Mitsubishi PQRY-P200YMF-C, PQRY-P250YMF-C, CMB-P104, CMB-P105, CMB-P106 Service Handbook

...Page 1

AIR CONDITIONERS CITY MULTI

Models PQRY-P200YMF-C, P250YMF-C

CMB-P104, P105, P106, P108, P1010, P1013, P1016V-E

Service Handbook

Page 2

Contents

1 PRECAUTIONS FOR DEVICES THAT USE R407C REFRIGERANT .... 3

[1] Storage of Piping Material................................................................. 4

[2] Piping Machining............................................................................... 5

[3] Necessary Apparatus and Materials and Notes on Their Handling .. 6

[4] Brazing.............................................................................................. 7

[5] Airtightness Test................................................................................ 8

[6] Vacuuming ........................................................................................ 8

[7] Charging of Refrigerant..................................................................... 9

[8] Dryer ................................................................................................. 9

2 COMPONENT OF EQUIPMENT ........................................................... 10

[1] Appearance of Components ........................................................... 10

[2] Refrigerant Circuit Diagram and Thermal Sensor........................... 17

[3] Electrical Wiring Diagram................................................................ 19

[4] Standard Operation Data ................................................................ 27

[5] Function of Dip SW and Rotary SW................................................ 29

[6] External Input/Output Specifications............................................... 32

3 TEST RUN ............................................................................................. 33

[1] Before Test Run .............................................................................. 33

[2] Address setting ............................................................................... 37

[3] Test Run Method ............................................................................. 42

4 GROUPING REGISTRATION OF INDOOR UNITS WITH REMOTE

CONTROLLER....................................................................................... 43

5 CONTROL.............................................................................................. 49

[1] Control of Heat Source Unit ............................................................ 49

[2] Control box cooling system............................................................. 53

[3] Control of BC Controller.................................................................. 54

[4] Operation Flow Chart...................................................................... 55

[5] List of Major Component Functions ................................................ 61

[6] Resistance of Temperature Sensor................................................. 64

6 REFRIGERANT AMOUNT ADJUSTMENT ............................................ 65

[1] Refrigerant Amount and Operating Characteristics ........................ 65

[2] Adjustment and Judgement of Refrigerant Amount ........................ 65

7 TROUBLESHOOTING ........................................................................... 70

[1] Principal Parts................................................................................. 70

[2] BC Controller Disassembly Procedure ........................................... 98

[3] Self-diagnosis and Countermeasures Depending on the

Check Code Displayed ................................................................. 104

[4] LED Monitor Display ..................................................................... 127

8 PREPARATION, REPAIRS AND REFRIGERANT REFILLING

WHEN REPAIRING LEAKS ................................................................. 137

[1] Location of leaks: Extension piping or indoor units (when cooling) ... 137

[2] Location of leaks: Heat Source Unit (Cooling mode) .................... 137

[3] Location of Leaks: Extension Piping or Indoor Units

(Heating mode) ............................................................................. 138

[4] Location of Leaks: Heat Source Unit (when Heating) ................... 138

9 CHECK THE COMPOSITION OF THE REFRIGERANT..................... 139

0 DIFFERENCES BETWEEN THE PREVIOUS REFRIGERANT

AND THE NEW REFRIGERANT ......................................................... 141

[1] Chemical Characteristics .............................................................. 141

[2] Chances in Composition ............................................................... 141

[3] Pressure Characteristics............................................................... 142

A REFRIGERATOR OIL .......................................................................... 143

[1] Refrigerator Oil with HFC Based Refrigerants .............................. 143

[2] Influence of Contaminants ............................................................ 143

–1–

Page 3

Safety precautions

Before installation and electric work

▲

Before installing the unit, make sure you read all

the “Safety precautions”.

▲

The “Safety precautions” provide very important

points regarding safety. Make sure you follow

them.

▲

This equipment may not be applicable to

EN61000-3-2: 1995 and EN61000-3-3: 1995.

▲

This equipment may have an adverse effect on

equipment on the same electrical supply system.

Please report to or take consent by the supply

▲

authority before connection to the system.

Symbols used in the text

Warning:

Describes precautions that should be observed to

prevent danger of injury or death to the user.

Caution:

Describes precautions that should be observed to

prevent damage to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts.

(This symbol is displayed on the main unit label.)

<Color: Y ellow>

: Indicates that the main switch must be turned off before

servicing. (This symbol is displayed on the main unit label.)

<Color: Blue>

: Beware of electric shock (This symbol is displayed on the

main unit label.) <Color: Yellow>

: Beware of hot surface (This symbol is displayed on the

main unit label.) <Color: Yellow>

: Please pay attention to electric shock fully because

ELV

this is not Safety Extra Low-Voltage (SELV) circuit.

And at servicing, please shut down the power supply

for both of Indoor Unit and Heat Source Unit.

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Ask the dealer or an authorized technician to install the air

conditioner.

- Improper installation by the user may result in water leakage,

electric shock, or fire.

• Install the air unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting

in injuries.

• Use the specified cables for wiring. Make the connections

securely so that the outside force of the cable is not

applied to the terminals.

- Inadequate connection and fastening may generate heat and

cause a fire.

• Prepare for typhoons and other strong winds and earthquakes and install the unit at the specified place.

- Improper installation may cause the unit to topple and result

in injury.

• Always use an air cleaner, humidifier, electric heater, and

other accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories.

Improper installation by the user may result in water leakage,

electric shock, or fire.

• Never repair the unit. If the air conditioner must be

repaired, consult the dealer.

- If the unit is repaired improperly, water leakage, electric

shock, or fire may result.

• Do not touch the heat exchanger fins.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate

the room.

- If the refrigerant gas comes into contact with a flame,

poisonous gases will be released.

• Install the air conditioner according to this Installation

Manual.

- If the unit is installed improperly, water leakage, electric

shock, or fire may result.

• Have all electric work done by a licensed electrician

according to “Electric Facility Engineering Standard” and

“Interior Wire Regulations”and the instructions given in

this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is

performed improperly, electric shock and fire may result.

• Securely install the cover of control box and the panel.

- If the cover and panel are not installed properly, dust or water

may enter the heat source unit and fire or electric shock may

result.

• When installing and moving the air conditioner to another

site, do not charge the it with a refrigerant different from

the refrigerant (R407C) specified on the unit.

- If a different refrigerant or air is mixed with the original

refrigerant, the refrigerant cycle may malfunction and the unit

may be damaged.

• If the air conditioner is installed in a small room, measures

must be taken to prevent the refrigerant concentration

from exceeding the safety limit even if the refrigerant

should leak.

- Consult the dealer regarding the appropriate measures to

prevent the safety limit from being exceeded. Should the

refrigerant leak and cause the safety limit to be exceeded,

hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult

the dealer or an authorized technician.

- If the air conditioner is installed improperly, water leakage,

electric shock, or fire may result.

• After completing installation work, make sure that refrigerant gas is not leaking.

- If the refrigerant gas leaks and is exposed to a fan heater,

stove, oven, or other heat source, it may generate noxious

gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection

device is shorted and operated forcibly, or parts other than

those specified by Mitsubishi Electric are used, fire or

explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety

against leakage according to local regulation or standards.

- Following standards may be applicable if local regulation are

not available.

• Pay a special attention to the place, such as a basement,

etc. where refrigeration gas can stay, since refrigerant is

heavier than the air.

–2–

Page 4

11

1 PRECAUTIONS FOR DEVICES THAT USE R407C REFRIGERANT

11

Caution

Do not use the existing refrigerant piping.

• The old refrigerant and refrigerator oil in the existing

piping contains a large amount of chlorine which may

cause the refrigerator oil of the new unit to deteriorate.

Use refrigerant piping made of **C1220T phosphorus deoxidized copper as specified in the *JIS H3300

“Copper and copper alloy seamless pipes and tubes”.

In addition, be sure that the inner and outer surfaces

of the pipes are clean and free of hazardous sulphur,

oxides, dust/dirt, shaving particles, oils, moisture, or

any other contaminant.

• Contaminants on the inside of the refrigerant piping

may cause the refrigerant residual oil to deteriorate.

*JIS: Japanese Industrial Standard

**: Comparable to CU-DHP (CUPROCLIMA), Cu-bl

(AFNOR), C12200 (ASTN), SF-Cu (DIN)

Store the piping to be used during installation indoors

and keep both ends of the piping sealed until just

before brazing. (Store elbows and other joints in a

plastic bag.)

• If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may

result.

Use a vacuum pump with a reverse flow check valve.

• The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerator oil to deteriorate.

Do not use the following tools that have been used

with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector , reverse flow check valve, refrigerant charge base,

vacuum gauge, refrigerant recovery equipment.)

• If the conventional refrigerant and refrigerator oil are

mixed in the R407C, the refrigerant may deteriorated.

• If water is mixed in the R407C, the refrigerator oil

may deteriorate.

• Since R407C does not contain any chlorine, gas

leak detectors for conventional refrigerants will not

react to it.

Do not use a charging cylinder .

• Using a charging cylinder may cause the refrigerant

to deteriorate.

Be especially careful when managing the tools.

• If dust, dirt, or water gets in the refrigerant cycle, the

refrigerant may deteriorate.

Use ester oil, ether oil or alkylbenzene (small

amount) as the refrigerator oil to coat flares and

flange connections.

• The refrigerator oil will degrade if it is mixed with a

large amount of mineral oil.

Use liquid refrigerant to seal the system.

• If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change

and performance may drop.

Do not use a refrigerant other than R407C.

• If another refrigerant (R22, etc.) is used, the chlorine

in the refrigerant may cause the refrigerator oil to deteriorate.

If the refrigerant leaks, recover the refrigerant in the

refrigerant cycle, then recharge the cycle with the

specified amount of the liquid refrigerant indicated

on the air conditioner.

• Since R407C is a nonazeotropic refrigerant, if additionally charged when the refrigerant leaked, the composition of the refrigerant in the refrigerant cycle will

change and result in a drop in performance or abnormal stopping.

–3–

Page 5

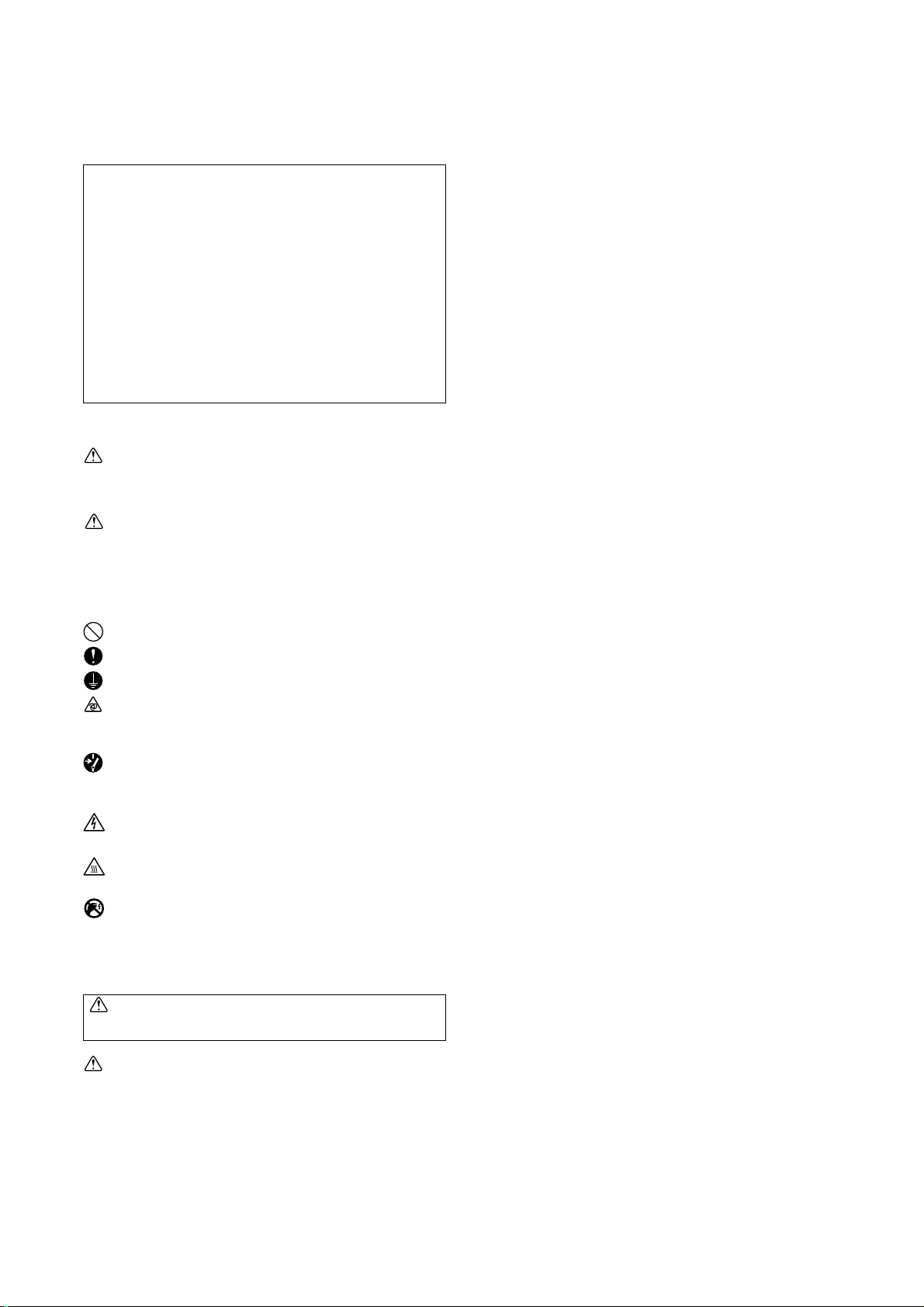

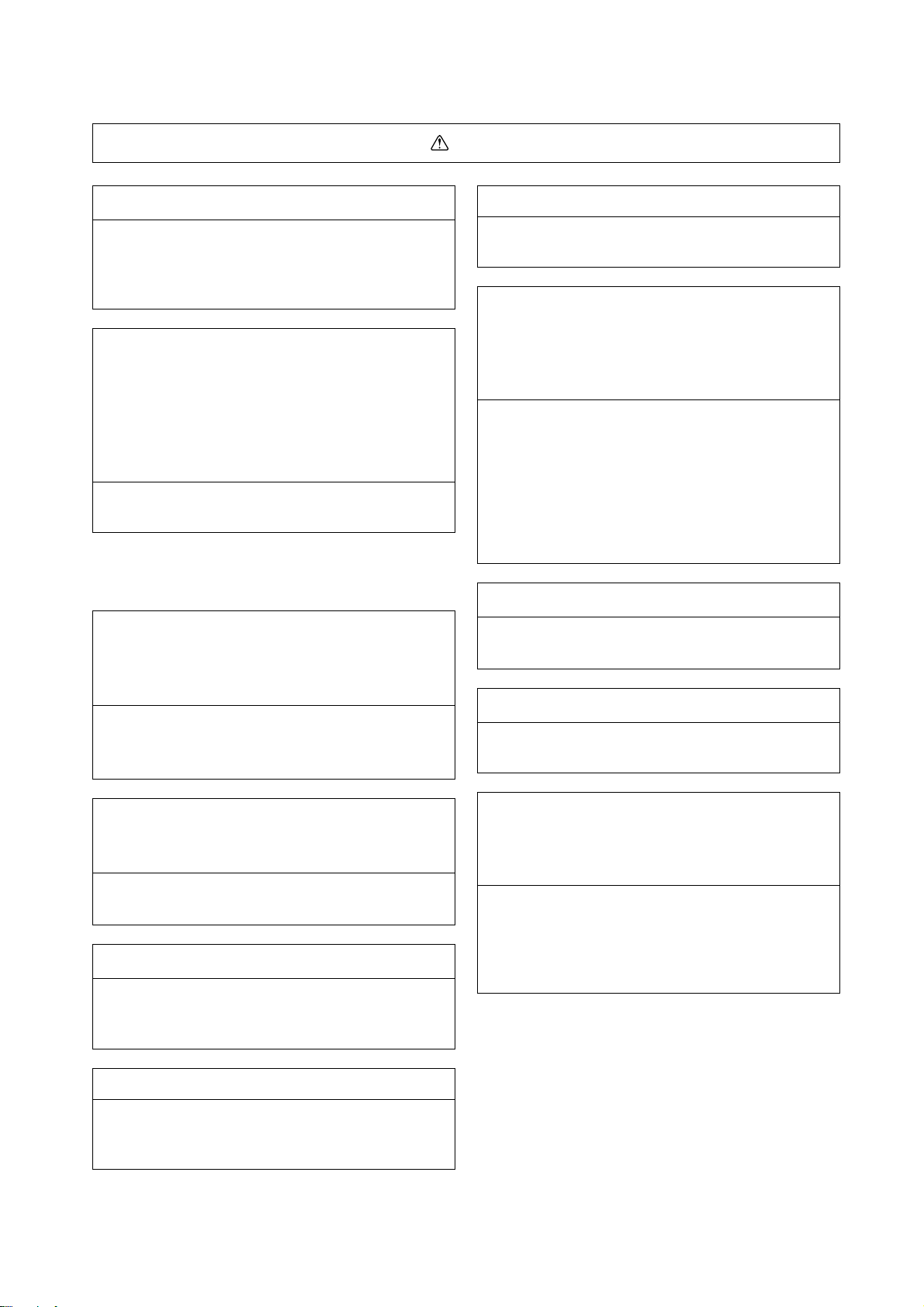

[1] Storage of Piping Material

(1) Storage location

Store the pipes to be used indoors. (Warehouse at site or owner’s warehouse)

Storing them outdoors may cause dirt, waste, or water to infiltrate.

(2) Pipe sealing before storage

Both ends of the pipes should be sealed until immediately before brazing.

Wrap elbows and T’s in plastic bags for storage.

* The new refrigerator oil is 10 times more hygroscopic than the conventional refrigerator oil (such as Suniso). Water

infiltration in the refrigerant circuit may deteriorate the oil or cause a compressor failure. Piping materials must be

stored with more care than with the conventional refrigerant pipes.

–4–

Page 6

[2] Piping Machining

Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator oil to coat flares and flange connections.

Use only the necessary minimum quantity of oil !

Reason :

1. The refrigerator oil used for the equipment is highly hygroscopic and may introduce water inside.

Notes :

• Introducing a great quantity of mineral oil into the refrigerant circuit may also cause a compressor failure.

• Do not use oils other than ester oil, ether oil or alkylbenzene.

