Page 1

Air-Conditioners For Building Application

A

U

R

A

B

INDOOR UNIT

G

E

P

Ü

R

CMB-P-V-E

FOR INSTALLER

FÜR INSTALLATEURE

T

T

F

ДЛЯ УСТАНОВИТЕЛЯ

VOOR DE INSTALLATEUR

POUR L’INSTALLATEUR

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the BC controller.

This installation manual describes the installation method of BC controller. For the installation method of indoor/outdoor units, please

see the installation manual of indoor/outdoor units respectively.

∗ Remote controller (PAR-F25MA) is available as an optional remote controller.

INSTALLATIONSHANDBUCH

Zum sicheren und richtigen Einsatz vor Installation der BC-Steuerung diese Installationsanweisungen gründlich durchlesen.

In dieser Installationsanweisung wird das Installationsverfahren für die BC-Steuerung beschrieben. Angaben zum Installationsverfahren für die Innen-/Außenanlagen finden sich in den Installationsanweisungen für die Innen-/Außenanlagen.

∗ Fernbedienung (PAR-F25MA) ist als Zubehör wahlweise erhältlich.

РУКОВОДСТВО ПО УСТАНОВКЕ

В целях безопасного и правильного использования, пожалуйста, ознакомьтесь тщательно с инструкциями данного

руководства по установке до установки пульта управления ВС.

В данном руководстве по установке указаны методы установки пульта управления ВС. Медоты установки внешнего/

внутреннего приборов указаны в соответствующих руководствах по установке внешнего/ внутреннего приборов.

∗ Пульт дистанционного управления (PAR-F25MA) поставляется дополнительно

For use with the R407C & R22

Bei Verwendung von R407C & R22

Для использования с моделями R407С и R22

ENGLISH

DEUTSCH

РУССКИЙ

INSTALLATIEHANDLEIDING

Lees voor een veilig en correct gebruik deze installatiehandleiding goed door voordat u de BC-bedieningseenheid installeert.

Deze installatiehandleiding beschrijft de wijze van installeren van de BC-bedieningseenheid. Voor de manier van installeren van

binnen- en buitenapparaten moet u de installatiehandleidingen van respectievelijk de binnen- en buitenapparaten raadplegen.

∗ De afstandsbedieningseenheid (PAR-F25MA) is verkrijgbaar als een optioneel toe te voegen afstandsbediening.

MANUEL D’INSTALLATION

Pour une utilisation correcte de l’appareil et en toute sécurité, veuillez lire attentivement le présent manuel d’installation avant d’installer

le contrôleur BC.

Ce manuel d’installation décrit le procédé d’installation du contrôleur BC. Pour les méthodes d’installation des appareils intérieurs/

extérieurs, veuillez vous reporter aux manuels d’installation des appareils respectifs.

∗ La télécommande (PAR-F25MA) est disponible en option.

Bij gebruik van R407C & R22

A utiliser avec le R407C et le R22

NEDERLANDS

FRANÇAIS

Page 2

Contents

1. Safety precautions ..................................................................... 3

1.1. Before installation and electric work ............................... 3

1.2. Precautions for devices that use R407C refrigerant....... 3

1.3. Before getting installed ................................................... 4

1.4. Before getting installed (moved) - electrical work........... 4

1.5. Before starting the test run ............................................. 4

2. Selecting an installation site ...................................................... 5

2.1. Installation site................................................................5

2.2. Securing installation and service space ......................... 5

2.3. Checking the installation site .......................................... 6

3. Installing BC controller...............................................................7

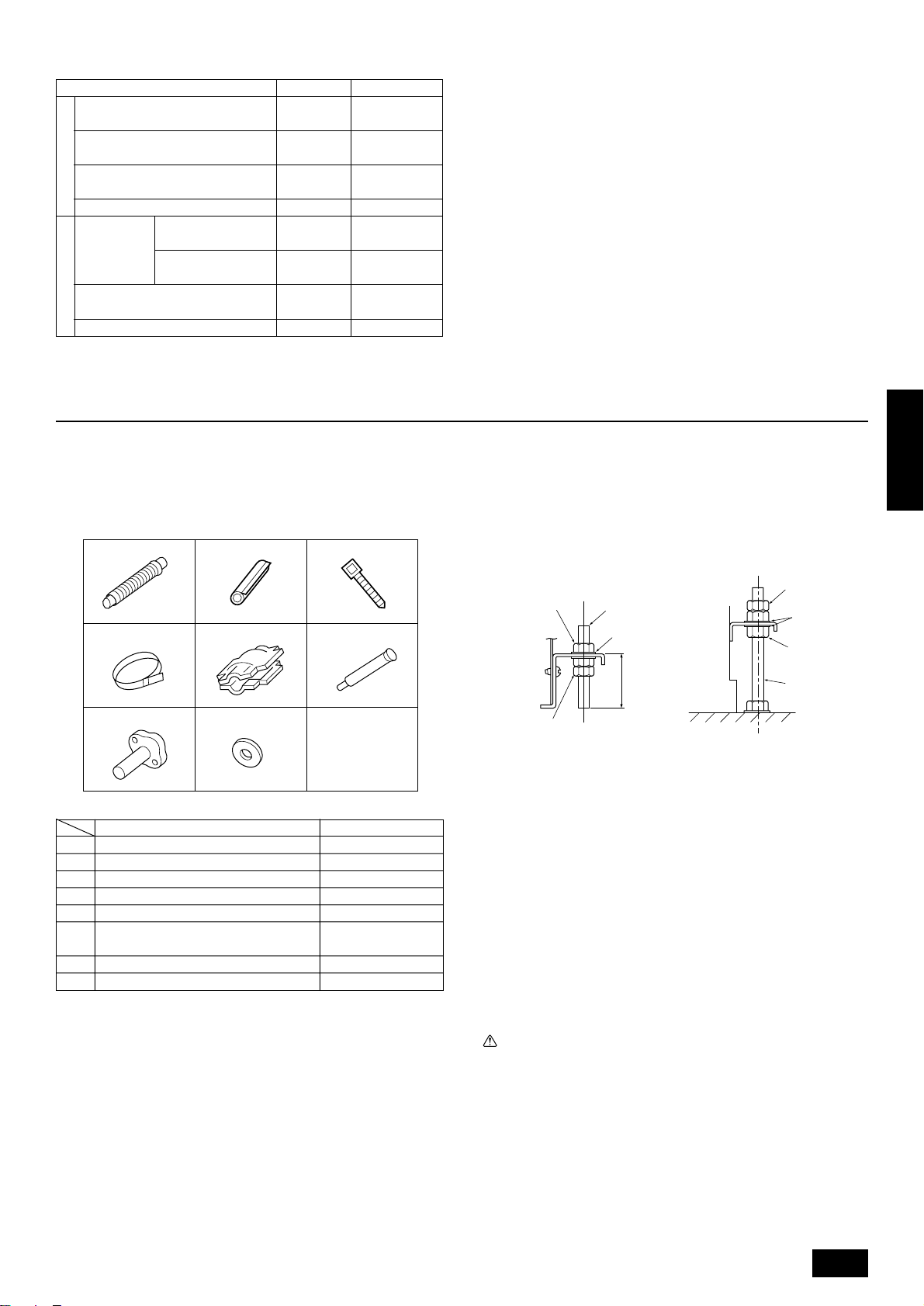

3.1. Checking the accessories with BC controller ................. 7

3.2. Installing BC controllers.................................................. 7

4. Connecting refrigerant pipes and drain pipes ............................ 8

ENGLISH

4.1. Connecting refrigerant pipes .......................................... 8

4.2. Refrigerant piping work................................................. 10

4.3. Insulating refrigerant pipes ........................................... 10

4.4. Drain piping work.......................................................... 10

5. Electrical work.......................................................................... 11

6. Setting addresses and operating units .................................... 12

7. Test run.................................................................................... 12

2

Page 3

1. Safety precautions

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the

“Safety precautions”.

s The “Safety precautions” provide very important

points regarding safety. Make sure you follow them.

s This equipment may not be applicable to EN61000-3-

2: 1995 and EN61000-3-3: 1995.

s This equipment may cause the adverse effect on the

same supply system.

s Please report to or take consent by the supply author-

ity before connection to the system.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger

of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage

to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This

symbol is displayed on the main unit label.) <Color: Yellow>

: Indicates that the main switch must be turned off before servic-

ing. (This symbol is displayed on the main unit label.) <Color:

Blue>

: Beware of electric shock (This symbol is displayed on the main

unit label.) <Color: Yellow>

: Beware of hot surface (This symbol is displayed on the main unit

label.) <Color: Yellow>

: Please pay attention to electric shock fully because this is

ELV

not Safety Extra Low-Voltage (SELV) circuit.

And at servicing, please shut down the power supply for

both of Indoor Unit and Outdoor Unit.

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, elec-

tric shock, or fire.

• Install the air unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in

injuries.

• Use the specified cables for wiring. Make the connections securely so that the outside force of the cable is not applied to the

terminals.

- Inadequate connection and fastening may generate heat and cause

a fire.

• Prepare for earthquakes and install the unit at the specified place.

- Improper installation may cause the unit to result in injury.

• Always use other accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper

installation by the user may result in water leakage, electric shock,

or fire.

• Never repair the unit. If the air conditioner must be repaired,

consult the dealer.

- If the unit is repaired improperly, water leakage, electric shock, or

fire may result.

• If refrigerant gas leaks during installation work, ventilate the

room.

- If the refrigerant gas comes into contact with a flame, poisonous

gases will be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or

fire may result.

• Have all electric work done by a licensed electrician according

to “Electric Facility Engineering Standard” and “Interior Wire

Regulations”and the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is per-

formed improperly, electric shock and fire may result.

• Securely install the cover of control box.

- If the cover and panel are not installed properly, dust or water may

enter the outdoor unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site,

do not charge the it with a refrigerant different from the refrigerant (R407C or R22) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant,

the refrigerant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must

be taken to prevent the refrigerant concentration from exceeding the safety limit even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent

the safety limit from being exceeded. Should the refrigerant leak

and cause the safety limit to be exceeded, hazards due to lack of

oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the

dealer or an authorized technician.

- If the air conditioner is installed improperly, w ater leakage , electric

shock, or fire may result.

