Mitsubishi 700, A7NETH-2P Instruction Manual

INVERTER

Ethernet multiprotocol communication interface

REGISTER NUMBERING

PRE-OPERATION INSTRUCTIONS

INSTALLATION

CONFIGURATION STUDIO

INVERTER SETTINGS

WEB SERVER

FILESYSTEM

FIRMWARE

3 2 1 4 6 7 8

5

Plug-in option

A7NETH-2P

INSTRUCTION MANUAL

November 2017

A-1

Thank you for c hoosing this inverter plug-i n optio n for t he

This section pertains specifically to safety

issues

Do not attempt to install, operate, maintain or inspect this

personnel safety.

WARNING

• Do not open the front cover of the inverter while power is on

heavy loads or pinching.

WARNING

CAUTION

Mitsubishi 700 Series Inverter. This instruction manual

provides handling information and precautions for use of this

equipment. Incorrect handling may cause unexpected failures

or damage. In order to ensure optimal performance, please

read this manual carefully prior to use of the equipment.

Please forw ard this manual to the end user of the equipment.

product until you have read through this instruction manual and

any related documents carefully, and can use the equipment

properly. Do not use this product until you have a full working

knowledge of the equipment, safety information and

instructions. In this instruction manual, the safety instruction

levels are classified into "WARNING" and "CAUTION" levels.

Please note that even the level may lead to

serious consequence depending on conditions. Please be sure

to follow the instructions of both levels as they are critical to

Assumes that incorrect handling

may cause hazardous conditions

resulting in death or severe injury.

Assumes that incorrect handling

may cause hazardous conditions

resulting in moderate or slight

injury, or may cause physical

damage only.

SAFETY INSTRUCTIONS

1. Electrical Shock Prevention

or while the inverter is running, as an electrical shock may

result.

• Do not operate the inverter with the front cover or wiring cover

removed, as accidental contact with exposed high-voltage

terminals and internal components may occur, resulting in an

electrical shock.

• If power is off, do not remove the front cover except when

necessary for wiring or periodic inspection. While the front

cover is removed, accidental contact with exposed highvoltage terminals and internal components may occur,

resulting in an electrical shock.

• Prior to starting wiring or inspection, confirm that input power

to the inverter has been switched off via observation of the

inverter’s display panel. Additionally, wait for at least 10

minutes after removal of input power, and then confirm that all

residual voltage has been dissipated by using a voltage meter.

Internal DC bus capacitors may contain high voltages for

several minutes after removal of input power, resulting in a

dangerous situation should anything come into contact with

them.

• All personnel involved in the installation or inspection of this

equipment should be fully competent to perform the required

work.

• Always install plug-in options prior to wiring main power.

• Do not touch the plug-in option with wet hands.

• Do not subject the cables to scratches, excessive stress,

A-2

2. Inj ury Prevention

CAUTION

• To prevent explosions or similar damage, apply only the

removed.

CAUTION

• Do not install or operate the plug-in option if it is damaged or

the inverter.

CAUTION

• To prevent unexpected equipment movement, confirm and

adjust all required parameters prior to starting operation.

WARNING

• Do not modify the equipment.

instructed to do so in this manual.

CAUTION

• Performing a “parameter clear” or “all parameter clear” will

a grounded piece of metal prior to touching any equipment.

CAUTION

• Do not perform hi-pot tests on the equipment.

CAUTION

• Contact the local or state environmental agency in your area

packaging.

For clarity purposes, illustrations in this manual may be drawn

safety guards are properly installed prior to starting operation.

3) Usage

voltages specified in the instruction manual to each terminal.

• To prevent explosions or similar damage, ensure that all

cables are properly connected to the correct terminals.

• To prevent explosions or similar damage, observe all wiring

polarity indicators.

• To prevent burns from hot components, do not touch the

inverter while power is on, or for some time after power is

3. Additional Instructions

Please note the follow ing points to prevent equipment

damage, inj ury or electrical shock.

