Page 1

HARDWARE MANUAL

A953 HANDY GOT

TARGET MODELS (FOR RS-232C CONNECTION)

A953GOT-LBD-M3-H

A953GOT-SBD-M3-H

Page 2

Foreword

• This manual contains text, diagrams and explanations which will guide the reader in the

correct installation and operation of the GOT-A900. It should be read and understood before

attempting to install or use the unit.

• Further information can be found in the GOT-900 Series Operating Manual (Introductory

Manual), GOT-A900 Series Operating Manual, GOT-A900 Series User’s Manual

• If in doubt at any stage of the installation of GOT-A900 always consult a professional

electrical engineer who is qualified and trained to the local and national standards which

apply to the installation site.

• If in doubt about the operation or use of GOT-A900 please consult the nearest Mitsubishi

Electric distributor.

• This manual is subject to change without notice.

A953 HANDY GOT

Page 3

i

A953 HANDY GOT

HARDWARE MANUAL

Manual number : JY992D99801

Manual revision : C

Date : September 2008

A953 HANDY GOT

Page 4

A953 HANDY GOT

ii

Page 5

FAX BACK

Mitsubishi has a world wide reputation for its efforts in continually developing and pushing back

the frontiers of industrial automation. What is sometimes overlooked by the user is the care

and attention to detail that is taken with the documentation. However, to continue this process

of improvement, the comments of the Mitsubishi users are always welcomed. This page has

been designed for you, the reader, to fill in your comments and fax them back to us. We look

forward to hearing from you.

Fax numbers: Your name: ...................................................

Mitsubishi Electric.... .....................................................................

America (01) 847-478-2253 Your company: .............................................

Australia (02) 638-7072 .....................................................................

Germany (0 21 02) 4 86-1 12 Your location:................................................

Spain (34) 93-589-1579 .....................................................................

United Kingdom (01707) 278-695

Please tick the box of your choice

What condition did the manual arrive in?

Good

Minor damage

Unusable

Will you be using a folder to store the manual?

Ye s

No

What do you think to the manual presentation?

Tidy

Unfriendly

Are the explanations understandable?

Ye s

Not too bad

Unusable

Which explanation was most difficult to understand: ..................................................................

....................................................................................................................................................

Are there any diagrams which are not clear?

Ye s

No

If so,which: ..................................................................................................................................

What do you think to the manual layout?

Good

Not too bad

Unhelpful

If there one thing you would like to see improved, what is it?.....................................................

....................................................................................................................................................

....................................................................................................................................................

Could you find the information you required easily using the index and/or the contents, if

possible please identify your experience: ...................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Do you have any comments in general about the Mitsubishi manuals? .....................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Thank you for taking the time to fill out this questionnaire. We hope you found both the product

and this manual easy to use.

A953 HANDY GOT

iii

Page 6

A953 HANDY GOT

iv

Page 7

A953 HANDY GOT

v

Guidelines for the Safety of the User and Protection of the A953 HANDY GOT

This manual provides information for the use of the A953 HANDY GOT. The manual has been

written to be used by trained and competent personnel. The definition of such a person or

persons is as follows;

a) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated with this manual should be of a competent

nature, trained and qualified to the local and national standards required to fulfill that

role. These engineers should be fully aware of all aspects of safety with regards to

automated equipment.

b) Any commissioning or service engineer must be of a competent nature, trained and

qualified to the local and national standards required to fulfill that job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely familiar with all associated documentation for the said product.

All maintenance should be carried out in accordance with established safety practices.

c) All operators of the completed equipment (see note) should be trained to use that

product in a safe manner in compliance to established safety practices. The operators

should also be familiar with documentation which is associated with the operation of the

completed equipment.

Note : The term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

Notes on the Symbols Used in this Manual

At various times through out this manual certain symbols will be used to highlight points of

information which are intended to ensure the users personal safety and protect the integrity of

equipment. Whenever any of the following symbols are encountered, its associated note must

be read and understood. Each of the symbols used will now be listed with a brief description of

its meaning.

Hardware Warnings

1) Indicates that the identified danger WILL cause physical and property damage.

2) Indicates that the identified danger could POSSIBLY cause physical and property

damage.

3) Indicates a point of further interest or further explanation.

Software Warnings

4) Indicates special care must be taken when using this element of software.

5) Indicates a special point which the user of the associate software element should

be aware of.

6) Indicates a point of interest or further explanation.

Page 8

A953 HANDY GOT

vi

• Under no circumstances will Mitsubishi Electric be liable responsible for any consequential

damage that may arise as a result of the installation or use of this equipment.

• All examples and diagrams shown in this manual are intended only as an aid to

understanding the text, not to guarantee operation. Mitsubishi Electric will accept no

responsibility for actual use of the product based on these illustrative examples.

• Please contact a Mitsubishi Electric distributor for more information concerning applications

in life critical situations or high reliability.