–5–

Page 7

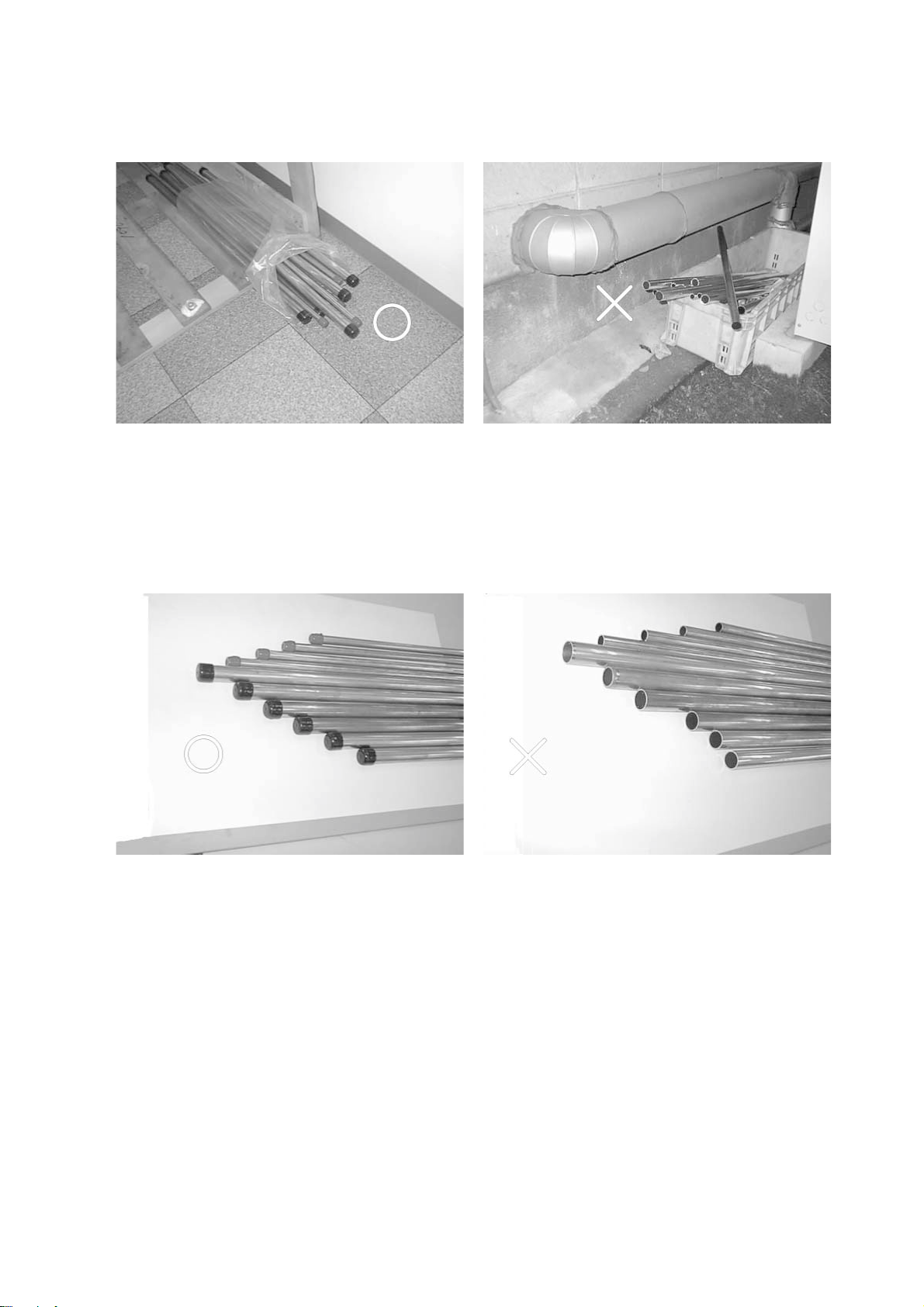

[3] Necessary Apparatus and Materials and Notes on Their Handling

The following tools should be marked as dedicated tools for R407C.

<<Comparison of apparatus and materials used for R407C and for R22>>

Apparatus Used Use R22 R407C

Gauge manifold Evacuating, refrigerant filling Current product

Charging hose Operation check Current product

Charging cylinder Refrigerant charging Current product Do not use.

Gas leakage detector Gas leakage check Current product Shared with R134a

Refrigerant collector Refrigerant collection R22 For R407C use only

Refrigerant cylinder Refrigerant filling R22

Identification of dedicated use for R407C

:Record refrigerant

name and put brown

belt on upper part of

cylinder.

Vacuum pump Vacuum drying Current product

Vacuum pump with a check valve Current product

Flare tool Flaring of pipes Current product

Bender Bending of pipes Current product

Application oil Applied to flared parts Current product

Torque wrench Tightening of flare nuts Current product

Pipe cutter Cutting of pipes Current product

Welder and nitrogen cylinder Welding of pipes Current product

Refrigerant charging meter Refrigerant charging Current product

Vacuum gauge Checking the vacuum degree Current product

Symbols :

Tools for R407C must be handled with more care than those for conventional refrigerants. They must not come into contact

with any water or dirt.

To be used for R407C only. Can also be used for conventional refrigerants.

Can be used by

attaching an adapter

with a check valve.

Ester oil or Ether oil or

Alkybenzene (Small

amount)

–6–

Page 8

[4] Brazing

No changes from the conventional method, but special care is required so that foreign matter (ie. oxide scale, water, dirt,

etc.) does not enter the refrigerant circuit.

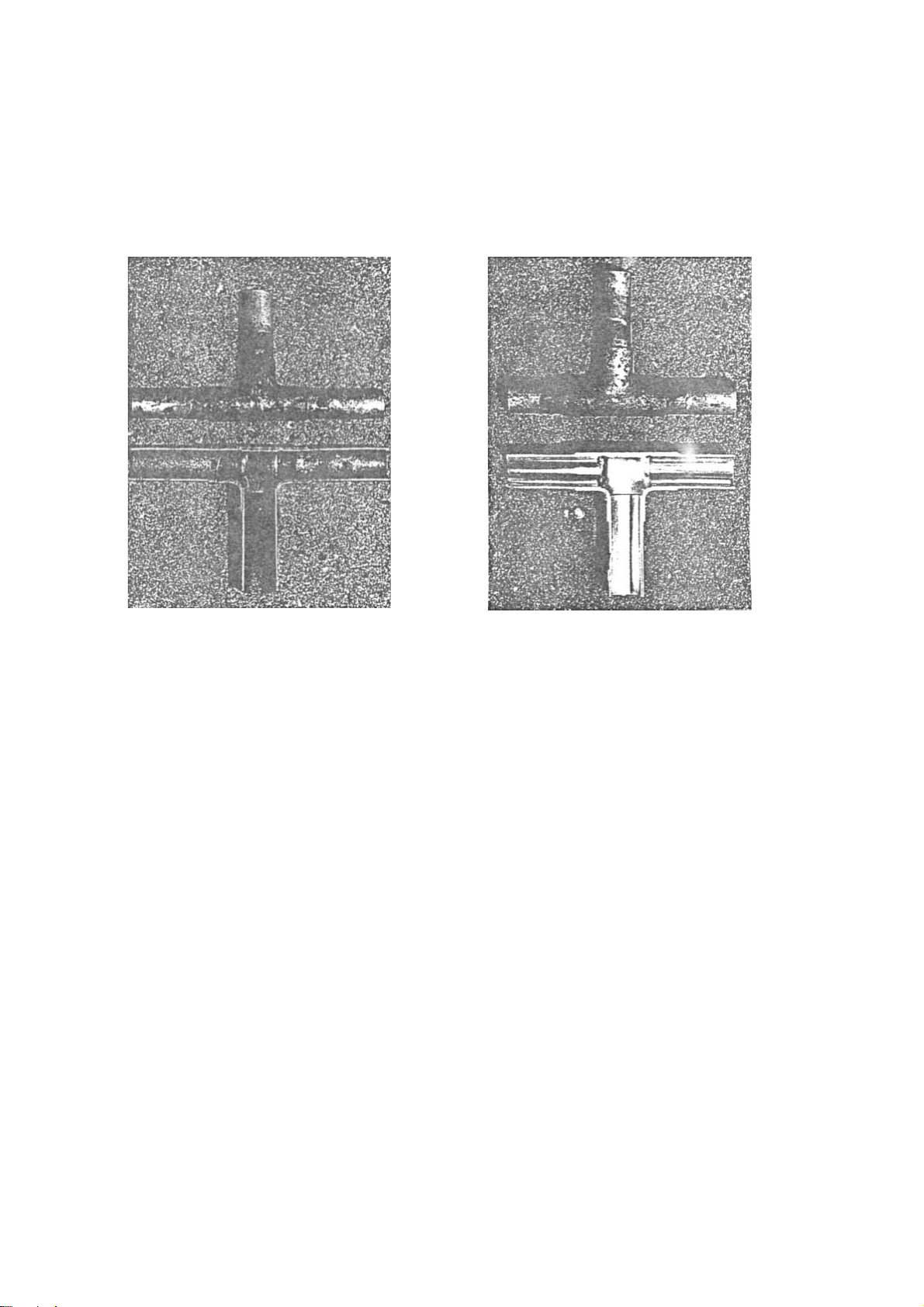

Example : Inner state of brazed section

When non-oxide brazing was not used When non-oxide brazing was used

Items to be strictly observed :

1. Do not conduct refrigerant piping work outdoors on a rainy day.

2. Apply non-oxide brazing.

3. Use a brazing material (Bcup-3) which requires no flux when brazing between copper pipes or between a copper pipe

and copper coupling.

4. If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends of them.

Reasons :

1. The new refrigerant oil is 10 times more hygroscopic than the conventional oil. The probability of a machine failure if

water infiltrates is higher than with conventional refrigerant oil.

2. A flux generally contains chlorine. A residual flux in the refrigerant circuit may generate sludge.

Note :

• Commercially available antioxidants may have adverse effects on the equipment due to its residue, etc. When

applying non-oxide brazing, use nitrogen.

–7–

Page 9

[5] Airtightness Test

No changes from the conventional method. Note that a refrigerant leakage detector for R22 cannot detect R407C

leakage.

Halide torch R22 leakage detector

Items to be strictly observed :

1. Pressurize the equipment with nitrogen up to the design pressure and then judge the equipment’s airtightness, taking

temperature variations into account.

2. When investigating leakage locations using a refrigerant, be sure to use R407C.

3. Ensure that R407C is in a liquid state when charging.

Reasons :

1. Use of oxygen as the pressurized gas may cause an explosion.

2. Charging with R407C gas will lead the composition of the remaining refrigerant in the cylinder to change and this

refrigerant can then not be used.

Note :

• A leakage detector for R407C is sold commercially and it should be purchased.

[6] Vacuuming

1. Vacuum pump with check valve

A vacuum pump with a check valve is required to prevent the vacuum pump oil from flowing back into the refrigerant

circuit when the vacuum pump power is turned off (power failure).

It is also possible to attach a check valve to the actual vacuum pump afterwards.

2. Standard degree of vacuum for the vacuum pump

Use a pump which reaches 0.5 Torr (500 MICRON) or below after 5 minutes of operation.

In addition, be sure to use a vacuum pump that has been properly maintained and oiled using the specified oil. If the

vacuum pump is not properly maintained, the degree of vacuum may be too low.

3. Required accuracy of the vacuum gauge

Use a vacuum gauge that can measure up to 5 Torr. Do not use a general gauge manifold since it cannot measure a

vacuum of 5 Torr.

4. Evacuating time

• Evacuate the equipment for 1 hour after –755 mmHg (5 Torr) has been reached.

• After envacuating, leave the equipment for 1 hour and make sure the that vacuum is not lost.

5. Operating procedure when the vacuum pump is stopped

In order to prevent a backflow of the vacuum pump oil, open the relief valve on the vacuum pump side or loosen the

charge hose to drawn in air before stopping operation.

The same operating procedure should be used when using a vacuum pump with a check valve.

–8–

Page 10

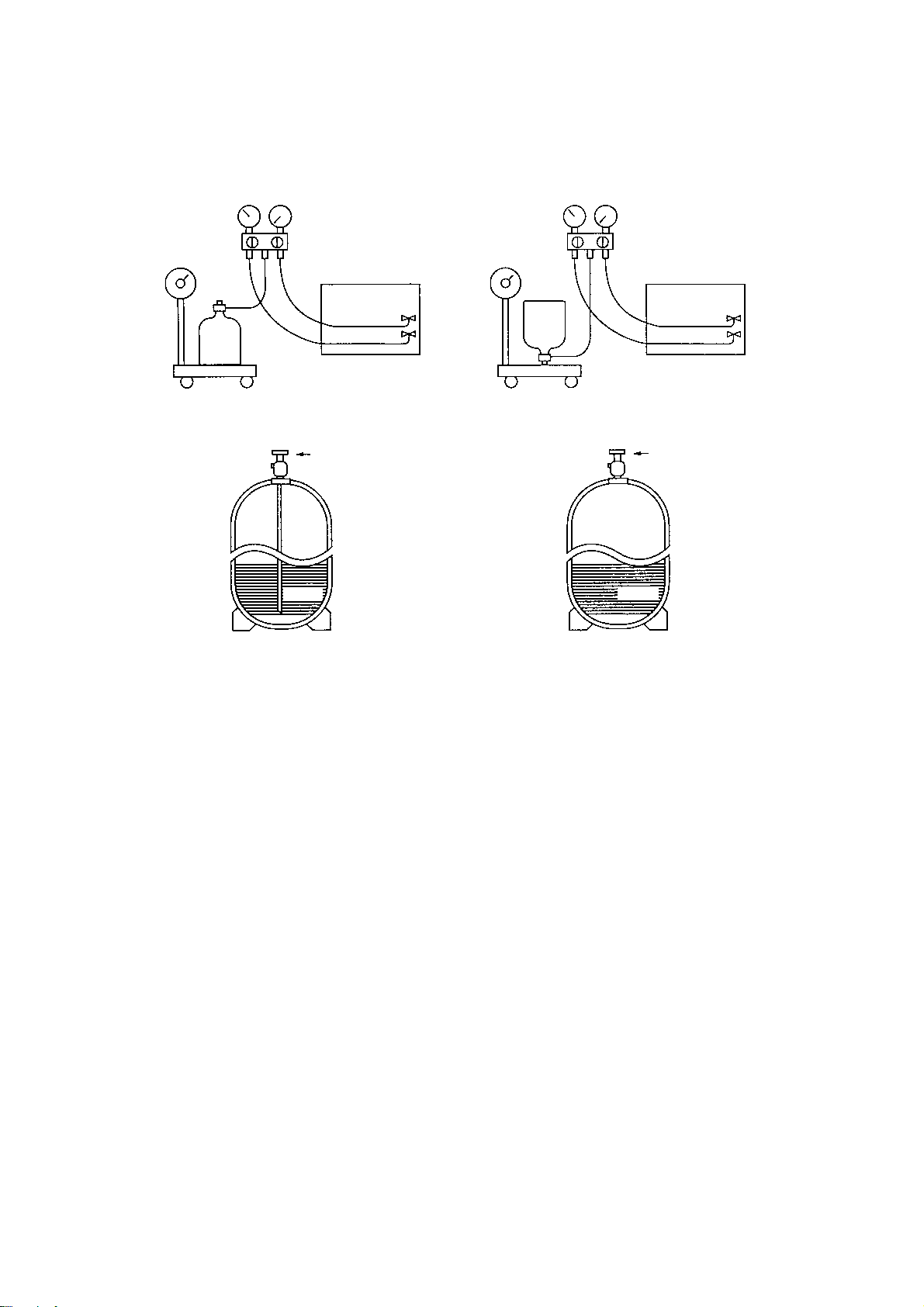

[7] Charging of Refrigerant

R407C must be in a liquid state when charging, because it is a non-azeotropic refrigerant.

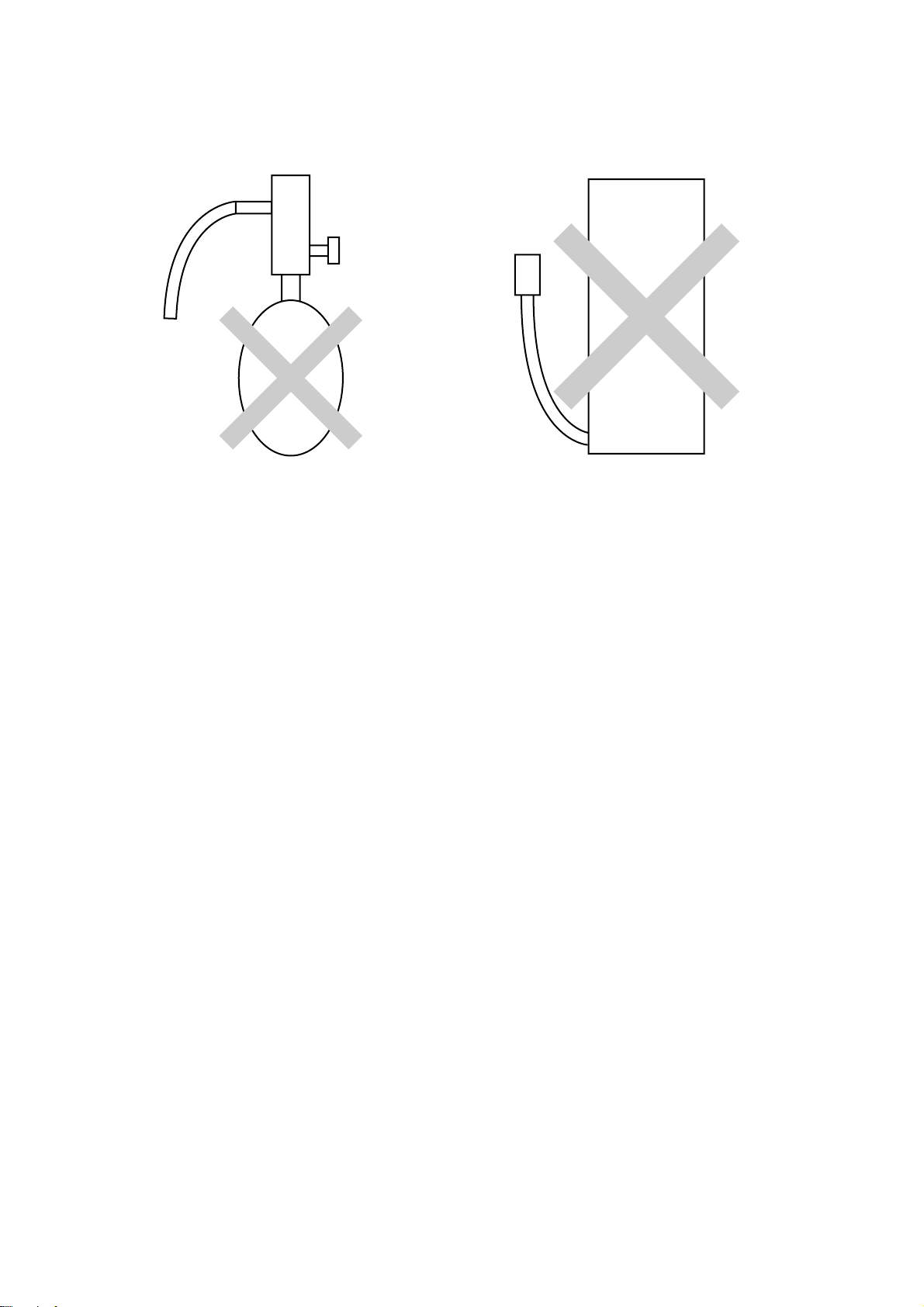

For a cylinder with a syphon attached For a cylinder without a syphon attached

Cylin-

Cylin-

der

Cylinder color identification R407C-brown Charged with liquid refrigerant

der

Valve

Liquid

Valve

Liquid

Reasons :

1. R407C is a mixture of 3 refrigerants, each with a different evaporation temperature. Therefore, if the equipment is

charged with R407C gas, then the refrigerant whose evaporation temperature is closest to the outside temperature is

charged first while the rest of refrigerants remain in the cylinder.

Note :

• In the case of a cylinder with a syphon, liquid R407C is charged without turning the cylinder up side down. Check the

type of cylinder before charging.

[8] Dryer

1. Replace the dryer when the refrigerant circuit is opened (Ex. Change the compressor, full gas leakage). Be sure to

replace the dryer with a CITY MULTI Series WR2 (PQRY) (For use with R407C).

If any other product is used, the unit will be damaged.

2. Opening the refrigerant circuit after changing to a new dryer is less than 1 hour. The replacement of the dryer should

be the last operation performed.

