Mitsubishi Electric A960GOT, A970GOT, A975GOT, A985GOT User Manual

C

MIT

SUBIS

C

GOT

Human Machine Interface

User’s Manual

HI ELECTRI

Art. no.: 103490

01 04 2002

SH (NA)-4005-H

Graphical Operator Terminal

A960GOT, A970GOT,

A975GOT, A985GOT

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

SAFETY PRECAUTIONS

•

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the CPU module user's manual.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

•

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence according to t he circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forw ard it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Design Precautions]

!

DANGER

Some failures of the GOT main unit, communication module, communication board or cable may

•

keep the outputs on or off.

An external monitoring circuit should be provided to check for output signals which may lead to

a serious accident.

Not doing so can cause an accident due to false output or malfunction.

If a communication fault (including cable disconnection) occurs during monitoring on t he GOT,

•

communication between the GOT and PLC CP U is suspended and t he GOT becomes

inoperative.

For bus connection : The CPU becomes faulty and the GOT inoperative.

For other than bus connection : The GOT becomes inoperative.

A system where the GOT is used should be configured to perform any significant operation to

the system by using the switches of a device other than the GOT on the assumption that a GOT

communication fault will occ ur.

Not doing so can cause an accident due to false output or malfunction.

Do not use the GOT as the warning device that may cause a serious accident.

•

An independent and redundant hardware or mechanical interloc k is required to configure the

device that displays and outputs serious warning.

Failure to observe this instruction may result in an accident due to incorrect output or

malfunction.

A - 1 A - 1

[Design Precautions]

!

DANGER

Incorrect operation of the touch switch(s) may lead to a serious accident if the GOT backlight is

•

gone out.

When the GOT backlight goes out, the display section turns black and causes the monitor

screen to appear blank, while the input of the touch swit ch(s) still remains act ive.

This may confuse an operator in thinking that the GOT is in “screensaver” mode, who then tries

to release the GOT from this mode by touching the display section, which may cause a touch

switch to operate.

Note that the following occurs on the GOT when the backlight goes out.

The monitor screen disappears even when the screensaver is not set.

•

The monitor screen will not come back on by t ouching the display section, even if the

•

screensaver is set.

!

CAUTION

Do not bundle the control and communication cables with main-circuit, power or other wiring.

•

Run the above cables separately from such wiring and keep them a minimum of 100mm apart.

Not doing so noise can cause a malfunction.

[Mounting Precautions]

!

DANGER

Before installing or removing t he GO T main unit t o or from an enclos ure, alway s s wit ch off th e

•

GOT power externally in all phases.

Not doing so can cause a module failure or malfunction.

Before loading or unloading the communication board, communication module or memory board

•

to or from the GOT, always switch off the GOT power externally in all phases.

Not doing so can cause a module failure or malfunction.

!

CAUTION

The GOT should be used in the environment given in the general specifications of the GO T

•

user's manual.

Not doing so can cause an electric shock, fire, malfunction or product damage or deterioration.

When mounting the GOT main unit to an enclosure, tighten the mounting screws in the specifie d

•

torque range.

Undertightening can cause a drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to the damage of the screws

or module.

A - 2 A - 2

[Mounting Precautions]

!

CAUTION

When loading the communication board or communication module to the G OT main unit, fit it to

•

the connection interface of the GOT and tighten the mounting screws in the specified torque

range.

Undertightening can cause a drop, failure or malfunction.

Overtightening can cause a drop, failure or malfunction due to the damage of the screws or

module.

When loading the memory board into the GOT main unit, load it into its corresponding GO T slot

•

and tighten the mounting screws in the specified torque range.

Undertightening can cause a malfunction due to a contact fault.

Overtightening can cause a malfunction due to the damage of the screws or module.

When loading the PC card into the GOT main unit, insert and push it into its corresponding GO T

•

slot until the PC card eject button comes up.

Not doing so can cause a malfunction due to a contact fault.

Before loading or unloading the PC card to or from the GOT, set the memory card access switch

•

to the OFF position.

Not doing so can cause the PC card data to be corrupted.

When taking out the PC card, hold it with one hand and remove.

•

If removed without a hand support, the PC card may drop, resulting in breakage or damage.

[Wiring Precautions]

!

DANGER

Before starting wiring, always switch off the GOT power externally in all phases.

•

Not doing so may cause an electric shock, product damage or malfunction.

!

CAUTION

Please make sure to ground FG terminal, LG terminal, and protective ground terminal of the

•

GOT power supply unit by applying Class D Grounding (Cla ss 3 Gr ounding Method) or higher

which is used exclusively for the GOT.

Not doing so may cause an electric shock or malfunction.

Correctly wire the power supply module on the GOT after confirming the rated voltage and

•

terminal arrangement of the product.

Not doing so can cause a fire or failure.

Tighten the terminal screws of the GOT power supply section in the specified torque range.

•

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or

module.

Exercise care to avoid foreign matter such as chips and wire offcuts entering the module.

•

Not doing so can cause a fire, failure or malfunction.

A - 3 A - 3

[Wiring Precautions]

!

CAUTION

Plug the bus connection cable by inserting it into the connector of the connected module until it

•

"clicks".

After plugging, check that it has been inserted snugly.

Not doing so can cause a malfunction due to a contact fault.

Plug the communication cable into the connector of the connected module and tighten the

•

mounting and terminal screws in the specified torque range.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or

module.

[Test Operation Precautions]

!

DANGER

Before performing test operation (bit device on/off, word device's present value changing,

•

timer/counter's set value and present value changing, buffer memory's present value changing)

for a user-created monitor screen, system monitoring, special module monitoring or ladder

monitoring, read the manual carefully to fully underst and how to operate the equipment.

During test operation, never change the data of the devices which are used to perform

significant operation for the system.

False output or malfunction can cause an accident.

[Startup/Maintenance Precautions]

!

DANGER

When power is on, do not touch the terminals.

•

Doing so can cause an electric shock or malfunction.

Before starting cleaning or terminal screw retightening, always switch off the power externally in

•

all phases.

Not switching the power off in all phases can cause a module failure or malfun ction.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or

module.

!

CAUTION

Do not disassemble or modify the module.

•

Doing so can cause a failure, malfunction, injury or fire.

Do not touch the conductive and electronic parts of the module directly.

•

Doing so can cause a module malfunction or failure.

A - 4 A - 4

[Startup/Maintenance Precautions]

!

CAUTION

Do not disassemble or modify the module.

•

Doing so can cause a failure, malfunction, injury or fire.

Do not touch the conductive and electronic parts of the module directly.

•

Doing so can cause a module malfunction or failure.

The cables connected to the module must be run in ducts or clamped.

•

Not doing so can cause the module or cable to be damaged due to the dangling, motion or

accidental pulling of the cables or can cause a malfunction due to a cable connection fault.

When unplugging the cable connected to the module, do not hold and pull the cable portion.

•

Doing so can cause the module or cable to be damaged or can cause a malfunction due to a

cable connection fault.

[Backlight Changing Precautions]

!

DANGER

Before changing the backlight, always switch off the GOT power externally in all phases (w hen

•

the GOT is connected to the bus, the PLC CPU power must also be swit ched off externally in all

phases) and remove the GOT main unit from the enclosure.

Not switching the power off in all phases may cause an electric shoc k.

Not removing the unit from the enclosure can cause injury due to a drop.

!

CAUTION

When replacing the backlight, use the gloves.

•

Otherwise, it may cause you to be injured.

If you should directly touch the plated area of the main unit case with hand, be sure to wipe off

the fingerprint and so on, and install the main unit case.

Otherwise, it may cause a trouble or malfunction.

Start changing the backlight more than 5 minutes after switching the GOT power off.

•

Not doing so can cause a burn due to the heat of the backlight.

[Disposal Precautions]

!

CAUTION

When disposing of the product, handle it as industrial waste.

•

A - 5 A - 5

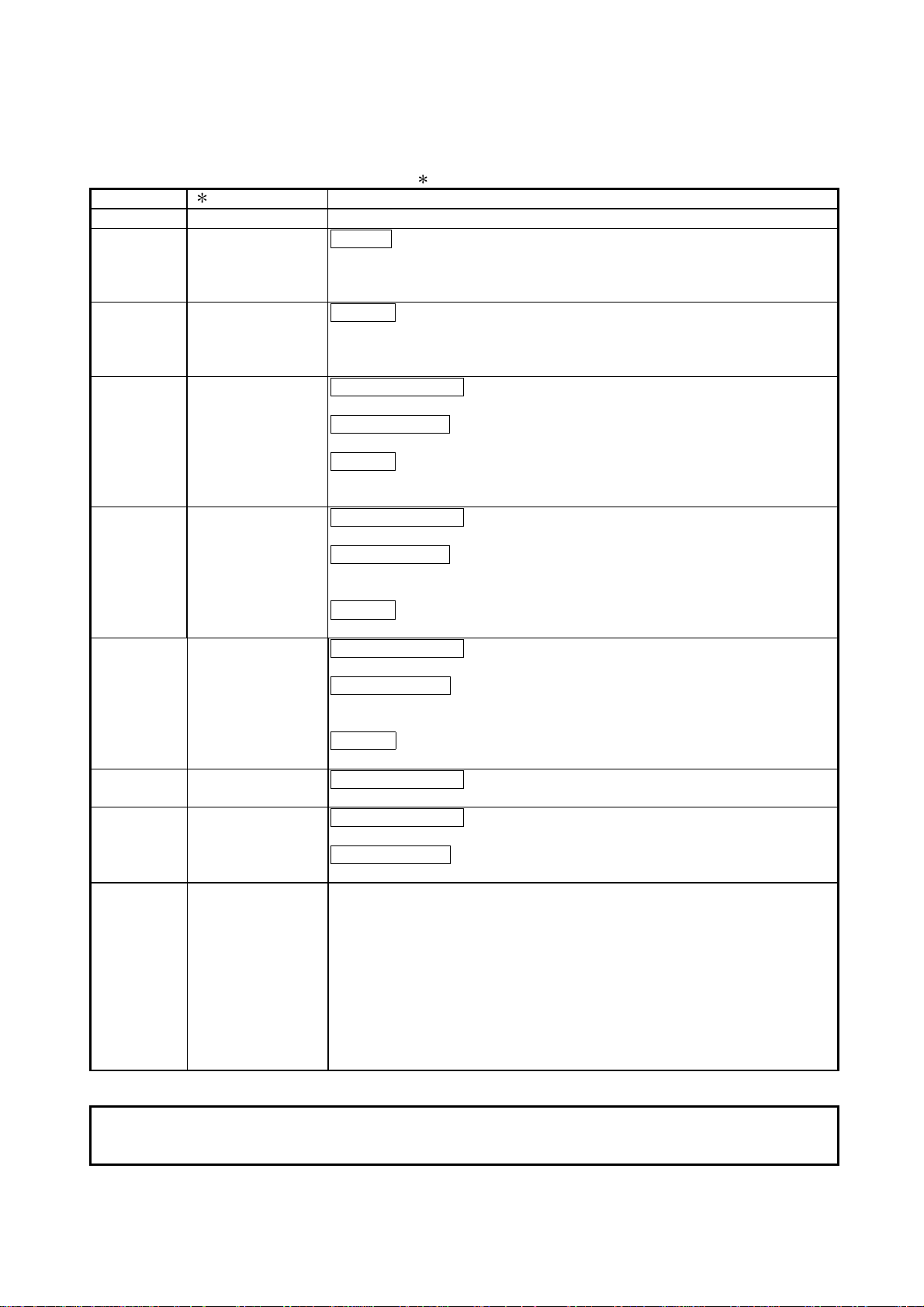

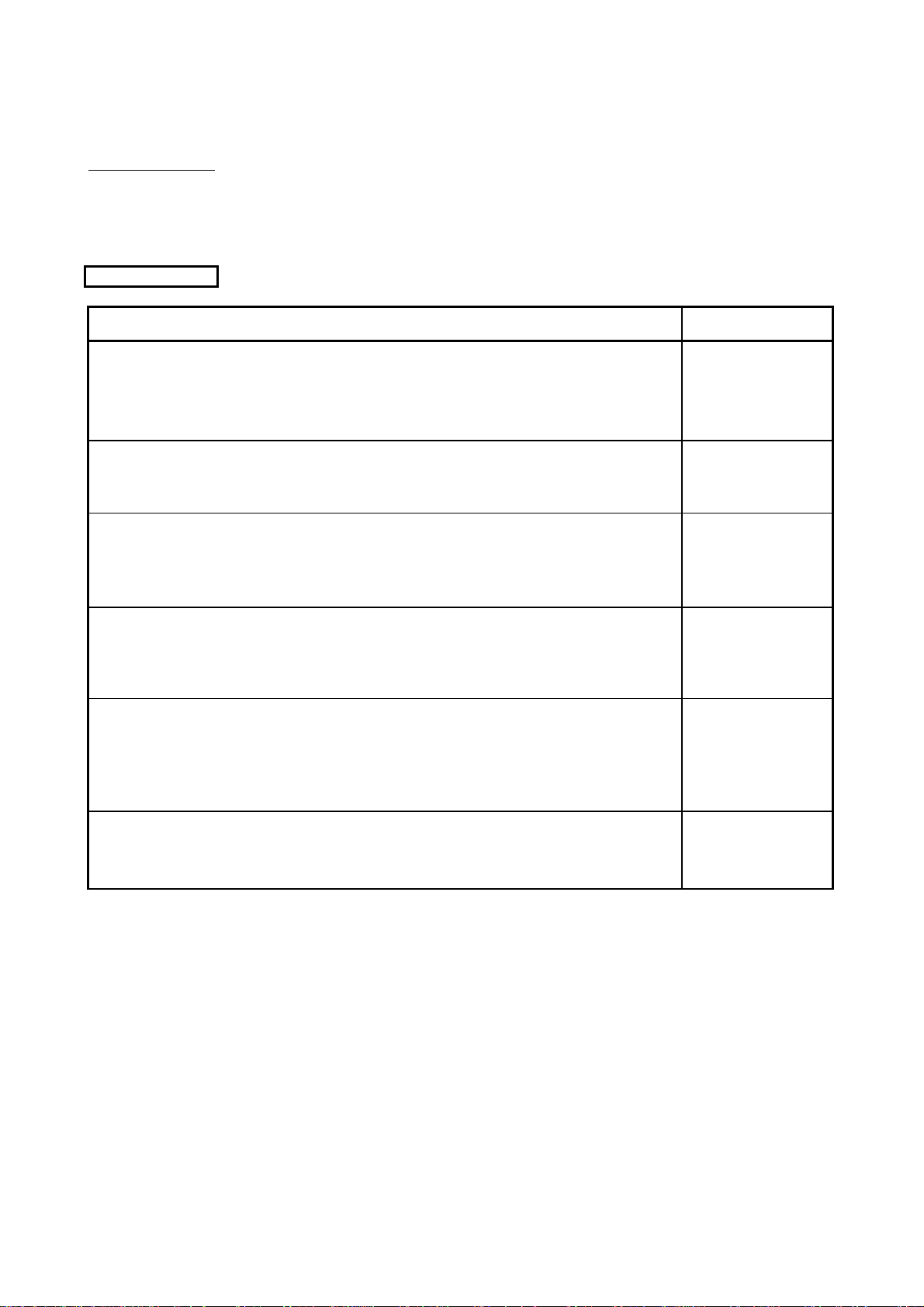

REVISIONS

The manual number is given on the bottom left of the back cover..

