Page 1

PCKN-0IL738-A

1

MITSUBISHI

ELECTRIC

Mitsubishi Digital Protection Relay

MELPRO

TM

– D Series

CBV2 – A01D1 VOLTAGE RELAY

INSTRUCTION MANUAL

MITSUBISHI ELECTRIC CORPORATION

Changed : Jan. 2005

Changes for the Better

Page 2

PCKN-OIL738

2

- Introduction -

Thank for your purchasing MITSUBISHI ELECTRIC MELPRO

TM

– D Series Digital Protection Relay.

Please read this manual carefully to be familiar with the functions and performances enough to use the

product properly.

Please note end users are required to be provided with this instruction manual.

For operation of the product, this manual should be used in conjunction with the following materials:

Title of document Document No.

MELPRO – D Series Protection Relay General Operation Manual PCKN-OIL750

When the protection relay is used together with a communication card, use the following documents too:

(For CC-Link)

Title of document Document No.

MELPRO – D Series Protection Relay CC-COM Communication Card (CC-Link)

Operation Manual (General information)

PCKN-OIL751

MELPRO – D Series Protection Relay CC-COM Communication Card (CC-Link)

Operation Manual (Model-specific information)

PCKN-OIL752

(For MODBUS)

Title of document Document No.

MELPRO–D Series Protection Relay RS-COM Communication Card (MODBUS)

Operation Manual (General information)

PCKN-OIL703

MELPRO–D Series Protection Relay RS-COM Communication Card (MODBUS)

Register Map (For CBV2-A01D1 Voltage Relay)

PCKN-OIL716

Page 3

PCKN-OIL738

3

– CONTENTS –

1

Features .......................................................................................................................................................4

1.1 General description ......................................................................................................................4

1.2 Features........................................................................................................................................4

2 Rating and specifications.............................................................................................................................6

2.1 General information ......................................................................................................................6

2.2 Protective elements ......................................................................................................................7

2.3 Measurement elements ................................................................................................................7

3 Characteristics .............................................................................................................................................8

3.1 Protective elements ......................................................................................................................8

3.2 Measurement elements ................................................................................................................8

3.3 Common technical data................................................................................................................9

4 Functions....................................................................................................................................................10

4.1 Protection....................................................................................................................................10

4.2 Measurement..............................................................................................................................13

4.3 Self-diagnosis .............................................................................................................................14

4.4 Communication...........................................................................................................................15

5 Configuration..............................................................................................................................................17

5.1 Internal configuration ..................................................................................................................17

5.2 External connection ....................................................................................................................20

6 Handling .....................................................................................................................................................25

6.1 Unpacking...................................................................................................................................25

6.2 Transportation and storage ........................................................................................................25

6.3 Appearance and how to pull sub unit out ...................................................................................25

6.4 How to use front control panel....................................................................................................28

7 Mounting ....................................................................................................................................................35

7.1 Mounting dimension ...................................................................................................................35

7.2 Standard operating environment ................................................................................................35

8 Test ............................................................................................................................................................36

8.1 Appearance inspection...............................................................................................................36

8.2 Characteristic test.......................................................................................................................37

9 Maintenance ..............................................................................................................................................39

9.1 Daily inspection ..........................................................................................................................39

9.2 Periodical inspection...................................................................................................................39

10 Ordering ..................................................................................................................................................... 40

Page 4

PCKN-OIL738

4

1 Features

1.1 General description

Mitsubishi Electric MELPRO-D Series is a digital protection relay product with a microprocessor for

protecting high/extra-high-voltage electric power system.

With its improved functions, including operation support using the advanced communication networks,

data saving at the power system faults and power system voltage/current measurement, this series of

protection relay will allow stable and effective control and monitoring of electric power systems as well as

provide high-reliable protection.

1.2 Features

(1) High-reliable protection

The product includes a three-phase undervoltage and a three-phase overvoltage element.

It is used to detect abnormal voltage between lines.

(2) Communication Network

- With an open field bus system, the relays can be used to build a high-speed, high-performance

network system. In addition, the relay’s multi-drop serial wiring reduces the amount of labor

required for communication wiring.

- Control of measurement values, operation status, as well as setting changes, etc., can be

performed from a remote location.

- In consideration of future network system variations and compatibility with communication

networks, communication features are mounted in the relay using a replaceable card.

(3) Measurement & Recording Functions

- Real time monitor of relay input data

The relay can measure steady state relay input values, supporting energy management.

- Fault Data Monitor

When a fault occurs, the relay saves the past 5 effective input values and harmonics data to

assist with fault analysis.

(4) Programmable Output Configuration

The operating output contacts (DO) can be set by combining the outputs of the protection relay

element using ‘OR’ logic, thereby simplifying sequence design.

(5) High Accurate Digital Computation

The digital computation using high-speed sampling minimizes the effect of high harmonics, etc., and

results in highly accurate protection.

(6) Self-diagnosis

The relay continuously monitors electronic circuits from input to output so that it can detect internal

failure before that failure causes damage on the power system, thereby improving reliability.

(7) Easy Replacement

The dimensions of the panel cutout are the same as the prior MULTICAP series. Changing from an

existing relay type to this new type is easy.

Page 5

PCKN-OIL738

5

(8) Easy Maintenance

The relays are adopted as draw-out unit mechanisms with automatic CT shorting at drawing, thereby

making maintenance easy.

(9) Easy wiring check

It is possible to carry out forced operation of the output contacts individually. This will allow an easy

wiring check.