–9–

Page 11

22

2 COMPONENT OF EQUIPMENT

22

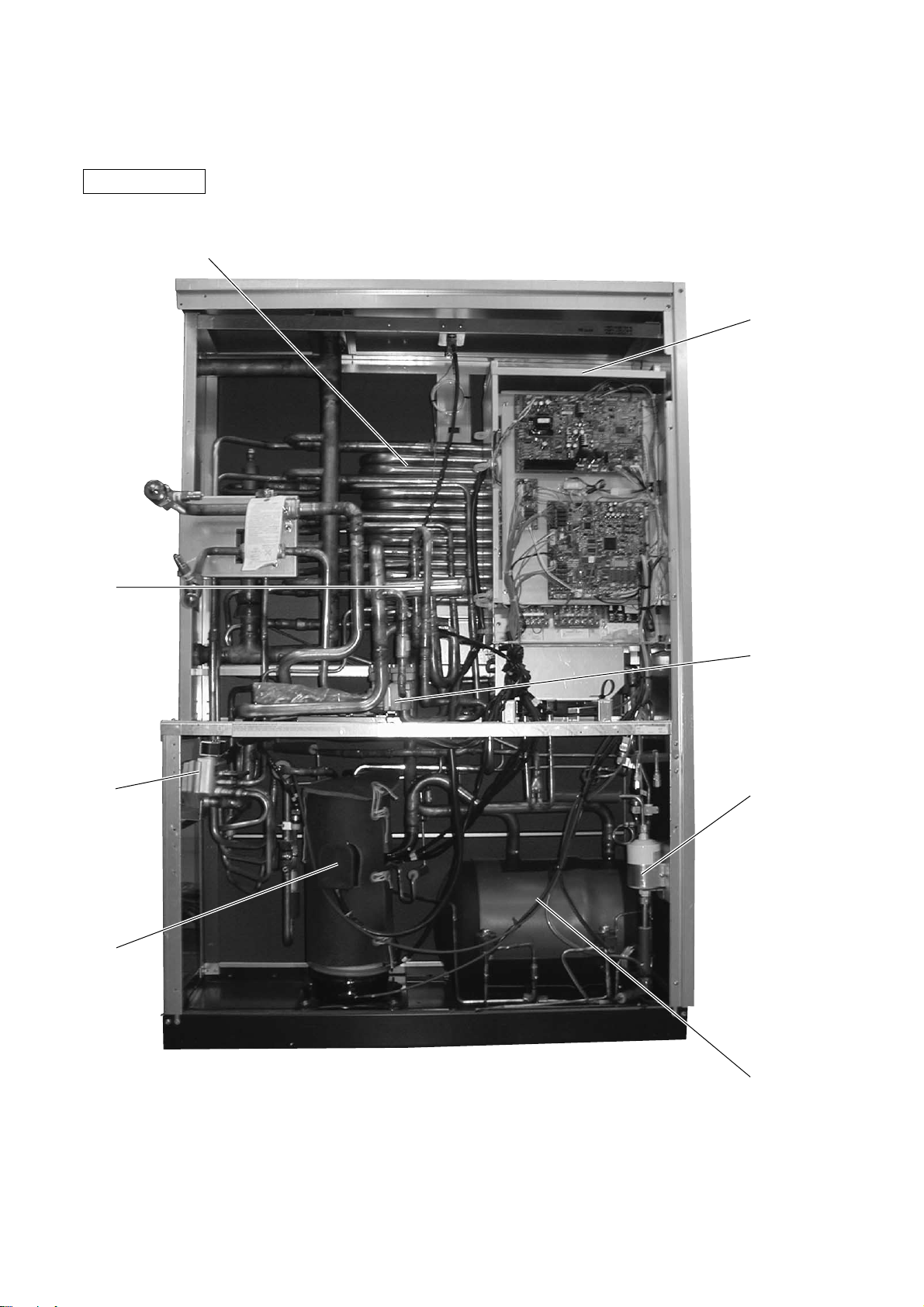

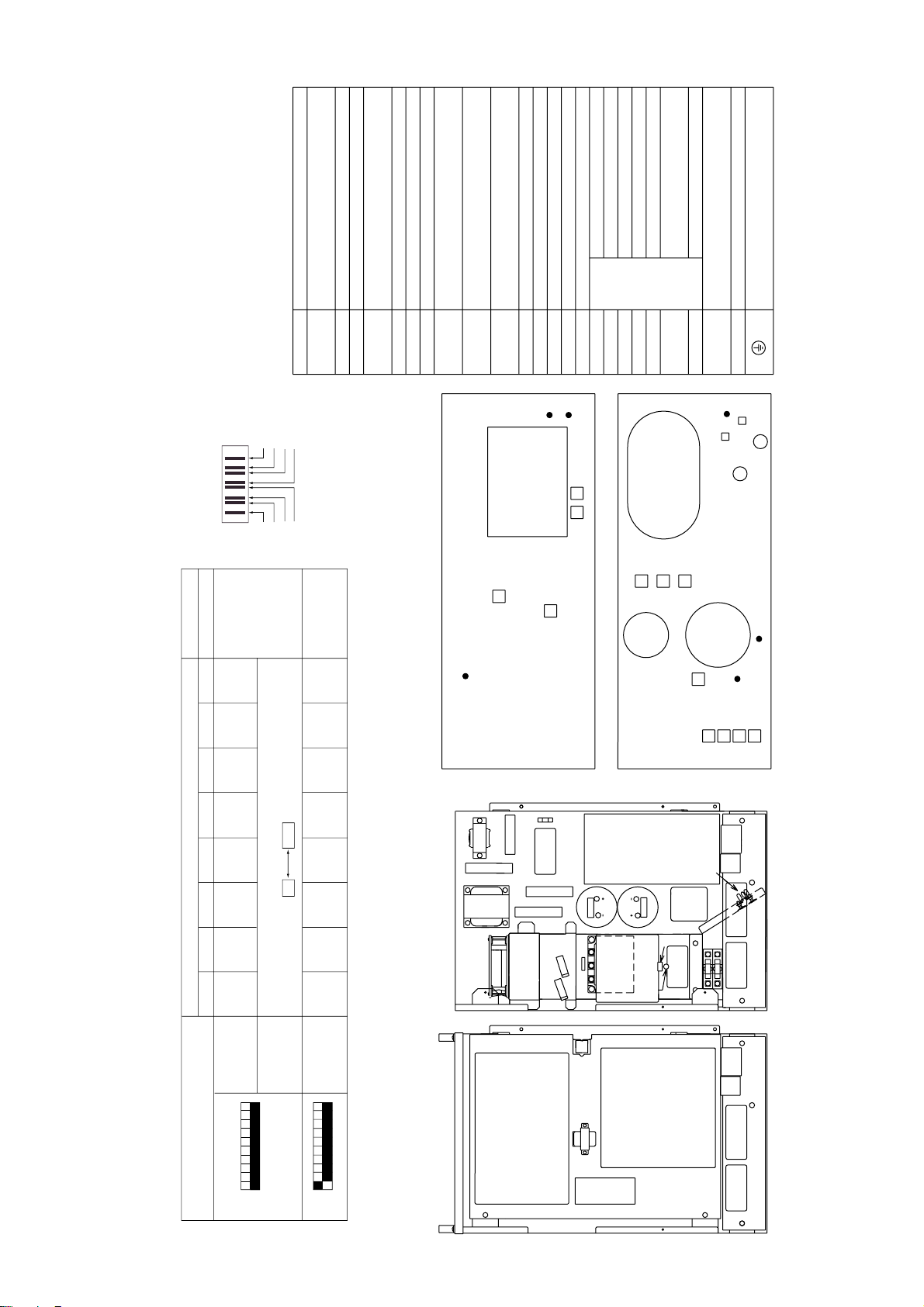

[1] Appearance of Components

Heat source unit

Heatexchanger

Control Box

4-way

Valve

SV

Block

Compressor

CV

Block

Drier

–10–

Accumulator

Page 12

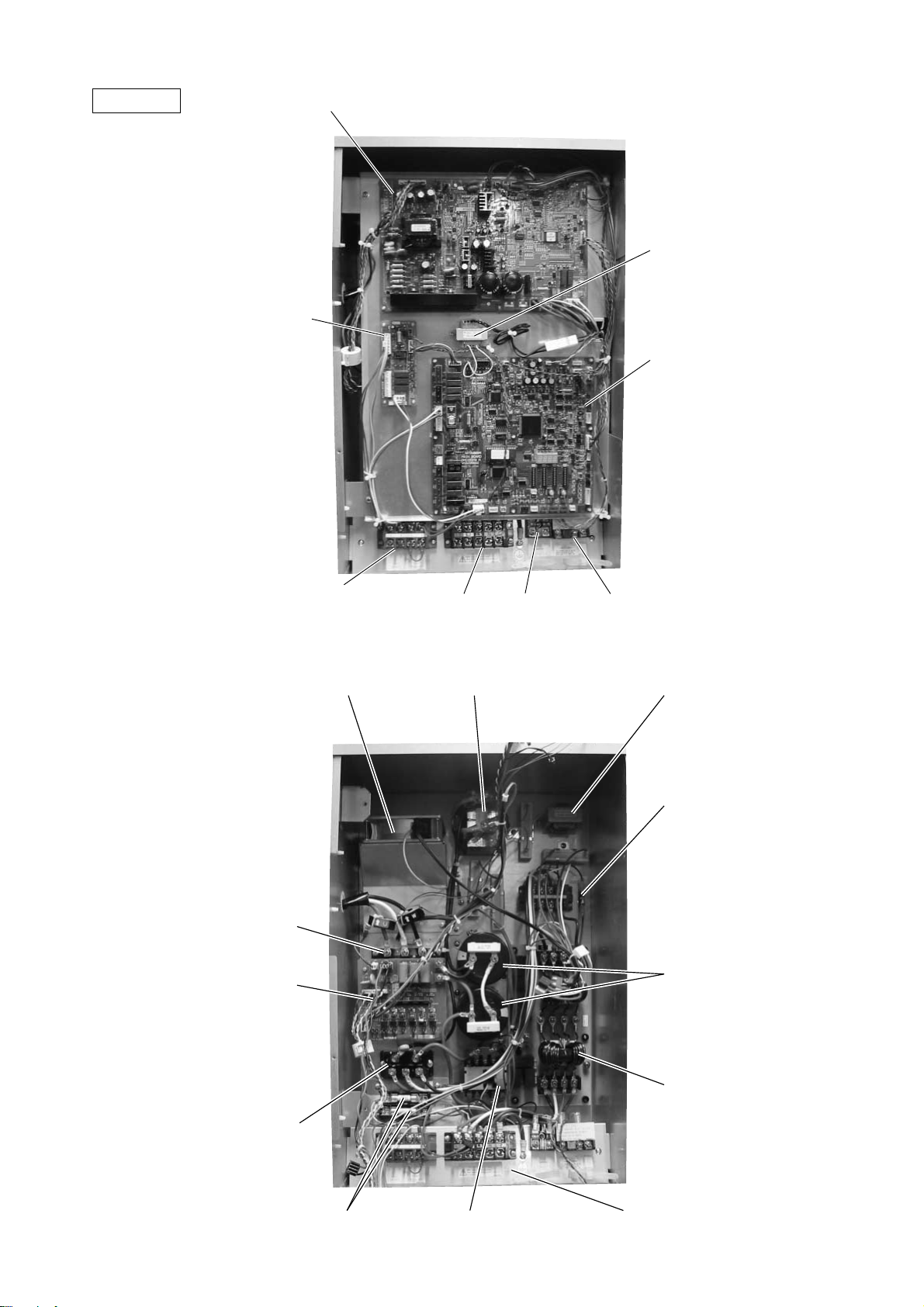

Control Box

Front View

INV board

Transformer

(T01)

RELAY

board

MAIN

board

Inner View

T erminal block TB8

UNIT ON/OFF,

Pump inter lock

Intelligent Power

Module (IPM)

G/A board

Cooling fan

(MF1)

T erminal block TB1A

Power Source

DC reactor

(DCL)

Terminal block

TB3 Transmission

T erminal block TB7

Transmission (Centralized Control)

Choke coil

(L2)

Fuse

(F3)

Capacitor

(C2, C3)

Diode

stack

(DS)

Fuse

(F5, F6)

Magnetic Contactor (52C)

–11–

Noise

Filter

SNB board

(Back Side)

Page 13

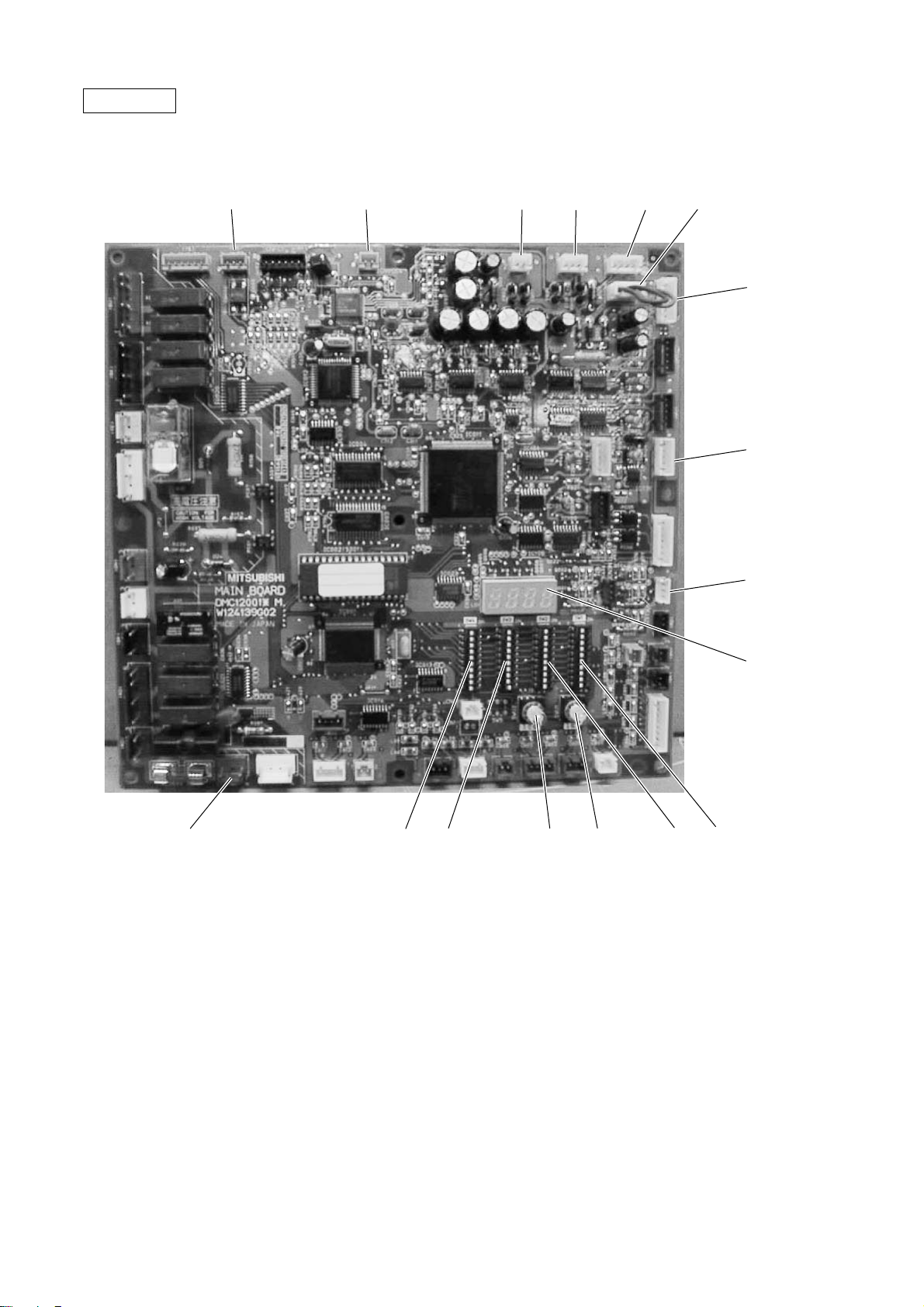

MAIN board

CNTR CNVCC4 CNS1 CNS2 CN40 CN41

Power source

for control (5V)

CNVCC3

Power source

for control

1-2 30 V,

1-3 30 V,

4-6 12 V,

5-6 5 V

CN51

CN3D

LD1

Service LED

SW3SW4CN20

SWU1SWU2

SW1SW2

–12–

Page 14

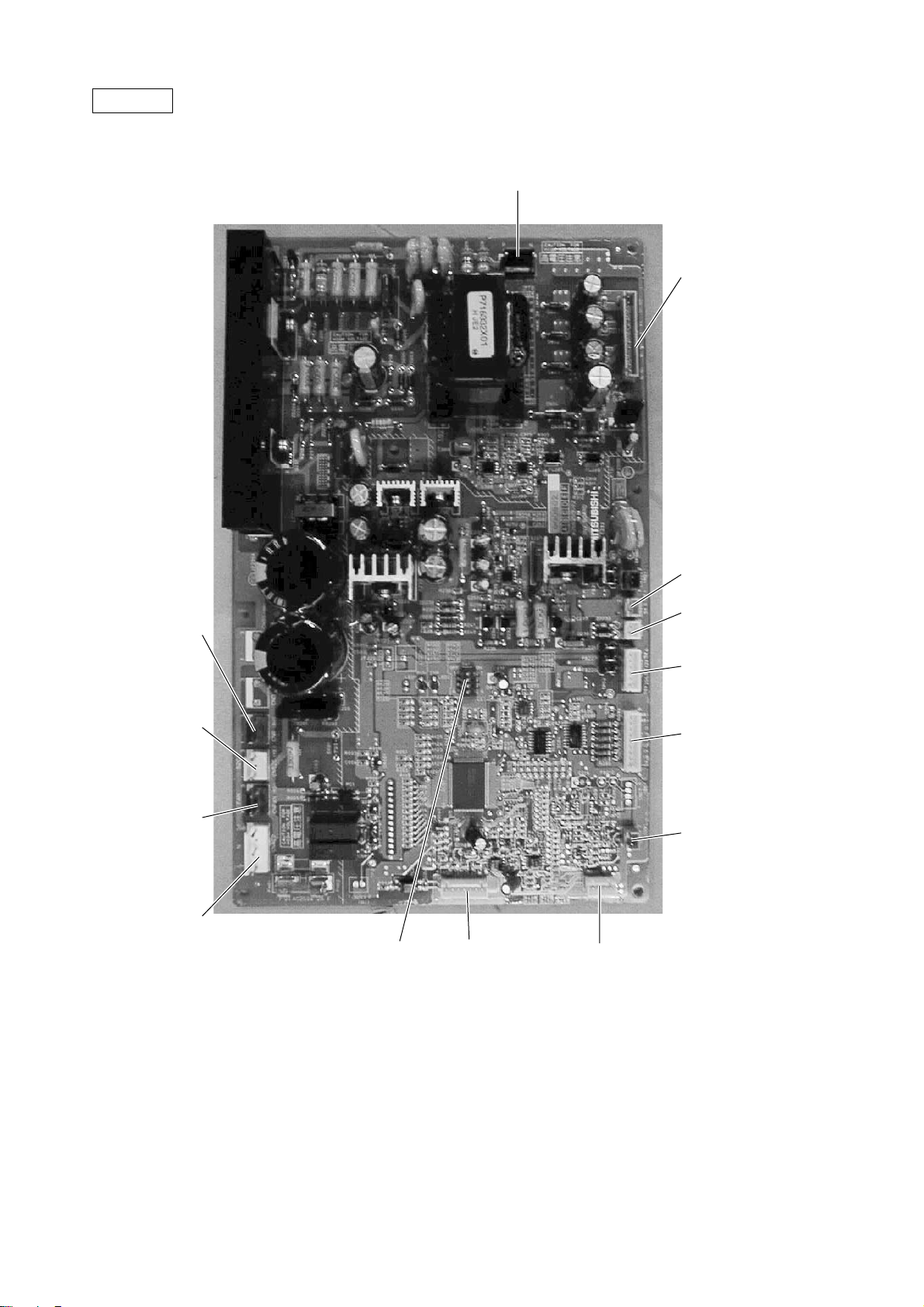

INV board

CNVDC

1-4

DC-560V

CN15V2

Power supply

for IPM control

CNR

CN52C

Control for

52C

CNFAN

Control

for MF1

CNAC2

Power

source

1 L2

3 N

5 G

SW1

CNRS2

Serial transmission

to MAIN board

CNVCC4

Power supply (5V)

