Page 1

Air Conditioning Control System

Centralized Controller

AE-200A/AE-50A/EW-50A

AE-200E/AE-50E/EW-50E

–Web Browser for Initial Settings–

Contents

1. Introduction ...................................................................................2

1-1. Terms Used in This Manual ..............................................................2

1-2. PC Requirements .............................................................................2

1-3. Notes on using the integrated centralized control software

TG-2000A ........................................................................................2

2. Setting the Operating Environment ..............................................3

2-1. Setting the IP Address of the PC ......................................................3

2-2. Setting the Web Browser ..................................................................5

2-3. Java settings ....................................................................................8

3. Logging in to the Web Browser for Initial Settings ......................10

4. Initial Settings .............................................................................14

4-1. Date and Time ................................................................................15

4-2. Basic System..................................................................................16

4-3. Groups............................................................................................25

4-4. Interlocked LOSSNAY ....................................................................28

4-5. Blocks .............................................................................................29

5. Functions 1 .................................................................................30

5-1. E-Mail .............................................................................................30

5-2. Peak Cut (Energy-save control function) .......................................34

5-3. Measurement .................................................................................43

5-4. Energy Management Settings ........................................................47

6. Functions 2 .................................................................................49

6-1. Set Temperature Range Limit .........................................................49

6-2. Night Mode (quiet operation) Schedule ..........................................50

6-3. System-changeover .......................................................................51

7. Functions 3 .................................................................................52

7-1. External Temperature Interlock ......................................................52

7-2. Night Setback Control ....................................................................54

7-3. Interlock control ..............................................................................56

7-4. AHC Port Name Settings ................................................................65

8. User Settings ..............................................................................66

9. Utility ...........................................................................................68

9-1. Back up/import settings data ..........................................................68

10. License registration for optional functions ..................................70

1 1. Software update .........................................................................71

11-1. Preparation ...................................................................................71

11-2. Update procedures .......................................................................73

12. Notes on connecting to Web browser ........................................75

12-1. Clearing cache .............................................................................75

12-2. Resetting Internet Explorer ..........................................................77

Appendix: Added functions in Ver. 7.20 ...........................................78

Instruction Book

Before using the controller, please read this Instruction Book carefully to ensure proper operation.

Retain this manual for future reference.

Page 2

1. Introduction

This Instruction Book explains how to make initial settings for the AE-200A/AE-50A/EW-50A and

AE-200E/AE-50E/EW-50E using a Web browser.

Note: Initial settings for the connected AE-50A/EW-50A or AE-50E/EW-50E cannot be made on the AE-200A/AE-200E Web

1-1. Terms Used in This Manual

- “Centralized Controller AE-200A/AE-200E” is referred to as “AE-200.”

- “Centralized Controller AE-50A/AE-50E” is referred to as “AE-50.”

- “Centralized Controller EW-50A/EW-50E” is referred to as “EW-50.”

- “Booster unit” and “Water HEX unit” are referred to as “Air To Water (PWFY) unit.”

- “Advanced HVAC CONTROLLER” is referred to as “AHC.”

- “Hot Water Heat Pump unit” is referred to as “HWHP (CAHV, CRHV) unit.”

- A PI controller that is built-in on AE-200/AE-50/EW-50 is referred to as “Built-in PI controller.”

- Screen images used in this manual are from Windows 7

Note: Windows is a registered trademark or trademark of Microsoft Corporation in the United States and other countries.

1-2. PC Requirements

CPU 1 GHz or faster

Memory 512 MB or more

Screen resolution 1366 x 768 or higher recommended

Browser

On-board LAN port or LAN card 100 BASE-TX

Pointing device e.g., mouse

Note: Microsoft is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

Note: Although no particular OS is required, the Web browser will not properly operate when it is started up from the Internet

browser, and must be made on each AE-50A/EW-50A or AE-50E/EW-50E Web browser respectively.

®

and Internet Explorer 9.0.

Table 1-1 PC Requirements

Item Requirement

®

Microsoft

Microsoft

Microsoft

Microsoft

* Java execution environment is required.

(Verified to run on Oracle

* Install Oracle

using a 64-bit OS, install a 32-bit and a 64-bit Java Plug-in.

* The version of the Oracle

Control Panel.

Oracle and Java are trademarks or registered trademarks of Oracle Inc. in the United States and/or other countries.

Explorer on the Windows 8.1 start screen. If the Web browser was started up on the start screen, close the Web browser and

switch the screen to the desktop screen, and then start up the Web browser again. Refer to the help functions of Windows 8.1

for how to switch the screens.

Internet Explorer 8.0

®

Internet Explorer 9.0

®

Internet Explorer 10.0

®

Internet Explorer 11.0

®

®

Java Plug-in that is appropriate for your operating system. When

Java Plug-in Ver. 1.8.0_25)

®

Java Plug-in can be verified by clicking [Java] in the

Start screen Desktop screen

1-3. Notes on using the integrated centralized control software TG-2000A

If the system is connected to a TG-2000A, make or change all settings from the TG-2000A so that the data in the

TG-2000A and AE-200/AE-50/EW-50 will match.

Note: Use TG-2000A Ver. 6.60 or later.

WT07138X02

2

Page 3

2. Setting the Operating Environment

This chapter explains how to make PC settings and Web browser settings to monitor and operate the air

conditioning units.

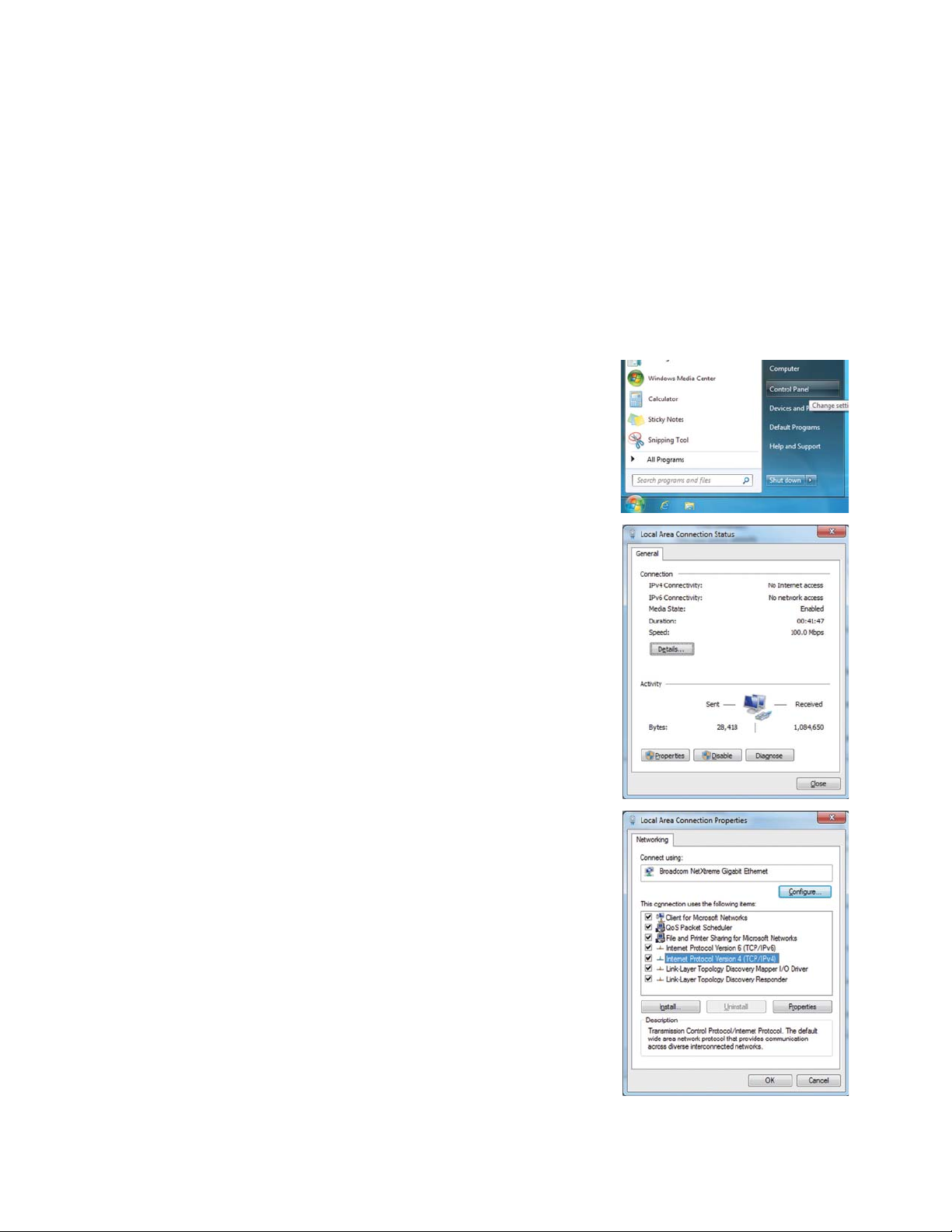

2-1. Setting the IP Address of the PC

Follow the instructions below to set the PC’s IP address for the Web browser to recognize the

AE-200/AE-50/EW-50 unit.

The PC’s IP address must have the same network address as the AE-200/AE-50/EW-50’s IP address.

(i.e., AE-200’s IP address: [192.168.1.1], PC’s IP address: [192.168.1.101])

When connecting an AE-200/AE-50/EW-50 to an existing LAN, consult the system administrator to decide the IP

addresses.

Note: When using an AE-200/AE-50/EW-50-dedicated LAN, it is recommended that the AE-200 unit and the EW-50 unit (only

(1)

(2)

when used alone) be assigned an IP address between the range [192.168.1.1] and [192.168.1.40], the AE-50/EW-50 unit

be assigned an IP address between the range [192.168.1.211] and [192.168.1.249], and that the PC connected to the

AE-200/AE-50/EW-50 be assigned an IP address between the range [192.168.1.101] and [192.168.1.150].

Click [Control Panel] in the Start menu.

Click [Network and Sharing Center]>[Local Area Setting].

In the [Local Area Connection Status] window, click [Properties].

(3)

Click [Internet Protocol Version 4 (TCP/IPv4)] to select it, and click

[Properties].

WT07138X02

3

Page 4

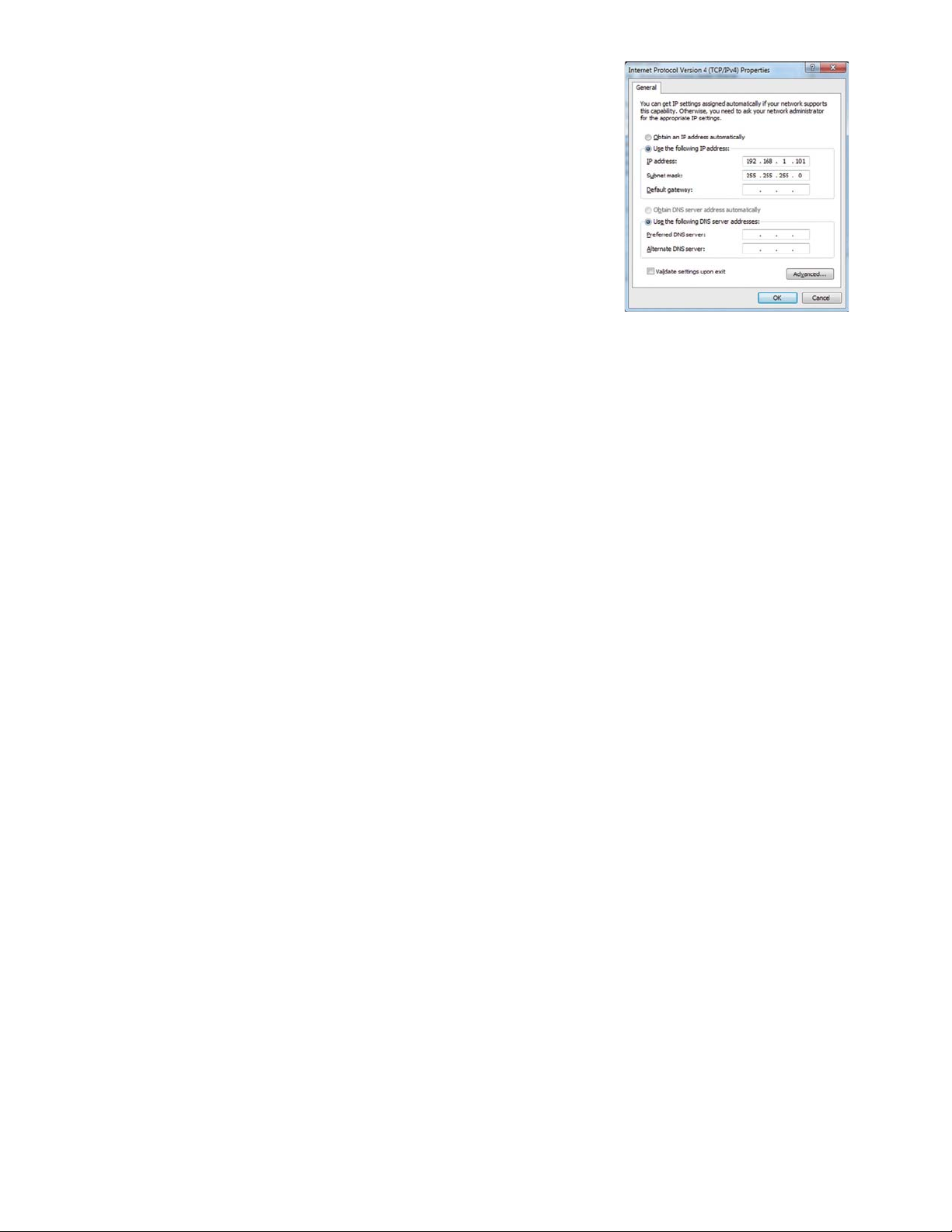

(4)

In the [Internet Protocol Version 4 (TCP/IPv4) Properties] window,

check the radio button next to [Use the following IP address].

Enter the PC’s IP address (e.g., [192.168.1.101]) in the [IP address]

field, and enter the subnet mask [255.255.255.0] (unless otherwise

specified) in the [Subnet mask] field.

In the [Default gateway] field, enter the gateway address as

necessary. (Refer to section 4-2-5 for details.)

Note: Consult the system administrator to decide the IP, subnet mask, and

(5)

Keep clicking [OK] or [Close] to close all windows.

gateway addresses.