Print Date Manual Number Revision

Sep, 1998 SH(NA)-4005-A First edition

Feb, 1999 SH(NA)-4005-B

Addition

Section 1.1, 2.1, 2.2, 3.2, 3.3, 4.1, 4.2, 6.1, 6.3, 6.10, 6.11, 6.12, 6.13,

7.4, Appendix 1,2

A985GOT-TBA/TBD

Apr, 1999 SH(NA)-4005-C

Addition

Section 1.2, 1.3, 2.2, 3.2, 3.3, 6.1, 6.5, 7.4, 8.2, INDEX

A975GOT-TBA-B/TBD-B, A970GOT-TBA-B/TBD-B

A975GOT-TBA-EU, A970GOT-TBA-EU/SBA-EU, A960GOT-EBA-EU

Mar, 2000 SH(NA)-4005-D

Partial corrections

Section 2.1, 3.1, 6.1, 6.3, 6.5, 6.12, 7.4, Appendix 1, 2, 3

Partial additions

Section 2.2, 3.2, 3.3, 6.4, 6.6, 6.7

Addition

Section 2.3, 2.4, 6.14, 8.5

A985GOT-TBA-EU, A970GOT-LBA/LBD

Dec, 2000 SH(NA)-4005-E

Partial corrections

Chapter 5, Section 2.1, 2.3, 6.5, 6.7, 6.8, 6.9, 6.11, 6.12, 8.3

Partial additions

Chapter 1, Section 1.1, 2.2, 2.4, 3.2, 3.3, 4.1, 6.1, 6.3, 6.4, 6.6, 6.10, 7.4,

8.2, Appendix 1,2

Addition

Section 6.1.6, 6.1.7, 6.15, A985GOT-TBA-V, A985GOT-TBD-V

Jun, 2001 SH(NA)-4005-F

Partial corrections

Section 1.2.1, 2.3

Partial additions

Section 1.1, 1.2.2, 2.2, 3.2.1, 3.2.2, 3.2.3, 3.3.1,3.3.2, 4.2, 6.1.2, 6.1.3,

6.1.4, 6.5.3, 6.7.1, 6.14.2, 8.2, Appendix 2

Addition

Section 2.3.1, 2.3.2, 2.3.3, 2.3.4, 2.3.5

Feb, 2002 SH(NA)-4005-G

Partial corrections

SAFETY PRECAUT I O NS

Apr, 2002 SH(NA)-4005-H

Partial corrections

Section 2.3.3

Partial additions

Section 2.3.4, 2.3.5, 6.1.4, 8.2

Japanese Manual Version SH-3311-J

This manual does not warrant or license any industrial property rights and other rights. Under no circumstances will

Mitsubishi Electric be liable or responsible for any consequential problems involving the industrial property rights

which may arise as a result of the use of this equipment described in this manual.

1998 Mitsubishi Electric Corporation

A - 6 A - 6

INTRODUCTION

Thank you for choosing the Mitsubishi Graphic Operation Terminal.

Before using the equipment, please read this manual carefully to use the equipment to its optimum.

A copy of this manual should be forwarded to the end user.

CONTENTS

SAFETY INSTRUCTIONS.............................................................................................................................A- 1

About the manuals .........................................................................................................................................A-10

Abbreviations and generic terms in this manual ...........................................................................................A-11

Packing list......................................................................................................................................................A-13

1. OVERVIEW 1- 1 to 1- 9

1.1 Features ...................................................................................................................................................1- 2

1.2 Requirements to match EMC Directives .................................................................................................1- 4

1.2.1 EMC Directives..................................................................................................................................1- 4

1.2.2 Installation inside Control Box...........................................................................................................1- 5

1.2.3 Noise filter (power supply line filter)..................................................................................................1- 6

1.3 Requirements for compliance with the Low Voltage Directive............................................................... 1- 7

1.3.1 Standard applied for GOT.................................................................................................................1- 7

1.3.2 Power supply.....................................................................................................................................1- 7

1.3.3 Control cabinet ..................................................................................................................................1- 8

1.3.4 Grounding..........................................................................................................................................1- 8

1.3.5 External wiring...................................................................................................................................1- 9

2. SYSTEM CONFIGURATION 2- 1 to 2- 9

2.1 Overall Configuration ...............................................................................................................................2- 1

2.2 Component List........................................................................................................................................2- 2

2.3 Cautions on use of EMC command- and low voltage command-compatible products.........................2- 5

2.3.1 Caution points when using PC card/Flash PC card.........................................................................2- 5

2.3.2 About Modules that the EMC directive do not apply to....................................................................2- 5

2.3.3 Connection Format............................................................................................................................2- 6

2.3.4 When the communication module/board is used............................................................................. 2- 7

2.3.5 About the Cable Used.......................................................................................................................2- 7

2.4 Software packages to be used ................................................................................................................2- 8

2.5 Unusable Conventional Products............................................................................................................2- 8

2.6 Notes on Q4ARCPU Duplex System......................................................................................................2- 9

3. PERFORMA NCE 3- 1 to 3- 9

3.1 General Specifications.............................................................................................................................3- 1

3.2 Performance specifications......................................................................................................................3- 2

3.2.1 Performance specifications of the A985GOT(-V).............................................................................3- 2

3.2.2 Performance specifications of the A975GOT/A970GOT/A960GOT...............................................3- 6

3.2.3 Power supply specifications..............................................................................................................3- 8

3.3 Power Supply Power Consumed when Communication Board or Communication Module Is Fitted .. 3- 9

3.3.1 GOT with AC type input power supply .............................................................................................3- 9

3.3.2 GOT with DC type input power supply.............................................................................................3- 9

A - 7 A - 7

4. NAMES OF THE PARTS AND THEIR SETTINGS 4- 1 to 4- 4

4.1 Names of The Parts And Their Settings of the A985GOT(-V) ...............................................................4- 1

4.2 Names of The Parts And Their Settings of the A975GOT/A970GOT/A960GOT..................................4- 3

5. ROUGH PRE-OPERATION PROCEDURE 5- 1 to 5- 2

6. HANDLING 6- 1 to 6-35

6.1 GOT Main Unit .........................................................................................................................................6- 1

6.1.1 Handling instructions.........................................................................................................................6- 1

6.1.2 Installation method............................................................................................................................6- 3

6.1.3 Wiring method ...................................................................................................................................6- 5

6.1.4 Wiring precautions the part which matches the EMC Directives.....................................................6- 6

6.1.5 Human sensor (A985GOT(-V) only).................................................................................................6-15

6.1.6 Video input function (A985GOT-V only)...........................................................................................6-16

6.1.7 RGB input function (A985GOT-V only) ............................................................................................6-17

6.2 Slot Cover.................................................................................................................................................6-18

6.2.1 Mounting and dismounting procedures ............................................................................................6-18

6.3 Protective Sheet.......................................................................................................................................6-19

6.3.1 Protective sheet types.......................................................................................................................6-19

6.3.2 Mounting procedure ..........................................................................................................................6-19

6.4 Memory Board..........................................................................................................................................6-20

6.4.1 Memory board types .........................................................................................................................6-20

6.4.2 Mounting procedure ..........................................................................................................................6-20

6.5 PC Card....................................................................................................................................................6-21

6.5.1 PC card types....................................................................................................................................6-21

6.5.2 Battery changing timing and method................................................................................................6-22

6.5.3 Loading and unloading procedures.................................................................................................. 6-23

6.6 Communication Board .............................................................................................................................6-25

6.6.1 Connection board types....................................................................................................................6-25

6.6.2 Mounting procedure ..........................................................................................................................6-25

6.7 Communication Module...........................................................................................................................6-27

6.7.1 Connection module types .................................................................................................................6-27

6.7.2 Mounting procedure ..........................................................................................................................6-27

6.8 Printer .......................................................................................................................................................6-28

6.8.1 Printer types ......................................................................................................................................6-28

6.8.2 Connection procedure.......................................................................................................................6-28

6.9 Speech Output Device.............................................................................................................................6-29

6.9.1 Speech output device type................................................................................................................6-29

6.9.2 Connection procedure.......................................................................................................................6-29

6.10 Debug Stand ..........................................................................................................................................6-30

6.10.1 Debug stand types ..........................................................................................................................6-30

6.10.2 Mounting procedure........................................................................................................................ 6-30

A - 8 A - 8

6.11 Bar Code Reader...................................................................................................................................6-31

6.11.1 Bar code reader types.....................................................................................................................6-31

6.11.2 Connecting procedure.....................................................................................................................6-31

6.12 External I/O Module ...............................................................................................................................6-32

6.12.1 External I/O module type ................................................................................................................6-32

6.12.2 Mounting procedure........................................................................................................................6-32

6.13 CRT Display, TFT Display (A985GOT only).........................................................................................6-33

6.13.1 CRT Display, TFT Display types ....................................................................................................6-33

6.13.2 Connecting procedure.....................................................................................................................6-33

6.14 Attachment .............................................................................................................................................6-34

6.14.1 Attachment types.............................................................................................................................6-34

6.14.2 Mounting procedure........................................................................................................................ 6-34

6.15 Video/RGB Input Interface Module (A985GOT-V only)........................................................................6-35

6.15.1 Video/RGB input interface module types....................................................................................... 6-35

6.15.2 Mounting procedure........................................................................................................................6-35

7. MAINTENANCE AND INSPECTION 7- 1 to 7- 5

7.1 Instructions for Maintenance and Inspection ..........................................................................................7- 1

7.2 Daily Inspection........................................................................................................................................7- 2

7.3 Periodic Inspection...................................................................................................................................7- 2

7.4 Backlight for Liquid Crystal......................................................................................................................7- 3

7.4.1 How to change the backlight for liquid crystal..................................................................................7- 4

8. ERROR CODES AND ERROR MESSAGES 8- 1 to 8-16

8.1 Definition of the Error Codes and Messages Displayed......................................................................... 8- 1

8.2 Error Code and Error Message List.........................................................................................................8- 2

8.3 Precautions for use of flash PC card.......................................................................................................8- 6

8.4 Precautions for installation of ROM_BIOS..............................................................................................8- 7

8.5 Troubleshooting in bus connection.......................................................................................................... 8- 8

8.5.1 Locating error positions.....................................................................................................................8- 8

8.5.2 Further locating error positions.........................................................................................................8-13

8.5.3 Specific example of troubleshooting.................................................................................................8-14

8.6 Troubleshooting for monitoring................................................................................................................8-15

APPENDICES APP- 1 to APP- 9

Appendix 1 Outline Dimension Drawings................................................................................................APP- 1

Appendix 2 Depth at the Time of Communication Board/Communication Module Loading.................APP- 4

Appendix 3 Outline Dimension Drawings of Bus Connection Cables....................................................APP- 8

INDEX INDEX- 1 to INDEX- 2

A - 9 A - 9

About the manuals

The following manuals are related to this product.

Refer to the following list and request the required manuals.

Related Manuals

Manual name

GT Works Version5/GT Designer Version5 Operating Manual (Start up M anual)

Describes how to install GT Works Version 5/GT Designer Version 5 into a personal computer and how

to browse the online manuals.

(Found in the packing of the GT Works Version5/GT Designer Version5)

GOT900 Series Operating Manual (Introductory Manual)

For those who use the GOT for the first time, describes the way to create a monitor screen on GT

Designer, transfer monitor data to the GOT, and display it on the screen. (Available as option)

GT Works Version5/GT Designer Version5 Reference Manual

Deals with the system configuration of GT Works Version5/GT Designer Version5, the screen makeup of

the GT Designer, the general description of various monitoring functions, the procedure for displaying the

monitor screen on the GOT, and how to use the help function. (Available as option)

GOT-A900 Series User’s Manual (GT Works Version5/GT D esigner Version5 compati ble

Connection System Manual)

Gives the specifications, system configuration, setting method and connection diagram of each

connection form available for the GOT-A900 series. (Available as option)

GOT-A900 Series Operating Manual (GT Works Version5/GT Designer Version5 co mpatible

Extended • Option Functions Manual)

Provides the specifications of the utility, system monitoring, ladder monitoring, special function unit

monitoring, network monitoring functions and list editor functions available for the GOT-A900 series and

how to operate the dedicated monitor screen. (Available as option)

Manual number

(Model code)

IB-0800143

(13JU06)

SH-080116

(13JU07)

SH-080117

(13JF95)

SH-080119

(13JR20)

SH-080118

(13JU08)

GT Simulator Version5 Operating Manual

Explains the system configuration, screen makeup and using methods of GT Simulator.

(Available as option)

SH-080120

(13JU09)

A - 10 A - 10

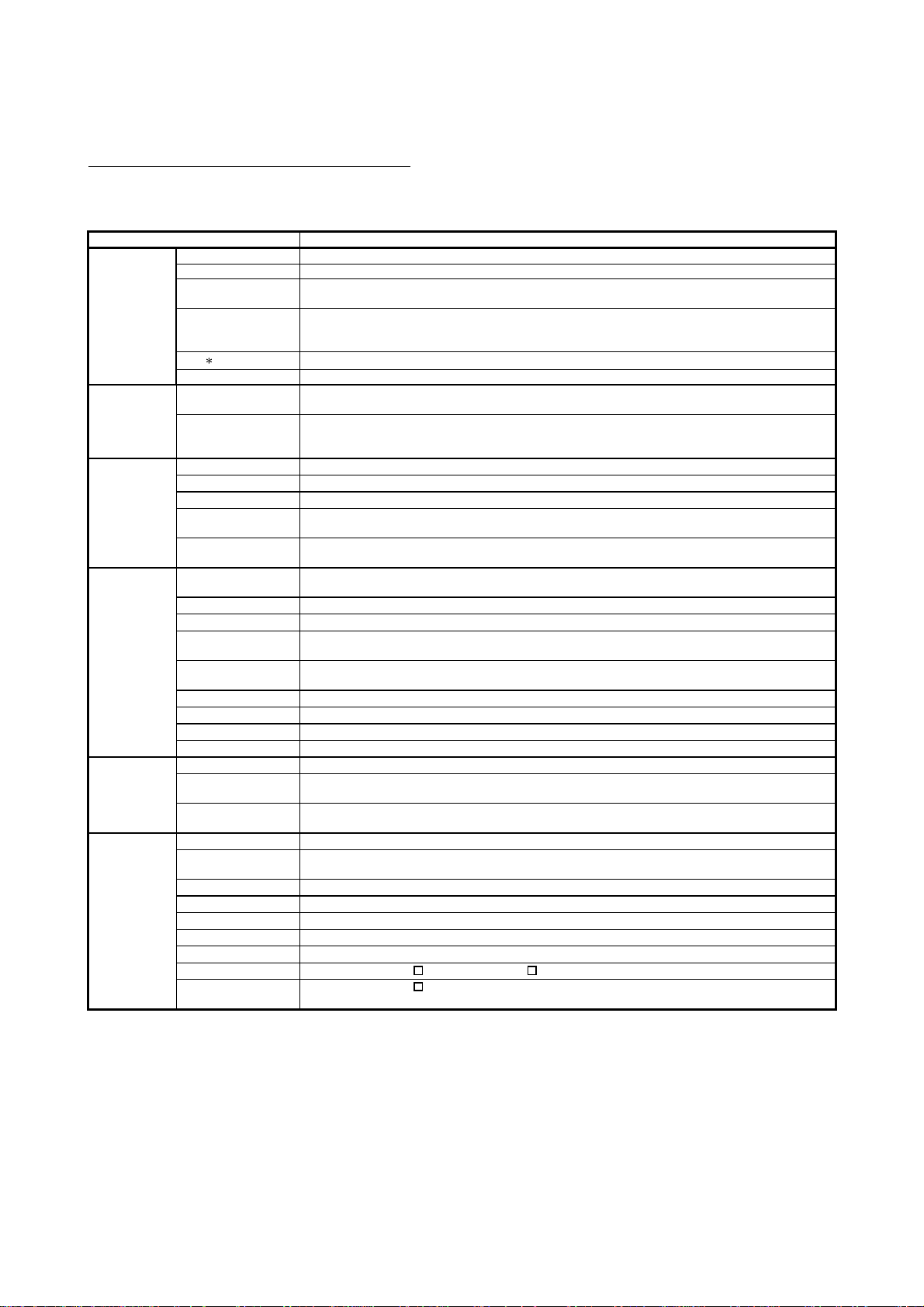

Abbreviations and generic terms in this manual

Abbreviations and generic terms used in this manual are described as follows:

Abbreviations and generic terms Description

A985GOT-V Generic term of A985GOT-TBA-V and A985GOT-TBD-V

GOT

Communication board

Communication unit

Option

Option unit

Software

A985GOT Generic term of A985GOT-TBA, A985GOT-TBD and A985GOT-TBA-EU

A975GOT

A970GOT

A97 GOT

A960GOT Generic term of A960GOT-EBA, A960GOT-EBD and A960GOT-EBA-EU

Bus connection

board

Serial

communication

board

Bus connection unit Gen e r i c t e r m of A 9 G T-BU S S U a nd A9 G T - B U S2SU