• After completing installation work, make sure that refrigerant

gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove,

oven, or other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is

shorted and operated forcibly, or parts other than those specified

by Mitsubishi Electric are used, fire or explosion may result.

1.2. Precautions for devices that use

R407C refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping con-

tains a large amount of chlorine which may cause the refrigerator

oil of the new unit to deteriorate.

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus

deoxidized copper as specified in the JIS H3300 “Copper and

copper alloy seamless pipes and tubes”. In addition, be sure

that the inner and outer surfaces of the pipes are clean and free

of hazardous sulphur, oxides, dust/dirt, shaving particles, oils,

moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the

refrigerant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep

both ends of the piping sealed until just before brazing. (Store

elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of

the oil and compressor trouble may result.

ENGLISH

3

Page 4

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of

mineral oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the

refrigerant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and

cause the refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow

check valve, refrigerant charge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the

R407C, the refrigerant may deteriorated.

- If water is mixed in the R407C, the refrigerator oil may deteriorate.

- Since R407C does not contain any chlorine, gas leak detectors for

ENGLISH

conventional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant

may deteriorate.

1.3. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion

may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the per-

formance of the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station,

or similar place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency

medical equipment, or radio communication equipment may cause

the air conditioner to operate erroneously , or f ail to operate . On the

other hand, the air conditioner may affect such equipment by creating noise that disturbs medical treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80% or when the drain pipe is

clogged, condensation may drip from the indoor unit or BC controller. P erform collective drainage w ork together with the outdoor unit,

as required.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper

wire may result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury or property damage.

• Install the drain piping according to this Installation Manual to

ensure proper drainage. Wrap thermal insulation around the

pipes to prevent condensation.

- Improper drain piping may cause water leakage and damage to

furniture and other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than

20 kg.

- Some products use PP bands for packaging. Do not use any PP

bands for a means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fin-

gers.

- When transporting the outdoor unit, suspend it at the specified po-

sitions on the unit base. Also support the outdoor unit at four points

so that it cannot slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts,

may cause stabs or other injuries.

- T ear apart and throw aw ay plastic packaging bags so that children

will not play with them. If children play with a plastic bag which was

not torn apart, they face the risk of suffocation.

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power

switch can result in severe damage to internal parts. Keep the power

switch turned on during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after

operation.

- During and immediately after operation, the refrigerant pipes are

may be hot and may be cold, depending on the condition of the

refrigerant flowing through the refrigerant piping, compressor, and

other refrigerant cycle parts. Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards

removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five min utes before turning off the power. Oth-

erwise, water leakage and trouble may occur.

1.4. Before getting installed (moved) electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning

rods, or telephone ground lines. Improper grounding may result in

electric shock.

• Install the power cable so that tension is not applied to the cable.

- T ension may cause the cable to break and generate heat and cause

a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity

and rating.

- Cables that are too small may leak, generate heat, and cause a

fire.

4

Page 5

2. Selecting an installation site

2.1. Installation site

• Place not exposed to rain (BC controller is a special machine for

indoor use.)

• Place with large enough service space

• Place in which refrigerant pipes can be provided within the limitations

• Place not exposed to direct radiant heat from other heat sources

• Do not install the unit in any oily steamy place or near any machine

that generates high frequencies. Doing so may cause a risk of fire,

erroneous operation or dew drop.

• Place with less noise effect generated from other units

• Place in which water piping, refrigerant piping and electrical wiring

can be done easily

• Avoid places e xposed to the generation, inflow , accumulation or leakage of flammable and sulfuric gases

• Place in which a downward pitch of more than 1/100 can be taken for

drain piping

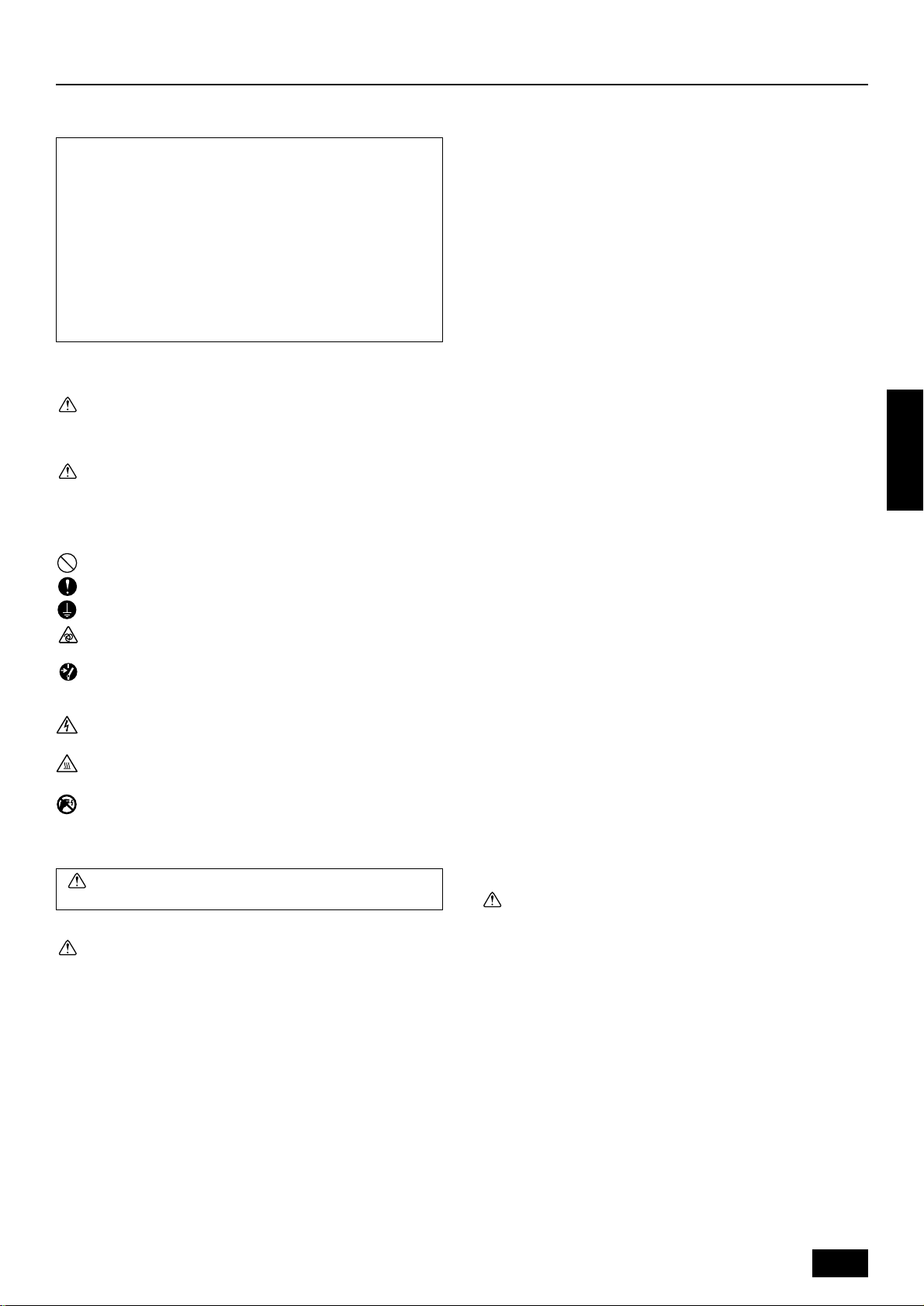

1. For hanging from the ceiling

• Place in which sufficient space can be obtained around a rack

• Place with floor strength that sustains the entire weight

Warning:

Be sure to install the unit in a place that well sustains the entire

weight.

If there is a lack of strength, it may cause the unit to fall down,

resulting in an injury.

Caution:

Be sure to install the unit at level.

2.2. Securing installation and service

space

1. For hanging from the ceiling

(This is a reference view showing the least installation space.)

<Top view>

ENGLISH

A

• Provide a inspection hole 450 mm square to the ceiling surface as

shown in 2.2.1 1.

• Above the ceiling of corridor, bath room, etc., where persons are not

regularly there

(Avoid installing at around center of the room.)

• Place with strength to the degree that hanging bolts can be mounted

(that sustains a pull-out load of 60kg per bolt)

• Be sure to install BC controllers at level.

