Page 1

CC-Link Embedded I/O Adapter

User's Manual

Page 2

Page 3

• SAFETY PRECAUTIONS •

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. Refer to the user's manual of the

CPU module to use for a description of the PLC system safety precautions.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Design Precautions]

!

DANGER

• When there are communication errors with the data link, the communication error station will

enter the following condition.

Build an interlock circuit into the sequence program to operate system safely by using the

communication state information.

An accident may occur by a false output or a malfunction.

(1) Turn off all input from Remote I/O station.

(2) Turn off all output from Remote I/O station.

• The output may be left ON or OFF due to trouble in the CC-Link embedded I/O adapter.

Configure a circuit to monitor I/O signals which may lead to a serious accident..

!

CAUTION

• Use the CC-Link embedded I/O adapter in an environment that meets the general specifications

contained in this manual.

Using this adapter in an environment outside the range of the general specifications could result

in electric shock, fire, malfunction, and damage to or deterioration of the product.

• Do not bunch the control wires or communication cables with the main circuit or power wires, or

install them close to each other.

They should be installed 100 mm (3.9 in.) or more from each other.

Not doing so could result in noise that would cause malfunction.

A - 1 A - 1

Page 4

[Installation Precautions]

!

CAUTION

• Do not directly touch the CC-Link embedded I/O adapter's conductive parts.

Doing so could cause malfunction or failure in the CC-Link embedded I/O adapter.

• Securely solder the CC-Link embedded I/O adapter to install it to a user board.

Defective contact could cause malfunction.

[Wiring Precautions]

!

DANGER

• Before beginning any installation or wiring work, make sure that all phases of the power supply

have been obstructed from the outside.

Failure to completely shut off the power supply phases may cause electric shock and/or damage

to the adapter.

!

CAUTION

• Always ground the FG terminal to the protective ground conductor.

Doing so may cause electric shock or malfunction.

• Correctly connect the CC-Link embedded I/O adapter after confirming the rated voltage and pin

numbers of the product.

Failure to do so could make a short circuit with bare solderless terminals.

• When wiring the CC-Link embedded I/O adapter, check the rated voltage and terminal layout

and make sure the wiring is done correctly.

Connecting a power supply that differs from the rated voltage or wiring it incorrectly may cause

fire, failure or malfunction.

• Make sure that there are no foreign substances such as sawdust or wiring debris inside the CCLink embedded I/O adapter.

Such debris could cause fire, failure or malfunction.

• Make sure that the communication cable connected to the adapter is kept in the duct or fixed

with cramps.

Failure to do so may cause a damage to the user board or cables due to dangling, shifting or

inadvertent handling of cables, or misoperation because of bad cable contacts.

• Do not grab on the cable when removing the communication cable connected to the adapter.

When removing the cable with a connector, hold the connector on the side that is connected to

the adapter.

When removing the cable without a connector, loose the screws on the side that is connected to

the adapter.

Pulling the cable that is still connected to the adapter may cause a damage to the user board or

cable, or malfunction due to bad cable contacts.

A - 2 A - 2

Page 5

[Starting and Maintenance Precautions]

!

DANGER

• Do not touch the terminals or connector while the power is on.

Doing so may cause electric shock or malfunction.

• Make sure to switch all phases of the external power supply off before cleaning or re-tightening

the terminal screws.

Failure to do so may damage the CC-Link embedded I/O adapter or cause malfunction.

!

CAUTION

• Do not disassemble or modify the CC-Link embedded I/O adapter.

Doing so could cause failure, malfunction, injury or fire.

• Because the case of the CC-Link embedded I/O adapter is made of resin, be careful not to drop

it or expose it to strong impact.

It may damage the CC-Link embedded I/O adapter.

• Before mounting or dismounting the user board loaded with the CC-Link embedded I/O adapter

to or from an enclosure, always switch power off externally in all phases.

Failure to do so may damage the CC-Link embedded I/O adapter or cause malfunction.

[Disposal Precautions]

!

CAUTION

• When disposing of this product, treat it as industrial waste.

A - 3 A - 3

Page 6

REVISIONS

* The manual number is given on the bottom left of the back cover.

Print Date * Manual Number Revision

May., 2002 SH(NA)-080324E-A First printing

Aug., 2002 SH(NA)-080324E-B

Addition

Section 4.1.2, 4.2.2, Appendix 1.2

Correction

Conformation to the EMC Directive and Low Voltage Instruction,

Section 1.2, 1.3, 1.4, Chapter 2, Section 4.2.1, 4.3.1, 5.1, 5.2

Mar., 2006 SH(NA)-080324E-C

Correction

Chapter 3, Section 5.1

Sep., 2006 SH(NA)-080324E-D

Addition

Section 6.2.2

Correction

Section 6.2.1

Japanese Manual Version SH-080323-D

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 2002 MITSUBISHI ELECTRIC CORPORATION

A - 4 A - 4

Page 7

INTRODUCTION

Thank you for purchasing the MELSEC-A series PLC.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the A-series PLC you have purchased, so as to ensure correct use.

Please forward a copy of this manual to the end user.

CONTENTS

1 OVERVIEW 1- 1 to 1- 5

1.1 Features .................................................................................................................................................. 1- 1

1.2 Identifying the Compact CC-Link Embedded I/O Adapter Type ........................................................... 1- 2

1.3 Cautionary Notes when Selecting a CC-Link Embedded I/O Adapter.................................................. 1- 3

1.4 Specification List ..................................................................................................................................... 1- 4

1.5 About the Generic, Abbreviated and Technical Terms Used in This Manual....................................... 1- 4

2 NAMES AND SETTINGS FOR EACH PART 2- 1 to 2- 2

3 SPECIFICATIONS 3- 1 to 3- 2

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER 4- 1 to 4- 10

4.1 Specifications for Input Adapters ............................................................................................................ 4- 1

4.1.1 AJ65MBTL1N-16D CC-Link embedded input adapter ................................................................... 4- 1

4.1.2 AJ65MBTL1N-32D CC-Link embedded input adapter ................................................................... 4- 3

4.2 Specifications for Output Adapters ......................................................................................................... 4- 5

4.2.1 AJ65MBTL1N-16T CC-Link embedded output adapter ................................................................. 4- 5

4.2.2 AJ65MBTL1N-32T CC-Link embedded output adapter ................................................................. 4- 7

4.3 Specifications for Combined Adapters ................................................................................................... 4- 9

4.3.1 AJ65MBTL1N-16DT CC-Link embedded combined adapter ......................................................... 4- 9

5 HANDLING CC-Link EMBEDDED I/O ADAPTER 5- 1 to 5- 7

5.1 Precautionary Notes for Handling and Installation................................................................................. 5- 1

5.2 Cascading Method .................................................................................................................................. 5- 5

5.3 Connection Method of CC-Link Dedicated Cable.................................................................................. 5- 6

6 TROUBLESHOOTING 6- 1 to 6- 5

6.1 Verifying Errors from LED Status ........................................................................................................... 6- 1

6.2 Examples of Errors for CC-Link Embedded I/O Adapter ....................................................................... 6- 3

6.2.1 Errors occurring in the input circuit and corrective actions .............................................................6- 3

6.2.2 Errors occurring in the output circuit and corrective actions ........................................................... 6- 5

APPENDIX App- 1 to App- 2

Appendix 1 External Dimensions.............................................................................................................App- 1

Appendix 1.1 AJ65MBTL1N-16

Appendix 1.2 AJ65MBTL1N-32

A - 5 A - 5

........................................................................................................App- 1

........................................................................................................App- 2

Page 8

About Manuals

The following manuals are also related to this product.

In necessary, order them by quoting the details in the tables below.

Related Manuals

Manual Name

Control Communication Link System Master/Local Module User's Manual

This manual describes the system configuration, performance specification, function, handling, wiring

and troubleshooting for QJ61BT11 (Sold separately)

Manual Number

(Model Code)

SH-080016

(13JL91)

CC-Link System Master ( Local Module type AJ61BT11/A1SJ61BT11 User's Manual

This manual describes the system configuration, performance specification, function, handling, wiring

and troubleshooting for AJ61BT11 and A1SJ61BT11. (Sold separately)

CC-Link System Master ( Local Module type AJ61QBT11/A1SJ61QBT11 User's Manual

This manual describes the system configuration, performance specification, function, handling, wiring

and troubleshooting for AJ61QBT11 and A1SJ61QBT11. (Sold separately)

IB-66721

(13J872)

IB-66722

(13J873)

Conformation to the EMC Directive and Low Voltage Instruction

For details on making Mitsubishi PLC conform to the EMC directive and low voltage instruction when

installing it in your product, please see Chapter 3, "EMC Directive and Low Voltage Instruction" of the PLC

CPU User's Manual (Hardware).

The CE logo is printed on the main body of the PLC that conforms to the EMC directive and low voltage

instruction.

By making this product conform to the EMC directive and low voltage instruction, it is not necessary to make

those steps individually.

A - 6 A - 6

Page 9

A

1 OVERVIEW

MELSEC-

1 OVERVIEW

1.1 Features

This manual describes the specifications of the CC-Link embedded I/O adapter used

as the remote I/O station of a Control & Communication Link (hereafter abbreviated to

CC-Link) system.

The following are the features of the CC-Link embedded I/O adapter.

(1) Device-embedded CC-Link remote I/O

This adapter is a modular remote I/O used as a device-embedded adapter.

(2) Direct installation to user board

Using a pin header as the external interface for adapter power supply,

transmission, I/O signals and others, the adapter can be installed directly to a

user board.

(3) Flexible noise reduction measures

Depending on external noise environment, the user board can be equipped with

a noise filter to enhance noise resistance as necessary.

(4) Insulation method

The adapter power supply uses a transformer insulation method and the external

I/O uses a photocoupler insulation method.

(5) Overload protection function, overvoltage protection function and

overheat protection function

The transistor output section has the overload, overvoltage and overheat

protection functions.

(6) Cascade connection

The CC-Link embedded I/O adapters can be cascaded. Two CC-Link embedded

I/O adapters can be installed side by side within the same board.

