repaired by the user. Ask an authorised installer or technician. If the

unit is installed improperly or modied after installation by the user water leakage, electric shock or re may result.

The outdoor unit should be securely xed to a hard level surface capable of bearing its weight.

The hydrobox should be positioned on a hard vertical surface capable of supporting its lled weight to prevent excessive sound or vibration.

Do not position furniture or electrical appliances below the outdoor unit or hydrobox.

The discharge pipework from the emergency/safety devices of the hydrobox should be installed according to local law.

Only use accessories and replacement parts authorised by Mitsubishi Electric ask a qualied technician to t the parts.

Electrical

All electrical work should be performed by a qualied technician according to local regulations and the instructions given in this manual.

The units must be powered by a dedicated power supply and the correct voltage and circuit breakers must be used.

Wiring should be in accordance with national wiring regulations. Connections must be made securely and without tension on the terminals.

Earth unit correctly.

General

Keep children and pets away from both the hydrobox and outdoor units.

Do not use the hot water produced by the heat pump directly for drinking or cooking. This could cause illness to the user.

Do not stand on the units.

Do not touch switches with wet hands.

Annual maintenance checks on both the hydrobox and the outdoor unit should be conducted by a qualied person.

Do not place contains with liquids on top of the hydrobox. If they leak or spill onto the hydrobox damage to the unit and/or re could occur.

Do not place any heavy items on top of the hydrobox.

When installing, relocating, or servicing the hydrobox, use only the specied refrigerant (R410A) to charge the refrigerant lines. Do not mix it with any other refrigerant and do not allow air to remain in the lines. If air is mixed with the refrigerant, then it can be the cause of abnormal high pressure in the refrigerant line,

and may result in an explosion and other hazards.

The use of any refrigerant other than that specied for the system will cause mechanical failure or system malfunction or unit breakdown. In the worst case, this

could lead to a serious impediment to securing product safety.

In heating mode, to avoid the heat emitters being damaged by excessively hot water, set the target ow temperature to a minimum of 2ºC below the maximum

allowable temperature of all the heat emitters. For Zone2, set the target ow temperature to a minimum of 5ºC below the maximum allowable ow temperature

of all the heat emitters in Zone2 circuit.

CAUTION

Use clean water that meets local quality standards on the primary circuit.

The outdoor unit should be installed in an area with sufcient airow according to the diagrams in the outdoor unit installation manual.

The hydrobox should be located inside to minimise heat loss.

Water pipe-runs on the primary circuit between outdoor and indoor unit should be kept to a minimum to reduce heat loss.

Ensure condensate from outdoor unit is piped away from the base to avoid puddles of water.

Remove as much air as possible from water circuit.

Refrigerant leakage may cause suffocation. Provide ventilation in accordance with EN378-1.

Be sure to wrap insulation around the piping. Direct contact with the bare piping may result in burns or frostbite.

Never put batteries in your mouth for any reason to avoid accidental ingestion.

Battery ingestion may cause choking and/or poisoning.

Install the unit on a rigid structure to prevent excessive sound or vibration during operation.

If power to the hydrobox is to be turned off (or system switched off) for a long time, the water should be drained.

Preventative measures should be taken against water hammer, such as installing a Water Hammer Arrestor on the primary water circuit, as directed by the man-

ufacturer.

In order to prevent condensation on emitters, adjust ow temperature appropriately and also set the lower limit of the ow temperature on site.

As for the handling of refrigerant, refer to the outdoor unit installation manual.

Please read the following safety precautions carefully.

WARNING:

Precautions that must be observed to prevent injuries or death.

CAUTION:

Precautions that must be observed to prevent damage to unit.

This installation manual along with the user manual should be left with the product after installation for future reference.

Mitsubishi Electric is not responsible for the failure of locally-supplied parts.

• Besuretoperformperiodicalmaintenance.

• Besuretofollowyourlocalregulations.

• Besuretofollowtheinstructionsprovidedinthismanual.

OCH571

Page 4

4

CAUTION (SPLIT MODELS ONLY)

<Using R410A refrigerant heat pumps>

Use C1220 copper phosphorus, for copper and copper alloy seamless pipes, to connect the refrigerant pipes. Make sure the insides of the pipes are clean and

do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust. Use pipes with the specied thickness. (Refer to 4.4 in the installation manual.) Note the following if reusing existing pipes that carried R22 refrigerant.

- Replace the existing are nuts and are the ared sections again.

- Do not use thin pipes. (Refer to 4.4

in the installation manual.

)

Store the pipes to be used during installation indoors and keep both ends of the pipes sealed until just before brazing. (Leave elbow joints, etc. in their packaging.) If dust, debris, or moisture enters the refrigerant lines, oil deterioration or compressor breakdown may result.

Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration oil applied to the ared sections. If mineral oil is mixed in the refrigeration oil, oil dete-

rioration may result.

Do not use refrigerant other than R410A refrigerant. If another refrigerant is used, the chlorine will cause the oil to deteriorate.

Use the following tools specically designed for use with R410A refrigerant. The following tools are necessary to use R410A refrigerant. Contact your nearest

dealer for any questions.

Tools (for R410A)

Gauge manifold Flare tool

Charge hose Size adjustment gauge

Gas leak detector Vacuum pump adapter

Torque wrench Electronic refrigerant charging scale

Be sure to use the correct tools. If dust, debris, or moisture enters the refrigerant lines, refrigeration oil deterioration may result.

Do not use a charging cylinder, a cylindrical measuring container, when charging R410A refrigerant gas. If the refrigerant gas is transferred to a charging cylinder,

the composition of the refrigerant will change and system efciency will be reduced.

WARNING (SPLIT MODELS ONLY)

Do not discharge refrigerant into the atmosphere if refrigerant leaks during installation, ventilate the room.

Use appropriate tools for high pressure refrigerant.

When pumping down refrigerant , stop the compressor before disconnecting the refrigerant pipes.

During installation securely fasten the refrigerant pipes before starting the compressor.

Check that refrigerant gas does not leak after the completion of installation.

Use R410A refrigerant only. Do not allow air to enter the lines. Failure to observe these instructions will cause mechanical failure, system failure or, in the worst

case, serious breach of product safety.

OCH571

Page 5

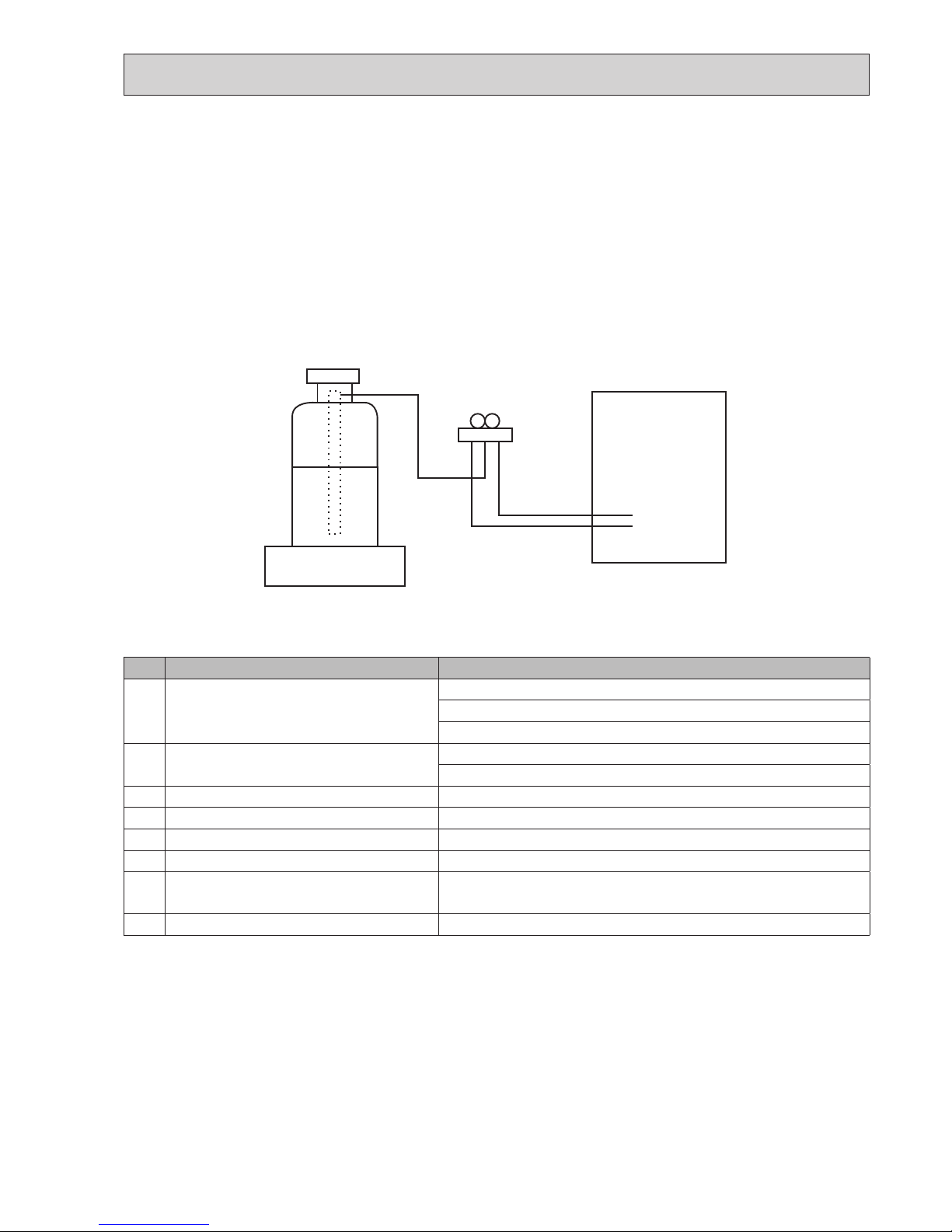

Gravimeter

Unit

5

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from refrigerant cylinder

· Check that refrigerant cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

[3] Service tools

Use the service tools below as exclusive tools for R410A refrigerant.

No. Tool name Specifications

1

Gauge manifold

· Only for R410A

· Use the existing fitting

specifications

. (UNF1/2)

· Use high-tension side pressure of 5.3 MPa·G or over.

2

Charge hose

· Only for R410A

· Use pressure performance of 5.09 MPa·G or over.

3

Electronic scale

—

4

Gas leak detector · Use the detector for R134a, R407C or R410A

5

Adaptor for reverse flow check · Attach on vacuum pump.

6

Refrigerant charge base

—

7

Refrigerant cylinder

· Only for R410A ·Top of cylinder (Pink)

· Cylinder with syphon

8

Refrigerant recovery equipment

—

OCH571

Page 6

6

SPECIFICATIONS

3

Model name

EHSD-MEC EHSD-VM2C EHSC-MEC EHSC-VM2C EHSC-VM2EC EHSC-VM6C EHSC-VM6EC EHSC-YM9C EHSC-YM9EC EHSC-TM9C ERSD-VM2C ERSC-MEC ERSC-VM2C EHPX-VM2C EHPX-YM9C

Overall unit dimensions 800 × 530 × 360 mm (Height × Width × Depth)

Weight (empty) 38 kg 44 kg 42 kg 48 kg 43 kg 49 kg 44 kg 49 kg 44 kg 49 kg 45 kg 43 kg 49 kg 37 kg 38 kg

Weight (full) 44 kg 50 kg 49 kg 55 kg 50 kg 56 kg 51 kg 56 kg 51 kg 56 kg 51 kg 50 kg 56 kg 42 kg 43 kg

Plate heat exchanger (MWA2) — —

— — —

Plate heat exchanger (MWA1)

— — — — — — — — — — — —

Cooling mode NOT available Available NOT available

Unvented expansion

vessel(Primary heat-

ing)

Nominal volume — 10 L — 10 L — 10 L — 10 L — 10 L — 10 L

Charge pressure — 1 bar — 1 bar — 1 bar — 1 bar — 1 bar — 1 bar

Safety

device

Water

circuit

(Pri-

mary)

Control thermistor 1 - 80°C

Pressure relief valve 0.3 Mpa (3bar)

Flow sensor Min ow 5.0 L/min

Booster

heater

Manual reset thermostat — 90°C — 90°C — 90°C

Thermal Cut-out (for dry run prevention) — 121°C — 121°C — 121°C

Primary circuit circulating Pump Grundfos UPM2 15 70 - 130

Connections

Water 28mm compression (primary circuit) G1 (Male)

28mm compression

(primary circuit)

Refrigerant

(R410A)

Liquid 6.35 mm 9.52 mm 6.35 mm 9.52 mm —

Gas 12.7 mm 15.88 mm 12.7 mm 15.88 mm —

Target tempera-

ture range

Flow

temperature

Heating 25 - 60°C

Cooling — 5 - 25°C —

Room

temperature

Heating 10 - 30 °C

Cooling — NOT available —

Guaranteed oper-

ating range

Ambient *1 0 - 35°C (

80 %RH)

Outdoor

temperature

Heating See outdoor unit spec table.

Cooling —

See outdoor unit spec table

(min. 10°C). *2

—

Electrical data

Control board

Power supply

(Phase, voltage, frequency)

~/N, 230 V, 50 Hz

Breaker (*when powered

from independent source)

10A

Booster

heater

Power supply

(Phase, voltage, frequency)

—

~/N, 230 V,

50 Hz

—

~/N, 230 V,

50 Hz

~/N, 230 V,

50 Hz

~/N, 230 V,

50 Hz

~/N, 230 V,

50 Hz

3~, 400 V,

50 Hz

3~, 400 V,

50 Hz

3~, 230 V,

50 Hz

~/N, 230 V,

50 Hz

—

~/N, 230 V,

50 Hz

~/N, 230 V,

50 Hz

3~, 400 V,

50 Hz

Capacity — 2kW — 2kW 2kW

2kW+

4kW

2kW+

4kW

3kW+

6kW

3kW+

6kW

3kW+

6kW

2kW — 2kW 2kW

3kW+

6kW

Current — 9 A — 9 A 9 A 26 A 26 A 13A 13A 23A 9 A — 9 A 9 A 13A

Breaker — 16 A — 16 A 16 A 32 A 32 A 16A 16A 32A 16 A — 16 A 16 A 16A

Sound level 28 dB(A)

Optional extras

●Wireless Remote Controller PAR-WT50R-E ●

Tank thermistor (THW5) (30 m)

PAC-TH011TKL-E *1 The environment must be frost-free.