Data link unit Generic term of A7GT-J71AP23, A7GT-J71AR23 and A7GT-J71AT23B

Network unit Generic term of A7GT-J71LP23 and A7GT-J71BR13

CC-Link

communication unit

Ethernet

communication unit

Protection sheet

Backlight Abbreviation of A9GT-80LTT, A9GT-70LTTB, A9GT-70LTT and A9GT-70LTS type backlights

Debug stand Abbreviation of A9GT-80STAND and A9GT-70STAND type debug stand

PC card ( memory

card )

Memory board

Attachment Generic term of A77GT-96ATT/A87GT-96ATT/A87GT-97ATT attachments

Ten-key Panel Abbreviation of A8GT-TK ten-key Panel

A7GT-CNB Abbreviation of A7GT-CNB bus connector conversion box

A9GT-QCNB Abbreviation of A9GT-QCNB bus connector conversion box

External I/O unit Abbreviation of A9GT-70KBF type external I/O interface unit

Video input interface

unit

RGB input interface

unit

GT Works Ve rsion 5 Abbreviation of SW5D5C-GTWORKS-E software package

GT Designer

Version 5

GT Designer Abbreviation of image creation software GT Designer for GOT900

GT Simulator Abbreviation of GT Simulator screen simulator GOT900

GT Converter Abbreviation of data conversion software GT Converter for GOT900

GT Debugger Abbreviation of debugging software GT Debugger

GT Manager Abbreviation of GT Manager data editing software for GOT900

GT Developer Generic term of SW D5C-GPPW-E/SW D5F-GPPW-E software packages

GT Simulator

Generic term of A975GOT-TBA-B, A975GOT-TBD-B, A975GOT-TBA, A975GOT-TBD and

A975GOT-TBA-EU

Generic term of A970GOT-TBA-B A970GOT-TBD-B, A970GOT-TBA, A970GOT-TBD,

A970GOT-SBA, A970GOT-SBD, A970GOT-LBA, A970GOT-LBD, A970GOT-TBA-EU and

A970GOT-SBA-EU

Generic term of A975GOT and A970GOT

Generic term of A9GT-QBUSS, A9GT-QBUS2S, A9GT-BUSS and A9GT-BUS2S

Generic term of A9GT-RS4, A9GT-RS2 and A9GT-RS2T

Generic term of A8GT-J61BT13 and A8GT-J61BT15

Abbreviation of A9GT-J71E71-T

Abbreviation of A9GT-80PSC, A9GT-70PSC and A9GT-60PSC type transparent protection

sheets

Abbreviation of PC card with PCMCIA Ver.2.1

Abbreviation of A9GT-FNB, A9GT-FNB1M, A9GT-FNB2M, A9GT-FNB4M, A9GT-FNB8M,

A9GT-QFNB, A9GT-QFNB4M, A9GT-QFNB8M type option function memory board

Abbreviation of A9GT-80V4 type Video input interface unit

Abbreviation of A9GT-80R1 type RGB input interface unit

Generic term of SW5D5C-GOTR-PACKE software package and SW5D5C-GOTR-PACKEV

software package

Generic term of SW

LLT-E or later)

D5C-LLT-E ladder logic test tool function software package (SW5D5C-

A - 11 A - 11

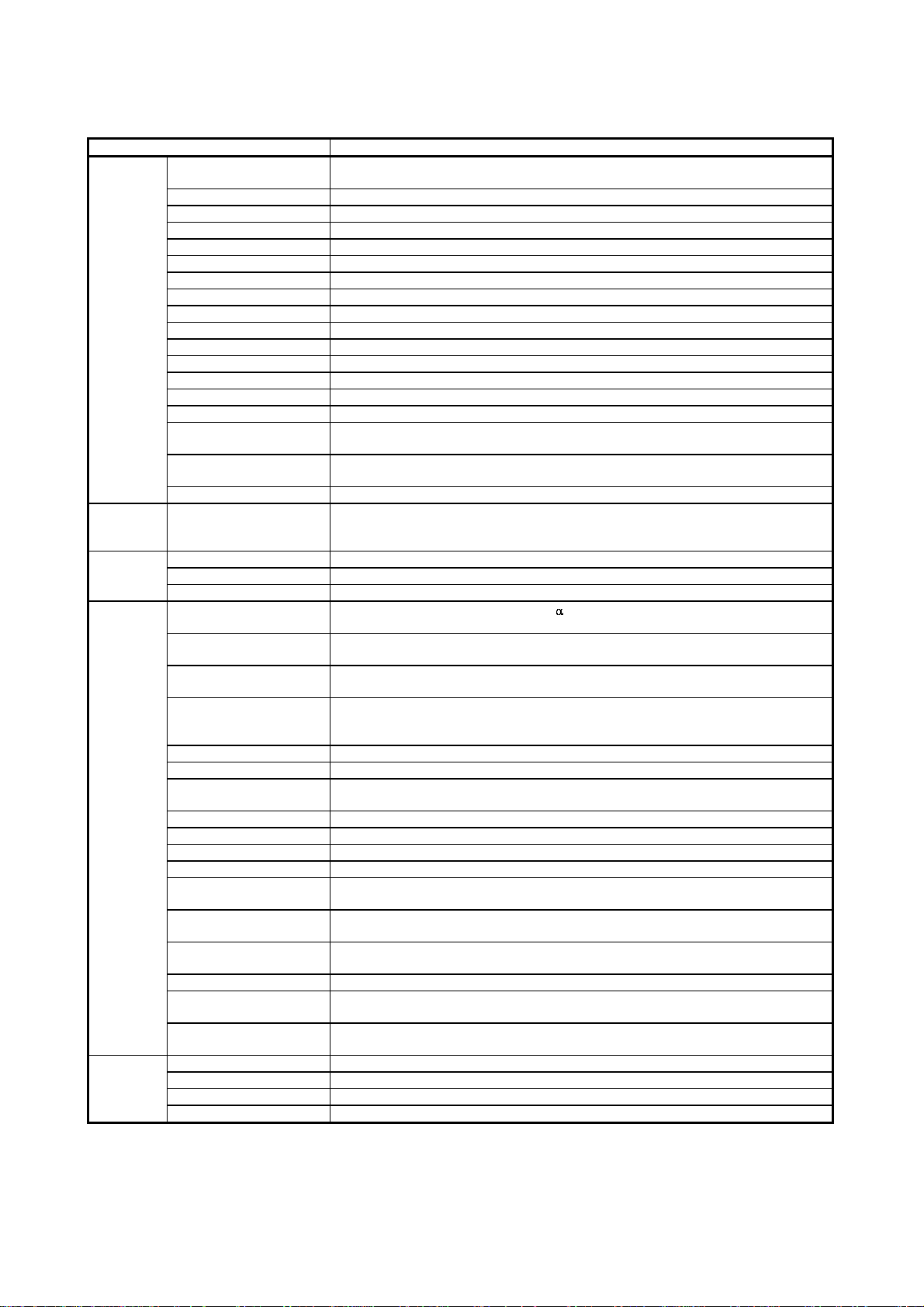

Abbreviations and generic terms Description

QCPU (Q Mode)

Generic term of Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU,

Q12HCPU and Q25HCPU CPU units

QCPU (A Mode) Generic term of Q02CPU-A, Q02HCPU-A and Q06HCPU-A CPU units

QCPU Generic term of QCPU (Q Mode) and QCPU (A Mode)

QnACPU (Large Type) Generic term of Q2ACPU, Q2ACPU-S1, Q3ACPU, Q4ACPU and Q4ARCPU CPU units

QnACPU (Small Type) Generic term of Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU and Q2ASHCPU-S1 CPU units

QnACPU Generic term of QnACPU (Large Type) and QnACPU (Small Type)

AnUCPU Generic term of A2UCPU, A2UCPU-S1, A3UCPU and A4UCPU CPU units

AnACPU Generic term of A2ACPU, A2ACPU-S1 and A3ACPU CPU units

AnNCPU Generic term of A1NCPU, A2NCPU, A2NCPU-S1 and A3NCPU CPU units

CPU

ACPU (Large Type) Generic term of AnUCPU, AnACPU and AnNCPU CPU units

A2US(H)CPU Generic term of A2USCPU, A2USCPU-S1 and A2USHCPU-S1 CPU units

AnS(H)CPU Generic term of A1SCPU, A1SHCPU, A2SCPU and A2SHCPU CPU units

A1SJ(H)CPU Generic term of A1SJCPU-S3 and A1SJHCPU CPU units

ACPU (Small Type) Generic term of A2US(H)CPU, AnS(H)CPU and A1SJ(H)CPU CPU units

ACPU Generic term of ACPU (Large Type), ACPU (Small Type) and A1FXCPU CPU units

FXCPU

Motion controller CPU

Generic term of FX

2

series , FX

FX

0

2C

series, FX

series, FX

Generic term of A373UCPU, A373UCPU-S3, A273UCPU, A273UHCPU, A273UHCPU-S3,

A171SCPU-S3, A171SHCPU, A172SHCPU CPU unit

0N

2N

series, FX

series, FX

FA controller Generic term of LM610, LM7600, LM8000 CPU unit

GPP function

peripheral

connection unit

G4 Abbreviation of AJ65BT-G4-S3

E71 Generic term of AJ71E71-S3, A1SJ71E71-B2-S3 and A1SJ71E71-B5-S3

QE71 Generic term of AJ71QE71, A1SJ71QE71-B2, AJ71QE71-B5 and A1SJ71QE71-B5Ethernet unit

Q series-compatible E71 Generic term of QJ71E71, QJ71E71-B2 and QJ71E71-100

Omron PLC

Yasukawa PLC

SLC500 Series

Generic term of C200HS, C200H, C200H

C1000H,C2000H,CV500, CV1000, CV2000, CVM1-CPU11, CVM1-CPU21, CS1 CPU unit

Generic term of GL60S, GL60H, GL70H, GL120, GL130, CP-9200SH, CP-9300MS, MP-9 20,

MP-930, MP-940, CP-9200(H) and PROGIC-8 CPU unit

Generic term of SLC500-20, SLC500-30, SLC500-40, SLC5/01 SLC5/02, SLC5/03,

SLC5/04 SLC5/0 5

Generic term of 1761-L10BWA, 1761-L10BWB, 1761-L16AWA, 1761-L16BWA, 1761MicroLogix1000 Series

L16BWB, 1761-L16BBB, 1761-L32AWA, 1761-L32BWA, 1761-L32BWB, 1761-L32BBB,

1761-L32AAA, 1761-L20AWA-5A, 1761-L20BWA-5A, 1761-L20BWB-5A

MicroLogix1500 Series Abbreviation of 1764-LSP

Allen-Bradley PLC Generic term of SLC 500 Series, MicroLogix1000 Series, MicroLogix1500 Series

Generic term of JW-21CU, JW-22CU, JW-31CUH, JW-32CUH, JW-33CUH, JW-50CUH,

JW-70CUH, JW-100CUH CPU unit

Other PLC

Sharp PLC

PROSEC T Series Generic term of T3, T3H CPU unit

PROSEC V Series Abbreviation of Model3000 CPU unit

Toshiba PLC Generic term of PROSEC T Series and PROSEC V Series

SIEMENS PLC Generic term of SIMATIC S7-300 Series and SIMATIC S7-400 Series CPU unit

Large type H series

H200 to 252 Series

H Series board type

Generic term of H-302(CPU2-03H), H-702(CPU2-07H), H-1002(CPU2-10H), H-2002(CPU2-

20H), H-4010(CPU3-40H), H-300(CPU-03Ha), H-700(CPU-07Ha), H-2000(CPU-20Ha)

Generic term of H-200(CPU-02H, CPE-02H), H-250(CPU21-02H), H-252(CPU22-02H), H-

252B(CPU22-02HB), H-252C(CPU22-02HC, CPE22-02HC)

Generic term of H-20DR, H-28DR, H-40DR, H-64DR, H-20DT, H-28DT, H-40DT, H-64DT,

HL-40DR, HL-64DR

EH-150 Series Generic term of EH-CPU104, EH-CPU208, EH-CPU308, EH-CPU316

HITACHI PLC

(HIDIC H Serie s)

Matsushita Electric Works

PLC

Generic term of large type H series,H-200 to 252 Series H Series board type, EH-150 Series

Generic term of FP0-C16CT, FP0-C32CT, FP1-C24C, FP1-C40C, FP2, FP3, FP5, FP10(S),

FP10SH, FP-M(C20TC) and FP-M(C32TC)

Memory abbreviation of memory (flash memory) in the GOT

Others

OS Abbreviation of GO T system softwar e

Object Setting data for dynamic image

Personal Computer Personal computer where the corresponding software package is installed

0S

series, FX1 series, FX

2NC

series CPU unit

1N

series, FX

1S

series(C200HX, C200HG, C200HE), CQM1,

series,

A - 12 A - 12

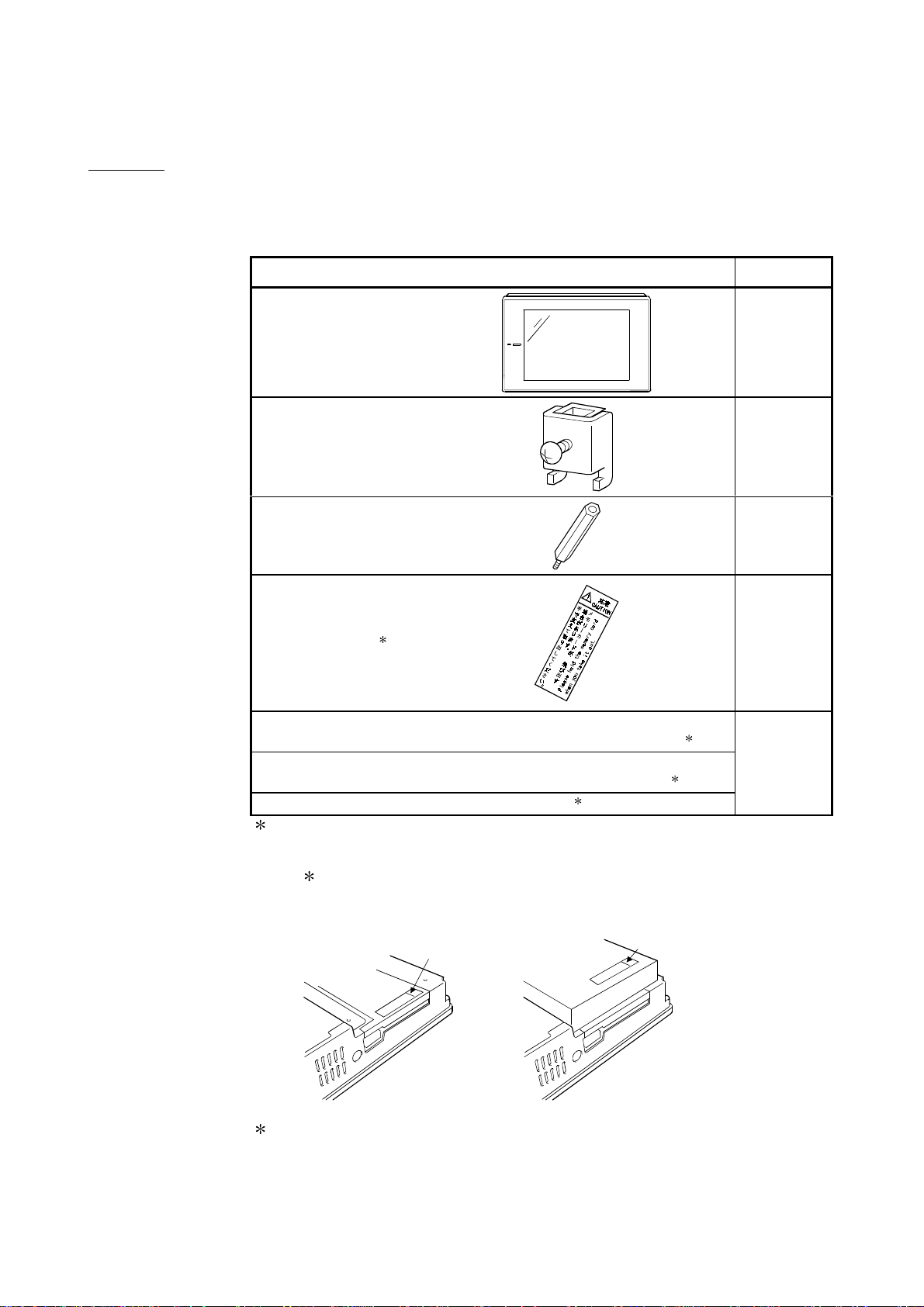

Packing list

e

After unpacking, confirm that you have received the following products.