Page 6

PCKN-OIL738

6

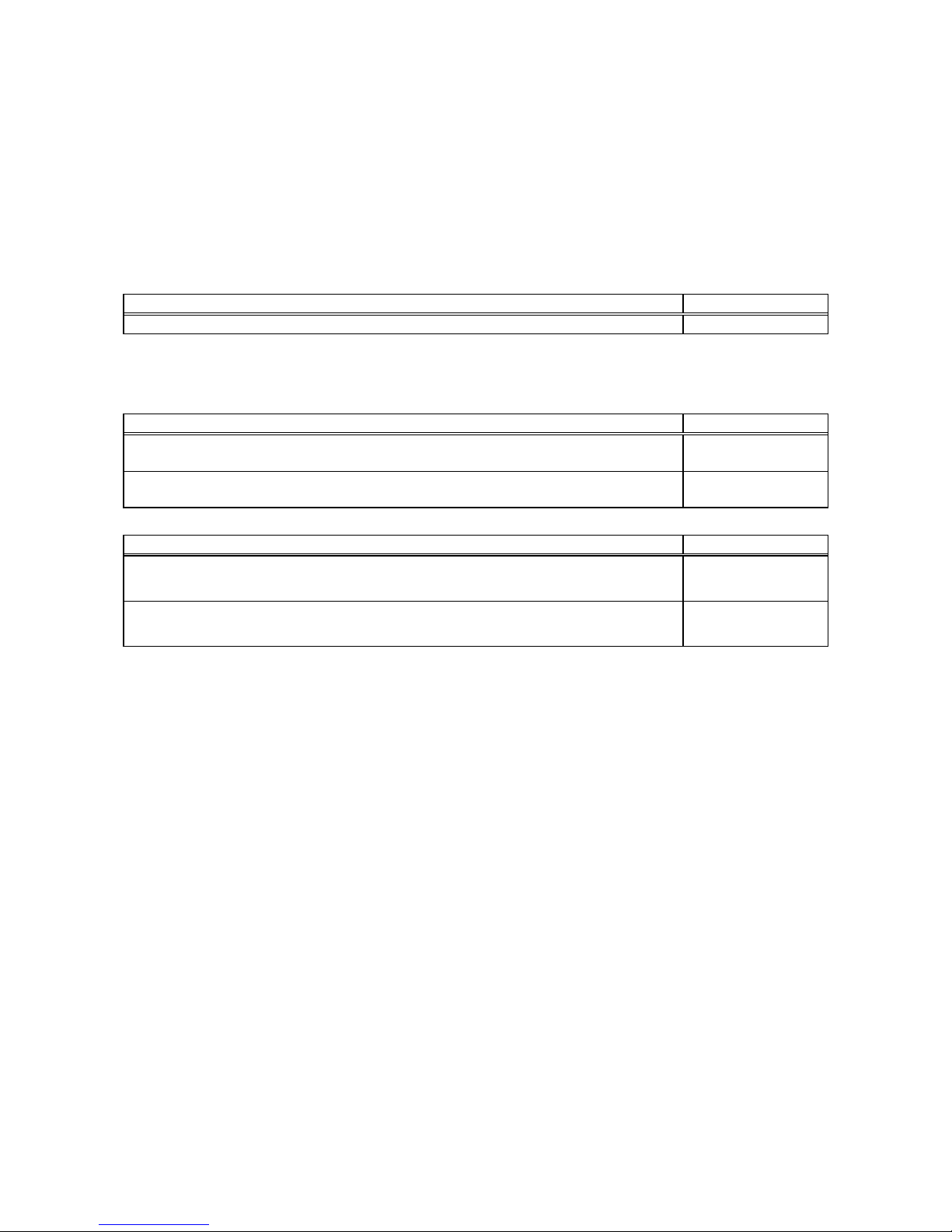

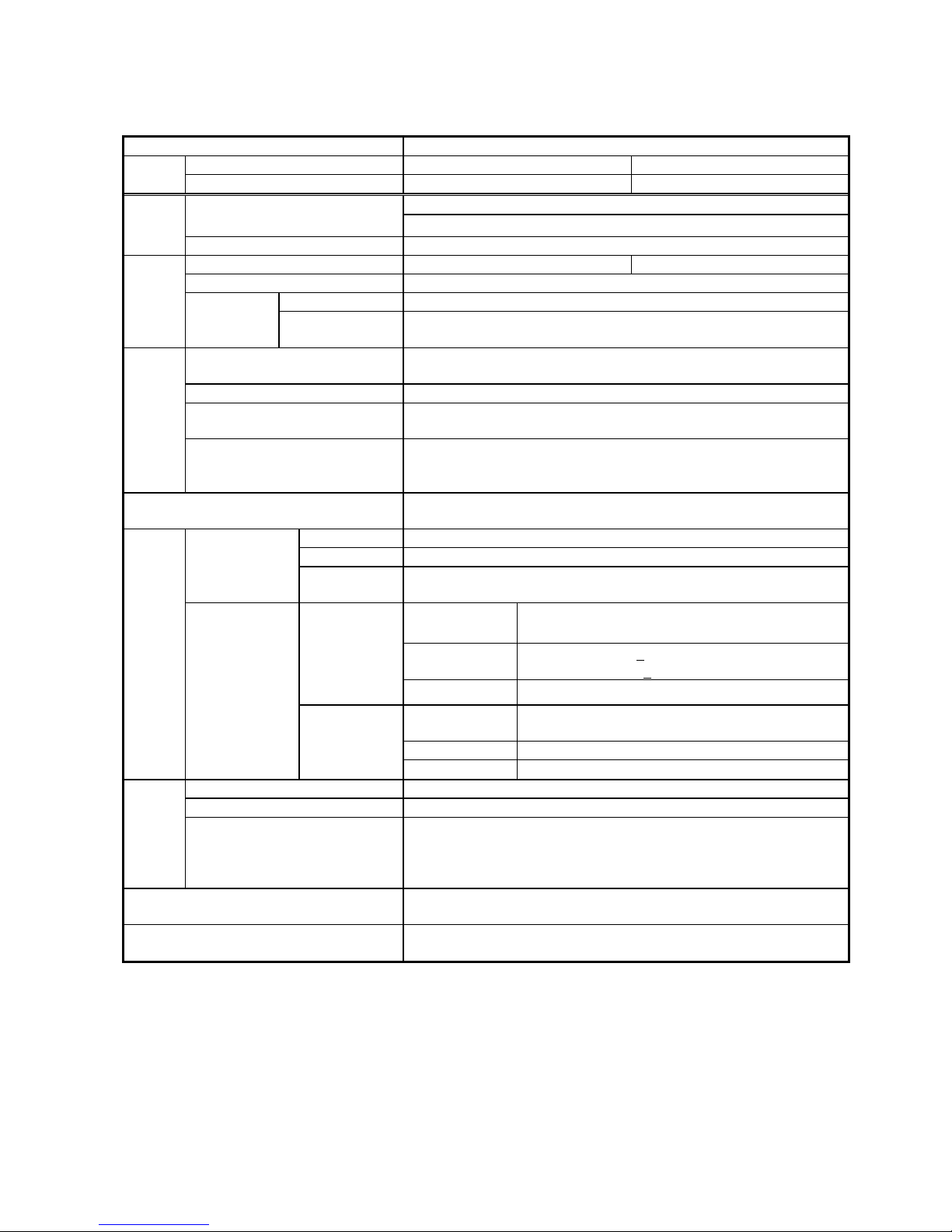

2 Rating and specifications

2.1 General information

Type name CBV2-A01D1

Relay without RS232C I/F 354PMB 355PMB

Style

Relay with RS232C I/F 541PMB 542PMB

Undervoltage element ×31

Protection

Overvoltage element × 3

Element

Measurement Voltage

Frequency 50 Hz 60 Hz

Voltage 57 ~ 120 V

Voltage Common use for 100 ~ 220VDC / 100 ~ 220VAC

Rating

Auxiliary

power supply

*21

Operative range

DC : 85 ~ 242 V (Range of 80 ~ 286VDC is allowable temporarily.)

AC : 85 ~ 242 V (Range of 80 ~ 253VAC is allowable temporarily.)

RUN

Indicate the result of

self-diagnosis. The lamp is lit for normal conditions

and off for abnormal.

Unit Indicate the unit symbol for measurements.

Item No., Item data

Display measurement, status, setting and option data selected with an item

number.

Display

Communication

With a communication card installed: the lamp is lit for normal conditions,

blinking during communication and off for abnormal.

With a communication card not installed: the lamp is off.

Self-diagnosis

Monitor the electronic circuit and internal power supply to output signal to

the RUN LED and

self-diagnosis output (ALARM).

For trip 2 make contacts: X4 and X5 (programmable output)

For signaling 4 make contacts: X0 to X3 (programmable output)

Configurations

For self-diagnosis

output

1 break contact: Y (open for normal result of self-diagnosis with power on)

Make

110VDC, 15A, 0.5 s (L/R = 0 s)

220VDC, 10A, 0.5 s (L/R = 0 s)

Break

110VDC, 0.3A (L/R<

40 ms)

220VDC, 0.15A (L/R<

40 ms)

For trip

Carry

1.5 A, continuously

Make and Break

500 VA (cosφ= 0.4),

60W (L/R = 0.007 s)

Max. current 5 A

Output

contacts

Capacity

For signaling and

self-diagnosis

output

Max. voltage 380VAC, 125VDC

Voltage circuit 1 VA or less (with rated current)

Zero-phase voltage circuit 0.15 VA or less (with rated current)

Burden

Auxiliary power supply circuit

For 100VDC: approx. 5 W (approx. 7W including communication card)

For 100VAC : approx. 7 VA (approx. 9VA including communication card)

For 220VDC: approx. 6 W (approx. 8W including communication card)

For 220VAC : approx. 12 VA(approx. 14VA including communication card)

Mass

Net weight of relay unit : approx. 2.3 kg

Including case : approx. 3.0 kg

Case/cover

Size : D1 type

Color : N1.5

*21 When an uninterruptible AC power source is not provided in your system for the auxiliary supply voltage, use the

type CPS1 AC/DC converter or commercially available uninterruptible power supply (UPS).

Power supply product of 24VDC or 48VDC is also available if ordered (non-standard product).

In addition, the power supply duration of the type CPS1 AC/DC converter is confirmed about 2 seconds in

combination with one MELPRO-D series relay. Therefore, in the case that the required power supply duration after

power source loss exceeds 2 seconds, please use a suitable commercial uninterruptible power supply.

When the power supply back up for the control power supply of a circuit breaker is required, it is necessary to

prepare the backup power supply different from the type CPS1 AC/DC converter.

Page 7

PCKN-OIL738

7

2.2 Protective elements

Relay without RS232C I/F 354PMB 355PMB

Style

Relay with RS232C I/F 541PMB 542PMB

Operation voltage LOCK - 10 ~ 110V (1V step)

Operation time INST - 0.1 ~ 10 s (0.1 s step)

Undervoltage

UV test

OFF

– AB phase test – BC phase test – CA phase test

When execute the relay test, enable to use the selected input

phase only. “UV test” LED turn on during selecting "UV TEST".

Operation voltage LOCK – 60 ~ 155V (1V step)

Setting

*24

Overvoltage

Operation time INST - 0.1 ~ 10 s (0.1 s step)

Forced operation Forced operation is available for any trip or signaling contact individually.

Operation indication Operation indicator LED (red) comes on when the relay operates.

2.3 Measurement elements

Relay without RS232C I/F 354PMB 355PMB

Style

Relay with RS232C I/F 541PMB 542PMB

VT primary voltage

100 ~ 999V (1V step)

1000 ~ 9990V (10V step)

10.0k ~ 99.9kV (0.1kV step)

100k ~300kV (1kV step)

Option *24

VT secondary voltage

100/√3 -110/√3 -115/√3 -120/√3 -100-110-115-120[V]

(57.7) (63.5) (66.4) (69.3)

Conversion

Indication value = Relay input value

×VT primary setting / VT secondary setting

Range *22 0.00 ~ VT primary setting / VT secondary setting ×165 [V]

Real time

Update Approx. 200 ms

Conversion

Indication value = Relay input value

×VT primary setting / VT secondary setting

Max. record

Range *22 0.00 ~ VT primary setting / VT secondary setting ×165 [V]

Conversion

Indication value = Relay input value

×VT primary setting / VT secondary setting

Display

Voltage

Fault record

*23

Range *22 0.00 ~ VT primary setting / VT secondary setting ×165 [V]

*22 The form of display depends on value range as shown in the tables below:

VT primary setting value determines the minimum number of digits to be displayed on each measurement display.

When a value to be displayed exceeds the max. value of the display range, the max. value will blink.

VT primary setting 100 ~ 500[V] 501 ~ 10000[V] 11 ~ 300[kV]

0 ~ 999[V] □□□[V] □.□□[kV] □.□[kV]

1.00 ~ 9.99[kV] □.□□[kV] □.□□[kV] □.□[kV]

10.0 ~ 99.9[kV] □□.□[kV] □□.□[kV] □□.□[kV]

Form of

display

100 ~ 999[kV] □□□[kV] □□□[kV] □□□[kV]

*23 When a communication card is connected, waveform data in the event of system fault can be read.

(See the section 4 “Function”).

*24 When the product is shipped from the factory, each setting value is “Lock” (With lock setting element) or “minimum

setting value“ (Without lock setting element).

Page 8

PCKN-OIL738

8

3 Characteristics

Common conditions

(1) Rated frequency: ±1%

(2) Ambient temperature: 20°C±10°C

(3) Aux. supply voltage: Rated voltage±2%

The conditions shown on the left

should be applied unless otherwise

specified.

3.1 Protective elements

Items Conditions Guaranteed performance

Undervoltage

element

Operation

value

Overvoltage

element

(Common conditions) Setting value ±5%

Undervoltage

element

Operation value × 105% or

less

Reset value

Overvoltage

element

(Common conditions)

Operation value × 95% or

more

Undervoltage

element

Rated voltage Æ Setting×70%

- For setting of INST

40ms or less

- For setting of 0.4s or less

Setting value ± 25ms

- For setting of 0.5s or more

Setting value ± 5%

Operation

time

Overvoltage

element

0 Æ Setting×120%

- For setting of INST

50ms or less

- For setting of 0.4s or less

Setting value ± 25ms

- For setting of 0.5s or more

Setting value ± 5%

Undervoltage

element

Setting×70% Æ Rated voltage

Reset time

Overvoltage

element

Setting×120% Æ 0

60ms or less

3.2 Measurement elements

Items Condition Guaranteed performance

Real time and max. records ±1%

Fault record

VT primary setting /

VT secondary setting ×165

±1%

Page 9

PCKN-OIL738

9

3.3 Common technical data

ITEM DESCRIPTION CONDITION STANDARD

Ambient operating

temperature

-10°C to +55°C IEC60255-6

Ambient storage and

transport temperature

-25°C to +70°C IEC60255-6

Environment

Damp heat +40°C, 95%RH, 4 days IEC60068-2-3

VT 1.15Vn, 3h Thermal

withstand

CT 40In, 1s

Circuit of 60V or below 500VAC, 1min.

Circuit of more than

60V and 500v or below

2000VAC 1min.

