Mitsubishi Electric City Multi CMH-WM250V-A, City Multi CMH-WM350V-A, City Multi CMH-WM500V-A Installation Manual

Air-Conditioners For Building Application

INDOOR/OUTDOOR UNIT

CMH-WM250V-A, CMH-WM350V-A, CMH-WM500V-A

<ORIGINAL>

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

ΕΓΧΕΙΡΙ∆ΙΟ Ο∆ΗΓΙΩΝ ΕΓΚΑΤΑΣΤΑΣΗΣ

Για ασφάλεια και σωστή χρήση, παρακαλείστε διαβάσετε προσεχτικά αυτό το εγχειρίδιο εγκατάστασης πριν αρχίσετε την εγκατάσταση της μονάδας

κλιματισμού.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

INSTALLATIONSMANUAL

Læs venligst denne installationsmanual grundigt, før De installerer airconditionanlægget, af hensyn til sikker og korrekt anvendelse.

INSTALLATIONSHANDBOK

Läs den här installationshandboken noga innan luftkonditioneringsenheten installeras, för säker och korrekt användning.

MONTAJ ELKİTABI

Emniyetli ve doğru biçimde nasıl kullanılacağını öğrenmek için lütfen klima cihazını monte etmeden önce bu elkitabını dikkatle okuyunuz.

РЪКОВОДСТВО ЗА МОНТАЖ

За безопасна и правилна употреба, моля, прочетете внимателно това ръководство преди монтажа на климатизатора.

PODRĘCZNIK INSTALACJI

W celu bezpiecznego i poprawnego korzystania należy przed zainstalowaniem klimatyzatora dokładnie zapoznać się z niniejszym podręcznikiem

instalacji.

INSTALLASJONSHÅNDBOK

For sikker og riktig bruk, skal du lese denne installasjonshåndboken nøye før du installerer klimaanlegget.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по установке до

выполнения установки кондиционера.

PŘÍRUČKA K INSTALACI

V zájmu bezpečného a správného používání si před instalací klimatizační jednotky důkladně pročtěte tuto příručku k instalaci.

NÁVOD NA INŠTALÁCIU

Pre bezpečné a správne použitie si pred inštalovaním klimatizačnej jednotky, prosím, starostlivo prečítajte tento návod na inštaláciu.

TELEPÍTÉSI KÉZIKÖNYV

A biztonságos és helyes használathoz, kérjük, olvassa el alaposan ezt a telepítési kézikönyvet, mielőtt telepítené a légkondicionáló egységet.

PRIROČNIK ZA NAMESTITEV

Za varno in pravilno uporabo pred namestitvijo klimatske naprave skrbno preberite priročnik za namestitev.

MANUAL CU INSTRUCŢIUNI DE INSTALARE

Pentru o utilizare corectă şi sigură, vă rugăm să citiţi cu atenţie acest manual înainte de a instala unitatea de aer condiţionat.

PRIRUČNIK ZA UGRADNJU

Radi sigurne i ispravne uporabe, temeljito pročitajte ovaj priručnik prije ugradnje klimatizacijskog uređaja.

