Page 1

2001

Service

Manual

DVD PLAYER

MODEL

DD-4021

TABLE OF CONTENTS

SPECIFICATIONS .......................................................................................................................................... 1-1-1

LASER BEAM SAFETY PRECAUTIONS........................................................................................................ 1-2-1

IMPORTANT SAFETY PRECAUTIONS .......................................................................................................... 1-3-1

STANDARD NOTES FOR SERVICING .......................................................................................................... 1-4-1

CABINET DISASSEMBLY INSTRUCTIONS................................................................................................... 1-5-1

BLOCK DIAGRAMS ........................................................................................................................................ 1-6-1

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS ................................................................................. 1-7-1

WAVEFORMS.................................................................................................................................................. 1-8-1

WIRING DIAGRAM.......................................................................................................................................... 1-9-1

SYSTEM CONTROL TIMING CHARTS ........................................................................................................ 1-10-1

IC PIN FUNCTION DESCRIPTIONS..............................................................................................................1-11-1

LEAD IDENTIFICATIONS.............................................................................................................................. 1-12-1

EXPLODED VIEWS....................................................................................................................................... 1-13-1

MECHANICAL PARTS LIST .......................................................................................................................... 1-14-1

ELECTRICAL PARTS LIST ........................................................................................................................... 1-15-1

MITSUBISHI ELECTRIC

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2001 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

HOW TO INITIALIZE THE SETUP MENU

After turning the power ON, without a disc in the tray, press the "1," "2," "3," "4," "DISPLAY" and "ENTER" buttons

on the remote control unit in this order. Then, after turning the power OFF temporarily, turn the power ON again

to intialize the Setup Menu.

HOW TO CLEAR THE PASSWORD PROTECTION

(In case the Parental Lock password is forgotten)

To release parental lock, initialize the setup menu using the procedure above.

HOW TO SET OR CLEAR THE TRAY LOCK

To set the tray lock mode to on, follow the procedures below:

1. With loading a disc, set the DVD player to the stop mode.

2. Press the "SETUP" button to display the SETUP menu.

3. Press the "TITLE" button.

4. Press the "3" button.

5. Press the "AUDIO" button.

6. Press the "0" button.

7. Press the SETUP" button. Tray Lock mode is set to ON and "Tray Lock On" is displayed on the top right of

the screen.

While the Tray Lock mode is on, the tray cannot be opened or closed. Other operations are available.

To release the Tray Lock mode, perform the above procedures again. Tray Lock mode is set to OFF and "Tray

Lock Off" is displayed on the top right of the screen.

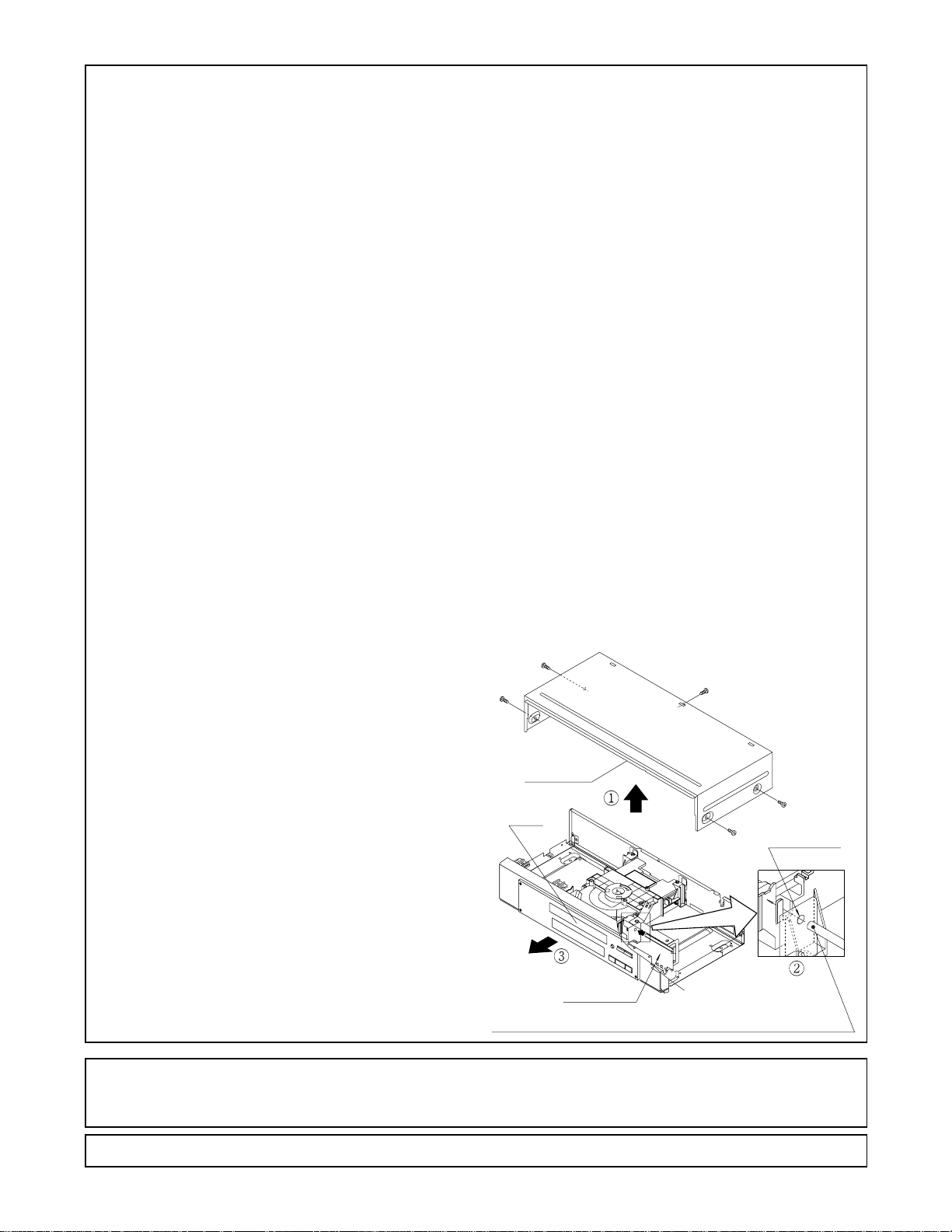

HOW TO MANUAL EJECT

1. Remove the Top Case.

2. Insert the eject-bar (length = approximately 3 mm,

diameter = approximately 8 mm) into the manual eject

hole on the PCB Holder. Then, press it until the tray

is ejected.

3. Pull out the tray.

Tray

Top Case

PCB Holder

Manual

Eject Hole

Eject-Bar (Length = approximately 80 mm, Diameter = approximately 3 mm)

Manufatured under license from Dolby Laboratories. "Dolby" and the double-D symbol are trademarks of Dolby

Laboratories. Confidential Unpublished Works.

(©1992-1997 Dolby Laboratories, Inc. All rights reserved.)

"DTS" and "DTS Digital Out" are trademarks of Digital Theater Systems Inc.

Page 3

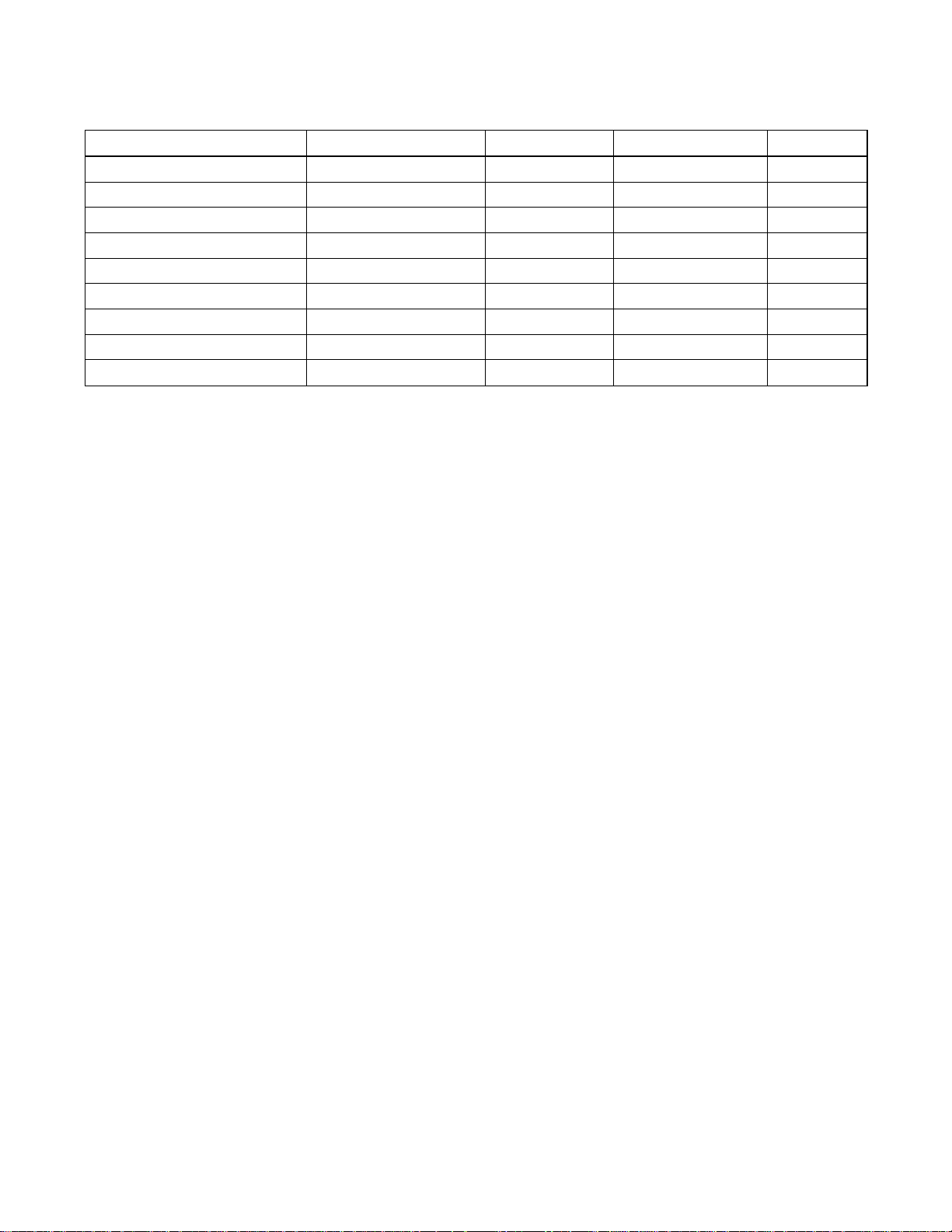

SPECIFICATIONS

ITEM CONDITIONS UNIT NOMINAL LIMIT

1 Video Output 75 ohm load Vpp 1.0

2 Optical Digital Out dBm -18

3 Audio(PCM)

3-1. Output Level 1kHz 0dB Vrms 2.0

3-2. S/N dB 110

3-3. Freq. Response

DVD fs=48kHz 20~22kHz dB ± 2

CD fs=44.1kHz 20~20 kHz dB ± 2

3-4. THD+N 1 kHz 0dB % 0.005

NOTES:

1. All Items are measured without pre-emphasis unless otherwise specified.

2. Power supply : AC120 V 60 Hz

3. Load imp. : 100 K ohm

4. Room ambient : +25 °C

1-1-1 E5500SP

Page 4

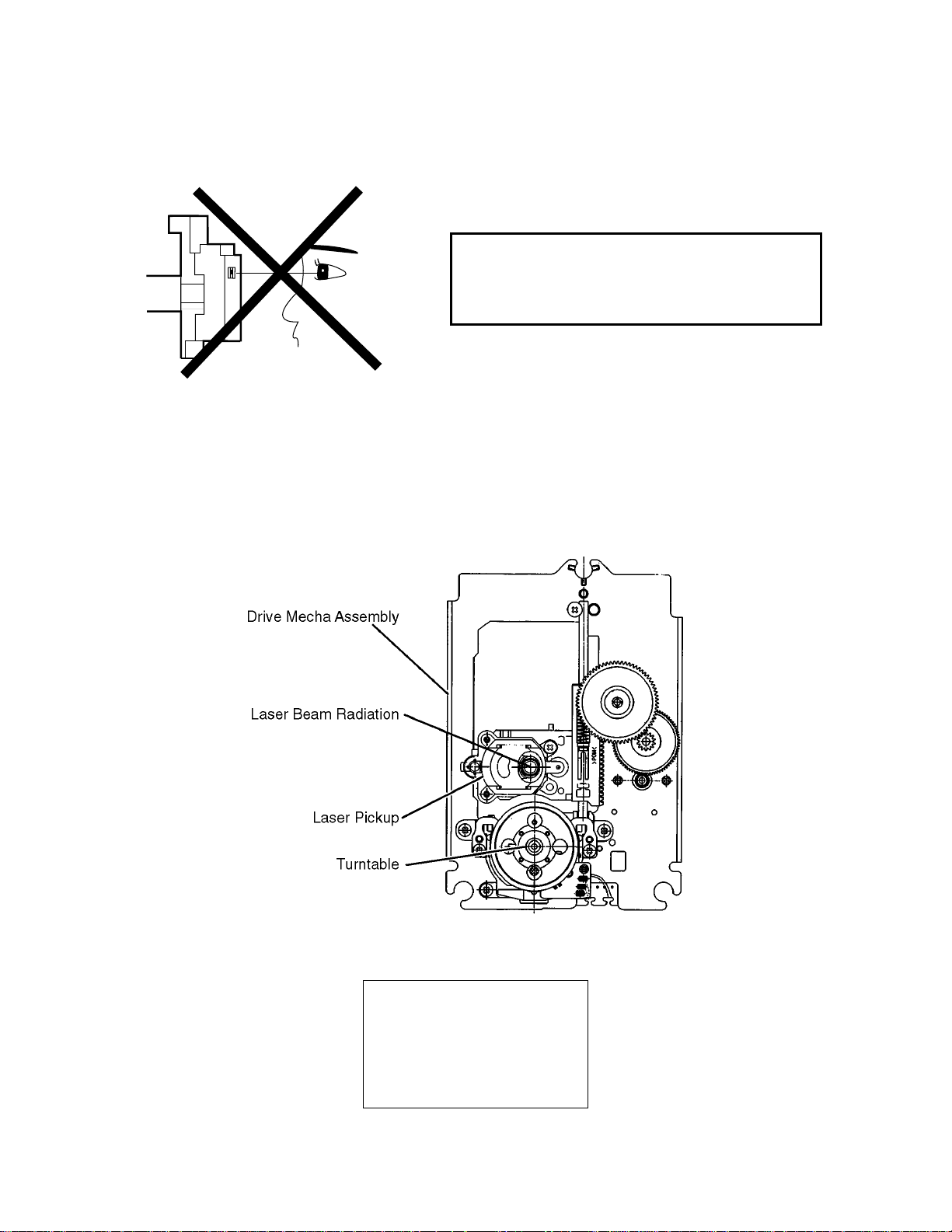

LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against

your skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep your

eyes at least 30cm away from the pickup lens when the diode is turned on. Do not look directly at the laser beam.

