Page 1

;; _

• - ^ ^

-V. •' -

INSTRUCTIONS

AND

PARTS

BOOK

FOR

'V

>•.

_

-•

- - J

IIMSTRUCTION

WRAPPED-AROUND

MITSUBISHI

_

MODEL

A •

AtJVANCtDA'KlDEVtRAliVANClNii

A.

MITSUBISHI

INDUSTRIAL

FOR

: CB-610

ATTACHMENTS

{SHANK

MACHINE

(BUTTON

SEWING

BUTTON

and

BUTTON)

ON

SEWER)

ELECTRIC

Page 2

'Mitsubishi"

Model

CB-610

(button

sewer)

By mounting this shank

shank

button

at

the

• However, accordingtothe

portionofbutton

At first, please

the

shank

guide

remove

button

button

maximum

plate.

the

clamp

attachmentinthe

clamp

diameter

typeofshank

fiat

button

attachment,

of

button,

clamp

INDEX

The

shank

button

clamp

attachment

1.

Specifications:

2.

Nameofthe

3.

Instruction

— 1.

Preparation

main

parts.

howtomount.

Removingofchanging

2

2

3

— 2. Assembling Feed plate 11). feed plate (2)

Button

clamp

arm

4.

Adjustment:

— 1.

Button

— 2.

Automatic

— 3.

Treadle

(1) Changing

(2)

— 4.

Adjustmentofneedle

clamp

arm

(small).

liftingofbutton

liftingofbutton

Mountingofstopper.

into

clamp

treadle

bar

5

Positionofright

clamp

arm.

arm.

lifting.

height.

you can work with

30mm.

you

must

attachment,

following orders:

(jarts.

(large).

Button

clamp

and

left,

forward

adjust

and

presser

and

some

mount

bar.

backward.

II.

The

wrapped-around

1.

Nameofthe

2.

Howtosew

3.

Adjustment.

the

button

main

parts

wrapped-around

attachment

(wrapped-around

button,

button

and

howtomount

attachment).

the

attachment.—9

8

13

Page 3

I

The

1.

Specifications:

— 1.

— 2.

— 3.

— 4.

Shank

Shitabte.needle

Shank

button

Available

Other

button.

specifications

button

TQ

x 7

attachment,

Max.

are

(175x5)

part

30mm

the

same

clamp

No.

W324591

dia.

approx.

