Page 1

Mitsubishi Electric Industrial Robot

BFP-A3625

CR800-D/R/Q series controller

Preventive Maintenance Function

User’s Manual

Page 2

Page 3

Safety Precautions

Always read the following precautions and the separate "Safety

Manual" before starting use of the robot to learn the required

measures to be taken.

CAUTION All teaching work must be carried out by an operator who has received special

training. (This also applies to maintenance work with the power source turned

ON.)

Enforcement of safety training

CAUTION For teaching work, prepare a work plan related to the methods and procedures of

operating the robot, and to the measures to be taken when an error occurs or

when restarting. Carry out work following this plan. (This also applies to

maintenance work with the power source turned ON.)

Preparation of work plan

WARNING Prepare a device that allows operation to be stopped immediately during teaching

work. (This also applies to maintenance work with the power source turned ON.)

Setting of emergency stop switch

CAUTION During teaching work, place a sign indicating that teaching work is in progress on

the start switch, etc. (This also applies to maintenance work with the power source

turned ON.)

Indication of teaching work in progress

DANGER Provide a fence or enclosure during operation to prevent contact of the operator

and robot.

Installation of safety fence

CAUTION Establish a set signaling method to the related operators for starting work, and

follow this method.

Signaling of operation start

CAUTION As a principle turn the power OFF during maintenance work. Place a sign

indicating that maintenance work is in progress on the start switch, etc.

Indication of maintenance work in progress.

CAUTION Before starting work, inspect the robot, emergency stop switch and other related

devices, etc., and confirm that there are no errors.

Inspection before starting work

Page 4

The points of the precautions given in the separate "Safety Manual" are given below.

Refer to the actual "Safety Manual" for details.

DANGER When automatic operation of the robot is performed using multiple control devices

(GOT, programmable controller, push-button switch), the interlocking of operation

rights of the devices, etc. must be designed by the customer.

CAUTION Use the robot within the environment given in the specifications. Failure to do so

could lead to a drop or reliability or faults. (Temperature, humidity, atmosphere,

noise environment, etc.)

CAUTION Transport the robot with the designated transportation posture. Transporting the

robot in a non-designated posture could lead to personal injuries or faults from

dropping.

CAUTION Always use the robot installed on a secure table. Use in an instable posture could

lead to positional deviation and vibration.

CAUTION Wire the cable as far away from noise sources as possible. If placed near a noise

source, positional deviation or malfunction could occur.

CAUTION Do not apply excessive force on the connector or excessively bend the cable.

Failure to observe this could lead to contact defects or wire breakage.

CAUTION Set work masses, including hands, so as not to exceed the rated load or permitted

torque.

Exceeding either of these can cause an alarm or breakdown.

WARNING Securely install the hand and tool, and securely grasp the workpiece.

Failure to observe this could lead to personal injuries or damage if the object

comes off or flies off during operation.

WARNING Securely ground the robot and controller. Failure to observe this could lead to

malfunctioning by noise or to electric shock accidents.

CAUTION Indicate the operation state during robot operation. Failure to indicate the state

could lead to operators approaching the robot or to incorrect operation.

WARNING When carrying out teaching work in the robot's movement range, always secure

the priority right for the robot control. Failure to observe this could lead to personal

injuries or damage if the robot is started with external commands.

CAUTION Keep the jog speed as low as possible, and always watch the robot. Failure to do

so could lead to interference with the workpiece or peripheral devices.

CAUTION After editing the program, always confirm the operation with step operation before

starting automatic operation. Failure to do so could lead to interference with

peripheral devices because of programming mistakes, etc.

CAUTION Make sure that if the safety fence entrance door is opened during automatic

operation, the door is locked or that the robot will automatically stop. Failure to do

so could lead to personal injuries.

Page 5

CAUTION Never carry out modifications based on personal judgments, or use non-

designated maintenance parts.

Failure to observe this could lead to faults or failures.

WARNING When the robot arm has to be moved by hand from an external area, do not place

hands or fingers in the openings. Failure to observe this could lead to hands or

fingers catching depending on the posture.

CAUTION Do not stop the robot or apply emergency stop by turning the robot controller's

main power OFF. If the robot controller main power is turned OFF during

automatic operation, the robot accuracy could be adversely affected. Moreover, it

may interfere with the peripheral device by drop or move by inertia of the arm.

CAUTION Do not turn off the main power to the robot controller while rewriting the internal

information of the robot controller such as the program or parameters. If the main

power to the robot controller is turned off while in automatic operation or rewriting

the program or parameters, the internal information of the robot controller may be

damaged.

DANGER Do not connect the Handy GOT when using the GOT direct connection function of

this product. Failure to observe this may result in property damage or bodily injury

because the Handy GOT can automatically operate the robot regardless of

whether

the operation rights are enabled or not.

DANGER Do not connect the Handy GOT to a programmable controller when using an iQ

Platform compatible product with the CR800-R/CR800-Q controller. Failure to

observe this may result in property damage or bodily injury because the Handy

GOT can automatically operate the robot regardless of whether the operation

rights are enabled or not.

DANGER Do not remove the SSCNET III cable while power is supplied to the multiple CPU

system or the servo amplifier. Do not look directly at light emitted from the tip of

SSCNET III connectors or SSCNET III cables of the Motion CPU or the servo

amplifier. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as specified

in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

DANGER Do not remove the SSCNET III cable while power is supplied to the controller.

Do not look directly at light emitted from the tip of SSCNET III connectors or

SSCNET III cables. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as specified

in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

DANGER Attach the cap to the SSCNET III connector after disconnecting the SSCNET III

cable. If the cap is not attached, dirt or dust may adhere to the connector pins,

resulting in deterioration connector properties, and leading to malfunction.

Page 6

CAUTION Make sure there are no mistakes in the wiring. Connecting differently to the way

specified in the manual can result in errors, such as the emergency stop not being

released. In order to prevent errors occurring, please be sure to check that all

functions (such as the teaching box emergency stop, customer emergency stop,

and door switch) are working properly after the wiring setup is completed.

CAUTION Use the network equipments (personal computer, USB hub, LAN hub, etc)

confirmed by manufacturer. The thing unsuitable for the FA environment (related

with conformity, temperature or noise) exists in the equipments connected to USB.

When using network equipment, measures against the noise, such as measures

against EMI and the addition of the ferrite core, may be necessary. Please fully

confirm the operation by customer. Guarantee and maintenance of the equipment

on the market (usual office automation equipment) cannot be performed.

CAUTION To maintain the safety of the robot system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the

safety against unauthorized access via the Internet, take measures such as

installing a firewall.

Page 7

■ Revisions

Revision Date

Instruction Manual No.

Revision Details

BFP-A3625

• First print

2018-09-20

Page 8

This indicates an item for which incorrect handling could present imminent

danger of death or serious injury.

This indicates an item for which incorrect handling could present a danger of

death or serious injury.

This indicates an item for which incorrect handling could present a danger of

injury. It could also present a danger of just physical damage.

• No part of this manual may be reproduced by any means or in any form, without prior consent from

Mitsubishi.

• The details of this manual are subject to change without notice.

• The specification value is based on our standard test method.

• An effort has been made to make full descriptions in this manual. However, if any discrepancies or

unclear points are found, please contact your dealer.

• This specifications is original.

• Company names and product names described in this document are trademarks or registered

trademarks of each company.

• and TM are omitted in the text of this guide.

Copyright(C) 2018 MITSUBISHI ELECTRIC CORPORATION ALL RIGHTS RESERVED

R

Warning

Danger

Caution

Introduction

Thank you for purchasing the Mitsubishi industrial robot "MELFA Smart Plus Card/Card Pack Option".

This instruction manual explains the "Preventive Maintenance Function" that can be used with the MELFA

Smart Plus Card/Card Pack Option.

This product provides features that support maintenance and inspection so that the robot can be used for a

long time without trouble.

Efficient maintenance is supported though notification of the time of maintenance parts replacement or

overhaul based on the actual operating status of the robot.

Furthermore, due to the feature of estimating the parts replacement time or the recommended

maintenance time, this function can be used for decision making on the maintenance cycle.

To ensure correct usage of the product, always read through this manual before starting to use

"Preventive maintenance function".

For details of basic robot operation, refer to the separate "Instruction Manual / Detailed Explanations of

Functions and Operations".

Notation method in this document

Page 9

Contents

1. Before starting use ................................................................................................................................................................................................... 1

1.1 Contents of the instruction manual ........................................................................................................................................................... 1

1.2 Compatible products ......................................................................................................................................................................................... 2

1.3 Related manuals .................................................................................................................................................................................................. 3

1.4 Maintaining the robot ......................................................................................................................................................................................... 4

1.4.1 Type of maintenance and inspection ............................................................................................................................................... 4

1.4.2 Inspecting/replacing timing belt ........................................................................................................................................................... 5

1.4.3 Lubrication ....................................................................................................................................................................................................... 6

1.4.4 Replacing the battery ................................................................................................................................................................................ 7

1.4.5 About Overhaul ............................................................................................................................................................................................. 8

2. Basic specifications ................................................................................................................................................................................................. 9

2.1 Overview of basic specification of the preventive maintenance function .......................................................................... 9

2.1.1 Maintenance simulation ........................................................................................................................................................................... 10

2.1.2 Consumption degree calculation function ..................................................................................................................................... 12

2.1.3 Target models/target axes ..................................................................................................................................................................... 16

2.2 How to utilize the preventive maintenance function ........................................................................................................................ 18

3. Startup and initial settings .................................................................................................................................................................................... 20

3.1 Enabling the preventive maintenance function .................................................................................................................................. 21

3.2 Initial setting of the preventive maintenance function .................................................................................................................... 24

3.2.1 Setting how to notify .................................................................................................................................................................................. 24

3.2.2 Setting signals ............................................................................................................................................................................................... 25

3.3 Setting of maintenance simulation ............................................................................................................................................................ 26

4. Basic screen structure ............................................................................................................................................................................................ 30

5. Total score .................................................................................................................................................................................................................... 32

6. Consumption degree calculation function ................................................................................................................................................... 34

7. Operating information ............................................................................................................................................................................................. 37

8. Maintenance simulation ........................................................................................................................................................................................ 38

8.1 "1 Cycle" operation ............................................................................................................................................................................................. 40

8.2 Program operation .............................................................................................................................................................................................. 45

9. When consumption occurred ............................................................................................................................................................................. 50

9.1 Consumption Degree ........................................................................................................................................................................................ 50

9.1.1 Maintenance parts ...................................................................................................................................................................................... 50

9.1.2 Overhaul parts ............................................................................................................................................................................................... 51

9.1.3 Servo ON time ............................................................................................................................................................................................... 53

10. Maintenance ................................................................................................................................................................................................................ 54

10.1 Warning Pause ............................................................................................................................................................................................. 55

10.2 Maintenance Reset .................................................................................................................................................................................... 56

10.3 Backup and restore .................................................................................................................................................................................... 57

10.3.1 Backup (robot personal computer) .................................................................................................................................. 58

10.3.2 Restore (personal computer robot) ................................................................................................................................. 59

10.4 Maintenance Log ......................................................................................................................................................................................... 60

10.4.1 Maintenance Log screen ............................................................................................................................................................. 60

10.4.2 Data to be recorded in the maintenance log .................................................................................................................... 61

11. Batch management of maintenance information .................................................................................................................................... 62

11.1 Functional overview ................................................................................................................................................................................... 62

11.2 Output data ..................................................................................................................................................................................................... 63

11.3 Request ID (MelfaRXM.ocx) specified by RequestService ................................................................................................. 64

12. Robot (system) status variables ....................................................................................................................................................................... 66

12.1 Robot (system) status variable list .................................................................................................................................................... 66

Consumption degree calculation function .................................................................................................................................................. 66

MELFA Smart Plus ..................................................................................................................................................................................................... 68

12.2 Consumption degree calculation function ..................................................................................................................................... 69

12.2.1 Serial number ..................................................................................................................................................................................... 69

12.2.2 Operating information .................................................................................................................................................................... 71

12.2.3 Maintenance Log .............................................................................................................................................................................. 77

12.2.4 Consumption degree ...................................................................................................................................................................... 89

12.2.5 Consumption status ........................................................................................................................................................................ 98

12.2.6 Notification ........................................................................................................................................................................................... 106

Page 10

12.3 MELFA Smart Plus ..................................................................................................................................................................................... 112

12.3.1 MELFA Smart Plus card .............................................................................................................................................................. 112

13. Parameter ...................................................................................................................................................................................................................... 114

13.1 Common to preventive maintenance functions .......................................................................................................................... 114

13.2 Consumption degree calculation function ..................................................................................................................................... 115

13.2.1 Setting parameters .......................................................................................................................................................................... 115

13.2.2 Data acquisition parameter ........................................................................................................................................................ 116

13.2.3 Operation parameters ................................................................................................................................................................... 120

14. Dedicated input/output signals .......................................................................................................................................................................... 126

14.1 Consumption degree calculation function ..................................................................................................................................... 126

15. Troubleshooting ......................................................................................................................................................................................................... 130

15.1 Error number list .......................................................................................................................................................................................... 130

15.1.1 Common to preventive maintenance functions .............................................................................................................. 130

15.1.2 Consumption degree calculation function .......................................................................................................................... 131

15.1.3 MELFA Smart Plus card .............................................................................................................................................................. 134