Caution: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

CAUTION

LASER RADIATION

WHEN OPEN. DO NOT

STARE INTO BEAM.

Location: Inside Top of DVD mechanism.

1-2-1 DVD_LASER

Page 5

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not evident from visual inspection, nor can the protection they

give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts

that have special safety characteristics are identified by

a # on schematics and in parts lists. Use of a substitute replacement that does not have the same safety

characteristics as the recommended replacement part

might create shock, fire, and/or other hazards. The

Product’s Safety is under review continuously and new

instructions are issued whenever appropriate. Prior to

shipment from the factory, our products are carefully

inspected to confirm with the recognized product safety

and electrical codes of the countries in which they are

to be sold. However, in order to maintain such compliance, it is equally important to implement the following

precautions when a set is being serviced.

Precautions during Servicing

A.Parts identified by the # symbol are critical for

safety. Replace only with part number specified.

B.In addition to safety, other parts and assemblies are

specified for conformance with regulations applying

to spurious radiation. These must also be replaced

only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C.Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D.Use specified insulating materials for hazardous live

parts. Note especially:

1) Insulation tape

2) PVC tubing

3) Spacers

4) Insulators for transistors

E.When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of wires

securely about the terminals before soldering.

F. Observe that the wires do not contact heat produc-

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.).

G.Check that replaced wires do not contact sharp

edges or pointed parts.

H.When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

I.Also check areas surrounding repaired locations.

J.Use care that foreign objects (screws, solder drop-

lets, etc.) do not remain inside the set.

K.Crimp type wire connector

The power transformer uses crimp type connectors

which connect the power cord and the primary side

of the transformer. When replacing the transformer,

follow these steps carefully and precisely to prevent

shock hazards.

Replacement procedure

1)Remove the old connector by cutting the wires at a

point close to the connector.

Important: Do not re-use a connector. (Discard it.)

2)Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands

to avoid frayed conductors.

3)Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

4)Use a crimping tool to crimp the metal sleeve at its

center. Be sure to crimp fully to the complete closure

of the tool.

L.When connecting or disconnecting the internal con-

nectors, first, disconnect the AC plug from the AC

outlet.

1-3-1 DVD_SFN1

Page 6

Safety Check after Servicing

Examine the area surrounding the repaired location for

damage or deterioration. Observe that screws, parts,

and wires have been returned to their original positions.

Afterwards, do the following tests and confirm the specified values to verify compliance with safety standards.

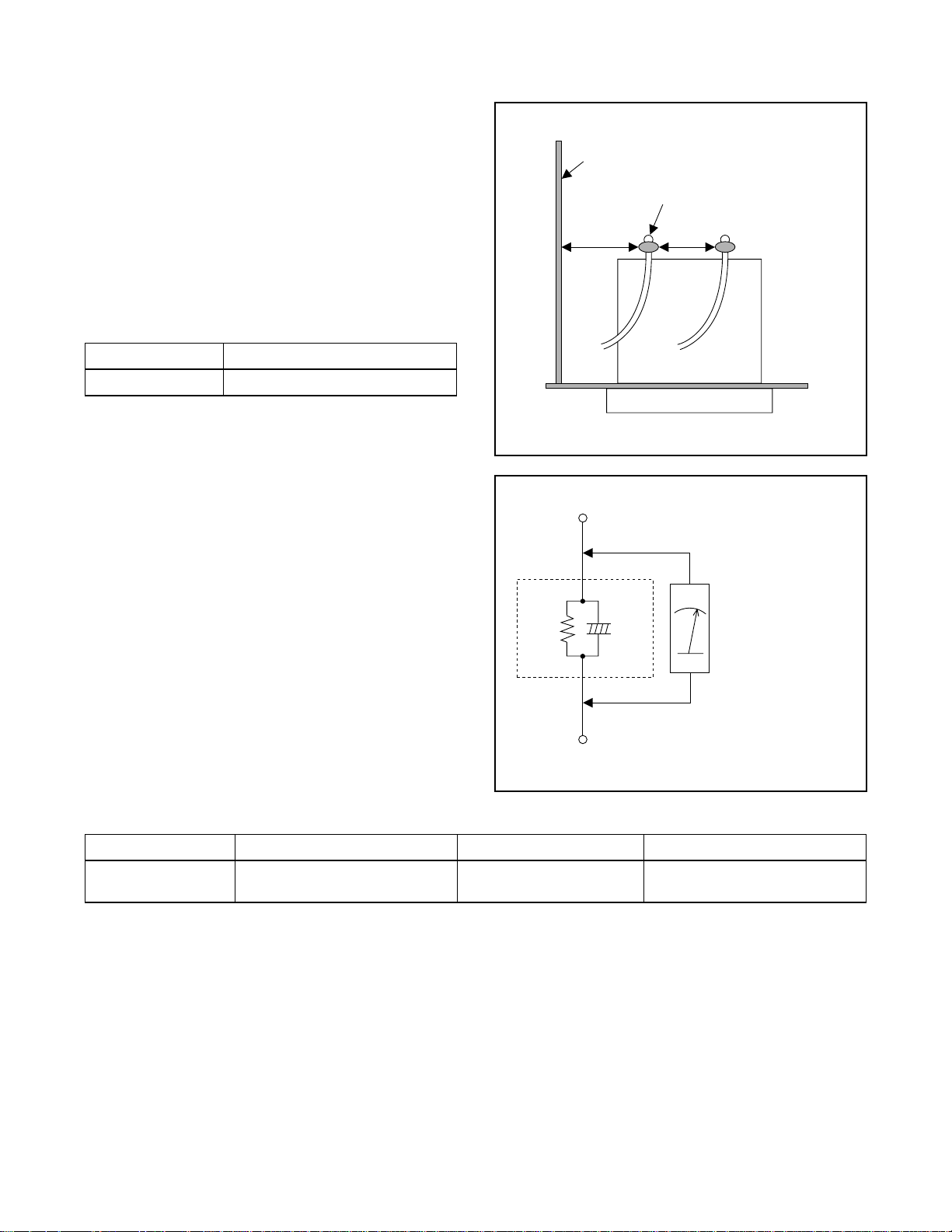

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Clearance Distance (d) (d’)

120 V ≥ 3.2 mm (0.126 inches)

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.) is lower

than or equal to the specified value in the table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

Z

1.5kΩ

Chassis or Secondary Conductor

Primary Circuit Terminals

dd'

Exposed Accessible Part

AC Voltmeter

0.15µF

Earth Ground

B

Power Cord Plug Prongs

(High Impedance)

Fig. 1

Fig. 2

Table 2 : Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

120 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

0.15µF CAP. & 1.5kΩ RES.

Connected in parallel

i ≤ 0.5mA Peak Exposed accessible parts

1-3-2 DVD_SFN1

Page 7

STANDARD NOTES FOR SERVICING

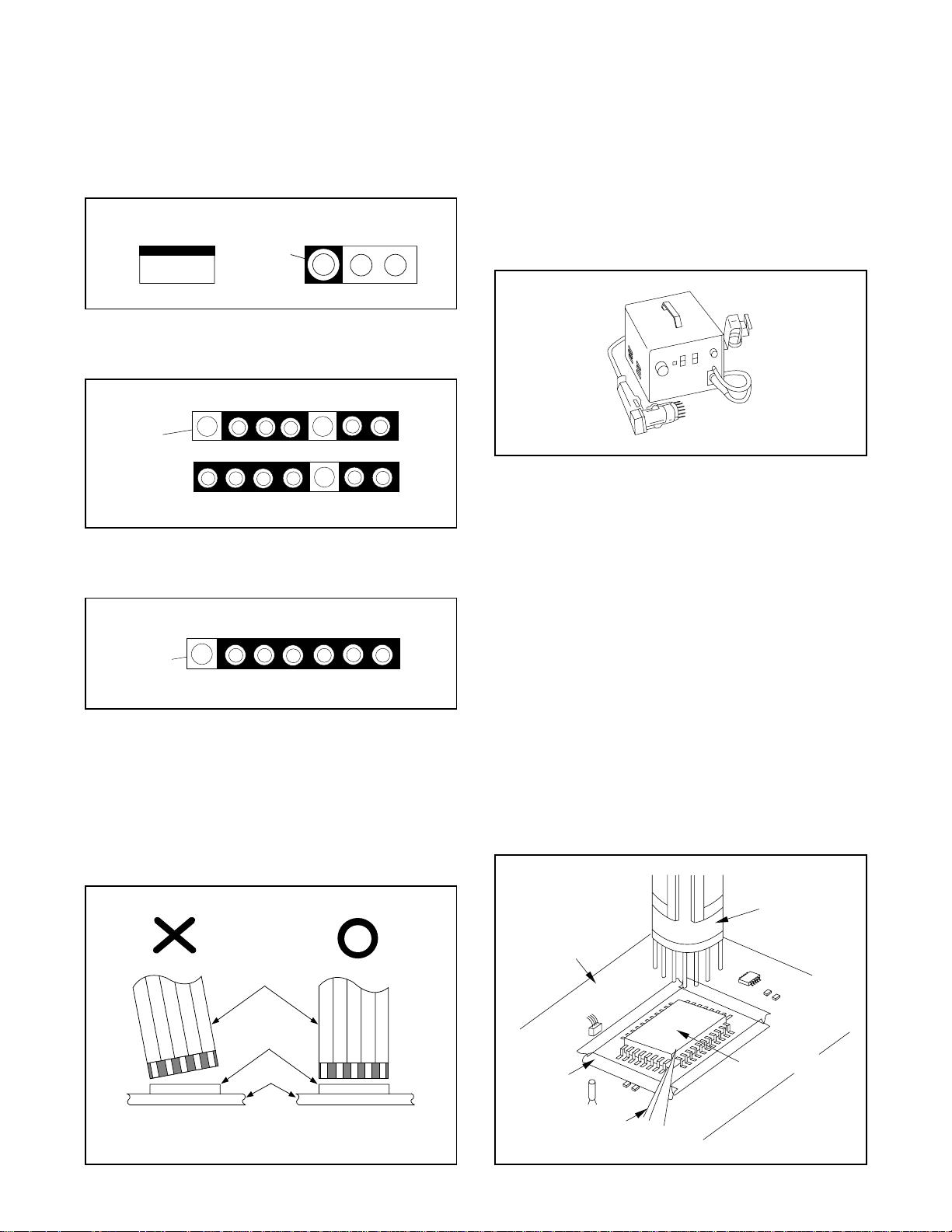

Circuit Board Indications

a.The output pin of the 3 pin Regulator ICs is indicated

as shown.

Top View

Out

b.For other ICs, pin 1 and every fifth pin are indicated

as shown.

Input

In

Pin 1

c.The 1st pin of every male connector is indicated as

shown.

Bottom View

5

10

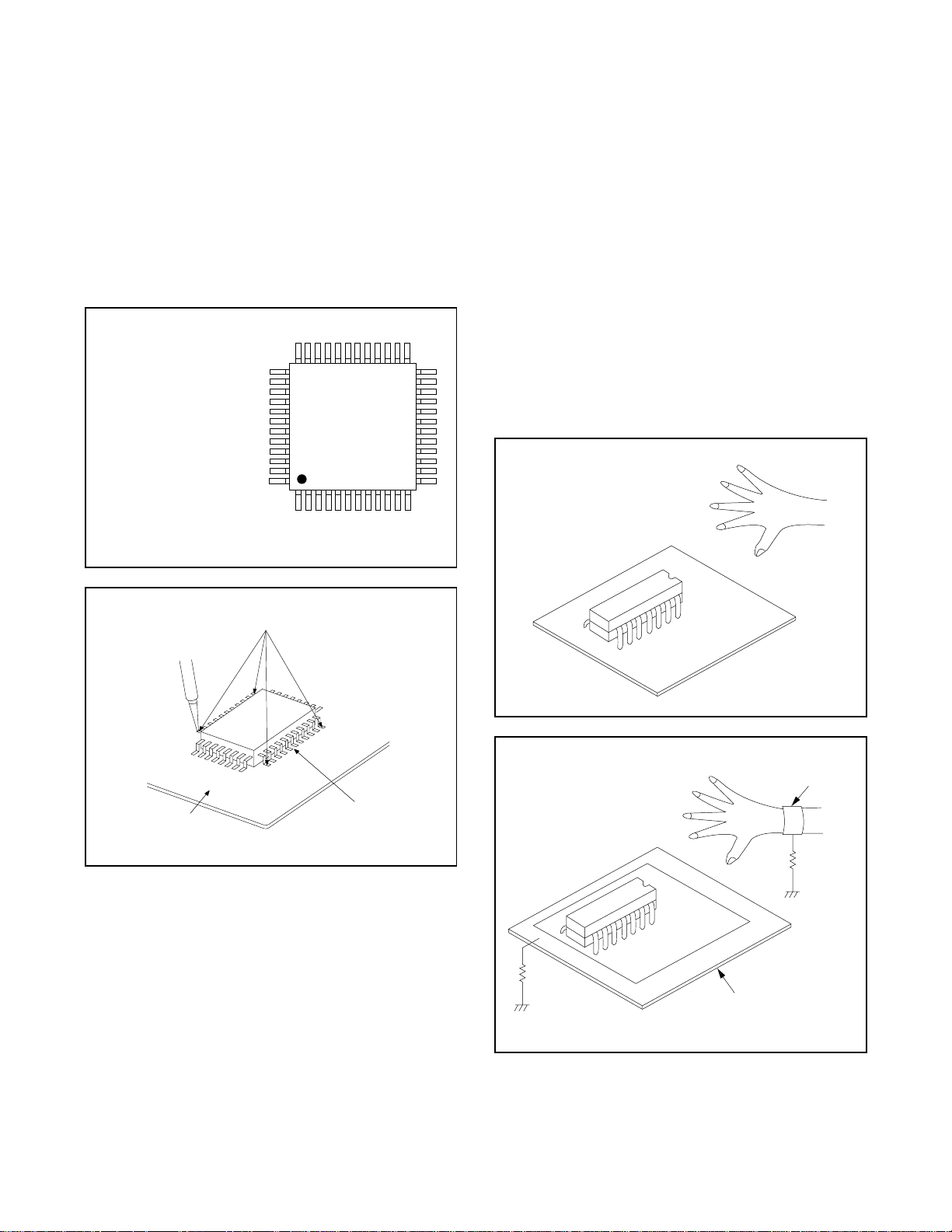

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

(1)Prepare the hot-air flat pack-IC desoldering ma-

chine, then apply hot air to the Flat Pack-IC (about

5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

(2)Remove the flat pack-IC with tweezers while apply-

ing the hot air.

(3)Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4)Release the flat pack-IC from the CBA using tweez-

ers. (Fig. S-1-6)

Pin 1

Instructions for Connectors

1.When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect the

AC cord.

2.FFC (Flexible Foil Connector) cable should be inserted parallel into the connector, not at an angle.

