Page 1

MITSUBISH ELECTRIC

2002

Service

Manual

DVD Player

Model

DD-6030

CAUTION

Before servicing this chassis, it is important that the service person reads all SAFETY PRECAUTIONS and the

SAFETY NOTICE in this manual.

SPECIFICATIONS

Power Supply: 120V AC, 60 Hz

Power Consumption: 17W

Weight: 5.5 lb.

External Dimensions: 17"x 2-3/4"x8-7/8"

(W/H/D)

Signal System: Standard NTSC

Laser: Semiconductor laser,

wavelength 650nm/780nm

Frequency Range: (Digital Audio)

DVD Linear -

48 kHZ Sampling: 4 Hz to 22 kHz

96 kHZ Sampling: 4 Hz to 44 kHz

Signal-To-Noise Ratio: More than 112 dB (EIAJ)

Audio Dynamic Range: More than 108 dB (EIAJ)

Harmonic Distortion: Less than 0.002%

Wow and flutter: Below measurable level

(less than ± 0.001%

(W.PEAK)) (EIAJ)

Operating conditions: Temperature: 5°C to 35°C

Operation status: Horizontal

Video output: 1.0 V (p-p), 75Ω, negative

sync., pin jack x 1

S Video output: (Y) 1.0 V (p-p), 75Ω, nega-

tive sync., Mini DIN 4-pin x 1

(C) 0.286 V (p-p), 75Ω

Component Video output: (Y) 1.0 V (p-p), 75Ω,

negative sync., pin jack x 1

(Cr, Pr)/(Cb, Pb) 0.7 V (p-p),

75Ω, pin jack x 2

Digital Audio output: (Bitstream/PCM) 0.5 V (p-p),

75Ω, pin jack x 1,

Optical connector x 1

Analog Audio output: 2.0 V (rms), 680Ω, pin jack

2 CH L R x 2,

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Rd. Irvine, CA 92618

Copyright © 2002 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

SAFETY NOTICE

SAFETY PRECAUTIONS

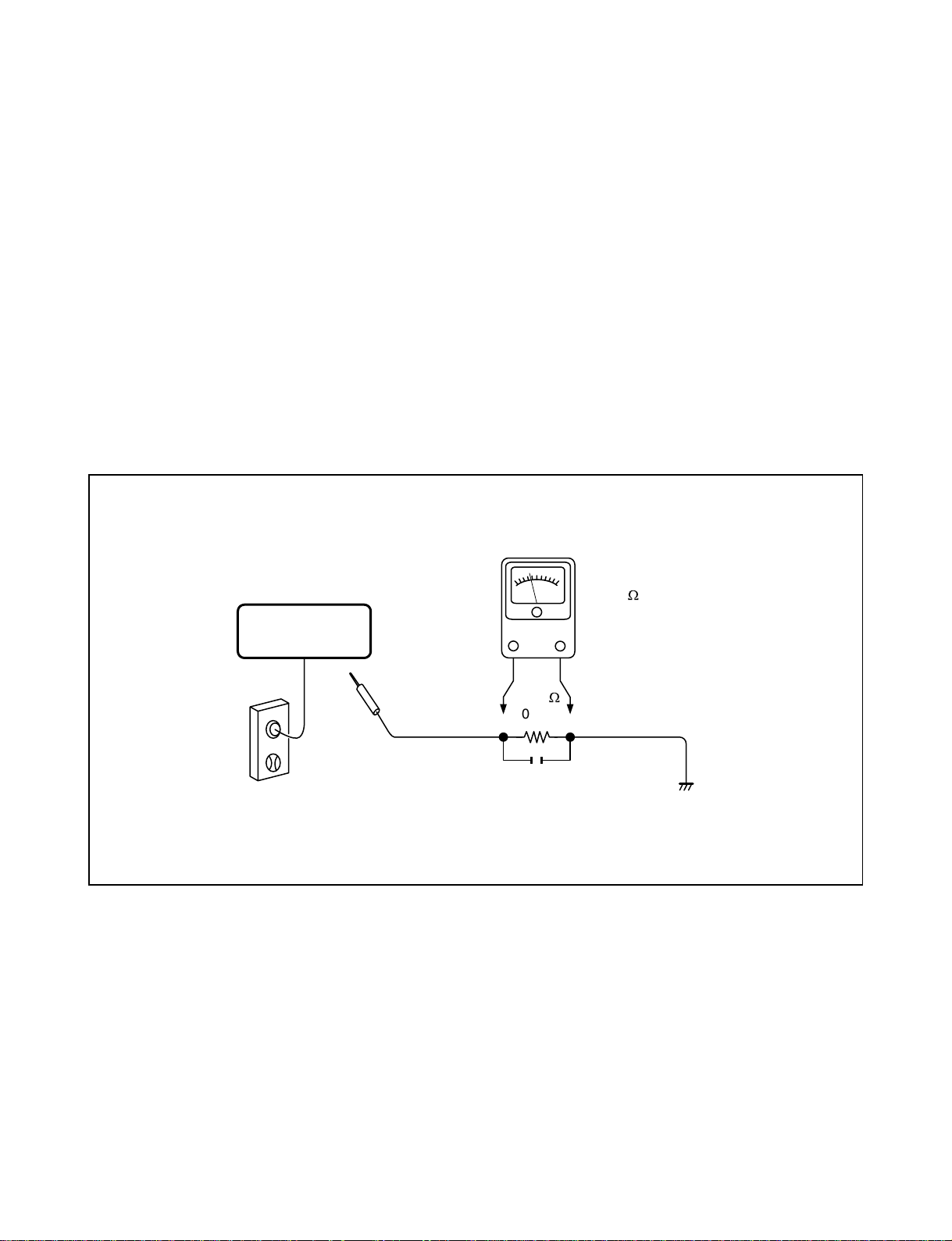

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120V AC outlet (do

not use an isolation transformer for this check). Use an

AC voltmeter, having 5000 Ω per volt or more sensitivity.

Connect a 1500 Ω 10 W resistor, paralleled by a 0.15 µF

150V AC capacitor between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of

cabinet (antennas, handle bracket, metal cabinet

screwheads, metal overlays, control shafts, etc.).

READING SHOULD NOT EXCEED 0.3V

Measure the AC voltage across the 1500 Ω resistor.

The test must be conducted with the AC switch on and

then repeated with the AC switch off. The AC voltage

indicated by the meter may not exceed 0.3 V. A reading

exceeding 0.3 V indicates that a dangerous potential

exists, the fault must be located and corrected.

Repeat the above test with the DVD VIDEO PLAYER

power plug reversed.

NEVER RETURN A DVD VIDEO PLAYER TO THE

CUSTOMER WITHOUT T AKING NECESSAR Y

CORRECTIVE ACTION.

DVD VIDEO PLAYER

AC OUTLET

Test all exposed metal.

Voltmeter Hook-up for Leakage Current Check

1500

W

10 W

0.15 µF 150V AC

AC VOLTMETER

(5000 W per volt

or more sensitivity)

Good earth ground

such as a water pipe,

conduit, etc.

Page 3

SAFETY NOTICE

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

LASER BEAM CAUTION LABEL

When the power supply is turned on, you may not remove this laser caution label. If it is removed, laser radiation

may be recceived.

Page 4

GENERAL DESCRIPTIONS

S

GENERAL DESCRIPTIONS

SECTION 1

GENERAL DESCRIPTIONS

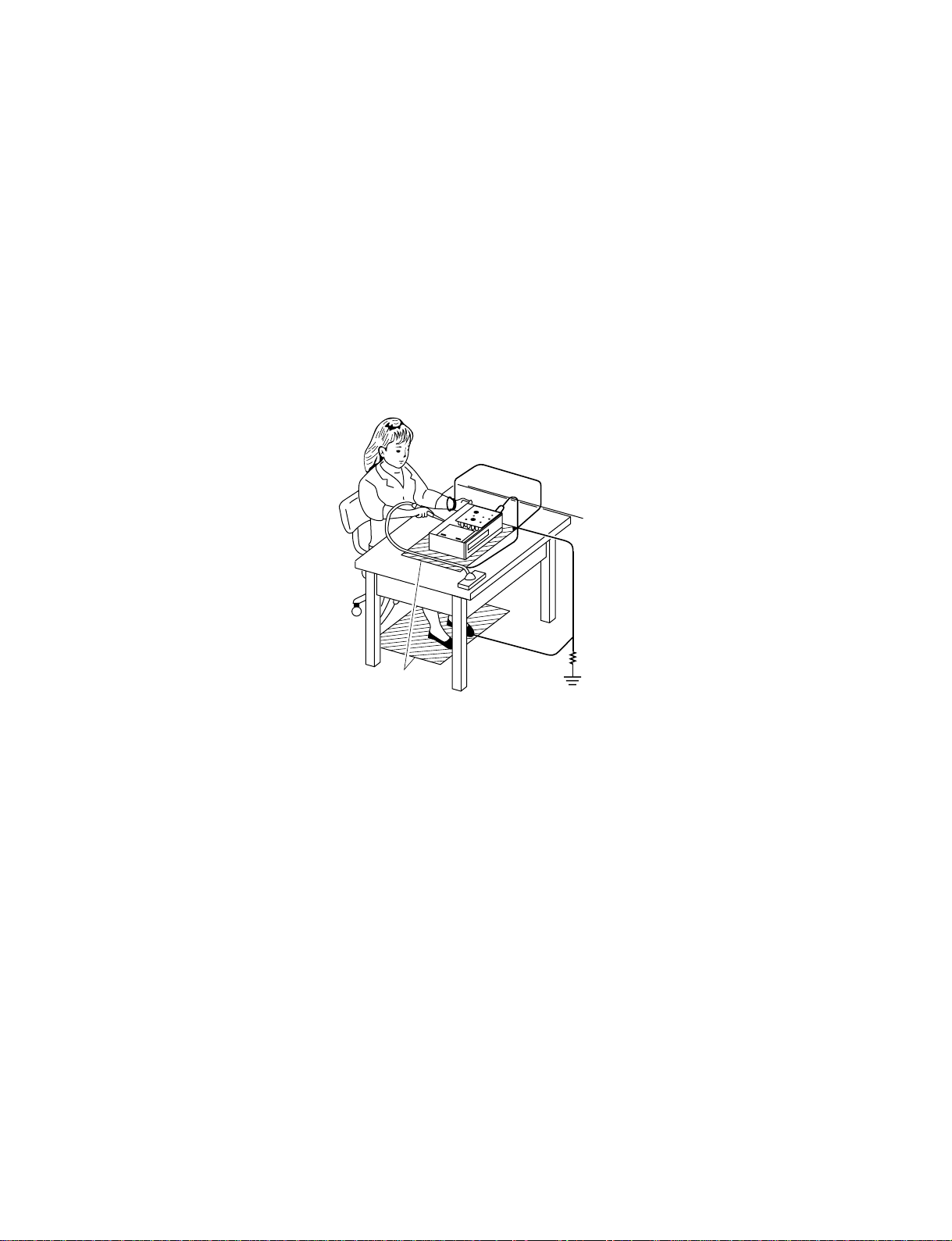

1. PREPARATION FOR SERVICING

The Pickup Head consists of a laser diode that is very susceptible to external static electricity.

Although it may operate properly after replacement, if subjected to electrostatic discharge during replacement,

its life might be shortened. When replacing the laser diode, LSI's and IC's, use a conductive mat, soldering iron

with ground wire, etc. to protect against damage from static electricity.

Ground conductive

wrist strap for body.

oldering iron

with ground wire

or ceramic type

SECTION 1

1MΩ

Conductive mat

The ground resistance

between the ground line

and the ground is less than 10Ω.