1

User board

(7) CC-Link Ver. 1.10 compatibility

The CC-Link embedded I/O adapter is compatible with CC-Link Ver. 1.10.

1 - 1 1 - 1

DA

DB

DG

SLD

Page 10

A

1 OVERVIEW

1.2 Identifying the Compact CC-Link Embedded I/O Adapter Type

MELSEC-

1

The following shows how to identify the type of a CC-Link embedded I/O adapter.

AJ65MBTL1N-16DT

D

: 24VDC input

T

: Transistor output

DT

: 24VDC input, transistor output complex

16: 16 points

32: 32 points

1 - 2 1 - 2

Page 11

A

1 OVERVIEW

1.3 Cautionary Notes when Selecting a CC-Link Embedded I/O Adapter

The following explains the cautionary notes and specifications that apply when

selecting a CC-Link embedded I/O adapter for use in the CC-Link system:

(1) This is a embedded I/O adapter designed specifically for the CC-Link system.

Do not connect the adapter to other data-link systems, such as the

MELSECNET/MINI.

(2) 32 points are assigned per station for a CC-Link embedded I/O adapter.

The second-half 16 points of a 16-point CC-Link embedded I/O adapter are empty

but are not usable.

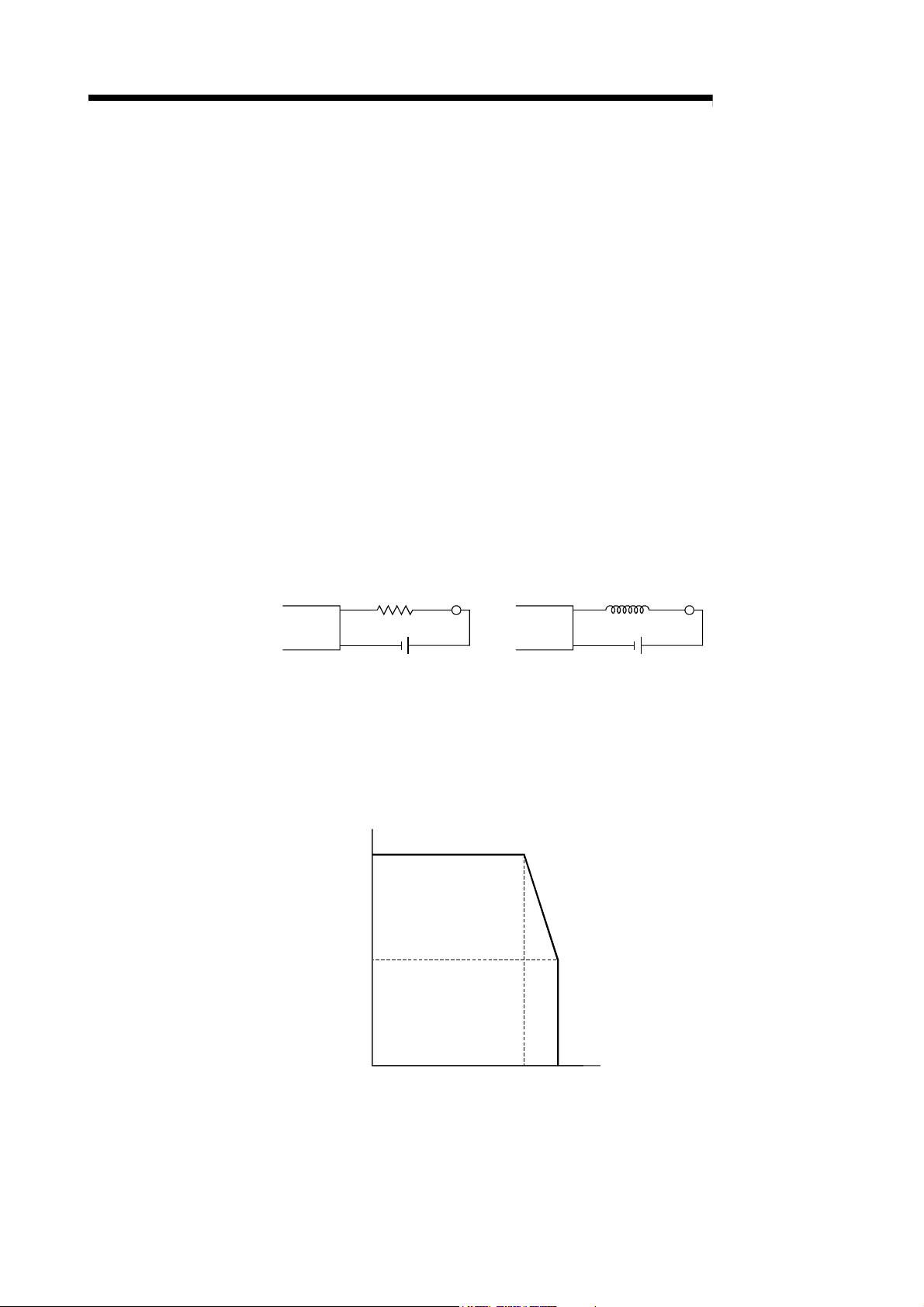

(3) For the maximum switching frequency when driving a load in the CC-Link

embedded output adapter, set to one second or more each for ON and OFF.

(4) When using a counter, a timer or the like that uses a DC/DC converter as the load

for a CC-Link embedded transistor output adapter having a maximum load current

of 0.1A, a rush current flows when the adapter is turned on and at fixed intervals

during operation. For this reason, malfunctions may occur if the average current

is set. When the above load is used, connect resistance or inductance in parallel

to the load, or use an output adapter having a large maximum load current in

order to minimize the effects of the rush current.

Resistance Load

Output

adapter

Output

adapter

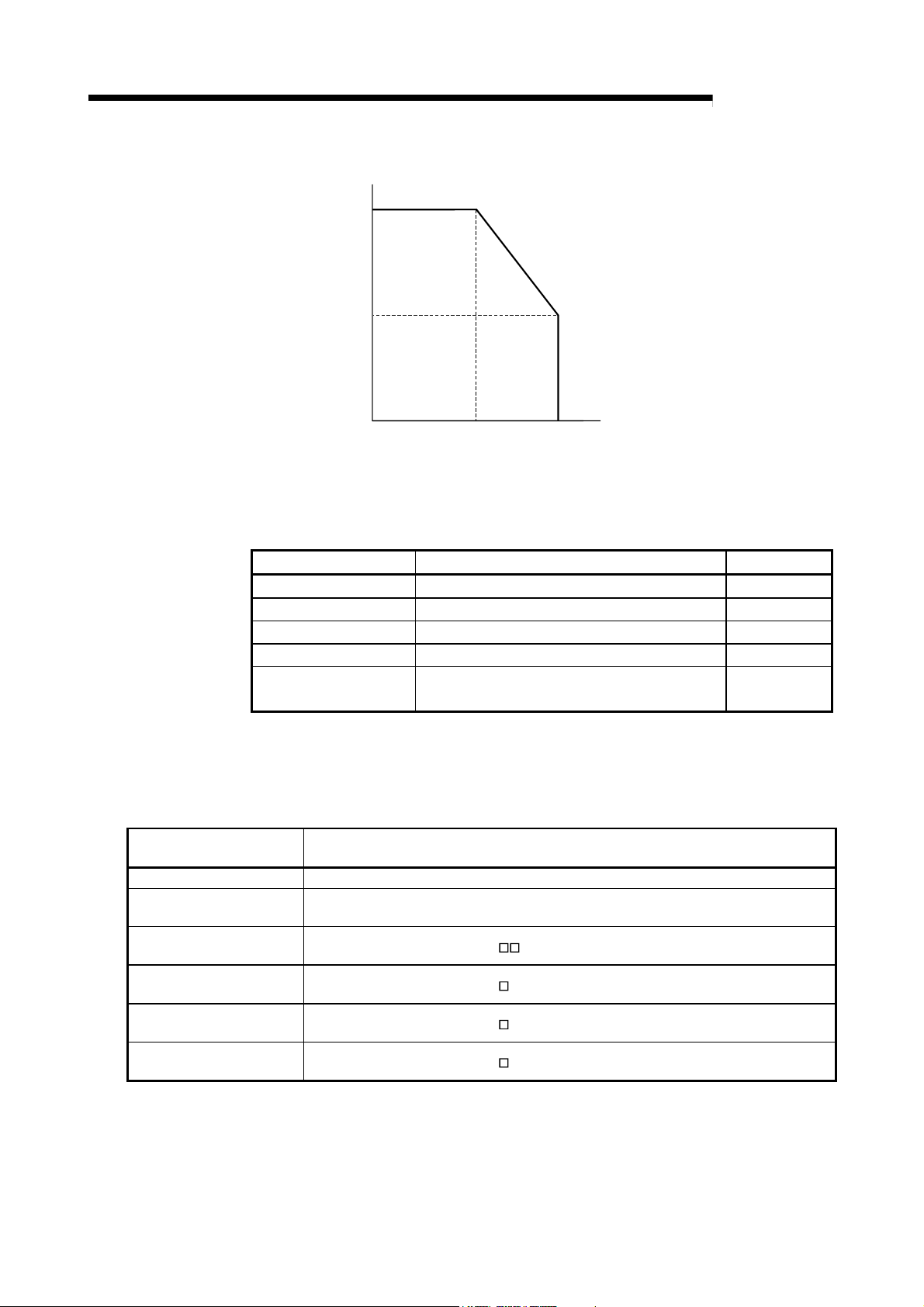

(5) When using the AJ65MBTL1N-16D, AJ65MBTL1N-16DT or AJ65MBTL1N-32D

CC-Link embedded I/O adapter, the maximum number of simultaneous input

points listed in the specifications will change, depending on the ambient

temperature.