1) Transportation and Mounting

has parts missing.

• Do not stand on or rest heavy objects on the equipment.

• Check that the mounting orientation is correct.

• Prevent conductive items such as screws and metal

fragments, or flammable substances such as oil from entering

2) Trial Run

• Do not remove any inverter or option parts unless specifically

reset all inverter parameters to their factory default settings.

After performing one of these operations, remember to reenter

any custom parameter values prior to starting operation.

• To prevent damage from electrostatic discharge, always touch

4) Maintenance, Inspection and Parts Replacement

5) Disposal

for details on the disposal of electrical components and

6) General Instructions

with covers or safety guards removed. Ensure all covers and

I

−

CONTENTS −

1 PRE-OPERATION INSTRUCTIONS 1

1.1 Product Overview ................................................................................................................. 1

1.2 Features and Specifications ................................................................................................ 3

1.3 Inverter Compatibility ......................................................................................................... 18

1.4 Unpacking and Product Confirmation .............................................................................. 20

1.4.1 Shipment Confirmation............................................................................................................................. 20

1.4.2 Component Overview .............................................................................................................................. 22

1.5 LED Indicators .................................................................................................................... 23

1.5.1 Port Status LED Description .................................................................................................................... 23

1.5.2 Standard LED Description ........................................................................................................................ 24

1.5.3 EtherCAT LED Description ...................................................................................................................... 25

2 INSTALLATION 27

2.1 Pre-Installation Instructions .............................................................................................. 27

2.2 A700 & F700 Installation Procedure .................................................................................. 29

2.2.1 Installation of the Communication Option LED Display Cover .................................................................. 29

2.2.2 Installation of the Communication Option on Control Board ..................................................................... 30

II

2.3 E700 Installation Procedure............................................................................................... 32

2.4 Wiring .................................................................................................................................. 33

3 INVERTER SETTINGS 34

3.1 Network Setting .................................................................................................................. 35

3.2 Operation Mode Setting ..................................................................................................... 37

3.2.1 Operation Mode Indication ....................................................................................................................... 37

3.2.2 Operation Mode Switching & Comm. Startup Mode (Pr. 79, Pr. 340) ......................................................... 38

3.3 Operation & Speed Command Source (Pr. 338, Pr. 339, Pr. 550) ...................................... 42

3.4 Communication EEPROM Write Selection (Pr. 342) ......................................................... 46

4 REGISTER NUMBERING AND BEHAVIOR 47

4.1 Register Numbers ............................................................................................................... 47

4.2 Scanned Registers ............................................................................................................. 50

4.3 Inverter Command Register............................................................................................... 52

4.4 Frequency Command Register .......................................................................................... 53

4.5 Operation Mode Register ................................................................................................... 54

4.6 Inverter Reset Register ...................................................................................................... 54

III

4.7 Alarm History Clear Register ............................................................................................. 55

4.8 All Parameter Clear Register ............................................................................................. 55

4.9 Inverter Status Register ..................................................................................................... 56

4.10 Operation Mode Status Register ....................................................................................... 57

4.11 Alarm History Codes .......................................................................................................... 57

5 MITSUBISHI CONFIGURATION STUDIO 58

5.1 Overview.............................................................................................................................. 58

5.2 General Object Editing Activities ...................................................................................... 63

5.3 Ethernet Settings ................................................................................................................ 66

5.3.1 Authentication .......................................................................................................................................... 66

5.3.2 Network Configuration.............................................................................................................................. 67

5.4 Internal Logic Settings ....................................................................................................... 67

5.4.1 Fail-safe Values ....................................................................................................................................... 67

5.4.1.1 Overview ....................................................................................................................................... 67

5.4.2 Timeout Time ........................................................................................................................................... 68

5.4.2.1 Timeout Object Configuration ........................................................................................................ 68

5.5 Discovery over Ethernet .................................................................................................... 70

5.6 Manage Device Parameters ............................................................................................... 71

IV

5.7 Backup and Restore Parameters ...................................................................................... 73

