Mitsubishi CMB-P105V-G1, CMB-P104V-G1, CMB-P1013V-G1, CMB-P106V-G1, CMB-P1016V-G1 Installation Manual

...Page 1

Air-Conditioners For Building Application

INDOOR UNIT

CMB-P-V-G1

CMB-P-V-GA1 (MAIN BC CONTROLLER) CMB-P-V-GB1 (SUBBC CONTROLLER)

CMB-P-V-HA1 (MAIN BC CONTROLLER) CMB-P-V-HB1 (SUB BC CONTROLLER)

GB

D

F

E

I

NL

P

GR

RU

TR

CZ

HG

PO

SL

SV

SW

HR

BG

RO

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDB UCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANU AL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANU ALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

E°XEIPI¢IO O¢H°IøN E°KATA™TA™H™

°И· ·ЫК¿ПВИ· О·И ЫˆЫЩ‹ ¯Ъ‹ЫЛ, ·Ъ·О·ПВ›ЫЩВ ‰И·‚¿ЫВЩВ ЪФЫВ¯ЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ ВБО·Щ¿ЫЩ·ЫЛ˜ ЪИУ ·Ъ¯›ЫВЩВ ЩЛУ

ВБО·Щ¿ЫЩ·ЫЛ ЩЛ˜ МФУ¿‰·˜ ОПИМ·ЩИЫМФ‡.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по

установке до выполнения установки кондиционера.

MONTAJ ELK‹TABI

Emniyetli ve do¤ru biçimde nas›l kullan›laca¤›n› ö¤renmek için lütfen klima cihaz›n› monte etmeden önce bu elkitab›n› dikkatle okuyunuz.

INSTALLATIONSHANDBOK

Läs den här installationshandboken noga innan luftkonditioneringsenheten installeras, för säker och korrekt användning.

РЪКОВОДСТВО ЗА МОНТАЖ

За безопасна и правилна употреба, моля, прочетете внимателно това ръководство преди монтажа на климатизатора.

Page 2

INDOOR UNIT SIDE

450

130

*1

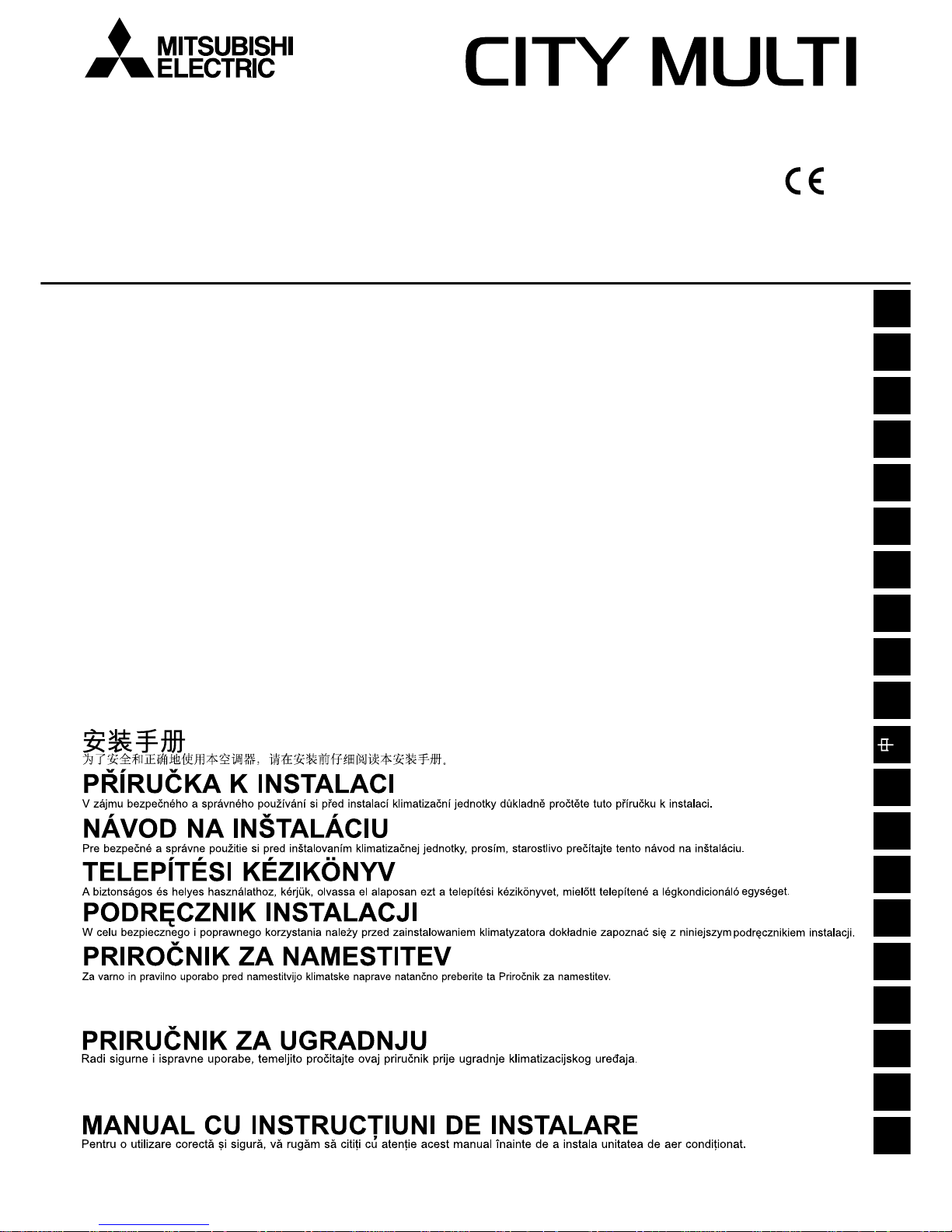

100

A

B

200

(700)