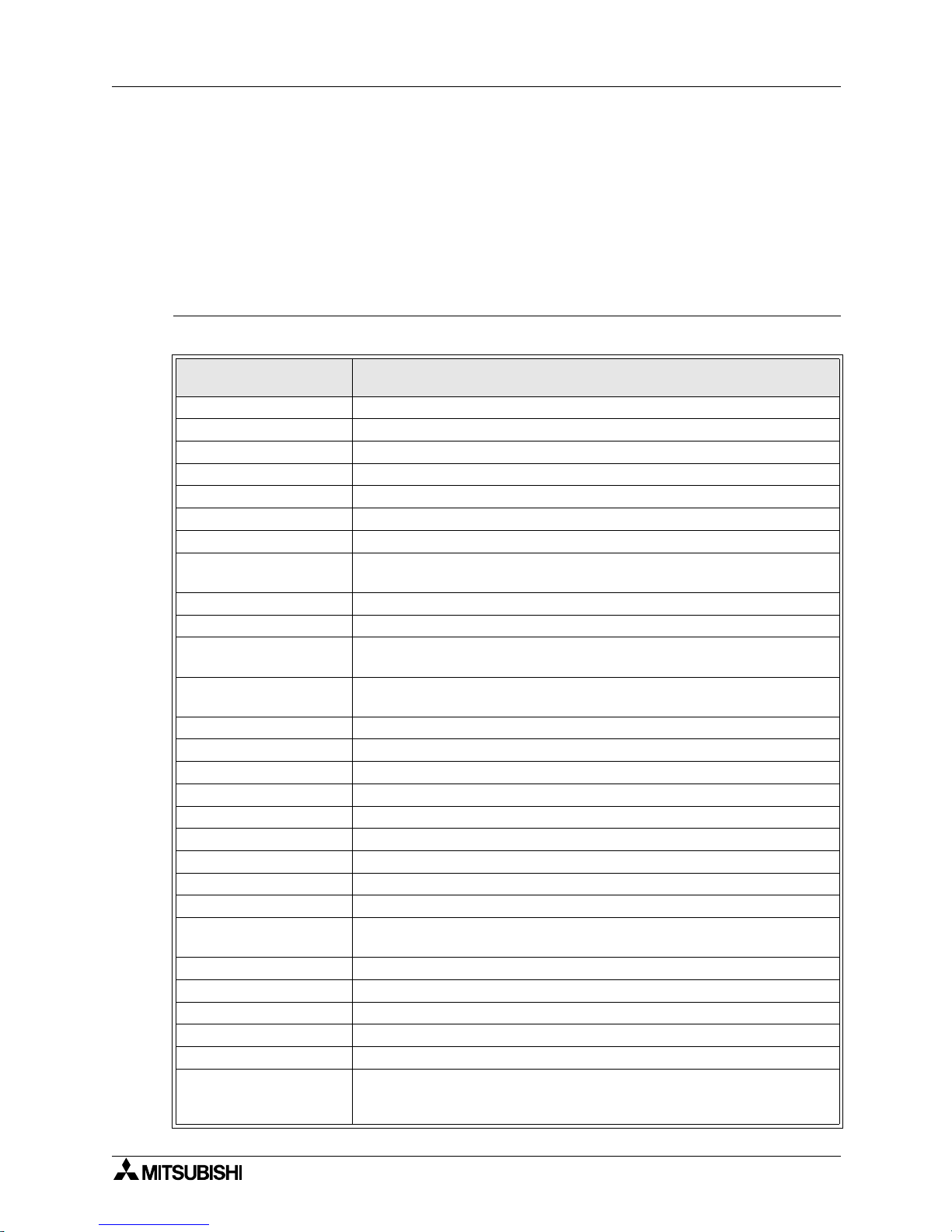

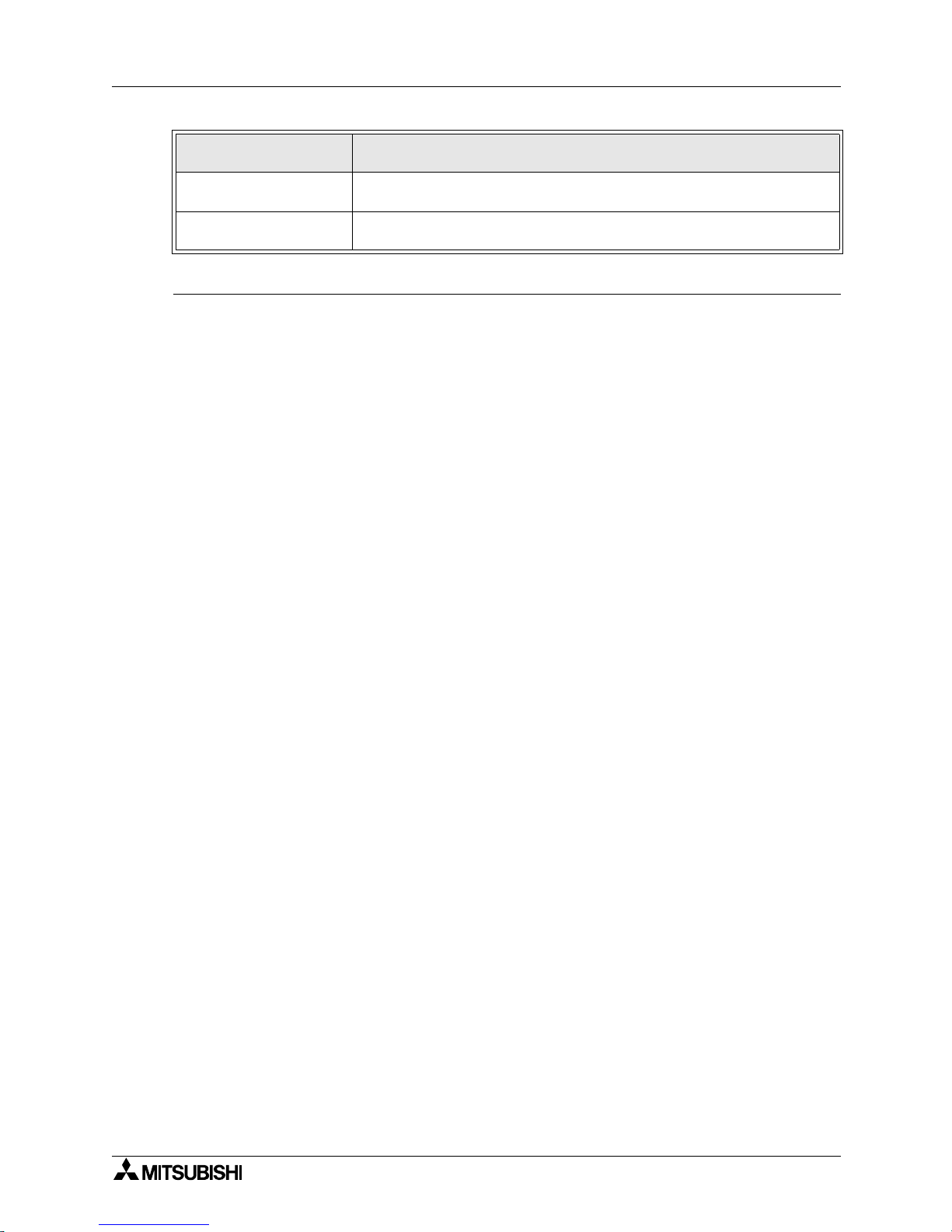

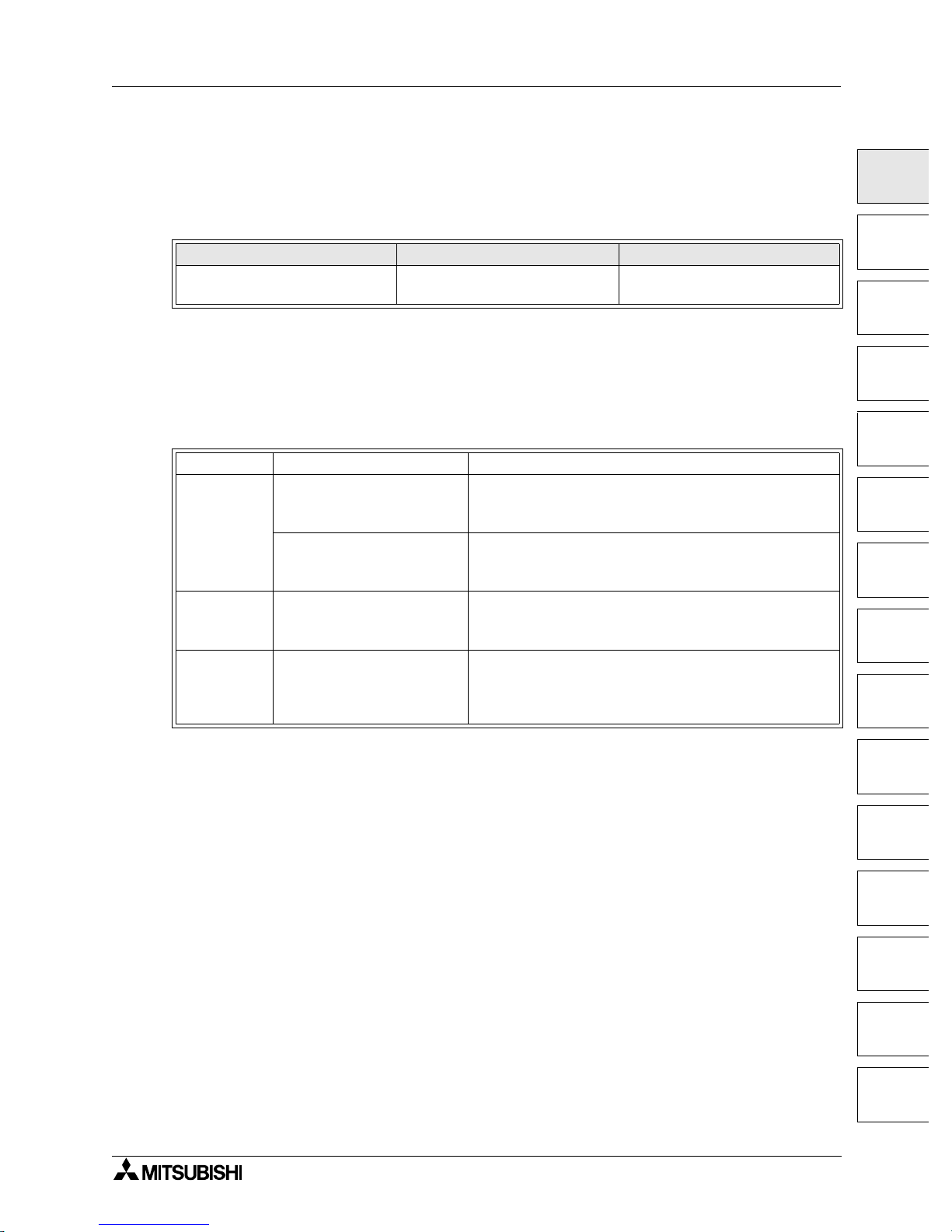

Abbreviations

The table below shows abbreviations, generic names and terms used in this manual.

Abbreviation/

generic name/term

Description

Handy GOT Generic name of A953GOT-LBD-M3-H and A953GOT-SBD-M3-H

A953 Handy GOT Generic name of A953GOT-LBD-M3-H and A953GOT-SBD-M3-H

A950GOT Generic name of A95*GOT

Built-in memory Abbreviation of memory (flush ROM) built in GOT

OS Abbreviation of GOT system software

External I/O unit Abbreviation of external I/O interface unit A8GT-50KBF

Printer interface unit Abbreviation of printer interface unit A9GT-50PRF

QCPU (Q mode)

Generic name of Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU and

Q25HCPU CPU units

QCPU (A mode) Generic name of Q02CPU-A, Q02HCPU-A and Q06HCPU-A CPU units

QCPU Generic name of QCPU (Q mode) and QCPU (A mode) CPU units

QnACPU (large type)

Generic name of Q2ACPU, Q2ACPU-S1, Q3ACPU, Q4ACPU and

Q4ARCPU CPU units

QnACPU (small type)

Generic name of Q2ASCPU, Q2ASCPU-S1, Q2ASHCPU and

Q2ASHCPU-S1 CPU units

QnACPU

Generic name of QnACPU (large type) and QnACPU (small type) CPU units

AnUCPU

Generic name of A2UCPU, A2UCPU-S1, A3UCPU and A4UCPU CPU units

AnACPU Generic name of A2ACPU, A2ACPU-S1 and A3ACPU CPU units

AnNCPU

Generic name of A1NCPU A2NCPU, A2NCPU-S1 and A3NCPU CPU units

ACPU (large type) Generic name of AnUCPU, AnACPU and AnNCPU CPU units

A2US(H)CPU

Generic name of A2USCPU, A2USCPU-S1 and A2USHCPU-S1 CPU units

AnS(H)CPU Generic name of A1SCPU, A1SHCPU, A2SCPU and A2SHCPU CPU units

A1SJ(H)CPU Generic name of A1SJCPU-S3 and A1SJHCPU CPU units

ACPU (small type) Generic name of A2US(H)CPU, AnS(H)CPU and A1SJ(H)CPU CPU units

ACPU

Generic name of ACPU (large type), ACPU (small type) and A1FXCPU

CPU units

FX

1S

Series Generic name of FX1S Series CPU units

FX

1N

Series Generic name of FX1N Series CPU units

FX

2N

Series Generic name of FX2N Series CPU units

FX

2NC

Series Generic name of FX

2NC

Series CPU units

FXCPU Generic name of FX

1S

, FX1N, FX2N and FX

2NC

Series CPU units

Motion controller CPU

Generic name of A373UCPU, A373UCPU-S3, A273UCPU, A273UHCPU,

A273UHCPU-S3, A171SCPU-S3, A171SHCPU, A172SHCPU and

A173UHCPU

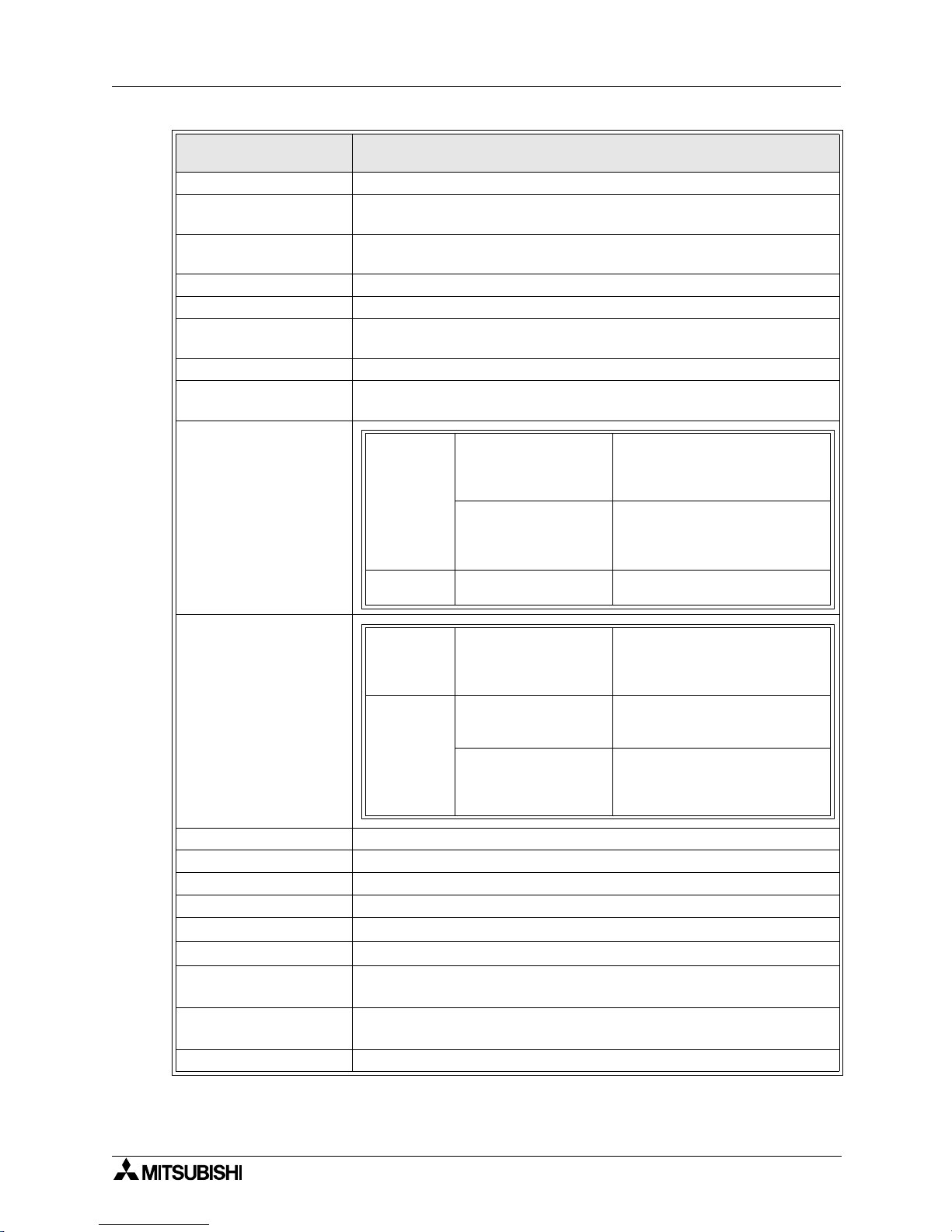

Page 9

A953 HANDY GOT

vii

FA controller Generic name of LM610, LM7600 and LM8000

PLC by Omron

Generic name of C200HS, C200H, C200HX, C200HG, C200HE, CQM1,

C1000H, C2000H and CV1000

PLC by Yaskawa Electric

Generic name of GL60S, GL60H, GL70H, GL120, GL130, CP-9200SH,

CP-9300MS, MP-920 and MP-930

PLC by Allen-Bradley Generic name of SLC 5/03 and SLC 5/04

PLC by Siemens Generic name of SIMATIC S7-300 and SIMATIC S7-400

PLC by Sharp

Generic name of JW-21CU, JW-22CU, JW-31CUH, JW-32CUH, JW-33CUH,

JW-50CUH, JW-70CUH and JW-100CUH

PLC by Toshiba Generic name of T3 and T3H

PLC by another company

Generic name of PLC by Omron, PLC by Yaskawa Electric, PLC by Allen-

Bradley, PLC by Siemens, PLC by Sharp and PLC by Toshiba

GT Designer2

SWD5C-GOTR-PACKE

Screen creation software

Abbreviation of GOT Screen Designer (screen creation software for GOT900)