Product Quantity

GOT main unit 1

Mounting fixture 4

Communication module

securing fixture

Caution plate (seal)

1

A975GOT-TBA/TBD(-B), A970GOT-TBA/TBD(-B), A970GOT-SBA/SBD,

A970GOT-LBA/LBD, A960GOT-EBA/EBD User's Manual (Hardware)

2

A985GOT-TBA-EU, A975GOT-TBA-EU, A970GOT-TBA-EU,

A970GOT-SBA-EU, A960GOT-EBA-EU User's Manual (Hardware)

A985GOT-TBA/TBD(-V) User's Manual (Hardware)

2

2

1 Affix a caution plate in a conspicuous position such as memory card interface part.

(Affix a caution plate on a communication module during its use.)

The caution plate is included only in the following GOT models.

A97 GOT

A960GOT

When affixing a coution plate on the

memory card interface

(except -EU):

(except -EU):

Caution plate

Hardware version L (jun., 2001) or later.

Hardware version H (jun., 2001) or later.

When affixing a coution plate on the

communication module

Caution plat

3

1

1

2 Changes with the GOT you purchased.

A - 13 A - 13

1 OVERVIEW

1 OVERVIEW

MELSEC-GOT

1

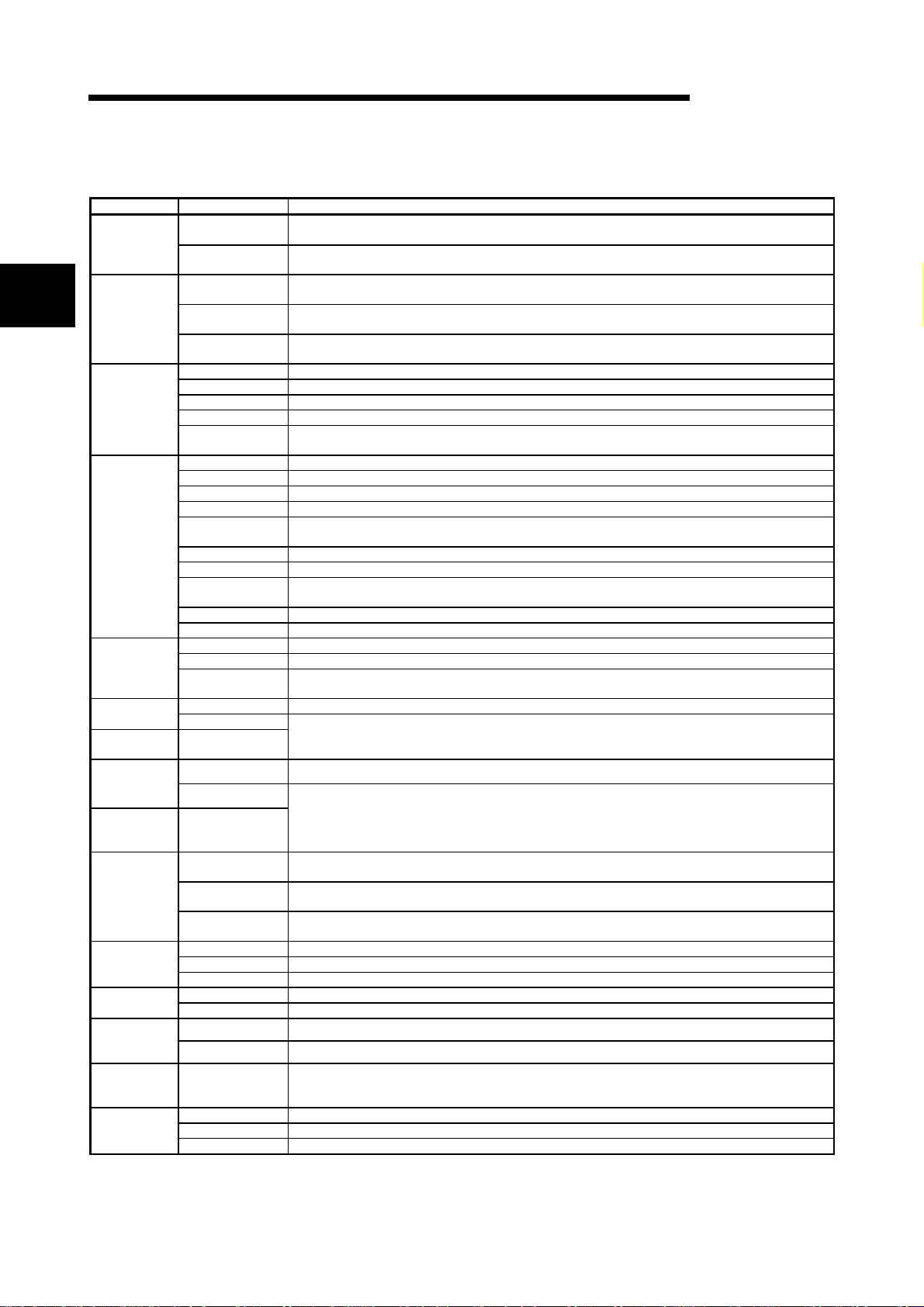

Type

A985GOT-TBA- V 100 to 240VAC

A985GOT-TBD- V 24VDC

A985GOT-TBA 100 to 240VAC

A985GOT-TBD 24VDC

A985GOT-TBA-EU 100 to 240VAC

A975GOT-TBA 100 to 240VAC

A975GOT-TBD 24VDC

A975GOT-TBA-B 100 to 240VAC

A975GOT-TBD-B 24VDC

A975GOT-TBA-EU 100 to 240VAC

A970GOT-TBA 100 to 240VAC

A970GOT-TBD 24VDC

A970GOT-TBA-B 100 to 240VAC

A970GOT-TBD-B 24VDC

A970GOT-TBA-EU 100 to 240VAC

A970GOT-SBA 100 to 240VAC

A970GOT-SBD 24VDC

A970GOT-SBA-EU 100 to 240VAC

A970GOT-LBA 100 to 240VAC

A970GOT-LBD 24VDC

A960GOT-EBA 100 to 240VAC

A960GOT-EBD 24VDC

A960GOT-EBA-EU 100 to 240VAC

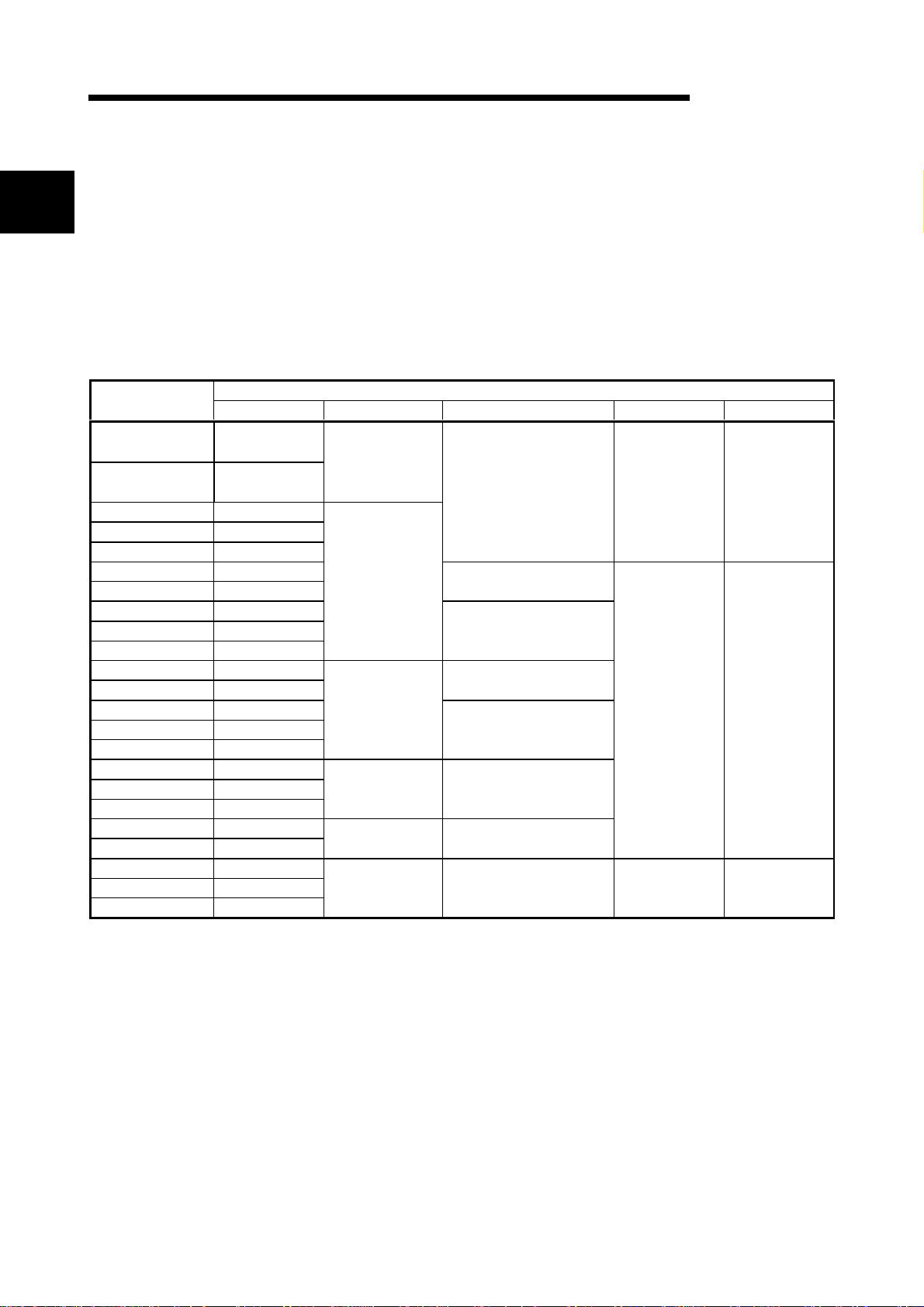

This user's manual explains the specifications, handling and other information of the

GOT-A900 series graphic operation terminal module (abbreviated to the GOT).

The GOT can be used as an electronic operator panel which has achieved on its

monitor screen the switch operation, lamp indication, data display, message display

and other operations which were previously performed on an operator panel.

The following GOT ty pe s are available.

Rough Specifications

Power supply type Display color [Color] Display section Resolution [Dots] Screen size [cm]

256

(During image

display: 65536)

256

16

8 D-STN color liquid crystal

2

(Monochrome)

2

(Yellow orange,

black)

High luminance TFT color

liquid crystal

Wide viewing angle

TFT color liquid crystal

High luminance

TFT color liquid crystal

Wide viewing angle

TFT color liquid crystal

High luminance

TFT color liquid crystal

STN monochrome liquid

crystal

High-luminance EL 640 × 400 23 (9inch)

800 × 600 31 (12inch)

640 × 480 26 (10inch)

1 - 1 1 - 1

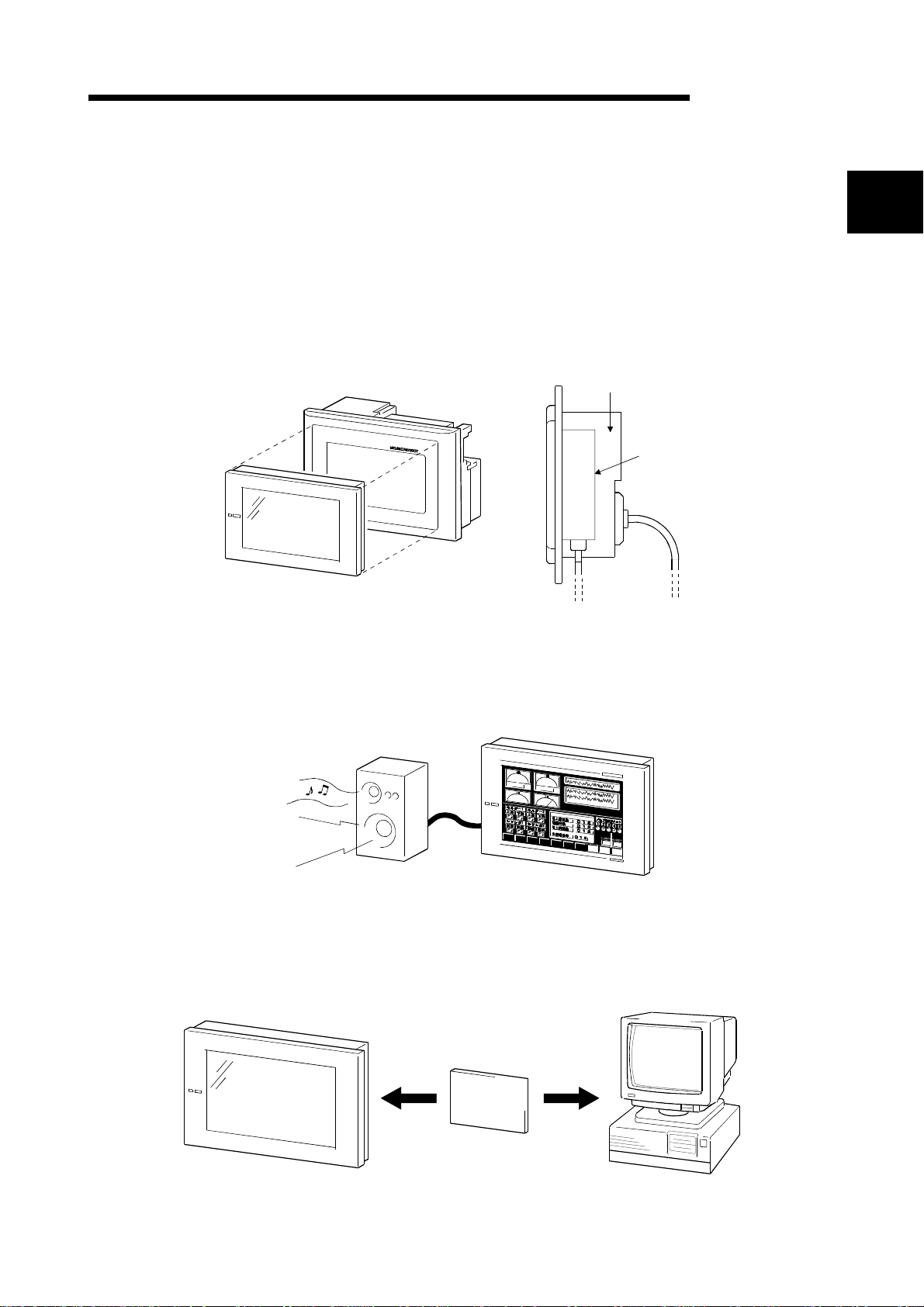

1 OVERVIEW

1.1 Features

MELSEC-GOT

(1) Compact display device in pursui t of mounting, outline dimensions

and thinness

With the display screen size identical to that of the conventional type, the outline

dimensions and depth are substantially reduced to achieve a compact size and

thin design.

The GOT is designed to connect cables at its bottom to ensure that extra space

is not needed for the connectors and bending of the cables when the GOT is

mounted on a control box or the like.

A870GOT

A970GOT

A870GOT

A970GOT

(2) User-friendly multi media di spl ay device

Clear, high-grade display has been achieved by 256-color representation.

(A975GOT, A985GOT(-V) only)

Ear-appealing information transmission has also been achieved by supporting

speech output using the Windows WAV file.

1

ine 1 stopped!

(3) Fast data transfer of OS and screen data by memor y car d

The PC card for OS and screen data can be created easily on a personal

computer. By load in g the crea te d ca rd in to th e GOT, y ou can e xchan ge the OS

and screen data rapidly. (RS-232C data transfer can also be made as

conventionally.)

Commercially available PC card

(Compliant with PCMCIA Ver.2.1)

1 - 2 1 - 2

1 OVERVIEW

MELSEC-GOT

(4) Compatible with a wide var i ety of connection forms

The GOT is compatible with various connection forms such as the MELSEC and

computer link connections, including the bus connection which permits fast

communication. You can choose the connection form matching the system.