CNL2

Choke coil

CNVCC2

Power supply

1-2 30V, 1-3 30V

4-6 12V, 5-6 5V

CNDR2

Out put to

G/A board

CNTH

CNACCT

–13–

Page 15

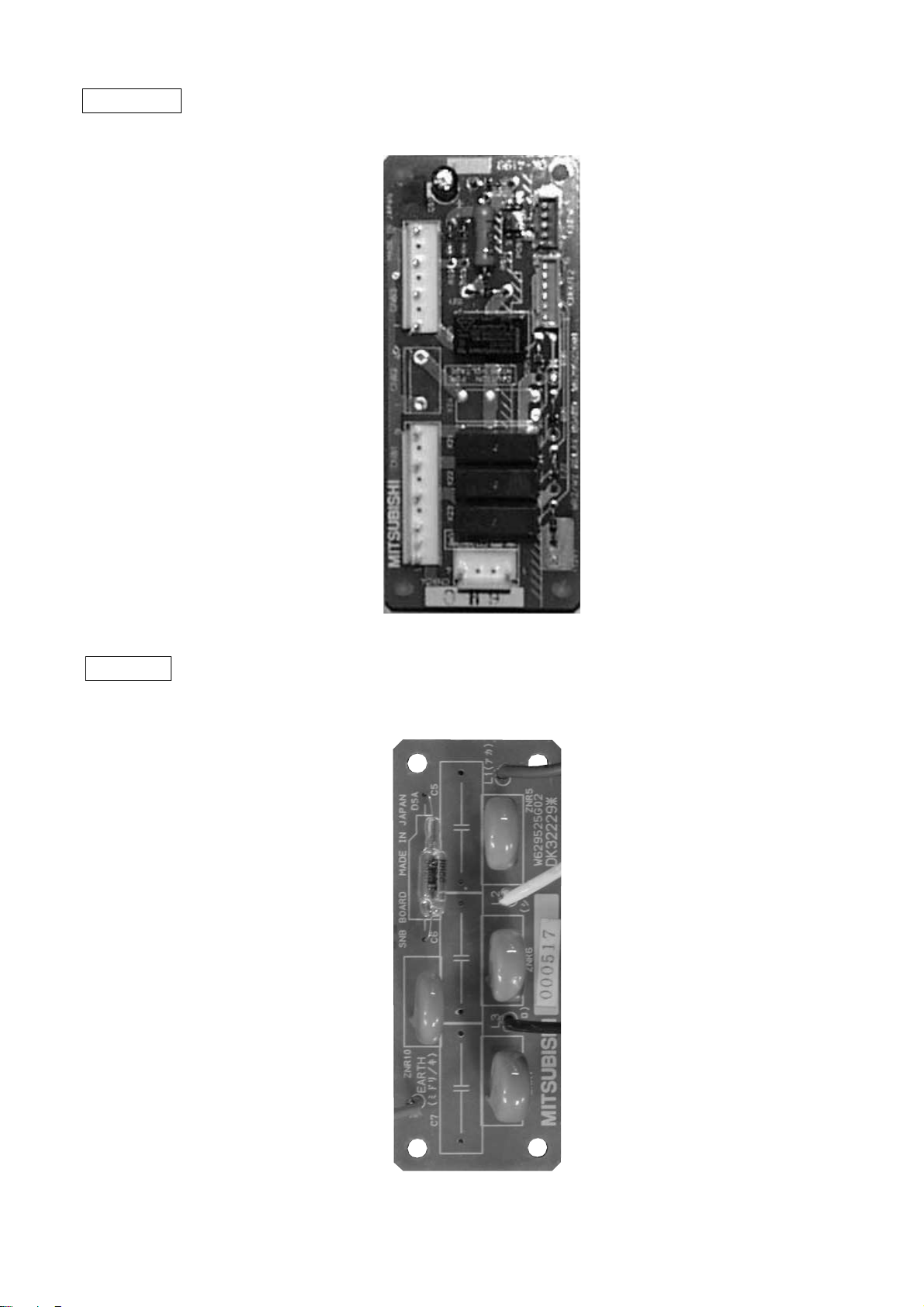

RELAY board

SNB board

–14–

Page 16

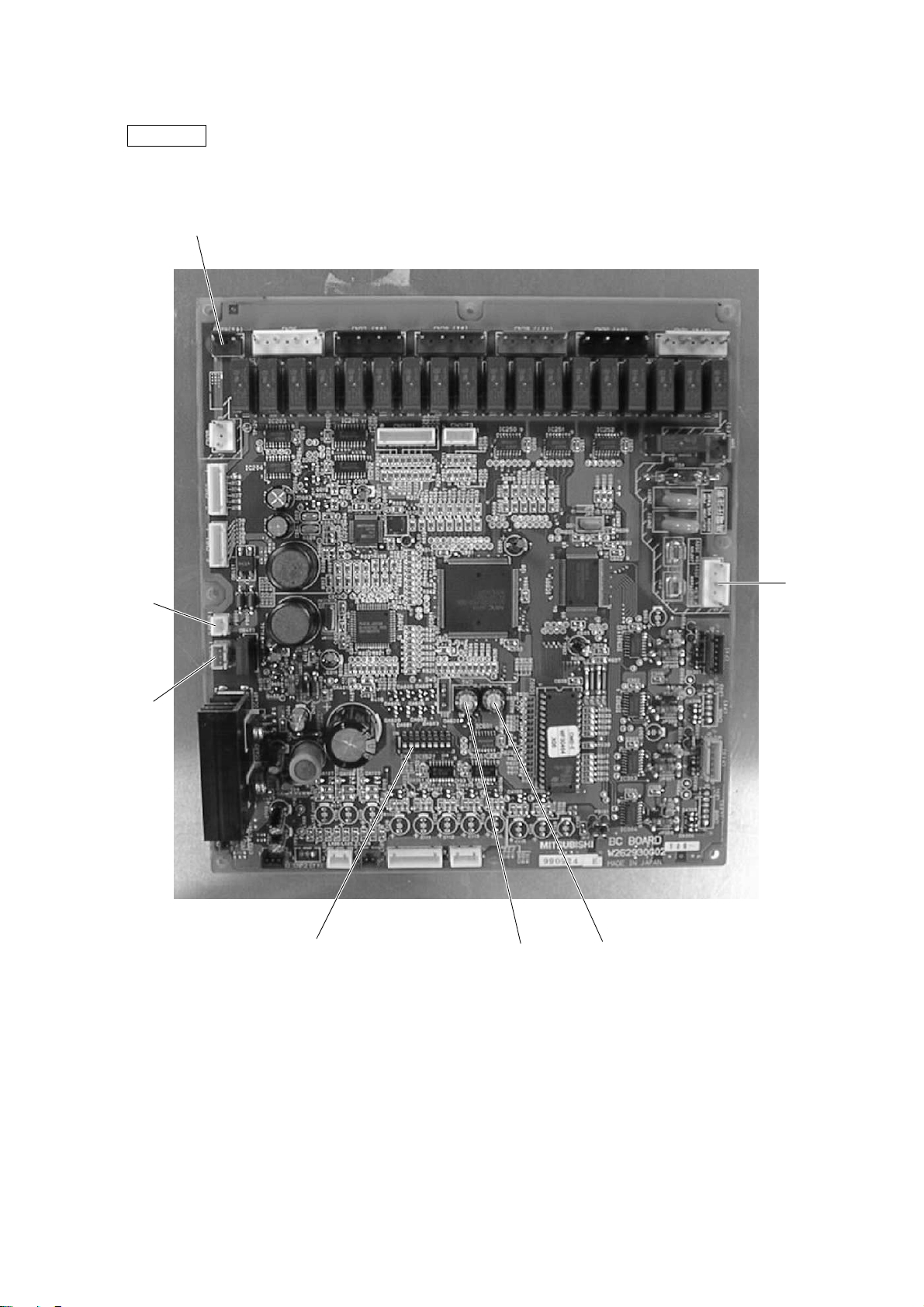

BC controller

BC board

CNTR

CN02

M-NET

transmission

CN03

CN12

Power

supply

1 EARTH

3 N

5 L

SW4 SW2 SW1

–15–

Page 17

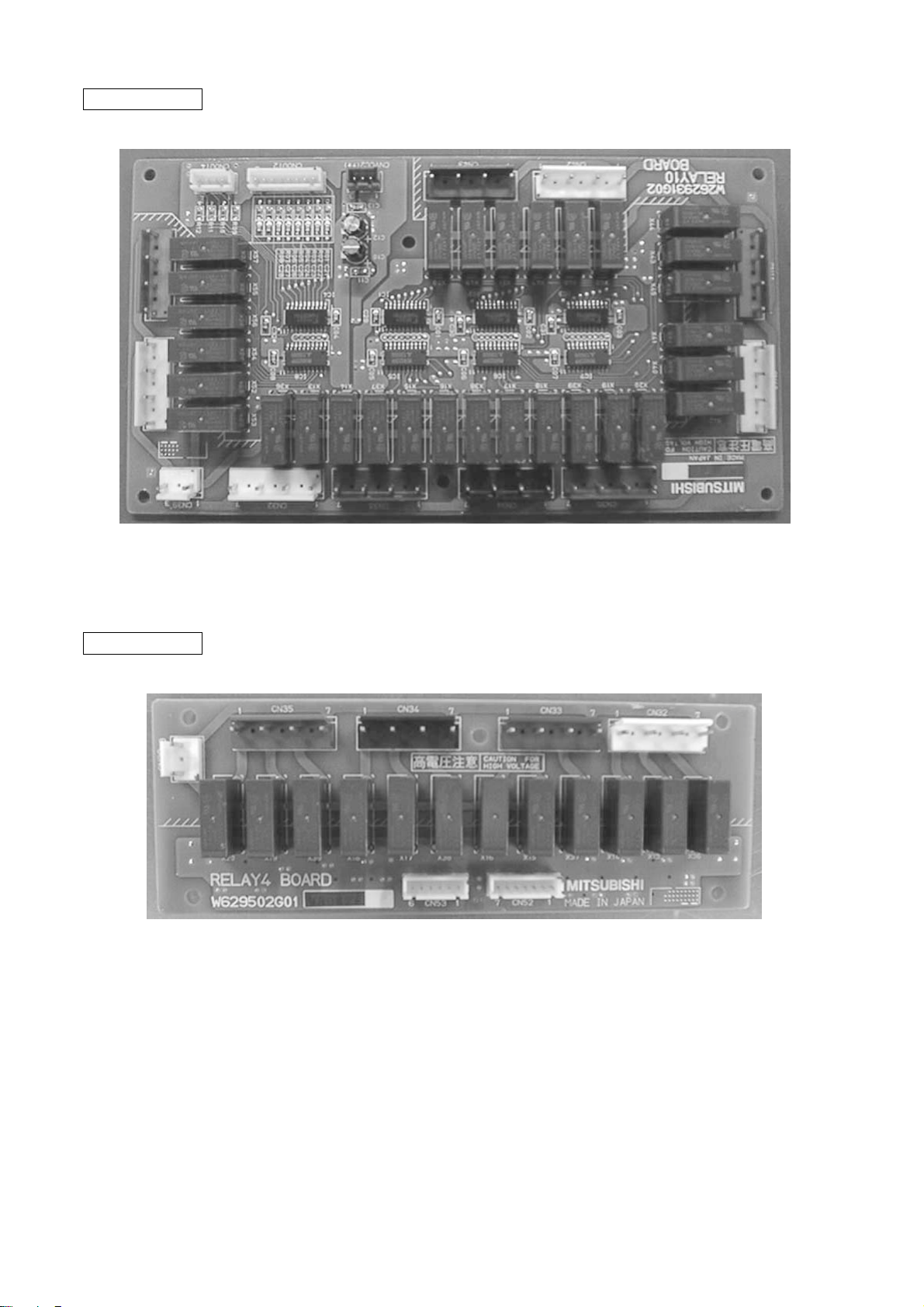

RELAY 10 board

RELAY 4 board

–16–

Page 18

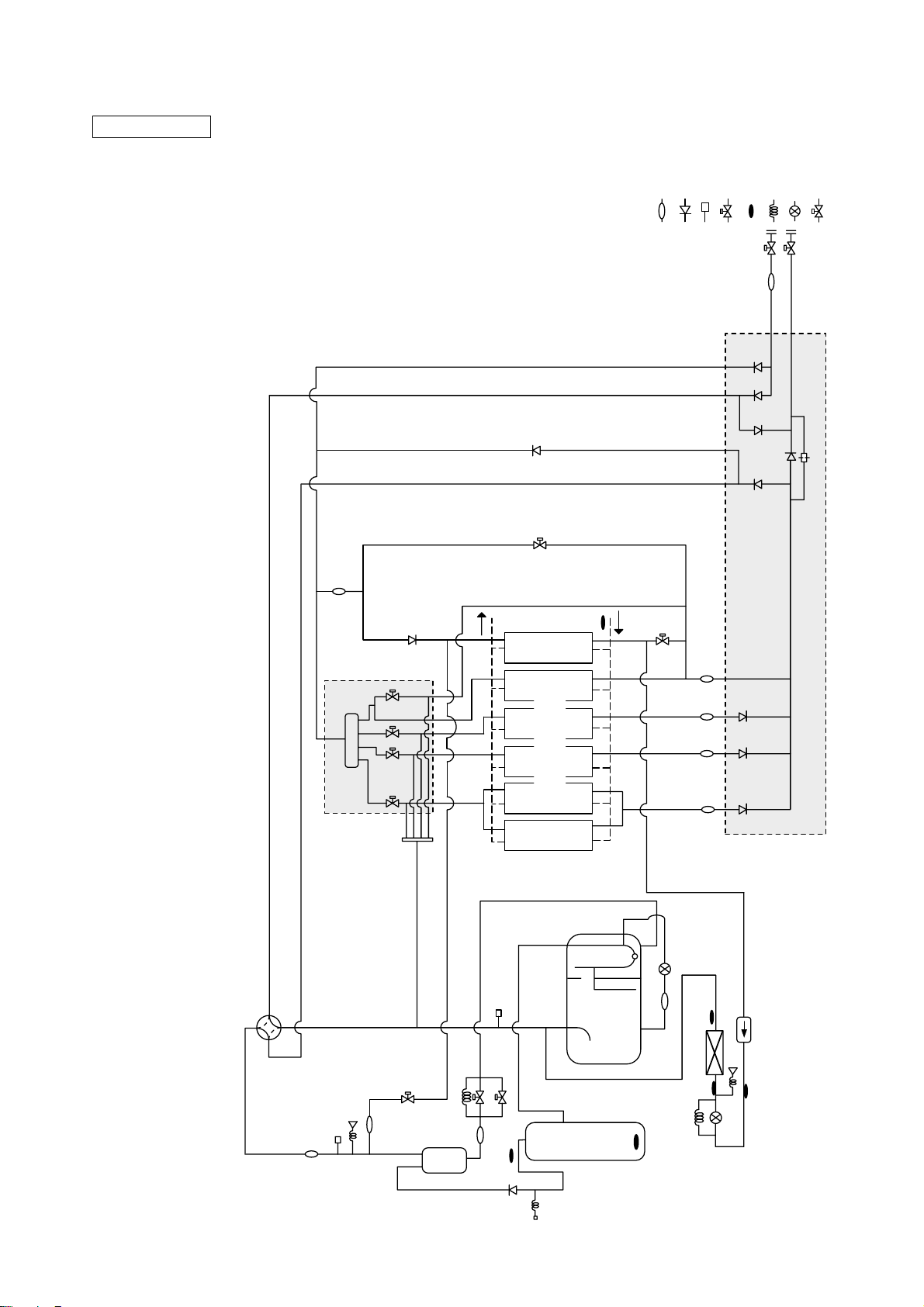

[2] Refrigerant Circuit Diagram and Thermal Sensor

: Strainer

: Check valve

: Service port

: Solenoid valve

: Thermal sensor

: Capillary

: Liner valve expansion

: Ball valve

ST

CV

SP

SV

LEV

TH

CP

BV

Heat source unit

ST8

CV11

CV7

SV72

TH6

SV71

BV1

CV3

CV2

CV5

CV4

ST1

CV6

BV2

Orifice

CV10

CV9

CV8

Solenoid Valv es

Distributor

Block

SV6

SV4

SV3

SV5

Water heat exchanger

(Double coil type)

Water

Circulating

ST7d

ST7b ST7cST7a

Check V alves Block

SLEV

CP1

CJ2

SV1

ST6

SV2

TH1

Comp

Accumulator

TH10

ST4

THINV

Low pressure sensor

Air Heat Exchanger

TH2

CP4

LEV2

Drier

TH9

4way valve

SV73

High pressure sensor

SP1

ST2

ST5

Oil

separator

CV1

High pressure

Switch

–17–

Page 19

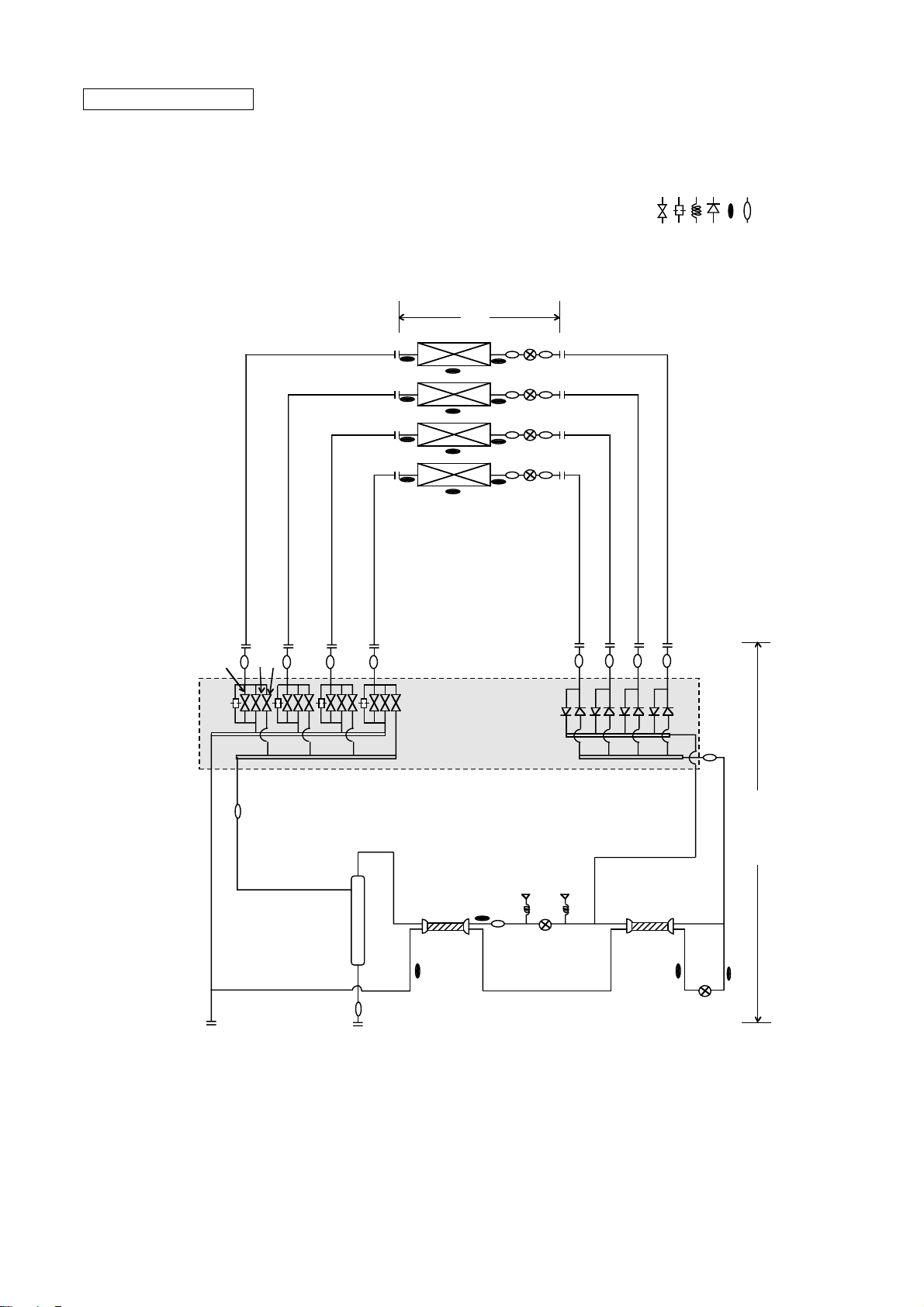

: Solenoid valve

: Orifice

: Capillary

: Check valve

: Thermal sensor

: Strainer

SP : Service port

ACC : Accumulator

BC controller, Indoor unit

Indoor

units

SVC

Valves Block

SVA

SVB

TH23

TH21

TH11

TH22

PS1

LEV

LEV1

PS3

BC controller

CMB-P104V-E

Gas/liquid separator

TH12

TH15

LEV3

TH16

–18–

Page 20

<ELECTRICAL WIRING DIAGRAM>

FB1

SNB board

EARTH

BOX BODY

BOX BODY

8A F

600VAC

F5

8A F

600VAC

F6

L3L1L2

Green

ACCT

-U

PQRY-P250YMF-C

PQRY-P200YMF-C 30A

50A

no fuse breaker

(4P)

CNACCT

4

(14P)

CN15V1

(9P)

CNDR1

IPM

FB2

(G/A board)

Gate amp board

N

P

WVU

432

1

5

White

Gray

Black

Purple

Orange

Orange

Yellow

987612345 14131110 12

987612345

987612345

987612341234

1234

5 14131110 12

(4P)

CNDC1

(2P)

CNE

Refer to the service handbook

about the switch operations.