●Wir ele ss Re ceiv er PAR-WR51R-E ●Th erm ist or PAC-TH011-E *2 Low ambient cooling is NOT allowed.

●Rem ote Se nsor PAC-SE41TS-E ●High temperature thermistor PAC-TH011HT-E

●Tank thermistor (THW5) (5 m) PAC-TH011TK-E ●ecodan Wi-Fi Interface PAC-WF010-E

<Table 3-1>

OCH571

Page 7

7

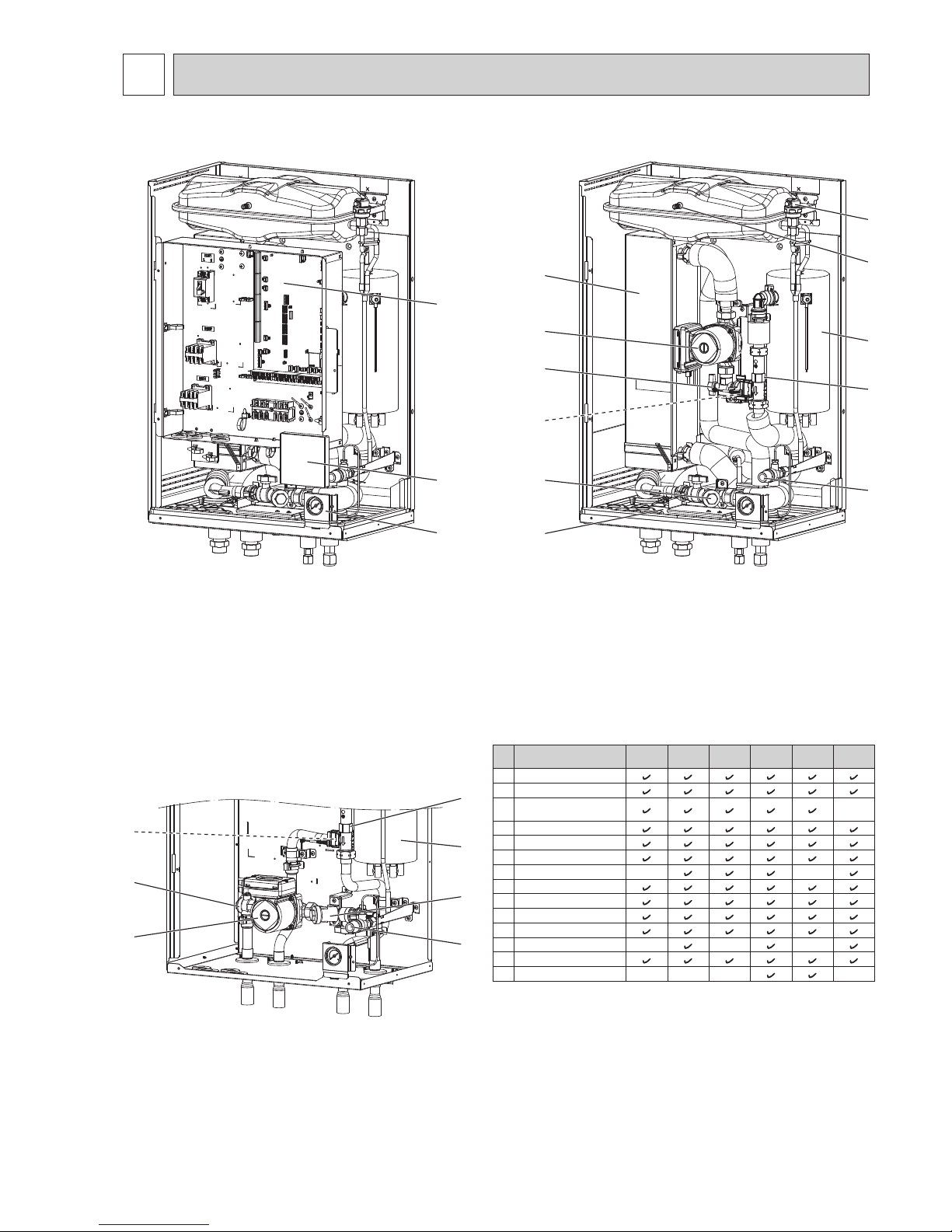

PART NAMES AND FUNCTIONS

4

1

2

9

11

7

8

10

8

7

10

13

12

3

4

5

13

14

5

4

6

6

<E*S*-*M**C> (Split model system)

<EHPX-*M*C> (Packaged model system)

No. Part name

EHS*-MEC

EHS*-

*M*C

EHSC*M*EC

ERS*VM2C

ERSC-

MEC

EHPX-

*M*C

1 Control and electrical box

2 Main controller

3

Plate heat exchanger

(Refrigerant - Water)

-

4 Water circulation pump 1

5 Pump valve

6 Drain cock (Primary circuit)

7 Booster heater 1,2

- -

8 Flow sensor

9 Manometer

10 Pressure relief valve (3bar)

11 Automatic air vent

12 Expansion vessel

- - -

13 Strainer valve

14 Drain pan

- - - -

<Table 4-1>

<Figure 4-1> <Figure 4-2>

<Figure 4-3>

OCH571

Page 8

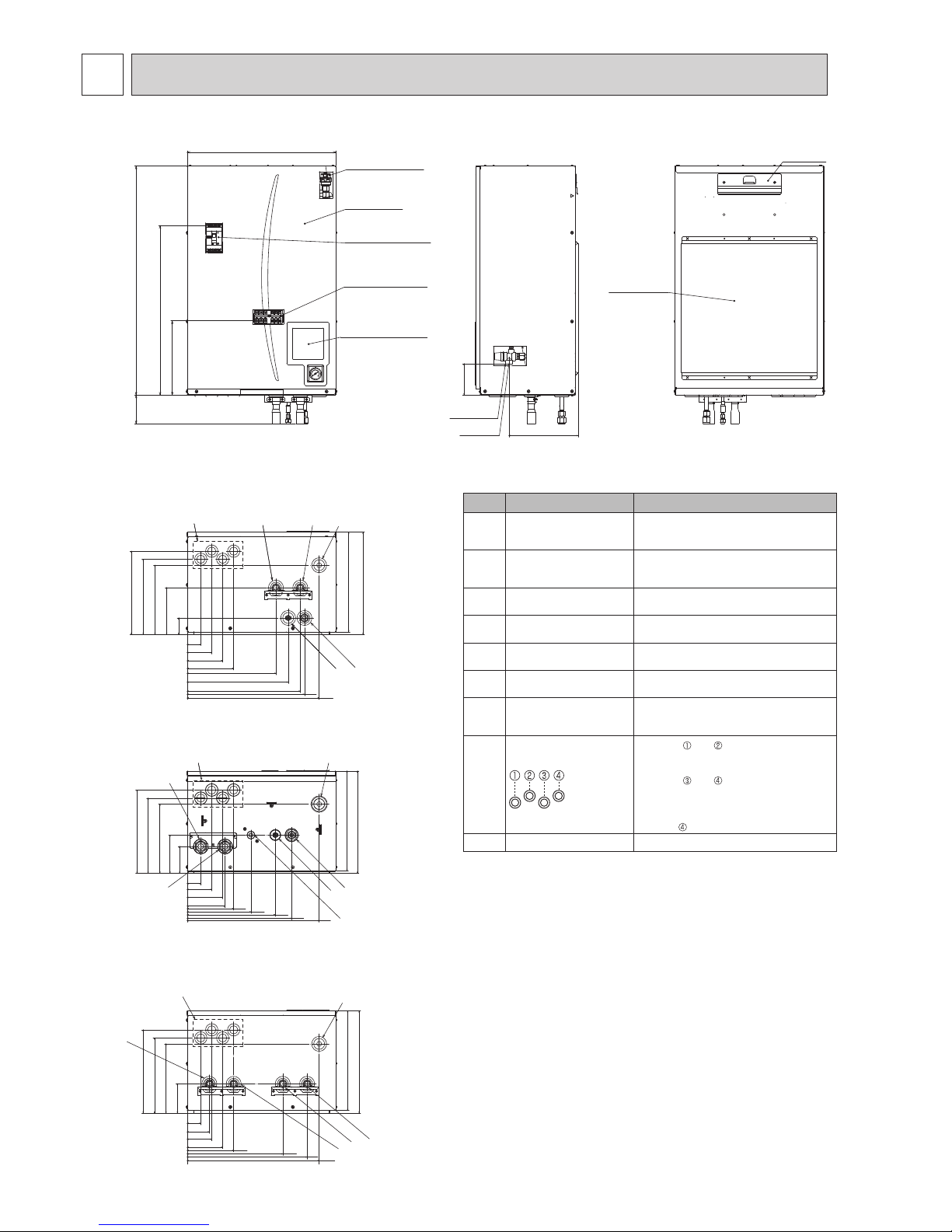

8

OUTLINES AND DIMENSIONS

5

(

348)

357

291

263

242

103

461

419

334

163

124

86

78

48

242

(348)

357

291

263

134

94

133

365

308

163

223

124

461

86

48

100±5

592

800

260

530

B

H

H

A

H

G

F

E

B

A

B

I

C D

G

A G

C

(348)

461

410

395

353

310

163

124

86

48

291

263

357

242

164

58

(242)

110

D

Unit: mm

<EHS*> (Split model system)

<Front>

Automatic air vent

Front panel

Earth leakage circuit

breaker

Terminal block

Main Controller

Pressure

relief valve

G1/2

Back panel

support

Hook

<View from below>

<View from below>

<View from below>

<Side> <Rear>

<ERS*> (Split model system for heating and cooling)

<EHPX> (Packaged model system)

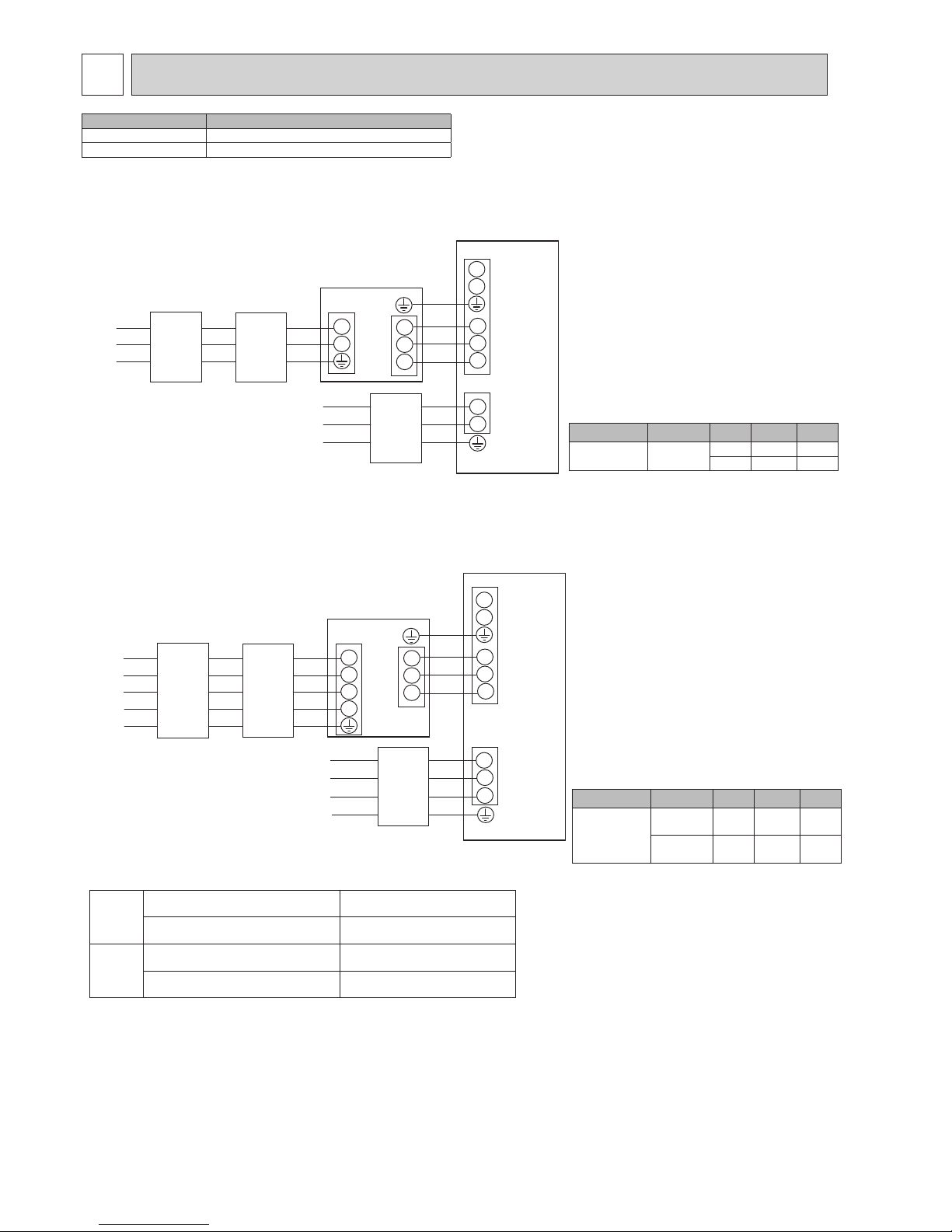

Letter Pipe description Connection size/type

A

Space heating/Indirect

DHW tank (primary) return

connection

28 mm/Compression (EHS*-*and EHPX-*)

G1 nut (ERS*-*)

B

Space heating/Indirect

DHW tank (primary) ow

connection

28 mm/Compression (EHS*-*and EHPX-*)

G1 nut (ERS*-*)

C Refrigerant (Liquid)

6.35 mm/Flare (E*SD-*)

9.52 mm/Flare (E*SC-*)

D Refrigerant (Gas)

12.7 mm/Flare (E*SD-*)

15.88 mm/Flare (E*SC-*)

E

Flow connection from heat

pump

28 mm/Compression (EHPX-*)

F

Return connection to heat

pump

28 mm/Compression (EHPX-*)

G

Discharge pipe (by installer) from pressure relief

valve

G1/2” female (valve port within hydrobox

casing)

H

Electrical cable inlets

For inlets and , run high-voltage wires

including power cable, indoor-outdoor

cable, and external output wires.