en

defresit

nlru

el

pt

da

sv

tr

bg

pl

no

cs

sk

hu

sl

ro

hr

安装手册

为了安全和正确地使用本空调器,请在安装前仔细阅读本安装手册。

中<简>

22.2

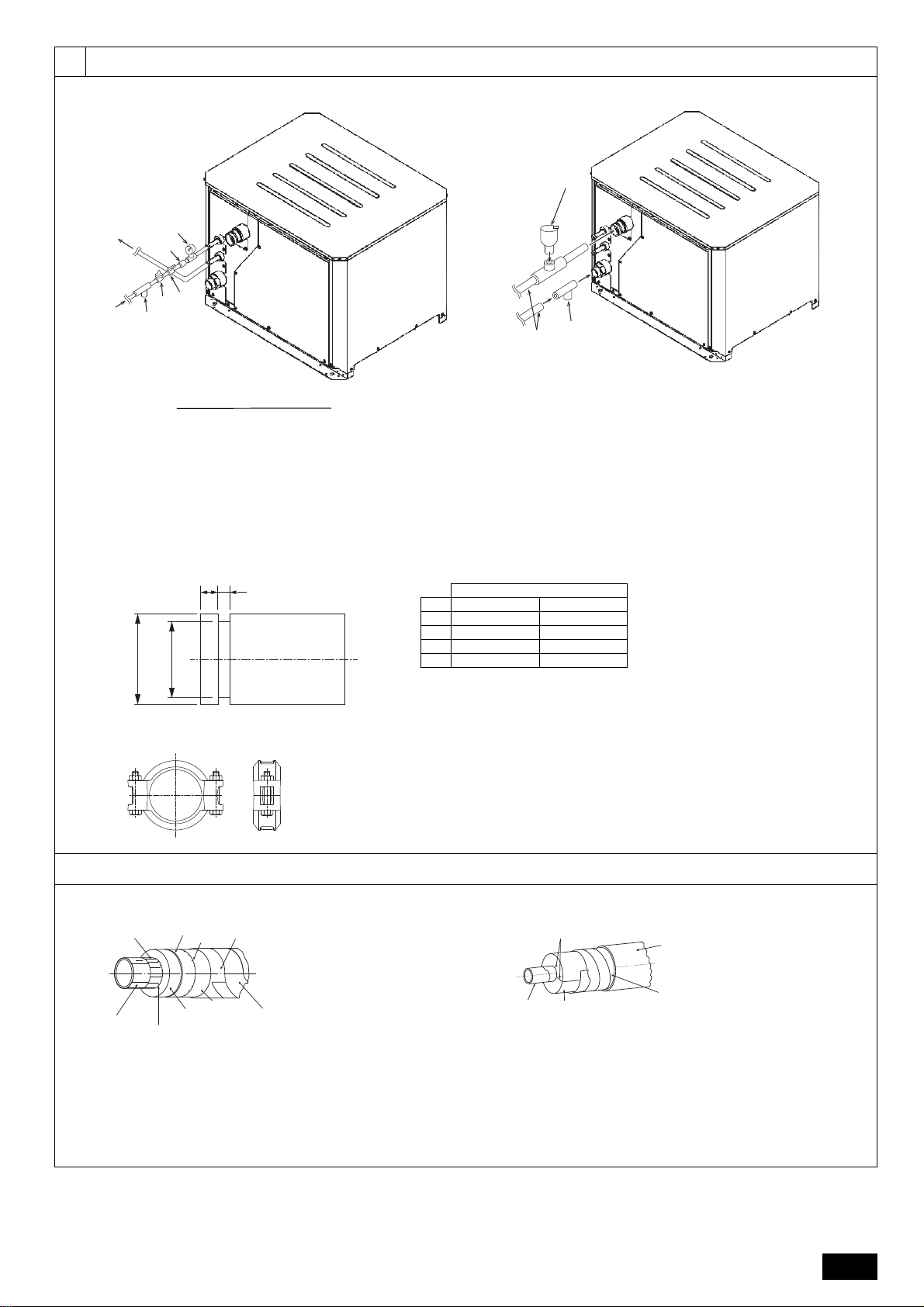

<A> Refrigerant piping side

<B> Water piping side

<A> Front view

<B> Top view

A Service space

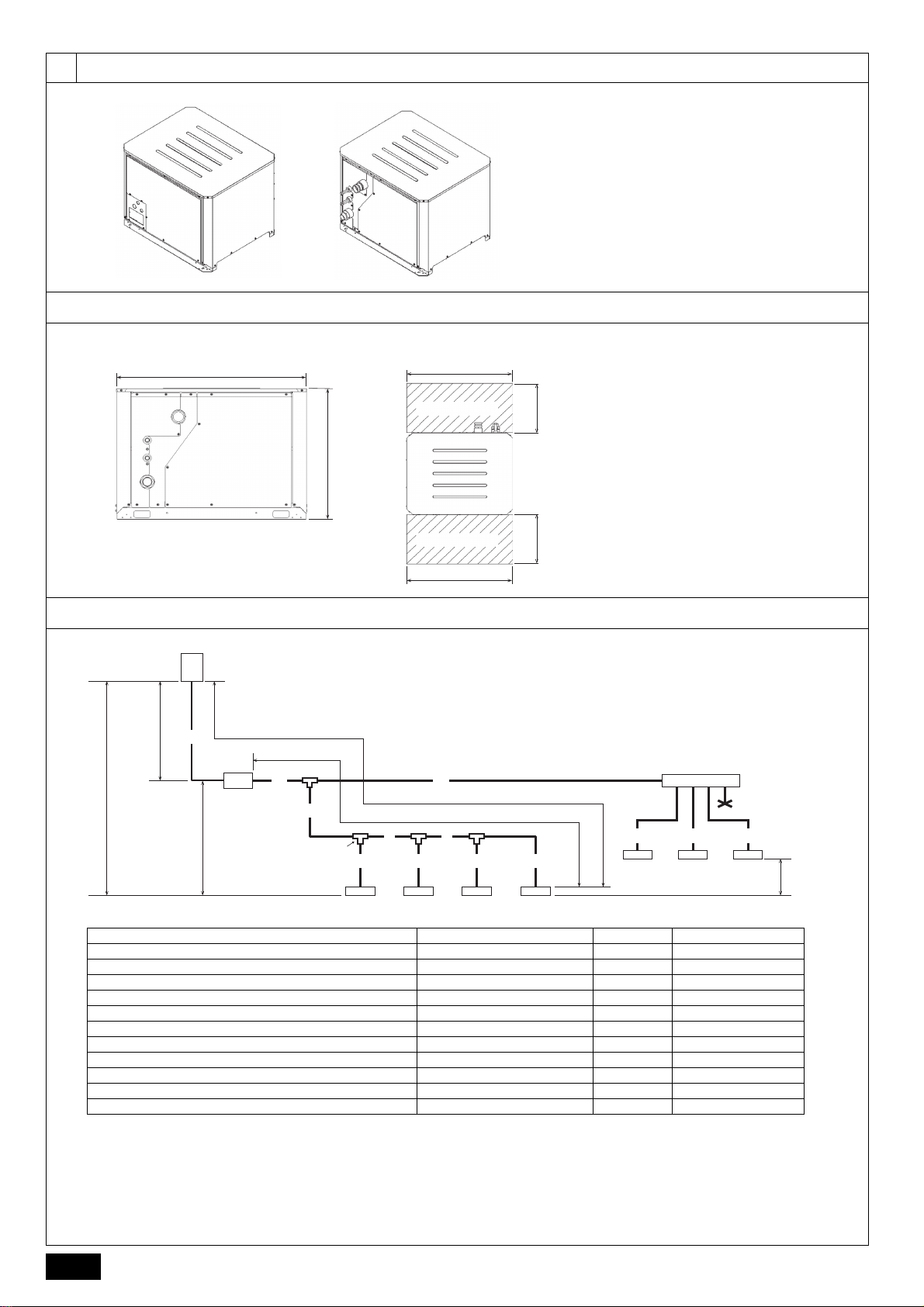

A Outdoor unit B 1st branching

C Indoor unit D Hydro unit

E Cap F Joint

G Header branching H Refrigerant piping

I Water piping

(Unit: m)

*1 The maximum length is 90 m, depending on the unit model and installation conditions. For more detailed information, contact your local distributor.

*2 The maximum length is 60 m, depending on the unit model and installation conditions. For more detailed information, contact your local distributor.

Item Piping in the figure Max. length Max. equivalent length

Total piping length A+A'+B+C+D+E+a+b+c+d+e+f+g 1000 Farthest indoor unit from outdoor unit (L1) A+A'+C+D+E+g/A+B+c 165 190

Between outdoor unit and hydro unit (refrigerant pipework) A 110 Farthest indoor unit from hydro unit (L3) A'+C+D+E+g/A'+B+c 60 60

Height between outdoor unit and indoor unit (outdoor unit above indoor unit)

H90-

Height between outdoor unit and indoor unit (outdoor unit below indoor unit)

H' 60 -

Height between outdoor unit and hydro unit (outdoor unit above hydro unit)

H1 50 *1 -

Height between outdoor unit and hydro unit (outdoor unit below hydro unit)

H1' 40 *2 -

Height between hydro unit and indoor unit (hydro unit above indoor unit)

H2 50 -

Height between hydro unit and indoor unit (hydro unit below indoor unit)

H2' 40 -

Height between indoor units h1 30 -

[Fig. 2.2.1]

<A>

<B>

2.3

[Fig. 2.3.1]

<A> <B>

920

920

[Fig. 2.4.1]