200

250

<B><A>

B

B

A

D

C

2

<A> T op view

<B> Front view

A Inspection hole

B On the side of outdoor unit piping

C Control box

D On the side of indoor unit piping

*1 Dimensions with which pipe connection can be handled at site

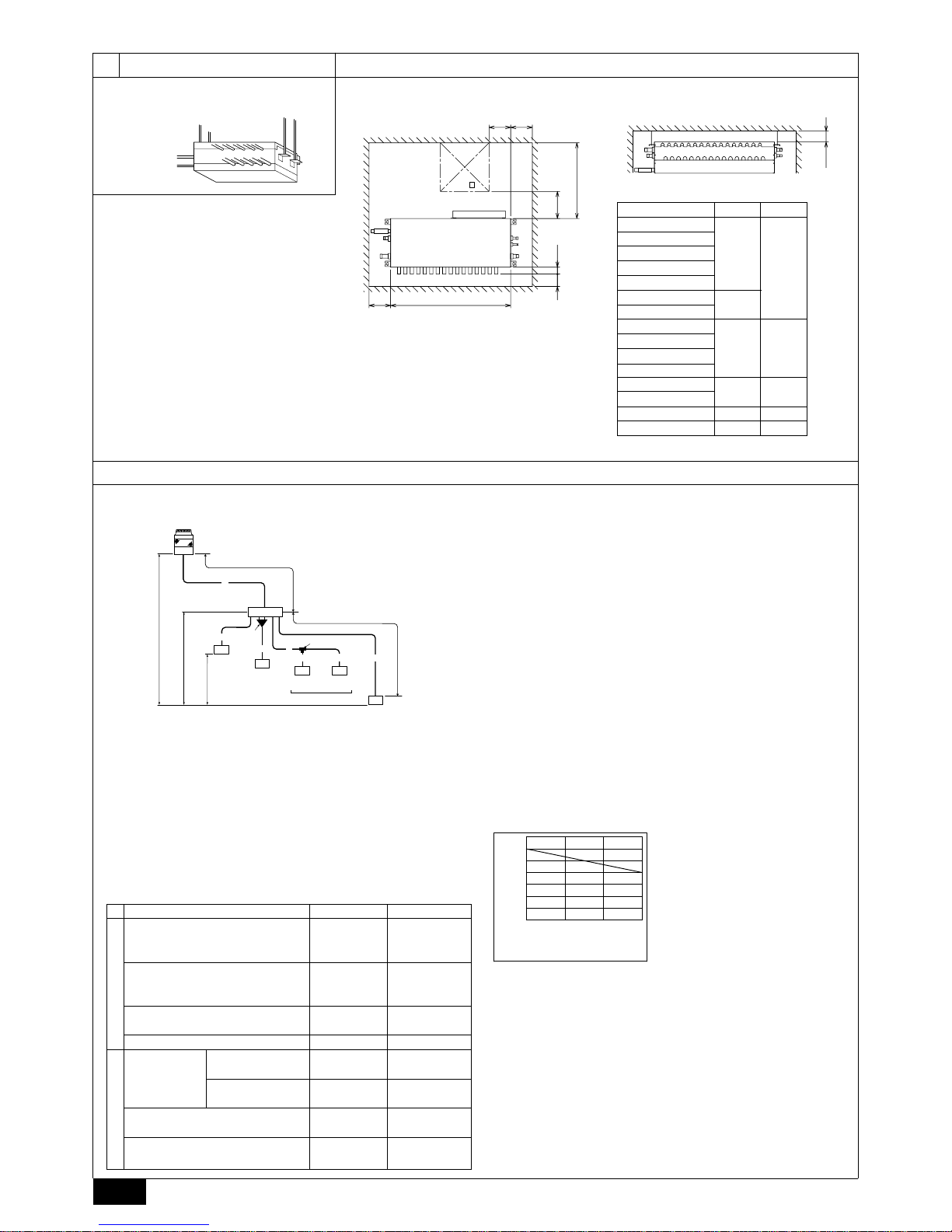

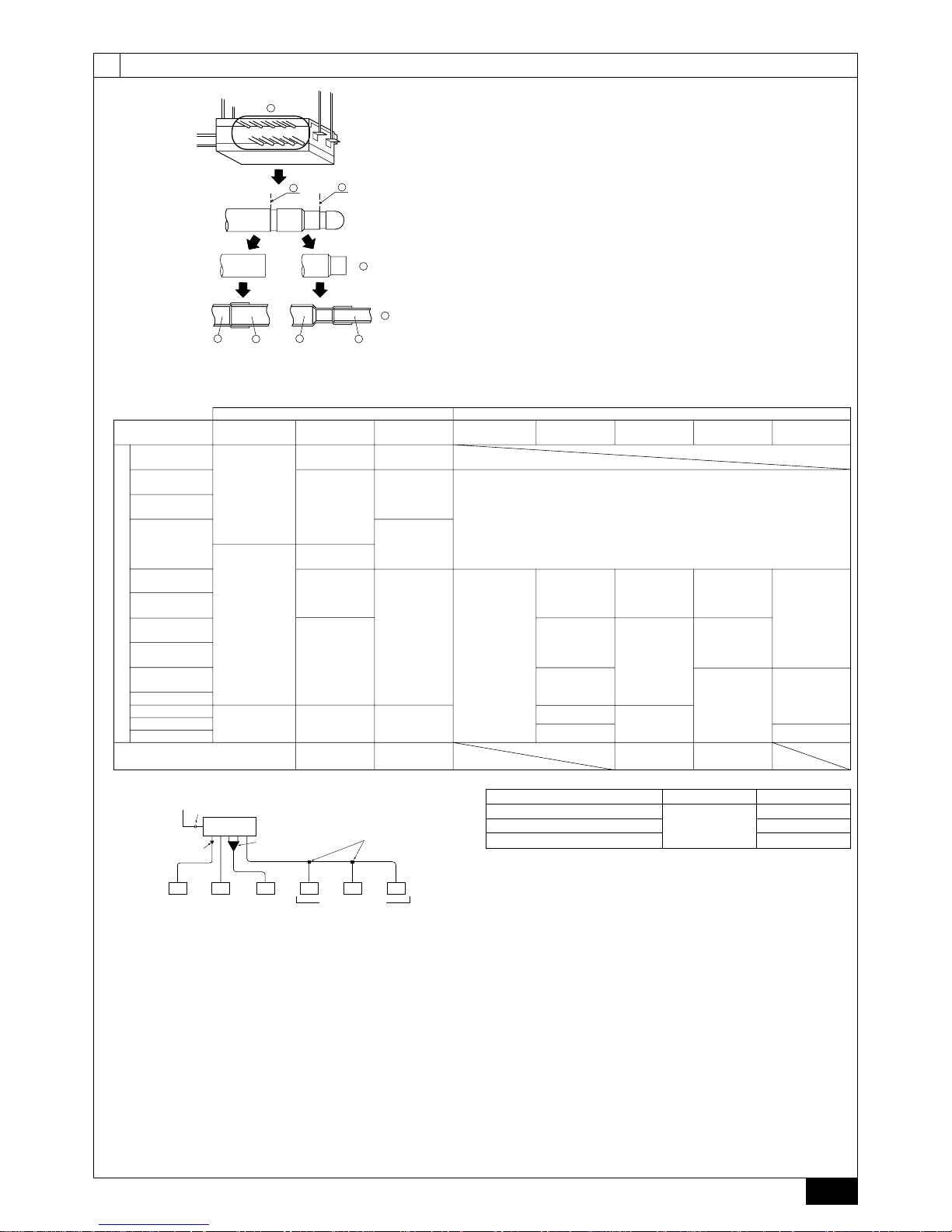

A Outdoor unit B BC controller

C Indoor unit D P100 - P250 model: 2 ports merged.

E Less than H=50 m (when the outdoor unit is higher than the indoor unit)

F Less than H1=40 m (when the outdoor unit is lower than the indoor unit)

G Twinning pipe (for Y Series) CMY-Y102S-G2

H Combined pipe (CMY-R160-J1: optional)

I Less than 110 m J Less than 40 m

K Up to three units for 1 branch hole

Total capacity: less than 80 (but same in cooling/heating mode)

L Less than h1=15 m (10 m or less for 200, 250 unit type)

M Less than h2=15 m

2

[Fig. 2.2.1] [Fig. 2.3.1]

[Fig. 2.4.1]

2.32.2

C

C

D

CC

K

C

F

A

B

I

J

H

G

E

L

M

A

B

cde

b

a

H

H1

h1

h2

2.4

Notes:

*1 Refer to “Restrictions on piping length” on P. 4.

*2 Please refer to the figure “Distance between BC controller and farthest

Indoor unit” when the distance between BC controller and farthest indoor unit exceeds 40 m. (Not applicable to the P250 model indoor unit)

*3 The values in the parentheses show the maximum piping length to be

followed when the connection capacity of the indoor unit is 200 or more.

*4 In the system to which indoor units of the P200 model or above are con-

nected, neither a branch joint nor a branch header may be used.

*5 Do not connect the P200 or P250 models of indoor units and other mod-

els of indoor units at the same port.

*6 In the system to which indoor units of the P100 through P140 models are

connected, merge the two ports before connecting them. (Set DIP SW4-6

on the BC controller to ON.)

*7 It is possible to connect the P100 through P140 models of indoor units to

a single port. (Set DIP SW4-6 to OFF.) Note that the cooling capacity will

somewhat decrease. (The factory setting for DIP SW4-6 is OFF.)

*8 Indoor units that are connected to the same branch joint cannot be si-

multaneously operated in different operation modes.

Distance between BC controller

and farthest indoor unit

Height difference between

BC controller and farthest

indoor unit (m)

15105

20

10

0

0

Distance between BC contoroller

and farthest indoor unit (m)

70

60

50

40

30

CMB-P104, 105, 106, 108, 1010, 1013, 1016G1 (In the case the outdoor unit is 14-hp (P350 model) or less, and 16 or fewer ports are used.)

Length

(Unit: m)

Item Piping portion Allowable value

A+B+a+b

Total piping length

+c+d+e

Longest piping length A+e

Between outdoor unit and

A Below 110

BC controller

Between indoor units and BC controller e Below 40 *2

Above outdoor unit H Below 50

Below outdoor unit H1 Below 40

Between indoor units and BC controller h1

Below 15

(Below 10)*3

Between indoor units h2

Below 15

(Below 10)*3

Difference of elevation

Between

indoor and

outdoor units

Not to exceed the

maximum refrigerant piping length *1

165 m or less

(Equivalent length

of 190 m or less)

Model name A B

CMB-P104V-G1

CMB-P105V-G1

CMB-P106V-G1 648

CMB-P108V-G1

CMB-P1010V-G1

CMB-P1013V-G1

1098

CMB-P1016V-G1

CMB-P108V-GA1

CMB-P1010V-GA1

1110 200

CMB-P1013V-GA1

CMB-P1016V-GA1

CMB-P104V-GB1

648

CMB-P108V-GB1

CMB-P1016V-HA1 1110 200

CMB-P1016V-HB1 1098

-

Page 3

Length

(Unit: m)

Item Piping portion Allowable value

F+G+A+B+C

Total piping length +D+E+a+b

+c+d+e+f

Longest piping length F(G)+A+C+E+f

Between outdoor unit and

F(G)+A Below 110

BC controller

Between indoor units and BC controller

B+d or C+D+e or C+E+f

Below 40 *2

Between outdoor units F+G Below 5

Above outdoor unit H Below 50

Below outdoor unit H1 Below 40

Between indoor units and BC controller h1

Below 15

(Below 10)*3

Between indoor units h2

Below 15

(Below 10)*3

Between BC controller (main or sub)

h3 Below 15

and BC controller (sub)

Between outdoor units h4 Below 0.1

Difference of elevation

Between

indoor and

outdoor units

Not to exceed the

maximum refrigerant piping length *1

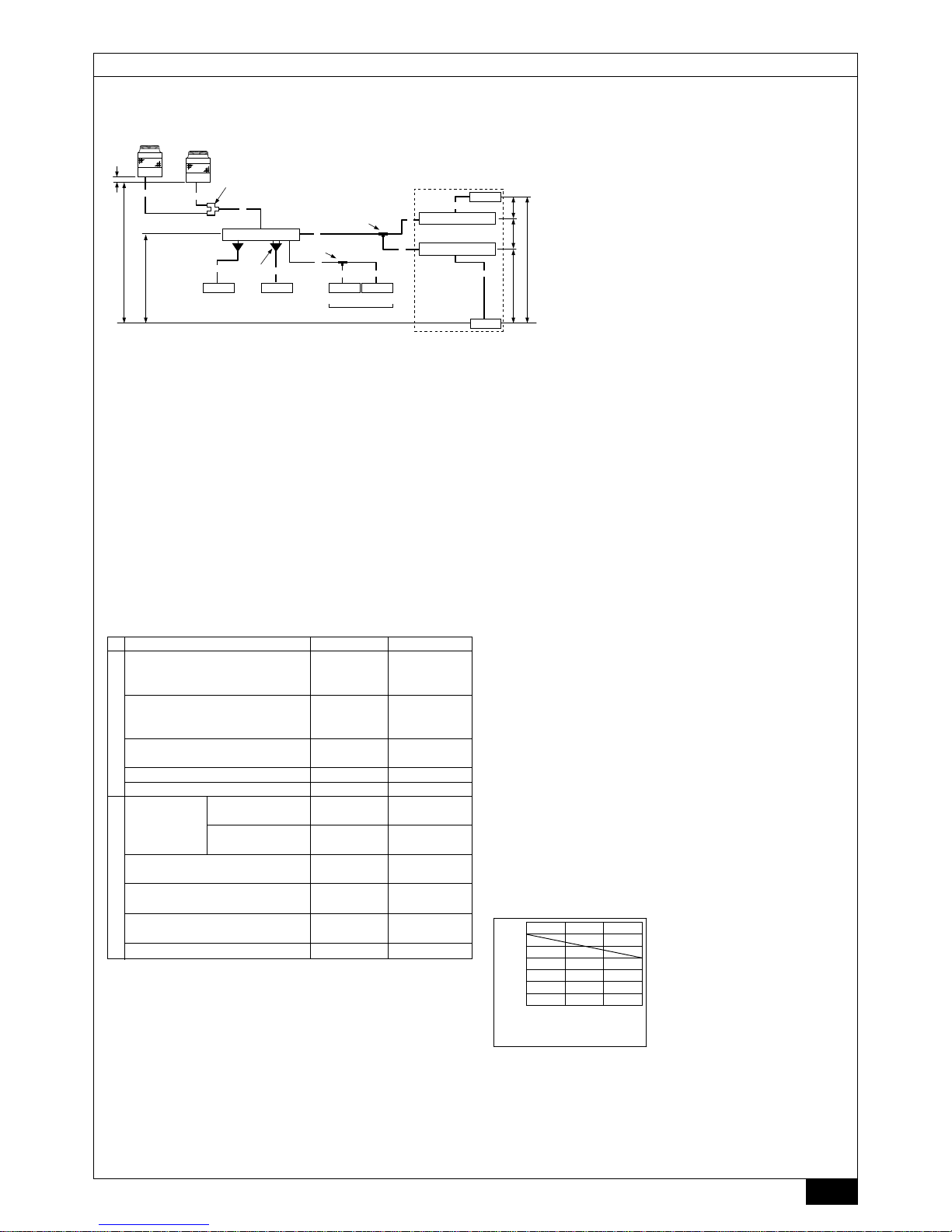

[Fig. 2.4.2]

2.4

CMB-P108, 1010, 1013, 1016GA1, P104, 108GB1 (GA1: In the case the outdoor unit is 26-hp (P650 model) or less.)