Data conversion software Abbreviation of GOT Converter (data conversion software for GOT900)

Debugging software Abbreviation of GOT Debugger (software for debugging function)

Object Set data to be made into dynamic images

Windows 95

Microsoft

®

Windows® 95 Operating system English version

Windows 98

Microsoft

®

Windows® 98 Operating system English version

Windows Me

Microsoft

®

Windows® Millennium Edition Operating system English

version

Windows NT 4.0

Microsoft

®

Windows NT® 4.0 Workstation Operating system English

version

Windows 2000

Microsoft

®

Windows® 2000 Operating system English version

Abbreviation/

generic name/term

Description

GT Works2

SW

D5C-GTWK2-E

Integrated screen development

software for GOT-900 Series

(SW

D5C-GTD2-E + GT Simulator

2 + GT Soft GOT2) (English version)

SWD5C-GTWS-E

Integrated screen development

software for GOT-900 Series

(SW

D5C-GTWK2-E + A9GTSOFT-

LKEY-P) (English version)

GT Designer2 SW

D5C-GTD2-E

Screen creation software for GOT900 Series (English version)

GT Works SWD5C-GTWORKS-E

Integrated screen development

software for GOT900 Series

(SW

D5C-GOTR-PACKE + GT

Simulator) (English version)

GT Designer

SW

D5C-GOTR-PACKE

Screen creation software for

GOT900 Series SWD5C-GOTRPACKE (English version)

SW

D5C-GOTR-

PACKEV

Software dedicated to version

upgrade from conventional version to

latest SW

D5C-GOTR-PACKE

(English version)

Page 10

A953 HANDY GOT

viii

Associated Manuals

The configuration of manuals related to this Handy GOT is as shown below.

Explanation on specifications, installation, wiring and switches

A manual of the used Handy GOT is required.

• A953 HANDY GOT HARDWARE MANUAL

Describes the specifications, wiring, installation, etc. of the A953GOT-SBD-M3-H/A953GOTLBD-M3-H.

Manual No.: JY992D99801

Explanation on the display unit

Separate manual (Ask the sales agency from which you have purchased the Handy GOT.)

• A950GOT/A951GOT/A953GOT/A956GOT USERS MANUAL (DETAILED)

Describes the specifications of the A95*GOT, outline system configuration, components,

name of each part, unit attaching method, installation/wiring method, maintenance/

inspection method and error codes.

• GOT-A900 SERIES OPERATING MANUAL (EXTENTION FUNCTIONS/OPTIONAL

FUNCTIONS)

Describes the specifications of the utility function, system monitoring function, circuit

monitoring function, special function, unit monitoring function, network monitoring function

and list edition function which are provided in the A953 Handy GOT and available in the

A953GOT as well as the operation method of the dedicated monitor screen.

In the A953 Handy GOT, the PC card interface, external I/O interface and printer interface

are not available. Any bar code reader cannot be connected.

• GOT900 SERIES OPERATING MANUAL (INTRODUCTION)

Describes how to create monitor screens using the GT Designer, transfer the monitor data

to the GOT and display the screens for those who use the GOT for the first time.

Windows

Generic name of Windows95, Windows98, Windows Me, WindowsNT4.0

and Windows2000

Personal computer

Personal computer to Install the GT Designer or GT Designer 2 application

software

Abbreviation/

generic name/term

Description

Page 11

A953 HANDY GOT

ix

Screen creation software

• GT Works2/GT Designer2 OPERATING MANUAL (STARTUP)

Describes how to install the GT Works2/GT Designer2 to a personal computer and how to

refer to the online manual.

• GT Designer2 (SWD5C-GTD2-E) REFERENCE MANUAL -separate manualDescribes how to install and start up the screen creation software (GT Designer2).

• GT Designer2 (SWD5C-GTD2-E) OPERATING MANUAL -separate manualDescribes how to operate the screen creation software (GT Designer2).

• GT Works Version 5/GT Designer Version 5 OPERATING MANUAL (STARTUP)

Describes how to install the GT Works Version 5/GT Designer Version 5 to a personal

computer and how to refer to the online manual.

(This manual is packed together with the GT Works Version 5/GT Designer Version 5.)

• GT Works Version 5/GT Designer Version 5 REFERENCE MANUAL -separate manualDescribes the system configuration of the GT Works Version 5/GT Designer Version 5, the

screen configuration of the GT Designer, various monitoring functions, procedures up to

displaying the monitor screen in the GOT and the help function use method.

• GT Simulator Version 5 OPERATING MANUAL -separate manualDescribes the system configuration, screen configuration and use method of the GT

Simulator.

Registration

Microsoft® Windows®, Windows® 95, Windows® 98, Windows® Millennium Edition, Windows

NT

®

4.0 Workstation and Windows® 2000 are either registered trademarks or trademarks of

Microsoft Corporation in United States and/or other countries.

The company name and the product name to be described in this manual are the registered

trademarks or trademarks of each company.

Page 12

A953 HANDY GOT

x

Wiring procedure

The work procedures from starting up to making ready the Handy GOT using this manual are

explained below.

Outline

Reference page

1

1.2 Product configuration

1-3

Introduces the model name expression of the Handy GOT and accessories.

1.3 Introduction of cables and screen creation software (options) and

their applications

1-4

Introduces optional products (cables and connector conversion box) and explains their easy

applications.

1.4 Part identification

1-5

Explains the name and function of switches, lamps and connectors of the Handy GOT.

1.5 Applicable versions of OS and screen creation software

1-7

Explains versions of the system program (OS) and the screen creation software which are

compatible with the Handy GOT and to be prepared.

Outline of connection

Reference page

2

2.2.1 Outline of connection

2-5

Introduces configurations in accordance with applications.

2.2.2 Cable selection

2-7

Introduces combinations of cables between the Handy GOT and the PLC.

2.2.3 Pin arrangement and signal names of cables and connectors

2-8

Explains signal names of external cables and connector conversion box.

Installation

Reference page

3

2.1 Installation method

2-1

Introduces how to fix or hold by hand the Handy GOT.

2.2.4 Connection of external cable

2-9

Explains how to let an external cable go through the cable mounting slot of the Handy GOT and

fix it with screws.

2.3 Panel face processing

2-12

Introduces cables and connector box and explains the panel cut size for cases in which the

Handy GOT is attached to and detached from the panel face.

Page 13

A953 HANDY GOT

xi

Wiring

Reference page

4

2.2.5 Wiring of power supply

2-11

Explains connection of an external cable and the DC power supply.

3.2 Wiring of operation switches

3-5

Explains how to wire four operation switches and control the LED indication.

3.3 Wiring of emergency stop switch

3-8

Explains the wiring of the emergency stop switch and the cautions.

3.4 Setting of grip switch

3-9

Explains the wiring of the grip switch and the cautions.

Page 14

A953 HANDY GOT

xii

MEMO

Page 15

A953 HANDY GOT

xiii

Contents

Table of Contents

Guideline of Safty.................................................................................v

Abbreviations...................................................................................................... vi

Associated Manuals...........................................................................................viii

Registration......................................................................................................... ix

Wiring procedure .................................................................................................x

1. Introduction............................................................................................1-1

1.1 Outline of product ................................................................................................1-1

1.2 Product configuration........................................................................................... 1-3

1.2.1 Handy GOT ............................................................................................................... 1-3

1.3 Introduction of cables and screen creation software (options) and their

applications.......................................................................................................... 1-4

1.3.1 Common options ....................................................................................................... 1-4

1.3.2 Options dedicated to A953 Handy GOT .................................................................... 1-4

1.4 Part identification .................................................................................................1-5

1.4.1 Front panel ................................................................................................................1-5

1.4.2 Rear panel.................................................................................................................1-6

1.5 Applicable versions of OS and screen creation software ....................................1-7

1.5.1 Applicable OS versions ............................................................................................. 1-7

1.5.2 Applicable screen creation software versions ........................................................... 1-7

2. Installation Wiring ..................................................................................2-1

2.1 Installation method .............................................................................................. 2-1

2.1.1 Holding ...................................................................................................................... 2-2

2.1.2 Hanging on wall ......................................................................................................... 2-3

2.1.3 Flat surface mounting................................................................................................ 2-3

2.2 Wiring .................................................................................................................. 2-4

2.2.1 Outline of connection................................................................................................. 2-5

2.2.2 Cable selection .......................................................................................................... 2-6

2.2.3 Pin arrangement and signal names of cables and connectors.................................. 2-7

2.2.4 Connection of external cable..................................................................................... 2-8

2.2.5 Wiring of power supply ............................................................................................ 2-10

2.3 Panel face processing .......................................................................................2-11

2.3.1 A953 Handy GOT .................................................................................................... 2-11

2.3.2 Appearance of relay cables ..................................................................................... 2-12

2.3.3 Panel cut size for relay cable .................................................................................. 2-13

A953 HANDY GOT

Page 16

A953 HANDY GOT

xiv

Contents

3. Wiring and Handling of Switches...........................................................3-1

3.1 Outline of switches ..............................................................................................3-2

3.2 Wiring of operation switches................................................................................3-5

3.2.1 Inputs of operation switches ...................................................................................... 3-5

3.2.2 Lighting of operation indicator LEDs ......................................................................... 3-6

3.3 Wiring of emergency stop switch ......................................................................... 3-8

3.4 Setting of grip switch ........................................................................................... 3-9

3.4.1 Effectiveness/ineffectiveness of grip switch .............................................................. 3-9

3.4.2 Grip switch operation timing .................................................................................... 3-10

3.4.3 Communication with PLC ........................................................................................ 3-12

3.5 Creation of operation switch name sheet ..........................................................3-14

3.5.1 Creation of name sheet ........................................................................................... 3-14

3.5.2 Attachment of sheet ................................................................................................ 3-15

4. Specifications ........................................................................................4-1

4.1 General specifications .........................................................................................4-2

4.1.1 Outside dimensions ................................................................................................... 4-2

4.1.2 Power unit specifications ........................................................................................... 4-3

4.1.3 General specifications ............................................................................................... 4-3

4.2 PLC CPU which can be monitored ...................................................................... 4-5

4.2.1 In case of A953 Handy GOT ..................................................................................... 4-5

4.3 Devices names which can be monitored ............................................................. 4-6

5. Connection to Peripheral Equipment.....................................................5-1

5.1 Connection to peripheral equipment for Handy GOT .......................................... 5-1

5.2 Cable connection procedure................................................................................5-1

5.3 Connection diagram ............................................................................................5-2

6. CPU Direct Connection .........................................................................6-1

6.1 System configuration ........................................................................................... 6-1

6.1.1 Connection to QCPU ................................................................................................. 6-1

6.1.2 Connection to FXCPU ............................................................................................... 6-2

6.2 Connection cable.................................................................................................6-3

7. Computer Link Connection....................................................................7-1

7.1 System configuration ........................................................................................... 7-1

7.2 Initial setting......................................................................................................... 7-2

