Page 1

2000

MITSUBISH ELECTRIC

DD-5000

POWER

STANDBY

TITLE TRK CHP TOTAL REMAIN MEMORY

HDCD

CDVD

SerSer

Ser

SerSer

ManualManual

Manual

ManualManual

vicevice

vice

vicevice

DVD Player

Model

DD-5000

OPEN/CLOSE

STOP PLAY PAUSE/STEP

REV

FWD

/

SKIP

CAUTION

Before servicing this chassis, it is important that the service person reads all SAFETY PRECAUTIONS and the

SAFETY NOTICE in this manual.

SPECIFICATIONS

Power Supply: 120V AC, 60 Hz

Power Consumption: 19W

Weight: 6.7 lb.

External Dimensions: 17"x 3-1/4"x12-1/4"

(W/H/D)

Signal System: Standard NTSC

Laser: Semiconductor laser,

wavelength 650 nm

Frequency Range: (Digital Audio)

Audio CD: 4 Hz to 20 kHz

DVD Linear -

48 kHZ Sampling: 4 Hz to 22 kHz

96 kHZ Sampling: 4 Hz to 44 kHz

Signal-To-Noise Ratio: More than 112 dB (EIAJ)

Audio Dynamic Range: More than 106 dB (EIAJ)

Harmonic Distortion: Less than 0.001%

Wow and flutter: Below measurable level

(less than ± 0.001%

(W.PEAK)) (EIAJ)

Operating conditions: Temperature: 5 °C to 35°C

Operation status: Horizontal

Video output: 1.0 V (p-p), 75Ω, negative

sync., pin jack x 1

S Video output: (Y) 1.0 V (p-p), 75Ω, nega-

tive sync., Mini DIN 4-pin x 1

(C) 0.286 V (p-p), 75Ω

Color Difference output: (Y) 1.0 V (p-p), 75Ω, nega-

tive sync., pin jack x 1

(Cr)/(Cb) 0.7 V (p-p), 75Ω, pin

jack x 2

Digital Audio output: (Bitstream/PCM) 0.5 V (p-p),

75Ω, pin jack x 1,

Optical connector x 1

Analog Audio output: 2.0 V (rms), 330Ω, pin jack

2 CH L R x 2,

5.1 CH SURROUND x 6

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Rd. Irvine, CA 92618

Copyright © 2000 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

LASER BEAM CAUTION LABEL

When the power supply is on, do not remove this laser caution label. If it is removed, laser radiation may be recceived.

SAFETY NOTICE

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

Page 3

SAFETY PRECAUTIONS

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120V AC outlet (do

not use an isolation transformer for this check). Use an

AC voltmeter, having 5000 Ω per volt or more sensitivity.

Connect a 1500 Ω 10 W resistor, paralleled by a 0.15 µF

150V AC capacitor between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of

the cabinet (antennas, handle bracket, metal cabinet

screwheads, metal overlays, control shafts, etc.).

READING SHOULD NOT EXCEED 0.3V

Measure the AC voltage across the 1500 Ω resistor.

The test must be conducted with the AC switch on and

then repeated with the AC switch off. The AC voltage

indicated by the meter may not exceed 0.3 V. A reading

exceeding 0.3 V indicates that a dangerous potential

exists, the fault must be located and corrected.

Repeat the above test with the DVD VIDEO PLAYER

power plug reversed.

NEVER RETURN A DVD VIDEO PLAYER TO THE

CUSTOMER WITHOUT TAKING NECESSARY

CORRECTIVE ACTION.

DVD VIDEO PLAYER

AC OUTLET

Test all exposed metal.

Voltmeter Hook-up for Leakage Current Check

1500

W

10 W

0.15 µF 150V AC

AC VOLTMETER

(5000 W per volt

or more sensitivity)

Good earth ground

such as a water pipe,

conduit, etc.

Page 4

CONTENTS

GENERAL DESCRIPTIONS

1. PREPARATION FOR SERVICING ......................................... 1-1

2. LOCATION OF MAIN PARTS AND

MECHANISM PARTS ............................................................... 1-2

2-1. Location of Main Parts ....................................................... 1-2

2-2. Location of Mechanism Parts ............................................ 1-3

SECTION 1

3. TROUBLESHOOTING .............................................................. 1-6

3-1. Main Circuit ........................................................................ 1-6

3-1-1. Servo System ................................................................... 1-6

3-1-2. Location Diagram of Servo Test Point ....................... 1-13

PART REPLACEMENT AND ADJUSTMENT PROCEDURES

1. REPLACEMENT OF MECHANICAL PARTS ...................... 2-1

1-1. Cabinet Replacement .......................................................... 2-1

1-1-1. Top Cover ........................................................................ 2-1

1-1-2. Clamper Stay ................................................................... 2-1

1-1-3. Tray Panel ....................................................................... 2-2

1-1-4. Front Panel and Tray ..................................................... 2-3

1-1-5. Rear Panel ....................................................................... 2-3

1-2. PC Board Replacement ...................................................... 2-4

1-2-1. Main PC Board ............................................................... 2-4

1-2-2. Output PC Board ............................................................ 2-4

1-2-3. Power PC board .............................................................. 2-5

SERVICING DIAGRAMS

1. STANDING PC BOARDS FOR SERVICING ......................... 3-1

2. CIRCUIT SYMBOLS AND

SUPPLEMENTARY EXPLANATION ..................................... 3-2

2-1. Precautions for Part Replacement .................................... 3-2

2-2. Solid Resistor Indication .................................................... 3-2

2-3. Capacitance Indication ....................................................... 3-2

2-4. Inductor Indication ............................................................. 3-3

2-5. Waveform and Voltage Measurement .............................. 3-3

2-6. When Replaced ROM ICs or Upgraded Firmware ........ 3-4

3. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM .......................................................... 3-5

4. BLOCK DIAGRAMS.................................................................. 3-7

4-1. Overall Block Diagram ...................................................... 3-7

4-2. Power Supply Block Diagram ........................................... 3-9

4-3. Front Display, Power Switch Block Diagram ................3-10

SECTION 2

1-2-4. Front PC Board ............................................................... 2-5

1-3. Mechanism Parts ................................................................. 2-6

1-3-1. Mechanism Chassis Assembly ....................................... 2-6

1-3-2. Loading Belt .................................................................... 2-6

1-3-3. Loading Motor ................................................................ 2-7

1-3-4. Sub Chassis (with a pickup mechanism) ...................... 2-7

1-3-5. Pickup Mechanism Assembly ........................................ 2-8

1-3-6. Gear A Assembly, Gear B and

Rack Gear Assembly ...................................................... 2-8

1-3-7. Feed Motor ...................................................................... 2-9

SECTION 3

4-4. Main Block Diagrams ....................................................... 3-13

4-5. Output Block Diagram ..................................................... 3-17

5. CIRCUIT DIAGRAMS ............................................................. 3-18

5-1. Power Supply Circuit Diagram ....................................... 3-18

5-2. Front Display, Power Switch Circuit Diagram .............. 3-21

5-3. Main Circuit Diagram ......................................................3-24

5-4. Output Circuit Diagram ................................................... 3-41

5-5. Motor System Circuit Diagrams ..................................... 3-47

6. PC BOARDS .............................................................................. 3-49

6-1. Power Supply PC Board ................................................... 3-49

6-2. Main PC Board ................................................................. 3-50

6-3. Output PC Board .............................................................. 3-55

SAFETY PRECAUTION ................................................................. 4-1

NOTICE ............................................................................................. 4-1

ABBREVIATIONS ........................................................................... 4-1

1. Integrated Circuit (IC) ............................................................ 4-1

2. Capacitor (Cap) ....................................................................... 4-1

3. Resistor (Res) ........................................................................... 4-1

SECTION 4

PARTS LIST

4. EXPLODED VIEWS................................................................... 4-2

4-1. Packing Assembly ............................................................... 4-2

4-2. Chassis Assembly ................................................................ 4-3

4-3. Mechanism Assembly ......................................................... 4-4

5. PARTS LIST ................................................................................ 4-5

Page 5

SECTION 1

General Descriptions

1. PREPARATION FOR SERVICING

The Pickup Head consists of a laser diode that is very susceptible to external static electricity.

Although it may operate properly after replacement, if subjected to electrostatic discharge during replacement, its

life may be shortened. When replacing the laser diode, LSI's and IC's, use a conductive mat, soldering iron with

ground wire, etc. to protect against damage from static electricity.

Ground conductive

wrist strap for body.

Soldering iron

with ground wire

or ceramic type

Conductive mat

1MΩ

The ground resistance

between the ground line

and the ground is less than 10Ω.

