Mitsubishi AA121XN11 Specification

Global LCD Panel Exchange Center

Preliminary

www.panelook.com

TENTATIVE

All information in this technical data sheet is tentative

and subject to change without notice.

12.1” XGA

TECHNICAL SPECIFICATION

Sample Product Name : AA121XN11-CE-01

MITSUBISHI ELECTRIC Corp.

Date: Aug.8,’12

MITSUBISHI Confidential (1/29) AA121XN11-CE-01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

CONTENTS

No. Item Page

-- COVER 1

-- CONTENTS 2

1 APPLICATION 3

2 OVERVIEW 4

3 ABSOLUTE MAXIMUM RATINGS 5

4 ELECTRICAL CHARACTERISTICS 5, 6, 7, 8

www.panelook.com

5 INTERFACE PIN CONNECTION 9, 10, 11, 12

6 INTERFACE TIMING 13, 14, 15, 16, 17

7 BLOCK DIAGRAM 18

8 MECHANICAL SPECIFICATION 19, 20, 21

9 OPTICAL CHARACTERISTICS 22, 23, 24

10 RELIABILITY TEST CONDITION 25

11 OTHER FEATURE 26

12 HANDLING PRECAUTIONS FOR TFT-LCD MODULE 27, 28, 29

MITSUBISHI Confidential (2/29) AA121XN11-CE-01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

1. APPLICATION

This specification applies to color TFT-LCD module, AA121XN11-CE-01.

These specification papers are the proprietary product of Mitsubishi Electric Corporation

(“MITSUBISHI) and include materials protected under copyright of MITSUBISHI. No part of this

document may be reproduced in any form or by any means without the express written permission

of MITSUBISHI.

MITSUBISHI does not assume any liability for infringement of patents, copyrights or other

intellectual property rights of third parties by or arising from use of a product specified in this

document. No license, express, implied or otherwise, is granted under any patents, copyrights or

other intellectual property rights of MITSUBISHI or of others.

MITSUBISHI classifies the usage of the TFT-LCD module as follows. Please confirm the usage

before using the product.

www.panelook.com

(1) Standard Usage

Computers, office equipment, factory automation equipment, test and measurement

equipment, communications, transportation equipment(automobiles, ships, trains, etc.),

provided, however, that operation is not influenced by TFT-LCD directly.

(2) Special Usage

Medical equipment, safety equipment, transportation equipment, provided, however, that

TFT-LCD is necessary to its operation.

(3) Specific Usage

Cockpit Equipment, military systems, aerospace equipment, nuclear reactor control

systems, life support systems and any other equipment. MITSUBISHI should make a

contract that stipulate apportionment of responsibilities between MITSUBISHI and our

customer.

The product specified in this document is designed for “Standard Usage” unless otherwise specified

in this document. If customers intend to use the product for applications other than those specified

for “Standard Usage”, they should first contact MITSUBISHI sales representative for it's intended

use in writing.

MITSUBISHI has been making continuous effort to improve the reliability of its products.

Customers should implement sufficient reliability design of their application equipments such as

redundant system design, fail-safe functions, anti-failure features.

MITSUBISHI assumes no responsibility for any damage resulting from the use of the product that

does not comply with the instructions and the precautions specified in this document.

Please contact and consult a MITSUBISHI sales representative for any questions regarding this

product.

