Page 1

A8GT-50KBF

External I/O Interface Module

User’s Manual

(Hardware)

Thank you for choosing the MELSEC-GOT Series.

To ensure correct use of this equipment, please read this manual

carefully before operating it.

MODEL A8GT-50KBF-U

MODEL

CODE

1DM053

IB(NA)-68908-C(0406)MEE

MITSUBISHI Graphic Operation Terminal

Page 2

A-1

DANGER

CAUTION

!

SAFETY PRECAUTIONS

!

(Always read before starting use)

When using Mitsubishi equipment, thoroughly read this manual and the

associated manuals introduced in the manual. Also pay careful attention to

safety and handle the module properly.

These precautions apply only to the installation of Mitsubishi equipment and the

wiring with the external device. Refer to the user’s manual of the CPU module

to be used for a description of the PLC system safety precautions.

These

SAFETY PRECAUTIONS classify the safety precautions into two

categories: "DANGER" and "CAUTION".

Procedures which may lead to a dangerous condition and

cause death or serious injury if not carried out properly.

Procedures which may lead to a dangerous condition and

cause superficial to medium injury, or physical damage

only, if not carried out properly.

Depending on circumstances, procedures indicated by

CAUTION

may also

be linked to serious results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

[DESIGN PRECAUTIONS]

DANGER

!

Some faults of the GOT, this unit or connection cables may keep the

outputs on or off.

An external monitoring circuit should therefore be provided to check for

output signals which may lead to a serious accident.

Otherwise, mis-output or misoperation can cause an accident.

Page 3

A-2

[INSTALLATION PRECAUTIONS]

DANGER

!

When installing and removing this module from the GOT main module be

sure to shut off the power at all external switches. If all the switches are not

turned off, the module could be damaged or malfunction.

!

When connecting the bus connection cable to this module be sure to turn

off the switch to all external power switches to the GOT and PC CPU. If all

the switches are not turned off, it may cause malfunction.

CAUTION

!

Use this module in an environment that is within the general specifications

written in the GOT User's Manual. If the power supply is used in an

environment that is outside of the general specifications then electric

shock, fire, malfunction, or product damage or degradation could occur.

!

For a correct installation, insert the bus connection cable to this module,

A7GT-BUS2S, bus connector conversion module, and base unit connector

until you hear it click.

A bad connection could cause erroneous input or output.

!

When installing this module in the GOT main module, install it in the GOT

installation area and be sure it is fastened with a module fastening screw

that is tightened within the specified torque range.

If the module fixing screws are loosen, it may cause malfunction, damage

or falling of the module.

If the module fixing screws are too tight, the GOT main module or the

screws could break.

[Wiring Instructions]

DANGER

!

Before starting wiring, always switch off all phases of the power supply

externally.

CAUTION

!

During wiring, care should be taken so that foreign matter such as shield

and wire offcuts do not enter this unit.

Otherwise, a fire, fault or misoperation can occur.

Page 4

A-3

[STARTING AND MAINTENANCE PRECAUTIONS]

DANGER

!

Do not change the switch setting while power is on.

!

Switch all phases of the GOT external power supply off before cleaning.

Not doing so could result in electric shock.

CAUTION

!

Never disassemble or modify the module. This may cause breakdowns,

malfunctioning, injury, and/or fire.

!

Do not directly touch the conducted area and electric parts of this module.

It may cause damage and malfunctioning of the module.

!

This module is made of resinous materials, and should be protected from

strong shock or impact. It may cause breakdown.

!

When disconnecting the communication or power cable from the module,

do not hold and pull the cable part.

When disconnecting the cable having a connector, hold the connector

plugged in the module.

Before disconnecting the cable having no connector, loosen the screws in

the module.

If the cable connected to the module is pulled, the module or cable may be

damaged or a malfunction may occur due to a cable connection fault.

!

Before handling the unit, touch a grounded metal or similar object to

discharge the static electricity from the human body.

Failure to do so may cause the unit to fail or mulfunction.

[DISPOSAL PRECAUTIONS]

CAUTION

!

When disposing of this product, treat it as industrial waste.

Page 5

A-4

Revisions

* The manual number is noted at the lower left of the back cover.

Print Date *Manual Number Revision

Jun., 1997 IB(NA)-68908-A First printing

May, 2001 IB(NA)-68908-B

Partial correction

Chapter 1, Chapter 3, Chapter 4,

Chapter 5, Chapter 7

Jun., 2004 IB(NA)-68908-C

Partial correction

SAFETY PRECAUTION, Manuals

MODEL CODE change

Changed from 13JL17 to 1DM053

This manual confers no industrial property rights or any rights of any other kind, nor does

it confer any patent licenses. Mitsubishi electric Corporation cannot be held responsible

for any problems involving industrial property rights which may occur as a result of using

the contents noted in this manual.

1997 MITSUBISHI ELECTRIC CORPORATION

Page 6

A-5

CONTENTS

1. Overview........................................................................................................1

2. Components Including in the Package ..........................................................1

3. Specifications ................................................................................................2

4. System configuration.....................................................................................7

5. User-fabricasted connection cables...............................................................9

5.1 Connection cable ....................................................................................9

5.2 Wiring diagrams ....................................................................................13

6. Parts Identifcation........................................................................................17

7. Installation Procedure.................................................................................. 18

8. Outline Dimension Drawing......................................................................... 19

Manuals

The following manuals are relevant to this product.

Refer to the following list and order the required manuals.

