Page 1

CM400DX-12A

MITSUBISHI IGBT MODULES

CM400DX-12A

HIGH POWER SWITCHING USE

¡IC ...................................................................400A

CES ............................................................ 600V

¡V

¡Dual

¡Flatbase Type / Insulated Package /

Copper (non-plating) base plate

¡RoHS Directive compliant

APPLICATION

General purpose Inverters, Servo Amplifiers, Power supply, etc.

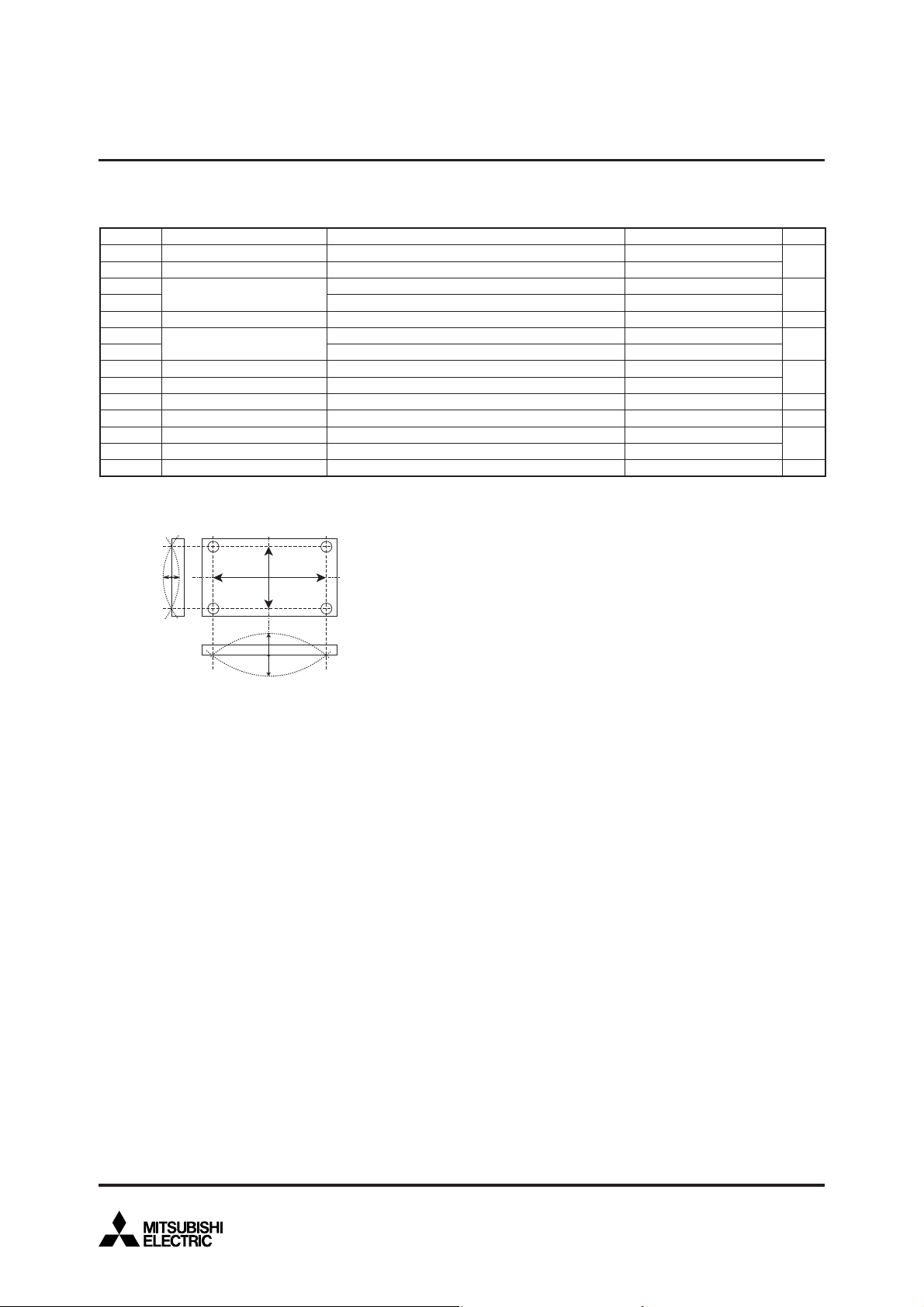

OUTLINE DRAWING & CIRCUIT DIAGRAM

152

137

Di1

Tr1

E1(16)