MITSUBISHI Confidential (3/29) AA121XN11-CE-01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

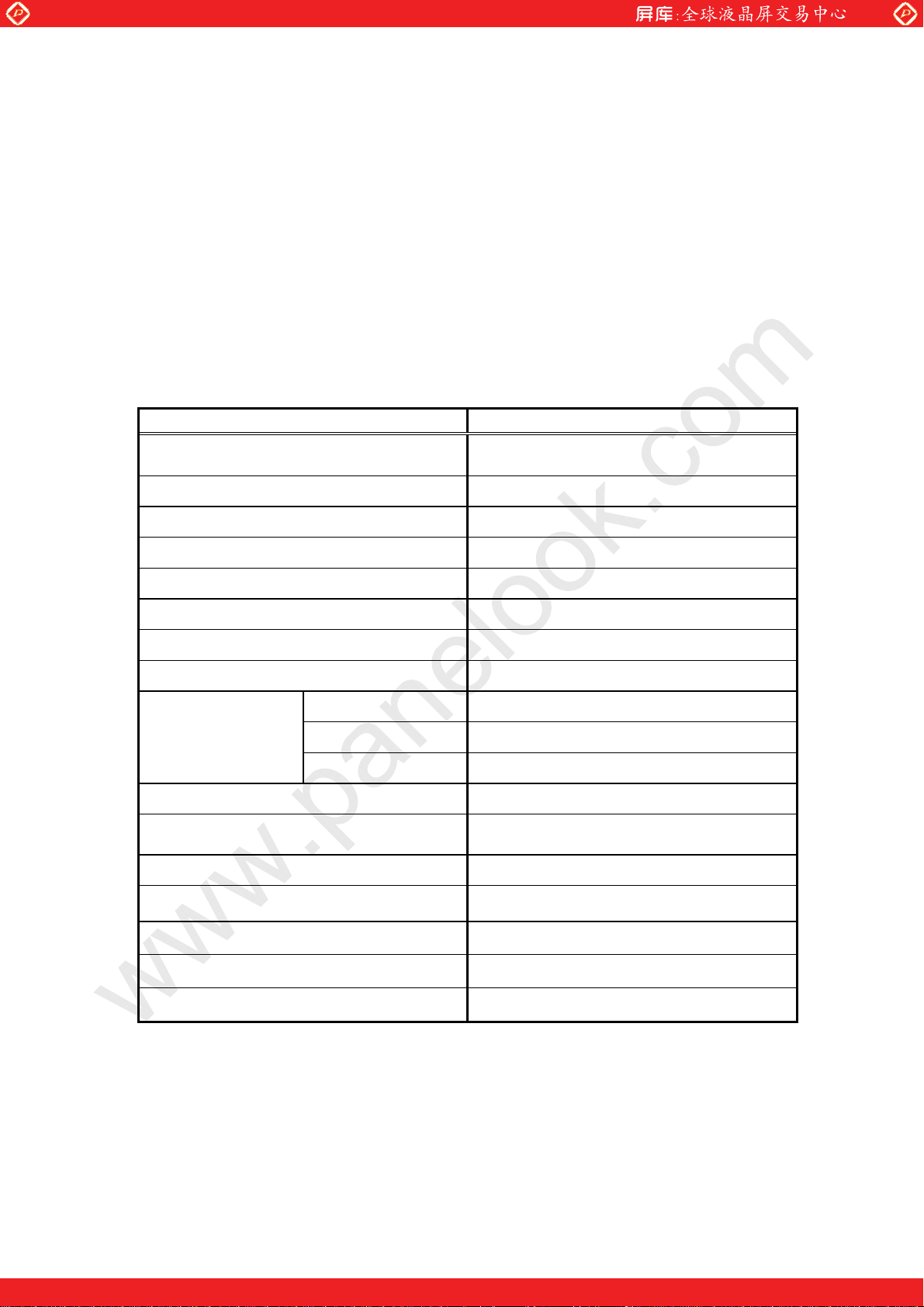

2. OVERVIEW

AA121XN11-CE-01 is 12.1” color TFT-LCD (Thin Film Transistor Liquid Crystal Display) module

composed of LCD panel, driver ICs, control circuit, backlight unit, touch panel, and cover glass.

By applying 6 bit or 8 bit digital data, 1024u 768, 262k-color or 16.7M-color images are displayed

on the 12.1” diagonal screen. Input power voltage is single 3.3 V for LCD driving.