1-1

Page 5

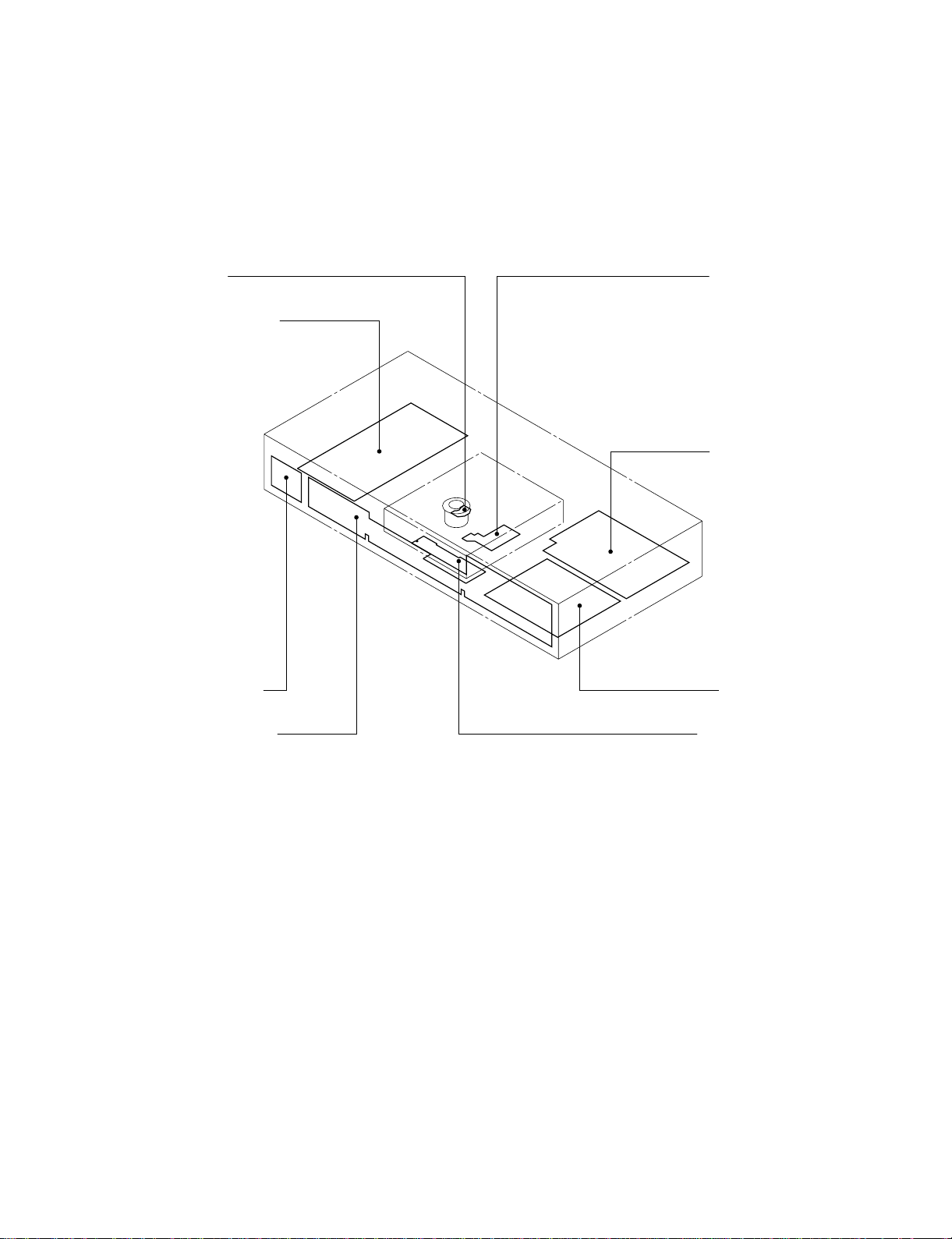

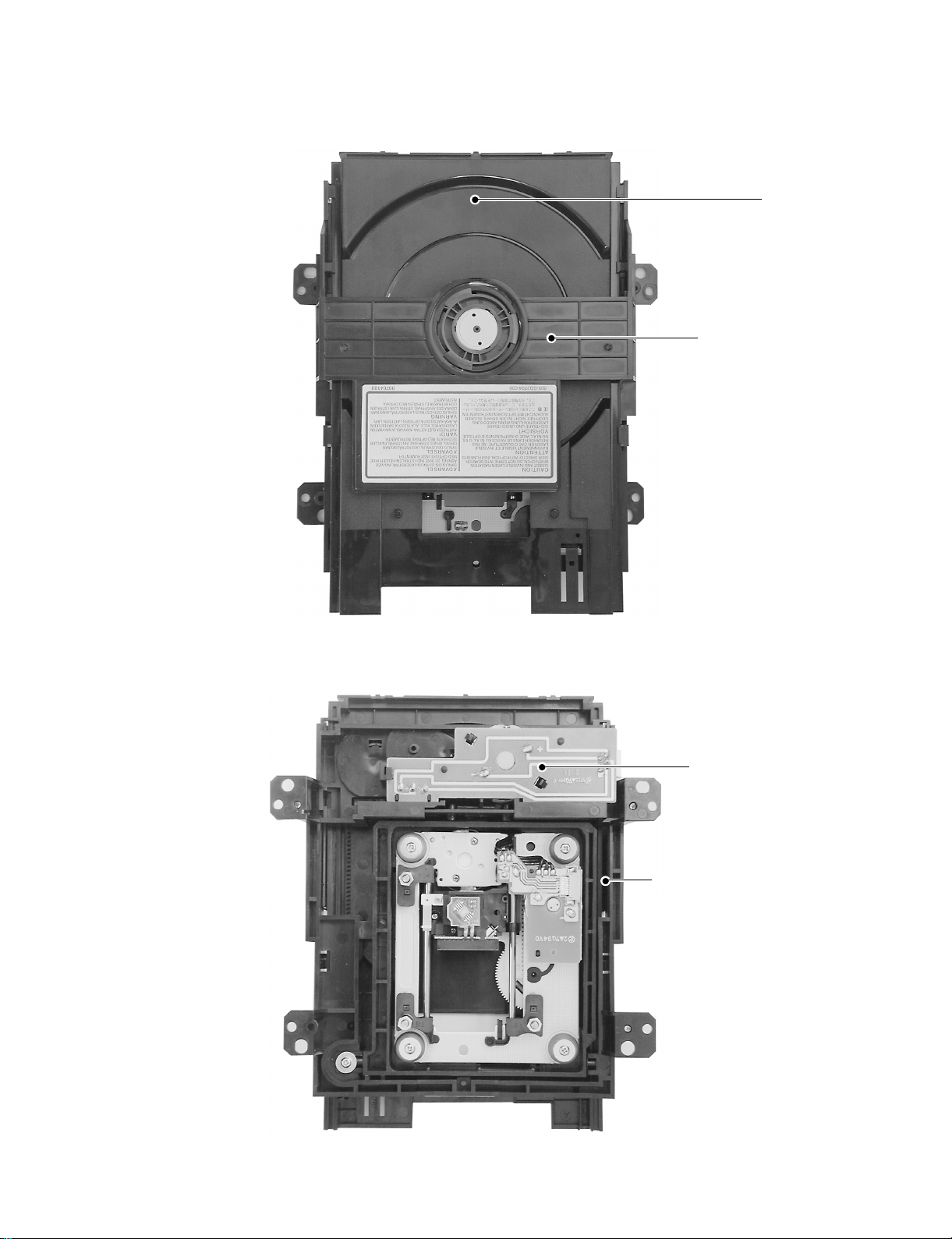

2. LOCATION OF MAIN PARTS AND MECHANISM PARTS

2-1. Location of Main Parts

Disc motor PC board Feed motor PC board

EU02 Power supply PC board

EU05 Output PC board

EU04 Power SW PC board

EU03 Front display PC board

EU01 Main PC board

Loading motor PC board

Fig. 1-2-1

Page 6

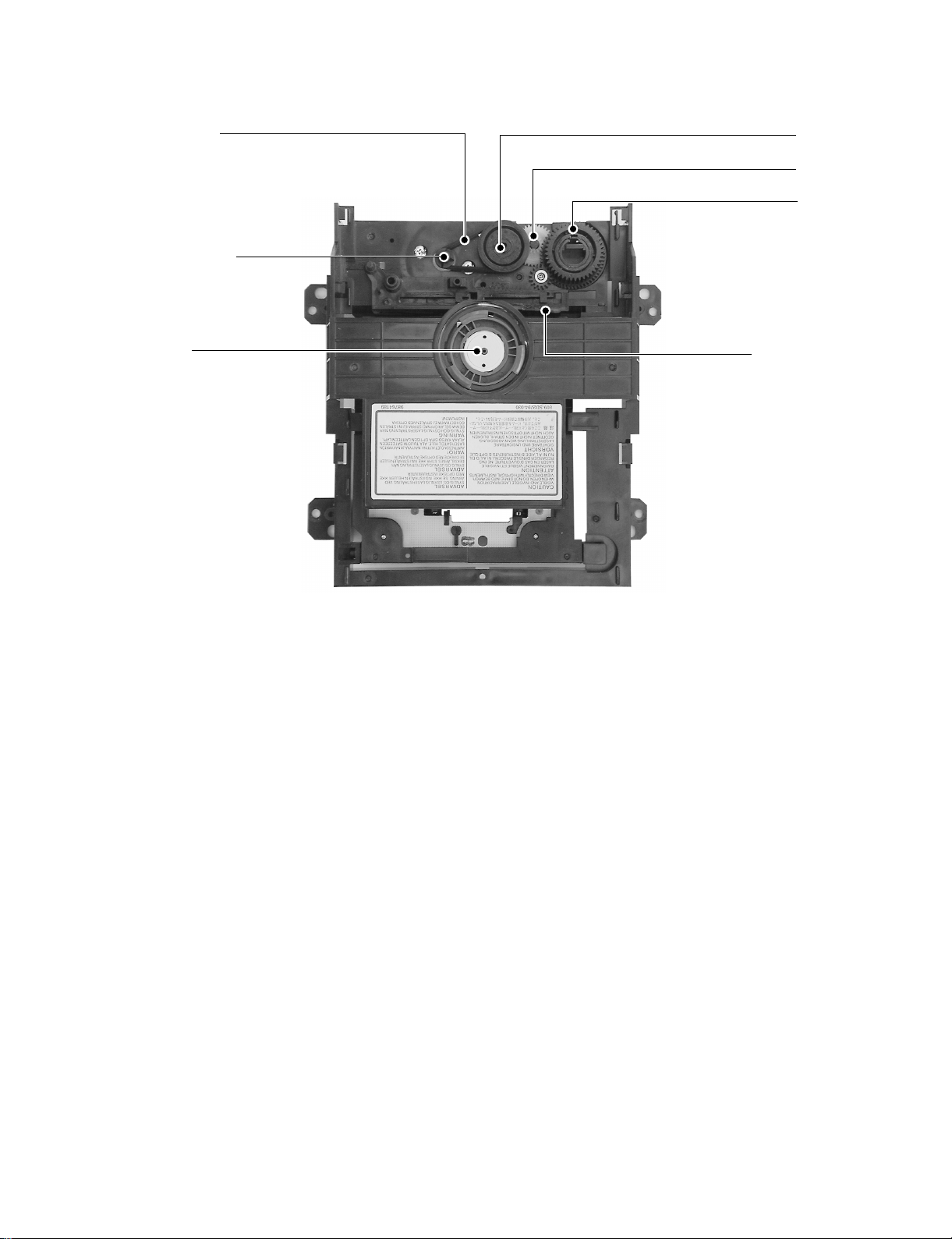

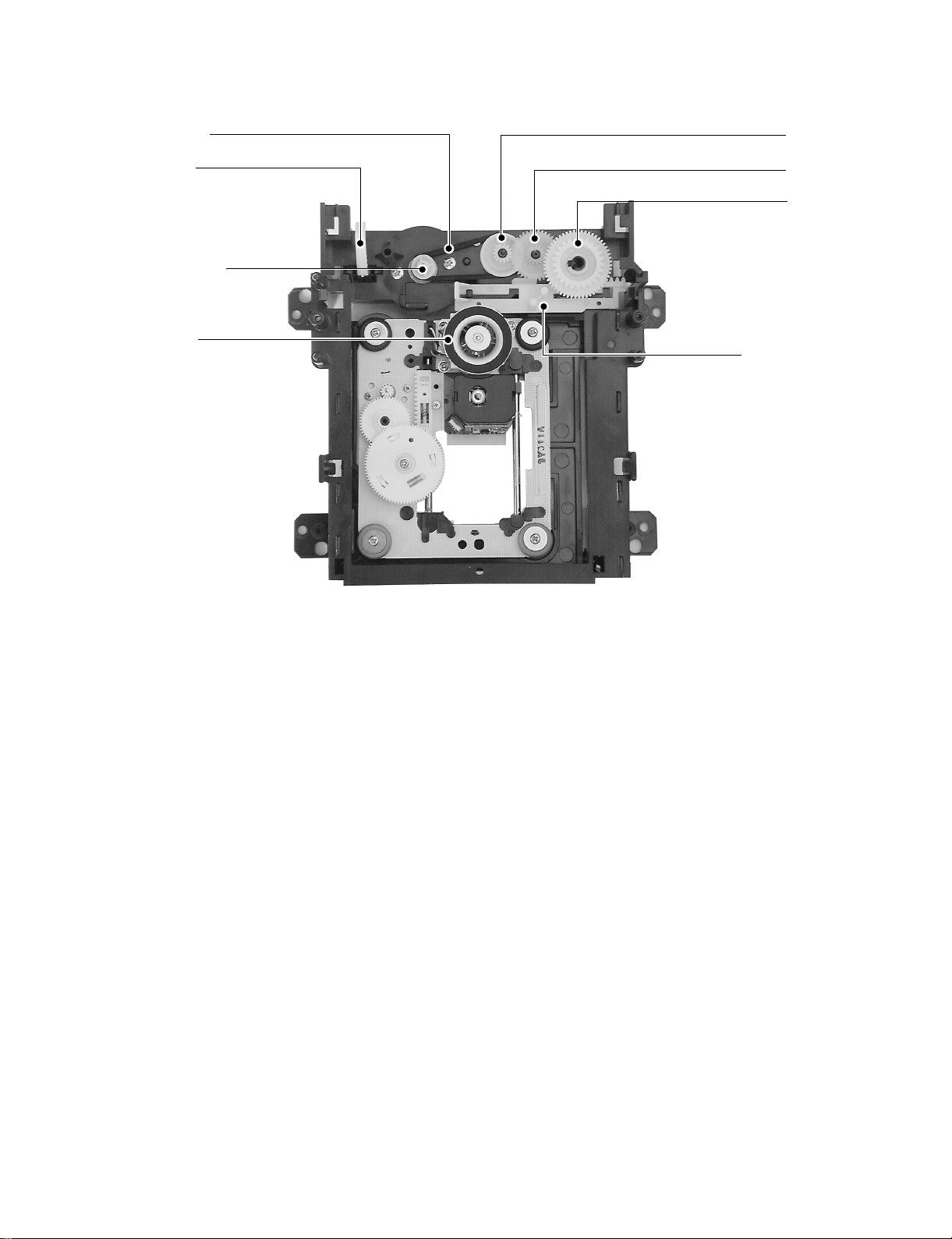

2-2. Location of Mechanism Parts

y

y

r

2-2-1. Type A

Tra

Clamper sta

Fig. 1-2-2 Mechanism chassis assembly (Top side)

Loading moto

PC board

Mechanism chassis

Fig. 1-2-3 Mechanism chassis assembly (Bottom side)

Page 7

Loading belt

r

r

r

r

Loading motor

Gea

Gea

Gea

Clamper

Cam Slide

Fig. 1-2-4 Mechanism chassis assembly (Internal side)

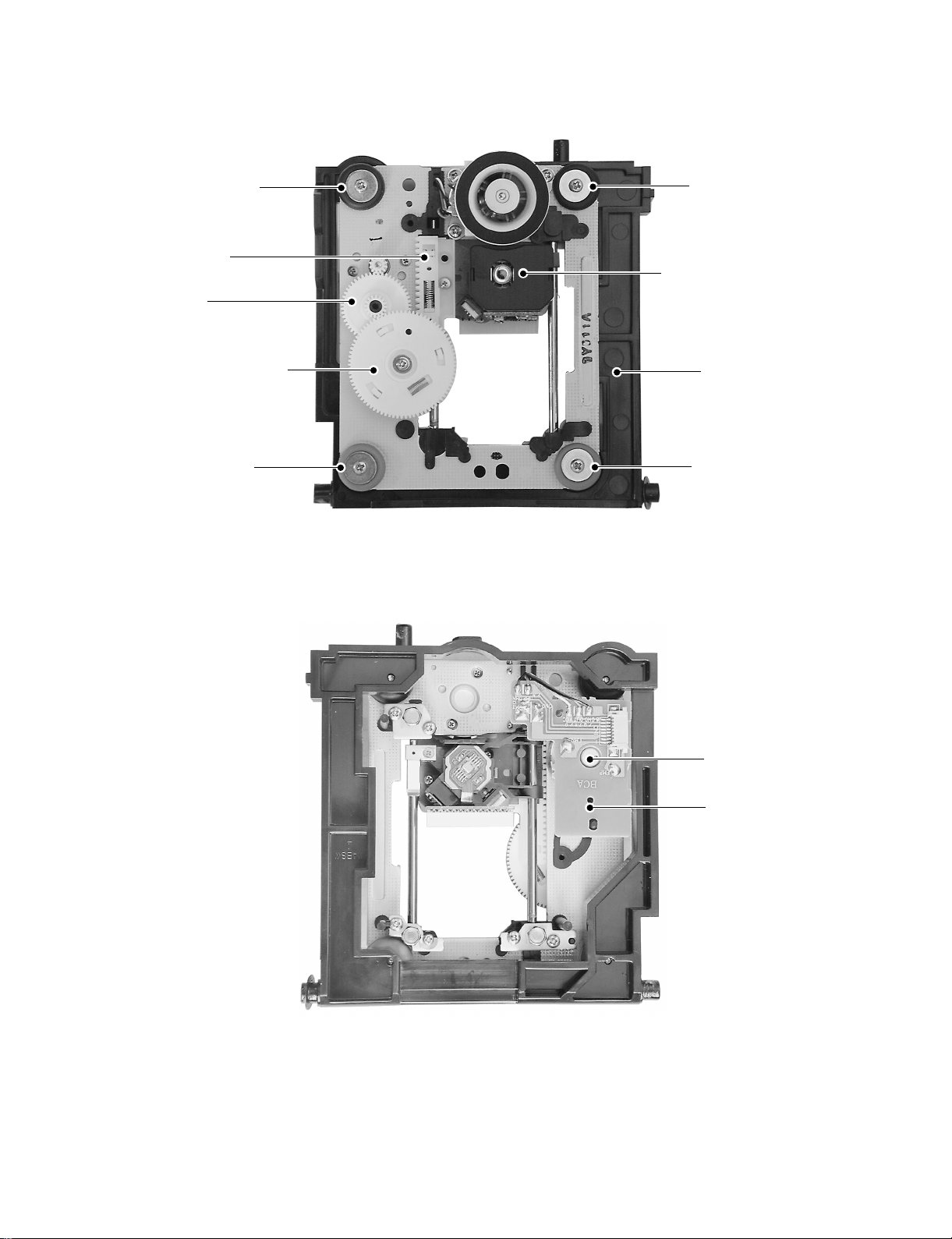

Page 8

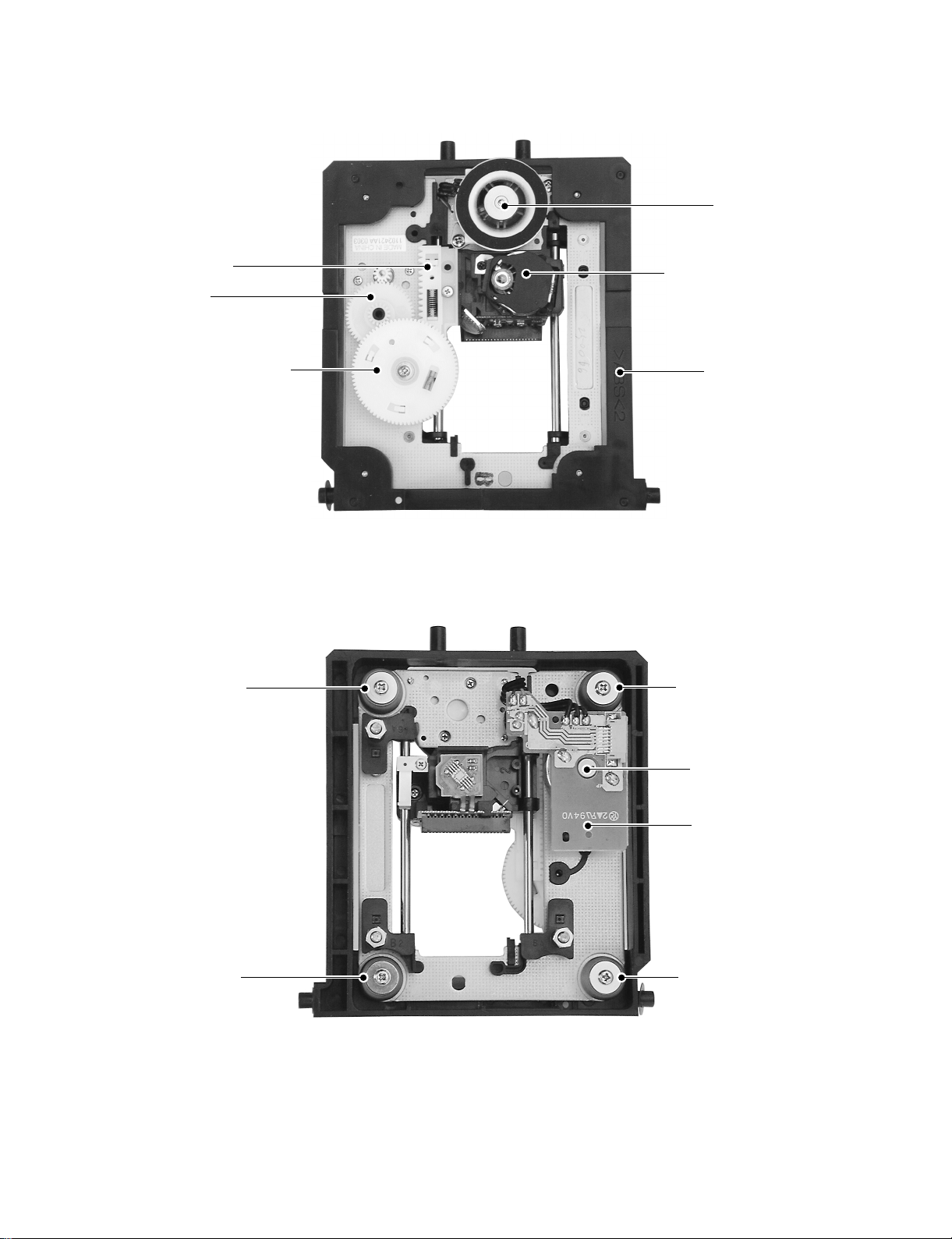

Rack gear

r

r

r

assembly

Gear A

Disc moto

Pickup assembly

Gear B assembly

Front damper

Sub chassis

Fig. 1-2-5 Pickup mechanism chassis assembly (Top side)

Front dampe

Feed motor

Rear damper

Feed motor

PC board

Rear dampe

Fig. 1-2-6 Pickup mechanism chassis assembly (Bottom side)

Page 9

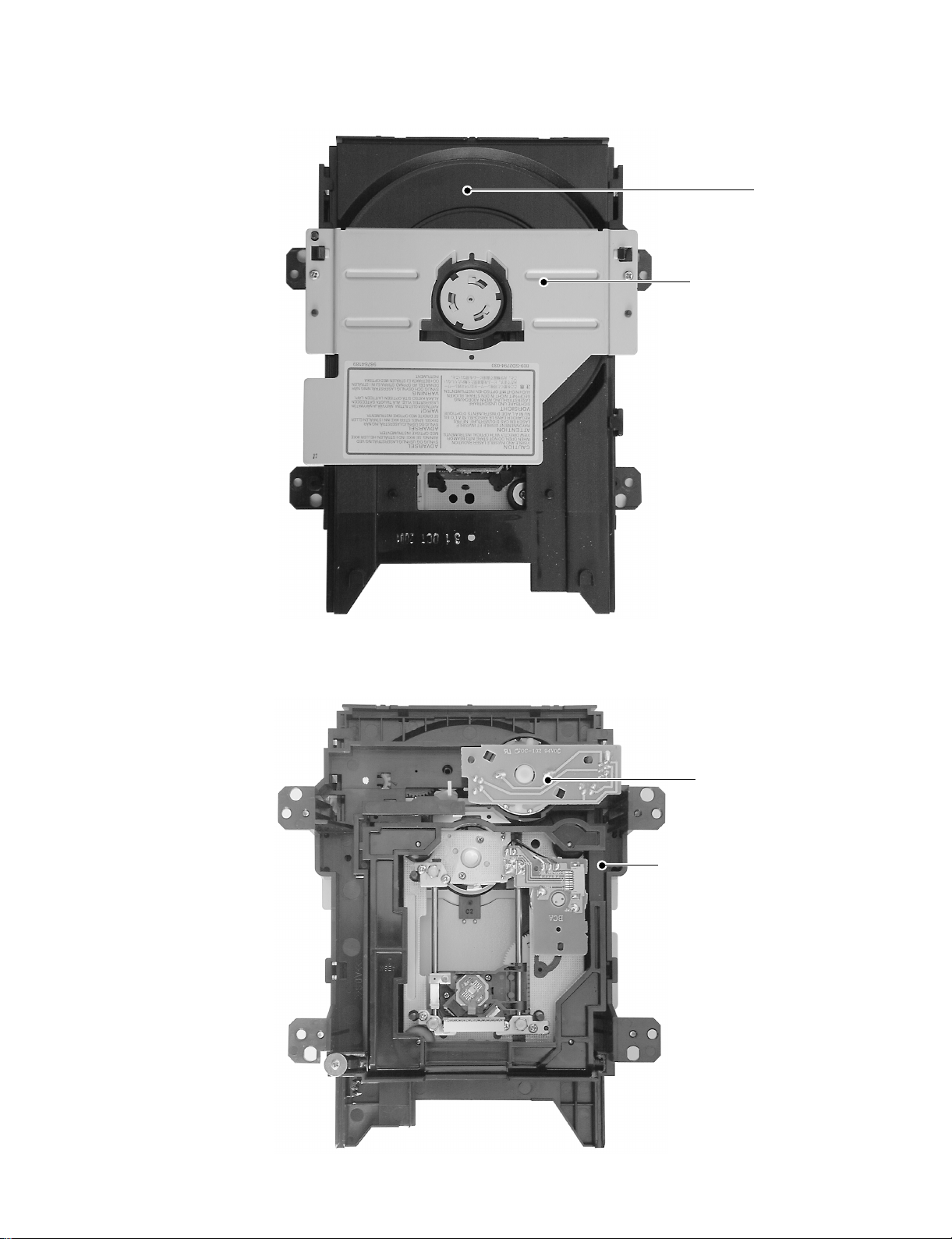

2-2-2. Type B

y

y

r

Tr a

Clamper sta

Fig. 1-2-7 Mechanism chassis assembly (Top side)

Loading moto

PC board

Mechanism chassis

Fig. 1-2-8 Mechanism chassis assembly (Bottom side)

Page 10

Loading belt

r

r

r

r

Gea

Kick lever

Loading motor

Disc motor

Gea

Gea

Cam Slide

Fig. 1-2-9 Mechanism chassis assembly (Internal side)

Page 11

Front damper

r

r

r

r

d

Rack gear

assembly

Gear A

Front dampe

Pickup assembly

Gear B assembly

Rear damper

Sub chassis

Rear dampe

Fig. 1-2-10 Pickup mechanism chassis assembly (Top side)

Feed moto

Feed moto

PC boar

Fig. 1-2-11 Pickup mechanism chassis assembly (Bottom side)