Page 11

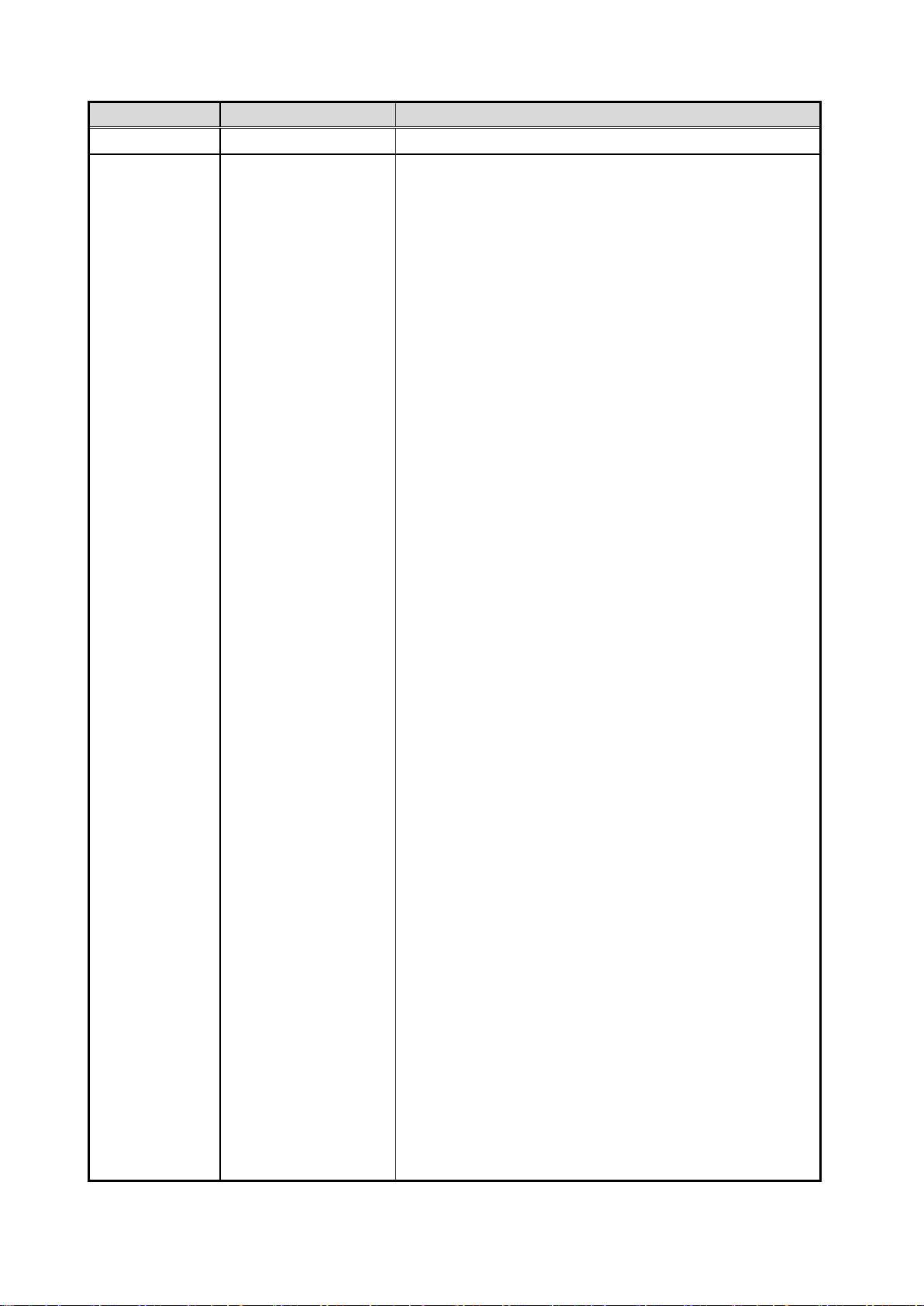

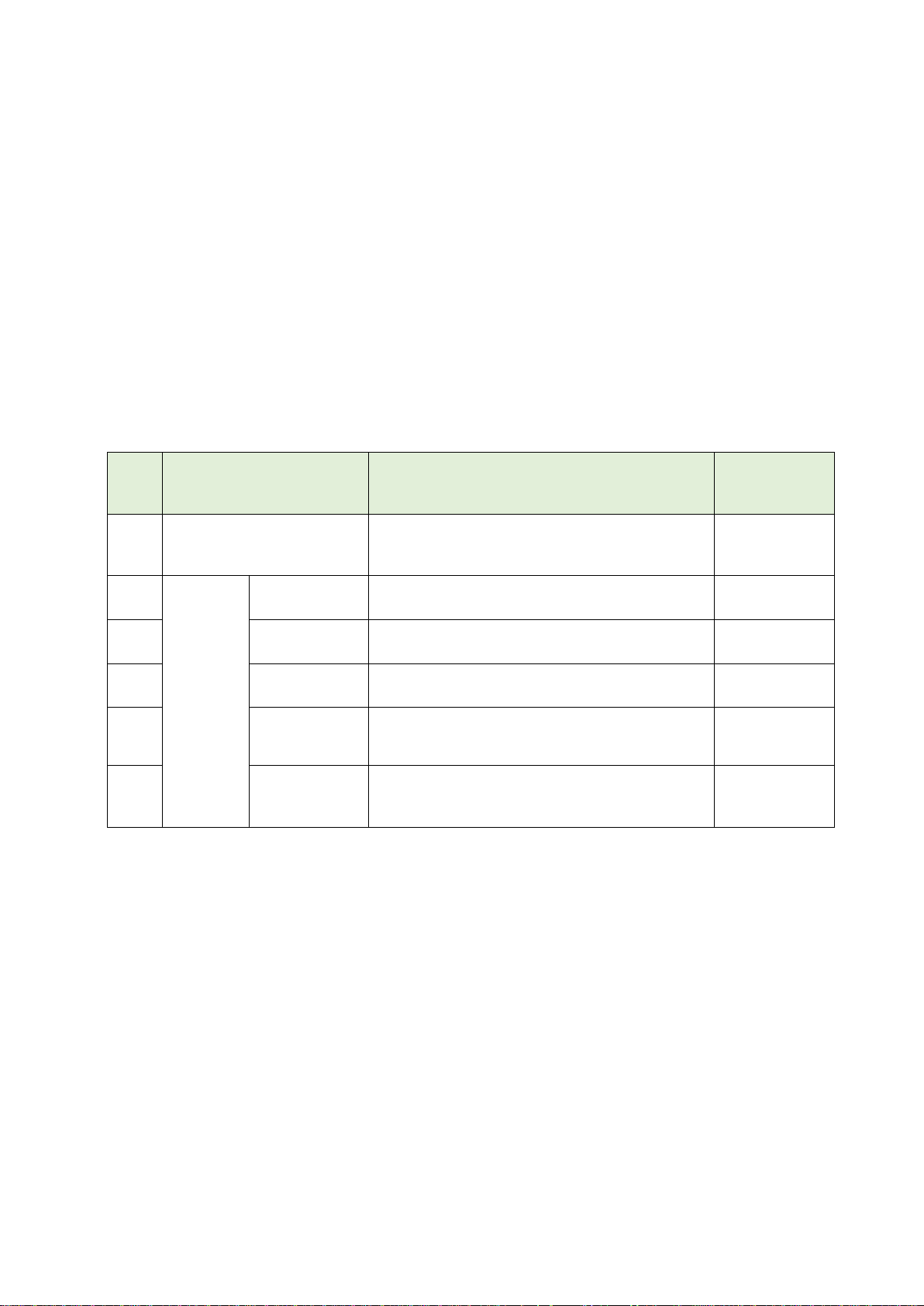

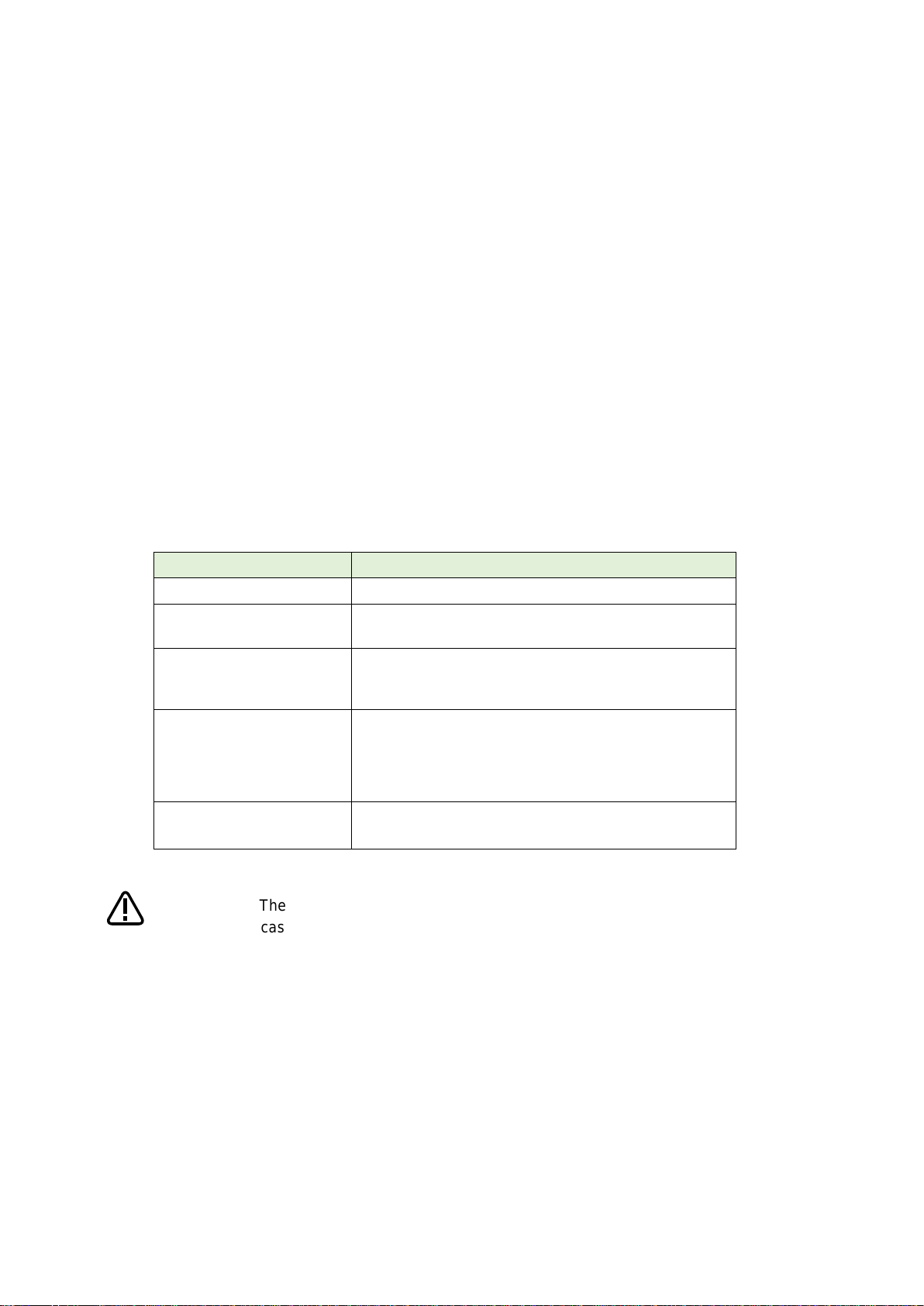

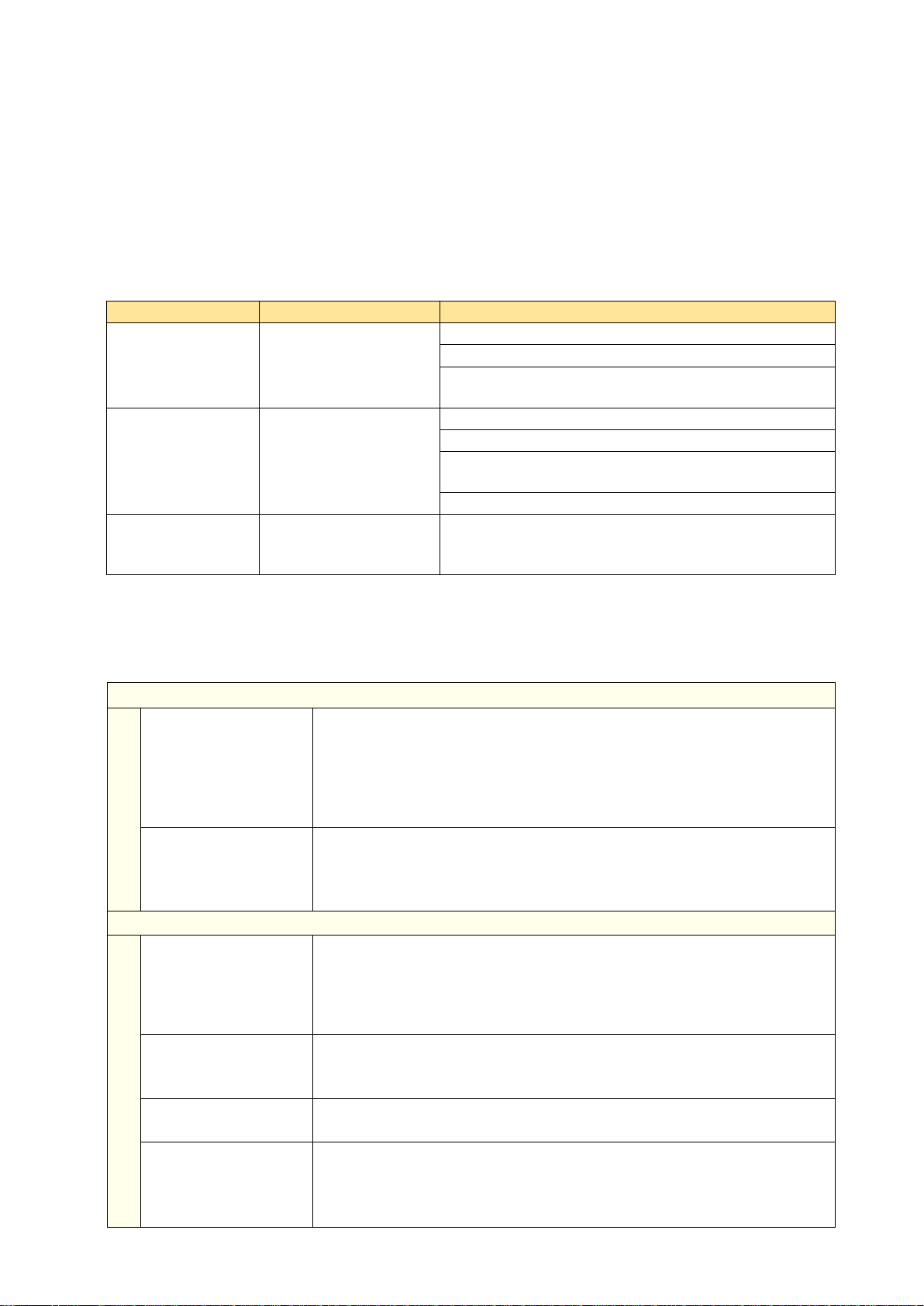

Chapter

Title

Description

1

Before starting use

Explains the structure of this manual, products compatible

with this function, related manuals, and

maintenance/inspection.

2

Basic specifications

Explains the specification of the preventive maintenance

function.

3

Startup and initial settings

Explains how to start the preventive maintenance function

and the initial setting method.

4

Basic screen structure

Each preventive maintenance function is explained using

examples of the RT ToolBox3 Preventive Maintenance

screens.

5

Total score

6

Consumption degree

calculation function

7

Operating information

8

Maintenance simulation

9

When consumption occurred

Explains actions to take when consumption is detected.

10

Maintenance

Explains pause of warning occurrence related to this

function and operation at the time of maintenance using

examples of the RT ToolBox3 Preventive Maintenance

screens.

11

Batch management of

maintenance information

Explains how to collectively manage maintenance

information of the entire production line with the host

system.

12

Robot (system) status

variables

Explains robot (system) status variables, parameters, and

dedicated input/output signals related to the preventive

maintenance function.

13

Parameter

14

Dedicated input/output signals

15

Troubleshooting

Explains error details related to the preventive

maintenance function and actions to take.

1. Before starting use

1.1 Contents of the instruction manual

This function can be used with the RT ToolBox3 Preventive Maintenance screen, parameters, status

variables, and dedicated input/output signals.

In this manual, the following structure is used to explain how the preventive maintenance function using

examples of the RT ToolBox3 Preventive Maintenance screens.

For functions and operation methods provided in the standard robot controller, refer to the "Instruction

Manual" supplied for the robot controller.