)

)

C

C

below

above

A

A

H (

H' (

)

D

above

A

H1 (

A

)

D

below

A

A

H

H1' (

)

C

above

D

H2 (

D

)

C

below

D

H2' (

A

450450

660

A

920

2.4

I

B

A'

C

F

D E

d e f g

CCCC

B

L1

L3

a

CCC

G

E

b c

h1

2

33.2

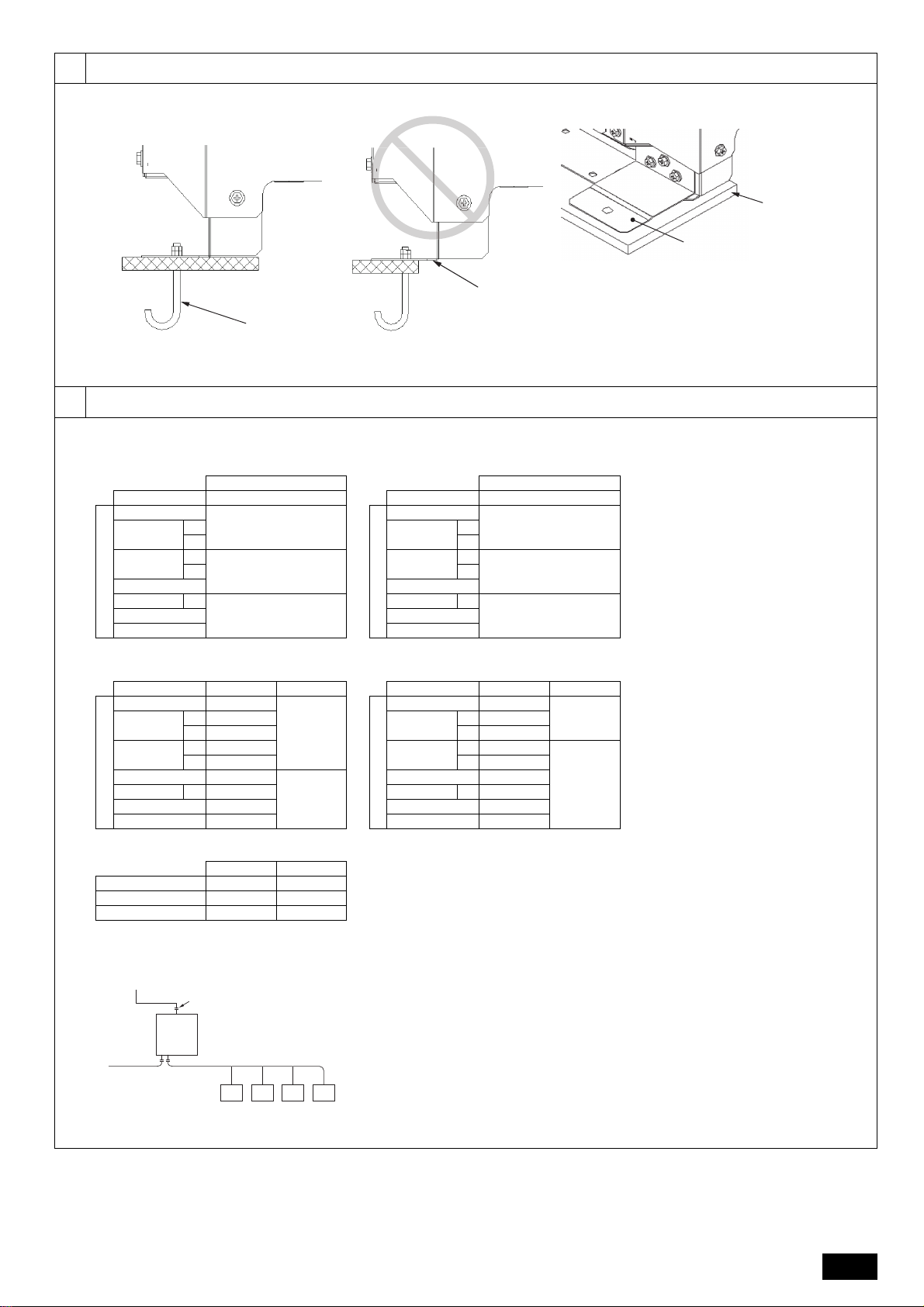

A M10 anchor bolt (not supplied)

B (Incorrect installation) The corner section is not securely received.