For inlets

and , run low-voltage

wires including external input wires and

thermistor wires.

For a wireless receiver (option) cable,

use inlet

.

I Drain socket

O.D. ø20

<Table 5-1>

5-1. Technical Drawings

OCH571

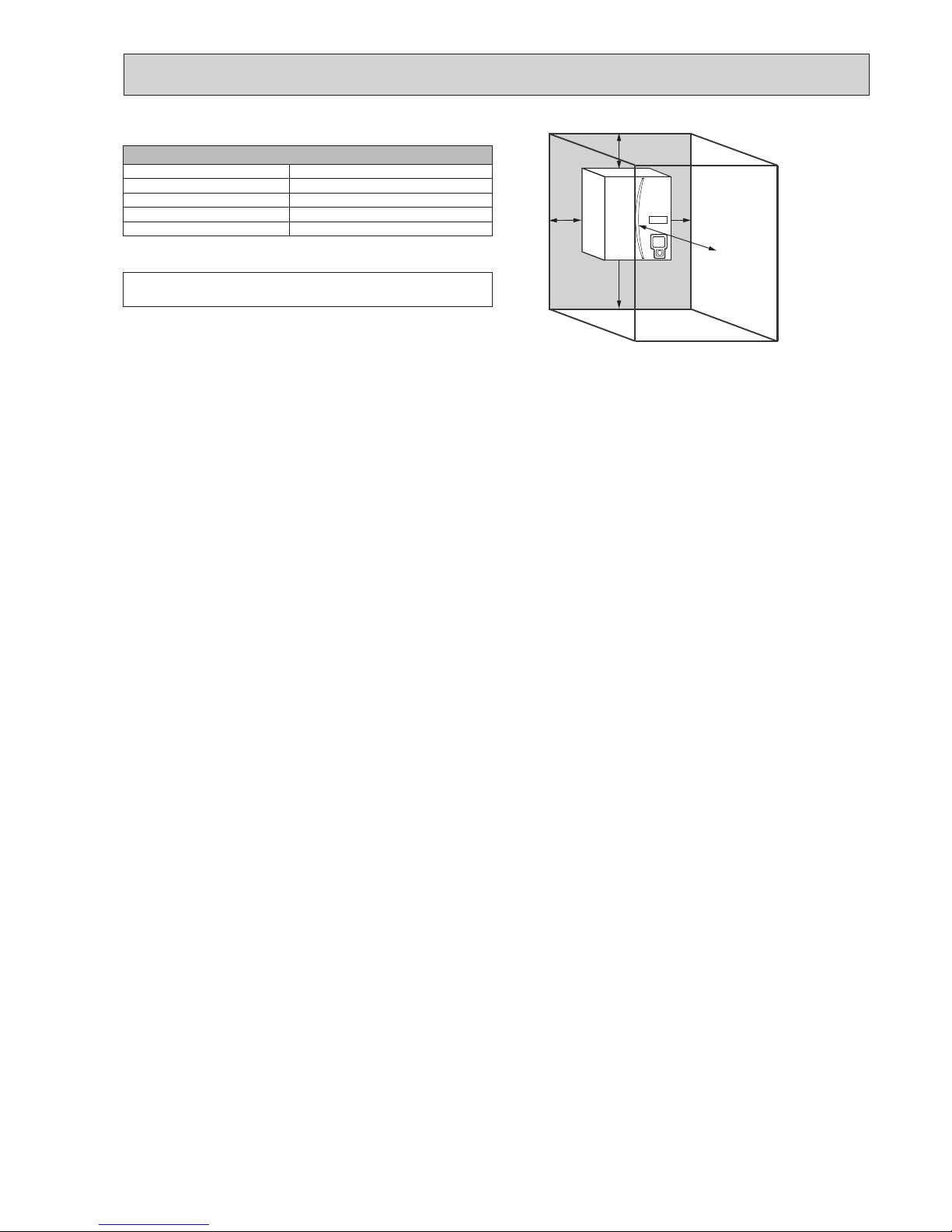

Page 9

a

b

b

d

c

9

Service access

5-2. Service access diagrams

Service access

Parameter Dimension (mm)

a 200

b 150

c 500

d 500

Sufcient space MUST be left for the provision of discharge pipework as detailed

in National and Local building regulations.

The hydrobox must be located indoors and in a frost-free environment, for

example in a utility room.

OCH571

Page 10

NL

S3S2S1

NL

S3S2S1

To outdoor

unit

TB1

ORN

ORN

YLW

YLW

GRN/YLW

To outdoor

unit

Power supply

~/N 230V 50Hz

TB1

ORN

BLU

RED

BLU

RED

YLW

GRN/YLW

1

3

CN3C

(BLU)

BLK

BLK

BLK

BLK

1

3

ORN

BRN

CN3C

(BLU)

ORN

ORN

BRN

YLW

Indoor unit powered

by independent source

Indoor unit powered

via outdoor unit

CIRCUIT

BREAKER

1

3

CN3C

(BLU)

1

3

CNPWM

(WHT)

LED1

LED2

LED3

LED4

TBI.1

1310 12 141174 65 932 81

TBI.2

1310 12 141174 65 932 81

t°t

°

THW8

THW7

THW6

t

°

THW9

t

°

THWB1

t

°

THWB2

t

°

Main

controller

1 2

1

2

CN20

(RED)

TH1

t

°

1

3

CN21

(YLW)

TH2

t

°

1

4

THW1

THW2

CNW12

(RED)

t°t

°

2

1

THW5

CNW5

(WHT)

t

°

CN108

5

1

Wireless receiver

(Option)

WiFi adapter

(Option)

5

1

5

1

CNRF

(WHT)

CN105

(RED)

CN22

(BLU)

1

2

3

4

5

6

1

*1

5

Close

Open

N

X15

X12

TBO.4

TBO.3

TBO.2

TBO.1

F1

F2

M

2WV2a

MXV

MP2

MP1

M

1

~

1

3

CNV1

(WHT)

1

3

CNBHT

(BLK)

X11

X9

X8

X13

X10

X4

X14

X3

X2

X1

X5B

X5A

1

2

3

4

5

6

7

8

1

2

3

4

5

6

1

2

3

4

5

6

1

1

3

3

3

CNP1

(WHT)

CNPWM

(WHT)

TBO.1

TBO.2

TBO.3

TBO.4

CNP1

(WHT)

CNP4

(RED)

CNV1

(WHT)

CN22

(BLU)

CNIT

(BLU)

TAB1

CN01

(WHT)

F2 F1

6.3A 250V 10A 250V

SW1

SW2

SW3

SW4

SW5

1

8

1

8

1

1

5

1

3

1

3

8

1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

8

1

6

CN01

(WHT)

CN01

(WHT)

CN01

(WHT)

2

1

4

6

2

1

1

2

4

6

4

6

CNBH

(WHT)

CNBC

(GRY)

1

1

3

1

2

1

2

1

2

CNBHT

(BLK)

1

3

1

3

7

CNIH

(ORN)

1

4

1

3

CNW5

(WHT)

CN21

(YLW)

CNW12

(RED)

CN20

(RED)

TBI.2

126 10148

137 11945321

6

4

2

1

CNIH

(ORN)

MP3

M

1

~

IN8

IN9

IN10

1310 12 141174 65 932 81

TBI.3

TBI.3

2 4 6 8 10 12 14

1

357 91113

1

4

CN1A

(WHT)

2 4 6 8 10 12 14

1

357 91113

TBI.1

2WV2b

M

1

~

TBO.2

3WV

*1

3WV

M

1

~

4 5 6

TBO.2

2WV1

2WV1

M

1

~

4 5 6

M

1

~

IN6

IN1

IN2

IN3

IN4

IN5

IN7

CNP4

(RED)

MP4

M

1

~

M

1

~

1

3

Signal output

(Boiler)

Signal output

(Error)

Signal output

(Defrost)

Signal output

(Comp ON)

Signal output

(Cooling)

–+–+–

+

Tool

Tool

Conductor

Conductor

Outline view Top view

<How to use TBO.1 to 4>

Connect them using either way as shown below.

1

3

5

7

X6

X7

1

3

CNBC

(GRY)

CNBH

(WHT)