1) Between each circuit

and the exposed

conductive parts, the

terminals of each

independent circuit

being connected

together

2) Between independent

circuits, the terminals of

each independent circuit

being connected together

Dielectric test

Open contact 1000VAC, 1min. Between open contact poles

IEC60255-5

Impulse voltage test 5kV, 1.2µs/50µs

1) Between each circuit

and the exposed

conductive parts, the

terminals of each

independent circuit

being connected

together

2) Between independent

circuits, the terminals of

each independent circuit

being connected together

IEC60255-5

Common mode

2.5kV peak, 1MHz with 200Ω

source impedance for 2s

Between independent

circuits, and between

independent circuit and earth

High-frequency

disturbance test

Differential mode

1.0kV peak, 1MHz with 200Ω

source impedance for 2s

Across terminals of the same

circuit

IEC60255-22-1

class 3

8kV Contact discharge

Electrostatic discharge test

15kV Air discharge

IEC60255-22-2

Class 4

Radiated electromagnetic field

disturbance test

68 to 87Mhz

146 to 174MHz

420 to 470MHz

IEC60255-22-3

class 3

Fast transient disturbance test 2.0kV, 5ns/50ns, 1min IEC60255-22-4

Vibration test Refer to class 1

IEC60255-21-1

Class 1

Shock response Refer to class 2

IEC60255-21-2

Class 2

Shock withstand Refer to class 1

IEC60255-21-2

Class 1

Bump Refer to class 1

IEC60255-21-2

Class 1

Enclosure protection IP51 IEC60529

Vn: Rated voltage, In: Rated current

Page 10

PCKN-OIL738

10

4 Functions

4.1 Protection

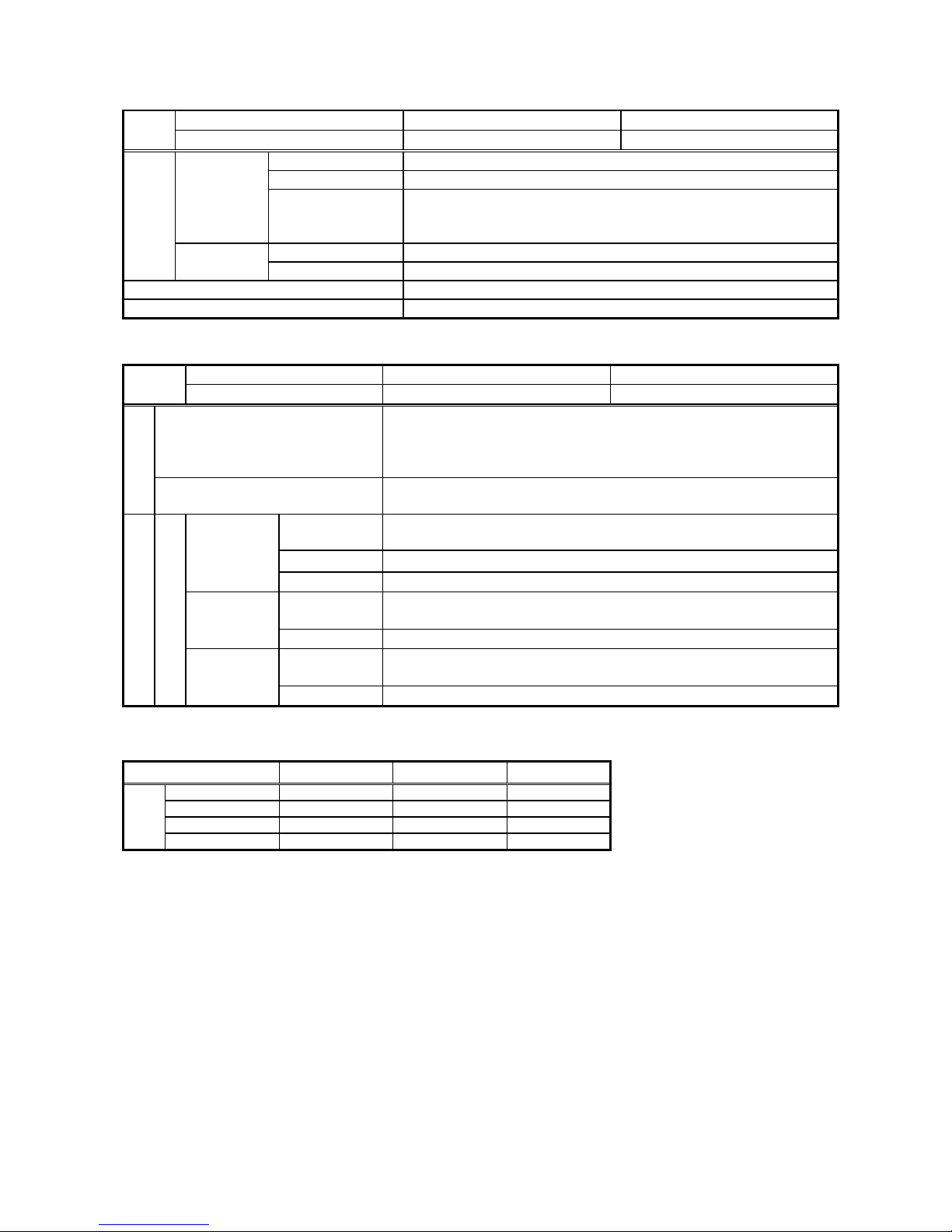

4.1.1. Undervoltage elements

Fig. 4.1 “Undervoltage element internal function block diagram” shows operation of the undervoltage

elements.

Undervoltage element compares input voltages of voltage circuit with the operation setting. If an input

voltage is less than the specified operation level, the element outputs an operation signal when the timer

expires.

Undervoltage elem ent detected

(Operation indicator LED blinking)

Undervoltage elem ent detected

(Operation indicator LED lit)

Operation signal

(Undervoltage element)

V

AB

Undervoltage element

Voltage comparison

Timer

(trip/reset)

A

B-phase processing

BC-phase processing

Same as processing in AB-phase

V

BC

V

CA

CA-phase processing

Same as processing in AB-phase

Figure 4.1 Undervoltage element internal function diagram

4.1.2. Overvoltage elements

Fig. 4.2 “Overvoltage element internal function block diagram” shows operation of the overvoltage

elements.

Overvoltage element compares input voltages of voltage circuit with the operation setting. If an input

voltage is larger than the specified operation level, the element outputs an operation signal when the timer

expires.

Overvoltage element detected

(Operation indicator LED blinking)

Overvoltage element detected

(Operation indicator LED lit)

Operation signal

(Overvoltage element)

V

AB

Overvoltage element

Voltage comparison

Timer

(trip/reset)

A

B-phase processing

BC-phase processing

Same as processing in AB-phase

V

BC

V

CA

CA-phase processing

Same as processing in AB-phase

Figure 4.2 Overvoltage element internal function diagram

Page 11

PCKN-OIL738

11

4.1.3 General functions

(1) Setting of operation voltage

The operation voltage settings for undervoltage and overvoltage elements are indicated with voltage

values [V].

When the setting “Lock”, the elements selected are locked for operation.

(2) Setting of operation timer

The operation time settings for undervoltage and overvoltage elements are indicated with second [s].

(3) Operation display

For undervoltage element, when the input voltage becomes less than the operation setting, the

corresponding operation indicator LED will blink to allow you check the starting value.

For overvoltage element, when the input voltage becomes larger than the operation setting, the

corresponding operation indicator LED will blink to allow you check the starting value.

The LED lamp will come on as soon as an operation output is made when a period of operation time

has elapsed.

The operation indicator LED has been set to “self-hold” in the factory. This setting can be freely

changed to “auto reset”.

With the “self-hold” setting, data of the latest operation indication will be stored in the internal memory

even if the auxiliary power supply runs down.

The data stored will be cleared when the “indicator reset” switch is pressed.

Up to latest five phenomena can be stored and displayed as a history record. (Older data than the

latest five phenomena will automatically be cleared).

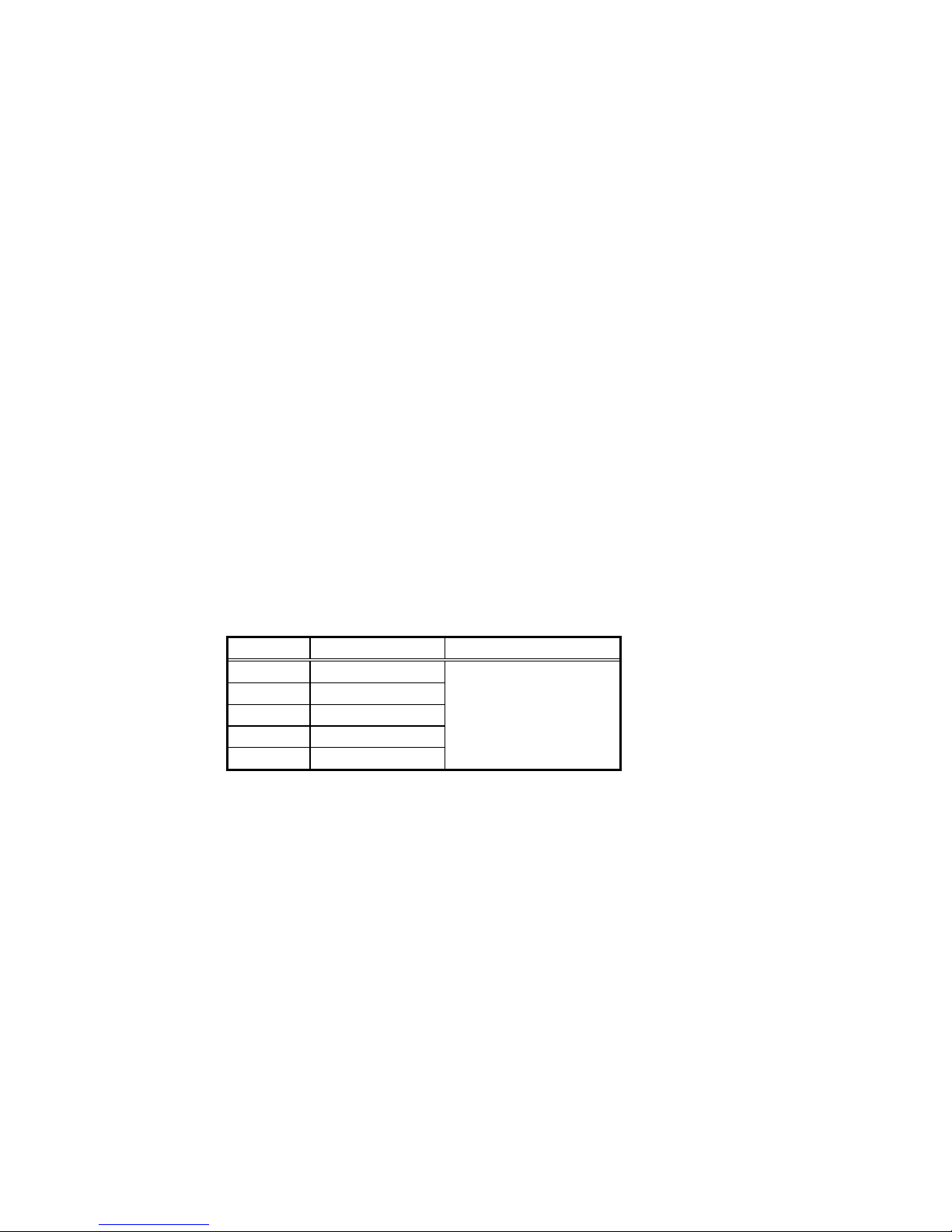

Item No. History Sequence of recording

311 1st phenomena

312 2nd phenomena

313 3rd phenomena

314 4th phenomena

315 5th phenomena

Latest fault record data

↓

↓

↓

Oldest fault record data

Page 12

PCKN-OIL738

12

(4) Output contacts

The signaling outputs X

0

to X3 and trip outputs X4 and X5 are all programmable type.