The maximum number of simultaneous input points is shown in the diagram

below:

(a) Dilating curve for the AJ65MBTL1N-16D or AJ65MBTL1N-16DT

]

[%]

%

[

s

t

100

n

i

o

p

t

u

p

n

i

s

u

o

e

n

a

t

l

u

50

m

i

s

f

o

r

e

b

m

u

n

m

u

m

i

x

a

010203040 55

M

Ambient temperature [°C]

45

[°C]

LoadInductance

MELSEC-

1 - 3 1 - 3

Page 12

A

1 OVERVIEW

1.4 Specification List

(b) Dilating curve for the AJ65MBTL1N-32D

]

[%]

%

[

s

t

100

n

i

o

p

t

u

p

n

i

s

u

o

e

n

a

t

l

u

50

m

i

s

f

o

r

e

b

m

u

n

m

u

m

i

x

a

010203040 55

M

Ambient temperature [°C]

50

[°C]

MELSEC-

Specification list for each compact remote I/O adapter is shown below.

Model Specification Reference

AJ65MBTL1N-16D 16 points 24VDC positive common (sink) input Section 4.1.1

AJ65MBTL1N-32D 32 points 24VDC positive common (sink) input Section 4.1.2

AJ65MBTL1N-16T 16 points transistor output 0.1A sink output Section 4.2.1

AJ65MBTL1N-32T 32 points transistor output 0.1A sink output Section 4.2.2

AJ65MBTL1N-16DT

8 points 24VDC positive common (sink) input,

8 points transistor output 0.1A sink output.

1.5 About the Generic, Abbreviated and Technical Terms Used in This Manual

Generic/abbreviated/

technical term

CC-Link Abbreviation of Control & Communications Link

Master/local module

CC-Link embedded I/O

adapter

CC-Link embedded input

adapter

CC-Link embedded output

adapter

CC-Link embedded combined

adapter

The abbreviated and technical terms used in this manual are listed below:

Description

Generic term for the QJ61BT11, AJ61BT11, A1SJ61BT11, AJ61QBT11 and A1SJ61QBT11 CC-

Link system master/local module

Generic term for the AJ65MBTL1N-

Generic term for the AJ65MBTL1N-

Generic term for the AJ65MBTL1N-

Generic term for the AJ65MBTL1N-

CC-Link embedded I/O adapter

D CC-Link embedded input adapter

T CC-Link embedded output adapter

DT CC-Link embedded combined adapter

Section 4.3.1

1 - 4 1 - 4

Page 13

A

1 OVERVIEW

MEMO

MELSEC-

1 - 5 1 - 5

Page 14

A

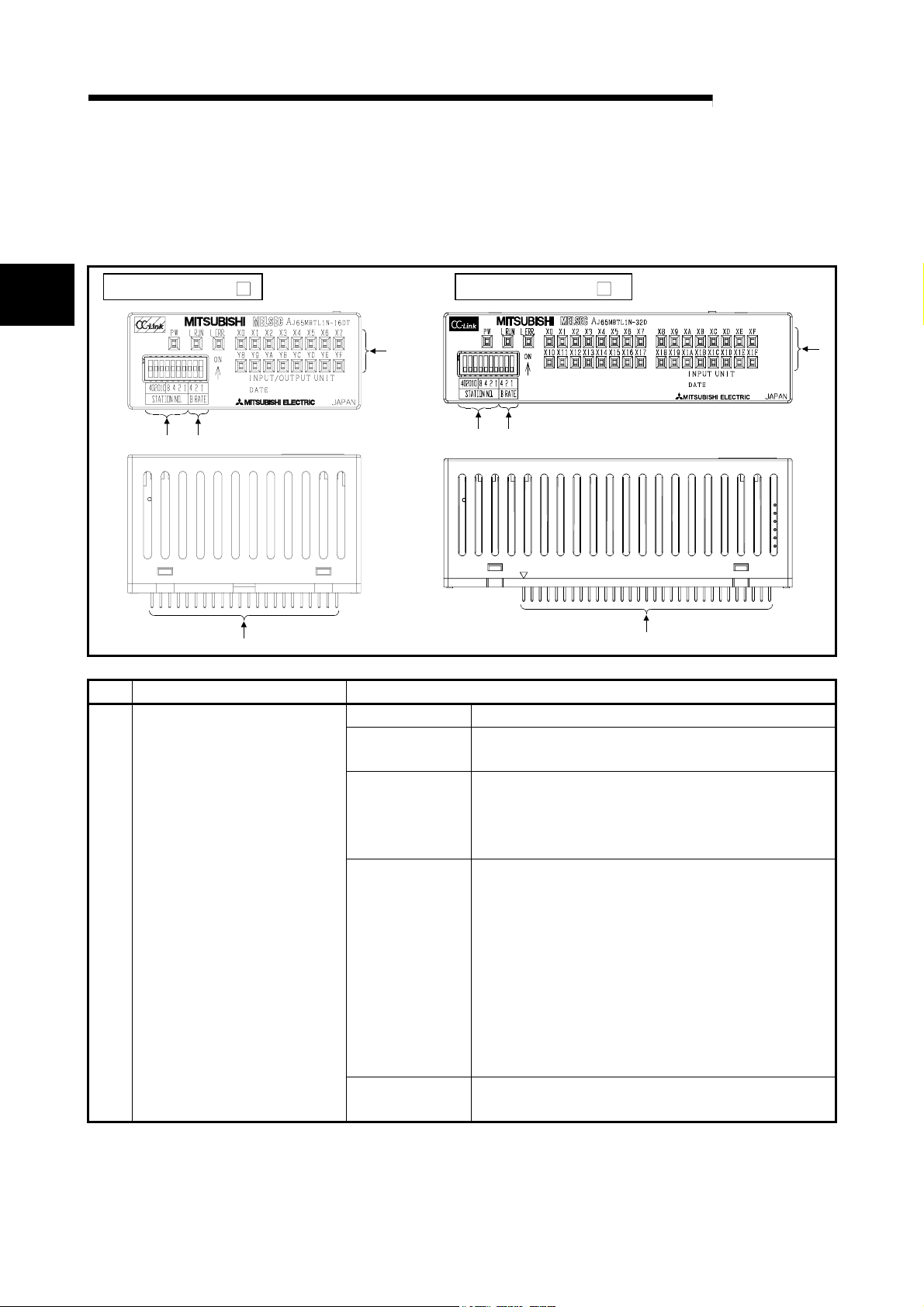

2 NAMES AND SETTINGS FOR EACH PART

2 NAMES AND SETTINGS FOR EACH PART

MELSEC-

2

AJ65MBTL1N-16

The names and settings for the component of the CC-Link embedded I/O adapter are

shown below.

AJ65MBTL1N-32

1)

3) 2)

3) 2)

4)

No. Item Description

1) Operating status indicator LEDs

X0 to XF/X0 to X1F

Y0 to YF/Y0 to Y1F

LED name Confirmation details

PW

L RUN

L ERR

Turns on when power supply of CC-Link embedded I/O

adapter is turned on.

Checks if the input adapter is communicating with the

master station of CC-Link embedded I/O adapter normally.

Turns on when normal data is received from master

station, and turns off when time has expired.

On: Communication data error.

Flicker at regular intervals:

Indicates that the station number setting or

transmission speed setting switch position was

changed while power is on.

Flicker at irregular intervals:

Indicates that the terminal resistor is left unconnected

or that the CC-Link embedded I/O adapter or CC-Link

dedicated cable is affected by noise.

Off: Normal communication.

Shows on/off status of I/O.

Lit when on, unlit when off.

4)

1)

2 - 1 2 - 1

Page 15

A

2 NAMES AND SETTINGS FOR EACH PART

MELSEC-

No. Item Description

2) Transmission speed setting

Setting switch status

0 OFF OFF OFF 156 kbps

1 OFF OFF ON 625 kbps

2 OFF ON OFF 2.5 Mbps

3 OFF ON ON 5.0 Mbps

4 ON OFF OFF 10 Mbps

Setting value

4 2 1

Transmission

speed

Be sure to set the transmission speed within the above range.

3) Station number setting switches

Select "10," "20" or "40" to set the ten's place of the station number.

Select "1," "2," "4" or "8" to set the one's place of the station number.

Always set the station number within the range of 1 to 64.

1 Duplicate station number cannot be set.

(Example) Set the switches as below when setting the station number to 32:

number

1 OFF OFF OFF OFF OFF OFF ON

2 OFF OFF OFF OFF OFF ON OFF

3 OFF OFF OFF OFF OFF ON

4 OFF OFF OFF OFF OFF OFF OFF

: : : : : : : :

10 OFF OFF ON OFF OFF OFF OFF

11 OFF OFF ON OFF OFF OFF ON

: : : : : : : :

64 ON ON OFF OFF ON OFF OFF

number

32 OFF ON ON OFF OFF ON OFF

Ten's place One's place Station

40 20 10 8 4 2 1

Ten's place One's place Station

40 20 10 8 4 2 1

4) External I/F pin header Pin header for connection of the adapter power supply, communication line,

I/O power supply, external supply power, and input/output signals (refer to

Chapter 4 for the pin numbers.)

2

2 - 2 2 - 2

Page 16

A

3 SPECIFICATIONS

3 SPECIFICATIONS

MELSEC-

Item Specifications

Operating ambient

temperature

Storage ambient

temperature

Operating ambient

humidity

3

Storage ambient

humidity

Vibration

resistance

Shock resistance

Operating

environment

Operating height

Installation area On the control board

Over-voltage

category 1

Pollution rate 2

This section explains the CC-Link embedded I/O adapter general specifications.

Table 3.1 General specifications

-20 to 75 °C

10 to 90 % RH, No condensation

10 to 90 % RH, No condensation

Frequency Acceleration Amplitude Sweep Count

Conforming

to JIS B

3502, IEC

61132-2

Conforming to JIS B 3502, IEC 61131-2 (147 m/s

intermittent

vibration

When there is

continuous

vibration

10 to 57 Hz — 0.075 mm When there is

57 to 150 Hz

10 to 57 Hz — 0.035 mm

57 to 150 Hz

No corrosive gas present

2000 m(6562 ft) or less 3

1 Indicates the location where the device is connected from the public cable network to the

device structure wiring area.

Category II applies to the devices to which the power is supplied from a fixed equipment.