CMB-P1016HA1, 1016HB1 (HA1: In the case the outdoor unit is 28-hp (P700 model) or more.)

a

C

b

B

c

d

f

D

E

A

e

F

G

h2

h1 h3 h1

C

C

DD DD

D

D

F

A

A

B

I

J

H

G

E

L

M

N

O

H1

H

h4

*6

K

A Outdoor unit B MAIN BC controller

C SUB BC controller D Indoor unit

E The twinning kit is connected inside the outdoor unit on the low-pressure side.

When outdoor units of different capacities are connected, connect the twinning kit

to the unit with a higher capacity.

F Twinning pipe (for R2 series) CMY-R100VBK, CMY-R200VBK

(for WR2 series) CMY-Q100VBK

G Twinning pipe (for Y series) CMY-Y202-G2, CMY-Y102L-G2, CMY-Y102S-G2

H Twinning pipe (CMY-R160-J1: optional)

I Twinning pipe (for Y series) CMY-Y102S-G2

J P100 - P250 model: 2 ports merged

K Maximum of 3 units per a pair of ports

Total capacity of 80 or below

All units connected to the same port must be in the same operation mode.

L Less than H=50 m (when the outdoor unit is higher than the indoor unit)

M Less than H1=40 m (when the outdoor unit is lower than the indoor unit)

N Less than h1=15 m (10 m or less for 200, 250 unit type)

O Less than h2=15 m

Notes:

A system that has more than 16 branching points requires 2 to 3 BC control-

lers (main and sub) and 3 pipes to connect the main and the sub BC controllers.

*1 Refer to “Restrictions on piping length” on P. 4.

*2 Please refer to the figure “Distance between main BC contr oller and far-

thest Indoor unit” when the distance between main BC controller and

farthest indoor unit exceeds 40 m. (Not applicable to the P250 model

indoor unit)

*3 The values in the parentheses show the maximum piping length to be

followed when the connection capacity of the indoor unit is 200 or more.

*4 In the system to which indoor units of the P200 model or above are con-

nected, neither a branch joint nor a branch header may be used.

*5 When connecting two sub BC controllers, the total piping length m ust be

equal to or less than the maximum length as listed in on the left.

*6 When connecting two sub BC controllers, install them in parallel.

*7 In the system to which indoor units of the P100 through P140 models are

connected, merge the two ports before connecting them. (Set DIP SW4-6

on the main BC controller to ON.)

*8 It is possible to connect the P100 through P140 models of indoor units to

a single port. (Set DIP SW4-6 to OFF.) Note that the cooling capacity will

somewhat decrease. (The factory setting for DIP SW4-6 is OFF.)

*9 When the outdoor unit is 28-hp (P700 model) or more, use the HA-type

main BC controller. The G-type BC controller cannot be connected to the

models between 16-hp (P400 model) and 26-hp (P650 model), and the G-

and GA-type BC controllers cannot be connected to the 28-hp (P650

model) or more.

*10 For Sub BC controller GB type, the connectable indoor unit capacities

may sum to equal that of a P350 unit or less. However, if two sub control-

lers are used the TOTAL sum of connectable units connected to BOTH

sub controllers must also not exceed that of a P350 unit.

For sub BC controller HB type, the connectable indoor unit capacities

may sum to equal that or a P350 unit or less. However, if two sub control-

lers are used the TOTAL sum of connectable units connected to BOTH

sub controllers must also not exceed that of a P450 unit.

*11 Indoor units that are connected to the same branch joint cannot be si-

multaneously operated in different operation modes.

*12 Do not connect the P200 or P250 models of indoor units and other mod-

els of indoor units at the same port.

<System that has more than 16 branching points>

Distance between MAIN BC controller

and farthest indoor unit

Height difference between

MAIN BC controller and

farthest indoor unit (m)

15105

20

10

0

0

Distance between MAIN BC controller

and farthest indoor unit (m)

70

60

50

40

30

165 m or less

(Equivalent length

of 190 m or less)

3

Page 4

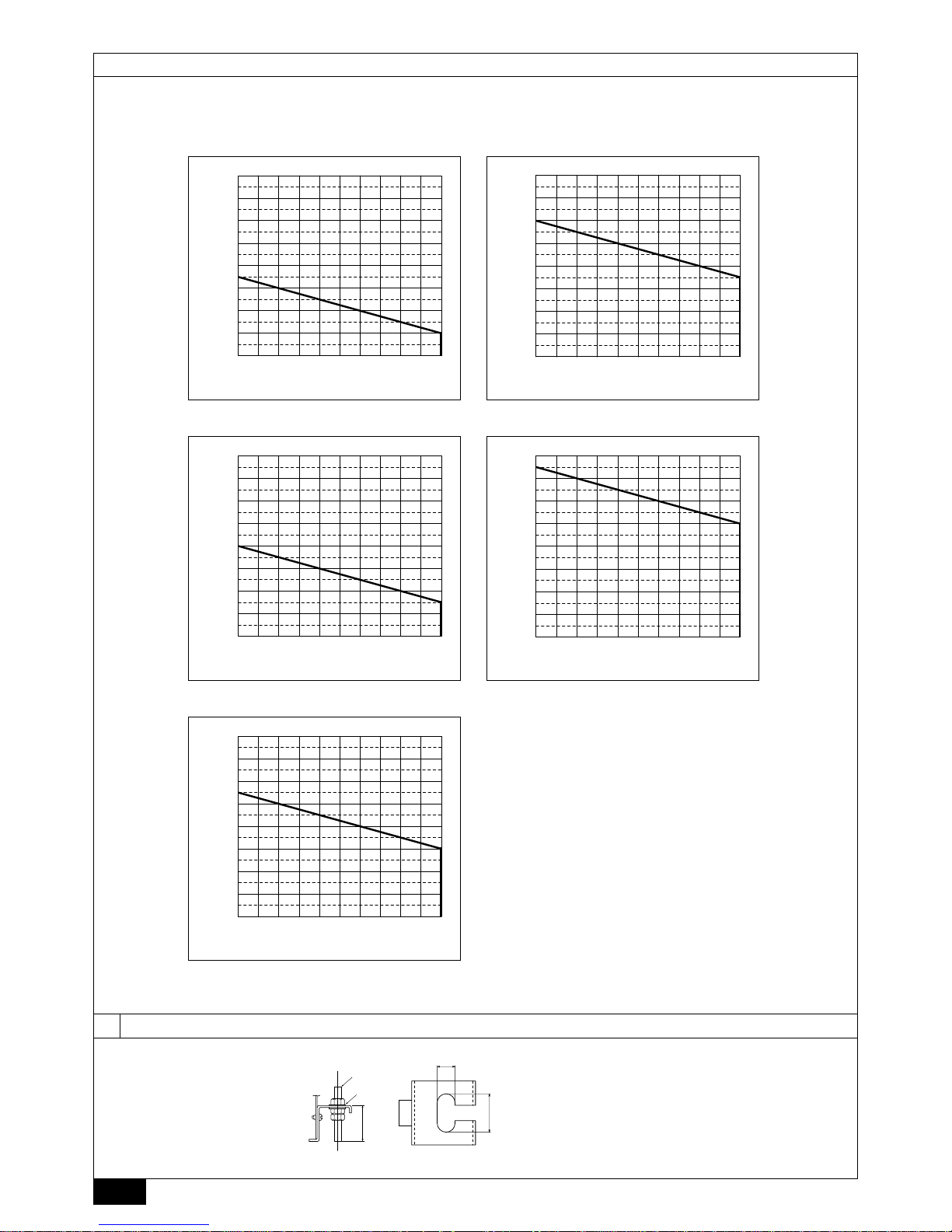

[Fig. 2.4.3]