The factory default setting of the arrangement of these outputs is as shown in the internal function

block diagram of Figure 5.2. This setting can be freely changed by specifying outputs of the internal

elements based on the OR logic.

All the outputs have been set to “auto reset” in the factory. Any of them can be changed to “self hold”.

X

0

X

5

X

3

X4

I >>

I

>

I

>>

I >

Signaling

(4 circuits)

Trip

(2 circuits)

Set output logic as

desired by using

OR logic.

Figure 4.3 Schematic image of Programmable Outputs (example: COC4-A01)

(5) Forced operation

It is possible to carry out forced operation of any of the signaling outputs X

0

to X3 and trip outputs X4

and X

5

independently. Forced operation is useful for checking the wiring.

When forced operation is carried out, the corresponding LED lamps will come on to show the current

status of the programmable outputs. Checking the lamp status will be useful not only for wiring check

but also to check the programmable outputs arrangement.

Page 13

PCKN-OIL738

13

4.2 Measurement

Voltages input to the relay are measured and converted into freely set VT primary voltages, then indicated

in the display.

(1) Real time measurement

The effective voltage input to the relay under steady state is displayed.

(2) Max. record

The maximum effective voltage is recorded and stored.

The max. record will be all cleared when “aux. power supply OFF” or “max. record reset” operation is

made.

(3) Fault record

In the event of system fault, the effective voltage and waveform data that have been measured at the

time when one of the protection elements operates to issue an output signal are stored. Data of up to

five phenomena can be stored and displayed for each phase.

With “aux. power supply OFF”, only the waveform data will be cleared and the effective voltage data

will remain. With “fault record reset” operation, however, both of the data items will be all cleared.

(Records older than the 5

th

phenomenon will automatically be cleared.)

Item No. History Sequence of recording

211 1st phenomena

212 2nd phenomena

213 3rd phenomena

214 4th phenomena

215 5th phenomena

Latest fault record data

↓

↓

↓

Oldest fault record data

The following fault waveform data can be collected if a communication card is installed:

Item Specification

Data sampling cycle Fixed to the electric angle of 30° of rated frequency

Data storing capacity (for

a phenomenon)

224 cycles of rated frequency

(Data point: 224×360°/30° = 2688 points)

Permissible setting range 224 cycles before trip ~ 224 cycles after trip

Collected data

The range for data collection can be set by cycle within the

“data storing capacity” in the “permissible set range”.

224 cycles after t rip→

←224 cycles before trip

Collected data

Up to 224 cycles

Data sampling cycle

Trip occu rs!

Output contact

ON

OFF

Permissible set

Figure 4.4 Concept of recording fault waveform

Page 14

PCKN-OIL738

14

4.3 Self-diagnosis

The self-diagnosis function monitors the electronic circuit and built-in power source continuously. If an

abnormal condition occurs, the protection elements will be locked for operation. Also, the RUN LED lamp

will go off and the self-diagnosis output contact (break contact) will be closed.

(1) Checking defect code at failure detection

When a failure is detected, the defect code will be recorded. This defect code can be checked

through the self-diagnosis (ALARM) status indication.

(2) Resetting self-diagnosis output

If a failure is detected, the failure status may be reset by turning off/on the power

.

In this case, be sure to lock the trip circuit on the external wiring of the relay

before resetting. (If

the failure persists, an erroneous output may be caused).

(3) Clearing the defect code

The defect code data stored at failure detection can not be cleared only by carrying out the power

on/off procedure in the item (2) above. All the defect code numbers that have been detected since

the previous “self-diagnosis reset” (RESET ALARM) operation was made are accumulated in the

memory. To clear the record data, carry out “self-diagnosis reset” (RESET ALARM) operation.

Table 4.1 Output for protection relay failures

Output

Display

Status Detected items

RUN

Defect

code

ALARM

(break

contact)

Operation

output lock

Normal

−

On Open Not locked

Power circuit

failure

−

Locked

CPU failure

−

No

display

Not locked

ROM check 0001

RAM check 0002

A/D accuracy check 0003

A/I check 0004

A/D check 0005

SRAM check 0006

D/O status check 0008

D/O operation check 0009

Analog filter check 0010

A/I double check 0011

D/I check *41

0012

E2PROM check 0013

Computing function check 0014

WDT check 0015

Data transfer check *42

0016

Differential current check *43

Off

0017

Closed

Locked

Communication card check *44

0028

Communication card channel No. switch setting error *44

0029

Communication card portrait switch setting error *44

0030

Communication card channel No. switch change error *44

0031

Monitor

error

Communication card portrait switch change error *44

On

0032

Open Not locked

*41 Monitored only in the models with built-in D/I function.

*42 Monitored only in the models with D2 unit.

*43 Monitored only the biased differential relay.

*44 Monitored only when the relay is installed with communication card.

Page 15

PCKN-OIL738

15

4.4 Communication

Figure 4.5 shows an example of network system configuration.

For more information on the communication facilities, see the materials shown in the introduction (page

2).

Figure 4.5 Example of communication network system configuration

Central Control System

The network system enables the central control system to full

y

access to the protection relays, and achieve remote monitoring o

f

the measurement values, operational status etc as well as

remote operation such as change of settings. Thereby efficien

t

operation and maintenance are realized.

- ModBus

(RS485)

- CC-Link

RTU

Remote Operation and Monitorin

g

By connecting PC with relay via the RS232C port located on the

relay panel, local operation and monitoring are enabled as same

as the remote operation and monitoring. Thereby the

maintenance work at site is strongly supported.

RS232C

Local Operation and Monitoring for Site Maintenance

- Measurement value

- Relay settings

- Relay operation status

- Fault Record

- Monitoring status

- Time

- Measurement setting

- Relay setting

- Time Adjustment

Remote Operation

Remote Monitoring

Local Operation Local Monitoring

Page 16

PCKN-OIL738

16

Using the communication facilitates, it is possible to perform Remote Monitoring and Remote Operation

with the various useful functions shown in Table 4.2.

Table 4.2 Outline of functions enabled by communication network

Direction of

communication

Item Description

Setting Read the settings stored in the protection relay.

Measurement Read the measurements stored in the protection relay.

Max. value Read the max. values stored in the protection relay.

Fault record Read the measurements at the time of trip.

Self-diagnosis (ALARM) Read the result of self-diagnosis.

Operation element Read the elements that operated at the time of trip.

Operation time Read the time at the time of trip.

Current time Read the internal time of the communication card.

Remote

Monitoring

RTU

Protection

relay

Waveform record Read the wave form at the time of trip.

Setting Change the setting of the protection relay.

Indicator reset Reset the LED lamp that came on at the time of trip.

Self-diagnosis (ALARM) reset Clear the result of self-diagnosis.

Fault record reset Clear the fault record, operation elements and

operation time data.

Max. record reset Clear the max. record.

Forced operation Carry out forced operation of output contact.

Remote

Operation

RTU

Protection

relay

Time Set time of communicate card.