Fig. 1-1-1

1-1

Page 6

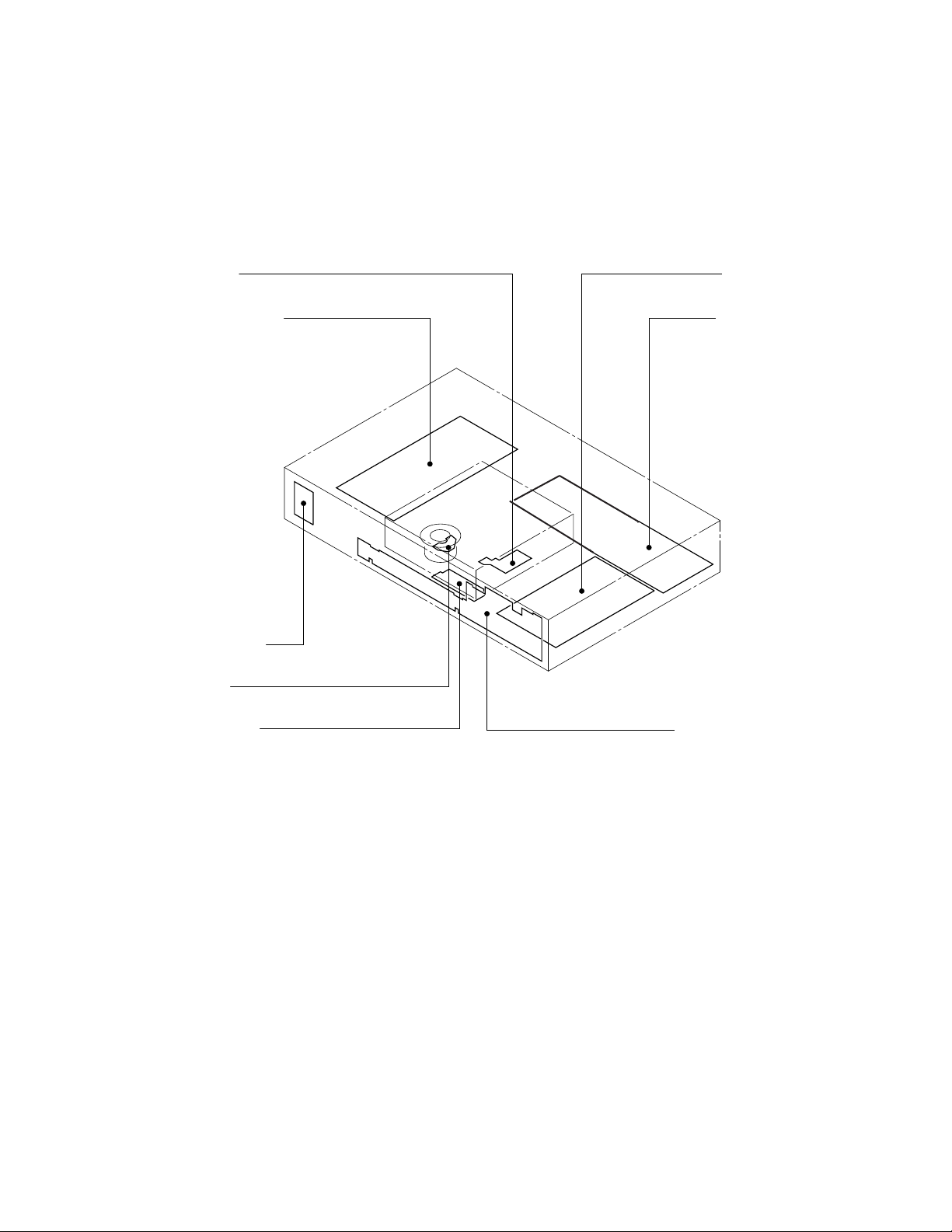

2. LOCATION OF MAIN PARTS AND MECHANISM PARTS

EU05 Output PC board

Feed motor PC board

EU03 Front display PC board

Loading motor PC board

Disc motor PC board

EU04 Power SW PC board

EU01 Main PC board

EU02 Power supply PC board

2-1. Location of Main Parts

Fig. 1-2-1

1-2

Page 7

2-2. Location of Mechanism Parts

y

y

r

d

s

Tr a

Clamper sta

Fig. 1-2-2 Mechanism chassis assembly (Top side)

Loading moto

PC boar

Mechanism chassi

Fig. 1-2-3 Mechanism chassis assembly (Bottom side)

1-3

Page 8

Loading belt

r

r

r

r

Gea

Kick lever

Loading motor

Disc motor

Gea

Gea

Cam Slide

Fig. 1-2-4 Mechanism chassis assembly (Internal side)

1-4

Page 9

Front damper

r

r

y

r

r

d

Gear A

Gear B assembly

Rack gear

assembly

Front dampe

Sub chassis

Pickup assembl

Rear damper

Rear dampe

Fig. 1-2-5 Pickup mechanism chassis assembly (Top side)

Feed moto

Feed moto

PC boar

Fig. 1-2-6 Pickup mechanism chassis assembly (Bottom side)

1-5

Page 10

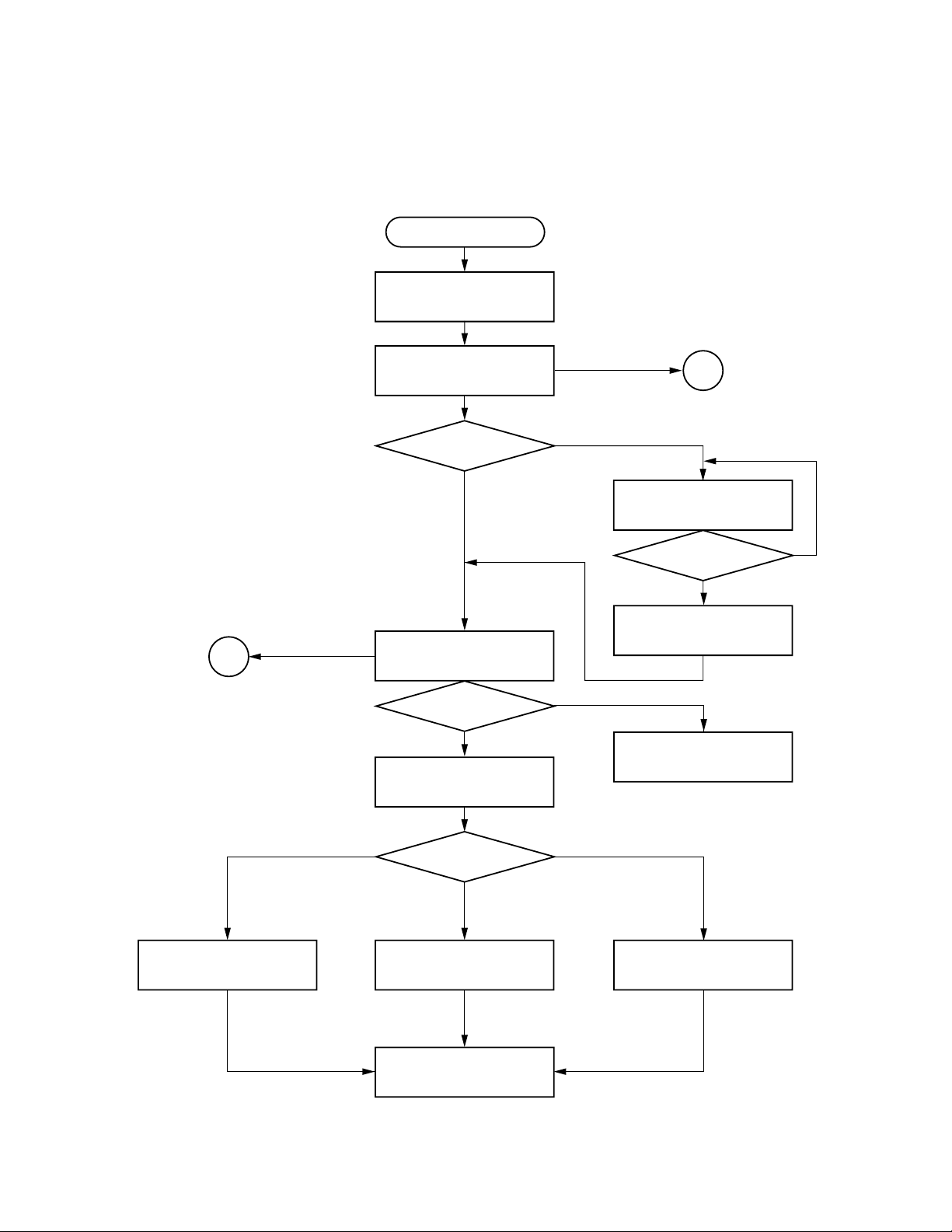

3. TROUBLESHOOTING

3-1. Main Circuit

3-1-1. Servo System

(1) Initial Operation after Power ON

Power ON

Send each LSI hard RST

command and initial command.

Pickup head is positioned at

transmission initial position.

Is tray closed?

Pin 5 of CN502,

TCLS=L

Y

2

NG

Disc presence/absence and

disc judgement

Is a disc present?

Y

DVD or CD initial setting.

N

Tray close operation

Pin 6 of IC601: LDMP = H/L

Pin 7 of IC601: LDMN = L

Tray stops.

Pin 6 of IC601: LDMP = H

Pin 7 of IC601: LDMN = L

N

Laser OFF

Display: INSERT DISC

Monitor screen: NO DISC

1

Is tray closed?

Pin 5 of CN502:

TCLS = L

Y

N

H

DVD single (single-layer)

DVD single

Initial setting.

DVD single

(single-layer)/DVD dual

(dual-layer)/CD?

DVD dual (dual-layer)

DVD dual

Initial setting.

To each disc playback process.

Fig. 1-3-1

1-6

CD

CD

Initial setting.

Page 11

1

Pickup (P.U.) transmission initial

operation does not occur.

The pickup transmission initial operation is carried out to

determine the initial position by transmitting the pickup to the

innermost position once (start-limit switch (pin 4 of CN503)

develops "L".) and to the external direction at low speed

(start-limit switch develops "H", turning off the switch.).

Does pulse of

1.65V 1.65V develop at

pin 162 of IC502?

Y

Check feed gear.

N

Check BUS between IC502

and IC601 and oscillation.

Fig. 1-3-2

2-1

"No disc" misjudgement display of

N

disc presence.

Does lens move with

UP/DOWN full stroke in

focus direction?

Y

N

3

Does focus search

voltage of 1.65V 0.4V develop

at pin 1 of IC504 (E597)?

Y

Does search signal

output at both edges of focus coil?

(Pins 10 to 13 of CN501)

Y

Check pickup head

and wiring.

Is laser current normal?

Y

Does SBAD signal

develop more than 0.3V?

Y

Check peripheral

circuit of IC601.

N

N

Check IC502.

Check IC505.

Fig. 1-3-3

N

Check IC501.

Lens cleaning.

Replace pickup head.

1-7

Page 12

2-2

3

Disc kind misjudgement

(Initial setting is NG.)

N

Are FE and SBAD

signals for each disc normal?

Check peripheral

circuit of IC601.

Check IC501.

Lens cleaning.

Replace pickup head.