2. For stacking on a rack

C

B

D

300 A 200

A Inspection hole

B On the side of outdoor unit piping

C Control box

D On the side of indoor unit piping

213

130*1 298 281

5

Page 6

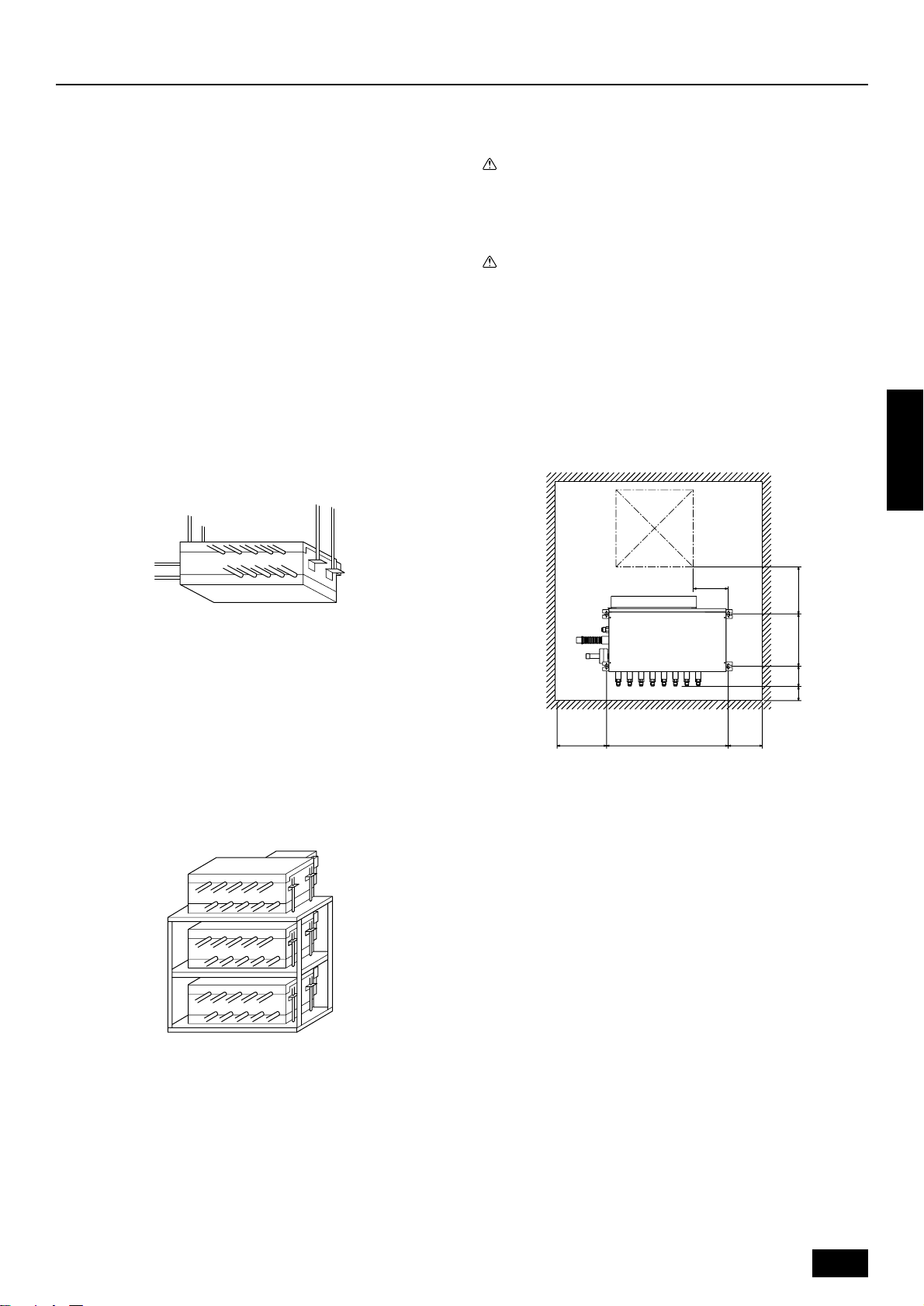

<Front view> (when hanging to install)

B

*1 Dimensions with which pipe connection can be handled at site

Model name A

CMB-P104V-E 702

CMB-P105V-E 702

CMB-P106V-E 702

CMB-P108V-E 702

CMB-P1010V-E 702

CMB-P1013V-E 1152

CMB-P1016V-E 1152

ENGLISH

2. When stacking on a rack

(This is a reference view showing the least installation space.)

B

A

B

A

150 298 85

533

Model name A

CMB-P104V-E 702

CMB-P105V-E 702

CMB-P106V-E 702

CMB-P108V-E 702

CMB-P1010V-E 702

CMB-P1013V-E 1152

CMB-P1016V-E 1152

50 A 50

100

500

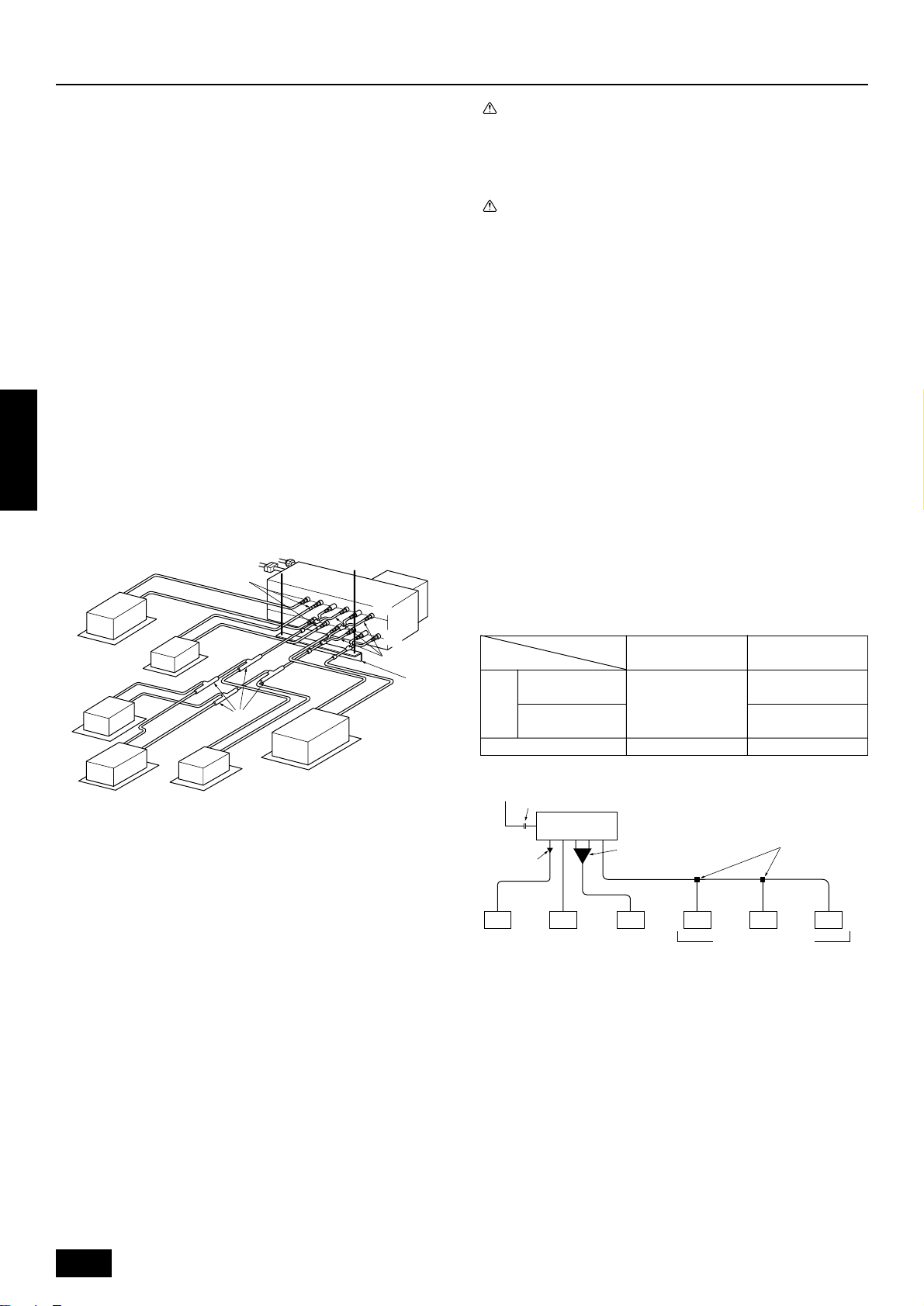

2.3. Checking the installation site

Check that the difference of ele v ation between indoor and outdoor units

and the length of refrigerant piping are within the following limitations.

A

I

A

B

F

E

L

M

A Outdoor unit

B BC controller

C Indoor unit

D More than 81

E Less than H=50mm (when the outdoor unit is higher than the indoor unit)

F Less than H=40mm (when the outdoor unit is lower than the indoor unit)

G Branch pipe (for Y Series) CMY-Y-102S-F

H Combined pipe (optional)

I Less than 70 (60m)

J Less than 30m

K Up to three units for 1 branch hole

Total capacity: less than 80 (but same in cooling/heating mode)

L Less than h1=15m (10m or less for 125 unit type)

M Less than h2=15m

Notes:

*1 In the table, if the total capacity of indoor units exceeds 130% of

outdoor units, it will be the values inside parentheses.

*2 10m or less, with indoor units with model numbers of 125.

H

a

B

b

C

c d e

C

D

J

G

CC

K

C

A On the side of outdoor unit piping

B On the side of indoor unit piping

6

Page 7

(Unit: m)