Page 17

PCKN-OIL738

17

5 Configuration

5.1 Internal configuration

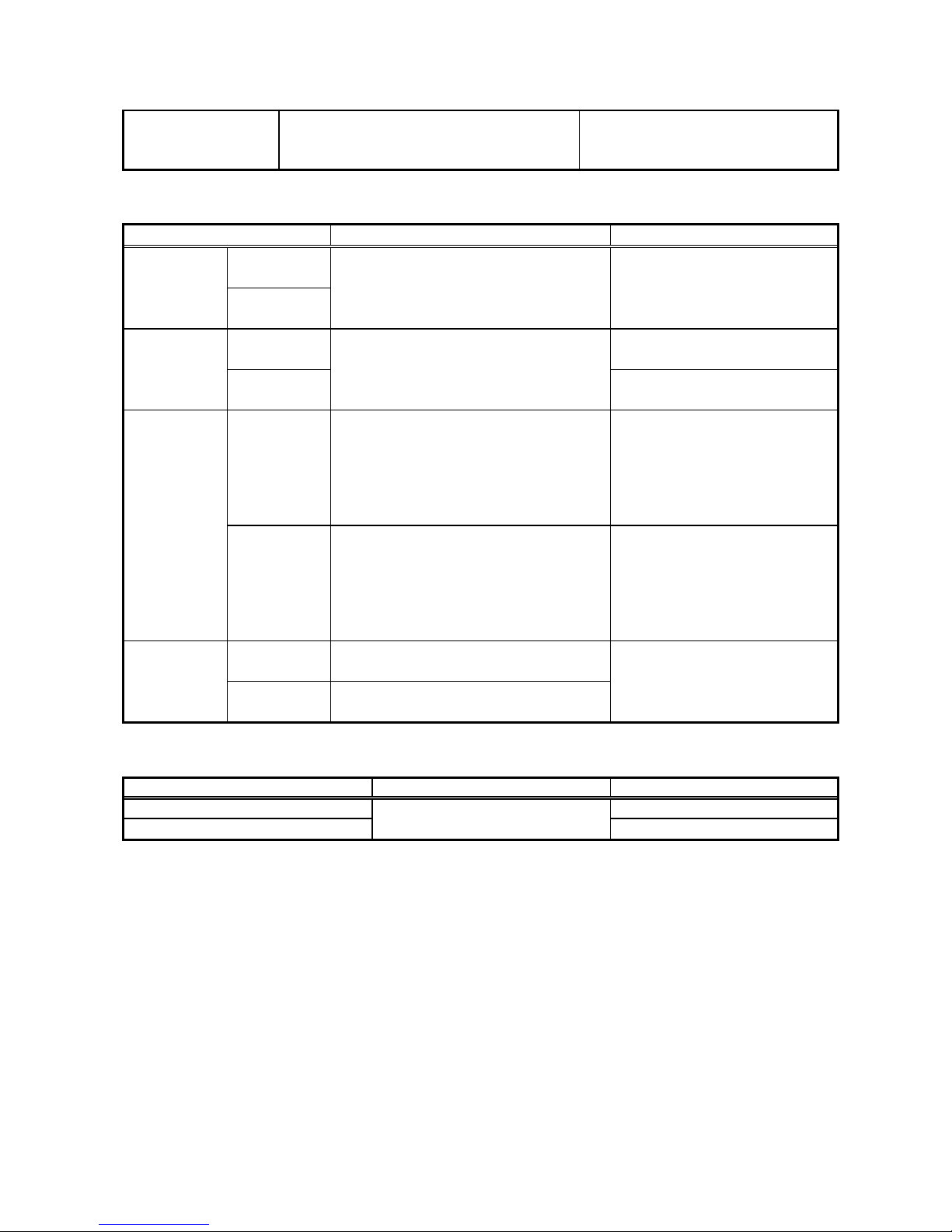

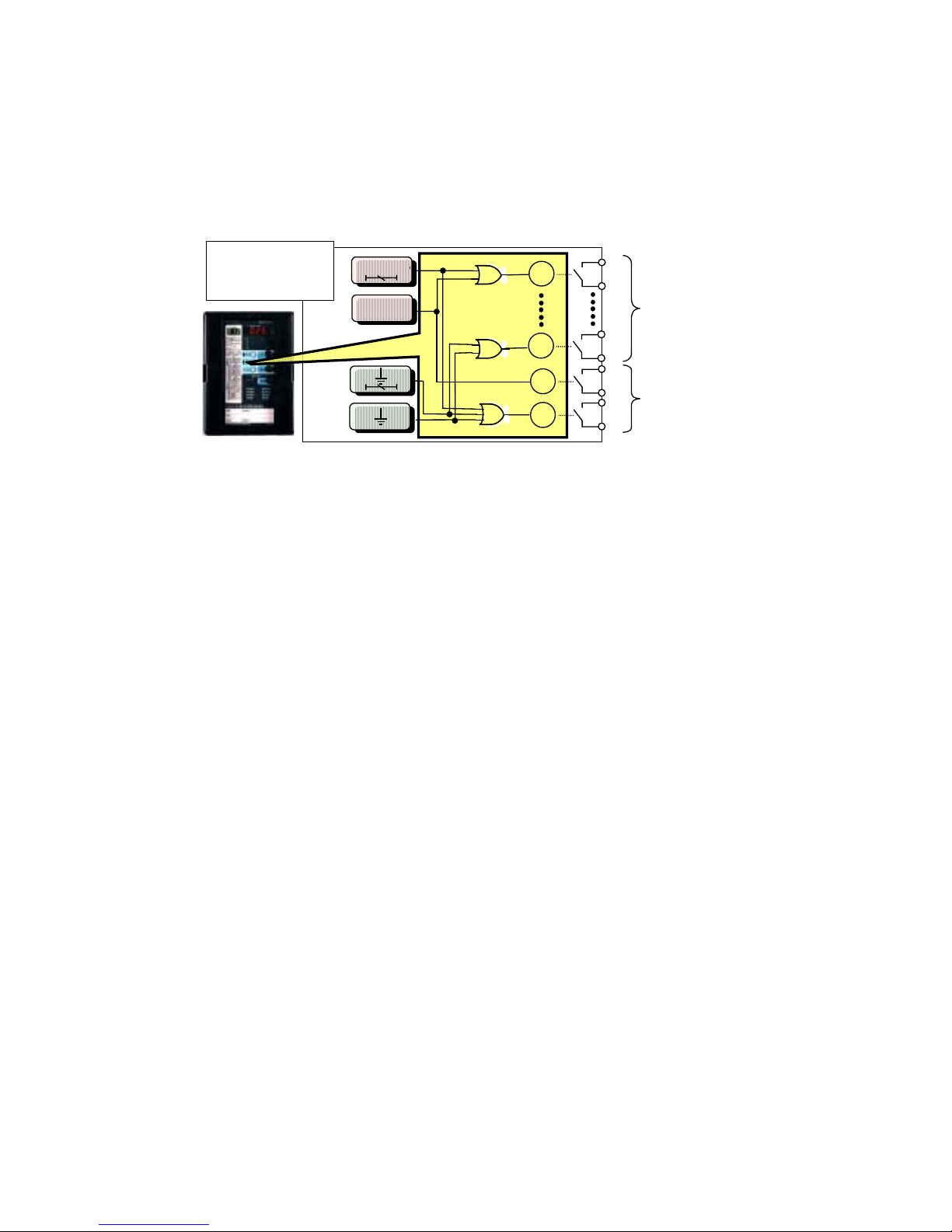

(1) I/O and CPU circuits

Fig. 5.1 shows the internal block diagram of the model CBV2-A01D1.

Voltage input is converted into AC signals at the electronic circuit level via the auxiliary transformer

and filter circuits. These signals are retained as a form of DC signal in the sample hold circuit on each

channel sharing a same time. The multiplexer selects a channel to take the signal and sends it to an

A/D converter. The signals are converted to digital signals sequentially in the converter to be sent to

the CPU.

The setting circuit is used to input setting data into the CPU.

These inputs will be used to carry out the functions shown in Fig. 5.2 “Internal function block diagram”,

and then issue output signals to the display and output relay.

(2) Self-diagnosis circuit

When the self-diagnosis function detects that the electronic and power circuits are normal, the output

relay will be energized to open the self-diagnosis output contact (break contact).

The self-diagnosis output contact (break contact) will be closed when a failure occurs in the circuits

above or when the built-in power fuse burns.

Page 18

18 PCKN-OIL738

Undervoltage CA phase Ind.

Undervoltage AB phase Ind.

Undervoltage BC phase Ind.

Overvoltage CA phase Ind.

Overvoltage AB phase Ind.

Overvoltage BC phase Ind.

U >

Setting

switches

A/D

Numerical display

A-07

VAB

A-0

8

S/HFilter

Trip

X5

X4

X3

X2

X1

X0

Communication indication

Unit indication

Trip indication

Power circuit

monitoring

A-01

AC/DC

DC/DC

Power

source

Auxiliary

power supply

A-03

+

Y

X

5

B-19

B-20

X4

B-17

B-18

Tri

p

contacts

Programmable output

B-07

B-08

X0

B-09

B-10

X1

B-11

B-12

X2

B-13

B-14

X3

Signaling

Self-diagnosis output

Y

Self-diagnosis output

B-05

B-06

Serial

communication

bus

D

A

B-01

DB

B-02

DG

B-03

SLD

B-04

E

A-02

Run indication

Self-diagnosis

(Except comm. card)

Communication card

Self-diagnosis (only comm. card)

Reception circuit

Transmission circuit

MPX

CPU

Overvoltage

element

A-09

VBC

A-10

S/HFilter

A-11

VCA

A-12

S/HFilter

UV Test indication

Undervoltage

element

U <

Figure 5.1 Internal block diagram of Type CBV2-A01D1 relay

Page 19

19 PCKN-OIL738

Signaling

Undervoltage AB phase Ind.

A

-07

Undervoltage BC phase Ind.

Power circuit

monitoring

Self-diagnosis

(Except comm. card)

A

-01

A

-03

+

Programmable output

V

AB

A-08

Undervoltage CA phase Ind.

Trip indication

X1

X0

X2

X3

Trip

X4

X5

Self-diagnosis output

Y

B-0

5

B-06

YX5

B-19

B-20

X

4

B-17

B-1

8

Trip

X

3

B-13

B-14

X

2

B-11

B-12

X1

B-09

B-10

X

0

B-07

B-0

8

DA

B-01

DB

B-02

DG

B-03

SLD

B-04

E

A

-02

Run indication

Communication indication

Auxiliary

power supply

AC/DC

DC/DC

Power

sourse

Communication card

Self-diagnosis (only comm. card)

Reception circuit

Transmission circuit

Serial

communication

bus

Self-diagnosis output

Programmable

output

U >

Overvoltage

element

A

-09

VBC

A

-10

A

-11

VCA

A

-12

Undervoltage

Undervoltage

Undervoltage

Overvoltage

Overvoltage

Overvoltage

Overvoltage AB phase Ind.

Overvoltage BC phase Ind.

Overvoltage CA phase Ind.

Undervoltage

element

U <

Figure 5.2 Internal function block diagram of Type CBV2-A01D1 relay

Page 20

PCKN-OIL738

20

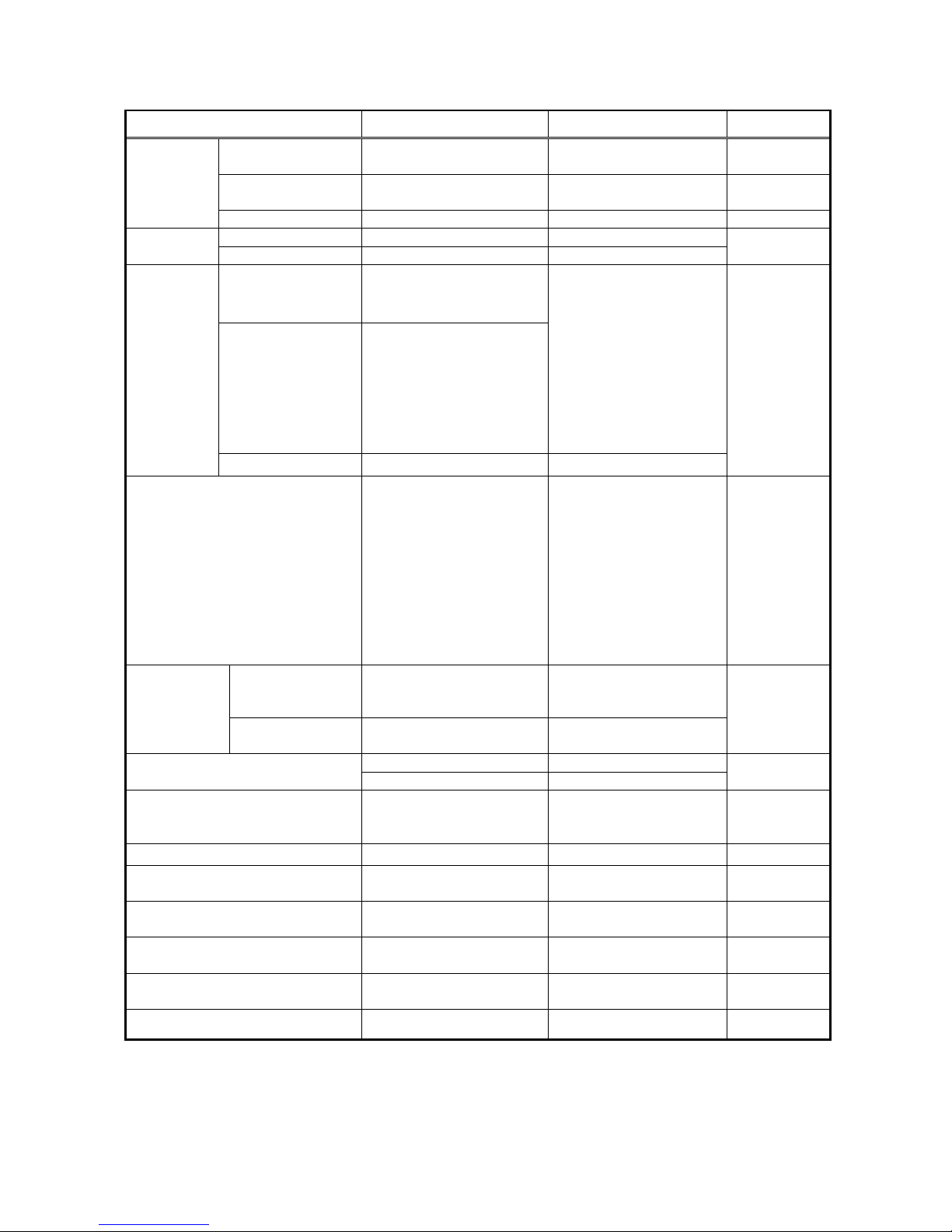

5.2 External connection

(1) Connection diagram

Figures 5.4 to 5.5 show examples of input circuit (AC circuit) connection, Figure 5.6 an example of

control circuit (DC circuit) connection and Figure 5.7 a terminal arrangement.