Before starting use 1

Page 12

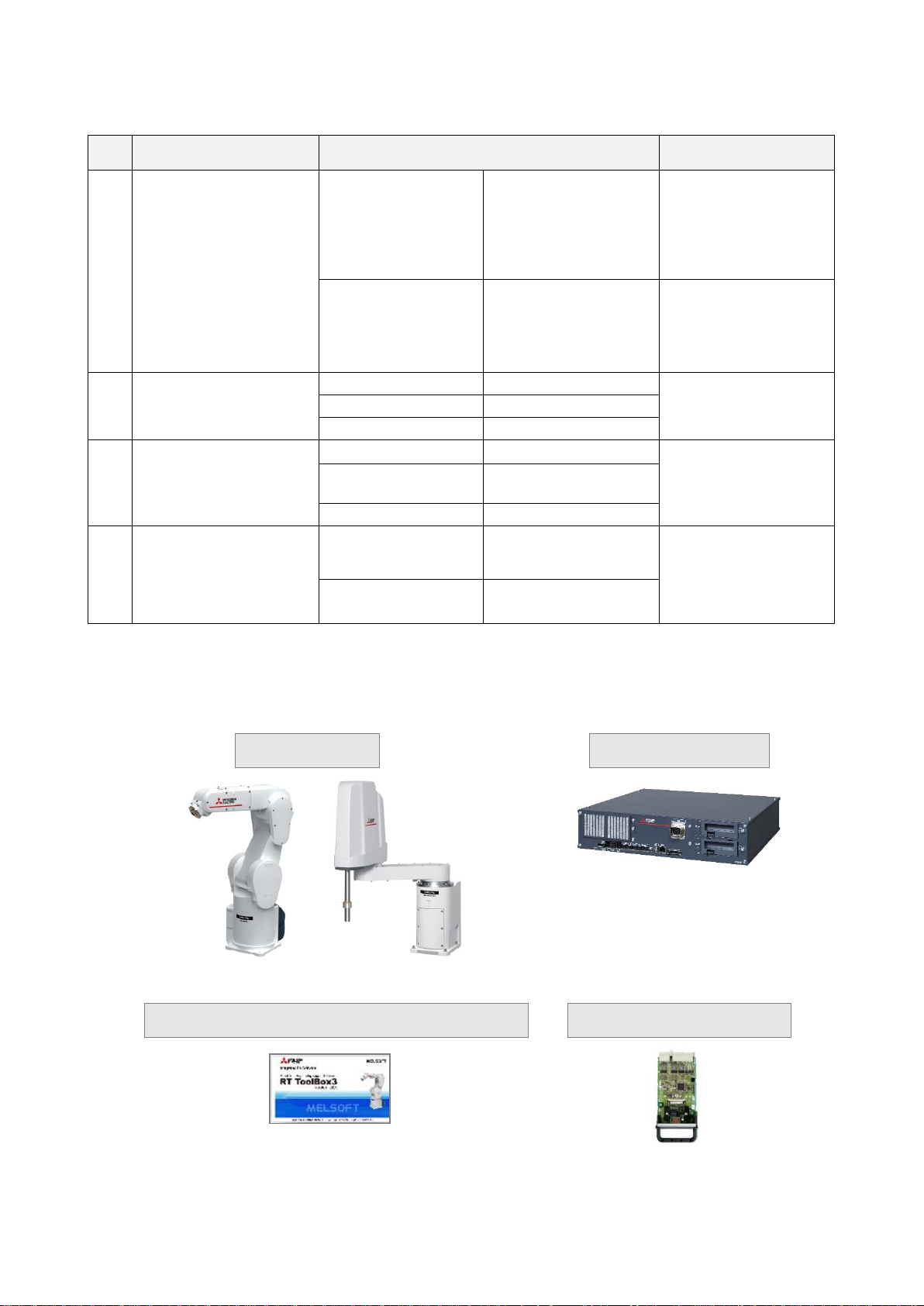

1.2 Compatible products

Item

Description

Remarks

1)

Robot arm

Vertical multi-joint

type RV-FR series

RV-2FR series,

RV-4FR series,

RV-7FR series,

RV-13FR series,

RV-20FR series

Standard model

6-axis robot only

Horizontal multi-joint

type RH-FR series

RH-3FRH series,

RH-6FRH series,

RH-12FRH series,

RH-20FRH series,

RH-3FRHR series

Standard model only

2)

Robot controller

CR800-D

Ver.A3 or later

CR800-R

Ver.A3 or later

CR800-Q

Ver.A3 or later

3)

Robot total engineering

support software

(Note 1)

RT ToolBox3

Ver.1.30G or later

Robot program

language:

MELFA-BASIC VI

RT ToolBox3 mini

(Note 2)

Ver.1.30G or later

RT ToolBox3 Pro

Ver.1.30G or later

4)

Function expansion card

MELFA Smart Plus

Card Pack

(Note 3)

A type (2F-DQ510)

AB type (2F-DQ520)

Either one

MELFA Smart Plus

Card

(Note 3)

A type (2F-DQ511)

Vertical multi-joint type

Horizontal multi-joint type

2) Robot controller

CR800 series

3) Robot total engineering support software

4) Function expansion card

1) Robot arm

RT ToolBox3

The following products are compatible with this function.

Note 1) Must be purchased separately.

Note 2) When RT ToolBox3 mini is used, simulation on RT ToolBox3 cannot be used.

Note 3) In this instruction manual, "MELFA Smart Plus card" may be used as the general term for MELFA

Smart Plus card pack and MELFA Smart Plus card.

Before starting use 2

Page 13

Manual name

Description

Robot Arm Setup & Maintenance

Explains the procedures required to operate the robot arm

(unpacking, transportation, installation, confirmation of operation),

and the maintenance and inspection procedures.

Detailed explanations of functions

and operations

Explains details on the functions and operations such as each

function and operation, commands used in the program,

connection with the external input/output device, and parameters,

etc.

CR800 Series Controller Instruction

Manual

Troubleshooting

Explains the causes and remedies to be taken when an error

occurs. Explanations are given for each error No.

RT ToolBox3 / RT ToolBox3 mini

User's Manual

The operation manuals for the robot total engineering support

software "RT ToolBox3", "RT ToolBox3 mini", "RT ToolBox3 Pro"

(Option).

MELFA Smart Plus User’s Manual

Describes the installation method and setting method of MELFA

Smart Plus card (Option).

Communication Middleware Manual

(MelfaRXM.ocx)

The operation manual for ActiveX controller "MelfaRXM.ocx" that

communicates with the robot controller.

Ethernet Function Instruction

Manual

The operation manual for the Ethernet function that enables

Ethernet communication with PCs using the TCP/IP protocol.

Also, explains the SLMP connection.

1.3 Related manuals

The following manuals are related to the preventive maintenance function.