2.4

3

3.2

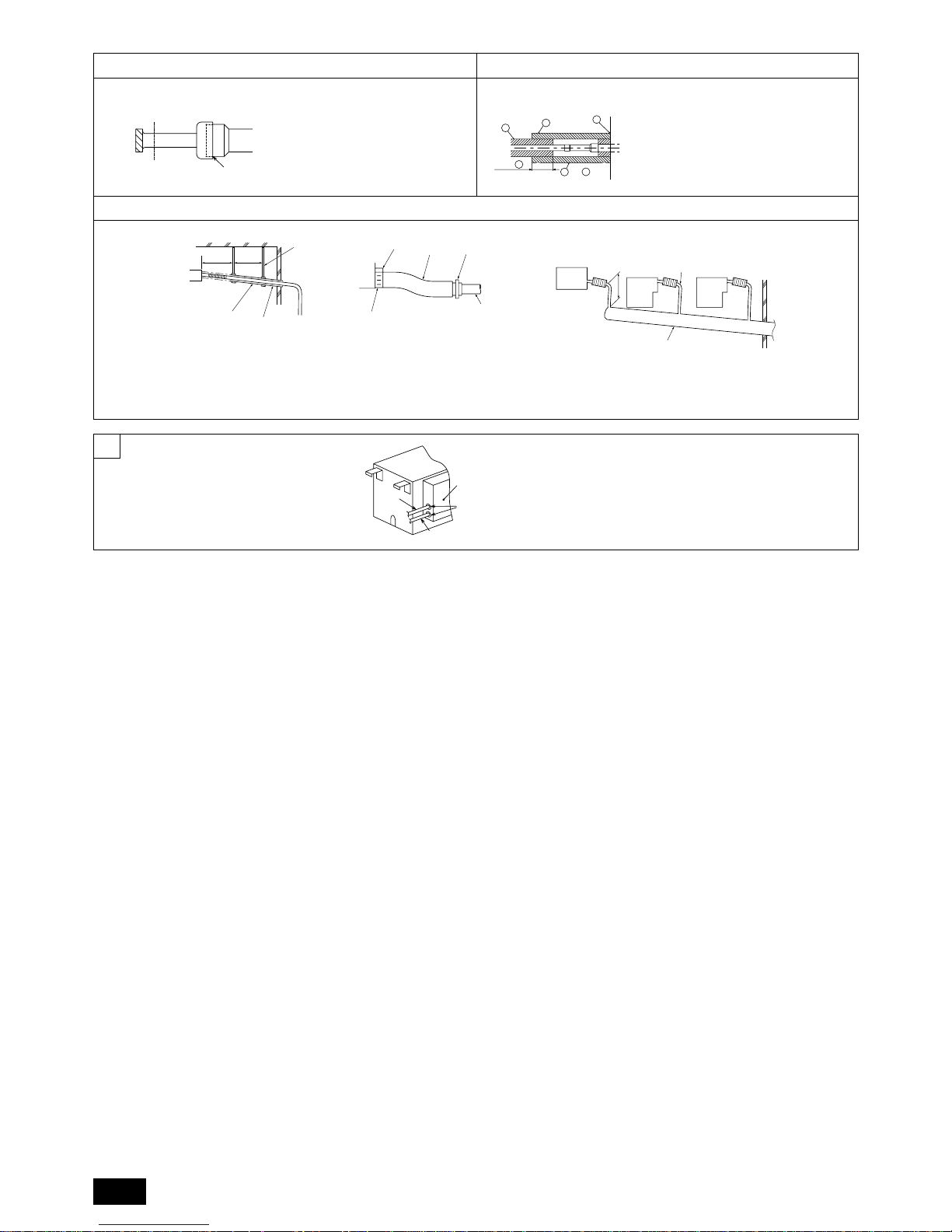

[Fig. 3.2.1]

1

A

B

A

1 Hanging method

A: Min. 30 mm

A Hanging bolt ø10 (field supply)

B Washer (field supply)

PURY-P200/250/300YHM-A, PURY-EP200YHM-A

PQRY-P200/250/300YHM-A

●Restrictions on piping length

PURY-P600/650YSHM-A, PURY-EP600YSHM-A

PURY-P350/400/450Y(S)HM-A, PURY-EP250/300YHM-A

PURY-P700/750/800YSHM-A

PURY-P500/550YSHM-A, PURY-EP400/450/500/550YSHM-A(1)

PQRY-P400/450/500/550/600YSHM-A

400

500

600

700

800

900

1000

A

800

900

1000

200

300

400

500

600

700

800

900

1000

10 20 30 40 50 60 70 80 90 100 110

A

200

300

10 20 30 40 50 60 70 80 90 100 110

400

500

600

700

800

900

1000

200

300

400

500

600

700

800

10 20 30 40 50 60 70 80 90 100 110

A

900

1000

A

200

300

400

500

600

700

A

10 20 30 40 50 60 70 80 90 100 110

10 20 30 40 50 60 70 80 90 100 110

B

B

B

B

B

300

200

4

14

30

(Top view)

A Total piping length (m) B Piping length between outdoor unit and BC controller (m)

Page 5

5

4.1

[Fig. 4.1.1]

4

B

C

D

E

F

A

A

F

A

A Indoor unit connecting port

B Cutting point : ø9.52 (Liquid side) or ø15.88 (Gas side)

(Indoor unit model : bigger than P50)

C Cutting point : ø6.35 (Liquid side) or ø12.7 (Gas side)

(Indoor unit model : P50 or smaller)

D Cut the piping at the cutting point

E Have pipe expansion of indoor unit connecting port

F Field pipe

Note:

Remove burr after cutting the piping to prevent entering the piping.

Check that there is no crack at the pipe expansion part.

A To outdoor unit (MAIN BC CONTROLLER)

B End connection (brazing)

C BC controller (MAIN BC CONTROLLER / SUB BC CONTROLLER)

D Reducer E Indoor unit

F Less than 50

G Combined piping kit (Model name: CMY-R160-J1)

H Twinning pipe (Model name: CMY-Y102S-G2)

I Up to three units for 1 branch hole; total capacity: below 80 (but same in cooling/

heating mode)

E

EE

EEIE

A

B

G

*2

H

*1

D

63-80 100-250 *3

C

F

Total capacity of indoor units Liquid line Gas line

Below 140 ø15.88

141 to 200 ø9.52 ø19.05

201 to 250 ø22.2

*1. For connecting 15 to 50 type indoor units

Have pipe expansion of indoor unit connecting port by cutting the piping at the

cutting point which depends on the indoor unit capacity.

Note:

Remove burr after cutting the piping to prevent entering the piping.

Check that there is no crack at the pipe expansion part.

*2. To connect a unit with a capacity of higher than 81.

After combining two branches using an optionally available piping kit (CMY-R160J1), connect indoor units.

*3. Connection of plural indoor units with one connection (or joint pipe)

•Total capacity of connectable indoor units: Less than 80 (Less than 250 with

joint pipe)

• Number of connectable indoor units: Maximum 3 Sets

•Twinning pipe: Use the twinning pipe for CITY MULTI Y Series (CMY-Y102S-G2)

• Selection of refrigerant piping

Select the size according to the total capacity of indoor units to be installed

downstream.

*1 Use the supplied pipe.

Outdoor unit side

PURY-(E) P400

PQRY-P400

PURY-(E) P450

PQRY-P450

PURY-(E) P500

PQRY-P500

PURY-(E) P550

PQRY-P550

PURY-(E) P600

PQRY-P600

PURY-P650

PURY-P700

PURY-P750

PURY-P800

BC CONTROLLER/MAIN BC CONTROLLER SUB BC CONTROLLER

Unit model Model name

High pressure

side

Low pressure

side

Model name

Total capacity

of indoor units

High pressure

(gas) side

Low pressure

(gas) side

Liquid side

PURY-(E) P200

PQRY-P200

PURY-(E) P250

PQRY-P250

PURY-(E) P300

PQRY-P300

PURY-P350

Indoor unit side

(BC CONTROLLER)

CMB-P104V-G1

CMB-P105V-G1

CMB-P106V-G1

CMB-P108V-G1

CMB-P1010V-G1

CMB-P1013V-G1

CMB-P1016V-G1

(MAIN BC

CONTROLLER)

CMB-P108V-GA1

CMB-P1010V-GA1

CMB-P1013V-GA1

CMB-P1016V-GA1

(MAIN BC

CONTROLLER)

CMB-P1016V-HA1

When a system that has more than 16 branching points, use BC controllers (main and

sub) to connect the pipes.

CMB-P104V-GB1

CMB-P108V-GB1

CMB-P1016V-HB1

ø15.88*1

(Brazing)

ø19.05

(Brazing)

ø19.05*1

(Brazing)

ø22.2

(Brazing)

ø28.58*1

(Brazing)

ø28.58

(Brazing)

ø9.52 or ø6.35

(Brazing)

ø19.05*1

(Brazing)

ø22.2

(Brazing)

ø28.58*1

(Brazing)

ø28.58

(Brazing)

ø34.93*1

(Brazing)

ø15.88 or ø12.7

(Brazing)

below 200

ø15.88*1

(Brazing)

ø19.05*1

(Brazing)

ø9.52

(Brazing)

201~300

ø19.05

(Brazing)

ø22.2

(Brazing)

301~350

351~400

ø22.2*1

(Brazing)

ø28.58*1

(Brazing)

401~450

ø9.52 or ø6.35

(Brazing)

ø15.88 or ø12.7

(Brazing)

ø12.7*1

(Brazing)

ø15.88*1

(Brazing)

[Fig. 4.1.2]

Page 6

6

[Fig. 4.4.1]

4.4

1

A

A

B

C

B

A: 25 cm B: 1.5 – 2 m

A Downward pitch of more than 1/100

B Insulating material C Supporting bracket

D Drain discharge port E Drain hose (200 mm long, accessory)

F Tie band (accessory) G Hose band (accessory)

BB

A

D

3

C

VP-30

A BC controller B Indoor unit

C Collecting pipe D Please ensure this length is at least 10 cm.

[Fig. 4.4.2]

[Fig. 5.0.1]

A Control box

B Power source wiring

C ø21 hole (closed rubber bushing)

D Tr ansmission wiring

5

B

A

C

D

VP-25

2

D

E

G

F

4.2

[Fig. 4.2.1]

F

E

D

A

C

B

4.3

[Fig. 4.3.1]

A Cut here

B Remove brazed cap

B

A

A Locally procured insulating mater ial

for pipes

B Bind here using band or tape.

c Do not leave any opening.

D Lap margin: more than 40

E Insulating material (field supply)

F Unit side insulating material

Page 7

7

GBDFEINLPGRRUTRCZSVSLHGPO

Contents

1. Safety precautions

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the “Safety

precautions”.

s The “Safety precautions” provide very important points re-

garding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock (This symbol is displayed on the main unit label.)

<Color: Yellow>

Warning:

Carefully read the labels affixed to the main unit.

HIGH VOL T AGE W ARNING:

• Control box houses high-voltage parts.

• When opening or closing the front panel of the control box, do not let it

come into contact with any of the internal components.

• Before inspecting the inside of the control box, turn off the power, keep

the unit off for at least 10 minutes.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric shock,

or fire.

• Install the unit at a place that can withstand its weight.

- Failure to do so may cause the unit to fall down, resulting in injuries and

damage to the unit.

• Use the specified cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for earthquakes and install the unit at the specified place.

- Improper installation may cause the unit to fall down and result in injury and

damage to the unit.

• Always use accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper installation

by the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the air conditioner must be repaired, consult the

dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may

result.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will

be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fire may

result.

• Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and “Interior Wire Regulations”and

the instructions given in this manual and always use a dedicated power

supply.

- If the power source capacity is inadequate or electric work is performed im-

properly, electric shock and fire may result.

• Securely install the cover of control box.

- If the cover is not installed properly, dust or water may enter the outdoor unit

and fire or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge it with a refrigerant different from the refrigerant specified on the

unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrig-

erant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration from exceeding the safety limit if

the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the safety

limit from being exceeded. Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or

fire may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

or operated forcibly, or parts other than those specified by Mitsubishi Electric

are used, fire or explosion may result.

•To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- Choose the appropriate wire size and the switch capacities for the main power

supply described in this manual if local regulations are not available.

• Pay special attention to the place of installation, such as basement, etc.

where refrigeration gas can accumulate, since refrigerant is heavier than

the air.

1.2. Precautions for devices that use R410A

refrigerant

Caution:

• Do not use existing refrigerant piping.