5.8 Restore Factory Settings ................................................................................................... 76

5.9 Diagnostic Object ............................................................................................................... 76

5.10 Help ...................................................................................................................................... 77

6 EMBEDDED WEB SERVER 78

6.1 Overview.............................................................................................................................. 78

6.2 Monitor Tab ......................................................................................................................... 80

6.2.1 Information Window ................................................................................................................................. 80

6.2.2 Parameter Group Selection List ............................................................................................................... 80

6.2.3 Parameter List.......................................................................................................................................... 81

6.2.4 Parameter List Filter ................................................................................................................................. 83

6.2.5 Radix Selection ........................................................................................................................................ 83

6.3 Dashboard Tab ................................................................................................................... 85

6.3.1 Information Window ................................................................................................................................. 86

6.3.2 Gauge Window Navigation ....................................................................................................................... 86

6.3.3 Gauge Window Configuration .................................................................................................................. 87

6.3.4 Submitting Changes ................................................................................................................................. 92

6.4 Customizing the Embedded Web Server .......................................................................... 93

6.4.1 Customization Overview .......................................................................................................................... 93

V

6.4.2 XTPro Overview ....................................................................................................................................... 94

6.4.3 XTPro Web Browser-Based Implementation ............................................................................................ 94

6.4.4 XTPro HMI-Based Implementation ........................................................................................................... 96

6.4.5 XTPro Supported Commands .................................................................................................................. 97

7 FILESYSTEM 98

7.1 Overview.............................................................................................................................. 98

7.2 USB with Windows Explorer .............................................................................................. 99

7.3 FTP With Windows Explorer ............................................................................................ 100

7.4 Loading New Web Server Content .................................................................................. 102

8 FIRMWARE 103

8.1 Overview............................................................................................................................ 103

8.2 Update Procedure ............................................................................................................. 103

9 PROTOCOL-SPECIFIC INFORMATION 105

9.1 Modbus/TCP Server ......................................................................................................... 105

9.1.1 Overview ................................................................................................................................................ 105

9.1.2 Holding & Input Registers ...................................................................................................................... 106

9.1.3 Coil & Discrete Input Mappings .............................................................................................................. 107

VI

9.1.4 Connection Timeout Options .................................................................................................................. 108

9.1.5 Node Settings ........................................................................................................................................ 110

9.1.6 Holding/Input Register Remap Settings ................................................................................................. 110

9.2 EtherNet/IP Server ............................................................................................................ 112

9.2.1 Overview ................................................................................................................................................ 112

9.2.2 Server Settings ...................................................................................................................................... 114

9.2.3 Connection Timeout Options .................................................................................................................. 114

9.2.4 Generic Class 1 I/O Produced and Consumed Data Settings ................................................................ 116

9.2.5 Generic Class 1 (I/O) Connection Access .............................................................................................. 118

9.2.6 AC/DC Drive Profile Class 1 (I/O) Connection Access ........................................................................... 118

9.2.7 Explicit Messaging Via Get/Set Attribute Single Services....................................................................... 125

9.2.8 Explicit Messaging Via Data Table Read/Write Services........................................................................ 126

9.2.9 Inverter Register Access Tag Format ..................................................................................................... 126

9.2.10 ControlLogix Examples: Setup ............................................................................................................... 128

9.2.11 ControlLogix Example: EDS Add-On Profile (AOP) ................................................................................ 129

9.2.11.1 ControlLogix Example: EDS Add-On Profile (AOP) Generic I/O Messaging ................................ 135

9.2.11.2 ControlLogix Example: EDS Add-On Profile (AOP) AC/DC Drive Profile ..................................... 138

9.2.12 ControlLogix Example: I/O Messaging ................................................................................................... 141

9.2.12.1 ControlLogix Example: Generic Default I/O Add-On Instruction................................................... 146

9.2.12.2 ControlLogix Example: AC/DC Drive Profile Add-On Instruction .................................................. 149