Surge withstand voltage for devices with up to 300 V of rated voltage is 2500 V.

2 This is an index which indicates the degree of conductive object generation in the

environment Pollution level 2 is when only non-conductive pollution occurs.

A temporary conductivity caused by condensation must be expected occasionally.

3 Do not use or store the PLC in the environment where the pressure is higher than the

atmospheric pressure at sea level. Otherwise, malfunction may result. To use the PLC in

high-pressure environment, contact your nearest Mitsubishi representative.

0 to 55 °C

II or less

2 or less

2

9.8 m/s

4.9 m/s

2

2

, 3 times each in 3 directions)

—

—

10 times

each in X, Y

and Z axis

(80 minutes)

3 - 1 3 - 1

Page 17

A

3 SPECIFICATIONS

MELSEC-

MEMO

3

3 - 2 3 - 2

Page 18

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

4.1 Specifications for Input Adapters

4.1.1 AJ65MBTL1N-16D CC-Link embedded input adapter

MELSEC-

Specification AJ65MBTL1N-16D Surface shape

Number of input points 16 points

Isolation method Photocoupler

Rated input voltage 24V DC

Rated input current Approx. 4mA

Operating voltage range 19.2 to 26.4V DC

Max. simultaneous ON

input points

ON voltage/ON current 18V or higher/3.5mA or higher

OFF voltage/OFF current 6V or lower/1.7mA or lower

4

Input resistance Approx. 5.1kΩ

Response OFF ON 1.5ms or lower (at 24V DC)

time ON OFF 1.5ms or lower (at 24V DC)

Input type Positive common (sink)

Wiring method for common 16 points/1 common

CC-Link station type Remote I/O station

Number of occupied stations 1 station 32 points assignment (use 16 points)

I/O adapter Voltage 20.4 to 26.4V DC (ripple rate: within 5%)

power supply Current 35mA or lower (at 24V DC)

Noise durability DC type noise voltage 500Vp-p, noise width 1μs, noise carrier

Dielectric withstand voltage 500V AC for 1 minute between all DC external terminals and

Insulation resistance 10MΩ or higher, measured with a 500V DC insulation resistance

Weight 0.03kg

External wiring system 44-pin, 2-row, 2mm-pitch pin header

Form DC input adapter

(ripple ratio: within 5%)

50% (See section 1.3)

frequency 25 to 60Hz (noise simulator condition)

ground

tester

4 - 1 4 - 1

Page 19

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

MELSEC-

Adapter power supply

24V DC

Signal

name

DA

DB

DG

SLD

X0

X1

X2

X3

X4

X5

X6

X7

X8

X9

XA

XB

XC

XD

XE

XF

COM

+24V

24G

FG

Circuit board

1

22000pF

630V

External connection

Singnal

Pin No.

name

B22

DA

DB

A22

DG

B21

FG

A21

OE-OUT

B20

OE-IN

A20

SD-OUT

B19

SD-IN

A19

RD

B18

RDGON

A18

B17

A17

B16

A16

B15

A15

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

B09

A09

B08

A08

B07

A07

B06

A06

B05

A05

B04

A04

B03

A03

B02

A02

B01

A01

Empty

GND

Empty

Empty

Empty

Empty

X0

X1

X2

X3

X4

X5

X6

X7

X8

X9

XA

XB

XC

XD

XE

XF

COM

COM

Empty

Empty

Empty

Empty

Empty

Empty

+24V

+24V

24G

24G

2

AJ65MBTL1N-16D

Link

IC

R

R

DC/DC

To G/A

To G/A

To G/A

R

R

Insulation

Pin No.

B22 DA A22 DB

B21 DG A21 FG

B20 OE-OUT A20 OE-IN

B19 SD-OUT A19 SD-IN

B18 RD A18 RDGON

B17 Empty A17 GND

B16 Empty A16 Empty

B15 Empty A15 Empty

B14 X0 A14 X1

B13 X2 A13 X3

B12 X4 A12 X5

B11 X6 A11 X7

B10 X8 A10 X9

B09 XA A09 XB

B08 XC A08 XD

B07 XE A07 XF

B06 COM A06 COM

B05 Empty A05 Empty

B04 Empty A04 Empty

B03 Empty A03 Empty

B02 + 24V A02 + 24V

B01 24G A01 24G

1: Add circuit for noise reduction capability.

(Refer to Section 5.1 for details.)

2: Connect A17 and A18 when the adapters

are not cascaded.

Signal

name

Pin No.

Signal

name

4

4 - 2 4 - 2

Page 20

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

MELSEC-

4.1.2 AJ65MBTL1N-32D CC-Link embedded input adapter

Form DC input adapter

Specification AJ65MBTL1N-32D Surface shape

Number of input points 32 points

Isolation method Photocoupler

Rated input voltage 24V DC

Rated input current Approx. 4mA

Operating voltage range 19.2 to 26.4V DC

Max. simultaneous ON

input points

ON voltage/ON current 18V or higher/3.5mA or higher

OFF voltage/OFF current 6V or lower/1.7mA or lower

Input resistance Approx. 5.1kΩ

Response OFF ON 1.5ms or lower (at 24V DC)

time ON OFF 1.5ms or lower (at 24V DC)

Input type Positive common (sink)

Wiring method for common 32 points/1 common

CC-Link station type Remote I/O station

Number of occupied stations 1 station 32 points assignment (use 32 points)

I/O adapter Voltage 20.4 to 26.4V DC (ripple rate: within 5%)

power supply Current 45mA or lower (at 24V DC)

Noise durability DC type noise voltage 500Vp-p, noise width 1μs, noise carrier

frequency 25 to 60Hz (noise simulator condition)

Dielectric withstand voltage 500V AC for 1 minute between all DC external terminals and

ground

Insulation resistance 10MΩ or higher, measured with a 500V DC insulation resistance

tester

Weight 0.04kg

External wiring system 62-pin, 2-row, 2mm-pitch pin header

(ripple ratio: within 5%)

50% (See section 1.3)

4 - 3 4 - 3

Page 21

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

External connection

24V DC

Adapter power supply

Signal

name

DA

DB

DG

SLD

X0

X1

X2

X3

X4

X5

X6

X7

X8

X9

XA

XB

XC

XD

XE

XF

X10

X11

X12

X13

X14

X15

X16

X17

X18

X19

X1A

X1B

X1C

X1D

X1E

X1F

COM

COM

+24V

24G

FG

Circuit board

2

22000pF

630V

1

Pin No.

B31

A31

B30

A30

B29

A29

B28

A28

B27

A27

B26

A26

B25

A25

B24

A24

B23

A23

B22

A22

B21

A21

B20

A20

B19

A19

B18

A18

B17

A17

B16

A16

B15

A15

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

B09

A09

B08

A08

B07

A07

B06

A06

B05

A05

B04

A04

B03

A03

B02

A02

B01

A01

Signal

name

DA

DB

DG

FG

OE-OUT

OE-IN

SD-OUT

SD-IN

RD

RDGON

Empty

GND

Empty

Empty

Empty

Empty

X0

X1

X2

X3

X4

X5

X6

X7

X8

X9

XA

XB

XC

XD

XE

XF

X10

X11

X12

X13

X14

X15

X16

X17

X18

X19

X1A

X1B

X1C

X1D

X1E

X1F

COM

COM

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

+24V

+24V

24G

24G

Link

IC

AJ65MBTL1N-32D

R

R

R

R

Insulation

DC/DC

To G/A

To G/A

To G/A

Pin No.

B31 DA A31 DB

B30 DG A30 FG

B29 OE-OUT A29 OE-IN

B28 SD-OUT A28 SD-IN

B27 RD A27 RDGON

B26 Empty A26 GND

B25 Empty A25 Empty

B24 Empty A24 Empty

B23 X0 A23 X1

B22 X2 A22 X3

B21 X4 A21 X5

B20 X6 A20 X7

B19 X8 A19 X9

B18 XA A18 XB

B17 XC A17 XD

B16 XE A16 XF

B15 X10 A15 X11

B14 X12 A14 X13

B13 X14 A13 X15

B12 X16 A12 X17

B11 X18 A11 X19

B10 X1A A10 X1B

B09 X1C A09 X1D

B08 X1E A08 X1F

B07 COM A07 COM

B06 Empty A06 Empty

B05 Empty A05 Empty

B04 Empty A04 Empty

B03 Empty A03 Empty

B02 +24V A02 +24V

B01 24G A01 24G

1: Add circuit for noise reduction capability.

(Refer to secton 5.1 for details.)

2: Connect A26 and A27 when the adapters

are not cascaded.

Signal

name

MELSEC-

Pin No.

Signal

name

4 - 4 4 - 4

Page 22

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

4.2 Specifications for Output Adapters

4.2.1 AJ65MBTL1N-16T CC-Link embedded output adapter

MELSEC-

Form Transistor output adapter

Specification AJ65MBTL1N-16T

Number of output points 16 points

Isolation method Photocoupler

Rated load voltage 12/24V DC

Operating load voltage

range

Max. load current 0.1A/point, 1.6A/1 common

Max. inrush current 0.7A 10ms or lower

Leakage current at OFF 0.1mA or lower

Max. voltage drop at ON 0.1V or lower (TYP) 0.1A

Output method Sink type

Protection functions Overload, over-voltage and overheat protection

Response OFF ON 1ms or lower

time ON OFF 1ms or lower (rated load, resistive load)

External Voltage 10.2 to 26.4V DC (ripple ratio: within 5%)

Power supply

for output

Surge suppression Zener diode

Wiring method for common 16 points/1 common

CC-Link station type Remote I/O station

Number of occupied

stations

I/O adapter Voltage 20.4 to 26.4V DC (ripple ratio: within 5%)

power suppl y Current 50mA or lower (When all points are ON at 24V DC)

Noise durability DC type noise voltage 500Vp-p, noise width 1μs, noise carrier

Dielectric withstand voltage 500V AC for 1 minute between all DC external terminals and

Insulation resistance 10MΩ or higher, measured with a 500V DC insulation resistance

Weight 0.03kg

External wiring system 44-pin, 2-row, 2mm-pitch pin header

Current 10mA or lower (When all points are ON at 24V DC)

frequency 25 to 60Hz (noise simulator condition)

ground

tester

10.2 to 26.4V DC (ripple ratio: within 5%)

0.2V or lower (MA X) 0.1A

Not including external load current

1 station 32 points assignment

(use 16 points)

Surface shape

4 - 5 4 - 5

Page 23

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

External connection

12/24V DC

Adapter power supply

Circuit board

1

22000pF

630V

Singnal

Pin No.

name

B22

DA

DB

A22

DG

B21

FG

A21

OE-OUT

B20

OE-IN

A20

SD-OUT

B19

SD-IN

A19

RD

B18

RDGON

A18

2

B17

A17

B16

A16

B15

A15

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

B09

A09

B08

A08

B07

A07

B06

A06

B05

A05

B04

A04

B03

A03

B02

A02

B01

A01

Empty

GND

Empty

Empty

Empty

Empty

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

Y9

YA

YB

YC

YD

YE

YF

CTL+

CTL+

COM-

COM-

Empty

Empty

Empty

Empty

+24V

+24V

24G

24G

Signal

name

DA

DB

DG

SLD

L

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

Y9

YA

YB

YC

YD

YE

L

YF

CTL+

COM-

+24V

24G

FG

AJ65MBTL1N-16T

Link

IC

Constant

voltage

circuit

DC/DC

Insulation

To G/A

To G/A

To G/A

Pin No.