Fig. 1-3-4

Check laser current.

lop 50 mA

Y

Check pins 14, 15

and 16 of IC501

serial bus.

Check peripheral

circuits of IC501,

Q501 and Q502.

Check laser current.

50 mA lop 90 mA

lop = Voltage between

E522 and E523/3.3Ω

Y

Check peripheral circuits

of IC501, Q501 and Q502.

lop 90 mA

Check wiring for

pickup head.

Replace pickup

mechanism.

Fig. 1-3-5

DVD single (single-layer) disc

detection waveform

FE signal

Pin150 (TP504) of IC502

SBAD signal

Pin152 (TP506) of IC502

V : 500 mV/div

H : 2 ms/div

Fig. 1-3-6 Fig. 1-3-7 Fig. 1-3-8

1.65V

DVD dual (dual-layer) disc

detection waveform

V : 500 mV/div

H : 2 ms/div

CD disc

detection waveform

V : 500 mV/div

H : 2 ms/div

1-8

Page 13

(2) Picture appears (PLAY)

PLAY

4

2-1

N

N

Disc motor (D.M.) forced

accelleration (500 ms)

Focus search

Is forcus servo

CLV servo ON.

Tracking balance adjustment

Tracking servo ON.

Focus gain adjustment

Tracking gain adjustment

Y

Y

Y

Y

Y

ON?

Repeat three times.

N

N

N

:

Automatic adjustment is carried

out when a disc is replaced after

power ON.

5

4

6

Focus balance adjustment

RF gain adjustment

N

N

Does NG continue

more than 3 s.?

Y

Disc playback NG

Is address code

possible to read?

Y

Search Picture appears.

Fig. 1-3-9

1-9

Page 14

4

Disc motor (D.M.) does not rotate.

Do signals output to

pins 4 to 9 of CN501?

Y

Check IC501.

Does pin 117 of IC502

(TP511) PLCK oscillate around

10 MHz ?

Check peripheral circuits

of IC510 and IC503.

Check disc motor and wiring.

5

Focus servo is NG.

N

N

Are FE, SBAD,

FSON signals normal?

Y

Check peripheral circuit of IC601.

Check wiring for

pickup head.

Lens cleaning.

Replace pickup

mechanism.

Y

Fig. 1-3-10

N

Check peripheral

circuit of IC503.

Focus servo ON

signal waveform

Focus search Focus servo on

Fig. 1-3-12

FE signal

Pin 150 (TP504)

of IC502

0.3V

1.65V

0.3V

SBAD signal

Pin 152 (TP506)

of IC502

Fig. 1-3-11

1-10

Page 15

6

Tracking servo is NG.

Signal waveform at

tracking servo ON (CD)

N

Check IC501.

Fig. 1-3-13

TE signal

Pin 151 (TP503) of IC502

1.65V

RFRP signal

Pin 153 (TP501) of IC502

Is TE signal normal?

Y

Check peripheral

circuit of IC601.

Signal waveform at

tracking servo ON (DVD)

ON search Tracking servo on

Fig. 1-3-14

Search ON (SRCH)

Pin 38 (TP508) of IC502

Fig. 1-3-15

1-11

Page 16

7

Disc playback is NG (DVD).

Is PLL locked?

(Refer to waveforms.)

Y

Check signal process

system following to IC503.

N

Check peripheral circuits of

IC502 and IC601.

N

Check peripheral circuits

of IC501and IC502.

Fig. 1-3-16

Does pulse of

L = 1.65V and H = 3.3V

develop at pin 131 and

L = 0V and H = 1.65V

develop at pin 132

of IC502?

Y

Does RF output

higher than 1.5 V(p-p)

develop at pin 45 (TP515)

of IC501 ?

Y

Pin 57 of IC501 = 2.4V

Pin 58 of IC501 = 3.0V

Y

N

Check peripheral circuits

of IC502 and IC601.

N

Check IC501.

Lens cleaning.

Pickup mechanism

replacement

DVD RF signal

CD RF signal

Fig. 1-3-17

DVD RF signal

Pin 45 (TP515) of IC501

V : 500 mV/div

H : 50 ns/div

CD RF signal

Pin 45 (TP515) of IC501

PLL works as a servo loop to generate a clock signal for reading

RF signal binary data. With the PLL locked, the eye pattern is

identified clearly when triggered with the read clock PLCK.

DVD playback waveform

DVD RF signal

Pin 45 (TP515) of IC501

DVD PLCK

Pin 117 (TP511) of IC502

CH1 : TP515 DVDRF 500 mV/div

CH2 : TP511 DVDPLCK 5 V/div

50 ns/div

Fig. 1-3-19

CD playback waveform

CD RF signal

Pin 45 (TP515) of IC501

Fig. 1-3-18

V : 500 mV/div

H : 100 ns/div

1-12

CH1 : TP515 CDRF 500 mV/div

CH2 : TP511 CDPLCK 5 V/div

100 ns/div

Fig. 1-3-20

CD PLCK

Pin 117 (TP511) of IC502

Page 17

3-1-2. Location Diagram of Servo Test Point

E594 DMDRV

E595 FMDRV

E596 TRDRV

E597 FODRV

CN503

CN502

CN602

E523

E522

TP515 RF

IC504

IC501

IC601

TP506 RFSB

(SBAD)

IC502

CN501

TP503 TE

IC502

CN801

CN901

IC305

CN301

TP505 VREF

TP504 FE

TP501 RFRP

TP511 PLCK

TP507 FSON

TP509 VMCK

(23MHz)

TP508 SRCH

Fig. 1-3-21

1-13

Page 18

This page is not printed.

1-14

Page 19

SECTION 2

PART REPLACEMENT AND

ADJUSTMENT PROCEDURES

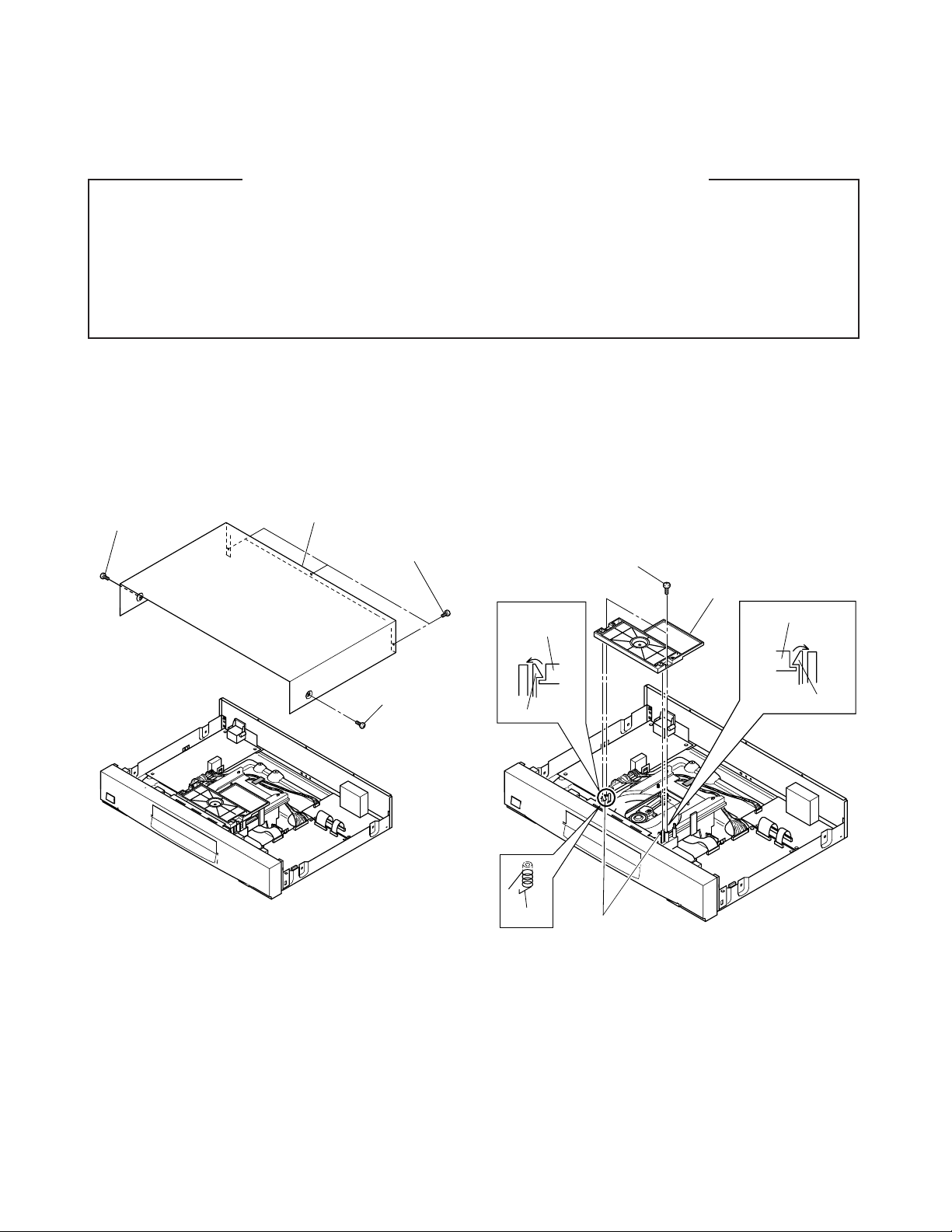

CAUTIONS BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to take a proper ground-

ing treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a magnetized

screwdriver in servicing. Several kinds of screws are used and some of them need special cautions. That is, take care

of the tapping screws securing molded parts and fine pitch screws used to secure metal parts. If they are used improp-

erly, the screw holes will be easily damaged and the parts can not be fixed.

