Mitsubishi Electric Ecodan PUHZ-W50VHA-BS, Ecodan PUHZ-W85VHA-BS, Ecodan PUHZ-HW140VHA-BS, Ecodan PUHZ-HW140YHA-BS Homeowner's Manual

1

Ecodan® Air Source Heat Pump

Home Owner Guide

PUHZ-W50VHA-BS

PUHZ-W85VHA-BS

PUHZ-HW140VHA-BS / YHA-BS

2

Contents

INTRODUCTION

• Heat Pump Overview 3

• Co-efficient of performance 3

• Varying Factors 3

• How a heat pump works 4

• Room thermostat 5

• Controller PAR-W21MAA 5

• Hot Water / Space Heating 5

• Selecting cylinder thermostat 5

• Weather Compensation 5

COMPONENT PARTS

• Key Parts 6

SPECIFICATION

• PUHZ-W50VHA-BS 7

• PUHZ-W85VHA-BS 8

• PUHZ-HW140VHA-BS / YHA-BS 9

CONTROLLER SET-UP

• Display and Operation 10

• Change Language 11

• Setting Day and Time 11

• Heating Set-up 12

• Recommended Settings 13

• Radiators 13

• Hot water Set-up 13

• Available Modes 14

• How to lock/unlock buttons 15

• Error codes indication 15

• Displays 16

OPERATING CONDITIONS

• Flow Rates 17

• Start Up 17

• Control Strategy 17

RUNNING COSTS

• Running Costs 18

ADDITIONAL INFORMATION

• Time Clock Set-Up/ Patterns 19

• Domestic Hot Water Immersion Heater 20

• Legionnaires Disease 20

• FAQ’s 20

TROUBLESHOOTING

• Troubleshooting 21

• Maintenance 21

Abbreviations / Glossary of terms

Ambient Temperature The outdoor temperature

Anti freeze mode Heating to prevent water pipe from freezing

ASHP Air source heat-pump boiler

COP Coefficient of performance, see page 3 for full explanation

∆T / Delta Change in temperature between two variables

Flow Rate The speed the water travels within the circuit that is heated by the Ecodan® unit

Flow Temperature The temperature of the water within the circuit that is heated by the Ecodan® unit

FTC Flow Temperature Controller, see page 6 for full explanation

Heating Eco mode Similar to ’heating mode’ with weather compensation

Heating Mode For heating space either through radiators or under floor heating

Hot water mode Heating of the tank to provide hotwater

Immersion Heater Booster heater to raise temperatures, see page 21 for use with Ecodan® unit

Refrigerant A compound used within a heat cycle that goes through a phase change during this cycle

changing from gas to liquid and back again

UFH Under Floor Heating

Weather compensation Flow temperatures change dependent on outdoor conditions, see page 5 for full explanation

3

Heat Pump Boiler Overview

A heat pump works in a similar way to that of a domestic fridge, although in reverse. Heat is moved from one source to another. The outdoor based Ecodan

exploits the physical properties of a refrigerant to heat water that flows into the

dwelling to the radiators/ under-floor heating and the hot water cylinder for hot

water usage. This is a very efficient way to heat water compared to conventional

gas, oil and solid fuel boilers.

Co-efficient of Performance

Sometimes referred to as COP, it is the amount of heat energy provided by the

heat pump, divided by the electrical energy consumed by the heat pump.

The efficiency of a heat pump boiler is high compared to a gas boiler. Typically for

every 1kW of input energy, 3kW of outputted heat energy can be achieved, that

creates a COP of 3.0. If heat energy increases for the same input the COP would

rise.

Compared to a gas fired conventional boiler, 1kW of input energy provides less

than 1kW of output energy or heat. A heat pump boiler utilises heat energy from

the outside air even at low temperatures to provide either central heating or hot

water for the house.

The COP for an ASHP will vary as it is dependent on the outside temperatures

and the desired temperature of hot water/ space heating. The smaller the difference between these figures the more efficient the Ecodan® will become. When it

is cold outside power input increases as the Ecodan® works harder to extract

heat from the air, thus COP drops in cold conditions.