(5) Heavy-duty body usable in rig or ous envi r onment and oper ation

The display section of the GOT complies with the IP65F, IP67F and NEMA4

Waterproof, Dustproof Standard and is usable in a wide range of environment.

(6) Maintenance function further enhanced in a f finity wi th PLC

• Supporting the factor search mode which searches for the contact of a failure

factor at the device search time in the ladder monitoring function, the GOT has

shortened the fai lu r e fa cto r analysis time.

• Upgraded alarm history function

The GOT can support the failure occurrence counting function, cumulative

failure time totalizing function and history printing function, and start ladder

monitoring wi th the cor respo nd in g de vi ce sea rch ed wit h a singl e key st ro ke at

the failure detail display time.

(7) Improvement of safety by upgraded secur i ty function

• Supporting the operation protective function using up to 16 levels of passwords,

the GOT can hide the display or disable input operation according to the

password level. You can achieve hidden screens and hidden operations and

easily change th e di splay data per GOT used.

• You can specify the time delay function (ON delay/OFF delay) of the touch

switches, double-pushing switches and interlock conditions to reduce

malfunctions due to wrong key pushing.

(8) Energy saving mode using human sensor ( A985GOT(- V) onl y)

• The human sensor detects operators in the sensor detection area and turns the

backlight ON/OFF automatically.

The backlight can be turned off automatically if no operator motions are not

detected for a given period of time. (This time can be set by the user.)

1 - 3 1 - 3

1 OVERVIEW

1.2 Requirements to match EMC Directives

EMC Directives which are among European Directives become forced.

EMC Directives are those which require "any strong electromagnetic force is not output

to the external.: Emission (electromagnetic interference)" and "It is influenced by the

electromagnetic wave from the external.: Immunity (electromagnetic sensitivity)".

Items 1.2.1 thru 1.2.3 summarize the precautions to use GOT and configure the

mechanical unit in order to match the EMC directives.

Though the data described herein are produced with our best on the basis of the

requirement items and standards of the restrictions gathered by Mitsubishi, they do not

completely guaranteed that all mechanical unit manufactured according to the data do

not always match the above directives. The manufacturer itself which manufactures

the mechanical unit must finally judge the method and others to match the EMC

directives.

1.2.1 EMC Directives

The standards of the EMC Directives are shown below.

Specifications Test Item Test Description Standard Values

EN55011

Radiated noise

EN50081-2:

1995

EN55011

Conduction noise

EN61000-4-2

Static electricity immunity

EN61000-4-4

First transient burst noise

ENV50140

EN50082-2:

1995

Radiated electromagnetic

field AM modulation

ENV50204

Radiated electromagnetic

field Pulse modulation

ENV50141

Conduction noise

MELSEC-GOT

30M-230MHz QP :

30dBµ V/m (30m

2

2

2

Measure the emission released by

the product.

Measure the emission released by

the product to the power line.

Immunity test by applying static

2

electricity to the module enclosure.

Immunity test by applying burst

noise to the power line and signal

2

cable., 2kV

Immunity test by applying

aradiated electric field to the

2

product.

Immunity test by applying

aradiated electric field to the

2

product.

Immunity test by inducting an

electromagnetic field in the power

line signal cable.

measurement)

230M-1000MHz QP :

37dBµ V/m (30 m

measurement)

150K-500kHzQP:

79dB, Mean : 66dB

500K-30MHz QP :

73dB, Mean: 60dB

±4kV contact discharge

±8kV air discharge

±2kV

10V/m, 80-1000MHz,

80% AM modulation @

1kHz

10V/m, 900MHz, 200Hz

pulse modulation, 50%

duty

10Vrms, 0.15-80MHz,

80% modulation @ 1kHz

1

1

1 QP: Quasi-peak value, Mean: Average value

2 The GOT is an open ty pe dev ice (device insta lle d t o a not he r device) and must be

installed in a conductive control pauel or cabinet.

About these test items, install the control panel, combine with a PLC from this

company, and run a test.

1 - 4 1 - 4

1 OVERVIEW

1.2.2 Installation inside Control Box

The GOT is an open type device (device installed to another device) and must be

installed in a conductive control pauel or cabinet.

It not only assu re th e sa fe ty but al so ha s a la r ge effect t o shut dow n the noi se

generated from GOT, on the control panel.

1) Control cabinet

a) Use a conductive control cabinet.

b) When attaching the control cabinet's top plate or base plate, mask painting

and weld so that good surface contact can be made between the cabinet and

plate.

c) To ensure good electrical contact with the control cabinet, mask the paint on

the installation bolts of the inner plate in the control cabinet so that contact

between surfaces can be ensured over the widest possible area.

MELSEC-GOT

d) Earth the control cabinet with a thick wire so that a low impedance connection

to ground can be ensured even at high frequencies. (22mm

recommended.)

e) Holes made in the control cabinet must be 10cm (3.94in.) diameter or less. If

the holes are 10cm (3.94in.) or larger, radio frequency noise may be emitted.

In addition, because radio waves leak through a clearance between the

control panel door and the main unit, reduce the clearance as much as

practicable.

The leakage of radio waves can be suppressed by the direct application of an

EMI gasket on the paint surface.

Our tests have been ca rri ed out on a pan el havi ng th e da mping cha ra c ter i sti cs

of 37 dB max. and 30 dB mean (mea s u red by 3 m meth o d wi th 30 to 300

MHz).

2

wire or thicker is

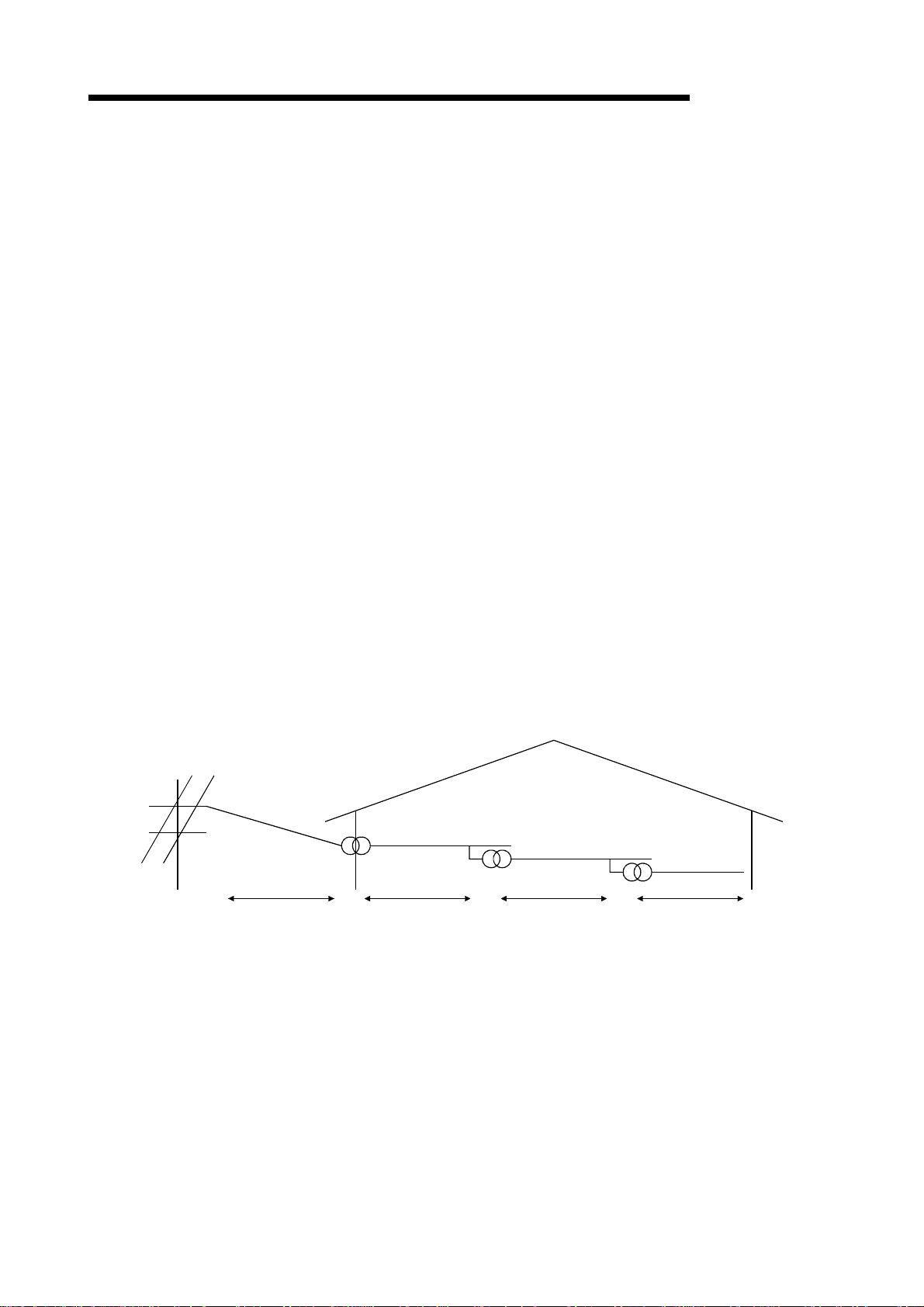

2) Connection of power and ground w i r es

Ground and power supply wires for the GOT must be connected as described

below.

a) Provide an earthing point near the GOT. Earth the power supply's LG and FG

terminals (LG : Line Ground, FG : Frame Ground) with the thickest and

shortest wire possible. (The wire length must be 30cm (11.18in.) or shorter.)

The LG and FG terminals function is to pass the noise generated in the PC

system to the ground, so an impedance that is as low as possible must be

ensured. As the wires are used to relieve the noise, the wire itself carries a

large noise content and thus short wiring means that the wire is prevented

from acting as an antenna.

Note) A long condu ct o r will be come a more e ffi cie nt an t enn a at hig h

frequency.

b) The earth wire led from the earthing point must be twisted with the power

supply wires. By twisting with the earthing wire, noise flowing from the power

supply wires can be relieved to the earthing. However, if a filter is installed on

the power supply wires, the wires and the earthing wire may not need to be

twisted.

1 - 5 1 - 5

1 OVERVIEW

1.2.3 Noise filter (power supply line filter)

The noise filter (power supply line filter) is a device effective to reduce conducted

noise. Except some models, installation of a noise filter onto the power supply lines is

not necessary. However co ndu cted noi se can be redu ce d if i t is inst all ed. (The no i se

filter is generally effective for reducing conducted noise in the band of 10MHz or less.)

Usage of the following filters is recommended.

Model name FN343-3/01 FN660-6/06 ZHC2203-11

Manufacturer SCHAFFNER SCHAFFNER TDK

Rated current 3A 6A 3A

Rated voltage 250V

The precautions required when installing a noise filter are described below.

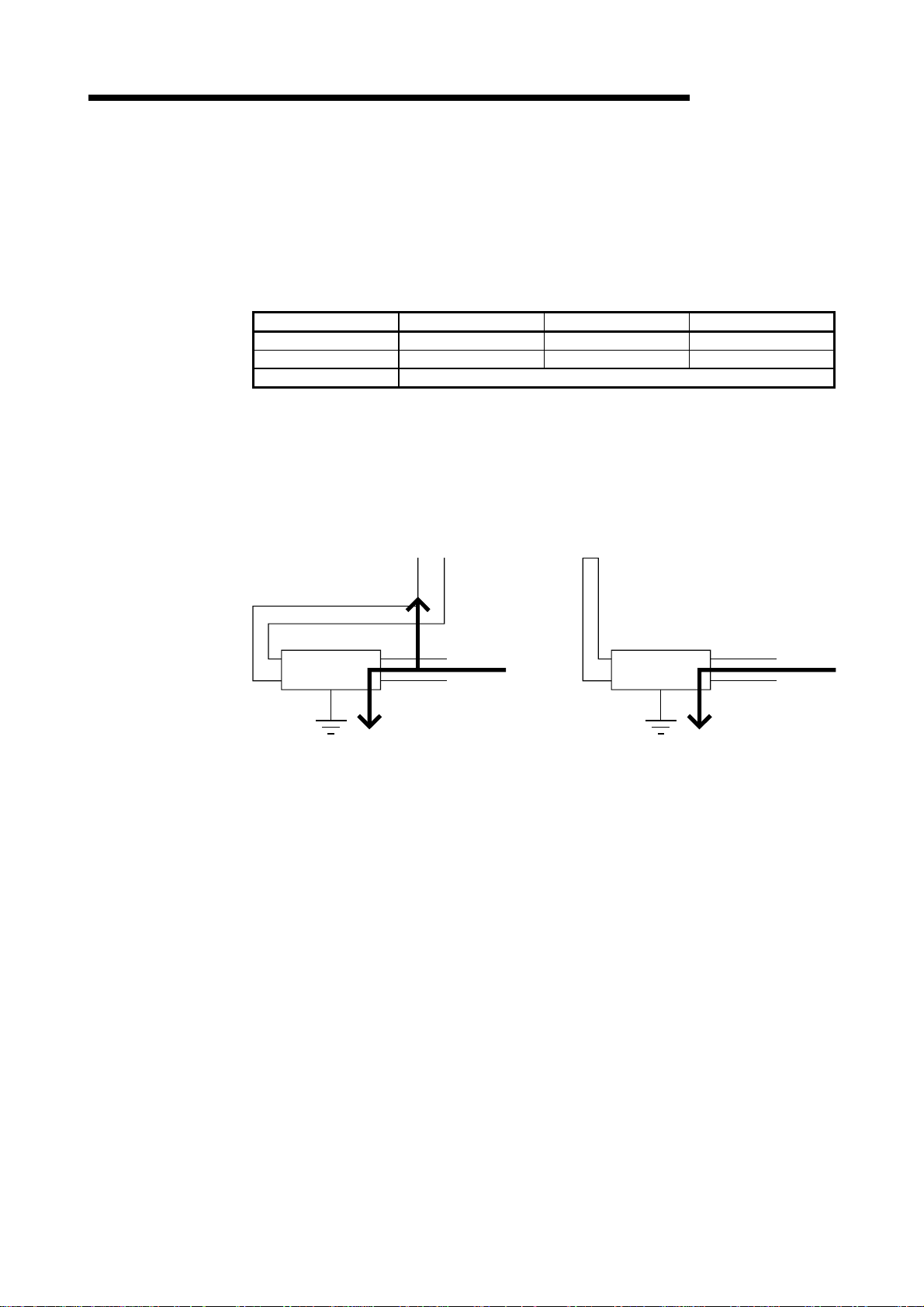

1) Do not bundle the wires on the input side and output side of the noise filter. When

bundled, the output side noise will be induced into the input side wires from which

the noise was fil ter ed .

MELSEC-GOT

Input side

(power supply side)

Induction

Filter

Output side

(device side)

a) The noise will be included when the input and

output wires are bundled.

Input side

(power supply side)

Filter

Output side

(device side)

b) Separate and lay the input and output wires.

2) Earth the noise filter earthing terminal to the control cabinet with the shortest wire

possible (appro x. 10 cm (3.9 4 in . )).

1 - 6 1 - 6

1 OVERVIEW

1.3 Requirements for compliance w i th the Low Voltage Directive

The Low Voltage Directive is mandatory within Europe, effective 1st January 1997.

The Low Voltage Directive requires each device which operates with power supply

ranging from 50VAC to 1000V and 75VDC to 1500V to satisfy necessary safety items.

In the Sections from 1.3.1 to 1.3.5, cautions on installation and wiring of the GOT to

conform to the Low Voltage Directive requires are described.

We have put the maximum effort to develop this material based on the requirements

and standards of the Directive that we have collected. However, compatibility of the

devices which are fabricated according to the contents of this manual to the above

Directive is not guaranteed. Each manufacturer who fabricates such device should

make the final judgement about the application method of the Low Voltage Directive

and the product compatibility.

1.3.1 Standard applied for GOT

The standard applied for GOT is EN61010-1 safety of devices used in measurement

rooms, control rooms, or laboratories.

MELSEC-GOT

1.3.2 Power supply

The insulation specification of the GOT was designed assuming installation category II.

Be sure to use the installation category II power supply to the GOT.

The installation category indicates the durability level against surge voltage generated

by lightning strike. Category I has the lowest durability; category IV has the highest

durability.