C Fixing bracket for post-installed anchor bolts (not supplied) (To be

fixed with three screws)

D Anti-vibration rubber pad (The pad needs to be large enough to

cover the entire width of each unit leg.)

*1 When the piping length from the outdoor unit to the hydro unit is less than

90 m (295 ft)

*2 When the piping length from the outdoor unit to the hydro unit is

90 m (295 ft) or more

*3 When the piping length from the outdoor unit to the hydro unit is less than

40 m (131 ft)

*4 When the piping length from the outdoor unit to the hydro unit is

40 m (131 ft) or more

*5 When the unit is used alone

A To outdoor unit

B End connection (brazing)

C Hydro unit

D To main piping

E Indoor unit

1. Hydro units connectable to outdoor units

Standard models High-efficient models

2. Connecting pipe diameter of outdoor unit

Standard models High-efficient models

3. Connecting pipe diameter of hydro unit

If the connecting pipe diameter of hydro unit differs

from that of outdoor unit, expand or reduce the pipe

diameter at the inlet of the hydro unit.

Hydro unit

Unit model Model name

Outdoor unit side

PUHY-M200

CMH-WM250V-A

PUHY-M250

*1

*2

PUHY-M300

*3

CMH-WM350V-A*4

PUHY-M350

PUHY-M400 *5

CMH-WM500V-APUHY-M450

PUHY-M500

Hydro unit

Unit model Model name

Outdoor unit side

PUHY-EM200

CMH-WM250V-A

PUHY-EM250

*1

*2

PUHY-EM300

*3

CMH-WM350V-A*4

PUHY-EM350

PUHY-EM400 *5

CMH-WM500V-APUHY-EM450

PUHY-EM500

Unit model Liquid Gas

Outdoor unit side

PUHY-M200 ø9.52 (ø3/8)

ø22.2

(ø7/8)

PUHY-M250

*1 ø9.52 (ø3/8)

*2 ø12.7 (ø1/2)

PUHY-M300

*3 ø9.52 (ø3/8)

*4 ø12.7 (ø1/2)

PUHY-M350 ø12.7 (ø1/2)

ø28.58

(ø1-1/8)

PUHY-M400 *5 ø12.7 (ø1/2)

PUHY-M450 ø15.88 (ø5/8)

PUHY-M500 ø15.88 (ø5/8)

Unit model Liquid Gas

Outdoor unit side

PUHY-EM200 ø9.52 (ø3/8)

ø22.2

(ø7/8)

PUHY-EM250

*1 ø9.52 (ø3/8)

*2 ø12.7 (ø1/2)

PUHY-EM300

*3 ø9.52 (ø3/8)

ø28.58

(ø1-1/8)

*4 ø12.7 (ø1/2)

PUHY-EM350 ø12.7 (ø1/2)

PUHY-EM400 *5 ø12.7 (ø1/2)

PUHY-EM450 ø15.88 (ø5/8)

PUHY-EM500 ø15.88 (ø5/8)

Liquid Gas

CMH-WM250V-A ø9.52 (ø3/8) ø22.2 (ø7/8)

CMH-WM350V-A ø12.7 (ø1/2) ø25.4 (ø1)

CMH-WM500V-A ø15.88 (ø5/8) ø25.4 (ø1)

[Fig. 3.2.1]

D

C

B

A

44.1

[Fig. 4.1.1]

A

B

C

D

EEEE

3

[Fig. 4.1.2]