Relevant Manuals

Manual name

Manual No.

(Model code)

A8GT-TK type Numeric Keypad Panel User's Manual

(Found in the packing of the A8GT-TK)

IB-66832

(1DM094)

GOT-A900 Series User's Manual (GT Works Version5/GT

Designer Version5 compatible connection Sysytem

Manual)

(Available as option)

SH-080119

(1DM189)

SW3NIW-A8GOTP Graphic Settings Software Package

Operating Manual (Monitor Screen Creation Manual)

(Found in the packing of the software package)

IB-66793

(1DM176)

Page 7

1

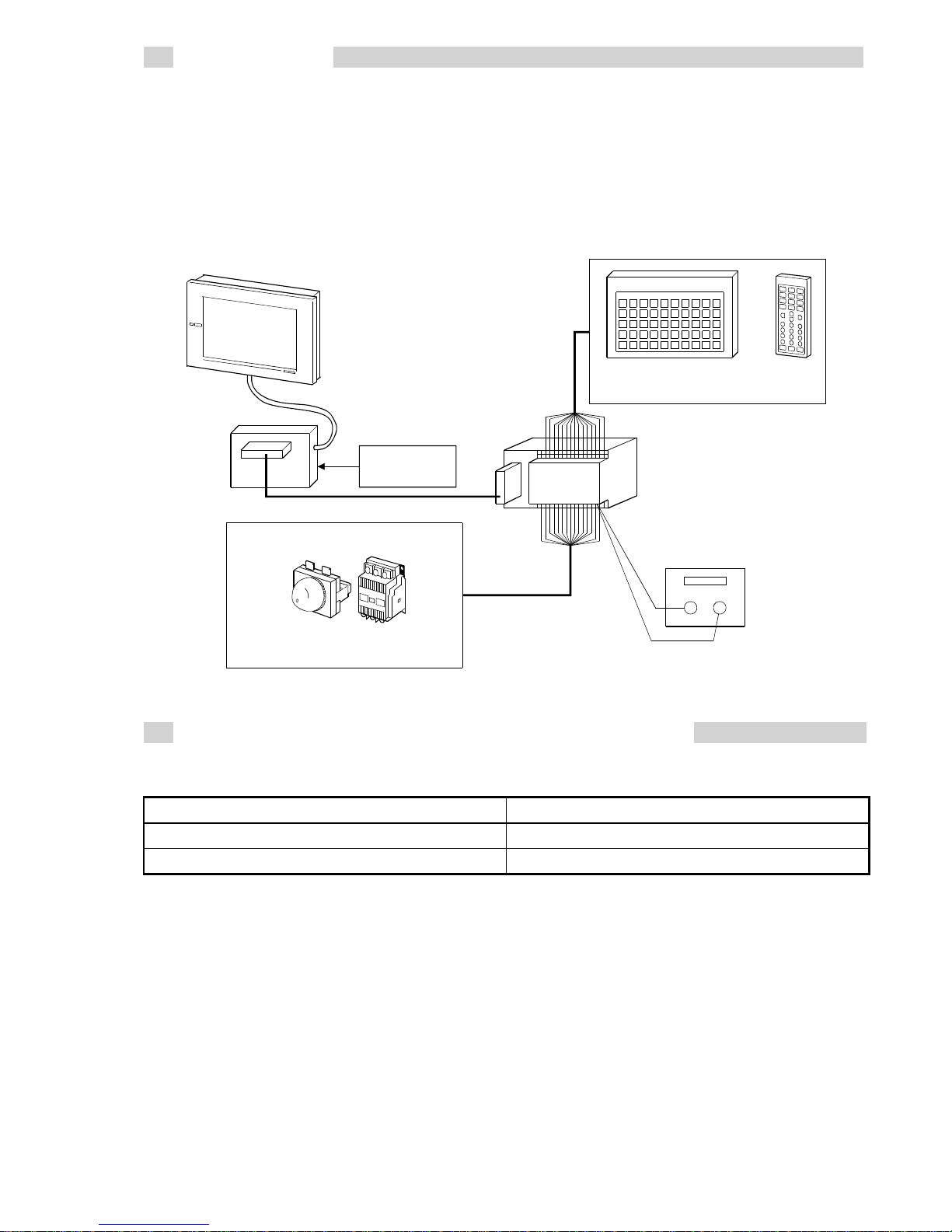

1. Overview

This user's manual gives the specifications, system configurations, parts

identifi-cation, installation procedure and outline dimensions of the A8GT50KBF type external I/O unit (referred to as the external I/O unit).

The external I/O unit is fitted to the A956WGOT/A95*GOT/A85*GOT (referred

to as the GOT) to receive up to 8/64 points of inputs and provide up to 16

points of outputs.

Lamp, relay, etc.

Connector terminal

block conversion unit

Operation panel, pushbutton,

numeric keypad panel, etc.

DC power supply 12/24V

External

I/O module

GOT

2. Components Including in the Package

After opening the container, check that the following products are present.