FFC Cable

Connector

CBA

Caution:

1.Do not supply hot air to the chip parts around the flat

pack-IC for over 6 seconds because damage to the

chip parts may occur. Put masking tape around the

flat pack-IC to protect other parts from damage.

(Fig. S-1-2)

2.The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when removing

it.

Hot-air

Flat Pack-IC

Desoldering

Machine

CBA

Masking

Tape

Flat Pack-IC

* Be careful to avoid a short circuit.

Tweezers

Fig. S-1-2

1-4-1 DVD_NOTE

Page 8

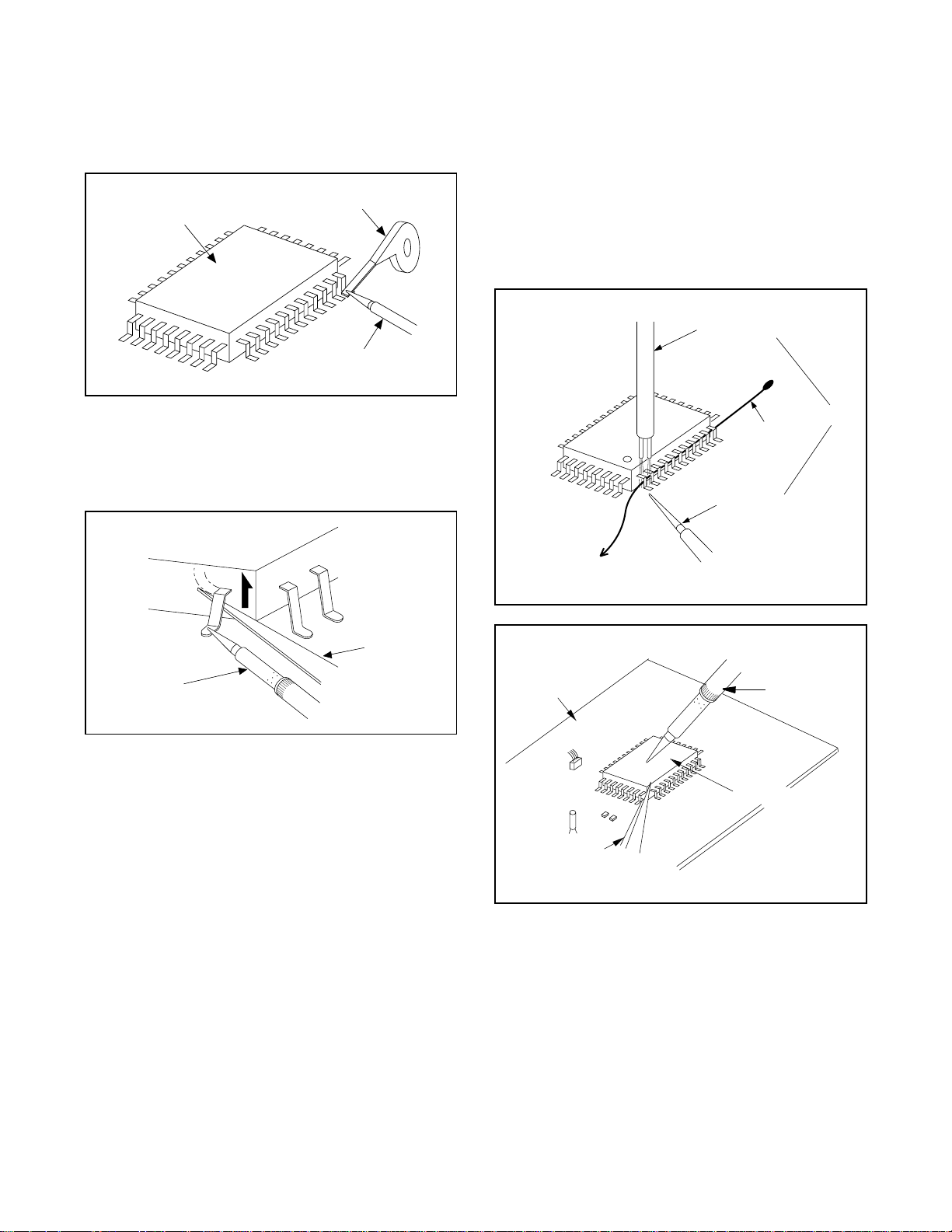

With Soldering Iron:

(1)Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

Desoldering Braid

Flat Pack-IC

Soldering Iron

Fig. S-1-3

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(5)Release the flat pack-IC from the CBA using tweez-

ers. (Fig. S-1-6)

Note:

When using a soldering iron, care must be taken to

ensure that the flat pack-IC is not being held by glue.

When the flat pack-IC is removed from the CBA,

handle it gently because it may be damaged if force

is applied.

Hot Air Blower

(2)Lift each lead of the flat pack-IC upward one by one,

using a sharp pin or wire to which solder will not

adhere (iron wire). When heating the pins, use a fine

tip soldering iron or a hot air desoldering machine.

(Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

Fig. S-1-4

(3)Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4)Release the flat pack-IC from the CBA using tweez-

ers. (Fig. S-1-6)

To Solid Mounting Point

CBA

Tweezers

Iron Wire

or

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

With Iron Wire:

(1)Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

(2) Affix the wire to a workbench or solid mounting point,

as shown in Fig. S-1-5.

(3)While heating the pins using a fine tip soldering iron

or hot air blower, pull up the wire as the solder melts

so as to lift the IC leads from the CBA contact pads

as shown in Fig. S-1-5.

(4)Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

Fig. S-1-6

1-4-2 DVD_NOTE

Page 9

2. Installation

(1)Using desoldering braid, remove the solder from the

foil of each pin of the flat pack-IC on the CBA so you

can install a replacement flat pack-IC more easily.

(2)The " ● " mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

pre- solder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

(3)Solder all pins of the flat pack-IC. Be sure that none

of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " ● " mark.

Fig. S-1-7

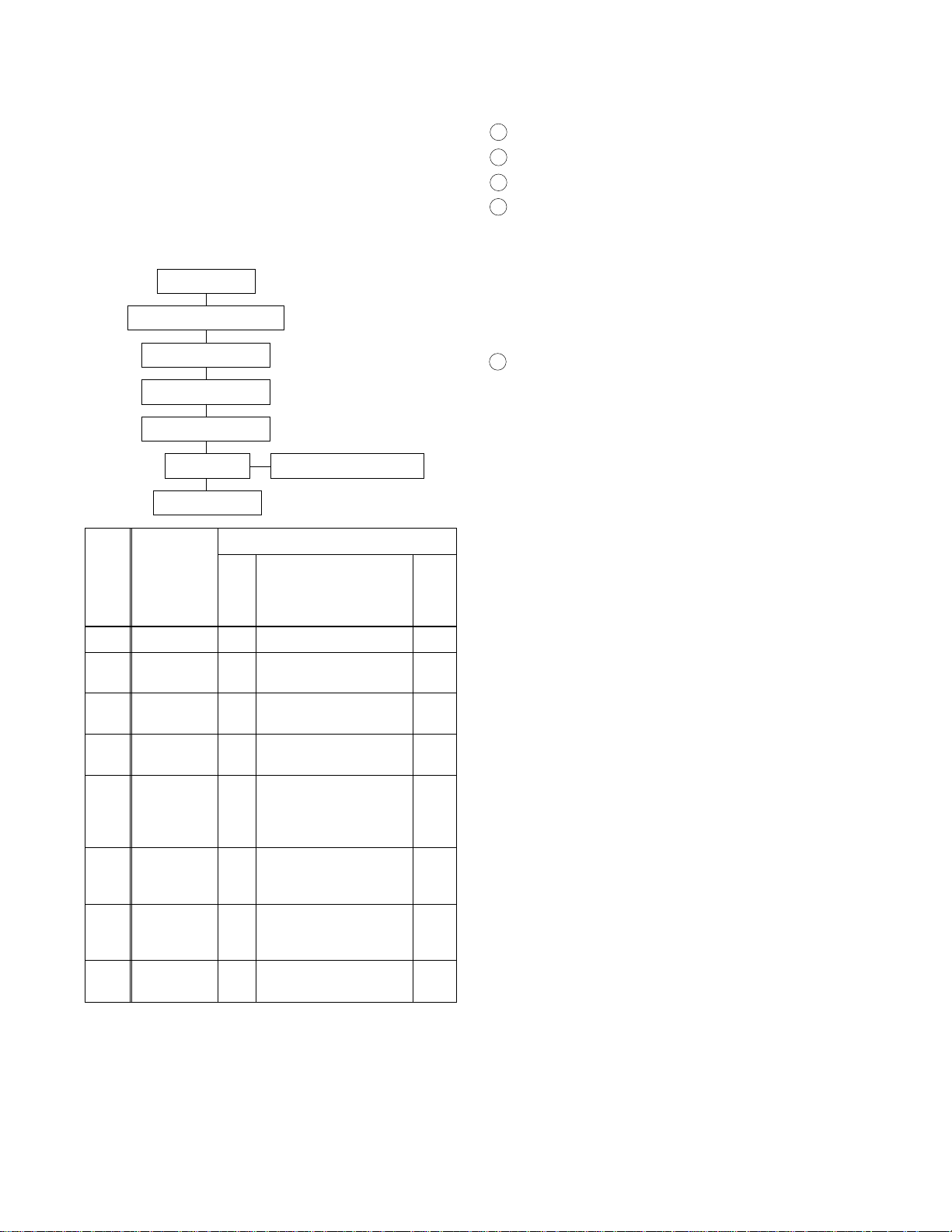

Instructions for Handling

Semiconductors

Electrostatic breakdown of the semiconductors may

occur due to a potential difference caused by electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1MΩ) that is properly

grounded to remove any static electricity that may be

charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate with

proper grounding (1MΩ) on the workbench or other

surface, where the semiconductors are to be placed.

Because the static electricity charge on clothing will not

escape through the body grounding band, be careful to

avoid contacting semiconductors with your clothing.

< Incorrect >

Soldering Iron

CBA

Presolder

CBA

< Correct >

Grounding Band

Flat Pack-IC

Fig. S-1-8

1MΩ

CBA

1MΩ

Conductive Sheet or

Copper Plate

1-4-3 DVD_NOTE

Page 10

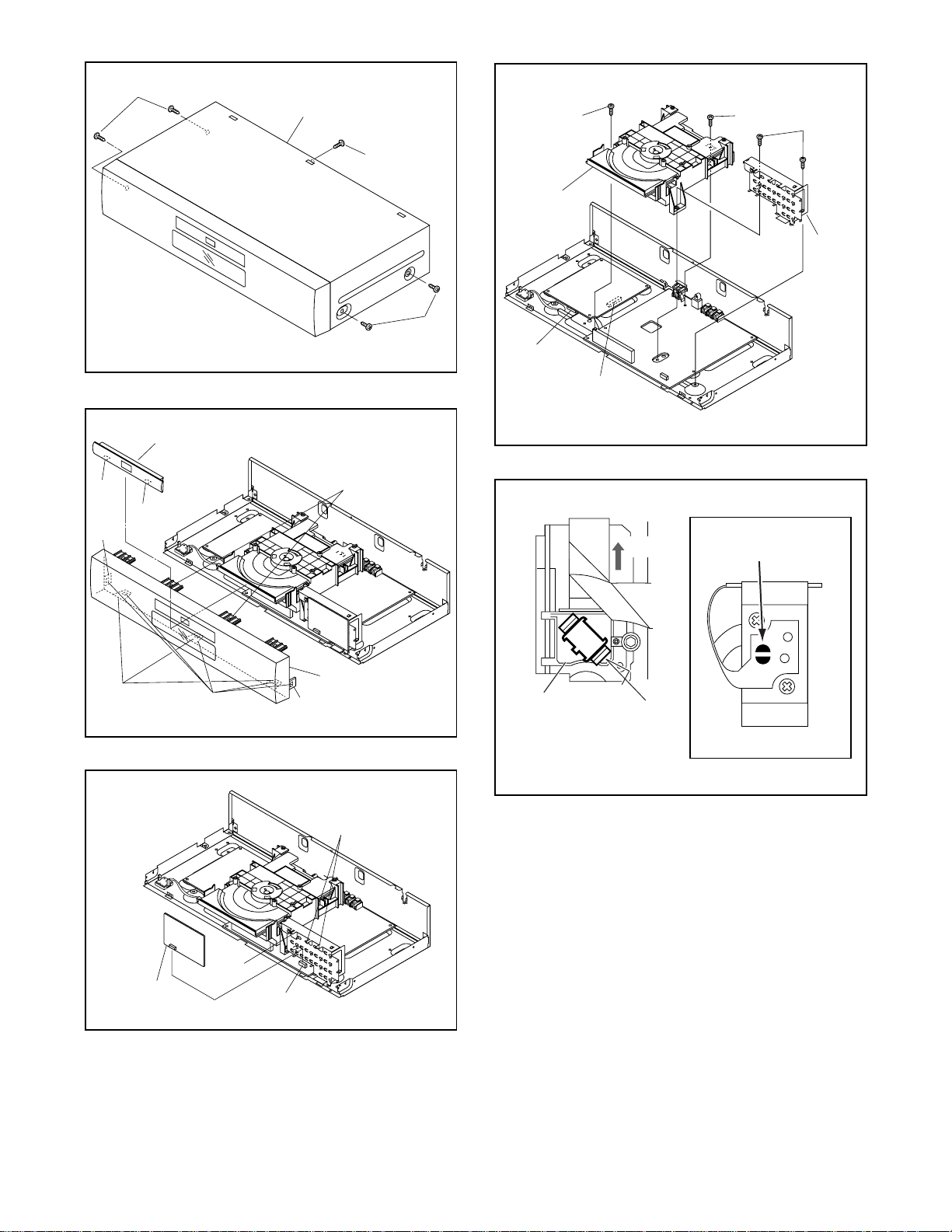

CABINET DISASSEMBLY INSTRUCTIONS

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and dress

the cables as they were originally.

2. Disassembly Method

[1] Top Case

[2] Front Assembly

[3] Function CBA

[4] PCB Holder

[5] DVD Mecha

[7] DVD Main CBA Unit[6] AV CBA

[8] Rear Panel

REMOVAL

ID/

LOC.

No.

[1] Top Case 1 5(S-1) -

[2]

[3]

[4]

[5]

[6] AV CBA 6

[7]

[8]

↓

➀

PART

Front

Assembly

Function

CBA

PCB

Holder

DVD

Mecha

DVD

Mecha

CBA Unit

Rear

Panel

↓

➁

REMOVE/

Fig.

*UNHOOK/UNLOCK/

No.

RELEASE/UNPLUG/

DESOLDER

*2(L-1), Tray Panel,

2

*2(L-2), *5(L-3)

3 *3(L-4), *(CN2001) -

42(S-2) -

*(CN001, CN201),

4,5

2(S-3)

4(S-4), 4(S-5),

*2(L-5), *(CN701,

CN501)

64(S-6) -

73(S-7) -

↓

➂

↓

➃

Note

1-1

1-2

2-1

2-2

2-3

3

-

↓

➄

1 : Identification (location) No. of parts in the figures

2 : Name of the part

3 : Figure Number for reference

4 : Identification of parts to be removed, unhooked, un-

locked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw,

CN=Connector

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

5 :Refer to "Reference Notes."