Varying Factors

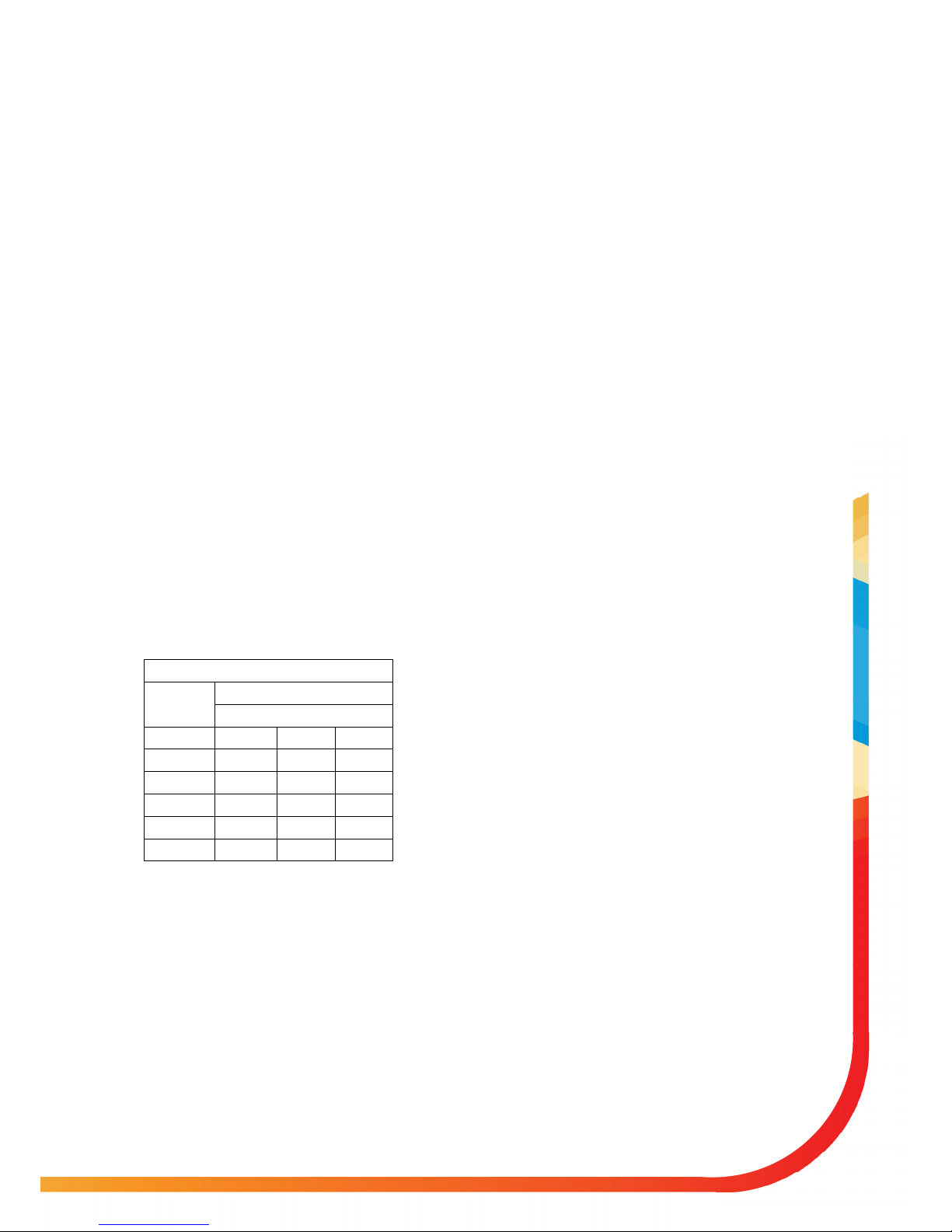

The table below shows how performance will vary. The Inlet/ Outlet temperature

represents the water temperature

progressing through the Ecodan®

unit and heating up.