B22 DA A22 DB

B21 DG A21 FG

B20 OE-OUT A20 OE-IN

B19 SD-OUT A19 SD-IN

B18 RD A18 RDGON

B17 Empty A17 GND

B16 Empty A16 Empty

B15 Empty A15 Empty

B14 Y0 A14 Y1

B13 Y2 A13 Y3

B12 Y4 A12 Y5

B11 Y6 A11 Y7

B10 Y8 A10 Y9

B09 YA A09 YB

B08 YC A08 YD

B07 YE A07 YF

B06 CTL+ A06 CTL+

B05 COM- A05 COM-

B04 Empty A04 Empty

B03 Empty A03 Empty

B02 + 24V A02 + 24V

B01 24G A01 24G

1: Add circuit for noise reduction capability.

(Refer to Section 5.1 for details.)

2: Connect A17 and A18 when the adapters

are not cascaded.

Signal

name

MELSEC-

Pin No.

Signal

name

4 - 6 4 - 6

Page 24

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

4.2.2 AJ65MBTL1N-32T CC-Link embedded output adapter

MELSEC-

Form Transistor output adapter

Specification AJ65MBTL1N-32T

Number of output points 32 points

Isolation method Photocoupler

Rated load voltage 12/24V DC

Operating load voltage

range

Max. load current 0.1A/point, 3.2A/1 common

Max. inrush current 0.7A 10ms or lower

Leakage current at OFF 0.1mA or lower

Max. voltage drop at ON 0.1V or lower (TYP) 0.1A

Output method Sink type

Protection functions Overload, over-voltage and overheat protection

Response OFF ON 1ms or lower

time ON OFF 1ms or lower (rated load, resistive load)

External Voltage 10.2 to 26.4V DC (ripple ratio: within 5%)

Power supply

for output

Surge suppression Zener diode

Wiring method for common 32 points/1 common

CC-Link station type Remote I/O station

Number of occupied

stations

I/O adapter Voltage 20.4 to 26.4V DC (ripple ratio: within 5%)

power suppl y Current 60mA or lower (When all points are ON at 24V DC)

Noise durability DC type noise voltage 500Vp-p, noise width 1μs, noise carrier

Dielectric withstand voltage 500V AC for 1 minute between all DC external terminals and

Insulation resistance 10MΩ or higher, measured with a 500V DC insulation resistance

Weight 0.04kg

External wiring system 62-pin, 2-row, 2mm-pitch pin header

Current 15mA or lower (When all points are ON at 24V DC)

frequency 25 to 60Hz (noise simulator condition)

ground

tester

10.2 to 26.4V DC (ripple ratio: within 5%)

0.2V or lower (MA X) 0.1A

Not including external load current

1 station 32 points assignment

(use 32 points)

Surface shape

4 - 7 4 - 7

Page 25

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

External connection

12/24V DC

Adapter power supply

Circuit board

1

2

22000pF

630V

Pin No.

B31

A31

B30

A30

B29

A29

B28

A28

B27

A27

B26

A26

B25

A25

B24

A24

B23

A23

B22

A22

B21

A21

B20

A20

B19

A19

B18

A18

B17

A17

B16

A16

B15

A15

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

B09

A09

B08

A08

B07

A07

B06

A06

B05

A05

B04

A04

B03

A03

B02

A02

B01

A01

Signal

name

DA

DB

DG

FG

OE-OUT

OE-IN

SD-OUT

SD-IN

RD

RDGON

Empty

GND

Empty

Empty

Empty

Empty

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

Y9

YA

YB

YC

YD

YE

YF

Y10

Y11

Y12

Y13

Y14

Y15

Y16

Y17

Y18

Y19

Y1A

Y1B

Y1C

Y1D

Y1E

Y1F

CTL+

CTL+

COM-

COM-

COM-

COM-

Empty

Empty

Empty

Empty

+24V

+24V

24G

24G

Signal

name

DA

DB

DG

SLD

L

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

Y9

YA

YB

YC

YD

YE

YF

Y10

Y11

Y12

Y13

Y14

Y15

Y16

Y17

Y18

Y19

Y1A

Y1B

Y1C

Y1D

Y1E

L

Y1F

CTL+

CTL+

COM-

COM-

COM-

COM-

+24V

24G

FG

Link

IC

AJ65MBTL1N-32T

Constant

voltage

circuit

DC/DC

Insulation

To G/A

To G/A

To G/A

Pin No.

B31 DA A31 DB

B30 DG A30 FG

B29 OE-OUT A29 OE-IN

B28 SD-OUT A28 SD-IN

B27 RD A27 RDGON

B26 Empty A26 GND

B25 Empty A25 Empty

B24 Empty A24 Empty

B23 Y0 A23 Y1

B22 Y2 A22 Y3

B21 Y4 A21 Y5

B20 Y6 A20 Y7

B19 Y8 A19 Y9

B18 YA A18 YB

B17 YC A17 YD

B16 YE A16 YF

B15 Y10 A15 Y11

B14 Y12 A14 Y13

B13 Y14 A13 Y15

B12 Y16 A12 Y17

B11 Y18 A11 Y19

B10 Y1A A10 Y1B

B09 Y1C A09 Y1D

B08 Y1E A08 Y1F

B07 CTL+ A07 CTL+

B06 COM- A06 COM-

B05 COM- A05 COM-

B04 Empty A04 Empty

B03 Empty A03 Empty

B02 +24V A02 +24V

B01 24G A01 24G

1: Add circuit for noise reduction capability.

(Refer to Section 5.1 for details.)

2: Connect A26 and A27 when the adapters

are not cascaded.

Signal

name

MELSEC-

Pin No.

Signal

name

4 - 8 4 - 8

Page 26

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

MELSEC-

4.3 Specifications for Combined Adapters

4.3.1 AJ65MBTL1N-16DT CC-Link embedded combined adapter

Form DC input transistor output combined adapter

Specification AJ65MBTL1N-16DT Surface shape

Input specification Output specification

Number of input points 8 points Number of output points 8 points

Isolation method Photocoupler Isolation method Photocoupler

Rated input voltage 24V DC Rated load voltage 24V DC

Rated input current Approx. 7mA

Operating voltage range 19.2 to 26.4V DC

Max. simultaneous input

points

ON voltage/ON current 14V or higher/3.5mA or higher Leakage current at OFF 0.1mA or lower

Input resistance

OFF ON 1.5ms or lower (at 24V DC) OFF ON 1ms or lower Response time

OFF

ON

Input type Positive common (Sink type) Surge suppression Zener diode

Wiring method for common 16 points/1 common

CC-Link station type Remote I/O station

Number of occupied stations 1 station 32 points assignment (use 16 points)

I/O adapter Voltage 20.4 to 26.4V DC(ripple ratio: within 5%)

power suppl y Current 50mA or lower (when all points are ON at 24V DC) Not including external load current

Noise durability DC type noise voltage 500Vp-p, noise width 1μs, noise carrier frequency 25 to 60Hz(noise

Dielectric withstand voltage 500V AC for 1 minute between all DC external terminals and ground

Insulation resistance 10MΩ or higher, measured with a 500V DC insulation resistance tester between all DC external

Weight 0.03kg

External wiring system 44-pin, 2-row, 2mm-pitch pin header

(ripple ratio: within 5%)

50% (See section 1.3)

6V or lower/1.7mA or lower

A pprox. 3.3k Ω

1.5ms or lower (at 24V DC)

simulator condition)

terminals and ground

Operating load voltage range

Max. load current 0.1A/point

Max. inrush current

Max. voltage drop at ON

Output type

Protection functions Overload, over-voltage and overheat

Response

time

External Voltage

Power supply

for output

ON OFF 1ms or lower

Current 5mA or lower

19.2

to 26.4V DC(ripple ratio: within 5%)

0.8A/common

0.7A 10ms or lower

0.1V or lower (TYP)0.1A OFF voltage/OFF current

0.2V or lower (MA X)0.1A

Sink type

protection

(rated load, resistive load)

19.2 to 26.4V DC (ripple ratio: within 5 %)

(When all points are ON at 24V DC)

Not including external load current

4 - 9 4 - 9

Page 27

A

4 SPECIFICATIONS FOR CC-LINK EMBEDDED I/O ADAPTER

External connection

24V DC

Adapter power supply

Circuit board

1

22000pF

630V

Singnal

Pin No.

name

B22

DA

DB

A22

DG

B21

FG

A21

OE-OUT

B20

OE-IN

A20

SD-OUT

B19

SD-IN

A19

RD

B18

RDGON

A18

2

B17

A17

B16

A16

B15

A15

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

B09

A09

B08

A08

B07

A07

B06

A06

B05

A05

B04

A04

B03

A03

B02

A02

B01

A01

Empty

GND

Empty

Empty

Empty

Empty

X0

X1

X2

X3

X4

X5

X6

X7

Y8

Y9

YA

YB

YC

YD

YE

YF

24V DC

24V DC

24G DC

24G DC

Empty

Empty

Empty

Empty

+24V

+24V

24G

24G

AJ65MBTL1N-16DT

Link

IC

Constant

voltage

circuit

R

R

DC/DC

R

R

Insulation

To G/A

To G/A

To G/A

Signal

name

DA

DB

DG

SLD

X0

X1

X2

X3

X4

X5

X6

X7

L

Y8

Y9

YA

YB

YC

YD

YE

L

YF

24V DC

24G DC

+24V

24G

FG

Pin No.