Description Quantity

External I/O unit 1

External connector (soldered type) 1

Page 8

2

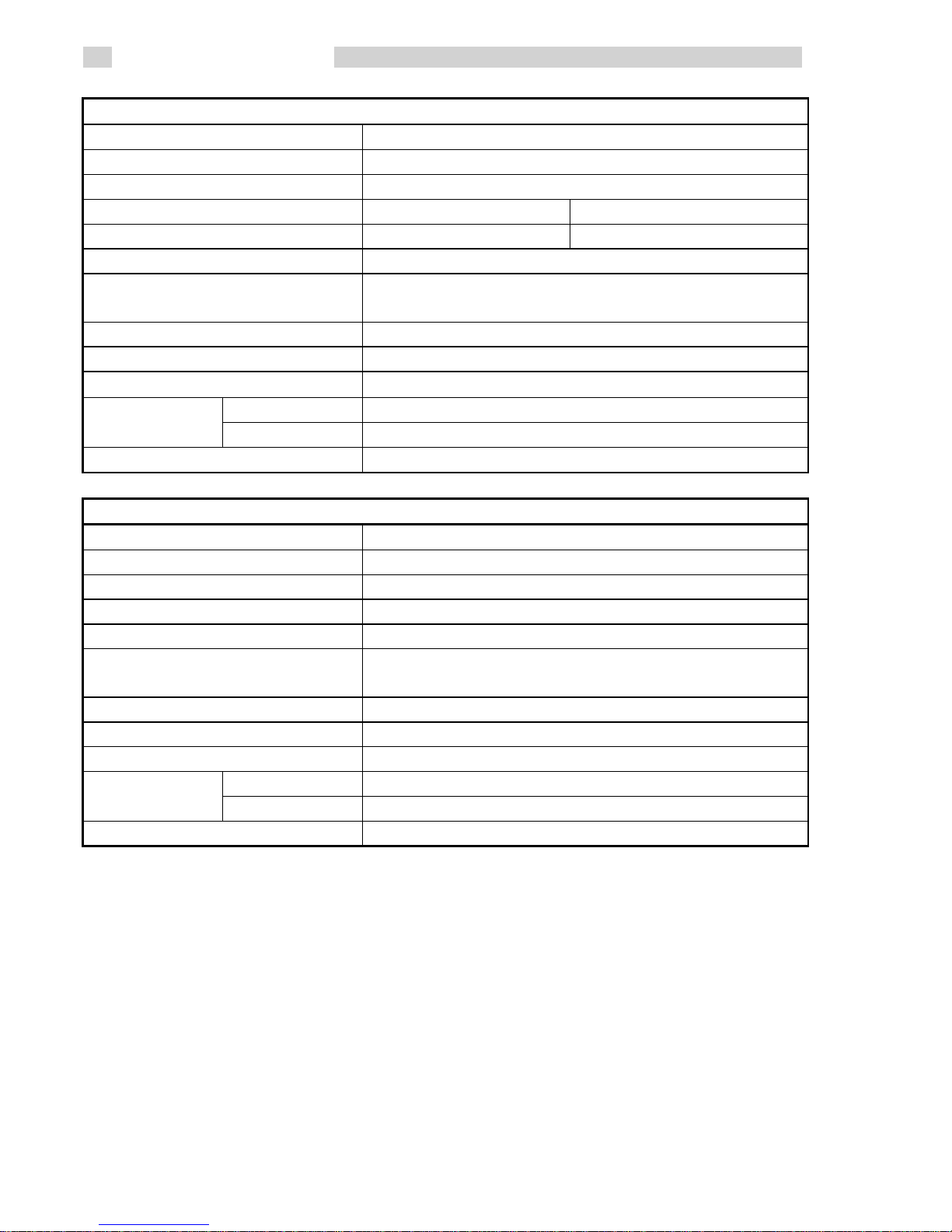

3. Specifications

Input Specifications

Input system Dynamic scan

Number of input points 8/64 points

Isolation system Photocoupler isolation

Rated input voltage 12VDC 24DVC

Rated input current Approx. 4mA Approx. 9mA

Operating voltage range 10.2 to 26.4VDC (ripple percentage within 5%)

Max. number of

simultaneous input points

100% simultaneous ON (at 26.4VDC)

ON voltage/ON current 8VDC or more/2mA or more

OFF voltage/OFF current 4VDC or less/1mA or less

Input resistance

Approx. 2.4K

Ω

ON to OFF Approx. 0.4ms or less (24VDC)

Response

time *1

OFF to ON Approx. 0.4ms or less (24VDC)

Dynamic scan cycle 13.3ms

Output Specifications

Output system Direct

Number of output points 16 points

Isolation system Photocoupler isolation

Rated load voltage 12/24DVC

Max. load current*4 0.1A/1 point

Operating load voltage

range

10.2 to 26.4VDC (ripple percentage within 5%)

Max. inrush current 0.4A

Leakage current at OFF 0.1mA or less

Max. voltage drop at ON 2.5VDC (0.1A)

ON to OFF 2ms or less

Response

time*1

OFF to ON 2ms or less (resistive load)

Surge suppressor Clamp diode

Page 9

3

I/O Specifications

External connection system 40-pin connector

Applicable wire size 0.3mm2

Operation indicator None

Voltage*3

12/24VDC

(10.2 to 26.4V, ripple percentage 5% or less)

External

supply power

Current

1.65A for external output

0.05A for internal consumption only

Fuse rating*2 2.0A fuse, unreplaceable

Internal current consumption 0.1A

Weight 250g(0.55lb)

Accessory

1 piece of external wiring connector

(soldered type)

*1: Time in the I/O section.