7.2.1 Setting in communication link unit and serial communication unit............................. 7-2

7.2.2 Setting in GOT........................................................................................................... 7-6

7.3 Transmission specifications.................................................................................7-6

7.4 Connection cable.................................................................................................7-7

Page 17

A953 HANDY GOT

xv

Contents

8. Connection to PLC by Omron ...............................................................8-1

8.1 System configuration ........................................................................................... 8-1

8.1.1 System configuration when C200H/C200HS/C200Ha Series PLC is connected ...... 8-1

8.1.2 System configuration when CQM1 is connected....................................................... 8-2

8.1.3 System configuration when C1000H/C2000H is connected...................................... 8-2

8.1.4 System configuration when CV1000 is connected .................................................... 8-3

8.2 Initial setting......................................................................................................... 8-4

8.2.1 Setting of switches in upper link unit ......................................................................... 8-4

8.2.2 Setting in CV1000 ..................................................................................................... 8-6

8.2.3 Initialization of CQM1 ................................................................................................ 8-7

8.2.4 Communication board initialization program ............................................................. 8-7

8.3 Connection cable.................................................................................................8-8

9. Connection to PLC by Yaskawa Electric ...............................................9-1

9.1 System configuration ........................................................................................... 9-1

9.2 Initial setting......................................................................................................... 9-2

9.3 Connection cable.................................................................................................9-3

9.3.1 RS-232C cable .......................................................................................................... 9-3

10.Connection to PLC by Allen-Bradley ..................................................10-1

10.1 System configuration ......................................................................................... 10-1

10.2 Communication setting in PLC by Allen-Bradley ............................................... 10-1

10.3 Transmission specifications...............................................................................10-2

10.4 Connection cable...............................................................................................10-2

11.Connection to PLC by Sharp..............................................................11-1

11.1 System configuration ......................................................................................... 11-1

11.2 Initial setting....................................................................................................... 11-2

11.2.1 When GOT is directly connected to PLC CPU ........................................................ 11-2

11.2.2 When link unit is connected..................................................................................... 11-3

11.3 Transmission specifications...............................................................................11-4

11.4 Connection cable...............................................................................................11-5

12.Connection to Microcomputer ............................................................12-1

12.1 System configuration ......................................................................................... 12-1

12.2 Transmission specifications...............................................................................12-2

12.3 Connection cable...............................................................................................12-2

12.3.1 When DTR is used .................................................................................................. 12-2

12.3.2 When DTR is not used ............................................................................................ 12-4

12.4 Device data area ............................................................................................... 12-5

12.5 Communication command .................................................................................12-6

12.5.1 Command list .......................................................................................................... 12-6

12.5.2 Data transfer format ................................................................................................ 12-7

12.5.3 Caution on use ........................................................................................................ 12-8

12.5.4 Batch read command (RD)...................................................................................... 12-9

12.5.5 Batch write command (WD) .................................................................................. 12-10

12.5.6 Random read command (RR) ............................................................................... 12-11

12.5.7 Random write command (RW) .............................................................................. 12-12

Page 18

A953 HANDY GOT

xvi

Contents

13.Connection to PLC by Siemens .........................................................13-1

13.1 System configuration ......................................................................................... 13-1

13.2 Initial setting....................................................................................................... 13-2

13.3 Connection cable...............................................................................................13-3

14.Diagnostics.........................................................................................14-1

14.1 When POWER LED does not light ....................................................................14-1

14.2 When an operation switch or emergency stop switch does not operate............14-2

14.3 When LC screen is dark ....................................................................................14-3

14.4 Error messages and error codes.......................................................................14-3

Appendix A: .............................................................................................. A-1

A-1: System Configuration Example in Microcomputer Connection............................A-1

A-1-1: System configuration .................................................................................................A-1

A-1-2: Communication setting in GOT and contents of setting on monitor screen ..............A-1

A-1-3: Sample program in host ............................................................................................A-3

A-1-4: Outline of system operations .....................................................................................A-3

Page 19

A953 HANDY GOT

xvii

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

1 Introduction

2 Installation Wiring

3 Wiring and Handling of Switches

4 Specifications

5 Connection to Peripheral Equipment

6 CPU Direct Connection

7 Computer Link Connection

8 Connection to PLC by Omron

9 Connection to PLC by Yaskawa Electric

10 Connection to PLC by Allen-Bradley

11 Connection to PLC by Sharp

12 Connection to Microcomputer

13 Connection to PLC by Siemens

14 Diagnostics

A Appendix A

A953 HANDY GOT

Page 20

A953 HANDY GOT

xviii

1 Introduction

2 Installation Wiring

3 Wiring and Handling of Switches

4 Specifications

5 Connection to Peripheral Equipment

6 CPU Direct Connection

7 Computer Link Connection

8 Connection to PLC by Omron

9 Connection to PLC by Yaskawa Electric

10 Connection to PLC by Allen-Bradley

11 Connection to PLC by Sharp

12 Connection to Microcomputer

13 Connection to PLC by Siemens

14 Diagnostics

A Appendix A

Page 21

Introduction 1

1-1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

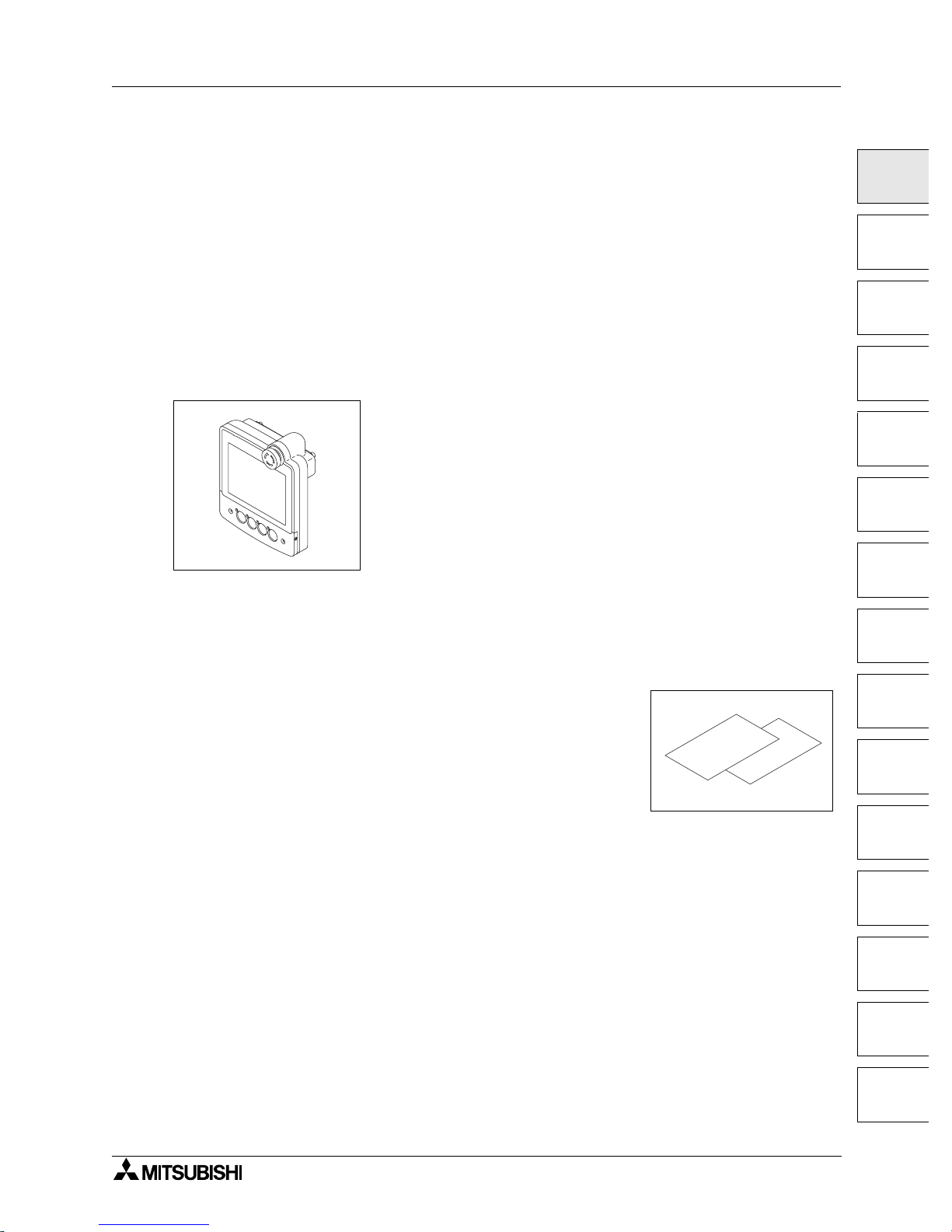

1. Introduction

This section describes the product configuration and the system configuration of the A95

handy graphic operation terminal (abbreviated as "Handy GOT" in the text).

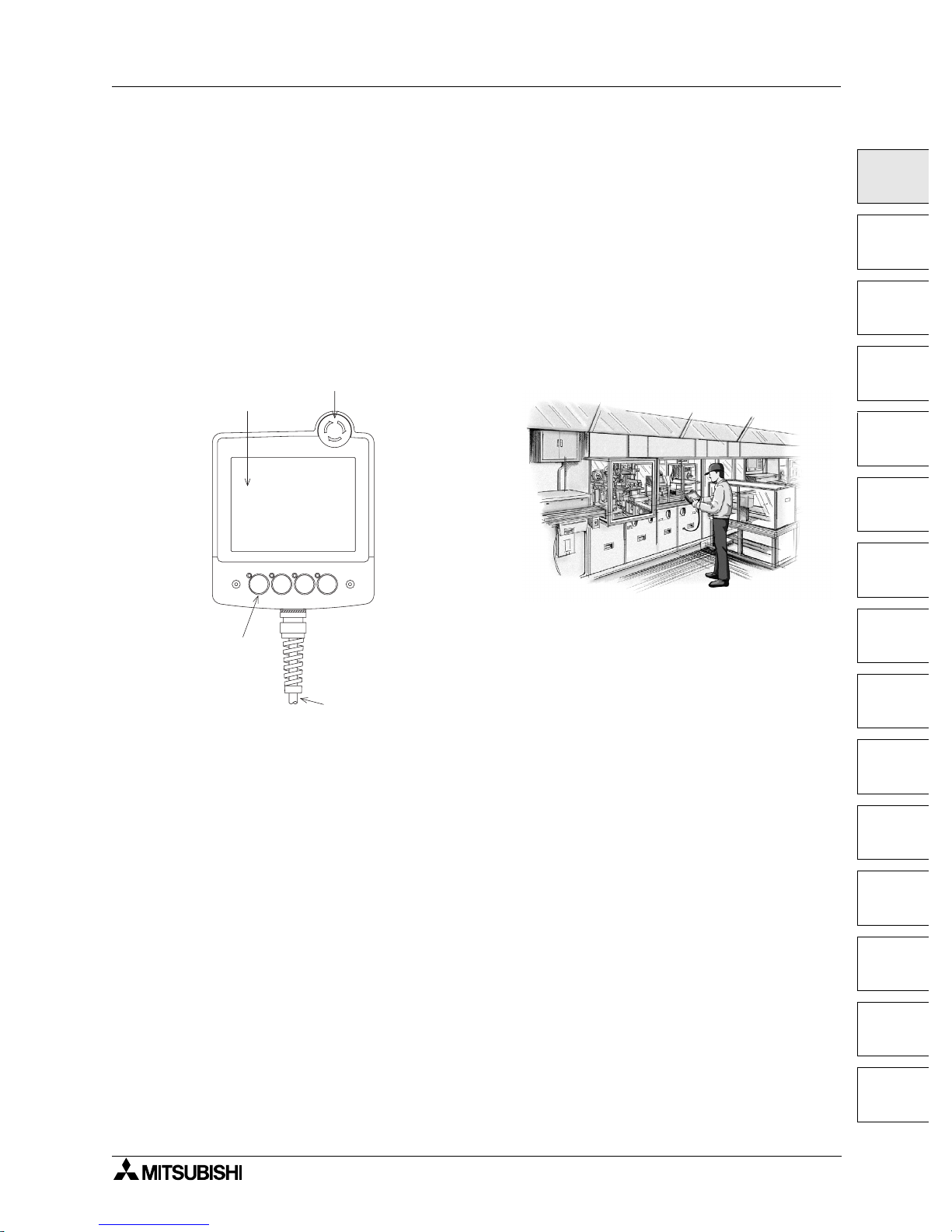

1.1 Outline of product

The Handy GOT is used as an operation terminal connected to a controller such as the

MELSEC FX/QnA/Q Series PLC and a PLC manufactured by another company.