Category ICategory IICategory IIICategory IV

Installation Category

Category II in di cat e s a pow e r supply whose voltag e ha s bee n re du ced by tw o or more

levels of isolating transformers from the public power distribution.

1 - 7 1 - 7

1 OVERVIEW

1.3.3 Control cabinet

MELSEC-GOT

Because the GOT is op en t y pe equi p men t (a devi ce de si gne d to be sto red wi th in

another module), be sure to use it only when installed in a control cabinet.

1) Electrical shock prevention

In order to such as the operators from electric shocks, the control box must have

the followin g fun c ti on s :

a) The control cabi ne t must be equ ipp ed wi th a lo ck so t ha t only skilled or

qualified personnel.

b) The control cabinet must be fitted with advice which automatically stops the

power supply when the cabinet is opened.

2) Dustproof and waterproof features

The control cabinet also provides protection from dust, water and ether

substances. Insufficient ingression protection may lower the insulation withstand

voltage, resulting in insulation destruction. The insulation in our GOT is designed

to cope with the pollution level 2, so use in an environment with pollustion level 2

or better.

Pollution level 1 : An environment where the air is dry and conductive dust

does not exist.

Pollution level 2 : An environment where conductive dust does not usually

exist, but occasional temporary conductivity occurs due to

the accumulated dust.

Generally , this is the level for in si d e th e co nt rol bo x

equivalent a control room or on the floor of a typical factory.

Pollution level 3 : An environment where conductive dust exits and

conductivity may be generated due to the accumulated

dust.

An environment for a typical factory floor.

Pollution level 4 : Continuous conductivity may occur due to rain, snow, etc.

An outdoor environment.

1.3.4 Grounding

There are two kin d s of g r ounding terminals a s show n be l ow . Bo th ter min al s must be

grounded.

Be sure to ground the grounding for the safety reasons and EMC Directives.

Protective g roun ding

Functional grounding

1 - 8 1 - 8

:

Maintains the safety of the GOT and improves the noise

resistance.

:

Improves the noise resistance.

1 OVERVIEW

1.3.5 External wiring

MELSEC-GOT

1) External devices

When a device with a hazardous voltage circuit is externally connected to the

PC, select a model which complies with the Low Voltage Directive's requirements

for isolation between the primary and secondary circuits.

2) Insulation requirements

Dielectric withstand voltages are shown in the following table.

Intensive Insulation Withstand Voltage

(Installation Category II, source : IEC664)

Rated voltage of hazardous voltage area Surge withstand voltage (1.2/50 µs)

150 VAC or below 2500V

300 VAC or below 4000V

1 - 9 1 - 9

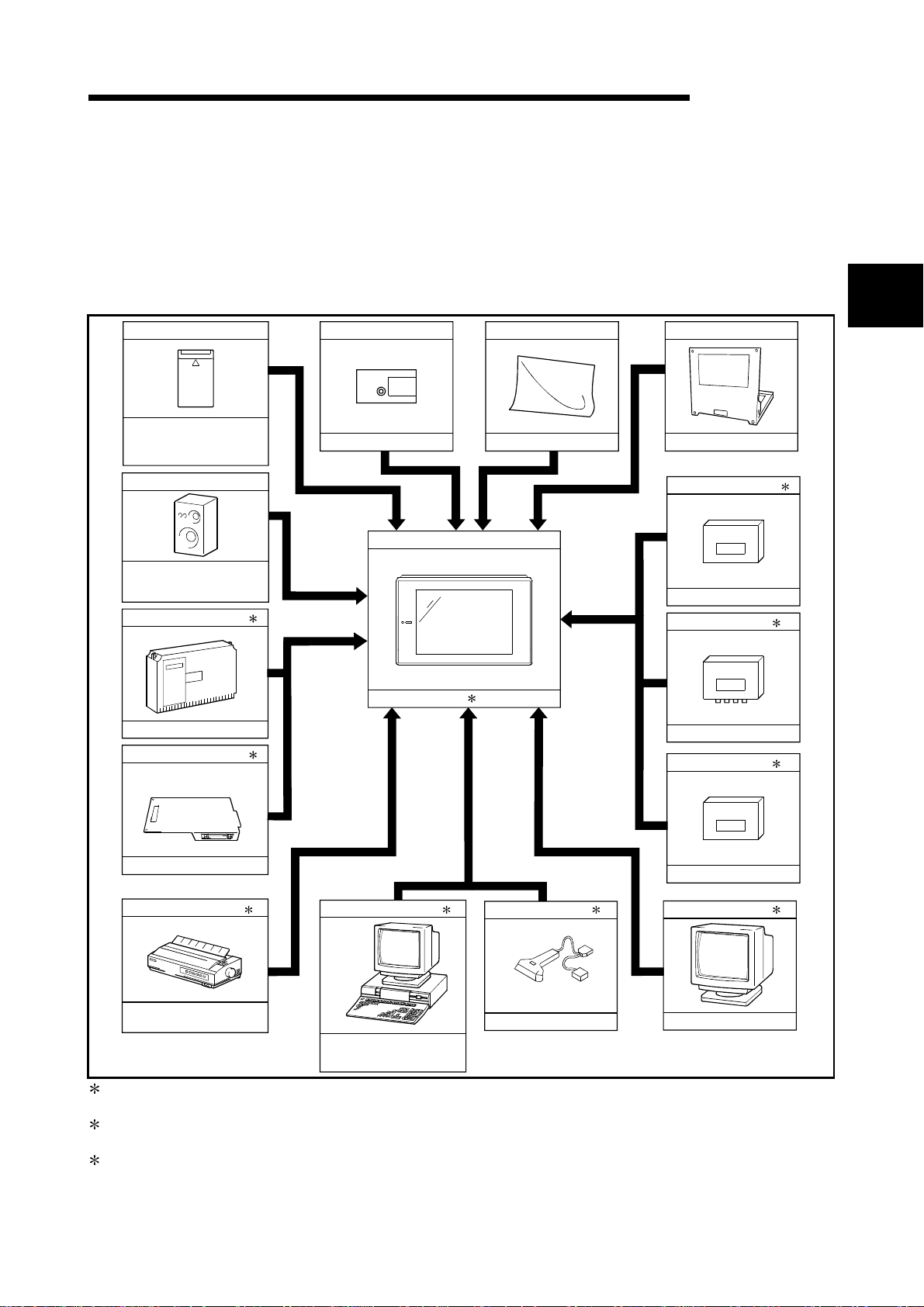

2 SYSTEM CONFIGURATION

2 SYSTEM CONFIGURATION

This chapter explains the system configuration of the GOT.

2.1 Overall Configuration

MELSEC-GOT

PC card (Memeory card)

Commercially available

Based on JEIDA Ver4.2

(Based on PCMCIA2.1)

Speech output device

Commercially available

(Compatible with stereo

mini-jack)

Communication module

e.g. A7GT-J71AP23

Communic ation board

The overall configuration of the GOT is shown below.

Memory board

e.g. A9GT-FNB

GOT

1

A985GOT(-V)/A97 GOT/A960GOT

1

Protective sheet

e.g. A9GT-70PSC

Debug stand

e.g. A9GT-70STAND

External I/O module

A9GT-70KBF

Video input unit

A9GT-80V4

RGB input unit

2

1

1

1

e.g. A9GT-BUSS

Pinter

Commercially available

Window compatible printer

Personal computer

Commercially available

(Compatible with Windows 95,

Windows 98, Windows N T4.0

2 1 31

Bar code reader

OPT-5125-RS1232C(H)

A9GT-80R1

CRT

Commercially available

1 For details of the system configuration, refer to the [GOT-A900 Series User's Manual (GT Works

Version5/GT Designer Version5 compatible Connection System Manual)].

2 For details of the system configuration, refer to the [GT Works Version5/GT Designer Version5 Reference

Manual].

3 Only the A985GOT may be connected to the CRT. (A985GOT-V can not be used.)

2 - 1 2 - 1

2 SYSTEM CONFIGURATION

2.2 Component List

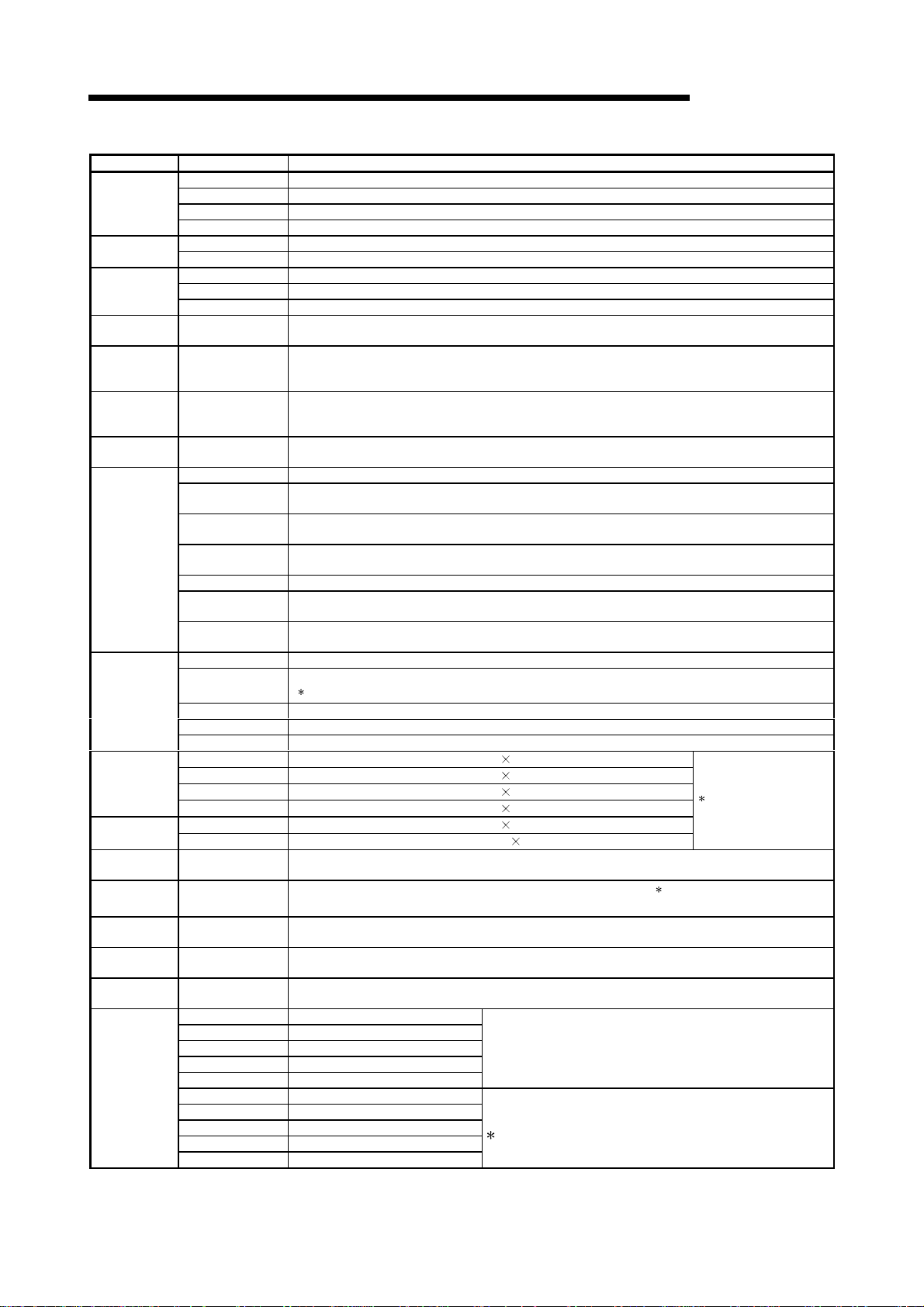

Component Type Remarks

A985GOT-V

2

A985GOT

A975GOT

A970GOT

A960GOT

Bus connection

board

Bus connection

module

Multidrop bus

connection

board

Multidrop bus

connection

module

Serial

communication

board

Data link

module

Network

module

CC-Link

communication

module

Ethernet

communication

module

Protective

sheet

A985GOT-TBA-V

A985GOT-TBD-V

A985GOT-TBA

A985GOT-TBD

A985GOT-TBA-EU

A975GOT-TBA 26cm (10inch), 256 color display, wide viewing angle TFT color liquid crystal, 100 to 240VAC

A975GOT-TBD 26cm (10inch), 256 color display, wide viewing angle TFT color liquid crystal, 24VDC

A975GOT-TBA-B 26cm (10inch), 256 color display, high-luminance TFT color liquid crystal, 100 to 240VAC

A975GOT-TBD-B 26cm (10inch), 256 color display, high-luminance TFT color liquid crystal, 24VDC

A975GOT-TBA-EU

A970GOT-TBA 26cm (10inch), 16 color display, wide viewing angle TFT color liquid crystal, 100 to 240VAC

A970GOT-TBD 26cm (10inch), 16 color display, wide viewing angle TFT color liquid crystal, 24VDC

A970GOT-TBA-B 26cm (10inch), 16 color display, high-luminance TFT color liquid crystal, 100 to 240VAC

A970GOT-TBD-B 26cm (10inch), 16 color display, high-luminance TFT color liquid crystal, 24VDC

A970GOT-TBA-EU

A970GOT-SBA 26cm (10inch), 8 color display, D-STN color liquid crystal, 100 to 240VAC

A970GOT-SBD 26cm (10inch), 8 color display, D-STN color liquid crystal, 24VDC

A970GOT-SBA-EU

A970GOT-LBA 26cm (10inch), STN monochrome liquid crystal, 100 to 240VAC

A970GOT-LBD 26cm (10inch), STN monochrome liquid crystal, 24VDC

A960GOT-EBA 23cm (9inch), 2 color display, high-luminance EL, 100 to 240VAC

A960GOT-EBD 23cm (9inch), 2 color display, high-luminance EL, 24VDC

A960GOT-EBA-EU

A9GT-QBUSS For bus connection, small connector type (For QCPU (Q mode))

A9GT-BUSS

A9GT-BUSSU

A9GT-QBUS2S For multidrop bus connection, small connector type (For QCPU (Q mode))

A9GT-BUS2S

A9GT-BUS2SU

A9GT-RS4

A9GT-RS2

A9GT-RS2T

A7GT-J71AP23 For MELSECNET(II) optical link connection, for use as local station

A7GT-J71AR23 For MELSECNET(II) coaxial link connection, for use as local station

A7GT-J71AT23B For MELSECNET/B connection, for use as local station

A7GT-J71LP23 For MELSECNET/10 optical loop network connection, for use as ordinary station

A7GT-J71BR13 For MELSECNET/10 coaxial bus network connection, for use as ordinary station

A8GT-J61BT13 For CC-Link connection, for use as intelligent device station

A8GT-J61BT15 For CC-Link connection, for use as remote device station

A9GT-J71E71-T For Ethernet connection

A9GT-80PSC Transparent protective sheet for A985GOT(-V), MITSUBISHI logotype can be removed.

A9GT-70PSC Transparent protective sheet for A975/970GOT, MITSUBISHI logotype can be removed.

A9GT-60PSC Transparent protective sheet for A960GOT, MITSUBISHI logotype can be removed.