Item

Total piping length A+B+a+b Below 220

Longest piping length A+e Below 100

Length

Between outdoor and BC A Below 70

controllers (Below 60)*1

Between indoor and BC controllers e Below 30

Between

indoor and

outdoor

Between indoor and BC controllers

Between indoor and indoor h2 Below 15

Difference of elevation

Above outdoor H Below 50

Below outdoor H1 Below 40

Piping portion

+c+d+e

h1 Below 15

Allowable value

(Below 90)*1

(Below 10)*2

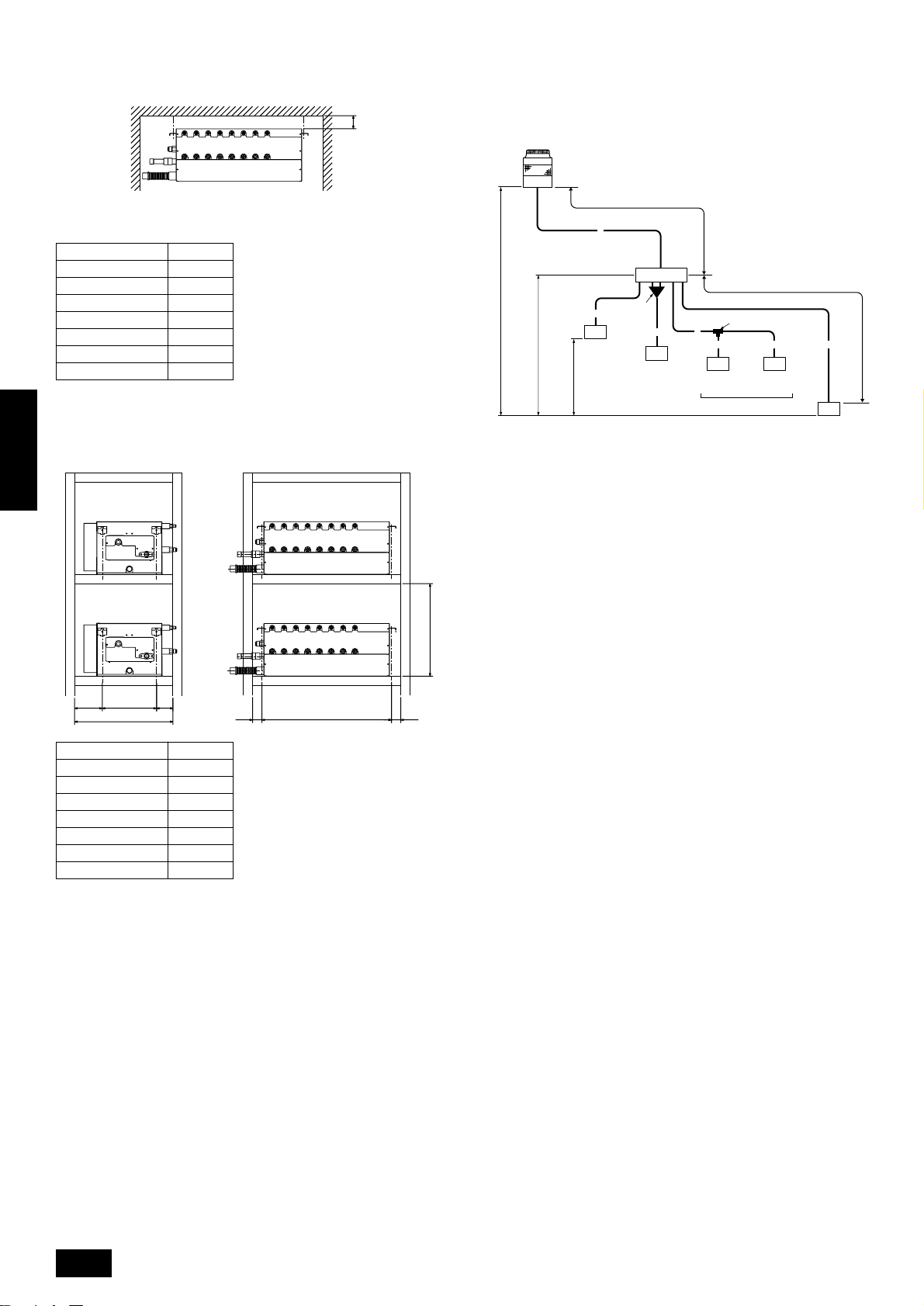

3. Installing BC controller

3.1. Checking the accessories with BC

controller

The following items are supplied with each BC controller.

1 23

3.2. Installing BC controllers

Installing hanging bolts

Install locally procured hanging bolts (all screws) firmly following the procedure given in the figure. The hanging bolt size is ø10 (M10 screw).

To hang the unit, use a lifting machine to lift and pass it through the

hanging bolts.

ENGLISH

456

78

Item Qty

1 Drain hose 1

2 Pipe cover for drain hose 1

3 Tie band 2

4 Hose band 1

5 Flange cover 1

6 Reducer (large & small) Same number as

branch holes

7 Copper pipe with flange 1

8 Packing for flange 1

D

B

A

C

C

B

A

E

D

1

A: Min.30

A Hanging bolt ø10 (field supply)

B Nut (field supply)

C Washer (field supply)

D Double nuts (field supply)

E Anchor bolt M10 (field supply)

1 Hanging method

2 Installing-on-the-floor method

s Be sure to install the BC controllers at level. Installing obliquely

may cause a risk of drain leakage. Use a level to chec k the unit’s

level. If it is oblique, loosen the fixing nut and make an adjustment.

2

Caution:

Be sure to install the unit body at level.

7

Page 8

4. Connecting refrigerant pipes and drain pipes

B

E

EE

EEIE

A

B

*2

G

H

*1

D

50-63 125 *3

C

*4

F

4.1. Connecting refrigerant pipes

1. Connect the liquid and gas pipes of each indoor unit to the same end

connection numbers as indicated on the indoor unit flare connection

section of each BC controller. If connected to wrong end connection

numbers, there will be no normal operation.

2. List indoor unit model names in the name plate on the BC controller

control box (for identification purposes), and BC controller end connection numbers and address numbers in the name plate on the

indoor unit side.

3. If the number of connected indoor units is less than the number of

branch holes, it does not matter which end connections you leave.

Seal unused end connections using flare nuts with end caps just as

they were capped when shipped from the factory . No end cap means

refrigerant leakage.

4. When using branch pipes (CMY-Y102S-F), be sure to connect them

at level.

5. Be sure to tighten the flare nuts using a double spanner. Otherwise

ENGLISH

the refrigerant may leak.

6. Be sure to use non-oxidative brazing where necessary. If you do not

use non-oxidative brazing, it may clog the pipes.

7. After completing pipe connection, support the pipes to prevent that

load is imparted to the BC controller’s end connections (particularly

to the gas pipes of indoor units).

Warning :

When installing and moving the unit, do not charge it with refrigerant other than the refrigerant (R407C or R22) specified on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cy-

cle to malfunction and result in severe damage.

Caution:

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus

deoxidized copper as specified in the JIS H3300 “Copper and

copper alloy seamless pipes and tubes”. In addition, be sure

that the inner and outer surfaces of the pipes are clean and free

of hazardous sulphur, oxides, dust/dirt, shaving particles, oils,

moisture, or any other contaminant.

• Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerator oil in the existing piping will cause the new refrigerant to

deteriorate.

• Store the piping to be used during installation indoors and keep

both ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will dete-

riorate and the compressor may fail.

• Use Suniso 4GS or 3GS (small amount) refrigerator oil to coat

the flare and flange connection part. (For models using R22)

• Use ester oil, ether oil or alkylbenzene (small amount) as the

refrigerator oil to coat flares and flange connections. (For models using R407C)

- The refrigerant used in the unit is highly hygroscopic and mixes

with water and will degrade the refrigerator oil.

A

C

50-63

32

40

50

A Example of connecting refrigerant pipes to BC controllers

B To outdoor unit

C Reducer (supplied with BC controller)

D Gas pipe

E Liquid pipe

F Combined piping kit CMY-R160-F (optionally available)

G Branch pipe CMY-Y102S-F (optionally available)

H Pipe support (field supply)

G

40

D

E

F

H

100,125

1. Size of BC controller’s end connection piping

(Unit: mm)

Piping portion High pressure Low pressure

Item (liquid) side (gas) side

PURY-200YMF-B ø19.05 ø25.4 (Flange)

PURY-P200YMF-B

PURY-250YMF-B (Flare) ø28.58 (Flange)

Outdoor

unit side

PURY-P250YMF-B

Indoor unit side ø9.52 (Flare) ø15.88 (Flare)

A To outdoor unit

B End connection

High pressure side: flare

Low pressure side: flange (accessory)

C BC controller

D Reducer (accessory)

E Indoor unit

F Less than 40

G Combined piping kit (Model name: CMY-R160)

H Branch pipe (Model name: CMY-Y102S-F)

I Up to three units for1 branch hole; total capacity: below J80 (but same in

cooling/heating mode)

8

The size of BC controller’s branch hole piping is for 50 to 63 type indoor

units.

Therefore, if you want to connect indoor units other than the above, do

pipe connection following the procedure below.

Page 9

2. For connecting 20 to 40 type indoor units (*1)

Connect indoor units using the reducers (specials) supplied with BC

controllers.

70

A

A Liquid pipe side: 3/8F (flare)

Gas pipe side: 5/8F (flare)

B Liquid pipe side: ø6.35 ID

Gas pipe side: ø12.7 ID

B

4. Connection of plural indoor units with one connection (or joint

pipe) (*3)

• Total capacity of connectable indoor units: Less than 80 (Less than

160 with joint pipe)

• Number of connectable indoor units: Maximum 3 Sets

• Branch pipe: Use the branch pipe for CITYMULTI Y Series (CMY-

Y102S-F)

• Selection of refrigerant piping (Piping size of A/B sections in the above

figure)

Select the size according to the total capacity of indoor units to be

installed downstream.

Total capacity of indoor units Liquid line Gas line

Below 80 ø9.52 ø15.88

81 to 160 ø12.7 ø19.05

Note:

The flare nuts supplied with BC controllers should be used together .

3. For connecting 100 to 125 type indoor units (or more than a

total indoor unit capacity of 81) (*2)

After combining two branch holes using an optionally available combined piping kit (Model name: CMY-R160-F), connect indoor units.

325

D

E

C

A

C Connecting pipe on liquid pipe side

D ø12.7 ID

E ø9.52 OD

F Liquid pipe side: ø9.52 ID (with insulation cover)

Gas pipe side: ø19.05 ID (with insulation cover)

F

5. Connecting to outside pipes (low pressure side pipes)

• For PURY-250YMF-B

PURY-P250YMF-B

A

D

E

F

G

C

B

• For PURY-200YMF-B

PURY-P200YMF-B

A

J

I

G

H

B

A Packing (accessory)

B BC controller

C External diameter ø28.58

D Tightening torque 25Nm (250kgf·cm) (Be careful not to tighten unevenly.)

E Connecting pipe (accessory)

F Locally procured pipe ø28.58

G Elongate the pipe end, and braze it to the connecting pipe.

H External diameter ø25.4

I Locally procured pipe ø25.4

J Cut the connecting pipe at a section of ø25.4.

ENGLISH

Note:

Be sure to use non-oxidative brazing.

9

Page 10

4.2. Refrigerant piping work

After connecting the refrigerant pipes of all indoor and outdoor units with

the outdoor units’ stop valves remained fully closed, evacuate vacuum

from the outdoor units’ stop valve service ports.

After completing the above, open the valve rods of the indoor units’ stop

valves. This connects the refrigerant circuit (between outdoor and BC

controller) completely.

How to handle stop valves is described on each outdoor unit.

Notes:

• Before tightening the flare nut, apply refrigerating machine oil

lightly over the valve flare surface and its seating surface.

• Use a double spanner for pipe connection.

• After pipe connection, be sure to check that there is no gas leak-

age, using a leak detector or soap-and-water solution.

Warning:

Do not mix anything other than the specified refrigerant (R-22 or

R407C) into the refrigerating cycle when installing or moving. Mixing air may cause the refrigerating cycle to get abnormally high

temperature, resulting in a burst.

ENGLISH

4.3. Insulating refrigerant pipes

Be sure to wind heat-resisting polyethylene form of more than 10mm in

thickness onto both liquid and gas pipes and also put it into the joints

between indoor unit and insulating material so that there will be no gap.

Incomplete insulation may cause a risk of dew drop. Pay careful attention, particularly when insulating above the ceiling.

Connections between unit and locally procured pipe

C

A

B

Insulating using accessory pipe cover

I

A

G

H

G Sealing tape

H Joint (Do not have any opening.)