Figures for 8.5kW heat pump

* Ambient Temperature –10°C

INTRODUCTION

°C ambient

Water temp °C

Inlet / Outlet

30 / 35 40 / 45 50 / 55

-15 1.77 1.41 1.37*

-7 2.41 1.89 1.46

2 2.97 2.27 1.81

7 3.96 3.05 2.28

20 5.39 3.90 2.87

COP at varying factors

4

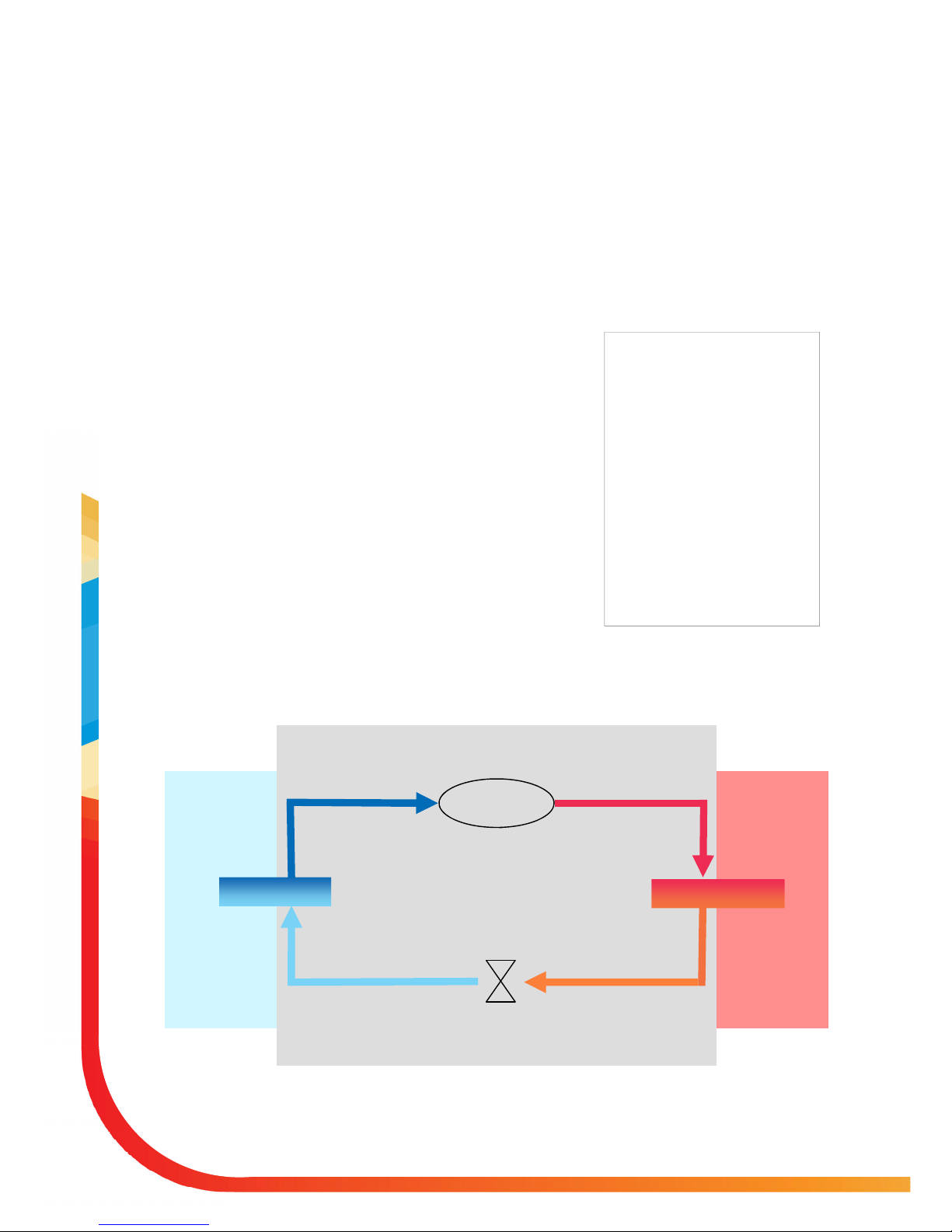

How a heat pump works

The heat pump essentially works the same way as your refrigerator but in reverse.

The Ecodan® is hermetically sealed (no refrigeration piping involved) with R410A

refrigerant, the cycle it completes to produce heat is known as the vapourcompression refrigeration cycle:

The first phase begins with the refrigerant being cold and low pressure.

The refrigerant within the circuit is compressed as it passes through the

compressor. It becomes a hot highly pressurized gas. The temperature also

rises typically to 60°C

The refrigerant is then condensed as it passes across a plate heat ex-

changer. Having a cooler side to the heat exchanger it decreases the temperature, so it changes the property of the refrigerant from a gas to a liquid.

Now a cold liquid it still has a high pressure. For expansion to occur it passes

through an expansion valve. The pressure drops but it is still a cold liquid.

The final stage of the cycle is when the refrigerant passes into the evaporator

and evaporates. It is at this point when some of the free heat energy in the

outside air is absorbed by the refrigerant.