- The old refrigerant and refrigerant oil in the existing piping contains a large

amount of chlorine which may cause the refrigerant oil of the new unit to

deteriorate.

- R410A is a high-pressure refrigerant and can cause the existing piping to

burst.

• Use refrigerant piping made of phosphorus deoxidized copper and copper alloy seamless pipes and tubes. In addition, be sure that the inner

and outer surfaces of the pipes are clean and free of hazardous sulphur,

oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refriger-

ant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor failure may result.

• Apply a small amount of ester oil, ether oil, or alkyl benzene to flares. (for

indoor unit)

- Infiltration of a large amount of mineral oil may cause the refrigerant oil to

deteriorate.

1. Safety precautions ...................................................................................... 7

1.1. Before installation and electric work .......................................... 7

1.2. Precautions for devices that use R410A refrigerant .................. 7

1.3. Before installation ...................................................................... 8

1.4. Before installation (relocation) - electrical work ......................... 8

1.5. Before starting the test run ........................................................ 8

2. Selecting an installation site ....................................................................... 8

2.1. About the product ...................................................................... 8

2.2. Installation site ........................................................................... 8

2.3. Securing installation and service space .................................... 9

2.4. Checking the installation site ..................................................... 9

3. Installing BC controller .............................................................................. 10

3.1. Checking the accessories with BC controller .......................... 10

3.2. Installing BC controllers ........................................................... 10

4. Connecting refrigerant pipes and drain pipes ........................................... 10

4.1. Connecting refrigerant pipes ................................................... 10

4.2. Refrigerant piping work ........................................................... 11

4.3. Insulating refrigerant pipes ...................................................... 12

4.4. Drain piping work ..................................................................... 12

5. Electrical work ........................................................................................... 12

6. Setting addresses and operating units ..................................................... 12

7. Test run ..................................................................................................... 12

Page 8

8

GBDFEINLPGRRUTRCZSVSLHGPO

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to fill the system, the composition of the refrigerant

in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is mixed with R410A, the chlorine in the

refrigerant may cause the refrigerant oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the

refrigerant oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve,

refrigerant charge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerant oil are mixed in the R410A, the

refrigerant may deteriorate.

- If water is mixed in the R410A, the refrigerant oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for conven-

tional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Do not use antioxidant or leak-detection additive.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets into the refrigerant cycle, the refrigerant may dete-

riorate.

1.3. Before installation

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- Inverter equipment, private power generator, high-frequency medical equip-

ment, or radio communication equipment may cause the air conditioner to

operate erroneously, or fail to operate. On the other hand, the air conditioner

may affect such equipment by creating noise that disturbs medical treatment

or image broadcasting.

• Do not install the unit on or over things that are subject to water damage.

- When the room humidity exceeds 80 % or when the drain pipe is clogged,

condensation may drip from the indoor unit or BC controller. Perform collective drainage work together with the outdoor unit, as required.

1.4. Before installation (relocation) - electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

• Install the power cable so that tension is not applied to the cable.

-Tension may cause the cable to break and generate heat and cause a fire.

• Install a leak circuit breaker, as required.

- If a leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

-A fuse or circuit breaker of a larger capacity, or the use of substitute simple

steel or copper wire may result in a general unit failure or fire.

• Do not wash the air conditioner units.

-Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage causing damage to furniture

and other possessions.

• Be very careful about transporting the product.

- One person should not carry the product. Its weight is in excess of 20 kg.

- Some products use PP bands for packaging. Do not use any PP bands as a

means of transportation. It is dangerous.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

-Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which has not been torn

apart, they face the risk of suffocation.

1.5. Before starting the test run

Caution:

•Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can

result in irreversible damage to internal parts. Keep the power switch turned

on during the operational season.

• Do not touch the switches with wet fingers.

-Touching a switch with wet fingers can result in an electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes may be hot or

cold, depending on the condition of the refrigerant flowing through the refrigerant piping, compressor, and other refrigerant cycle parts. Your hands may

suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least 5 minutes before turning off the power. Otherwise, drain-

age water leakage or mechanical failure of sensitive parts may occur.

2. Selecting an installation site

2.1. About the product

• This unit uses R410A-type refrigerant.

• Piping for systems using R410A may be different from that for systems using

conventional refrigerant because the design pressure in systems using R410A

is higher. Refer to the Data Book for more information.

• Some of the tools and equipment used for installation with systems that use

other types of refrigerant cannot be used with the systems using R410A. Refer

to the Data Book for more information.

• Do not use the existing piping, as it contains chlorine, which is found in conventional refrigerating machine oil and refrigerant. This chlorine will deteriorate

the refrigerant machine oil in the new equipment. The existing piping must not

be used as the design pressure in systems using R410A is higher than that in

the systems using other types of refrigerant and the existing pipes may burst.

2.2. Installation site

• Install the unit in a place not exposed to rain. The BC controller is designed to

be installed indoors.

• Install the unit with adequate space around it for servicing.

• Do not install the unit in a place that would result in the piping length restric-

tions being exceeded.

• Install the unit in a place not exposed to direct radiant heat from other heat sources.

• Do not install the unit in any oily steamy place or near any machine that gener-

ates high frequencies. Doing so may cause a risk of fire, erroneous operation

or dew drop.

• Install the unit in a location where the noise from the unit will not be a problem.

(Install indoor unit and BC controller at least 5 m away from each other when

installed in a space with low background noise, e.g., hotel rooms).

• Allow enough space and access to ensure water piping, refrigerant piping and

electrical wiring can be easily connected.

• Avoid places exposed to the generation, inflow, accumulation or leakage of

flammable and sulfuric gases.

• Ensure a downward gradient of at least 1/100 for drain piping.

• Properly install the unit on a stable, load-bearing surface.

Page 9

9

GBDFEINLPGRRUTRCZSVSLHGPO

1. For hanging from the ceiling [Fig. 2.2.1] (P.2)

• Provide an inspection hole 450 mm square in the ceiling surface as shown in

[Fig. 2.3.1] (P.2).

• Install the unit in a suitable location (such as in the ceiling of a corridor or in the

bathroom etc) away from places regularly occupied. Avoid installing in the center

of a room.

• Ensure a pull out strength of at least 60 kg per bolt for hanging bolts.

• Be sure to install the BC controller horizontally.

Warning:

Be sure to install the unit in a place that can sustain the entire weight.

If there is a lack of strength, it may cause the unit to fall down, resulting in an

injury.

Caution:

Be sure to install the unit horizontally.

2.3. Securing installation and service space

1. For hanging from the ceiling

(This is a reference view showing the least installation space.)

[Fig. 2.3.1] (P.2)

<A> Top view <B> Front view

A Inspection hole B On the side of outdoor unit piping

C Control box D On the side of indoor unit piping

*1 Dimensions with which pipe connection can be handled at site

Notes:

*1 Refer to “Restrictions on piping length” on P . 4.

*2 Please refer to the figure “Distance between BC controller and farthest

Indoor unit” when the distance between BC controller and farthest indoor unit exceeds 40 m. (Not applicable to the P250 model indoor unit)

*3 The values in the parentheses show the maximum piping length to be

followed when the connection capacity of the indoor unit is 200 or more.

*4 In the system to which indoor units of the P200 model or above are con-

nected, neither a branch joint nor a branch header may be used.

*5 Do not connect the P200 or P250 models of indoor units and other mod-

els of indoor units at the same port.

*6 In the system to which indoor units of the P100 through P140 models are

connected, merge the two ports before connecting them. (Set DIP SW4-6

on the BC controller to ON.)

*7 It is possible to connect the P100 through P140 models of indoor units to

a single port. (Set DIP SW4-6 to OFF.) Note that the cooling capacity will

somewhat decrease. (The factory setting for DIP SW4-6 is OFF.)

*8 Indoor units that are connected to the same branch joint cannot be simul-

taneously operated in different operation modes.

Model name A B

CMB-P104V-G1

CMB-P105V-G1

CMB-P106V-G1 648

CMB-P108V-G1

CMB-P1010V-G1

CMB-P1013V-G1

1098

CMB-P1016V-G1

CMB-P108V-GA1

CMB-P1010V-GA1

1110 200

CMB-P1013V-GA1

CMB-P1016V-GA1

CMB-P104V-GB1

648

CMB-P108V-GB1

CMB-P1016V-HA1 1110 200

CMB-P1016V-HB1 1098

-

Length

(Unit: m)

Item Piping portion Allowable value

A+B+a+b

Total piping length

+c+d+e

Longest piping length A+e

Between outdoor unit and

A Below 110

BC controller

Between indoor units and BC controller e Below 40 *2

Above outdoor unit H Below 50

Below outdoor unit H1 Below 40

Between indoor units and BC controller h1

Below 15

(Below 10)*3

Between indoor units h2

Below 15

(Below 10)*3

Difference of elevation

Between

indoor and

outdoor units

Not to exceed the

maximum refrigerant piping length *1

165 m or less

(Equivalent length

of 190 m or less)

2.4. Checking the installation site

Check that the difference of elevation between indoor and outdoor units and the

length of refrigerant piping are within the following limitations.

1. CMB-P104, 105, 106, 108, 1010, 1013, 1016G1 (In the case the outdoor unit

is 14-hp (P350 model) or less, and 16 or fewer ports are used.)

[Fig. 2.4.1] (P.2)

A Outdoor unit B BC controller

C Indoor unit D P100 - P250 model: 2 ports merged.

E Less than H=50 m (when the outdoor unit is higher than the indoor unit)

F Less than H1=40 m (when the outdoor unit is lower than the indoor unit)

G Twinning pipe (for Y Series) CMY-Y102S-G2

H Combined pipe (CMY-R160-J1: optional)

I Less than 110 m J Less than 40 m

K Up to three units for 1 branch hole

Total capacity: less than 80 (but same in cooling/heating mode)

L Less than h1=15 m (10 m or less for 200, 250 unit type)

M Less than h2=15 m

Distance between BC controller

and farthest indoor unit

Height difference between

BC controller and farthest

indoor unit (m)

15105

20

10

0

0

Distance between BC contoroller

and farthest indoor unit (m)

70

60

50

40

30

2. CMB-P108, 1010, 1013, 1016GA1, P104, 108GB1 (GA1: In the case the outdoor unit is 26-hp (P650 model) or less.)

CMB-P1016HA1, 1016HB1 (HA1: In the case the outdoor unit is 28-hp

(P700 model) or more.)