Before starting use 3

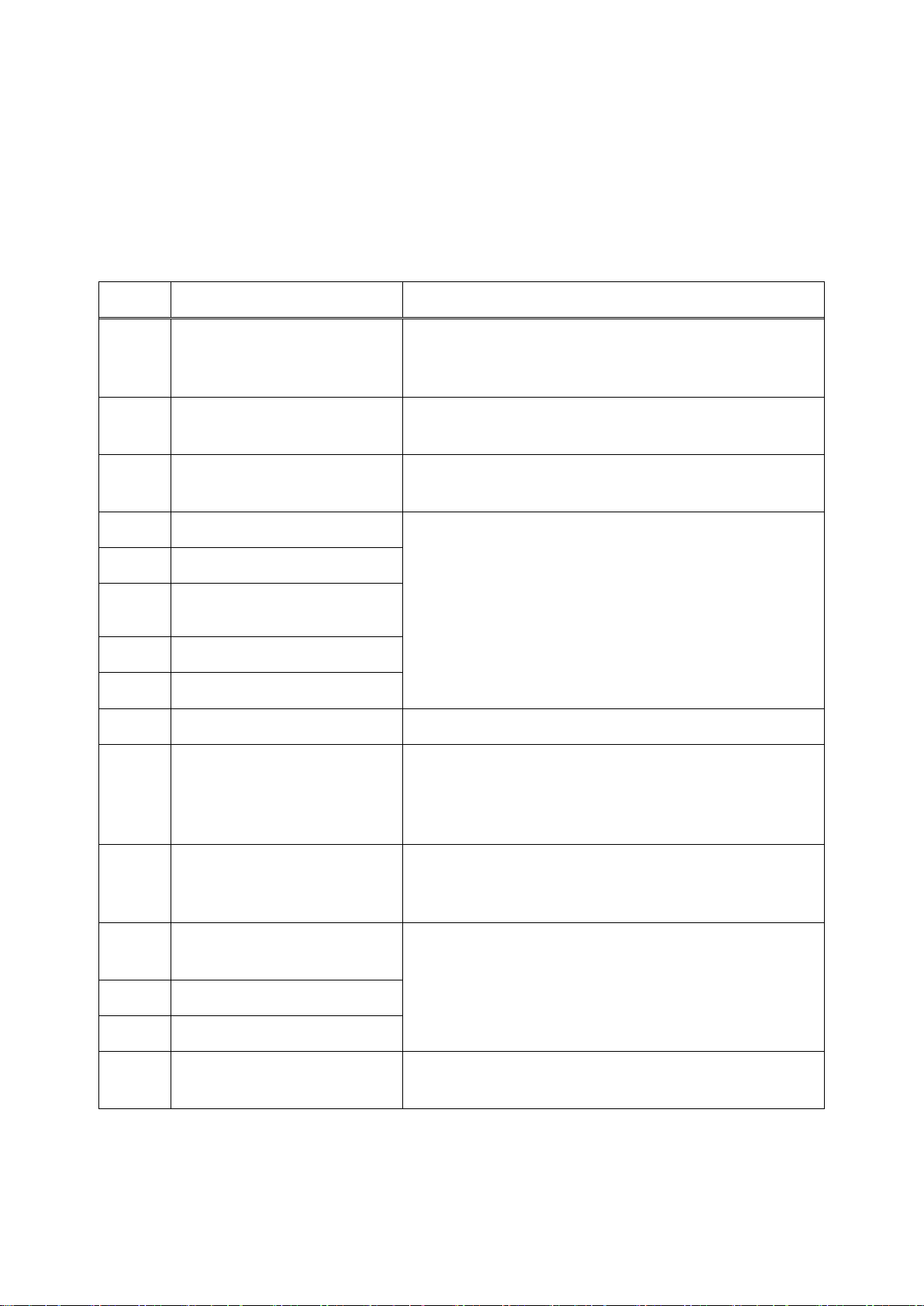

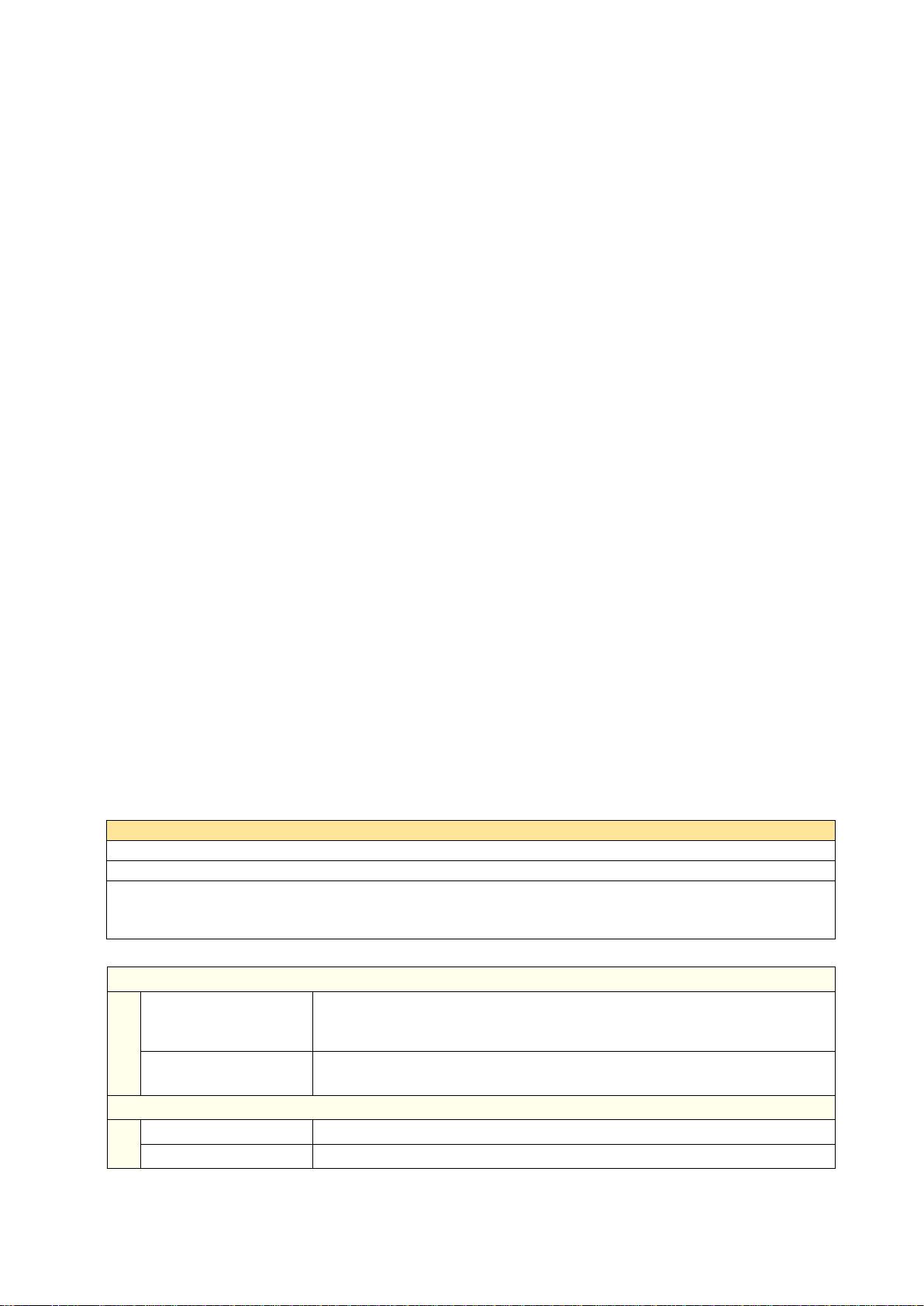

Page 14

1.4 Maintaining the robot

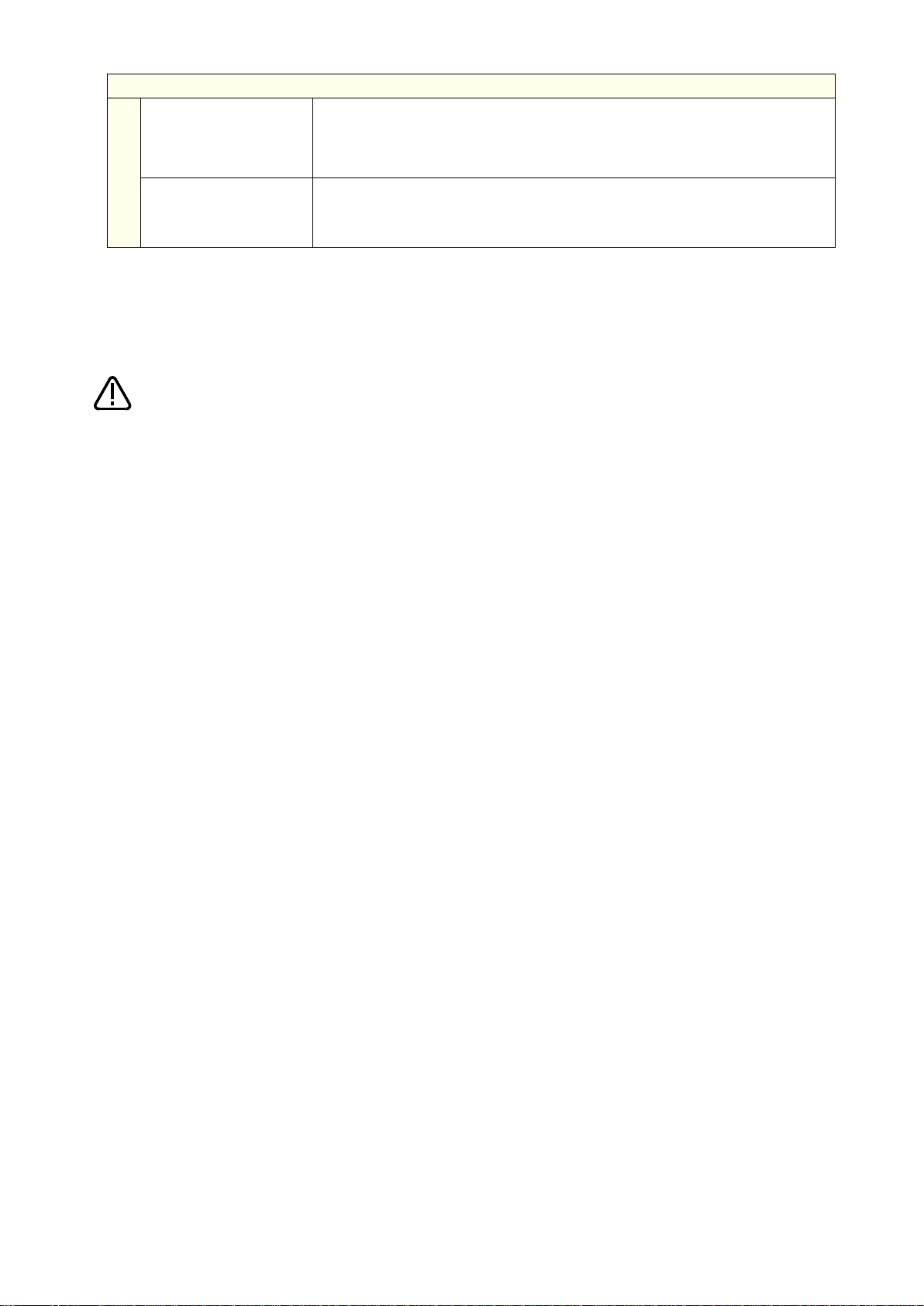

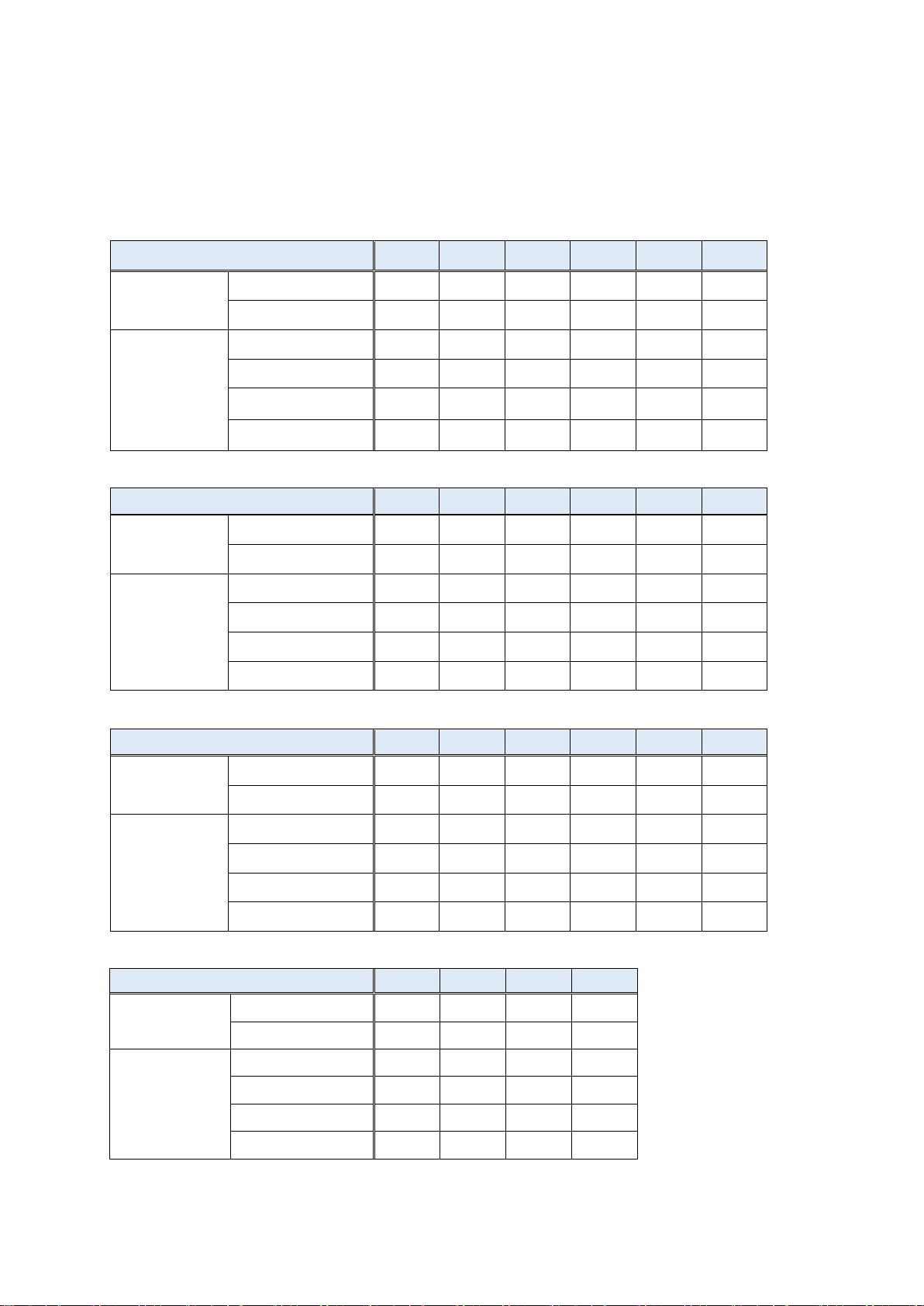

No.

Type of inspection and

maintenance works

Description

Operating

time

(Note1)

1

Daily inspection

Inspection works to be performed every day

before starting operation for the safe use of the

robot.

2

Periodic

inspection

Monthly

inspection

Inspection and maintenance works to be

performed every month.

Every 300 hr

3

6-month

inspection

Inspection and maintenance works to be

performed every 6 months.

Every 1,800 hr

4

2-year

inspection

Inspection and maintenance works to be

performed every 2 years.

Every 7,200 hr

5

Battery

replacement

Replacement of the backup battery of the robot.

Replace the battery every year regardless of

the operating hours.

6

Lubrication

Lubrication of each axis of the robot.

Refer to "1.4.3 Lubrication" for the lubrication

schedule.

This function supports maintenance and inspection so that the robot can be used for a long time without

trouble.

Efficient maintenance is supported though notification of the time of maintenance parts replacement or

overhaul based on the actual operating status of the robot. However, in order to prevent failure

beforehand and ensure prolonged service life and safety of the robot, we strongly recommend periodic

maintenance and inspection be carried out.

This chapter explains maintenance and inspection of parts that are subject to this function.

For details on robot inspection items, implementation time of periodic inspection, calculation of operating

time, and maintenance and inspection procedures, refer to "5. Maintenance and Inspection" in the

separate volume "Instruction Manual/Robot Arm Setup & Maintenance".

1.4.1 Type of maintenance and inspection

There are two types of maintenance and inspection, daily inspection and periodic inspection.

The following table shows the type of maintenance and inspection.

Type of maintenance and inspection

Note 1) Robot operating hours are based on 15 hours/day, 20 days/month. If the robot operates 8

hours/day, the operation hours per month are about half the above condition. Therefore,

monthly inspection shall be performed once every two months.

Before starting use 4

Page 15

The timing belt can be replaced by customers; however, if adjustment is not

appropriate, it could lead to failure of related parts. When the timing belt needs to be

replaced, we recommend that you contact our Mitsubishi Service Department to

request replacement.

If you need to remove the timing belt for repair and others, measure the tension

before removing the belt.

When installing the belt, make sure to install with the same degree of tension as

before removal.

Failure to do so could shorten the service life of the belt and related parts.

Caution

Caution

1.4.2 Inspecting/replacing timing belt

This robot uses a timing belt for the drive conveyance system.

Compared to gears and chains, the timing belt does not require lubrication and has a low noise. However,

if the belt usage method and tension adjustment are inadequate, the life could drop and noise could be

generated. depending on the robot working conditions, elongation will occur gradually over a long time.

The tension must be confirmed during the periodic inspection.

The inspection/replacement method of the timing belt differs depending on the model. Perform

inspection/replacement by referring to "5. Maintenance and Inspection" in the separate volume

"Instruction Manual/Robot Arm Setup & Maintenance".

Timing belt replacement period

The timing belt life is greatly affected by the robot working conditions, so a set time cannot be given.

However, if the following symptoms occur, replace the belt.

1) The belt tension value becomes less than the guideline value.

2) Position mismatch or gear teeth skipping occurs.

3) Cracks or wear occurs on the belt.

4) The tooth bottom of the belt is worn out and the core is exposed.

Before starting use 5

Page 16

1.4.3 Lubrication

Robot type

Lubrication interval

RV-2FR / RV-2FRL

All axes: 6,000 hr

RV-4FR / RV-4FRL

RV-7FR / RV-7FRL

All axes: 24,000 hr

RV-7FRLL

RV-13FR / RV-13FRL

RV-20FR

J1 axis to J3 axis: 20,000 hr

J4 axis to J6 axis: 24,000 hr

RH-3FRH series

RH-6FRH series

RH-12FRH series

RH-20FRH series

J1 axis to J2 axis: 24,000 hr

Shaft part (ball screw / spline): 2,000 km/travel

RH-3FRHR series

J1 axis to J2 axis: 6,000 hr

Shaft part: 2,000 km/travel

• The lubrication intervals are the cumulative value of operation at maximum speed. In

case of intermittent operation or slow specified speed, the lubrication interval can be

• Since the lubrication interval changes depending on the operation status of the

• Avoid excessive lubrication as it could cause grease leakage. Also, lubrication shall

Caution

Grease is used for the reduction gears of the robot. Grease has various roles, such as suppressing of

wear of reduction gears, removal of frictional heat, and prevention of burn-in.

If you use a robot for a long period of time, the grease will deteriorate due to loads during operation

(operating speed, operation frequency, heat generation condition, and others.). Degraded grease loses

initial performance and adversely affects machine service life.

Therefore, periodic replacement of grease is essential.

Lubrication intervals, lubrication locations, lubrication specifications and lubrication methods for grease

are different for each model.

Lubricate the robot before the lubrication interval shown in the following table elapses.

In addition, before the servo ON time reaches the specified hours (24,000 hours), overhaul work to

replace the grease inside the robot is necessary.

If it is unavoidable that overhaul cannot be performed at the specified interval, lubricate at the lubrication

intervals shown in the following table.

For details on overhaul, refer to "1.4.5 About Overhaul".

Refer to "5. Maintenance and Inspection" in the separate volume "Instruction manual/Robot Arm Setup &

Maintenance" for lubrication locations, lubrication specifications, and lubrication methods.

Lubrication interval

extended accordingly.

robot, make decisions as necessary so that grease will not run out.

be performed a maximum of three times. For maintenance after that, overhaul work

is required to replace the grease inside.

Before starting use 6

Page 17

1.4.4 Replacing the battery

An absolute encoder is used for the position detector, so while power of controller is turned off the

position must be saved by the backup battery. These batteries are installed when the robot is shipped

from the factory, but as these are consumable parts, they must be replaced periodically by the customer.

The guideline for replacing the battery is one year, but this will differ according to the robot's usage state.

When a battery-related error occurred, replace the battery of the robot arm.

The robot arm battery replacement method differs depending on the model. Refer to "5. Maintenance and

Inspection" in the separate volume "Instruction Manual/Robot Arm Setup & Maintenance".

Before starting use 7

Page 18

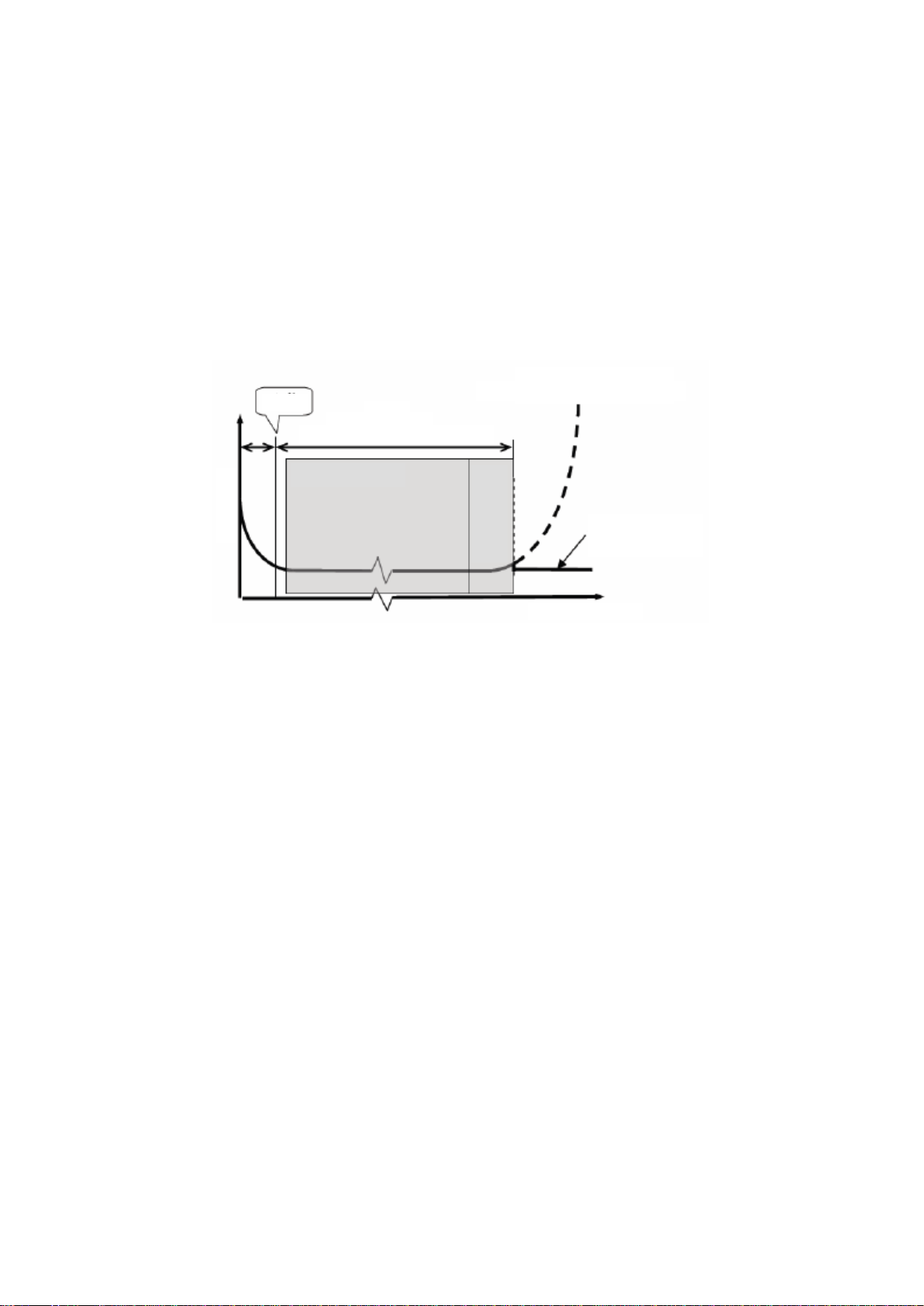

1.4.5 About Overhaul

Predetermined time period

If overhaul is not performed

If overhaul is performed

Servo-on time

Failure rate

λ

Periodic inspection

Overhaul

Shipment

Robots which have been in operation for an extended period of time can suffer from wear and other forms

of deterioration. In regard to such robots, we define overhaul as an operation to replace parts running out

of specified service life or other parts which have been damaged, so that the robots may be put back in

shape for continued use.