withofmodel

attachment

CB-610

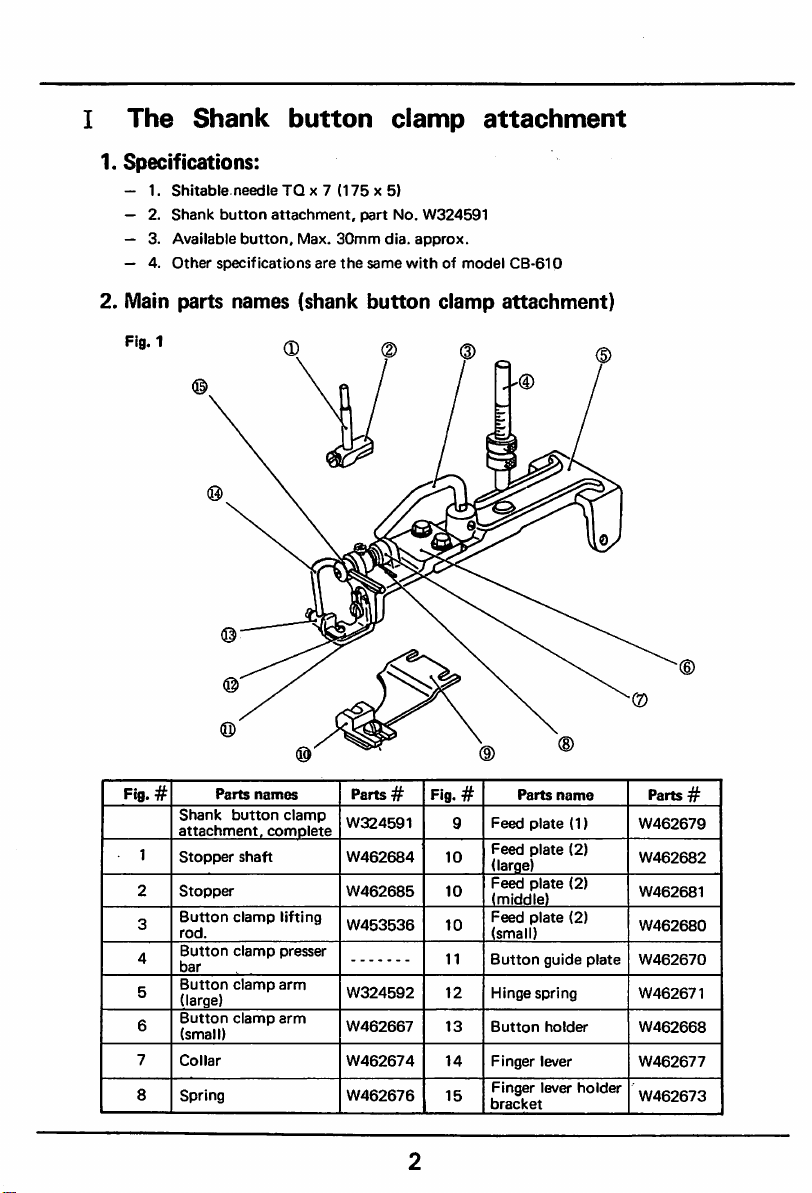

2. Main parts names (shank

Fig.i Q

©

Fig. #

1

2

3

4

5

6

7

8

Parts

Shank

attachment,

Stopper

Stopper

Button

rod.

Button

bar

Button

(large)

Button

(small)

Collar

Spring

names

button

shaft

clamp

clamp

clamp

clamp

clamp

complete

lifting

presser

arm

arm

button

Parts

W324591

W462684

W462685

W453536

W324592

W462667

W462674

W462676

clamp

#

Fig.#

9

10

10

10

11

12

13

14

15

attachment)

Parts

name

Feed

plate

(1)

Feed

plate

plate

plate

guide

spring

holder

lever

lever

(2)

(2)

(2)

(large)

Feed

(middle)

Feed

(small)

