Mitsubishi Electric City Multi PAC-LV11M-J Installation Manual

AIR CONDITIONING SYSTEMS

CONNECTION KIT

PAC-LV11M-J

GB

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thorou ghly before installing the indoor unit.

2

GB

Contents

1. Safety precautions ........................................................................ 2

1.1. Before installation and electric work .............................. 2

1.2. Precautions for devices that use R410A refrigerant ...... 2

1.3. Before getting installed .................................................. 3

1.4. Before getting installed (moved) - electrical work..........3

1.5. Before starting the test run............................................. 3

2. Overview of units........................................................................... 4

2.1. System outline ............................................................... 4

2.2. Unit construction............................................................ 4

2.3. Installation...................................................................... 5

2.4. Dip switch setting..........................................................18

3. Specifications...............................................................................18

4. Outlines and dimensions..............................................................1 9

5. Wiring diagram.............................................................................20

6. Refrigerant system diagram.........................................................21

7. Troubleshooting...........................................................................22

7.1. Test run.........................................................................22

7.2. Check methods.............................................................23

7.3. Dip switch setting (Factory setting)...............................26

1. Safety precautions

1.1. Before installation and electric work

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

Warning:

• Ask the dealer or an authorized technician to install the connection kit.

- Improper installation by the user may result in water leakage, electric shock,

or fire.

• Install the unit at a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in injuries.

• Use the specified cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for typhoons and other strong winds and earthquakes and

install the unit at the specifie d pl ac e.

- Improper installation may cause the unit to topple and result in injury.

• Always use an air cleaner, humidifier, electric heater, and other accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper installation

by the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the unit must be repaired, consult the dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may

result.

• When handling this product, always wear protective equipment.

EG: Gloves, full arm protection namely boiler suit, and safety glasses.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will

be released.

• Install the unit according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fire may

result.

• Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and “Interior Wire Regulations” and

the instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electri c work is performed

improperly, electric shock and fire may result.

• Keep the electric parts away from water (washing water etc.).

- It might result in electric shock, catching fire or smoke.

• When installing and moving the unit to another site, do not charge the it

with a refrigerant different from the refrigerant specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrig-

erant cycle may malfunction and the unit may be damaged.

• If the unit is installed in a small room, measures must be taken to prevent the refrigerant concentration from exceeding the safety limit even

if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the safety

limit from being exceeded. Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the unit, consult the dealer or an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or

fire may result.

• After completing installation work, make sure that ref rigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

and operated forcibly, or parts other than those specified by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• Do not use a leak detection additive.

1.2. Precautions for devices that use

R410A refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping contains a large amount

of chlorine which may cause the refrigerator oil of the new unit to deteriorate.

• Use refrigerant piping made of C1220 (Cu-DHP) phosphorus deoxidized

copper as specified in the JIS H3300 “Copper and copper alloy seamless pipes and tubes”. In addition, be sure that the inner and outer surfaces of the pipes are clean and free of hazardous sulphur, oxides, dust/

dirt, shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refriger-

ant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor trouble may result.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the refriger-

ant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may

cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the

refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check

valve, refrigerant charge base, vacuum gauge, refrigerant recovery

equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the R410A, the

refrigerant may deteriorated.

- If water is mixed in the R410A, the refrigerator oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for conven-

tional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

Before installing the unit, make sure you read all the “Safety precau-

tions”.

The “Safety precautions” provide very important points regarding

safety. Make sure you follow them.

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This symbol is

displayed on the main unit label.) <Color: yellow>

: Beware of electric shock (This symbol is displayed on the main unit label.)

<Color: yellow>

Warning:

Carefully read the labels affixed to the main unit.

3

GB

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

1.3. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the connection kit where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the unit in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of

the unit or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- T he inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air conditioner to operate erroneously, or fail to operate. On the other hand, the unit

may affect such equipment by creating noise that disturbs medical treatment

or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80% or when the drain pipe is clogged,

condensation may drip from the indoor unit. Perform collective drainage

work together with the outdoor unit, as required.

• The unit should be installed the ceiling over than 2.5 m from floor.

1.4. Before getting installed (moved) -

electrical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or tele-

phone ground lines. Improper grounding may result in electric shock.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Install a leak circuit breaker, as required.

- If a leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may

result in a general unit failure or fire.

• Do not wash the unit.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping a ccording to this In stallation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture and

other possessions.