S

M2

M1

L1

1

PE

R6

31422

3

123

5

1

F01

250VAC

2A F

13

CN20

(3P)

221

CNVCC4

(2P)

CNVCC3

(6P)

CNVCC2

(6P)

CNVCC4

(2P)

31

CNS1

(2P)

CN51

(5P)

CNAC2

(5P)

2

CNS2

(3P)

CNAC3

(4P)

1

CNX10

(3P)

CNR

(3P)

2

CN52C

(3P)

3

CNVDC

CNTH

(2P)

12V

5 : SW3-3 OFF : water freeze signal

4 : Compressor ON/OFF

N

L3

Power source

3N~

380/400/415V

50/60Hz

(MAIN board)

TB1A

L2

L1NL3

L2

F1

250VAC

2A F

PE

White

Red

Black

Blue

White

Red

Black

Blue

White

Red

Black

Blue

Green/

Yellow

Connect to

Indoor and

remote

controller

TB3

M1

M2

TB7

~

DS

~ –

~

+

ZNR4

C1

R5

R1

52C

+

+

DCL

C2

C3

R2

R3

T01

F3

250VAC

1A F

CNTR1

White

V

Red

Black

3

21

21213212132

23412

1

2

1

7654321

7654321

5

6

23415

6

52C

X02

X01

X10

CNRS3

(7P)

CNRS2

(7P)

CNFAN

(3P)

THHS

CNTR

(3P)

CN15V2

(14P)

CNDR2

(9P)(4P)

CNL2

(2P)

CN30V

(2P)

MF1

R7

L2

Power circuit board

(INV board)

Controller Box

Red

Brown

Brown

Black

White

Red

Blue

Control circuit board

TB1B

NF

L1L2L3

N

L1L2L3

N

L1L2L3

N

Terminal

Block

Terminal

Block

Noise

Filter

Diode

stack

BOX BODY

BOX BODY

12

BOX BODY

BOX BODY

ACCT

-W

Inverter

U

W

MC1

Motor

(Compressor)

(4P)

CNPW

432

1

432

1

123

4

CNAC4

(4P)

123

4

(9P)

CN81

56789

X21

X22

X23

SV72

SV71

SV73

135

7

(7P)

CN83

X25

432

1

TB8

63PW

CNOUT2

(6P)

12345

6

12345

6

AC1AC4

(to CNAC3)

(3P)

CN3D

231

TH6

THINV

321321

Red

White

Black

Red

White

Black

TH1

63LS63HS

21

LEV2SLEV

(5P)

CNLV2

(5P)

CNLV1

54321543215438762132121

(3P)

CNL

(3P)

CNH

(2P)

CN01

(8P)

CN02

(3P)

CN03

(2P)

CN06

21

(2P)

CN09

21

(2P)

CN12

321321

26W

SV5

X10

SV6

SV3

SV4

21S4

SV2

63H

CH1

SV1

(to CNAC4)

AC4

AC1

412

3

X01

X04

X05

(3P)

CN32

(3P)

CN33

(6P)

CN34

(6P)

CN36

(6P)

CN37

(3P)

CN38

X02

32132

1

32165

4

32165

4

32165

4

32154

X07

X06

123

X09

X08

CNRT1

(5P)

(4P)

CN63PW

(6P)

CNOUT1

detection

circuit

detection

circuit

circuit

detection

DEMAND

RELAY board

Freeze protect

switch

High pressure

switch

Crank case heater

(Compressor)

Unit ON/OFF

Pump interlock

TH9TH10 TH2

ON

: trouble signal

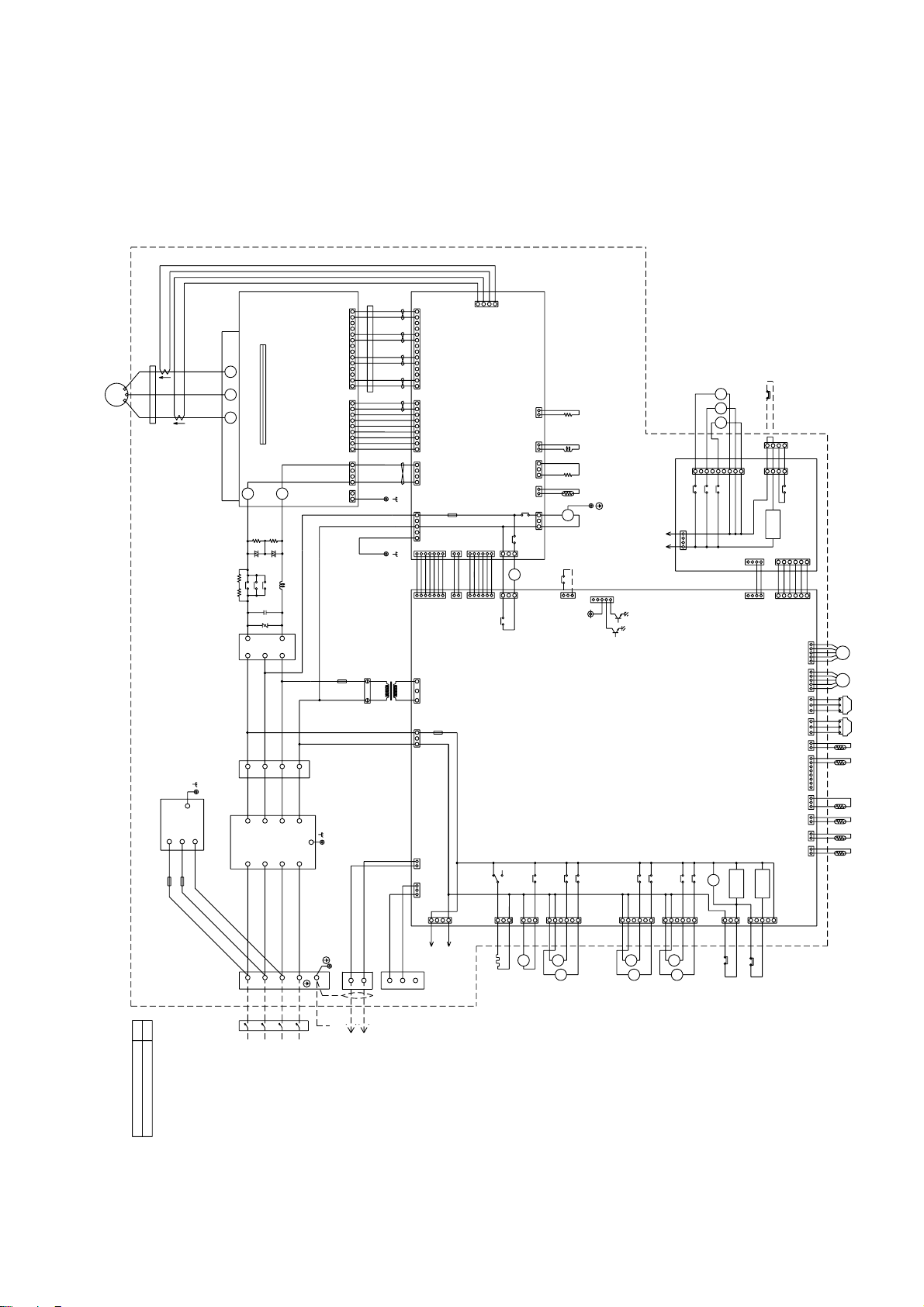

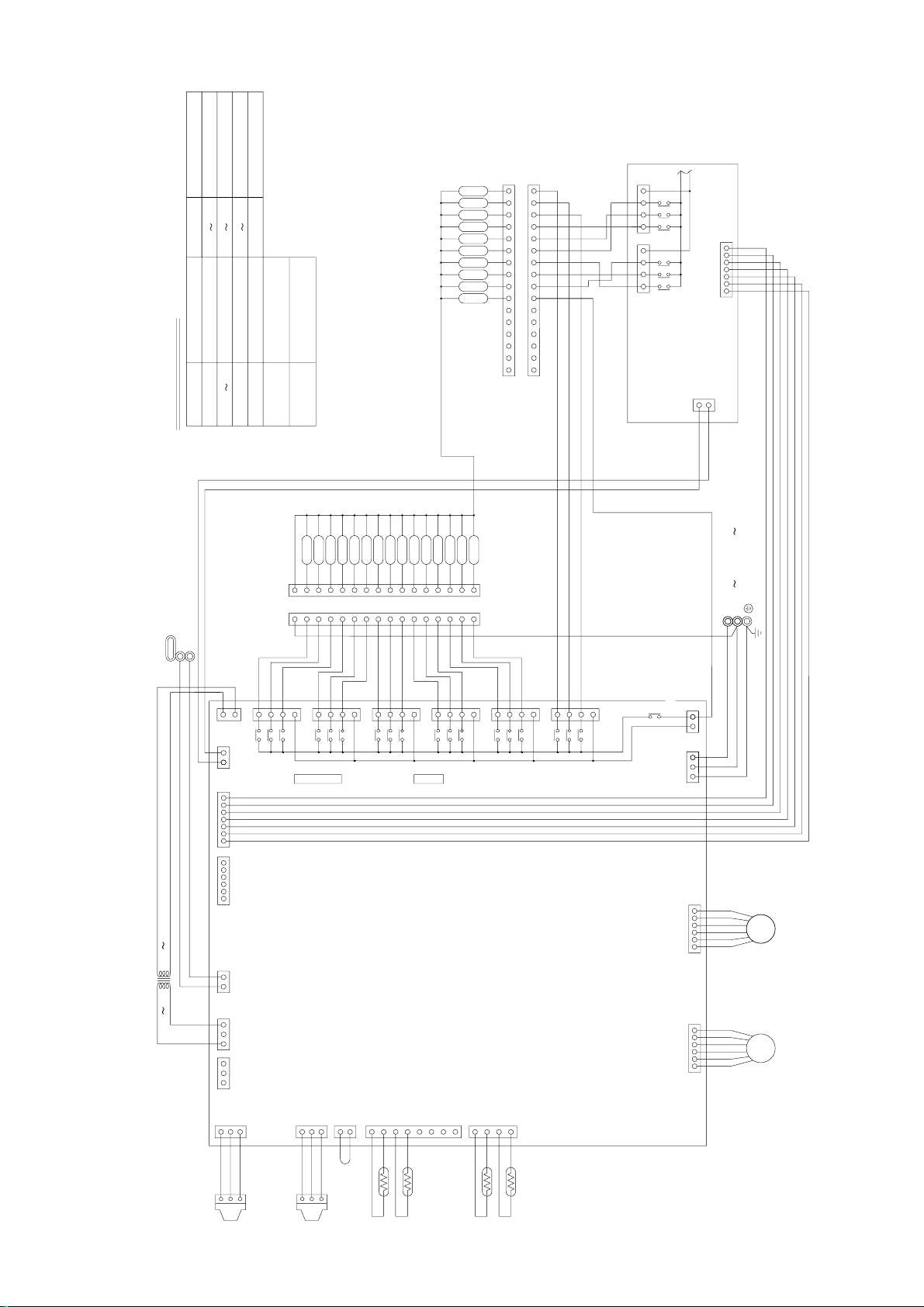

[3] Electrical Wiring Diagram

• PQRY-P200·250YMF-C

–19–

Page 21

21S4

SV1

SV2

SV3

SV4

SV72SV71SV5

SV6

SV73

SSR

<Operation of self-diagnosis switch (SW1) and LED display>

<LED display>

Display

Relay output

display

(Lighting)

Check display1

(Blinking)

(at factory shipment)

Display at LED lighting (blinking) Remarks SW1 operation

FLAG1 FLAG2 FLAG3 FLAG4 FLAG5 FLAG6 FLAG7 FLAG8

Display the address and error code by turns

Always

lighting

FLAG8 always lights

at microcomputer

power ON

During

compressor

run

Crankcase

heater

51

1102

FLAG1

FLAG2

FLAG3

FLAG4

FLAG8

FLAG7

FLAG6

FLAG5

ON:1

OFF:0

1 2 3 4 5 6 7 8 9 10

ON:1

OFF:0

1 2 3 4 5 6 7 8 9 10

* please refer to the service handbook about other switch settings of LED display.

LD1

INV board

MAIN board

RELAY

board

TB8

TB1A

TB3

TB7

T01

G/A board

IPM

C1

ZNR4

THHS

DCL

ACCT

R2

C2

C3

R3

NF

52C

MF1

L2

R5

R1

R7

F3

R6

DS

F6

F5

TB1B

TB8

TB3

TB7

TB1A

SNB

board

FB1~2

Ferrite core

Earth terminal

Aux. relay

L2

Discharge pipe temp. detect

Saturation evapo. temp. detect

Thermistor

TH2

TH1

TH6

OA temp. detect

(Heat exchanger capacity control)

Solenoid valve

(Heat exchanger capacity control)

(Heat exchanger for inverter)

Solenoid valve

SV3~6

High pressure sensor

Low pressure sensor63LS

63HS

SLEV

Choke coil (Transmission)

Intelligent power module

IPM

Electronic expansion valve

Electronic expansion valve (Oil return)

LEV2

Fan motor (Radiator panel)

SV1, SV2 Solenoid valve (Discharge-suction bypass)

4-way valve21S4

Varistor

NameSymbol

DCL

(Power factor improvement)

< Symbol explanation >

DC reactor

ACCT-U, W

Current Sensor

ZNR4

(Inverter main circuit)

52C

MF1

Magnetic contactor

X1~10

SV71~73

X21~25

THINV

TH10

TH9

Compressor shell temp.

High pressure liquid temp.

THHS

Radiator panel temp. detect

heat exchanger for inverter

Outlet temp. detect of

< Controller box internal layout >

(Upside) (Underside)

< Unit internal layout >

SV73

SV1

(Upside)

(Underside)

SEPARATOR

BOX

CONTROLLER

63LS

63HS

TH10

TH1

63H

SV2

SLEV

LEV2

TH9

ACCUMULATOR

MC

OIL

SV71SV72

INVERTER

26W

21S4

TH2

THINV

TH6

SV6

SV5

SV4

SV3

• PQRY-P200·250YMF-C

–20–

Page 22

Symbol explanation

PE

1

2

3

1

2

3

EARTH

Terminal block

(for Transmission)

TB02

Terminal block

(for power source)

TB01

NameSymbol

Solenoid valve

Solenoid valve

Solenoid valve

Solenoid valve

Expansion valve

Thermister sensor

Transformer

NameSymbol

SV1 5A

SV1 5B

SV1 5C

SVM

TR

TH11 16

LEV1,3

PS1,3 Pressure sensor

Transmission line

Shield wire

/N 220V 240V 50Hz

Power source

BC Board

LEV1

TB01

16

15

2

1

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SV4B

SV4A

SV4C

SV3B

SV3A

SV3C

SV2B

SV2A

SV2C

SV1C

SV1A

SV1B

}

3

1

CNTR

CN02

CN12

153

31

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

TR

X2

X1

X30

X4

X3

X31

X6

X5

X32

X8

X7

X33

X21

}

DC 30V

654321654321

LEV3

1

2

3

CNP1

1

2

3

CNP3

2

1

1

2

3

4

5

6

7

8

4

3

2

1

12321

CN03

CN13

CN10

CN11

CN07 CN05

L

N

TH11

TH12

TH15

TH16

PS1

PS3

20 22V

TB02

M2

M1

CN26

CN27

CN28

CN29

TB01

220 240V

SV5C

SV5A

SV5B

7

5

3

1

X10

X9

X34

CN30

SVM

CN36

∗1

∗1

∗1

∗1

Note:1.TB02 is terminal block for transmission.

Never connect power line to it.

2.

∗1

:SVM is not built in depending on models.