The type of data and control signals are digital and transmitted via LVDS interface per Typ. 65

MHz clock cycle.

Driver circuit for LED backlight is not included in this module. General specifications are

summarized in the following table:

ITEM SPECIFICATION

Display Area (mm)

Number of Dots

www.panelook.com

245.76(H) u 184.32(V)

(12.1-inch diagonal)

1024 u3 (H) u 768 (V)

Pixel Pitch (mm)

Color Pixel Arrangement RGB vertical stripe

Display Mode Normally white

Number of Color 262k(6 bit/color), 16.7M(8 bit/color)

Luminance (cd/m2) (1100)

Viewing Angle (CR t10) (80a80q) (H), (80a60q) (V)

Surface Treatment Anti-reflection

Cover glass

Electrical Interface LVDS (6 bit/8 bit)

Viewing Direction

Module Size (mm)

Module Mass (g) (1150)

Backlight Unit LED, edge-light, Unreplaceable

Touch Panel Projective capacitive

Thickness (mm) 1.8

Glass Type Strengthened glass

Less gray scale reversal: 12 o'clock

0.240 (H) u 0.240 (V)

Higher Contrast ratio: 6 o'clock

281.8 (W) u 220.8 (H) u 14.4 (D)

Touch Panel Interface UART / USB *1)

Characteristic value without any note is typical value.

*1) UART: Universal Asynchronous Receiver Transmitter

UART and USB are used exclusively.

MITSUBISHI Confidential (4/29) AA121XN11-CE-01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

3. ABSOLUTE MAXIMUM RATINGS

ITEM SYMBOL MIN. MAX. UNIT

www.panelook.com

Power Supply Voltage for LCD VCC

Logic Input Voltage VI

0.3

0.3

4.0 V

VCC+0.3 V

Backlight (LED) Current IF 0 180 mA

Touch Panel Voltage VDD5 0 6.0 V

Touch Panel Input Voltage VI

Operation Temperature (Touch Panel)

Operation Temperature (Ambient)

Storage Temperature

Note 2)

T

Note 1,2)

Note 2)

T

T

op(TouchPanel)

op(Ambient)

stg

TP

0.3

20

20

20

VDD5+0.3 V

70 °C

70 °C

80 °C

[Note]

1) Measured at the center of active area and at the center of panel back surface

2) Top,Tstgd 40qC : 90%RH max. without condensation

Top,Tstg > 40qC : Absolute humidity shall be less than the value of 90%RH at 40qC without

condensation.

4. ELECTRICAL CHARACTERISTICS

(1) TFT-LCD Ambient temperature: Ta = 25°C

ITEM SYMBOL MIN. TYP. MAX. UNIT Remarks

Power Supply Voltages for LCD VCC 3.0 3.3 3.6 V *1)

Power Supply Currents for LCD ICC -- (380) (720) mA *2)