Page 12

3. TROUBLESHOOTING

3-1. Main Circuit

3-1-1. Servo System

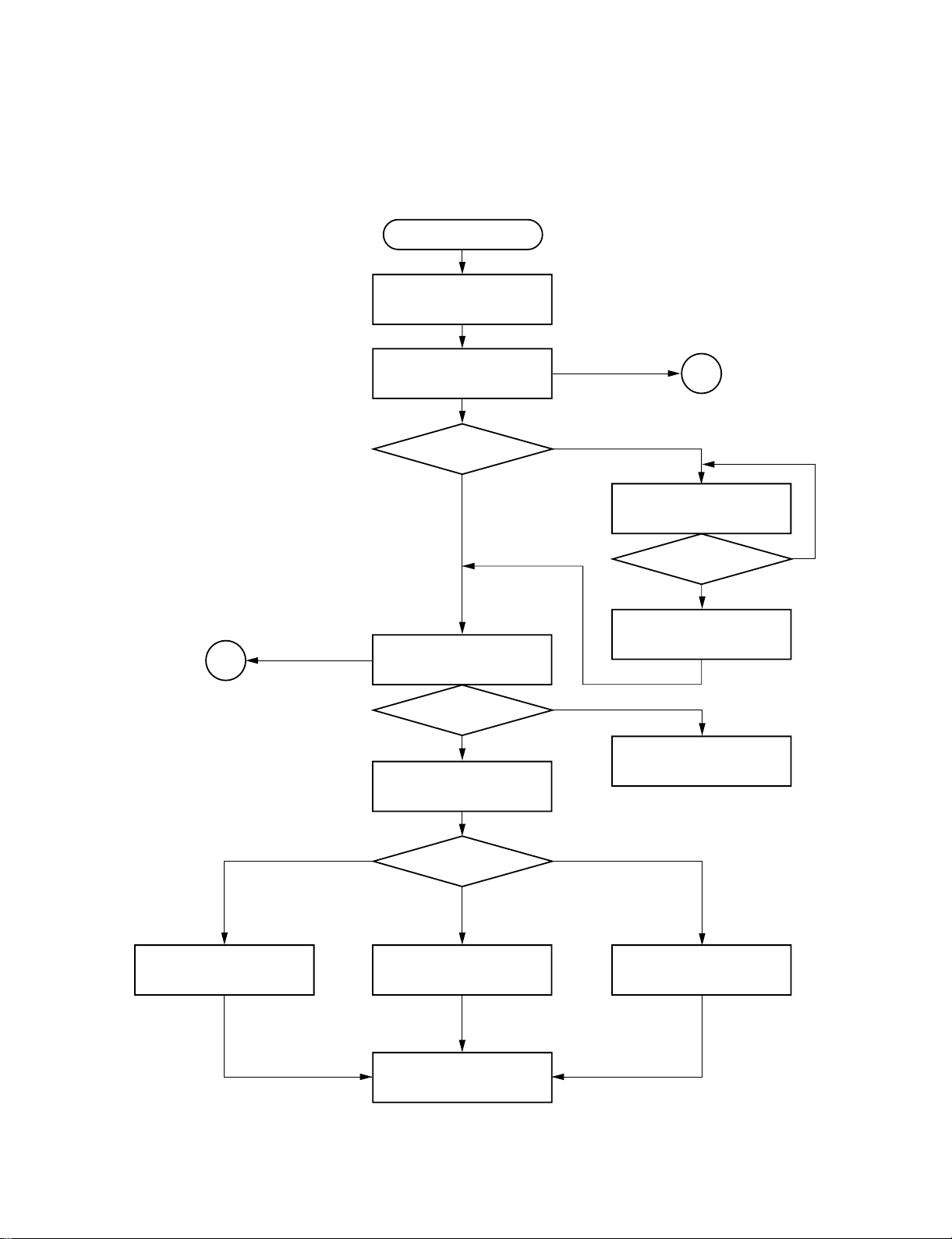

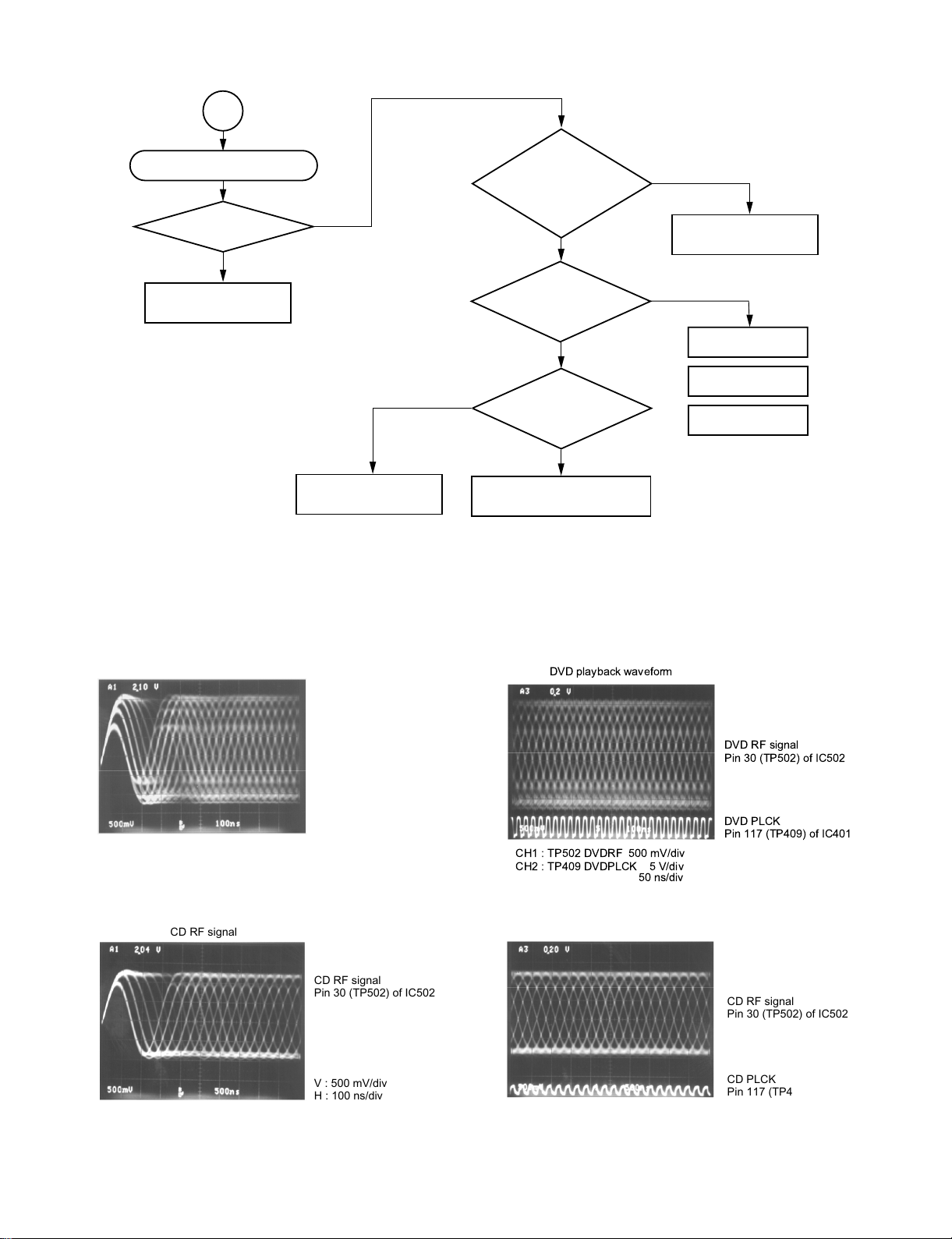

(1) Initial Operation after Power ON

Power ON

Send each LSI hard RST

command and initial command.

Pickup head is positioned at

transmission initial position.

Is tray closed?

Pin 5 of CN502,

TCLS=L

Y

2

NG

Disc presence/absence and

disc judgement

Is a disc present?

Y

DVD or CD initial setting.

N

Tray close operation

Pin C9 of IC306 (E537): LDMP = H/L

Pin Y19 of IC306 (E538): LDMN = L

Tray stops.

Pin C9 of IC306 : LDMP = H

Pin Y19 of IC306 : LDMN = L

N

Laser OFF

Display: INSERT DISC

Monitor screen: NO DISC

1

Is tray closed?

Pin 5 of CN502:

TCLS = L

Y

N

DVD single (single-layer)

DVD single

Initial setting.

DVD single

(single-layer)/DVD dual

(dual-layer)/CD?

DVD dual (dual-layer)

DVD dual

Initial setting.

To each disc playback process.

Fig. 1-3-1

CD

CD

Initial setting.

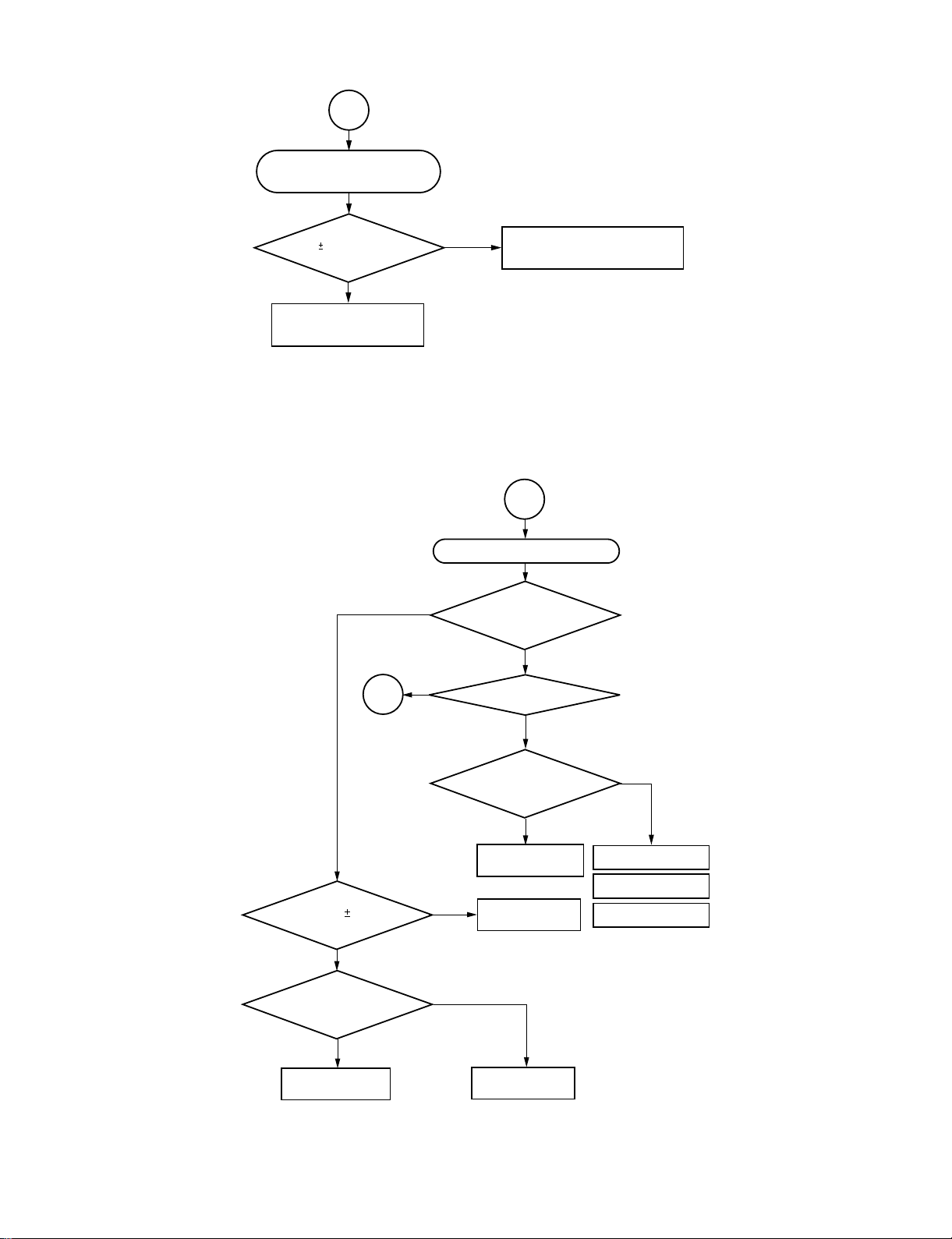

Page 13

1

Pickup (P.U.) transmission initial

operation does not occur.

The pickup transmission initial operation is carried out to

determine the initial position by transmitting the pickup to the

innermost position once (start-limit switch (pin 4 of CN503)

develops "L".) and to the external direction at low speed

(start-limit switch develops "H", turning off the switch.).

Does pulse of

1.65V 1.65V develop at

pin 162 of IC401?

Y

Check feed gear.

N

Check BUS between IC401-IC306

and oscillation.

Fig. 1-3-2

2-1

"No disc" misjudgement display of

N

disc presence.

Does lens move with

UP/DOWN full stroke in

focus direction?

Y

N

3

Does focus search

voltage of 1.65V 0.4V develop

at pin 23 of IC503 (E544)?

Y

Does search signal

output at both edges of focus coil?

(Pins 15 to 18 of CN501)

Y

Check pickup head

and wiring.

Is laser current normal?

Y

Does RFSB signal

develop more than 0.3V?

Y

Check peripheral

circuit of IC605.

N

N

Check IC401.

Check IC503.

Fig. 1-3-3

N

Check IC502.

Lens cleaning.

Replace pickup head.

Page 14

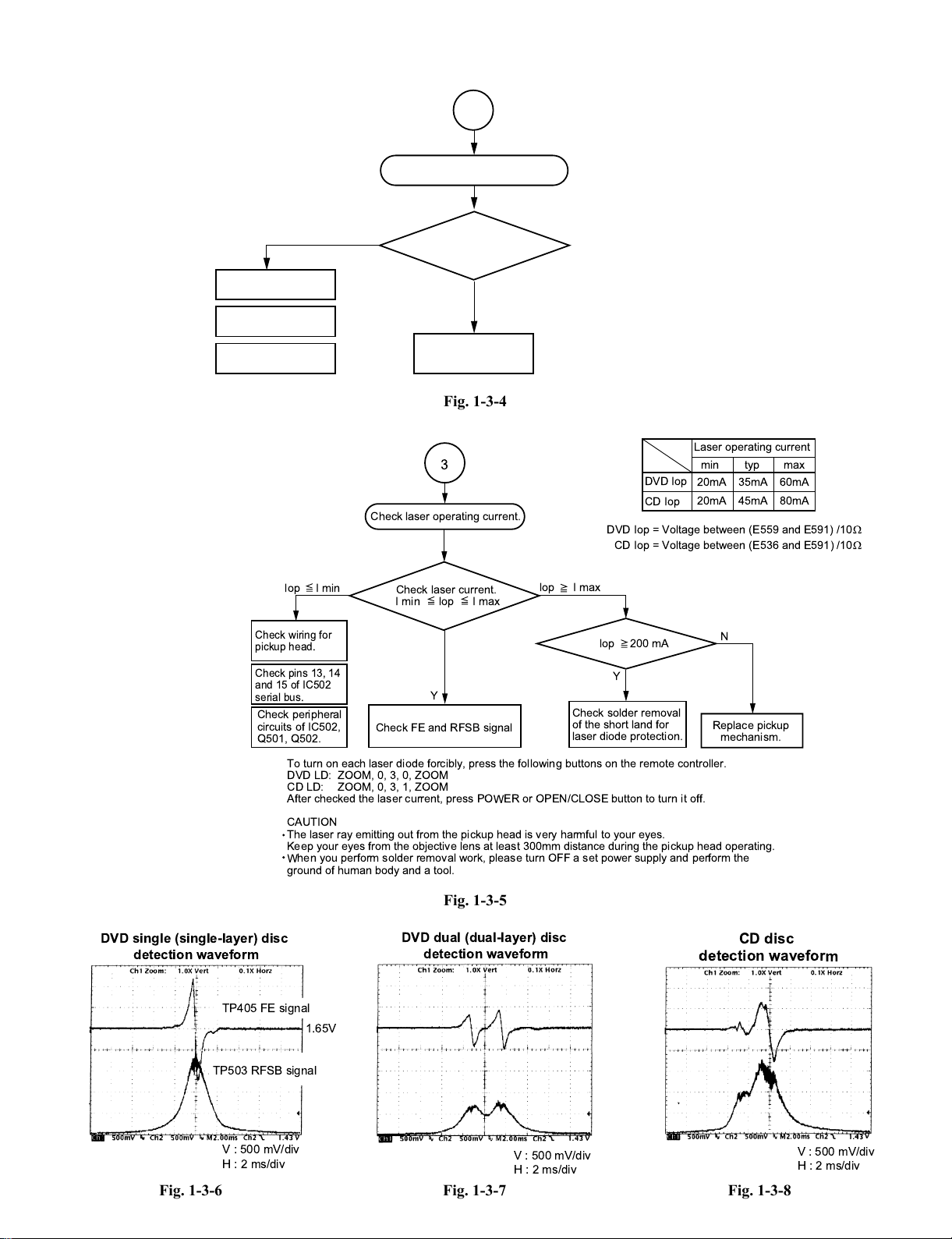

2-2

Check laser operating current.

Check laser current.

I min lop I max

Check pins 13, 14

and 15 of IC502

serial bus.

Check peripheral

circuits of IC502,

Q501, Q502.

Check solder removal

of the short land for

laser diode protection.

Check FE and RFSB signal

lop I max

lop I min

3

Check wiring for

pickup head.

Replace pickup

mechanism.

Y

Y

N

lop 200 mA

Laser operating current

DVD Iop

DVD Iop = Voltage between (E559 and E591) /10

W

CD Iop = Voltage between (E536 and E591) /10

W

CD Iop

min

20mA

20mA

35mA

45mA

60mA

80mA

typ max

CAUTION

The laser ray emitting out from the pickup head is very harmful to your eyes.

Keep your eyes from the objective lens at least 300mm distance during the pickup head operating.

When you perform solder removal work, please turn OFF a set power supply and perform the

ground of human body and a tool.

To turn on each laser diode forcibly, press the following buttons on the remote controller.

DVD LD:ZOOM, 0, 3, 0, ZOOM

CD LD: ZOOM, 0, 3, 1, ZOOM

After checked the laser current, press POWER or OPEN/CLOSE button to turn it off.

V : 500 mV/div

H : 2 ms/div

CD disc

detection waveform

Disc kind misjudgement

(Initial setting is NG.)

N

Check IC502.

Lens cleaning.

Replace pickup head.

Are FE and RFSB

signals for each disc normal?

Y

Check peripheral

circuit of IC605.

Fig. 1-3-4

DVD single (single-layer) disc

detection waveform

TP405 FE signal

TP503 RFSB signal

V : 500 mV/div

H : 2 ms/div

Fig. 1-3-6 Fig. 1-3-7 Fig. 1-3-8

1.65V

Fig. 1-3-5

DVD dual (dual-layer) disc

detection waveform

V : 500 mV/div

H : 2 ms/div

Page 15

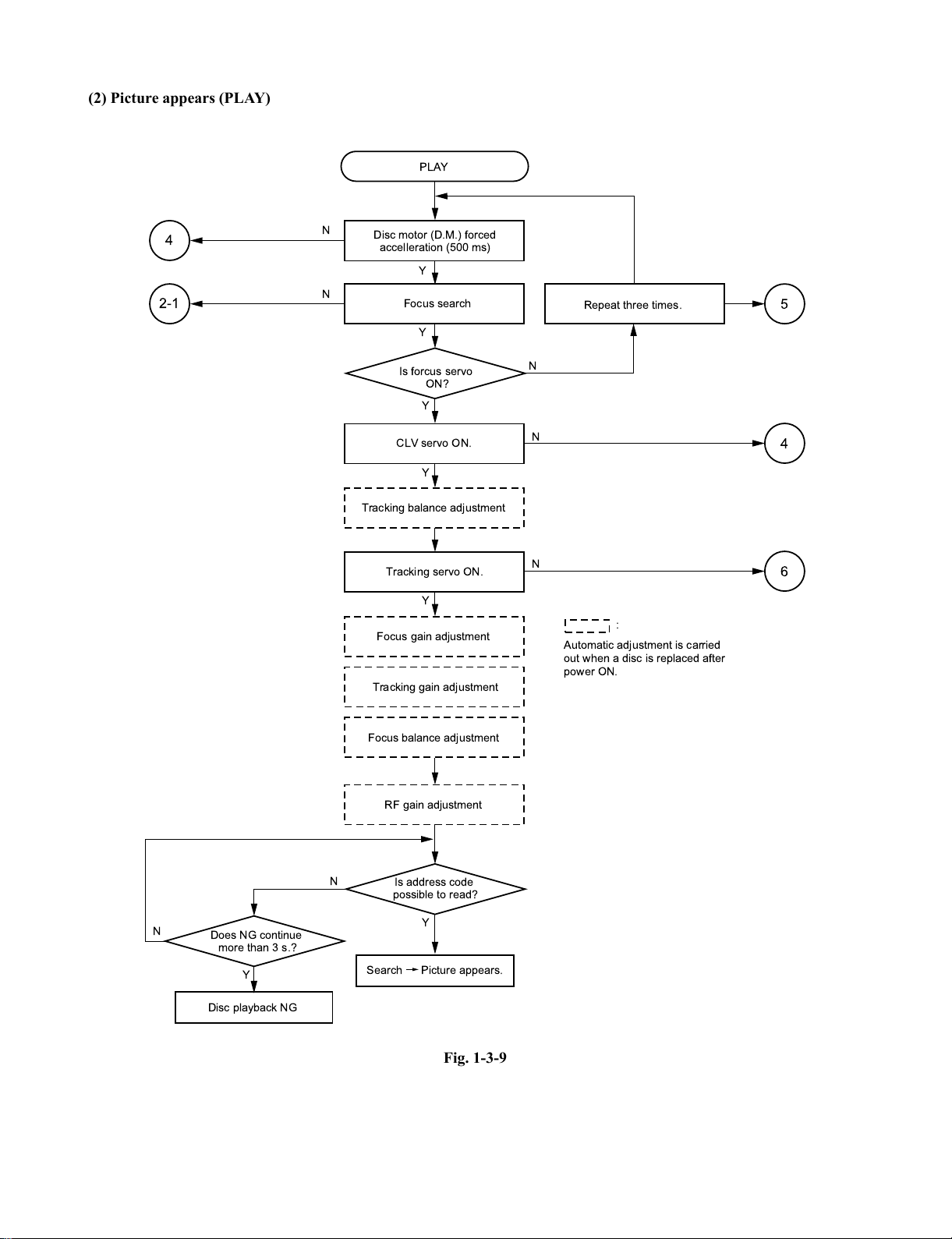

(2) Picture appears (PLAY)

PLAY

4

2-1

N

N

Disc motor (D.M.) forced

accelleration (500 ms)

Focus search

Is forcus servo

CLV servo ON.