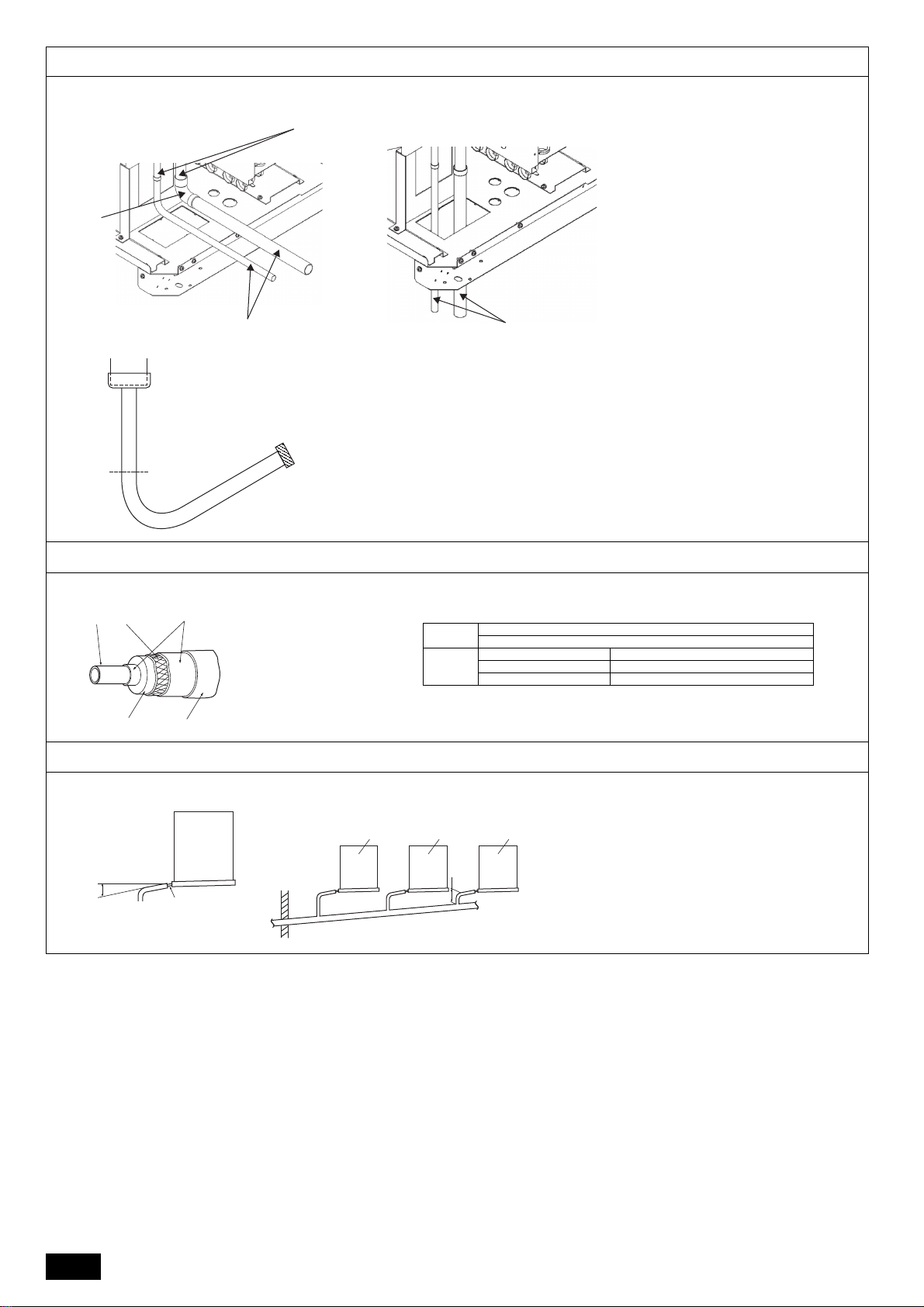

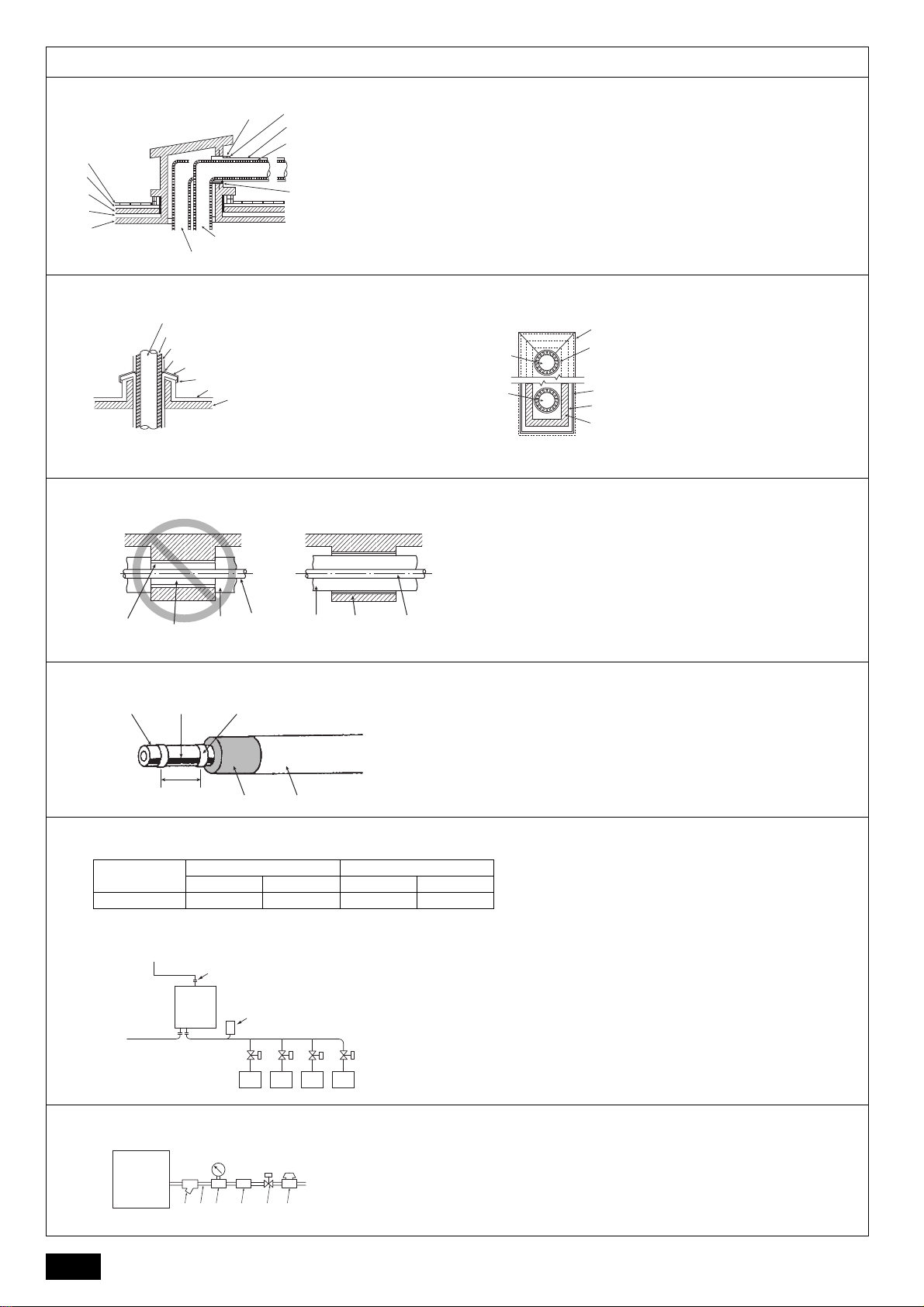

(1) When routing the pipes through the front of the unit (2) When routing the pipes through the bottom of the unit

(3) Pipe connection port and connecting pipe

C

C

<A> Liquid side

<B> Gas side

A Refrigerant piping

B Elbow

C On-site piping

A Steel w ire

B pipe

C Oily mastic asphalt or asphalt

D Insulation material A

E Outer covering B

* If a polyethylene cover is used as an outer covering, asphalt roofing is not necessary.

Insulation

material A

Glass fiber + Steel wire

Adhesive + Heat-resistant polyethylene foam + Adhesive tape

Outer

covering B

Indoor Vinyl tape

Under the floor and exposed Waterproof hemp cloth + Bronze asphalt

Outdoor Waterproof hemp cloth + Zinc plate + Oily paint

A Downward slope 1/100 or more

B Drain hose

C Unit

D Collective piping

E Maximize this length to approx. 10 cm

* A drain pan is separately sold (for indoor use only).

4.1

B

[Fig. 4.3.1]

<A> <B>

A

<A> <B>

4.3

Ⓑ

Ⓐ

Ⓓ

Ⓒ

Ⓔ

4.4

[Fig. 4.4.1]

C

A

B

1

D

C

E

C

2

4

55.1

Hydro unit sample installation

A Expansion vessel (not supplied) B Pressure gauge (not supplied)

C Check valve (not supplied) D Shutoff valve (not supplied)

E Pressure reducing valve (not supplied) F Strainer (not supplied)

G Water inlet H Auto air vent valve (supplied)

I Strainer (supplied) J Water pipe s

(*1)

Note:

*1. Connect the pipes to the water pipes according to the local regulations.