Reference Notes

CAUTION 1: Locking Tabs (L-1) are fragile. Be careful

not to break them.

1-1.Connect the wall plug to an AC outlet and press the

OPEN/CLOSE button to open the Tray.

1-2.First, remove the Tray Panel by releasing two Lock-

ing Tabs (L-1). Second, release two Locking Tabs

(L-2). Then, release five Locking Tabs (L-3) (to do

this, first release three Locking Tabs (A) at the

bottom, and then two Locking Tabs (B) at the side.)

(Fig. 2)

CAUTION 2: Electrostatic breakdown of the laser diode

in the optical system block may occur as a potential

difference caused by electrostatic charge accumulated

on cloth, human body etc, during unpacking or repair

work.

To avoid damage of pickup follow next procedures.

2-1.Slide out the pickup unit as shown in Fig. 5.

2-2.Short the copper pattern (half-moon shape) of FPC

cable with solder before removing the FFC cable

(CN001) from it. If you disconnect the FFC cable

(CN001), the laser diode of pickup will be destroyed.

(Fig. 5)

2-3.Disconnect Connector (CN201). Remove two

Screws (S-3) and lift the DVD Mecha. (Fig. 4)

CAUTION 3: When reassembling, confirm the FFC

cable (CN001) is connected completely. Then remove

the solder from copper pattern (half-moon shape) of

FPC cable. (Fig. 5)

1-5-1 E5540DC

Page 11

(S-1)

[1] Top Cover

(S-1)

(S-1)

(S-3)

[5] DVD

Mecha

(S-3)

(S-2)

[4] PCB

Holder

(L-1)

(B)

(A)

(L-1)

Tray Panel

(L-3)

(L-2)

[2] Front Assembly

(B)

Fig. 1

Fig. 2

CN201

CN001

Pickup Unit

DVD Mecha

Bottom View

Slide

A

Fig. 4

Short the copper pattern

by soldering

View for A

Fig. 5

[3] Function

CBA

(L-4)

CN2001

(L-4)

Fig. 3

1-5-2 E5540DC

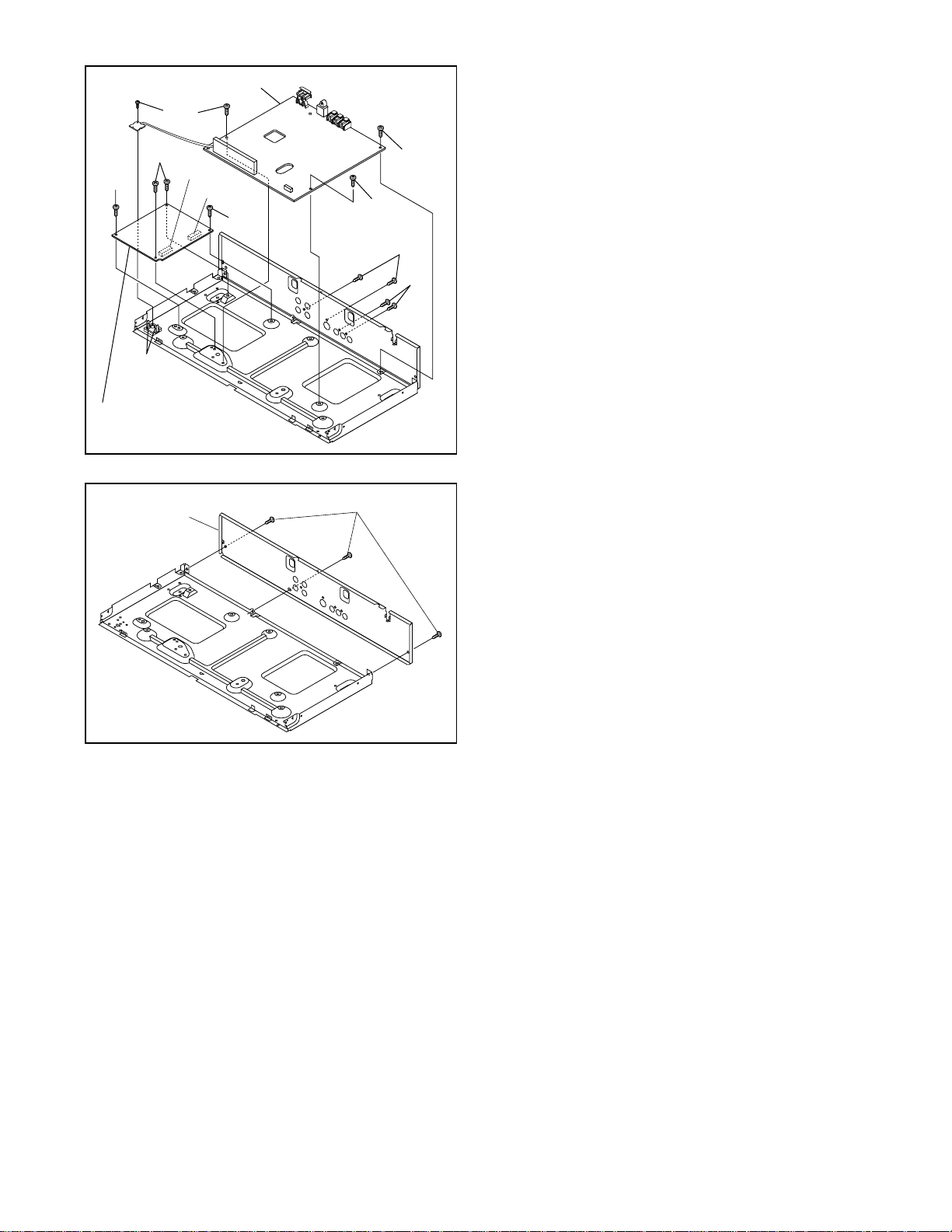

Page 12

[6] AV CBA

(S-5)

(S-6)

(S-6)

(L-5)

[7] DVD Main CBA Unit

[8] Rear Panel

CN501

CN701

(S-6)

(S-5)

(S-5)

(S-4)

(S-4)

Fig. 6

(S-7)

Fig. 7

1-5-3 E5540DC

Page 13

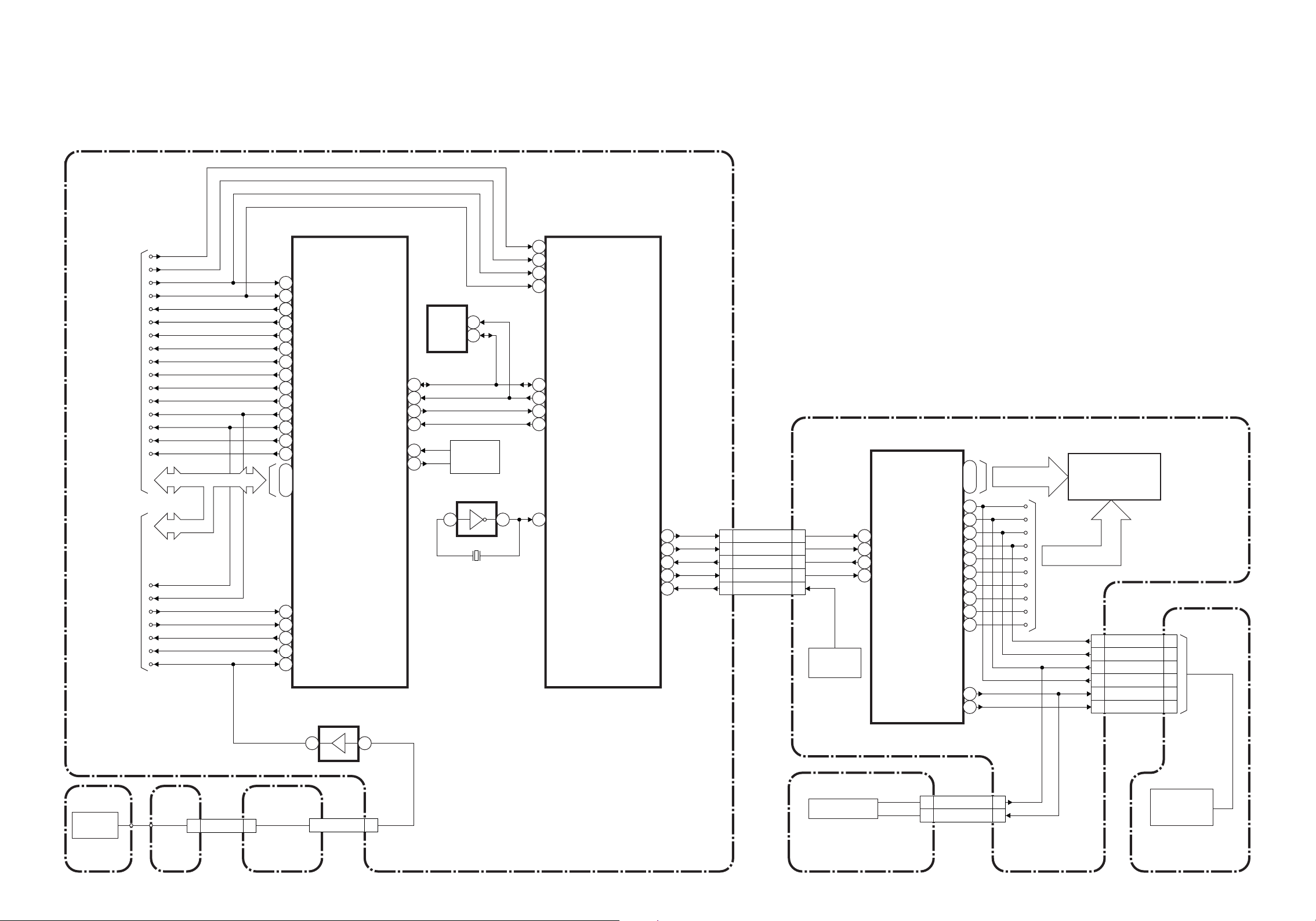

System Control Block Diagram

BLOCK DIAGRAMS

FROM/TO

RF SIGNAL

PROCESS

/SERVO

BLOCK

DIAGRAM

FROM/TO

DVD SIGNAL

PROCESS

BLOCK

DIAGRAM

TFW

TREV

TIN

TOUT

SCLKH

SDATA

CSL

MUTE

PS

RS

HINT

HCS

HWR

HRD

HA0

HA1

HRD

HWR

JITTER

MRDY

MCS

MALE

FG

HD0-HD7

IC400

(FRONT END PROCESSOR)

TIN

60

61

TOUT

3 SCLKH

4 SDATA

5 CSL

99 MUTE

100

PS

1 RS

51 HINT

95 HCS

HWR

10

HRD

8

HA0

92

HA1

93

HD0

83

~

~

HD7

90

37 JITTER

14 MRDY

94 MCS

7 MALE

52 FG

IC002

(OP AMP)

RDY-HIF

/FERS

XOUT8180

SDA

SCL

XIN

IC603

(MEMORY)

25

26

30

50

SCL

6

5

SDA

X401

16MHz

IC608

(INVERTER)

2 4

X601

27MHz

IC601

(DVD HOST PROCESSOR)

TFW

200

TREV

201

187

TIN

TOUT

188

SDA

196

SCL

195

RDY-HIF

208

186

/FERS

CLOCK

120

VFD-DOUT

VFD-CLK

REMOTE

3VFD-STB

1VFD-DIN

2

204

125

CN501 CN1001

FP-STB 19

19

FP-DIN 20

20

FP-DOUT 21

21

FP-CLK 22

22

REMOTE 24

24

RM2001

REMOTE

SENSOR

IC2003

(FRONT PANEL CONTROL)

1G

~

11G

a/KEY-1

b/KEY-2

9

FP-STB

7

FP-DIN

6

FP-DOUT

FP-CLK

8

c/KEY-3

d/KEY-4

e

f

g

h

i

j

K2

K1

42

32

14

15

16

17

18

19

20

21

22

23

11

10

FL2002

~

GRID FIP

SEGMENT

CN2001

KEY-4 1

1

KEY-3 2

2

KEY-2 3

3

KEY-1 4

4

K2 5

5

K1 6

6

CN2003

FG

SENSOR

CN3004 CN3003

FG-IN 6

6

INNER

CBA

1 3

FG-IN 10

1-6-1

CN201

MAIN CBA UNIT

POWER SW

SWITCH CBAFG CBA MECHA CBA

AV CBA

KEY-2 1

1

K2 2

2

JP1003JP1004

1-6-2

KEY MATRIX

FUNCTION CBA

E5542BLS

Page 14

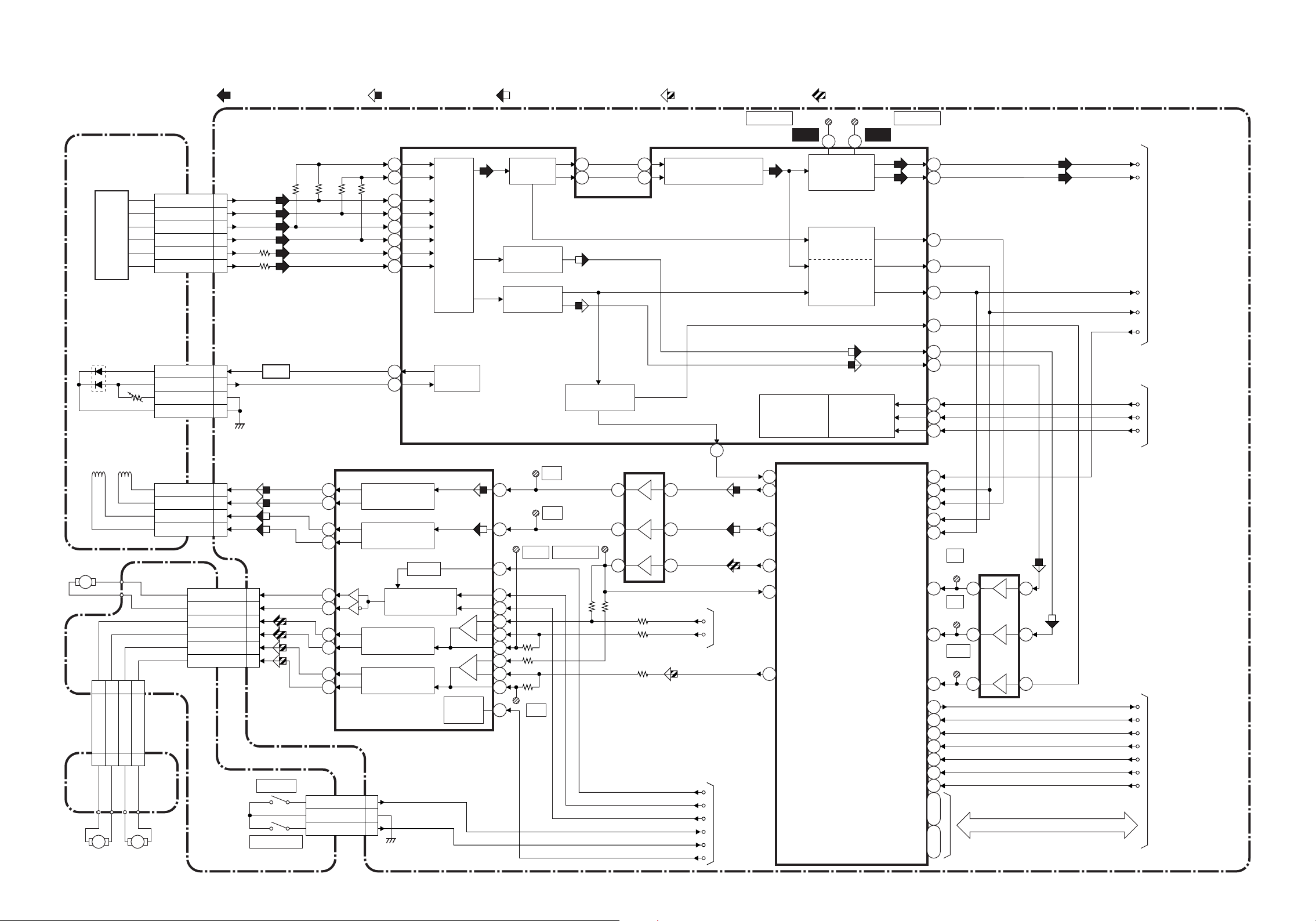

RF Signal Process/Servo Block Diagram

PICK-UP UNIT

DETECTOR

A 3

D 4

C 1

B 2

F 7

E 8

LD 11

MON 12

GND 9

GND 10

RF(VIDEO/AUDIO) SIGNAL FOCUS SERVO SIGNAL TRACKING SERVO SIGNAL

IC001

(RF SIGNAL PROCESS)