WT07138X02

4

Page 5

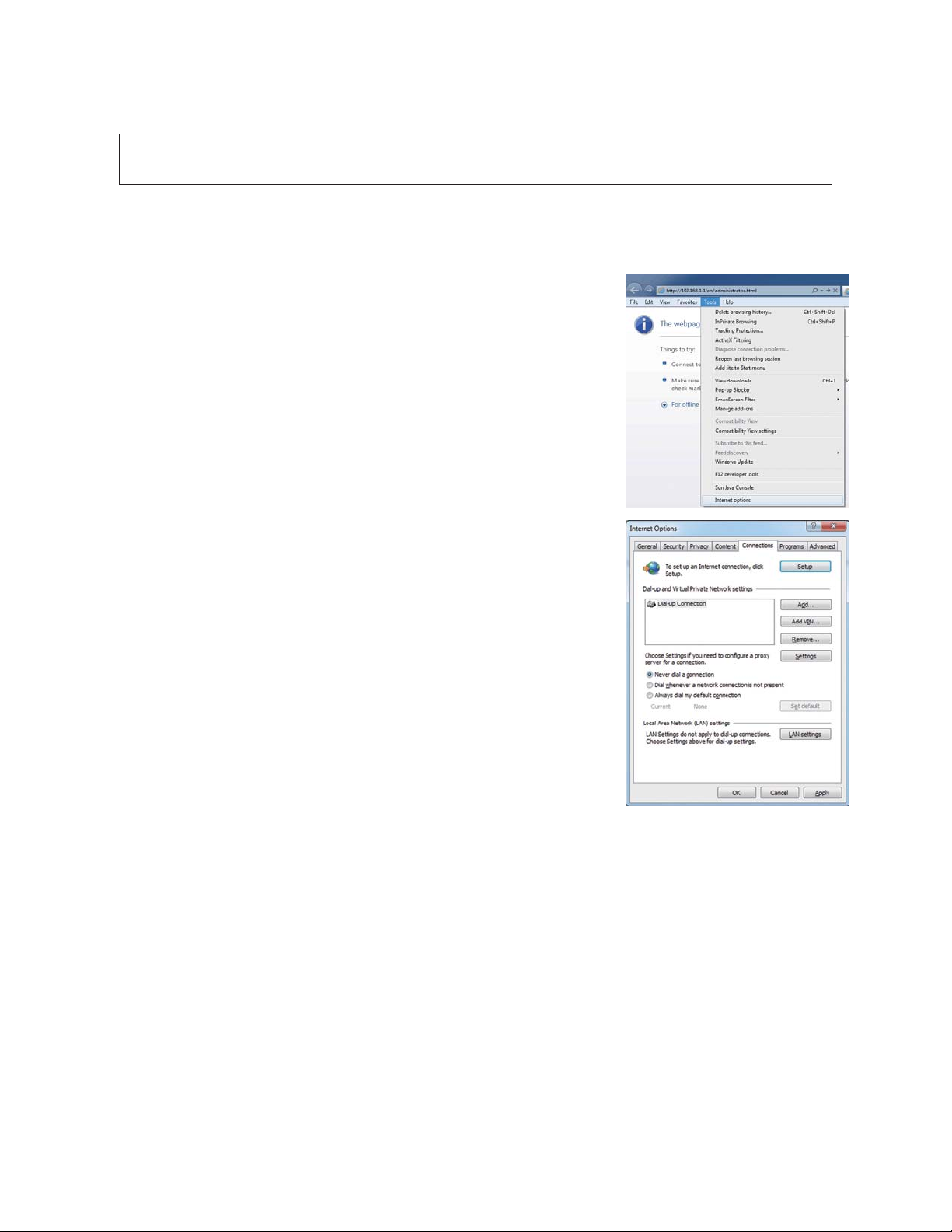

2-2. Setting the Web Browser

Web browser setting varies with the Internet connection type. See the sections below for how to make Web

browser settings for different types of Internet connection.

To prevent unauthorized access, always use a security device such as a VPN router when

connecting the AE-200/AE-50/EW-50 to the Internet.

2-2-1. No Internet connection

To monitor and operate the air conditioning units from a PC with no Internet connection, follow the instructions

below to set the environment for the Web browser.

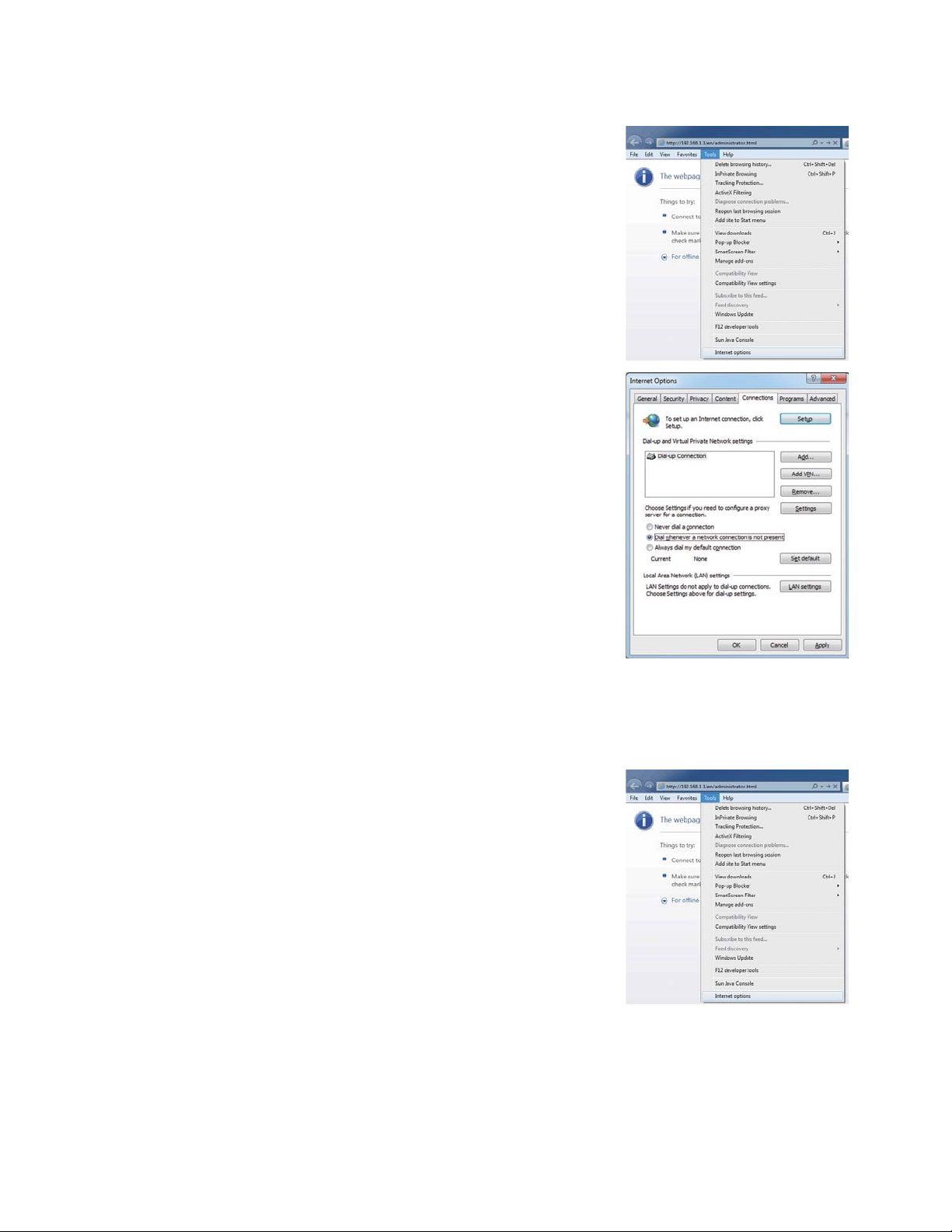

(1)

Click [Tools] in the menu bar, then click [Internet options].

(2)

In the [Internet Options] window, click the [Connections] tab.

(3)

Check the radio button next to [Never dial a connection] in the middle

of the window, and click [OK] to close the window.

WT07138X02

5

Page 6

2-2-2. Dial-up Internet connection

To monitor and operate the air conditioning units from a PC that connects to the Internet through a dial-up

connection, follow the instructions below to set the environment for the Web browser.

(1)

Click [Tools] in the menu bar, then click [Internet options].

(2)

In the [Internet Options] window, click the [Connections] tab.

(3)

Check the radio button next to [Dial whenever a network connection

is not present] in the middle of the window, and click [OK] to close the

window.

By making these settings, a message will appear asking whether

or not to use a dial-up connection when an Internet connection is

necessary. Follow the message to connect to the Internet.

2-2-3. Connecting to the Internet via proxy server using an existing LAN

To monitor and operate the air conditioning units from a PC that connects to the Internet through a proxy server

by connecting to an existing LAN, such as a LAN within your company, follow the instructions below to set the

environment for the Web browser.

(1)

Click [Tools] in the menu bar, then click [Internet options].

WT07138X02

6

Page 7

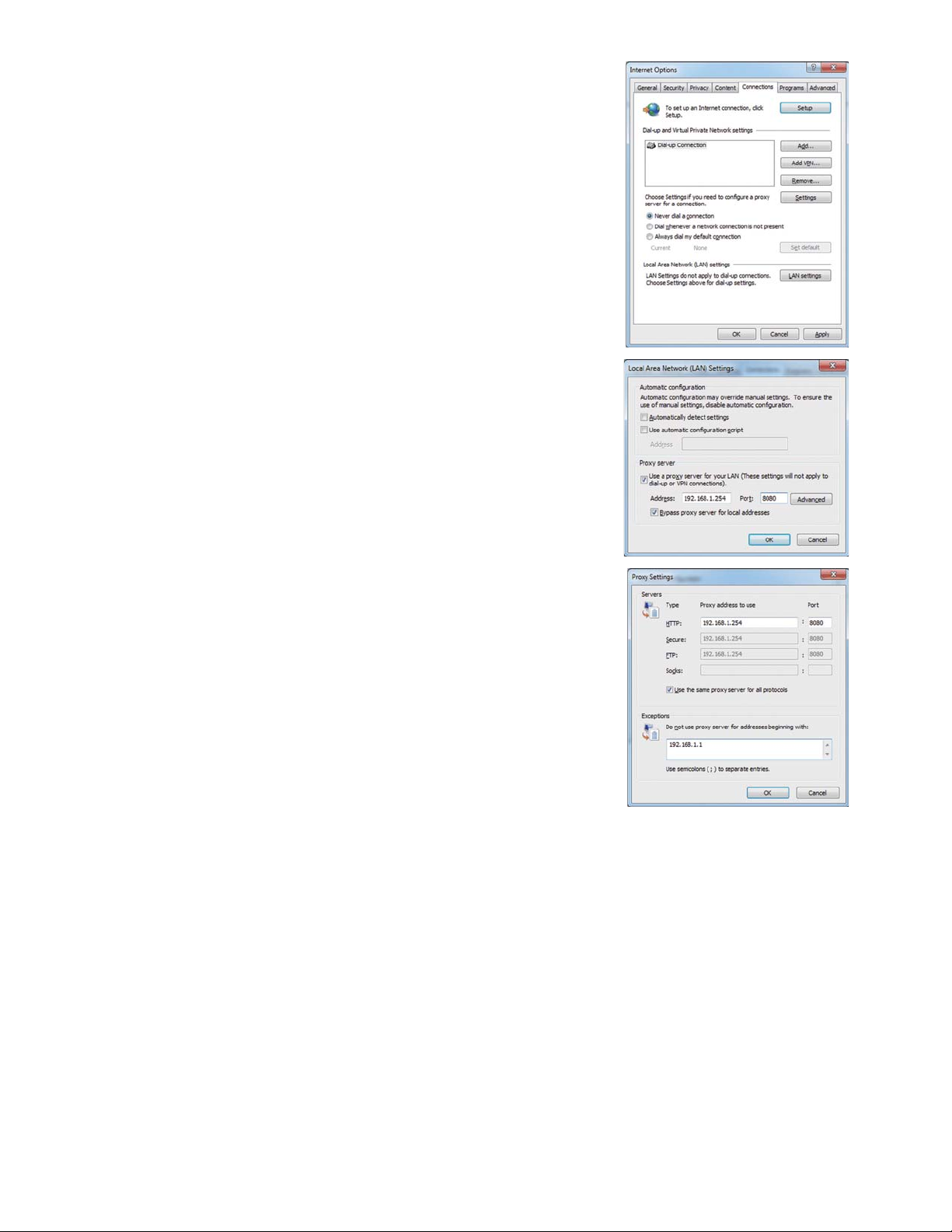

(2)

In the [Internet Options] window, click the [Connections] tab.

(3)

Check the radio button next to [Never dial a connection] in the middle

of the window.

(4)

Click [LAN settings] under [Local Area Network (LAN) settings].

(5)

In the [Local Area Network (LAN) Settings] window, check [Bypass

proxy server for local addresses], and click [Advanced].

(6)

In the [Proxy Settings] window, enter the AE-200/AE-50/EW-50’s

IP address (e.g., 192.168.1.1) in the [Exceptions] field. Then, keep

clicking [OK] or [Close] to close all windows.

If connecting multiple AE-200/AE-50/EW-50 units, enter their

addresses (e.g., [192.168.1.1; 192.168.1.2]). It is also possible to use

an asterisk as a wildcard (e.g., [192.168.1.*]).

WT07138X02

7

Page 8

2-3. Java settings

2-3-1. How to register exception site list

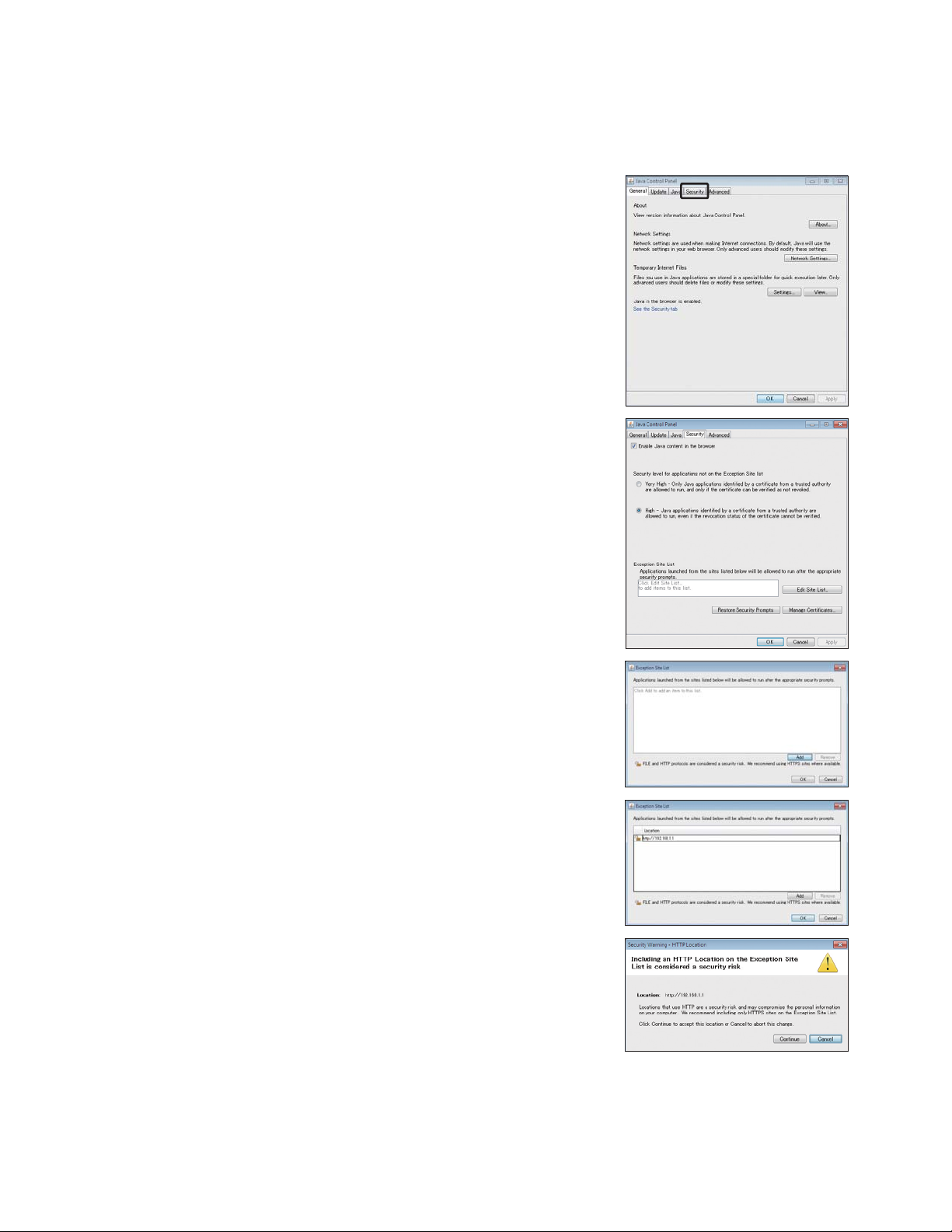

(1)

Click [Control Panel]>[Java].