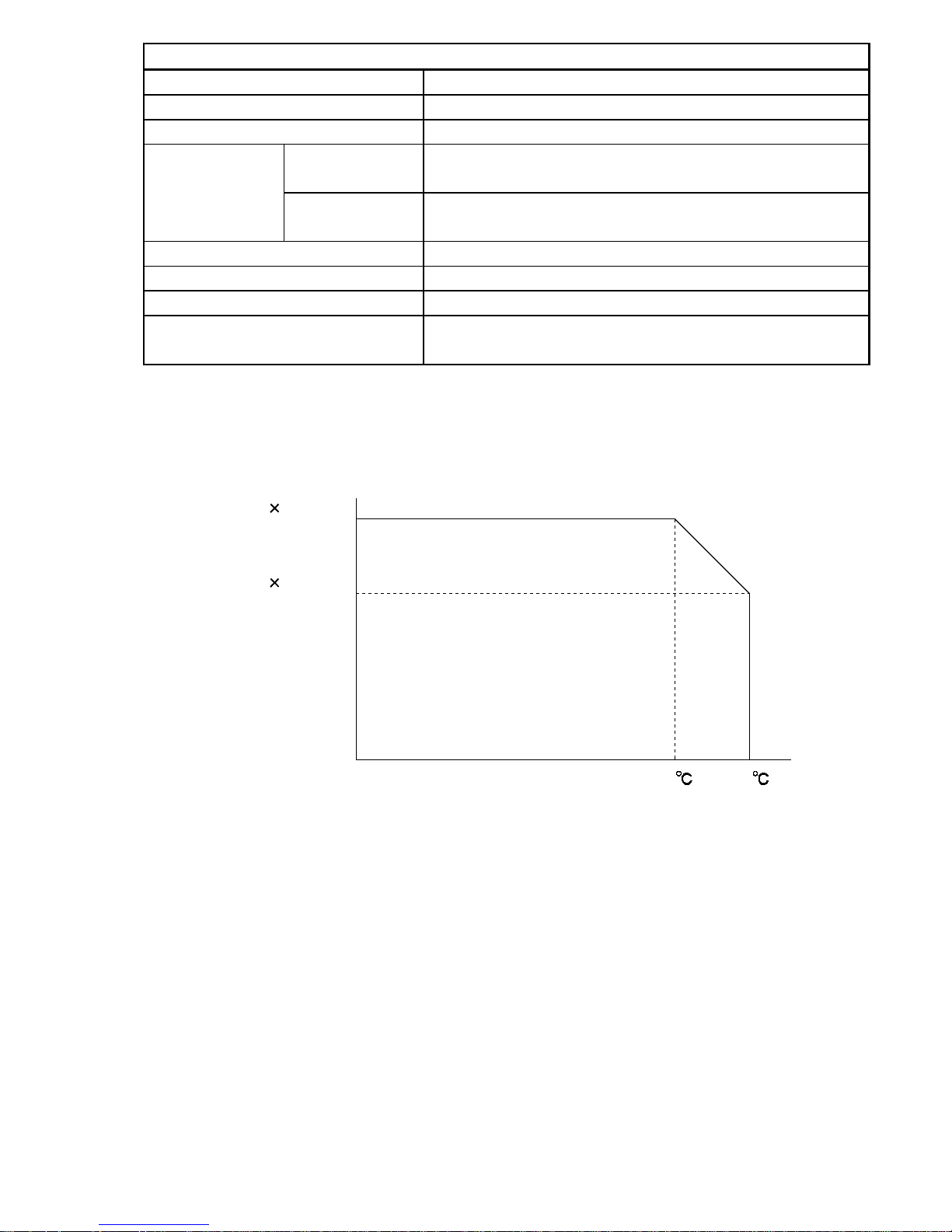

*2: The maximum load current varies with the number of simultaneous ON

points. Refer to the following information:

Relationships between output load current (common current), number of

simultaneous ON points and ambient temperature

5551

0.1A 16points

=1.6A

0.08A 16points

=1.28A

Common current

Ambient temperature

*3: A fuse-blown error will also be displayed when the external supply power

switches off.

*4: The fuse in the output unit is provided to prevent the external wiring from

burning out if the outputs of the unit are shorted.

Therefore, it may not protect the output elements.

The fuse may not be blown if the output elements are damaged in the fault

mode other than a short circuit.

Page 10

4

External Connector Pin-Outs

View from the unit front Connector used: Fujitsu's FCN-365P040-AU

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10B11B12B13B14B15B16B17B18B19B20

A1 A2 A3 A4 A5 A6 A7 A8 A9 A10A11A12A13A14A15A16A17A18A19A20

Pin Numbers and Signal Names of External Connector

Pin Number Signal Name Pin Number Signal Name

A1 XD7 B1 XD6

A2 XD5 B2 XD4

A3 XD3 B3 XD2

A4 XD1 B4 XD0

A5 XSCN7 B5 XSCN8

A6 XSCN5 B6 XSCN4

A7 XSCN3 B7 XSCN2

A8 XSCN1 B8 XSCN0

A9 YD15 B9 YD14

A10 YD13 B10 YD12

A11 YD11 B11 YD10

A12 YD9 B12 YD8

A13 YD7 B13 YD6

A14 YD5 B14 YD4

A15 YD3 B15 YD2

A16 YD1 B16 YD0

A17 DC12/24V B17 DC12/24V

A18 DC12/24V B18 0V

A19 0V B19

A20 B20 FG

Page 11

5

External Connection Diagram (1) (8-point inputs, 16-point outputs)

XD1

XD2

XD3

XD4

XD5

XD6

XD7

A8

B7

A7

B6

A6

B5

A5

XSCN0

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

A16 YD1

B15 YD2

A15 YD3

B14 YD4

A14 YD5

B13 YD6

A13

YD7

B12 YD8

A12 YD9

B11 YD10

A11

YD11

B10 YD12

A10

YD13

B9 YD14

A9

YD15

R

R

B4

A4

B3

A3

B2

A2

B1

A1

XD0

B8

R

B16RYD0

L

L

B18,A19

DC12/24V

(12/24VDC)

+-

A17,B17,A18

Pin number

Internal

control

circuit

Internal

control

circuit

Internal

control

circuit

Internal

scan is

made at

1/8 duty.