9.2.13 ControlLogix Example: Read Registers.................................................................................................. 153

9.2.14 ControlLogix Example: Reading and Writing Multiple MSG Instructions ................................................ 159

VII

9.3 Allen Bradley CSP (PCCC) Server ................................................................................... 162

9.3.1 Overview ................................................................................................................................................ 162

9.3.2 Explicit Messaging Via Read/Write Services .......................................................................................... 162

9.3.3 Inverter Register File Number Offset Format ......................................................................................... 163

9.3.4 SLC-5/05 Example: Read Registers ...................................................................................................... 166

9.3.5 SLC-5/05 Example: Reading and Writing ............................................................................................... 173

9.4 BACnet/IP Server .............................................................................................................. 175

9.4.1 Protocol Implementation Conformance Statement ................................................................................. 175

9.4.2 Default Supported Objects ..................................................................................................................... 185

9.4.3 Default Supported Object Details ........................................................................................................... 189

9.4.4 Server Settings ...................................................................................................................................... 193

9.4.5 Node Settings ........................................................................................................................................ 193

9.4.6 Device Object Settings ........................................................................................................................... 193

9.4.7 BACnet Object Settings ......................................................................................................................... 194

9.4.7.1 Analog Input Object Settings ....................................................................................................... 194

9.4.7.2 Analog Output Object Settings .................................................................................................... 195

9.4.7.3 Analog Value Object Settings ...................................................................................................... 196

9.4.7.4 Binary Input Object Settings ........................................................................................................ 197

9.4.7.5 Binary Output Object Settings ..................................................................................................... 199

9.4.7.6 Binary Value Object Settings ....................................................................................................... 201

9.4.7.7 Multi-state Input Object Settings .................................................................................................. 203

9.4.7.8 Multi-state Output Object Settings ............................................................................................... 203

9.4.7.9 Multi-state Value Object Settings ................................................................................................. 204

VIII

9.5 MELSEC / SLMP Server.................................................................................................... 205

9.5.1 Overview ................................................................................................................................................ 205

9.5.2 Read/W rite Commands .......................................................................................................................... 206

9.5.3 Server Settings ...................................................................................................................................... 207

9.5.4 Connection Timeout Options .................................................................................................................. 208

9.6 CC-Link IE Field Basic Server ......................................................................................... 210

9.6.1 Overview ................................................................................................................................................ 210

9.6.2 Server Settings ...................................................................................................................................... 210

9.6.3 Produced and Consumed Data Settings ................................................................................................ 211

9.7 MELSEC Client .................................................................................................................. 214

9.7.1 Overview ................................................................................................................................................ 214

9.7.2 Read/W rite Commands .......................................................................................................................... 215

9.7.3 Connection Timeout Options .................................................................................................................. 215

9.7.4 Remote Device Settings......................................................................................................................... 216

9.7.5 Command and Monitor Data Object Settings ......................................................................................... 217

9.7.6 Diagnostic Objects ................................................................................................................................. 219

9.8 SLMP Client....................................................................................................................... 220

9.8.1 Overview ................................................................................................................................................ 220

9.8.2 Read/W rite Commands .......................................................................................................................... 221

9.8.3 Connection Timeout Options .................................................................................................................. 221

9.8.4 Remote Device Settings......................................................................................................................... 222

IX

9.8.5 Command and Monitor Data Object Settings ......................................................................................... 223

9.8.6 Diagnostic Objects ................................................................................................................................. 225

9.9 PROFINET IO ..................................................................................................................... 226

9.9.1 Overview ................................................................................................................................................ 226

9.9.2 Device Settings ...................................................................................................................................... 227

9.9.3 Connection Timeout Options .................................................................................................................. 227

9.9.4 Cyclic I/O Produced and Consumed Data Access Settings.................................................................... 228

9.9.5 PROFIdrive Profile ................................................................................................................................. 231

9.9.5.1 PROFIdrive Standard Telegram 1 ............................................................................................... 231