10

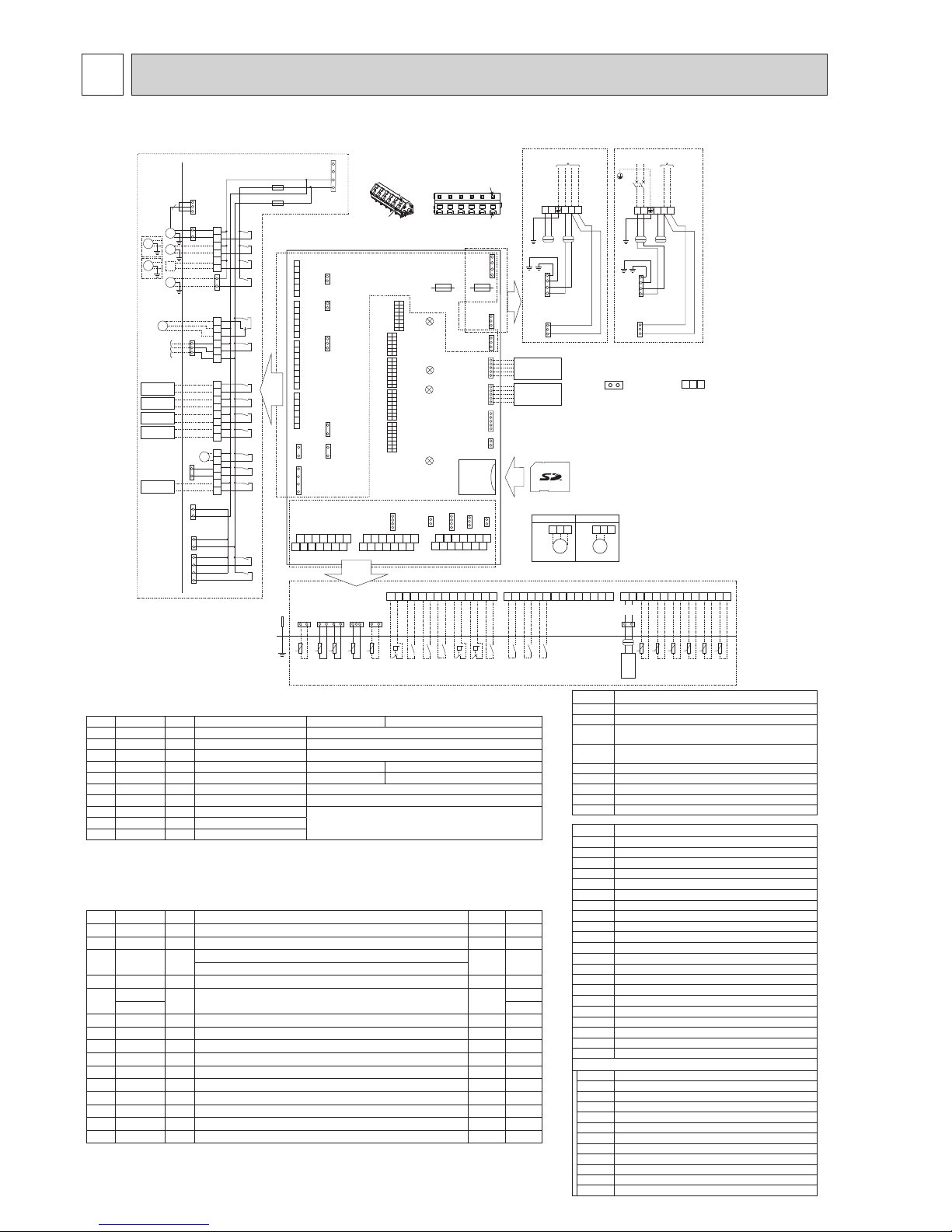

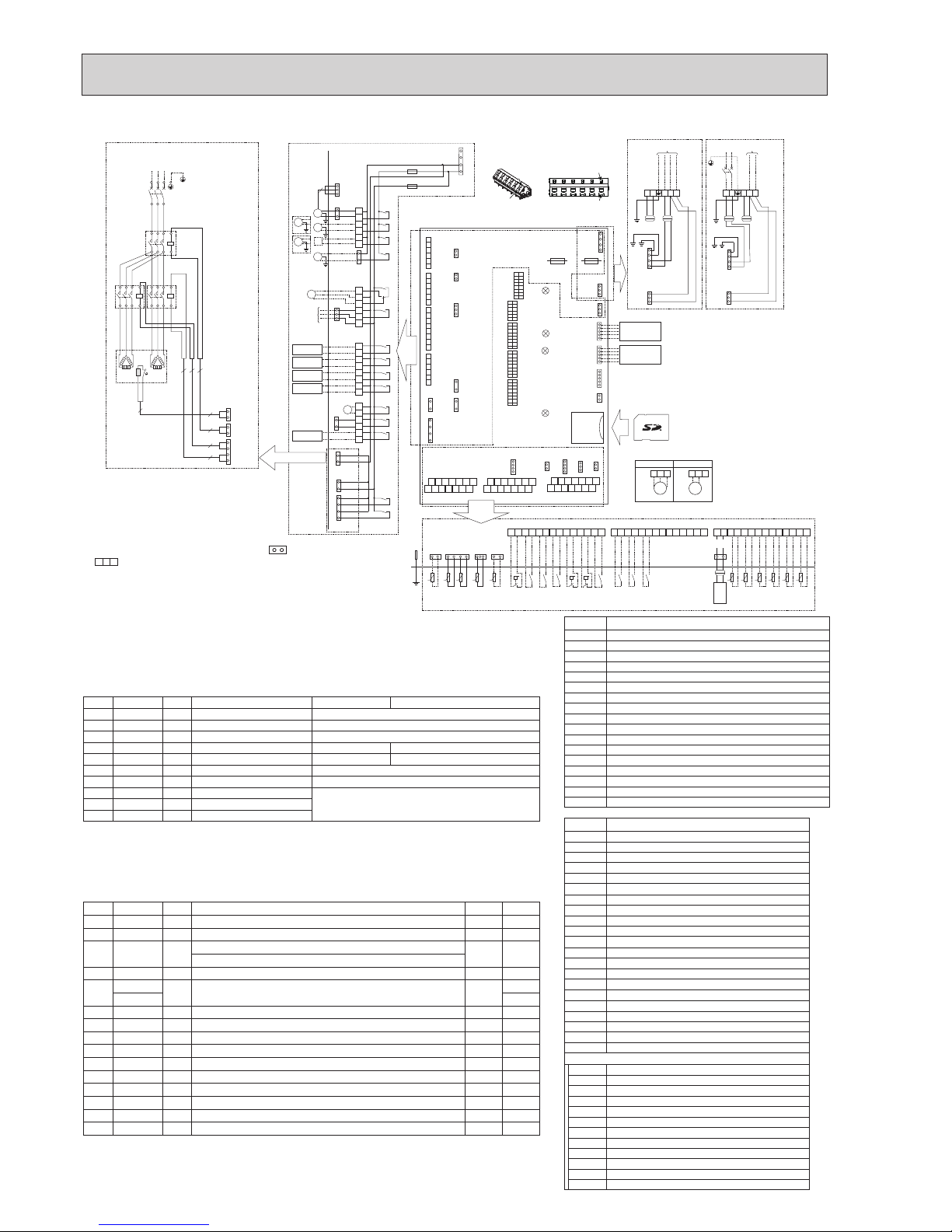

6 WIRING DIAGRAM

6-1. EHSC-MEC, EHSD-MEC, ERSC-MEC

1. Symbols used in wiring diagram are,

: connector, : terminal block.

2. Indoor unit and outdoor unit connecting wires

have polarities, make sure to match terminal

numbers (S1, S2, S3) for correct wirings,

3. Since the outdoor unit side electric wiring may

change, be sure to check the outdoor unit electric

wiring diagram for service.

Symbol Name

TH1 Thermistor (Room temp.)(Option)

TH2 Thermistor (Ref. liquid temp.)

THW1 Thermistor (Flow water temp.)

THW2 Thermistor (Return water temp.)

THW5 Thermistor (DHW tank water temp.)(Option)

THW6 Thermistor (Zone1 ow temp.)(Option)

THW7 Thermistor (Zone1 return temp.)(Option)

THW8 Thermistor (Zone2 ow temp.)(Option)

THW9 Thermistor (Zone2 return temp.)(Option)

THWB1 Thermistor (Boiler ow temp.)(Option)

THWB2 Thermistor (Boiler return temp.)(Option)

IN1 Room thermostat 1 (Local supply)

IN2 Flow switch 1 (Local supply)

IN3 Flow switch 2 (Local supply)

IN4 Demand control (Local supply)

IN5 Outdoor thermostat (Local supply)

IN6 Room thermostat 2 (Local supply)

IN7 Flow switch 3 (Local supply)

IN8 Electric energy meter 1 (Local supply)

IN9 Electric energy meter 2 (Local supply)

IN10 Heat meter (Local supply)

FLOW TEMP. CONTROLLER (FTC5)

TBO.1−4

Terminal block <Outputs>

TBI.1

−

3 Terminal block <Signal Inputs, Thermistor>

F1 Fuse (T10AL250V)

F2 Fuse (T6.3AL250V)

SW1

−

5 DIP switch *See Table 3

X1

−

15 Relay

LED1 Power supply (FTC5)

LED2 Power supply (Main controller)

LED3 Communication (FTC5-Outdoor unit)

LED4 Reading or writing data to SD card

CNPWM

Pump speed control signal for MP1

CN108 SD card connector

Table 1 Signal Inputs

Name

Terminal block

Connector

Item OFF (Open) ON (Short)

IN1 TBI.1 13-14 — Room thermostat 1 input Refer to SW2-1 in <Table 3 DIP Switch Functions>.

IN2 TBI.1 11-12 — Flow switch 1 input Refer to SW2-2 in <Table 3 DIP Switch Functions>.

IN3 TBI.1 9-10 — Flow switch 2 input (Zone1) Refer to SW3-2 in <Table 3 DIP Switch Functions>.

IN4 TBI.1 7-8 — Demand control input Normal Heat source OFF/ Boiler operation *2

IN5 TBI.1 5-6 — Outdoor thermostat input *1 Standard operation Heater operation/ Boiler operation *2

IN6 TBI.1 3-4 — Room thermostat 2 input Refer to SW3-1 in <Table 3 DIP Switch Functions>.

IN7 TBI.1 1-2 — Flow switch 3 input (Zone2) Refer to SW3-3 in <Table 3 DIP Switch Functions>.

IN8 TBI.3 1-2 — Electric energy meter 1

Refer to installation manual.IN9 TBI.3 3-4 — Electric energy meter 2

IN10

TBI.3 5-6 — Heat meter

*1. If using outdoor thermostat for controlling operation of heaters, the lifetime of the heaters and related parts may be

reduced.

*2. To turn on the boiler operation, use the main controller to select “Boiler” in “External input setting“ screen in the

service menu.

Table 2 Outputs

Name

Terminal block

Connector

Item OFF ON

OUT1

TBO.1 1-2 CNP1 Water circulation pump 1 output (Space heating/cooling & DHW) OFF ON

OUT2

TBO.1 3-4 — Water circulation pump 2 output (Space heating/cooling for Zone1) OFF ON

OUT3

TBO.1 5-6 —

Water circulation pump 3 output (Space heating/cooling for Zone2) *1

OFF ON

2-way valve 2b output *2

OUT4

TBO.2 4-6 CNV1 3-way valve (2-way valve) output Heating DHW

OUT5

TBO.2 1-2

— Mixing valve output *1 Stop

Close

TBO.2 2-3 Open

OUT6

—

CNBH 1-3

Booster heater 1 output OFF ON

OUT7

—

CNBH 5-7

Booster heater 2 output OFF ON

OUT8

TBO.4 5-6 — Cooling signal output OFF ON

OUT9

TBO.4 3-4 CNIH Immersion heater output OFF ON

OUT10

TBO.3 1-2 — Boiler output OFF ON

OUT11

TBO.3 3-4 — Error output Normal Error

OUT12

TBO.3 5-6 — Defrost output Normal Defrost

OUT13

TBO.4 1-2 — 2-way valve 2a output *2 OFF ON

OUT14

— CNP4 Water circulation pump 4 output (DHW) OFF ON

OUT15

TBO.3 7-8 — Comp ON signal OFF ON

Do not connect to the terminals that are indicated as “—” in the “Terminal block” eld.

*1. For 2-zone temperature control.

*2. For 2-zone valve ON/OFF control.

Symbol Name

TB1 Terminal block <Power supply, Outdoor unit>

MP1 Water circulation pump 1(Space heating & DHW)

MP2 Water circulation pump 2

(Space heating for Zone1)(Local supply)

MP3 Water circulation pump 3

(Space heating for Zone2)(Local supply)

MP4 Water circulation pump 4 (DHW)(Local supply)

3WV(2WV1)

3-way valve (2-way valve 1)(Local supply)

2WV2a 2-way valve (For Zone 1)(Local supply)

2WV2b 2-way valve (For Zone 2)(Local supply)

MXV Mixing valve (Local supply)

OCH571

Page 11

NL

S3S2S1

NL

S3S2S1

To outdoor

unit

TB1

ORN

ORN

YLW

YLW

GRN/YLW

To outdoor

unit

Power supply

~/N 230V 50Hz

TB1

ORN

BLU

RED

BLU

RED

YLW

GRN/YLW

1

3

CN3C

(BLU)

BLK

BLK

BLK

BLK

1

3

ORN

BRN

CN3C

(BLU)

ORN

ORN

BRN

YLW

Indoor unit powered

by independent source

Indoor unit powered

via outdoor unit

CIRCUIT

BREAKER

1

3

CN3C

(BLU)

1

3

CNPWM

(WHT)

LED1

LED2

LED3

LED4

TBI.1

1310 12 141174 65 932 81

TBI.2

1310 12 141174 65 932 81

t°t

°

THW8

THW7

THW6

t

°

THW9

t

°

THWB1

t

°

THWB2

t

°

Main

controller

1 2

1

2

CN20

(RED)

TH1

t

°

1

3

CN21

(YLW)

TH2

t

°

1

4

THW1

THW2

CNW12

(RED)

t°t

°

1

2

THW5

CNW5

(WHT)

t

°

CN108

5

1

Wireless receiver

(Option)

WiFi adapter

(Option)

5

1

5

1

CNRF

(WHT)

CN105

(RED)

CN22

(BLU)

1

2

3

4

5

6

1

*1

5

Close

Open

N

X15

X12

TBO.4

TBO.3

TBO.2

TBO.1

F1

F2

M

2WV2a

MXV

MP2

MP1

M

1

~

1

3

CNV1

(WHT)

1

3

CNBHT

(BLK)

X11

X9

X8

X13

X10

X4

X14

X3

X2

X1

X5B

X5A

1

2

3

4

5

6

7

8

1

2

3

4

5

6

1

2

3

4

5

6

1

1

3

3

3

CNP1

(WHT)

CNPWM

(WHT)

TBO.1

TBO.2

TBO.3

TBO.4

CNP1

(WHT)

CNP4

(RED)

CNV1

(WHT)

CN22

(BLU)

CNIT

(BLU)

TAB1

CN01

(WHT)

F2 F1

6.3A 250V 10A 250V

SW1

SW2

SW3

SW4

SW5

1

8

1

8

1

1

5

1

3

1

3

8

1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

8

1

6

CN01

(WHT)

CN01

(WHT)

CN01

(WHT)

2

1

4

6

2

1

1

2

4

6

4

6

CNBH

(WHT)

CNBC

(GRY)

1

1

3

1

2

1

2

1

2

CNBHT

(BLK)

1

3

1

3

7

CNIH

(ORN)

1

4

1

3

CNW5

(WHT)

CN21

(YLW)

CNW12

(RED)

CN20

(RED)

TBI.2

126 10148

137 11945321

6

4

2

1

CNIH

(ORN)

MP3

M

1

~

IN8

IN9

IN10

1310 12 141174 65 932 81

TBI.3

TBI.3

2 4 6 8 10 12 14

1

357 91113

1

4

CN1A

(WHT)

2 4 6 8 10 12 14

1

357 91113

TBI.1

2WV2b

M

1

~

TBO.2

3WV

*1

3WV

M

1

~

4 5 6

TBO.2

2WV1

2WV1

4 5 6

M

1

~

IN6

IN1

IN2

IN3

IN4

IN5

IN7

WHT

WHT

M

1

~

CNP4

(RED)

MP4

M

1

~

M

1

~

1

3

–+–+–

+

Signal output

(Boiler)

Signal output

(Error)

Signal output

(Defrost)

Signal output

(Comp ON)

Signal output

(Cooling)

Tool

Tool

Conductor

Conductor

Outline view Top view

<How to use TBO.1 to 4>

Connect them using either way as shown below.