17

18

FOCUS ON

GATE SIGNAL

CN001

CN001

Q001

AMP

29

30

28

25

26

27

40

39

60

58

RF

AMP

INPUT

MATRIX

TRACKING

ERROR DET

FOCUS

ERROR DET

PB-ALPC

SLIDE SERVO SIGNAL DISK SERVO SIGNAL

16

15

AGC AMP

PROGRAMMABLE EQ

MONREF MONREP

TP001 TP002

WF1 WF2

DATA SLICER

ASYMMETRY

CONTROL

MIRROR DET

DEFECT DET

CONTROL

REGISTERS

5 6

MCU

I/F

76

77

69

74

73

51

52

53

66

67

68

MAIN CBA UNIT

NRZN

NRZP

DEFECT

TC

SRV33M

SCLKH

SDATA

CSL

TO DVD SIGNAL

PROCESS

BLOCK DIAGRAM

FROM

SYSTEM CONTROL

BLOCK DIAGRAM

LOADING

MOTOR

M

CN3004 CN3003

M M

SPINDLE

MOTOR

SPL(-) 11

FSTS

SL(-) 33

SPL(+) 22

SLIDE

MOTOR

SL(+) 44

INNER

FS(+) 17

FS(-) 16

TS(+) 15

TS(-) 18

SPL(-) 6

SPL(+) 7

CBA

MECHA CBA

CN001

LD(+) 1

LD(-) 2

SL(+) 9

SL(-) 8

CN201

TRAY-IN

TRAY-OUT

IC200 (SERVO DRIVE)

12 6

11

14

13

10

9

18

17

16

15

TRAY-IN 3

GND 5

TRAY-OUT 4

FOCUS

DRIVE

TRACKING

DRIVE

MUTE

LOADING

MOTOR DRIVE

SPINDLE

MOTOR DRIVE

SLIDE

MOTOR DRIVE

POWER

SAVE

CN201

TP202

FS

TP201

TS

5

TP203

PWM

21

1

2

24

+

-

23

22

27

+

-

26

25

TP205

4

SL

TP104

VREF165

IC002

(OP AMP)

14 12

8 10

7 5

PWM1

PWM2

MUTE

TREV

TRAY-IN

TRAY-OUT

70

FROM

DVD SIGNAL

PROCESS

BLOCK

TFW

FROM/TO

SYSTEM

CONTROL

BLOCK

PS

IC100 (SERVO DSP)

41

PDM2

3 52

PDM0

7

1

PDM3

19

ADC4

PDM1

5

CLKINFSGATE

TC

MIRROR

TZC

DEFECT

ADC1

ADC0

ADC2

RS

HINT

HCS

HWR

HRD

HA0

HA1

HD0

~

HA7

95

27

26

34

FE

IC102

(OP AMP)

TP103

22 10

23

21 14 12

68

76

77

78

79

81

80

90

86

84

82

8

TE

TP102

1 3

ASO

TP101

~

~

HD0-HD7

RS

HINT

HCS

HWR

HRD

HAO

HA1

FROM/TO

SYSTEM CONTROL

BLOCK DIAGRAM

1-6-4

E5542BLRF1-6-3

Page 15

DVD Signal Process Block Diagram

IC300 (DVD SIGNAL PROCESS)

WF4

WF5

FROM RF SIGNAL

PROCESS/SERVO

BLOCK DIAGRAM

NRZN

NRZP

TC

DEFECT

118

117

94

95

DATA(VIDEO/AUDIO) SIGNAL DATA(VIDEO) SIGNAL DATA(AUDIO) SIGNALRF(VIDEO/AUDIO) SIGNAL

MAIN CBA UNIT

PLL

VCO

HD0

24

27

HD1

HD2

DATA

SLICER

BCA

DVD

DEMODULATOR

VIDEO/AUDIO

INTERFACE

HD3

HD4

HD5

HD6

HD7

30

34

37

40

43

46

HD0-HD7

TO VIDEO BLOCK

FROM/TO

SYSTEM CONTROL

BLOCK DIAGRAM

TO RF SIGNAL

PROCESS/SERVO

BLOCK DIAGRAM

HD0-HD8

MCS

JITTER

MRDY

HRD

HWR

MALE

FG

X301 (33MHz)

SRV33M

PWM1

PWM2

HD0

69

~

~

HD7

77

86

MCS

124

JITTER

83 MRDY

81 HRD

79 HWR

80 MALE

155

156

57

99

100

101

MASTER

CLOCK

CLV/CAV

CPU

INTERFACE

MEMORY

MANAGER

IC301 (4M D-RAM)

RAS

189

174

UCAS

173

LCAS

190

WE

175

OE

RA0 RA0

187

~

RD0

~

RD15 2

~

177

207

~

191

1

RA0-RA8

RD0-RD15

14

28

29

13

27

16

~

26

2

~

10

31

~

39

RAS

UCAS

LCAS

WE

OE

~

RA8RA8

RD0

~

RD15

1-6-6

E5542BLD1-6-5

Page 16

Video Block Diagram

DATA(VIDEO) SIGNAL VIDEO SIGNAL AUDIO SIGNALDATA(AUDIO) SIGNAL

IC601 (DVD HOST PROCESSOR)

FROM

DVD SIGNAL

PROCESS

BLOCK

PARA0-PARA7

6

13

PARA0

~

PARA7

~

INTERNAL

PERIPHERALS

PORTS

CPU

CENTRAL

COMMAND

PORT

ST20 ARBITER &

MEMORY CONTROLLER

MPEG2 PER

PARSER & MPEG1

SYSTEM PARSER

VIDEO

CD FIFO

AUDIO

CD FIFO

DATA(VIDEO/AUDIO) SIGNAL DATA(VIDEO) SIGNAL

CACHE

SUBSYSTEM

FRONT-END

& LINK

INTERFACE

AUDIO

DECODER

SUB

PICTURE

CD FIFO

51

52

53

54

55

56

57

PCM-SCLK

PCM-DATA0

PCM-DATA1

PCM-DATA2

PCM-MCLK

PCM-LRCLK

SPDIF

TO AUDIO

BLOCK

Q1481, Q1482

6dB AMP

Q1461, Q1462

6dB AMP

Q1483

75Ω

BUFFER

Q1463

75Ω

BUFFER

Q1443

75Ω

BUFFER

JK1202

VIDEO-V

OUT

VIDEO-U

OUT

VIDEO-Y

OUT

IC602

(16M SD-RAM)

A0

~

A18

DQ0

~

DQ15

WE

CE

OE

25

16

29

45

11

26

28

8

1

~

~

~

A0-A18

DQ0-DQ15

161

170

173

181

141

158

128

132

117

~

A0

A18

~

DQ0

~

DQ15

DQM(0)

CS3

OE

~

PROGRAMMABLE

CPU INTERFACE

~

SHARED SDRAM INTERFACE

~

AD0

AD13

58 63~69 66~ 84

20 26~ 2 13~29 35~ 42 53~

~

AD0

AD13

VIDEO

DECODER

~

DQ0

DQ15

102

~70 73~

~

DQ0

DQ15

SDRAM ARBITER

VIDEO

FILTERING

DQML

DQMU

LDQM

UDQM

WE

WE

RAS

CAS

79 80 78

7677

17 18 39 16

15

RAS

CAS

OSD, SP

DECODER

& MIXING

DENC &

DAC

27

25

34

33

32

WF5

CN701

1 1VIDEO-V

3 3VIDEO-U

5 5VIDEO-Y

7 7

VIDEO-CVBS

9 9VIDEO-C

WF7WF6

CN1601

Q1441, Q1442

6dB AMP

Q1401, Q1402

6dB AMP

Q1421, Q1422

6dB AMP

Q1445

75Ω

AMP

BUFFER

Q1423

75Ω

BUFFER

Q1403

75Ω

BUFFER

3 4

3 4

21

21

JK1401

S-VIDEO

OUT

JK1201

COMPOSITE

VIDEO OUT

AV CBA

IC606

(64Mbit SDRAM)

MAIN CBA UNIT

1-6-8

E5542BLV1-6-7

Page 17

Audio Block Diagram

VIDEO SIGNAL AUDIO SIGNALDATA(AUDIO) SIGNAL

FROM

VIDEO

BLOCK

FROM

SYSTEM

CONTROL

BLOCK

SPDIF

PCM-SCLK

PCM-DATA0

PCM-LRCK

ADAC-MD

ADAC-MC

ADAC-ML

WF11WF10

WF9

IC801 (AUDIO DAC)

1

2

3

13

14

15

SERIAL

PORT

SERIAL

CONTROL

4X/8X

OVERSAMPLING

DIGITAL FILTER

/FUNCTION

CONTROLLER

ENPHANCED

MULTI-LEVEL

DELTA-SIGMA

MODULATOR

ZERP DETECT

SYSTEM CLOCK

16

DAC LPF+AMP

DAC

LPF+AMP

L-CH

R-CH

7

8

12

11

WF12

CN701

1212SPDIF

CN701 CN1601

15 15AUDIO-L

1717AUDIO-R

14 14A-L MUTE

16 16A-R MUTE

18 18A-MUTE

CN1601

REF

Q1204

3

2

6

5

+3.3V

Q1203

IC1201

Q1351

AMP

(AMP)

1

7

Q1202

JK1202

DIGITAL

AUDIO OUT

JK1201

AUDIO-L

OUT

AUDIO-R

OUT

Q1201

TO

VIDEO

BLOCK

PCM-MCLK

A-MUTE

+3.3V

MAIN CBA UNIT

1-6-9 1-6-10

AV CBA

E5542BLA

Page 18

Power Supply Block Diagram

CAUTION !

Fixed voltage power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, check to see that all components in the

power supply circuit are not defective before you connect the AC plug to

the AC power supply. Otherwise it may cause some components in the

power supply circuit to fail.

AC1001

AC CORD

F1001

1A 250V

F

A V

L1001

CHOKE

COIL

D1001, D1002

D1004, D1005

BRIDGE

RECTIFIER

Q1003

SWITCHING

CONTROL

A V

Q1001

SWITCHING

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

F

REPLACE ONLY WITH THE SAME TYPE FUSE.

ATTENTION : POUR UNE PROTECTION CONTINUE LES RISQES

D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

RISK OF FIRE

"This symbol means fast operating fuse."

"Ce symbole reprèsente un fusible à fusion rapide."

-REPLACE FUSE AS MARKED.

T1001

2

4

7

11

12

13

14

15

16

17

D1003

RECTIFIER

D1030

RECTIFIER

D1008

RECTIFIER

D1009

RECTIFIER

D1013

RECTIFIER

D1016

RECTIFIER

Q1010

Q1002

Q1006

IC1004

+3.3V

REG.

+12V

REG.

Q1007

REG

Q1004

IC1003

Q1005

NOTE :

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

IC302

CN1001

1

EV+2.5V

2

EV+2.5V

3

P-ON+5V

4

P-ON+5V

12

EV+9V

13

EV+9V

14

EV+3.3V

15

EV+3.3V

16

P-ON+3.3V

17

P-ON+3.3V

18

PWRCON

CN501

1

2

3

4

12

13

14

15

16

17

18

+3.3V

5 4

REG.

P-ON+3.3V(A)

EV+2.5V

P-ON+5V(D)

P-ON+5V(A)

EV+9V

EV+3.3V

P-ON+3.3V(D)

PWRCON

MAIN CBA UNIT

FROM

SYSTEM

CONTROL

BLOCK

DIAGRAM

Q1008

LATCH

HOT

AV CBA

6

IC1001

ERROR

VOLTAGE DET

4

3

18

1

2

Q1009

(SHUNT REGULATOR)

REG

COLD

1-6-12

P-ON+12V

F2

F1

-FL

P-ON+5V

P-ON+3.3V

EV+5V

E5542BLP1-6-11

Page 19

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS

Standard Notes

Warning

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts that have these special safety characteristics are identified in this manual and its supplements; electrical components having such features are

identified by the mark " #" in the schematic diagram

and the parts list. Before replacing any of these components, read the parts list in this manual carefully. The

use of substitute replacement parts that do not have the

same safety characteristics as specified in the parts list

may create shock, fire, or other hazards.

Capacitor Temperature Markings

Mark

(B) ±10% 20°C -25~+85°C

(F) +30 -80% 20°C -25~+85°C

(SR) ±15% 20°C -25~+85°C

(Z) +30 -80% 20°C -10~+70°C

Capacity

change rate

Standard

temperature

Temperature

range

Note:

1.Do not use the part number shown on these drawings for ordering. The correct part number is shown

in the parts list, and may be slightly different or

amended since these drawings were prepared.

2.

All resistance values are indicated in ohms (K=10

6

M=10

).

3.Resistor wattages are 1/4W or 1/6W unless otherwise specified.

4.All capacitance values are indicated in µF

−6

(P=10

5.All voltages are DC voltages unless otherwise specified.

µF).

3

,

Capacitors and transistors are represented by the following symbols.