Button

Hinge

Button

Finger

Finger

bracket

plate

holder

Parts #

W462679

W462682

W462681

W462680

W462670

W462671

W462668

W462677

W462673

Page 4

\

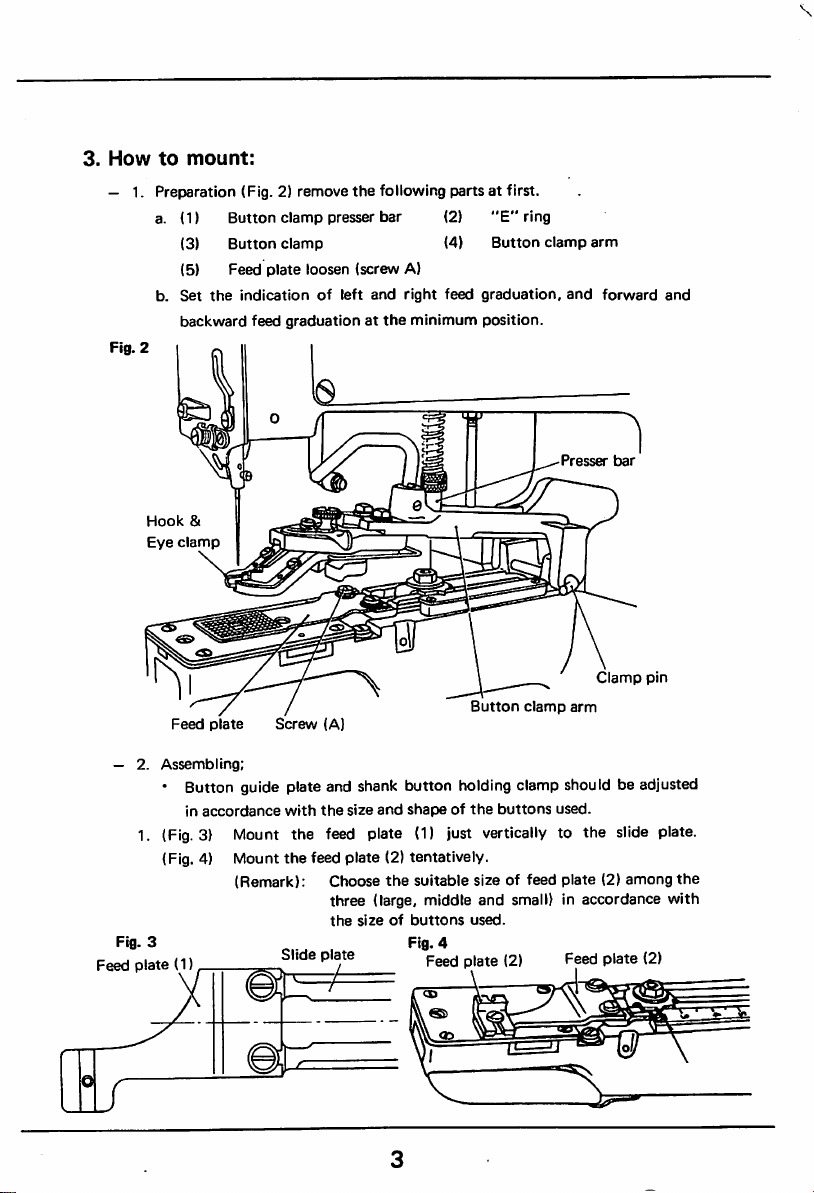

3.

How

to

mount:

Preparation (Fig. 2) remove

- 1.

a. (1)

(3)

Button

Button

clamp

clamp

the

following parts at first,

presser bar (2)

(4)

"E"

Button

ring

clamp

arm

(5) Feed plate loosen (screw A)

Set

the

Fig.

2

Hook

Eye

b.

backward

clamp

indicationofleft

&

feed

graduationatthe

and

right

feed

minimum

graduation,

position.

and

Presser

forward

bar

and

Clamp

Button

clamp

arm

— 2.

Feed

plate

Assembling;

Screw

(A)

• Button guide plate and shank button holding clamp should be adjusted

in

accordance

(Fig.3) Mount the feed plate (1) just vertically to the slide plate.

1.

with

the

size

and

shapeofthe

buttons

used.

(Fig. 4) Mount the feed plate (2) tentatively.

Feed

Fig.

3

plate

(Remark): Choose

(1)

Slide

plate

the

suitable size of feed plate (2)

three (large, middle

the

sizeofbuttons

Fig.

4

Feed

and

used.

plate

small) in

(2)

accordance

Feed

plate

pin

among

(2)