2 2

2

ECB1

L

(1)N(3)

BHCP

BLU

BLU

RED

WHT/No.2

WHT/No.1

RED

VLT

VLT

GRY

GRY

BHC1

BHT

642

531

A1

A2

BH1

BHF

2

4

Power supply

to Booster heater

642

531

A1

A2

CNBH

(WHT)

CNBHT

(BLK)

2

2

2

CNBC

(GRY)

1

1

3

3

1

3

~/N 230V 50Hz

1

3

5

7

X6

X7

1

3

CNBC

(GRY)

CNBH

(WHT)

11

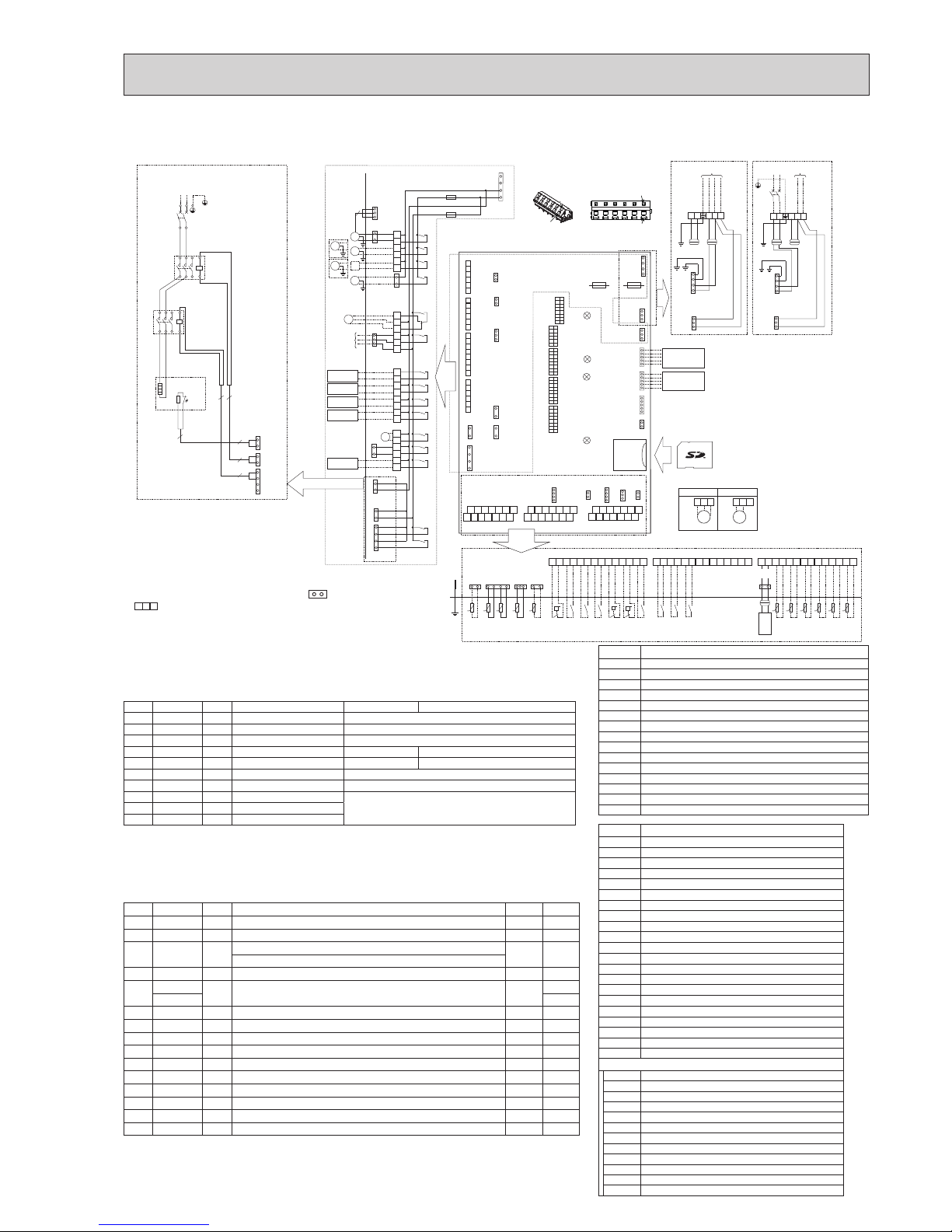

6-2. EHSC-VM2C, EHSC-VM2EC, EHSD-VM2C, ERSC-VM2C, ERSD-VM2C, EHPX-VM2C

Symbol Name

TH1 Thermistor (Room temp.)(Option)

TH2 Thermistor (Ref. liquid temp.)

THW1 Thermistor (Flow water temp.)

THW2 Thermistor (Return water temp.)

THW5 Thermistor (DHW tank water temp.)(Option)

THW6 Thermistor (Zone1 ow temp.)(Option)

THW7 Thermistor (Zone1 return temp.)(Option)

THW8 Thermistor (Zone2 ow temp.)(Option)

THW9 Thermistor (Zone2 return temp.)(Option)

THWB1 Thermistor (Boiler ow temp.)(Option)

THWB2 Thermistor (Boiler return temp.)(Option)

IN1 Room thermostat 1 (Local supply)

IN2 Flow switch 1 (Local supply)

IN3 Flow switch 2 (Local supply)

IN4 Demand control (Local supply)

IN5 Outdoor thermostat (Local supply)

IN6 Room thermostat 2 (Local supply)

IN7 Flow switch 3 (Local supply)

IN8 Electric energy meter 1 (Local supply)

IN9 Electric energy meter 2 (Local supply)

IN10 Heat meter (Local supply)

FLOW TEMP. CONTROLLER (FTC5)

TBO.1−4

Terminal block <Outputs>

TBI.1

−

3 Terminal block <Signal Inputs, Thermistor>

F1 Fuse (T10AL250V)

F2 Fuse (T6.3AL250V)

SW1

−

5 DIP switch *See Table 3

X1

−

15 Relay

LED1 Power supply (FTC5)

LED2 Power supply (Main controller)

LED3 Communication (FTC5-Outdoor unit)

LED4 Reading or writing data to SD card

CNPWM

Pump speed control signal for MP1

CN108 SD card connector

Table 1 Signal Inputs

Name

Terminal block

Connector

Item OFF (Open) ON (Short)

IN1 TBI.1 13-14 — Room thermostat 1 input Refer to SW2-1 in <Table 3 DIP Switch Functions>.

IN2 TBI.1 11-12 — Flow switch 1 input Refer to SW2-2 in <Table 3 DIP Switch Functions>.

IN3 TBI.1 9-10 — Flow switch 2 input (Zone1) Refer to SW3-2 in <Table 3 DIP Switch Functions>.

IN4 TBI.1 7-8 — Demand control input Normal Heat source OFF/ Boiler operation *2

IN5 TBI.1 5-6 — Outdoor thermostat input *1

Standard operation

Heater operation/ Boiler operation *2

IN6 TBI.1 3-4 — Room thermostat 2 input Refer to SW3-1 in <Table 3 DIP Switch Functions>.

IN7 TBI.1 1-2 — Flow switch 3 input (Zone2) Refer to SW3-3 in <Table 3 DIP Switch Functions>.

IN8 TBI.3 1-2 — Electric energy meter 1

Refer to installation manual.IN9 TBI.3 3-4 — Electric energy meter 2

IN10

TBI.3 5-6 — Heat meter

*1. If using outdoor thermostat for controlling operation of heaters, the lifetime of the heaters and related parts may be

reduced.

*2. To turn on the boiler operation, use the main controller to select “Boiler” in “External input setting“ screen in the

service menu.

Table 2 Outputs

Name

Terminal block

Connector

Item OFF ON

OUT1

TBO.1 1-2 CNP1 Water circulation pump 1 output (Space heating/cooling & DHW) OFF ON

OUT2

TBO.1 3-4 — Water circulation pump 2 output (Space heating/cooling for Zone1) OFF ON

OUT3

TBO.1 5-6 —

Water circulation pump 3 output (Space heating/cooling for Zone2) *1

OFF ON

2-way valve 2b output *2

OUT4

TBO.2 4-6 CNV1 3-way valve (2-way valve) output Heating DHW

OUT5

TBO.2 1-2

— Mixing valve output *1 Stop

Close

TBO.2 2-3 Open

OUT6

—

CNBH 1-3

Booster heater 1 output OFF ON

OUT7

—

CNBH 5-7

Booster heater 2 output OFF ON

OUT8

TBO.4 5-6 — Cooling signal output OFF ON

OUT9

TBO.4 3-4 CNIH Immersion heater output OFF ON

OUT10

TBO.3 1-2 — Boiler output OFF ON

OUT11

TBO.3 3-4 — Error output Normal Error

OUT12

TBO.3 5-6 — Defrost output Normal Defrost

OUT13

TBO.4 1-2 — 2-way valve 2a output *2 OFF ON

OUT14

— CNP4 Water circulation pump 4 output (DHW) OFF ON

OUT15

TBO.3 7-8 — Comp ON signal OFF ON

Do not connect to the terminals that are indicated as “—” in the “Terminal block” eld.

*1. For 2-zone temperature control.

*2. For 2-zone valve ON/OFF control.

1. Symbols used in wiring diagram are, : connector,

: terminal block.

2. Indoor unit and outdoor unit connecting wires have polarities, make

sure to match terminal numbers (S1, S2, S3) for correct wirings,

3. Since the outdoor unit side electric wiring may change, be sure to

check the outdoor unit electric wiring diagram for service.

Symbol Name

TB1 Terminal block <Power supply, Outdoor unit>

ECB1 Earth leakage circuit breaker for booster heater

MP1 Water circulation pump 1(Space heating & DHW)

MP2

Water circulation pump 2 (Space heating for Zone1)(Local supply)

MP3

Water circulation pump 3 (Space heating for Zone2)(Local supply)

MP4 Water circulation pump 4 (DHW)(Local supply)

3WV(2WV1)

3-way valve (2-way valve 1)(Local supply)

2WV2a 2-way valve (For Zone 1)(Local supply)

2WV2b 2-way valve (For Zone 2)(Local supply)

MXV Mixing valve (Local supply)

BHT Thermostat for booster heater

BHF Thermal fuse for booster heater

BH1 Booster heater 1

BHC1 Contactor for booster heater 1

BHCP Contactor for booster heater protection

OCH571

Page 12

NL

S3S2S1

NL

S3S2S1

To outdoor

unit

TB1

ORN

ORN

YLW

YLW

GRN/YLW

To outdoor

unit

Power supply

~/N 230V 50Hz

TB1

ORN

BLU

RED

BLU

RED

YLW

GRN/YLW

1

3

BLK

BLK

BLK

BLK

1

3

ORN

BRN

ORN

ORN

BRN

YLW

Indoor unit powered

by independent source

Indoor unit powered

via outdoor unit

CIRCUIT

BREAKER

1

3

CN3C

(BLU)

1

3

CNPWM

(WHT)

LED1

LED2

LED3

LED4

TBI.1

1310 12 141174 65 932 81

TBI.2

1310 12 141174 65 932 81

t°t

°

THW8

THW7

THW6

t

°

THW9

t

°

THWB1

t

°

THWB2

t

°

Main

controller

1 2

1

2

CN20

(RED)

TH1

t

°

1

3

CN21

(YLW)

TH2

t

°

1

4

THW1

THW2

CNW12

(RED)

t°t

°

1

2

THW5

CNW5

(WHT)

t

°

CN108

5

1

Wireless receiver

(Option)

WiFi adapter

(Option)

5

1

5

1

CN22

(BLU)

1

2

3

4

5

6

1

*1

5

Close

Open

N

X15

X12

TBO.4

TBO.3

TBO.2

TBO.1

F1

F2

M

2WV2a

MXV

MP2

MP1

M

1

~

1

3

CNV1

(WHT)

1

3

CNBHT

(BLK)

X11

X9

X8

X13

X10

X4

X14

X3

X2

X1

X5B

X5A

1

2

3

4

5

6

7

8

1

2

3

4

5

6

1

2

3

4

5

6

1

1

3

3

3

CNP1

(WHT)

CNPWM

(WHT)

TBO.1

TBO.2

TBO.3

TBO.4

CNP1

(WHT)

CNP4

(RED)

CNV1

(WHT)

TAB1

F2 F1

6.3A 250V 10A 250V

SW1

SW2

SW3

SW4

SW5

1

8

1

8

1

1

5

1

3

1

3

8

1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

8

1

6

CN01

(WHT)

2

1

4

6

2

1

1

2

4

6

4

6

CNBH

(WHT)

CNBC

(GRY)

1

1

3

1

2

1

2

1

2

CNBHT

(BLK)

1

3

1

3

7

CNIH

(ORN)

1

4

1

3

CNW5

(WHT)

CN21

(YLW)

CNW12

(RED)

CN20

(RED)

TBI.2

126 10148

137 11945321

6

4

2

1

CNIH

(ORN)

MP3

M

1

~

IN8

IN9

IN10

1310 12 141174 65 932 81

TBI.3

TBI.3

2 4 6 8 10 12 14

1

357 91113

1

4

CN1A

(WHT)

2 4 6 8 10 12 14

1

357 91113

TBI.1

2WV2b

M

1

~

TBO.2

3WV

*1

3WV

M

1

~

4 5 6

TBO.2

2WV1

2WV1

4 5 6

M

1

~

M

1

~

IN6

IN1

IN2

IN3

IN4

IN5

IN7

WHT

WHT

CNP4

(RED)

MP4

M

1

~

M

1

~

1

3

1

3

5

7

X6

X7

1

3

CNBC

(GRY)

CNBH

(WHT)

CNRF

(WHT)

CN105

(RED)

CN22

(BLU)

CNIT

(BLU)

CN01

(WHT)

CN3C

(BLU)

CN01

(WHT)

CN3C

(BLU)

CN01

(WHT)

–

+–+–+

Tool

Tool

Conductor

Conductor

Outline view Top view

<How to use TBO.1 to 4>

Connect them using either way as shown below.