CBA Symbols

(Top View) (Bottom View)

+

Electrolytic Capacitor

(Bottom View)

Transistor or Digital Transistor

E C B

(Top View)

NPN Transistor

E C B

(Top View)

NPN Digital Transistor

E C B

(Top View)

E C B

(Top View)

E C B

Schematic Diagram Symbols

Digital Transistor

PNP Transistor

PNP Digital Transistor

1-7-1 DVD_SC01

Page 20

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON THE FOLLOWING

PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME

F

A V

TYPE FUSE.

ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQES D’INCELE N’UTILISER QUE

DES FUSIBLE DE MEMO TYPE.

RISK OF FIRE-REPLACE FUSE AS MARKED.

This symbol means fast operating fuse.

2. CAUTION:

Ce symbole represente un fusible a fusion rapide.

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F001) is blown, first check to see that all components in the power supply circuit are not defective

before you connect the AC plug to the AC power supply. Otherwise it may cause some components in the power

supply circuit to fail.

3. Note:

(1)Do not use the part number shown on the drawings for ordering. The correct part number is shown in the parts

list, and may be slightly different or amended since the drawings were prepared.

(2)To maintain original function and reliability of repaired units, use only original replacement parts which are listed

with their part numbers in the parts list section of the service manual.

4. Wire Connectors

(1)Prefix symbol "CN" means "connector" (can disconnect and reconnect).

(2)Prefix symbol "CL" means "wire-solder holes of the PCB" (wire is soldered directly).

5. Note: Mark "•" is a leadless (chip) component.

6. Mode: SP

7. Voltage indications for PLAY mode on the schematics are as shown below:

PLAY mode

5.0

231

5.0

Indicates that the voltage

is not consistent here.

8. How to read converged lines

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to area "D3".

2. "1-B1" means that line number "1" goes to area "B1".

3

AREA D3

2

1

1-D3

ABCD

Unit: Volts

1-B1

AREA B1

9. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

: Used to indicate a test point with a test pin.

1-7-2 DVD_SC02

Page 21

Main 1/5 Schematic Diagram

1-7-3

1-7-4

1-7-5

E5542SCM1

Page 22

Main 2/5 Schematic Diagram

1-7-6 1-7-7

1-7-8

E5542SCM2

Page 23

Main 3/5 Schematic Diagram

1-7-9

1-7-10

1-7-11

E5542SCM3

Page 24

Main 4/5 Schematic Diagram

1-7-12

1-7-13

1-7-14

E5542SCM4

Page 25

Main 5/5 Schematic Diagram

1-7-15 1-7-16

E5542SCM5

Page 26

AV 1/3 Schematic Diagram

CAUTION !

Fixed voltage power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, check to see that all components in the power supply circuit

are not defective before you connect the AC plug to the AC power supply. Otherwise it may

cause some components in the power supply circuit to fail.

NOTE :

The voltage for parts in hot circuit is measured

using hot GND as a common terminal.

F

A V

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE FUSE.

ATTENTION : POUR UNE PROTECTION CONTINUE LES RISQES

D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

RISK OF FIRE-REPLACE FUSE AS MARKED.

"This symbol means fast operating fuse."

"Ce symbole reprèsente un fusible à fusion rapide."

1-7-17 1-7-18 E5542SCAV1

Page 27

AV 2/3 Schematic Diagram

1-7-19

1-7-20

E5542SCAV2

Page 28

AV 3/3 & Function Schematic Diagram

PBCCDVIDEODVDB

CHP

TTL TRK

A

11G 9G10G 8G 7G 6G 5G 4G 3G 2G 1G

a

b

c

d

e

f

g

c

d

e

f

g

h

i

j

c

d

e

f

g

c

d

e

f

g

c

d

e

f

g

h

i

c

d

e

f

g

c

d

e

f

g

c

d

e

f

g

c

d

e

f

g

c

d

e

f

g

c

d

e

f

g

h

i

j

a

b

a

b

c

d

e

f

g

a

b

a

b

a

b

a

b

a

b

a

b

a

b

a

b

a

b

FL2001 MATRIX CHART

TRK

DVD CD PBC

CHP

AB

10G11G

a

j

b

i

h

c

d

g

e

f

9G

7G8G

a

cb

d

e

f

gh

i

6G

5G

jj

4G

i

i

3G

2G

i

i

1G

a

cb

d

ef

g

1-7-21 1-7-22 E5542SCAV3

Page 29

AV CBA Top View

CAUTION !

Fixed voltage power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, check to see that all components in the power

supply circuit are not defective before you connect the AC plug to the AC

power supply.

Otherwise it may cause some components in the power supply circuit to fail.

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

F

A/ V

REPLACE ONLY WITH THE SAME TYPE FUSE.

ATTENTION : POUR UNE PROTECTION CONTINUE LES RISQES

D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

RISK OF FIRE-REPLACE FUSE AS MARKED.

"This symbol means fast operating fuse."

"Ce symbole reprèsente un fusible à fusion rapide."

BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER

SUPPLY CIRCUIT, AN ISOLATION TRANSFORMER MUST BE USED.

ALSO, IN ORDER TO HAVE THE ABILITY TO INCREASE THE INPUT

SLOWLY, WHEN TROUBLESHOOTING THIS TYPE POWER SUPPLY

CIRCUIT, A VARIABLE ISOLATION TRANSFORMER IS REQUIRED.

1-7-23

1-7-24

BE5500F01016-A

Page 30

AV CBA Bottom View

Switch CBA

Top View

Switch CBA

Bottom View

BE5500F01016-B

CAUTION !

Fixed voltage power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, check to see that all components in the power

supply circuit are not defective before you connect the AC plug to the AC

power supply.

Otherwise it may cause some components in the power supply circuit to fail.

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

F

A/ V

BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER

SUPPLY CIRCUIT, AN ISOLATION TRANSFORMER MUST BE USED.

ALSO, IN ORDER TO HAVE THE ABILITY TO INCREASE THE INPUT

SLOWLY, WHEN TROUBLESHOOTING THIS TYPE POWER SUPPLY

CIRCUIT, A VARIABLE ISOLATION TRANSFORMER IS REQUIRED.

REPLACE ONLY WITH THE SAME TYPE FUSE.

ATTENTION : POUR UNE PROTECTION CONTINUE LES RISQES

D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

RISK OF FIRE-REPLACE FUSE AS MARKED.

"This symbol means fast operating fuse."

"Ce symbole reprèsente un fusible à fusion rapide."

1-7-25

1-7-26

BE5500F01016-A

Page 31

Function CBA Top View

Function CBA Bottom View

1-7-27

1-7-28

BE5560F01013

Page 32

WAVEFORMS

WF1

MONREF

WF2

Pin 5 of IC001

0.2V 0.2usec

Pin 6 of IC001

WF5

WF6

Pin32 of IC601

VIDEO-Y

Pin33 of IC601

0.2V 20usec

WF9

PCM-DATA0

WF10

Pin2 of IC801

1V 0.2usec

Pin1 of IC801

NOTE:

Input

CD: 1KHz PLAY

(WF8~WF11)

DVD: BLUE BACK (STOP MODE)

(WF1~WF7)

MONREP

Pin 117 of IC300

WF3

NRZP

Pin 118 of IC300

WF4

0.2V 0.2usec

0.2V 0.2usec

WF7

WF8

VIDEO-C

Pin34 of IC601

VIDEO

Pin3 of IC801

0.2V 20usec

0.2V 20usec

PCM-MCLK

WF11

AUDIO-L

1V 0.2usec

Pin7 of IC801

1V 0.5msec

NRZN

0.2V 0.2usec

1-8-1

PCM-LRCK

1V 0.2usec

1-8-2

E5540WF

Page 33

WIRING DIAGRAM

VIDEO-Y

OUT

EV+2.5V 11

EV+2.5V 22

VIDEO-U

OUT

P-ON+5V 44

P-ON+5V 33

GND 55

VIDEO-V

OUT

GND 66

GND 77

EV+3.3V 1414

EV+3.3V 1515

AUDIO

OUT(L)

P-ON+3.3V 1616

P-ON+3.3V 1717

VIDEO

OUT

CN1001

GND 88

GND 99

GND 1010

GND 1111

EV+9V 1212

EV+9V 1313

CN501

PWRCON 1818

AUDIO

OUT(R)

FP-STB 1919

FP-DIN 2020

AV CBA

(BE5500F01016-A)

FP-DOUT 2121

FP-CLK 2222

D-GND 2323

REMOTE 2424

DIGITAL

AUDIO OUT

VIDEO-V 11

GND 22

S-VIDEO

OUT

GND 44

VIDEO-U 33

AC CORD

CN2001 CN2003

KEY-4 1

1

KEY-3 2

2

KEY-2 3

3

KEY-1 4

4

K2 5

5

K1 6

6

CN1601

VIDEO-Y 55

GND 66

VIDEO-C 77

GND 88

VIDEO-CVBS 99

GND 1010

GND 1111

SPDIF 1212

P-ON+5V 1313

A-L-MUTE 1414

AUDIO-L 1515

A-R-MUTE 1616

AUDIO-R 1717

A-MUTE 1818

CN701

JP1003 JP1004

KEY-2 1

1

K2 2

2

NU 3

3

GND 4

4

FUNCTION CBA

(BE5501F01012)

SWITCH CBA

(BE5500F01016-B)

M

LOADING

MOTOR

SPINDLE

MOTOR

M

1 LM(+)

2 LM(-)

3 TRAY-IN

4 TRAY-OUT

TRAY-IN

TRAY-OUT

CN3003

CN3004

GND

5

6 SPL(-)

7 SPL(+)

8 SL(-)

9 SL(+)

SPL(-) 11SPL(+) 22SL(-) 33SL(+) 44GND 55FG-IN 66P-ON+3.3V 7

P-ON+3.3V(D)

10 FG-IN

11

MECHA CBA

7

MAIN CBA UNIT

CN301

1 TEST0

2 TEST1

3 TEST2

4 TEST3

5 TEST4

(NO CONNECTION)

6 TEST12

7 GND

8 TEST13

9 TEST16

10 MODE0

1 C

2 B

3 A

DETECTOR

4 D

5 VREF+2.5V

CN001CN201

6 P-ON+5V(A)

7 F

8 E

9 GND

PICK UP UNIT

10 GND

11 LD

12 MON

13 GND

14 GND

15 TS(+)

16 FS(-)

FS

TS

17 FS(+)

18 TS(-)

1 NU

2 GND

3 TRIG-OUT

4 GND

5 TRIG-IN

6 GND

7 NU

8 GND

(NO CONNECTION)

CN603

9 TMS

10 GND

11 TCK

12 GND

13 TDI

14 GND

15 TDO

16 GND

17 JTAG-RST

18 GND

19 TRST

20 GND

M

SLIDE

MOTOR

FG

SENSOR

INNER CBA FG CBA

1-9-1

1-9-2

E5542WI

Page 34

SYSTEM CONTROL TIMING CHARTS

Tray close ~ Play / Play ~ Tray open

Eject key on

LSW2

LSW1

LM-

LM+

I/o

(TL123)

0V

+5V

+6V

0V

+6V

0V

+2V

0V

Tray close Tray open

Disc

Rotation

4.4s

2.0s

Eject key on

Play

700ms

SP

( TP122 )

Tv

( TL122 )

+5V

1.2s

0V

1.7s

+2V

0V

1-10-1 E5540TI

Page 35

IC PIN FUNCTION DESCRIPTIONS

IC2003 ( PT6315 )

Pin

No.

10 In K1 Key Data 1 Input

11 In K2 Key Data 2 Input

12 - VSS GND

13 - VDD Power Supply

14 Out a / KEY-1

15 Out b / Key-2

16 Out c / Key-3

17 Out d / Key-4

18 OUT e Display Segment

19 OUT f Display Segment

20 OUT g Display Segment

21 OUT h Display Segment

22 OUT i Display Segment

23 OUT j Display Segment

24 - N.U. Not Used

25 - N.U. Not Used

26 - N.U. Not Used

27 - N.U. Not Used

28 - N.U. Not Used

29 - N.U. Not Used

30 - VEE Pull Down Level

31 - N.U. Not Used

In/

Out

1 - N.U. Not Used

2 - N.U. Not Used

3 - N.U. Not Used

4 - N.U. Not Used

5 In OSC Oscillator Input

6 Out DOUT Serial Data Output

7 In DIN Serial Data Input

8 In CLK Clock Input

9 In STB Serial Interface Strobe

Signal

Name

Function

Segment Output

/ Key Souce-1

Segment Output

/ Key Souce-2

Segment Output

/ Key Souce-3

Segment Output

/ Key Souce-4

Pin

No.

32

33 10G

34 9G

35 8G

36 7G

37 6G

38 5G

39 4G

40 3G

41 2G

42 1G

43 - VDD Power Supply

44 - VSS GND

In/

Out

OUT

Signal

Name

11G

Function

Grid Output

1-11-1 E5540PIN

Page 36

LEAD IDENTIFICATION

E C B

NJM4558D

8 5

2SA1015-Y (TPE2)

2SC1815-Y (TPE2)

KTA1266 (Y)

2SC1815-GR (TPE2)

2SA966 (Y)

2SC2236-Y-TPE6,C

KTC3205(Y)

28

E C B

PT6315

2SC2785 (J, H, F)

KTC3199 (Y, GR)

KRA110M

KTA1273 (Y)

KRC110M-AT

BA1L3Z-T

BN1L3Z (P)

15

2SK2599

S D G

KIA431

AN1431-(NSC)

1 4

LTV-817B-F

LTV-817C-F

PS2501-1 (D, H, L, M, W)

PF-5001-B, C

PC817 (A, B, AB)

A

K

1

C

E

14

BA033ST-V5

15

R A K

Note:

A: Anode

K: Cathode

E: Emitter

C: Collector

B: Base

R: Reference

1 VCC

2 GND

3 OUT

1-12-1 E5540LE

Page 37

Cabinet

EXPLODED VIEWS

2L011

2L011

See Electrical Parts List

for parts with this mark.

Some Ref. Numbers are

not in sequence.

A2

DVD Main

CBA Unit

2L031

2L031

W1001

2L051

Function CBA

2L031

W1601

2L021

2L031

2L021

2L081

1B1

JK1202

2L031

2B6

JK1401

JK1201

2L021

F1001

2L031

2B17

A16

2L011

2L081

2B5

AC1001

2L022

2B2

A1X

S8

WJ1001

AV CBA

A13

2L022

2L071

A17

A26

2L071

A13

2L041

2L041

2L071

A15

1-13-1 E5542EX

Page 38

Packing

X31

X27

X25

S2

X10

X1

X5

X2

X4

S4

S2

Unit

A30

A22

A30

A22

S1

1-13-2 E5542EX

Page 39

MECHANICAL PARTS LIST

PRODUCT SAFETY NOTE: Products marked with a

have special characteristics important to safety.

Before replacing any of these components, read carefully the product safety notice in this service manual.

Don't degrade the safety of the product through

improper servicing.

Ref. No. Description Part No.