Fuse-blown

detector

circuit

*1: A fuse-blown error will also be displayed when the external supply power

switches off.

*2: The fuse in the output unit is provided to prevent the external wiring from

burning out if the outputs of the unit are shorted.

Therefore, it may not protect the output elements.

The fuse may not be blown if the output elements are damaged in the fault

mode other than a short circuit.

Page 12

6

External Connection Diagram (2) (64-point inputs, 16-point outputs)

DC12/24V

(12/24VDC)

A17,B17,A18

0109111921293139

020A121A222A323A

030B131B232B333B

040C141C242C343C

050D151D252D353D

060E161E262E363E

070F171F272F373F

XD1

XD2

XD3

XD4

XD5

XD6

XD7

A8

B7

A7

B6

A6

B5

A5

XSCN0

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

A16 YD1

B15 YD2

A15 YD3

B14 YD4

A14

YD5

B13 YD6

A13

YD7

B12 YD8

A12 YD9

B11 YD10

A11

YD11

B10 YD12

A10

YD13

B9

YD14

A9

YD15

R

R

B4

A4

B3

A3

B2

A2

B1

A1

XD0

B8

R

B16RYD0

L

L

B18,A19

+

-

0008101820283038

Pin number

Input terminals

Internal

control

circuit

Internal

control

circuit

Internal

control

circuit

Internal

scan is

made at

1/8 duty.

Fuse-blown

detector

circuit

*1: When there is a probability that two or more switches are

pressed simultaneously, each switch must be provided with a

diode. (Refer to the right figure.)

*2: A fuse-blown error will also be displayed when the external

supply power switches off.

*3: The fuse in the output unit is provided to prevent the external wiring from

burning out if the outputs of the unit are shorted.

Therefore, it may not protect the output elements.

The fuse may not be blown if the output elements are damaged in the

fault mode other than a short circuit.

Page 13

7

4. System Configuration

(1) System configurations and connection conditions

The following system configuration assumes connection of a printer.

The numbers (

to ) given in the system configurations denote the

numbers (

to ) in "(2) System equipment". Refer to these numbers

when you want to confirm the types and applications.

Connection

Conditions

System Configuration

Numeric Keypad Panel

Max. 20m

Connection cable

For input

only

Operation panel

Max. 20m

Connection cable

General-purpose

input devices

(e.e. pushbuttons)

General-purpose

output devices

(e.e. pushbuttons)

Connection cable

Connector terminal block

conversion unit

Max. 20m

Connection cable

Max. 10m

Connection cable

General-purpose

output

devices

(e.e. pushbuttons)

Connection cable

Connector terminal block

conversion unit

Max. 20m

Connection cable

Max. 10m

Connection cable

Numeric Keypad Panel

For I/O

Operation panel

General-purpose

output

devices

(e.e. pushbuttons)

Connection cable

Connector terminal block

conversion unit

Max. 20m

Connection cable

Max. 10m

Connection cable

Page 14

8

(2) System equipment

The following table indicates the system equipment needed for

connection of external I/O equipment.

Type

Image No. Applocation

GOT unit

External I/O

interface unit

External I/O equipment-connected

GOT

A956WGOT,

A95*GOT,

A85*GOT

A8GT-50KBF

Ten-key panel A8GT-TK

Operation panel*1

FP5-MD41-A

(Kanaden Corp. make),

FP5-MD41-B

(Kanaden Corp. make)

Connector terminal block conversion

unit*2

A6TBY36-E, A6TBY54-E

Connection cable between [GOT] and

[ten-key panel]*2*3

A8GT-C05TK(0.5m)

Connection cable between [GOT] and

[operation panel]*1*2*5

Connection cable

(Kanaden Corp. make)

Connection cable between [GOT] and

[connector terminal block conversion

unit]*2*5

A8GT-C30TB(3m)

Connection cable between [connector

terminal block conversion unit] and

[general-purpose I/O equipment]

(Refer to Section 5.1 and

fabricate on user side.)

Connection cable between [connector

terminal block conversion unit] and

[ten-key panel]

(Refer to A8GT-TK Numeric

Keypad Panel User's Manual

and fabricate on user side.)

Connection cable between [connector

terminal block conversion unit] and

[operation panel]*5

Connection cable (Kanaden

Corp. make)

*1: The operation panel and cable for input only may also be fabricated on user

side.

Refer to Section 5.2 for details of the fabricating method.

*2: 12/24VDC power must be supplied for external I/O units.

*3: The connection cable may also be fabricated on user side.

Refer to the A8GT-TK Type Numeric Keypad Panel User's Manual for

details of the fabricating method.

*4: The connection cable may also be fabricated on user side. Refer to Section

5.2 for details of the fabricating method.

*5: The operation panel and cables for I/O may also be fabricated on user side.

Refer to Section 5.1 for details of the fabricating method.