• Be very careful about product transportation.

- Some products use PP bands for packaging. Do not use any PP bands for a

means of transportation. It is dangerous.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may

cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which was not torn apart,

they face the risk of suffocation.

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can

result in severe damage to internal parts. Keep the power switch turned on

during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are may be hot

and may be cold, depending on the condition of the refrigerant flowing

through the refrigerant piping, compressor, and other refrigerant cycle parts.

Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the unit with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise,

water leakage and trouble may occur.

• If the supply cord is damaged, it must be replaced by the manufacturer,

its service agent or similarly qualified persons in order to avoid a hazard.

• This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental cap abiliti es, or lack of exper ience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for

their safety.

• Children should be supervised to ensure that they do not play with the

appliance.

4

GB

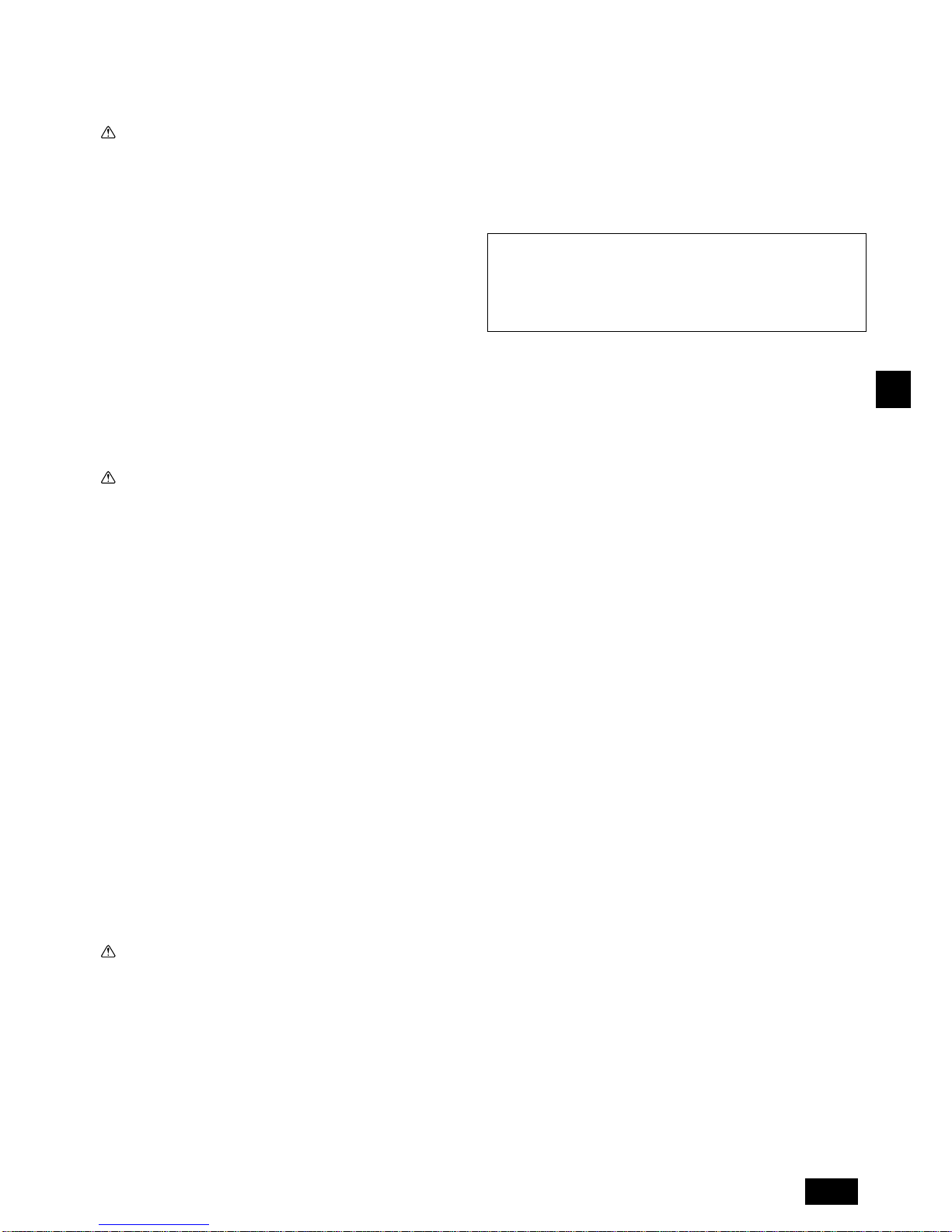

2. Overview of units

2.1. System outline

2.1.1. System example

2.2. Unit construction

Outdoor unit

Indoor unit that

can be

connected

Capacity

Refer to manuals of the outdoor unit.