Note: If [Category] is selected in the top right corner, next to [View by:], change it to [Large icons] or [Small icons].

(2)

Java Control Panel will open.

Click the [Security] tab.

(3)

The security setting window will open.

Click the [Edit Site List...] button.

(4)

The [Exception Site List] dialog will appear.

Click [Add].

(5)

The [Exception Site List] dialog will appear.

In the white box, enter the following, and then click [OK].

http://[IP address of AE-200, AE-50, or EW-50]

Note: If the IP address of the AE-200 is [192.168.1.1], enter

Note: When using HTTPS (SSL) connection, prefix the web address with

(6)

The security warning screen will appear.

[http: //192.168.1.1].

[https]. (https: //[IP address of AE-200, AE-50, or EW-50])

Click [Continue].

Note: The security warning screen will not appear when HTTPS (SSL)

connection is used.

WT07138X02

8

Page 9

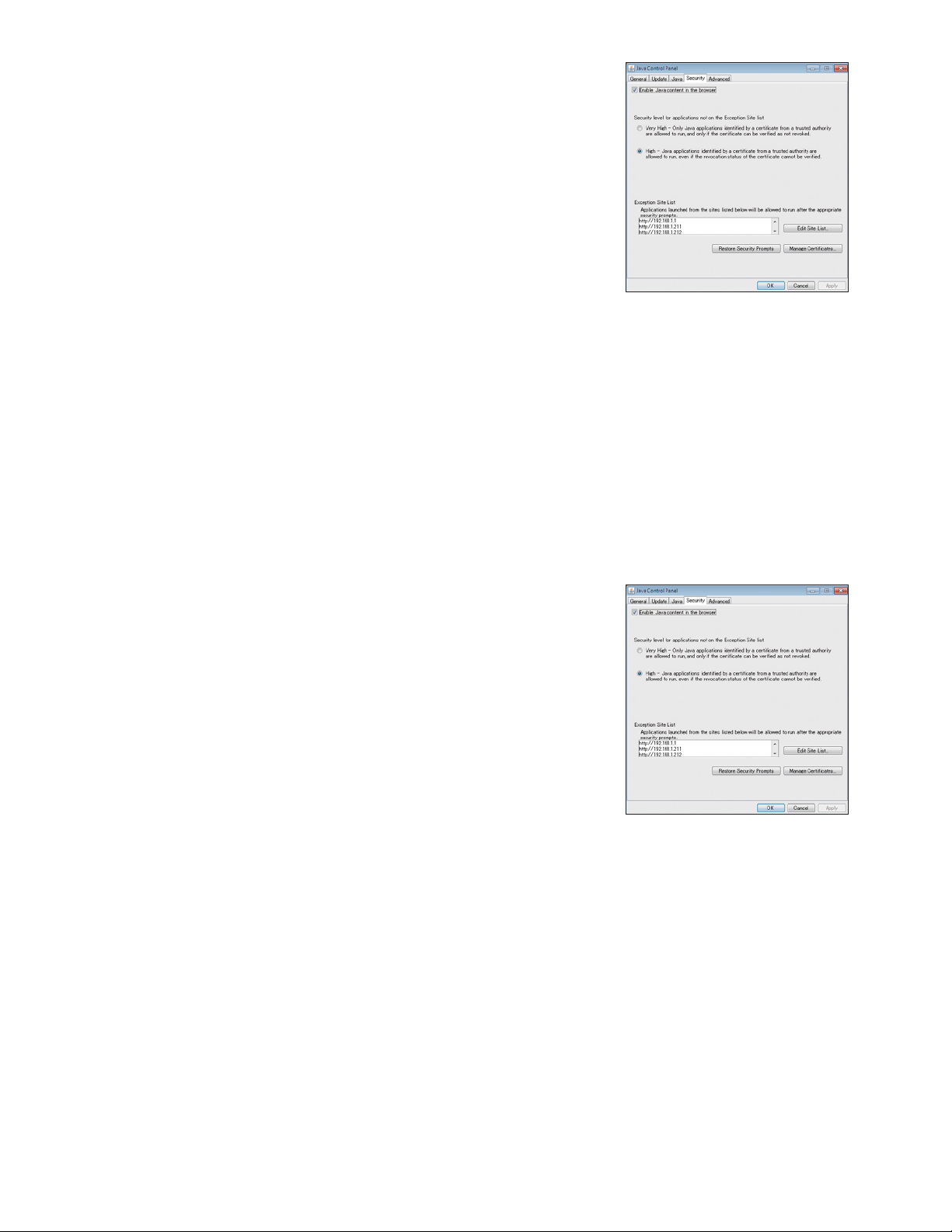

(7)

Add all AE-200/AE-50/EW-50 to the list in the same manner, and

click [OK].

(8)

If a PC with 32-bit OS is used, after completing the settings, close all Internet Explorer windows, and access

the Web page again to make sure the appropriate window will appear.

If a PC with 64-bit OS is used, go to step (9) below.

(9)

Click [My Computer]>[Local Disk (C:)]>[Program Files (x86)]

*1

>[Java]>[jre*] (The asterisk indicates a version

number. (i.e., jre1.8.0_31))>[bin] to open the [bin] folder.

*1 If a PC with 64-bit OS is used, both [Program Files] and [Program Files (x86)] folders will appear. Make sure to select [Program

Files (x86)].

(10)

Double click the “javacpl.exe” file in the [bin] folder.

(11)

Java Control Panel will open. Follow the steps (3) through (8) again.

2-3-2. How to enable Java content

(1)

Open the security setting window. (See section 2-3-1 “How to register exception site list”.)

(2)

Click on the checkbox next to [Enable Java content in the browser]

unless it is already checked.

Click [Apply] at the right bottom corner of the screen, and then click

[OK].

(3)

After completing the settings, close all Internet Explorer windows, and access the Web page again to make

sure the appropriate window will appear.

WT07138X02

9

Page 10

3. Logging in to the Web Browser for Initial Settings

(1)

Enter the web page address in the address field of the Web browser as follows:

http://[IP address of each AE-200, AE-50, or EW-50]/init/administrator.html

Press the [Enter] key. A login screen will appear.

Note: If the IP address of the AE-200/AE-50/EW-50 is [192.168.1.1],

Note: Default IP address of AE-200, AE-50, and EW-50 is

Note: When one or more AE-50/EW-50 controllers are connected, log

Note: If the login screen does not appear then take the steps explained

Note: The web page will be displayed in the same language as the operating system on the PC.

the web page address is [http: //192.168.1.1/init/administrator.

html].

[192.168.1.1].

When one or more AE-50/EW-50 controllers are connected,

none of their IP addresses should overlap. The recommended IP

address ranges are as follows.

AE-200: Between [192.168.1.1] and [192.168.1.40]

AE-50/EW-50 (when used for system expansion):

Between [192.168.1.211] and [192.168.1.249]

EW-50 (when used alone):

Between [192.168.1.1] and [192.168.1.40]

Refer to section 4-2 “Basic System” for how to change the IP

addresses.

in to all AE-200, AE-50, and EW-50 Web browsers to make initial

settings for AE-200, AE-50 and EW-50 respectively. The Web

browser cannot be switched among the AE-200, AE-50, and

EW-50.

in chapter 12 to delete the temporary files.

The web page can be displayed in other languages by entering the web page address as follows:

Chinese http://[IP address of each AE-200, AE-50, or EW-50]/init/zh/administrator.html

English http://[IP address of each AE-200, AE-50, or EW-50]/init/en/administrator.html

French http://[IP address of each AE-200, AE-50, or EW-50]/init/fr/administrator.html

German http://[IP address of each AE-200, AE-50, or EW-50]/init/de/administrator.html

Italian http://[IP address of each AE-200, AE-50, or EW-50]/init/it/administrator.html

Japanese http://[IP address of each AE-200, AE-50, or EW-50]/init/ja/administrator.html

Portuguese http://[IP address of each AE-200, AE-50, or EW-50]/init/pt/administrator.html

Russian http://[IP address of each AE-200, AE-50, or EW-50]/init/ru/administrator.html

Spanish http://[IP address of each AE-200, AE-50, or EW-50]/init/es/administrator.html

Note: You can add the web page address to your Favorites on the login screen for easy access in the future.

WT07138X02

10

Page 11

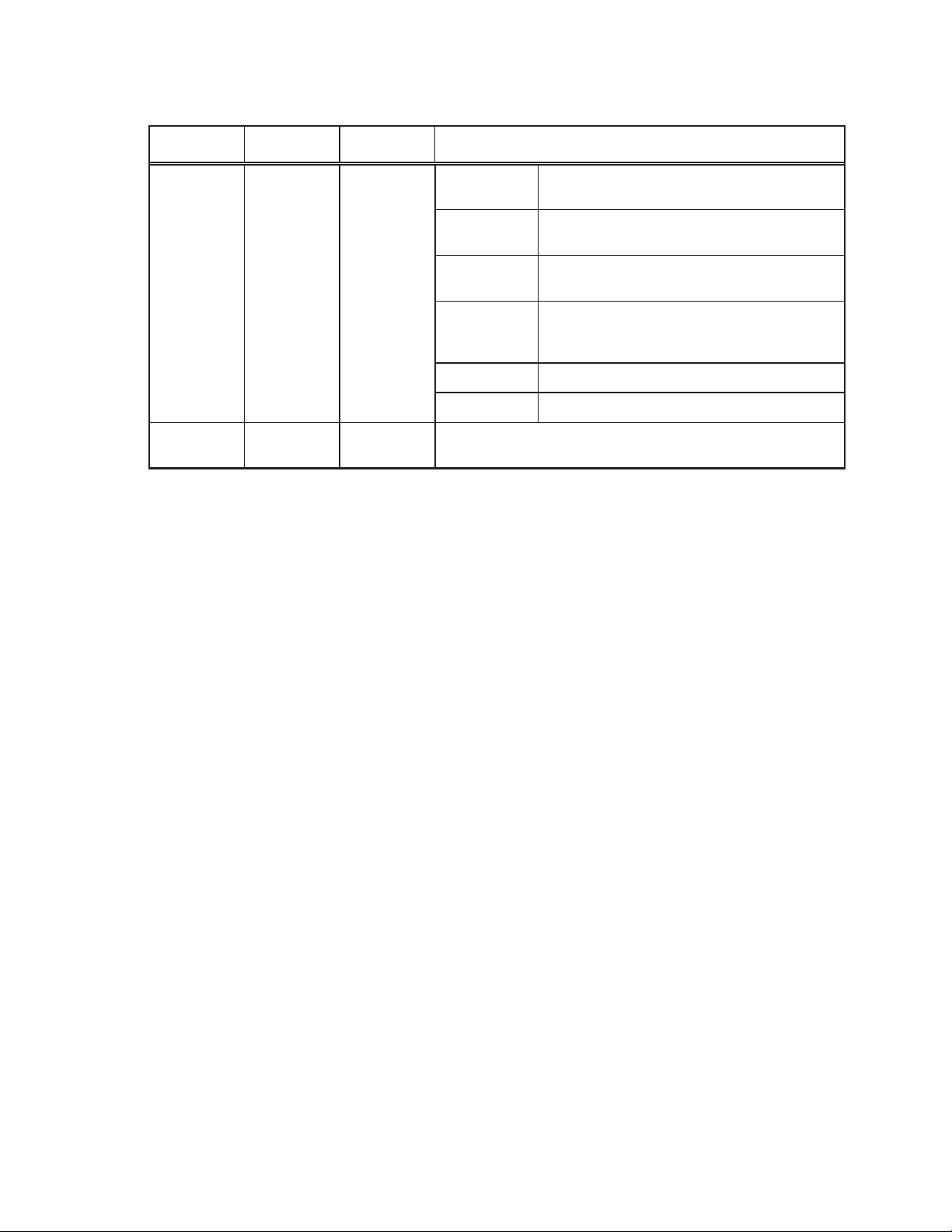

(2)

Enter the user name and the password in the login screen, and click [Login]. A setting screen will appear.

The table below shows the default user names, passwords, and functions that are available for maintenance

users and building managers.

User

Maintenance

user

Default

user name

initial init

Default

password

Initial Settings

Functions 1

Functions 2

Available functions

Date and Time, Basic System, Groups,

Interlocked LOSSNAY, Blocks

E-Mail, Peak Cut, Measurement,

Energy Management Settings

Set Temperature Range Limit,

Night Mode Schedule, System-changeover

External Temperature Interlock,

Functions 3

Night Setback Control, Interlock control,

AHC Port Name Settings

User Settings User Settings

Utility Back up/import settings data

Building

manager

Note: A building manager will use the same user name and password for the Web Browser for System Maintenance Engineer.

Note: A maintenance user can specify the functions to be made available for building managers. Refer to chapter 8 “User

Settings” for details.

Note: It is recommended to change the default user name and password so that the users other than the maintenance users

and building managers will not be able to change the settings.

Note: When one or more AE-50/EW-50 controllers are connected, log in to all AE-200, AE-50, and EW-50 Web browsers

to make initial settings for AE-200, AE-50, and EW-50 respectively. The Web browser cannot be switched among the

AE-200, AE-50, and EW-50.

administrator admin

Out of the functions listed above, the items to which access rights

have been given on the User Settings screen are available.

WT07138X02

11

Page 12

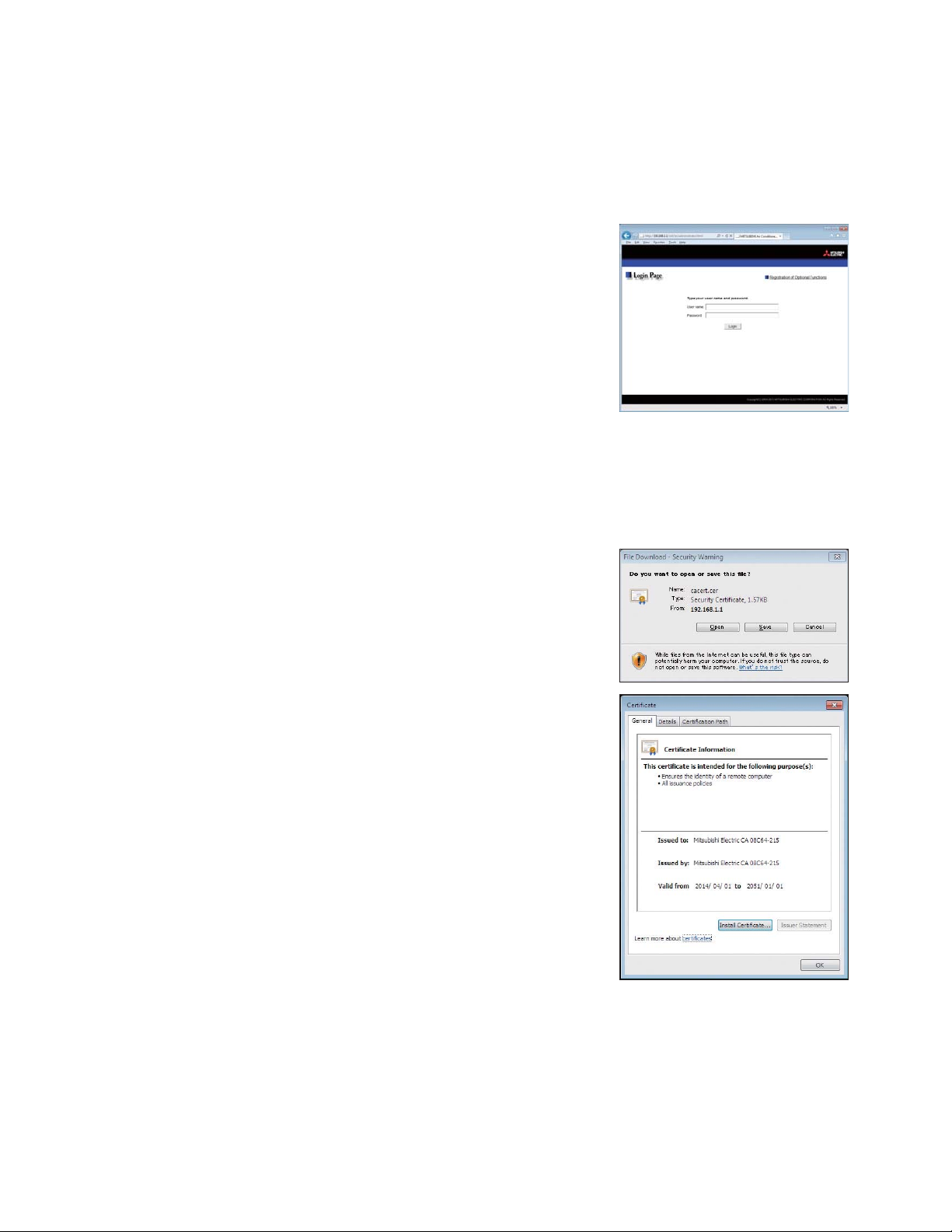

Encrypting the communication data and logging in to the Web browser

(HTTPS connection)

AE-200/AE-50/EW-50 can encrypt communication data using HTTPS (SSL).