Page 15

9

5. User-fabricated Connection Cables

The following is the way of fabricating the connection cable which can be

fabricated by the user:

5.1 Connection cable

(1) Cable for connection between external I/O unit and original operator panel

Fabricate the connection cable in accordance with the following wiring

diagram, parts diagram and assembly drawing: (Maximum cable length:

20m (16.4feet))

(a) Connection diagram

Original operator

panel side

Shieleded cableconnect with FG

Cables for connection of

external input power supply

DC12/24V

Shield

External I/O

unit side

B4

A4

B3

A3

B2

A2

B1

A1

B8

A8

B7

A7

B6

A6

B5

A5

A9

B9

A10

B10

A11

B11

A12

A13

B13

A14

B14

A15

B15

A16

B16

A17

B17

A18

B18

A19

B19

A20

B20

B12

Pin

number

Signal

name

XD0

XD1

XD2

XD3

XD4

XD5

XD6

XD7

XSCN0

YD15

DC12/24V

FG

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

YD14

YD13

YD12

YD11

YD10

YD9

YD8

YD5

YD4

YD3

YD2

YD1

YD0

YD7

YD6

DC12/24V

DC12/24V

0V

0V

XD0

XD1

XD2

XD3

XD4

XD5

XD6

XD7

XSCN0

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

Pin

number

Signal

name

None

None

Page 16

10

(b) Parts list

Number Name Type Maker

1) 2) Connector (with cover) A6CON1

Mitsubishi

Electric

1) Connector FCN-361JO40-AU

2) Connector cover FCN-360CO40-B

Fujitsu

3) Pair shielded cable UL 2464 AWG26 or equivalent

4) FG wire UL 1015 AWG14 or equivalent

5)

Wires for connection

of external input power

UL 1007 AWG24 or equivalent

(c) Assembly

1) 2) User's desired connecto

r

3)

DC power supply 12/24V

5)

4)

POINT

"

The cable fabricated should be within 3m in length .

"

Connect the FG cable to the nearest ground

"

The grounding wire (green wire, approx. 1m) coming out of the connector of

the user-fabricated connection cable must be connected to the control box

or the like.

"

Grounding should be independent where possible.

"

Use class D grounding (class 3 grounding) method (grounding resistance is

100 Ω max.).

"

The grounding point should be as near as possible to the external I/O

module to minimize the grounding cable length.

"

Adjust the grounding cable length according to the grounding position and

install a terminal or the like for grounding.

"

When grounding, always connect the FG cable for connection with the GOT

’s power supply terminal block and the FG wire of the user-fabricated

connection cable separately.

Page 17

11

(2) Cable for connection between external I/O unit and terminal block

conversion unit.

Fabricate the connection cable in accordance with the following wiring

diagram, parts diagram and assembly drawing: (Maximum cable length:

10m (32.79feet)).

(a) Connection diagram

XD0

XD1

XD2

XD3

XD4

XD5

XD6

XD7

XSCN0

YD0

DC12/24V

None

FG

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

YD1

YD2

YD3

YD4

YD5

YD6

YD7

YD10

YD11

YD12

YD13

YD14

YD15

YD8

YD9

None

20B

20A

19B

19A

18B

18A

17B

17A

16B

16A

15B

15A

14B

14A

13B

13A

12B

12A

11B

11A

10B

10A

9B

8B

8A

7B

7A

6B

6A

5B

5A

4B

4A

3B

3A

2B

2A

1B

1A

9A

XD0

XD1

XD2

XD3

XD4

XD5

XD6

XD7

XSCN0

YD0

None

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

YD1

YD2

YD3

YD4

YD5

YD6

YD7

YD10

YD11

YD12

YD13

YD14

YD15

YD8

YD9

None

None

Original operator

panel side

Shield

External I/O

unit side

Pin

number

Signal

name

Pin

number

Signal

name

DC12/24V

DC12/24V

0V

0V

24V

24V

24V

0V

0V

B4

A4

B3

A3

B2

A2

B1

A1

B8

A8

B7

A7

B6

A6

B5

A5

A9

B9

A10

B10

A11

B11

A12

A13

B13

A14

B14

A15

B15

A16

B16

A17

B17

A18

B18

A19

B19

A20

B20

B12

Page 18

12

(b) Parts list

Number Name Type Maker

1) 2) Connector (with cover) A6CON1

Mitsubishi

Electric

1) Connector FCN-361JO40-AU

2) Connector cover FCN-360CO40-B

Fujitsu

3) Pair shielded cable UL 2464 AWG26 or equivalent

4) FG wire UL 1015 AWG14 or equivalent

(c) Assembly

1) 2) 3)4) 1) 2)

POINT

"

The cable fabricated should be within 3m in length .

"

Connect the FG cable to the nearest ground

"

The grounding wire (green wire, approx. 1m) coming out of the connector of

the user-fabricated connection cable must be connected to the control box

or the like.

"

Grounding should be independent where possible.

"

Use class D grounding (class 3 grounding) method (grounding resistance is

100 Ω max.).

"

The grounding point should be as near as possible to the external I/O

module to minimize the grounding cable length.

"

Adjust the grounding cable length according to the grounding position and

install a terminal or the like for grounding.

"

When grounding, always connect the FG cable for connection with the GOT

’s power supply terminal block and the FG wire of the user-fabricated

connection cable separately.