9.9.5.2 PROFIdrive Control and Status Words ........................................................................................ 232

9.9.5.3 PROFIdrive Reference Speed Setpoint and Actual Speed .......................................................... 236

9.9.5.4 PROFIdrive-Specific Parameters ................................................................................................. 239

9.9.5.5 PROFIdrive State Diagram .......................................................................................................... 240

9.9.6 Acyclic Data Access ............................................................................................................................... 241

9.9.7 TIA Portal (STEP 7) Hardware Configuration Example .......................................................................... 241

9.9.7.1 Register the GSDML File ............................................................................................................. 241

9.9.7.2 Add the Device to the Configuration ............................................................................................ 243

9.9.7.3 Select the IO Controller ............................................................................................................... 244

9.9.7.4 Assign the I/O Module ................................................................................................................. 244

9.9.7.5 Configure the Device Properties .................................................................................................. 245

9.9.7.6 Online Device Discovery and Configuration................................................................................. 248

9.9.7.7 Save the Configuration ................................................................................................................ 250

9.9.8 GE Proficy Configuration Example ......................................................................................................... 250

9.9.8.1 Register the GSDML File ............................................................................................................. 250

X

9.9.8.2 Add the Device to the Configuration ............................................................................................ 252

9.9.8.3 Configure the Device Properties .................................................................................................. 254

9.9.8.4 Save the Configuration ................................................................................................................ 255

9.10 IEC 61850 Server .............................................................................................................. 256

9.10.1 Overview ................................................................................................................................................ 256

9.10.2 Server Settings ...................................................................................................................................... 256

9.10.3 GOOSE Communication Parameters ..................................................................................................... 257

9.10.4 Generic Process I/O Status and Control Object Settings ....................................................................... 258

9.11 EtherCAT Slave ................................................................................................................. 260

9.11.1 Overview ................................................................................................................................................ 260

9.11.2 Device Settings ...................................................................................................................................... 260

9.11.3 Transmit and Receive Process Data Word Settings ............................................................................... 261

10 TROUBLESHOOTING 263

PRE-OPERATION INSTRUCTIONS

1

1

1 PRE-OPERATION INSTRUCTIONS

1.1 Product Overview

The A7NETH-2P Ethernet multiprotocol communication interface allows information to be transferred

seamlessly between a 700-series inverter and several different Ethernet-based fieldbus networks with

minimal configuration requirements. The interface installs directly onto the inverter’s control board, and

presents two RJ-45 jacks with an embedded 10BASE-T/100BASE-TX Ethernet switch for connection to

the Ethernet network. In addition to the supported fieldbus protocols, the interface also hosts a fully

customizable embedded web server, which provides access to inverter information via a standard web

browser for remote monitoring and control.

Before using the interface, please familiarize yourself with the product and be sure to thoroughly read

the instructions and precautions contained in this manual. In addition, please make sure that this

instruction manual is delivered to the end user of the interface, and keep this instruction manual in a

safe place for future reference or unit inspection.

Note that different interface firmware versions may provide varying levels of support for the various

protocols. When using this manual, therefore, always keep in mind that the release date of the firmware

version running on your interface as it must match this manual’s respective release date in order for all

documented aspects to apply.

The A7NETH-2P may be referred to throughout the remainder of the manual as the device, interface,

card, and option or any combination thereof.

PRE-OPERATION INSTRUCTIONS

2

Supported Protocols

The interface currently provides support for the following fieldbus protocols:

• Modbus/TCP Server

• EtherNet/IP Server (DLR node)

• Allen Bradley CSP Server (also known as “PCCC” and “AB Ethernet”)

• BACnet/IP Server

• Mitsubishi MELSEC / SLMP Server (also known as “MC protocol”)