Number of units

Total system wide

capacity

Outdoor unit

Connection kit

Connection kit

Connection kit

Connection kit

Branching Pipe

Wall mounted

Connection kit

+

* For connectable indoor unit

models, consult your dealer.

5

GB

2.3. Installation

2.3.1. Installing the connection kit

Parts to procure locally

• Suspension bolts or anchor bolts : W3/8 (M10)

• Nut : W3/8 (M10)

• Washer : W3/8 (M10)

Installing the unit in a ceiling

(1) Install the suspension bolts.

(2) Install the connection kit.

Installing the unit on a wall

(1) Install the anchor nuts.

(2) Install the connection kit.

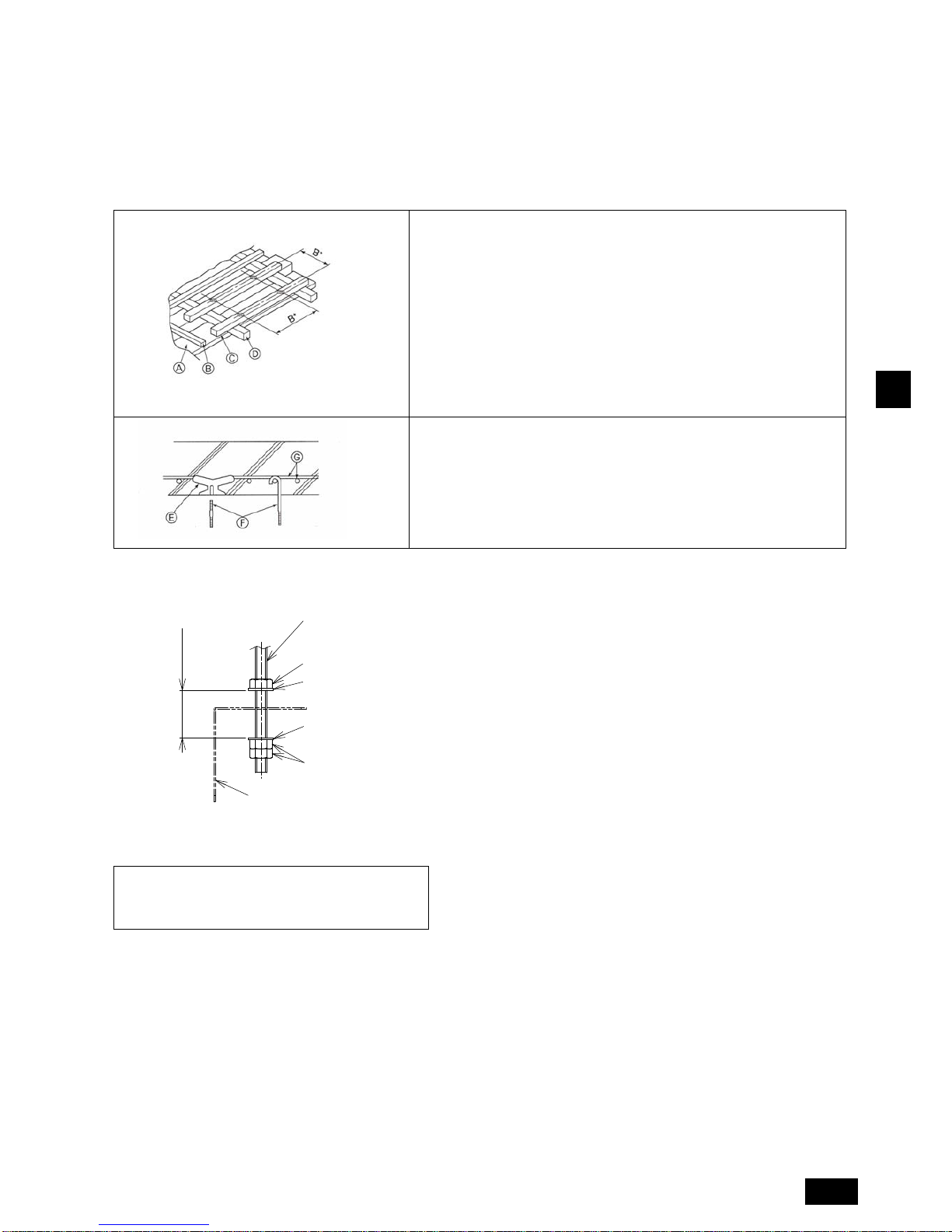

Wooden structures

• Use tie beams (single storied houses) or second floor beams (two

story houses) as reinforcing members.