MELSEC-GOT

31cm (12inch), 256 color display, high-luminance TFT color liquid crystal, 100 to 240VAC,

Video/RGB display supports

31cm (12inch), 256 color display, high-luminance TFT color liquid crystal, 24VDC, Video/RGB display

supports

31cm (12inch), 256 color display, high-luminance TFT color liquid crystal, 100 to 240VAC, built-in

CRT interface

31cm (12inch), 256 color display, high-luminance TFT color liquid crystal, 24VDC, built-in CRT

interface

31cm (12inch), 256 color display, high-luminance TFT color liquid crystal, 100 to 240VAC, built-in

CRT interface, EMC Directive and Low Voltage Directive compliant product

26cm (10inch), 256 color display, high-luminance TFT color liquid crystal, 100 to 240VAC,

EMC Directive and Low Voltage Directive compliant product

26cm (10inch), 16 color display, high-luminance TFT color liquid crystal, 100 to 240VAC,

EMC Directive and Low Voltage Directive compliant product

26cm (10inch), 8 color display, D-STN color liquid crystal, 100 to 240VAC,

EMC Directive and Low Voltage Directive compliant product

23cm (9inch), 2 color display, high-luminance EL, 100 to 240VAC,

EMC Directive and Low Voltage Directive compliant product

For bus connection, small connector type (For A/QnA/Motion controller CPU)

For multidrop bus connection, small connector type (For A/QnA/Motion controller CPU)

For Direct connection to CPU/Computer link connection/Microcomputer connection and RS-422

connection (Without clock function)

For Direct connection to CPU/Computer link connection/Microcomputer connection and RS-232C

connection (Without clock function)

For Direct connection to CPU/Computer link connection/Microcomputer connection and RS-232C

connection (Incorporating clock function)

2 - 2 2 - 2

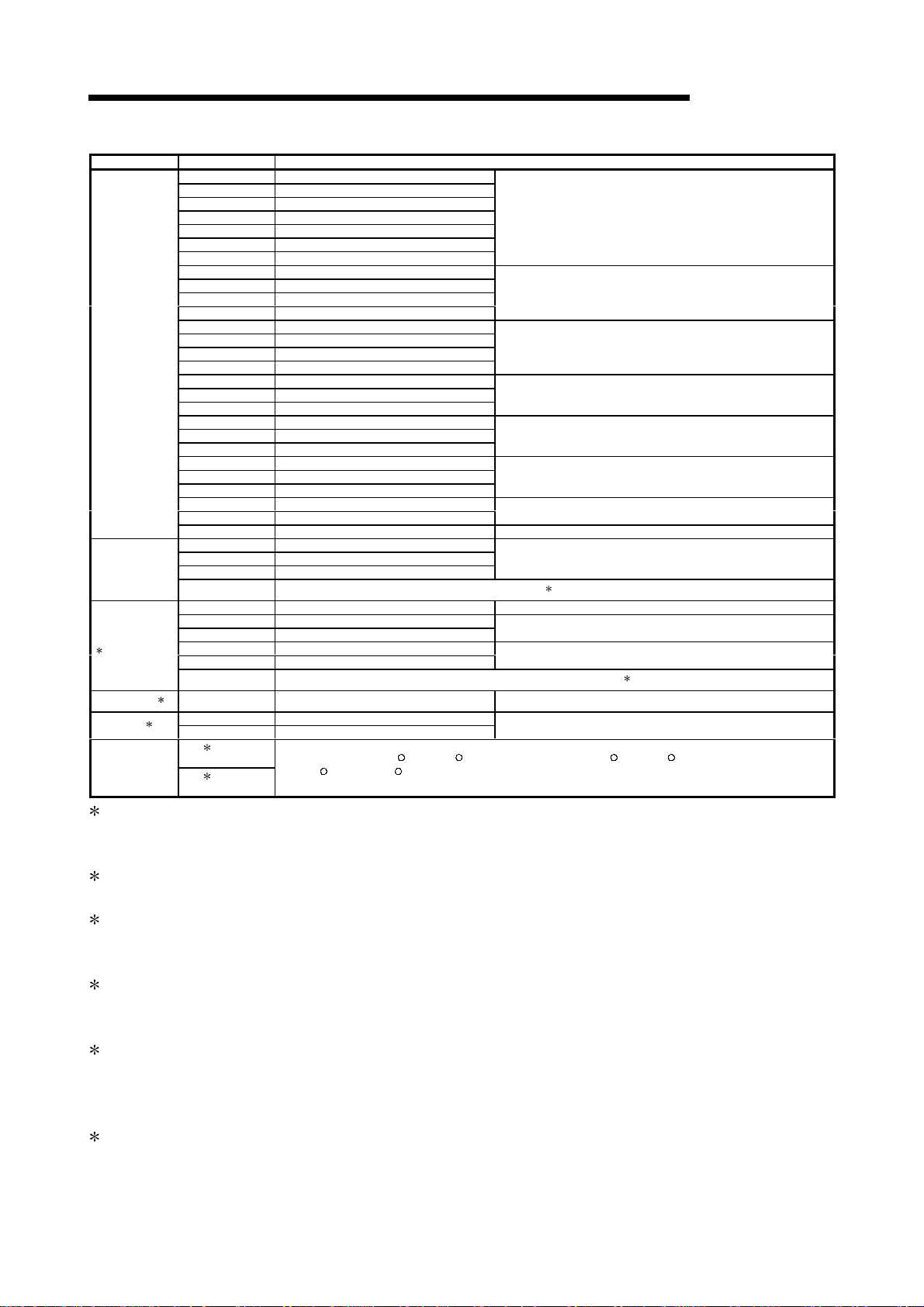

2 SYSTEM CONFIGURATION

Component Type Remarks

A9GT-80LLT Backlight for A985GOT(-V)

Backlight

Debug stand

Attachment

External I/O

module

Video input

interface

module

RGB input

interface

module

Numeric

keypad panel

Memory board

PC card/

memory card

CRT display

TFT display

Bar code

reader

Printer —

Speech output

device

Bus extension

connector box

Bus connector

conversion box

Bus connection

cable QCPU

(Q mode)

A9GT-70LTT Backlight for A975/970GOT wide viewing angle TFT color liquid crystal type

A9GT-70LTTB Backlight for A975/970GOT high-luminance TFT color liquid crystal type

A9GT-70LTS Backlight for A970GOT D-STN color/monochrome liquid crystal type

A9GT-80STAND Debug stand for A985GOT(-V)

A9GT-70STAND Debug stand for A975/970/960GOT

A77GT-96ATT Attachment used for replacement from A77GOT to A960GOT

A87GT-96ATT Attachment used for replacement from A870GOT to A960GOT

A87GT-97ATT Attachment used for replacement from A870GOT to A975/970GOT

A9GT-70KBF For external I/O equipment connection

A9GT-80V4 For video camera connection

A9GT-80R1 For personal computer connection

A8GT-TK Data entry Numeric Keypad Panel

A9GT-FNB Exclusively used for optional OS storage (MELSEC-A/FX Ladder monitor-compatible)

A9GT-FNB2M

A9GT-FNB4M

A9GT-FNB8M

A9GT-QFNB Exclusively used for optional Os storage (MELSEC-Q/QnA/A/FX Ladder monitor-compatible)

A9GT-QFNB4M

A9GT-QFNB8M

— Commercially available SRAM type PC card (based on JEIDA Ver4.2 (based on PCMCIA2.1))

—

A9GTMEM-10MF For GOT, Memory 1 6 M by te , ( h a r d w are v e r sio n D or la te r ) fla sh PC ca r d , fo r mat te d

A9GTMEM-20MF For GOT, Memory 3 2 M by te , ( h a r d w are v e r sio n D or la te r ) fla sh PC ca r d , fo r mat te d

A9GTMEM-40MF For GOT, Memory 4 8 M by te , ( h a r d w are v e r sio n D or la te r ) fla sh PC ca r d , fo r mat te d

RD15M II

RD17MX

RDF19X

RD19NF

RDT150S

RDT180S

—

— Stereo mini-jack compatible speaker (built-in amplifier)

A9GT-QCNB Used for connection of the QCPU (Q mode) long-distance bus

A7GT-CNB

QC06B Cable length 0.6m

QC12B Cable length 1.2m

QC30B Cable length 3.0m

QC50B Cable length 5.0m

QC100B Cable length 10.0m

A9GT-QC150BS Cable length 15.0m

A9GT-QC200BS Cable length 20.0m

A9GT-QC250BS Cable length 25.0m

A9GT-QC300BS Cable length 30.0m

A9GT-QC350BS Cable length 35.0m

For optional function OS storage + built-in memory extension, 2M byte

(MELSEC-A/FX Ladder monitor-compatible)

For optional function OS storage + built-in memory extension, 4M byte

(MELSEC-A/FX Ladder monitor-compatible)

For optional function OS storage + built-in memory extension, 8M byte

(MELSEC-A/FX Ladder monitor-compatible)

For optional function OS storage + built-in memory extension, 4M byte

(MELSEC-Q/QnA/A/FX Ladder monitor-compatible)

For optional function OS storage + built-in memory extension, 8M byte

(MELSEC-Q/QnA/A/FX Ladder monitor-compatible)

Commercially available flash PC card (based on Compact FlashTM)

(

Compact FlashTM is a trademark of Sun Disk

Mitsubishi Electric make, 15inch, 1280

Mitsubishi Electric make, 17inch, 1280

Mitsubishi Electric make, 19inch, 1600

Mitsubishi Electric make, 19inch, 1600 1200dots

Mitsubishi Electric make, 15inch, 1280

Mitsubishi Electric make, 18.1inch, 1280

Names of manufacturer: Token, Opt-electronics, Keyence, Imex, OLYMPUS-symbol, Omron and

Denso

Printer compliant with ESC/P24-J84 (ESC/P command compatible)

Hewlett Packard printers (PLC command compatible)

For conversion from large type connector to small type connector

(Used for long-distance bus connection)

1024dots

1024dots

1200dots

768dots

1024dots

For connection between Q base unit and GOT

For connection between GOT and GOT

For connection between Q base unit and GOT

For connection between GOT and GOT

These cable are Mitsubishi Electric system Service Co., Ltd.

products.

MELSEC-GOT

)

1

Introduced products

2

2 - 3 2 - 3

2 SYSTEM CONFIGURATION

MELSEC-GOT

Component Type Remarks

Bus connection

cable

RS-422 cable

RS-232C cable

4

Printer cable

CRT cable

Compatible

software package

AC06B Cable l ength 0.6 m

AC12B Cable l ength 1.2 m

AC30B Cable l ength 3.0 m

AC50B Cable l ength 5.0 m

AC12B-R Right angle, cable length 1.2m

AC30B-R Right angle, cable length 3.0m

AC50B-R Right angle, cable length 5.0m

A1SC07B Cable length 0.7m

A1SC12B Cable length 1.2m

A1SC30B Cable length 3.0m

A1SC50B Cable length 5.0m

A1SC05NB Cable length 0.5m

A1SC07NB Cable length 0.7m

A1SC30NB Cable length 3.0m

A1SC50NB Cable length 5.0m

A8GT-C12NB Cable length 1.2m

A8GT-C30NB Cable length 3.0m

A8GT-C50NB Cable length 5.0m

A8GT-C100EXSS Cable length 10.0m

A8GT-C200EXSS Cable length 20.0m

A8GT-C300EXSS Cable length 30.0m

A8GT-C100BS Cable length 10.0m

A8GT-C200BS Cable length 20.0m

A8GT-C300BS Cable length 30.0m

A370C12B Cabl e leng th 1.2 m

A370C25B Cabl e leng th 2.5 m

A9GT-J2C10B Cable l eng th 1 .0m For connectio n be twee n A 0J2H CP U an d GOT

AC30R4-25P Cable length 3m (D -sub 25-p i n at both e nds )

AC100R4-25P Cable length 10 m (D- sub 25- p in at bo th end s)

AC300R4-25P Cable length 30 m (D- sub 25- p in at bo th end s)

—

QC30R2 Cable length 3m For connection between GOT and QCPU

AC30R2-9P Cable length 3m (D-sub 9-pin, D-sub 25-pin)

AC30R2-9SS Cable length 3m (D-sub 9-pin at both ends)

AC30R2 Cable length 3m (D-sub 25-pin at bot h e nds)

AC30N2A Cable length 3m (D-sub 25-pi n at both ends )

—

6

AC30PIO-20P Cable length 3m For connection between GOT and printer

AC50VG Cab l e leng th 5m

6

AC300VG Cable length 30 m

SW D5C-

GTWORKS-E

D5C-GOTR-

SW

PACKE

For connection between GOT and computer link module

For connectin g the GO T w ith th e pow e r su pp ly uni t of the bar cod e re ade r

R

Compatible with Microsoft

R

Microsoft

Windows NTR Workstation 4.0 operating system

WindowsR95 operating system, MicrosoftR WindowsR 98 operating system,

For connection be tw ee n larg e type base unit and A7G T- CNB

For connection between small type base unit and GOT

For connection between GOT and GOT

For connection between small type base unit and A7GT-CNB

For connectio n betw ee n l arg e ty pe ba se unit an d GO T

For connection be tw ee n s mall type bas e unit /

A7GT-CNB and GOT

For long-distance connection between GOT and GOT

For connectio n betw ee n mu lti -axis control and GO T

For connection between GOT and PC CPU

For connection between GOT and serial communication module

For connection between GOT and FXCPU

3

For connection between GOT and computer link module

For connection between GOT and personal computer for data transfer

For connection between GOT and personal computer for data transfer

(9-pin conver sio n co nn ec tor req u ir ed)

5

For connection between GOT and CRT

1 Introduced products Products which have been verified to have the specifications (standards) connectable

to our modules. Use the introduced products in compliance with the specifications

(standards) of the products.

2 The printer of ESC/P raster specifications such as the PM series cannot be connected and used with the

GOT.

3 The RS-422 cable for use between GOT and computer link module should be fabricated on the user side

by referring to the [GOT-A900 Series User's Manual (GT Works Version5/GT Designer Version5

compatible Connection System Manual)].

4 The RS-232C cable may be fabricated by the user.

For details of the cable specifications, refer to the [GT Works Version5/GT Designer Version5 Reference

Manual].

5 Please refer to the [GOT-A900 Series User's Manual (GT Works Version5/GT Designer Version5

compatible Co nn e ctio n Sy st e m Ma nu al )] and p r epar e th e RS -2 32C cabl e be tw e en the GOT a nd th e

power supply unit of the bar code reader. (Some bar code readers do not need to be connected with the

RS-232C cabl e. )

6 The printer cabl e an d t he CR T cable may be fabri cat e d by th e u s e r.

Refer to [Cha pt e r 3] fo r fu ll in fo r mation on the spe cifications need ed to fa b ri cat e t he cabl e.