1. REPLACEMENT OF MECHANICAL PARTS

1-1. Cabinet Replacement

1-1-1. Top Cover

1. Remove five screws (1) and remove the top cover (2).

Screw (1)

Top cover (2)

Screws (1)

Screw (1)

1-1-2. Clamper Stay

<Removal>

1. Remove two screws (1).

2. Release two claws and remove the clamper stay (2).

Screws (1)

Clamper stay (2)

Clamper

stay (2)

Claw

A

Clamper stay (2)

Claw

Fig. 2-1-1

2-1

Spring

Claws

Fig. 2-1-2

Page 20

<Mounting >

1. The spring for tray side pressure is inserted into the

portion “A”. (Refer to Fig. 2-1-2.)

2. By referring to Fig. 2-1-3, insert the spring normally

and mount the clamper stay.

This part should be touch

to the left side of the tray.

NG

1-1-3. Tray Panel

<Tray Ejection>

1. Slide the slider (2) of the mechanism chassis assem-

bly (1) with a screwdriver, etc. in the arrow direction,

so that the tray (3) is ejected.

Note:

• Take care not to damage the pickup and other parts.

OK

Mechanism

chassis assembly

Press down by finger

unitil fix the clamper assembly

NG

Spring

Tray

Screw

driver

Mechanism

chassis assembly (1)

Slider (2)

Tray (3)

Front panel

Fig. 2-1-4

No floating

OK

Fig. 2-1-3

Floating NG

NG

<Tray Panel Removal>

1. Eject the tray (3).

2. Twist the tray panel (4) a little in the arrow A

direction with the tray (3) hold by hand to release

two claws and lift up the tray panel (4) in the arrow B

direction, then the tray panel (4) is removed.

(Refer to Fig. 2-1-5.)

3. When mounting the tray panel (4), insert the tray

panel (4) along the grooves of the both sides of the

tray (3) until clicking.

2-2

Page 21

B

Tray (3)

• After inserting the tray (3), confirm that the mark of

the gear (4) matches with that of the rack gear on the

tray (first tooth of the gear). (Refer to Fig. B.)

Figure A

Gear (4)

Triangle mark

Tray panel (4)

Tray (3)

A

Claws

Tray panel (4)

Fig. 2-1-5

1-1-4. Front Panel and Tray

1. Remove the flexible cable (1).

2. Release four claws and remove the front panel (2).

3. Pull out the tray (3) to this side.

The first tooth of the gear of

this side on the tray rack gear.

Rack gear

Position of the line

Pickup mechanism

assembly

Gear (4)

Slider

Tray (3)

Gear (4)

Claw

Tray (3)

Claws

Front panel (2)

Flexible cable (1)

Claw

Fig. 2-1-6

Note:

• Insert the tray (3) with the front side of the pickup

mechanism assembly descended. (The slider positions to the left side.)

• The gears are required to match their phases each

other. After setting the gear (4) as shown in the figure

“A”, insert the tray (3). When inserting a tray (3),

push the rack gear side shown by the arrow.

Marking

Figure B

Fig. 2-1-7

1-1-5. Rear Panel

1. Remove three screws (1) and remove the rear panel (2).

Screw (1)

Rear panel (2)

Fig. 2-1-8

2-3

Page 22

Tape (3)

Connector (2)

Screws (4)

Screws (5)

Flexible cables (1)

Output

PC board (6)

Twist more than 9 times.

1-2. PC Board Replacement

1-2-1. Main PC Board

Note:

• Before removing the main PC board (4), be sure to

short-circuit the laser diode output land.

After replacing, open the land as it was after inserting

the flexible cables (1).

1. Remove the top cover. (Refer to item 1-1-1.)

2. Remove six flexible cables (1) and remove one

connector (3).

3. Remove four screws (2).

4. Release two claws and remove the main PC board (4).

Note:

• When mounting, be sure to twist the wire for the

connector (3) several times.

Pickup head

1-2-2. Output PC Board

1. Remove the rear panel. (Refer to item 1-1-4

2. Peel off the tape (1).

3. Remove the connector (2).

4. Disconnect two flexible cables (3).

5 Remove the wire part of the connector (5) from the

binding band (4).

6. Remove three screws (6) and remove the output PC

board (7).

Note:

• When mounting, keep the wire part of the connector

(5) with the banding band (4).

Output PC board (7)

Tape (1)

Binding band (4)

Screws (6)

Laser diode

output land

Flexible

cables (1)

Main PC board (4)

Claws

Connector (2)

Screws (2)

Connector (3)

Flexible

cables (1)

Flexible cables (3)

Connector (5)

Fig. 2-1-10

Twist more than 7 times.

Fig. 2-1-9

2-4

Page 23

1-2-3. Power PC board

1. Peel off the tape (1).

2. Remove the connectors (2) and (3).

3. Release the wire part of the connector with the

binding band (4) tightened.

4. Remove three screws (5).

5. Remove two screws (6).

6. Release two claws and remove the power supply PC

board (7).

Power PC board (7)

1-2-4. Front PC Board

1. Remove the front panel. (Refer to item 1-1-4.)

2. Remove four screws (1) and remove the front display

PC board (2)

3. Remove two screws (3) and remove the power switch

PC board (4).

Power SW

PC board (4)

Screws (3)

Front display

PC board (2)

Screws (1)

Screws (5)

Claws

Connector (2)

Tape (1)

Screws (6)

Connector (3)

Fig. 2-1-12

Binding band (4)

Fig. 2-1-11

2-5

Page 24

1-3. Mechanism Parts

1-3-1. Mechanism Chassis Assembly

Note:

• When removing the mechanism chassis assembly (3),

be sure to short-circuit the laser diode output land

before removing the connector and the flexible

cables.

After replacing, open the land as it was after inserting

the connector and flexible cables.

1. Remove the tray. (Refer to items 1-1-3 and 1-1-4.)

2. Remove three flexible cables (1).

3. Remove four screws (2) and remove the mechanism

chassis assembly (3).

1-3-2. Loading Belt

1. Remove the gear (1) by releasing the claw.

2. Remove the gear (2).

3. Remove the gear (3) and the loading belt (4).

4. Replace the loading belt (4) with a new one.

5. When mounting, perform the reverse order of the

removal.

Note:

• When mounting the loading belt (4), twisting and

attaching of a grease, etc. are not allowed.

Gear (1)

Gear (2)

Mechanism

chassis assembly (3)

Screws (2)

Pickup head

Laser diode

output land

Flexible cables (1)

Loading belt (4)

Gear (3)

Claw

Mechanism

chassis assembly

Fig. 2-1-14

Fig. 2-1-13

2-6

Page 25

1-3-3. Loading Motor

1. Remove the loading belt. (Refer to item 1-3-2.)

2. Remove two screws (1) and two claws. Then remove

the loading motor (2) (with the loading motor PC

board (3) attached).

3. Desolder the terminal section of the loading motor (2)

and remove the loading motor PC board (3).

4. Replace the loading motor (2) with a new one.

5. When mounting, perform the reverse order of the

removal.

Note:

• When replacing the loading motor, meet the polarity

phase of the terminals. (Mount the motor with the

label positioned as shown in Fig. 2-1-15.)

1-3-4. Sub Chassis (with a pickup mechanism)

1. Turn the mechanism chassis assembly (1) upside down.

2. Remove one screw (2) and release the boss “A” from the

claw. Then remove the sub chassis (3) (with the pickup

mechanism) by sliding in the arrow direction.

3. When mounting, perform the reverse order of the

removal.

Note:

• When mounting the sub chassis (3) (with the pickup

mechanism), first, insert the boss “C” along the

groove of the cam slider up/down cam (4) and next,

the boss “B” and “A”.

• The boss “A” and “B” may be used with washers.

(One or two washers are used to prevent from the slust

rattling. In some cases, no washer is used.)

When the washer(s) is used, be sure to assemble as it

was without losing.

Mechanism

chassis assembly

Claw

Loading motor (2)

Desolder

Fig. 2-1-15

Screws (1)

Claw

Motor label

side

Loading motor

PC board (3)

Screw (2)

Claw

Sub chassis (3)

(with the pickup mechanism attached)

Boss A

Washers

Boss A

Boss C

Boss B

Groove

Groove

Cam slider

up/down cam (4)

Mechanism chassis

assembly (1)

2-7

Claw

Boss B

Groove

Fig. 2-1-16

Page 26

1-3-5. Pickup Mechanism Assembly

<Removal>

1. Remove four screws (1) and four washers (2) and

then remove the pickup mechanism assembly (3).

<Mounting>

1. Replace the pickup mechanism assembly (3) with a

new one.

2. When mounting, perform the reverse order of the

removal.

Screw (1)

Washers (2)

Damper

(Black)

Damper

(Blue)

Damper

(Black)

1-3-6. Gear B Assembly, Gear A and Rack Gear

Assembly

<Removal>

1. Remove one screw (5) and remove the gear B assem-

bly (1).

2. Remove the gear A (2).

3. Remove one screw (3) and remove the rack gear

assembly (4).

Screw (3)

Gear B assembly (1)

Rack gear

assembly (4)

Gear A (2)

Screw (5)

Claw

Damper

(Blue)

Pickup mechanism

assembly (3)

Fig. 2-1-17

Note:

• The dampers’ color differs when used for the front

side and the rear.

• When mounting the pickup mechanism assembly (2)

with the screws (1), push the pickup mechanism

assembly (2) downward without being caught and

tighten the screws (1) after placing the washer with

the damper bent.

Screw (1)

Washer (2)

Pickup mechanism

assembly (3)

(W6.6P0.5D12)

Pickup mechanism

assembly

Fig. 2-1-19

<Mounting>

1. When mounting, perform the reverse order of the

removal.

2. Mount the gear B assembly (1) by pushing the pickup

head (5) to the disc motor side (arrow A direction)

and shifting the upper gear of the rack gear assembly

(4) in the arrow B direction. (Refer to Fig. 2-1-20.)

3. Fit the positioning holes on the upper gear and lower

gear of the gear B assembly (1) and mount on the

pickup mechanism assembly with the phase matched.

At this time, note that the phase of the gear B

assembly (1) and the gear A (2) shows the status in

the Fig. 2-1-21.