• Wooden beams for suspending air conditioners must be sturdy and

their sides must be at least 6 cm long if the beams are separated by

not more than 90 cm. The size of the suspension bolts should be

M10 (W3/8). (The bolts are not supplied with the unit.)

A Ceiling

B Rafter

C Beam

D Roof beam

B* Suspension bolt pitch

Ferro-concrete structures

Secure the suspension bolts using the method shown, or use

steel or wooden hangers, etc. to install the suspension bolts.

E Use inserts rated at 100-150 kg each (procure locally)

F Suspension bolts M10 (W3/8) (procure locally)

G Steel reinforcing rod

Do not install the refrigerant pipes on top of the

unit when installing the unit on a wall, otherwise

condensation can enter the electrical devices,

which can cause an electric shock or a fire.

Unit

Washer (procure locally)

Washer (procure locally)

Nuts (procure locally)

Nut (procure locally)

Suspension bolt M10

ޓ(procure locally)

(When unit is hung

and nuts tightened)

MIN.30

(Unit: mm)

6

GB

Connect the Connection Kit to the liquid pipe and install it inside the ceiling or on a wall (Do not install in an outdoor location. It may

cause a breakdown). Make sure to install the access door on the ceiling.

Installation location

• The installation patterns below are available. Select the installation pattern according to the preferred installation method. The

distance between indoor unit and Connection Kit is within 15 m. (Pipe:15 m, Cable:2.5 m)

• Install the connection kit at a height of 2.5 m or above from the floor, where it is not easily accessible for the users.