• CC-Link IE Field Basic Server

• Mitsubishi MELSEC Client

• SLMP Client

• PROFINET IO Device (MRP client)\

• IEC 61850 Server

• EtherCAT Slave

PRE-OPERATION INSTRUCTIONS

3

1

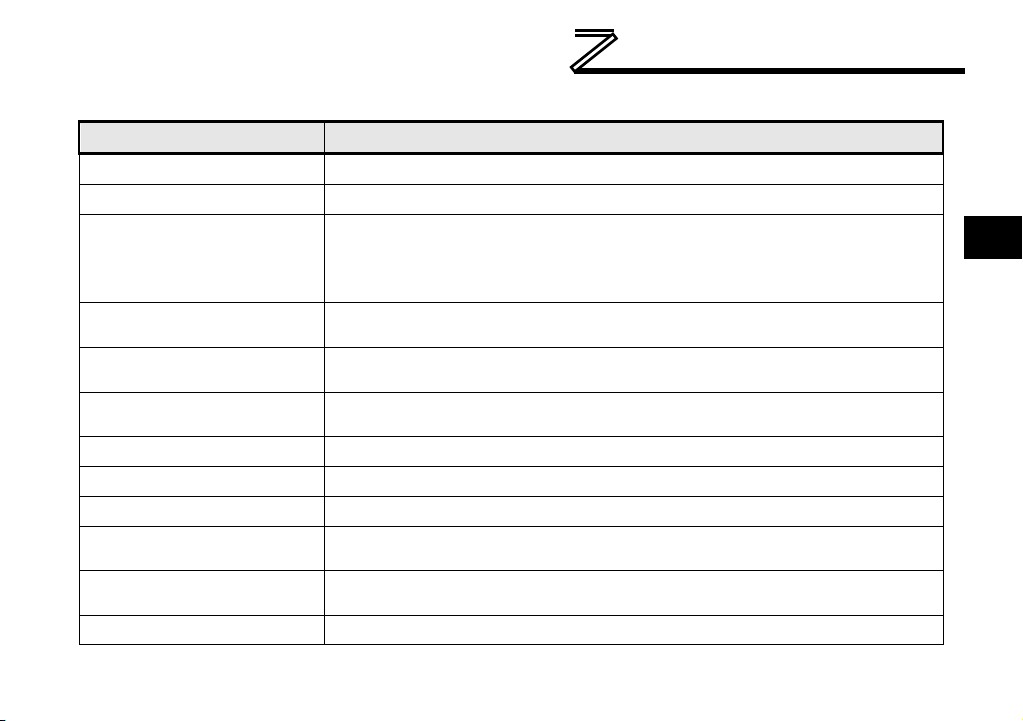

Item

Description

Supports all standard unmodified Ethernet (SUE) protocols

simultaneously

Mitsubishi Configuration

Studio

Graphical user interface for discovery, configuration, and firmware

update

Access all parameters, dashboard with gauges, customizable with