[Fig. 2.4.2] (P.3)

A Outdoor unit B MAIN BC controller

C SUB BC controller D Indoor unit

E The twinning kit is connected inside the outdoor unit on the low-pressure side.

When outdoor units of different capacities are connected, connect the twinning

kit to the unit with a higher capacity.

F Twinning pipe (for R2 series) CMY-R100VBK, CMY-R200VBK

(for WR2 series) CMY-Q100VBK

G Twinning pipe (for Y series) CMY-Y202-G2, CMY-Y102L-G2, CMY-Y102S-G2

H Twinning pipe (CMY-R160-J1: optional)

I Twinning pipe (for Y series) CMY-Y102S-G2

J P100 - P250 model: 2 ports merged

K Maximum of 3 units per a pair of ports

Total capacity of 80 or below

All units connected to the same port must be in the same operation mode.

L Less than H=50 m (when the outdoor unit is higher than the indoor unit)

M Less than H1=40 m (when the outdoor unit is lower than the indoor unit)

N Less than h1=15 m (10 m or less for 200, 250 unit type)

O Less than h2=15 m

Page 10

10

GBDFEINLPGRRUTRCZSVSLHGPO

3.1. Checking the accessories with BC controller

The following items are supplied with each BC controller.

Distance between MAIN BC controller

and farthest indoor unit

Height difference between

MAIN BC controller and

farthest indoor unit (m)

15105

20

10

0

0

Distance between MAIN BC controller

and farthest indoor unit (m)

70

60

50

40

30

4.1. Connecting refrigerant pipes

1. Connect the liquid and gas pipes of each indoor unit to the same (correct) end

connection numbers as indicated on the indoor unit connection section of each

BC controller. If connected to wrong end connection numbers, there will be no

normal operation.

2. List indoor unit model names in the name plate on the BC controller control

box (for identification purposes), and BC controller end connection numbers

and address numbers in the name plate on the indoor unit side.

3. If the number of ports is greater than the number of indoor units to be connected,

use any ports.

Seal unused end connections using cover caps just as they were capped when

shipped from the factory. Not replacing on end cap will lead to refrigerant leak-age.

4. When using CMY-Y102S-G2, CMY-Y102L-G2, or CMY-Y202-G2, connect it

horizontally.

5. Be sure to have pipe expansion of indoor unit connecting port by cutting the

piping at the cutting point which depends on the indoor unit capacity.

Note:

Remove burr after cutting the piping to prevent entering the piping.

Check that there is no crack at the pipe expansion part.

[Fig. 4.1.1] (P.5)

A Indoor unit connecting port

B Cutting point : ø 9.52 (Liquid side) or ø15.88 (Gas side)

(Indoor unit model : bigger than P50)

C Cutting point : ø 6.35 (Liquid side) or ø12.7 (Gas side)

(Indoor unit model : P50 or smaller)

D Cut the piping at the cutting point

E Have pipe expansion of indoor unit connecting port

F Field pipe

4. Connecting refrigerant pipes and drain pipes

3.2. Installing BC controllers

Installing hanging bolts

Install locally procured hanging bolts (threaded rod) following the procedure given

in the figure. The hanging bolt size is ø10 (M10 screw).

To hang the unit, use a lifting machine to lift and pass it through the hanging bolts.

Suspension bracket has an oval hole. Use a large diameter washer.

[Fig. 3.2.1] (P.4)

1 Hanging method

A: Min.30 mm

A Hanging bolt ø10 (field supply) B Washer (field supply)

s Be sure to install the BC controller horizontally, using a level. If the

controller is installed at an angle, drain water may leak out. If the controller

is slanted, loosen the fixing nuts on the hanging brackets to adjust its

position.

Caution:

Be sure to install the unit horizontally.

Length

(Unit: m)

Item Piping portion Allowable value

F+G+A+B+C

Total piping length +D+E+a+b

+c+d+e+f

Longest piping length F(G)+A+C+E+f

Between outdoor unit and

F(G)+A Below 110

BC controller

Between indoor units and BC controller

B+d or C+D+e or C+E+f

Below 40 *2

Between outdoor units F+G Below 5

Above outdoor unit H Below 50

Below outdoor unit H’ Below 40

Between indoor units and BC controller h1

Below 15

(Below 10)*3

Between indoor units h2

Below 15

(Below 10)*3

Between BC controller (main or sub)

h3 Below 15

and BC controller (sub)

Between outdoor units h4 Below 0.1

Difference of elevation

Between

indoor and

outdoor units

Not to exceed the

maximum refrigerant piping length *1

165 m or less

(Equivalent length

of 190 m or less)

Notes:

A system that has more than 16 branching points requires 2 to 3 BC control-

lers (main and sub) and 3 pipes to connect the main and the sub BC controllers.

*1 Refer to “Restrictions on piping length” on P . 4.

*2 Please refer to the figure “Distance between main BC controller and far-

thest Indoor unit” when the distance between main BC controller and

farthest indoor unit exceeds 40 m. (Not applicable to the P250 model

indoor unit)

*3 The values in the parentheses show the maximum piping length to be

followed when the connection capacity of the indoor unit is 200 or more.

*4 In the system to which indoor units of the P200 model or above are con-

nected, neither a branch joint nor a branch header may be used.

*5 When connecting two sub BC controllers, the total piping length must be

equal to or less than the maximum length as listed in on the left.

*6 When connecting two sub BC controllers, install them in parallel.

*7 In the system to which indoor units of the P100 through P140 models are

connected, merge the two ports before connecting them. (Set DIP SW4-6

on the BC controller to ON.)

*8 It is possible to connect the P100 through P140 models of indoor units to

a single port. (Set DIP SW4-6 to OFF.) Note that the cooling capacity will

somewhat decrease. (The factory setting for DIP SW4-6 is OFF.)

*9 When the outdoor unit is 28-hp (P700 model) or more, use the HA-type

main BC controller. The G-type BC controller cannot be connected to the

models between 16-hp (P400 model) and 26-hp (P650 model), and the Gand GA-type BC controllers cannot be connected to the 28-hp (P650

model) or more.

*10 For Sub BC controller GB type, the connectable indoor unit capacities

may sum to equal that of a P350 unit or less. However, if two sub controllers are used the TOTAL sum of connectable units connected to BOTH

sub controllers must also not exceed that of a P350 unit.

For sub BC controller HB type, the connectable indoor unit capacities

may sum to equal that or a P350 unit or less. However, if two sub controllers are used the TOTAL sum of connectable units connected to BOTH

sub controllers must also not exceed that of a P450 unit.

*11 Indoor units that are connected to the same branch joint cannot be si-

multaneously operated in different operation modes.

*12 Do not connect the P200 or P250 models of indoor units and other mod-

els of indoor units at the same port.

3. Installing BC controller

1 Drain hose

2 Tie band

3 Hose band

4 Refrigerant

connection pipe

Item

Qty

CMBP104V-G1

P105V-G1

P106V-G1

P108V-G1

P1010V-G1

P1013V-G1

P1016V-G1

1

1

1

3

Model name

CMBP108V-GA1

P1010V-GA1

P1013V-GA1

P1016V-GA1

1

1

1

3

CMBP104V-GB1

P108V-GB1

1

1

1

8

CMBP1016V-HA1

1

1

1

1

CMBP1016V-HB1

1

1

1

8

[Fig. 2.4.3] (P.4)

A Total piping length (m)

B Piping length between controller unit and BC controller (m)

Page 11

11

GBDFEINLPGRRUTRCZSVSLHGPO

A To outdoor unit (MAIN BC CONTROLLER)

B End connection (brazing)

C BC controller (MAIN BC CONTROLLER/SUB BC CONTROLLER)

D Reducer E Indoor unit

F Less than 50

G Combined piping kit (Model name: CMY-R160-J1)

H Twinning pipe (Model name: CMY-Y102S-G2)

I Up to three units for 1 branch hole; total capacity: below 80 (but same in cooling/

heating mode)

The size of BC controller’s branch piping is for 63 to 140 type indoor units.

Therefore, if you want to connect indoor units other than the above, connect piping

following the procedures below.

*1. For connecting 15 to 50 type indoor units

Have pipe expansion of indoor unit connecting port by cutting the piping at the

cutting point which depends on the indoor unit capacity.

Note:

Remove burr after cutting the piping to prevent entering the piping.

Check that there is no crack at the pipe expansion part.

*2. To connect a unit with a capacity of higher than 81.

After combining two branches using an optionally available piping kit (CMY-R160J1), connect indoor units.

*3. Connection of plural indoor units with one connection (or joint pipe)

• Total capacity of connectable indoor units: Less than 80 (Less than 250 with

joint pipe)

• Number of connectable indoor units: Maximum 3 Sets

• Twinning pipe: Use the twinning pipe for CITY MULTI Y Series (CMY-Y102S-

G2)

• Selection of refrigerant piping

Select the size according to the total capacity of indoor units to be installed

downstream.

Total capacity of indoor units Liquid line Gas line

Below 140 ø15.88

141 to 200 ø9.52 ø19.05

201 to 250 ø22.2

6. Be sure to use non-oxidative brazing where necessary. If you do not use nonoxidative brazing, it may clog the pipes.

While under a nitrogen purge, braze the indoor unit connecting port before

brazing the outdoor unit connecting port of BC controller.

When brazing the indoor unit connecting port, supply a nitrogen gas into the

outdoor unit connecting port of BC controller.

When brazing the outdoor unit connecting port of BC controller, supply a nitrogen

gas into the pipe between the outdoor unit and BC controller.

7. After completing pipe connection, support the pipes to ensure that load is not

imparted to the BC controller’s end connections (particularly to the gas pipes

of indoor units).

Warning :

When installing and moving the unit, do not charge it with refrigerant other

than the refrigerant (R410A) specified on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to mal-

function and result in severe damage.

Caution:

•

Use refrigerant piping made of phosphorus deoxidized copper and copper alloy seamless pipes and tubes. In addition, be sure that the inner and

outer surfaces of the pipes are clean and free of hazardous sulphur , oxides,

dust/dirt, shaving particles, oils, moisture, or any other contaminant.

-

R410A is a high-pressure refrigerant and can cause the existing piping to burst.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor failure may result.

• Apply a small amount of ester oil, ether oil, or alkyl benzene to flares. (for

indoor unit)

- Infiltration of a large amount of mineral oil may cause the refrigerant oil to

deteriorate.

• Do not vent R410A into the atmosphere.

• R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol

with a Global Warming Potential (GWP) = 1975.