2 2 2

2

ECB1

L

(1)N(3)

BHCP

BLU

BLU

BLU

REDRED

BLU/No.3

WHT/No.2

WHT/No.1

BLU/No.4

RED

VLT

VLT

PNK

PNK

GRY

GRY

BHC2

BHC1

BHT

642

531

A1

A2

642

531

A1

A2

BH1

BHF

BH2

2

4

Power supply

to Booster heater

642

531

A1

A2

CNBH

(WHT)

CNBHT

(BLK)

2

2

2

2

CNBC

(GRY)

1

1

3

5

7

3

1

3

~/N 230V 50Hz

Signal output

(Boiler)

Signal output

(Error)

Signal output

(Defrost)

Signal output

(Comp ON)

Signal output

(Cooling)

12

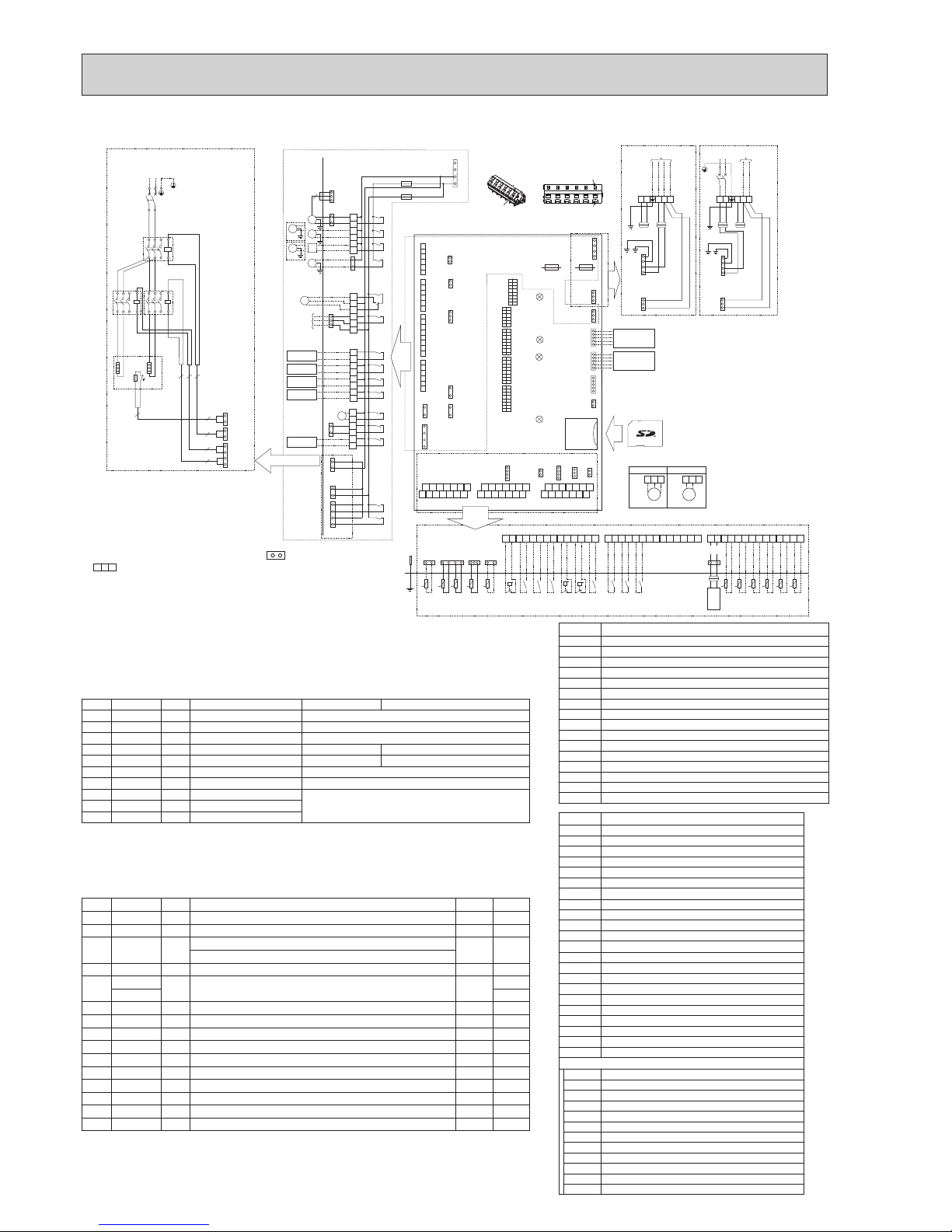

6-3. EHSC-VM6C, EHSC-VM6EC

Symbol Name

BHCP Contactor for booster heater protection

TH1 Thermistor (Room temp.)(Option)

TH2 Thermistor (Ref. liquid temp.)

THW1 Thermistor (Flow water temp.)

THW2 Thermistor (Return water temp.)

THW5 Thermistor (DHW tank water temp.)(Option)

THW6 Thermistor (Zone1 ow temp.)(Option)

THW7 Thermistor (Zone1 return temp.)(Option)

THW8 Thermistor (Zone2 ow temp.)(Option)

THW9 Thermistor (Zone2 return temp.)(Option)

THWB1 Thermistor (Boiler ow temp.)(Option)

THWB2 Thermistor (Boiler return temp.)(Option)

IN1 Room thermostat 1 (Local supply)

IN2 Flow switch 1 (Local supply)

IN3 Flow switch 2 (Local supply)

IN4 Demand control (Local supply)

IN5 Outdoor thermostat (Local supply)

IN6 Room thermostat 2 (Local supply)

IN7 Flow switch 3 (Local supply)

IN8 Electric energy meter 1 (Local supply)

IN9 Electric energy meter 2 (Local supply)

IN10 Heat meter (Local supply)

FLOW TEMP. CONTROLLER (FTC5)

TBO.1−4

Terminal block <Outputs>

TBI.1

−

3 Terminal block <Signal Inputs, Thermistor>

F1 Fuse (T10AL250V)

F2 Fuse (T6.3AL250V)

SW1

−

5 DIP switch *See Table 3

X1

−

15 Relay

LED1 Power supply (FTC5)

LED2 Power supply (Main controller)

LED3 Communication (FTC5-Outdoor unit)

LED4 Reading or writing data to SD card

CNPWM

Pump speed control signal for MP1

CN108 SD card connector

Table 1 Signal Inputs

Name

Terminal block

Connector

Item OFF (Open) ON (Short)

IN1 TBI.1 13-14 — Room thermostat 1 input Refer to SW2-1 in <Table 3 DIP Switch Functions>.

IN2 TBI.1 11-12 — Flow switch 1 input Refer to SW2-2 in <Table 3 DIP Switch Functions>.

IN3 TBI.1 9-10 — Flow switch 2 input (Zone1) Refer to SW3-2 in <Table 3 DIP Switch Functions>.

IN4 TBI.1 7-8 — Demand control input Normal Heat source OFF/ Boiler operation *2

IN5 TBI.1 5-6 — Outdoor thermostat input *1 Standard operation Heater operation/ Boiler operation *2

IN6 TBI.1 3-4 — Room thermostat 2 input Refer to SW3-1 in <Table 3 DIP Switch Functions>.

IN7 TBI.1 1-2 — Flow switch 3 input (Zone2) Refer to SW3-3 in <Table 3 DIP Switch Functions>.

IN8 TBI.3 1-2 — Electric energy meter 1

Refer to installation manual.IN9 TBI.3 3-4 — Electric energy meter 2

IN10

TBI.3 5-6 — Heat meter

*1. If using outdoor thermostat for controlling operation of heaters, the lifetime of the heaters and related parts may

be reduced.

*2. To turn on the boiler operation, use the main controller to select “Boiler” in “External input setting“ screen in the

service menu.

Table 2 Outputs

Name

Terminal block

Connector

Item OFF ON

OUT1

TBO.1 1-2 CNP1 Water circulation pump 1 output (Space heating/cooling & DHW) OFF ON

OUT2

TBO.1 3-4 — Water circulation pump 2 output (Space heating/cooling for Zone1) OFF ON

OUT3

TBO.1 5-6 —

Water circulation pump 3 output (Space heating/cooling for Zone2) *1

OFF ON

2-way valve 2b output *2

OUT4

TBO.2 4-6 CNV1 3-way valve (2-way valve) output Heating DHW

OUT5

TBO.2 1-2

— Mixing valve output *1 Stop

Close

TBO.2 2-3 Open

OUT6

—

CNBH 1-3

Booster heater 1 output OFF ON

OUT7

—

CNBH 5-7

Booster heater 2 output OFF ON

OUT8

TBO.4 5-6 — Cooling signal output OFF ON

OUT9

TBO.4 3-4 CNIH Immersion heater output OFF ON

OUT10

TBO.3 1-2 — Boiler output OFF ON

OUT11

TBO.3 3-4 — Error output Normal Error

OUT12

TBO.3 5-6 — Defrost output Normal Defrost

OUT13

TBO.4 1-2 — 2-way valve 2a output *2 OFF ON

OUT14

— CNP4 Water circulation pump 4 output (DHW) OFF ON

OUT15

TBO.3 7-8 — Comp ON signal OFF ON

Do not connect to the terminals that are indicated as “—” in the “Terminal block” eld.

*1. For 2-zone temperature control.

*2. For 2-zone valve ON/OFF control.

1. Symbols used in wiring diagram are, : connector,

: terminal block.

2. Indoor unit and outdoor unit connecting wires have polarities,

make sure to match terminal numbers (S1, S2, S3) for correct

wirings,

3. Since the outdoor unit side electric wiring may change, be sure to

check the outdoor unit electric wiring diagram for service.

Symbol Name

TB1 Terminal block <Power supply, Outdoor unit>

ECB1 Earth leakage circuit breaker for booster heater

MP1 Water circulation pump 1(Space heating & DHW)

MP2

Water circulation pump 2 (Space heating for Zone1)(Local supply)

MP3

Water circulation pump 3 (Space heating for Zone2)(Local supply)

MP4 Water circulation pump 4 (DHW)(Local supply)

3WV(2WV1)

3-way valve (2-way valve 1)(Local supply)

2WV2a 2-way valve (For Zone 1)(Local supply)

2WV2b 2-way valve (For Zone 2)(Local supply)

MXV Mixing valve (Local supply)

BHT Thermostat for booster heater

BHF Thermal fuse for booster heater

BH1 Booster heater 1

BH2 Booster heater 2

BHC1 Contactor for booster heater 1

BHC2 Contactor for booster heater 2

OCH571

Page 13

NL

S3S2S1

NL

S3S2S1

To outdoor

unit

TB1

ORN

ORN

YLW

YLW

GRN/YLW

To outdoor

unit

Power supply

~/N 230V 50Hz

TB1

ORN

BLU

RED

BLU

RED

YLW

GRN/YLW

1

3

BLK

BLK

BLK

BLK

1

3

ORN

BRN

ORN

ORN

BRN

YLW

Indoor unit powered

by independent source

Indoor unit powered

via outdoor unit

CIRCUIT

BREAKER

1

3

1

3

LED1

LED2

LED3

LED4

TBI.1

1310 12 141174 65 932 81

TBI.2

1310 12 141174 65 932 81

IN6

IN1

IN2

IN3

IN4

IN5

IN7

t°t

°

THW8

THW7

THW6

t

°

THW9

t

°

THWB1

t

°

THWB2

t

°

Main

controller

1 2

1

2

CN20

(RED)

TH1

t

°

1

3

CN21

(YLW)

TH2

t

°

1

4

THW1

THW2

CNW12

(RED)

t°t

°

1

2

THW5

CNW5

(WHT)

t

°

CN108

5

1

Wireless receiver

(Option)

WiFi adapter

(Option)

5

1

5

1

CN22

(BLU)

1

2

3

4

5

6

1

3

5

7

1

*1

5

Close

Open

N

X6

X15

X12

X7

TBO.4

TBO.3

TBO.2

TBO.1

F1

F2

M

2WV2a

MXV

MP2

MP1

M

1

~

1

3

1

3

CNV1

(WHT)

1

3

CNBHT

(BLK)

CNBC

(GRY)

CNBH

(WHT)

X11

X9

X8

X13

X10

X4

X14

X3

X2

X1

X5B

X5A

1

2

3

4

5

6

7

8

1

2

3

4

5

6

1

2

3

4

5

6

1

1

3

3

3

CNP1

(WHT)

CNP4

(RED)

CNPWM

(WHT)

TBO.1

TBO.2

TBO.3

TBO.4

TAB1

F2 F1

6.3A 250V 10A 250V

SW1

SW2

SW3

SW4

SW5

1

8

1

8

1

1

5

1

3

1

3

8

1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

8

1

6

2

1

4

6

2

1

1

2

4

6

4

6

CNBH

(WHT)

CNBC

(GRY)

1

1

3

1

2

CNBHT

(BLK)

1

3

1

3

7

CNIH

(ORN)

TBI.2

126 10148

137 11945321

6

4

2

1

CNIH

(ORN)

MP3

M

1

~

2 2 2

ECB1

L2

(3)L1(1)L3(5)

BHCP

BLK

BLK

WHT

WHTWHT

BLK

REDRED

BLU/No.4

WHT/No.2

WHT/No.3

WHT/No.1

BLU/No.5

BLU/No.6

RED

VLT

VLT

PNK

PNK

WHT

WHT

GRY

GRY

BHC2

BHC1

BHT

642

531

A1

A2

642

531

A1

A2

BH1

BHF

BH2

2

4 6

Power supply

to Booster heater

642

531

A1

A2

2

2

2

2

2

1

1

3

5

7

3

1

3

3~ 400V 50Hz

IN8

IN9

IN10

1310 12 141174 65 932 81

TBI.3

TBI.3

2 4 6 8 10 12 14

1

357 91113

2 4 6 8 10 12 14

1

357 91113

TBI.1

2WV2b

M

1

~

TBO.2

3WV

*1

3WV

M

1

~

4 5 6

TBO.2

2WV1

2WV1

M

1

~

4 5 6

M

1

~

MP4

M

1

~

1

3

CNBHT

(BLK)

CNBC

(GRY)

CNBH

(WHT)

Signal output

(Boiler)

Signal output

(Error)

Signal output

(Defrost)

Signal output

(Comp ON)

Signal output

(Cooling)

CNP1

(WHT)

CNP4

(RED)

CNV1

(WHT)

CN3C

(BLU)

CNPWM

(WHT)

CNRF

(WHT)

CN105

(RED)

CN22

(BLU)

CNIT

(BLU)

CN01

(WHT)

–

+–+–+

CN3C

(BLU)

CN3C

(BLU)

CN01

(WHT)

CN01

(WHT)

CN01

(WHT)

Tool

Tool

Conductor

Conductor

Outline view Top view

<How to use TBO.1 to 4>

Connect them using either way as shown below.