I Supplied pipe cover

J Bind here using accessory band.

K Glue here using adhesive. Peel off separator for use.

K

J

F

4.4. Drain piping work

1. Drain piping work

• Ensure that the drain piping is downward (pitch of more than 1/100)

to the outdoor (discharge) side. If it is impossible to take any downward pitch, use an optionally available drain-up mechanism to obtain

a downward pitch of more than 1/100.

• Ensure that any cross-wise drain piping is less than 20m. If the drain

piping is long, provide metal braces to prevent it from waving. Never

provide any air vent pipe. Otherwise drain may be ejected.

• Connect the supplied drain hose to the discharge port on the unit

body . Use hard vinyl chloride pipes VP-25 (ø32) f or drain piping (2).

Tighten the supplied drain hose onto the discharge port using the

supplied hose band. (For this, do not use any adhesive because the

drain hose will be removed for service later.)

• Do not have any odor trap around the discharge port.

D

E

A Locally procured insulating material for pipes

B Bind here using band or tape.

C Do not have any opening.

D Lap margin: more than 40

E Insulating material (field supply)

F Unit side insulating material

F

10

Page 11

C

A

B

• Although it is free to choose to take out piping in any direction, be

sure to observe the instructions above.

• When using an optionally available drain-up mechanism, follow its

instruction manual for drain piping.

A

1

D

G

A: 25 cm

B: 1.5 – 2 m

A Downward pitch of more than 1/100

B Insulating material

C Supporting bracket

D Drain discharge port

E Insulated pipe (accessory)

F Tie band (accessory)

G Hose band (accessory)

H Drain hose (200mm long)

• As shown in 3, install a collecting pipe about 10cm below the drain

ports and give it a downward pitch of more than 1/100. This collecting pipe should be of VP-30.

• Set the end of drain piping in a place without any risk of odor generation.

• Do not put the end of drain piping into any drain where ionic gases

are generated.

F

H

2

B

E

F

VP-25

A

A BC controller

B Indoor unit

C Collecting pipe

D Take as large as possible. About 10cm.

2. Discharge test

After completing drain piping work, open the BC controller panel, fill water,

and test drain discharge. At this moment, check to see that there is no

water leakage from the connections.

3. Insulating drain pipes

Provide sufficient insulation onto the drain pipes just as for refrigerant

pipes.

Caution:

Be sure to provide drain piping and heat-insulate it in order to prevent dew condensation. If there is a deficiency in piping work, it

may cause a risk of water leakage and so wet your property.

D

BB

C

VP-30

3

ENGLISH

5. Electrical work

s Consult all related regulations and power companies before-

hand.

Warning:

Electrical work should be handled by qualified electric engineers

in accordance with all related regulations and attached instruction

manuals. Special circuits should also be used. If there is a lack of

power capacity or a deficiency in electrical work, it may cause a

risk of electric shock or fire.

s Connect all wires without looseness.

• Fix power source wiring to control box by using buffer bushing for

tensile force (PG connection or the like).

B

D

C

E

A Control box

B Power source wiring

C To prevent external tensile force from applying to the wiring connection

section of power source terminal block, use buffer bushing like PG connection or the like.

D ø21 knockout hole

E Transmission wiring

A

11

Page 12

s Never connect the power cable to the terminal board for control

cables. (Otherwise it may be broken.)

s Be sure to wire between the control wire terminal boards for

indoor unit, outdoor unit and BC controller.

Switch (A) Wire size

Capacity Fuse

15 15 20A 20A 30mA 1.6mm

Molded case

circuit breaker

Earth leakage breaker

0.1 s or less

Transmission cables are of crossover wiring method by non-polarized

2-wires.

Use 2-core shielding cables (CVVS, CPEVS) of more than 1.25mm2 in

diameter for transmission cables.

The switch capacity of the main power to BC controllers and the wire

size are as follows:

6. Setting addresses and operating units

ENGLISH

• The address switch of each BC controller is set to “000” when shipped

from the factory. Check it.

• Set the address switch to 1 + the address of the outdoor unit.

s The BC controller address should generally be set to 1 + the

address of the outdoor unit. However, if this would result in it

having the same address as another outdoor unit, set the ad-

dress between 51 and 100, making sure that it is different from

the address of other controllers.

• Please refer to the outdoor unit installation manual.

• For other detailed information, refer to the outdoor unit installation

manual.

Caution:

Do not use anything other than the correct capacity fuse and

breaker. Using fuse, conductor or copper wire with too large capacity may cause a risk of malfunction or fire.

Ensure that the outdoor units are put to the ground. Do not connect the earth cable to any gas pipe, water pipe, lightening rod or

telephone earth cable. Incomplete grounding may cause a risk of

electric shock.

7. T est run

Before getting test run checked

s After installing, piping and wiring the indoor units and BC con-

trollers, check to see again that there is no refrigerant leakage

or no slack on power and control cables.

s Use a 500V megger to check that there is an insulation resist-

ance of more than 1.0MΩ between the power terminal bed and

the ground. If it is less than 1.0MΩ, do not get operated.

Caution:

Never measure the insulation resistance of the terminal bed for

control cables.

12

Page 13

ENGLISH

13

Page 14

Содержание

1. Меры предосторожности ....................................................... 27

1.1. Перед установкой прибора и выполнением

электроработ .............................................................. 27

1.2. Меры предосторожности для приборов, в

которых используется хладагент R407C.................. 27

1.3. Перед выполнением установки ................................. 28

1.4. Выполнение электроработ до установки

(перемещения) ............................................................ 28

1.5. Перед началом пробной эксплуатации.................... 28

2. Выберите место установки................................................... 29

2.1. Место установки ......................................................... 29

2.2. Обеспечение необходимого пространства для

установки и техобслуживания................................... 29

2.3. Проверка места установки ....................................... 30

3. Инсталляция Регулятора ВС ................................................ 31

3.1. Проверка наличия дополнительных

принадлежностей, поставляемых в комплекте с

Регулятором ВС .......................................................... 31

3.2. Инсталляция Регуляторов ВС ................................... 31

4. Подсоединение труб хладагента и дренажных труб ......... 32

4.1. Подсоединение труб хладагента ............................... 32

4.2. Прокладка труб хладагента ...................................... 34

4.3. Изоляция труб хладагента ......................................... 34

4.4. Прокладка дренажных труб ...................................... 34

5. Электроработы ...................................................................... 35

6. Установка адресов и операционных блоков....................... 36

7. Выполнение испытания ........................................................ 36

РУССКИЙ

26

Page 15

1. Меры предосторожности

1.1. Перед установкой прибора и

выполнением электроработ

s До установки прибора убедитесь, что Вы прочли

все “Меры предосторожности”.

s “Меры предосторожности” содержат важные

указания по технике безопасности. Убедитесь, что

Вы им следуете.

s Данноме оборудование, возможно, не применимо

к стандартам EN61000-3-2: 1995 и EN61000-3-3:1995.

s Данное оборудование может вызвать

нежелательный эффект при подключении к той

же системе питания другого оборудования.

s Пожалуйста, проконсультируйтесь с органами

электроснабжения до подключения системы.

Символика, используемая в тексте

Предупреждение:

Описывает меры предосторожности, необходимые для

предотвращения получения травмы или гибели пользователя.

Осторожно:

Описывает меры предосторожности, необходимые для

предотвращения повреждения прибора.

Символика, используемая в иллюстрациях

: Указывает действие, которое следует избегать.

: Указывает на важную инструкцию

: Указывает, что данная часть должна быть заземлена

: Указывает на необходимость проявлять осторожность по

отношению к вращающимся частям. (Этот символ указан на

этикетке основного прибора). <Цвет: Желтый>

: Указывает на необходимость отключения главного

выключателя перед проведением техобслуживания. (Этот

символ указан на этикетке основного прибора). <Цвет:

Синий>

: Опасайтесь электрошока (Этот символ указан на этикетке

основного прибора). <Цвет: Желтый>

: Опасайтесь горячих поверхностей (Этот символ показан на

этикетке основного прибора). <Цвет: Желтый>

: Пожалуйства, проявляйте внимание, чтобы не получить

ELV

электрошока, т.к. это не безопасная схема экстранизкого напряжения.

При проведении техобслуживания отключите подачу

электропитания от внутреннего и от наружного прибора.

Предупреждение:

Внимательно прочтите текст на этикетках главного

прибора.

Предупреждение:

• Обратитесь к дилеру или квалифицированному технику для

выполнения установки кондиционера воздуха.

- Неправильная установка, выполненная пользователем, может вызвать

утечку воды, электрошок или пожар.

• Установите прибор на такой конструкции, которая выдержит его вес.

- Недостаточно прочное основание может вызвать падение прибора и

привести к т равме.

• Используйте указанные кабели для электропроводки. Выполняйте

соединения с соблюдением требований безопасности, чтобы кабели

не приводили к повреждению клемм.

- Недостаточно надежные соединения могут вызвать перегрев и стать

причиной пожара.

• Подготовьтесь к возможным землетрясениям: установите прибор в

соответствующем месте.

- Неправильная установка прибора может привести к травме.

• Всегда используйте дополнительные принадлежности,

рекомендуемые Митцубиси Электрик.

- Обратитесь к услугам квалифицированногоу техника для установки

дополнительных приспоосблений. Неправильная установка,

выполненная пользователем, может вызвать утечку воды, электрошок

или пожар.

• Никогда не ремонтируйте прибор самостоятельно. Если требуется

ремонт кондиционера воздуха, обратитесь к дилеру.

- Если прибор неправильно отремонтирован, это может вызвать утечку

воды, электрошок или пожар.

• При утечке газа охлаждения во время установки проветрите

помещение.

- При контакте газа охлаждения с огнем будут выделяться ядовитые

газы.

• Устанавливайте кондиционер согласно инструкциям, приведенным

в данном Руководстве по установке.

- Неправильная установка может вызвать утечку воды, электрошок или

пожар.

• Все электроработы должны выполняться квалифицированным

лицензированным электриком согласно Электротехническим

Станадартам и Нормам проведения внутренней проводки и

инструкциям, приведенным в данном руководстве; всегда

используйте отдельную схему.

- При недостаточной мощности источника питания или неправильном

выполнении электроработ может возникнуть электрошок или пожар.