Damper

Fig. 2-1-18

2-8

Page 27

Positioning holes

Gear B assembly (1)

Pickup Head (5)

A

B

Gear A (2)

Pickup mechanism

assembly

Rack gear assembly (4)

Fig. 2-1-20

Note:

• Mount the gear B assembly (1) and the gear A (2)

with their gear teeth placed more than one tooth at

least inside the shaded portion.

Innermost position

of pickup head

Within the position shown

by the shaded porition.

1-3-7. Feed Motor

<Removal>

1. Remove the gear B assembly (1) and the gear A (2).

(Refer to item 1-3-6.)

2. Remove two screws (1) and remove the feed motor (2)

(with the feed motor PC board (3) attached).

(Refer to Fig. 2-1-22.)

3. Desolder the terminals of the feed motor (2) and

remove the feed motor PC board (3).

<Mounting>

1. Tighten the feed motor (2) on the pickup mechanism

assembly with two screws (1).

2. Insert the feed motor PC board (3) with the position-

ing pin on the chassis matched and solder the

terminals.

3. Perform the reverse order of the removal.

Note:

• After mounting, put the lead wires through the notch

of the pickup mechanism assembly.

• When replacing the loading motor, meet the polarity

phase of the terminals. (Mount the motor with the

label positioned as shown in Fig. 2-1-22.)

Screws (1)

Rack gear assembly (4)

Gear A (2)

Fig. 2-1-21

Gear B assembly (1)

Pickup mechanism

assembly

Notch

Lead wires

Feed motor (2)

Motor label

side

Desolder

Feed motor

PC board (3)

Fig. 2-1-22

2-9

Page 28

This page is not printed.

2-10

Page 29

SECTION 3

SERVICING DIAGRAMS

1. STANDING PC BOARDS FOR SERVICING

EU02 Power supply PC board

EU04 Power SW PC board

EU05 Output PC board

EU03 Front display PC board

EU01 Main PC board

Fig. 3-1-1

3-1

Page 30

2. CIRCUIT SYMBOLS AND SUPPLEMENTARY EXPLANATION

100k

Rated Wattage Type Tolerance

100µ

Temperature

response

Rated

voltage

Tolerance

2-1. Precautions for Part Replacement

• In the schematic diagram, parts marked (ex.

F801) are critical part to meet the safety regulations,

so always use the parts bearing specified part codes

(SN) when replacing them.

2-2. Solid Resistor Indication

Unit None ...........Ω

K ...........kΩ

M ...........MΩ

Tolerance None ...........±5%

B ........... ±0.1%

C ........... ±0.25%

D ...........±0.5%

F ...........±1%

G ...........±2%

K ...........±10%

M ...........±20%

Rated Wattage (1) Chip Parts

None ......... 1/16W

(2) Other Parts

None ......... 1/6W

Other than above, described in the Circuit Diagram.

Type None ...........Carbon film

S ...........Solid

R ........... Oxide metal film

W ...........Metal film

W ...........Cement

FR ...........Fusible

• Using the parts other than those specified shall violate

the regulations, and may cause troubles such as

operation failures, fire etc.

Eg. 1

FIg. 3-2-1

2-3. Capacitance Indication

Symbol

Unit None ...........F

Rated voltage None ...........50V

Tolerance (1) Ceramic, plastic, and film capacitors of which

Temperature characteristic None ...........SL

(Ceramic capacitor) For others, temperature characteristics are

Static electricity capacity Sometimes described with abbreviated letters as

(Ceramic capacitor) shown in Eg. 3.

+

...........Electrolytic, Special electrolytic

NP

...........Non polarity electrolytic

...........Ceramic, plastic

M

...........Film

...........Trimmer

µ ...........µF

p ........... pF

For other than 50V and electrolytic capacitors,

described in the Circuit Diagram.

capacitance are more than 10 pF.

None ...........±5% or more

B ........... ±0.1%

C ........... ±0.25%

D ...........±0.5%

F ...........±1%

G ...........±2%

(2) Ceramic, plastic, and film capacitors of which

capacitance are 10 pF or less.

None ...........more than ±5% pF

B ........... ±0.1 pF

C ........... ±0.25 pF

(3) Electrolytic, Trimmer

Tolerance is not described.

described. (For capacitors of 0.01 µF and

no indications are described as F.)

Eg. 2

Fig. 3-2-2

Eg. 3

104

4

pF (0.1µF)

10x10

Temperature characteristic

(or Temperature characteristic+

Static electricity capacity tolerance)

Fig. 3-2-3

3-2

Page 31

2-4. Inductor Indication

10µ

Type Tolerance

Unit None ...........Η

µ ...........µH

m ...........mH

Tolerance None ...........±5%

B ........... ±0.1%

C ........... ±0.25%

D ...........±0.5%

F ...........±1%

G ...........±2%

K ...........±10%

M ...........±20%

2-5. Waveform and Voltage Measurement

• The waveforms for CD/DVD and RF shown in the

circuit diagrams are obtained when a test disc is

played back.

• All voltage values except the waveforms are expressed

in DC and measured by a digital voltmeter.

Eg. 4

Type name

Fig. 3-2-4

Eg. 5

Fig. 3-2-5

3-3

Page 32

2-6. When Replaced ROM ICs or Upgraded Firmware

1. When replaced the following ROM ICs, it is necessary

to write the data into the new ICs.

1) IC615 (firmware)

2) IC613 (Setup default data and other information)

2. When the firmware is upgraded, rewriting the new

firmware into IC615 may be requested for servicing.

DATA UPDATE KIT

(RS-232C Interface/cable)

RS-232C

cable

3. Connect a computer to the main PC board of the DVD

video player with using DATA UPDATE KIT (P/No.

79080074). (Fig. 3-2-6)

4. Writing operation

Refer to the instruction attached to the data floppy

disc.

Computer

(MS-DOS/PC-DOS)

Fig. 3-2-6

Note:

• The firmware and setup data floppy discs are not available as service parts.

CN601

3-4

Page 33

7

6

5

4

3

2

1

VCC+5V

GND

NC

VEE-9V

GND

E+6V

VCC+9V

ANALOG 5V

GND

-5V

-9V

GND

NON REG+6V

ON-OFF 9V

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

GND

DA3CSX

DA2CSX

SCLK

SD ATA

AD ATA1

AD ATA3

BCK

LRCK

MCK

MIC ON

ZEROX

X2fs

4448X

G+6dB

RSTX

2131X

MIC-DATA

HMUTE

BIAS+5V

Rch-IN

AGND

Lch-IN

AGND

IEC958IN

VGND

C

R

-INPUT

VGND

C-INPUT

VGND

C

B

-INPUT

VGND

Y-INPUT

DGND

S1

NTPALX

NC

NC

VGND

C

R

-OUTPUT

VGND

C-OUTPUT

VGND

C

B

-OUTPUT

VGND

Y-OUTPUT

DGND

S1

NTPALX

NC

NC

F-

F+

VKK-24V

GND

DSTBX

DSPCKX

DSPSO

DSPSI

DSPRST

STBYX

E+5V

GND

GND

GND

DA3CSX

DA2CSX

SCLK

SD ATA

AD ATA1

AD ATA3

BCK

LRCK

MCK

MIC ON

ZEROX

X2fs

4448X

G+6dB

RSTX

2131X

MIC-DATA

HMUTE

BIAS+5V

Rch-OUT

AGND

Lch-OUT

AGND

IEC958OUT

1

2

3

4

5

6

7

8

9

10

11

12

13

13

12

11

10

9

8

7

6

5

4

3

2

1

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

18

171615

141312

11

10

987654321

123456789

10

111213

141516

17

18

GND

VREF

VCC

F0

E0

A0

D0

C0

B0

F+

T -T+F -

VCC

GND

LD

MON

VOR

GND

LDMP

TOPN

LDMN

TCLS

TRAY

GND

5V

TXD

CTS

RXD

RTS

GND

5V

TXD

CTS

RXD

RTS

FMN

FMP

GND

LMT

DMN

DMP

VCC

DMFG

123456789

1011121314

E12V

EVER 5V

PO ON-OFF SIG

ANALOG 5V

NON REG +6V

ON-OFF 8V

DIGITAL 5V

DIGITAL 3V

GND

GND

GND

-24V

F2 (-)

F1 (+)

GND

E+5V

POWLED

POWKEY

DC+12V

E+5V

PWON

VCC+5V

VCC+6V

M+8V

VDD+5V

VDD+3V

GND

GND

MGND

VKK-24V

F-

F+

123456789

10

11

12

13

14

8765432

1

1234567

8

65432

1

12345

6

123

4

123

4

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

10

11

12

13

12345

6

12345

6

7P

Press-fit

7P

Press-fit

14P

Press-fit

W501

FFC 1mm 18P

FFC 1.25mm 6P W502

FFC 1mm 8P W503

FFC 1mm 4P

W102

FFC 1mm 13P

W602

FFC 1mm 25P

W901

FFC 1mm 13P

W301

CNY03

Board-in

CN802

Lch +6dB

Lch OUT

Lch 0dB

Rch +6dB

Rch OUT

Rch 0dB

CTL

9V

Lch +6dB

Lch OUT

Lch 0dB

Rch +6dB

Rch OUT

Rch 0dB

CTL

9V

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

WW91

(Sub output circuit is not

provided depending on units.)

CNW91

B88-PH-K-S

PUH

TRY

MOTOR

CN501

CN502

CN503

CN801

CN103 CN102

CN801

Board-in

CNY01 CNX01

CN901 CN301

CN603

CN601

CN602

CN101

EU05 OUTPUT

EU52 SUB OUTPUT

MECHA

EU02

POWER

EU04 POWER-SW

EU03 FRONT

EU01 MAIN

3-5 3-6

3. PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

Fig. 3-3-1

Page 34

PUH

Display-CPU

TMP47C416F

Display

(FL)

Feed

Motor

Tray

Motor

PUH Driver

Motor Driver

KA3032

2M-DRAM

HY512264JC-50

2M-DRAM

HY512264JC-50

Video Encoder

ADV7170

Decryption,

Video Process,MPEG-2 Decoder

Dolby-Digital Decoder, OSD

ZORAN

MD36710X

16M-S-DRAM

HY57V16160ALTC-10 x2

1chip-SERVO

Data Processor

TC9453F

SPM

LPF&VideoOut

x 4ch

Composit Video

Out

S Video Out

Y,C

B,CR video

Out

Coaxial Digital

Audio Out

22. 5792

MHz

Main-CPU

TMP94CS40AF

8M-FROM

MBM29F800TA-55

EE-PROM

S24C04BFJ-TB

9MHz

CeraOSC

27MHz

Xtal OSC

RF Amp.