As a rule of thumb, it is recommended that overhaul be carried out before the total amount of servo-on

time reaches the specified time (24,000 hours for the robot arm and 36,000 hours for the controller).

(Refer to the figure below.)

However, the degree of the equipment's wear and deterioration presumably varies depending on their

operating conditions. Especially for operation with high load and frequency, the maintenance cycle may

be shorter.

Before starting use 8

Page 19

Function

Overview

1

Maintenance

simulation

Using the real machine or simulations on RT ToolBox3, this function

estimates the parts replacement time or the recommended maintenance

time when specific motion patterns are repeated.

This can be used for pre-study of maintenance cycles or parts-friendly

operation verification of robots.

(Refer to "8 Maintenance simulation".)

2

Consumption

degree calculation

function

This function calculates the consumption degree [%] of robot components

based on the actual operating status (motor speed, load status, and

others), and displays/notifies the period up to maintenance/inspection or

overhaul.

This supports efficient maintenance through notification of maintenance

timing and deciding the maintenance priority order.

<Target parts>

Maintenance parts : Grease, timing belt

Overhaul parts : Reduction gear, bearing, ball screw, ball spline

(Refer to "6 Consumption degree calculation function ".)

The consumption degree of the robot arm is saved in the robot controller, thus it is

necessary to use the correct combination of the robot arm and robot controller.

To replace the robot arm or robot controller only, perform backup/restore of

preventive maintenance information to migrate the preventive maintenance

information.

(For backup/restore, refer to "

When using this function by upgrading from a non-compatible controller software

version to a compatible controller software version, the consumption degree during

the period of the non-compatible software version is not added up, thus the result of

consumption degree calculation function cannot be the correct value.

Caution

2. Basic specifications

2.1 Overview of basic specification of the preventive maintenance function

The preventive maintenance function roughly consists of the following two functions.

The maintenance simulation can be checked on the preventive maintenance function screen of

RT ToolBox3.

Information on preventive maintenance by the consumption degree calculation function can be checked

on the Preventive Maintenance screen, status variables, and parameters of RT ToolBox3. The following

features are also available.

• Allows preventive maintenance information to be output to the host system of your production line and

collectively managed.

(Compatible with MelfaRXM.ocx and SLMP)

• If you are using a CR800 series Ver.A3 or later robot controller, by enabling this function using the

MELFA Smart Plus card, this function can be used by taking over the previous consumption degree

even during operation of the robot. (For compatible cards, refer to "1.2 Compatible products , 4) Function

extension card".)

10.3 Backup and restore".)

Basic specifications 9

Page 20

2.1.1 Maintenance simulation

Output data

Number of years up to the time of replenishing grease (for each joint axis)

Number of years up to the time of timing belt replacement (for each joint axis)

Number of years up to the recommended maintenance time for overhaul parts (for each joint axis)

(Of reduction gear, bearing, ball screw, and ball spline, the part for which there is the shortest number of years of

maintenance)

Estimation method

Real machine (online)

· Program operation

· Estimates the number of years from the current consumption degree of the

robot.

Simulation

· 1 Cycle operation, Program operation

· Estimates the number of years from the brand new robot state.

Usage

Usage

RT ToolBox3 Preventive Maintenance screen (Refer to 8.Maintenance simulation)

Setting item

· Operation hours per day, operation days per month

Using the real machine (online) or simulations on RT ToolBox3, this function estimates the parts

replacement time or the recommended maintenance time when specific motion patterns (robot

programs) are repeated.

Maintenance simulation estimates the following items.

1) Number of years up to the time of replenishing grease

2) Number of years up to the time of timing belt replacement

3) Recommended number of years up to the maintenance time for overhauling parts

(Of reduction gear, bearing, ball screw, and ball spline, the part for which there is the shortest

number of years of maintenance)

There are two types of estimation methods, "Program operation" and "1 Cycle operation".

For the real machine (online), estimation is possible using "Program operation", and for simulation, in

addition to "Program operation", "1 Cycle operation" can also be used.

•1 Cycle operation: Specify the start line and end line of the robot program to estimate the parts

replacement/ the recommended maintenance time based on its 1 cycle operation

pattern.

Because 1 cycle can be accurately specified on a robot program, it is possible to

more accurately estimate the number of years when 1 cycle operation is repeated

than when using Program operation.

The estimation result of the number of years is from the brand new robot state.

• Program operation: While running a robot program automatically, the parts replacement/ the parts

replacement/ the recommended maintenance time is estimated based on the

operation pattern from when the start button is pressed to when the end button is

pressed.

Accurate 1 cycle (start line and end line) cannot be specified but Program

operation is used when it is difficult to specify 1 cycle on the program, such as

when the program uses external signals.

The estimation result for a real machine (online) is the number of years from the

current consumption degree of the robot.

The estimation result for simulation is the number of years from the brand new

robot state.

* For models and joint axes subject to this function, refer to "2.1.3 Target models/target axes".

Basic specifications 10

Page 21

When RT ToolBox3 mini is used, simulation on RT ToolBox3 cannot be used.

The recommended number of years up to the replacement/maintenance time output

by this function is the value calculated when the specified operation is repeated.

Also, the result may vary depending on the performance of the personal computer

used and the load status. The actual time changes depending on the actual

operating status or load status of the robot.

Use as reference values for planning of maintenance and inspection.

Correctly set hand work conditions (weight, center of gravity, shape) actually used. If

the settings differ from the actual robot settings, the consumption degree cannot be

calculated correctly.

Use parameters HNDDAT* and WRKDAT* to set hand work conditions and use

Loadset commands to specify hand work conditions.

For details of hand work condition setting, refer to the separate "Instruction

Manual/Detailed Explanations of Functions and Operations".

Do not use M_TIMER(8) while programming. This function uses M_TIMER(8) for the

estimation of parts replacement time and maintenance time. If M_TIMER(8) is used

while programming, the number of years of replacement and maintenance cannot be

estimated accurately.

After changing to M_TIMER(1) to M_TIMER(7), perform the maintenance simulation.

Caution

Note on 1 Cycle operation

(1) For command line that waits for signals to be input or robot status changes, use a comment to

set the stop time.

For a program waiting for input of signal from outside or change of the robot status variable, comment

out that portion and instead set a stop time (assumed) and specify the start line and end line including

that line.

(2) Use a program with no infinite loop.

A program that executes an infinite loop does not give the correct calculation result.

Check that the program is not an infinite loop in a FOR or GOTO statement.

(3) Include all instructions required for 1 cycle in the line selection range.

When selecting the start line and end line of a program, specify line numbers in such a way that all

instructions such as jump destinations of Gosub or hand word settings required for the robot to

perform 1 cycle operation are included in the range.

When sending/receiving external signals, set the stop time as a substitute for the signal

sending/receiving time and specify the line numbers including that line.

(4) About robot program "ESTPROG.prg"

When executing 1 cycle operation, "ESTPROG" is displayed as the robot program on the operating

panel.

This is a program that is automatically generated when 1 cycle operation is executed. After 1 cycle

operation, you can delete this program if it is unnecessary.

Basic specifications 11

Page 22

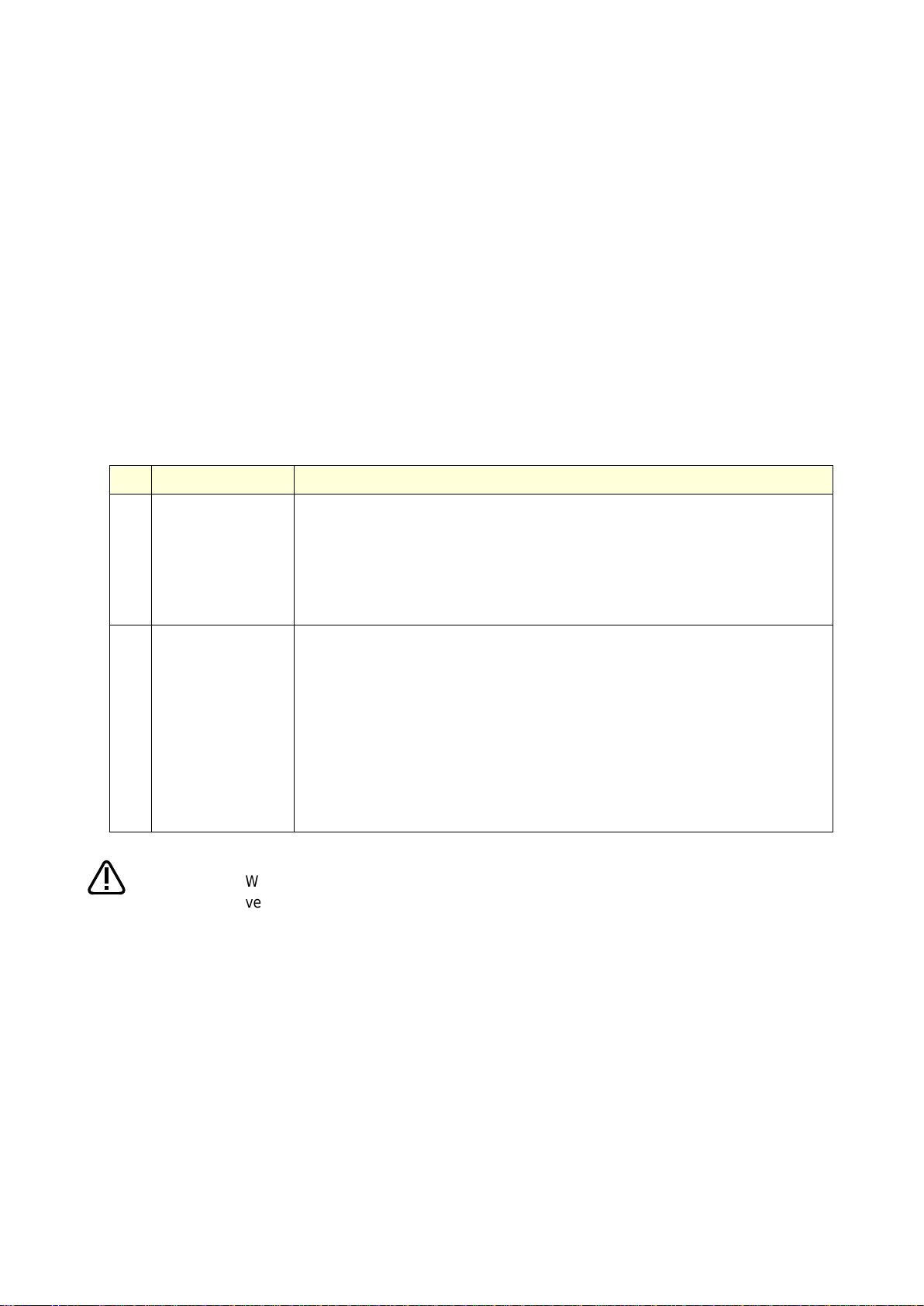

2.1.2 Consumption degree calculation function

Target parts

Output data

Maintenance parts

Grease

Timing belt

Grease consumption degree [%] (for each joint axis)

Timing Belt consumption degree [%] (for each joint axis)

Total Score (Consumption Degree [%], Up to Maintenance

[h])*1

Overhaul parts

Reduction gear

Bearing

Ball screw/ball spline

Gear consumption degree [%] (for each joint axis)

Bearing consumption degree [%] (for each joint axis)

Ball Screw/Ball Spline consumption degree [%] (for each joint

axis)

Total Score (Consumption Degree [%])*2

Operating Information

-

Servo ON Time [h], Operation Time [h], Actual Operation

Time [h], Power ON Time [h], Servo ON Count [times], Motor

Cumulative Rotation Count [rotation] (for each joint axis)

Information confirmation

Information

· Consumption Degree: See above

· Up to Maintenance: See above (Total Score Maintenance Parts)

· Operating Information: See above

· [Consumption Status]: Existence of wear in each target part

· Maintenance Log: Log data under Maintenance Reset (date & time, parts, joint

axes)

Check method

RT ToolBox3 Preventive Maintenance screen (Refer to 5. Total score,

6 Consumption degree calculation function)

[Parameters] (Refer to 13.2.2 Data acquisition parameter.)

[Status Variable] (Refer to 12.2 Consumption degree calculation function)

Setting/operation

Setting item

· Notification Day setting: Warning Remaining Number of Days, Operation Time of

a Day, Notification Interval

· How to Notify setting (maintenance parts): Warning Occurrence, Signal Output

· How to Notify setting (overhaul parts): Warning Occurrence, Signal Output

· ["I/O Signals assignment"]

Setting method

RT ToolBox3 Preventive Maintenance screen (Refer to 3.2.1.Setting how to

notify)

[Parameters] (Refer to 13.2.1 Setting parameters.)

Operation item

· Maintenance Reset (reset of consumption degree)

· [Notification Pause]

Operation method

RT ToolBox3 Preventive Maintenance screen

(Refer to 10.1 Warning Pause, 10.2 Maintenance Reset)

[Parameters] (Refer to 13.2.3 Operation parameters.)

[I/O Signal]*1(Refer to 14 Dedicated input/output signals.)

This function calculates the consumption degree [%] of robot components based on the actual operating

status (motor speed, load status, and others), and calculates the period up to maintenance/inspection or

overhaul.

Consumption Degree [%] is calculated based on the recommended maintenance time of each part as 100

[%].

Beside consumption degree [%] of each robot component, the Total Score (Consumption Degree [%] and

Up to Maintenance) of maintenance parts (grease, timing belt), and the Total Score (Consumption

Degree [%]) of overhaul parts (reduction gear, bearing, ball screw, ball spline) are calculated, respectively

and are displayed on the comprehensive evaluation screen.

*1: Of the maintenance parts (grease, timing belt), the Consumption Degree [%] and Up to Maintenance

[h] of the part (joint axis) having the least remaining time are used.

*2: Of the overhaul parts (reduction gear, bearing, ball screw, ball spline), the Consumption Degree [%] of

the part (joint axis) having the least up to maintenance time is used.

Basic specifications 12

Page 23

Notification

Notification content

· [Consumption Status] (maintenance parts): Output for each part, for each joint

axis

· [Consumption Status] (overhaul parts): Output for each part, for each joint axis

· Servo ON Time*2

Notification method

RT ToolBox3 Preventive Maintenance screen

*3

(3.2.1.Setting how to notify)

Warning Occurrence

*1

(Refer to 3.2.1.Setting how to notify)

Signal Output

*1

(Refer to 3.2.2 Setting signals.)