When connecting the AE-200/AE-50/EW-50 to the LAN that is accessible to the general public, it is

recommended that the following settings be made so that the units are monitored and controlled on the

encrypted web page.

Note: Depending on the operating system or the Java version, HTTPS encrypted communication may not be enabled properly.

(1)

(2)

If this happens, use an HTTP connection as explained in the previous page.

Prefix the web address with [https], enter the rest of the address, and

press the [Enter] key.

https://[IP address of each AE-200, AE-50, or EW-50]/init/

administrator.html

Note: If the IP address of the AE-200/AE-50/EW-50 is [192.168.1.1], the web page

address is [https: //192.168.1.1/init/administrator.html].

The encrypted data communication will begin, and the Login screen

will appear.

When the first time the Web browser is accessed, a security certificate

error page appears instead of the Login screen. Go to step (2) below.

Enter the following web page address in the address field of the Web browser, and press the [Enter] key:

http://[IP address of each AE-200, AE-50, or EW-50]/cacert.cer

(3)

A notification bar or a window to confirm about file download will

appear.

Click [Open].

(4)

A certificate dialog will appear.

Click [Install Certificate...].

WT07138X02

12

Page 13

(5)

A Certificate Import Wizard window will appear.

Click [Next].

(6)

Choose [Place all certificates in the following store] and click the

[Browse...] button.

Select [Trusted Root Certification Authorities], click [OK], and then

click [Next].

(7)

Click [Finish] on completing the Certificate Import Wizard.

(8)

Click [Yes] on the security warning to install the certificate.

(9)

Certificate import process starts. A window will appear when the import

completes successfully.

Click [OK].

Note: The valid period of the certificate is from April 1st, 2014 to January 1st,

2051. The system date and time of the PC must be within the period.

WT07138X02

13

Page 14

4. Initial Settings

This chapter explains how to set the initial settings on the Web Browser for Initial Settings.

Note: When one or more AE-50/EW-50 controllers are connected, initial settings must be made on each AE-50/EW-50’s Web

Important

Ɣ If the system is connected to a TG-2000A, make or change all settings from the TG-2000A so that the data in the

TG-2000A and AE-200 will match.

Ɣ Any control (such as interlock control or Peak Cut control) between the outdoor and indoor units connected to the AE-200,

AE-50, and EW-50, as well as between the units connected to different AE-50/EW-50 controllers, cannot be performed.

browser. However, only Date and Time settings (section 4-1) and Basic System settings (section 4-2) must be made on

the AE-200 Web browser.

WT07138X02

14

Page 15

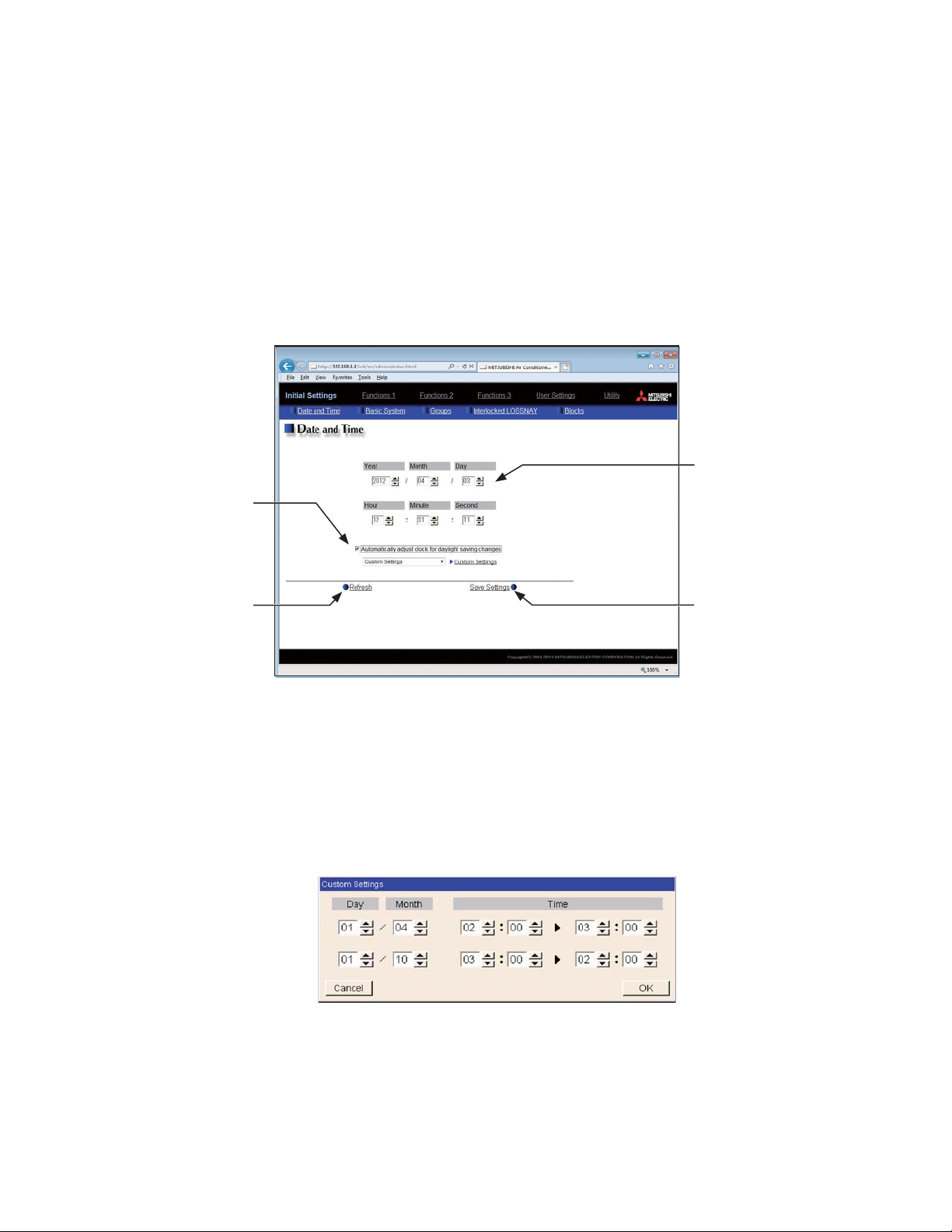

4-1. Date and Time

Click [Initial Settings] in the menu bar, and then click [Date and Time] to access the date and time settings

screen.

Set the current date and time, and then click [Save Settings].

Note: The date and time settings may not be accessible if logged in as a building manager.

Note: The date and time settings made on this screen will be reflected on all the units in the M-NET system, all connected

Note: The date and time cannot be set on this screen if the [Time Master] setting is set to [Sub].

Note: The daylight saving time setting is required only on the AE-200.

Note: Changing the date and/or time when the charging function is in use can affect the calculation of the charges.

Note: When AE-50/EW-50 controller, DIDO controller (PAC-YG66DCA), AI controller (PAC-YG63MCA), or PI controller (PAC-

Note: Although date and time settings can be made on each AE-50/EW-50, the date and time synchronization from AE-200 is

Click to enable the daylight

AE-50/EW-50 units, and the AE-200 units whose [Time Master] setting is set to [Sub].

YG60MCA) is added to the system, set the current date and time on this screen to synchronize the date and time on the

added controller.

performed once a day. Make the date and time settings on the AE-50/EW-50 only after the AE-50/EW-50 is replaced.

Current date and time

Enter the current date and

Daylight saving time

setting

saving time setting.

time.

Click to acquire the current

date and time from the

AE-200/AE-50/EW-50.

(1)

Enter the current date and time.

(2)

To adjust the daylight saving time automatically, check the [Automatically adjust clock for daylight saving

Refresh

Save Settings

Click to save the changes

made.

changes] checkbox, and select the applicable country in the pulldown menu.

If the applicable country is not in the pulldown menu, select [Custom Settings] instead. A [Custom Settings]

button will appear on the right of the pulldown menu.

Click the [Custom Settings] button to open the Custom Settings screen, and configure the daylight saving

time setting.

Custom Settings screen

WT07138X02

15

Page 16

4-2. Basic System

Click [Initial Settings] in the menu bar, and then click [Basic System] to access the Basic System settings screen.

Make necessary basic system settings such as AE-200/AE-50/EW-50 unit settings, network settings, and M-NET

settings, and then click [Save Settings] to send the settings to the AE-200/AE-50/EW-50. A message will appear

asking whether or not to restart the AE-200/AE-50/EW-50. Click [OK] to restart the AE-200/AE-50/EW-50 to

reflect the changes.

Note: The Basic System settings may not be accessible if logged in as a building manager.

M-NET Settings

Set the

AE-200/AE-50/EW-50

M-NET address and range

Unit Settings

Set the

AE-200/AE-50/EW-50 name

and unit ID.

Network Settings

Set the

AE-200/AE-50/EW-50 IP

address and subnet mask.

Display Format

Set the screen display items

for the AE-200/AE-50/EW-50

and the Web browser.

of prohibited controllers.

External Input Setting

Set the

AE-200/AE-50/EW-50

external signal input mode.

Advanced Setting

Click to display the screen

for making advanced

settings.

Click to import the settings

Refresh

from AE-200/AE-50/EW-50.

Save Settings

Click to save the changes

made.

4-2-1. Unit Settings

Follow the instructions below to set the AE-200/AE-50/EW-50 unit name and unit ID in the [Unit Settings] section.

The AE-200/AE-50/EW-50 serial number and software version will appear.

(1) Enter the unit name in the [Name] field in 40 alphanumeric or symbol characters or less. The name entered

here will be used on the screen of the software that controls multiple AE-200/AE-50/EW-50 units and will

also be used as a sender name in the error notification e-mail and e-mail alarm.

Note: The following characters cannot be used in the [Name] field: <, >, &, “, or ‘

(2) Enter the unit ID in the [Unit ID] field in 6 figures. Use this setting to manage the multiple unit IDs. The unit

ID entered here will be used on the screen of the software that controls multiple AE-200/AE-50/EW-50 units

and will also be used as a sender ID in the error notification e-mail and e-mail alarm.

WT07138X02

16

Page 17

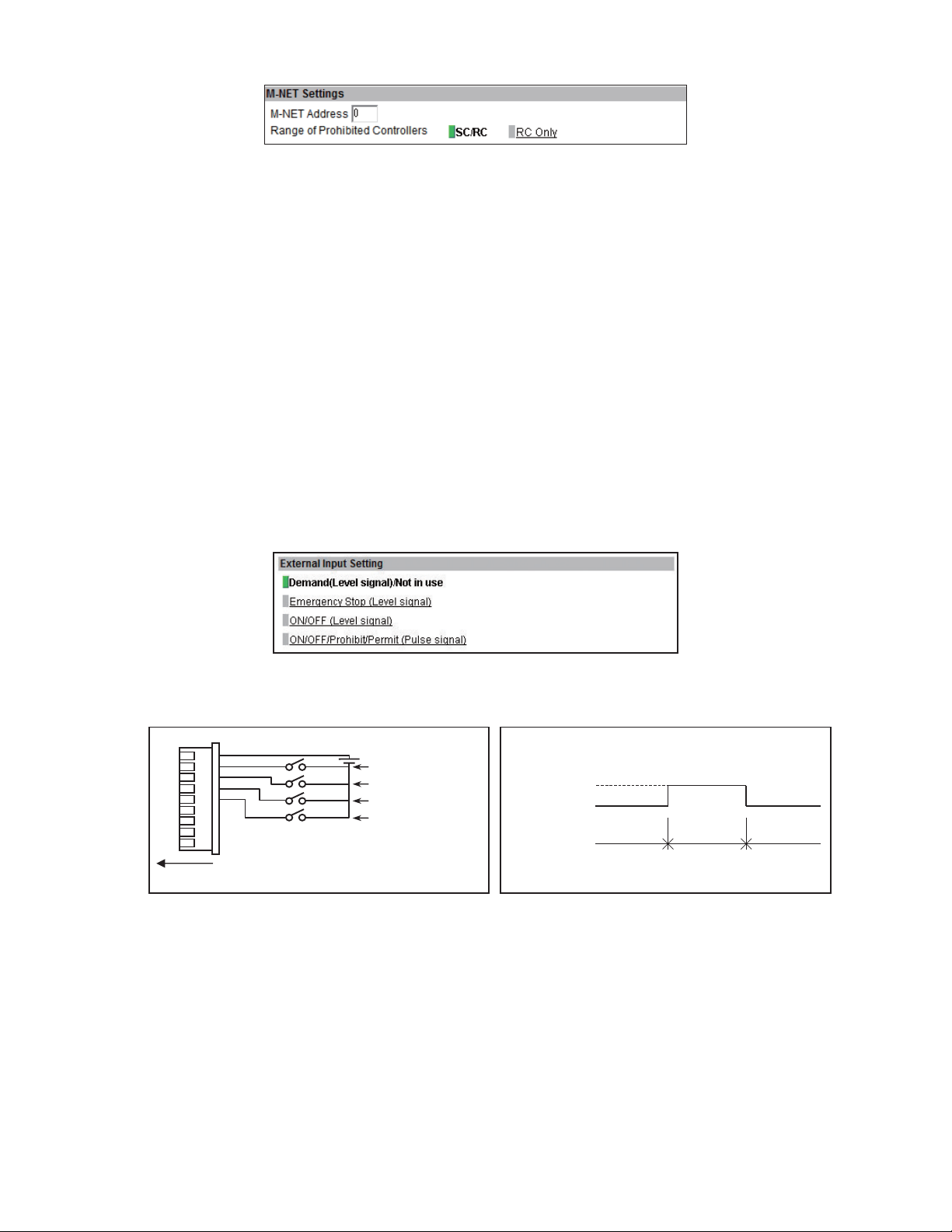

4-2-2. M-NET Settings

(1) Enter [0] in the [M-NET Address] field (unless otherwise specified).

(2) When the local remote controller operation is prohibited on the Web Browser for System Maintenance

Engineer, this setting determines the scope of its applicability. Select [SC/RC] to prohibit the operation from

both the sub system controllers and the remote controllers. Select [RC Only] to prohibit the operation only

from the remote controllers.

4-2-3. External Input Setting

Using the external signal input function, the following types of collective operations can be performed for all

connected air conditioning units: Emergency stop, ON/OFF operation, and Prohibit/Permit local remote controller

operation.

A separately-sold external input/output adapter (PAC-YG10HA-E) is required for each AE-200, AE-50 and EW-50.

Select the external signal input mode, referring to the explanations below.