TA1293F

Data/Control Bus

DVD AV Data

SP DIF Data

Buffer

TC74HCU04AF

LPF&

Amplifier

Audio Out

SL,SR Analog

Audio Out

Y,C Mixer

&Buffer

Track Buffer

4M-DRAM

MSM514800C-70

TC203G08AF

-0103(Z)

Audio-DAC

Audio-DAC1

ICY01

AD71010

Audio-DAC3

ICY31

AD1854

PCM1727

PCM1727

384fs Audio

Master Clock

SW POWER SUPPLY

FRONT DISPLAY UNIT

MAIN PROCESSOR UNIT AUDIO/VIDEO OUTPUT UNIT

IC501

X501

X601

IC504

IC613

IC614

IC615

IC601

IC503

IC502

IC301

IC101

IC306

IC305,302

IC202

IC201

IC901

ICY09

LPF&

Amplifier

Audio Out

FL,FR Analog

Audio out

LPF&

Amplifier

Audio Out

Center SW

Analog

Audio Out

FL2,FR2 Analog

Audio Out

TOS Link Digital

Audio Out

4-1. Overall Block Diagram

4. BLOCK DIAGRAMS

REDUCTION

NOISE

3D

TC209C08HS

2M-FIFO

MSM51V8221A

IC309

IC310

3-83-7

Fig.3-4-1

Page 35

4-2. Power Supply Block Diagram

3-9

Fig. 3-4-2

Page 36

4-3. Front Display, Power Switch Block Diagram

4-3-1. Front Display

4-3-2. Front Display Pattern

Fig. 3-4-3

3-10

Fig. 3-4-4

Page 37

3-11 3-12

4-3-3. Front Display, Power Switch Block Diagram

GP1U263X

BF

Fig. 3-4-5

Page 38

@

7(%&

(4%&

'3'&

)(%&

+)0RG

021

/'

925

'&$

%

9FF

(

)

/' '59

9U$9

)RFXV

&RLO

7UDFNLQJ

&RLO

9GG

9

,& 5)$

,& 5)$

0

0

3

3

7

7

$

$

)

)

(4%

5)*DLQ

)*DLQ

)($03

)(*DLQ

5)(4

5)53

‘ob

/9/'HW

5)$'6%$'

'3'7(DPS

%7(DPS

7(*DLQ

7*DLQ

9UHI &LUFXLW

7(%

7(2

/9/

)(2

5)2

9U'9

9U$

)(%

6HULDO %86 ,)

G%

G%

$

^

'

'LJLWDO HTXDOL]HU

$XWRPDWLF

DGMXVWPHQW

520

5$0

'DWD

VOLFHU

'9' 6\QFKURQRXV

'HWHFWLRQ3URWHFWLRQ

&' 6\QFKURQRXV

'HWHFWLRQ3URWHFWLRQ

GHFRGH

()0 GHFRGH

(&&

(UURU

&RUUHFWLRQ

&RGH

,&

0 '5$0

9&2

3//

70$;

$GGUHVV

&LUFXLW

6HDUFK FRQWURO

˚

FRQ %86 ,)

&''9' 'DWD ,)

&/9 VHUYR

'

^

$

6\VWHP FORFN

9&2

,&

0 '5$0

W

W

R

R

$

$

9

9

SURF

SURF

H

H

VVRU

VVRU

/6

/6

,

,

,&

5)53

,&

,&

7

7

UDFN EXIIHU FRQWUR

UDFN EXIIHU FRQWUR

O

O

@

@@@@@@@@@@@@@

5)&'

5)'9'

)(,

5)6%

7(,

5)53

3:0

'02

)02

'3'%

@

)&6(55

6%$''

@@@@@@@@@@

@@@ @

,&

,&

0$

0$

,

,

1&

1&

3

3

8

8

&RQWURO %86

6(592 6<67(0

6WDQGDUG YROWDJH

/(9(/ 6+,)7

6:

9UU9

9U'9

@

@@@@@@@@@@@@@@@

)FRLO

)FRLO

7FRLO

7FRLO

)03

/(9(/ 6+,)7

/(9(/ 6+,)7

/(9(/ 6+,)7

/(9(/ 6+,)7

)01

'03

'01

&1

&1

&1

)0

'0

6/7 6:

)*

/0

/'03

/'01

7231 6:

7&/6 6:

)2GUY

75GUY

)0GUY

'0GUY

)22

752

/'3

/'1

7231

7&/6

38+20(6/7 6:

'0)*

7UDFN EXIIHU FRQWURO

'HVFUDPEOH

&' 6XEFRGH4 GHFRGH

9&' +HDGHU GHFRGH

,&

,&

6HUYR

6HUYR

^

'DWD SU

'DWD SU

R

R

F

F

H

H

V

V

VR

VR

U

U

7&

7&

)

)

,& 0RWR

,& 0RWR

U

U

'ULYH

'ULYH

U

U

,&.$

,&.$

3/&.

&''9' 'DWD

3-13 3-14

4-4. Main Block Diagrams

4-4-1. Servo System Block Diagram

Fig.3-4-6

Page 39

4-4-2. Logical System Block Diagram

3-163-15

Fig. 3-4-7

Page 40

3-17

1 Q803

AC120V 60Hz input

ON MODE

V:100 V/div

H:5 µs/div

C-3

1 2

4-5. Output Block Diagram

Fig. 3-4-8

5-1. Power Supply Circuit Diagram

5. CIRCUIT DIAGRAMS

3-18

Fig. 3-5-1

Page 41

3-203-19

Fig. 3-5-2

Page 42

3-21 3-22

5-2. Front Display, Power Switch Circuit Diagram

FWY620-1

Fig. 3-5-3

RN2402

220

FWY620-2

10K

Page 43

IC101, Pin

1

IC101, Pin

2

IC101, Pin

3

IC101, Pin

4

14

X-OUT

V: 2 V/div

H: 100 ns/div

22

STB G1

V: 2 V/div

H: 5 ms/div

21

SI

V: 2 V/div

H: 5 ms/div

20

SO

V: 2 V/div

H: 5 ms/div

E-5

E-6

E-6

E-6

IC101, Pin

5

IC101, Pin

6

IC101, Pin

7

19

SCK

V: 2 V/div

H: 5 ms/div

49

V: 10 V/div

H: 5 ms/div

50

S1

V: 10 V/div

H: 5 ms/div

E-6

C-6

C-6

Fig. 3-5-4

Part Loca No. tion

A101 B 2

C101 E 6

C102 D6

C103 F6

C104 F6

CN101 F1

CN102 F7

CN103 F8

D101 F5

D102 D 3

D141 F9

E002 F 3

E004 E 5

E005 E 5

E006 E 5

E007 E 5

E008 E 5

E025 D 6

E026 D 6

E027 D 6

E028 D 6

E029 D 6

E030 D 6

E031 D 6

E032 D 6

E036 D 6

E037 D 6

E038 D 6

E071 D 4

E072 D 4

E073 D 4

E074 D 4

E075 D 4

E076 D 4

E077 D 4

E078 D 4

E080 D 4

E101 F 1

E102 F 1

E103 F 1

E104 F 1

E105 F 1

E106 F 1

E107 F 1

E108 F 1

E109 F 1

E110 F 1

E111 G 1

E113 F 7

E114 F 7

E121 E 3

E122 F 3

E123 D 3

E124 E 6

E125 E 4

E126 F 2

E127 F 2

E128 F 2

E129 F 2

E130 F 2

E131 F 2

E132 C 2

E133 C 3

E134 C 6

E135 E 6

E141 F 8

E142 F 8

E143 F 8

E144 F 8

E145 F10

E146 F 9

E147 F10

E148 F10

EF+1 B 6

EG01 B 3

EG02 B 3

Part Loca No. tion

EG03 B 3

EG04 B 3

EG05 B 3

EG06 B 4

EG07 B 4

EG08 B 4

EG09 B 4

EG10 B 4

EG11 B 4

EG12 B 4

EG13 B 4

EP01 B5

EP02 B5

EP03 B5

EP04 B5

EP05 B5

EP06 B5

EP07 B5

EP08 B5

EP09 B5

EP10 B5

EP11 B5

EP12 B5

EP13 B4

EP14 B4

EP15 B4

EP16 B4

FG101 G2

FG102 G7

IC101 D 5

L101 F6

MT101 E6

Q101 D 6

Q141 F 10

Q142 F 9

R101 F2

R102 F2

R103 F2

R105 F2

R106 F2

R107 F2

R108 F2

R109 F2

R110 F2

R112 F7

R113 F7

R114 G7

R115 E 3

R119 E 2

R120 E 2

R121 F6

R122 F2

R123 E 6

R124 E 6

R125 D6

R126 C6

R128 B7

R129 B7

R130 B7

R131 E 5

R135 F4

R141 F10

R142 F10

R143 F10

R144 F9

R145 F9

R146 F10

S101 E 3

S102 E 3

S103 D 3

S104 D 3

S105 D 3

S106 E 3

S141 F8

SP101 F4

X101 F 5

3-23

Page 44

5-3. Main Circuit Diagrams

5-3-1. Main ICs Information

TC9453F

MD36710X, TMP94CS40AF

TC203G08AF

ADV7170

MBM29F800TA-55

PCM1727

TA1293F

KA3032

S24C01AFJ-TB

3-24

Page 45

Main ICs Function

Table 3-5-1

Ref. No.