121.7

±0.5

110

99

94.5

*45.48

*41.66

LABEL

C1(22)G1(15)

*72.14

*68.34

E1C2

(24)

E1C2

(23)

4-M6 NUTS

24

±0.5

62

39

57.5

23

22

212019181716151413121110987654321

4-φ5.5 MOUNTING HOLES

(102.25)

*95

50

(5.4)

+1

-0.5

12.5

17

(SCREWING DEPTH)

Toleranceotherwisespecified

Division of Dimension

0.5 to 3

over 3 to 6

over 6 to 30

over 30 to 120

over 120 to 400

*58.4

22

(14) (14) (4.2)

(13.5) (13.5)

46

45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25

17

12

66

12

17

6.5

(21.14)

3.5

E2(47)

C1(48)

TH1(1)

47

48

0

E2(39) G2(38)

Th

NTC

TH2(2)

CIRCUIT DIAGRAM

(7.75)

Di2

A

*18.8

*15

Tr2

0.8

(20.5)

17

7

13

(3)

*Pin positions

with tolerance

Tolerance

Dimensions in mm

(7.4)

1.2

1.15

0.65

(3.81)

TERMINAL t = 0.8

φ4.3

φ2.5

φ2.1

1.5

12.5

SECTION A

±0.2

±0.3

±0.5

±0.8

±1.2

φ0.5

Jan. 2009

Page 2

MITSUBISHI IGBT MODULES

CM400DX-12A

HIGH POWER SWITCHING USE

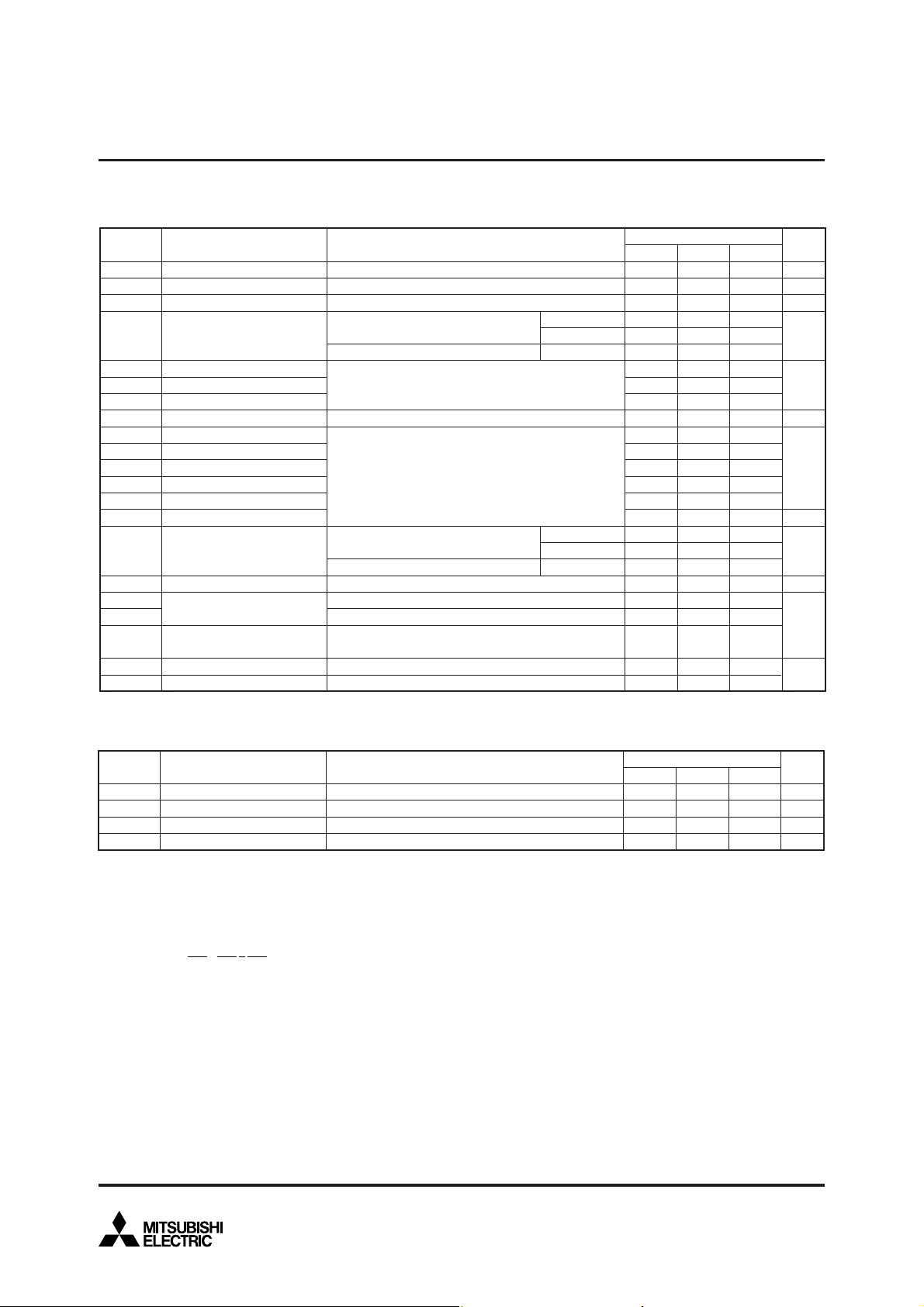

ABSOLUTE MAXIMUM RATINGS (T

j

= 25°C, unless otherwise specified)

INVERTER PART

Symbol Parameter Conditions Rating Unit

CES

V

V

GES

I

C

I

CRM

P

C

I

E (Note.3)