*1 Use the supplied pipe.

[Fig. 4.1.2] (P.5)

Note:

Be sure to use non-oxidative brazing.

4.2. Refrigerant piping work

After connecting the refrigerant pipes of all indoor and outdoor units with the outdoor units’ stop valves remained fully closed, evacuate vacuum from the outdoor

units’ stop valve service ports.

After completing the above, open the outdoor units’ stop valves. This connects the

refrigerant circuit (between outdoor and BC controller) completely.

How to handle stop valves is described on each outdoor unit.

Notes:

• After pipe connection, be sure to check that there is no gas leakage,

using a leak detector or soap-and-water solution.

• Before brazing the refrigerant piping, always wrap the piping on the main

body, and the thermal insulation piping, with damp cloths to prevent heat

shrinkage and burning the thermal insulation tubing. Take care to ensure

that the flame does not come into contact with the main body itself.

• Do not use leak-detection additives.

Warning:

Do not mix anything other than the specified refrigerant (R410A) into the

refrigerating cycle when installing or moving. Mixing air may cause the refrigerating cycle to reach abnormally high temperature, resulting in burst pipes.

Caution:

Cut the tip of the outdoor unit piping, remove the gas, and then remove the

brazed cap.

[Fig. 4.2.1] (P.6)

A Cut here B Remove brazed cap

1. Size of BC controller’s end connection piping

Outdoor unit side

PURY-(E) P400

PQRY-P400

PURY-(E) P450

PQRY-P450

PURY-(E) P500

PQRY-P500

PURY-(E) P550

PQRY-P550

PURY-(E) P600

PQRY-P600

PURY-P650

PURY-P700

PURY-P750

PURY-P800

BC CONTROLLER/MAIN BC CONTROLLER SUB BC CONTROLLER

Unit model Model name

High pressure

side

Low pressure

side

Model name

Total capacity

of indoor units

High pressure

(gas) side

Low pressure

(gas) side

Liquid side

PURY-(E) P200

PQRY-P200

PURY-(E) P250

PQRY-P250

PURY-(E) P300

PQRY-P300

PURY-P350

Indoor unit side

(BC CONTROLLER)

CMB-P104V-G1

CMB-P105V-G1

CMB-P106V-G1

CMB-P108V-G1

CMB-P1010V-G1

CMB-P1013V-G1

CMB-P1016V-G1

(MAIN BC

CONTROLLER)

CMB-P108V-GA1

CMB-P1010V-GA1

CMB-P1013V-GA1

CMB-P1016V-GA1

(MAIN BC

CONTROLLER)

CMB-P1016V-HA1

When a system that has more than 16 branching points, use BC controllers (main and

sub) to connect the pipes.

CMB-P104V-GB1

CMB-P108V-GB1

CMB-P1016V-HB1

ø15.88*1

(Brazing)

ø19.05

(Brazing)

ø19.05*1

(Brazing)

ø22.2

(Brazing)

ø28.58*1

(Brazing)

ø28.58

(Brazing)

ø9.52 or ø6.35

(Brazing)

ø19.05*1

(Brazing)

ø22.2

(Brazing)

ø28.58*1

(Brazing)

ø28.58

(Brazing)

ø34.93*1

(Brazing)

ø15.88 or ø12.7

(Brazing)

below 200

ø15.88*1

(Brazing)

ø19.05*1

(Brazing)

ø9.52

(Brazing)

201~300

ø19.05

(Brazing)

ø22.2

(Brazing)

301~350

351~400

ø22.2*1

(Brazing)

ø28.58*1

(Brazing)

401~450

ø9.52 or ø6.35

(Brazing)

ø15.88 or ø12.7

(Brazing)

ø12.7*1

(Brazing)

ø15.88*1

(Brazing)

Page 12

12

GBDFEINLPGRRUTRCZSVSLHGPO

s Consult all related regulations and power companies beforehand.

Warning:

Electrical work should be handled by qualified electrical engineers in accordance with all related regulations and attached instruction manuals. Special circuits should also be used. If there is a lack of power capacity or a

deficiency in electrical work, it may cause a risk of electric shock or fire.

s Connect all wires securely.

• Fix power source wiring to control box by using buffer bushing for tensile force

(PG connection or the like).

[Fig. 5.0.1] (P.6)

A Control box B Power source wiring

C ø21 hole (closed rubber bushing) D Transmission wiring

s Never connect the power cable to the terminal board for control cables.

(Otherwise it may be broken.)

s Be sure to wire between the control wire terminal boards for indoor unit,

outdoor unit and BC controller.

Use non-polarized 2-wire as transmission cables.

Use 2-core shielding cables (CVVS, CPEVS) of more than 1.25 mm

2

in diameter

as transmission cables.

4.3. Insulating refrigerant pipes

Be sure to add insulation work to refrigerant piping by covering high-pressure pipe and

low-pressure pipe separately with enough thickness heat-resistant polyethylene, so

that no gap is observed in the joint between indoor unit and insulating material, and

insulating materials themselves. When insulation work is insufficient, there is a possibility

of condensation drip, etc. Pay special attention to insulation work in the ceiling plenum.

[Fig. 4.3.1] (P.6)

A Locally procured insulating material for pipes

B Bind here using band or tape. C Do not leave any opening.

D Lap margin: more than 40 E Insulating material (field supply)

F Unit side insulating material

• Insulation materials for the pipes to be added on site must meet the following

specifications:

Outdoor unit High-pressure pipe 10 mm or more

-BC controller Low-pressure pipe 20 mm or more

BC controller Pipe size 6.35 mm to 25.4 mm 10 mm or more

-indoor unit Pipe size 28.58 mm to 38.1 mm 15 mm or more

Temperature Resistance 100°C min.

• Installation of pipes in a high-temperature high-humidity environment, such as

the top floor of a building, may require the use of insulation materials thicker

than the ones specified in the chart above.

• When certain specifications presented by the client must be met, ensure that

they also meet the specifications on the chart above.

• The brazed connections must be covered with the insulations, its cutting surface

upward and fastened with the bands.

4.4. Drain piping work

1. Drain piping work

• Ensure that the drain piping is downward (pitch of more than 1/100) to the

outdoor (discharge) side. If it is impossible to take any downward pitch, use an

optionally available drain-up mechanism to obtain a downward pitch of more

than 1/100.

• Ensure that any cross-wise drain piping is less than 20 m. If the drain piping is

long, support it with metal brackets to prevent it from bending, warping, or

vibrating.

Molded case

circuit breaker

Earth leakage

breaker

• Connect the supplied drain hose to the discharge port on the unit body. Use

hard vinyl chloride pipes VP-25 (ø32) for drain piping (2). Tighten the supplied

drain hose onto the discharge port using the supplied hose band. (For this, do

not use any adhesive because the drain hose will need to be removed for

servicing at a later date.)

• Do not use any odor trap around the discharge port.

[Fig. 4.4.1] (P.6)

A: 25 cm B: 1.5 – 2 m

A Downward pitch of more than 1/100

B Insulating material C Supporting bracket

D Drain discharge port E Drain hose (200 mm long, accessory)

F Tie band (accessory) G Hose band (accessory)

•

As shown in 3, install a collecting pipe about 10 cm below the drain ports and give

it a downward pitch of more than 1/100. This collecting pipe should be of VP-30.

• Set the end of drain piping in a place without any risk of odor generation.

•

Do not put the end of drain piping into any drain where ionic gases are generated.

• Drain piping may be installed in any direction. However, please be sure to

observe the above instructions.

• When using an optionally available drain-up mechanism, follow its instruction

manual regarding its installation and use.

[Fig. 4.4.2] (P.6)

A BC controller B Indoor unit

C Collecting pipe D Please ensure this length is at least 10 cm.

2. Discharge test

After completing drain piping work, open the BC controller panel, and test drain

discharge using a small amount of water. Also, check to see that there is no water

leakage from the connections.

3. Insulating drain pipes

Provide sufficient insulation to the drain pipes just as for refrigerant pipes.

Caution:

Be sure to provide drain piping with heat inslation in order to prevent excess

condensation. Without drain piping, water may leak from the unit causing

damage to your property.

The switch capacity of the main power to BC controllers and the wire size are as

follows:

Switch (A)

Wire size

Capacity Fuse

16 16 20 A 20 A 30 mA 1.5 mm

2

0.1 s or less

• For other detailed information, refer to the outdoor unit installation manual.

• Power supply cords of appliances shall not be lighter than design 245 IEC 53

or 227 IEC 53.

• A switch with at least 3 mm contact separation in each pole shall be provided

by the Air conditioner installation.

Caution:

Do not use anything other than the correct capacity fuse and breaker. Using

fuse, conductor or copper wire with too large capacity may cause a risk of

malfunction or fire.

Ensure that the outdoor units are put to the ground. Do not connect the earth

cable to any gas pipe, water pipe, lightening rod or telephone earth cable.

Incomplete grounding may cause a risk of electric shock.

6. Setting addresses and operating units

7. Test run

Before commencing a test run please check the following:

s After installing, piping and wiring the indoor units and BC controllers,

check to see again that there is no refrigerant leakage and no slack on

power and control cables.

s Use a 500 V megger to check that there is an insulation resistance of

more than 1.0 MΩ between the power terminal block and the ground. If it

is less than 1.0 MΩ, do not operate the unit.

5. Electrical work

The address switch of each BC controller is set to “000” when shipped from the

factory.

• Set the address switch to 1 + the address of the outdoor unit.

s The BC controller address should generally be set to 1 + the address of

the outdoor unit. However, if this would result in it having the same address as another outdoor unit, set the address between 51 and 100, making sure that it is different from the address of other controllers.

• Please refer to the outdoor unit installation manual.

Caution:

Never measure the insulation resistance of the terminal block for any control

cables.

Page 13

63

GBDFEINLPGR

RUTRCZSVSLHGPO

Содержание

1. Меры предосторожности

1.1. До установки и монтажа проводки

s Перед установкой системы необходимо внимательно

ознакомиться с разделом “Меры предосторожности”.

s Раздел “Меры предосторожности” содержит важную

информацию по безопасности. Правила безопасности

следует соблюдать в обязательном порядке.

Символы, используемые в тексте

Предупреждение:

Несоблюдение данных предупреждений может привести к

травмированию людей или летальному исходу.

Внимание:

Несоблюдение данных инструкций может привести к выходу

оборудования из строя.

Символы, используемые в иллюстрациях

: Служит для обозначения действий, запрещенных к выполнению.