IC613

IC306

IC301

IC502

IC501

IC504

IC901

IC601

IC201

IC615

IC309

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

S24C01AFJ-TB

ADV7170

MD36710X

TC9453F

TA1293F

KA3032

PCM1727

TMP94CS40AF-0103(Z)

TC203G08AF

MBM29F800TA-55

TC203G08AF-0101(Z)

Table 3-5-2 (1/2) ADV7170 Table 3-5-2 (2/2) ADV7170

Name

V

AA

P5-P12

GND

V

AA

P13-P15

HSYNC

FIELD/

VSYNC

BLANK

ALSB

GND

V

AA

GND

RESET

SCLOCK

SDATA

COMP

Power supply

8 bit, 4:2:2 Multiplexed Y/Cr/Cb pixel port

(P7-P0) or

16 bit Y/Cr/Cb pixel port (P15-P0).

P0 represents the LSB.

Ground

Power supply

8 bit, 4:2:2 Multiplexed Y/Cr/Cb pixel port

(P7-P0) or

16 bit Y/Cr/Cb pixel port (P15-P0).

P0 represents the LSB.

HSYNC (Modes 1 & 2) control signal.

Master Mode: control signal output

Slave Mode: control signal acceptance

Dual function field (Mode 1) and VSYNC

(mode 2) control signal.

Master Mode: control signal output

Slave Mode: control signal acceptance

Video blanking control signal. The pixel

inputs are ignored when this is logic level

"0". This signal is optional.

TTL address input. This signal set up the

LSB of the MPU address.

Ground pin

Power supply

Ground pin

This pin resets the on-chip timing generator

and sets the ADV7170 into default mode.

NTSC operation, timing slave mode 0, 8 bit

operation, 2 x composite & S VHS OUT.

MPU port serial interface clock input

MPU port serial data input/output

Compensation pin. Connect a 0.1µF

capacitor from COMP to VAA. For

optimum dynamic performance in low

power mode, the value of the COMP

capacitor can be varied as described in

low power mode section.

IC Name

Function

EE-PROM

Video Encorder

AV Decorder

SERVO & Data Processor

RF Signal processing IC

5-CH Motor Driver

DA Converter

Main Micro Processor

Track Buffer

Flash ROM

3D DNR

Function

Detail

Setup default, memorization of specification setting.

Built-in D/A converter. Encodes digital video signal to analog video

signal of NTSC/PAL system.

Decryption, MPEG-2 Decode, Audio Decode, Sub Picture Decode,

OSD.

Performs servo control of DVD or CD, and performs demodulation

and correction of RF signal.

Equalizes of playback RF signal and generates error detection signal

required for each servo operation.

5ch driver for motor driving.

Stereo audio DA converter with a dual PPL built-in.

Performs system control for all circuits.

Rate control and Buffer control.

Memorization for firmware.

3 Dimension Digital Noise Reduction.

Pin

No.

26

Name

RED/

RED/S-VHS C/V analog output.

Function

CHROMA/V

27

GREEN/

Green/S-VHS Y/Y analog output.

LUMA/Y

28

29

30

31

V

AA

GND

V

AA

BLUE/

Power supply

Ground pin

Power supply

Blue/Composite/U analog output

CVBS/U

32

COMPO-

PAL/NTSC composite video output.

SITE

(CVBS)

33

34

V

R

REF

SET

Voltage reference input for DACs or

voltage reference output.

A 150 ohm resistor connected from this

pin to GND is used to control full scale

amplitudes of the video signal.

35

SCRESET/

RTC

This pin can be configured as an input by

setting MR22 and MR21 of mode register

2. It can be configured as a subcarrier

reset pin, in which case a high to low

transition on this pin will reset the

subcarrier to field 0. Alternately it may be

configured as a real time control (RTC)

input.

36

TTX REQ

Teletext data request signal

Defaults to GND when teletext not selected

(enables backward compatibility to

ADV7175/ADV7176).

37

TTX V

Teletext data

AA

Defaults to VAA when teletext not selected

(enables backward compatibility to

ADV7175A/ADV7176.)

38

39

40

41

P0-P4

8 bit, 4:2:2 Multiplexed Y/Cr/Cb pixel port

(P7-P0) or

16 bit Y/Cr/Cb pixel port (P15-P0). P0

represents the LSB.

42

43

44

GND

CLOCK

Ground pin

TTL clock input.

3-25

Page 46

Table 3-5-3 KA3032

Table 3-5-4 MBM29F800TA-55

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Name

OUT1

IN2.1

IN2.2

OUT2

IN3.1

GND

IN3.2

OUT3

IN4.1

IN4.2

OUT4

CTL

FWD1

REV1

SGND

OPOUT

GND

OPIN(+)

IPIN(–)

MUTE4

MUTE3

MUTE1,2

PVCC1

DO5.2

DO5.1

DO4.2

DO4.1

GND

DO3.2

DO3.1

PGND

DO2.2

DO2.1

DO1.2

DO1.1

PVCC2

GEG50

REG050

GND

RES50

SVCC

REF

IN1.1

IN1.2

Function

CH1 OP-AMP output

CH2 OP-AMP input (+)

CH2 OP-AMP input (–)

CH2 OP-AMP output

CH3 OP-AMP input (+)

Ground

CH3 OP-AMP input (–)

CH3 OP-AMP output

CH4 OP-AMP input (+)

CH4 OP-AMP input (–)

CH4 OP-AMP output

CH5 motor speed control

CH5 forward input

CH5 reverse input

Signal ground

OP-AMP output

Ground

OP-AMP input (+)

OP-AMP input (–)

CH4 mute

CH3 mute

CH1,2 mute

Power supply voltage (for CH5)

CH5 drive output

CH5 drive output

CH4 drive output

CH4 drive output

Ground

CH3 drive output

CH3 drive output

Power ground

CH2 drive output

CH2 drive output

CH1 drive output

CH1 drive output

Power supply voltage

(for CH1, CH2, CH3, CH4)

Regulator output

Regulator 5V output

Ground

Regulator reset

Signal supply voltage

Bias voltage input

CH1 OP-AMP input (+)

CH1 OP-AMP input (–)

Pin

No.

1

8

16

24

25

45

48

29

36

38

45

26

28

11

12

15

47

27

37

9

10

13

14

|

|

|

|

Name

A–1,

A0 – A

18

DQ0 – DQ

CE

OE

WE

RESET

RY/BY

BYTE

V

SS

V

CC

N.C.

Address input

Data I/O

15

Chip enable

Output enable

Write enable

Hardware reset

Ready/busy output

8 bit, 16 bit mode switch

Ground

Power supply

Not connected.

Function

3-26

Page 47

Table 3-5-5 MD36710X (1/5) Table 3-5-5 MD36710X (2/5)

Pin

No.

Host Interface, CD-DSP interface, Sub ode interface (32 pins)

3

4

5

6

7

9

10

11

12

14

|

16

19

|

21

22

24

25

26

27

29

30

31

32

34

Name

HD [15:12]

CDERR (HD [15])

CDFRM (HD [14])

CDDAT (HD [13])

CDDAT (HD [12])

HD [11:8]

SCCLK (HD [11])

SCDAT (HD [10])

SCSYN (HD [9])

SCFRM (HD [8])

HD [7:0]

HA [3:0]

HWR# (HR/W#)

HCS#

HRD# (HDS#)

HRDY

HACK#

HIRQ#

Function

When connecting HWID to VDD,

become data lines 15:12 of 16 bit host

data bus. When connecting HWID to

GND, the lines become CD-DSP serial

input port pins defined as below.

CD-DSP data error input

CD-DSP LR clock (frame) input

CD-DSP data input

CD-DSP bit clock input

When connecting HWID to VDD,

become data lines 11:8 of 16 bit host

data bus. When connecting HWID to

GND, the lines become sub code port

pins defined as below.

Sub code bit clock output

Sub code bit clock input

Sub code sync signal display input

Sub code frame sync input

8 I.s. host data bus. When connecting

HWID to GND, only the 8 I.s. signal is

defined as a host data signal. When

connecting HWID to VDD, 8 I.s. line is

used for of 16 bit data bus.

Host address input. Inputs address

signal that specifies physical address

inside MD36710X.

Host protocol, type A

(HTYPE=GND): HR/W#. Decides

direction of host access.

Host protocol, type B (HTYPE=VDD):

HWR#. Host writing input (active low).

Host chip select input. Active low.

Host protocol, type A (HTYPE=GND):

HDS#.

Data strobe input (active low).

Host protocol, type B (HTYPE=VDD):

HRD#.

Host writing input (active low).

Host ready output (active high). Use

this signal to transmit bit stream via

host bus. External pull-up resistor is

required.

Transmission of CodBurstLen byte

length is determined as 1 packet.

Check that the signal is active before

transmitting each packet. Possible to

write the bit stream serially up to

CodBurstLen byte to MD36710X.

Host acknowledge output (active low).

Protocol is type A, MD36710X asserts

this output and notify completion of

reading or writing cycle.

If this signal is not active, 3-state

condition occurs (External pull-up

resistor is required.).

If protocol is type B, the signal

functions as wait output signal. When

high speed host (microprocessor) is

used, this signal may not be used.

Interruption requirement (active low).

Deassert when host reads interruption

status resister of MD36710X. Also

deassert after host masks interruption in

the interrupt mask resister of

MD36710X or reseting.

If HIRQ# is not asserted, 3-state

condition occurs (External pull-up

resistor is required.)

Pin

No.

35

36

37

130

141

142

GPI/O signal (4 pins)

2

122

123

159

PLL signal (6 pins)

126

128

129

135

137

136

Name

HWID

HORD

HTYPE

STNDBY#

RESET#

IDLE

GPSI

GPAI/O [1:0]

GPSO

GCLK1

XO

GCLK

PLLCFG [1:0]

PLLCA

Function

Determines data bus width of host

interface. It can be changed only

during reset. Host interface of

MD36710X is set to 8 bit width at low

level (GND) and set to 16 bit width at

high level (VDD).