Permissive Input Ripple Voltage VRP -- -- 100 mVp-p VCC=+3.3V

High VIH

0.8uVCC

-- VCC V MODE, SC

Logic Input Voltage

Low VIL 0 --

0.2uVCC

V MODE, SC

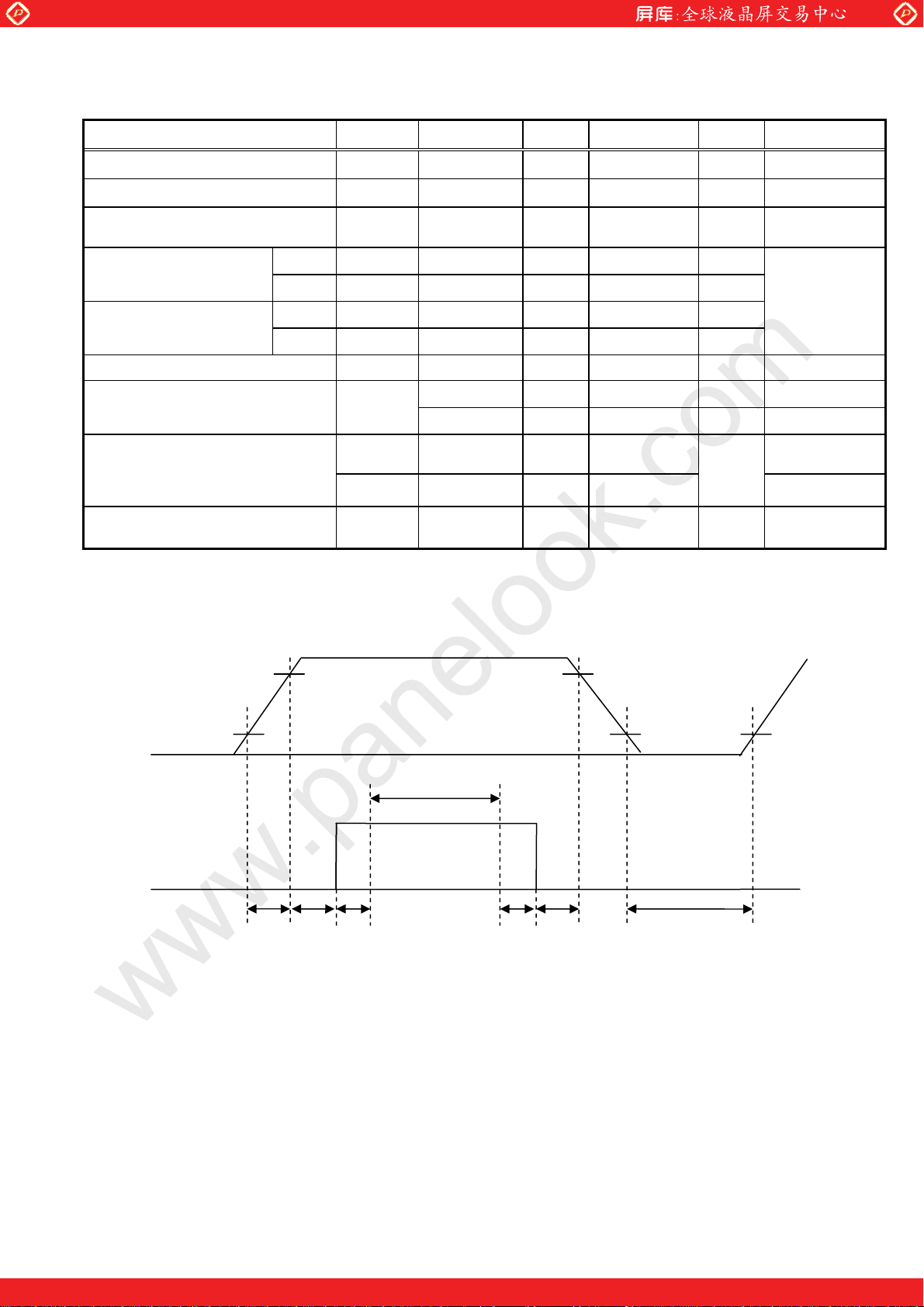

*1) Power and signals sequence:

t3

d t4

0.9VCC

0.1VCC

t4

0.1VCC

LCD Power Supply

Logic Signal

0.9VCC

0.1VCC

0.1 ms d t1 d10ms 200ms

0 < t2

0 < t3

d 50ms 200ms d t5

d 50ms 0 d t6

VCC

data

t2

t1

Backlight Power Supply

t5 t6

data: RGB DATA, DCLK, DENA, MODE, SC

MITSUBISHI Confidential (5/29) AA121XN11-CE-01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

A

A

A

A

VCC-dip conditions:

www.panelook.com

1) When 2.6 V

d VCC < 3.0 V, td d 10 ms

2) When VCC < 2.6 V

VCC-dip conditions should also follow the power and signals sequence.