1

2

1

2

1

4

1

3

CNW5

(WHT)

CN21

(YLW)

CNW12

(RED)

CN20

(RED)

1

4

CN1A

(WHT)

M

1

~

13

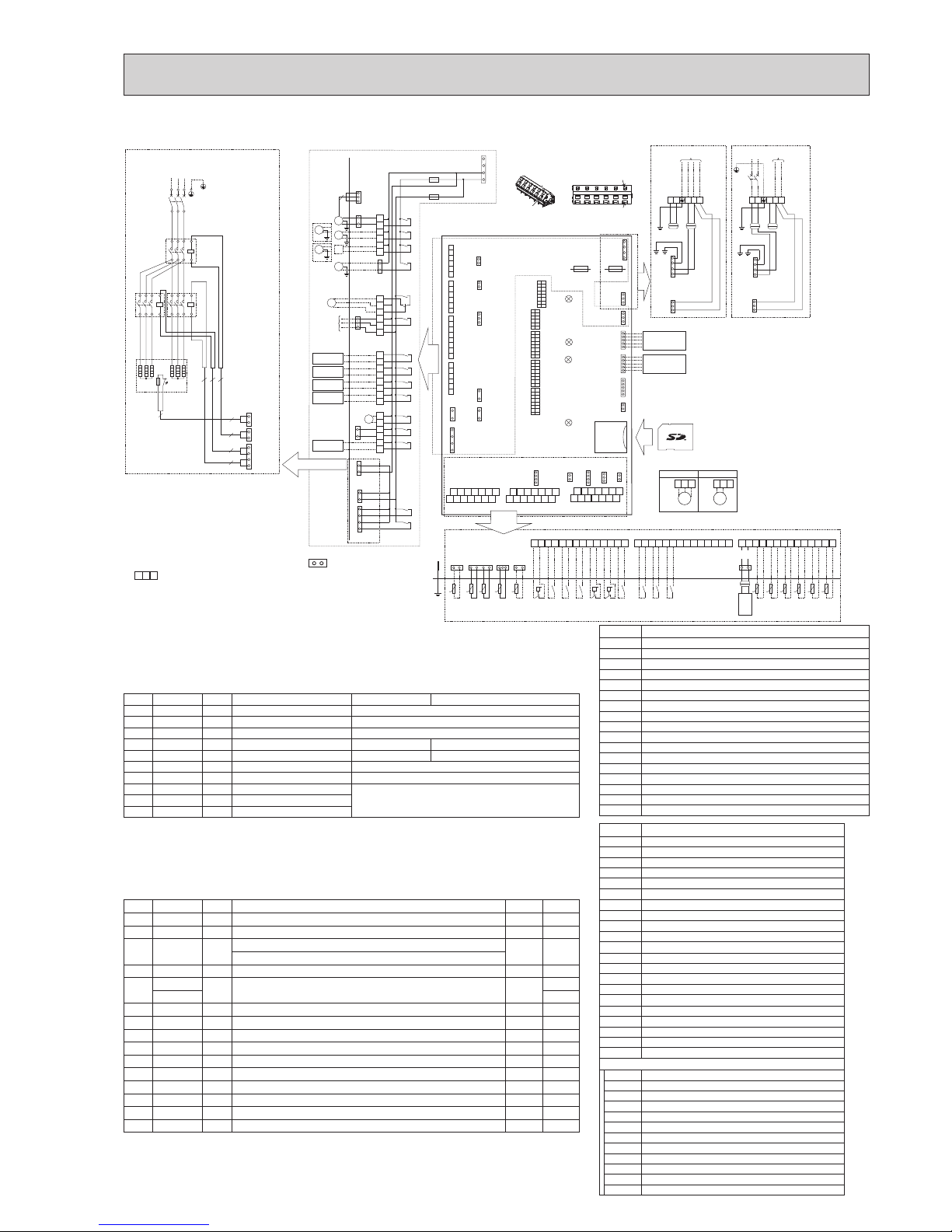

6-4. EHSC-YM9C, EHSC-YM9EC, EHPX-YM9C

Symbol Name

TH1 Thermistor (Room temp.)(Option)

TH2 Thermistor (Ref. liquid temp.)

THW1 Thermistor (Flow water temp.)

THW2 Thermistor (Return water temp.)

THW5 Thermistor (DHW tank water temp.)(Option)

THW6 Thermistor (Zone1 ow temp.)(Option)

THW7 Thermistor (Zone1 return temp.)(Option)

THW8 Thermistor (Zone2 ow temp.)(Option)

THW9 Thermistor (Zone2 return temp.)(Option)

THWB1 Thermistor (Boiler ow temp.)(Option)

THWB2 Thermistor (Boiler return temp.)(Option)

IN1 Room thermostat 1 (Local supply)

IN2 Flow switch 1 (Local supply)

IN3 Flow switch 2 (Local supply)

IN4 Demand control (Local supply)

IN5 Outdoor thermostat (Local supply)

IN6 Room thermostat 2 (Local supply)

IN7 Flow switch 3 (Local supply)

IN8 Electric energy meter 1 (Local supply)

IN9 Electric energy meter 2 (Local supply)

IN10 Heat meter (Local supply)

FLOW TEMP. CONTROLLER (FTC5)

TBO.1−4

Terminal block <Outputs>

TBI.1−3 Terminal block <Signal Inputs, Thermistor>

F1 Fuse (T10AL250V)

F2 Fuse (T6.3AL250V)

SW1−5 DIP switch *See Table 3

X1−15 Relay

LED1 Power supply (FTC5)

LED2 Power supply (Main controller)

LED3 Communication (FTC5-Outdoor unit)

LED4 Reading or writing data to SD card

CNPWM

Pump speed control signal for MP1

CN108 SD card connector

Table 1 Signal Inputs

Name

Terminal block

Connector

Item OFF (Open) ON (Short)

IN1 TBI.1 13-14 — Room thermostat 1 input Refer to SW2-1 in <Table 3 DIP Switch Functions>.

IN2 TBI.1 11-12 — Flow switch 1 input Refer to SW2-2 in <Table 3 DIP Switch Functions>.

IN3 TBI.1 9-10 — Flow switch 2 input (Zone1) Refer to SW3-2 in <Table 3 DIP Switch Functions>.

IN4 TBI.1 7-8 — Demand control input Normal Heat source OFF/ Boiler operation *2

IN5 TBI.1 5-6 — Outdoor thermostat input *1 Standard operation Heater operation/ Boiler operation *2

IN6 TBI.1 3-4 — Room thermostat 2 input Refer to SW3-1 in <Table 3 DIP Switch Functions>.

IN7 TBI.1 1-2 — Flow switch 3 input (Zone2) Refer to SW3-3 in <Table 3 DIP Switch Functions>.

IN8 TBI.3 1-2 — Electric energy meter 1

Refer to installation manual.IN9 TBI.3 3-4 — Electric energy meter 2

IN10

TBI.3 5-6 — Heat meter

*1. If using outdoor thermostat for controlling operation of heaters, the lifetime of the heaters and related parts may be

reduced.

*2. To turn on the boiler operation, use the main controller to select “Boiler” in “External input setting“ screen in the

service menu.

Table 2 Outputs

Name

Terminal block

Connector

Item OFF ON

OUT1

TBO.1 1-2 CNP1 Water circulation pump 1 output (Space heating/cooling & DHW) OFF ON

OUT2

TBO.1 3-4 — Water circulation pump 2 output (Space heating/cooling for Zone1) OFF ON

OUT3

TBO.1 5-6 —

Water circulation pump 3 output (Space heating/cooling for Zone2) *1

OFF ON

2-way valve 2b output *2

OUT4

TBO.2 4-6 CNV1 3-way valve (2-way valve) output Heating DHW

OUT5

TBO.2 1-2

— Mixing valve output *1 Stop

Close

TBO.2 2-3 Open

OUT6

—

CNBH 1-3

Booster heater 1 output OFF ON

OUT7

—

CNBH 5-7

Booster heater 2 output OFF ON

OUT8

TBO.4 5-6 — Cooling signal output OFF ON

OUT9

TBO.4 3-4 CNIH Immersion heater output OFF ON

OUT10

TBO.3 1-2 — Boiler output OFF ON

OUT11

TBO.3 3-4 — Error output Normal Error

OUT12

TBO.3 5-6 — Defrost output Normal Defrost

OUT13

TBO.4 1-2 — 2-way valve 2a output *2 OFF ON

OUT14

— CNP4 Water circulation pump 4 output (DHW) OFF ON

OUT15

TBO.3 7-8 — Comp ON signal OFF ON

Do not connect to the terminals that are indicated as “—” in the “Terminal block” eld.

*1. For 2-zone temperature control.

*2. For 2-zone valve ON/OFF control.

1. Symbols used in wiring diagram are, : connector,

: terminal block.

2. Indoor unit and outdoor unit connecting wires have polarities,

make sure to match terminal numbers (S1, S2, S3) for correct

wirings,

3. Since the outdoor unit side electric wiring may change, be sure to

check the outdoor unit electric wiring diagram for service.

Symbol Name

TB1 Terminal block <Power supply, Outdoor unit>

ECB1 Earth leakage circuit breaker for booster heater

MP1 Water circulation pump 1(Space heating & DHW)

MP2

Water circulation pump 2 (Space heating for Zone1)(Local supply)

MP3

Water circulation pump 3 (Space heating for Zone2)(Local supply)

MP4 Water circulation pump 4 (DHW)(Local supply)

3WV(2WV1)

3-way valve (2-way valve 1)(Local supply)

2WV2a 2-way valve (For Zone 1)(Local supply)

2WV2b 2-way valve (For Zone 2)(Local supply)

MXV Mixing valve (Local supply)

BHT Thermostat for booster heater

BHF Thermal fuse for booster heater

BH1 Booster heater 1

BH2 Booster heater 2

BHC1 Contactor for booster heater 1

BHC2 Contactor for booster heater 2

BHCP Contactor for booster heater protection

OCH571

Page 14

NL

S3S2S1

NL

S3S2S1

To outdoor

unit

TB1

ORN

ORN

YLW

YLW

GRN/YLW

To outdoor

unit

Power supply

~/N 230V 50Hz

TB1

ORN

BLU

RED

BLU

RED

YLW

GRN/YLW

1

3

BLK

BLK

BLK

BLK

1

3

ORN

BRN

ORN

ORN

BRN

YLW

Indoor unit powered

by independent source

Indoor unit powered

via outdoor unit

CIRCUIT

BREAKER

1

3

CN3C

(BLU)

1

3

LED1

LED2

LED3

LED4

TBI.1

1310 12 141174 65 932 81

TBI.2

1310 12 141174 65 932 81

t°t

°

THW8

THW7

THW6

t

°

THW9

t

°

THWB1

t

°

THWB2

t

°

Main

controller

1 2

1

2

CN20

(RED)

TH1

t

°

1

3

CN21

(YLW)

TH2

t

°

1

4

THW1

THW2

CNW12

(RED)

t°t

°

1

2

THW5

CNW5

(WHT)

t

°

CN108

5

1

Wireless receiver

(Option)

WiFi adapter

(Option)

5

1

5

1

CN22

(BLU)

1

2

3

4

5

6

1

*1

5

Close

Open

N

X15

X12

TBO.4

TBO.3

TBO.2

TBO.1

F1

F2

M

2WV2a

MXV

MP2

MP1

M

1

~

1

3

CNV1

(WHT)

1

3

CNBHT

(BLK)

X11

X9

X8

X13

X10

X4

X14

X3

X2

X1

X5B

X5A

1

2

3

4

5

6

7

8

1

2

3

4

5

6

1

2

3

4

5

6

1

1

3

3

3

CNP1

(WHT)

CNPWM

(WHT)

TBO.1

TBO.2

TBO.3

TBO.4

TAB1

F2 F1

6.3A 250V 10A 250V

SW1

SW2

SW3

SW4

SW5

1

8

1

8

1

1

5

1

3

1

3

8

1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

8

1

6

2

1

4

6

2

1

1

2

4

6

4

6

1

1

3

1

2

1

3

1

3

7

TBI.2

126 10148

137 11945321

6

4

2

1

CNIH

(ORN)

MP3

M

1

~

IN8

IN9

IN10

1310 12 141174 65 932 81

TBI.3

TBI.3

2 4 6 8 10 12 14

1

357 91113

2 4 6 8 10 12 14

1

357 91113

TBI.1

2WV2b

M

1

~

TBO.2

3WV

*1

3WV

M

1

~

4 5 6

TBO.2

2WV1

2WV1

4 5 6

M

1

~

IN6

IN1

IN2

IN3

IN4

IN5

IN7

M

1

~

CNP4

(RED)

MP4

M

1

~

M

1

~

1

3

1

3

5

7

X6

X7

1

3

CNBC

(GRY)

CNBH

(WHT)

Signal output

(Boiler)

Signal output

(Error)

Signal output

(Defrost)

Signal output

(Comp ON)

Signal output

(Cooling)

–+–+–

+

CNPWM

(WHT)

CNRF

(WHT)

CN105

(RED)

CN22

(BLU)

CNIT

(BLU)

CN01

(WHT)

CNP1

(WHT)

CNP4

(RED)

CNV1

(WHT)

CNBH

(WHT)

CNBC

(GRY)

CNBHT

(BLK)

CNIH

(ORN)

CN3C

(BLU)

CN3C

(BLU)

CN01

(WHT)

CN01

(WHT)

CN01

(WHT)

Tool

Tool

Conductor

Conductor

Outline view Top view

<How to use TBO.1 to 4>

Connect them using either way as shown below.

2 2 2

ECB1

L2

(3)L1(1)L3(5)

BHCP

BLK

BLK

WHT

WHTWHT

BLK

REDRED

BLU/No.4

WHT/No.2

WHT/No.3

WHT/No.1

BLU/No.5

BLU/No.6

RED

VLT

VLT

PNK

PNK

GRY

GRY

BHC2

BHC1

BHT

642

531

A1

A2

642

531

A1

A2

BH1

BHF

BH2

2

4

6

Power supply

to Booster heater

642

531

A1

A2

2

2

2

2

2

1

1

3

5

7

3

1

3

3~ 230V 50Hz

CNBHT

(BLK)

CNBC

(GRY)

CNBH

(WHT)

WHT

WHT

1

2

1

2

1

4

1

3

CNW5

(WHT)

CN21

(YLW)

CNW12

(RED)

CN20

(RED)

1

4

CN1A

(WHT)

14

6-5. EHSC-TM9C

Symbol Name

TH1 Thermistor (Room temp.)(Option)

TH2 Thermistor (Ref. liquid temp.)

THW1 Thermistor (Flow water temp.)

THW2 Thermistor (Return water temp.)