the

with

Page 5

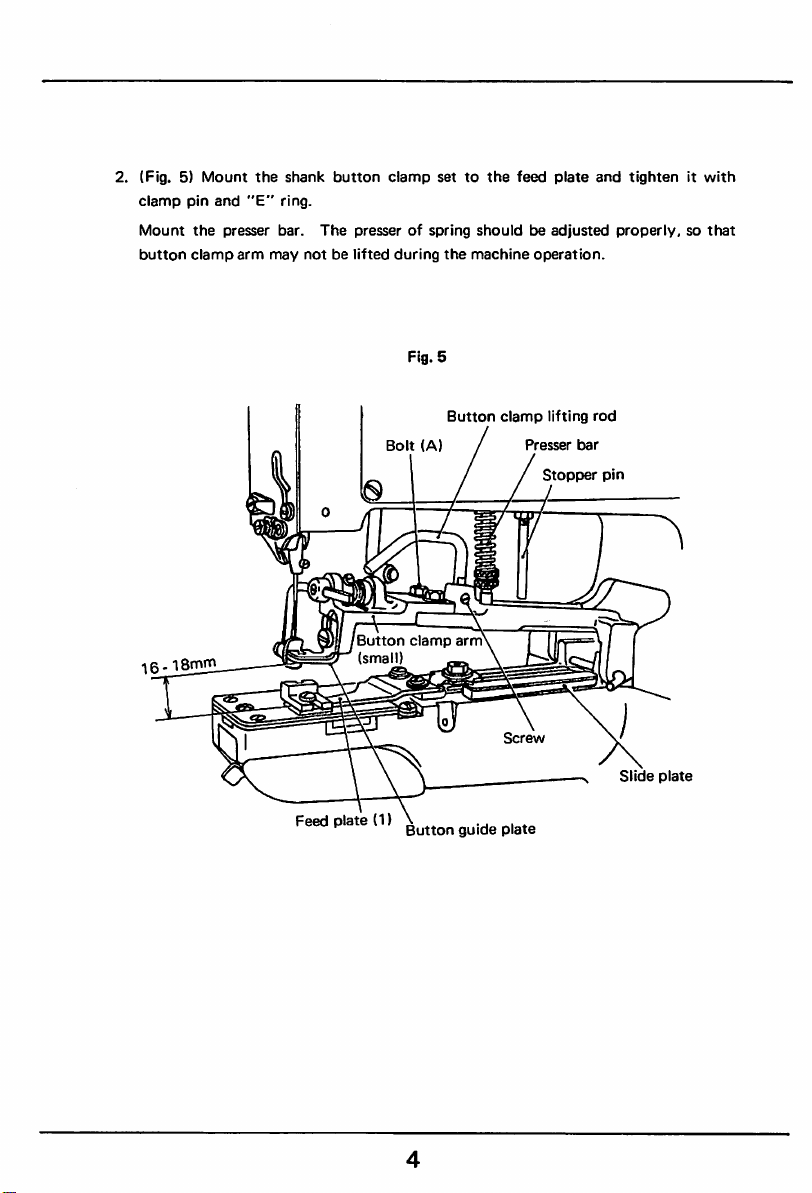

2. (Fig. 5)

clamp

Mount

button

16-

iSmhi

Mount

pin

the

clamp

and

presser

arm

the

"E"

shank

ring.

bar.

may

notbelifted

button

The

presserofspring

Bolt

8

Button

(small)

clamp

during

Fig. 5

clamp

settothe

shouldbeadjusted

the

machine

Button

(A)

/

arm

feed

clamp

Screw

plate

operation.

lifting

Presser

Stopper

and

tightenitwith

properly,sothat

rod

bar

pin

s

Feed

plate

(1)

Button

guide

plate

Slide

plate

Page 6

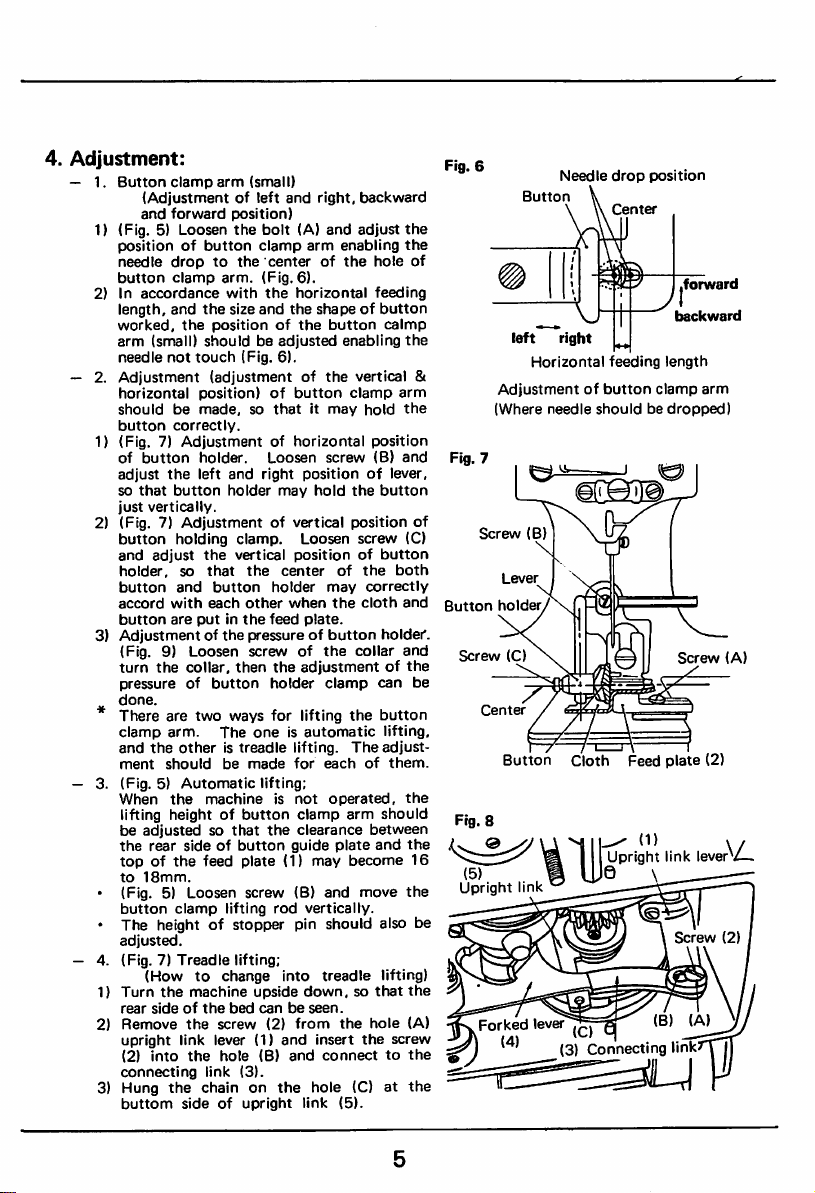

4.