VCC

3.0 V

2.6 V

td

*2) VCC = +3.3 V , f

= 48.4 kHz, fV= 60 Hz, f

H

= 65 MHz

CLK

Display image at typical power supply current value is 256-gray-bar pattern (8 bit), 768 line mode.

*3) Fuse

Parameter Fuse Type Name Supplier Remark

VCC FCC16162AB Kamaya Electric Co., Ltd. *)

*) The power supply capacity should be designed to be more than the fusing current.

(2) Backlight

ITEM SYMBOL MIN. TYP. MAX. UNIT Remarks

-- (18) (21.6) V IF = 120 mA, Ta = 25°C, *2)

LED Voltage VF

-- -- (22.2) V IF = 120 mA, Ta = 0°C

-- -- (22.6) V

IF = 120 mA, Ta = 20°C

LED Current IF -- (120) (130) mA Ta = 25°C, *1), *3)

LED Life Time LT 80,000 100,000 -- h

IF = 120 mA, Ta = 25°C

*4), *5), Continuous operation

[Note]

*1) Constant Current Drive

*2) The Voltage deviation between strings: |V

fMAX

– V

fMIN

| d 2V

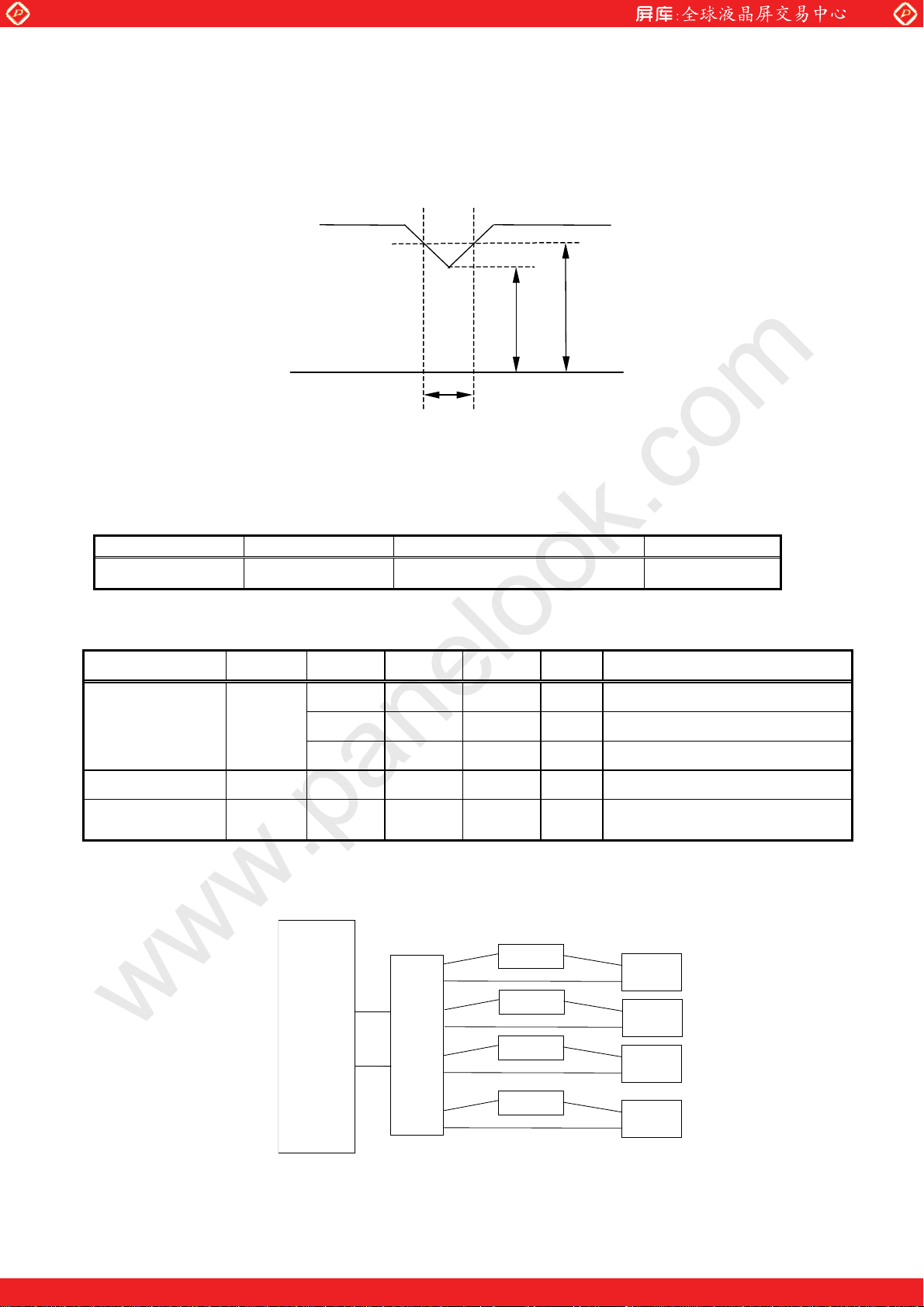

*3) LED Current measurement method:

LCD

Module

C1

1

C2

2

㩷

C3

3

A

A

A

Power

Supply

Power

Supply

Power

Supply

C4

4

A

Power

Supply

*4) LED life time is defined as the time when the brightness becomes 50% of the initial value.

*5) The life time of the backlight depends on the ambient temperature. The life time will decrease

under high temperature.

MITSUBISHI Confidential (6/29) AA121XN11-CE-01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

p

(3) Touch Panel

Electrical Characteristics Ambient temperature: Ta = 25°C

ITEM SYMBOL MIN. TYP. MAX. UNIT Remarks

Touch Panel Voltage VDD5 (4.5) 5.0 (5.5) V *1)