In the terminals, M3.5 screws should be used and wires of 2 mm

2

or less are recommended to be

used.

(2) Precautions for wiring work

a. Important facilities should be provided with fail safe measures such as dual system to improve

reliability of the facilities.

b. Effects of external surge

Some type of surge with a certain condition may inversely affect the relay. If so, take it into account

to install MF type surge absorbers made by TM T&D.

c. Guarantee of AC auxiliary power supply against power interruption

The AC auxiliary power supply of the relay is not guaranteed against power interruption. When

you do not have an

uninterruptible AC power source, use an AC/DC converter of CPS1 type

manufactured by TM T&D or

uninterruptible power source (UPS) that is commercially available.

d. Inrush current of auxiliary supply

Since inrush current may flow in the relay when the auxiliary power supply is turned on as shown

in the figure below, make consideration of this point when selecting the breaker for the auxiliary

power supply circuit.

Input voltage Inrush current Ip

110V

Approx. 20A

DC

220V

Approx. 55A

100V

Approx. 25A

AC

220V

Approx. 65A

Figure 5.3 Inrush current of auxiliary power supply

e. Trip circuit

Only the contacts X

4

and X5 can be used for the trip circuit. Please keep in mind that the contacts X0

to X

3

can not be used for the trip circuit. (If used, the contact may burn).

Connect the pallet contact (52a) of the circuit breaker to the trip circuit.

f. Self-diagnosis output circuit

The self-diagnosis output contact is so configured that the auxiliary relay can be energized (break

contact) with normal result of monitoring, in order to be able to continue monitoring even if the

Ip

A

pprox.

2ms

Inputting

Input voltage

Input current

0V

0V

Page 21

PCKN-OIL738

21

built-in power fuse burns. Therefore, connect the timer to the external wiring. (See Fig. 5.6 “DC

circuit connection diagram”)

g. Earth circuit

Be sure to earth the earth terminal located on the back of the relay according to the Class D earth

wiring method.

Page 22

PCKN-OIL738

22

E

DA

DB

SLD

DG

B-06

B-05

B-07

B-08

B-09

B-10

B-11

B-12

B-13

B-14

B-17

B-18

B-19

B-20

B-01

B-02

B-03

B-04

A

-02

+

A

-01

A

-03

Y

X

0

X

1

X

3

X

4

X

5

X

2

Auxiliary

power supply

Serial

communication

bus

Comm. card

A

-07

A

-08

A

-09

A

-10

A

-11

A

-12

A B

C

V

CA

VT

VAB

V

BC

U >

Self-diagnosis output

Signaling

Trip

Programmable output

U <

Figure 5.4 External connection diagram for CBV2-A01D1 relay (Phase-to-phase voltage detection)

E

DA

DB

SLD

DG

B-06

B-05

B-07

B-08

B-09

B-10

B-11

B-12

B-13

B-14

B-17

B-18

B-19

B-20

B-01

B-02

B-03

B-04

A

-02

+

A

-01

A

-03

Y

X

0

X

1

X

3

X

4

X

5

X

2

Auxiliary

power supply

Serial

communication

bus

Comm. card

A

-07

A

-08

A

-09

A

-10

A

-11

A

-12

A B

C

V

C

VT

VA

V

B

U >

Self-diagnosis output

Signaling

Trip

Programmable output

U <

Figure 5.5 External connection diagram for CBV2-A01D1 relay (Phase-to-earth voltage detection)

Page 23

PCKN-OIL738

23

Self-diagnosis

output

Trip

DA

DB

SLD

DG

B-06

B-05

B-07

B-08

B-09

B-10

B-11

B-12

B-13

B-14

B-17

B-18

B-19

B-20

B-01

B-02

B-03

B-04

Serial communication

bus

E

A-02

+

Auxiliary

power

supply

A-01

A-03

Programmable

output

Signaling

U>

Overvoltage

U<

Undervoltage

Y

X

0

X

1

X

3

X

4

X

5

X

2

CPS1 type

AC/DC

converter

or

UPS

To control

system (alarm

and other

signals)

52a

Time-delayed

operation

contact

(make contact)

Approx. 1 s

100VDC ~ 220VDC

100VAC ~ 220VAC

TL

TC

To master

station (when

communication

card installed)

Note 1) The self-diagnosis output contact is so configured that the auxiliary relay can be energized (“break contact” opened) when normal result of self-diagnosis is rec eived.

This type of contact will allow the relay to continue automatic self-check even after the built- in power fuse burns. Therefore, the “break contact” is closed when the power

is applied and will be opened after about 50ms. If the auxiliary power supply of the relay and the self-diagnosis output contact shares a same power source, the “break

contact” will be closed temporarily after the auxiliary power supply is turned on. In the case where the phenomenon stated in the above would conflict with your

system requirement, it is recommended that the self-diagnosis output contact should be connected via the time-delayed timer as shown in the left of the figure.

Note 2) Regarding to the type CPS1 AC/DC converter or commercially available uninterruptible power supply (UPS), refer to the note *21 in the section 2.1 General information.

Figure 5.6 Auxiliary power supply circuit connection example of type CBV2-A01D1 relay

Page 24

PCKN-OIL738

24

02

04

06

08

10

12

01

03

05

07

09

11

02

04

06

08

10

12

14

16

18

20

01

03

05

07

09

11

13

15

17

19

A B

A

uxiliary

power supply

+

Earth circuit

E

D

32-M3.5 screws

Figure 5.6 Rear view of type CBV2-A01D1 relay

Page 25

PCKN-OIL738

25

6 Handling

6.1 Unpacking

Usually this relay is packed in a D1 case for transportation. However, it may occur that only the sub unit is

transported independently for the convenience at repair. In such a case, fully brush off the dust, dirt, etc.

adhered to the sub unit after completion of unpacking, and further visually check that the parts mounted

on the front panel or built in the sub unit are not damaged.

6.2 Transportation and storage

To carry the equipment within the place of use, handle it carefully so that the parts installed on the front

panel of the sub unit or built-in parts cannot be deformed or broken.

6.3 Appearance and how to pull sub unit out

The relay is so constructed that the sub unit can be drawn out, in order to facilitate inspection or test. It is

possible to pull the sub unit out without disconnecting the external wiring.

Note that the sub unit should not be drawn out with the line hot. Before drawing out, be sure to take the

following actions.

- Lock the tripping circuit including breakers.

- Stop the main circuit.

- Open the auxiliary power supply circuit.

Bear in mind that careless opening of circuits may result in opening the other control circuits too to impair

the protective function. Be sure to only shut off the concerned circuit.

Communication card

Case

Sub unit

Cover

Lock levers

Draw-out handles

Cover operating buttons

Figure 6.1 Outside view of type CBV2-A01D1 relay

Page 26

PCKN-OIL738

26

6.3.1 How to draw sub unit out

(1) Removing the cover

Hold the lock levers, which are located at both

sides of the cover, on their front sections. Take off

the cover straight toward you

while pushing the

levers inwards

.

(2) Drawing the sub unit

Grip the draw-out handles (located at both sides of

the front of the sub unit). Press the locking pieces

installed in the upper portion of the draw-out

handles with your thumbs to pull the sub unit

towards you.

Note) The sub unit is so designed that it can not be

removed unless it is pulled out with a

relatively strong force, in consideration of

quake-proof measures. When the relay unit

is to be removed independently, it is

recommended to draw it out with the case

held by other operator.

When about a half portion of the sub unit is pulled

out of the case, just stop the drawing motion. Then,

hold the top and bottom of the sub unit to pull it

out completely, in order to prevent the unit from

falling.

Note) Be careful not to touch the printed circuit

board and parts inside the sub unit.

Page 27

PCKN-OIL738

27

6.3.2 Housing the sub unit

(1) Housing the sub unit

Hold the sub unit on the top and bottom to push the

unit into the case approx. a half of the unit.

Note)

- Be careful not to touch the PCB and parts inside

the sub unit.

- The sub unit is so constructed that it can not be

housed in the case upside down.

Fully insert the sub unit into the case until you

hear a click while pressing the handles located on

both sides of the front of the sub unit.

Note) Please note that inserting the sub-unit

incompletely may only establish a poor

contact of the terminals located on the back

of the unit, which may cause operational

failure or heating.

(2) Attaching the cover

Fit the cover straight to the case. Hold the cover

frame to fully push the cover until it is clicked

and locked.

Note) After setting the cover, check if the buttons

can be smoothly pressed from over the

cover.