Tracking balance adjustment

Tracking servo ON.

Focus gain adjustment

Tracking gain adjustment

Y

Y

Y

Y

Y

ON?

Repeat three times.

N

N

N

:

Automatic adjustment is carried

out when a disc is replaced after

power ON.

5

4

6

Focus balance adjustment

RF gain adjustment

N

N

Does NG continue

more than 3 s.?

Y

Disc playback NG

Is address code

possible to read?

Y

Search Picture appears.

Fig. 1-3-9

Page 16

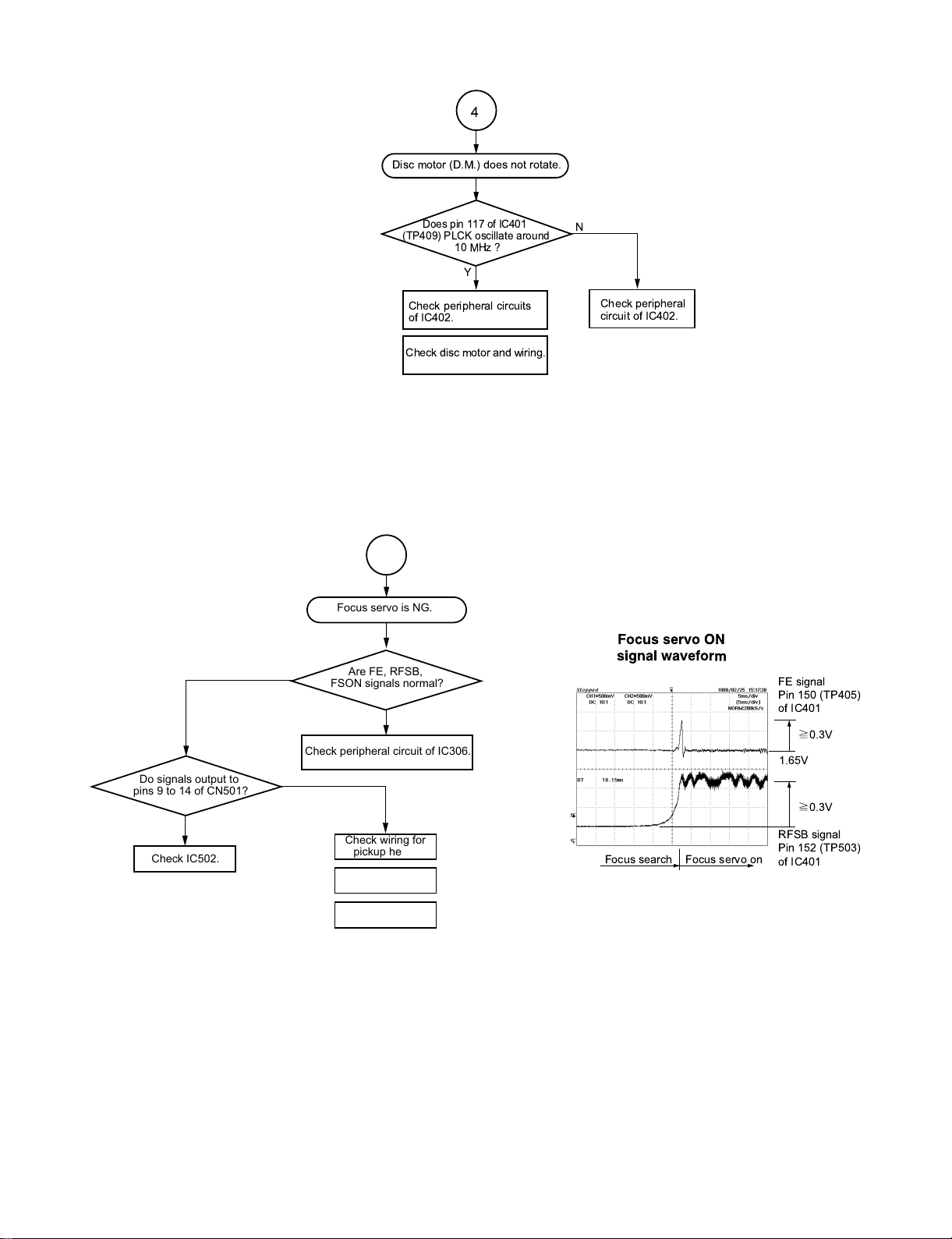

4

Disc motor (D.M.) does not rotate.

Does pin 117 of IC401

(TP409) PLCK oscillate around

10 MHz ?

Check peripheral

circuit of IC402.

Check peripheral circuits

of IC402.

Check disc motor and wiring.

N

Y

Do signals output to

pins 9 to 14 of CN501?

Y

Check IC502.

5

Focus servo is NG.

N

N

Are FE, RFSB,

FSON signals normal?

Y

Check peripheral circuit of IC306.

Check wiring for

pickup head.

Lens cleaning.

Replace pickup

mechanism.

Fig. 1-3-10

Focus servo ON

signal waveform

Focus search Focus servo on

Fig. 1-3-12

FE signal

Pin 150 (TP405)

of IC401

0.3V

1.65V

0.3V

RFSB signal

Pin 152 (TP503)

of IC401

Fig. 1-3-11

Page 17

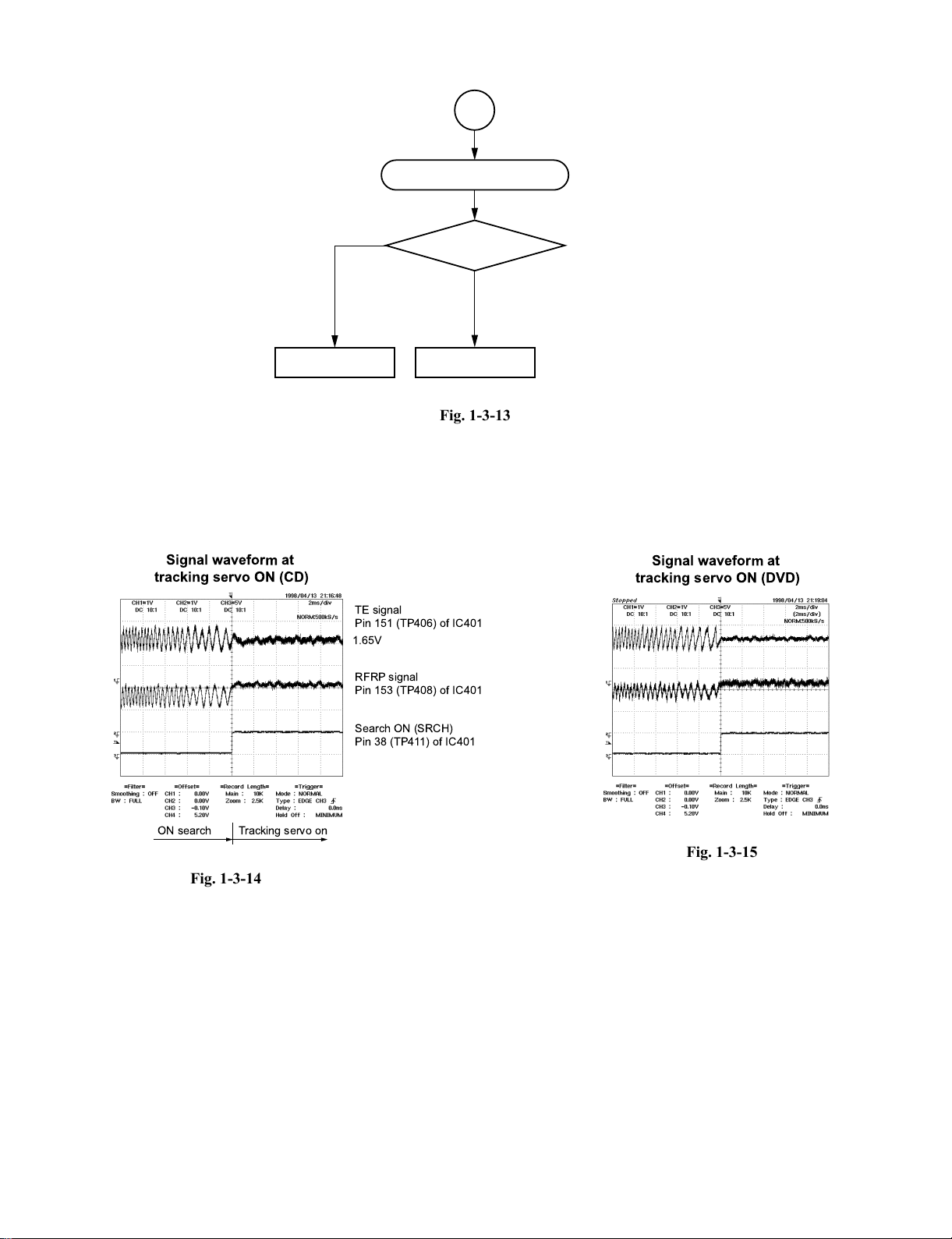

6

Signal waveform at

tracking servo ON (DVD)

Tracking servo is NG.

Signal waveform at

tracking servo ON (CD)

Check IC502.

TE signal

Pin 151 (TP406) of IC401

1.65V

RFRP signal

Pin 153 (TP408) of IC401

N

Is TE signal normal?

Y

Check peripheral

circuit of IC306.

Fig. 1-3-13

ON search Tracking servo on

Search ON (SRCH)

Pin 38 (TP411) of IC401

Fig. 1-3-15

Fig. 1-3-14

Page 18

7

Disc playback is NG (DVD).

Is PLL locked?

(Refer to waveforms.)

Y

Check signal process

system following to IC402.

N

Check peripheral circuits of

IC401 and IC306.

N

Check peripheral circuits

of IC502 and IC401.

Fig. 1-3-16

Does pulse of

L = 1.65V and H = 3.3V

develop at pin 131 and

L = 0V and H = 1.65V

develop at pin 132

of IC401?

Y

Does RF output

higher than 1 V(p-p)

develop at pin 30 (TP502)

of IC502?

Y

Pin 43 of IC502 = 2.4V

Pin 44 of IC502 = 3.0V

Y

N

Check peripheral circuits

of IC401 and IC306.

N

Check IC502.

Lens cleaning.

Pickup mechanism

replacement

DVD RF signal

Fig. 1-3-17

CD RF signal

DVD RF signal

Pin 30 (TP502) of IC502

V : 500 mV/div

H : 50 ns/div

CD RF signal

Pin 30 (TP502) of IC502

PLL works as a servo loop to generate a clock signal for reading RF

signal binary data. With the PLL locked, the eye pattern is identified

clearly when triggered with the read clock PLCK.

DVD playback waveform

DVD RF signal

Pin 30 (TP502) of IC502

DVD PLCK

Pin 117 (TP409) of IC401

CH1 : TP502 DVDRF 500 mV/div

CH2 : TP409 DVDPLCK 5 V/div

50 ns/div

Fig. 1-3-19

CD playback waveform

CD RF signal

Pin 30 (TP502) of IC502

Fig. 1-3-18

V : 500 mV/div

H : 100 ns/div

CH1 : TP502 CDRF 500 mV/div

CH2 : TP409 CDPLCK 5 V/div

100 ns/div

Fig. 1-3-20

CD PLCK

Pin 117 (TP409) of IC401

Page 19

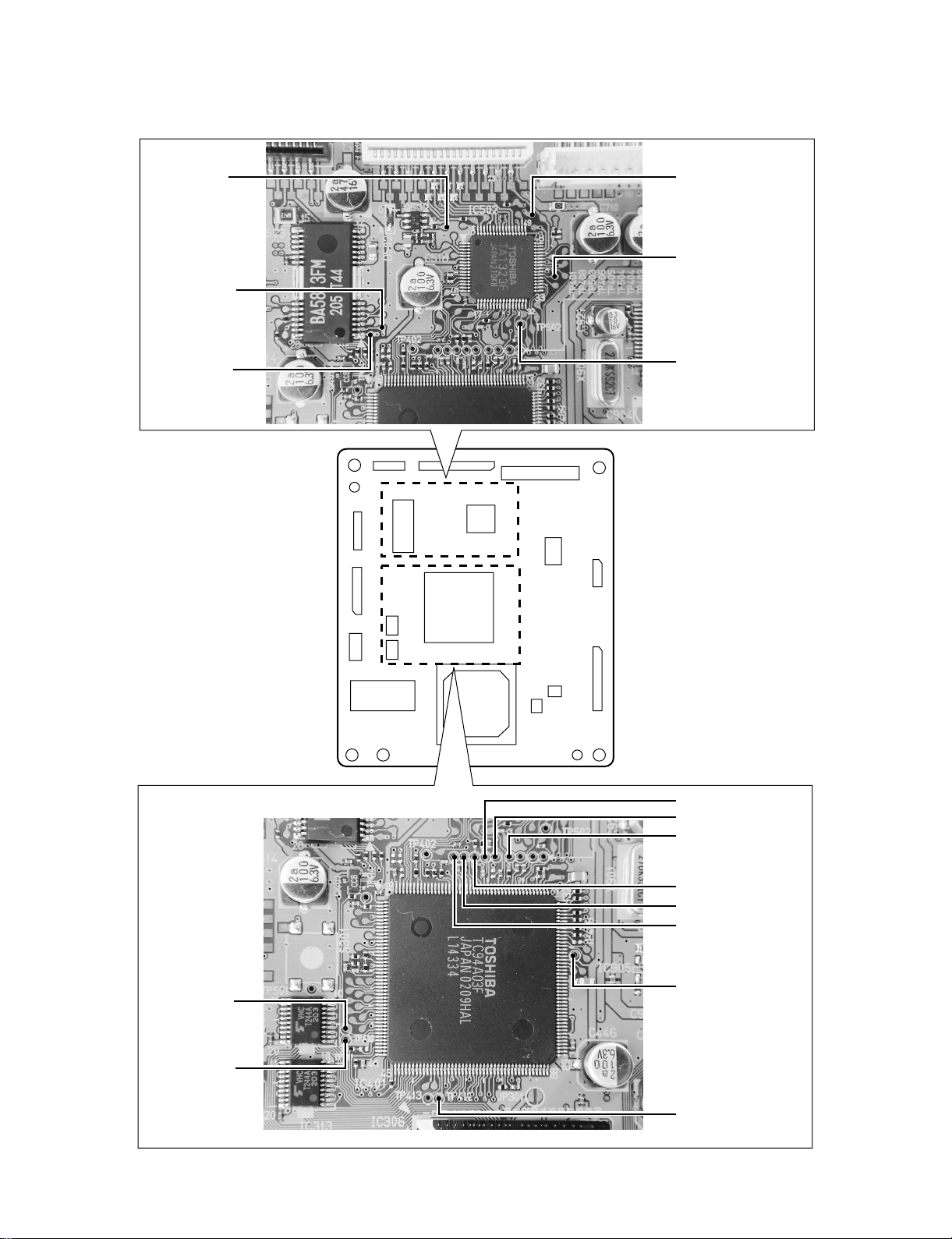

3-1-2. Location Diagram of Servo Test Point

)

(D

D

9

5

5

V

E

)

M

N

D

(L

8

3

5

E

M

)

P

D

(L

7

3

5

E

)

(C

6

3

5

D

E

)

V

5

(+

4

3

5

E

O

R

F

2

0

5

P

T

CN502

CN603

CN601

IC305

CN503

IC503

IC312

IC313

IC306

CN501

IC502

IC401

CN701

IC902

IC310

IC307

CN901

CN302

T

6

0

E

4

P

T

F

5

0

E

4

P

T

T

C

R

F

4

0

5

P

T

B

S

R

F

3

0

5

P

T

P

R

R

F

8

0

4

P

T

D

E

F

V

R

1

0

4

P

T

F

0

G

1

L

4

P

T

4

P

T

A

F

1

1

G

L

B

T

V

K

M

2

1

4

P

T

C

K

C

P

L

9

0

4

P

Fig. 1-3-21

Page 20

SECTION 2

PART REPLACEMENT AND

ADJUSTMENT PROCEDURES

CAUTIONS BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to take a proper grounding

treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a magnetized screw-

driver in servicing. Several kinds of screws are used and some of them need special cautions. That is, take care of the

tapping screws securing molded parts and fine pitch screws used to secure metal parts. If they are used improperly, the

screw holes will be easily damaged and the parts can not be fixed.

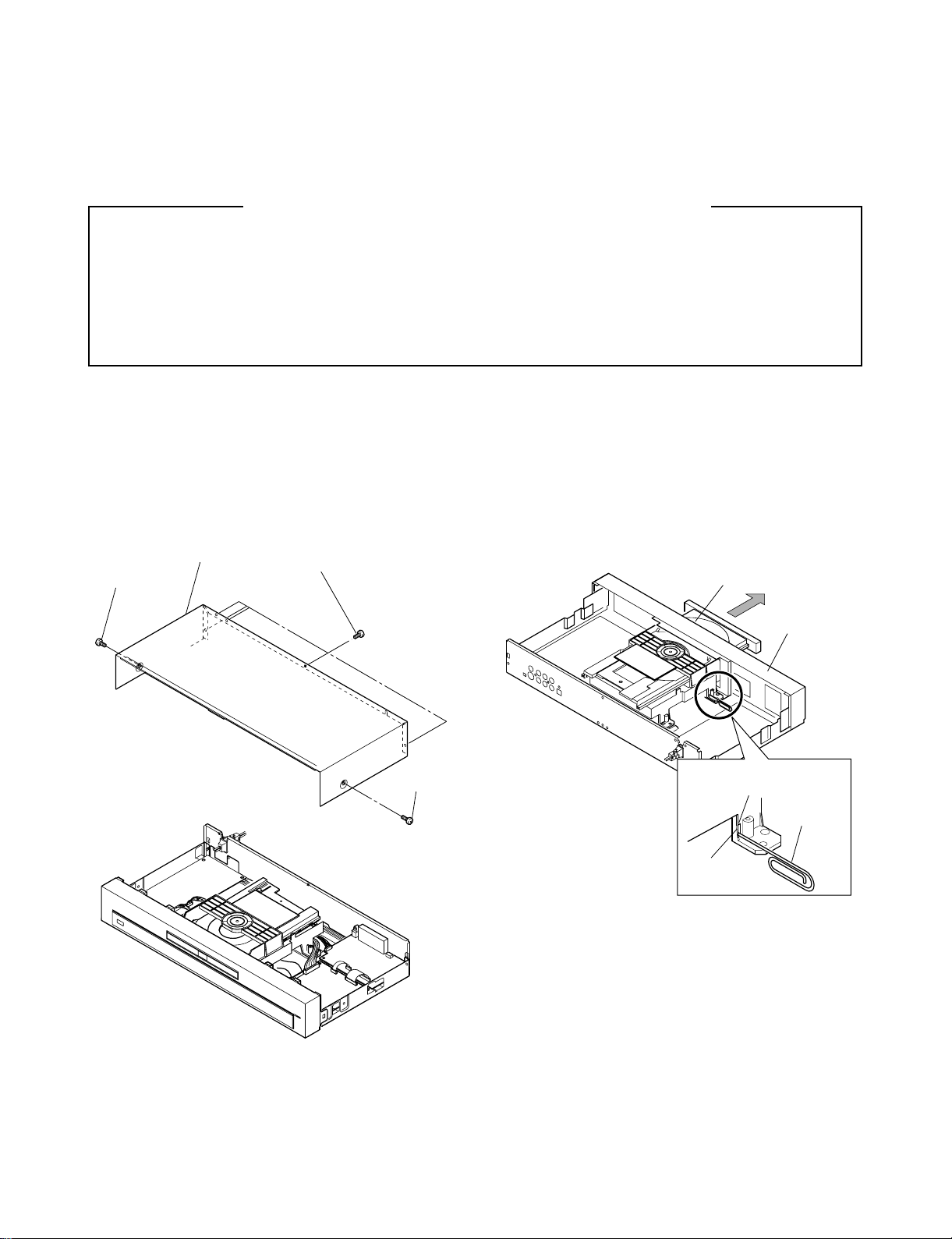

1. REPLACEMENT OF MECHANICAL PARTS (TYPE A)

1-1. Cabinet Replacement

1-1-1. Top Cover

1. Remove seven screws (1), then remove the top cover

(2).