Touch Panel Current ICCtp -- (50) (200) mA

Permissive Input

Ripple Voltage

High VIHtp

Logic Input Voltage

Low VILtp 0 --

High IOH

Logic Output Current

Low IOL 0 -- (5) mA

Multi-Touch Points -- 2 -- point

Position Accuracy

Position Coordinate

Output Rate (standard)

www.panelook.com

VRPtp -- -- 100 mVp-p

(0.8uVDD5)

(5.0)

'Ex

'Ey

-- -- (100) --

-- -- (60) --

(3)

(4.5)

-- VDD5 V

(0.2uVDD5)

-- 0 mA

-- (3) mm Inner area*4)

-- (4.5) mm Outer frame*4)

sps

VDD5 = +5.0 V

V

Single touch

Dual touch

CKW

RESET

*2)

*3)

SC

DIN

*5)

Dual Touch Detection Distance

*1) Power and signals sequence:

0.1 ms d t1 d10ms (200) ms d t4

0 < t2 d 50 ms (2000) ms d t5

0 < t3 d 50 ms 0 d t6

0.9×VDD5

0.1×VDD5

㪣㫆㪾㫀㪺㩷 㪪㫀㪾㫅㪸㫃㩷

t1 t2 t5 t6 t3 t4

Initialization of touch panel controller (calibration of touch panel) is carried out during period

between power supply turning on and start of touch panel operation (t1+t2+t5), therefore please do

not touch surface with finger, hold hands near touch surface, nor put conductive material like

metal on touch panel.

If the calibration is not able to be carried out successfully at the initialization process, touch panel

may not work properly for sometime.

'dx

'dy

Touch

(40) -- -- mm *4)

VDD5

0.9×VDD5

0.1×VDD5

anel operatingperiod

*2) Ripple noise of touch panel power supply affects stability of touch detection and position accuracy.

Therefore please use stabilized power supply to touch panel.