Note: Peak Cut control is performed based on the demand level signal (level 1 to 4) input from the connected demand

Note: If an external signal is input to the AE-200 only, the collective operations will not be performed for the units connected to

Note: Refer to the AE-200 Installation Manual for details about the external signal input function.

Note: General equipment connected via DIDO controller (PAC-YG66DCA) cannot be collectively run or stopped by using the

controller. (A separate license is required to use the Peak Cut function.)

the AE-50/EW-50 controllers.

external signal input function unless [Emergency Stop (Level signal)] is selected and relevant switches on the DIDO

controller are set.

(1) Select [Demand(Level signal)/Not in use] when using a level signal to receive a demand level or when not

using the external signal input function.

Note: Refer to the AE-200 Installation Manual for details about the demand level.

9

8

7

6

5

4

3

2

1

Connection to AE-200/AE-50/EW-50 (CN5)

12 or 24 VDC

Demand level 4

Demand level 3

Demand level 2

Demand level 1

Contact ON

Contact OFF

Demand

OFF

Demand ONDemand

OFF

WT07138X02

17

Page 18

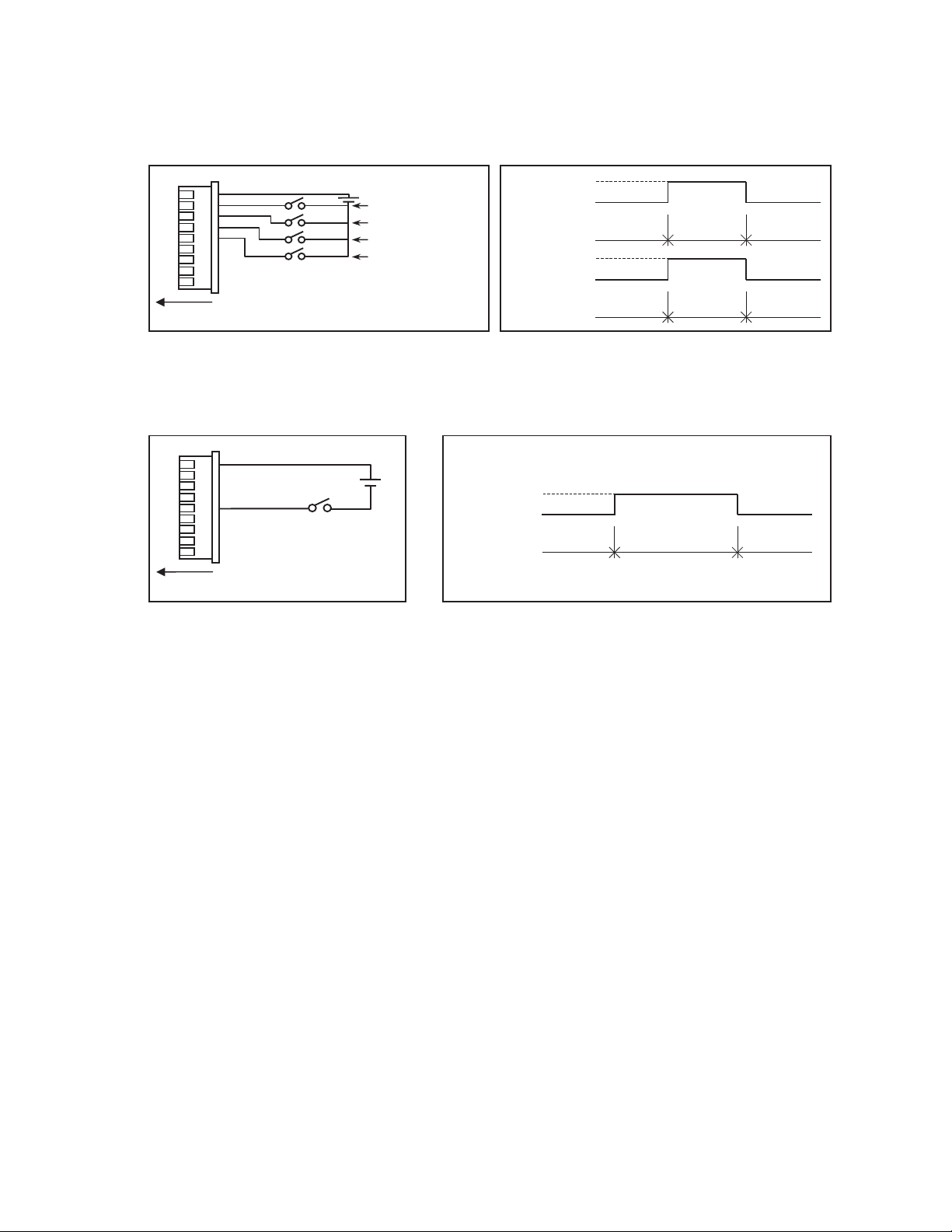

(2) Select [Emergency Stop (Level signal)] when using a level signal to collectively run or stop all the air

conditioning units connected to the AE-200, AE-50, or EW-50 in an emergency. During an emergency stop,

the ON/OFF operation from the local remote controllers will be prohibited, and the ON/OFF operation and

Prohibit/Permit settings on the AE-200, AE-50, or EW-50 will be prohibited.

Note: Refer to the AE-200 Installation Manual for details about the demand level.

12 or 24 VDC

9

8

7

6

5

4

3

2

1

Demand level 4

Demand level 3

Demand level 2

Emergency stop/

Normal operation

Connection to AE-200/AE-50/EW-50 (CN5)

Contact ON

Contact OFF

Contact ON

Contact OFF

Normal

Demand

OFF

Emergency

stop

Normal

Demand ONDemand

OFF

(3) Select [ON/OFF (Level signal)] when using a level signal to collectively run or stop all the air conditioning

units connected to the AE-200, AE-50, or EW-50. The ON/OFF operation from the local remote controllers

will be prohibited, and the ON/OFF operation and Prohibit/Permit settings on the AE-200, AE-50, or EW-50

will be prohibited.

9

8

7

6

5

4

3

2

1

Connection to AE-200/AE-50/EW-50 (CN5)

12 or 24 VDC

ON signal,

OFF signal

Contact ON

Contact OFF

Stop Run Stop

WT07138X02

18

Page 19

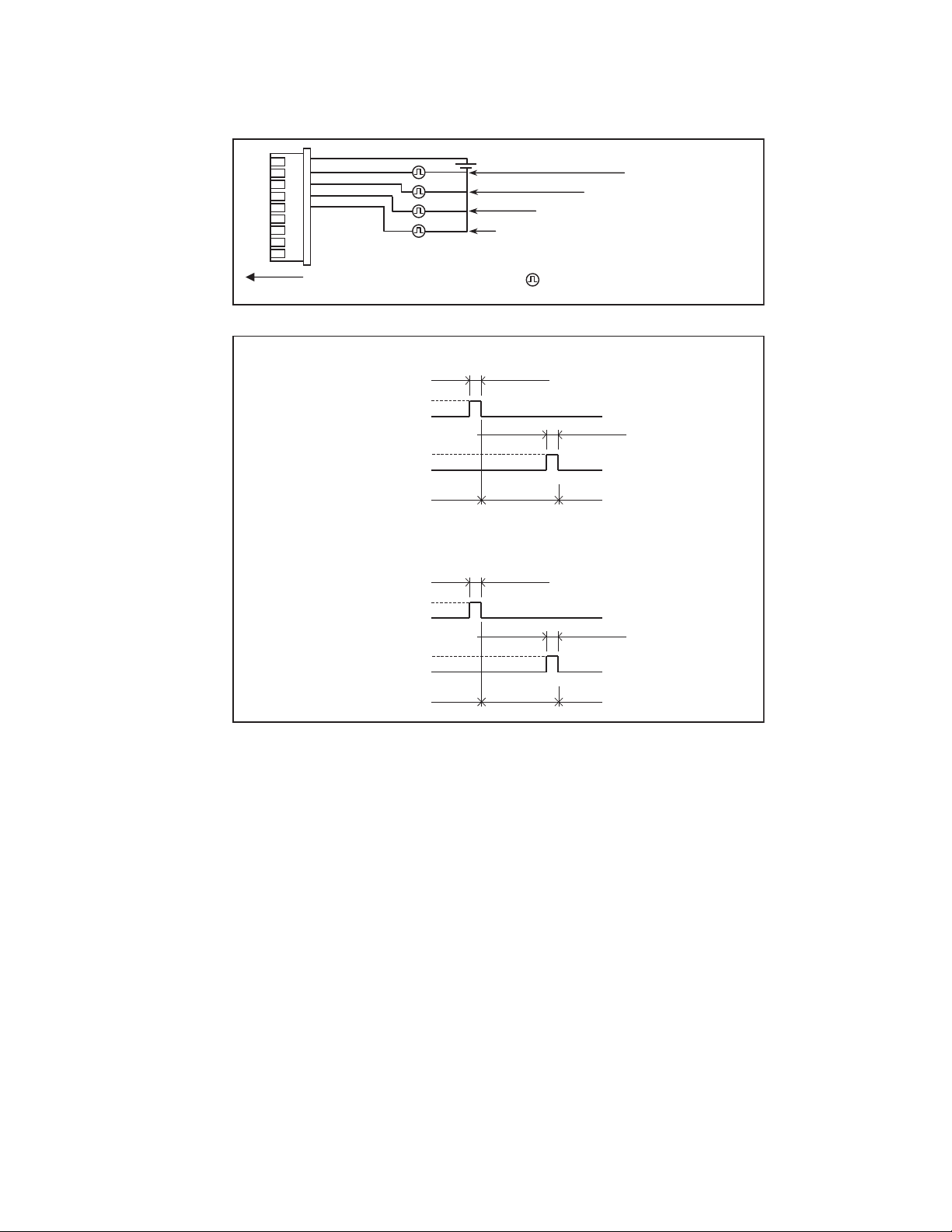

(4) Select [ON/OFF/Prohibit/Permit (Pulse signal)] when using a pulse signal to collectively run or stop all the

air conditioning units connected to the AE-200, AE-50, or EW-50, or to collectively prohibit or permit the

operation from the local remote controllers.

9

8

7

6

5

4

3

2

1

12 or 24 VDC

Connection to AE-200/AE-50/EW-50 (CN5)

(Example) ON/OFF

(ON)

(OFF)

Contact ON

Contact OFF

Contact ON

Contact OFF

Stop Run

(Example) Prohibit/Permit

(Prohibit)

Contact ON

Contact OFF

Permit signal

Prohibit signal

OFF signal

ON signal

: Pulse generator

0.5–1.0 second

0.5–1.0 second

Stop

0.5–1.0 second

0.5–1.0 second

(Permit)

Contact ON

Contact OFF

Permit

Prohibit Permit

WT07138X02

19

Page 20

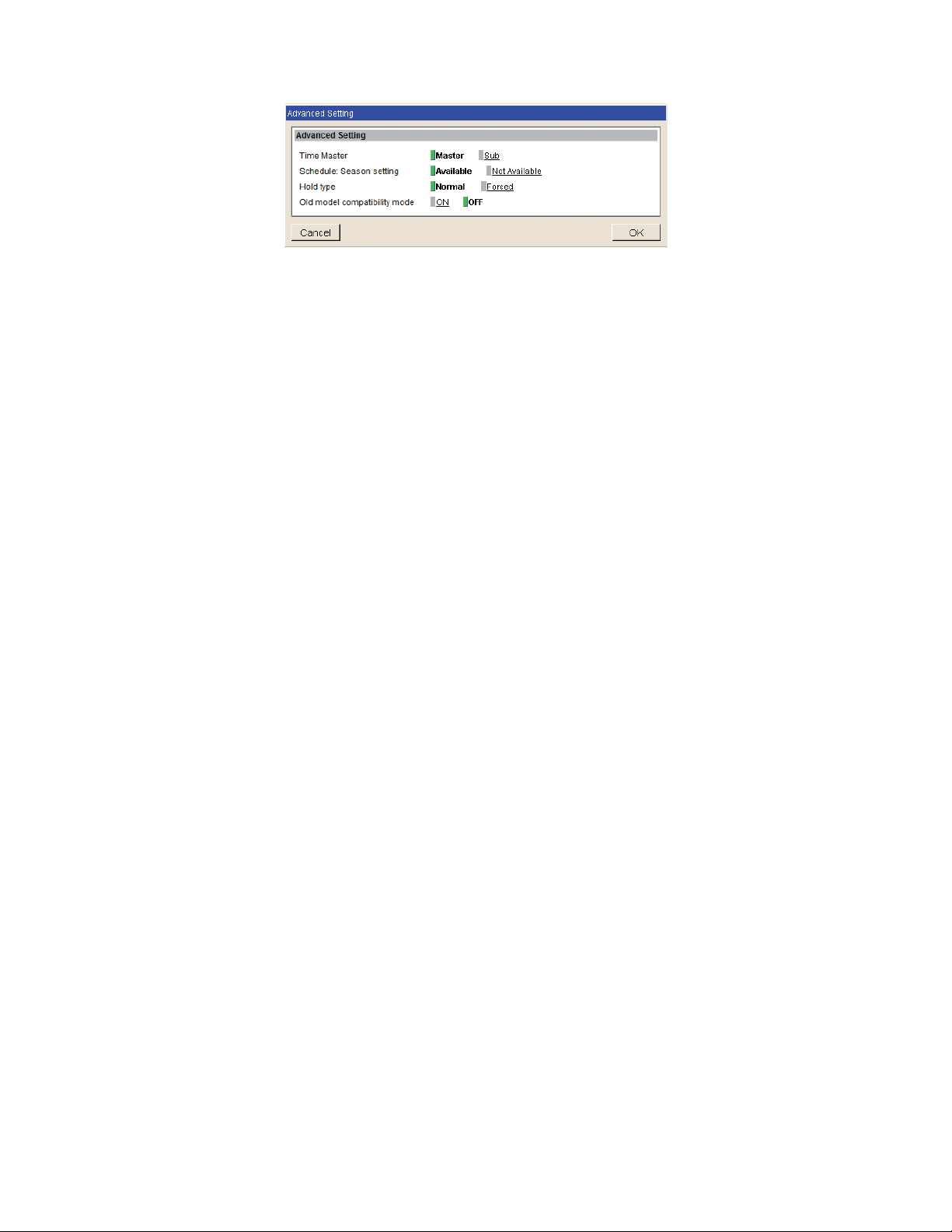

4-2-4. Advanced Setting

4-2-4-1. Time Master/Sub

In the [Time Master] section, select [Master] or [Sub]. The default setting is [Master].

This setting is required to change only for a system with multiple AE-200 controllers. Set to [Master] on only

one of the AE-200 controllers in a system, and set to [Sub] on the rest of the AE-200 controllers. The date and

time synchronization is performed from the AE-200 whose [Time Master] setting is set to [Master] to the AE-200

whose [Time Master] setting is set to [Sub].

Note: When only one AE-200 controller is connected to the system, leave the default setting [Master] as it is.

Note: When multiple AE-50 controllers are connected to the system, leave the default setting [Master] as it is on all AE-50

4-2-4-2. Schedule: Season setting

In the [Schedule: Season setting] section, select [Available] to enable the seasonal settings of the weekly

schedules and [Not Available] to disable. Unless otherwise specified, leave the default setting [Available] as it is.

Note: The settings made on this screen on the AE-200 will be reflected on this screen on the AE-50/EW-50.

controllers.

4-2-4-3. Hold type

In the [Hold type] section, select [Normal] or [Forced].

The Hold function is a function to disable the operations that were scheduled for air conditioning unit groups.

If the setting for [Hold] is set to [ON] on the Condition List screen of the Web Browser for System Maintenance

Engineer and the [Hold type] on the screen above is set to [Forced], the [Hold] setting can be cancelled only

from the AE-200/AE-50/EW-50. If the [Hold type] is set to [Normal], the [Hold] setting can be cancelled from

AE-200/AE-50/EW-50, other system controllers, or remote controllers.