Caution

[About calculation of the consumption degree]

• The consumption degree of each part is calculated on the assumption that the robot

• The consumption degree of each part is used as a reference value for supporting the

maintenance and inspection schedule calculated based on the robot operating status.

• Irrespective of the consumption degree, carry out daily inspection and periodic

• When the servo ON time exceeds the specified time (24,000 hours) or the

consumption degree exceeds the warning remaining number of days, we recommend

• Reset operation of the consumption degree of each part must not be executed except

• For the total score of maintenance parts and overhaul parts, the value of the part

• The remaining time is a reference value calculated based on the operating status of

*1 Setting is required.

*2 Notification of overhaul intervals by servo ON time follows "How to notify the consumption degree of

overhaul parts".

*3 A maintenance message is displayed.

* For models and joint axes subject to this function, refer to "2.1.3 Target models/target axes".

is used in the environment (ambient temperature, humidity) within the specification

scope described in the instruction manual (standard specifications).

It does not guarantee the service life of the robot.

maintenance and inspection described in the instruction manual (Standard

Specifications Manual, Robot Arm Setup & Maintenance).

you perform overhaul of the robot arm.

during maintenance or part replacement.

among all joint axes having the least remaining time (Up to Maintenance) to the

recommended maintenance time is output, respectively. For that reason, the

consumption degree of the total score could be smaller than the maximum

consumption degree value of each part.

the robot from the previous maintenance time. Also, the remaining time is when you

use the robot in the same way as before.

Therefore, if operation is changed, the remaining time may increase or decrease.

Basic specifications 13

Page 24

Correctly set hand work conditions (weight, center of gravity, shape) actually used.

If the settings differ from the actual robot settings, the consumption degree cannot

be calculated correctly.

Use parameters HNDDAT* and WRKDAT* to set hand work conditions and use

Loadset commands to specify hand work conditions.

For details of hand work condition setting, refer to the separate "Instruction

Manual/Detailed Explanations of Functions and Operations".

Depending on the operating status at startup, correct results may not be obtained

at the beginning due to fluctuations until sufficient data is accumulated.

When the preventive maintenance function is valid, the maintenance forecast is not

displayed and warning signals of maintenance forecast are not output.

information is reset by the preventive maintenance function or maintenance

forecast, the information in the other function is reset as well.

[About the robot controller]

• When using this function by upgrading from a non-compatible controller software

version to a compatible controller software version, the consumption degree during

the period of the non-compatible software version is not added up, thus the result of

• The consumption degree of the robot arm is saved in the robot controller, thus it is

Caution

Caution

Caution

Caution

consumption degree calculation function cannot be the correct value.

necessary to use the correct combination of the robot arm and robot controller.

To replace the robot arm or robot controller only, perform backup/restore of

preventive maintenance information to migrate the preventive maintenance

information.

(For backup/restore, refer to "10.3 Backup and restore".)

When the

Basic specifications 14

Page 25

<< MEMO >>

Basic specifications 15

Page 26

2.1.3 Target models/target axes

Joint axis

J1 axis

J2 axis

J3 axis

J4 axis

J5 axis

J6 axis

Maintenance

parts

Grease

Timing belt

Overhaul parts

Reduction gear

Bearing

Ball screw

- - - - -

-

Ball spline

- - - - -

-

Joint axis

J1 axis

J2 axis

J3 axis

J4 axis

J5 axis

J6 axis

Maintenance

parts

Grease

Timing belt

-

Overhaul parts

Reduction gear

Bearing

-

Ball screw

- - - - -

-

Ball spline

- - - - -

-

Joint axis

J1 axis

J2 axis

J3 axis

J4 axis

J5 axis

J6 axis

Maintenance

parts

Grease

Timing belt

- - -

Overhaul parts

Reduction gear

Bearing

- - -

Ball screw

- - - - -

-

Ball spline

- - - - -

-

Joint axis

J1 axis

J2 axis

J3 axis

J4 axis

Maintenance

parts

Grease

-

Timing belt

-

-

Overhaul parts

Reduction gear

-

-

Bearing

-

-

*1

Ball screw

-

-

*2

-

Ball spline

- - -

2

(1) Consumption degree calculation function/maintenance simulation

The table below shows the joint axes for which target parts of the consumption degree calculation

function of each robot type are used.

(Compatible robots are the standard models only.)

(: Uses target parts, -: Not use target parts)

(1) RV-2FR / RV-2FRL

(2) RV-4FR / RV-4FRL / RV-7FR / RV-7FRL

Basic specifications 16

(3) RV-13FR / RV-13FRL / RV-20FR / RV-7FRLL

(4) RH-3FRH / RH-6FRH / RH-12FRH / RH-20FRH

*1: For RH-3FRH, J3 axis does not use a bearing, shown as (-).

*2: RH-3FRH uses a ball screw/spline but this function assumes that the J3 axis uses a ball screw and

the J4 axis uses a ball spline.

Page 27

Joint axis

J1axis

J2 axis

J3 axis

J4 axis

Maintenance

parts

Grease

-

Timing belt

Overhaul parts

Reduction gear

-

-

Bearing

-

Ball screw

-

-

*3

-

Ball spline

- - -

*3

(5) RH-3FRHR

*3:The RH-3FRHR series uses a ball screw/spline but this function assumes that the J3 axis uses a ball screw and

the J4 axis uses a ball spline.

Basic specifications 17

Page 28

2.2 How to utilize the preventive maintenance function

The preventive maintenance function assumes the following usages.

(1) At system startup

It is possible to estimate the replacement time of maintenance parts or the recommended maintenance

time of overhaul parts when an operation pattern of the robot is repeated using "Maintenance Simulation".

This function can be used for planning a maintenance schedule when starting up a system.

(For details, refer to "8 Maintenance simulation".)

(2) System operation time (at periodic inspection)

You can check the consumption degree using the "Consumption degree calculation function".

Because the consumption degree calculation function calculates the consumption degree based on the

actual robot operation status (motor speed, loads, and others), you can check the current robot

consumption degree and remaining time to replacement/maintenance.

This function is useful for reviewing or planning a maintenance schedule.

(For function details, refer to "6 Consumption degree calculation function".)

(3) System operation time (when a part is consumed)

As a result of the remaining time to replacement/maintenance calculated by the consumption degree

calculation function, if the set remaining time is reached, that effect is notified by the method you set.

Check detailed information and arrange or carry out maintenance.

By carrying out appropriate maintenance, it is possible to prevent the production line from stopping due

to a sudden failure of the robot and reduce down time.

(For function details, refer to "6 Consumption degree calculation function".)

Basic specifications 18

Page 29

<< MEMO >>

Basic specifications 19

Page 30

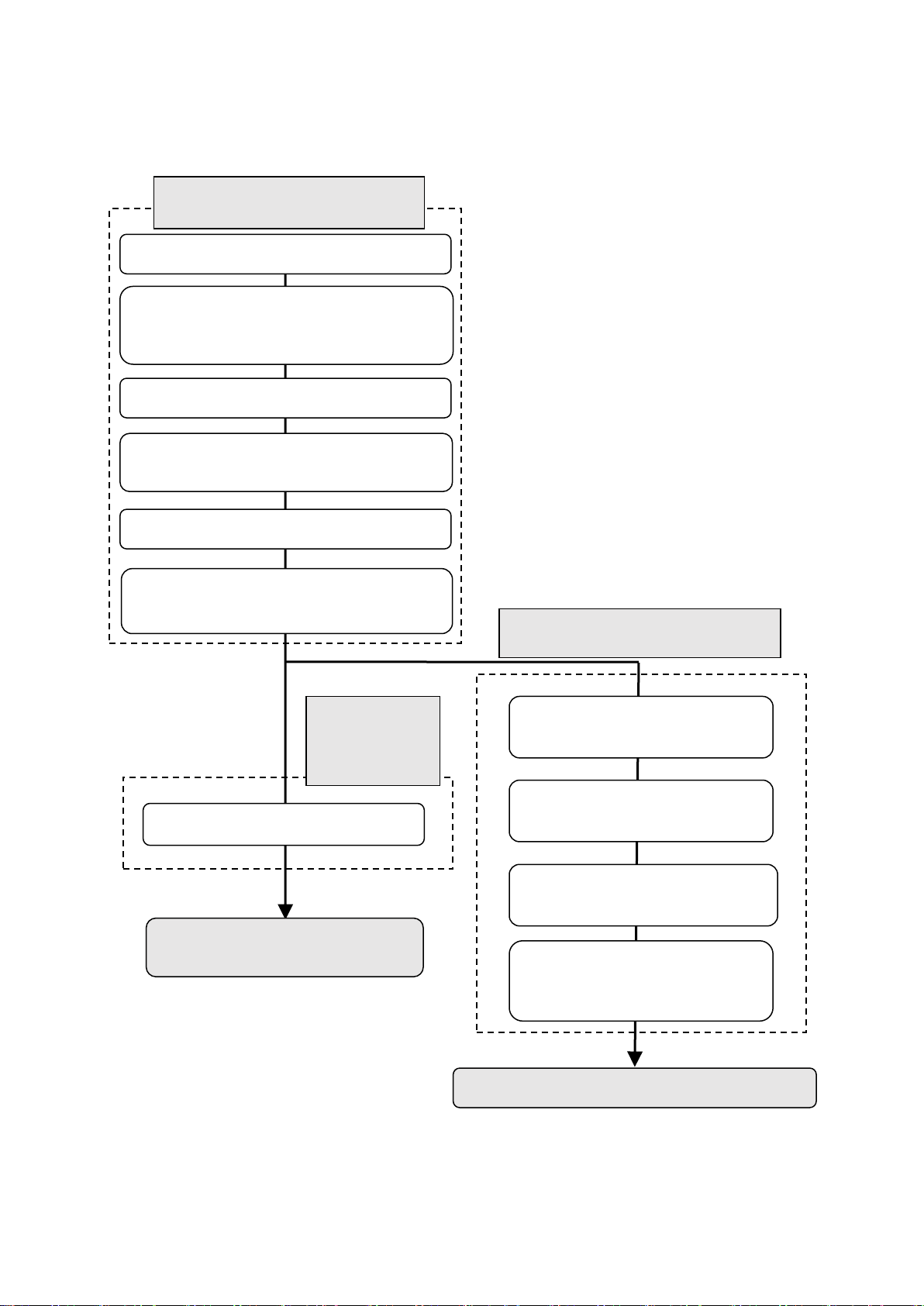

3. Startup and initial settings

7. Set the notification method.

Now you can use the preventive

4. Start the preventive

simulation mode.

1. Get the function code of the

"MELFA Smart Plus Card".

4. Set the MELFA Smart Plus enable

parameter.

3. Turn on the power of the robot controller.

2. Insert the "MELFA Smart Plus Card" or

controller.

1. Turn off the power of the robot controller.

2. Enter the function code of the

"MELFA Smart Plus Card".

5. Restart the robot controller.

3. Set the MELFA Smart Plus

enable parameter.

Initial setting of

function (3.2)

enance function (3.1)

Maintenance simulation can be used.

Setting of maintenance simulation

(3.3)

6. Check if the preventive maintenance

function is in enable state.

• Consumption degree calculation

Maintenance simulation

(RT ToolBox3 simulation)

This section describes the procedure to start the preventive maintenance function.

Validation of the preventive maint

"MELFA Smart Plus Card Pack" into the

the preventive

maintenance

• Maintenance simulation (real

machine (online))

maintenance function in

Startup and initial settings 20

Page 31

Turn off the power of the robot controller.

Switch

Earth leakage circuit breaker

1) Turn off the switch of the earth leakage

circuit breaker.

1) Turns off the power of the robot CPU system.

breaker.

1

CR800-D type

CR800-R/Q type

Insert the MELFA Smart Plus card into the robot controller.

Insert the "MELFA Smart Plus Card" or the "MELFA Smart Plus Card Pack" in an available

2

Robot controller

CR800 series

SLOT1

SLOT2

Interface cover

Interface cover

Connection connector

Removal lever

(lower side)

LED

Handle

(Note)

"1.2 Compatible products 4) Function

expansion card".

Install only one MELFA Smart Plus card.

If multiple MELFA Smart Plus cards have been installed, the LED will not flash and an

error (L3782) will occur. For error details, refer to "

".

Caution

3.1 Enabling the preventive maintenance function

Insert the "MELFA Smart Plus Card" into the robot controller and set parameters.

2) Turn off the switch of the earth leakage circuit

slot on the robot controller. (Note: For compatible cards, refer to "1.2 Compatible products C

ompatible products, 4) Function extension card".)

1) Lightly hold the interface cover removal lever to pull out the interface cover.

2) Hold the handle of the MELFA Smart Plus card and insert it into SLOT1 or SLOT2.

At that time, insert in such a way that both ends of the card fit into the groove of the slot (SLOT1

or SLOT2 in the illustration).

3) Insert the connection connector all the way to the end until the removal lever clicks into place to

be locked.

Removal lever

MELFA Smart Plus card or

MELFA Smart Plus card

pack (Note)

For compatible cards, refer to

15.1.3. MELFA Smart Plus card

Startup and initial settings 21

Page 32

Earth leakage circuit breaker

Turn on the power of the robot controller.

Switch

1) Turn on the switch of the earth leakage circuit

breaker.

2) The POWER lamp of the robot controller lights.

1) Turn on the switch of the earth leakage circuit

3) Next, turn on the power of the robot CPU system.

3

CR800-D type

CR800-R/Q type

* When the robot controller starts up, the LED of the MELFA Smart Plus card flashes.

Selecting the MELFA Smart Plus function and setting the preventive

maintenance function enable parameters.

4

With a robot controller where the "MELFA Smart Plus Card" has been inserted, set the MELFA

breaker.

2) The POWER lamp of the robot controller lights.

• MELFA Smart Plus Card ... Flashes in red.

• MELFA Smart Plus Card Pack ... Flashes in blue.

Smart Plus function selection parameter "SMART+1" and the preventive maintenance function

enable parameter "PMENA".

For this operation, use the teaching pendant or RT ToolBox3.

* Be aware that parameters to be set are different between the "MELFA Smart Plus Card" and

"MELFA Smart Plus Card Pack". For parameters, refer to "13. Parameter".

[When using the MELFA Smart Plus card]

1) Change the parameter "SMART+1" value to [4].

2) Change the parameter "PMENA" value to [1].

[When using the MELFA Smart Plus card pack]

1) Change the parameter "PMENA" value to [1].

Startup and initial settings 22

Page 33

Restart the robot controller.

5

1) Turn off the switch of the earth leakage circuit breaker.

2) Turn on the switch of the earth leakage circuit breaker.

1) Turns off the power of the robot CPU system.

CR800-D type

CR800-R/Q type

Check that the preventive maintenance function is enabled.

6

1) When the MELFA Smart Plus card is used, the LED of the MELFA Smart Plus card flashes

RT ToolBox3

project tree

Preventive Maintenance

Maintenance

2) Turn off the switch of the earth leakage circuit breaker.

3) Turn on the switch of the earth leakage circuit breaker.

4) After the POWER lamp of the robot controller lights, turn on the power of the robot

CPU system.

green.

When the MELFA Smart Plus card pack is used, the LED flashes blue.

2) Check that the preventive maintenance function has been enabled.

• For the teaching pendant

Check that the "MSPPMENA" parameter is set to [1].