Page 28

PCKN-OIL738

28

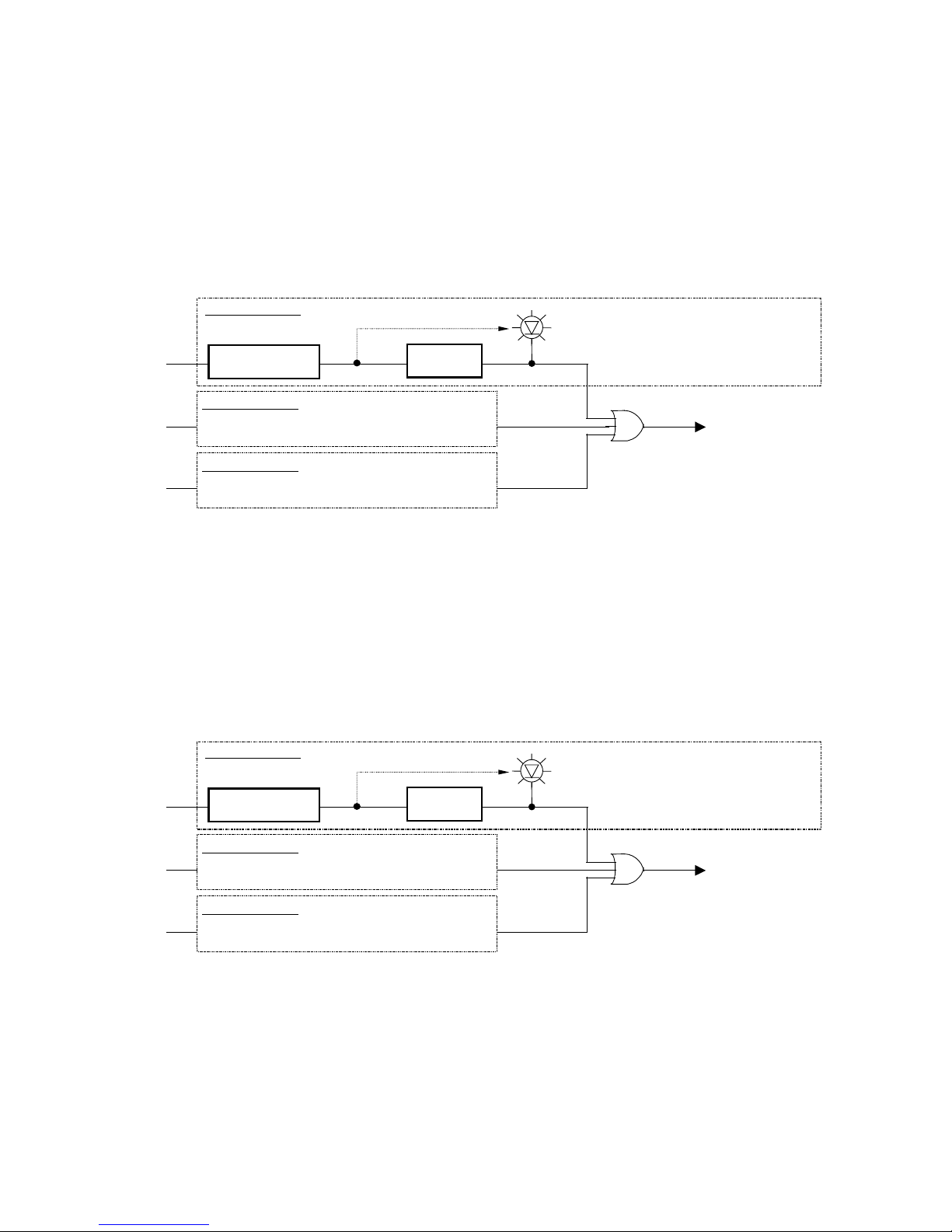

6.4 How to use front control panel

6.4.1 Front control panel layout

U

BC

(

U

B

)

>

U

A

B

(UA)

>

U

CA

(

U

C

)

>

〜

50

FORCED OPERATION

CONTACT X

5

OP.

CONTACT X

0

OP.

7

〜

00

VOLTAGE.

(V)

15

〜

11

ITEM DATA

MITSUBISHI

MELPRO

TM

- D

U

BC

(

U

B

)

<

U

A

B

(

U

A

)

<

COMM

.

RUN

ITEM No.

VkV

2

0

MEASUREMENT

FAULT-RECORD

MAX.-RECORD

11

REAL-TIME

10

15

11

STATUS

3

OP.-ELEMENT

〜

ALARM

4

00

SETTING

5

22

21

20

12

11

10

TIME.

(s)

U <

VOLTAGE

(V)

TIME (s

)

IND.

END

IND.

TRIP

SET.END

SET

SELECT

CANCEL

SETTING

DOWN

UP

MADE IN JAPAN

TM T&D CORPORATION

YEAR:

SERIAL:

RATING:

A

ux. V:STYLE:

VOLTAGE RELAY

CBV2-A01D1

RESET

TRIP

OPERATION INDICATOR

VT-SECONDARY(V

)

02

03

04

RESET MAX.-REC.

05

RESET

06

RESET ALARM

TEST LED

VT-PRIMARY

(V)

60

〜

50

00

OPTION

(

REF.MANUAL

)

OP.IND.-HOLD

01 9

8

(

REF.MANUAL

)

CONT. X

0

〜

X

5

OP.

13

UV-TEST

UV-TEST

U

CA

(

U

C

)

<

CA

-PHASE

BC

-PHASE

A

B

-PHASE

U>

1.Setting/Cancel switch

16.Operation indicator LEDs

7.Operation Indicator Reset

switch

6.Indication/Indication End

switch

11.Communication LED

15.Setting End/Trip LED

3.Setting End/Trip switch

14.Setting/Cancel indicator LED

8.Item No. indicator LED

2.Select/Set switch

4.UP switch

5.Down switch

12.Unit LED

13.Phase LED

9.Item Data LED

10.RUN LED

Figure 6.2 Front view of type CBV2-A01D1 relay

Page 29

PCKN-OIL738

29

Table 6.1 Front control panel guide

No. Designation Symbol Description

1 Setting / Cancel

SETTING/CANCEL

Pressing this switch will start the procedure for setting,

forced operation or option.

When this switch is pressed again instead of the

SET.END/TRIP

switch, data that has been programmed

will be all cleared to terminate the selected procedure.

The SETTING/CANCEL indicator LED is lit during the

procedure.

2 Select / Set

SELECT/SET

This switch is used to select an item number and to program

item data during setting, forced operation or option

procedure.

When data is programmed to be ready for replacing the

currently used setting, the SET.END/TRIP LED will blink.

3 Setting End / Trip

SET. END/TRIP

When the SET.END/TRIP switch is pressed with its LED

blinking during setting, forced operation or option procedure,

the currently enabled setting will be replaced by data given

by programming. The new setting will be thus enabled.

4 UP select

UP

5 DOWN select

DOWN

These switches are used for selecting data elements.

Pressing these switches for a while will allow fast forwarding.

With the cover operating buttons, you can use the switches

without removing the cover.

6 Indication / Indication End

IND./IND.END

Pressing this switch will start or end the display of settings

and measurements.

With the cover operating button, you can use the switch

without removing the cover.

7

Operational key switches

Reset

RESET

Pressing this switch will reset output contacts after the relay

operated and extinguish the operation indicator LEDs.

With the cover operating button, you can use the switch

without removing the cover.

8 Item No. Green

‑

A number allocated to the selected setting, forced operation

or option item is indicated here.

9 Item Data Red

‑

Data that corresponds to the item number selected is

displayed here.

For the indication of individual letters, see Table 6.2.

10 RUN Green

‑

Indicate the result of the automatic self-check. The lamp will

be lit for normal results while off for abnormal.

11 Communication Green

‑

Indicate the operational status of the communication card.

- With a communication card installed: the lamp will be lit for

normal conditions, blinking during communication and off

for abnormal conditions.

- With a communication card not installed: the lamp will be

off.

12 Unit Yellow

‑

Indicate the unit used for the item data.

13 Phase Yellow

‑

Indicate the phase that corresponds to the item data.

14 Setting / Cancel Yellow

‑

This lamp will be lit during setting, forced operation or option

procedure.

15 Setting End / Trip Yellow

‑

This lamp will blink when new data is programmed to be

ready for replacing the currently enabled setting.

16

Indicator LEDs

Operation Red

‑

Indicate the corresponding operation elements and phases

of the relay.

Page 30

PCKN-OIL738

30

Table 6.2 Letter representation of item data indicator LEDs

Item

Item

Designation Letters

Display in item data

box

Designation Letters

Display in item data

box

On ON

USE OFF

Off OFF

AB-

phase

AB

Yes YES

BC-

phase

BC

No NO

UV Test

CA-

phase

CA

Operation

lock

LOCK

Instantaneou

s

INST

Page 31

PCKN-OIL738

31

6.4.2 Operational procedure

For more information about the operational procedure shown below, see the MELPRO-D Series General

Operation Manual (PCKN-OIL750).

6.4.2.1 Relay without RS232C communication I/F

Table 6.3 Operational procedure

Item

Corresponding section of

general operation manual

No. Designation Description

Indication

mode

Setting / forced

operation /

option mode

010 Real time

Measure and display effective value voltages input

to the relay all the time.

A-1

011 Max. record Display the max. effective value voltage.

A-2

211 1st phenomena

212 2

nd

phenomena

213 3rd phenomena

214 4th phenomena

215

Measurement

Fault

record

5th phenomena

Keep in record and display effective value currents

for up to five latest phenomena of relay trip caused

by system fault.

The 1

st

phenomena is the latest trip and the 5th the

oldest.

A-3

311 1st phenomena

312 2

nd

phenomena

313 3rd phenomena

314 4th phenomena

315

Operation

elements

5th phenomena

Keep in record and display the status of the

operation indicator LEDs for up to five latest

phenomena of relay trip caused by system fault.

The 1

st

phenomena is the latest trip and the 5th the

oldest.

A-4

400

Status

Self-diagnosis (ALARM)

Keep in record and display defect codes in the

case where an abnormal condition is detected by

the

self-diagnosis.

A-6

511 Operation voltage [V]

512 Operation time [s]

513

Undervoltage

UV TEST

521 Operation voltage [V]

522

Setting

Overvoltage

Operation time [s]

Set and display settings.

A-7 B-1

700 Contact X0 operation

710 Contact X1 operation

720 Contact X2 operation

730 Contact X3 operation

740 Contact X4 operation

750

Forced

operation

Contact X5 operation

Carry out forced operation of output contacts

individually.

The setting of the programmable outputs can be

checked through the operation indicator LEDs.

C-1

800 Contact X0

810 Contact X1

820 Contact X2

830 Contact X3

840 Contact X4

850

Contact

arrangement

Contact X

5

Configure the programmable outputs. Also, set

and display self-hold/reset setting of the

programmable outputs.

For the guide for setting, see the section 6.4.2.3

(1) below.

D-1

860 Operation indicator LED hold

Set and display self-hold/auto reset setting of the

operation indicator LEDs. For the guide for setting,

see the section 6.4.2.3 (2) below.

D-2

901 VT primary side [V]

Set the VT primary voltage of voltage circuit

connected to the relay.

902 VT secondary side [V]

Set the VT secondary voltage of voltage circuit

connected to the relay.