The Handy GOT is an all-in-one type graphic operation terminal equipped with a display unit

with touch switches and mechanical keys (operation switches) available to input commands to

the machine.

Operation switches:

They are mechanical keys directly connected to inputs of the PLC.

Because they give commands directly to inputs of the PLC, they can be used for inputs

requiring immediate responses to the machine such as inputs for operation and stop.

These switches are offered for the operator who gives operation commands to the machine.

• Start/stop

• Preparation for operation

• Setup change

• Error reset

• Mode selection between automatic and individual

* You can arbitrarily change the name of these operation switches using a transparent sheet

and a mount sheet offered as accessories.

P O W E R G R I P S W

E m e r g e n c y s t o p s w i t c h

D i s p l a y u n i t

O p e r a t i o n

s w i t c h e s

C o n n e c t i o n c a b l e

( o p t i o n )

Use example:

A953 HANDY GOT

Page 22

A953 HANDY GOT Introduction 1

1-2

Display unit:

The display unit is an LCD with touch switches equivalent to that of the graphic operation

terminal A950GOT.

The operator can easily monitor the ON/OFF status of bit devices of the PLC, set such bit

devices to ON or OFF, monitor the set value and the present value of word devices of the PLC,

and change such values of word devices.

This display unit can be used to change the setup, change the set values, and perform

troubleshooting by the engineer, as well as give guidance to the operator.

• Selection of individual operation

• Independent operation

• One-cycle operation

• Monitoring

• Forcedly turning ON/OFF

• Change of set values

• Troubleshooting

(You can create screens displayed on the display unit using the screen creation software which

runs in a personal computer.)

Connection cable:

An optional connection cable is offered to connect the PLC.

Page 23

A953 HANDY GOT Introduction 1

1-3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

1.2 Product configuration

The model name of the Handy GOT is expressed as follows.

A95GOT-BD-M3-H

1) 2)

1) 3: RS-232C communication type

2) S: STN type eight-color liquid crystal

L: STN type black-and-white liquid crystal

1.2.1 Handy GOT

The handy graphic operation terminal consists of the following components.

Handy GOT

Accessories: The following accessories are attached to the Handy GOT (in each model).

A transparent sheet 1) and a mount sheet 2) are offered as accessories so that the operation

switch names can be changed.

For the switch name changing procedure, refer to section 3.5.

1) Transparent sheet

2) Mount sheet

3) Manual (this manual)

Explains how to connect the PLC and the power supply.

P O W E R

G R IP S W

1 )

2 )

M o u n t

s h e e t

T r a n s p a r e n t

s h e e t

Page 24

A953 HANDY GOT Introduction 1

1-4

1.3 Introduction of cables and screen creation software (options) and their

applications

Order the following options in accordance with the connected PLC configuration.

1.3.1 Common options

1) Screen creation software

For the details of versions applicable in the Handy GOT and the

software working environment, refer to 1.5.

- Screen creation system startup software SWD5C-GOTRPACKE (V)

"V" at the end of the model name indicates that this software is

for version upgrade.

- Screen creation system startup software SWD5C-GTD2-E

2) Protective sheets F9GT-40PSC (5 sheets in 1 set)

Each of these sheets protects the display unit against dirt when

adhered on the display unit.

1.3.2 Options dedicated to A953 Handy GOT

External cable

• External cable F9GT-HCAB-3M (with a 25-pin D-Sub connector on

one side) (3m

, 9' 10"

)

This cable connects the Handy GOT and an external equipment

(such as communication unit, power supply unit, operation switches

and emergency stop switch).

• External cable F9GT-HCAB1-3M (with untied wires on one side)

(3m, 9' 10")

This cable connects the Handy GOT and an external equipment

(such as communication unit, power supply unit, operation switches

and emergency stop switch).

Use this cable when connecting an external equipment to the PLC

directly or through a relay connector.

PLC connection cable

• Relay cable F9GT-HCAB5-150 (1.5m, 4' 11") for PLC connection

This cable is equipped with the 6-pin MINI DIN connector to directly

connect the Q Series PLC and untied wires to connect the power

supply, the operation switches and the emergency stop switch.

Use this cable together with the external cable F9GT-HCAB-3M

(with 25-pin D-Sub connector).

F o r u n t i e d

w i r e s

F o r 2 5 - p i n

D - S u b

c o n n e c t o r

T o P L C

F o r p o w e r s u p p l y a n d

o p e r a t i o n s w i t c h e s

Page 25

A953 HANDY GOT Introduction 1

1-5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

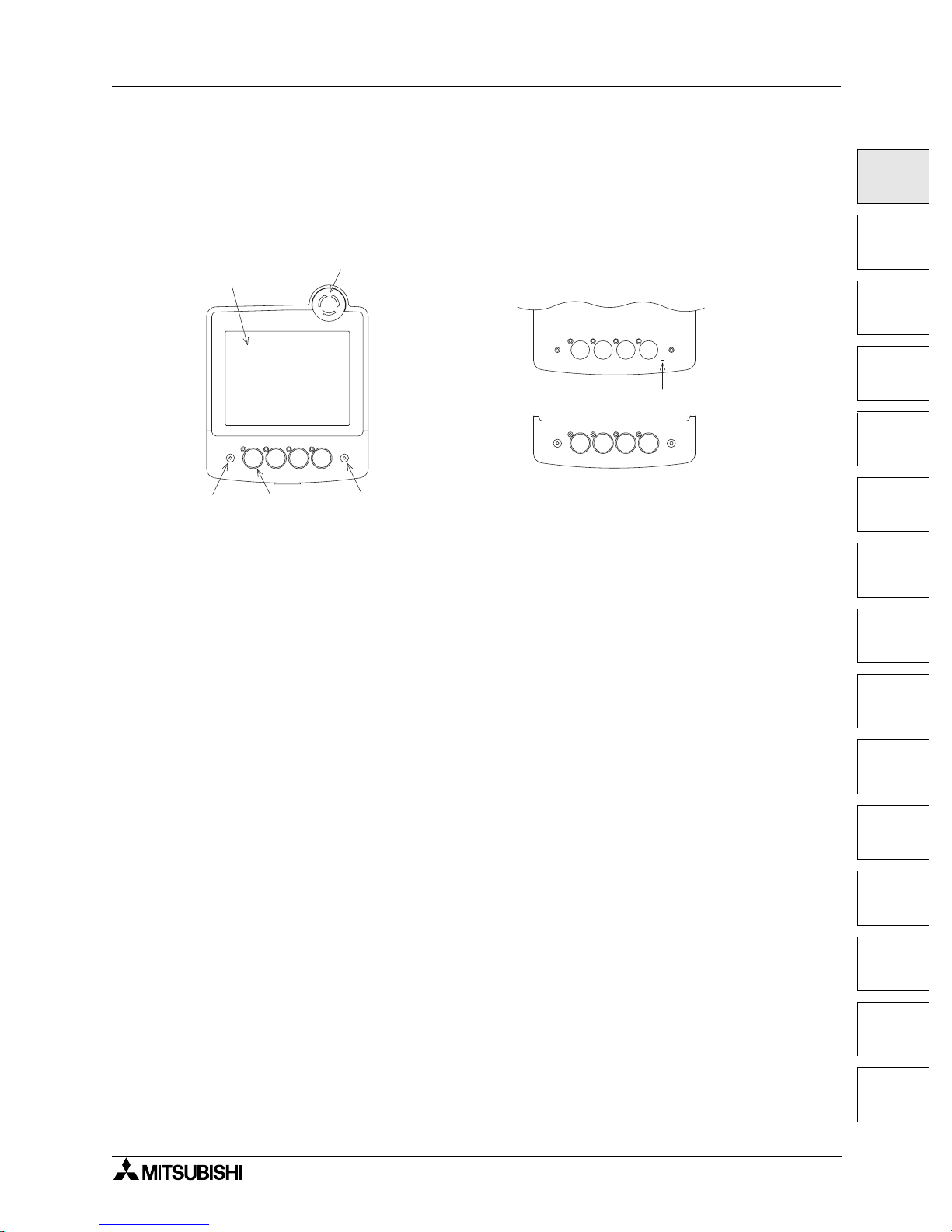

1.4 Part identification

This section roughly explains the name and function of each part of the Handy GOT.

1.4.1 Front panel

The name and function of each part of the front panel of the Handy GOT are described below.

1) POWER LED

Lit while 24V DC power is supplied to the Handy GOT.

2) LC display unit with touch switches

Offers 8 colors in the A953GOT-SBD-M3-H or 2 colors (black and white) in the A953GOTLBD-M3-H.

This display unit offers the functions equivalent to those offered by the display unit of the

graphic operation terminal A950GOT.

Display size: 320 × 240 dots

Effective display size: 115(4.53") W × 86(3.39") H mm

3) Operation switches (Refer to section 3.2.)

Directly connected to inputs of the PLC.

Each of these four switches is equipped with a green LED which indicates the pressing

status. The information on the green LED lighting command is transferred between the PLC

through serial communication.

The operator can arbitrarily set the display control using a PLC program.

The operator can arbitrarily change the name of these four switches using sheets offered as

accessories. (Refer to section 3.5.)

4) Emergency stop switch (Refer to section 3.3.)

Is a switch with independent contact of 24V DC specification.

5) Grip switch LED (Refer to section 3.4.)

Lit while the grip switch provided on the side is pressed and held.

6) Operation switch name sheet insertion slot (Refer to section 3.5.)

Can be seen when the operation switch cover is removed from the lower portion of the

Handy GOT.

P O W E R G R I P S W

1 )

2 )

3 )

4 )

5 )

P O W E R G R I P S W

W h e n t h e o p e r a t i o n s w i t c h c o v e r i s r e m o v e d

O p e r a t i o n s w i t c h c o v e r

6 )

Page 26

A953 HANDY GOT Introduction 1

1-6

1.4.2 Rear panel

The name and function of each part of the rear panel of the Handy GOT are described below.

When the rear cover is removed, diversified connectors can be seen.

1) Hand strap

Is a strap whose length is adjustable to allow the operator to comfortably hold the Handy

GOT.

2) Metal hook for mounting on the wall

Is offered to mount the Handy GOT on the wall for operation and accommodation.

3) External cable (Refer to section 2.2.)

Is offered as an option to connect a PLC (for RS-232C communication), power supply and

operation switches, and connected to the connectors 3)' in two positions.