A1X FRONT ASSEMBLY E5542UD 0VM203258

A2 TRAY PANEL ASSEMBLY E5541JD 0VM411923

A13 FOOT K7010UA 0VM403657

A14 FOOT ASSEMBLY E5542UD 0VM412440

A15 MAIN CHASSIS E5500UD 0VM100944

A16 TOP COVER E5541JD 0VM304814

A17 REAR PANEL E5542UD 0VM203263

1B1 DVD MECHA N79F0EVM

ACCESSORIES

X1 REMOTE CONTROL UNIT DVD 0842 VCDVR020 orN9476UD

REMOTE CONTROL UNIT DVD 0842 VCDVR020 N9076UD

X5 2+1RCA RED -WHITE+YELLOW AWG26 1.5M WPZ0152LG001

X10 OWNER'S MANUAL E5540UD 0VMN02710A

20010719 1-14-1 E5542CA

Page 40

ELECTRICAL PARTS LIST

PRODUCT SAFETY NOTE: Products marked with a

have special characteristics important to safety.

Before replacing any of these components, read carefully the product safety notice in this service manual.

Don't degrade the safety of the product through

improper servicing.

NOTE:

Tolerance of Capacitors and Resistors are noted with

the following symbols.

C.....±0.25% D.....±0.5% F.....±1%

G.....±2% J......±5% K.....±10%

M.....±20% N.....±30% Z.....+80/-20%

Main CBA

Ref. No. Description Part No.

DVD MAIN CBA N79M0EUP

AV CBA

Ref. No. Description Part No.

AV CBA

Consists of the following:

CAPACITORS

C1001 METALLIZED FILM CAP. 0.01µF/250V K or CT2E103DC011

METALLIZED FILM CAP. 0.01µF/250V M CT2E103MS037

C1002 ELECTROLYTIC CAP. 22µF/50V M CE1JMASDL220

C1003 ELECTROLYTIC CAP. 2.2µF/250V M or CA2E2R2S6009

ELECTROLYTIC CAP. 2.2µF/250V M(105ºC) CE2EMASTH2R2

C1004 ELECTROLYTIC CAP. 100µF/200V M CE2DMZNDL101

C1005 CERAMIC CAP. B K 120pF/500V CCD2JKP0B121

C1006 SAFETY CAP. 2200pF/250V or CCG2EMA0F222

SAFETY CAP. 2200pF/125V or CCG2BMA0E222

SAFETY CAP. 2200pF/250V CCG2EMA0E222

C1007 ELECTROLYTIC CAP. 1000µF/6.3V M CE0KMASDL102

C1012 ELECTROLYTIC CAP. 1000µF/16V M CE1CMASDL102

C1013 FILM CAP.(P) 0.0033µF/50V J or CMA1JJS00332

FILM CAP.(P) 0.0033µF/50V J CA1J332MS029

C1014 ELECTROLYTIC CAP. 1000µF/10V M CE1AMASDL102

C1015 ELECTROLYTIC CAP. 220µF/10V M CE1AMASDL221

C1016 ELECTROLYTIC CAP. 47µF/16V M CE1CMASDL470

C1018 ELECTROLYTIC CAP. 100µF/10V M CE1AMASDL101

C1021 CERAMIC CAP. B K 0.01µF/50V CCD1JKS0B103

C1022 CERAMIC CAP.(AX) X K 5600pF/16V CCA1CKT0X562

C1024 ELECTROLYTIC CAP. 470µF/6.3V M CE0KMASDL471

C1025 CHIP CERAMIC CAP. B K 0.1µF/25V or CHD1EK30B104

CHIP CERAMIC CAP. B K 0.1µF/16V CHD1CK30B104

C1026 CHIP CERAMIC CAP. B K 0.1µF/25V or CHD1EK30B104

CHIP CERAMIC CAP. B K 0.1µF/16V CHD1CK30B104

C1029 CERAMIC CAP.(AX) X K 5600pF/16V CCA1CKT0X562

C1030 ELECTROLYTIC CAP. 220µF/6.3V M CE0KMASDL221

C1031 FILM CAP.(P) 0.01µF/50V J or CMA1JJS00103

FILM CAP.(P) 0.01µF/50V J CA1J103MS029

C1032 ELECTROLYTIC CAP. 10µF/16V M CE1CMASDL100

C1033 CERAMIC CAP. YV Z 0.022µF/50V or CCD1JZSYV223

0VSA11636

Ref. No. Description Part No.

CERAMIC CAP. F Z 0.022µF/50V CCD1JZS0F223

C1034 ELECTROLYTIC CAP. 220µF/6.3V M CE0KMASDL221

C1035 ELECTROLYTIC CAP. 470µF/16V M CE1CMASDL471

C1201 ELECTROLYTIC CAP. 10µF/16V M CE1CMASDL100

C1202 ELECTROLYTIC CAP. 10µF/16V M CE1CMASDL100

C1203 CHIP CERAMIC CAP. CH J 680pF/50V CHD1JJ3CH681

C1204 CHIP CERAMIC CAP. CH J 680pF/50V CHD1JJ3CH681

C1205 CHIP CERAMIC CAP. CH J 390pF/50V CHD1JJ3CH391

C1206 CHIP CERAMIC CAP. CH J 390pF/50V CHD1JJ3CH391

C1207 CHIP CERAMIC CAP. CH D 9pF/50V CHD1JD3CH9R0

C1208 CHIP CERAMIC CAP. CH D 9pF/50V CHD1JD3CH9R0

C1221 ELECTROLYTIC CAP. 10µF/16V M CE1CMASDL100

C1222 ELECTROLYTIC CAP. 10µF/16V M CE1CMASDL100

C1245 CHIP CERAMIC CAP. F Z 0.1µF/50V or CHD1JZ30F104

CHIP CERAMIC CAP. F Z 0.1µF/25V CHD1EZ30F104

C1246 CHIP CERAMIC CAP. F Z 0.1µF/50V or CHD1JZ30F104

CHIP CERAMIC CAP. F Z 0.1µF/25V CHD1EZ30F104

C1247 ELECTROLYTIC CAP. 470µF/16V M CE1CMASDL471

C1249 ELECTROLYTIC CAP. 47µF/16V M CE1CMASDL470

C1353 CHIP CERAMIC CAP. B K 0.1µF/25V or CHD1EK30B104

CHIP CERAMIC CAP. B K 0.1µF/16V CHD1CK30B104

C1354 CHIP CERAMIC CAP. CH J 100pF/50V CHD1JJ3CH101

C1356 ELECTROLYTIC CAP. 47µF/6.3V M CE0KMASDL470

C1401 ELECTROLYTIC CAP. 33µF/6.3V M CE0KMASDL330

C1402 CHIP CERAMIC CAP. F Z 0.1µF/50V or CHD1JZ30F104

CHIP CERAMIC CAP. F Z 0.1µF/25V CHD1EZ30F104

C1403 ELECTROLYTIC CAP. 470µF/6.3V M CE0KMASDL471

C1405 ELECTROLYTIC CAP. 470µF/16V M CE1CMASDL471

C1421 CHIP CERAMIC CAP. F Z 0.1µF/50V or CHD1JZ30F104

CHIP CERAMIC CAP. F Z 0.1µF/25V CHD1EZ30F104

C1423 ELECTROLYTIC CAP. 1µF/50V M CE1JMASDL1R0

C1441 ELECTROLYTIC CAP. 33µF/6.3V M CE0KMASDL330

C1443 ELECTROLYTIC CAP. 470µF/6.3V M CE0KMASDL471

C1447 ELECTROLYTIC CAP. 470µF/6.3V M CE0KMASDL471

C1461 ELECTROLYTIC CAP. 33µF/6.3V M CE0KMASDL330

C1463 ELECTROLYTIC CAP. 470µF/6.3V M CE0KMASDL471

C1481 ELECTROLYTIC CAP. 33µF/6.3V M CE0KMASDL330

C1483 ELECTROLYTIC CAP. 470µF/6.3V M CE0KMASDL471

C2002 CHIP CERAMIC CAP. B K 1000pF/50V CHD1JK30B102

C2003 CHIP CERAMIC CAP. F Z 0.1µF/50V or CHD1JZ30F104

CHIP CERAMIC CAP. F Z 0.1µF/25V CHD1EZ30F104

C2004 ELECTROLYTIC CAP. 22µF/6.3V M H7 CE0KMASSL220

C2007 CHIP CERAMIC CAP. F Z 0.1µF/50V or CHD1JZ30F104

CHIP CERAMIC CAP. F Z 0.1µF/25V CHD1EZ30F104

C2011 CHIP CERAMIC CAP. F Z 0.1µF/50V or CHD1JZ30F104

CHIP CERAMIC CAP. F Z 0.1µF/25V CHD1EZ30F104

C2012 CHIP CERAMIC CAP. F Z 0.1µF/50V or CHD1JZ30F104

CHIP CERAMIC CAP. F Z 0.1µF/25V CHD1EZ30F104

CONNECTORS

CN1001 FMN CONNECTOR, TOP 24P 24FMN-BTRK JCFNG24JG002

CN1601 FMN CONNECTOR, TOP 18P 18FMN-BTK JCFNG18JG001

CN2001 CONNECTOR BASE, 6P TUC-P06P-B1 J3TUA06TG001

DIODES

D1001 RECTIFIER DIODE 1N4005 or NDQZ001N4005

RECTIFIER DIODE 1N4005 ND8Z001N4005

D1002 RECTIFIER DIODE 1N4005 or NDQZ001N4005

RECTIFIER DIODE 1N4005 ND8Z001N4005

20010719 1-15-1 E5542EL

Page 41

Ref. No. Description Part No.

D1003 RECTIFIER DIODE BA157 or NDQZ000BA157

FAST RECOVERY DIODE ERA18-04 QDPZ0ERA1804

D1004 RECTIFIER DIODE 1N4005 or NDQZ001N4005

RECTIFIER DIODE 1N4005 ND8Z001N4005

D1005 RECTIFIER DIODE 1N4005 or NDQZ001N4005

RECTIFIER DIODE 1N4005 ND8Z001N4005

D1006 RECTIFIER DIODE 1N4005 or NDQZ001N4005

RECTIFIER DIODE 1N4005 ND8Z001N4005

D1008 SCHOTTKY BARRIER DIODE SB340 or NDQZ000SB340

SCHOTTKY BARRIER DIODE ERC81-004 QDPZERC81004

D1009 RECTIFIER DIODE FR202 or NDQZ000FR202

FAST RECOVERY DIODE ERB32-01L3 QDQZ0ERB3201

D1011 RECTIFIER DIODE BA157 or NDQZ000BA157

FAST RECOVERY DIODE ERA18-04 QDPZ0ERA1804

D1012 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D1013 SCHOTTKY BARRIER DIODE SB140 or NDQZ000SB140

SCHOTTKY BARRIER DIODE ERB81-004 AERB81004***

D1015 ZENER DIODE MTZJT-779.1C QDTC0MTZJ9R1

D1016 RECTIFIER DIODE BA157 or NDQZ000BA157

FAST RECOVERY DIODE ERA18-04 QDPZ0ERA1804

D1017 ZENER DIODE MTZJT-7722B QDTB00MTZJ22

D1020 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D1022 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D1023 ZENER DIODE MTZJT-775.6B QDTB0MTZJ5R6

D1024 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D1025 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D1030 RECTIFIER DIODE FR202 or NDQZ000FR202

FAST RECOVERY DIODE ERB32-01L3 QDQZ0ERB3201

D1031 RECTIFIER DIODE 1N4005 or NDQZ001N4005

RECTIFIER DIODE 1N4005 ND8Z001N4005

D1035 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D1036 ZENER DIODE MTZJT-7713B QDTB00MTZJ13

D1038 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D1039 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D2001 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D2002 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D2003 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D2004 SWITCHING DIODE 1SS133(T-77) or QDTZ001SS133

SWITCHING DIODE 1N4148 NDTZ001N4148

D2023 PCB JUMPER D0.6-P5.0 JW5.0T

D2024 PCB JUMPER D0.6-P5.0 JW5.0T

D2025 PCB JUMPER D0.6-P5.0 JW5.0T

D2026 PCB JUMPER D0.6-P5.0 JW5.0T

ICS

IC1001 PHOTOCOUPLER LTV-817C-F or NPEC0LTV817F

PHOTOCOUPLER LTV-817B-F or NPEB0LTV817F

PHOTO COUPLER PF5001-B,C or QPE300PF5001

PHOTOCOUPLER PS2501-1H or QPEH0PS25011

PHOTO COUPLER PS2501-1L or QPEL0PS25011

Ref. No. Description Part No.

PHOTO COUPLER PS2501-1M or QPEM0PS25011

PHOTOCOUPLER PS2501-1W or QPEW0PS25011

PHOTOCOUPLER PS2501-1D or QPED0PS25011

PHOTOCOUPLER PC817(A) or QPPA000PC817

PHOTOCOUPLER PC817(B) or QPPB000PC817

PHOTO COUPLER PC817(AB) or QPP1000PC817

PHOTOCOUPLER EL817A or NPEA000EL817

PHOTOCOUPLER EL817B or NPEB000EL817

PHOTOCOUPLER EL817C NPEC000EL817

IC1003 IC KIA431 or NSZLA0ZJY001

IC AN1431-(NSC) QSBLA0ZMS001

IC1004 3.3V REGULATOR(1A) BA033ST-V5 QSZBA0SRM013

IC1201 IC NJM4558D QSMLA0STR001

IC2003 FL DRIVER IC PT6315 NSZBA0RG2002

COILS

L1001 LINE FILTER 20MH SA-00911 LLBG00ZSA003

L1002 BEAD CORE B16 RH 3.5X10X1.3 or XL03010XM001

BEAD CORE HF70BB3.5X10X1.3 XL03010TE001

L1003 CHOKE COIL 22µH-K LLBD00PKV006

L1004 BEAD CORE B16 RH 3.5X10X1.3 or XL03010XM001

BEAD CORE HF70BB3.5X10X1.3 XL03010TE001

L1005 CHOKE COIL 22µH-K LLBD00PKV006

L1007 PCB JUMPER D0.6-P5.0 JW5.0T

L1009 PCB JUMPER D0.6-P5.0 JW5.0T

L1251 INDUCTOR 0.47µH-K-26T LLAXKATTUR47

L1401 CHOKE COIL 22µH-K LLBD00PKV006

L2001 INDUCTOR 100µH-K-26T LLAXKATTU101

L2002 INDUCTOR 100µH-K-26T LLAXKATTU101

L2003 INDUCTOR 33µH-K-26T LLAXKATTU330

TRANSISTORS

Q1001 FET 2SK2599 QFQZ02SK2599

Q1002 TRANSISTOR 2SC2236-Y-TPE6,C or QQSY02SC2236

TRANSISTOR KTC3205(Y) NQSY0KTC3205

Q1003 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1004 TRANSISTOR 2SA966(Y) or QQSY002SA966

TRANSISTOR KTA1273(Y) NQSY0KTA1273

Q1005 RES. BUILT-IN TRANSISTOR BA1L3Z-T or QQSZ00BA1L3Z

RES. BUILT-IN TRANSISTOR KRC110M-AT NQSZ0KRC110M

Q1006 RES. BUILT-IN TRANSISTOR BN1L3Z(P) or QQSP00BN1L3Z

RES. BUILT-IN TRANSISTOR KRA110M NQSZ0KRA110M

Q1007 TRANSISTOR 2SC2236-Y-TPE6,C or QQSY02SC2236

TRANSISTOR KTC3205(Y) NQSY0KTC3205

Q1008 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1009 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

20010719 1-15-2 E5542EL

Page 42

Ref. No. Description Part No.