It is only the refrigerant that is being passed through this cycle; the water is heated

up by the plate heat exchanger. The cooler water extracts energy from the hotter

refrigeration cycle, the water heats up as it passes across the exchanger. This water flows towards the heating system and hot water storage tank.

Boiling points:

The refrigerant used within the cycle

has a different boiling point to water,

which boils (turns from liquid to gas)

at 100°C. This is only true at atmospheric pressure. When the pressure

increases so does the boiling temperature; decrease the pressure and boiling

temperature drops. Liquid turns to gas

at a lower temperature. The boiling

point changes when the pressure

changes. Refrigerants have different

properties to water and have much

lower boiling temperatures. During the

fourth stage of the cycle the outside

ambient temperature is much hotter

than the temperature of the refrigerant and will heat it.

Step 1

Step 2 Step 3 Step 4

INTRODUCTION

compressor

Heat Exchanger

Evaporator

Expansion

1 compressed

2 condensed

3 expansion

4 evaporates

Outside Air

Sealed Ecodan® Unit

Hot water for heat-

ing and hot water

5

Room Thermostat

The aim of the thermostat is to control the room temperature, although one model used will vary from

one home to another its function will not. This is the homeowner’s connection to the heat pump boiler.

The room thermostat and the time clock (both supplied by 3rd party manufacturers.) are the 2 main controls for the home owner to use.

Controller PAR-W21MAA

This controller is supplied with the Ecodan® heat pump. Its primary function is as a commissioning tool to

set the target flow temperature. It has a display to show the actual flow temperature and the target temperature. The set-up, displays and modes available are explained later in the manual. Once installed there

are factory settings that will allow the heat pump boiler to start operating immediately, optimising these

temperatures to suit your home will improve running conditions and lower your energy consumption.

These temperatures should be selected during the commissioning stage.

Hot water / space heating

Space heating and hot water heat up cannot be performed at the same time. Hot water will always take

priority over space heating should there be a demand for both; once the tank is heated and up to temperature the unit will change over to the heating of the property. This setting cannot be changed.

Due to lower flow temperature provided by a heat pump boiler additional care must be taken when sizing

the radiators. Ensure that the total heating demand of the property is met by the correct size of heat

pump.

Selecting cylinder thermostats

Care should be taken when selecting a cylinder thermostat. If the thermostat is set higher than the achievable storage temperature of 55°C then space heating will be held off due to hot water priority. It is recommended that a thermostat on which the maximum temperature can be locked is used. This will prevent

the stat asking for a temperature that cannot be achieved thus preventing space heating from occurring.

(See page 18 for typical heat up times for the hot water tank).

Weather Compensation

The Ecodan® system has a weather compensation mode. This feature is called Eco-heating. This mode

offers varying flow temperatures to the radiators depending on the outside temperature. These temperatures are selected and set by the installer when commissioning the Ecodan® system for further details see

the controller set-up. It is recommended that Eco-heating mode is used for central heating.