Top cover (2)

Screw (1)

Screws (1)

Screw (1)

1-1-2. Tray Panel

<Tray Ejection>

1. Insert a paper clip, etc. into the hole A to eject the tray

(1).

Tray (1)

Front panel

Insert a paper clip, etc.

in this hole

Paper clip, etc.

Hole A

Fig. 2-1-1

Fig. 2-1-2

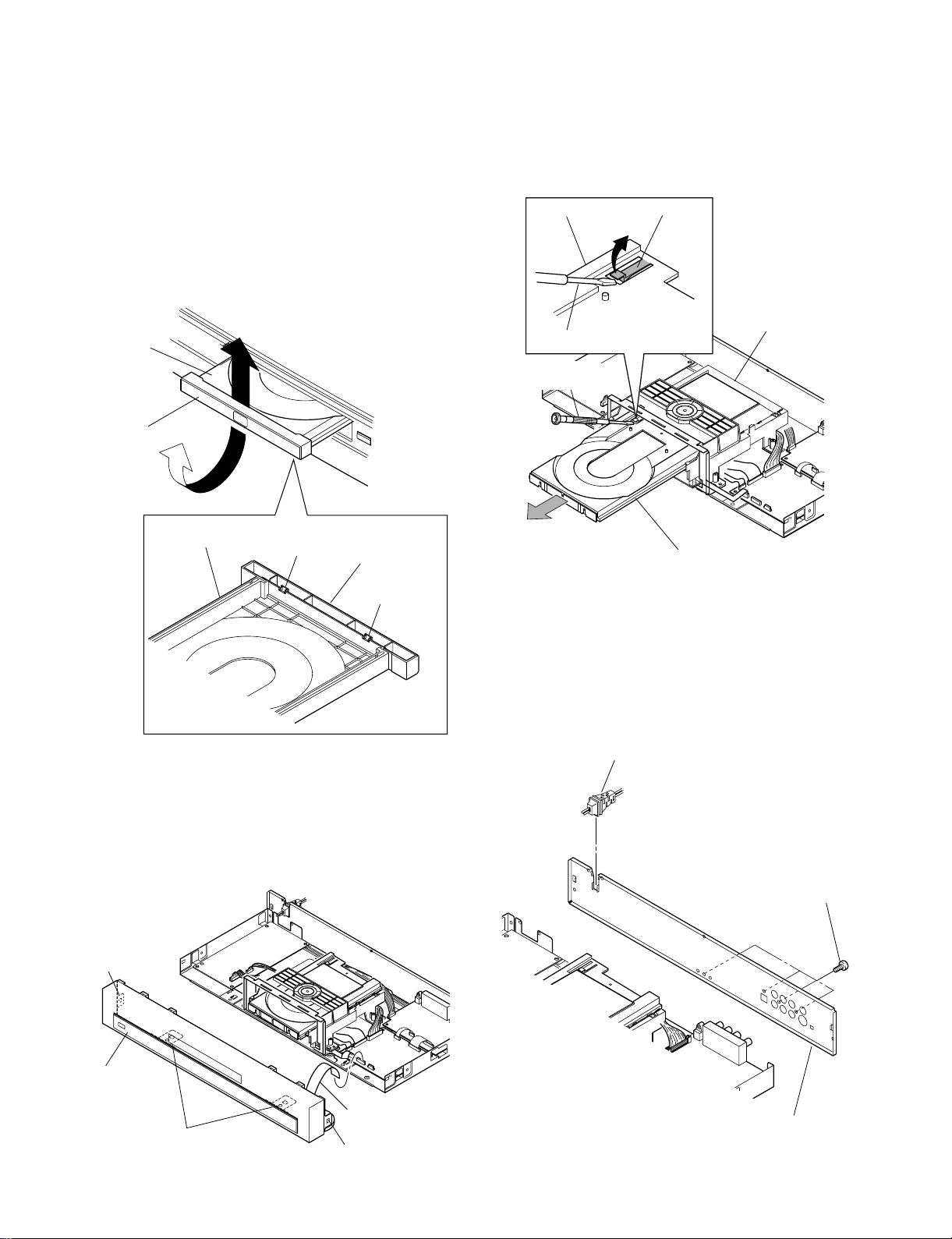

Page 21

<Tray Panel Removal>

Mechanism

chassis assembly

Tray (1)

Pull out the tray (1)

toward you.

Tray (1)

Minus screwdriver

Claw A

Minus

screwdriver

1. Eject the tray (1). (Refer to item 1-1-2.)

2. Twist the tray panel (2) a little in the arrow A direction

with the tray (1) hold by hand to release two claws and

lift up the tray panel (2) in the arrow B direction, then

the tray panel (2) is removed.

3. When mounting the tray panel (2), insert the tray panel

(2) along the grooves of the both sides of the tray (1)

until clicking.

1-1-4. Tray

1. Pull out the tray (1) towards you until it stops.

2. Lift up claw A with a minus screwdriver, and pull out

the tray (1) towards you, then remove the tray (1).

Tray (1)

Tray

panel (2)

A

Tray (1)

B

B

A

Fig. 2-1-3

Claw

Tray

Panel (2)

Claw

Fig. 2-1-5

1-1-5. Rear Panel

1. Remove the bush (1).

2. Remove four screws (2), then remove the rear panel

(3).

Bush (1)

1-1-3. Front Panel

1. Remove one flexible cable (1).

2. Release four claws, then remove the front panel (2).

Claw

Front

panel (2)

Claws

Screws (2)

Flexible cable (1)

Rear panel (3)

Claw

Fig. 2-1-6

Fig. 2-1-4

Page 22

1-2. PC Board Replacement

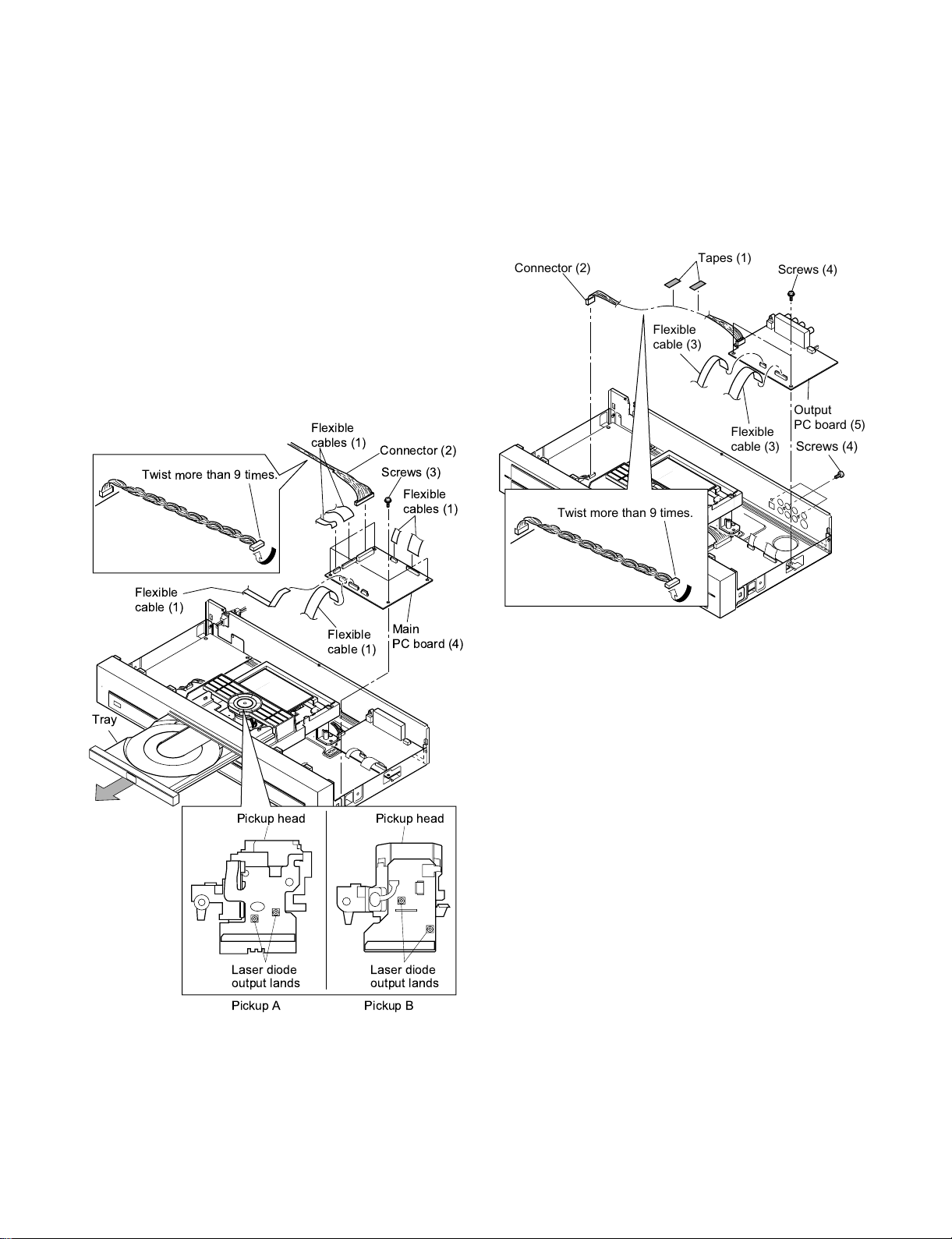

1-2-1. Main PC Board

Note:

• Before removing the main PC board (4), be sure to

short-circuit the laser diode output land.

After replacing, open the land as it was after inserting

the flexible cables (1).

1. Remove the top cover. (Refer to item 1-1-1.)

2. Eject the tray. (Refer to item 1-1-2.)

3. Remove six flexible cables (1) and remove one

connector (2).

4. Remove four screws (3), then remove the main PC

board (4).

Flexible

cables (1)

Twist more than 9 times.

Connector (2)

Screws (3)

Flexible

cables (1)

1-2-2. Output PC Board

1. Remove the top cover. (Refer to item 1-1-1.)

2. Peel off two tapes (1) and remove the connector (2).

3. Remove two flexible cables (3).

4. Remove five screws (4), then remove the output PC

board (5).

Flexible

cable (3)

Tapes (1)

Flexible

cable (3)

Screws (4)

Output

PC board (5)

Screws (4)

Connector (2)

Twist more than 9 times.

Tray

Flexible

cable (1)

Flexible

cable (1)

Pickup head

Laser diode

output lands

Pickup A Pickup B

Main

PC board (4)

Pickup head

Laser diode

output lands

Fig. 2-1-8

Fig. 2-1-7

Page 23

1-2-3. Power PC board

Power SW

PC board (5)

Front display

PC board (3)

Screws (2)

Screws (6)

Screws (4)

Flexible

cable (1)

1. Remove the bush (1).

2. Peel off two tapes (2) and remove two connectors (3).

3. Remove four screws (4), then remove the power

supply PC board (5).

Screws (4)

Connector (3)

Power bush (1)

Power supply

PC board (5)

Tapes (2)

Connector (3)

1-2-4. Front PC Board

1. Remove the front panel. (Refer to item 1-1-3.)

2. Remove the flexible cable (1).

3. Remove nine screws (2), then remove the front display

PC board (3).

4. Remove two screws (4), then remove the power switch

PC board (5).

5. Remove three screws (6), then remove the ENTER

switch (7).

Twist more than 9 times.

Fig. 2-1-10

Fig. 2-1-9

Page 24

1-3. Mechanism Parts

1-3-1. Mechanism Chassis Assembly

Note:

• When removing the mechanism chassis assembly (3),

be sure to short-circuit the laser diode output land

before removing the connector and the flexible cables.

After replacing, open the land as it was after inserting

the connector and flexible cables.

1. Remove the front panel. (Refer to item 1-1-3.)

2. Remove three flexible cables (1).

3. Remove four screws (2), then remove the mechanism

chassis assembly (3).

Pickup head

Screws (2)

Mechanism

chassis assembly (3)

Flexible

cables (1)

Laser diode

output lands

Pickup A

Pickup head

Laser diode

output lands

Pickup B

Fig. 2-1-11

Page 25

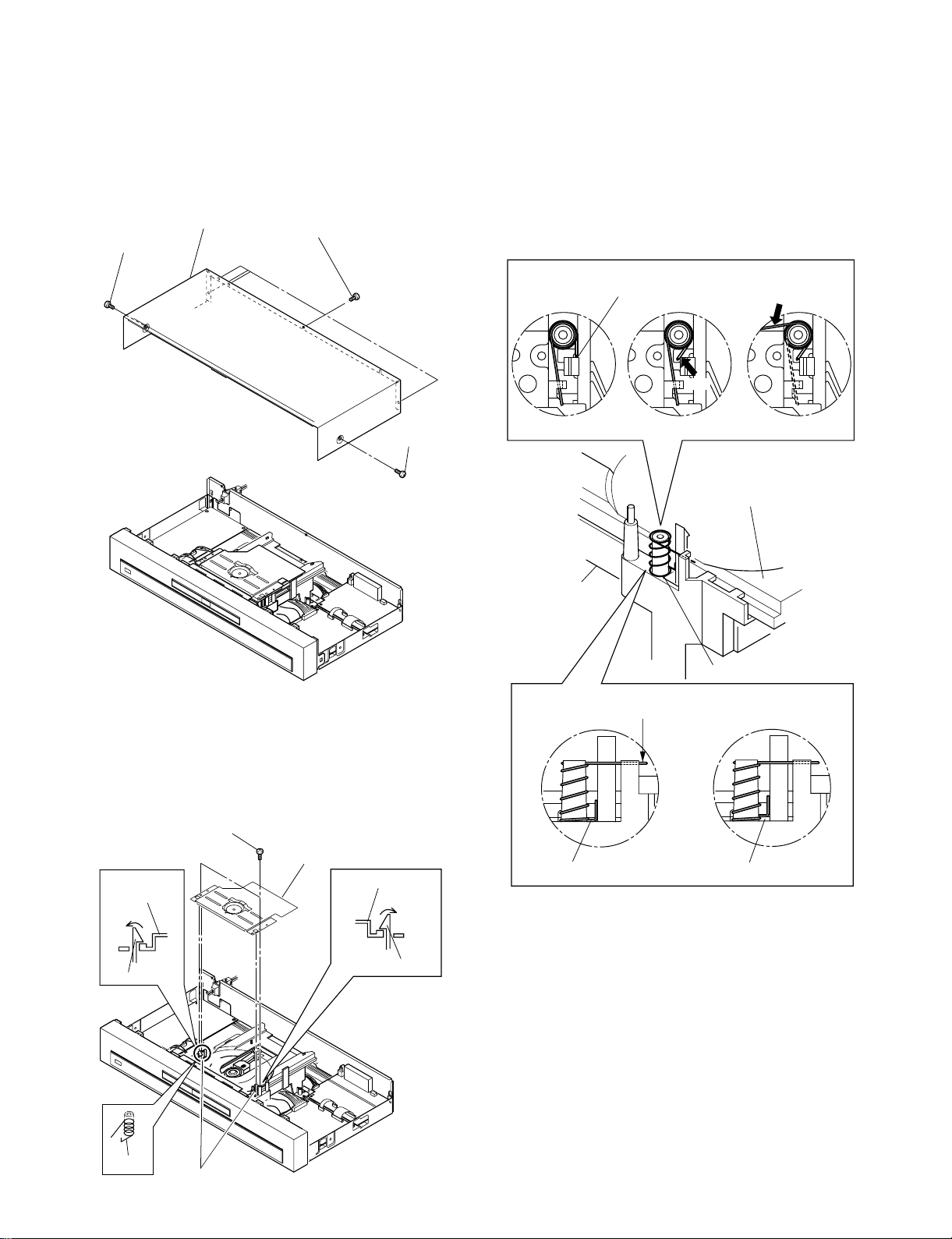

2. REPLACEMENT OF MECHANICAL PARTS (TYPE B)

2-1. Cabinet Replacement

2-1-1. Top Cover

1. Remove seven screws (1), then remove the top cover

(2).

Screw (1)

Top cover (2)

Screws (1)

Screw (1)

<Mounting >

1. The spring for tray side pressure is inserted into the

portion “A”. (Refer to Fig. 2-1-13.)

2. By referring to Fig. 2-1-14, insert the spring normally

and mount the clamper stay.

This part should be touched

to the left side of the tray.

NG

OK

Mechanism

chassis assembly

NG

Tray

Fig. 2-1-12

2-1-2. Clamper Stay

<Removal>

1. Remove two screws (1).

2. Release two claws and remove the clamper stay (2).

Screws (1)

Clamper stay (2)

Clamper

stay (2)

Claw

A

Clamper stay (2)

Claw

Press down by finger

unitil fix the clamper assembly

OK

No floating

Fig. 2-1-14

Spring

NG

Floating NG

Spring

Claws

Fig. 2-1-13

Page 26

2-1-3. Tray Panel

Front

panel (2)

Tray (3)

Claws

Claw

Flexible cable (1)

Claw

<Tray Ejection>

1. Slide the slider (2) of the mechanism chassis assembly

(1) with a screwdriver, etc. in the arrow direction, so

that the tray (3) is ejected.

Note:

• Take care not to damage the pickup and other parts.

Tray (3)

Tray

panel (4)

B

B

A

A

Screw

driver

Slider (2)

Mechanism

chassis assembly (1)

Tray (3)

Front panel

Fig. 2-1-15

<Tray Panel Removal>

1. Eject the tray (3).

2. Twist the tray panel (4) a little in the arrow A direction

with the tray (3) hold by hand to release two claws and

lift up the tray panel (4) in the arrow B direction, then

the tray panel (4) is removed. (Refer to Fig. 2-1-16.)

3. When mounting the tray panel (4), insert the tray panel

(4) along the grooves of the both sides of the tray (3)

until clicking.

Tray (3)

Claw

Tray

Panel (4)

Claw

Fig. 2-1-16

2-1-4. Front Panel and Tray

1. Remove the flexible cable (1).

2. Release four claws and remove the front panel (2).

3. Pull out the tray (3) towards you.

Fig. 2-1-17

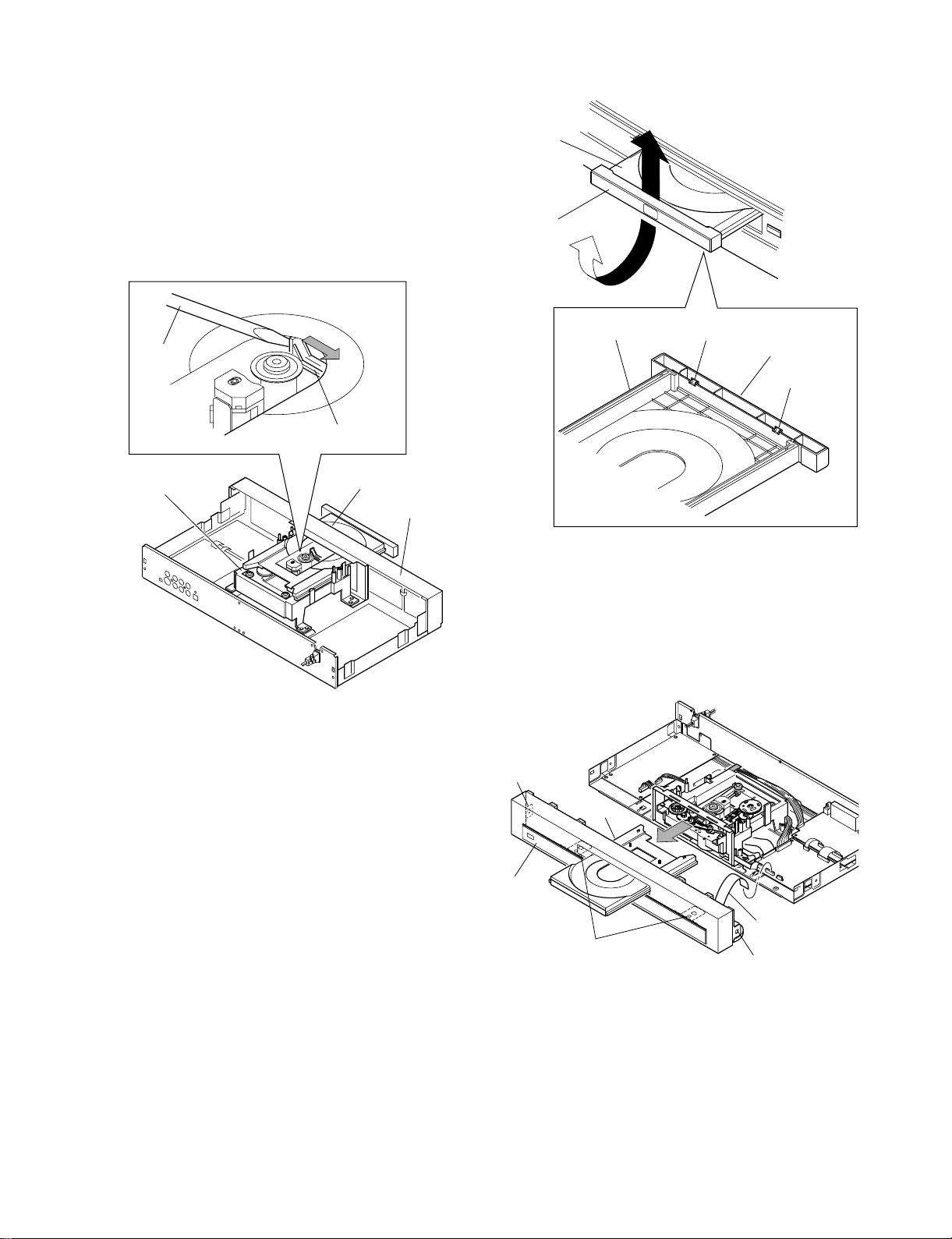

Note:

• Insert the tray (3) with the front side of the pickup

mechanism assembly descended. (The slider positions

to the left side.)