Note: The Hold function can be used on the AE-200A/AE-50A/EW-50A, but not on the AE-200E/AE-50E/EW-50E.

Note: The Hold function cannot be used on general equipments.

Note: The setting [Forced] will not be effective on Air To Water (PWFY) unit groups, LOSSNAY unit groups, and air conditioning

unit groups that do not support the Hold function (i.e., Mr. Slim M-Series/P-Series indoor units).

If the setting for [Hold] is set to [ON] on those unit groups on the Condition List screen and the [Hold type] on the screen

above is set to [Forced], the setting [Normal] will be effective.

4-2-4-4. Old model compatibility mode

In the [Old model compatibility mode] section, select [ON] or [OFF].

Select [ON] when not using the Dual set point function.

When [ON] is selected, the Prohibit Remote Controller function (Timer, Air Direction, Fan Speed) cannot be used.

Note: If the setting is changed, the controller will reboot.

WT07138X02

20

Page 21

4-2-5. Network Settings

Network settings vary depending on whether the AE-200/AE-50/EW-50 is connected to a dedicated LAN or an

existing LAN. See the sections below for how to set the AE-200/AE-50/EW-50 IP, subnet mask, and gateway

addresses in the [Network Settings] section.

Note: Do not use the LAN2 port.

Note: Although the settings for LAN1 (Network Settings) and LAN2 (Network Settings 2) will appear on the screen, only the

Note: After the AE-200 IP address is changed, the AE-50/EW-50 power will be reset.

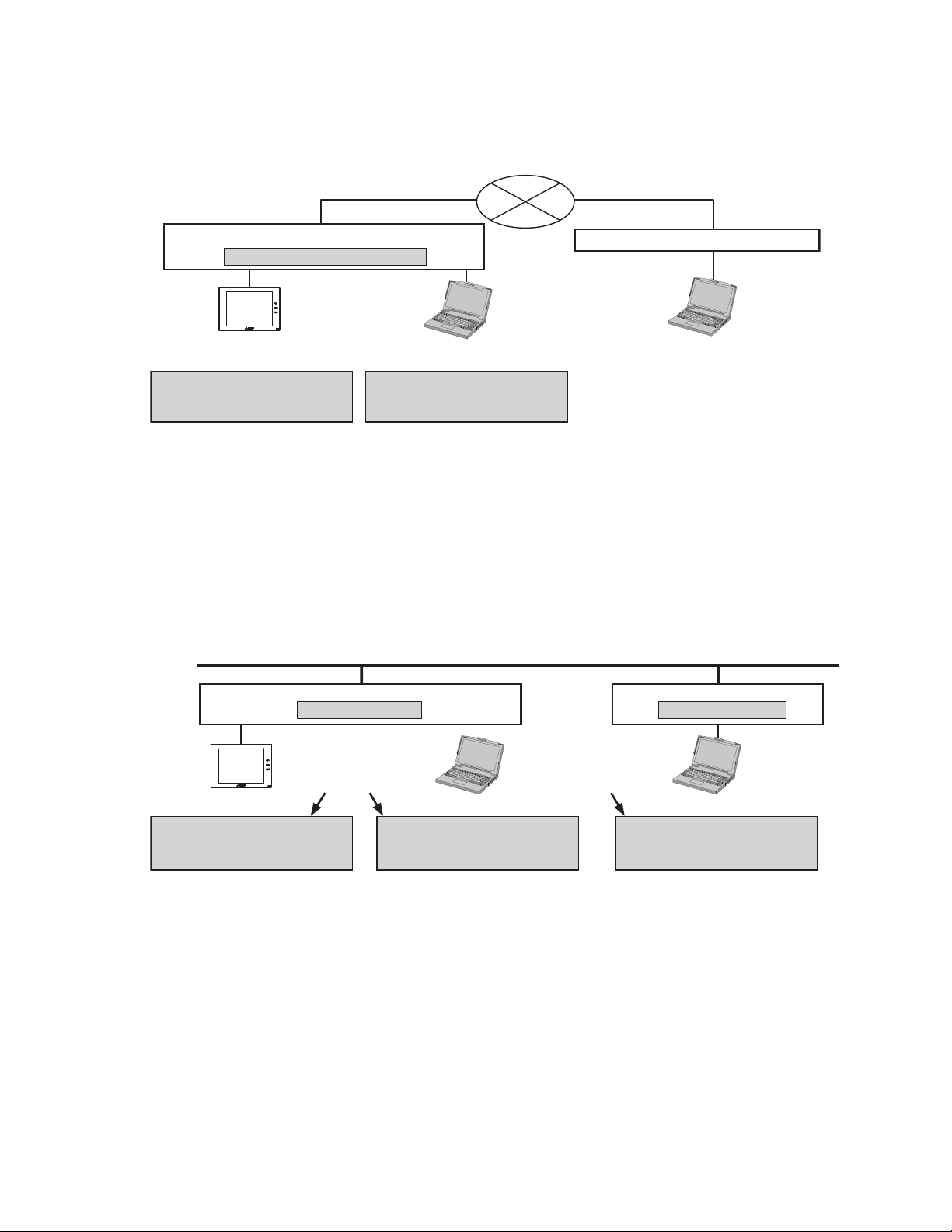

4-2-5-1. Settings for connecting the AE-200/AE-50/EW-50 to a dedicated LAN

(1) Enter the AE-200, AE-50, or EW-50’s IP address in the [IP Address] field. If the LAN has been newly set up,

settings for LAN1 is required. However, only when the LAN1 IP address is required to be set to [192.168.2.1], change the

default LAN2 IP address to avoid address overlap.

allocate IP addresses to the AE-200 units in a sequential order starting with [192.168.1.1]. For example, the

first AE-200 unit will have an IP address of [192.168.1.1], the second AE-200 unit will have an IP address of

[192.168.1.2] and so on.

Allocate IP addresses to the AE-50/EW-50 units in a sequential order starting with [192.168.1.211].

Note: The recommended IP address ranges are as follows.

AE-200: Between [192.168.1.1] and [192.168.1.40]

AE-50/EW-50: Between [192.168.1.211] and [192.168.1.249]

PC: Between [192.168.1.101] and [192.168.1.150]

[IP address setting example]

Hub

100 BASE-TX LAN straight cable

AE-200 AE-50 AE-50

Note: Some hubs have dedicated ports for connection with another hub.

Connect the AE-200/AE-50/EW-50 and PC to the normal ports.

(2) Enter [255.255.255.0] in the [Subnet Mask] field (unless otherwise specified).

PC

192.168.1.101 192.168.1.1 192.168.1.211 192.168.1.212

WT07138X02

21

Page 22

(3) When monitoring the system remotely or using e-mail function via a dial-up router, enter the router IP

address in the [Gateway] field.

Leave the [Gateway] field blank when not connecting a dial-up router.

[Remote Monitoring System example]

Telecommunication Network

Dial-up router

Dial-up router, cellular phone etc.

IP Address: 192.168.1.254

AE-200

PC

IP Address: 192.168.1.1

Subnet Mask: 255.255.255.0

Gateway: 192.168.1.254

Note: [192.168.1.254] is recommended for use as the IP address of the dial-up router. Refer to the dial-up router

instruction manual for details of how to set the IP address.

Note: The use of a dial-up router with no modem requires a modem (for analog or ISDN) to be connected between the

router and the public phone line.

IP Address: 192.168.1.101

Subnet Mask: 255.255.255.0

Gateway: Blank

PC

4-2-5-2. Settings for connecting the AE-200/AE-50/EW-50 to an existing LAN

(1) When connecting the AE-200/AE-50/EW-50 to an existing LAN, consult the system administrator to decide

the IP, subnet mask, and gateway addresses.

[Existing LAN System example]

Backbone LAN

AE-200

Obtain the addresses from

the system administrator.

IP Address: 10.1.1.1

Subnet Mask: 255.255.255.0

Gateway: 10.1.1.250

Gateway

Gateway

10.1.1.250 10.1.2.250

Obtain the addresses from

the system administrator.

PC

IP Address: 10.1.1.101

Subnet Mask: 255.255.255.0

Gateway: 10.1.1.250

IP Address: 10.1.2.51

Subnet Mask: 255.255.255.0

Gateway: 10.1.2.250

PC

WT07138X02

22

Page 23

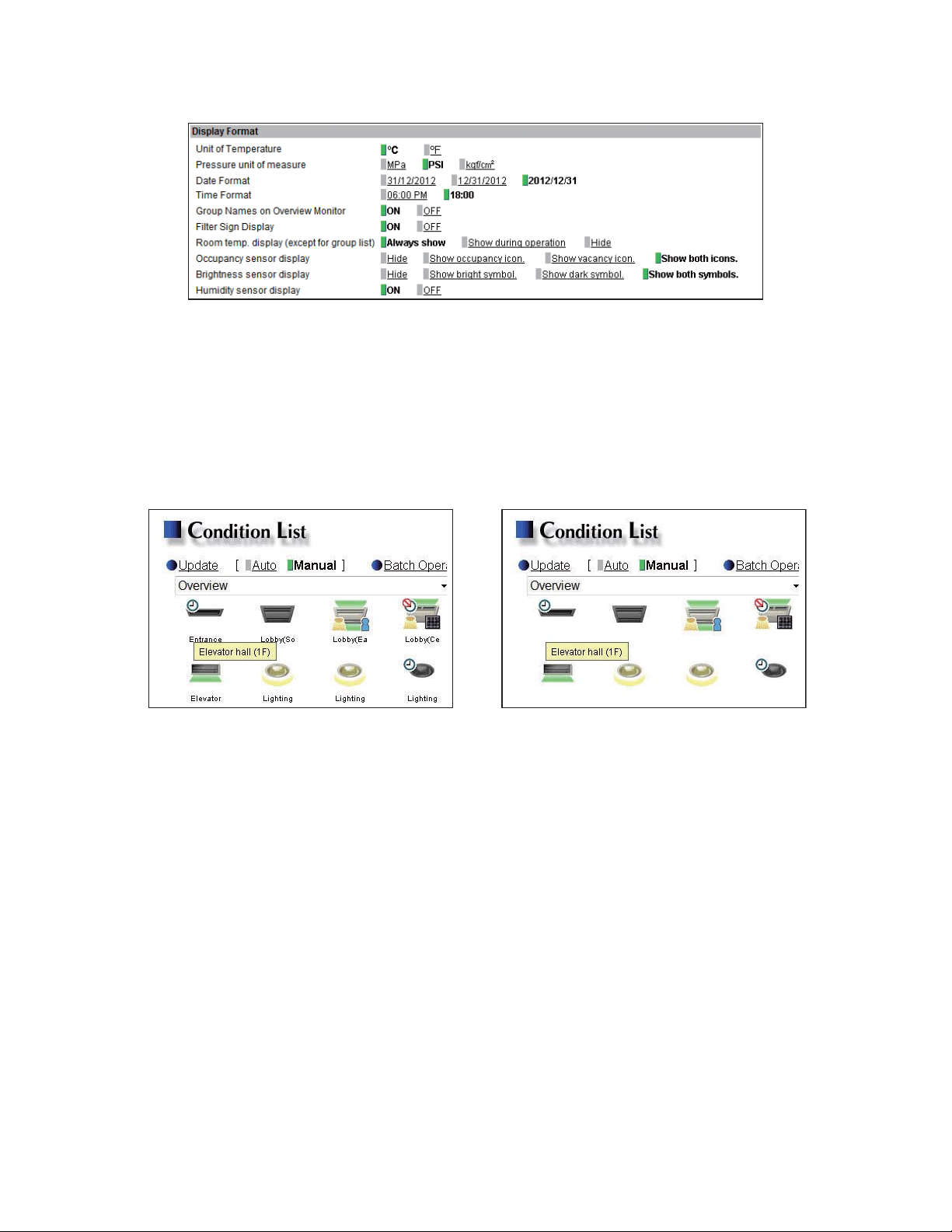

4-2-6. Display Format

Follow the instructions below to set the items in the [Display Format] section.

(1) In the [Unit of Temperature] section, select [ºC] or [ºF].

(2) In the [Pressure unit of measure] section, select [MPa], [PSI], or [kgf/cm

(3) In the [Date Format] section, select the desired display format for year, month, and date.

(4) In the [Time Format] section, select the desired display of time format.

(5) In the [Group Names on Overview Monitor] section, select [ON] to display the group names under the icons

on the Condition List screen. Select [OFF] not to display the group names.

Note: Only the first 8 characters will be visible under the icons. To display all characters, move the cursor to the icon.

2

].

Icons with group names

Icons without group names

(6) In the [Filter Sign Display] section, select [ON] to display the filter sign, and select [OFF] not to.

When the [Filter Sign Display] is set to [OFF], the filter sign will not appear on the Condition List screen even

when the indoor unit detects a filter cleaning signal.

If the filter is regularly cleaned and the sign display is unnecessary, set it to [OFF].

(7) In the [Room temp. display (except for group list)] section, select the desired temperature display option to

be used on the Block display of the Condition List screen.

Select [Always show] to display the temperature at all times, [Show during operation] to display the

temperature only during operation, and [Hide] not to display the temperature.

WT07138X02

23

Page 24

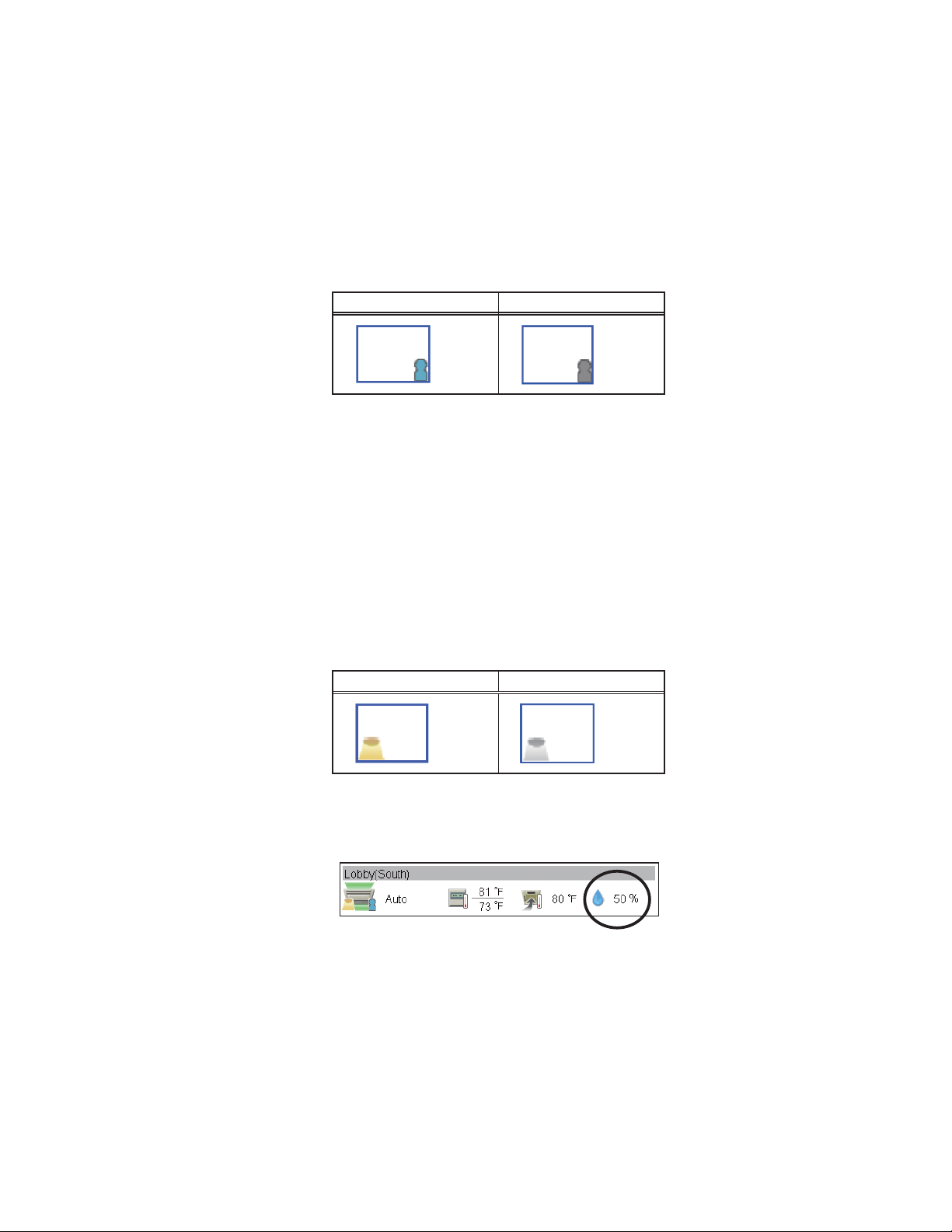

(8) In the [Occupancy sensor display] section, make the Show/Hide setting for the occupancy/vacancy status

that is detected by the built-in occupancy sensor on the ME remote controller (North America: PARU01MEDU, Europe: PAR-U02MEDA).