THW5 Thermistor (DHW tank water temp.)(Option)

THW6 Thermistor (Zone1 ow temp.)(Option)

THW7 Thermistor (Zone1 return temp.)(Option)

THW8 Thermistor (Zone2 ow temp.)(Option)

THW9 Thermistor (Zone2 return temp.)(Option)

THWB1 Thermistor (Boiler ow temp.)(Option)

THWB2 Thermistor (Boiler return temp.)(Option)

IN1 Room thermostat 1 (Local supply)

IN2 Flow switch 1 (Local supply)

IN3 Flow switch 2 (Local supply)

IN4 Demand control (Local supply)

IN5 Outdoor thermostat (Local supply)

IN6 Room thermostat 2 (Local supply)

IN7 Flow switch 3 (Local supply)

IN8 Electric energy meter 1 (Local supply)

IN9 Electric energy meter 2 (Local supply)

IN10 Heat meter (Local supply)

FLOW TEMP. CONTROLLER (FTC5)

TBO.1−4

Terminal block <Outputs>

TBI.1

−

3 Terminal block <Signal Inputs, Thermistor>

F1 Fuse (T10AL250V)

F2 Fuse (T6.3AL250V)

SW1

−

5 DIP switch *See Table 3

X1

−

15 Relay

LED1 Power supply (FTC5)

LED2 Power supply (Main controller)

LED3 Communication (FTC5-Outdoor unit)

LED4 Reading or writing data to SD card

CNPWM

Pump speed control signal for MP1

CN108 SD card connector

Table 1 Signal Inputs

Name

Terminal block

Connector

Item OFF (Open) ON (Short)

IN1 TBI.1 13-14 — Room thermostat 1 input Refer to SW2-1 in <Table 3 DIP Switch Functions>.

IN2 TBI.1 11-12 — Flow switch 1 input Refer to SW2-2 in <Table 3 DIP Switch Functions>.

IN3 TBI.1 9-10 — Flow switch 2 input (Zone1) Refer to SW3-2 in <Table 3 DIP Switch Functions>.

IN4 TBI.1 7-8 — Demand control input Normal Heat source OFF/ Boiler operation *2

IN5 TBI.1 5-6 — Outdoor thermostat input *1 Standard operation Heater operation/ Boiler operation *2

IN6 TBI.1 3-4 — Room thermostat 2 input Refer to SW3-1 in <Table 3 DIP Switch Functions>.

IN7 TBI.1 1-2 — Flow switch 3 input (Zone2) Refer to SW3-3 in <Table 3 DIP Switch Functions>.

IN8 TBI.3 1-2 — Electric energy meter 1

Refer to installation manual.IN9 TBI.3 3-4 — Electric energy meter 2

IN10

TBI.3 5-6 — Heat meter

*1. If using outdoor thermostat for controlling operation of heaters, the lifetime of the heaters and related parts may be

reduced.

*2. To turn on the boiler operation, use the main controller to select “Boiler” in “External input setting“ screen in the

service menu.

Table 2 Outputs

Name

Terminal block

Connector

Item OFF ON

OUT1

TBO.1 1-2 CNP1 Water circulation pump 1 output (Space heating/cooling & DHW) OFF ON

OUT2

TBO.1 3-4 — Water circulation pump 2 output (Space heating/cooling for Zone1) OFF ON

OUT3

TBO.1 5-6 —

Water circulation pump 3 output (Space heating/cooling for Zone2) *1

OFF ON

2-way valve 2b output *2

OUT4

TBO.2 4-6 CNV1 3-way valve (2-way valve) output Heating DHW

OUT5

TBO.2 1-2

— Mixing valve output *1 Stop

Close

TBO.2 2-3 Open

OUT6

—

CNBH 1-3

Booster heater 1 output OFF ON

OUT7

—

CNBH 5-7

Booster heater 2 output OFF ON

OUT8

TBO.4 5-6 — Cooling signal output OFF ON

OUT9

TBO.4 3-4 CNIH Immersion heater output OFF ON

OUT10

TBO.3 1-2 — Boiler output OFF ON

OUT11

TBO.3 3-4 — Error output Normal Error

OUT12

TBO.3 5-6 — Defrost output Normal Defrost

OUT13

TBO.4 1-2 — 2-way valve 2a output *2 OFF ON

OUT14

— CNP4 Water circulation pump 4 output (DHW) OFF ON

OUT15

TBO.3 7-8 — Comp ON signal OFF ON

Do not connect to the terminals that are indicated as “—” in the “Terminal block” eld.

*1. For 2-zone temperature control.

*2. For 2-zone valve ON/OFF control.

1. Symbols used in wiring diagram are, : connector,

: terminal block.

2. Indoor unit and outdoor unit connecting wires have polarities,

make sure to match terminal numbers (S1, S2, S3) for correct

wirings,

3. Since the outdoor unit side electric wiring may change, be sure to

check the outdoor unit electric wiring diagram for service.

Symbol Name

TB1 Terminal block <Power supply, Outdoor unit>

ECB1 Earth leakage circuit breaker for booster heater

MP1 Water circulation pump 1(Space heating & DHW)

MP2

Water circulation pump 2 (Space heating for Zone1)(Local supply)

MP3

Water circulation pump 3 (Space heating for Zone2)(Local supply)

MP4 Water circulation pump 4 (DHW)(Local supply)

3WV(2WV1)

3-way valve (2-way valve 1)(Local supply)

2WV2a 2-way valve (For Zone 1)(Local supply)

2WV2b 2-way valve (For Zone 2)(Local supply)

MXV Mixing valve (Local supply)

BHT Thermostat for booster heater

BHF Thermal fuse for booster heater

BH1 Booster heater 1

BH2 Booster heater 2

BHC1 Contactor for booster heater 1

BHC2 Contactor for booster heater 2

BHCP Contactor for booster heater protection

OCH571

Page 15

15

Automatic switch to heat source only operation

Back-up heat source operation (*1) will automatically run when the outdoor unit stops abnormally. To enable the function, switch DIP SW 2-5 to ON. During the back-up operation, an error code(s) and the contact number will be displayed alternately. External output (OUT11) will be available. To clear the fault(s), reset the power breakers on the indoor and outdoor units.

<Applicable error codes (*2)>

E6 to E9, ED, P6, P8, U1 to U8, UD, UE, UF, UL, UP

(*1) Prolonged running of the back-up operation may affect the life of the heat source.

(*2) For safety reasons, this function is not available for certain faults. (System operation must be stopped and only pump keeps running.)

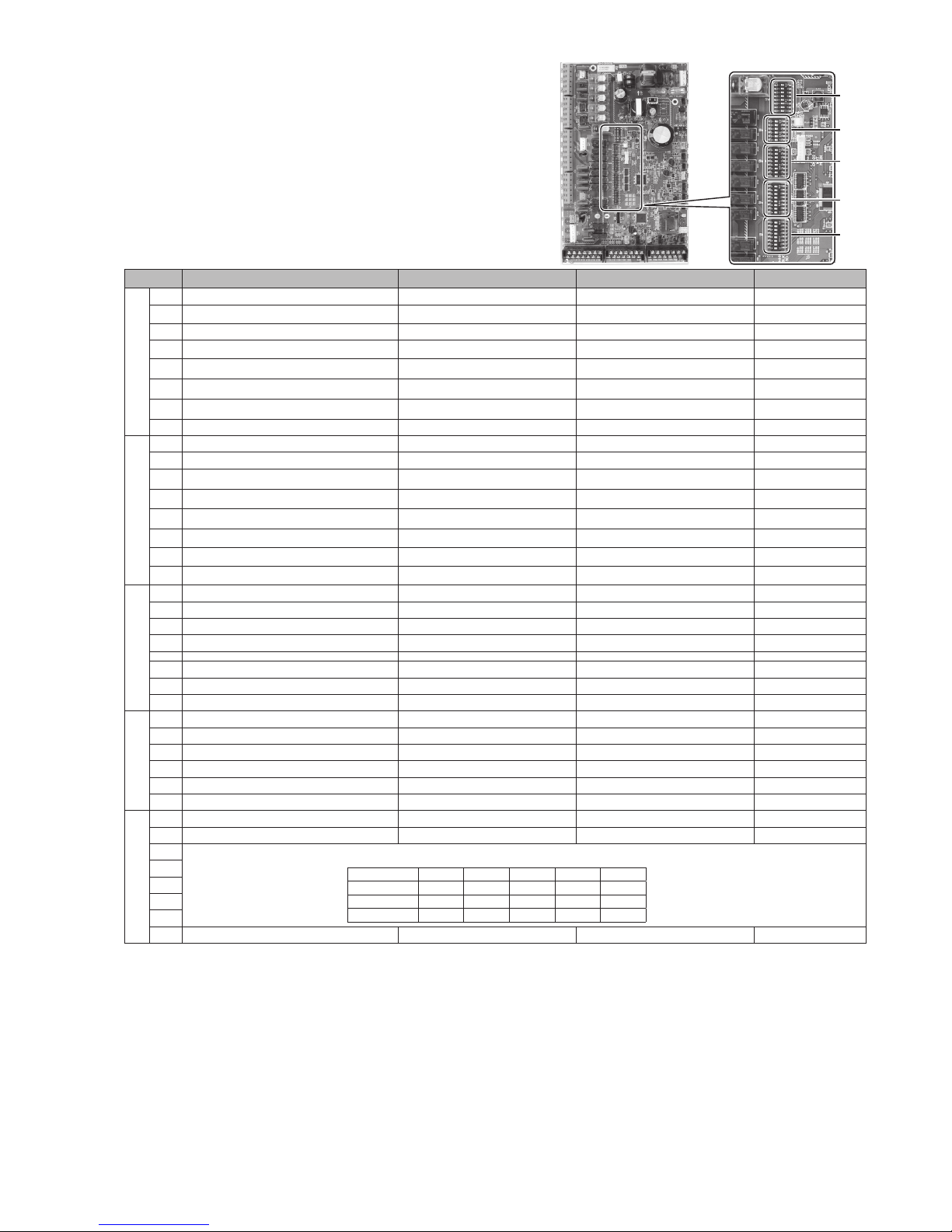

6-6. DIP switch setting

Located on the FTC printed circuit board are 5 sets of small white switches

known as DIP switches. The DIP switch number is printed on the circuit board

next to the relevant switches. The word ON is printed on the circuit board and on

the DIP switch block itself. To move the switch you will need to use a pin or the

corner of a thin metal ruler or similar.

DIP switch settings are listed in the table below.

Make sure to turn off both indoor unit and outdoor unit power supplies before

changing the switch settings.

DIP switch Function OFF ON

Default settings:

Indoor unit model

SW1

SW1-1 Boiler WITHOUT Boiler WITH Boiler OFF

SW1-2 Heat pump maximum outlet water temperature 55ºC 60ºC ON *1

SW1-3 DHW tank WITHOUT DHW tank WITH DHW tank OFF

SW1-4 Immersion heater WITHOUT Immersion heater WITH Immersion heater OFF

SW1-5 Booster heater WITHOUT Booster heater WITH Booster heater

OFF: E***-M*C

ON : E***-*M2/6/9C

SW1-6 Booster heater function For heating only For heating and DHW

OFF: E***-M*C

ON : E***-*M2/6/9C

SW1-7 Outdoor unit type Split type Packaged type

OFF: E*S*-*M*C

ON : EHPX-*M*C

SW1-8 Wireless remote controller WITHOUT Wireless remote controller WITH Wireless remote controller OFF

SW2

SW2-1 Room thermostat1 input (IN1) logic change

Zone1 operation stop at thermostat short Zone1 operation stop at thermostat open

OFF

SW2-2 Flow switch1 input (IN2) logic change Failure detection at short Failure detection at open OFF

SW2-3 Booster heater capacity restriction Inactive Active

OFF: Except E***-VM2*C

ON : E***-VM2*C

SW2-4 Cooling mode function Inactive Active

OFF: Except ERS*-*M**C

ON : ERS*-*M**C

SW2-5

Automatic switch to backup heat source operation

(When outdoor unit stops by error)

Inactive Active *2 OFF

SW2-6 Mixing tank WITHOUT Mixing tank WITH Mixing tank OFF

SW2-7 2-zone temperature control Inactive Active *6 OFF

SW2-8 Flow sensor WITHOUT Flow sensor WITH Flow sensor ON

SW3

SW3-1 Room thermostat 2 input (IN6) logic change Zone2 operation stop at thermostat short Zone2 operation stop at thermostat open OFF

SW3-2 Flow switch 2 input (IN3) logic change Failure detection at short Failure detection at open OFF

SW3-3 Flow switch 3 input (IN7) logic change Failure detection at short Failure detection at open OFF

SW3-4 Electric energy meter WITHOUT Electric energy meter WITH Electric energy meter OFF

SW3-5 Heating mode function *3 Inactive Active ON

SW3-6 2-zone valve ON/OFF control Inactive Active OFF

SW3-7 Heat exchanger for DHW Coil in tank External plate HEX OFF

SW3-8 Heat meter WITHOUT Heat meter WITH Heat meter OFF

SW4

SW4-1 Multiple outdoor units control Inactive Active OFF

SW4-2 Position of multiple outdoor units control *7 Slave Master OFF

SW4-3 — — — OFF

SW4-4

Indoor unit only operation (during installation work) *4

Inactive Active OFF

SW4-5 Emergency mode (Heater only operation) Normal

Emergency mode (Heater only operation)

OFF *5

SW4-6 Emergency mode (Boiler operation) Normal Emergency mode (Boiler operation) OFF *5

SW5

SW5-1

DHW tank water temperature over heat protection (L4)

Active Inactive *8 OFF

SW5-2 — — — OFF

SW5-3

SW5-4

SW5-5

SW5-6

SW5-7

SW5-8 — — — OFF

Note:

*1. When the hydrobox is connected with a PUHZ-RP/SUHZ-SW outdoor unit of which maximum outlet water temperature is 55ºC, DIP SW1-2 must be changed to OFF.

*2.

OUT11 will be available. For safety reasons, this function is not available for certain errors. (In that case, system operation must be stopped and only the water circulation pump keeps running.)

*3 This switch functions only when the hydrobox is connected with a PUHZ-FRP outdoor unit. When another type of outdoor unit is connected, the heating mode function is active

regardless of the fact that this switch is ON or OFF.