• The gears are required to match their phases each

other. After setting the gear (4) as shown in the figure

“A”, insert the tray (3). When inserting a tray (3), push

the rack gear side shown by the arrow.

Page 27

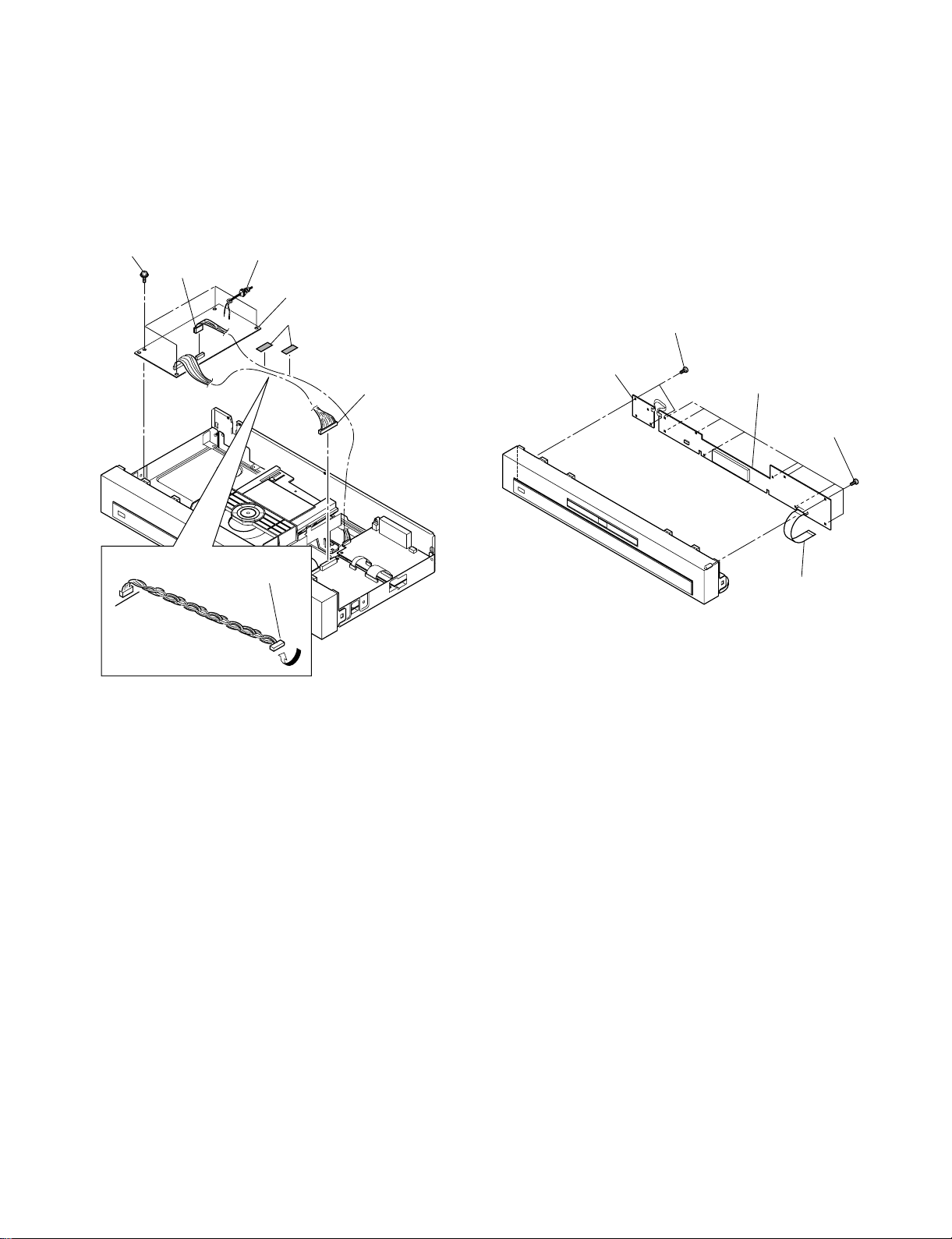

Screws (3)

Twist more than 9 times.

Connector (2)

Flexible

cables (1)

Flexible

cable (1)

Flexible

cable (1)

Flexible

cables (1)

Main

PC board (4)

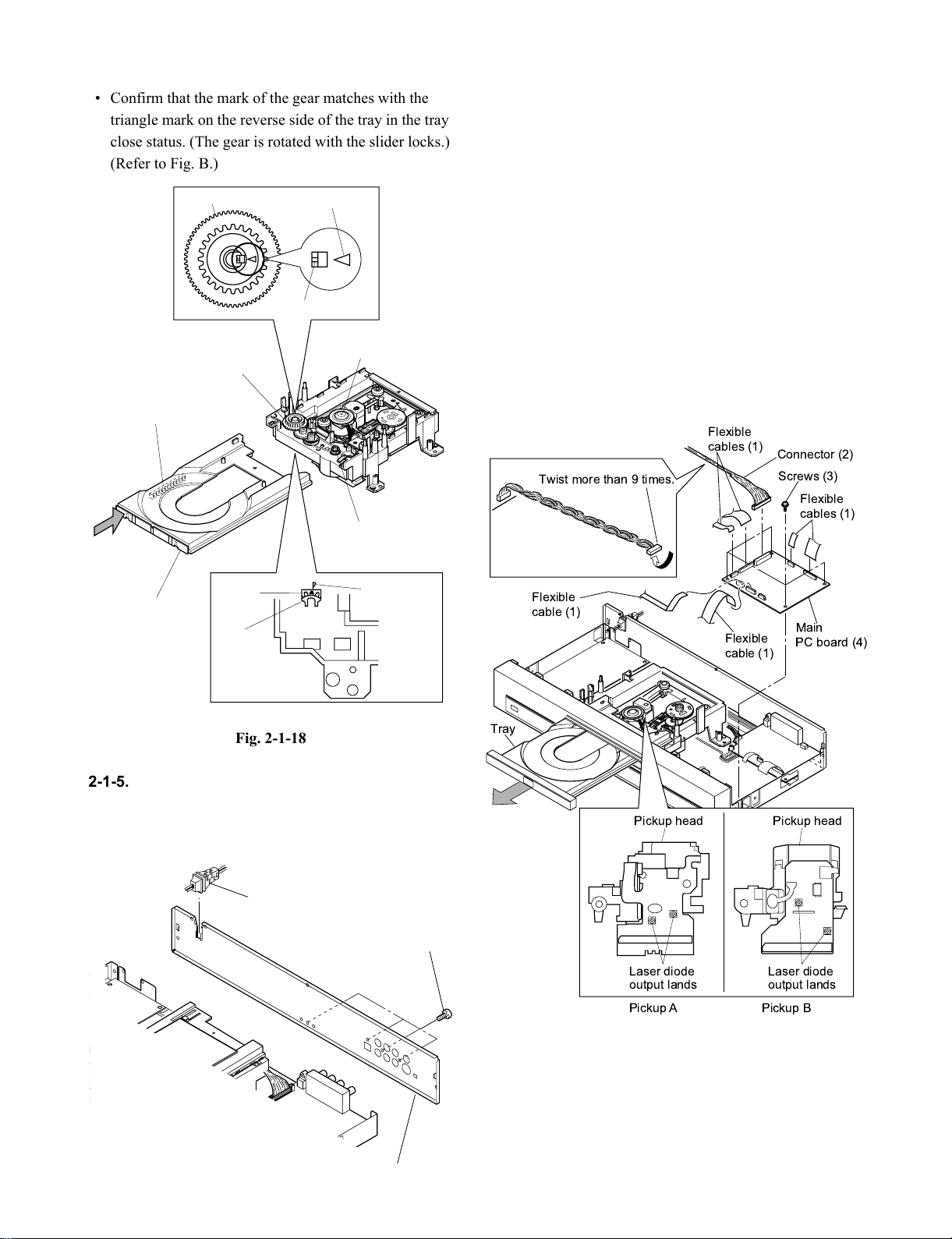

Tray

Pickup head

Pickup A Pickup B

Laser diode

output lands

Pickup head

Laser diode

output lands

• Confirm that the mark of the gear matches with the

triangle mark on the reverse side of the tray in the tray

close status. (The gear is rotated with the slider locks.)

(Refer to Fig. B.)

Fig. A

Gear (4) Triangle mark

Position of the line

Pickup mechanism

assembly

Gear (4)

Tray rack gear

Slider

2-2. PC Board Replacement

2-2-1. Main PC Board

Note:

• Before removing the main PC board (4), be sure to

short-circuit the laser diode output land.

After replacing, open the land as it was after inserting

the flexible cables (1).

1. Remove the top cover. (Refer to item 2-1-1.)

2. Eject the tray. (Refer to item 2-1-3.)

3. Remove six flexible cables (1) and remove one

connector (2).

4. Remove four screws (3), then remove the main PC

board (4).

Tray (3)

Gear

Fig. 2-1-18

Fig. B

2-1-5. Rear Panel

1. Remove the bush (1).

2. Remove four screws (2), then remove the rear panel

(3).

Bush (1)

Triangle markMarking

Screws (2)

Fig. 2-1-20

Fig. 2-1-19

Rear panel (3)

Page 28

2-2-2. Output PC Board

1. Remove the top cover. (Refer to item 2-1-1.)

2. Peel off two tapes (1) and remove the connector (2).

3. Remove two flexible cables (3).

4. Remove five screws (4), then remove the output PC

board (5).

Flexible

cable (3)

Tapes (1)

Flexible

cable (3)

Screws (4)

Output

PC board (5)

Screws (4)

Connector (2)

Twist more than 9 times.

2-2-3. Power PC board

1. Remove the power bush (1).

2. Peel off two tapes (2) and remove two connectors (3).

3. Remove four screws (4), then remove the power

supply PC board (5).

Screws (4)

Connector (3)

Power bush (1)

Power supply

PC board (5)

Tapes (2)

Connector (3)

Fig. 2-1-21

Twist more than 9 times.

Fig. 2-1-22

Page 29

2-2-4. Front PC Board

1. Remove the front panel. (Refer to item 2-1-4.)

2. Remove the flexible cable (1).

3. Remove six screws (2), then remove the front display

PC board (3).

4. Remove two screws (4), then remove the power switch

PC board (5).

5. Remove three screws (6), then remove the ENTER

switch (7).

Screws (4)

Power SW

PC board (5)

Front display

PC board (3)

Screws (2)

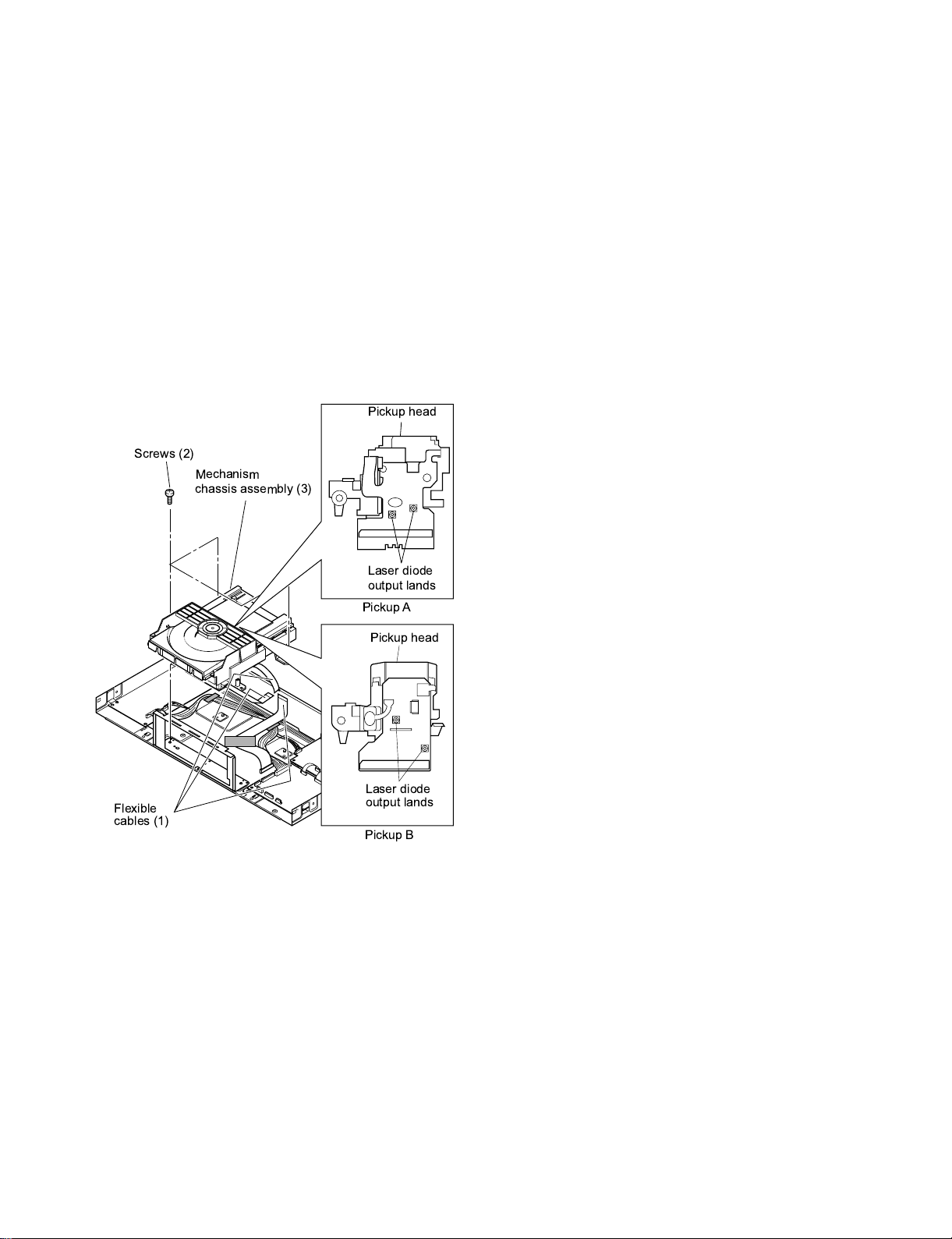

2-3. Mechanism Parts

2-3-1. Mechanism Chassis Assembly

Note:

• When removing the mechanism chassis assembly (3),

be sure to short-circuit the laser diode output land

before removing the connector and the flexible cables.

After replacing, open the land as it was after inserting

the connector and flexible cables.

1. Remove the tray. (Refer to items 2-1-3 and 2-1-4.)

2. Remove three flexible cables (1).

3. Remove four screws (2), then remove the mechanism

chassis assembly (3).

Pickup head

Screws (2)

Mechanism

chassis assembly (3)

Fig. 2-1-23

Flexible

cable (1)

Flexible

cables (1)

Laser diode

output lands

Pickup A

Pickup head

Laser diode

output lands

Pickup B

Fig. 2-1-24

Page 30

SECTION 3

SERVICING DIAGRAMS

1. STANDING PC BOARDS FOR SERVICING

EU02 Power supply PC board

EU01 Main PC board

EU05 Output PC board

EU04 Power SW PC board

EU03 Front display PC board

Fig. 3-1-1

Page 31

2. CIRCUIT SYMBOLS AND SUPPLEMENTARY EXPLANATION

100k

Rated Wattage Type Tolerance

100

m

Temperature

response

Rated

voltage

Tolerance

2-1. Precautions for Part Replacement

• In the schematic diagram, parts marked (ex.

F801) are critical part to meet the safety regulations,

so always use the parts bearing specified part codes

(SN) when replacing them.

2-2. Solid Resistor Indication

Unit None ........... Ω

K ........... kΩ

M ........... MΩ

Tolerance None ........... ±5%

B ........... ±0.1%

C ........... ±0.25%

D ........... ±0.5%

F ........... ±1%

G ........... ±2%

K ........... ±10%

M ........... ±20%

Rated Wattage (1) Chip Parts

None .........1/16W

(2) Other Parts

None .........1/6W

Other than above, described in the Circuit Diagram.

Type None ........... Carbon film

S ........... Solid

R ........... Oxide metal film

W ...........Metal film

W ...........Cement

FR ........... Fusible

• Using the parts other than those specified shall violate

the regulations, and may cause troubles such as

operation failures, fire etc.

Eg. 1

Fig. 3-2-1

2-3. Capacitance Indication

Symbol

Unit None ........... F

Rated voltage None ........... 50V

Tolerance (1) Ceramic, plastic, and film capacitors of which

Temperature characteristic None ........... SL

(Ceramic capacitor) For others, temperature characteristics are

Static electricity capacity Sometimes described with abbreviated letters as

(Ceramic capacitor) shown in Eg. 3.

+

........... Electrolytic, Special electrolytic

NP

........... Non polarity electrolytic

........... Ceramic, plastic

M

........... Film

........... Trimmer

µ ...........µF

p ........... pF

For other than 50V and electrolytic capacitors,

described in the Circuit Diagram.

capacitance are more than 10 pF.

None ........... ±5% or more

B ........... ±0.1%

C ........... ±0.25%

D ........... ±0.5%

F ........... ±1%

G ........... ±2%

(2) Ceramic, plastic, and film capacitors of which

capacitance are 10 pF or less.

None ........... more than ±5% pF

B ........... ±0.1 pF

C ........... ±0.25 pF

(3) Electrolytic, Trimmer

Tolerance is not described.

described. (For capacitors of 0.01 µF and

no indications are described as F.)

Eg. 2

Fig. 3-2-2

Eg. 3

104

4

pF (0.1µF)

10x10

Temperature characteristic

(or Temperature characteristic+

Static electricity capacity tolerance)

Fig. 3-2-3

Page 32

2-4. Inductor Indication

Type name

10

µ

Type Tolerance

Unit None ........... Η

µ ...........µH

m ...........mH

Tolerance None ........... ±5%

B ........... ±0.1%

C ........... ±0.25%

D ........... ±0.5%

F ........... ±1%

G ........... ±2%

K ........... ±10%

M ........... ±20%

2-5. Waveform and Voltage Measurement

• The waveforms for CD/DVD and RF shown in the

circuit diagrams are obtained when a test disc is

played back.

• All voltage values except the waveforms are expressed

in DC and measured by a digital voltmeter.

2-6. Others

• The parts indicated with "NC" or "KETU" etc. are not

used in the circuits of this model.