Page 19

13

5.2 Wring diagrams

(1) Wiring diagram for use between external I/O unit and connector terminal

block conversion unit

(a) For use of the connector terminal block conversion unit (A6TBY36-E)

XD0

XD1

XD2

XD3

XD4

XD5

XD6

XD7

XSCN0

YD0

DC12/24V

FG

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

YD1

YD2

YD3

YD4

YD5

YD6

YD7

YD10

YD11

YD12

YD13

YD14

YD15

YD8

YD9

B4

A4

B3

A3

B2

A2

B1

A1

B5

A5

B6

A6

B7

A7

B8

A8

B9

A9

B10

A10

B11

A11

B12

A12

B13

A13

B14

A14

B15

A15

B16

A16

B17

A17

B18

A18

B19

A19

B20

A20

0 2 4 6 8 A C E

24V

1 3 5 7 9 B D F 0V

10 12 14 16 18 1A 1C 1E

24V

11 13 15 17 19 1B 1D 1F 0V

A6TBY36-E

A8GT-70KBF

Shield

Empty

Empty

Cable for connection

between external

I/O unit and

connector terminal block

conversion unit

DC12/24V

DC12/24V

0V

0V

B4

A4

B3

A3

B2

A2

B1

A1

B8

A8

B7

A7

B6

A6

B5

A5

A9

B9

A10

B10

A11

B11

A12

A13

B13

A14

B14

A15

B15

A16

B16

A17

B17

A18

B18

A19

B19

A20

B20

B12

Page 20

14

(b) For use of the connection terminal block conversion unit (A6TBY54-E)

XD0

XD1

XD2

XD3

XD4

XD5

XD6

XD7

XSCN0

YD0

DC12/24V

Empty

FG

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

YD1

YD2

YD3

YD4

YD5

YD6

YD7

YD10

YD11

YD12

YD13

YD14

YD15

YD8

YD9

0V

0V

B4

A4

B3

A3

B2

A2

B1

A1

B5

A5

B6

A6

B7

A7

B8

A8

B9

A9

B10

A10

B11

A11

B12

A12

B13

A13

B14

A14

B15

A15

B16

A16

B17

A17

B18

A18

B19

A19

B20

A20

0 2 4 6 8 A C E

1 3 5 7 9 B D F

24V

10 12 14 16 18 -C 1C 1E

11 13 15 17 19 -C 1D 1F

24V

A6TBY54-E

A8GT-70KBF

Cable for connection

between external

I/O unit and

connection terminal block

conversion unit

-C

-C

-C

-C

-C

-C

0V-C

-C

-C

-C

-C

1A

1B

-C

-C

-C

-C

0V-C

Empty

Shield

DC12/24V

DC12/24V

B4

A4

B3

A3

B2

A2

B1

A1

B8

A8

B7

A7

B6

A6

B5

A5

A9

B9

A10

B10

A11

B11

A12

A13

B13

A14

B14

A15

B15

A16

B16

A17

B17

A18

B18

A19

B19

A20

B20

B12

Page 21

15

(2) Connection of external inputs and external outputs to the connector

terminal block conversion unit.

(a) For use of the connector terminal block conversion unit (A6TBY36-E)

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

38

30

28

20

18

10

08

0

XD0

39

31

29

21

19

11

09

01

XD1

3A

32

2A

22

1A

12

0A

02

XD2

3B

33

2B

23

1B

13

0B

03

XD3

3C

34

2C

24

1C

14

0C

0C

XD4

3D

35

2D

25

1D

15

0D

05

XD5

3E

36

2E

26

1E

16

0E

06

XD6

3F

37

2F

27

1F

17

0F

07

XD7

3 4 5 6 71 2

10 11 12 13 14 15 16 17 18 19 1A

XSCN0

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

A6TBY36-E

9 A B C D E F

1B 1C 1D 1F1E 24V 0V

DC12/24V

8

00

User-fabricated original operator panel

Loads:Lamps,relays,etc.

Page 22

16

(b) For use of the terminal block conversion unit (A6TBY54-E)

38

30

28

20

18

10

08

0

XD0

39

31

29

21

19

11

09

01

XD1

3A

32

2A

22

1A

12

0A

02

XD2

3B

33

2B

23

1B

13

0B

03

XD3

3C

34

2C

24

1C

14

0C

0C

XD4

3D

35

2D

25

1D

15

0D

05

XD5

3E

36

2E

26

1E

16

0E

06

XD6

3F

37

2F

27

1F

17

0F

07

XD7

3 4 5 6 71 2-C -C -C -C

10 11

8

12 13 14 15 16 17 18 19 1A-C -C -C -C -C -C 1B 1C 1D

XSCN0

XSCN1

XSCN2

XSCN3

XSCN4

XSCN5

XSCN6

XSCN7

A6TBY54-E

9 A-C -C B C D E-C -C F -C

1F1E-C -C -C 24V 0V

DC12/24V

00

User-fabricated original operator panel

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Loads:Lamps,relays,etc.

Page 23

17

6. Pates Identification

A8GT-50KBF

2)

4) 2)

1)

3)

No. Name Description

1)

I/O cable connection

interface

Interface for connection of the I/O cable

2) Unit fixing screws Screws used to fix the unit to the GOT

3) Connector

Connector used to plug the unit to the

GOT.

4) Rating plate

Page 24

18

7. Installation Procedure

Install the unit to the GOT in the following procedure:

(1) Thread External I/O unit mounting screw holes in the control box or the

like. (2-φ3.5 mounting holes)

The External I/O unit’s GOT connection cable is 50cm long.