2 - 4 2 - 4

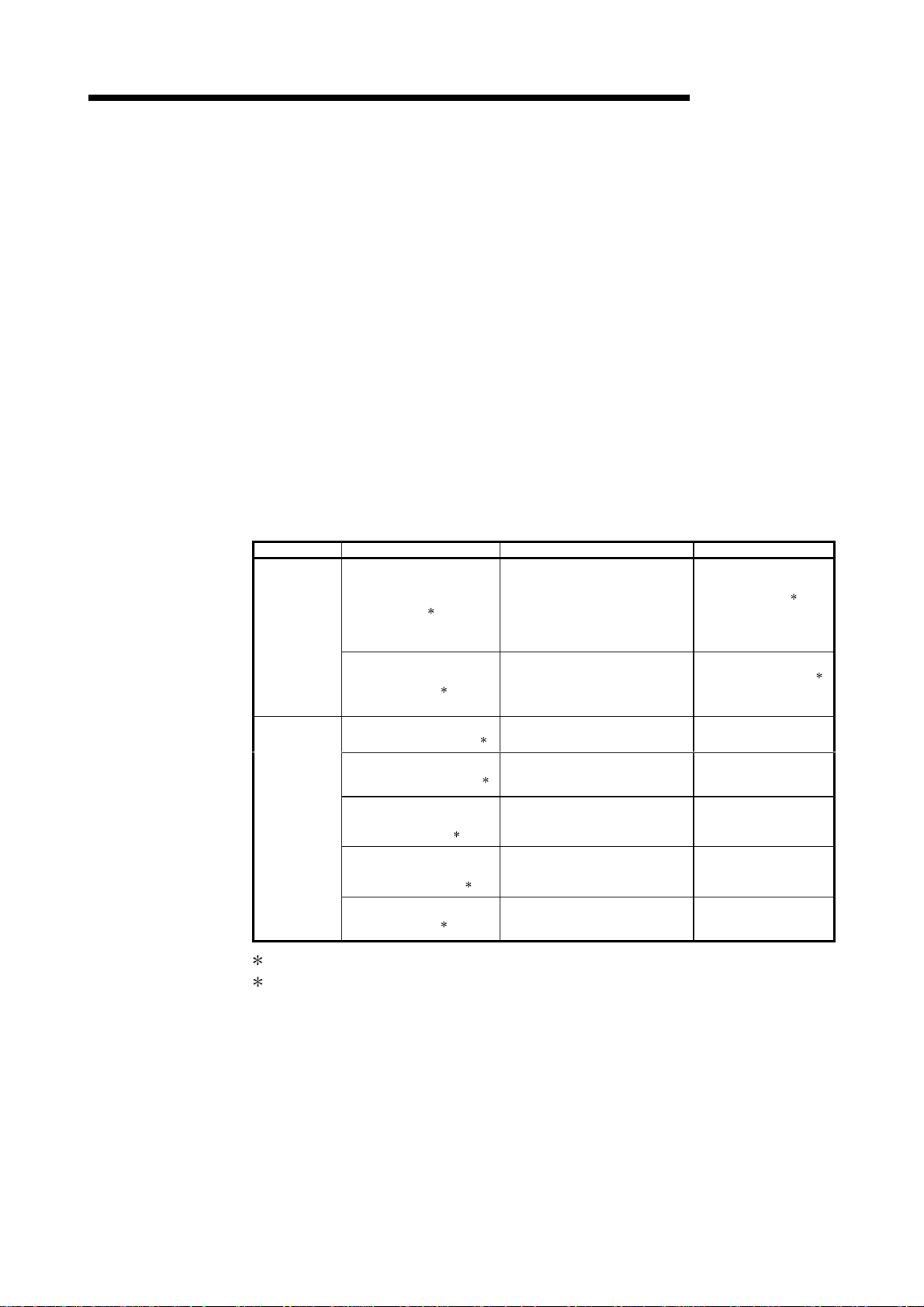

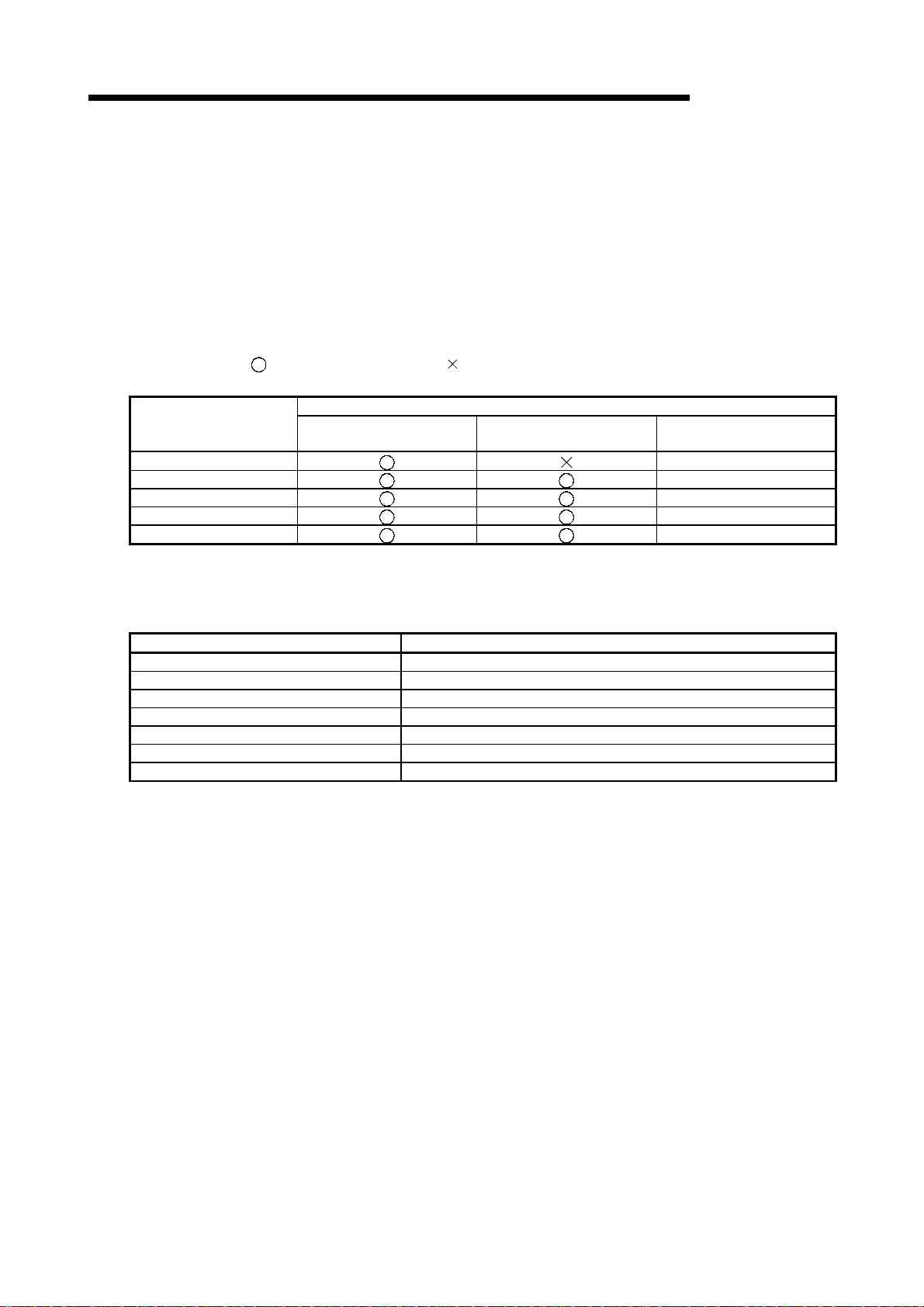

2 SYSTEM CONFIGURATION

MELSEC-GOT

2.3 Cautions on use of EMC command-and l ow voltage command-compatible products

2.3.1 Caution points when using PC card/Fl ash PC card

The EMC directiv e may not be ap pli c able whe n usin g a PC ca rd or fl a sh PC card,

depending on the GOT used.

The table below shows whether the EMC directive is applicable when using each type

of GOT.

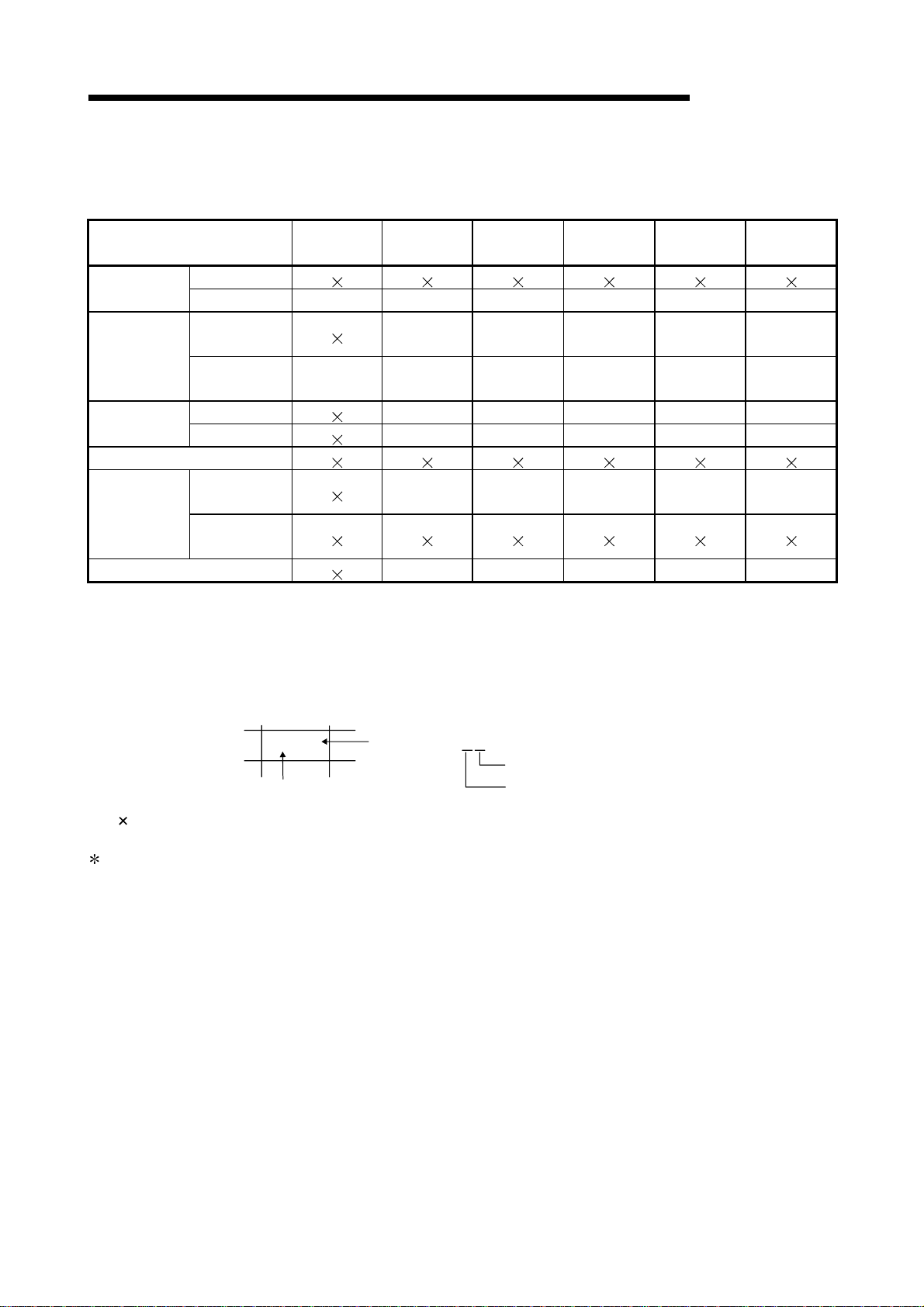

: EMC directive ap pli c ab le : EMC directive not appl icable

: Connection impossible

When the PC card is used

Type

A985GOT-TBA-EU

A975GOT-TBA-EU

A970GOT-TBA-EU

A970GOT-SBA-EU

A960GOT-EBA-EU

Commercial PC card

(SRAM type)

Flash PC card

(A9GTMEM-*MF)

Commercial flash PC card

2.3.2 About Modules that the EMC directive do not apply to

The EMC directive is not applicable when using the modules below.

Item Type

Bus connection board A9GT-QBUSS, A9GT-QBUS2S

Bus connection module A9GT-BUSSU, A9GT-BUS2SU

Serial communication board A9GT-RS2T

Data link module A7GT-J71AP23, A7GT-J71AR23, A7GT-J71AT23B

Network module A7GT-J71LP23, A7GT-J71BR13

CC-Link communication module A8GT-J61BT15

External I/O module A9GT-70KBF

2 - 5 2 - 5

2 SYSTEM CONFIGURATION

MELSEC-GOT

2.3.3 Connection Format

Connection conditions where the GOT applies to the EMC directive are shown below.

Connection format

Bus

Connection

CPU direct

connection

Computer link

connection

MELSECNET connection

CC-Link

connection

Ethernet connection Y(0203) Y(0203) M(0203) E(0203) Q(0203)

QCPU

QnA/ACPU A A A A A A

QCPU

(RS-232C)

QnA/ACPU

(RS-422)

RS-232C T(0105) T(0105) E(0105) A L(0105)

RS-422

Intelligent

device

Remote device

station

A985GOT-

TBA-EU

AAAAAA

A975GOT-

TBA-EU

T(0105) T(0105) E(0105) A L(0105)

AAAAA

T(0105) T(0105) E(0105) A L(0105)

A970GOT-

TBA-EU

A970GOT-

SBA-EU

A970GOT-

LBA-EU

A960GOT-

EBA-EU

<How to read the table>

The table indicates the GOT-compatible hardware version for each connection pattern and the

compatibility date. (The compatibility date of the GOT compatible with hardware version A is not

indicated.)

Please use the GOT whose hardware version is later than that described.

E(0105)

Hardware version

Compatibility

date

(0105)

Month

Year (Last 2 digits of A.D. year)

indicates the product is not compliant with the EMC Directive.

1 F or details about each connecti on condition, refer to the GOT-A900 Series Us er’s Manual (GT W orks

Version5/GT Designer Version5 compatible Connection System Manual).

2 - 6 2 - 6

2 SYSTEM CONFIGURATION

POINT

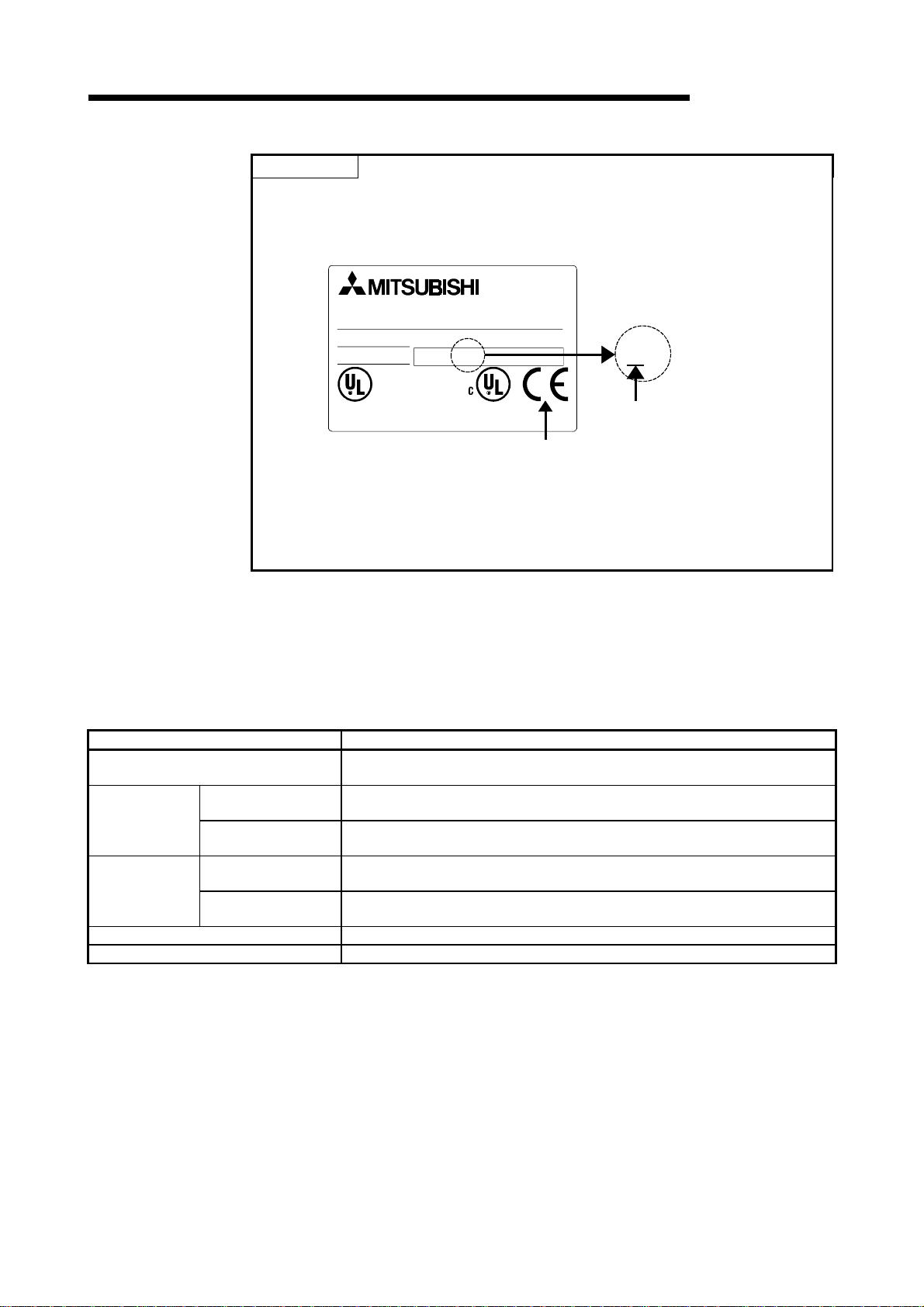

• About the hardware version

Confirm the hardware version with the products rating plate.

(Products that the EMC directive applies to are marked with the CE mark logo.)

MODEL

DATE

MITSU B IS HI E LE C TR IC CO R P OR A TIO N

MADE IN JAPAN

• About the connection destination device

If connecting to a PLC not from this company (MELSEC-Q series, MELSEC-QnA

series, MELSEC-A series), refer to the manual of the connected device (PLC,

microcomputer) for information about the applicability of the EMC directive.

GRAP HIC O P ER AT IO N TER M IN AL

A960GOT-EBA-EU

IN 100-240VAC 50/60Hz POWER M AX 115VA

0105LR

LISTED 80M1

IND. CONT. EQ.