• For RT ToolBox3

Connect RT ToolBox3 to the robot controller and start a project from "Online"

Click [Online] - [Maintenance] to expand the project tree and check that "Preventive

Maintenance" is displayed.

Startup and initial settings 23

Page 34

3.2 Initial setting of the preventive maintenance function

Set the notification method.

7

[Setting] - [Synthesis] screen

1) From the RT ToolBox3 project tree, double-click [Online] - [Maintenance] - [Preventive

the [Setting] - [Synthesis] screen appears.

4) Writing

1) Consumption

calculation

2) Notification day

3) Notification

interval

Set how to notify when consumption of parts is detected.

Specify the notification method (presence of warning/signal output, notification day) when the warnings

occurr.

If you have not set the notification method, upon starting the preventive maintenance function, the

[Setting] - [Synthesis] screen appears.

[Note] In the default setting, notification is disabled. Make sure to set according to your environment.

3.2.1 Setting how to notify

Maintenance].

2) From the preventive maintenance tree, click [Setting] - [Synthesis].

* If you have not set the notification method, upon clicking [Preventive Maintenance],

degree

Preventive maintenance becomes available after setting the notification method.

1) Consumption degree notification method:

Set how to notify consumption of maintenance parts and overhaul parts. You can select Warning

Occurrence or Signal Output, or both.

Warning Occurrence ... A warning occurs and the error number and error message are displayed

according to the situation.

Signal Output ... The status can be checked with dedicated output signals.

(Setting of signal numbers are required. Refer to "3.2.2 Setting signals ".)

2) Consumption degree notification day:

Warning Remaining Number of Days: Set the number of remaining days for warning to occur.

Operation Time of a Day: Set the number of hours of operation of the robot per day.

3) Consumption degree notification interval: Set the interval of notification of warning.

4) Write: Writes setting items on the robot controller.

Startup and initial settings 24

Page 35

1) From the RT ToolBox3 project tree, double-click [Online] - [Maintenance] - [Preventive

set in the parameters are 0 to 255, 2000 to 5071, 6000 to 8047, and 10000 to 18191.

Preventive Maintenance Signal screen

4) IODATA setting

4) IODATA setting screen

5) Writing

3.2.2 Setting signals

Set signal numbers when you wish to use signal input/output to implement notification when consumption

or parts is detected, reset the consumption degree, or pause warning occurrence/signal output.

For dedicated input/output signals of the preventive maintenance function, refer to "14 Dedicated

input/output signals".

Maintenance].

2) From the Preventive Maintenance tree, click [Setting] - [Signal].

3) Enter the signal number for the item to be set.

4) When setting an axis bit pattern for reset/pause, click "IODATA Setting". When IODATA Setting

screen appears, set necessary information and click "Write".

5) After changing the parameter values, click the Write button to write them to the robot controller.

Note 1) Set the signal numbers according to the system to be used. The range of values that can be

(Note 1)

Startup and initial settings 25

Page 36

3.3 Setting of maintenance simulation

Get the function code of the MELFA Smart Plus card.

1

1) Use the RT ToolBox3 connected to the robot controller where the MELFA Smart Plus card and

First, get the function code from the robot controller where the MELFA Smart Plus card and

function" is completed).

[When using the maintenance simulation on a personal computer connected to the real machine]

3) When you click the "Get function code" button, the function code of the "MELFA Smart Plus Card"

2) Parameter list

3) MSPCODE

Parameter List screen

4) Write down the function code in a memo.

In order to use "Maintenance Simulation" for the simulation of RT ToolBox3, the function code and

parameter of the MELFA Smart Plus card need to be set to RT ToolBox3.

This section explains the procedure for setting the function code of the MELFA Smart Plus card to RT

Toolbox3, which is not connected to the robot controller where the MELFA Smart Plus card has been

installed.

(For maintenance simulation, refer to "8. Maintenance simulation".)

preventive maintenance function have been enabled ("3.1 Enabling the preventive maintenance

preventive maintenance function have been enabled.

2) From the RT ToolBox3 project tree, select [Parameter List].

3) Enter "MSPCODE" for the parameter name on the Parameter List screen.

4) The function code (24 alphanumeric characters) of the "MELFA Smart Plus Card" is displayed;

write it down in a memo.

*It is possible to read the "MSPCODE" parameter with the teaching pendant.

1) Select [Option] from the [Workspace] tab of RT ToolBox3.

2) From the left tree on the Option screen, select MELFA Smart Plus.

is displayed in the "Function code" field. (See the screen on the next page.)

* Now you can use the maintenance simulation with a personal computer connected to the real

Startup and initial settings 26

machine.

Page 37

Set the function code of the MELFA Smart Plus card.

2

1) Start RT ToolBox3 that performs the maintenance simulation. At that time, click the right button of

Next, enter the function code obtained in Step 1 to the RT ToolBox3 that performs the maintenance

simulation.

2) Option

3) MELFA Smart Plus

Option screen

5) Setting

Set the preventive maintenance function enable parameter.

3

Set the parameter to enable preventive maintenance.

PMENA

Parameter List screen

Set the "PMENA"

the mouse on the desktop icon of RT ToolBox3 and select "Implement as administrator" from the

displayed menu.

2) Select [Option] from the [Workspace] tab of RT ToolBox3.

3) From the left tree on the Option screen, select MELFA Smart Plus.

4) Enter the MELFA Smart Plus card function code obtained in Step 1 to the "Function code" field.

5) Press the Set button.

6) Restart RT ToolBox3.

1) Open the workspace that performs the maintenance simulation. Open the project.

2) Open the parameter list of the project that performs the maintenance simulation.

3) Set the "PMENA" preventive maintenance function parameter to [1: Enable].

parameter for

each project.

Startup and initial settings 27

Page 38

Check that the preventive maintenance function is enabled.

4

1) Change the operation mode to <Simulation>.

If parameter setting in Step 3 is performed using <Simulation>, start up Simulation once again.

Preventive Maintenance

Maintenance

(The "PMENA" parameter requires rebooting.)

2) From the project tree, expand [Maintenance] and check that [Preventive Maintenance] is

displayed.

Startup and initial settings 28

Page 39

<< MEMO >>

Startup and initial settings 29

Page 40

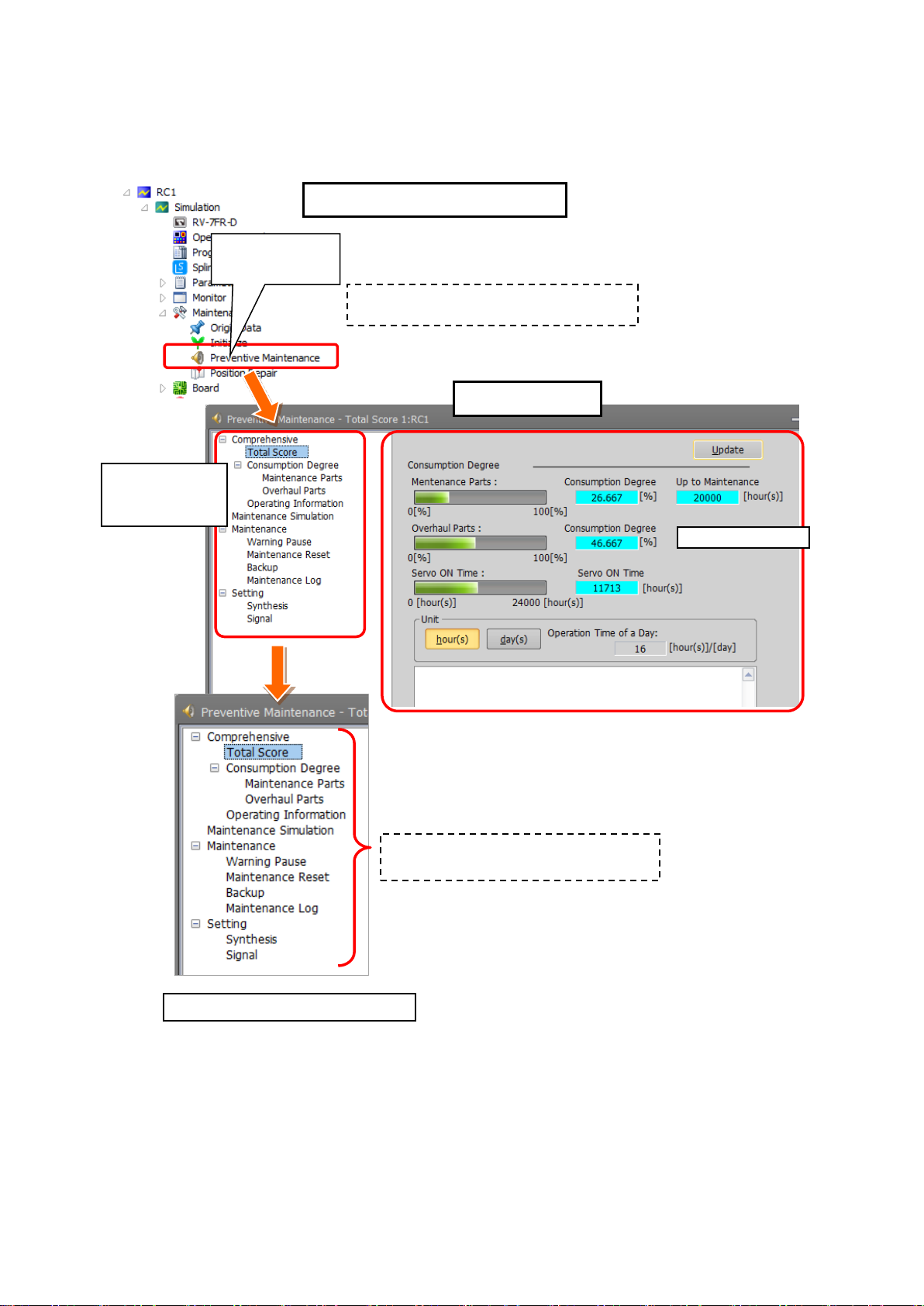

4. Basic screen structure

RT ToolBox3 project tree

1) Preventive

Maintenance

(1) Total score

Preventive

Preventive maintenance function tree

[Preventive Maintenance] is displayed

under [Maintenance] of the project tree.

on the right side changes.

(2) Consumption degree calculation

Main screen

The "Total Score" screen is displayed first when starting the preventive maintenance function.

This screen displays the total evaluation result of the consumption degree calculation function.

maintenance

function tree

1) From the RT ToolBox3 project tree, when you double-click [Maintenance] - [Preventive Maintenance], the

preventive maintenance function starts and the Total Score screen appears.

2) In the Total Score screen, the preventive maintenance function tree is displayed on the left side and the main

screen on the right side.

3) When you click the + mark in the preventive maintenance function tree, menus of the preventive maintenance

function appear.

4) When you click an item on the preventive maintenance function tree, the main screen on the right changes.

Basic screen structure 30

When you click an item, the main screen

(3) Operating information

(4) Maintenance simulation

(5) Maintenance

(6) Setting

Page 41

(1) Total score

The screen that is displayed first when starting the preventive maintenance function.

This screen displays the total evaluation result of the consumption degree calculation function, and

maintenance messages.

For details, refer to "5 Total score".

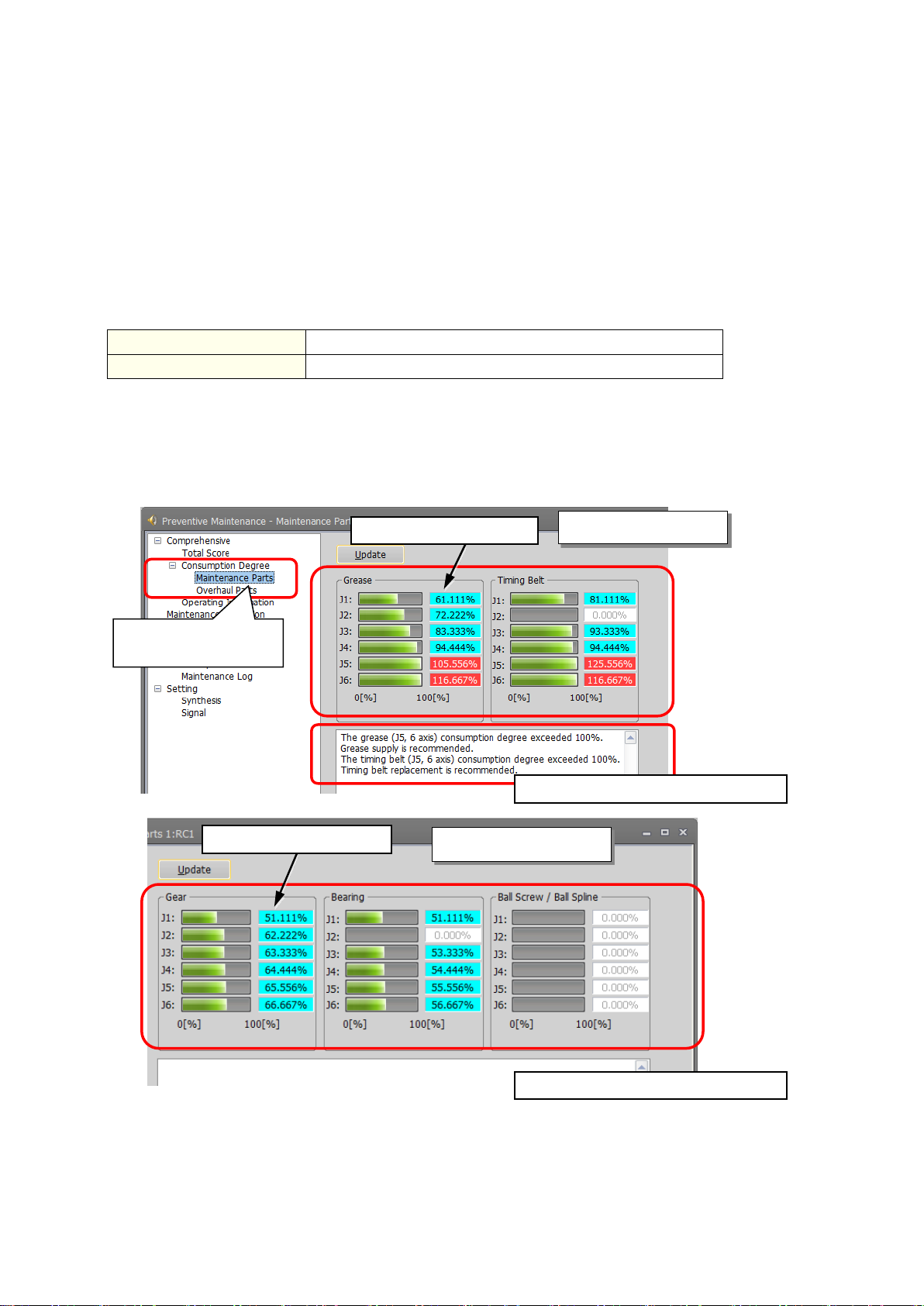

(2) Consumption degree calculation

The screen indicates the consumption degree of each part and each joint axis of maintenance parts and

overhaul parts calculated by the consumption degree calculation function.

For details, refer to "6 Consumption degree calculation function".

(3) Operating information

The screen that displays the integration time and accumulation count from the time when the previous

overhaul was carried out.

• Integration Time [hours]: Power ON Time, Servo ON Time, Operation Time, Actual Operation Time

• Accumulation Count [times] : Servo ON Count, Motor Cumulative Rotation Count

For details, refer to "7 Operating information".