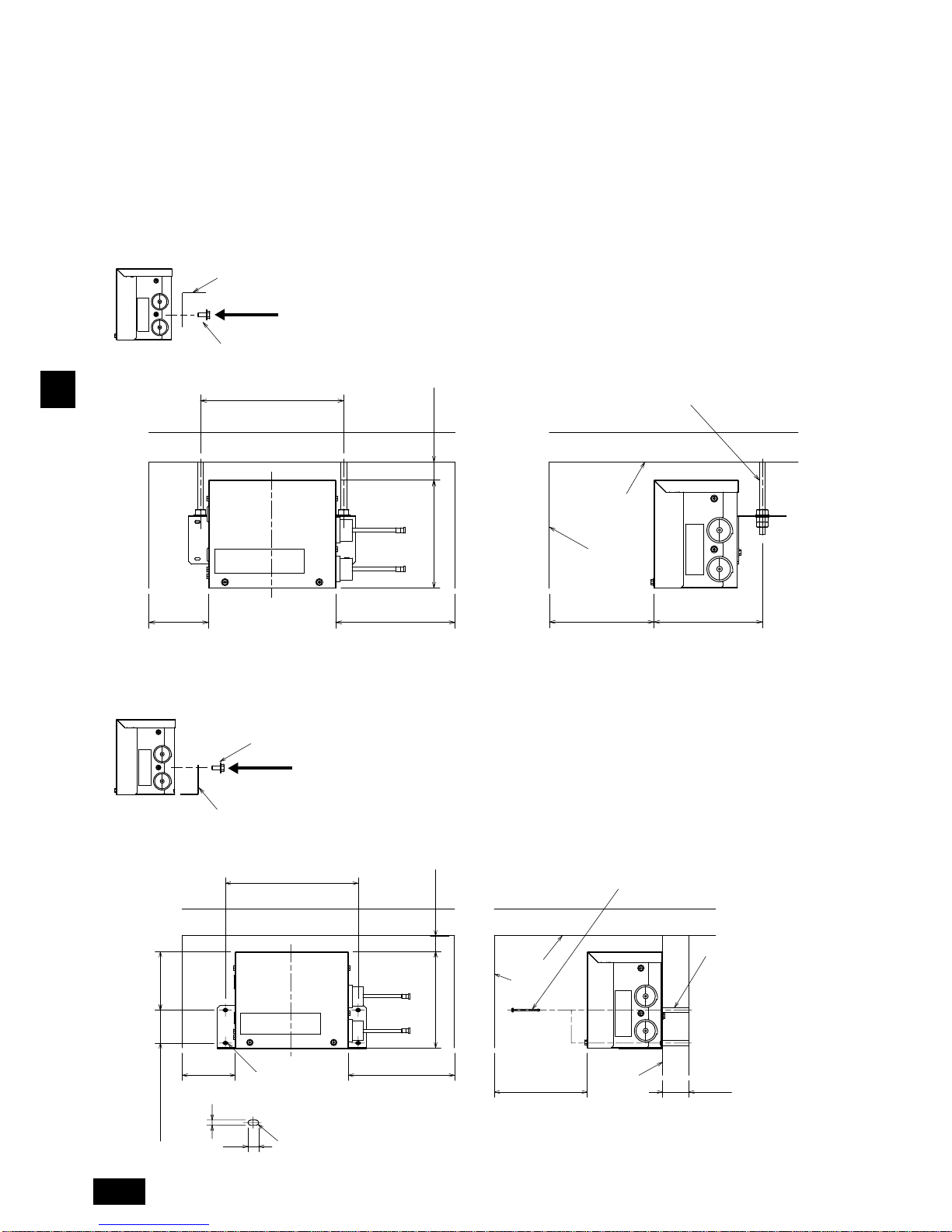

Installation pattern A (Using suspension bolt ; recommended pa tte rn)

Set the Connection Kit mounting plate as shown below.

The mounting plate can also be fixed to suspension bolts before it is fixed to the Connection Kit.

Installation pattern B (Installing the unit on a wall.)

Set the Connection Kit mounting plate as shown below.

Mounting plate

Install the two screws (5 × 10)

Wall

Ceiling

Suspension bolt M10

182

SERVICE SPACE

MIN.500

MIN.100 MIN.200

181

MIN.30

Suspension bolt pitch

240

Mounting plate

Install the two screws (5 × 10)

Wall

Wall

Ceiling

4-Oval holes

Anchor nuts

(procure locally)

Oval hole dimension

Install the four screws (4×50 procure

locally) in oval holes.

(R)

10

5

MIN.50

110

ANCHOR NUT PITCH

62

ANCHOR NUT PITCH

250

SERVICE SPACE

MIN.500

MIN.100 MIN.200

181 MIN.30

(Unit: mm)

(Unit: mm)