INTRODUCTION

6

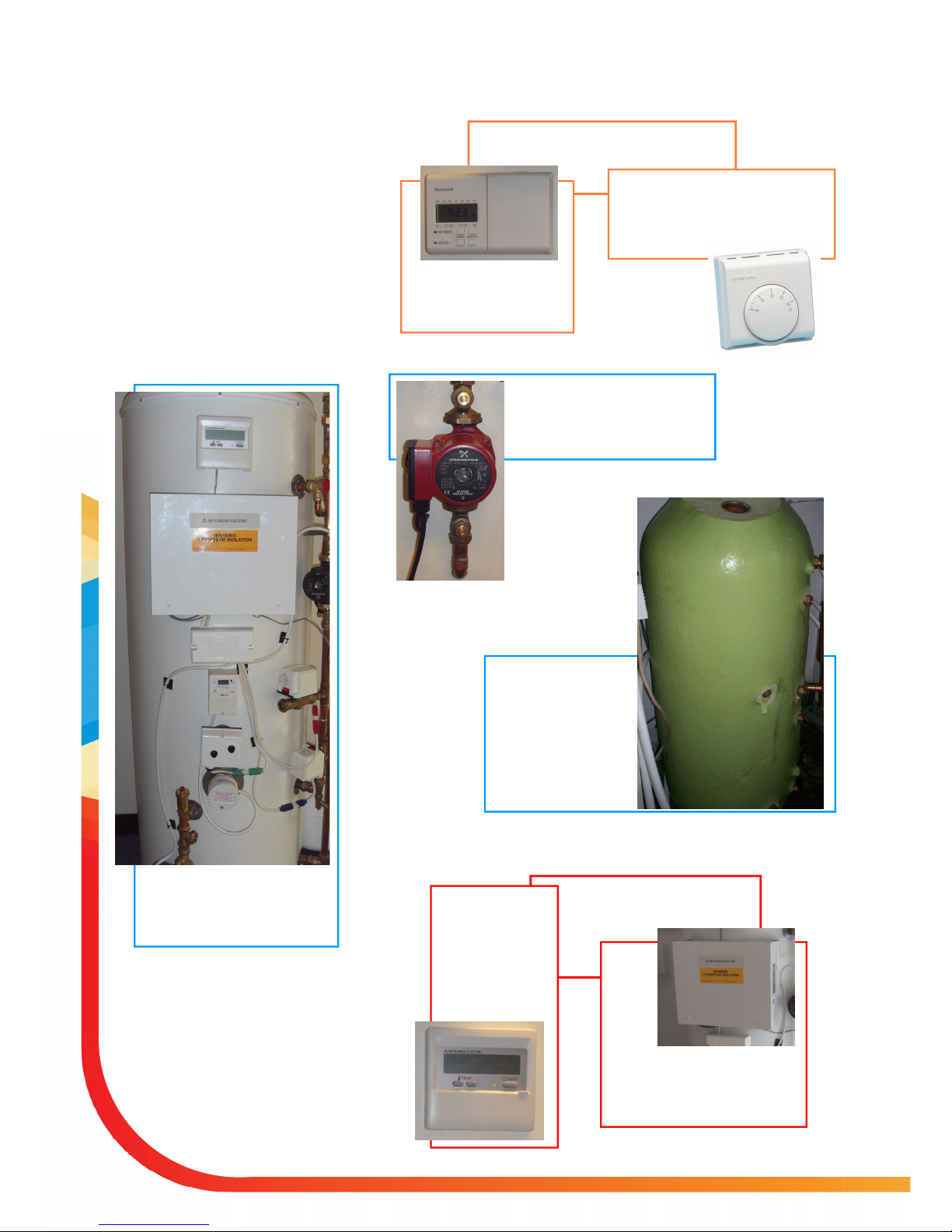

Hot water tank:

Within this tank the

water is heated via a

coil positioned inside,

the heated water leaves

the top of the tank for

showers, baths and

taps.

Pump:

This moves the flow of heated

water from the Ecodan® to the

heating system and hot water tank.

Controls, pumps and other components supplied and packaged

together

Component Parts

The installed Ecodan® will include

several key parts. Some of their functions will require human input to control the effect of the unit,

COMPONENT PARTS

Main Home Owner Controls

Room Thermostat:

Used by homeowner to set the required temperature of the household

Two Channel Timer Clock:

Used by homeowner to set

on/off running periods

Mitsubishi Supplied Parts

PAR-W21MAA:

Controller used

to activate settings on Ecodan®.

These settings are

explained in later

pages.

Flow Temperature Controller::

Within this box is the brains behind the system that allows the

Ecodan® to speak to the boiler

7

Specifications PUHZ-W50VHA-BS

Dimensions (mm) Width 950

Depth 330+30*

Height 740

Weight (kg) 64

Airflow (m3/min) 50

Nominal sound level (dBA) 45 ◊

Low noise mode (dBA) @ 7°C 40

Guaranteed operating range (Outdoor) - 15 ~ +35°C

Electrical Supply 220-240v, 50Hz

Phase Single

Running current (A) [Max] 5.4 [13]

Fuse Rating (A) 16

Heating A2/W35 Capacity (kW) 5.0

COP 3.13

Power Input (kW) 1.6

Nominal Flow Rate (L/min) 14.3

Heating A7/W35 Capacity (kW) 5.0

COP 4.1

Power Input (kW) 1.22

Nominal Flow Rate (L/min) 14.3

Primary Flow Rate Maximum (L/min) 25.8

Minimum (L/min) 10

PUHZ-W50VHA-BS

SPECIFICATION

Nominal Conditions A2 / W35 A7 / W35

Outside air temperature (humid) 1°C 6°C

Water temperature (inlet/outlet) 30 / 35°C 30 / 35°C

* Grille

◊ At distance of 1m from the outdoor unit

Outside air temperature (dry) 2°C 7°C

Loading...

Loading...