I

ERM(Note.3)

T

j

T

stg

V

iso

Note. 8: The base plate flatness measurement points are in the following figure.

Collector-emitter voltage

Gate-emitter voltage

Collector current

Maximum collector dissipation

Emitter current

(Free wheeling diode forward current)

Junction temperature

Storage temperature

Isolation voltage

—

Base plate flatness

—

Torque strength

—

Torque strength

—

Weight

Y

+

–

X

Heatsinkside

–

G-E Short

C-E Short

DC, T

C

= 60°C

Pulse

T

C

= 25°C

T

C

= 25°C

Pulse

Terminals to base plate, f = 60Hz, AC 1 minute

On the centerilne X, Y

Main terminals M6 screw

Mounting M5 screw

(Typical)

+:convex

–:concave

(Note. 1)

(Note. 4)

(Note. 1, 5)

(Note. 1)

(Note. 4)

(Note. 8)

600

±20

400

800

1340

400

800

–40 ~ +150

–40 ~ +125

2500

±0 ~ +100

3.5 ~ 4.5

2.5 ~ 3.5

330

V

A

W

A

°C

Vrms

μm

N·m

g

+

Heatsinkside

Jan. 2009

2

Page 3

ELECTRICAL CHARACTERISTICS (Tj = 25°C, unless otherwise specified)

INVERTER PART

Symbol Parameter Conditions

I

CES

V

GE(th)

I

GES

V

CE(sat)

C

ies

C

oes

C

res

Q

G

t

d(on)

t

r

t

d(off)

t

f

t

rr (Note.3)

Q

rr (Note.3)