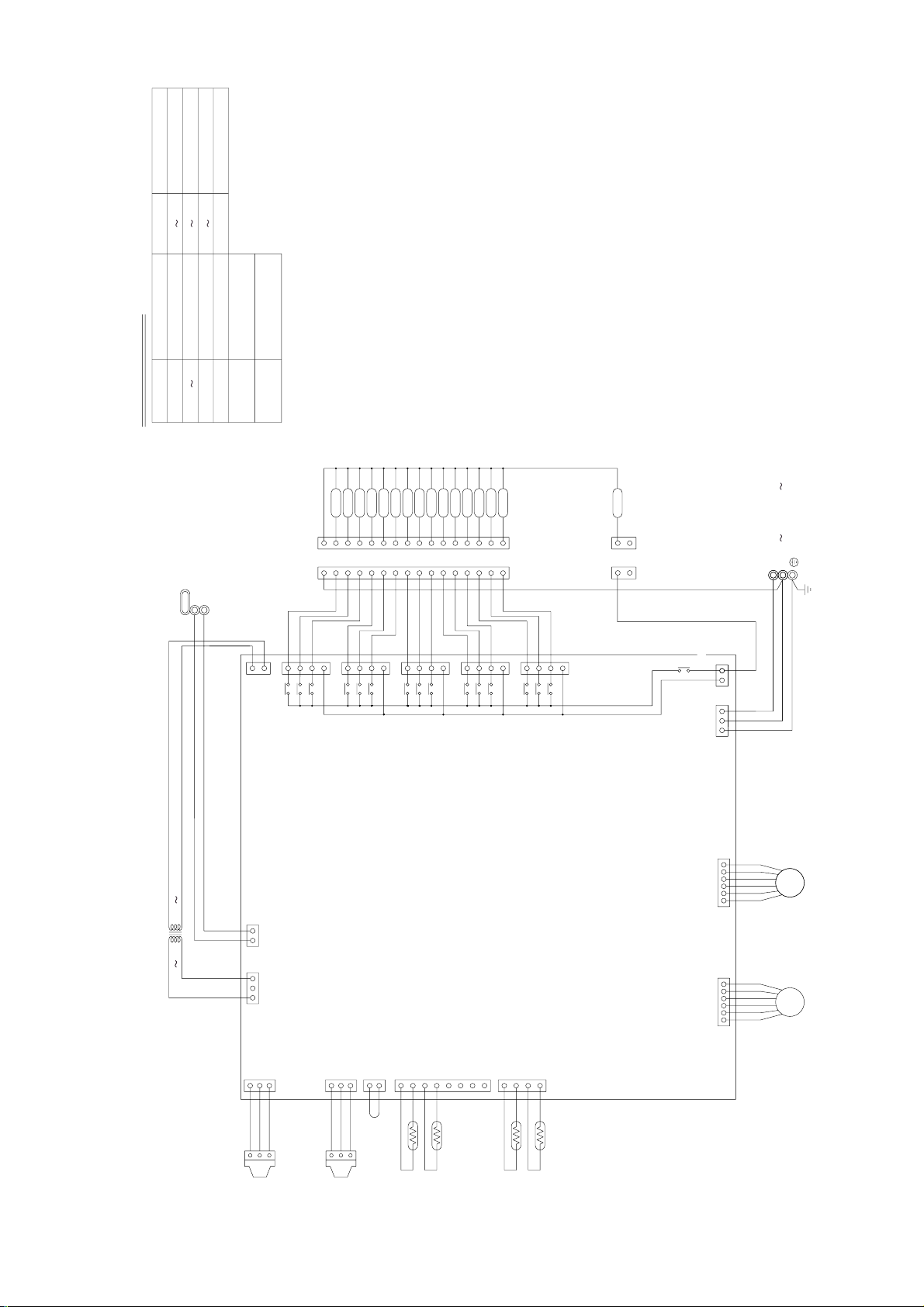

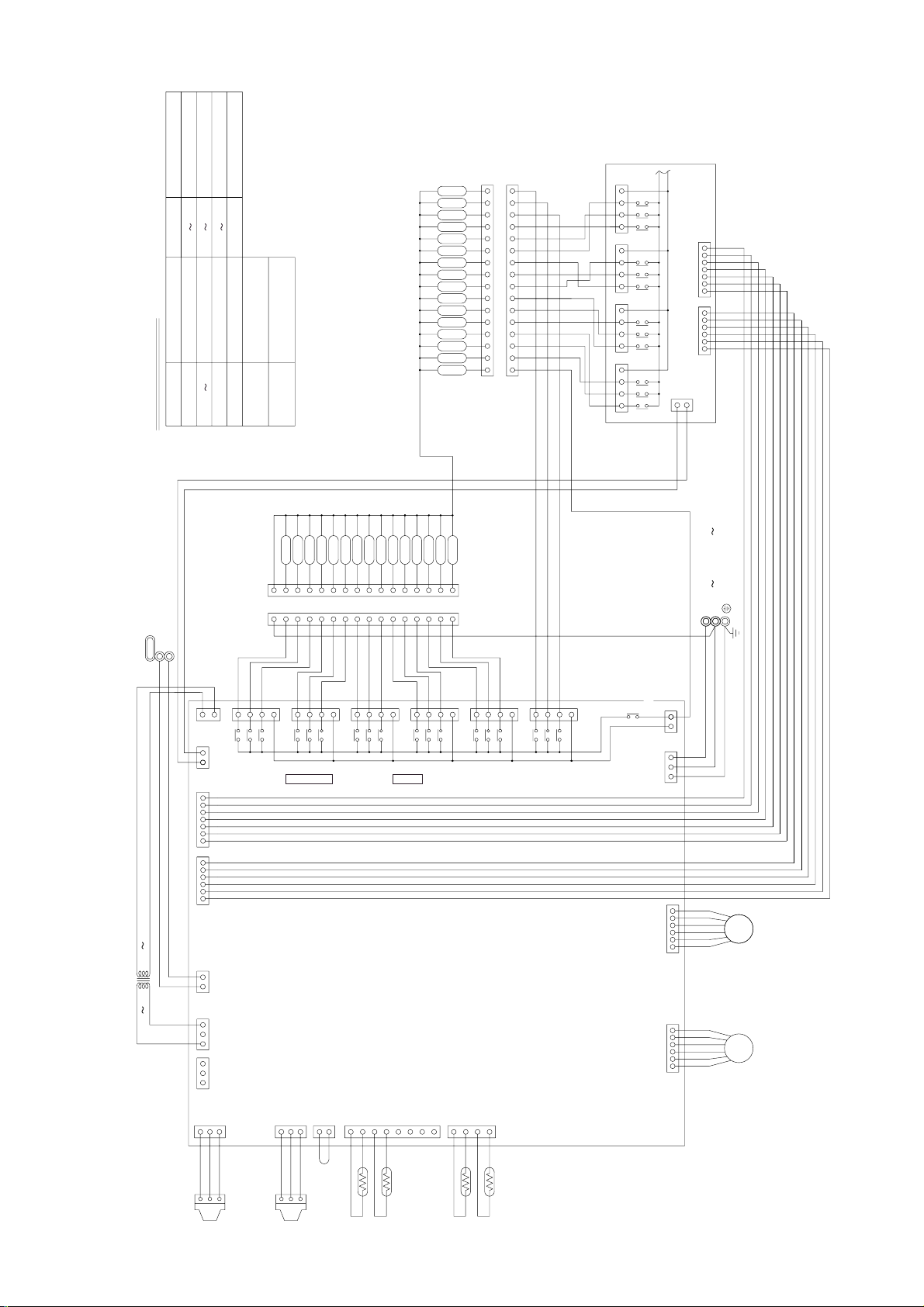

• CMB-P105V-E

–21–

Page 23

PE

1

2

3

1

2

3

EARTH

Transmission line

Shield wire

/N 220V 240V 50Hz

Power source

BC Board

31

LEV1

TB01

SV6B

SV6A

SV6C

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SV5C

SV5A

SV5B

SV4B

SV4A

SV4C

SV3B

SV3A

SV3C

SV2B

SV2A

SV2C

SVM

SV1C

SV1A

SV1B

}

4321

1234

CN38

3

1

CNTR

CN02

CN12

153

31

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

TR

3

CNVCC1

12

X2

X1

X30

X4

X3

X31

X6

X5

X32

X8

X7

X33

X10

X9

X34

X12

X11

X35

X21

}

DC 30V

654321654321

LEV3

1

2

3

CNP1

1

2

3

CNP3

2

1

1

2

3

4

5

6

7

8

4

3

2

1

12321

CN51 CN50

CNOUT 1

CNOUT 3

CN03

CN13

CN10

CN11

CN07 CN05

L

N

TH11

TH12

TH15

TH16

PS1

PS3

20 22V

TB02

M2

M1

CN26

CN27

CN28

CN29

CN30

CN31

TB01

220 240V

CN36

Symbol explanation

Terminal block

(for Transmission)

TB02

Terminal block

(for power source)

TB01

NameSymbol

Solenoid valve

Solenoid valve

Solenoid valve

Solenoid valve

Expansion valve

Thermister sensor

Transformer

NameSymbol

SV1 6A

SV1 6B

SV1 6C

SVM

TR

TH11 16

LEV1,3

PS1,3 Pressure sensor

∗1

∗1

∗1

∗1

7654321123456

Note:1.TB02 is terminal block for transmission.

Never connect power line to it.

2.

∗1

:SVM is not built in depending on models.

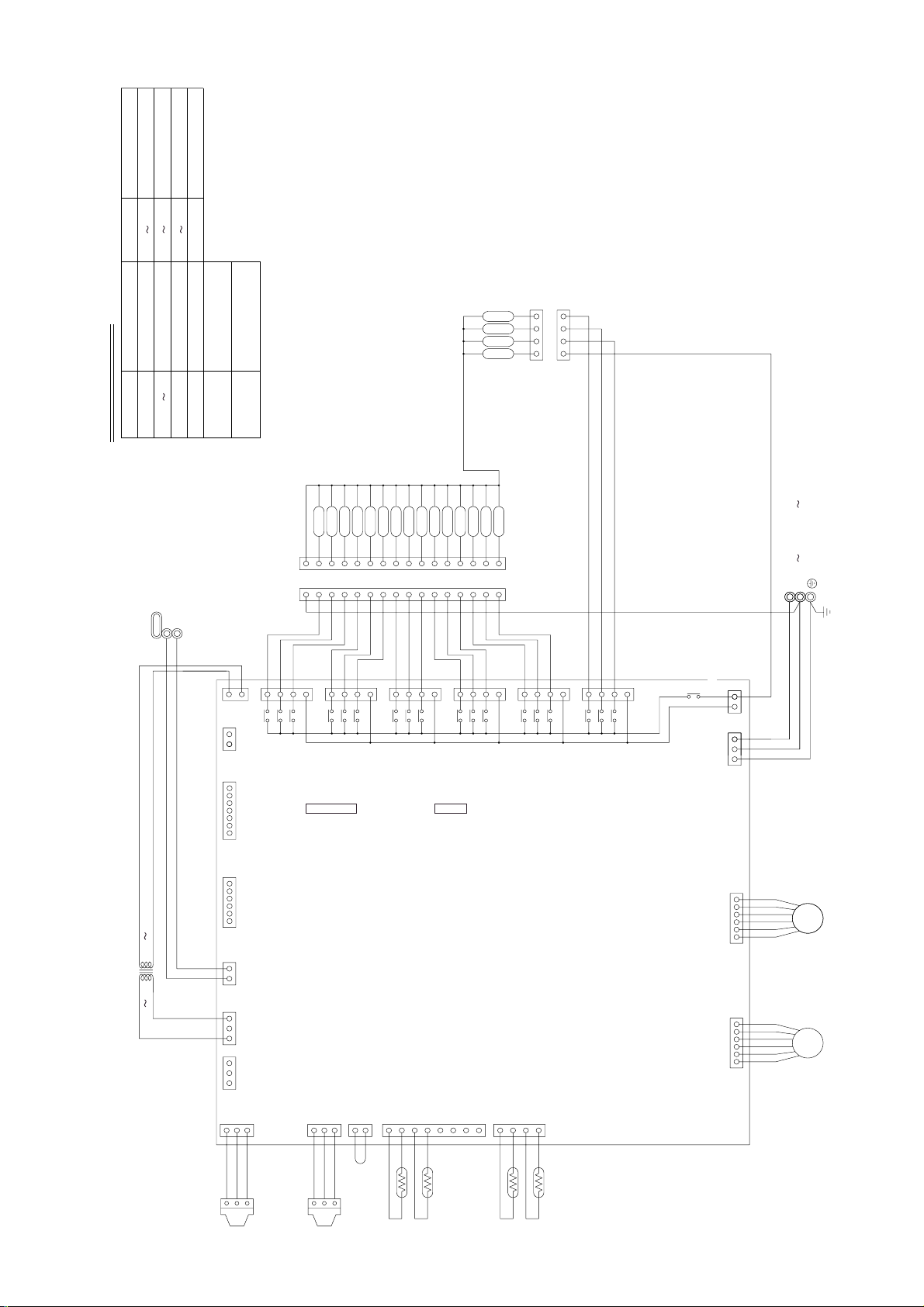

• CMB-P106V-E

–22–

Page 24

PE

1

2

3

1

2

3

EARTH

}

Power source

}}

L

N

Power source

/N 220V 240V 50Hz

Transmission line

Shield wire

SVM

BC Board

CN38

1

3

1

CNTR

CN50

CN51

7654321123456

CN02

CN12

153

31

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

3

TR

3

CNVCC1

12

X2

X1

X30

X4

X3

X31

X6

X5

X32

X8

X7

X33

X10

X9

X34

X12

X11

X35

X21

}

DC 30V

654321654321

LEV3 LEV1

1

2

3

CNP1

1

2

3

CNP3

2

1

1

2

3

4

5

6

7

8

4

3

2

1

123

21

CN03

CN13

CN10

CN11

CN07 CN05

CN36

TH11

TH12

TH15

TH16

PS1

PS3

20 22V

TB02

M2

M1

CN26

CN27

CN28

CN29

CN30

CN31

TB01

220 240V

LEV1

7654321

TB01

SV6B

SV6A

SV6C

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

RELAY4 Board

SV5C

SV5A

SV5B

SV4B

SV4A

SV4C

SV3B

SV3A

SV3C

SV2B

SV2A

SV2C

CN32

CN33

CN39

3

1

SV7C

SV7A

SV7B

SV8C

SV8A

SV8B

SV1C

SV1A

SV1B

X14

X13

X36

X37

X15

X16

98765432116 15 1011121314

12345678910111213141516

CN52

75317531

Symbol explanation

Terminal block

(for Transmission)

TB02

Terminal block

(for power source)

TB01

NameSymbol

Solenoid valve

Solenoid valve

Solenoid valve

Solenoid valve

Expansion valve

Thermister sensor

Transformer

NameSymbol

SV1 8A

SV1 8B

SV1 8C

SVM

TR

TH11 16

LEV1,3

PS1,3 Pressure sensor

CNOUT 1

CNOUT 3

∗1

Note:1.TB02 is terminal block for transmission.

∗1

∗1

∗1

Never connect power line to it.

2.

∗1

:SVM is not built in depending on models.

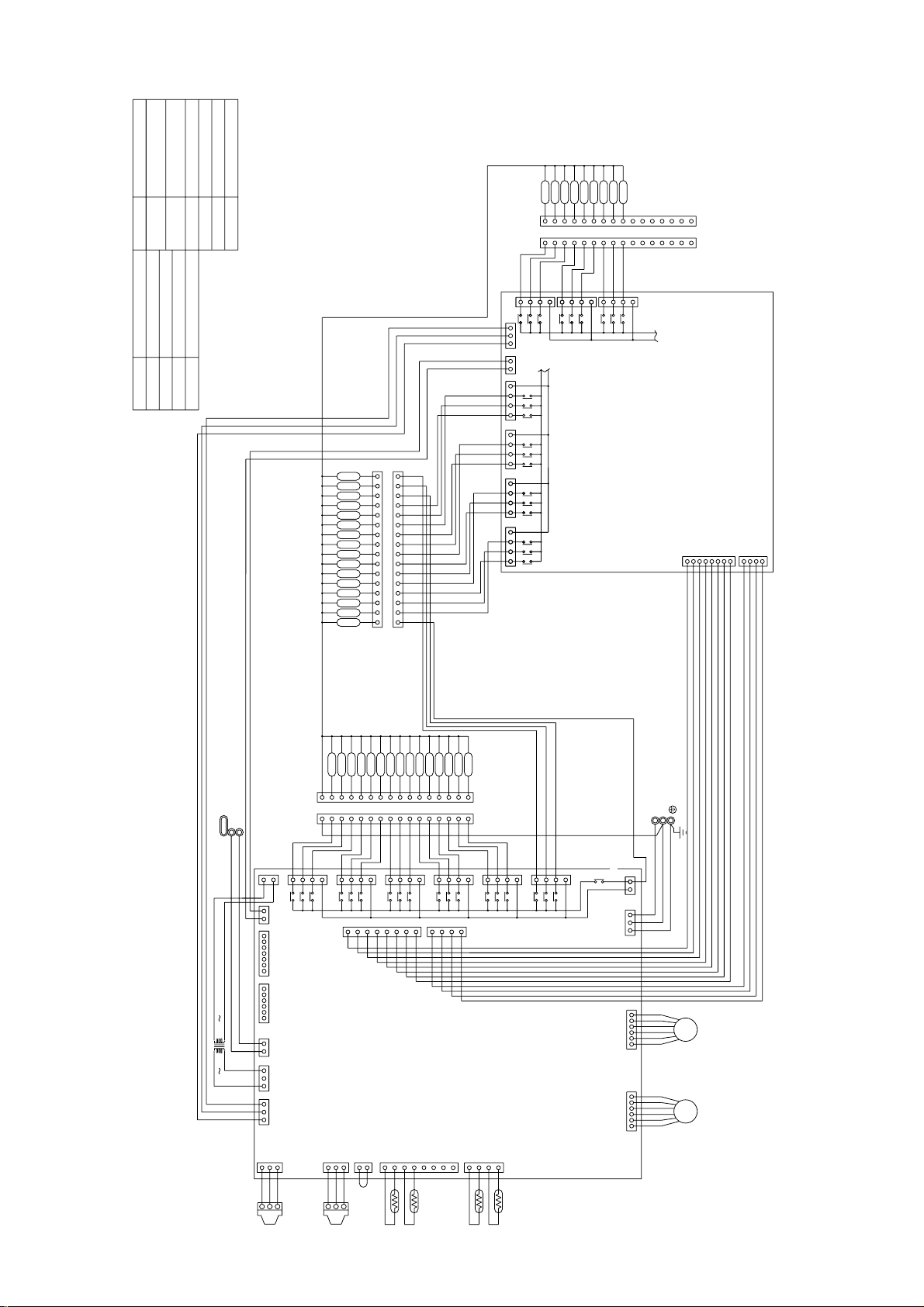

• CMB-P108V-E

–23–

Page 25

PE

1

2

3

1

2

3

EARTH

}

Power source

}}

L

N

Power source

/N 220V 240V 50Hz

Transmission line

Shield wire

SV10B

SV10A

SV10C

SV9B

SV9A

SV9C

BC Board

CN38

1

3

1

CNTR

CN50

CN51

7654321123456

CN02

CN12

153

31

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

7

5

3

1

3

TR

3

CNVCC1

12

X2

X1

X30

X4

X3

X31

X6

X5

X32

X8

X7

X33

X10

X9

X34

X12

X11

X35

X21

}

DC 30V

654321654321

LEV3 LEV1

1

2

3

CNP1

1

2

3

CNP3

2

1

1

2

3

4

5

6

7

8

4

3

2

1

123

21

CN03

CN13

CN10

CN11

CN07 CN05

CN36

TH11

TH12

TH15

TH16

PS1

PS3

20 22V

TB02

M2

M1

CN26

CN27

CN28

CN29

CN30

CN31

TB01

220 240V

LEV1

7654321123456

CN35

TB01

SV6B

SV6A

SV6C

SVM

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

RELAY4 Board

SV5C

SV5A

SV5B

SV4B

SV4A

SV4C

SV3B

SV3A

SV3C

SV2B

SV2A

SV2C

CN32

CN33

CN34

CN39

3

1

SV7C

SV7A

SV7B

SV8C

SV8A

SV8B

SV1C

SV1A

SV1B

X14

X13

X36

X37

X15

X16

98765432116 15 1011121314

12345678910111213141516

X18

X17

X38

X39

X19

X20

CN52CN53

5731753175317533 31

Symbol explanation

Terminal block

(for Transmission)

TB02

Terminal block

(for power source)

TB01

NameSymbol

Solenoid valve

Solenoid valve

Solenoid valve

Solenoid valve

Expansion valve

Thermister sensor

Transformer

NameSymbol

SV1 10A

SV1 10B

SV1 10C

SVM

TR

TH11 16

LEV1,3

PS1,3 Pressure sensor

CNOUT 1

CNOUT 3

∗1

∗1

∗1

∗1

Note:1.TB02 is terminal block for transmission.

Never connect power line to it.

2.

∗1

:SVM is not built in depending on models.