: Служит для обозначения инструкций, подлежащих выполнению.

: Служит для обозначения узла, который должен быть заземлен.

: Указывает на опасность поражения электрическим током. (Данный

символ отображается на предупреждающей наклейке, закрепленной

на основном блоке.) <Цвет: желтый>

Предупреждение:

Внимательно ознакомьтесь с содержанием

предупреждающих табличек на основном блоке.

ПРЕДУПРЕЖДЕНИЕ О ВЫСОКОМ НАПРЯЖЕНИИ:

• В блоке управления содержатся узлы под высоким напряжением.

• При открывании передней панели следует принять меры к

исключению их контакта с внутренними компонентами.

• Перед тем как приступить к осмотру внутренней части блока

управления, необходимо отключить питание не менее, чем на 10

минут.

Предупреждение:

• Установка кондиционера воздуха должна производиться силами

специалистов дилерского центра либо другим специалистом,

обладающим соответствующей квалификацией.

- Ненадлежащая установка самим пользователем может стать причиной

утечки воды, поражения электрическим током, возгорания и т.д.

• Монтаж должен осуществляться на таком месте, которое является

достаточно прочным, чтобы выдержать вес кондиционера.

- Невыполнение данного условия может привести к падению

кондиционера и травмированию людей.

• Для проводки используйте только специальные кабели. Убедитесь

в надежности подсоединения и в том, что внешние силы,

прикладываемые к кабелю, не передаются на клеммы.

- Ненадлежащим образом выполненные подсоединения и слабая

затяжка могут вызвать нагрев и последующее возгорание.

• Монтаж производится в специально предназначенном месте, с

запасом прочности на случай сильных ветров и землетрясений.

- Нарушение правил монтажа может привести к падению кондиционера

и травмированию людей.

• Aксессуары, указанные компанией Mitsubishi Electric, должны

использоваться в обязательном порядке.

- Для установки аксессуаров необходимо обратиться к помощи

квалифицированного специалиста. Ненадлежащая установка самим

пользователем может стать причиной утечки воды, поражения

электрическим током, возгорания и т.д.

• Запрещается ремонтировать кондиционер самостоятельно. При

необходимости выполнения ремонта следует обратиться в

дилерский центр.

- Ненадлежащим образом выполненный ремонт может стать причиной

утечки воды, поражения электрическим током, возгорания и т.д.

• При возникновении утечки хладагента во время проведения

монтажных работ необходимо проветрить помещение.

- В результате контактирования хладагента с открытым огнем

происходит выделение ядовитых газов.

• Установка кондиционера воздуха должна производиться в полном

соответствии с Руководством по установке.

- Ненадлежащим образом выполненная установка может стать причиной

утечки воды, поражения электрическим током, возгорания и т.д.

• Все работы, связанные с электричеством, должны выполняться

квалифицированным электриком в полном соответствии с

“Электротехническими стандартами” и “Нормами проведения

внутренней проводки” и инструкциями, указанными в Руководстве

по установке. Характеристики электропитания должны строго

соответствовать рекомендованным.

- Несоответствие характеристик подаваемого питания

рекомендованным или нарушение правил установки могут привести с

сбоям в работе кондиционера, поражению электрическим током или

возгоранию.

• Надежно устанавливайте крышку блока управления.

- Если крышка неправильно установлена, в наружный блок может

попасть вода или пыль, в результате чего может возникнуть пожар или

поражение электрическим током.

• При установке или переноске кондиционера воздуха на другое место

для его заправки следует применять только хладагент,

рекомендованный к применению с данным кондиционером.

- Использование иного хладагента, а также проникновение воздуха в

систему приведет к нарушениям его циркуляции и выходу кондиционера

из строя.

• При установке кондиционера воздуха в небольшом помещении

следует предварительно провести измерения и убедиться в том, что

в случае аварийной утечки в этом помещении не будет превышена

предельно допустимая концентрация паров хладагента.

- Для получения информации по размерам помещения обратитесь в

дилерский центр. Превышение концентрации паров хладагента в случае

его аварийной утечки повлечет за собой недопустимое снижение

содержания кислорода в воздухе.

• Перед проведением работ по перемещению или повторной его

установке необходимо проконсультироваться с сотрудниками

дилерского центра или квалифицированным специалистом.

- Ненадлежащим образом выполненная установка может стать причиной

утечки воды, поражения электрическим током, возгорания и т.д.

• После окончания монтажных работ следует убедиться в отсутствии

утечки хладагента.

- Контакт хладагента с нагревательными приборами, кухонной плитой и

иными источниками тепла может привести к выделению токсичных

газов.

• Запрещается вносить любые изменения в конструкцию защитных

устройств и изменять их настройки.

- Короткое замыкание реле давления, теплового реле и иных защитных

устройств, приложение к ним физического воздействие, равно как

применение компонентов, отличных от указанных компанией Mitsubishi

Electric, может привести к возгоранию или взрыву.

• По вопросам, связанным с утилизацией данного изделия следует

обращаться в дилерский центр.

• Мастер монтажа и электрик должны обеспечить защиту системы от

протечек в соответствии с требованиями местного законодательства

и стандартов.

- Выберите провод соответствующего размера и переключатели

необходимой мощности для основного блока питания, описанного в

данном руководстве, при отсутствии местных норм.

1. Меры предосторожности ....................................................................... 63

1.1. До установки и монтажа проводки ...................................... 63

1.2. Меры предосторожности для приборов, в которых

используется хладагент R410A ............................................ 64

1.3. Перед установкой .................................................................. 64

1.4. Перед монтажом (переносом) проводки ............................. 64

1.5. Перед началом тестового запуска ...................................... 64

2. Выберите место установки .................................................................... 65

2.1. Информация о продукте ....................................................... 65

2.2. Место установки .................................................................... 65

2.3. Обеспечение необходимого пространства для установки

и техобслуживания................................................................ 65

2.4. Проверка места установки ................................................... 65

3. Инсталляция Регулятора ВС ................................................................. 67

3.1. Проверка наличия дополнительных принадлежностей,

поставляемых в комплекте с Регулятором ВС .................. 67

3.2. Инсталляция Регуляторов ВС .............................................. 67

4. Подсоединение труб хладагента и дренажных труб ........................... 67

4.1. Подсоединение труб хладагента ......................................... 67

4.2. Прокладка труб хладагента ................................................. 68

4.3. Изоляция труб хладагента ................................................... 69

4.4. Прокладка дренажных труб ................................................. 69

5. Электроработы ....................................................................................... 69

6. Установка адресов и операционных блоков ........................................ 70

7. Выполнение испытания .......................................................................... 70

Page 14

64

GBDFEINLPGR

RUTRCZSVSLHGPO

• Особое внимание необходимо уделять области установки изделия,

и особенно его основанию, где возможно скопление паров

охлаждающего газа, который тяжелее воздуха.

1.2. Меры предосторожности для

приборов, в которых используется

хладагент R410A

Внимание:

• Не используйте имеющиеся трубы хладагента.

- Использование старых труб хладагента и старого масла охлаждения,

содержащих большие количества хлора, может привести к порче масла

охлаждения нового прибора.

- R410A является хладагентом высокого давления, что может привести

к разрыву существующих труб.

• Используйте трубы из раскисленной фосфором меди и бесшовные

трубы, выполненные из латуни. Кроме этого убедитесь, что

внутренняя и внешняя поверхность труб чистая, без частиц серы,

окисей, пыли/ грязи, частиц стружки, масел, влаги или других

загрязнений.

- Загрязнение внутренней поверхности труб хладагента может вызвать

ухудшение качеств компрессорного масла.

• Храните предназначенные для установки трубы в помещении,

герметически закрытыми с обоих концов до припайки. (изменения

и другие соединения храните в пластиковом пакете.)

- Попадание в контур охлаждения пыли, грязи или воды, может привести

к ухудшению эксплуатационных качеств масла и выходу компрессора

из строя.

• Нанесите небольшое количество сложного или простого эфира или

алкилбензола на патрубки и фланцевые соединения. (для

внутренних блоков)

- Масло охлаждения потеряет свои свойства при смешивании с большим

количеством минерального масла.

• Используйте для зарядки системы жидкий хладагент.

- При использовании газообразного хладагента для зарядки системы,

состав хладагента в баллоне изменится, а рабочие показатели прибора

могут ухудшиться.

• Разрешается использовать исключительно хладагент R410A.

- При использовании другого агента (например, R22 в смеси с R410A)

наличие в нем хлора может привести к ухудшению эксплуатационных

качеств холодильного масла.

• Используйте вакуумный насос с обратным клапаном.

- Проникновение масла вакуумного насоса в контур охлаждения может

привести к ухудшению эксплуатационных качеств холодильного масла.

• Запрещается использовать следующие инструменты, применяемые

с обычными видами хладагента.

(Штуцер манометра, заправочный шланг, течеискатель, обратный

клапан, заправочное основание, оборудование для сбора

хладагента)

- Попадание обычного хладагента и холодильного масла в R410A может

привести к ухудшению эксплуатационных свойств хладагента.

- Попадание воды R410A приведет к ухудшению эксплуатационных

свойств холодильного масла.

- Поскольку в состав R410A хлорин не входит, течеискатели,

используемые для работы с обычными хладагентами, не применимы.

• Запрещается использовать заправочные баллоны.

- Использование заправочного баллона может привести к ухудшению

эксплуатационных свойств хладагента.

• Не используйте противоокислительные или обнаруживающие

утечку добавки.

• При работе с инструментом следует принимать меры

предосторожности.

- Попадание в холодильный контур пыли, грязи или воды может привести

к ухудшению эксплуатационных свойств хладагента.

1.3. Перед установкой

Внимание:

• Запрещается устанавливать этот блок в местах, где возможна утечка

огнеопасных газов.

- Утечка газа и его скопление возле кондиционера может привести к

взрыву.

• Не используйте кондиционер в местах хранения продуктов питания,

точных инструментов, произведений искусств, а также местах

нахождения домашних животных и растений.

- Это може вызвать, например, порчу продуктов питания.

• Не используйте кондиционер воздуха в особых условиях

эксплуатации.

- Наличие масел, пара, испарений серы и т.д. может вызвать

значительное ухудшение рабочих показателей кондиционера или выход

его компонентов из строя.

• При установке прибора в больнице, на станции связи или в

аналогичном помещении обеспечьте достаточную защиту от шума.

- Преобразовательное оборудование, частный электрогенератор,