V

EC(Note.3)

R

lead

R

th(j-c)Q

R

th(j-c)R

R

th(c-f)

R

Gint

R

G

Collector cutoff current

Gate-emitter threshold voltage

Gate leakage current

Collector-emitter saturation voltage

Input capacitance

Output capacitance

Reverse transfer capacitance

Total gate charge

Turn-on delay time

Turn-on rise time

Turn-off delay time

Turn-off fall time

Reverse recovery time

Reverse recovery charge

Emitter-collector voltage

Module lead resistance

Thermal resistance

(Junction to case)

(Note. 1)

Contact thermal resistance

(Case to heat sink)

(Note. 1)

Internal gate resistance

External gate resistance

V

CE

= V

CES

, VGE = 0V

I

C

= 40mA, VCE = 10V

±V

GE

= V

GES

, VCE = 0V

I

C

= 400A, VGE = 15V

C

= 400A, VGE = 15V

I

V

CE

= 10V

V

GE

= 0V

CC

= 300V, IC = 400A, VGE = 15V

V

V

CC

= 300V, IC = 400A

V

GE

= ±15V, RG = 3.6Ω

Inductive load

E

= 400A)

(I

E

= 400A, VGE = 0V

I

E

= 400A, VGE = 0V

I

Main terminals-chip, per switch

per IGBT

per free wheeling diode

Thermal grease applied

per 1 module

T

C

= 25°C

(Note. 6)

(Note. 6)

T

j

= 25°C

T

j

= 125°C

Chip

j

= 25°C

T

T

j

= 125°C

Chip

MITSUBISHI IGBT MODULES

CM400DX-12A

HIGH POWER SWITCHING USE

Limits

Min. Typ. Max.

(Note. 6)

(Note. 2)

—

5

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

1.6

—

6

—

1.7

1.9

1.6

—

—

—

1100

—

—

—

—

—

2.0

1.95

1.9

1.1

—

—

0.015

0

—

0.5

2.1

—

—

50

5.3

1.6

—

200

200

400

600

200

—

2.8

—

—

—

0.093

0.16

—

—

16

Unit

mA

1

7

V

μA

V

nF

nC

ns

μC

V

mΩ

K/W

Ω

NTC THERMISTOR PART

Symbol Parameter Conditions

R

ΔR/R

B

(25/50)

P

25

Note.1: Case temperature (TC), heat sink temperature (Tf) measured point is just under the chips. (Refer to the figure of the chip location.)

Zero power resistance

Deviation of resistance

B constant

Power dissipation

2: Typical value is measured by using thermally conductive grease of λ = 0.9W/(m·K).

E, IERM, VEC, trr and Qrr represent ratings and characteristics of the anti-parallel, emitter-collector free wheeling diode (FWDi).

3: I

4: Pulse width and repetition rate should be such that the device junction temperature (T

5: Junction temperature (T

6: Pulse width and repetition rate should be such as to cause negligible temperature rise.

(Refer to the figure of the test circuit for V

7:

B

(25/50)

R25: resistance at absolute temperature T

50

: resistance at absolute temperature T

R

25

R

= In( )/( )

R

50

j) should not increase beyond 150°C.

1

1

T

T

25

50

T

C

= 25°C

T

C

= 100°C, R

100

= 493Ω

Approximate by equation

T

C

= 25°C

CE(sat) and VEC)

25

[K]; T

25

= 25 [°C]+273.15 = 298.15 [K]

50

[K]; T

50

= 50 [°C]+273.15 = 323.15 [K]

(Note. 7)

j) dose not exceed Tjmax rating.

Min. Typ. Max.