A-7

D-3

903 Max. record reset Clear data of the max. record.

904 Fault record reset Clear data of the fault record.

905

Self-diagnosis (ALARM) reset Clear data of the self-diagnosis record.

D-4

906

Option

LED lamp test

Carry out forced illumination of all the LED lamps

on the front of the relay unit.

D-5

Page 32

PCKN-OIL738

32

6.4.2.2 Relay with RS232C communication I/F

Item

Corresponding section of

general operation manual

No. Designation Description

Indication

mode

Setting / forced

operation /

option mode

As the same as Table 6.3 described in item 6.4.2.1 about the No. 010〜860.

901 VT primary side [V]

Set the VT primary voltage of the voltage circuit

connected to the relay.

902 VT secondary side [V]

Set the VT secondary voltage of the voltage circuit

connected to the relay.

D-3

903 Relay password enable/disable option Set relay password enable or disable for setting.

A-7

D-9

904 Max. record reset Clear data of the max. record.

905 Fault record reset Clear data of the fault record.

906

Self-diagnosis (ALARM) reset Clear data of the self-diagnosis record.

D-4

907

LED lamp test

Carry out forced illumination of all the LED lamps

on the front of the relay unit.

D-5

Page 33

PCKN-OIL738

33

6.4.2.3 Guide for option function

(1) Specifying contact arrangement data of output contacts

The table below shows the setting guide table. See the section D-1

of the general operation

manual for the detailed procedure.

Input

Digit

No.

Setting item

0 1

0 Self hold / auto reset upon reset

judgement

Reset Hold

1 Undervoltage AB-phase Off On

2 Undervoltage BC-phase Off On

3 Undervoltage CA-phase Off On

4 Not used X

5 Overvoltage AB-phase Off On

6 Overvoltage BC-phase Off On

7 Overvoltage CA-phase Off On

8 Not used X

9 Not used X

10 Not used X

11 Not used X

12 Not used X

13 Not used X

14 Not used X

15

OR element combination

Not used X

00000 0 00 0

ditto.

ditto.

0

Contact arrangement data

0

Conversion from binary number to hexadecimal

Binary Æ Hexadecimal Binary Æ Hexadecimal Binary Æ Hexadecimal

0 0 0 0 Æ 0 0 1 1 0 Æ 6 1100Æ C

0 0 0 1 Æ 1 0 1 1 1 Æ 7 1101Æ D

0 0 1 0 Æ 2 1 0 0 0 Æ 8 1110Æ E

0 0 1 1 Æ 3 1 0 0 1 Æ 9 1111Æ F

0 1 0 0 Æ 4 1 0 1 0 Æ A

0 1 0 1 Æ 5 1 0 1 1 Æ B

ditto.

When the product is shipped from the factory, contact arrangement data are set as follows..

Contact

Item

number

Contact

arrangement

data

Setting of the element Contact

Item

number

Contact

arrangement

data

Setting of the element

X0 800 000E Undervoltage X3 830 00E0 Overvoltage

X1 810 000E Undervoltage X4 840 00EE OR of all the elements

X2 820 00E0 Overvoltage X5 850 00EE OR of all the elements

*The “Self hold/auto reset” setting are “Reset” (auto reset) for all contacts.

Page 34

PCKN-OIL738

34

(2) Specifying operation indicator LED hold data

The table below shows the setting guide table. See the section D-2

in the general operation

manual for the detailed procedure.

Input

Digit

No.

Setting item

0 1

0 Trip Reset Hold

1 Undervoltage AB-phase Reset Hold

2 Undervoltage BC-phase Reset Hold

3 Undervoltage CA-phase Reset Hold

4 Not used X

5 Overvoltage AB-phase Reset Hold

6 Overvoltage BC-phase Reset Hold

7 Overvoltage CA-phase Reset Hold

8 Not used X

9 Not used X

10 Not used X

11 Not used X

12 Not used X

13 Not used X

14 Not used X

15 Not used X

00000 0 00 0

ditto.

ditto.

0

Operation indicator LED hold data

0

Conversion from binary number to hexadecimal

Binary Æ Hexadecimal Binary Æ Hexadecimal Binary Æ Hexadecimal

0 0 0 0 Æ 0 0 1 1 0 Æ 6 1100Æ C

0 0 0 1 Æ 1 0 1 1 1 Æ 7 1101Æ D

0 0 1 0 Æ 2 1 0 0 0 Æ 8 1110Æ E

0 0 1 1 Æ 3 1 0 0 1 Æ 9 1111Æ F

0 1 0 0 Æ 4 1 0 1 0 Æ A

0 1 0 1 Æ 5 1 0 1 1 Æ B

ditto.

When the product is shipped from the factory, all LEDs are set to self-hold.

Item number

Operation indicator LED hold data

860 00EF

Page 35

PCKN-OIL738

35

7 Mounting

7.1 Mounting dimension

Mount the case to the panel according to Fig. 7.1 “Mounting dimension”.

205

184

130151 203

(18)

35

114 (185)

4-M5 screws (for mounting)

M3.5 screw (for terminals)

194

150

4-φ6 holes

Figure 7.1 Outside dimension /drilling drawing

7.2 Standard operating environment

Install the relay in the environment described in section 3.3 Common technical data. In addition, the

following conditions should be kept:

- Abnormal vibration, shock, inclination or magnetic field should be avoided.

- Harmful smoke or gas, salt gas, excessive humidity, water drop or vapor, excessive dust or

fine powder, rain and wind should be avoided.

Page 36

PCKN-OIL738

36

8 Test

The relay has been fully tested prior to shipment. However, it is recommended to carry out a test again by

referring to the following test guide before use.

8.1 Appearance inspection

Check the relay for appearance according to the following procedure:

Objects Check points

Coil/conductor (1) Discoloring and burning due to overheat.

(2) Abnormal conditions including loosened screws.

Printed card (1) Discoloring of the printed card due to overheated parts.

(2) Contact between the printed card and connector

Unit

Mechanism (1) Deformation

(2) Operation of the operating key switches.

(3) Damage of the draw-out lever of the sub unit.

(4) Discoloring and deformation of the name plate on the front panel.

(5) Damage of the terminal section.

Case/cover (1) Damage of the cover.

(2) Stain of the cover.

(3) Clouding of the cover.

(4) Damage of the lock lever of the cover.

(5) Damage of the operating buttons of the cover.

(6) Operation of the operating buttons of the cover.

(7) Damage of the terminal section.

Others Invasion of foreign matters including dust and iron chips.

Page 37

PCKN-OIL738

37

8.2 Characteristic test

8.2.1 Precautions in testing

(1) Standard test conditions

Ensure the following test conditions whenever possible:

Note that carrying out a test under an environment that significantly differs from the following

conditions may produce an incorrect result.

- Ambient temperature : 20°C±10°C

- Rated frequency : ± 5%

- Waveform (AC) : 2% (distortion ratio)

- Auxiliary power supply voltage : rated voltage ±2%

(2) Characteristic control point

See the section 3 “Characteristics”.

The characteristic control point refers to the characteristic of a relay unit only. Note that, when a

characteristic test is carried out on a relay system connected with external equipment such as CT

and ZCT, the result obtained would be a combined characteristic added with the fluctuation of the

external equipment.

For special control in terms of a specific control point (for instance, using the operation setting), first

carry out a test at “Characteristic control point” at the time when the relay is received or put in service

to determine the acceptance/rejection. Thereafter, perform another test at each control point, so that

the data obtained can be used for future reference.

(3) Changing setting

Change the setting according to the section 6 “Handling”.

(4) Operation judgment

Determine the operation currents and time and other values of the relay unit basically by turning on

and off the corresponding output relay contact of each element.

To determine the starting value of the time-delayed elements of overcurrent relay, which cannot be

checked through the output contact, read the display of “elapsed time of time-delayed timer”.

(5) Communication card

Whatever the communication card is inside or not, for the test of withstand voltage and lightning

impulse withstand voltage, please avoid inputting test voltage to the serial communication network

circuit (DA, DB, DG, SLD terminals).

Note: it is not necessary to take the communication card out when test if the communication card was

inside unit.

Page 38

PCKN-OIL738

38

8.2.2 Characteristic test

(1) Test circuit

Connect the external wiring referring to the AC input circuit diagram shown below:

A-07

Voltage

CBV2-A01D1

A-08

~

V

~

Test Phase Teraminal No.

AB-phase A-07~A-08

BC-phase A-09~A-10

CA-phase A-11~A-12

Show the Ex. AB-phase

(2) Test items and characteristic control point

a. Forced operation test

See “Front control panel operational procedure” in the section 6 “Handling”.

b. Operation value test

See “Operation and reset values” in the” 3 “Characteristic”.

c. Operation time test

See “Operation time” in the” 3 “Characteristic”.

d. Reset time test

See “Reset time” in the”3 “Characteristic”.

Page 39

PCKN-OIL738

39

9 Maintenance

9.1 Daily inspection

Take every opportunity to carry out the following inspection:

- Check that the cover is not damaged and is attached properly.

- Check that no dust or iron chips have invaded into the unit.

- Check that the cover is not clouded notably.

- Check that abnormal noise is not generated.

- Check that the RUN LED lamp is lit.

9.2 Periodical inspection

It is recommended to carry out periodic inspections to check the relay for proper function.

For periodical inspections, perform the appearance inspection and characteristic test in accordance with

the section 8 “Test”.

Page 40

PCKN-OIL738

40

10 Ordering

The product and specification shown in this manual may subject to changes (including specification

change and production suspend) without notice. It is advisory to inquire the nearest TM T&D’s branch or

sales office, if required, to confirm that the latest information is given in the manual, prior to placing an

order.

Notify the following items when placing an order.

Item Example of order Remarks

Model CBV2-A01D1 For more information, see the section

2 “Rating and specification”.

Frequency 50 Hz Select 50Hz or 60Hz.

Rating Voltage : 57 ~ 120V For more information, see the section

2 “Rating and specification”.

Setting range Undervoltage element (27): 10 ~ 110V

0vervoltage element (59) : 60 ~ 155V

For more information, see the section

2 “Rating and specification”.

Communication

card

One of the followings can be selected:

a. MODBUS communication card (Manual

No.: PCKN-OIL703)

b. CC-Link communication card (Manual No.:

PCKN-OIL751, PCKN-OIL752)

c. No communication card

Only purchasing a communication

card separately will allow customer to

add the communication facilities.

If customer does not need the

communication facilitates at the time

of introducing the system, just

purchase the relay unit without

communication card. Customer can

add the communication facilities

whenever he/she needs to introduce

them. This will help decrease the

initial cost and upgrade the system in

stages.

Loading...

Loading...