Eg. 4

Fig. 3-2-4

Eg. 5

Fig. 3-2-5

Page 33

3 . (A) PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM - DD-6030

CNY02

Board-in

VDD+5V

VEE-9V

GND

VDD+5V

VEE-9V

GND

CN802

EU02

POWER

VCC+9V

GND

12345

12345

VCC+9V

GND

5P

Press-fit

Mechanism

PUH

TRAY

MOTOR

W501

FFC 1mm 23P

VCC

1

RF

2

LD2

3

MON2

4

VOR2

5

GND

6

VREF

7

VCC

8

F0

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

E0

A0

D0

C0

B0

F+

T-

T+

F-

VCC

GND

LD

MON

VOR

FFC 1.25mm 6P W502

GND

1

LDMP

2

TOPN

3

LDMN

4

TCLS

5

NC

6

FFC 1mm 8P W503

FMN

1

FMP

2

GND

3

LMT

4

DMN

5

DMP

6

VCC

7

DMFG

8

EU05 OUTPUT

1

2

3

4

5

6

7

8

9

10

11

CN501

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

CN502

4

5

6

1

2

3

4

CN503

5

6

7

8

FFC 1mm 7P

W901

CNY01

FR OUTPUT

POWER ON

FL OUTPUT

GND

FR OUTPUT

POWER ON

FL OUTPUT

GND

CN901

1234567

HMUTE F

IEC958IN

GND

IEC958OUT

HMUTE F

GND

1234567

EU01 MAIN

19

Cb(I/P)-INPUT

Cr(I/P)-INPUT

VGND

VGND

Cb(I/P)-OUTPUT

Cr(I/P)-OUTPUT

VGND

VGND

19

Y(I/P)-INPUT

C-INPUT

VGND

VGND

Y(I/P)-OUTPUT

C-OUTPUT

VGND

VGND

CNX01

VGND

VGND

CN302

101112131415161718

Y-INPUT

VGND

Y-OUTPUT

VGND

101112131415161718

CV-INPUT

GND

IPXI

CV-OUTPUT

GND

IPXI

IPXO

IPXO

ASP2

ASP2

ASP1

ASP1

SOUTX

SOUTX

123456789

RGBON

FFC 1mm 19P

W302

RGBON

123456789

CN801

Board-in

1

PWON

2

E+5V

GND

GND

M+8V

MGND

FF+

3

4

5

6

7

8

9

10

11

12

VDD+5V

VDD+3.3V

VDD+2.5V

VKK-34V

EU04 POWER-SW

1

2

3

4

5

6

7

8

9

10

11

12P

Press-fit

FFC 2mm 4P

W102

GND

1

EVER+5V

2

CN103 CN102

3

4

POWER LED

POWER KEY

12

1

2

3

4

PWON

E+5V

VDD+5V

VDD+3.3V

VDD+2.5V

GND

GND

M+8V

MGND

VKK-34V

FF+

CN701

EU03 FRONT

1

GND

2

5V

3

TXD

CN601

CN603

101112

13

DSPSIO_M-D

VKK-34V

DSPCKX

DSTBX

GND

F+

F-

DSPSIO_M-D

VKK-34V

DSPCKX

DSTBX

GND

F+

F-

101112

13

CN101

DSPSIO_D-M

DSPRST

HMUTE

E+5V

DSPSIO_D-M

DSPRST

HMUTE

E+5V

123456789

PWRCNT

RSTOX

PWRCNT

RSTOX

123456789

4

CTS

5

RXD

6

RTS

FFC 1mm 13P

W603

Fig. 3-3-1-A

Page 34

3. (B) PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM - DD-8030

CNY02

Board-in

VDD+5V

VEE-9V

GND

VDD+5V

VEE-9V

GND

CN802

EU02

POWER

GND

GND

VCC+9V

12345

5P

Press-fit

12345

VCC+9V

Mechanism

PUH

TRAY

MOTOR

W501

FFC 1mm 23P

VCC

1

RF

2

LD2

3

MON2

4

VOR2

5

GND

6

VREF

7

VCC

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

1

2

3

4

5

6

7

8

F0

E0

A0

D0

C0

B0

F+

TT+

F-

VCC

GND

LD

MON

VOR

FFC 1.25mm 6P W502

GND

LDMP

TOPN

LDMN

TCLS

NC

FFC 1mm 8P W503

FMN

FMP

GND

LMT

DMN

DMP

VCC

DMFG

EU05 OUTPUT

1

2

3

4

5

6

7

8

9

10

11

CN501

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

CN502

4

5

6

1

2

3

4

CN503

5

6

7

8

FFC 1mm 15P

W901

15

HMUTE CSW

SW OUTPUT

HMUTES

GND

HMUTE CSW

SW OUTPUT

HMUTES

GND

15

CNY01

1011121314

SR OUTPUT

C OUTPUT

GND

SR OUTPUT

C OUTPUT

GND

1011121314

CN901

FR OUTPUT

SL OUTPUT

GND

FR OUTPUT

SL OUTPUT

GND

POWER ON

FL OUTPUT

HMUTE

POWER ON

FL OUTPUT

HMUTE

EU01 MAIN

123456789

IED958IN

GND

IED958OUT

GND

123456789

19

Cb(I/P)-INPUT

Cr(I/P)-INPUT

VGND

VGND

Cb(I/P)-OUTPUT

Cr(I/P)-OUTPUT

VGND

VGND

19

Y(I/P)-INPUT

C-INPUT

VGND

VGND

Y(I/P)-OUTPUT

C-OUTPUT

VGND

VGND

CNX01

VGND

VGND

CN302

101112131415161718

CV-INPUT

Y-INPUT

VGND

CV-OUTPUT

Y-OUTPUT

VGND

101112131415161718

GND

GND

IPXI

IPXI

IPXO

IPXO

ASP2

ASP2

ASP1

ASP1

SOUTX

SOUTX

123456789

RGBON

FFC 1mm 19P

W302

RGBON

123456789

CN801

Board-in

E+5V

GND

GND

M+8V

F-

F+

1

2

3

4

5

6

7

8

9

10

11

12

PWON

VDD+5V

VDD+3.3V

VDD+2.5V

MGND

VKK-34V

EU04 POWER-SW

1

2

3

4

5

6

7

8

9

10

11

12P

Press-fit

FFC 2mm 4P

W102

1

2

CN103 CN102

3

4

GND

EVER+5V

POWER LED

POWER KEY

12

1

2

3

4

PWON

E+5V

VDD+5V

VDD+3.3V

VDD+2.5V

GND

GND

M+8V

MGND

VKK-34V

FF+

CN701

EU03 FRONT

13

F-

F-

13

VKK-34V

F+

VKK-34V

F+

101112

GND

GND

101112

CN603

DSPCKX

DSTBX

DSPCKX

DSTBX

CN101

CN601

DSPSIO_D-M

DSPSIO_M-D

DSPRST

HMUTE

DSPSIO_D-M

DSPSIO_M-D

DSPRST

HMUTE

PWRCNT

E+5V

PWRCNT

E+5V

GND

5V

TXD

CTS

RXD

RTS

123456789

RSTOX

FFC 1mm 13P

W603

RSTOX

123456789

1

2

3

4

5

6

Fig. 3-1-1-B

Page 35

4. BLOCK DIAGRAMS

4-1. (A) Overall Block Diagram - DD-6030

Data/Control Bus

DVD AV Data

SP DIF Data

Tray

Motor

SPM

PUH Driver

Motor Driver

IC503

BA5813FM

IC312

S24C02BFJ

E2PROM

PUH

Feed

Motor

RF Amp.

IC502

TA1323F

M11B11664A-30T

IC402

X501

22.5792

MHz

IC306

ZR36750

32M-FRAM

IC309

MBM29DV324BE

1M-DRAM

1chip-SERVO

Data Processor

Decryption,

Video Process,MPEG-2 Decoder

Dolby-Digital Decoder, OSD

MAIN CPU

64M-S-DRAM

IC305

MT48LC2M32B2

MAIN PROCESSOR UNIT

IC401

TC94A03F

IC902

AD1958

Xtal

27MHz

AV

Master Clock

Audio DAC

+ PLL

AUDIO/VIDEO OUTPUT UNIT

Buffer

ICY02

TC74HCU04AF

ICY01

NJM4580E

LPF &

Amplifier

Audio Out

ICX01

MM1568

VIDEO LPF

with

AMPLIFIRE

Coaxial

Digital

TOS Link Digital

Audio Out

FL, FR Analog

Audio Out

Composite

Video Out

S Video Out

R

B

,C

Y,C

Video

Out

SW POWER SUPPLY

Display

(FL)

Display-CPU

IC101

TMP86CK74AFG-3UA6

FRONT DISPLAY UNIT

Fig.3-4-1-A

Page 36

2-1. (B) Overall Block Diagram - DD-8030

Data/Control Bus

DVD AV Data

SP DIF Data

Tray

Motor

SPM

PUH Driver

Motor Driver

IC503

BA5813FM

IC307

S24C02BFJ

E2PROM

IC308

S24C02BFJ

E2PROM

PUH

Feed

Motor

RF Amp.

IC502

TA1323F

M11B11664A-30T

IC402

X501

22.5792

MHz

IC306

ZR36750

32M-FRAM

IC309

MBM29DV324BE

1M-DRAM

1chip-SERVO

Data Processor

Decryption,

Video Process,MPEG-2 Decoder

Dolby-Digital Decoder, OSD

MAIN CPU

64M-S-DRAM

IC305

MT48LC2M32B2

MAIN PROCESSOR UNIT AUDIO/VIDEO OUTPUT UNIT

IC401

TC94A03F

IC902

AD1958

IC903

PCM1742KE

IC904

PCM1742KE

Xtal

27MHz

PLL+DAC

Audio-DAC

Audio-DAC

ICX01

MM1568

VIDEO LPF

with

AMPLIFIRE

Buffer

ICY02

TC74HCU04A

ICY01

NJM4580E

LPF &

Amplifier

Audio Out

ICY06

NJM4580E

LPF &

Amplifier

Audio Out

ICY05

NJM4580E

LPF &

Amplifier

Audio Out

Coaxial

Digital

TOS Link Digital

Audio Out

2ch Analog

Audio Out

FL, FR Analog

Audio Out

SL, SR Analog

Audio Out

Center SW

Analog

Audio Out

Composite

Video Out

S Video Out

Y,C

B,CR

Video

Out

SW POWER SUPPLY

Display

(FL)

Display-CPU

IC101

TMP86CK74AFG-3UA6

FRONT DISPLAY UNIT

Fig.3-4-1-B

Page 37

4-2. Power Supply Block Diagram

D803, C805

RECTIFIER

SMOOTHIN

C801-C804

T801

AC FILTER

AC100-120V

50/60Hz

T802

TRANS

Q801

MOS-FET

D806, C809

RECTIFIER

SMOOTHING

Q802 Q803

CONTROL

IC

PHOTO

COUPLER

Q804

PHOTO

COUPLER

ERROR

AMP

Q830

ON/OFF

CHANGE

D824, Q833

RECTIFIER

SMOOTHING

D821, C821

RECTIFIER

SMOOTHING

D822, C822-C823

RECTIFIER

SMOOTHING

D825, C824

RECTIFIER

SMOOTHING

D826, C825

RECTIFIER

SMOOTHING

D827, C826

RECTIFIER

SMOOTHING

Q821

Q827

5V REG/SW

Q828

3.3V REG/SW

Q823, Q824

9V SW

Q825, Q826, D832-D835

-34V REG/SW

Q822

F+F- SW

E-9V

E+5V

D829

VDD+5V

PWON

VDD+3.3V

D830, D831

VDD+2.5V

E+9V

D836

M+8V

VKK-34V

F+F-

Fig. 3-4-2

Page 38

4-3. Front Display, Power Switch Block Diagram

4-3-1. Front Display

8G 7G 6G 5G 4G

3G 2G 1G

4-3-2. Front Display Pattern

8G 7G 6G

P1

P2

P3

P4

P5

a

f

g

e

j

h

r

k

s

n

p

col1col2

b

m

c

Fig. 3-4-3

d

(7G-2G)

5G 4G 3G 2G 1G

a

f

h

j

k

a

f

h

j

k

a

f

h

j

k

a

f

h

j

k

a

f

h

j

k

a

f

h

j

k

P6

P7

P8

P9

P10

P11

P12

P13

P14

P15

P16

P17

P18

b

g

s

m

e

r

p

n

c

d

b

g

s

m

e

r

p

n

c

d

col2 col1

b

g

s

m

e

r

p

n

c

d

b

g

s

m

e

r

p

n

c

d

b

g

s

m

e

r

p

n

c

d

b

g

s

m

e

r

p

n

c

d

Fig. 3-4-4

Page 39

4-3-3. Front Display , Power Switch Block Diagram

A101

HUV-08SS38T

8-BT-230GNK

EU03

FRONT DISPLAY

EU01

MAIN

F(-)

G1

G2

G3

G4

G5

G6

G7

G8

1

2

22

23

24

25

26

27

28

29

77

G1

76

G2

75

G3

74

G4

G4

73

G5

72

G6

71

G7

70

G8

30

KEY IN 0

31

KEY IN 1

32

KEY IN 2

33

KEY IN 3

KEY IN 4

34

19

PLAY K

20

TRAY KEY

18

POWER KEY

S18

S17

S16

S15

21

20

19

18

52

53

54

55

S18

S16

S17

S15

FLIP DRIVE

DISPLAY MEMORY

112byte

KEY

PROCESS

S14

S14

S13

S12

S11

S10

S9

S8

S7

S6

S5

S4

S3

S2

S1

17

16

15

14

13

12

11

10

9

8

7

6

5

4

56

57

58

59

60

61

62

63

64

65

66

67

68

69

S12

S10

S8

S6

S4

S13

S11

SERIAL

TRANSFER

S9

S7

S5

S2

S3

S1

F(+)

31

32

IC101

TMP86CK74AFG-3UA6

DISPLAY MICROCOMPUTER

8

16

15

17

9

3

2

11

X101

8MHz

EVER+5V

MT101

GP1U263X

REMOTE CONTROL

MODULE

1

SIGNAL

PROCESS

2

AMP

3

REMOTE CONTROL

RECEPTION

EVER+5V

CN101

CN101

EVER+5V

11

3

Vkk (-31V)

1

F(-)

4

GND

2

F(+)

9

DSPRSTX

8

DSPSIO D-M

7

DSPSIO M-D

6

DSPCKX

5

DSTBX

CN603

3

11

To POWER

13

10

12

CN603

5

6

To LOGICAL

7

8

9

EU04

POWER SWITCH

KIN0

KIN1

KIN2

KIN3

KIN4

VIN0

STOP

CURSOR

ENTER

CURSOR

RIGHT

FWD

VIN1

PAUSE

RETURN

CURSOR

LEFT

REV

VIN2

SKIP

UP

MENU

CURSOR

DOWN

VIN3

SKIP

DOWN

TOP

MENU

CURSOR

UP

VIN4

E+5V

PLAY

PLAYK

Vdd

5

VASS

38

OPEN/

CLOSE

TRAY KEY 1

POWER

LED

ZOOM

LED

23

24

POWER

CN103

4

3

2

1

POWKEY

POWLED

E+5V

GND

CN103

4

3

2

1

EVER+5V

D181

EL-3105-1VRT

Q181, Q182

RN2202

or DTA114ESATP

Fig. 3-4-5

Page 40

4-4. Main Block Diagrams

4-4-1. Servo System Block Diagram

Q502

Q501

m

PUDET2

IC306

Fig.3-4-6

Page 41

4-4-2. Logical System Block Diagram

From

IC502

PIN30

IC401

TC94A03F

DATA PRO-1

143

RFDVD

IC306

ZR36750

AV 1 CHIP PROCESSOR

60

62

PD0

65

67

PD7

69

73

PDCK

72

PDREQ

71

PDSYC

70

PD8 DVDERR

DISC STREAM

16M FROM

DATA 8bit

PD0

PD1

PD2

PD3

PD4

PD5

PD6

PD7

PDCK

PDRQ

PSYC

IC309

MBM29LV160BE

CVBS

G/Y

B/U

R/V

ALRCK0

ABCLK0

AOUT0

OUTPUT UNIT

CN302

8

Y

C

IC901

AD1958

AUDIO DAC

4

5

6

LRCK

BCK

SD ATA

VOUTL

VOUTR

23

20

10

12

14

16

18

5

7

10

12

14

16

18

8

5

7

CNX01

CV

Y

C

Y (I/P) G

C

B

C R

CNY01CN901

LOUT

ROUT

1M DRAM

IC402

M11B11664A-30T

64M-SDRAM

IC305

MT48LC2M32B2

Fig. 3-4-7

Page 42

4-5. (A) Output Block Diagram - DD-6030

EU01 MAIN

To MAIN

To MAIN

12 C-IN/OUTPUT

10

Y-IN/OUTPUT

16

Cb(I/P)-IN/OUTPUT

Cr(I/P)-IN/OUTPUT

18

FL OUTPUT

5

FR OUTPUT

7

12

10

16

18

5

7

CNX01

CNY01

ICX01

MM1568AJBE

VIDEO DRIVER

2

CIN

4

VIN

6

YIN1

14

C

B

IN

16

C

R

IN

ICY01

NJM4580E

2 1

6 7

ICY02

TC74HCU04AF

VOUT

COUT

YOUT

C

Y

C

B

R

C

OUT

OUT

OUT

31

33

28

20

22

19

QY04

HN-1C03F

MUTE

JX01

C

Y

R

P

P

B

Y

COMPOSITE

VIDEO

S TERMINAL

Lch OUT

Rch OUT

1

IEC958 OUT

1

13 2

DIGITAL OUT

4

6

8

ICY03

TOTX179

(COAXIAL)

Fig. 3-4-8-A

Page 43

4-5. (B) Output Block Diagram - DD-8030

EU01

MAIN

To MAIN

12 C-IN/OUTPUT

10

Y-IN/OUTPUT

16

Cb(I/P)-IN/OUTPUT

Cr(I/P)-IN/OUTPUT

18

FL OUTPUT

5

FR OUTPUT

7

12

10

16

18

5

7

CNX01

CNY01

Lch SIGNAL

Rch SIGNAL

ICX01

MM1568AJBE

VIDEO DRIVER

2

CIN

4

VIN

6

YIN1

14

C

BIN

16

C

RIN

VIDEO

AUDIO

ICY01

NJM4580E

2 1

6 7

VOUT

COUT

YOUT

YOUT

C

BOUT

C

C

ROUT

QY02

HN-1C03F

MUTE

JX02

CR SIGNAL

31

33

28

20

22

19

CB SIGNAL

CY

SIGNAL

COMPOSITE

VIDEO SIGNAL

C SIGNAL

Y SIGNAL

JX01

JY01

ICY04

TOTX179

C

Y

R

P

PB

Y

COMPOSITE

VIDEO

S TERMINAL

Lch OUT

Rch OUT

Front

To MAIN

IEC958 OUT

1

SL OUTPUT

SR OUTPUT

C OUTPUT

SW OUTPUT

H MUTE CSW

H MUTE F

H MUTE S

33

DIGITAL AUDIO

SIGNAL

1

88

1010

1111

1313

1414

1515

ICY02

TC74HCU04AF

13 2

ICY06

NJM4580E

2 1

6 7

ICY05

NJM4580E

2 1

6 7

CONTROL

4

6

8

QY08

HN-IC03F

CONTROL

QY11

HN-IC03F

CONTROL

MUTE

MUTE

MUTE

MUTE

MUTE

QY03

QY04

QY07

QY09

QY10

QY12

DIGITAL OUT

(COAXIAL)

SURROUND L

SURROUND R

L ch

Center

SW

R ch

Fig. 3-4-8-B

Page 44

A

B

2 5 6 7 89

5. CIRCUIT DIAGRAMS

5-1. Power Supply Circuit Diagram

EU02

POWER

5.2

(5.1)

[5.1]

10134

: OFF ( ) : ON [ ] : PLAY

C

D

E

167

(164)

[164]

5.9

(5.8)

[5.8]

5.1

(4.8)

[4.8]

10.0

(10.0)

[9.9]

2

1

11.3

(14.6)

[14.7]

7.2

(5.3)

[5.4]

-8.9

(-9.0)

[-9.0]

-39.5

(-41.0)

[-41.5]

0

(2.9)

[2.9]

0

(8.7)

[8.3]