Select [Hide] not to display the occupancy/vacancy status on the Condition List screen.

Select [Show occupancy icon] to display the occupancy icon when the sensor on the remote controller

detects occupancy.

Select [Show vacancy icon] to display the vacancy icon when the sensor on the remote controller detects

vacancy.

Select [Show both icons] to display the occupancy or vacancy icon according to the occupancy status of the

room.

Note: If the ME remote controller has no built-in occupancy sensor, the occupancy/vacancy icons will not be displayed on

the Condition List screen.

Occupancy icon Vacancy icon

(Blue) (Gray)

(9) In the [Brightness sensor display] section, make the Show/Hide setting for the brightness/darkness status

that is detected by the built-in brightness sensor on the ME remote controller (North America: PARU01MEDU, Europe: PAR-U02MEDA).

Select [Hide] not to display the brightness/darkness icons on the Condition List screen.

Select [Show bright symbol] to display the brightness icon when the brightness level in the room reaches the

predetermined brightness level.

Select [Show dark symbol] to display the darkness icon when the darkness level in the room reaches the

predetermined darkness level.

Select [Show both symbols] to display the brightness or darkness icon according to the brightness/darkness

level of the room.

Note: If the ME remote controller has no built-in brightness sensor, the brightness/darkness icons will not be displayed on

Note: The brightness/darkness detection thresholds are set on the ME remote controller (North America: PAR-U01MEDU,

the Condition List screen.

Europe: PAR-U02MEDA).

Brightness icon Darkness icon

(Yellow)

(Gray)

(10) In the [Humidity sensor display] section, make the Show/Hide setting for the humidity reading of the built-in

humidity sensor on the ME remote controller (North America: PAR-U01MEDU, Europe: PAR-U02MEDA).

Select [ON] to display the humidity reading on the Block display of the Condition List screen.

WT07138X02

24

Page 25

4-3. Groups

Click [Initial Settings] in the menu bar, and then click [Groups] to access the group settings screen. Register

the groups of air conditioning units, LOSSNAY units (ventilators), Air To Water (PWFY) units, AHC, HWHP

(CAHV, CRHV) units, or general equipment to be connected to the AE-200/AE-50/EW-50, and then touch [Save

Settings].

Note: Some settings may not be accessible if logged in as a building manager.

Air conditioner, Air

To Water (PWFY) unit,

LOSSNAY unit, HWHP

(CAHV, CRHV) unit,

and general equipment

registration

Click to display the screen

for registering the air

conditioners, Air To Water

(PWFY) units, LOSSNAY

Group No.

Group name

AHC registration

Click to display the screen

for registering the AHC.

Refresh

Click to import the settings

from AE-200/AE-50/EW-50.

units, HWHP (CAHV,

CRHV) units, and general

equipment.

System controller

registration

Click to display the screen

for registering the system

controllers.

Remote controller

registration

Click to display the screen

for registering the remote

controllers.

Save Settings

Click to save the changes

made.

4-3-1. Setting group names

In the [Group Name] field, enter the group name to be displayed in 20 characters or less.

Note: The following characters cannot be used in the [Group Name] field: <, >, &, “, or ‘

4-3-2. Registering air conditioners, Air To Water (PWFY) units, LOSSNAY units, or HWHP

(CAHV, CRHV) units to a group

(1)

To register air conditioners, Air To Water (PWFY) units,

LOSSNAY units, or HWHP (CAHV, CRHV) units to each group,

click the [Air conditioner, Air To Water (PWFY) unit, LOSSNAY

unit, HWHP (CAHV, CRHV) unit, and general equipment

registration] field next to the target group name. The [Select Unit

Addresses] screen will appear.

Check the radio button next to [Air-conditioners / Air to water

/ HWHP], and select the address numbers of the units to be

registered.

The selected unit addresses will appear with a yellow-green

background.

Click again to deselect. The deselected unit addresses will

appear with a light-gray background.

Note: Each group can contain up to 16 air conditioners.

Note: Air conditioners, Air To Water (PWFY) units, LOSSNAY units,

and HWHP (CAHV, CRHV) units cannot be combined with

general equipment in one group. To change the registered units

to air conditioners, Air To Water (PWFY) units, LOSSNAY units,

or HWHP (CAHV, CRHV) units in the group in which general

equipment is registered, unregister the general equipment first.

Note: The addresses of the units that have been registered to other

groups will appear with a gray background and cannot be

selected.

WT07138X02

25

Page 26

(2)

To change the icon, click the right or left arrow.

The selected icon will be displayed on the Web browser.

4-3-3. Registering remote controllers to a group

(1)

To register remote controllers to a group, click the [Remote

controller registration] field next to the target group name. The

[Select Unit Addresses] screen will appear.

Select the address numbers of the remote controllers to be

registered. The selected unit addresses will appear with a yellowgreen background.

Click again to deselect. The deselected addresses will appear

with a light-gray background.

Note: Each group can contain up to two remote controllers.

Note: Each group can contain up to four remote and system controllers

Note: MA remote controllers do not need to be registered to a group.

combined.

4-3-4. Registering system controllers to a group

(1)

To register system controllers to a group, click the [System

controller registration] field next to the target group name. The

[Select Unit Addresses] screen will appear.

Select the address numbers of the system controllers to be

registered. The selected unit addresses will appear with a yellowgreen background.

Click again to deselect. The deselected addresses will appear

with a light-gray background.

Note: Each group can contain up to four remote and system controllers

combined (excluding AE-200/AE-50/EW-50).

4-3-5. Registering AHC to a group

(1)

To register an AHC to a group, click the [AHC registration] field

next to the target group name. The [Select Unit Addresses]

screen will appear.

Select the address number of the AHC to be registered. The

selected unit address will appear with a yellow-green background.

Click again to deselect. The deselected address will appear with

a light-gray background.

Note: Each group can contain one AHC.

Note: AHC must be registered to a group in which air conditioners are

registered. Do not register AHC to a group in which Air To Water

(PWFY) units, LOSSNAY units, HWHP (CAHV, CRHV) units, or

general equipment (via PAC-YG66DCA) are registered.

WT07138X02

26

Page 27

4-3-6. Registering general equipment to a group

(1)

To register general equipment to a group, click the [Air

conditioner, Air To Water (PWFY) unit, LOSSNAY unit,

HWHP (CAHV, CRHV) unit, and general equipment

registration] field next to the target group name. The

[Select Unit Addresses] screen will appear.

Check the radio button next to [General Equipment (via

PAC-YG66DCA)].

Select the device number of the DIDO controller (PACYG66DCA) that is connected to the general equipment

to be registered. The selected number will appear with

a red frame. Also, select contact points to which the

general equipments are connected.

Click again to deselect. The deselected numbers will

appear with a light-gray background.

Note: Each contact of DIDO controller counts as one unit.

Note: Each group can contain up to 16 general equipment.

Note: Up to six general equipment can be registered for each DIDO controller.

Note: Air conditioners, Air To Water (PWFY) units, LOSSNAY units, and HWHP (CAHV, CRHV) units cannot be combined

Note: General equipment groups cannot include remote controllers or system controllers.

with general equipment in one group. To change the registered units to general equipment in the group to which air

conditioners, Air To Water (PWFY) units, LOSSNAY units, or HWHP (CAHV, CRHV) units are registered, unregister

the air conditioners, Air To Water (PWFY) units, LOSSNAY units, or HWHP (CAHV, CRHV) units first.

(2)

To change the icon, click the right or left arrow.

The selected icon will be displayed on the Web browser.

(3)

In the [Allow Operations] section, make the setting to allow or disallow operation.

Select [In batch and on individual group] to allow the operator to turn on or off the general equipment

collectively or by the groups.

Select [On individual group] to allow the operator to turn on or off the general equipment by the groups.

Select [No operations (Monitor only)] to disallow the operator to turn on or off the general equipment.

(4)

In the [Monitor] section, select which status will be used to reflect the units' ON/OFF status to the unit icons

on the Condition List screen, accessible via the Web Browser for System Maintenance Engineer. Select

[Output status] to use the status that is sent to the general equipment, and [Input status] to use the status

that is sent from the general equipment.

WT07138X02

27

Page 28

4-4. Interlocked LOSSNAY

The ON/OFF status of the LOSSNAY unit can be interlocked with the operation of indoor units. Click [Initial

Settings] in the menu bar, and then click [Interlocked LOSSNAY] to access the Interlocked LOSSNAY settings

screen. Set the interlocking conditions, and then click [Save Settings].

Note: The Interlocked LOSSNAY settings may not be accessible if logged in as a building manager.

Note: The ON/OFF status of the indoor units are not interlocked with the ON/OFF status of the LOSSNAY unit.

Note: The interlock settings between the units connected to the AE-200, AE-50, and EW-50, as well as between the units

connected to different AE-50/EW-50 controllers, cannot be made.

Interlocked LOSSNAY unit

Click to display the screen

for registering the LOSSNAY

Click to import the settings

from AE-200/AE-50/EW-50.

(1)

registration

unit.

Refresh

Click the [Interlocked LOSSNAY unit registration] field. The [Select a

Unit Address] screen will appear.

Select the address number of the LOSSNAY unit to be registered.

The selected unit address will appear with a yellow-green

background.

Click again to deselect. The deselected address will appear with a

light-gray background.

(2)

Click the [Interlocked indoor unit registration] field. The [Select Unit

Addresses] screen will appear.

Select the address numbers of the indoor units to which the selected

LOSSNAY unit will be interlocked. The selected unit addresses will

appear with a yellow-green background.

Click again to deselect. The deselected addresses will appear with a

light-gray background.

Note: Each LOSSNAY unit can be interlocked with up to 16 indoor units.

Interlocked indoor unit

registration

Click to display the screen

for registering the indoor

units.

Save Settings

Click to save the changes

made.

WT07138X02

28

Page 29

4-5. Blocks

By making block settings, multiple groups in a given block can be collectively monitored or operated on the

Web browser. Click [Initial Settings] in the menu bar, and then click [Blocks] to access the block settings screen.

Register the groups to each block, and then click [Save Settings].

Note: Some settings may not be accessible if logged in as a building manager.

Note: The groups of units connected to the AE-200, AE-50, and EW-50, as well as the groups of units connected to different

AE-50/EW-50 controllers, cannot be registered to the same block.

Block Name

Group registration

Click to import the settings

from AE-200/AE-50/EW-50.

(1)

Enter the block name in the [Block Name] field to be displayed on the Web browser in 20 characters or less.

Note: The following characters cannot be used in the [Block Name] field: <, >, &, “, or ‘

(2)

Click the [Group registration] field next to the target block. The [Select

Refresh

Save Settings

Click to save the changes

made.

Groups] screen will appear.

Select the group numbers to be registered. (To show the group name,

move the cursor to the group number.)

The selected group numbers will appear with a yellow-green

background.

Click again to deselect. The deselected group numbers will appear

with a light-gray background.

Note: HWHP (CAHV, CRHV) unit groups cannot be registered to a block.

WT07138X02

29

Page 30

5. Functions 1

5-1. E-Mail

E-mail settings must be configured properly to use the error notification e-mail function or the e-mail

communication function. Error notification e-mail function is the function to send the error information to the

specified e-mail addresses. E-mail communication function is the function to send the units’ maintenance data to

the specified e-mail addresses of the PCs to which Maintenance Tool is installed.

Click [Functions 1] in the menu bar, and then click [E-Mail] to access the e-mail settings screen. Make the various

e-mail settings, and then click [Save Settings].

Note: The E-mail settings may not be accessible if logged in as a building manager.

Mail Server Information

Set the mail server/DNS

server information.

E-Mail Settings of

AE-200/AE-50/EW-50

Mail Communication

Setting

Set the e-mail addresses

of the PCs that will receive

maintenance data through

e-mail communication

function.

Refresh

Click to import the settings

from AE-200/AE-50/EW-50.

Error Mail Settings

Enter the e-mail information

for error notification e-mail

function.

Save Settings

Click to save the changes

made.

5-1-1. E-Mail Settings of AE-200/AE-50/EW-50

Enter the AE-200/AE-50/EW-50’s e-mail information provided by the Internet Service Provider (ISP) or the

system administrator. The items required to be set vary, depending on the functions to be used. Refer to the table

below to determine which items need to be set.

Note: A contract with the ISP is required to send e-mail via an ISP.

Table 5-1 Items required to be set (E-Mail Settings of AE-200/AE-50/EW-50)

Error notification e-mail function E-mail communication function

Item

E-Mail Address V V V V

User ID - V V V

Password - V V V

Interval of checking incoming mails - - V V

Without SMTP

authentication

With SMTP

authentication

Without SMTP

authentication

(V) Required to be set, (-) Not required to be set

With SMTP

authentication

WT07138X02

30

Page 31

5-1-2. Mail Server Information

Enter the e-mail server information provided by the ISP or the system administrator. The items required to be set

vary, depending on the functions to be used. Refer to the table below to determine which items need to be set.

Either the IP address or the host name (server name) can be entered in the [Outgoing Mail Server (SMTP)] and

[Incoming Mail Server (POP3)] fields.

Note: The port number of the Outgoing Mail Server (SMTP) can be changed. (Factory setting: 25)

Note: When “587” is entered in the [Port] field, make sure to check the checkbox next to [Use SMTP Authentication].

Table 5-2 Items required to be set (Mail Server Information)

Error notification e-mail function E-mail communication function

Item

Outgoing Mail Server (SMTP)

Use SMTP Authentication -V-V

Incoming Mail Server (POP3) - -

DNS Server (Primary) (V)

DNS Server (Secondary) (V)

*1 Not required if the IP address is entered in the [Outgoing Mail Server (SMTP)] or [Incoming Mail Server (POP3)] field.

Without SMTP

authentication

V

IP address or

host name

*1

*1

With SMTP

authentication

V

Host name

V (V)

V (V)

Without SMTP

authentication

V

IP address or

host name

V

IP address or

host name

*1

*1

(V) Required to be set, (-) Not required to be set

With SMTP

authentication

V

Host name

V

IP address or

host name

V

V

5-1-3. Error Mail Settings

(1)

In the [Mail Subject] field, enter the mail subject to be used for the error notification e-mail function in 40

characters or less.

Note: The following characters cannot be used in the [Mail Subject] field: <, >, &, “, or ‘

(2)

In the [Kind of Errors] field, select the error type out of the following: [Unit Error], [Preliminary Unit Error],

[Communication Error], [General Equipment], and [User Setting 1] through [User Setting 6]. Then, in the

[E-Mail Address] field, enter the e-mail addresses of the recipients of the error notification e-mail.