4) Port for personal computer (9-pin D-Sub, male) (for RS-232C communication) (Refer to

chapter 5.)

Is offered to transfer the screen data created using the screen creation software.

1 )

2 )

3 ) '

N o t u s e d

3 )

4 )

3 ) '

W h e n t h e r e a r c o v e r i s r e m o v e d ( e n l a r g e d v i e w )

Page 27

A953 HANDY GOT Introduction 1

1-7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

1.5 Applicable versions of OS and screen creation software

When using the Handy GOT, make sure to prepare the OS and the screen creation software of

the version shown below.

1.5.1 Applicable OS versions

Because the BIOS is already assembled in the Handy GOT at the time of shipment, you do not

have to transfer it using the screen creation software.

Transfer the OS to the Handy GOT in accordance with the operating procedure described in

the manual of the screen creation software shown below.

(The PLC card interface and the printer interface are not available.)

1.5.2 Applicable screen creation software versions

"V" at the end of the model name indicates that the software is for version upgrade.

For connection of the screen creation software (personal computer) and the Handy

GOT, refer to chapter 5.

Handy GOT Applicable BIOS OS version

A95GOT-SBD-M3-H

A95GOT-LBD-M3-H

version M version 7.1.0 or later

GT Designer2 SWD5C-GTD2-E Screen creation software for GOT-900 Series

GT Works2

SWD5C-GTWK2-E

Integrated screen development software for GOT-900

Series

(SWD5C-GTD2-E + GT Simulator2 + GT SoftGOT2)

SWD5C-GTWS-E

Integrated screen development software for GOT-900

Series

(SWD5C-GTWK2-E + A9GTSOFT-LKEY-P)

GT Designer SWD5C-GOTR-PACKE(V)

Screen creation software for GOT-900 Series

: 4 or larger (version F or later)

Product shipped in May, 2000 or later

GT Works SWD5C-GTWORKS(-E)

Integrated screen development software for GOT-900

Series

"SWD5C-GOTR-PACKE + GT Simulator" is packed

together.

Page 28

A953 HANDY GOT Introduction 1

1-8

MEMO

Page 29

Installation Wiring 2

2-1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

2. Installation Wiring

This section describes installation of the Handy GOT and wiring of the power supply and the

operation switches.

Thoroughly understand the specifications before performing installation and wiring.

2.1 Installation method

Cautions on installation

• Use the Handy GOT in the general specifications environment described in this manual.

Do not use the Handy GOT in a place with dusts, soot, conductive dusts, corrosive gas or

flammable gas, place exposed to high temperature, dew condensation, direct sunlight,

wind and rain, or place exposed to vibration or impact.

If the Handy GOT is used in such a place, electrical shock, fire, malfunction, product

damage or deterioration may caused.

• Never drop cutting chips and electric wire chips into the ventilation window of the Handy

GOT when you drill screw holes or perform wiring.

Otherwise, fire, failure or malfunction may be caused.

• Connect connection cables securely to the specified connectors while the power is

turned OFF.

Imperfect connection may cause malfunction or failure.

• When connecting cables, pay attention to the contents described in this section.

Especially, attach the rear cover so that PCBs inside the Handy GOT are not interfered

with connection cables.

Cautions on wiring

• Make sure to attach the rear cover to the Handy GOT before turning on the power and

starting operation after the installation or wiring work.

Otherwise, electrical shock may be caused.

• Make sure to shut down all phases of the power outside the Handy GOT before starting

the installation or wiring work.

Otherwise, electrical shock and damage of Handy GOT may be caused.

A953 HANDY GOT

Page 30

A953 HANDY GOT Installation Wiring 2

2-2

Cautions on wiring

• The Handy GOT has the DC power specifications. Connect the DC power cable to the

dedicated terminals described in this manual.

If the AC power is supplied to the power supply, operation switches or emergency stop

switches, the Handy GOT may be burnt.

• Correctly connect the 24V DC power cable (terminals) of the Handy GOT to [+][-] of the

DC power supply unit as described in this manual.

If reversing the terminals will seriously damage the Handy GOT.

• Perform the groundings to the drain wire (FG) of the Handy GOT. Never perform common

grounding with the strong power system.

• When processing a cable or executing the wiring work, pay attention so that cutting chips

and wire chips do not enter the inside of the Handy GOT.

Such chips may cause fire, failure or malfunction.

Note

Even if the power is interrupted for less than 1 ms, the Handy GOT continues operation. If the

power is interrupted for a long time or the voltage is dropped, the Handy GOT stops operation.

When the power is restored, however, the GOT automatically restarts operation.

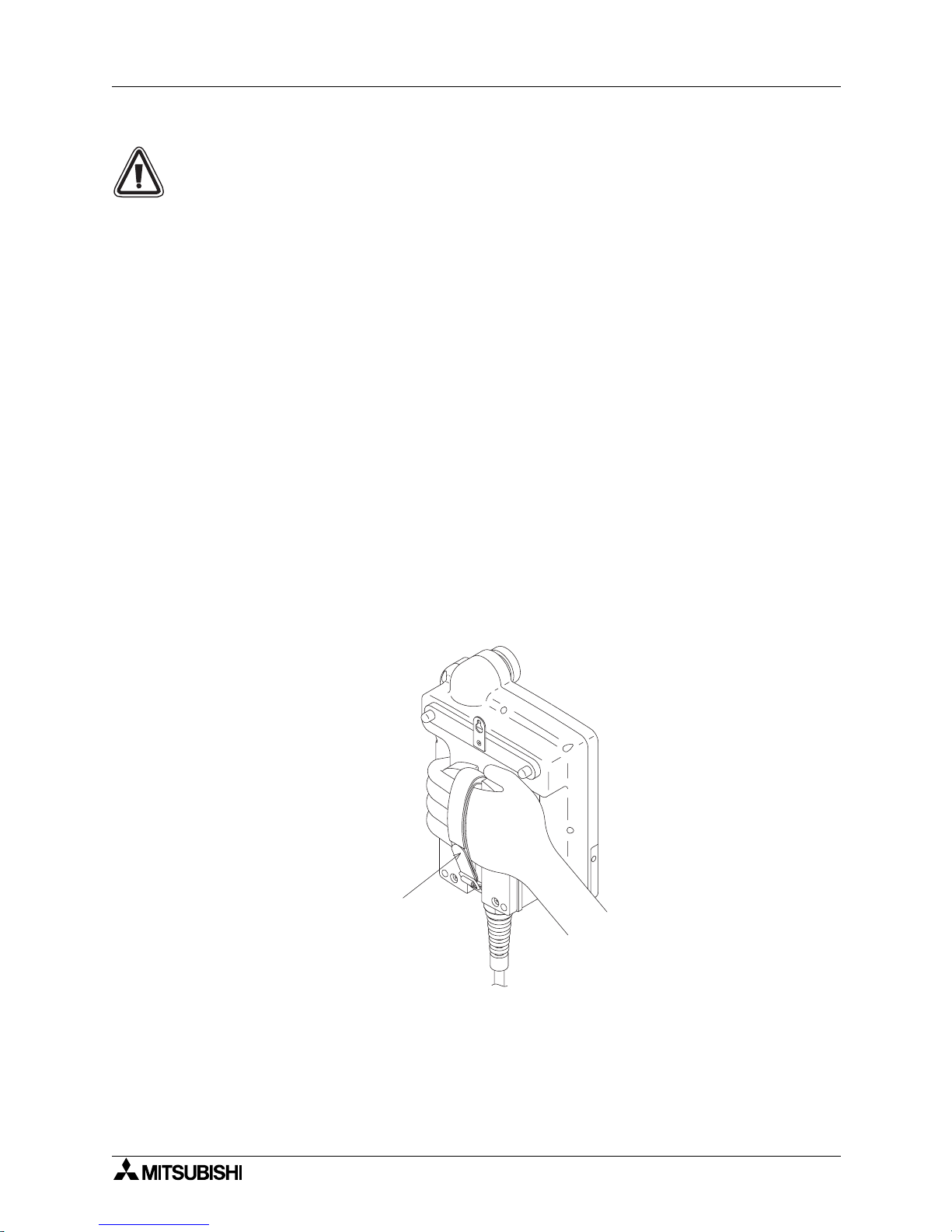

2.1.1 Holding

When holding the Handy GOT for operation, place your hand through the hand strap provided on its rear

face. You can adjust the length of the hand strap.

H a n d s t r a p

Page 31

A953 HANDY GOT Installation Wiring 2

2-3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

2.1.2 Hanging on wall

When operating the Handy GOT while keeping it hung on the wall, use the metal fixture for wall hanging

provided on the rear face of the Handy GOT.

On the wall face, the weight of the main unit (approximately 0.79 kg/1.74 lbs) and a load of approximately

1 ~ 3 kg (2.20 ~ 6.61 lbs) which varies depending on the communication cable length are applied. While

taking this into consideration, attach a suitable metal fixture on the wall.

2.1.3 Flat surface mounting

When using the Handy GOT on a flat surface, such as a desk or shelf, keep the Handy GOT parallel to

the surface so that it does not drop and, fix the communication cable to the desk.

W a l l f a c e

M e t a l h o o k f o r m o u n t i n g o n w a l l

f

5 m m ( 0 . 2 0 " )

f

1 0 m m ( 0 . 3 9 " )

F l a t h e a d s c r e w M 3 ( 0 . 1 2 " ) ´ 6

P O W E R

G R I P S W

I t i s r e c o m m e n d e d t o f i x

t h e c a b l e .

Page 32

A953 HANDY GOT Installation Wiring 2

2-4

2.2 Wiring

Cautions on wiring

• Make sure to shut down all phases of the power supply outside the Handy GOT before

starting the installation or wiring work.

If any phase is not shut down, you may get electrical shock or the Handy GOT may be

damaged.

• Before turning on the power or starting operation after the installation or wiring work, make

sure to attach the rear cover to the Handy GOT.

If the rear cover is not attached, you may get electrical shock.

• The Handy GOT is designed for DC power. Correctly connect the DC power supply as

described in this manual.

If the AC power supply is connected to the I/O terminals, the power terminals or the

emergency stop switch, the Handy GOT may be burnt.

• Never drop cutting chips or electric wire chips into the inside of the Handy GOT while

processing connection cables or performing the wiring work. Such chips may cause fire,

failure or malfunction.

• Perform Class D grounding to the drain wire (FG) of the Handy GOT. However, never

perform common grounding with a strong power system.

Note:

Even if instantaneous power interruption of less than 1ms occurs, the Handy GOT continues its

operation.

If long power interruption or voltage drop occurs, the Handy GOT stops its operation. And

when the power is recovered, the Handy GOT automatically restarts its operation.

Page 33

A953 HANDY GOT Installation Wiring 2

2-5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

2.2.1 Outline of connection

When attaching and detaching the Handy GOT or directly wiring the Handy GOT, perform

connection in either of the following methods.

When attaching/detaching the Handy GOT (using only an external cable)

When directly wiring the Handy GOT

F9GT-HCAB1 Prepared by user

When using a connector prepared by user

F9GT-HCAB

F9GT-HCAB5

PLC

External cable PLC connection cable

Wiring inside panel

Handy GOT

Wiring outside panel

24V DC supplied

from external power

supply unit or service

power supply of

PLC

RS232C

To PLC

For power supply and

operation switches

For untiled

cable

F9GT-HCAB1

PLC

External cable

Wiring inside panel

Handy GOT

Wiring outside panel

Prepared by user

For untiled

cable

24V DC supplied

from external power

supply unit or service

power supply of

PLC

Page 34

A953 HANDY GOT Installation Wiring 2

2-6

2.2.2 Cable selection

The figure below shows the outline of connection to the PLC.