B22 DA A22 DB

B21 DG A21 FG

B20 OE-OUT A20 OE-IN

B19 SD-OUT A19 SD-IN

B18 RD A18 RDGON

B17 Empty A17 GND

B16 Empty A16 Empty

B15 Empty A15 Empty

B14 X0 A14 X1

B13 X2 A13 X3

B12 X4 A12 X5

B11 X6 A11 X7

B10 Y8 A10 Y9

B09 YA A09 YB

B08 YC A08 YD

B07 YE A07 YF

B06 24V DC A06 24V DC

B05 24G DC A05 24G DC

B04 Empty A04 Empty

B03 Empty A03 Empty

B02 + 24V A02 + 24V

B01 24G A01 24G

1: Add circuit for noise reduction capability.

(Refer to Section 5.1 for details.)

2: Connect A17 and A18 when the adapters

are not cascaded.

Signal

name

MELSEC-

Pin No.

Signal

name

4 - 10 4 - 10

Page 28

A

5 HANDLING CC-LINK EMBEDDED I/O ADAPTER

5 HANDLING CC-Link EMBEDDED I/O ADAPTER

5.1 Precautionary Notes for Handling and Installation

MELSEC-

5

DANGER

CAUTION

The precautionary notes when handling and installing the CC-Link embedded I/O

adapter for the CC-Link system are described below.

• Do not touch the terminals or connector while the power is on.

Doing so may cause electric shock or malfunction.

• Make sure that there are no foreign substances such as sawdust or wiring debris

inside the CC-Link embedded I/O adapter.

Such debris could cause fire, failure or malfunction.

• Do not disassemble or modify the CC-Link embedded I/O adapter.

Doing so could cause failure, malfunction, injury or fire.

• Do not directly touch the CC-Link embedded I/O adapter's conductive parts.

Doing so could cause malfunction or failure in the CC-Link embedded I/O adapter.

• Because the case of the CC-Link embedded I/O adapter is made of resin, be careful

not to drop it or expose it to strong impact.

It may damage the CC-link embedded I/O adapter.

• When disposing of this product, treat it as industrial waste.

• Use the CC-Link embedded I/O adapter in an environment that meets the general

specifications contained in this manual.

Using this adapter in an environment outside the range of the general specifications

could result in electric shock, fire, malfunction, and damage to or deterioration of the

product.

• Before mounting or dismounting the user board loaded with the CC-Link embedded

I/O adapter to or from an enclosure, always switch power off externally in all

phases.

Failure to do so may damage the CC-Link embedded I/O adapter or cause

malfunction.

(1) Restrictions on close installation

Because of heat generation, do not install the CC-Link embedded I/O adapters

closely to each other.

Install the CC-Link embedded I/O adapters at least 5mm away from each other.

User board

5mm or more

5 - 1 5 - 1

Page 29

A

5 HANDLING CC-LINK EMBEDDED I/O ADAPTER

(2) Precautions for external wiring

Adapter power supply

Note the following when designing the user board side circuit and board patterns.

1) Use a user board of 1.6mm thickness.

2) When the noise immunity must be increased, insert a noise filter (FDK

make: NFR5UI203MB or equivalent) and Y capacitor (22000pF 630V) in the

adapter power supply line.

3) Connect the transmission SLD and FG within the board.

As a pattern, connect SLD and FG as near as possible to the external I/O

terminals.

4) Make the transmission patterns (DA, DB) as short as possible.

Design the patterns so that the capacitance is 20pF or less with the CC-Link

embedded I/O adapter mounted on the board. (Guidelines: Pattern length

5cm or less, pattern width 0.18mm or less)

5) Since the cascade communication signal pins (16-point adapter: A17 to A20

pins and B17 to B20 pins, 32-point adapter: A26 to A29 pins and B26 to B29

pins) are susceptible to noise, keep them as far away as possible from the

other patterns (power supply, I/O signal) that include noise.

6) When the adapters are not cascaded, always connect GND and RDGON

(16-point adapter: A17 pin and A18 pin, 32-point adapter: A26 pin and A27

pin) on the board side.

7) Wire the FG pattern so that it does not cross the I/O patterns on the front

and back sides of the board.

Doing so makes the adapter sensitive to noise.

(Example: AJ65MBTL1N-16DT)

1)

Pin No.

B22

A22

B21

A21

B20

A20

B19

A19

5)

B18

A18

6)

B17

A17

B16

A16

B15

A15

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

B09

A09

B08

A08

B07

A07

B06

A06

B05

A05

B04

A04

630V

B03

A03

B02

A02

B01

A01

22000pF

2)

24V DC

Signal

4)

name

DA

DB

DG

SLD

X0

X1

X2

X3

X4

X5

X6

X7

L

Y8

Y9

YA

YB

YC

YD

YE

L

YF

24V DC

24G DC

+24V

24G

FG

7)

3)

Singnal

name

DA

DB

DG

FG

OE-OUT

OE-IN

SD-OUT

SD-IN

RD

RDGON

Empty

GND

Empty

Empty

Empty

Empty

X0

X1

X2

X3

X4

X5

X6

X7

Y8

Y9

YA

YB

YC

YD

YE

YF

24V DC

24V DC

24G DC

24G DC

Empty

Empty

Empty

Empty

+24V

+24V

24G

24G

Link

IC

AJ65MBTL1N-16DTUser board

Constant

voltage

circuit

R

R

DC/DC

R

R

Insulation

To G/A

To G/A

To G/A

MELSEC-

5

5 - 2 5 - 2

Page 30

A

5 HANDLING CC-LINK EMBEDDED I/O ADAPTER

[Board pattern example]

(top view)

AJ65MBTL1N-16DT

MELSEC-

DA

DB

DG

SLD

FG

+24V

24G

Adapter power supply

B22 A22

B01 A01

I/O connector

I/O power supply

24VDC

24GDC

: When using a multi-layer board, eliminate the inner layers to prevent the

capacitance between DA and DB from increasing.

(3) Precautions for soldering

Note the following when soldering the CC-Link embedded I/O adapter to the user

board.

(a) Before soldering, do not store the CC-Link embedded I/O adapter in dusty,

gas-corrosive or similar environment that may deteriorate the solderability of

the adapter pins.

(b) Do not touch the pins of the CC-Link embedded I/O adapter directly.

Doing so can cause the deterioration of solderability.

(c) Do not bend or cut the pins of the CC-Link embedded I/O adapter.

In addition, do not use the CC-Link embedded I/O adapter that has been

dropped, impacted and/or stressed.

Doing so can cause a malfunction or like.

(d) Do not clean the adapter before and after soldering work.

(e) Do not use corrosive flux, e.g. acid or alkali.

(f) Carry out hand soldering or post soldering.

Do not perform flow soldering.

5 - 3 5 - 3

Page 31

A

5 HANDLING CC-LINK EMBEDDED I/O ADAPTER

(4) Precautions for T-branch system configuration

When configuring a T-branch system, use any of the following CC-Link master

modules.

Module type Hardware version

QJ61BT11 All versions usable

AJ61BT11 D or later

AJ61QBT11 D or later

A1SJ61BT11 E or later

A1SJ61QBT11 E or later

Confirm the module version as shown below.

Software version

Hardware version

MELSEC-

(5) The overload protection function, overvoltage protection function and overheat

protection function are described below.

• CC-Link embedded I/O adapters with overload protection function, overvoltage

protection function and overheat protection function

CC-Link embedded output adapter

CC-Link embedded combined adapter AJ65MBTL1N-16DT

AJ65MBTL1N-16T, AJ65MBTL1N-32T

Function Description

Common to overload protection

function, overvoltage protection

function and overheat protection

function

Overload protection function 1. The overload protection function is activated in a load condition of 1 A to 3 A per

Overvoltage protection function 1. This function protects elements from an abrupt surge caused when a coil load is

Overheat protection function 1. The overheat protection function works in two-point units.

1. When overcurrent due to an overload continues to exist, this generates heat and the

overheat protection function is activated.

2. These functions are for protecting the adapters' internal elements but not for

external devices.

point.

2. The overload protection function automatically returns to normal operation when the

load drops to the rated value.

used.

(The points are paired as Y0/Y1, Y2/Y3, etc., and the overheat protector is activated

for two points in a pair simultaneously. If the overheat condition is prolonged, the

heat spreads and other overheat protectors may also be activated.)

2. The actual output voltage oscillates in the range of 0 V to the load voltage only if the

output is ON when the overheat protection function was activated. In this case, the

average voltage during oscillation with the load voltage of 24 V is approximately 7 V.

(No oscillation occurs when the output is OFF.)

To ensure that output turns OFF when the overheat protection function is activated,

use an external load that turns OFF at 7 V or more.

3. The overheat protection function automatically returns to normal operation when the

heat drops.