• Надежно установите крышку коробки терминала.

- Если крышка и панель не установлены надлежащим образом, то в

наружный прибор может попасть пыль или вода, что, в свою очередь,

может привести к пожару или электрошоку.

• При установке и перемещении кондиционера на другой объект не

заряжайте его другим хладагентом, кроме хладагента (R407С или

R22), указанного на приборе.

- При смешении другого хладагента или воздуха с первоначальным

хладагентом может произойти сбой цикла охлаждения и прибор может

быть поврежден.

• Если кондиционер установлен в небольшом помещении, необходимо

принять меры для предотвращения концентрации хладагента свыше

безопасных пределов в случае утечки хладагента.

- Проконсультируйтесь с дилером относительно соответствующих мер

по предотвращению превышения допустимой концетрации. В случае

утечки хладагента и превышения допустимых лимитов концентрации

может возникнуть опасносная ситуация в связи с недостатком

кислорода в помещении.

• При перемещении и повторной установке кондиционера

проконсультируйтесь с дилером или квалифицированным

техником.

- Неправильная установка, выполненная пользователем, может вызвать

утечку воды, электрошок или пожар.

• По завершении установки убедитесь в отсутствии утечки газа

охлаждения.

- При утечке газа охлаждения и попадании его под воздействие

обогревателя, печи, духовки или другого источника тепла могут

образоваться ядовитые газы.

• Не переделывайте и не изменяйте предохранительных установок

на защитных устройствах.

- При коротком замыкании и насильственном включении выключателей

давления, термовыключателей или других элементов, кроме тех,

которые указаны Митцубиси Электрик, может возникнуть пожар или

взрыв.

1.2. Меры предосторожности для

приборов, в которых

используется хладагент R407C

Осторожно:

• Не используйте имеющиеся трубы хладагента.

- Использование старых труб хладагента и старого масла охлажднения,

содержащих большие количества хлорина, может привести к порче

масла охлаждения нового прибора.

РУССКИЙ

27

Page 16

• Используйте трубы хладагента, изготовленные из раскисленной

фосфором меди типа С1220 (CU-DHP), как указано в JIS H3300

“Бесшовные трубы из меди и медных сплавов”. Кроме этого

убедитесь, что внутренняя и внешняя поверхность труб чистая, без

частиц серы, окисей, пыли/грязи, частиц стружки, масел, влаги или

других загрязнений.

- Загрязнение внутренней поверхности труб хладагента может вызвать

ухудшение остаточного масла охлаждения.

• Храните предназначенные для установки трубы в помещении,

герметически закрытыми с обоих концов до припайки. (Углы и

другие соединнеия храните в пластмассовом пакете).

- Попадание в цикл охлаждения пыли, грязи или воды, может ухудшить

масло и вызвать проблемы с компрессором.

• Используйте в качестве масла охлаждения масло сложного или

простого эфира или алкинбензол (небольшое количество) для

покрытия раструбов и фланцевых соединений.

- Масло охлаждения испортится при смешивании с большим количеством

минерального масла.

• Используйте для заполнения системы жидкий хладагент.

- При использовании газового хладагента для герметизации системы,

состав хладагента в баллоне изменится, а рабочие показатели прибора

могут ухудшиться.

• Не используйте другие хладагенты, кроме хладагента R407С

- При использовании другого агента (например, R 22), наличие в нем

хлорина может вызвать сбой цикла охлаждения и привести к ухудшению

масла охлаждения.

• Используйте вакуумный насос с контрольным клапаном обратного

хода.

- Масло вакуумного насоса может проникнуть обратно в цикл охлаждения

и привести к ухудшению масла охлаждения.

• Не используйте указанные ниже инструменты с обычным

хладагентом.

(Контрольный манифольд, зарядный шланг, детектор обнаружения

утечки газа, запорный клапан обратного потока, основу заряда

хладагентом, оборудование для отбора хладагента)

- Смешивание обычного хладагента и масла охлаждения с R407С может

вызвать ухудшение масла охлаждения.

- Смешивание воды с R407С может вызвать ухудшение масла

охлаждения.

- Хладагент R407С не содержит хлорина. Поэтому детекторы утечек газа,

предназначенные для обычных хладагентов, не обнаруживают его.

• Не используйте зарядный баллон.

- Использовние зарядного баллона может вызвать ухудшение хладагента.

• Обращайтесь с инструментами особенно внимательно.

- Попадание в цикл охлаждения пыли, грязи или воды может вызвать

ухудшение масла охлаждения.

РУССКИЙ

1.3. Перед выполнением установки

Осторожно:

• Не устанавливайте прибор там, где возможна утечка горючего газа.

- При утечке газа и его скоплении около прибора может произойти взрыв.

• Не используйте кондиционер воздуха в местах содержания

продуктов, домашних животных, растений, точных приборов или

предметов искусства.

- Качество продуктов и т.д. может ухудшиться.

• Не используйте кондиционер воздуха в особых условиях.

- Наличие масел, пара, сульфурных испарений и т.д. может вызвать

значительное ухудшение рабочих показателей кондиционера или

повредить его элементы.

• При установке прибора в больнице, на станции связи или в

аналогичном помещении обеспечьте достаточную защиту от шума.

- Преобразовательное оборудование, частный электрогенератор,

высоковольтное медицинское оборудование или оборудование для

радиосвязи могут вызвать сбой в работе кондиционера или его

отключение. С другой стороны, кондиционер может мешать работе

такого оборудования создаваемым шумом, который нарушает ход

медицинских процедур или радиовещания.

• Не устанавливайте прибор на конструкции, которая может стать

причиной утечки.

- При влажности в помещении выше 80% или при засорении дренажной

трубы с внутреннего прибора или с регулятора “ВС” может капать

конденсирующаяся влага. Выполняйте дренаж одновременно

внутреннего прибора и наружного прибора, когда это требуется.

• Проложите сетевой кабель так, чтобы он не был натянут.

- Натяжение может привести к разрыву кабеля и стать источником

перегрева и пожара.

• Установите прерыватель цепи, если требуется.

- Если прерываетль цепи не установлен, это может приветси к

электрошоку.

• Используйте сетевой кабель достаточной мощности напряжения.

- Кабели слишком малой мощности могут прогореть, вызвать перегрев

и пожар.

• Используйте прерыватель цепи и предохранитель указанной

мощности.

- Предохранитель или прерыватель большей мощности или стальной или

медный провод могут вызвать поломку прибора или пожар.

• Не мойте детали кондиционера.

- Мытье деталей кондиционера может вызвать электрошок.

• Проявляйте осторожность, следите, чтобы установочное основание

не было повреждено после длительного использования.

- При неустранении повреждения основания прибор может упасть и

причинить травму или повреждение имущества.

• Проложите дренажные трубы в соответствии с инструкциями в

данном Руководстве по установке для обеспечения надлежащего

дренирования. Оберните трубы термоизоляционным материалом

для предотвращения конденсации.

- Неправильная прокладка дренажных труб может вызвать утечку воды

и повредить мебель и другое имущество.

• Будьте очень внимательным при транспортировке прибора.

- Нельзя, чтобы перемещение прибора выполнял один человек, если вес

прибора превышает 20 кг.

- Для упаковки некоторых изделий используются пластиковые ленты.

Не применяйте их для транспортировки, это опасно.

- Не трогайте лопасти теплообменника голыми руками. Вы можете

порезаться.

- При перемещении наружного прибора подвешивайте его в указанных

точках основания прибора. Также поддерживайте его в четырех точках,

чтобы он не соскользнул.

• Утилизируйте упаковочные материалы с соблюдением правил

безопасности

- Такие упаковочные материалы, как гвозди и другие металлические или

деревянные части, могут причинить порез и другую травму.

- Удалите пластиковый упаковочный пакет и устраните его так, чтобы

он был недоступен детям. Дети могут задохнуться и умереть, если будут

играть с пластиковым упаковочным пакетом.

1.5. Перед началом пробной

эксплуатации

Осторожно:

• Подключите электропитание прибора не менее чем за 12 часов до

начала работы .

- Запуск прибора сразу после подключения сетевого питания может

серьезно повредить внутренние части прибора. Сетевой выключатель

должен оставаться во включенном положении в течение всего периода

эксплуатации прибора.

• Не прикасайтесь к выключателям мокрыми руками.

- Прикосновение к выключателю мокрыми руками может вызвать

электрошок.

• Не прикасайтесь к трубам хладагента во время работы и сразу после

выключения прибора.

- В течение и сразу после эксплуатации прибора трубы хладагента могут

быть горячими или холодными, в зависимости от условий протекающего

в трубах, компрессоре и других элементах цикла охлаждения

хладагента. Вы можете обжечь или обморозить руки при прикосновении

к трубам хладагента.

• Не используйте кондиционер воздуха, если его панели и крышки

сняты.

- Вращающиеся, горячие части или части под напряжением могут

причинить травму.

• Не отключайте питание немедленно после выключения прибора.

- Всегда подождите не менее пяти минут до отключения питания. Иначе

может возникнуть утечка воды и другие проблемы.

1.4. Выполнение электроработ до

установки (перемещения)

Осторожно:

• Заземлите прибор.

- Не подсоединяйте провод заземления к газовой трубе, водяной трубе,

громоотводу или линии заземления телефонной проводки. При

неправильном заземлении может возникнуть электрошок.

28

Page 17

2. Выберите место установки

2.1. Место установки

• Не помещайте прибор там, где он может попасть под дождь

(Регулятор ВС является специальным устройством,

предназначенным для использования внутри помещений.)

• Предусмотрите достаточное место для техобслуживания

• Предусмотрите достаточное место для прокладки труб

хладагента

• Не помещайте в место, подверженное прямому воздействию

тепла от других источников тепла

• Не устанавливайте прибор в месте, где наблюдаются большие

объемы масел или пара, или вблизи оборудования, которое

генерирует высокие частоты. Это может вызвать риск пожара,

неправильную работу прибора или конденсацию.

• Помещайте прибор в таком месте, где он не подвергается

воздействию чрезмерного шума других приборов

• Поместите таким образом, чтобы обеспечить достаточную

легкость прокладки труб для воды, хладагента и

электропроводки

• Избегайте установки в местах, подверженных скоплению,

притоку, образованию или утечки возгорающихся и сернистых

газов

• Помещайте таким образом, чтобы обеспечить возможность

прокладки дренажных труб под наклоном вниз более 1/100.