• CMB-P1010V-E

–24–

Page 26

PE

EARTH

3

2

1

3

2

1

TB02

TB01

Name

Symbol

Terminal block

(for Transmission)

Solenoid valve

Solenoid valve

Solenoid valve

Solenoid valve

Terminal block

(for power source)

Pressure sensor

Expansion valve

Thermister sensor

Transformer

Name

SV1~13A

SV1~13B

SV1~13C

SVM

Symbol

TR

TH11~16

LEV1,3

PS1,3

M1

M2

DC 30V

}

Shield wire

Transmission line

Power source

}

L

N

Power source

~/N 220V~240V 50Hz

RELAY10

Board

BC Board

CN39

13

654321 1234567

CN51

CN50

135

CN12

13

CNOUT3

CNOUT1

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

7

5

3

1

1571571357

13

21

CNVCC2

3

CN42

X46

X47

X48

1

2

3

8

7

6

5

4

3

2

1

4

CNOUT2

CNOUT4

CN41

CN40

X41

X44

X40

X43

X42

X45

X20

X18

X19

X17

X39

X38

3

CNVCC1

12

X16

X15

X37

X36

X13

X14

X2

X1

X30

X4

X3

X31

X6

X5

X32

X8

X7

X33

X10

X9

X34

X12

X11

X35

X21

6

5432

1

6

5432

1

LEV3 LEV1

1

2

3

CNP1

1

2

3

CNP3

2

1

1

2

3

4

5

6

7

8

4

3

2

1

12321

CN03

CN02

CN13

CN10

CN11

CN07 CN05

33

CN34

CN33

1357

CN32

TH11

TH12

TH15

TH16

TR

TB02

CN38

CN26

CN27

CN28

CN29

CN30

CN31

TB01

CN35

3

1

CNTR

4

1

2

3

4

5

6

7

8

3

2

1

SV1B

SV1A

SV1C

SV2C

SV2A

SV2B

SV3C

SV3A

SV3B

SV4C

SV4A

SV4B

SV5B

SV5A

SV5C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

SV9C

SV9A

SV9B

SV10C

SV10A

SV10B

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

14 13 12 11 101516 123456789

SV8B

SV8A

SV8C

SV7B

SV7A

SV7C

SVM

SV6C

SV6A

SV6B

SV11C

SV11A

SV11B

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

SV12C

SV12A

SV12B

SV13C

SV13A

SV13B

PS1

PS3

Note : 1. TB02 is transmission terminal block.

Never connect power line to it.

2.

∗1

:SVM is not built in depending on models.

20 22V 220 240V

CN36

∗1

∗1

∗1

∗1

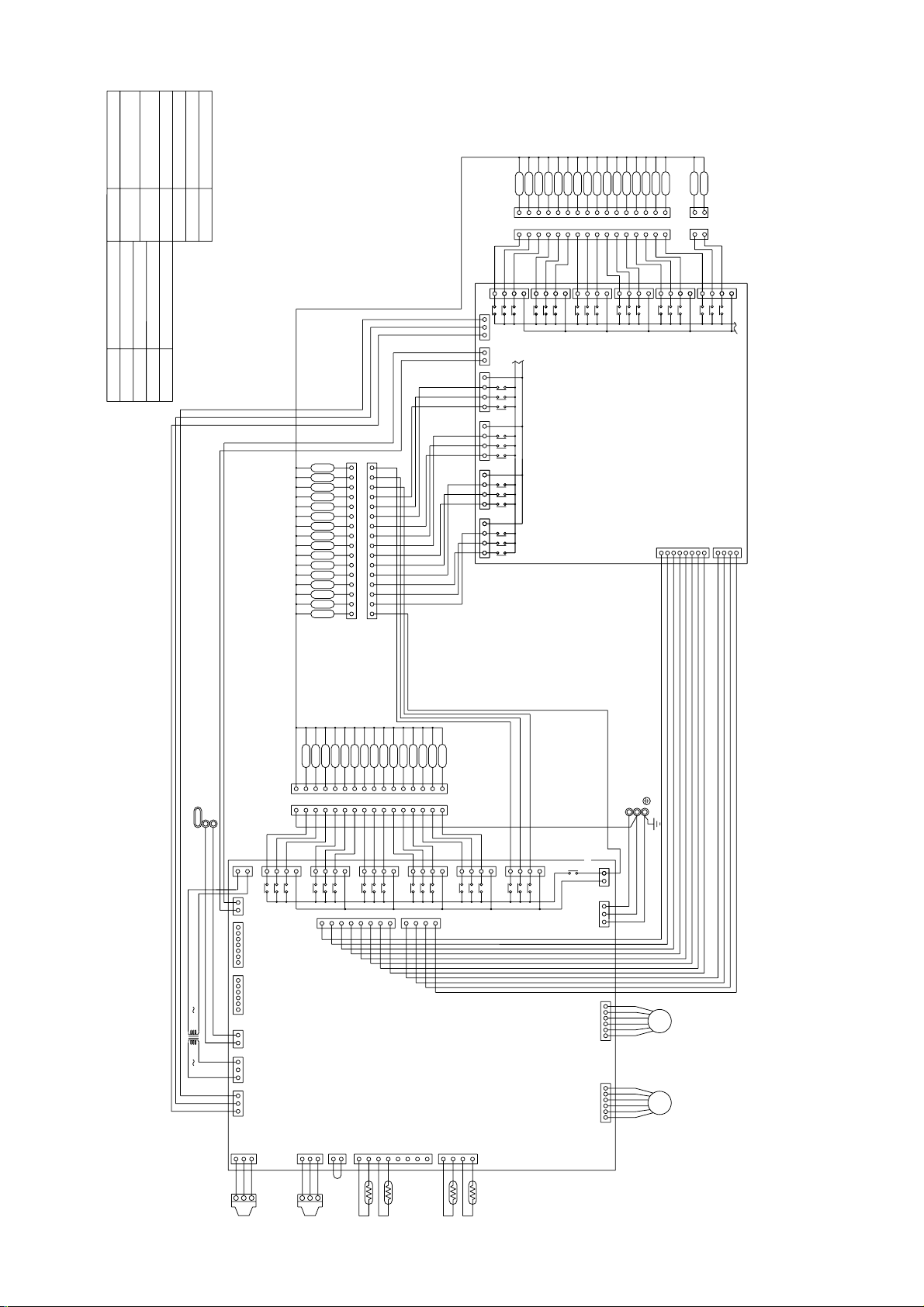

• CMB-P1013V-E

–25–

Page 27

PE

EARTH

3

2

1

3

2

1

TB02

TB01

Name

Symbol

Terminal block

(for Transmission)

Solenoid valve

Solenoid valve

Solenoid valve

Solenoid valve

Terminal block

(for power source)

Pressure sensor

Expansion valve

Thermister sensor

Transformer

Name

SV1~16A

SV1~16B

SV1~16C

SVM

Symbol

TR

TH11~16

LEV1,3

PS1,3

M1

M2

DC 30V

}

Shield wire

Transmission line

Power source

}

L

N

Power source

~/N 220V~240V 50Hz

CN39

13

654321 1234567

CN51

CN50

135

CN12

13

CNOUT3

CNOUT1

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

1

3

5

7

7

5

3

1

1571571357

13

21

CNVCC2

3

CN42

X46

X47

X48

1

2

3

8

7

6

5

4

3

2

1

4

CNOUT2

CNOUT4

CN41

CN40

X41

X44

X40

X43

X42

X45

X20

X18

X19

X17

X39

X38

3

CNVCC1

12

X16

X15

X37

X36

X13

X14

X2

X1

X30

X4

X3

X31

X6

X5

X32

X8

X7

X33

X10

X9

X34

X12

X11

X35

X21

6

5432

1

6

5432

1

LEV3 LEV1

1

2

3

CNP1

1

2

3

CNP3

2

1

1

2

3

4

5

6

7

8

4

3

2

1

12321

CN03

CN02

CN13

CN10

CN11

CN07 CN05

33

CN34

CN33

1357

CN32

TH11

TH12

TH15

TH16

TR

TB02

CN38

CN26

CN27

CN28

CN29

CN30

CN31

TB01

CN35

3

1

CNTR

4

1

2

3

4

5

6

7

8

3

2

1

SV1B

SV1A

SV1C

SV2C

SV2A

SV2B

SV3C

SV3A

SV3B

SV4C

SV4A

SV4B

SV5B

SV5A

SV5C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

SV9C

SV9A

SV9B

SV10C

SV10A

SV10B

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

14 13 12 11 101516 123456789

SV8B

SV8A

SV8C

SV7B

SV7A

SV7C

SVM

SV6C

SV6A

SV6B

SV11C

SV11A

SV11B

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

SV12C

SV12A

SV12B

SV13C

SV13A

SV13B

PS1

PS3

∗1

∗1

∗1

∗1

Note : 1. TB02 is transmission terminal block.

Never connect power line to it.

2.

∗1

:SVM is not built in depending on models.

1

2

2

1

1

3

5

7

1

3

5

7

1

3

5

7

X57

X53

X52

X56

X55

CN45

CN44

CN43

X50

SV14C

SV14A

SV14B

SV15A

SV15B

SV16C

SV16A

SV16B

SV15C

X54

X51

X49

RELAY10

Board

BC Board

20 22V 220 240V

CN36

• CMB-P1016V-E

–26–

Page 28

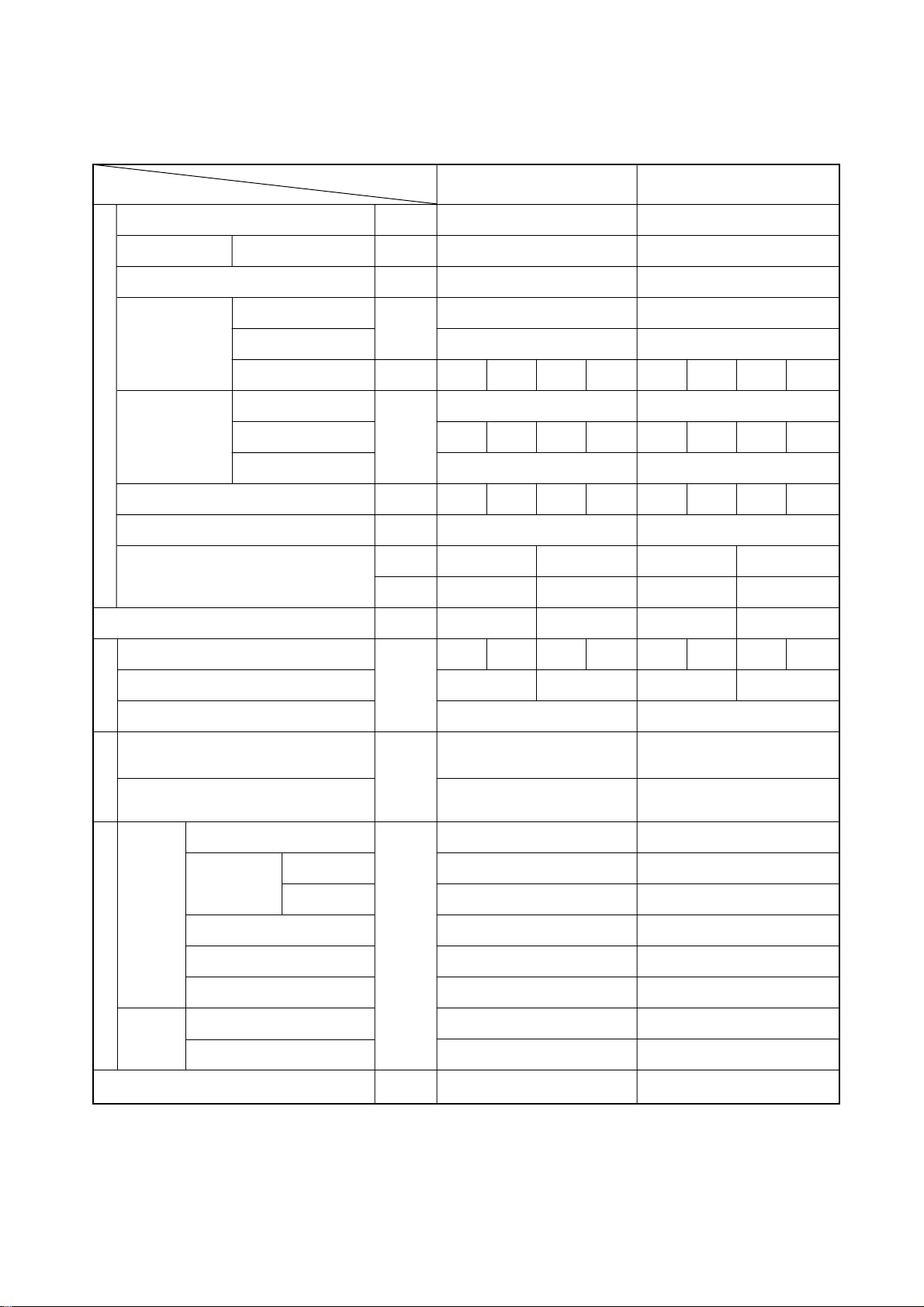

[4] Standard Operation Data

1 Cooling operation

Items

Power source

Ambient temp.

Indoor

Circulated water temp. (Intet)

Quantity

Indoor unit

Quantity in operation

Model

Main pipe

Condition

Piping

Branch pipe

Total piping length

Indoor unit fan notch

Refrigerant volume

Compressor volts / Frequency

Heat source unit

Heat source unit

V/Hz

DB/WB

°C

Q’ty

–

m

–

kg

V

V/Hz

A

PQRY-P200YMF-C PQRY-P250YMF-C

380-415V/50Hz • 60Hz 380-415V/50Hz • 60Hz

27.0/19.0 27.0/19.0

30 30

44

44

63 63 50 25 125 40 63 25

55

55555555

25 25

Hi Hi Hi Hi Hi Hi Hi Hi

11.4 12.2

380 415 380 415

270/77 270/77 340/95 340/95

14.0 12.8 18.8 17.2

Indoor unit

BC controller (1, 3)

Oil return

LEV opening

High pressure/Low pressure

BC controller liquid/Intermediate

Pressure

Discharge (TH1)

Accumulator

Heat

source

Suction (Comp)

unit

CS circuit (TH2)

Shell bottom (Comp)

Sectional temperature

Indoor

unit

LEV inlet

Heat exchanger outlet

αOC

Inlet

Outlet

Pulse

kg/cm

(MPa)

˚C

330 460 430 300 410 330 460 300

2000 240 2000 260

180 330

22.0/5.3 21.5/5.0

2

G

(2.20/0.52) (2.15/0.50)

20.9/20.9 20.4/20.4

(2.09/2.09) (2.04/2.04)

101 99.0

77

10 10

12 12

4.9 4.3

70 78

26 30

15 15

0.23 0.23

–27–

Page 29

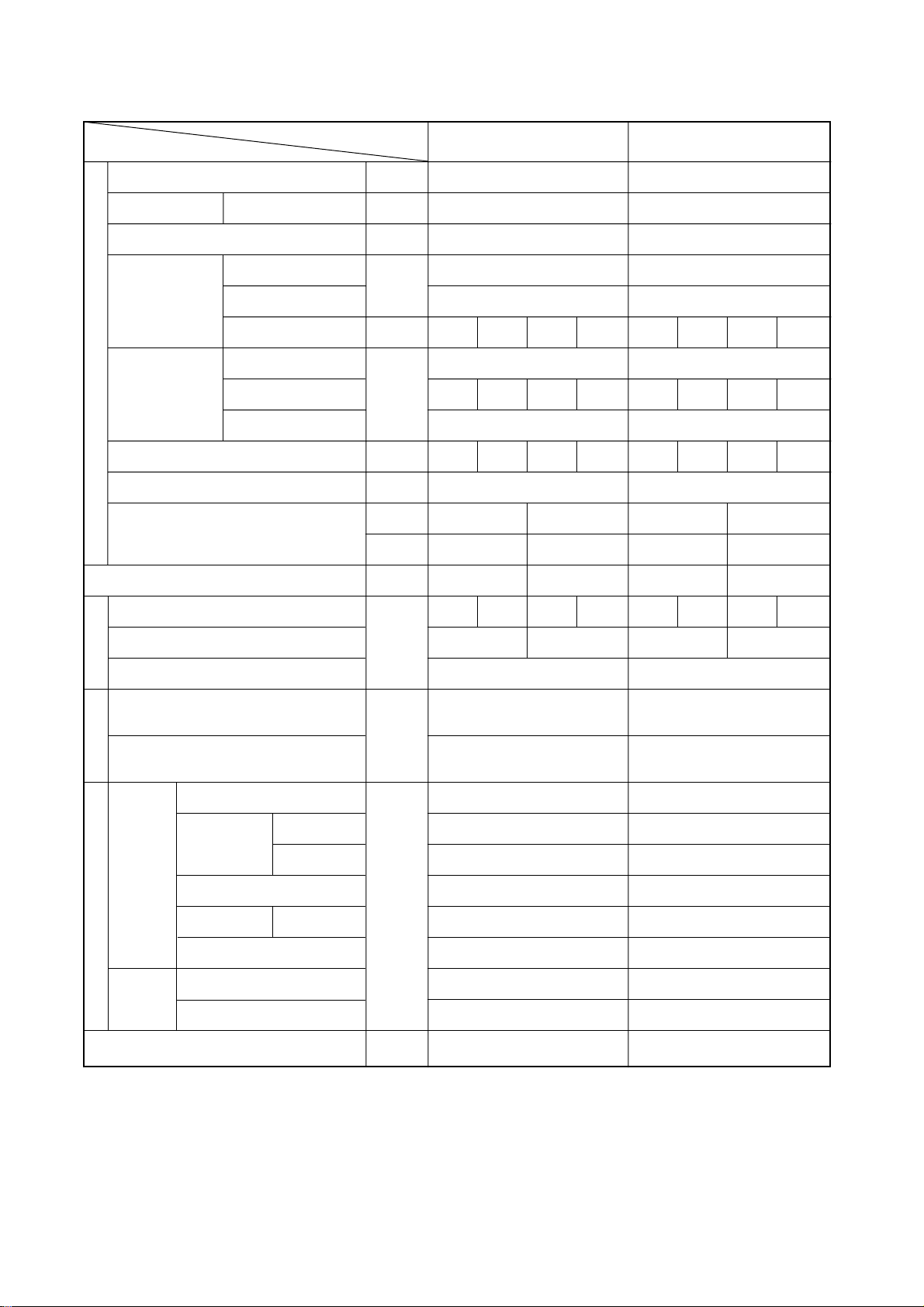

2 Heating operation

Items

Power source

Ambient temp.

C

Circulated water temp.