5 - 4 5 - 4

Page 32

A

5 HANDLING CC-LINK EMBEDDED I/O ADAPTER

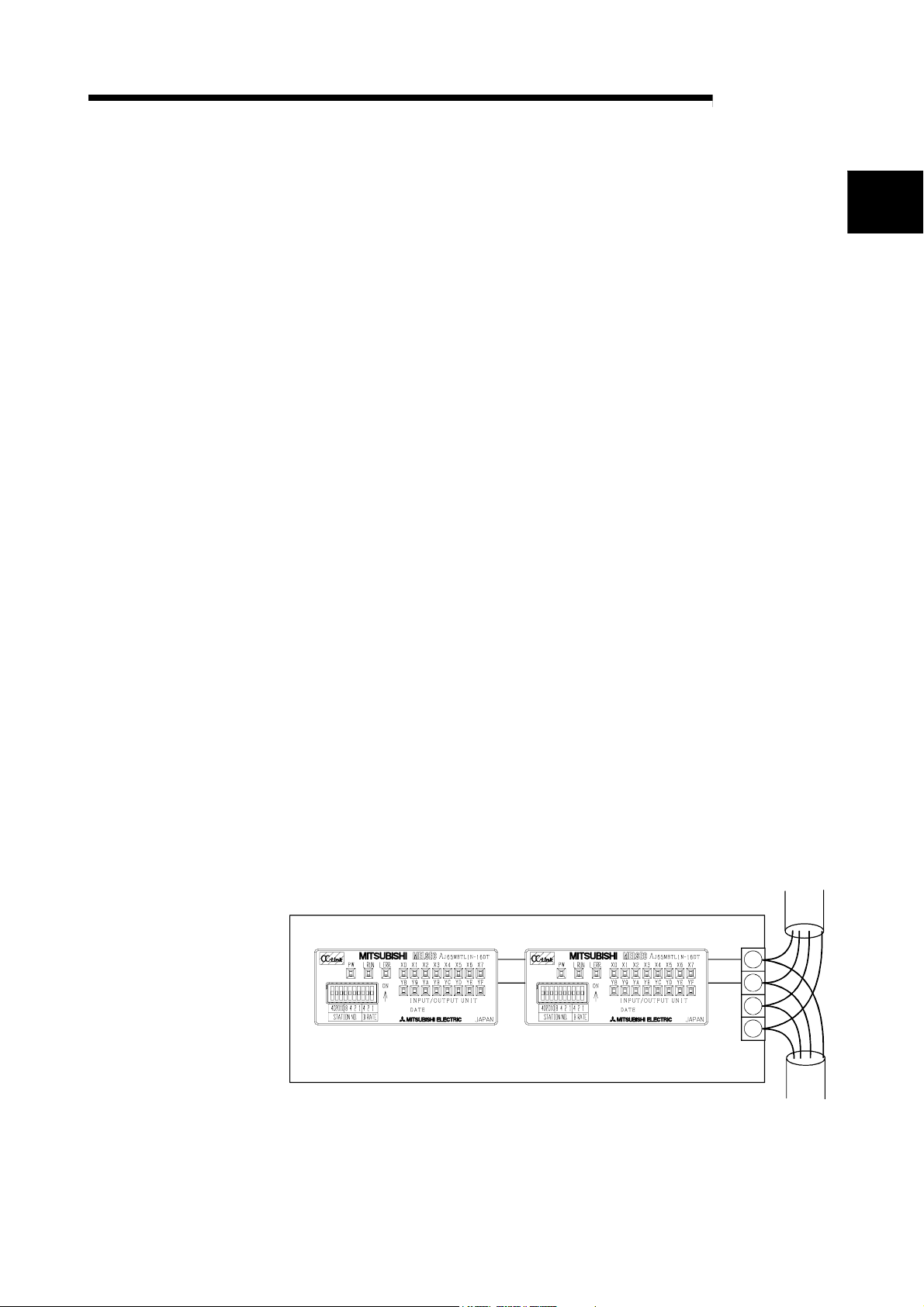

5.2 Cascading Method

The CC-Link embedded I/O adapters can be cascaded. Up to two adapters can be

installed side by side in the same board.

Cascade the adapters as shown below.

The following diagram gives an example of 16-point CC-Link embedded I/O adapters.

Review the pin numbers when 32-point CC-Link embedded I/O adapters are used.

OE-OUT

DA

DB

DG

FG

SD-OUT

OE-IN

SD-IN

RD

OE-IN

SD-IN

RD

POINT

A20

CC-Link enbedded

I/O adapter (2)

A19

B18

A18 A17

RDGON GND

(OPEN)

B20

B22

A22

B21

A21

B19

Since the cascade communication pattern is easily affected by noise, it must be

separated as far away as possible from the other noise-laden patterns (power

supply, I/O signals).

A20

CC-Link enbedded

I/O adapter (1)

A19

B18

A18

RDGON GND

A17

B20

B22

A22

B21

A21

B19

MELSEC-

OE-OUT

DA

DB

DG

FG

SD-OUT

DA

DB

DG

SLD

FG

5 - 5 5 - 5

Page 33

A

5 HANDLING CC-LINK EMBEDDED I/O ADAPTER

5.3 Connection Method of CC-Link Dedicated Cable

The procedure for connecting the master adapter and I/O adapter CC-Link dedicated

cable is shown below.

DANGER

CAUTION

• Before beginning any installation or wiring work, make sure all phases of the power

supply have been obstructed from the outside.

Failure to completely shut off the power supply phases may cause electric shock

and/or damage to the adapter.

• Make sure to switch all phases of the external power supply off before cleaning or

re-tightening the terminal screws.

Failure to do so may damage the CC-Link embedded I/O adapter or cause

malfunction.

• Do not bunch the control wires or communication cables with the main circuit or

power wires, or install them close to each other.

They should be installed 100 mm (3.9 in.) or more from each other.

Not doing so could result in noise that would cause malfunction.

• Always ground the FG terminal to the protective ground conductor.

Doing so may cause electric shock or malfunction.

• Securely solder the CC-link embedded I/O adapter to install it to a user board.

Defective contact could cause malfunction.

• Make sure that the communication cable connected to the adapter is kept in the

duct or fixed with cramps.

Failure to do so may cause a damage to the user board or cables due to dangling,

shifting or inadvertent handling of cables, or misoperation because of bad cable

contacts.

• Do not grab on the cable when removing the communication cable connected to the

adapter.

When removing the cable with a connector, hold the connector on the side that is

connected to the adapter.

When removing the cable without a connector, loose the screws on the side that is

connected to the adapter.

Pulling the cable that is still connected to the adapter may cause a damage to the

user board or cable, or malfunction due to bad cable contacts.

MELSEC-

5 - 6 5 - 6

Page 34

A

5 HANDLING CC-LINK EMBEDDED I/O ADAPTER

Terminal

resistor

(White)

(Yellow)

(1) The procedure for connecting the master module and I/O adapter is shown below:

Master module

NC

DA(Blue)

NC

DB

NC

DG

NC

SLD

NC

FG

User board

DG

SLD FG

User board

MELSEC-

DA DB

DG

SLD FGDA DB

Terminal

resistor

CC-Link dedicated cable

2

1

1 Connect the terminal resistor to the compact remote I/O adapter terminating

station in the locations shown below:

(The terminal resistor is provided with the master module.)

DA DB

Terminal resistor

DG

SLD FG

2 Use the CC-Link dedicated cables in the CC-Link system.

If the cables other than the CC-Link dedicated cables are used, we cannot

guarantee the performance of the CC-Link system.

Refer to the CC-Link Partner Association Home Page: http://www.cc-link.org/ for

the specifications and contact information of the CC-Link dedicated cables.

5 - 7 5 - 7

Page 35

A

6 TROUBLESHOOTING

MELSEC-

6 TROUBLESHOOTING

6.1 Verifying Errors from LED Status

The following table lists causes and corrective actions for errors indicated by LEDs on

the CC-Link embedded I/O adapter when the SW, M/S and PRM LEDs are all off (i.e.

module

TIME

LINE

or

TIME

LINE

LED status

CC-Link embedded I/O adapter Master

A B C

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

the master module is set properly) in the system configuration example shown below.

y

l

p

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

p

u

s

r

e

w

o

P

CPU

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

Master

module

Since the LEDs on the CC-Link

embedded I/O adapter A are all off, the

24 V power is not supplied or voltage is

low.

The CC-Link embedded I/O adapter A

is malfunctioning and the LEDs are

unstable (all lights are off, in many

cases).

The L RUN lights on the CC-Link

embedded I/O adapter B and beyond

are off, indicating the transmission cable

between the CC-Link embedded I/O

adapter A and B has been disconnected

or removed from the terminal block.

The transmission cable is shorted. Find the shorted cable among the three

The transmission cable is wired

incorrectly.

The transmission patterns have been

connected incorrectly.

The L RUN lights on the CC-Link

embedded I/O adapters A and C are off,

indicating the station numbers for A and

C are overlapping.

Station number 1

CC-Link embedded

I/O adapter A

Cause Corrective action

Normal —

Station number 2 Station number 3

CC-Link embedded

I/O adapter B

Check the voltage of the 24 V power supply,

and supply the proper power to the CC-Link

embedded I/O adapter.

Exchange the CC-Link embedded I/O adapter.

Identify the disconnected point by referring to

the LED status, and correct it.

transmission cables and repair it.

Check the wiring on the terminal block of the

user board and correct the incorrect wiring.

Check the transmission patterns on the user

board and correct the incorrectly connected

portions.

Restart the power supply after the overlapped

station numbers for the CC-Link embedded I/O

adapters are corrected.

: lit, : unlit, : flashing, : lit, flashing or unlit

CC-Link embedded

I/O adapter C

6

6 - 1 6 - 1

Page 36

A

6 TROUBLESHOOTING

module

LED status

CC-Link embedded I/O adapter Master

A B C

PW

L RUN

L ERR

PW

TIME

LINE

TIME

LINE

or

L RUN

L ERR

PW

L RUN

L ERR

PW

6

TIME

LINE

TIME

LINE

or

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

PW

L RUN

L ERR

Cause Corrective action

The L RUN light on the CC-Link

embedded I/O adapter B is off, indicating

the transmission speed setting for CC-

Link embedded I/O adapter B is invalid

within the setting range (0 to 4).

The L ERR of the CC-Link embedded

I/O adapter C is flashing at fixed

intervals, indicating the setting switch for

CC-Link embedded I/O adapter C has

been changed during normal operation.