Install the External I/O unit within this distance so that the GOT-end

connector of the cable may be fitted into the GOT’s connector.

When mounting the External I/O unit on the back of control box door,

exercise care to avoid screw holes passing through the control box

surface.

(2) Tighten the mounting screws to the specified torque range 39 to 59N.cm.

(3) Plug the GOT side connector of the External I/O unit to the option unit of

the GOT.

To remove the unit, reverse the installation procedure.

Page 25

19

8. Outline Dimension Drawing

3.2

(0.13)

A8GT-50KBF

42.6 (1.68)

65 (2.56)

3.5 (0.14)

73 (2.87)

92 (3.62)

44 (1.73)

105 (4.13)

500 (19.69)

67.8 (2.67)

9.5

(0.37)

MITSUBISHI

Unit: mm (inch)

Page 26

20

Page 27

21

Page 28

Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be the cause of

Mitsubishi; machine damage or lost profits caused by faults in the Mitsubishi products;

damage, secondary damage, accident compensation caused by special factors

unpredictable by Mitsubishi; damages to products other than Mitsubishi products; and to

other duties.

For safe use

" This product has been manufactured as a general-purpose part for general industries,

and has not been designed or manufactured to be incorporated in a device or system

used in purposes related to human life.

" Before using the product for special purposes such as nuclear power, electric power,

aerospace, medicine or passenger movement vehicles, consult with Mitsubishi.

" This product has been manufactured under strict quality control. However, when installing

the product where major accidents or losses could occur if the product fails, install

appropriate backup or failsafe functions in the system.

U.S.A Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway Vernon

Hills, IL 60061

Tel : +1-847-478-2100

Brazil MELCO-TEC Rep. Com.e Assessoria

Tecnica Ltda.

AV. Paulista 1471, Conj. 308,

Sao Paulo City, Sao Paulo State,

Brazil

Tel : +55-11-283-2423

Germany Mitsubishi Electric Europe B.V. German

Branch

Gothaer Strasse 8 D-40880 Ratingen,

GERMANY

Tel : +49-2102-486-0

U.K Mitsubishi Electric Europe B.V. UK

Branch

Travellers Lane, Hatfield, Herts., AL10

8XB,UK

Tel : +44-1707-276100

Italy Mitsubishi Electric Europe B.V. Italian

Branch

Centro Dir. Colleoni, Pal. Perseo-Ingr.2

Via Paracelso 12, 20041 Agrate B.,

Milano, Italy

Tel : +39-039-6053344

Spain Mitsubishi Electric Europe B.V. Spanish

Branch

Carretera de Rubi 76-80

08190 - Sant Cugat del Valles,

Barcelona, Spain

Tel : +34-93-565-3131

France Mitsubishi Electric Europe B.V. French

Branch

25 Boulevard des Bouvets, F-92741

Nanterre Cedex, France

TEL: +33-1-5568-5568

South Africa Circuit Breaker Industries LTD.

Tripsw itc h Driv e, El an ds fon tei n Ga uten g,

South Africa

Tel : +27-11-928-2000

Hong Kong Ryoden Automation Ltd.

10th Floor, Manulife Tower, 169 Electric

Road, North Point, HongKong

Tel : +852-28 87-8 870

China Ryoden Automation Shanghai Ltd.

3F Block5 Building Automation

Instrumentation Plaza 103 Cao Bao Rd.

Shanghai 200233 China

Tel : +86-21-6475-3228

Taiwan Setsuyo Enterprise Co., Ltd.

6F., No.105 Wu-Kung 3rd.RD, Wu-Ku

Hsiang, Taipei Hsine, Taiwan

Tel : +886-2-2299-2499

Korea HAN NEUNG TECHNO CO.,LTD.

1F Dong Seo Game Channel Bldg.,

660-11, Deungchon-dong Kangsec-ku,

Seoul, Korea

Tel : +82-2-3660-9552

Singapore Mitsubishi Electric Asia Pte, Ltd.

307 ALEXANDRA ROAD #05-01/02,

MITSUBISHI ELECTRIC BUILDING

SINGAPORE 159943

Tel : +65-6473-2308

Thailand F. A. Tech Co.,Ltd.

898/28,29,30 S.V.City Building,Office

Tower 2,Floor 17-18 Rama 3 Road,

Bangkpongpang, Yannawa,

Bangkok 10120

Tel : +66-2-682-6522

Indonesia P.T. Autoteknindo SUMBER MAKMUR

Jl. Muara Karang Selatan Block A Utara

No.1 Kav. No.11 Kawasan Industri/

Pergudangan Jakarta - Utara 14440

Tel : +62-21-663-0833

India Messung Systems Put,Ltd.

Electronic Sadan NO:111 Unit No15,

M.I.D.C BHOSARI,PUNE-411026

Tel : +91-20-712-2807

Australia Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, PostalBag, No 2,

Rydalmere, N.S.W 2116, Australia

Tel : +61-2-9684-7777

Country/Region Sales office/Tel

When exported from Japan, this manual does not require application to the Ministry

of Economy, Trade and Industry for service transaction permission.

Specifications subject to change without notice.

Printed in Japan on recycled paper.

HEAD OFFICE : 1-8-12, OFFICE TOWER Z 14F HARUMI CHUO-KU 104-6212, JAPAN

NAGOYA WORKS : 1-14, YADA-MINAMI 5-CHOME, HIGASHI-KU, NAGOYA, JAPAN

Country/Region Sales office/Tel

Loading...

Loading...