*3) Applied to CKW(2pin),SC(3pin),DIN(5pin),RESET(9pin).

For, please input signal of USB2.0 compliance to D(10pin) & D (11pin).

MITSUBISHI Confidential (7/29) AA121XN11-CE-01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

www.panelook.com

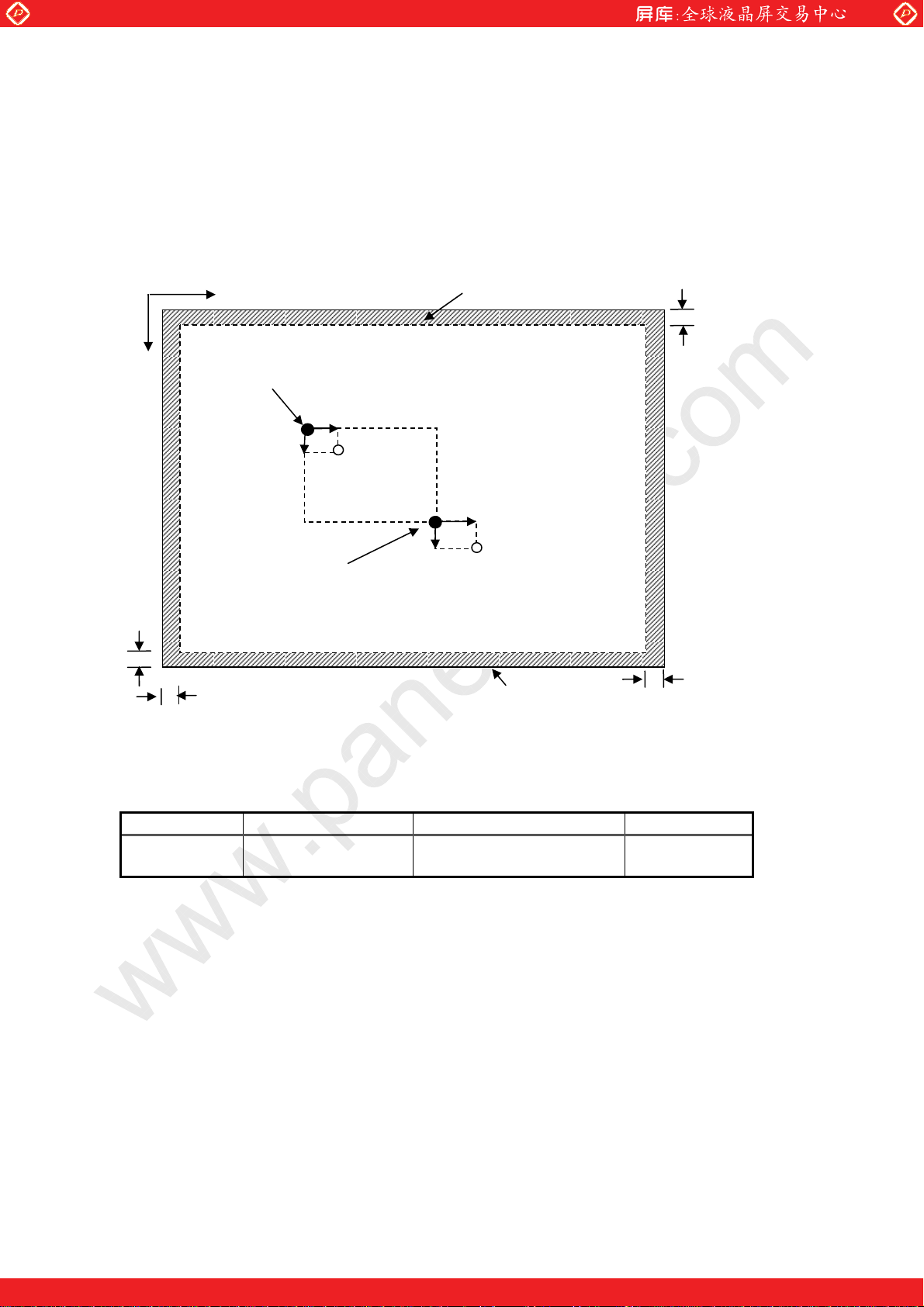

*4) Area of the finger touch is based on 10 mm in diameter.