Indoor

Quantity

Indoor unit

Quantity in operation

Model

Main pipe

Condition

Piping

Branch pipe

Total piping length

Indoor unit fan notch

Refrigerant volume

Compressor volts/Frequency

Heat source unit total current

Heat source unit

V/Hz

DB/WB

°C

Q’ty

–

m

–

kg

V

V/Hz

A

PQRY-P200YMF-C PQRY-P250YMF-C

380-415V/50Hz • 60Hz 380-415V/50Hz • 60Hz

20.0/– 20.0/–

20 20

44

44

63 63 50 25 125 40 63 25

55

55555555

25 25

Hi Hi Hi Hi Hi Hi Hi Hi

11.4 12.2

380 415 380 415

250/75 250/75 330/93 330/93

13.1 12.0 16.1 14.8

Indoor unit

BC controller (1, 3)

Oil return

LEV opening

High pressure/Low pressure

BC controller liquid/Intermediate

Pressure

Discharge (TH1)

Heat

Accumulator

source

unit

Suction (Comp)

CS circuit

Shell bottom (Comp)

Sectional temperature

Indoor

unit

LEV inlet

Heat exchanger outlet

αOC

Inlet

Outlet

(TH2)

Pulse

kg/cm

(MPa)

˚C

600 950 750 400 750 600 950 400

60 600 60 850

115 115

22.0/5.6 22.0/5.4

2

G

(2.20/0.56) (2.20/0.54)

21.0/18.0 21.0/18.0

(2.10/1.80) (2.10/1.80)

75 79

–1 –1

–4 –2

–1 –1

75

55 60

38 40

80 85

0.28 0.28

–28–

Page 30

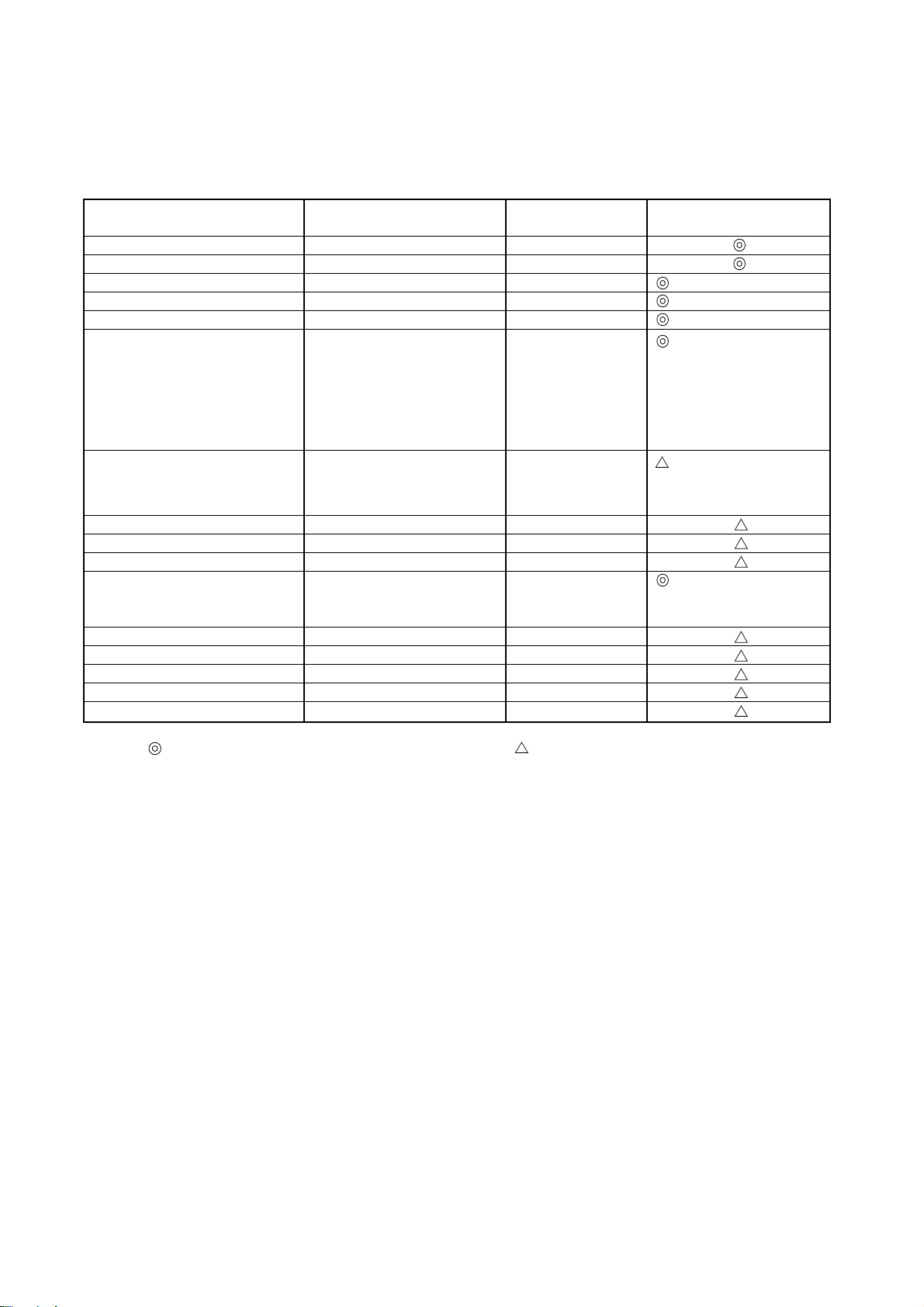

[5] Function of Dip SW and Rotary SW

(1) Heat source unit

Switch Function

1~2

SWU

SW1

SW2

SW3

SW4

Unit address setting

1~8

For self diagnosis/

operation monitoring

9~10

1

Centralized control switch

2

Deletion of connection

information.

3

Deletion of error history.

4

Adjustment of refrigerant

Volume

5

6

7

Operation ON signal

output switching

Relay contact output

TB8-1,2

8

Disregard pump interlock

trouble.

9

10

SW3-2 Function valid/

1

invalid

Indoor unit test operation

2

CN51-3,5 Output switching

3

Freeze prevention operation

4

Target Te (α) at cooling-

5

only

Pump down operation

6

Target Tc (High pressure)

7

at heating

8

9

10

1

SW4-2 function valid/

Invalid

2

Configuration compensa-

tion value

3

Models

Function according to switch operation Switch set timing

When off When on When off When on

Set on 51~100 with the dial switch.

LED monitering display

–

Centralized control not

connected.

Storing of refrigeration

system connection

information.

Ordinary control

–

–

The relay closes during

compressor operation.

Normal

–

–

SW3-2 Function invalid

Stop all indoor units.

Water heat exchanger

freeze prevention signal

Normal

–

–

Changes as shown below by on → off change

0% → 3% → 6% → 9% → 12% → –6% → –3% → 0%

–

–

–

–

–

–

–

–2˚C

Invalid

50˚C

–

–

Model P200

Invalid

–

Centralized control

connected.

Deletion of refrigeration

system connection

information.

Deletion

Refrigerant volume

adjustment operation.

The relay closes during

reception of the cooling or

the heating operation

signal from the controller.

(Note: It is output even if

the thermostat is OFF

(when the compressor is

stopped).)

Disregard trouble

SW3-2 Function valid

All indoor units test

operation ON.

Heat source unit abnormal

output

Freeze prevention operation*

–

–

–

–

–

–5˚C

Valid

53˚C

–

–

Model P250

Valid

–

Before power is turned on.

During normal operation when power

is on.

Should be set on OFF.

Before power is turned on.

Before power is turned on.

During normal operation when power

is on.

During normal

operation when

power is on.

At all times

At all times

During normal operation when power

is on.

When SW3-1 is ON after power is

turned on.

At all times

At all times

At all times

During Comp stop (only when power

changes from OFF → ON)

During normal operation when power

is on.

When switching on the power.

During normal operation when power

is on.

When SW4-1 in ON.

Invalid 2 hours

after compressor

starts.

–

–

–

–

–

–

–

Note:

• SWU1~2=00 when shipped from the factory. Other factory settings are indicated by shaded portions.

• If the address is set from 01 to 50, it automatically becomes 100.

* Freeze prevention operation

When the water temp. (TH6) below less 5˚C during compressor is stopping, the compressor starts to run with coolingmode to

prevent the water freeze.

–29–

Page 31

(2) Indoor unit

ON

OFF

ON

OFF

ON

OFF

DIP SW1, 3

Switch SW name

1

Room temp. sensor position

2

Clogged filter detect.

3

Filter duration

4

OA intake

5

Remote display select.

SW1

Humidifier control

6

Heating thermo. OFF airflow

7

Heating thermo. OFF airflow

8

Power failure automatic

9

return

10

Power source start/stop

1

Model selection

Cooling capacity saving

for PKFY-P. VAM,

effective/ineffective

SW3

2

Louver

3

Vane

4

Vane swing function

5

Vane horizontal angle

6

Vane angle set for cooling

7

Heating 4deg up

8

Operation by SW

OFF ON OFF ON

Indoor unit inlet

None

100h

Ineffective

Fan output display

At stationary heating

Very low speed

SW1-7 setting

Ineffective

Ineffective

Heat pump

None

None

None

1st setting

Down blow B, C

–

–

Effective

Built in remote controller

Provided

2500h

Effective

Thermo. ON signal display

Always at heat

Low speed

Set airflow

Effective

Effective

Cool.only

Provided

Provided

Provided

2nd setting

Horizontal

–

Ineffective

Switch set timing

At unit stopping

(at remote

controller OFF)

Remarks

Always ineffective for PKFY-P.VAM

Not provided for PKFY-P.VAM

Provided for PLFY-P.VGM (ON) setting

Always down blow B,C for PKFY-P.VAM

Horizontal (ON) setting for PLFY-P.VLMD

Ineffective (ON) setting for floor

standing

Note 1: The shaded part indicates the setting at factory shipment. (For the SW not being shaded, refer to the

table below.)

PDFY-P

PFFY-P PCFY-P PKFY-P

VM-AONVLRM-A, VLEM-A

OFF

OFF

ON OFF

VGM-AONVAM-A VGM-A

OFF

OFF

OFF

ON

ON OFF ON

Switch

SW1

SW3

Model

3

6

7

3

4

6

8

VBM-A

OFF

OFF

ON

OFF

PLFY-P

VLMD-A

ON

OFF

ON

OFFONON

VKM-A

VML-A VMH-A

OFF ON

ON

OFF

PEFY-P

20~80VMM-A

OFF

ON

OFF ON

100~140VMM-A

OFF

OFF

Note 2: The Dip SW setting is only effective during unit stopping (remote controller OFF) for SW1, 2, 3 and 4 commonly

and the power source is not required to reset.)

3: When both SW1-7 and SW1-8 are being set to ON, the fan stops at the heating thermostat of OFF.

Setting of DIP SW2

Model P20 P25 P32 P40 P50 P63

Capacity (model name) code

SW2 setting

45 681013

OFF

ON

OFF

ON

OFF

ON

OFF

ON

ON

OFF

Model P71 P80 P100 P125 P140 P200 P250

Capacity (model name) code

SW2 setting

14 16 20 25 28 40 50

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

–30–

Page 32

Setting of DIP SW4 Setting of DIP SW5

3

1

2

Model Circuit board used

PMFY-P-VBM-A

PLFY-P-VLMD-A

PDFY-P20 ~ 80VM-A

PLFY-P40 ~ 63VKM-A

PLFY-P80 ~ 125VKM-A

PCFY-P-VGM-A

PKFY-P-VGM-A

PKFY-P-VAM-A

PEFY-P20 ~ 80VMM-A

PFFY -P-VLEM-A, P-VLRM-A

PEFY-P20 ~ 32VML-A

PEFY-P40 ~ 140VMH-A

PEHY-P200·250VMH-A

PDFY-P100·125VM-A

PEFY-P100 ~ 140VMM-A

Phase control

Relay selection

1234

ON OFF ON OFF

––––

ON OFF ON OFF

OFF OFF OFF ON

ON OFF OFF ON

OFF ON OFF ON

OFF OFF ON ON

––––

ON ON OFF OFF

OFF OFF OFF –

ON ON ON –

OFF OFF OFF –

ON OFF OFF –

OFF OFF ON –

ON ON ON OFF

SW4

220V

240V

Switch Function Operation by switch Switch set timing

(PLFY-P-VKM-A) (PCFY-P-VGM-A)

Ceiling height

3 3.5 m

2 2.8 m

1 2.3 m

Always after powering

SWA

Ceiling height setting

3

2

1

*The ceiling

height is

changed by

SWB setting.

(PDFY-P20 ~ 80VM-A, PEFY-P20 ~ 80VMM-A)

SWA

External static

pressure setting

3

2

1

*

For other models, change the setting of static pressure by replacing the connector.

100Pa

50Pa

30Pa

(PLFY-P-VLMD-A)

SWA

SWB

For options

Setting of air outlet opening

3

*As this switch is used by interlocking with SWC,

2

1

refer to the item of SWC for detail.

(PLFY-P-VKM-A)

2-way

3-way

4-way

SWA

SWB

123

2-way 3.5 m 3.8 m 3.8 m

3-way 3.0 m 3.3 m 3.5 m

4-way 2.7 m 3.0 m 3.5 m

(PLFY-P-VKM-A, PCFY-P-VGM-A, PKFY-P-VGM-A, PDFY-P-VM-A)

SWC

Airflow control

Option

Standard

*Set to the option to install the high efficiency

filter

(3) BC controller unit

DIP SW4

Switch Function

SW4

1 Models V-E type V-D type

2~8 –– –

Function according to switch operation

When off When on

*If the EPROM for the BC controller is WF30334, the controller is exclusively V-D type.

Always after powering

Always after powering

Always after powering

Always after powering

–31–

Page 33

[6] External Input/Output Specifications

(1) Output

1 Operation ON signal

Terminal No. TB8-1, 2

Output Relay contacts output Rated voltage: L1 - N: 220 ~ 240 V

Rated load: 1 A

Operation

2 COMP ON/OFF signal

Connector No. CN51-3, 4 Connector : B5B-XH-A (JST)

Output DC 12 V

Operation DC 12 V is output during compressor operation.

3 Water freeze / trouble signal

Connector No. CN51-3, 5 Connector : B5B-XH-A (JST)

Output DC 12 V

Operation

•

When DIP switch 2-7 is OFF

The relay closes during compressor operation.

•

When DIP switch 2-7 is ON

The relay closes during reception of the cooling or the heating operation signal from the controller.

(Note: It is output even if the thermostat is OFF (when the compressor is stopped).)

•

When DIP switch 3-3 is OFF

If the water temperature (TH 6) drops below 5°C while the unit is stopped, DC 12 V is output.

•

When DIP switch 3-3 is ON

DC 12 V is output when the heat source unit is stopped abnormally.

(2) Input

1 Pump Interlock

Terminal No. TB8-3, 4

Input Level signal

Operation If the circuit between TB8-3 and TB8-4 is open, compressor operation is prohibited.

2 Demand

Connector No. CN3D-1, 3 Connector : B3B-EH (JST)

Input Level signal

Operation If the circuit between CN3D-1 and CN3D-3 is opened, compressor operation is prohibited.

–32–

Page 34

33

3 TEST RUN

33

[1] Before Test Run

(1) Check points before test run

Neither refrigerant leak nor loose power source/ transmission lines should be found.

1

Confirm that the resistance between the power source terminal block and the ground exceeds 2MΩ by measuring it with a DC500V megger. Do not run if it is lower than 2MΩ.

2

Note) Never apply the megger to the MAIN board. If applied, the MAIN board will be broken.

Confirm that the Ball valve at both gas and liquid sides is being fully opened.

3

Note) Certainly close the cap.

Be sure that the crankcase heater has been powered by turning the main power source on at least 12 hours

4

before starting the test run. The shorter powering time causes compressor trouble.

(2) Caution at inverter check

Because the inverter power portion in heat source unit electrical part box have a lot of high voltage portion, be sure to

follow the instructions shown below.

During energizing power source, never touch inverter power portion because high voltage (approx. 580V) is

1

applied to inverter power portion.

When checking,

1

Shut off main power source, and check it with tester, etc.

2

Allow 10 minutes after shutting off main power source.

2

Open the MAIN board mounting panel, and check whether voltage of both ends of electrolytic capacitor is

3

20V or less.

–33–

Page 35

(3) Check points for test run when mounting options

Built-in optional parts

Mounting of drain

water lifting-up

mechanism

1

2

3

Mounting of permeable film humidifier

(4) Attention for mounting drain water lifting-up mechanism

Work

Disassembling and

assembling of drain

water lifting-up

mechanism

Check humidifier operations and water

supply status in heating (test run) mode.

1

2

Content of test run

Release connector of pump circuit,

check error detection by pouring

water into drain pan water inlet.

After that, connect connector of

circuit.

Check pump operations and drainage status in cooling (test run) mode.

Content of test run

Lead wire from control box not

damaged.

Rubber cap properly inserted to

drain water outlet of drain pan?

Check point

Local remote controller displays code

No. “2503”, and the mechanism stops.

No overflow from drain pan.

Drain water comes out by operations of

drain pump.

Sound of pump operations is heard, and

drain water comes out.

No water leak from connecting portions

of each water piping.

Water is supplied to water supply tank,

and float switch is operating.

Check point Result

Insulation pipe

Result

Mounting of float

switch

Electric wiring

Insulation pipe of gas and liquid

3

pipes dealt with as shown in the right

figure?

Drain pan and piping cover mounted

4

without gap?

Drain pan hooked on cut projection

5

of the mechanism?

Float switch installed without contacting

with drain pan?

1

No mistakes in wiring?

Connectors connected surely and

2

tightly?

No tension on lead wire when sliding

3

control box?

No gap

1

Float switch moves smoothly .

Float switch is mounted on

2

mounting board straightly without

deformation.

Float switch does not contact with

3

copper pipe.

Wiring procedure is exactly followed.

Connector portion is tightly hooked.

–34–

Page 36

(5) Check points for system structure

ex. PQRY -P200YMF-B

Check points from installation work to test run.

Classification

Installation and

piping

Power source

wiring

Portion

1

2

3

4

5

6

7

8

1

2

3

Check item

Instruction for selecting combination of heat source

unit, and indoor unit followed? (Maximum number of

indoor units which can be connected, connecting model

name, and total capacity .)

Follow limitation of refrigerant piping length? For example, 70m or less (total length : 220m) at the farthest.

Connecting piping size of branch piping correct?

Refrigerant piping diameter correct?

Refrigerant leak generated at connection?

Insulation work for piping properly done?

Specified amount of refrigerant replenished?

Pitch and insulation work for drain piping properly done?

Specified switch capacity and wiring diameter of main

power source used?

Proper grounding work done on heat source unit?

The phases of the L line (L1, L2, L3) correct?

Trouble

Not operate.

Not cool (at cooling).

Not heat (at heating).

Not cool, not heat, error stop.

Condensation drip in piping.

Not cool, not heat, error stop.

Water leak, condensation drip in drain piping.

Error stop, not operate.

Electric shock.

Error stop, not operate.

4

L line and N line connected correct?

The some electric pars should be

damaged.

–35–

Page 37

CENTRALLY CONTROLLED

STAND BY

DEFROST

ERROR CODE

D A I L Y

AUTO OFF

CENTRALLY CONTROLLED

CLOCK

REMAINDER

ON OFF

˚C

1Hr.

NOT AVAILABLE

˚C

CHECK MODE

FILTER

CHECK

TEST RUN

LIMIT TEMP.

ON/OFF

TEMP

FILTER

CHECK TEST

ON OFF

CLOCK

PAR-F27MEA

TIMER SET

D A I L Y

AUTO OFF

CHECK

STAND BY

DEFROST

TEMP

2 31

PAR-F27MEA

TIMER SET

1Hr.

˚C

ON OFF

CLOCK

REMAINDER

ERROR CODE

˚C

ON OFF

CLOCK

NOT AVAILABLE

CHECK MODE

LIMIT TEMP.

ON/OFF

FILTER

TEST RUN

CHECK TEST

FILTER

M-NET Remote Controller

Classification

Transmission

line

System set

Portion Check item

Limitation of transmission line length followed? For

1

example, 200m or less (total length : 500m) at the farthest.

2 1.25mm2 or more transmission line used?

(Remote controller 10m or less 0.75mm

2

)

3 2-core cable used for transmission line?

Transmission line apart from power source line by 5cm or more?

4

5 One refrigerant system per transmission line?

The short circuit connector is changed form CN41 to

6

CN40 on the MAIN board when the system is centralized

control? (Just one outdoor unit. Not all outdoor units.)

7 • No connection trouble in transmission line?

8 Connection of wrong remote controller line terminals?

• MA Remote controller : TB15

• M-NET Remote controller : TB5

Address setting properly done? (M-NET Remote

1

controller, indoor unit and outdoor unit.)

Setting of address No. done when shutting off power

2

source?

Address numbers not duplicated?

3

Turned on SW3-8 on indoor unit circuit board when

4

mounting room thermistor sensor?

Trouble

Erroneous operation, error stop.

Erroneous operation, error stop.

Error stop in case multiple-core

cable is used.

Erroneous operation, error stop.

Not operate.

Not operate.

Error stop or not operate.

Never finish the initial mode.

Error stop or not operate.

Can not be properly set with power

source turned on.

Not operate.

Set temperature not obtained at

heating operations (Thermostat

stop is difficult)

Before starting

Refrigerant piping ball valve (Liquid pressure pipe, gas

1

pressure pipe) opened?

2

Turn on power source 12 hours before starting operations?

–36–

Error stop.

Error stop, compressor trouble.

Page 38

[2] Address setting

(1) Switch operation

In order to constitute CITY MULTI in a complete system, switch

operation for setting the unit address No. and connection No. is

required.

1 Unit address No. group No. and connection No.

The unit address No. is determined by the address setting

switch of the heat source unit, indoor unit and remote controller.

2 Caution for switch operations

Connection

No. setting

0

1

2

F

3

E

4

D

5

C

6

B

7

8

A

9

Rotary switch

Unit address No. setting

0

1

9

2

8

3

7

4

6

5

0

1

9

2

8

3

7

4