7

GB

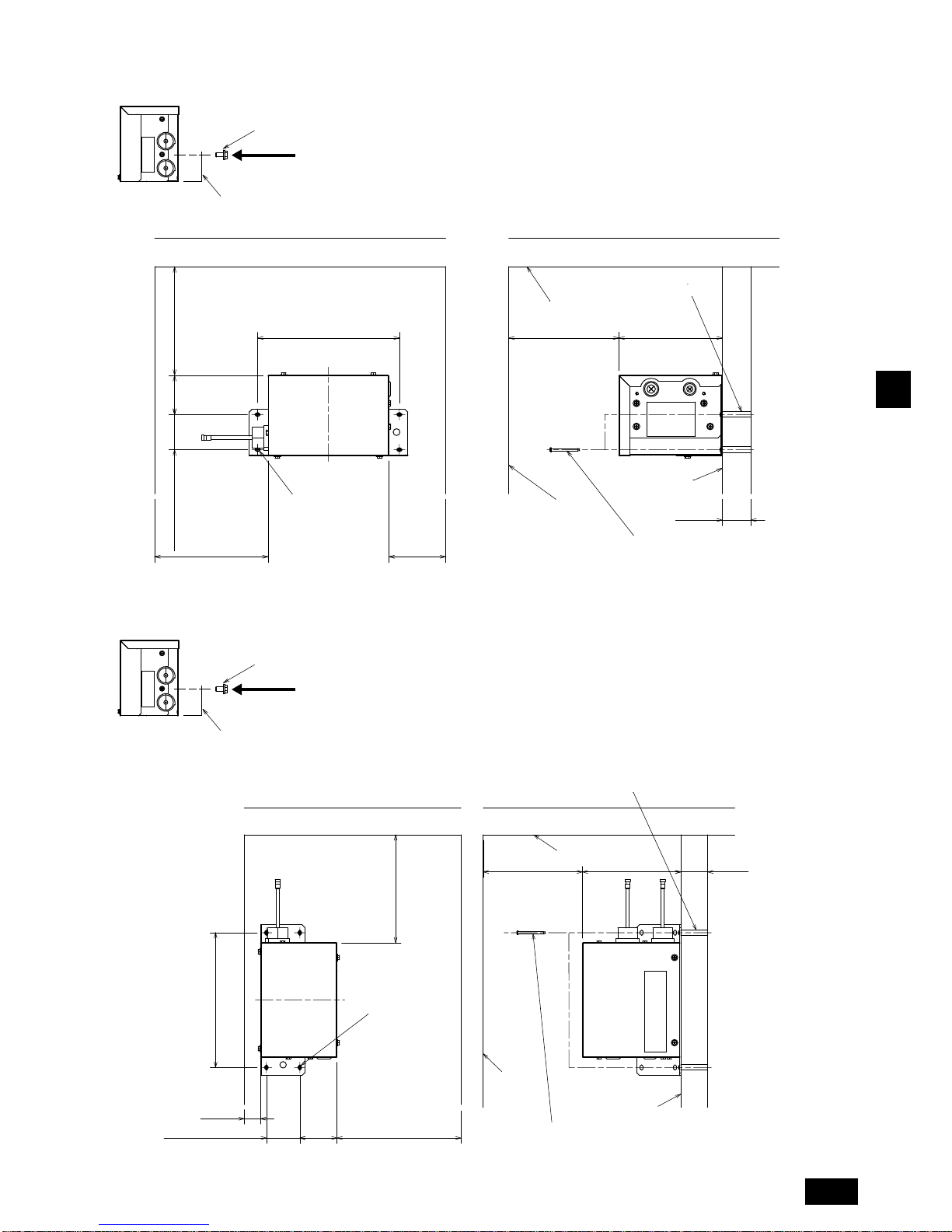

Installation pattern C (Installing the unit on a wall.)

Set the Connection Kit mounting plate as shown below.

Installation pattern D (Installing the unit on a wall.)

Set the Connection Kit mounting plate as shown below.

Mounting plate

Install the two screws (5 × 10)

Install the four screws (4×50 procure

locally) in oval holes.

Anchor nuts

(procure locally)

Wall

Wall

Ceiling

4-Oval holes

183

SERVICE SPACE

500

SERVICE SPACE

500

69

MIN.100MIN.200

ANCHOR NUT PITCH

62

ANCHOR NUT PITCH

250

MIN.50

Mounting plate

Install the two screws (5 × 10)

Install the four screws (4×50 procure

locally) in oval holes.

Wall

Wall

Ceiling

4-Oval holes

Anchor nuts

(procure locally)

ANCHOR NUT PITCH

250

MIN.50

183MIN.30

69

MIN.30

MIN.200

SERVICE SPACE

500

ANCHOR NUT PITCH

62

(Unit: mm)

(Unit: mm)

8

GB

2.3.2. Installing the refrigerant piping

Check the Connection Kit accessories and parts

1Pipe cover × 2

2Thermistor holder - ø9.52 × 1

3Thermistor holder - ø12.7 × 1

Connect Connection Kit to the liquid pipe.

When brazing the refrigerant pipes, be sure to braze, after covering a wet cloth to the insulation pipes of the units in order to prevent

it from burning and shrinking by heat.

Press the pipe cover 1 on the liquid piping against the Connection Kit and wrap it to hold it in place.

Fasten the supplied bands 20 mm from each of the pipe covers 1.

Wrap the pipe cover 1 with tape.

Connection kit

Refrigerant pipe (procure locally)

Brazing

To indoor unit

To outdoor unit

(120)

2020

Connection kit

Band (procure locally)

Refrigerant pipe

(procure locally)

1Pipe cove

r

Tape (procure locally)