Linearity is written as the difference of an actual touch position and the position coordinate which

a touch controller outputs as an error ('Ex and 'Ey stand for error length in the direction of X, Y,

respectively). Dual-point touch detection distance is shown in following figure.

The coordinates accuracy of peripheral part is valid when one-point touched.

Y

8mm

X

Touched position

6mm

Outer frame(hatched line area

)

8mm

Ex

Δ

Ey

Δ

Output

coordinate

x

Δd

Touched position

Ey

Δ

Δd

Ex

Δ

Output

coordinate

y

LCD active area

8mm

*5) The time interval of touch position coordinate output under an initial parameter condition

*6) Fuse

Parameter Fuse Type Name Supplier Remark

VCC FCC16501AB Kamaya Electric Co., Ltd. *)

*) The power supply capacity should be designed to be more than the fusing current.

MITSUBISHI Confidential (8/29) AA121XN11-CE-01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Global LCD Panel Exchange Center

V

5. INTERFACE PIN CONNECTION

(1)CN 1(INTERFACE SIGNAL)

Used connector: 20186-020E-11F (I-PEX) or FI-SEB20P-HFE (JAE)

Corresponding connector: 20197-20U-F (I-PEX) or FI-S20S, FI-SE20ME (JAE)

Pin

No.

*1) Metal frame is connected to signal GND.

*2) Recommended wiring of Pin 17,18 (6 bit input)

Symbol

1 VCC

2 VCC

3 GND

4 GND

5

Link 0

6 Link 0+ R0, R1, R2, R3, R4, R5, G0 R2, R3, R4, R5, R6, R7, G2 R0, R1, R2, R3, R4, R5, G0

7 GND

8

Link 1

9 Link 1+ G1, G2, G3, G4, G5, B0, B1 G3, G4, G5, G6, G7, B2, B3 G1, G2, G3, G4, G5, B0, B1

10 GND

11

Link 2

12 Link 2+ B2, B3, B4, B5, DENA B4, B5, B6, B7, DENA B2, B3, B4, B5, DENA

13 GND

14

CLKIN Clock m

15 CLKIN+

16 GND

17

Link3

18 Link3+ See: *2) R0, R1, G0, G1, B0, B1 R6, R7, G6, G7, B6, B7

19 MODE Low=ISP 6 bit compatibility mode

20 SC

R0, R1, R2, R3, R4, R5, G0 R2, R3, R4, R5, R6, R7, G2

G1, G2, G3, G4, G5, B0, B1 G3, G4, G5, G6, G7, B2, B3

B2, B3, B4, B5, DENA B4, B5, B6, B7, DENA

See: *2) R0, R1, G0, G1, B0, B1

Scan direction control. ( Low : Normal , High : Reverse )

Function (ISP 6 bit compatibility mode)

6 bit input 8 bit input

+3.3 V Power supply

+3.3 V Power supply

www.panelook.com

GND

GND

GND

GND

GND

Clock +

GND

Function (ISP 8 bit

compatibility mode)

m

m

m

m

R0, R1, R2, R3, R4, R5, G0

m

G1, G2, G3, G4, G5, B0, B1

m

B2, B3, B4, B5, DENA

m

m

m

R6, R7, G6, G7, B6, B7

High=ISP

8 bit compatibility mode

m

LVDS

transmitter

LOW data

Pin 17

Pin 18

or

680

620

CC

Ω

Pin 17

Pin 18

Ω

MITSUBISHI Confidential (9/29) AA121XN11-CE-01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...