Pipe size

40A 50A

d ø48.6 ø60.3 ± 0.61

G ø44.8 ø57.15

W 8 ± 0.5 7.95 ± 0.76

L 15 15.88 ± 0.76

+0

-0.7

+0

-0.38

+0.8

-0

A #7K tar felt

B Steel wire

C Blown asphalt

D Base paper

E Pipe

F Glass wool

(Note: Absorbent material)

G Asphalt felt

H Cotton tape (After wrapping it

around a pipe, brush polyester

synthetic resin over the tape.)

[Fig. 5.2.1]

[Fig. 5.2.2]

A Adhesive (Completely fill joints of foam polystyrene pipe insulation and a gap

between a pipe and foam polystyrene pipe insulation with adhesive.)

B Pipe

C Form polystyrene pipe insulation (Non-absorbent material)

D Exterior (When pipes are installed on a roof, cover the pipes with galvanized

steel sheets to protect the pipes from rainwater. This countermeasure is unnecessary when pipes are installed inside.)

E Adhesive tape (Ensure that it has sufficient heat resistance so that high hot water

temperature will not lower its adhesion.)

[Fig. 5.1.1]

H

To

G

A

F

E

C

B

D

J

I

[Fig. 5.1.2]

[Fig. 5.1.3]

A

E

L

W

Gd

5.2

B

F

D

C

G

H

C

A

B

C

D

E

5

A

A Finishing mortar (25–30 mm) B Cinder concrete (70–100 mm)

C Two layers of waterproofing membrane (10–12 mm) D Smoothing mortar (25–30 mm)

E Frame concrete F Filled with thermal insulation materials

G Caulking (Waterproof material) H Lagging (Molded paper, waterproof paper, galvanized cast iron

sheet, and paint of a specified color)

I Thermal insulation material (Glass wool or rock wool) J Iron pipe sleeve with collar

Determine the inner diameter of a sleeve in consideration of the

outer diameter of an iron pipe, thickness of thermal insulation,

and thickness of a filler.

K Cold (hot) water pipe (supply pipe) L Cold (hot) water pipe (return pipe)

[Fig. 5.2.3]

A Cold (hot) water pipe (supply and

return pipe)

B Thermal insulation material

C Lagging (covering with galvanized

steel sheet)

D Soldering

E Galvanized steel sheet cover

F Caulking (waterproof material)

elastomeric sealant

G Mortal waterproofing membrane

(30–100 mm)

H Concrete (150 mm)

A Cold (hot) water pipe (supply pipe)

B Bind here using band or tape.

C Galvanized steel sheet cover

D Soldering

E Caulking (waterproof material)

elastomeric sealant

F Mortal waterproofing membrane

G Concrete (150 mm)

B

A Sleeve

B No thermal insulation

C Thermal insulation materials

D Pipe

[Fig. 5.2.5]

Thermal and cold insulation work on a pipe penetrating through a beam

[Fig. 5.2.6]

A Pipe

B Heater

C Adhesive tape

D Insulating material

E Covering material

[Fig. 5.2.7]

Indoor unit

Connection size Pipe size

Water inlet Water outlet Water return Water out

PEFY-W·VMA O.D. 22.0 mm O.D. 22.0 mm I.D. 20 mm I.D. 20 mm

A To outdoor unit

B End connection

C Hydro unit

D To main piping

E Indoor unit

F Auto air vent valve (Highest point on the water pipe) (supplied)

* For other indoor units, refer to the indoor unit installation manual.

* The pipe diameter depends on the capacity of indoor units.

Refer to the indoor unit installation manual for details.

[Fig. 5.2.8]

A Hydro unit

B Strainer (supplied)

C Water pipe

D Pressure gauge (not supplied)

E Check valve (not supplied)

F Shutoff valve (not supplied)

G Pressure reducing valve (not supplied)

B

C

D

E

[Fig. 5.2.4]

5.2

G

F

H

I

J

K

L

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

A

A

B

250 mm

D

C

C

DE

C

AD

A

B

C

F

D

EEEE

6

A

B GDC FE

Loading...

Loading...