4.85

–7.3

Limits

5.00

—

—

3375

—

—

5.15

+7.8

—

10

Unit

kΩ

%

K

mW

Jan. 2009

3

Page 4

MITSUBISHI IGBT MODULES

CM400DX-12A

HIGH POWER SWITCHING USE

Chip Location (Top view) Dimensions in mm (tolerance: ±1mm)

(152)

(121.7)

(110)

(62)

(50)

0

21.5

32.0

0

46

45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25

47

Di2

TrTh2

48

29.6

36.3

43.2

Di1

Tr1

78.6

212019181716151413121110987654321

22

24

23

LABEL SIDE

Each mark points the center position of each chip. Tr*: IGBT, Di*: FWDi, Th: NTC thermistor

0

30.0

43.6

Jan. 2009

4

Page 5

MITSUBISHI IGBT MODULES

CM400DX-12A

HIGH POWER SWITCHING USE

V

V

VGE = 15V

V

GE

= 0V

VGE = 0V

C1(C1s)

G1

E1(E1s)

GE

I

C

V

C1(C1s)

= 0V

G1

E1(E1s)

E1C2

C1

G2

E2(E2s)

E2

r

1T

T

V

CE(sat)

test circuit

VGE = 15V

G2

E2(E2s)

C1

C1(C1s)

G1

E1(E1s)

GE

I

E

V

C1(C1s)

= 0V

G1

E1(E1s)

E1C2

C1

E1C2

V

I

C

E2

r

2

C1

E1C2

0V

V

GE

= 0V

G2

E2(E2s)

E2

D

i

1

EC

test circuit

V

VGE

0V

VCC+

IC

0A

td(on) td(off)

tr

Load

VCE

IE

C

I

Arm

–

V

GE

+

V

GE

R

G

V

–

V

GE

GE

Switching time test circuit and waveforms

90%

0%

90%

tf

VGE = 0V

10%

G2

E2(E2s)

I

E

0A

Di2

t

rr, Qrr

E2

Irr

test waveform

I

E

trr

V

t

1/2 ✕ Irr

Qrr = 1/2 ✕ Irr ✕ trr

Jan. 2009

5

Page 6

PERFORMANCE CURVES

OUTPUT CHARACTERISTICS

800

V

GE

20V

700

(A)

C

600

500

400

300

200

100

COLLECTOR CURRENT I

0

(TYPICAL) Inverter part

15

=

13

Tj = 25°C

12

11

10

9

8

100 246813579

MITSUBISHI IGBT MODULES

HIGH POWER SWITCHING USE

COLLECTOR-EMITTER SATURATION

VOLTAGE CHARACTERISTICS

3.5

(V)

3

CE(sat)

2.5

2

1.5

1

COLLECTOR-EMITTER

0.5

SATURATION VOLTAGE V

0

(TYPICAL) Inverter part

V

GE

= 15V

0 100

200 300 400 500 600 700 800

CM400DX-12A

Tj = 25°C

T

j

= 125°C

COLLECTOR-EMITTER VOLTAGE VCE (V)

COLLECTOR-EMITTER SATURATION

VOLTAGE CHARACTERISTICS

(TYPICAL) Inverter part

10

(V)

8

CE(sat)

6

4

COLLECTOR-EMITTER

2

SATURATION VOLTAGE V

0

GATE-EMITTER VOLTAGE VGE (V)

CAPACITANCE CHARACTERISTICS

(TYPICAL) Inverter part

2

10

7

5

3

2

1

10

7

5

3

2

0

10

7

CAPACITANCE (nF)

5

3

2

V

GE

= 0V

–1

10

10

–1

2

0

10

357 2

357 2

10

1

Tj = 25°C

IC = 400A

IC = 800A

IC = 160A

C

ies

C

oes

C

res

357

206 8 10 12 14 16 18

10

COLLECTOR CURRENT I

C

(A)

FREE WHEELING DIODE

FORWARD CHARACTERISTICS

(TYPICAL) Inverter part

3

10

7

5

(A)

E

3

2

2

10

7

5

3

EMITTER CURRENT I

2

1

10

0 0.5 1 1.5 2 2.5 3 3.5 4

EMITTER-COLLECTOR VOLTAGE V

Tj = 25°C

T

j

= 125°C

EC

(V)