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1010 TRANSISTOR 2SC2236-Y-TPE6,C or QQSY02SC2236

TRANSISTOR KTC3205(Y) NQSY0KTC3205

Q1201 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1202 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1203 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1204 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1351 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1401 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1402 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1403 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1421 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1422 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1423 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1441 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1442 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1443 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

Ref. No. Description Part No.

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1445 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1461 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1462 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1463 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1481 TRANSISTOR 2SC2785(J) or QQSJ02SC2785

TRANSISTOR 2SC2785(H) or QQSH02SC2785

TRANSISTOR 2SC2785(F) or QQSF02SC2785

TRANSISTOR 2SC1815-Y(TPE2) or QQSY02SC1815

TRANSISTOR 2SC1815-GR(TPE2) or QQS102SC1815

TRANSISTOR KTC3199(Y) or NQSY0KTC3199

TRANSISTOR KTC3199(GR) NQS10KTC3199

Q1482 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

Q1483 TRANSISTOR 2SA1015-Y(TPE2) or QQSY02SA1015

TRANSISTOR KTA1266(Y) NQSY0KTA1266

RESISTORS

R1002 CARBON RES. 1/4W J 330 Ω RCX4JATZ0331

R1003 CARBON RES. 1/4W J 330 Ω RCX4JATZ0331

R1004 METAL OXIDE FILM RES. 2W J 68k Ω or RN02683ZU001

METAL OXIDE FILM RES. 2W J 68k Ω RN02683KE010

R1005 CARBON RES. 1/4W J 1M Ω RCX4JATZ0105

R1006 CARBON RES. 1/4W J 1M Ω RCX4JATZ0105

R1008 CARBON RES. 1/4W J 1k Ω RCX4JATZ0102

R1010 CARBON RES. 1/6W J 22k Ω or RCX6JATZ0223

CARBON RES. 1/4W J 22k Ω RCX4JATZ0223

R1011 METAL OXIDE FILM RES. 1W J 1.2 Ω or RN011R2ZU001

METAL OXIDE FILM RES. 1W J 1.2 Ω RN011R2KE009

R1012 CARBON RES. 1/6W J 10k Ω or RCX6JATZ0103

CARBON RES. 1/4W J 10k Ω RCX4JATZ0103

R1013 CARBON RES. 1/6W J 1.5k Ω or RCX6JATZ0152

CARBON RES. 1/4W J 1.5k Ω RCX4JATZ0152

R1014 CARBON RES. 1/6W J 220 Ω or RCX6JATZ0221

CARBON RES. 1/4W J 220 Ω RCX4JATZ0221

R1016 CARBON RES. 1/6W J 2.2k Ω or RCX6JATZ0222

CARBON RES. 1/4W J 2.2k Ω RCX4JATZ0222

R1017 CARBON RES. 1/6W J 1.5k Ω or RCX6JATZ0152

CARBON RES. 1/4W J 1.5k Ω RCX4JATZ0152

R1019 CARBON RES. 1/6W J 1k Ω or RCX6JATZ0102

CARBON RES. 1/4W J 1k Ω RCX4JATZ0102

R1020 CARBON RES. 1/6W J 1.5k Ω or RCX6JATZ0152

CARBON RES. 1/4W J 1.5k Ω RCX4JATZ0152

R1021 CARBON RES. 1/6W J 22k Ω or RCX6JATZ0223

CARBON RES. 1/4W J 22k Ω RCX4JATZ0223

R1022 CARBON RES. 1/6W J 2.2k Ω or RCX6JATZ0222

CARBON RES. 1/4W J 2.2k Ω RCX4JATZ0222

R1023 CARBON RES. 1/6W J 390 Ω or RCX6JATZ0391

CARBON RES. 1/4W J 390 Ω RCX4JATZ0391

R1025 CARBON RES. 1/4W J 330 Ω RCX4JATZ0331

R1029 CARBON RES. 1/6W J 220k Ω or RCX6JATZ0224

CARBON RES. 1/4W J 220k Ω RCX4JATZ0224

20010719 1-15-3 E5542EL

Page 43

Ref. No. Description Part No.

R1030 METAL OXIDE FILM RES. 3W J 1.8 Ω or RN031R8ZU001

METAL OXIDE FILM RES. 3W J 1.8 Ω RN031R8KE009

R1031 CARBON RES. 1/6W G 560 Ω or RCX6GATZ0561

CARBON RES. 1/4W G 560 Ω RCX4GATZ0561

R1033 CARBON RES. 1/6W J 47 Ω or RCX6JATZ0470

CARBON RES. 1/4W J 47 Ω RCX4JATZ0470

R1034 CARBON RES. 1/4W J 390k Ω RCX4JATZ0394

R1035 CARBON RES. 1/6W J 1k Ω or RCX6JATZ0102

CARBON RES. 1/4W J 1k Ω RCX4JATZ0102

R1036 CARBON RES. 1/6W J 100k Ω or RCX6JATZ0104

CARBON RES. 1/4W J 100k Ω RCX4JATZ0104

R1037 CARBON RES. 1/6W J 10k Ω or RCX6JATZ0103

CARBON RES. 1/4W J 10k Ω RCX4JATZ0103

R1038 CARBON RES. 1/6W J 100k Ω or RCX6JATZ0104

CARBON RES. 1/4W J 100k Ω RCX4JATZ0104

R1039 CARBON RES. 1/6W J 470k Ω or RCX6JATZ0474

CARBON RES. 1/4W J 470k Ω RCX4JATZ0474

R1042 CARBON RES. 1/6W J 5.6 Ω or RCX6JATZ05R6

CARBON RES. 1/4W J 5.6 Ω RCX4JATZ05R6

R1043 METAL OXIDE FILM RES. 1W J 2.7 Ω or RN012R7ZU001

METAL OXIDE FILM RES. 1W J 2.7 Ω RN012R7KE009

R1044 CHIP RES.(1608) 1/16W J 22k Ω or RRXGJR5Z0223

CHIP RES.(1608) 1/10W J 22k Ω RRXAJR5Z0223

R1045 CARBON RES. 1/6W G 39 Ω or RCX6GATZ0390

CARBON RES. 1/4W G 39 Ω RCX4GATZ0390

R1046 CARBON RES. 1/6W G 150 Ω or RCX6GATZ0151

CARBON RES. 1/4W G 150 Ω RCX4GATZ0151

R1048 METAL OXIDE FILM RES. 2W J 68k Ω or RN02683ZU001

METAL OXIDE FILM RES. 2W J 68k Ω RN02683KE010

R1049 CARBON RES. 1/6W G 4.7k Ω or RCX6GATZ0472

CARBON RES. 1/4W G 4.7k Ω RCX4GATZ0472

R1050 CHIP RES.(1608) 1/16W 0 Ω or RRXGZR5Z0000

CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R1051 CHIP RES.(1608) 1/16W 0 Ω or RRXGZR5Z0000

CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R1052 METAL OXIDE FILM RES. 2W J 3.3 Ω or RN023R3ZU001

METAL OXIDE FILM RES. 2W J 3.3 Ω RN023R3KE010

R1053 METAL OXIDE FILM RES. 2W J 0.68 Ω or RN02R68ZU001

METAL OXIDE FILM RES. 2W J 0.68 Ω RN02R68KE010

R1054 CHIP RES.(1608) 1/16W J 47k Ω or RRXGJR5Z0473

CHIP RES.(1608) 1/10W J 47k Ω RRXAJR5Z0473

R1058 CHIP RES.(1608) 1/16W J 10k Ω or RRXGJR5Z0103

CHIP RES.(1608) 1/10W J 10k Ω RRXAJR5Z0103

R1061 CHIP RES.(1608) 1/16W 0 Ω or RRXGZR5Z0000

CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R1064 CHIP RES.(1608) 1/16W 0 Ω or RRXGZR5Z0000

CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R1201 CHIP RES.(1608) 1/16W J 220k Ω or RRXGJR5Z0224

CHIP RES.(1608) 1/10W J 220k Ω RRXAJR5Z0224

R1202 CHIP RES.(1608) 1/16W J 220k Ω or RRXGJR5Z0224

CHIP RES.(1608) 1/10W J 220k Ω RRXAJR5Z0224

R1203 CHIP RES. 1/16W F 12k Ω or RRXGFR5Z1202

CHIP RES.(100PPM) 1/16W F 12k Ω RRXGFR5H1202

R1204 CHIP RES. 1/16W F 12k Ω or RRXGFR5Z1202

CHIP RES.(100PPM) 1/16W F 12k Ω RRXGFR5H1202

R1205 CHIP RES. 1/16W F 18k Ω or RRXGFR5Z1802

CHIP RES.(100PPM) 1/16W F 18k Ω RRXGFR5H1802

R1206 CHIP RES. 1/16W F 18k Ω or RRXGFR5Z1802

CHIP RES.(100PPM) 1/16W F 18k Ω RRXGFR5H1802

R1207 CHIP RES.(1608) 1/16W J 39k Ω or RRXGJR5Z0393

CHIP RES.(1608) 1/10W J 39k Ω RRXAJR5Z0393

Ref. No. Description Part No.

R1208 CHIP RES.(1608) 1/16W J 39k Ω or RRXGJR5Z0393

CHIP RES.(1608) 1/10W J 39k Ω RRXAJR5Z0393

R1209 CHIP RES. 1/16W F 56k Ω or RRXGFR5Z5602

CHIP RES.(100PPM) 1/16W F 56k Ω RRXGFR5H5602

R1210 CHIP RES. 1/16W F 56k Ω or RRXGFR5Z5602

CHIP RES.(100PPM) 1/16W F 56k Ω RRXGFR5H5602

R1211 CHIP RES.(1608) 1/16W 0 Ω or RRXGZR5Z0000

CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R1212 CHIP RES.(1608) 1/16W 0 Ω or RRXGZR5Z0000

CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R1221 CHIP RES.(1608) 1/16W J 100k Ω or RRXGJR5Z0104

CHIP RES.(1608) 1/10W J 100k Ω RRXAJR5Z0104

R1222 CHIP RES.(1608) 1/16W J 100k Ω or RRXGJR5Z0104

CHIP RES.(1608) 1/10W J 100k Ω RRXAJR5Z0104

R1223 CHIP RES.(1608) 1/16W J 1k Ω or RRXGJR5Z0102

CHIP RES.(1608) 1/10W J 1k Ω RRXAJR5Z0102

R1224 CHIP RES.(1608) 1/16W J 1k Ω or RRXGJR5Z0102

CHIP RES.(1608) 1/10W J 1k Ω RRXAJR5Z0102

R1225 CHIP RES.(1608) 1/16W J 1k Ω or RRXGJR5Z0102

CHIP RES.(1608) 1/10W J 1k Ω RRXAJR5Z0102

R1226 CHIP RES.(1608) 1/16W J 1k Ω or RRXGJR5Z0102

CHIP RES.(1608) 1/10W J 1k Ω RRXAJR5Z0102

R1227 CHIP RES.(1608) 1/16W 0 Ω or RRXGZR5Z0000

CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R1228 CHIP RES.(1608) 1/16W 0 Ω or RRXGZR5Z0000

CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R1235 CHIP RES.(1608) 1/16W J 2.2k Ω or RRXGJR5Z0222

CHIP RES.(1608) 1/10W J 2.2k Ω RRXAJR5Z0222

R1236 CHIP RES.(1608) 1/16W J 2.2k Ω or RRXGJR5Z0222

CHIP RES.(1608) 1/10W J 2.2k Ω RRXAJR5Z0222

R1237 CHIP RES.(1608) 1/16W J 2.2k Ω or RRXGJR5Z0222

CHIP RES.(1608) 1/10W J 2.2k Ω RRXAJR5Z0222

R1238 CHIP RES.(1608) 1/16W J 2.2k Ω or RRXGJR5Z0222

CHIP RES.(1608) 1/10W J 2.2k Ω RRXAJR5Z0222

R1239 CHIP RES.(1608) 1/16W J 100k Ω or RRXGJR5Z0104

CHIP RES.(1608) 1/10W J 100k Ω RRXAJR5Z0104

R1240 CHIP RES.(1608) 1/16W J 100k Ω or RRXGJR5Z0104

CHIP RES.(1608) 1/10W J 100k Ω RRXAJR5Z0104

R1245 CHIP RES.(1608) 1/16W 0 Ω or RRXGZR5Z0000

CHIP RES.(1608) 1/10W 0 Ω RRXAZR5Z0000

R1246 CHIP RES.(1608) 1/16W J 33k Ω or RRXGJR5Z0333

CHIP RES.(1608) 1/10W J 33k Ω RRXAJR5Z0333

R1247 CHIP RES.(1608) 1/16W J 39k Ω or RRXGJR5Z0393

CHIP RES.(1608) 1/10W J 39k Ω RRXAJR5Z0393

R1352 CHIP RES.(1608) 1/16W J 2k Ω or RRXGJR5Z0202

CHIP RES.(1608) 1/10W J 2k Ω RRXAJR5Z0202

R1353 CHIP RES.(1608) 1/16W J 2.2k Ω or RRXGJR5Z0222

CHIP RES.(1608) 1/10W J 2.2k Ω RRXAJR5Z0222

R1354 CHIP RES.(1608) 1/16W J 2.2k Ω or RRXGJR5Z0222

CHIP RES.(1608) 1/10W J 2.2k Ω RRXAJR5Z0222

R1355 CHIP RES.(1608) 1/16W J 220 Ω or RRXGJR5Z0221

CHIP RES.(1608) 1/10W J 220 Ω RRXAJR5Z0221

R1356 CHIP RES.(1608) 1/16W J 75 Ω or RRXGJR5Z0750

CHIP RES.(1608) 1/10W J 75 Ω RRXAJR5Z0750

R1392 CARBON RES. 1/6W G 180 Ω or RCX6GATZ0181

CARBON RES. 1/4W G 180 Ω RCX4GATZ0181

R1393 CARBON RES. 1/6W G 150 Ω or RCX6GATZ0151

CARBON RES. 1/4W G 150 Ω RCX4GATZ0151

R1394 CARBON RES. 1/6W G 150 Ω or RCX6GATZ0151

CARBON RES. 1/4W G 150 Ω RCX4GATZ0151

R1395 CARBON RES. 1/6W G 220 Ω or RCX6GATZ0221

20010719 1-15-4 E5542EL

Page 44

Ref. No. Description Part No.