The L RUN of the CC-Link embedded

I/O adapter A is off and L ERR of the

same CC-Link embedded I/O adapter is

lit, indicating the setting switch for CC-

Link embedded I/O adapter A is set out

of range (transmission speed: 5 to 9,

station number: 65 or greater).

The L ERR of the CC-Link embedded

I/O adapter B is lit, indicating that CC-

Link embedded I/O adapter B is being

affected by noise. (L RUN may be off.)

The L ERR lights on the CC-Link

embedded I/O adapter B and beyond

are lit, indicating the transmission cable

is affected by noise in the area between

CC-Link embedded I/O adapters A and

B. (L RUN may be off.)

A terminal resistor is not attached.

(L RUN may be off.)

MELSEC-

Restart the power supply after the transmission

speed is set correctly.

Return the setting switch of the CC-Link

embedded I/O adapter to the original position.

Correct the setting switch of the CC-Link

embedded I/O adapter, and restart the power

supply.

Correctly perform grounding of the FGs for the

master module and all CC-Link embedded I/O

adapters.

Verify the grounding of the SLD of the

transmission cable.

Separate the wire from the power cable as

much as possible (100 mm (3.94 in.)or more).

Check if a terminal resistor is attached.

: lit, : unlit, : flashing, : lit, flashing or unlit

6 - 2 6 - 2

Page 37

A

6 TROUBLESHOOTING

MELSEC-

6.2 Examples of Errors for CC-Link Embedded I/O Adapter

This section explains examples of errors that occur in the input circuit, and the

appropriate corrective actions.

6.2.1 Errors occurring in the input circuit and corrective actions

Examples of errors that occur in the input circuit and corrective actions are explained

Error status Cause Corrective action

Example 1 Input signals do not turn off. • Activation via the LED display switch.

below:

• Connect a resistor so that the voltage

Leakage current

DC input (sink)

CC-Link

embedded

Input

adapter

between the input terminal and COM1

becomes lower than the OFF voltage.

Resistor

DC input (sink)

CC-Link

embedded

Input

adapter

Example 2 Input signals do not turn off. • Sneak path due to the use of two power

supplies.

E1 E2

E1 > E2

DC input

CC-Link

embedded

Input

adapter

A calculation example used to obtain the

resistance value to be connected is shown

on the following page.

• Reduce the number of power supplies

from two to one.

• Connect a diode to prevent sneak path.

(as below)

DC input

CC-Link

E1

E2

embedded

Input

adapter

6 - 3 6 - 3

Page 38

A

6 TROUBLESHOOTING

<Sample calculation for example 1>

AJ65MBTL1N-16D

MELSEC-

Leakage

current

4.7 k

• The voltage V

CC-Link

2.45 mA

24 V DC

across the terminal and common is obtained by the following

TB

embedded

input

adapter

When a 2.45 mA leakage current flows due

to a switch with LED indicator connected to

the AJ65MBTL1N-16D.

expression.

V

= 2.45 [mA] 5.1 [k ] = 12.5 [V]

TB

(The voltage drop across the LED is ignored.)

Since this result does not satisfy the OFF voltage of 6 [V] or less, the input

signal does not turn off. Hence, connect a resistor as shown below.

AJ65MBTL1N-16D

Input impedance

5.1 k

4.7 k

Current I

24 V DC

R

• Calculation of resistor R value

Current I should be as follows so that the terminal voltage of the

AJ65MBTL1N-16D is 6 [V] or less.

(24

6 [V] ) 4.7 [k ] = 3.83 mA

Therefore, connect a resistor R that will give a current I of 3.83 mA or more.

• Resistor R to be connected is as follows.

6 [V] R > 3.83

6 [V]

5.1 [k ]

6 [V] R > 3.83 1.18 [mA]

6 [V] 2.65 [mA] > R

2.26 [k ] > R

Assuming that resistor R is 2.2 k

, the power capacity W of the resistor when

the switch turned on is as follows.

2

W = (applied voltage)

W = (26.4 [V] )

2

/R

/2.2 [k ] = 0.32 [W]

• The power capacity of the resistor is 1 to 2 [W] since a factor of 3 to 5 as

compared to the actual power consumption is used to select the power

capacity.

Accordingly, connect a 2.2 [k

], 1 to 2 [W] resistor across the corresponding

terminal and COM.

6 - 4 6 - 4

Page 39

A

6 TROUBLESHOOTING

MELSEC-

6.2.2 Errors occurring in the output circuit and corrective actions

Examples of errors that occur in the output circuit and corrective actions are explained

Condition Cause Corrective action

below:

Erroneous output due to the stray capacitance (C)

between collector and emitter of hotocoupler.

There is no erroneous output at normal road.

An erroneous output may occur at high

sensitivity load (such as solid state relay).

Output module, Combined module

Photocoupler

C

Tr1

Ic

Constant

voltage c ircuit

Y0

CTL

COM-

When the external power turns ON/OFF,

check that the external power supply rising

edge must be 10ms or more, and switch the

SW1 to the primary side of external power

supply.

When switching to the secondary side of

L

the external power supply is required, the

external power supply rising edge

connected a condenser must be slow, and

measured 10ms or more.

SW

+

24V

Primary

side

SW1

Y0

external power supply

Secondary

side

PLC

Example 1

Whegn the external

power supply turns on,

the load turns on for a

moment.

If the external power supply is turned on precipitously,

Ic urrent flows due to the stray capacitance (C)

between collector and emitter of hotocoupler.

Ic current flows to the next stage of transister Tr1 gate

and Y0 utput turns on by 100 s

SW: External power

supply (24V) at On

10ms or less

Output Y0

Approx. 100 s

L

C1

R1

SW

24V

*1

) 2

*2

CTL+

COM-

R1: Several tens of ohms

Power capacity

C1: Several hundreds of microfarads F 50V

*1 Refer to consumption current of the

external power supply for modules used in

this manual.

*2 Select the power capacity of resistance

to be 3 to 5 times lager than the actual

power consumption.

(Example)

R1=40 , C1=300 F

Use the below expression to calculated a

time constant

C1 R1=300 10 -6 40

(external power supply

current

resistance value

(3 to 5)

=12

10 -3 s

=12ms

6 - 5 6 - 5

Page 40

A

A

(

)

(

)

PPENDIX

APPENDIX

Appendix 1 External Dimensions

Appendix 1.1 AJ65MBTL1N-16

MELSEC-

APP

3.5 22

31.5

(1.24) (0.14) (0.87)

53 (2.09)

3.5

0.14

Unit: mm (inch)

[Recommended board dimension drawing]

(top view)

0.95 0.04

A22

B22

2 (0.08) 0.05

42 (1.65) 0.1

5.5 (0.22)5.5 (0.22)

A01

B01

0.30

7.5

0.05

2 (0.08)

Unit: mm (inch)

App - 1 App - 1

Page 41

A

A

PPENDIX

MELSEC-

Appendix 1.2 AJ65MBTL1N-32

31.5 3.5

(1.24) (0.14)

22

(0.87)

3.5

(0.14)

85

(3.35)

Unit: mm (inch)

[Recommended board dimension drawing]

A31

B31

(top view)

5.5 (0.22)

60 (2.36) 0.1

2 (0.08) 0.05

19.5

(0.77)

A01

B01

7.5

(0.30)

0.05

0.95 0.04

APP

2 (0.08)

Unit: mm (inch)

App - 2 App - 2

Page 42

WARRANTY

Please confirm the following product warranty details before using this product.

1. Gratis Warranty Term and Gratis Warranty Range

If any faults or defects (hereinafter "Failure") found to be the responsibility of Mitsubishi occurs during use of the product

within the gratis warranty term, the product shall be repaired at no cost via the sales representative or Mitsubishi Service

Company.

However, if repairs are required onsite at domestic or overseas location, expenses to send an engineer will be solely at

the customer’s discretion. Mitsubishi shall not be held responsible for any re-commissioning, maintenance, or testing onsite that involves replacement of the failed module.

[Gratis Warranty Term]

The gratis warranty term of the product shall be for one year after the date of purchase or delivery to a designated

place.

Note that after manufacture and shipment from Mitsubishi, the maximum distribution period shall be six (6) months, and

the longest gratis warranty term after manufacturing shall be eighteen (18) months. The gratis warranty term of repair

parts shall not exceed the gratis warranty term before repairs.

[Gratis Warranty Range]

(1) The range shall be limited to normal use within the usage state, usage methods and usage environment, etc.,

which follow the conditions and precautions, etc., given in the instruction manual, user's manual and caution labels

on the product.

(2) Even within the gratis warranty term, repairs shall be charged for in the following cases.

1. Failure occurring from inappropriate storage or handling, carelessness or negligence by the user. Failure caused

by the user's hardware or software design.

2. Failure caused by unapproved modifications, etc., to the product by the user.

3. When the Mitsubishi product is assembled into a user's device, Failure that could have been avoided if functions

or structures, judged as necessary in the legal safety measures the user's device is subject to or as necessary

by industry standards, had been provided.

4. Failure that could have been avoided if consumable parts (battery, backlight, fuse, etc.) designated in the

instruction manual had been correctly serviced or replaced.

5. Failure caused by external irresistible forces such as fires or abnormal voltages, and Failure caused by force

majeure such as earthquakes, lightning, wind and water damage.

6. Failure caused by reasons unpredictable by scientific technology standards at time of shipment from Mitsubishi.

7. Any other failure found not to be the responsibility of Mitsubishi or that admitted not to be so by the user.

2. Onerous repair term after discontinuation of production

(1) Mitsubishi shall accept onerous product repairs for seven (7) years after production of the product is discontinued.

Discontinuation of production shall be notified with Mitsubishi Technical Bulletins, etc.

(2) Product supply (including repair parts) is not available after production is discontinued.

3. Overseas service

Overseas, repairs shall be accepted by Mitsubishi's local overseas FA Center. Note that the repair conditions at each FA

Center may differ.

4. Exclusion of loss in opportunity and secondary loss from warranty liability

Regardless of the gratis warranty term, Mitsubishi shall not be liable for compensation of damages caused by any cause