Note:

The connection distance between the handy graphic operation terminal and the PLC ("1) +

3)" or "2)") should be within 6m (19' 8").

Name Model name Remarks

1)

External cable

(with 25-pin D-Sub connector on one side)

F9GT-HCAB-3M(3m, 9' 10")

2)

External cable

(with untied 20-core wires on one side)

F9GT-HCAB1-3M(3m, 9' 10")

3)

Relay cable for PLC connection

(with 6-pin MINI DIN connector on PLC side)

F9GT-HCAB5-150(1.5m, 4' 11")

For Q Series

Cable for any other

series is to be

prepared by user.

Connect a cable to

the connector inside

the rear cover.

1) 3)

To Q Series PLC

2)

For the details, refer to section 2.2.4.

For the details, refer to

section 2.2.3.

For the details, refer to

section 2.2.3.

To the power supply and

operation switches

To power supply

To operation switches

To PLC

P O W E R

G R I P S W

Page 35

A953 HANDY GOT Installation Wiring 2

2-7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

2.2.3 Pin arrangement and signal names of cables and connectors

1) External cable F9GT-HCAB-3M

The figure and the table below show the pin arrangement of untied wires and connectors of

external cables F9GT-HCAB-3M and F9GT-HCAB1-3M.

External cable

Communication/power supply/

operation switch signal name

Application

Reference

F9GT-HCAB-3M

F9GT-HCAB1-3M

A950 Handy GOT A953 Handy GOT

D-Sub pin number

Untied wire color

RS-422 RS-232C

1 Drain wire FG (shield) Frame ground

Chapter 6

and later

2 Black TXD+(SDA) SD(TXD)

Signal wires for

communication with

PLC

(For connection to

the PLC, refer to

chapter 6 and later.)

3 White TXD-(SDB) ER(DTR)

4 Red RTS+(RSA) RD(RXD)

5 Green RTS-(RSB) DR(DSR)

6 Yellow RXD+(RDA) RS(RTS)

7 Brown RXD-(RDB) CS(CTS)

8 Blue CTS+(CSA) CD(DCD)

9 Gray CTS-(CSB) NC

10 Orange SG Signal ground

11

−

NC Unused

12 Purple

DC24V G

Minus side of 24V DC

power supply of

Handy GOT

2.2.3

13 Pink

14 Fresh green Switch common

For operation

switches

3.1

15 Sky blue SW1

16 Black/white SW2

17 Red/white SW3

18 Green/white SW4

19

−

NC

Unused

20

−

NC

21 Brown/white ES1 For emergency stop

switch (Both ends of

the switch contact

are exposed.)

22 Yellow/white ES1

23

−

NC Unused

24 Blue/white

DC24V+

Plus side of 24V DC

power supply of

Handy GOT

2.2.3

25 Gray/white

113

14

25

F9GT-HCAB-3M

25-pin D-Sub, male connector

. . . . . .

Distinguished

by color

F9GT-HCAB1-3M

Untied wires (20-core type)

Page 36

A953 HANDY GOT Installation Wiring 2

2-8

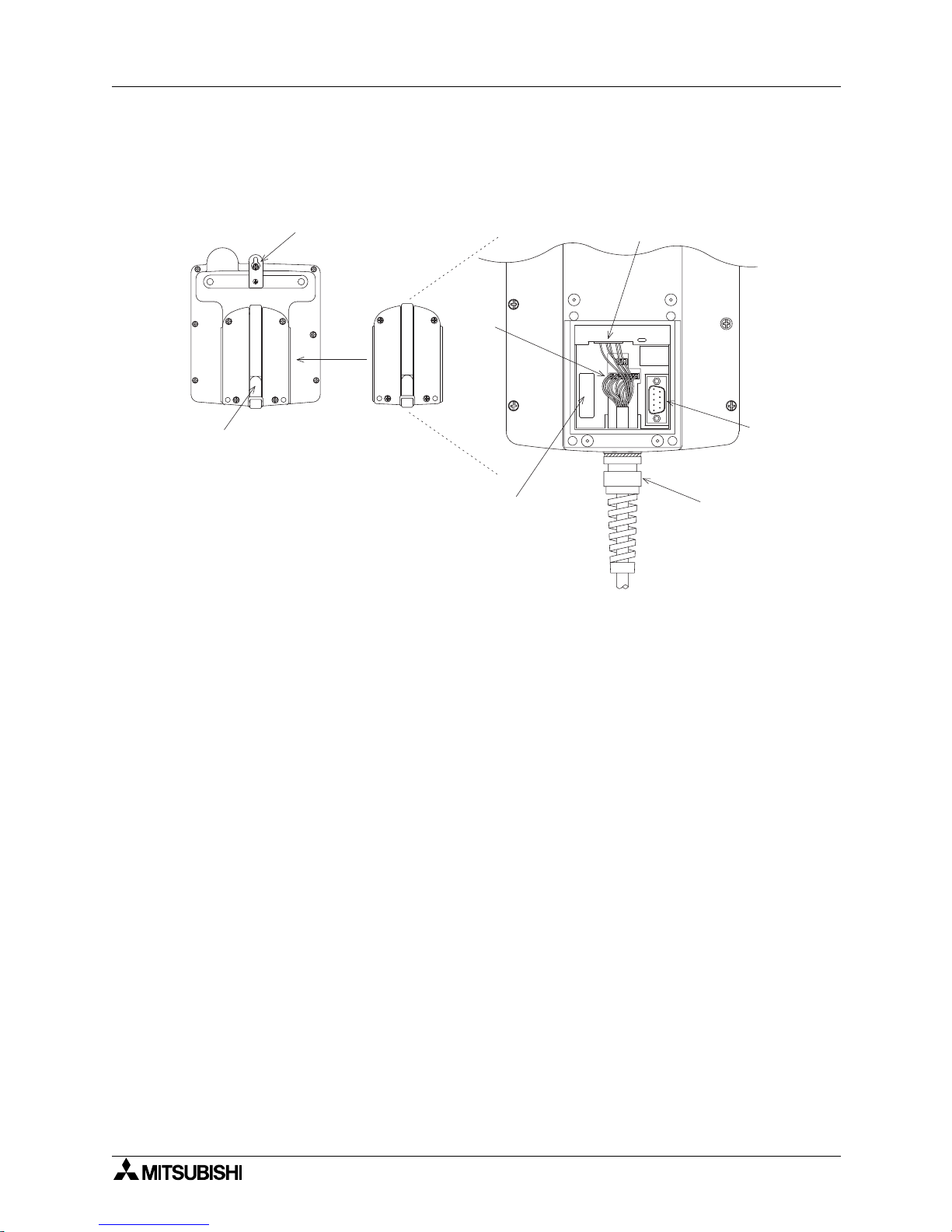

2.2.4 Connection of external cable

This section explains how to connect an optional external cable and the Handy GOT.

1) Remove the rear cover.

Rear face of Handy GOT

a) Loosen four mounting screws, and open the rear cover.

Note:

Remove only the mounting screws. Do not remove other

seven screws provided around the edge of the Handy GOT.

If such screws are removed, the waterproof ability may be

deteriorated or the Handy GOT may fail.

When the rear cover is open

(A) Power connector (8-pin)

(B) Connector for communication/operation switch (20-pin)

(C) Mounting slot

(D) Packing

2) Connect an external cable.

a) Let an external cable go through the mounting slot (C) in the Handy GOT, and connect it

to the connectors (A) and (B).

External cable

F9GT-HCAB-M:

With 25-pin D-Sub connector on one side

F9GT-HCAB1-M:

With untied 20-core wires on one side

a)

Note

( D )

( C )

( A ) ( B )

W h e n l e t t i n g t h e

c a b l e g o t h r o u g h ,

m a k e e a c h c o n n e c t o r

f a c e d o w n w a r d .

Page 37

A953 HANDY GOT Installation Wiring 2

2-9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

b) Tighten the hexagon nut for mounting of the external cable to the Handy GOT.

Make sure to tighten the hexagon nut for

mounting with a sufficient force to avoid

looseness.

As guideline, tighten it until the packing is

crushed by 0.5mm (0.02") or more.

c) Pull lightly the cable, and tighten lightly the

hexagon nut for tightening in the position in which

the cable is naturally stopped.

d) Tighten securely the hexagon nut for tightening

so that the cable will not come off or the

waterproof ability will not be deteriorated.

3) Attach the rear cover.

a) When closing the rear cover, make sure that the packing (D) has not come off.

b) Attach the rear cover.

c) Tighten the four mounting screws.

Make sure that the tightening torque is 0.49 to 0.68 N•m.

P a c k i n g

2 2 m m ( 0 . 8 7 " )

H e x a g o n n u t f o r m o u n t i n g

H e x a g o n n u t

f o r t i g h t e n i n g

P u l l i n g

d i r e c t i o n

A s g u i d e l i n e , m a k e s u r e

t h a t t h e c l e a r a n c e i s

3 . 5 m m ( 0 . 1 4 " ) o r l e s s .

Page 38

A953 HANDY GOT Installation Wiring 2

2-10

2.2.5 Wiring of power supply

To the Handy GOT, the power is supplied from the PLC or an external power supply unit.

The current consumption of the Handy GOT is 400mA/24V DC.

Example when the power is supplied from an external power supply

Connect a 24V DC external power supply unit to the power supply line (pin) of the external

cable (untied or with a connector) of the Handy GOT.

Pin arrangement

Signal name

External cable

F9GT-HCAB-3M F9GT-HCAB1-3M

24+ 24,25 Blue/white, gray/white

24G 12,13 Purple, pink

FG 1 Drain wire

E x t e r n a l

p o w e r

s u p p l y u n i t

P L C

C l a s s D g r o u n d i n g

H a n d y

G O T

F G

P L C

1 0 0 V A C

2 0 0 V A C

E x t e r n a l

p o w e r

s u p p l y u n i t

C l a s s D g r o u n d i n g

H a n d y

G O T

F G

a) When the input power is equivalent

When the input power for the PLC is equivalent to

the input power for the external power supply (24V

DC), perform grounding by connecting the frame

ground wire of the Handy GOT to the ground

terminal ( ) of the PLC.

b) When the input power is different

When the input power is different between the PLC

and the external power supply unit (PLC: 200V

AC, external power supply: 100V AC), perform

dedicated grounding to each of the ground

terminal ( ) of the PLC and the frame ground

wire of the Handy GOT.

*1 Cautions on Class D grounding according to the input power

P L C

T o o p e r a t i o n s w i t c h e s o f h a n d y G O T

H a n d y G O T

C l a s s D

g r o u n d i n g

C l a s s D

g r o u n d i n g

E x t e r n a l p o w e r

s u p p l y u n i t

F G

2 4 +

C O M

X 4

X 0

X 1

X 2

X 3

2 4 +2 4 G

* 1

Page 39

A953 HANDY GOT Installation Wiring 2

2-11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

2.3 Panel face processing

This section explains how to process the panel face when the Handy GOT is attached and

detached through a connector.

2.3.1 A953 Handy GOT

1) Attaching the connector on the panel face

a) External cable (with 25-pin D-Sub, male connector)

F9GT-HCAB-3M (3m, 9' 10")

b) Relay cable for PLC connection

For QCPU:

F9GT-HCAB5-150 (1.5m, 4' 11")

Any relay cable other than the above for the Q Series is to be prepared by the user.