1. При укреплении на потолке

• Размещайте прибор таким образом, чтобы вокруг подставки

было достаточное пространство

• Помещайте в таком месте, где перекрытие пола достаточно

прочное, чтобы выдерживать вес прибора

Предупреждение:

Обязательно устанавливайте прибор в таком месте, которое

выдержит его вес.

При недостаточной прочности места установки прибор может

упасть, что приведет к личной травме.

Осторожно:

Обязательно устанавливайте прибор ровно по горизонтали.

2.2. Обеспечение необходимого

пространства для установки и

техобслуживания

1. При подвешивании на потолке

(На иллюстрации показано пространство, необходимое для

установки)

<Вид сверху>

• Обеспечьте наличие квадратного инспекционного отверстия 450

мм на поверхности потолка, как указано на иллюстрации 2.2.11.

• Установите в потолке коридора ванной комнаты и т.д., где люди

бывают нечасто (Избегайте установки центре по мещения.)

• Помещайте в достаточно прочном месте, где возможно

закрепление навесных болтов (перекрытие должно

выдерживать нагрузку в 60 кг на болт )

• Устанавливайте регуляторы ВС в строго горизонтальной

плоскости.

2. При установке на подставки

A

C

213

B

D

300 A 200

A Инспекционное отверстие

B Со стороны труб наружного прибора

C Блок управления

D Со стороны труб внутреннего прибора

130*1 298 281

РУССКИЙ

29

Page 18

<Вид спереди> (при установке с подвешиванием)

100

B

*1 Необходимые габариты для работы с соединениями труб на

месте установки

2.3. Проверка места установки

Проверьте, что перепад высоты между местом установки

внутреннего и внешнего приборов, а также длина труб хладагента

соответствуют указанным ниже параметрам.

A

I

A

Наименование модели

CMB-P104V-E 702

CMB-P105V-E 702

CMB-P106V-E 702

CMB-P108V-E 702

CMB-P1010V-E 702

CMB-P1013V-E 1152

CMB-P1016V-E 1152

2. При установке на подставке

(На иллюстрации показано наименьшее необходимое

пространство при установке)

РУССКИЙ

150 298 85

533

Наименование модели

CMB-P104V-E 702

CMB-P105V-E 702

CMB-P106V-E 702

CMB-P108V-E 702

CMB-P1010V-E 702

CMB-P1013V-E 1152

CMB-P1016V-E 1152

B

B

A

A

A

50 A 50

A

500

B

E

F

L

M

H

a

B

b

C

c d e

C

D

J

G

CC

K

C

A Внешний прибор

B Регулятор BC

C Внутренний прибор

D Свыше 81

E Высота менее 50 мм (если внешнее устройство расположено выше

внутреннего устройства )

F Высота менее 40 мм (если внешнее устройство расположено ниже

внутреннего устройства)

G Труба ответвления (для серии Y) CMY-Y-102S-F

H Комбинированная труба (приобретается дополнительно)

I Менее 70 (60 м)

J Менее 30 м

K До трех приборов на 1 отверстие ответвления

Общая мощность: менее 80 (одинаковая в режиме охлаждения/

отопления)

L h1 менее = 15 м (10 м или менее для устройств модели 125)

M h2 менее = 15 м

Примечания:

*1 В таблице, приведенной ниже, значения, указанные в

скобках, приводятся в том случае, если общая мощность

внутренних приборов превышает 130% мощности внешних

приборов.

*2 Не выше 10 м. для внутренних устройств, имеющих номера

модели 125.

A Со стороны труб внешнего прибора

B Со стороны труб внутреннего прибора

30

Page 19

Часть Часть трубы Допустимое

значение

Общая длина трубы A+B+a+b Менее 220

+c+d+e

Самый длинный отрезок трубы A+e Ниже 100

Длина

Между внешним прибором и A Ниже 70

регуляторами ВС (ниже 60)*1

Между внутренним прибором и e Ниже 30

регуляторами ВС

Между

нутренним

и внешним

приборами

Между внутренним прибором и h1 Ниже 15

регуляторами ВС (Ниже 10)*2

Между внутренним прибором и h2 Ниже 15

Разница по высоте

другим внутренним прибором

Над внешним H Ниже 50

прибором

Ниже внешнего H1 ниже 40

прибора

(ниже 90)*1

3. Инсталляция Регулятора ВС

(Unit: m)

3.1. Проверка наличия

дополнительных

принадлежностей, поставляемых

в комплекте с Регулятором ВС

Указанные ниже материалы поставляются с каждым регулятором

BC.

1 23

456

78

Предмет К-во

1 Дренажный шланг 1

2 Кожух трубы дренажного шланга 1

3 Крепежная лента 2

4 Лента насоса 1

5 Кожух фланца 1

6 Переходник (большой и малый)

7 Медна труба с фланцем 1

8 Прокладка для фланца 1

Те же номера, что и на

отверстиях ответвлений

3.2. Инсталляция Регуляторов ВС

Установка навесных болов

Устанавливайте навесные болты, приобретаемые на месте (все

винтовые), тщательно следуя порядку действий, указанному на

иллюстрации.

Размер навесного болта: ø10 (винт М10)

Для того чтобы навесить прибор, используйте подъемное

оборудование и продвиньте прибор через навесные болты.

D

B

D

A: Минимально 30

A Навесной болт ø10 (Приобретается на месте.)

B Гайка (Приобретается на месте.)

C Прокладка (Приоретается на месте.)

D Двойные гайки (Приобретаются на месте.)

E Анкерный болт М10 (Приобретается на месте.)

1 Метод навешивания

2 Метод установки на полу

s Устанавливайте регуляторы ВС строго горизонтально.

Установка в наклонном положении может усилить риск

протечки дренажа. Для проверки используйте уровень.

Если устройство установлено с наклоном, ослабьте

крепежный болт и подрегулируйте уровень.

1

A

C

C

B

A

E

2

РУССКИЙ

Осторожно:

Убедитесь в том, что корпус прибора установлен ровно.

31

Page 20

4. Подсоединение труб хладагента и дренажных труб

B

E

EE

EEIE

A

B

*2

G

H

*1

D

50-63 125 *3

C

*4

F

4.1. Подсоединение труб хладагента

1. Подсоедините жидкостные и газовые трубы каждого внешнего

устройства к соответствующим номерам секции соединения

раструбов каждого установленного внутреннего регулятора ВС.

При подсоединениях к несоответствующим номерам раструбов

прибор не сможет нормально функционировать.

2. Запишите названия моделей внутренних устройств на именной

табличке регулирующей коробки регулятора ВС (с целью

идентификации), а номера соединений, номер регулятора ВС и

адресные номера - на именной табличке внутреннего

устройства, расположенной на его боковой панели.

3. Если число подсоединенных внутренних приборов меньше чем

количество отверстий ответвлений, то не имеет значение, какие

концевые соединения вы оставите незадействованными.

Закройте неиспользуемые концевые соединения с помощью гаек

со шляпками так, как они были закрыты при отправке с заводаизготовителя. Если вы не установите эти концевые колпачки,

то произойдет утечка хладагента.

4. При использовании труб ответвления (CMY-Y102S-F)

обязательно подсоединяйте их ровно.

5. Обзательно затягивайте гайки с помощью двойного гаечного

ключа. В противном случае может произоти утечка хладагента.

6. Обязательно используйте неокисляемую смазку, где это

необходимо. Если вы не будете использовать неокисляемую

смазку, то может произойти засорение труб.

7. После завершения подсоединений труб, закрепите их от

провисания с целью предотвращения переноса их массы на

конечные соединения регулятора ВС (в особенности на газовые

трубы внутренних устройств).

A

C

РУССКИЙ

50-63

32

D

F

E

H

Предупреждение:

При установке и монтаже прибора заряжайте его только

хладагентом, указанным на приборе (R407С или R22).

- Подмешивание другого хладагента, воздуха и т.д. может

нарушить цикл охлаждения и стать причиной серъезного

повреждения.

Осторожно:

• Используйте трубы хладагента, изготовленные из

раскисленной фосфором меди типа С1220 (CU-DHP), как

указано в JIS H3300 “Бесшовные трубы из меди и медных

сплавов”. Кроме этого убедитесь, что внутренняя и внешняя

поверхность труб чистая, без частиц серы, окисей, пыли/

грязи, частиц стружки, масел, влаги или других загрязнений.

• Никогда не пользуйтесь имеющимися трубами хладагента.

- Большое количество хлорина в обычном хладагенте и масле

охлаждения в имеющихся трубах вызовет ухудшение нового

хладагента.

• Храните трубы, предназначенные для установки, в

помещении; оба конца труб должны быть герметически

закрыты до непосредственного момента спайки.

- При попадании пыли, грязи или воды в цикл охлаждения масло

ухудшится и может выйти из строя компрессор.

• Используйте для покрытия раструбов и фланцевых

соединений масло охлаждения Сунисо 4-GS или 3-GS

(небольшие количества). (Для моделей, использующих R22)

•

Используйте для покрытия раструбов и фланцевых соединений

эфирное масло или алкилбензол (небольшие количества) в

качестве масла охлаждения. (Для моделей, использующих R407C)

- Применяемый в приборе хладагент очень гигроскопичен и

смешивается с водой, что ухудшит качество масла

охлаждения.

1. Размеры конечных трубных соединений регулятора ВС

(Единица измерения: мм)

Часть трубы

Часть

PURY-200YMF-B ø19,05 ø25,4 (фланец)

PURY-P200YMF-B

PURY-250YMF-B (колокообразный) ø28,58 (фланец)

PURY-P250YMF-B

Сторона

внешнего

прибора

Сторона внутреннего ø9,52 ø15,88

прибора (колокообразный) (колокообразный)

Сторона высокого

давления (жидкости)

Сторона низкого

давления (газа)

40

50

A Пример подсоединения охлаждающих труб к регуляторам ВС.