F

G

1 2 3 4

11.3

OFF

14.6

ON

14.7

PLAY

E

-39.5

OFF

-34.0

ON

-34.0

PLAY

1.5

1.0

1.0

Q826

C

0

-34.0

-34.0

Q802

0.5

1.7

1.7

B

-39.0

-33.0

-33.0

6 8

2.8

1.5

2.0

2.0

1 2 3 4 1 2 3 4

5.9

5.8

5.8

0

1.5

0

1.5

0

Q827 Q828

5.0

0

5.0

0

5.0

0

3.9

4.1

4.1

5.0

5.0

Q821

R

K

2.5

2.5

2.5

5.1

0

4.8

4.8

3.3

3.3

3.3

Q822

E

0

-30.3

-30.3

0

0

0

C

-7.2

-30.4

-30.4

0

2.5

2.5

B

0

-31.0

-31.0

E

0

0

0

A

0

0

0

E

9.2

9.4

9.1

Q830

C

1.0

0.01

0.01

Q823

C

0

9.3

9.0

B

0

5.0

5.0

9.2

8.7

8.4

Q824

B

C

E

0

0

0

9.2

0.1

0.1

B

0

0.7

0.7

0.7

0.7

Q825

C

E

0

-39.0

-13.3

-13.3

B

0

0

0

Fig. 3-5-1

Page 45

Power Supply Circuit Diagram

1

Q801

Drain-Sourse

ON MODE

AC 120V 60 Hz IN

V:100 V/div

H:5 µs/div

D-4

2

Q801

Gate-Sourse

ON MODE

AC 120V 60 Hz IN

V:5 V/div

H:5 µs/div

D-3

Fig. 3-5-2

Page 46

5-2. Front Display , Power Switch Circuit Diagram

Fig. 3-5-3

Page 47

Front Display, Power Switch Circuit Diagram

IC101, Pin

1

IC101, Pin

2

IC101, Pin

3

3

X-OUT

V: 2 V/div

H: 100 ns/div

9

V: 2 V/div

H: 5 ms/div

15

D-4

D-4

D-5

IC101, Pin

5

IC101, Pin

6

IC101, Pin

7

17

V: 2 V/div

H: 100 ms/div

77

G1

V: 10 V/div

H: 500 ms/div

69

D-5

D-4

D-4

IC101, Pin

4

V: 2 V/div

H: 200 ms/div

16

V: 2 V/div

H: 5 ms/div

S1

V: 10 V/div

H: 500 ms/div

D-5

Fig. 3-5-4

Page 48

5-3. Main Circuit Diagrams

5-3-1. Main ICs Information

TMP86CK74AFG

W986432DH

MBM29DL3240BE

86

48

80

81

100

25

TC74VHCT

50

51

31

30

1

44

43

1

24

244AFT

11

20

10

1

PCM1742

9

16

8

1

S24C02AFJA

5

8

4

1

MM1568AJ

BH7863

AD1958YRS

34

32

28

1

PQ3RD23

PQ05RD11

18

17

1

MPC2948T

17

16

1

15

14

1

2

3

4

4

1

2

3

1

Page 49

5-3-2. Main Circuit Diagram

Fig. 3-5-5

Page 50

5-3-2. Main Circuit Diagram

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Fig. 3-5-5

Page 58

5-4. (A) Output Circuit Diagram - DD-6030

Fig. 3-5-6-A

Page 59

5-4. (A) Output Circuit Diagram - DD-6030

Page 60

Page 61

Page 62

Page 63

Page 64

Fig. 3-5-6-A

Page 65

Output Circuit Diagram - DD-6030

1

JX01 Composite

video output

D-7

JX01 L ch output

4

/ R ch output

(1 kHz, FS)

D-6

D-6

2

JX01

(a) S-video output Y

(b) S-video output C

3

JX01 Y/PB/P

output

CVBS output

75Wterminated

100% color bar

V: 500 mV/div

H: 20ms/div

E-7

E-7

S-Y/C

75Wterminated

100% color bar

(a) Y

(b) C

V: 500 mV/div

H: 20ms/div

R

Component output

75Wterminated

100% color bar

(Play)

Y

P

B

P

R

V: 500 mV/div

H: 20ms/div

D-6

JX01 COAXIAL

5

-DIGITAL OUTPUT

L ch output

R ch output

V: 2 V/div

H: 200ms/div

C-6

75Wterminated

V: 500 mV/div

H: 0.1ms/div

Fig. 3-5-7-A

Page 66

5-4. (B) Output Circuit Diagram - DD-8030

Fig. 3-5-6-B

Page 67

5-4. (B) Output Circuit Diagram - DD-8030

Page 68

Page 69

Page 70

Page 71

Page 72

Fig. 3-5-6-B

Page 73

Output Circuit Diagram - DD-8030

1

JX01 Composite

video output

D-5

JY01 L ch output

4

/ R ch output

(1 kHz, FS)

B-7

B-7

CVBS output

75W terminated

100% color bar

V: 500 mV/div

H: 20 ms/div

2

JX01

(a) S-video output Y

(b) S-video output C

S-Y/C

75W terminated

100% color bar

(a) Y

(b) C

V: 500 mV/div

H: 20 ms/div

3

JX02 Y/CB/C

R

output

Component output

75W terminated

100% color bar

(Play)

Y

C

B

C

R

V: 500 mV/div

H: 20 ms/div

E-5

E-5

E-5

JY01 COAXIAL

5

-DIGITAL OUTPUT

L ch output

R ch output

V: 2 V/div

H: 200 ms/div

B-7

75W terminated

V: 500 mV/div

H: 0.1 ms/div

Fig. 3-3-7-B

Page 74

A

B

C

2 5 6 7 89

5-5. Motor System Circuit Diagram

10134

D

E

F

Fig. 3-5-8

G

Page 75

A

134

2 5

6. PC BOARDS

6-1. Power Supply PC Board

B

C

D

E

F

B

A

12345

Part Loca No. tion

C801 B1

C802 B2

C803 B1

C804 B2

C805 A1

C806 A2

C807 A2

C808 B2

C809 B2

C811 B2

C812 B2

C821 A4

C822 A4

C823 A4

C824 B4

C825 B3

C826 B3

C827 A4

C828 A4

C830 B4

C831 B5

C832 A5

C833 B3

C834 A5

C835 A5

C837 B5

C838 A4

C839 A5

C840 A4

C841 A5

CN801 B5

CN802 B4

CN803 B5

D803 B2

D805 A2

D806 A2

D807 B2

D808 B2

D810 A2

D821 A4

D822 A4

D824 A3

D825 A4

D826 B3

D827 B3

D828 A4

D829 A4

D830 B5

D831 B5

D832 B4

D833 B4

D834 B4

D835 B4

D836 B5

D841 B4

D842 A4

F821 A4

F822 A4

F823 A4

L801 A2

L821 A4

Part Loca No. tion

P801 A1

Q801 A2

Q802 B2

Q804 B3

Q821 A4

Q822 B3

Q823 B4

Q824 A5

Q825 B4

Q826 B3

Q827 B5

Q828 A5

Q830 B4

R801 A1

R802 A2

R803 A2

R804 B1

R805 B2

R806 B2

R807 B2

R808 B2

R809 A2

R810 B2

R811 B2

R812 B2

R813 B2

R814 B3

R815 B2

R816 A2

R817 B2

R818 B2

R821 A3

R822 A3

R823 A3

R824 A3

R825 A4

R826 B4

R827 B3

R828 B3

R829 A4

R830 A4

R831 B4

R832 B3

R833 A4

R834 B4

R835 B4

R837 B5

R841 A5

R843 A4

R844 A4

R845 B4

R846 B4

R847 A5

R848 A5

RF821 B3

RF822 B3

RF823 A3

RF824 A3

T801 B1

T802 A3

G

Fig. 3-6-1 EU02 Power Supply PC Board (Bottom side)

Page 76

6-3. Main PC Board

12

A

B

C

CN503

F-MARK2

E504

E522

E523

E524

E543

CN502

E525

E526

E527

E651

E652

E617

E601

E602

E603

E604

CN603

E605

E606

E608

E609

E610

E611

E612

E613

CN601

E614

E615

E616

C314 C318

C312

C326

R382

R381

E529

E531

E518 E519

E546

E322

IC305

E532

R524

C509

E544

R511

E547

R509

E549

C331

C330

E528

E530

C514

S301

TP501

IC312IC313

IC503

C511

E402

R402

E407

E416

E419

E421

E423

TP410

TP411

R448

E704

C701

R518

Q401

TP414

C414

R453

E405

E406

E332

E410

R445

R447

C438

C437

E413E414E415

E417

E418

E420

E422

E424

C445

R452

C325

C543

R557

E555

E554

C504

E541

E542

E540

E539

E538

E537

R517

R520

R521

C453

R444

R446

C407

R342

E557

E556

E558

D502

E534

R405

R410

C421

C452

R451

E335

E334

E336

E333

E330

E326

E328

E329

E327

E337

E314

E619

E618

E501E502

E503

E507

R552

Q502

R553R554

R556

C541

C542

C518

E403

TP402

C410

R417

R406

R424

R425

E425

E426

TP412TP413

CN501

E508

E510

E512

E509

E511

E513

R502

E580

E559

R555

E579

E585

E584

C524

C525

E588

E589

E550

E551

E552

E587

E553

E560 E561

E586

C527

TP401

R542

TP503 TP504

C401

R415

R416

R411

IC401

E514

E516E517

E515

E581

E582

C529

R508

C517

R403

R546

C402

C411

E506

E505

R505

C519

E548

E563

E562

TP403TP404TP405TP406 TP407TP408

R408

C409

R454

R449R450

JP301

IC306

E520E521

E535

E536

E583

E578

IC502

E569

E565

E568

TP502

E567

E564

R522

E566

E201

R407

R404

C418

E401

E315E316

E533

JP501

E577

E545

E576

E575

E571

E570

C416

R427

R429

R431

R433

R434

R435

R437

R439

E408

TP409

E409

E411E412

C444

C443

C320

R519

R525

E574

E573

E572

C446

E701E702E703

E707

R701

E331

E320

E321

E323

E324

E325

C710

C921

X901

C928

IC905

C926

C327

R301

CN701

E712E713E714E715

R903

C907

C927

C321C323

IC307

J301

RM301

C708

R904

R905

R907

C904C905

C909

R344

R374

R379

C336

IC310

E705E706

E710E711

IC902

R380

Q310

E708E709

C709

C908

C911C912 C920

R383

R384

R388

Q311

R378

C334

C335

IC308

R349

C902

C903

C906

C910

R910

E901

E902

E903

E904

E905

E906

E907

E908

E909

E910

E911

E912

E913

E914

E915

E301

E302

E303

E304

R324

E305

E306

R345

R370

E307

R375

E309

E310

E311

E312

E313

E308

F-MARK1

C707

CN901

CN302

L302

J302

R376

R377

Fig. 3-6-4 EU01 Main PC Board (Top pattern and Top parts location diagram)

Page 77

Main PC Board (Top Side)

Part Loca No. tion

C312 C1

C314 C1

C318 C1

C320 B2

C321 B2

C323 C2

C325 C1

C326 C1

C327 C2

C330 C1

C331 B1

C334 C2

C335 C2

C336 C2

C401 B1

C402 B1

C407 B1

C409 B1

C410 B1

C411 B1

C414 B1

C416 B2

C418 B2

C421 B1

C437 B1

C438 B1

C443 B2

C444 B2

C445 B1

C446 B2

C452 B1

C453 B1

C504 A1

C509 A1

C511 B1

C514 B1

C517 A1

C518 A1

C519 A2

C524 A1

C525 A1

C527 A1

C529 A1

C541 A1

C542 A1

C543 A1

C701 A1

C707 A2

C708 A2

C709 A2

C710 A2

C902 A2

C903 A2

C904 B2

C905 B2

C906 A2

C907 A2

C908 B2

C909 B2

C910 A2

C911 B2

C912 B2

C920 B2

C921 A2

C926 B2

C927 B2

C928 B2

CN302 C2

CN501 A1

CN502 A1

CN503 A1

CN601 B1

CN603 B1

CN701 A2

CN901 B2

D502 A1

E201 B2

E301 B2

E302 B2

E303 B2

Part Loca No. tion

E304 B2

E305 C2

E306 C2

E307 C2

E308 C2

E309 C2

E310 C2

E311 C2

E312 C2

E313 C2

E314 C1

E315 B2

E316 B2

E320 C2

E321 C2

E322 B1

E323 C2

E324 C2

E325 C2

E326 C1

E327 C1

E328 C1

E329 C1

E330 C1

E331 C2

E332 B1

E333 C1

E334 C1

E335 C1

E336 C1

E337 C1

E401 B2

E402 B1

E403 A1

E405 B1

E406 B1

E407 B1

E408 B2

E409 B2

E410 B1

E411 B2

E412 B2

E413 B1

E414 B1

E415 B1

E416 B1

E417 B1

E418 B1

E419 B1

E420 B1

E421 B1

E422 B1

E423 B1

E424 B1

E425 B1

E426 B1

E501 A1

E502 A1

E503 A1

E504 A1

E505 A2

E506 A2

E507 A1

E508 A1

E509 A1

E510 A1

E511 A1

E512 A1

E513 A1

E514 A1

E515 A1

E516 A1

E517 A1

E518 A1

E519 A2

E520 A2

E521 A2

E522 A1

E523 A1

E524 A1

Part Loca No. tion

E525 A1

E526 A1

E527 A1

E528 A1

E529 A1

E530 A1

E531 A1

E532 A1

E533 A2

E534 A1

E535 A2

E536 A2

E537 A1

E538 A1

E539 A1

E540 A1

E541 A1

E542 A1

E543 A1

E544 A1

E545 A2

E546 A1

E547 A1

E548 A2

E549 A1

E550 A1

E551 A1

E552 A1

E553 A1

E554 A1

E555 A1

E556 A1

E557 A1

E558 A1

E559 A1

E560 A1

E561 A2

E562 A2

E563 A2

E564 A2

E565 A2

E566 A2

E567 A2

E568 A2

E569 A2

E570 A2

E571 A2

E572 A2

E573 A2

E574 A2

E575 A2

E576 A2

E577 A2

E578 A2

E579 A1

E580 A1

E581 A1

E582 A1

E583 A2

E584 A1

E585 A1

E586 A1

E587 A1

E588 A1

E589 A1

E601 B1

E602 B1

E603 B1

E604 B1

E605 B1

E606 B1

E608 B1

E609 B1

E610 B1

E611 B1

E612 B1

E613 B1

E614 B1

E615 B1

E616 C1

Part Loca No. tion

E617 B1

E618 C1

E619 C1

E651 B1

E652 B1

E701 A2

E702 A2

E703 A2

E704 A1

E705 A2

E706 A2

E707 A2

E708 A2

E709 A2

E710 A2

E711 A2

E712 A2

E713 A2

E714 A2

E715 A2

E901 B2

E902 B2

E903 B2

E904 B2

E905 B2

E906 B2

E907 B2

E908 B2

E909 B2

E910 B2

E911 B2

E912 B2

E913 B2

E914 B2

E915 B2

F-MARK1 C2

F-MARK2 A1

IC305 C1

IC306 C1

IC307 C2

IC308 C2

IC310 C2

IC312 B1

IC313 B1

IC401 B1

IC502 A2

IC503 A1

IC902 A2

IC905 B2

J301 C2

J302 C2

JP301 B2

JP501 A2

L302 C2

Q310 C2

Q311 C2

Q401 B1

Q502 A1

R301 C2

R324 B2

R342 C1

R344 B2

R345 C2

R349 C2

R370 C2

R374 B2

R375 C2

R376 C2

R377 C2

R378 C2

R379 C2

R380 B2

R381 C1

R382 C1

R383 C2

R384 C2

R388 C2

R402 B1

R403 A1

R404 B2

Part Loca No. tion

R405 B1

R406 B1

R407 B2

R408 B2

R410 B1

R411 B1

R415 B1

R416 B1

R417 B1

R424 B1

R425 B1

R427 B2

R429 B2

R431 B2

R433 B2

R434 B2

R435 B2

R437 B2

R439 B2

R444 B1

R445 B1

R446 B1

R447 B1

R448 B1

R449 B2

R450 B1

R451 B1

R452 B1

R453 B1

R454 B1

R502 A1

R505 A2

R508 A1

R509 A1

R511 A1

R517 B1

R518 B1

R519 A2

R520 B1

R521 B1

R522 A2

R524 A1

R525 A2

R542 A1

R546 A1

R552 A1

R553 A1

R554 A1

R555 A1

R556 A1

R557 A1

R701 B2

R903 A2

R904 B2

R905 B2

R907 B2

R910 B2

RM301 C2

S301 B1

TP401 B1

TP402 B1

TP403 B2

TP404 B2

TP405 B1

TP406 B1

TP407 B2

TP408 B1

TP409 B2

TP410 B1

TP411 B1

TP412 B1

TP413 B1

TP414 B1

TP501 B1

TP502 A2

TP503 B1

TP504 B1

X901 B2

Page 78

Main PC Board (Bottom Side)

Part Loca No. tion

C301 C1

C302 C2

C303 C1

C304 C2

C305 B2

C306 B2

C307 C1

C308 C1

C309 C2

C310 C2

C311 C1

C313 C2

C315 C2

C316 C2

C317 C2

C319 C1

C322 C1

C324 C1

C328 C1

C329 C1

C332 B2

C333 C2

C337 C1

C403 B2

C404 B2

C405 B2

C406 B2

C408 B2

C412 B2

C413 B2

C415 B2

C417 A2

C419 B1

C420 B2

C422 B1

C423 B2

C424 B1

C425 B1

C426 B1

C427 B1

C428 B1

C429 B1

C430 B1

C431 B1

C432 B1

C433 B1

C434 B1

C435 B1

C436 B2

C439 B1

C440 B1

C441 B2

C442 B1

C447 B2

C448 B1

C449 B2

C450 B2

C451 B2

C501 A2

C502 A2

C503 A2

C505 A2

C506 A2

C507 A2

C508 A1

C510 A1

C512 B2

C513 A1

C515 A2

C516 A2

C520 A2

C521 A2

C522 A1

Part Loca No. tion

C523 A1

C526 A1

C528 A1

C530 A2

C532 A1

C533 A1

C534 A2

C539 A2

C601 B2

C602 B2

C603 B2

C702 A1

C703 A1

C704 A1

C705 A1

C706 A1

C711 A1

C712 A1

C713 A1

C714 A1

C715 A1

C901 B1

C913 A1

C914 A1

C915 B1

C916 B1

C917 B1

C918 B1

C919 B1

C922 B1

C923 B1

C924 B1

C925 B1

D501 A1

D901 B1

D902 B1

D903 B1

F-MARK3 C1

F-MARK4 A2

IC301 B2

IC302 B2

IC303 B2

IC304 B2

IC309 B2

IC402 B2

IC501 A2

IC504 A2

IC901 B1

IC903 B1

IC904 B1

Q301 C1

Q302 C1

Q303 C1

Q304 C1

Q305 C1

Q306 C1

Q307 C2

Q308 C1

Q309 C1

Q501 A1

Q503 B2

Q504 A2

Q505 A2

Q506 A2

R302 C2

R303 C1

R304 C2

R305 C2

R306 C1

R307 B2

R308 B2

R309 C2

R310 C1

Part Loca No. tion

R311 C2

R312 C2

R313 C1

R314 C2

R315 C2

R316 C2

R317 C2

R318 C2

R319 C1

R320 C1

R321 C1

R322 C1

R323 C1

R325 C1

R326 B1

R327 C1

R328 C1

R329 C1

R330 C1

R331 C1

R332 C1

R333 C1

R334 C1

R335 C1

R336 C1

R337 C1

R338 C1

R339 C1

R340 B2

R341 C1

R343 C2

R346 C2

R347 C2

R348 C2

R350 C2

R351 C1

R352 B1

R353 B1

R354 C1

R355 C1

R356 C1

R357 C2

R358 C2

R359 C1

R360 C1

R361 C2

R362 C2

R363 C2

R364 C2

R365 C2

R366 C1

R367 C1

R368 C1

R369 C1

R371 C1

R372 C1

R373 B1

R385 A1

R386 A1

R387 A1

R401 A2

R409 B2

R412 B1

R413 B2

R414 B2

R418 B1

R419 B2

R420 B2

R421 B2

R422 B2

R423 B2

R426 B1

R428 B1

Part Loca No. tion

R430 B1

R432 B1

R436 B1

R438 B1

R442 B1

R443 B1

R455 B2

R461 B2

R501 A2

R503 A2

R504 A2

R506 A1

R507 A1

R510 A1

R512 A1

R513 B2

R514 A2

R515 A2

R516 A2

R523 A2

R526 A2

R527 A2

R528 A2

R529 A2

R530 A2

R531 A2

R532 A2

R533 A2

R534 A2

R535 A1

R536 A1

R537 A2

R538 A2

R539 A1

R540 A2

R541 A2

R545 A1

R547 A2

R551 A2

R601 B2

R602 B2

R603 B2

R604 B2

R605 B2

R606 B2

R607 B2

R608 B2

R609 B2

R610 B2

R615 B2

R616 B2

R702 A1

R901 B1