9

GB

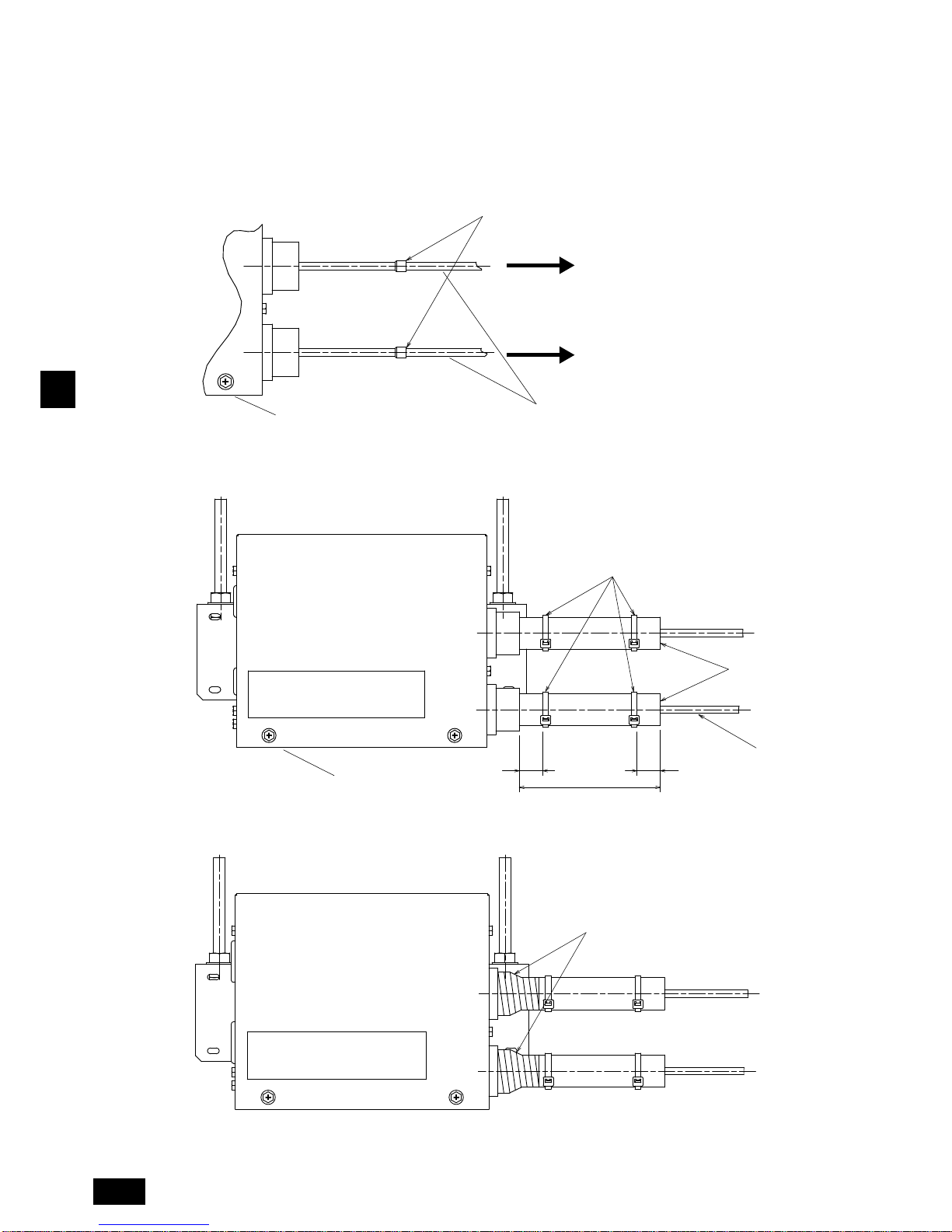

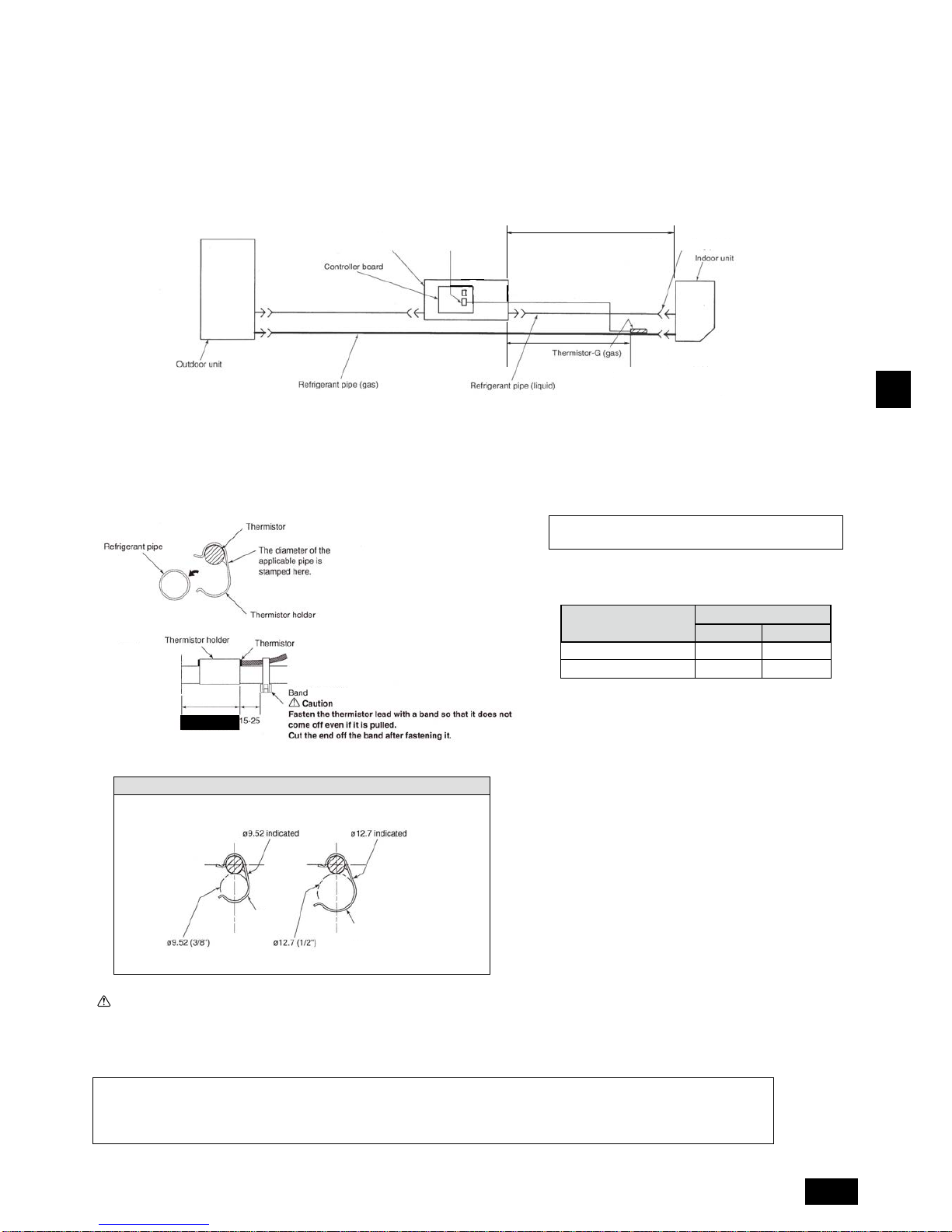

2.3.3. Installing the thermistors

Be sure to install the thermistors (gas) supplied with the unit as shown in the illustration.

• If the thermistors are not installed, the unit will not operate. If the thermistors are installed incorrectly, the unit will not operate

properly.

Take precaution so that condensation does contact the thermistor leads or enters the electrical devices.

Before installing thermal insulation to the frame connecting points of the indoor unit, be sure to install the thermistors

according to the procedures given on this page.

* Refer to section 8.4 "Wiring (mm)" for the location of CN44.

Thermistor installation order

(1) Securely fasten the thermistor (gas) supplied with the unit using the thermistor holders (2, 3) at the fastening points of indoor

unit refrigerant pipes.

• Set thermistor-G (gas) in thermistor holders 2 or 3, and then fasten the refrigerant pipes.

Caution:

• To prevent condensation from dripping on the thermistor fasteners, wrap them with sufficient thermal insulation.

• Install the thermistor so that the piping is on top (as shown in above illustration).

• Take out the thermistor lead from above the piping.

• Install the thermistor indoors.

Select thremistor holders that match the size

of the refrigerant piping.

Gas

• Route the following lead, line, and cable pairs so that they do not come into contact with each other.

- Thermistor lead and indoor unit-connection kit transmission line

- Thermistor lead and power supply cable

- Transmission line and power supply cable

Connection kit

Gas: CN44

1500

Brazed point

MAX. 15000

MAX. 2000

MAX. 1500 mm

(procure locally)

Indoor unit capacity pipe size (mm)

15-40

50

Liquid

ø6.35

ø6.35

Gas

ø9.52

ø12.7

2

3

Loading...

Loading...