Adjustment:

— 1.

Button

clamp

arm

(Adjustmentofleft

and

1) (Fig. 5) Loosen

2) In

— 2.

1) (Fig. 7)

2) (Fig. 7)

3)

forward

positionofbutton

needle

droptothe

button

clamp

accordance

length, and

worked,

arm

needle

Adjustment

horizontal

shouldbemade,sothatitmay

button

(small)

not

correctly.

the

Adjustmentofhorizontal

of

button

adjust

the

so

that

button

just

vertically.

button

and

holder,

button

accord

button

Adjustmentofthe

(Fig. 9)

turn

pressureofbutton

done.

Adjustment

holding clamp. Loosen

adjust

so

and

with

are

Loosen

the

collar,

• There are two

clamp

arm.

and

the

ment

— 3. (Fig. 5)

When

lifting

be

the

topofthe

to

• (Fig. 5) Loosen screw (B) and

button

• The height of stopper pin should also be

adjusted.

— 4. (Fig. 7)

1)

Turn

rear

2)

connecting

3) Hung

otheristreadle

should

Automatic

the

heightofbutton

adjustedsothat

rear

sideofbutton

18mm.

clamp

Treadle

(Howtochange

the

machine

sideofthe

Remove

upright

(2)

buttom

the

link lever (1)

into

the

the

sideofupright

(small)

and

position)

the

bolt

(A)

clamp

arm

centerofthe

arm.

(Fig.

the

and

(Fig. 6).

Loosen

right

6).

horizontal

the

positionoflever,

may

with

the

size

positionofthe

shouldbeadjusted

touch

(adjustmentofthe

position)ofbutton

holder.

left

and

holder

of vertical

the

vertical

that

button

each

putinthe

ways

The

be

machineisnot

feed

lifting

bed

screw

hole

link

chainonthe

positionofbutton

the

center

holder

other

when

feed

plate.

pressureofbutton

screwofthe

then

the

adjustmentofthe

holder

for

lifting

oneisautomatic

lifting.

made

for

lifting;

clamp

the

clearance

guide

plate

(1)

rod

vertically.

lifting;

into

upside

down,sothat

canbeseen.

(2)

from

and

(B)

and

(3).

link

right,

backward

and

adjust

enabling

hole

feeding

shapeofbutton

button

caimp

enabling

vertical &

clamp

arm

hold

position

screw

(B)

hold

the

button

position

screw

of

the

correctly

cloth

holder.

collar

can

both

may

the

clamp

the button

lifting,

The

adjust

eachofthem.

operated,

arm

should

between

plate

may

hole

and

become

move

treadle

lifting)

the

hole

insert

the

(C)atthe

(5).

screw

connecttothe

the

the

the

the

and

(C)

and

and

the

the

the

the

(A)

of

16

of

be

Fig.

6

left

Adjustmentofbutton

(Where

Fig. 7

Screw

Button

holdeiy\.-(vt

Screw

(C)

Center

Button

(5)

Upright

link

Forked

Needle

Button

right

Horizontal

needle

shouldbedropped)

(B)

Cloth

0 \

lever

(3) Connecting link

drop

r)osition

feeding

length

clamp

Feed

plate

Upright

link

(B)

,forward

backward

arm

Screw

(2)

lever^/-

Screw

(A)

(A)

(2)

Page 7

(2) Stopper should be mounted so that you can take out the button from the lever

opened at the same time when the thread is cut by the treadle lifting.

(Fig. 9) Mount the stopper shaft to the arm with screw (A).

•

Mount

the

Fig.

stoppertothe

• (Fig. 11)

button

position).

9

The

holder to

position of

open

stopper

when

the

the

Screw

shaft.

stopper

button

(Al

shouldbeadjusted

enabling

clamp arm is lifted (stopped

Fig.