(3)

If [User Setting 1] through [User Setting 6] is selected in the [Kind

of Errors] field, a [User Settings] button will appear. To send error

notification e-mail only upon occurrences of certain errors, click

[User Settings] to display the User Settings screen.

Enter the error codes to be notified.

Up to 20 error codes can be set for each user setting. In addition

to specific error codes such as [1302] or [6607], codes that use

asterisks as wildcards such as [10**] or [12**] can also be used.

If [10**] is entered, for example, error notification e-mail will be

sent upon an occurrence of any type of errors between [1000] and

[1099]. If error codes are entered on this screen, confirm that the

e-mail addresses of the recipients are registered.

WT07138X02

31

Page 32

(4)

If [General Equipment] is selected in the [Kind of Errors] field, a

[PLC Connection] button will appear. To send error notification

e-mail upon occurrences of errors on the general equipment that

are connected to PLC Software for General Equipment, click [PLC

Connection] to display the [PLC Connection] screen. Enter the IP

addresses of PLC Software for General Equipment.

The row number that corresponds to each IP address will appear

in the error notification e-mail as a PLC number. (e.g., When an

error occurs on the general equipment #20 connected to the PLC

Software in the second row, “PLC2-20” will appear in the [Error

unit] section in the error notification e-mail.)

Note: A TG-2000A is required to monitor the status of the general

equipment that is connected to the PLC Software for General

Equipment.

5-1-4. Mail Communication Setting

To use an e-mail communication function, enter the addresses of the PCs that will receive the units’ maintenance

data in the [Mail Communication Setting] section. Up to 10 e-mail addresses can be set.

WT07138X02

32

Page 33

5-1-5. E-mail format

Error notification e-mail will be sent in the format shown below.

From:Mitsubishi Building(000001)

Date:01/06/2014 16:32:12

Error unit:065

Error code:1302

Status:Occurrence

Mail subject The mail subject entered in section 5-1-3 will appear.

From The AE-200/AE-50/EW-50 unit name and unit ID entered in section 4-2-1 will appear.

Date Error occurrence date and time will appear in the format entered in section 4-2-6.

- When an error occurs on air conditioning units or general equipment, the M-NET address of the unit

in error will appear.

- When an error occurs on general equipment connected to PLC Software for General Equipment, PLC

number* (1 to 20) and connection number of general equipment (1 to 32) will appear.

- When a communication error occurs on PLC Software for General Equipment, PLC number* (1 to 20)

Error unit

will appear.

* PLC number indicates the row number on the [PLC Connection] screen. (Refer to section 5-1-3 (4).)

Error code

Status

Note: When an error occurs on the general equipment connected via DIDO controller, M-NET address of

the DIDO controller will appear. (The recipients will know that an error has occurred on one of the

general equipment that is connected to the DIDO controller.)

Error code (4-digit) will appear.

- When an error occurs on air conditioning units, refer to the service manual of the unit for the error

codes.

- When an error occurs on general equipment, “0091” (General equipment error) will appear.

- When a communication error occurs on PLC Software for General Equipment, “0003” (LAN

communication error to PLC) or “0007” (PLC program stopped) will appear.

Error status “Occurrence” (The error is occurring) or “Recovery” (The error has been resolved) will

appear.

WT07138X02

33

Page 34

5-2. Peak Cut (Energy-save control function)

According to the selected Peak Cut method, the AE-200/AE-50/EW-50 obtains the demand level or the electric

energy values to determine the control level, and operates outdoor units and blocks of indoor units below the

specified maximum capacity that corresponds to the control level.

Click [Functions 1] in the menu bar, and then click [Peak Cut] to access the Peak Cut control settings screen.

Make necessary settings, and then click [Save Settings].

Important: The amount of electricity that is actually used may exceed the maximum power demand due to unexpected

problems such as controller malfunctions or broken transmission cables. Mitsubishi Electric will not be

responsible for exceeding the maximum power demand.

Note: After completing the settings, perform a test run and confirm proper connections of equipment before using the Peak Cut

function.

Note: A separate license is required to use the Peak Cut function. Make sure that the required license has properly been

registered on the Registration of Optional Functions screen. (Refer to chapter 10 for details.)

Note: Some settings may not be accessible if logged in as a building manager.

Note: Peak Cut control cannot be performed on DIDO controller (PAC-YG66DCA), AHC, or Air To Water (PWFY) unit.

Note: The Peak Cut control of indoor units is performed per block. Be sure to make block settings to use the Peak Cut function.

Note: The Peak Cut control settings between the outdoor and indoor units connected to the AE-200, AE-50, and EW-50, as

well as between the units connected to different AE-50/EW-50 controllers, cannot be made.

Peak Cut method

Control details for

outdoor units

Setting details for the

selected Peak Cut method

Control details for blocks

of indoor units

Click to import the settings

from AE-200/AE-50/EW-50

Refresh

and PLC.

5-2-1. Peak Cut method

[Demand-Input PLC]

Demand level

signal is sent.

AE-200

Demand-Input

AE-50

AE-50

AE-50

PLC

Maximum ten

AE-200/AE-50/EW-50 units

Demand level is

input.

Demand

controller

[Electric Amount Count PLC]

Reads electric

energy values.

AE-200

AE-50

AE-50

AE-50

Electric Amount

Count PLC

Maximum fourteen

AE-200/AE-50/EW-50 units

Save Settings

Click to send the settings to

AE-200/AE-50/EW-50 and

PLC.

Pulse

Pulse-watthour meter

WT07138X02

34

Page 35

[PI Controller]

<When a PI controller (PAC-YG60MCA) is used> <When a built-in PI controller is used>

Reads electric

energy values.

AE-200

PI controller

AE-50

Reads control

level.

AE-50

Maximum three

AE-50

AE-200/AE-50/EW-50 units

Peak Cut method [Remote AE]

[External Contact point input] (1)

External input/output

adapter (PAC-YG10HA-E)

LAN

AE-200

AE-50

Reads control

level.

AE-50

AE-50

Maximum three

AE-200/AE-50/EW-50 units

Demand level is

input.

Pulse

Pulse-watt-

hour meter

Demand

controller

AE-200

(Built-in PI controller)

AE-50

Reads control

level.

AE-50

Maximum three

AE-50

AE-200/AE-50/EW-50 units

Peak Cut method [Remote AE]

[External Contact point input] (2)

External input/output

adapter (PAC-YG10HA-E)

AE-200

AE-50

AE-50

AE-50

Demand level is

input.

Pulse

Pulse-watthour meter

Demand

controller

Maximum three

AE-200/AE-50

/EW-50 units

Peak Cut method [Remote AE]

[From external system]

Demand level

signal is sent.

AE-200

AE-50

AE-50

AE-50

PLC etc.

Maximum ten

AE-200/AE-50/EW-50 units

Pulse

Pulse-watthour meter

WT07138X02

35

Page 36

(A) When the Peak Cut method [Demand-Input PLC] is selected

(1)

In the [IP Address] field, enter the IP address of the Demand-Input PLC.

(2)

When using the Demand-Input PLC for the first time, click [Initialize] to initialize its internal memory.

Note: Do not initialize the Demand-Input PLC after the operation has begun, for it will clear all operation data.

(3)

In the [Controlled AE] field, enter the IP addresses of the AE-200/AE-50/EW-50 units to which the demand

level signal is sent. Up to 10 IP addresses can be registered.

(4)

In the [Temperature difference between set point and inlet] section, a temperature differential can be set to

between 3 and 9 as necessary. The Peak Cut control setting that corresponds to the control level 0 will be

disregarded for the indoor unit groups in which the temperature difference between the set temperature and

the room temperature is greater than the specified temperature differential.

Note: The Peak Cut control setting that corresponds to the control levels 1 to 4 will be effective regardless of the

temperature differential setting.

(B) When the Peak Cut method [Electric Amount Count PLC] is selected

(1)

In the [IP address] field, enter the IP address of the Electric Amount Count PLC.

(2)

When using the Electric Amount Count PLC for the first time, click [Initialize] to initialize the internal memory.

Note: Do not initialize the Electric Amount Count PLC after the operation has begun, for it will clear all operation data.

(3)

In the [DI Board] field, select the DI board number to which the watt-hour meter is connected, and the

terminal number. If the watt-hour meter is connected to terminal 2 on a DI board 1, select 1-2.

Note: Select a DI board number 1 or 2, and select a terminal number/code between 0 and F.

(4)

In the [Pulse Unit] field, enter the pulse value that the watt-hour meter outputs. Set the pulse value according

to the watt-hour meter to be used.

Important: Check the watt-hour meter readings several times on the hour and the half-hour. Then, be sure to check

(5)

In the [Control levels] section, the range of the electric power must be set for each control level. For control

that the increase in the watt-hour meter reading for each 30-minute period and the average electric power

consumption in the same period that the Peak Cut function is used are the same amount.

The average electric power for the period that the Peak Cut function is used can be checked on the Trend

Graph display or in the CSV file that can be downloaded from the Trend Graph display. The Trend Graph

display can be found on the Peakcut Control Status screen, accessible via the Web Browser for System

Maintenance Engineer. Refer to the Instruction Book (Web Browser for System Maintenance Engineer) for

details.

level 4, enter the value that is 10% to 15% below the maximum power demand (average electric energy that

cannot be exceeded in any 30-minute period). For control levels 3 to 0, enter the value that is decreased

by about 10% from the set value of the previous control level. (The screenshot above shows the setting

example of the maximum demand of 200 kW.)

Note: The optimum setting depends on the system configuration of the electric equipment and on the indoor environment in

each building. Determine the appropriate values accordingly.

WT07138X02

36

Page 37

(6)

In the [Temperature difference between set point and inlet] section, a temperature differential can be set to

between 3 and 9 as necessary. The Peak Cut control setting that corresponds to the control level 0 will be

disregarded for the indoor unit groups in which the temperature difference between the set temperature and

the room temperature is greater than the specified temperature differential.

Note: The Peak Cut control setting that corresponds to the control levels 1 to 4 will be effective regardless of the

temperature differential setting.

(C) When the Peak Cut method [PI Controller] is selected

(1) In the [Watthour meter] field, select the watt-hour meter used for the Peak Cut function or the PI controller to

which the watt-hour meter is connected.

Note: Only the watt-hour meters that have been registered on the Measurement screen are selectable. Refer to section 5-3

Note: When a built-in PI controller is used, [“Meter” + Channel No. + (space) + Metering device name] will appear. (For

for how to register metering devices.

example, if the watt-hour meter used for the Peak Cut function is connected to channel 3 of CN7 of AE-200 and the

metering device name is “For Peak Cut function,” [Meter3 For Peak Cut function] will appear.)

When a PI controller (PAC-YG60MCA) is used, [“Address” + PI controller address + “-” + Channel No. + (space) +

Metering device name] will appear. (For example, if the watt-hour meter used for the Peak Cut function is connected

to channel 2 of a PI controller (address 10) and the metering device name is not registered, [Address10-2] will

appear.)

(2) In the [Control levels] section, the range of the electric power must be set for each control level. For control

level 4, enter the value that is 10% to 15% below the maximum power demand (average electric energy that

cannot be exceeded in any 30-minute period). For control levels 3 to 0, enter the value that is decreased

by about 10% from the set value of the previous control level. (The screenshot above shows the setting

example of the maximum demand of 200 kW.)

Note: The optimum setting depends on the system configuration of the electric equipment and on the indoor environment in

each building. Determine the appropriate values accordingly.

(3) In the [Temperature difference between set point and inlet] section, a temperature differential can be set to

between 3 and 9 as necessary. The Peak Cut control setting that corresponds to the control level 0 will be

disregarded for the indoor unit groups in which the temperature difference between the set temperature and

the room temperature is greater than the specified temperature differential.

Note: The Peak Cut control setting that corresponds to the control levels 1 to 4 will be effective regardless of the

temperature differential setting.

WT07138X02

37

Page 38

(D) When the Peak Cut method [Remote AE] is selected

(1) In the [IP address] field, enter the IP address of the AE-200/AE-50/EW-50 that uses one of the following.

- Built-in PI controller

- PI controller (PAC-YG60MCA)

- External contact input (Refer to (E) “When the Peak Cut method [External Contact point input] is

selected” for details.)

Note: As the control level is obtained every minute from the AE-200/AE-50/EW-50 that uses a built-in PI controller or a

Note: Up to three AE-200/AE-50/EW-50 units can be connected to the AE-200/AE-50/EW-50 unit that uses a built-in PI

(2) In the [Temperature difference between set point and inlet] section, a temperature differential can be set to

between 3 and 9 as necessary. The Peak Cut control setting that corresponds to the control level 0 will be

disregarded for the indoor unit groups in which the temperature difference between the set temperature and

the room temperature is greater than the specified temperature differential.

Note: The Peak Cut control setting that corresponds to the control levels 1 to 4 will be effective regardless of the

PI controller (PAC-YG60MCA), the control will be late for up to one minute on the AE-200/AE-50 whose Peak Cut

method setting is [Remote AE].

controller or a PI controller (PAC-YG60MCA). When five or more AE-200/AE-50/EW-50 units are connected, add the

settings in (C) “When the Peak Cut method [PI Controller] is selected” or use the Peak Cut method [Electric Amount

Count PLC].

temperature differential setting.

(E) When the Peak Cut method [External Contact point input] is selected

Note: The external signal can be input to AE-200, AE-50, and EW-50, so that all outdoor units and blocks of indoor units can be

(1) In the [Temperature difference between set point and inlet] section, a temperature differential can be set to

selected.

between 3 and 9 as necessary. The Peak Cut control setting that corresponds to the control level 0 will be

disregarded for the indoor unit groups in which the temperature difference between the set temperature and

the room temperature is greater than the specified temperature differential.

Note: The Peak Cut control setting that corresponds to the control levels 1 to 4 will be effective regardless of the

temperature differential setting.

WT07138X02

38

Page 39

(F) When the Peak Cut method [From external system] is selected

(1) In the [Temperature difference between set point and inlet] section, a temperature differential can be set to

between 3 and 9 as necessary. The Peak Cut control setting that corresponds to the control level 0 will be

disregarded for the indoor unit groups in which the temperature difference between the set temperature and

the room temperature is greater than the specified temperature differential.

Note: The Peak Cut control setting that corresponds to the control levels 1 to 4 will be effective regardless of the

temperature differential setting.

WT07138X02

39

Page 40

5-2-2. Control details for outdoor units (All Peak Cut methods)

Follow the instructions below to make the Peak Cut control settings for each control level for given outdoor units.

Note: If the outdoor unit is a City Multi unit, the M-NET address will appear. If the outdoor unit is an A-control (Mr. Slim) unit, the

Note: As for A-control outdoor units, only the inverter models can perform Peak Cut control. The Peak Cut control settings for

Note: Do not make the Peak Cut control settings for heat pump models of outdoor units or City Multi S series (PUMY) outdoor

M-NET address and group name will appear.

constant-speed models can not be made.

units.

Copy

Paste

Control level

Batch Operations

Click to make settings for

all outdoor units at once.

(1)

To make settings for all outdoor units at once,

check the [Batch Operations] checkbox.

Then, set the maximum operating capacity for

each control level.

The smaller the maximum operating capacity,

the more energy will be saved.

Note: Energy-saving effects cannot be expected

Note: For heat pump outdoor units and City Multi

during low-load operation with the capacity

below the selected maximum capacity.

S series (PUMY) outdoor units, leave the

default setting [100%] as it is not to activate

the capacity-save control.

Capacity

80%

Maximum Capacity

Select the upper limit of outdoor unit

operating capacity.

e.g., Maximum capacity at 80%

Operating

Capacity

No energy-saving effects Energy-saving effects