When using a connector in accordance with your specifications together with the external

cable F9GT-HCAB1-M (with untied wires), refer to section 2.2.

a )

b )

P L C

A 9 5 0 h a n d y G O T

C o n t r o l p a n e l o r

o p e r a t i o n p a n e l

P O W E R

G R I P S W

Page 40

A953 HANDY GOT Installation Wiring 2

2-12

2.3.2 Appearance of relay cables

The panel cut size is as shown in section 2.3.3.

Appearance of the relay cable F9GT-HCAB5-150 (dedicated to the Q Series PLC)

T o p o w e r s u p p l y a n d o p e r a t i o n s w i t c h e s

A n a m e l a b e l i s a t t a c h e d t o t h e t i p o f

e a c h u n t i e d w i r e .

T o P L C

6 -

p i n M I N I D I N c o n n e c t o r

C o n n e c t e d

t o e x t e r n a l

c a b l e

2 5 - p i n D - S u b ,

f e m a l e c o n n e c t o r

( p a n e l - f a c e

m o u n t i n g t y p e

)

A c c e s s o r i e s

J a c k s o c k e t s

N u t s

2 e a c h

1 . 5 m ( 4 ' 1 1 " )

0 . 5 m ( 1 ' 8 " )

F o r F G ( C l a s s D g r o u n d i n g )

F9GT-HCAB

F9GT-HCAB1

25-pin D-sub, female

connector

1

13

14 25

SHELL

(1)

(2)

(3)

(7)

(4)

(5)

(10)

Drain wire

F9GT-HCAB-M

FG (Class D

grounding)

Black

White

Green

Brown

Red

Orange

(1)

(5)

(6)

(2)

(3)

(12)

DC24VG

(13)

DC24VG

(14)

SW-COM

(15)

SW1

(16)

SW2

(17)

SW3

(18)

SW4

ES1

ES1

DC24V+

DC24V+

F9GT-HCAB1-M

Wire the power supply, operation

switches and emergency stop

switches.

(21)

(22)

(24)

(25)

Purple

Pink

Fresh green

Sky blue

Black/white

Red/white

Green/white

Brown/white

Yellow/white

Blue/white

Gray/white

6-pin MINI DIN, male connector

Q Series

4

1

2

3

5

6

Page 41

A953 HANDY GOT Installation Wiring 2

2-13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

2.3.3 Panel cut size for relay cable

When attaching the connector of a relay cable on the panel face so that the Handy GOT can be

attached and detached, process the panel face as shown below.

Insert a jack socket into a hole shown above, and tighten it with a nut (M3, 0.12")).

Handy GOT

Connector shape 25-pin D-sub

Cable model name F9GT-HCAB5-150

10

°

42.5 (1.67") or more

47.04 (1.85")

2-φ3.2±0.1 (0.13" ±0.004")

11.4 (0.45")

or more

Indicates the cut area.

Unit: mm

4-R3.4 (0.13")

(Panel thickness: 0.8 to 1.3mm, 0.03" to 0.05")

J a c k s o c k e t

C o n n e c t e d t o

e x t e r n a l c a b l e

C a b l e s i d e

N u t ( M 3 , 0 . 1 2 " )

P a n e l f a c e o n

w h i c h c o n n e c t o r

i s m o u n t e d

M 2 . 6 ( 0 . 1 0 " )

M 3 ( 0 . 1 2 " )

J a c k s o c k e t

4 . 8 ( 0 . 1 9 " )

Page 42

A953 HANDY GOT Installation Wiring 2

2-14

MEMO

Page 43

Wiring and Handling of Switches 3

3-1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

3. Wiring and Handling of Switches

This chapter explains wiring and handling of the operation switches and the grip switch as well

as control of the LEDs for confirming the switch pressing status.

Cautions on installation

• Use the Handy GOT in the general specifications environment described in this manual.

Do not use the Handy GOT in a place with dusts, soot, conductive dusts, corrosive gas or

flammable gas, place exposed to high temperature, dew condensation, direct sunlight,

wind and rain, or place exposed to vibration or impact.

If the Handy GOT is used in such a place, electrical shock, fire, malfunction, product

damage or deterioration may caused.

• Never drop cutting chips and electric wire chips into the ventilation window of the Handy

GOT when you drill screw holes or perform wiring.

Otherwise, fire, failure or malfunction may be caused.

• Connect connection cables securely to the specified connectors while the power is

turned OFF.

Imperfect connection may cause malfunction or failure.

• When connecting cables, pay attention to the contents described in Chapter 2.

Especially, attach the rear cover so that PCBs inside the Handy GOT are not interfered

with connection cables.

Cautions on wiring

• Make sure to attach the rear cover to the Handy GOT before turning on the power and

starting operation after the installation or wiring work.

Otherwise, electrical shock may be caused.

• Make sure to shut down all phases of the power outside the Handy GOT before starting

the installation or wiring work.

Otherwise, electrical shock and damage of Handy GOT may be caused.

Cautions on wiring

• The Handy GOT has the DC power specifications. Connect the DC power cable to the

dedicated terminals described in this manual.

If the AC power is supplied to the power supply, operation switches or emergency stop

switches, the Handy GOT may be burnt.

• Correctly connect the 24V DC power cable (terminals) of the Handy GOT to [+][-] of the

DC power supply unit as described in this manual.

If reversing the terminals will seriously damage the Handy GOT.

• Perform the groundings to the drain wire (FG) of the Handy GOT. Never perform common

grounding with the strong power system.

• When processing a cable or executing the wiring work, pay attention so that cutting chips

and wire chips do not enter the inside of the Handy GOT.

Such chips may cause fire, failure or malfunction.

A953 HANDY GOT

Page 44

A953 HANDY GOT Wiring and Handling of Switches 3

3-2

3.1 Outline of switches

The Handy GOT is equipped with the following switches and indicator LEDs.

1) Switch assignment

The figure below shows assignment of the switches. Each switch is abbreviated as shown in

the table below.

Switches requiring external wiring

The following switches are required to be connected to the PLC or an external input

equipment by way of a connector for operation switches.

- Operation switches

- Emergency stop switch

Switch and LEDs not requiring external switches

The following switch and LEDs are connected to the display unit CPU, and perform serial

communication with the PLC by way of the communication connector. Accordingly, wiring is

not required.

-Grip switch

- Operation indicator LEDs

Abbreviation Name Reference

SW1 to SW4 Operation switches

3.2

ES1 Emergency stop switch

L1 to L4 Indicator LEDs for operation switches 3.3

L5 Indicator LED grip stop switch

3.4

−

Grip switch

POWER GRIP SW

SW1

SW2

SW3

SW4

ES1

L1 L2 L3 L4

L5

Grip switch

Page 45

A953 HANDY GOT Wiring and Handling of Switches 3

3-3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

2) Switch internal wiring

Connection of each switch is as shown below inside the Handy GOT.

CPU memory

LCD panel

Touch switch circuit

Display circuit

Serial

communication

CPU/communication circuit

RS-232C (for PC)

DC24V

+

DC24G

FG

RS-232C

(for external

equipment)

Operation

switches

SW1

SW2

SW3

SW4

Emergency

stop

switches

ES1

ES1

To external cable

SW-COM

Power

circuit

Power

supply

L1(SW1)

L2(SW2)

L3(SW3)

L4(SW4)

L5

(GRIP SW)

Grip

switch

Indicator LEDs

for operation

switches

I/O interface

Page 46

A953 HANDY GOT Wiring and Handling of Switches 3

3-4

3) Connection diagram of external cables and connected equipment

SW-COM

SW1

SW2

Handy GOT

internal wiring

SW3

SW4

Connected

equipment

(PLC)

Inputs

ES1

ES1

Wire them for

emergency

stop

switches.

Fresh green

Sky blue

Black/white

Red/white

Green/white

Brown/white

Yellow/white

F9GT-HCAB-3M

F9GT-HCAB1-3M

Cables for

Handy

GOT

25pin D-Sub Untied cable

The untied cables above are distinguished

by the color. On these cables, a signal

name (SW1 to SW4, ES1) label is adhered

for distinction.

14

15

16

Power circuit

18

21

22

17

DC24VG

DC24VG

DC24V+

DC24V+

12

13

24

25

24V DC

Purple

Pink

Blue/white

Gray/white

Wiring of

power supply

FG

Drain wire

Class D

grounding

1

COM

X0

X1

X2

X3

Page 47

A953 HANDY GOT Wiring and Handling of Switches 3

3-5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

3.2 Wiring of operation switches

The operation switches are assigned as shown below, and connected to the PLC through an

external cable.

Connection example

Pin arrangement

In the wire color of the F9GT-HCAB1-3M, "color 1/color2" indicates stripes of the two colors.

3.2.1 Inputs of operation switches

Use the operation switches provided on the Handy GOT as follows.

Operation switch operating procedure

The operation switches SW1 to SW4 are directly connected to inputs of the PLC. Accordingly,

the operation switches can be arbitrarily controlled in a sequence program in the same way as

general inputs.

• The operation switches are received as momentary type a-contact switches by the PLC.

• When the operation switches are to be handled as b-contacts or alternate type switches,

create in a sequence program accordingly.

Signal name

External cable

F9GT-HCAB-3M F9GT-HCAB1-3M

SW COM 14 Fresh green

SW1 15 Sky blue

SW2 16 Black/white

SW3 17 Red/white

SW4 18 Green/white

P L C

X 0

X 1 X 2

1 6

1 5

1 4

X 4X 3

X 5

S W 1

S w i t c h

c o m m o n

1 8

1 7

S W 2

S W 3

S W 4

H a n d y G O T

C O M

X0

Y0

Example: When an operation switch is wired to X0 of PLC

ON

OFF

ON

OFF

Operation

switch status

X0

Page 48

A953 HANDY GOT Wiring and Handling of Switches 3

3-6

3.2.2 Lighting of operation indicator LEDs

Each of the four operation switches SW1 to SW4 is equipped with a green LED which indicates

the pressing status of the switch.

Each LED is assigned to the bit 0 to the bit 3 of a word device. When the bit value is "1", the

corresponding LED is lit. When the bit value is "0", the corresponding LED is extinguished.

1) Assigning a device which controls the LEDs

Assign a device to control the LEDs using the screen creation software. When "System

Information" of "Read device" in "Common" is set to 2 points, the set "Read device" +1 (the

output information storage area of the external I/O function) is assigned to LED control.

The figure below shows the relationship between each bit in the output information storage

area and the LEDs. When the bit value is "1", the corresponding LED is lit. When the bit

value is "0", the corresponding LED is extinguished.

Output information storage area of the external I/O function

For example, when "Read device" of "System Information" is set to "D100", the value of

each bit of the D101 is reflected on lighting/extinction of an LED.

b0 of D101 → LED of SW1

b1 of D101 → LED of SW2

b2 of D101 → LED of SW3

b3 of D101 → LED of SW4

2) Setting in the screen creation software

Set "Read Device" in "System Information" as follows according to the screen creation

software.

- GT Designer2 (SWD5C-

GTD2-E)

a) Select "Common"-"System

Environment" to open the

"System Environment"

window.

b) Select "System

Information".

c) Set "Read Device" (System

Signal 1).

d) Click the "External I/O

Function Output

Information" check box to

give a check mark.

e) Click the "OK" button to

close the "System

Environment" window.

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

SW4SW3SW2SW1

Page 49

A953 HANDY GOT Wiring and Handling of Switches 3

3-7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

- GT Designer (SWD5C-GOTR-PACKE)

a) Select "Common"-"System