HALF-BRIDGE

SWITCHING CHARACTERISTICS

(TYPICAL) Inverter part

4

10

7

5

3

2

3

10

7

5

3

2

2

10

7

5

SWITCHING TIME (ns)

3

2

1

10

2

10

1

t

f

t

d(off)

t

d(on)

t

r

23 57

10

2

Conditions:

V

CC

= 300V

V

GE

= ±15V

R

G

= 3.6Ω

T

j

= 125°C

Inductive load

23 57

10

3

COLLECTOR-EMITTER VOLTAGE VCE (V)

COLLECTOR CURRENT I

C

(A)

Jan. 2009

6

Page 7

MITSUBISHI IGBT MODULES

CM400DX-12A

HIGH POWER SWITCHING USE

SWITCHING CHARACTERISTICS

HALF-BRIDGE

(TYPICAL) Inverter part

3

10

7

5

3

2

t

d(on)

2

10

7

5

3

SWITCHING TIME (ns)

2

1

10

0

10

57

t

r

1

10

GATE RESISTANCE R

HALF-BRIDGE

SWITCHING CHARACTERISTICS

(TYPICAL) Inverter part

2

10

7

5

3

2

1

10

7

5

3

2

SWITCHING LOSS (mJ/pulse)

0

10

0

10

57

10

E

1

t

d(off)

t

f

Conditions:

V

CC

= 300V

V

GE

= ±15V

I

C

= 400A

T

j

= 125°C

Inductive load

23 5723

G

(Ω)

E

on

E

off

Conditions:

V

CC

= 300V

V

GE

= ±15V

rr

I

C

, IE = 400A

T

j

= 125°C

Inductive load

23 5723

10

10

SWITCHING CHARACTERISTICS

HALF-BRIDGE

(TYPICAL) Inverter part

2

10

Conditions:

7

V

CC

= 300V

5

V

GE

= ±15V

R

G

= 3.6Ω

3

T

j

= 125°C

2

Inductive load

1

10

7

5

3

2

SWITCHING LOSS (mJ/pulse) l

0

10

2

10

1

57

10

2

COLLECTOR CURRENT I

EMITTER CURRENT I

E

off

E

on

E

rr

3

23 5723

10

C

(A)

E

(A)

REVERSE RECOVERY CHARACTERISTICS

OF FREE WHEELING DIODE

(TYPICAL) Inverter part

3

10

Conditions:

7

V

CC

= 300V

5

V

GE

= ±15V

R

G

= 3.6Ω

3

T

j

= 25°C

2

Inductive load

(ns)

rr

2

10

(A), t

7

rr

5

3

2

1

10

2

10

1

57

10

2

I

rr

t

rr

3

23 5723

10

GATE RESISTANCE R

GATE CHARGE CHARACTERISTICS

(TYPICAL) Inverter part

20

IC = 400A

(V)

GE

VCC = 200V

15

10

5

GATE-EMITTER VOLTAGE V

0

0 200 400 600 800

GATE CHARGE QG (nC)

G

(Ω)

VCC = 300V

1000 1200 1400 1600

0

10

7

5

3

th(j–c)

2

–1

10

7

5

3

2

–2

10

7

5

NORMALIZED TRANSIENT

3

THERMAL IMPEDANCE Z

2

–3

10

10

7

EMITTER CURRENT I

E

(A)

TRANSIENT THERMAL

IMPEDANCE CHARACTERISTICS

Single pulse

T

C

= 25°C

Inverter IGBT part : Per unit base = R

Inverter FWDi part : Per unit base = R

–5

–4

10

23 57

10

–3

23 57

23 57

10

–2

23 57

th(j–c)

th(j–c)

–1

10

23 57

= 0.093K/W

= 0.16K/W

TIME (s)

10

0

23 57

1

10

Jan. 2009

Loading...

Loading...