10

Screw

finger

Button

Screw

(B)

N

lever

holde^

(C)

Needle

bar

button

bushing

Lever

holder

Screw

(A)

Fig.

11

Lever

Button

—Stopper

cn»

stopper

shaft

Collar

Stopper

Stopper

Screw

shaft

(A)

Button

— 4.

Adjustmentofthe

• TQ X 7 (long

^

needle

bar

height

side

needle)

• (Fig. 9) The timing of the needle bar should be adjusted by means of

indication

of

two

line

(B).

Page 8

01AI3IAI

Page 9

II

The

wrapped-around

button

attachment

1. Nameofthe

main parts (wrapped-around

Fig. 1.

button

attachment).

(1)

Thumbscrew

(4)

Adjustable

plate

(2)

(5)

Adopter

Guide

plate

(3)

(6)

8

Screw

Feed

plate

Page 10

2. How to sew

the

wrapped-around button, and how to mount

the

attachment.

1) Asshown in

between

the

Fig.

2, sew the button by means of makingsome gap

button

and

the

fabric.

Fig. 2.

Button

s

-zzzzzzzz

Fabric

/

v//////.

"A"

Mount

the

between

attachmentinthe

the

fabric

and

following way in

button.

ordertomake

some

gap

Page 11

a) Mount the adopter to the standard flat button clamp with screw (A),

as

shown

in Fig. 3.

Fig. 3.

Thumb

screw

A

Adopter

10

Page 12

2) Do

wrap-around

* In

ordertowrap-around

attachmentinthe

the

button.

following

the

button,

way;

mount

the

wrapped-around

button

a) Remove

3. Button clamp pin. 4. Button clamp attachment complete.

the

following parts (Fig. 4).

1. Button clamp presser bar. 2. E ring.

5. Feed plate (loose screw

"A").

Fig. 4

Presser

bar

Button

clamp

Button

clamp

holder

Feed

plate

Screw

(A)

11

pin

Page 13

b) Mount

* Mount

the screw

the

wrapped-around

the

attachment just vertically to

"A"

as shown in Fig. 5.

Screw

button

Fig. 5.

A

attachment.

the

Slide

plate

slide plate with

Wrapped-around

attachment

button

12

Page 14

3.

Adjustment:

1)

Adjustmentofthe

needle bar height.

a. Use the longer type needle (TQ x 7).

b. Adjust

the

height of

the

needle bar by means of refering

the two timing marks (B) indicated on the needle bar

as

shown

in Fig. 6.

Fig.

6.

Needle

bar

bushing

WrapiDed-around

attachment

button

13

Page 15

2)

Adjustmentofthe

In case of wrapping-around

and

backward

forward

feeding at

"0".

and

the

backward

button,

feeding:

adjust

the

forward

3) Adjust the gap (A) between the adjustable plate and the guide plate

with

the

screw

(B), so

is sewn allowing

the

that

the

proper

gap between fabric

button,

which

with

adopter,

can be tightly inserted as shown in Fig. 7.

Fig. 7.

Screw

Screw

(B)

Button-

Fabric

Needle

right&left

drop

Forward

Adjustable

Guide

Feed

14

(C|

and

plate

length

backward

plate

Page 16

4) Adjustment of the forward and backward position.

Adjust

the

the position of

button

and

needle

the

fabricasshown

enabling

in Fig. 7.

to drop to the center

Adjustment of the gap (A) between the adjustable plate and guide plate,

and

the

forward

and

backward

position

can be done by means of losseningthe screw (B) at the same time

between

5) Adjustment if

Adjust

so

that

sewn

the

6) Adjust

tobesewn,sothat

the

left and right position.

the

position of needle by loosening the screw (C),

needle drops properly on

buttonasshown

the

left and right feed length in accordance with

the

in Fig. 7.

needle

side of the button sewing thread (Fig. 7).

the

both sides of thread

dropsonthe

outer

the

button

15

Page 17

MEMO

16

Page 18

©

'''

•"

••

V,"'•??

^

jj-

"'f

V •-'- ' .

--

^

A

MITSUBISHI

No.

2-3

2-CHOME

ELECTRIC

MARUNOUCHI

CORPORATION

CHIYOOA-KU

TOKYO

'W

JAPAN

"

Js

rs

'4;t

Loading...

Loading...