Determines byte order for data bus of

host interface in 16 bit width setting.

(HWID: VDD).

It can be changed only during reset.

Set MD36710X to obtain I/O signals of

m.s. byte in HD [15:8] at low level

(GND) and those in HD [7:0] at high

level.

If HWID is GND level, connect to

GND.

Determines protocol of host bus. It

can be changed only during reset.

Sets MD36710X to type A at low level

and type B at High level.

Standby input (active low). All output

pins and bidirectional pins become

float state if asserting with RESET#

and MD36710X is cut electrically from

peripheral circuits. All internal

operation stop and power

consumption is confined to the

minimum.

Contents of SDRAM are not stored at

stanby.

Reset input (active low). Initializing

process of MD36710X starts at the

time deasserting is carried out from

assert state.

Idle, init or reset states display output

(active high).

General input controlled by DVP micro

code.

General bidirectional pin controlled by

ADP micro code. After resetting, this

pin is defined as an input pin. ADP

command specifies the setting.

General output conrolled by DVP

micro code.

Master clock input for audio. Must

be connected to GCLK for usual

operation.

Output to the crystal connected to

GCLK. If the crystal is not used for

GCLK, XO is not connected.

Clock for main processor or crystal

input.

PLL configuration input. It can be

changed only during reset. Both pins

must be connected to GND (digital)

for usual operation.

Capacitor connection pin for PLL.

Connect the other terminal of the

capacitor to PLLGND.

3-27

Page 48

Table 3-5-5 MD36710X (3/5) Table 3-5-5 MD36710X (4/5)

Pin

No.

Digital video port (24 pins)

84

85

87

89

90

91

92

94

|

97

99

|

101

98

102

104

105

106

107

109

|

111

124

Digital audio port (8 pins)

112

114

115

116

117

118

119

Name

VCLK

VMASTER

VDEN#

VSYNC

HSYNC

FI

Y [7:0]

CBLANK

C [7:0]

OSDPLT (C [4])

OSDPEL [3:0]

(C [3:0])

VCLKx2

AIN

AOUT [2:0]

S/PDIF

(AOUT [3])

ALRCLK

ABCLK

Function

VCLKx2 signal is divided by 2. Used

as a qualifier of data and sync signal.

Video master/slave selection input. At

high level, video sync in MD36710X

enters master mode. (Video sync and

clock signals are developed.) After

low level, video sync enters slave

mode. (Video sync and clock signals

are entered.)

Only during reset, setting of terminal

can be changed.

Video enable input (active low). When

active, MD 36710X develops video

data. When deasserting, pixel output

becomes 3-state condition. (But sync

and clock signals are kept to be

active.)

Input is changeable at any time but

becomes effective at the next

VCLKx2.

Vertical sync bidirectional signal pin.

Polarity and length are programmable.

Horizontal sync bidirectional signal

pin. Polarity and length are

programmable.

Field identification bidirectional signal

pin. Polarity is programmable.

At 16 bit video mode (Video 8=0),

develop luminance signals. At 8 bit

mode (Video 8=1), develop luminance

and color difference signals

multiplexed in time sequence

according to the ITU-R656 standard

(in no relation to presence of SAV and

EAV sync code).

Composite blank output. Waveforms are

programmable other than polarity.

At 16 bit video mode (Video 8=0),

develop color difference signal. At 8

bit mode (Video 8=1), m.s. line 3 pin

(c [7:5]) is not used, I.s.5 pin (C [4:0])

is used as input from external OSD

device.

On-chip OSD palette selector. Selects

OSD Palette0 at low level and OSD

Plette1 at high level.

OSD pixel input. Used as an entry

signal to on-chip OSD palette.

Main video clock input or output.

Serial input of PCM stereo audio for

ADC

Serial output of PCM stereo audio for

DAC. After reset, develop signals of

low level. Only AOUT [0] supports 24

bit sample width.

S/PDIF transmitter output. Possible to

connected to DAC as the forth audio

output (AOUT [3]). After reset,

develop signal of low level.

LR clock output of AOUT [3..0] and

AIN. Becomes square waveform in

sampling frequency. Polarity of LR is

programmable.

Bit clock output of AOUT [3..0] and

AIN. At rising/falling edges

(programmable) AOUT is developed

and AIN is latched.

Pin

No.

132

DVD-DSP interface (13 pins)

143

144

146

147

148

149

151

|

154

156

|

158

SDRAM interface (35 pins)

38

39

42

|

47

49

|

52

54

55

56

57

59

60

61

62

64

|

67

69

|

72

74

|

79

82

TEST signal (3 pins)

83

127

139

Name

AMCLK

DVDERR

DVDSOS

DVDVALID

DVDSTRB

DVDREQ

DVDDAT [7:0]

RAMADD [11:0]

RAMCS0#

RAMCS1#

RAMRAS#

PCLK

RAMCAS#

RAMWE#

RAMDQM

RAMDAT [15:0]

TESTMODE

SCNENBL

ICEMODE

Audio master clock I/O. 384 fs, 256 fs,

192 fs and 128 fs of sampling

frequency can be selected

(programmable).

DVD-DSP error input (Polarity

programmable)

DVD-DSP data selector start input

(Polarity programmable)

DVD-DSP data effective input

(Polarity programmable)

DVD-DSP data bit strobe (clock)

input. Polarity programmable.

DVD-DSP data requirement output

(Polarity programmable)

DVD-DSP data input bus

SDRAM address bus output

SDRAM chip select (active low)

output. Lower bit for 2 Mbyte device.

SDRAM ship select (active low).

Upper bit for 2 Mbyte device.

Row selection of SDRAM (active low)

output

SDRAM clock output (same as

internal process clock).

Column selection of SDRAM (active

high) output

SDRAM write enable (active low)

output

SDRAM data masking (active high)

output

SDRAM bidirectional data bus

Test pin. Connects to VDD for normal.

Test pin. Connects to GND for normal.

Test pin. Connects to VDD for normal.

Function

3-28

Page 49

Table 3-5-6 PCM1727Table 3-5-5 MD36710X (5/5)

Pin

No.

Name

Power signal (35 pins)

GND

1

40

41

53

68

80

81

93

108

120

121

125

131

145

160

VDD

8

28

33

48

58

63

73

86

78

113

133

140

150

155

PLLGND (GNDA)

134

PLLVDD (VDDA)

138

Function

Digital GND

Digital power supply (3.3V)

GND of internal PLL circuit

Power supply of internal PLL circuit

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Name

XT1

PGND

V

CP

MCKO

RSV

SCKO3

ML

MC

MD

RSTB

V

R

OUT

AGND

V

CA

V

L

OUT

CAP

ZERO

BCK

DATA

LRCK

SCKO2

SCKO1

V

DD

DGND

XT2

Function

PLL master clock input or crystal

connector terminal

PLL GND

PLL power supply

Master clock buffer output

Not connected. Use the pin with open.

PLL-2 generation system clock output.

Serial control data enable input.

Serial control data clock input.

Serial control data, data input.

External reset input, reset at L.

(1)

(1)

(1)

(1)

Rch analog audio output

Analog GND

Analog power supply

Lch analog audio output

Internal analog bias

(connected with a bypass capacitor)

Infinity zero detection output.

PCM audio data, bit clock input.

PCM audio data, data input.

PCM audio data, LRCK input (fs)

(2)

(3)

(3)

(3)

PLL-1 generation system clock output

PLL-1 generation system clock output

Digital power supply

Digital GND

Crystal oscillator connection terminal,

connected to GND at external clock input.

Note:

(1) With internal pull-up. Schmitt trigger input.

(2) Open drain output.

(3) Schmitt trigger input.

Table 3-5-7 S-24C01AFJ-TB-01

Pin

No.

1

2

3

4

5

6

7

8

Name

A0

A1

A2

GND

SDA

SCL

TEST

V

CC

Address input

Address input

Address input

Ground

Serial data I/O

Serial clock input

Connect to GND.

Power supply

Function

3-29

Page 50

Table 3-5-8 (1/2) TA1293F Table 3-5-8 (2/2) TA1293F

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

Name

GNDP

LDO2

MDI2

NC

VrA

Vrfi

VrD

Vdd

DPAC

DPBD

DPD1

DPD2

SCB

SCL

SCD

VRCK

NC

VCKF

VccP

NC

RFSW

VccS

NC

LV L

NC

TEO

FEO

NC

DFTN

RPZ

RPO

RPB

RPP

RFO

VccR

DPDB

TEB

FEB

PSC

VccO

Vcc2

NC

EQD

GND2

Function

GND terminal

Drive terminal

Monitor terminal

–––

Analog V

Filter capacity for reference

Digital V

Power supply terminal

DPD AC coupling capacity 1

DPD AC coupling capacity 2

DPD integration capacity 1

DPD integration capacity 2

Control line (bit clock)

Control line (latch signal)

Control line (serial data)

Reference clock input

Capacity for time constant adjustment

Power supply terminal

RFO control terminal

Power supply terminal

Servo addition output

TE output

FE output

DPD defect

RF ripple center output

RF ripple output

Bottom of RF ripple

Peak of RF ripple

Equivalent RF output

Power supply terminal (RF)

Pit depth adjustment

TE balance

FE balance

VRCK dividing ON/OFF

Power supply terminal

Power supply terminal

Group delay correction

GND terminal

REF

REF

–––

–––

–––

–––

–––

–––

Pin

No.

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Name

RFDC

EQB

EQF

MDI1

LDO1

P1TN

P1TP

P1FN

P1FP

LDP1

GNDR

P1DI

P1CI

P1BI

P1AI

LDP2

P2AI

P2BI

P2CI

P2DI

GNDS

P2FP

P2FN

P2TP

P2TN

Function

DC feed back capacity

Boost adjustment

Frequency adjustment

Monitor input

Drive output

TE– input (DVD)