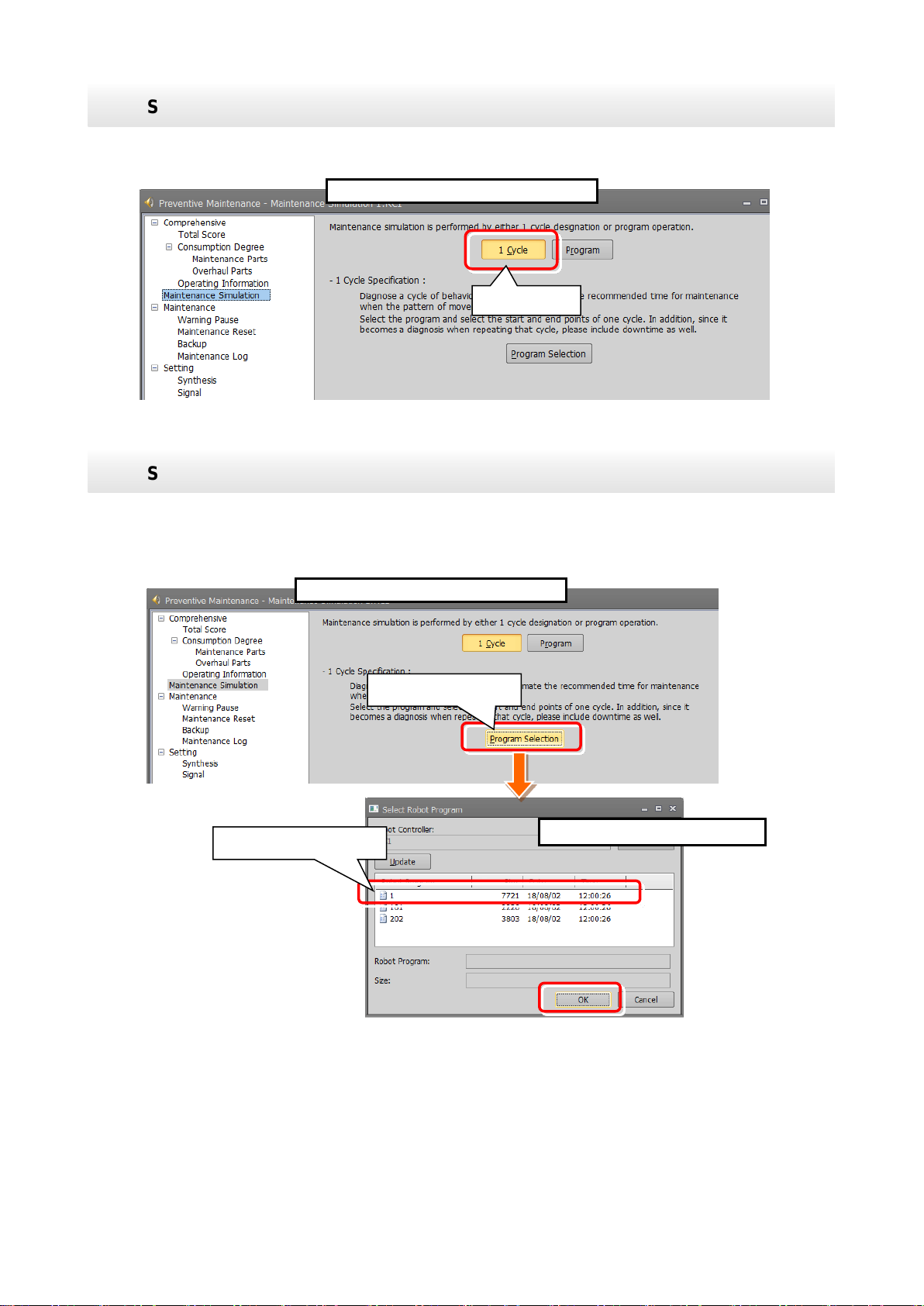

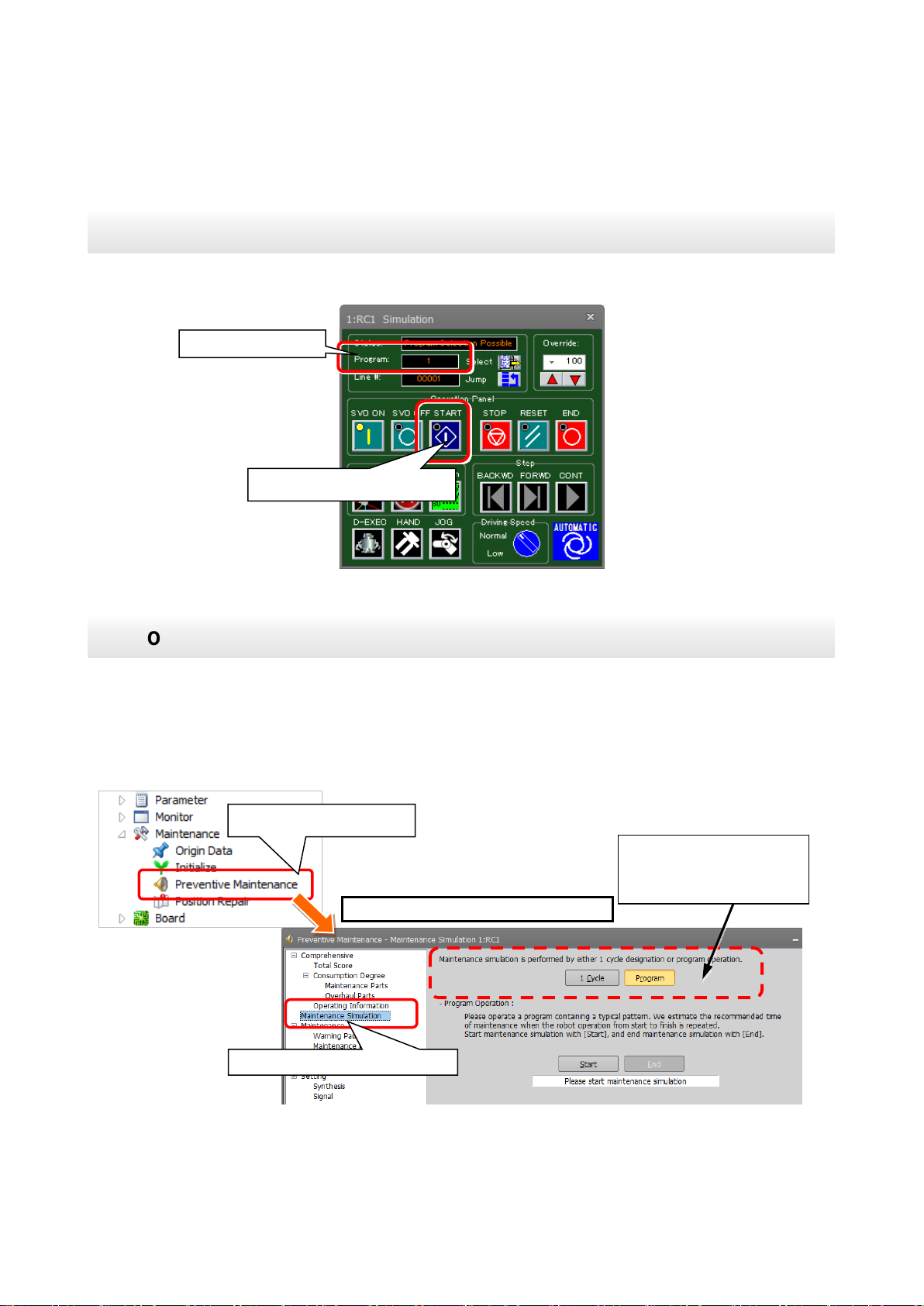

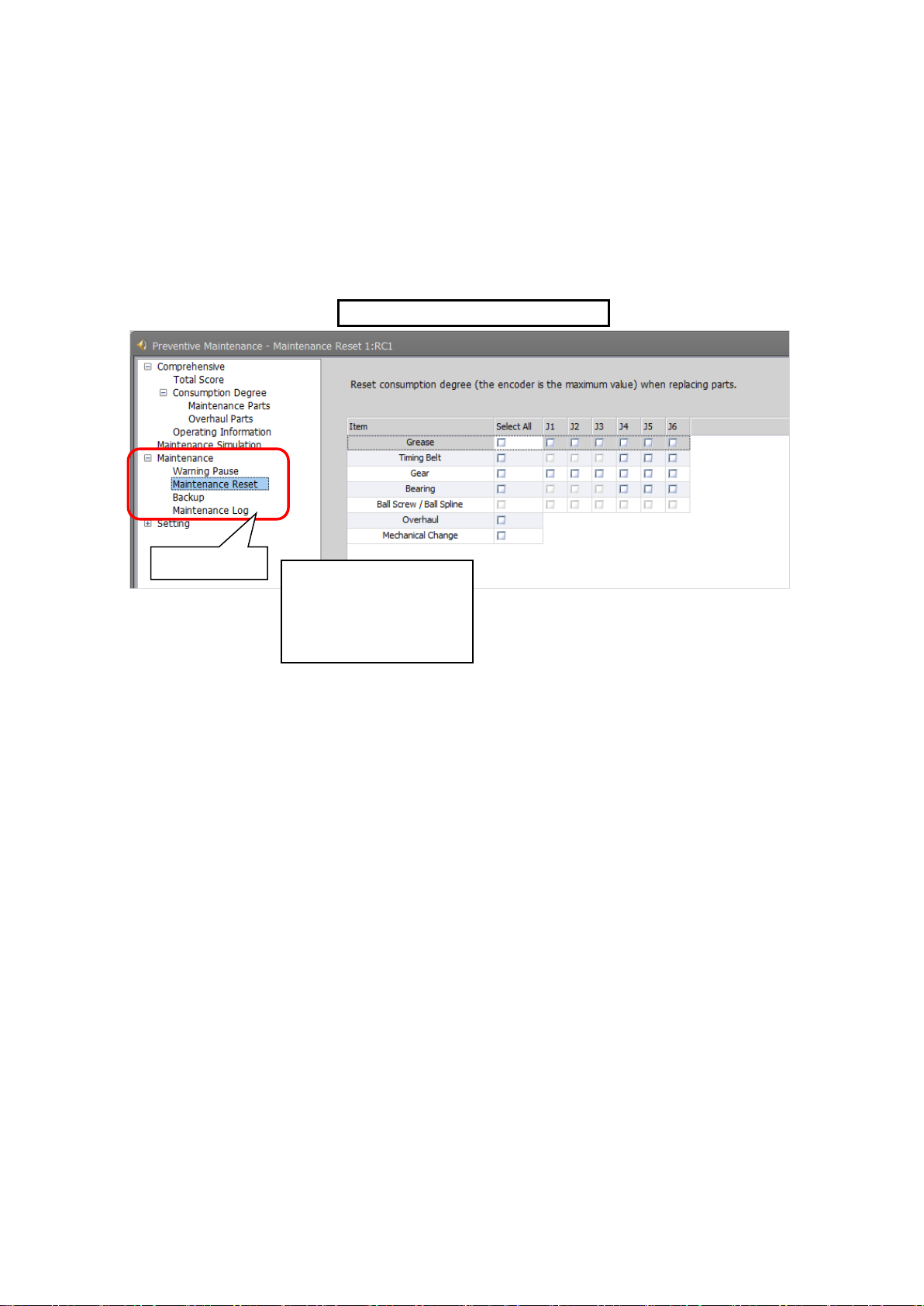

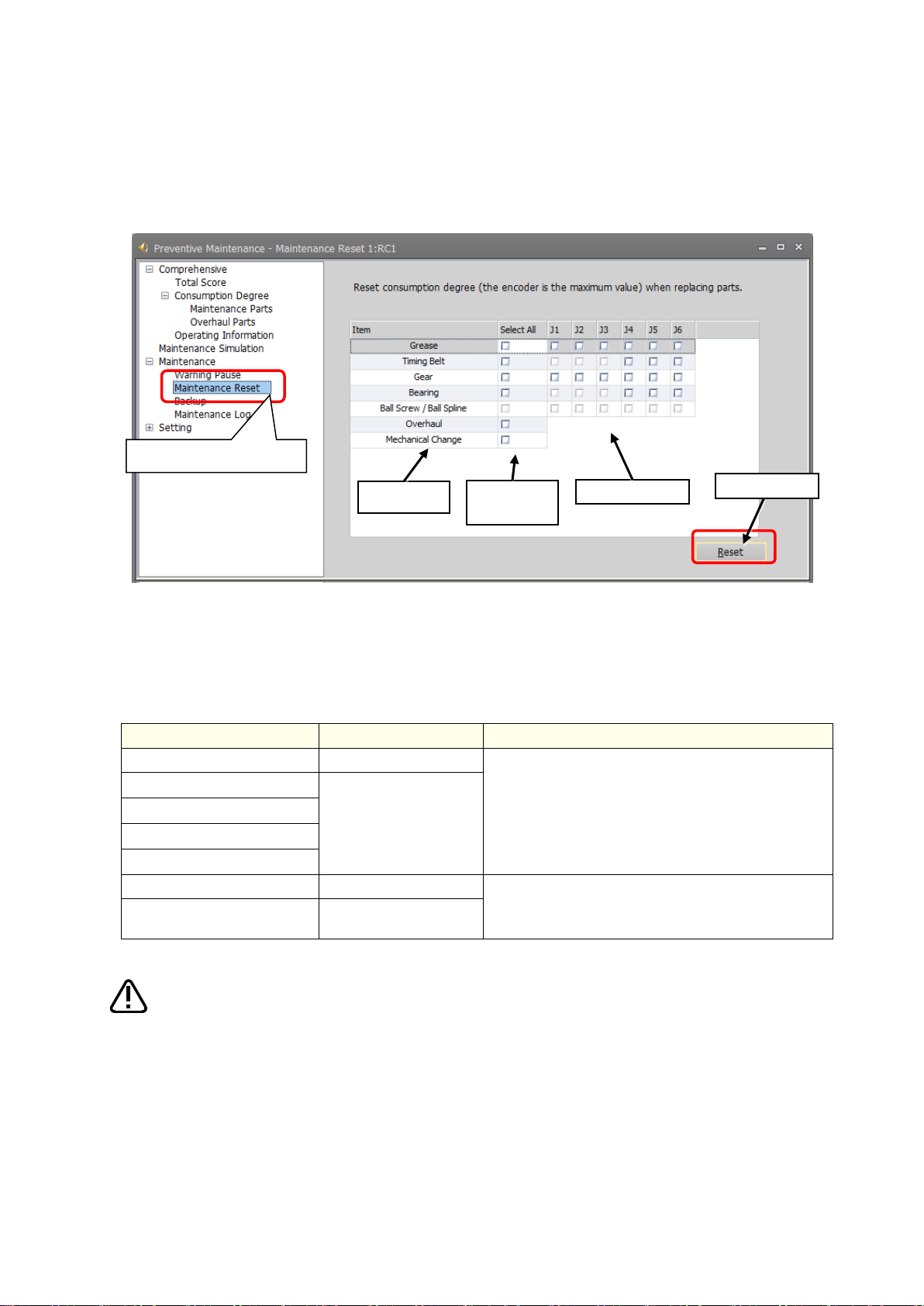

(4) Maintenance simulation