B К внешнему прибору

C Переходник (входят в комплект поставки регулятора ВС)

D Газовая труба

E Труба с жидкостью

F Комплект комбинированных труб CMY-R160-F (поставляется

дополнительно)

G Труба ответвления CMY-Y102S-F (поставляется дополнительно)

H Опора для трубы (приобретается на месте)

32

G

40

100,125

A К внешнему прибору

B Концевое соединение

Сторона высокого давления: колокообразное

Сторона низкого давления: фланец (поставлен)

C Регулятор BC

D Переходник (поставлен)

E Внутренний прибор

F Менее 40

G Набор соединения труб (название модели: CMY-R160)

H Труба ответвления (наименование модели: CMY-Y102S-F)

I До трех приборов на одно отверстие крепления; общая мощность:

ниже J80 (одинаковое в режиме охлаждения/отопления)

Приведенный размер отверстия трубного соединения тройника

регулятора ВС соответствует внутренним устройствам от 50-го до

63-го типов.

Поэтому если вы хотите подсоединять внутренние приборы другого

типа, выполняйте соединение труб, следуя указанному ниже

порядку действий.

Page 21

2. Для подсоединения внутренних приборов типа 20-40 (*1)

Соедините внутренние устройства, используя редукторы

(специальные), входящие в состав комплекта регуляторов ВС.

70

A

A Сторона трубы с жидкостью: 3/8F (колокообразный)

Сторона газовой трубы: 5/8F (колокообразный)

B Сторона трубы с жидкостью: ø6,35 внутренний диаметр

Сторона газовой трубы: ø12,7 внутренни й диаметр

Примечание:

Гайки раструбов, поставляемые с регуляторами ВС, следует

использовать вместе.

3. Соединение внутренних приборов типа от 100 до 125 (или

внутренних приборов с общей мощностью 81) (*2)

После соединения двух отверстий ответвлений с помощью

имеющемуся по дополнительному заказу набора соединения труб

(наименование модели: CMY-R160-F) подсоедините внутренние

приборы.

325

D

B

E

C

4. Соединение нескольких внутренних приборов одним

соединением (или общей трубой) (*3)

• Общая мощность соединяемых внутренних приборов: менее 80

(менее 160 с общей трубой)

• Число соединяемых внутренних приборов: не более 3

• Труба-ответвление: используйте трубу-ответвление для Серии

CITYMULTY (CMY-Y102S-F)

• Выбор труб хладагента (Размер труб секций А/В на иллюстрации

выше)

Выбирайте размер в соответствии с общей мощностью

внутренних приборов, устанавливаемых вниз по потоку.

Общая мощность внутренних Труба жидкости Труба газа

приборов

Ниже 80 ø9,52 ø15,88

от 81 до 160 ø12,7 ø19,05

5. Подсоединение наружных труб (боковые трубы низкого

давления)

• Для PURY-250YMF-B

PURY-P250YMF-B

A

D

E

F

G

C

B

• Для PURY-200YMF-B

PURY-P200YMF-B

A

C Подсоединение трубы со стороны трубы жидкости

D ø12,7 внутренний диаметр

E ø9,52 внешний диаметр

F Сторона трубы с жидкостью: ø9,25 внутренний диаметр (с изоляцией)

Сторона газовой трубы: ø19,05 внутренний диаметр (с изоляцией)

F

A

J

I

G

H

B

A Прокладка (поставлена)

B Регулятор BC

C Внешний диаметр ø28,58

D Крутящий момент при затягивании 25Nm (250kgf·cm) (Будьте

внимательны и выполняйте затягивание ровно.)

E Соединительная труба (поставлена)

F Труба, приобретаемая на месте ø28,58

G Удлините конец трубы и припаяйте ее твердым припоем к

подсоединяемой трубе.

H Внешний диаметр ø25,4

I Труба, приобретаемая на месте, ø25,4

J Отрезайте соединительную трубу по сечению ø25,4

Примечание:

Обязательно используйте неокисляемый припой

РУССКИЙ

33

Page 22

4.2. Прокладка труб хладагента

После соединения труб хладагента всех внутренних и наружных

приборов, при этом клапаны останова наружных приборов должны

быть полностью закрыты, удалите вакуум из сервисных портов

клапана останова наружных приборов.

Выполним вышеуказанное, откройте стержни клапанов останова

внутренних приборов. Это подсоединяет цикл хладагента (между

внешним устройством и регулятором ВС) полностью.

Указания о том, как обращаться с клапанами останова, обозначены

на каждом внешнем приборе.

Изоляция с помощью поставленного кожуха трубы

Примечания:

• Прежде чем закручивать колокообразную гайку, нанесите

легкий слой охлаждающего машинного масла на

колокообразную поверхность клапана и поверхность его

седла.

• Для соединения используйте двойной гаечный ключ.

• После соединения труб обязательно проверьте, что нет

утечки газа, пользуйтесь при этом детектором утечки или

мыльным раствором.

Предупреждение:

Не подмешивайте в циклах хладагента ничего, кроме

указанного агента (R-22 или R407C) при установке или

перемещении. Попадание воздуха в цикл хладагента может

вызвать ненормально высокую температуру и привести к

взрыву.

4.3. Изоляция труб хладагента

Обязательно обверните полиэтиленовую температуроустойчивую

изоляцию свыше 10 мм толщиной на трубы жидкости и газа, а также

поместите ее в места соединения между внутренним прибором и

изолирующим материалом таким образом, чтобы не было зазора.

Неполная изоляция может привести к образованию конденсации.

Проявляйте особое вни мание в особенности при установке прибора

в потолке.

Соединения между прибором и трубами, приобретаемыми на

месте

РУССКИЙ

I

A

G

H

G Запечатывающая лента

H Соединение (не оставляйте отверстий)

I Поставленный кожух для трубы

J Перевяжите здесь, используя поставленную ленту

K Приклейте здесь клеем. Снимите защитный слой.

K

J

F

4.4. Прокладка дренажных труб

1. Прокладка дренажных труб

• Убедитесь, что трубы прокладываются с наклоном вниз (наклон

свыше 1/100) к внешней стороне (слив). Если невозможно

обеспечить наклон, используйте приобретенный дополнительно

дренажный механиз для получения наклона вниз свыше 1/100.

• Обеспечьте перекрестные дренажные трубы менее 20 м. Если

дренажные трубы длинные, установите металлические скобы

для придания им стабильности. Никогда не используйте

вентиляционную воздушную трубу. Это может привести к

выталкиванию стока.

• Подсоедините поставленный дренажный шланг к сливному

порту на корпусе прибора. Используйте из твердого

винилхлорида VP-25 (ø32) для дренажных труб. (2). Закрепите

поставленный дренажный шланг на порту слива, используя

поставленную шланговую ленту. (Не используйте здесь клей,

поскольку впоследствии дренажный шланг потребуется удалять

для техобслуживания.)

• Убедитесь в отсутствии улавливателя запаха вокруг порта

слива.

C

A

B

D

E

A Изолирующий материал для труб, приобретаемый на месте

B Обмотка с помощью ленты или тесьмы.

C Не оставляйте отверстий.

D Перехлестка свыше 40.

E Изолирующий материал (приобретается на месте).

F Изолирующий материал боковой стороны прибора

F

34

Page 23

C

A

B

• Хотя вы можете выбирать направление труб, убедитесь в

соблюдении указанных выше инструкций.

• При использовании поставляемого по желанию дренажного

механизма следуйте указанным в нем инструкциям по прокладке

дренажных труб.

A

1

D

G

A: 25 см

B: 1,5 – 2 м

A Наклон вниз свыше 1/100

B Изолирующий материал

C Поддерживающая скоба

D Порт слива дренажа

E Изоли рующая труба (поставлена)

F Закрепляющая лента (поставлена)

G Шланговая лента (поставлена)

H Дренажный шланг (200 мм длиной)

• Как показано на диаграмме 3, установите трубу сбора примерно

на 10 см ниже выходов дренажа под углом наклона вниз не менее

1/100. Данная труба сбора должна быть выполнена из VP-30.

• Установите конец дренажной трубы там, где не скапливаются

запахи.

• Не помещайте конец дренажной трубы в какой-либо сток, где

происходит генерация ионных газов.

F

H

2

B

E

F

VP-25

A

A Регулятор BC

B Внутренний прибор

C Коллекторная труба

D Возьмите как можно большой. Примерно 10 см.

2. Испытание слива

После завершения трубных соединений дренажа откройте панель

регулятора ВС, добавьте воды и проверьте дренажный слив. На

данном этапе убедитесь в отсутствии утечки воды в соединениях.

3. Изоляция дренажных труб

Обеспечьте достаточную изоляцию дренажных труб таким же

образом, как для труб хладагента.

Осторожно:

Прокладывая дренажные трубы, изолируйте их для

предотвращения конденсации. При неудовлетворительной

прокладке труб возникает риск утечки воды, что может

повредить ваше имущество.

D

BB

C

VP-30

3

5. Электроработы

s Предварительно проконсультируйтесь о существующих

местных правилах с местными предприятиями.

Предупреждение:

Электроработы должны выполняться квалифицированным

электриком в соответствии со всеми примени мыми правилами

и стандартами и инструкциями в прилагаемых руководствах.

Следует использовать специальные линии электропитания.

При недостаточной мощности электропитания или

неудовлетворительной электропроводке возникает риск

электрошока или пожара.

s Соедините все провода, не допуская слабых соединений.

• Прикрепите проводку источника питания к блоку управления,

применив буферную втулку для придания прочности на

растяжение (соединение PG или подобное).

B

D

C

E

A Блок управления

B Проводка источника питания

C Для предотвращения воздействия внешнего растягивающего усилия

на участке подсоединения проводки от источника питания к блоку

концевиков используйте буферную втулку по типу соединения PG.

D Пропускное отверстие ø21

E Проводка трансмиссии

A

РУССКИЙ

35

Page 24

s Ни в коем случае не подсоединяйте кабель питания к

коммутатору терминалов кабелей регулировки. (В

противном случае он может быть выведен из строя).

s Не забудьте провести проводку между коммутаторами

проводов регулировки внутреннего устройства, внешнего

устройства и регулятора ВС.

Переключатель (А) Размер

Мощность

Предохранитель

15 15 20A 20A 30мA 1,6мм

Прерыватель

в цельном

корпусе

Прерыватель

цепи

заземления

0,1 сек.