XTPro

Communication Loss

Detection

Field Upgradeable

Firmware updates automatically handled by the studio

Parameter Management

Advanced management of parameter access and scan priority

Parameter Backup and

Restore

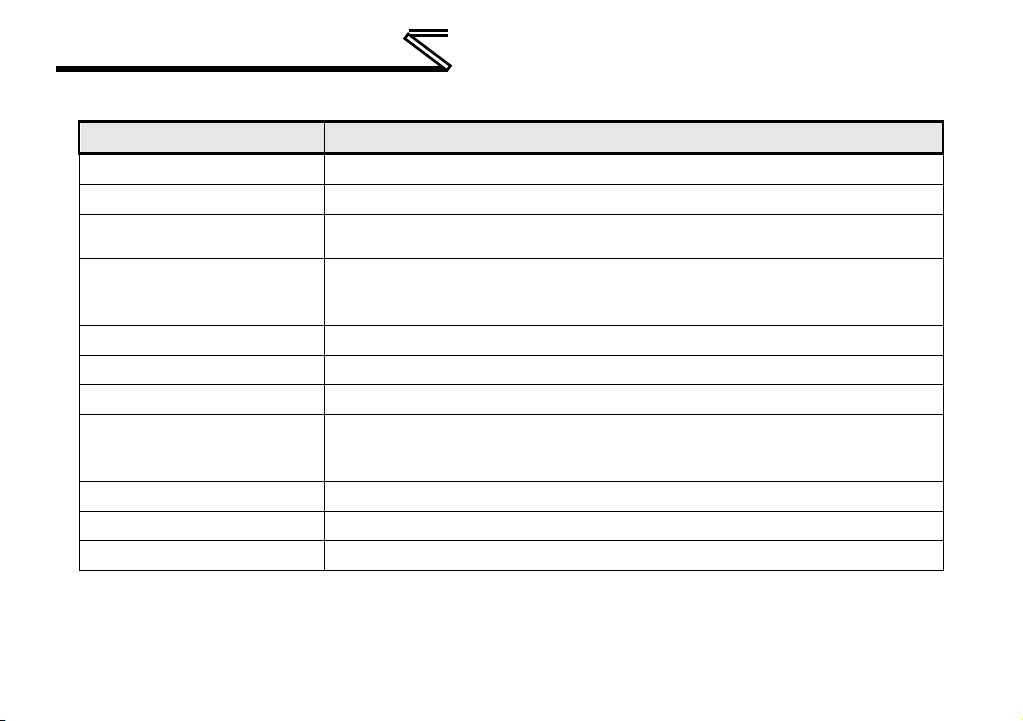

1.2 Features and Specifications

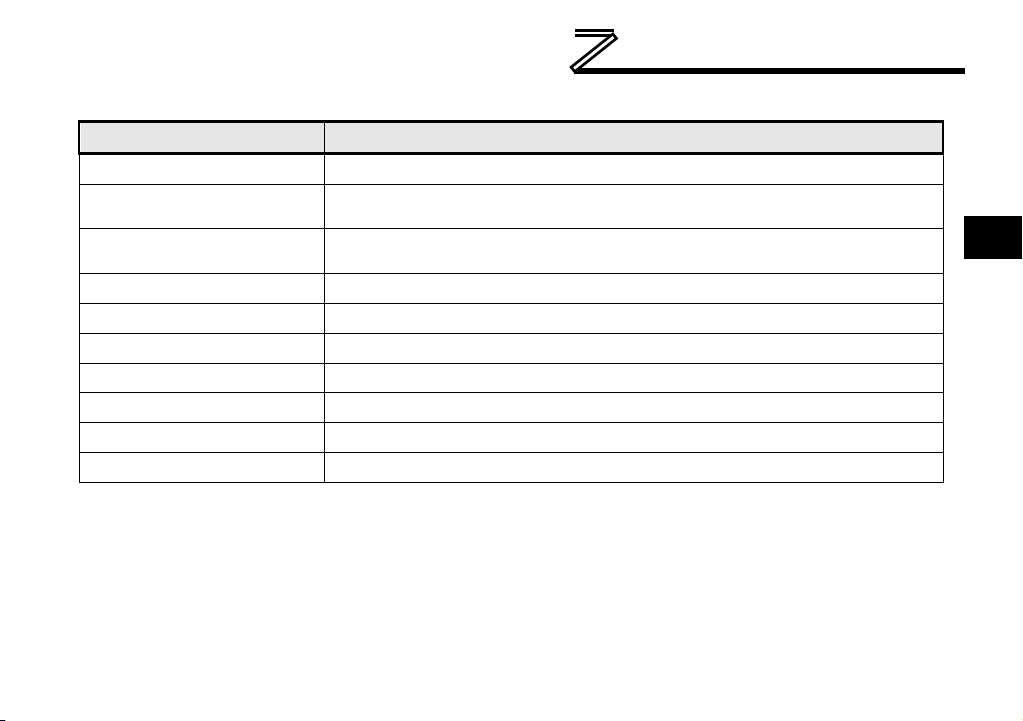

Table 1: Features

Simultaneous Protocols

WEB Server (HTTP)

Configurable actions for “fail-safe” conditions

Drive cloning

PRE-OPERATION INSTRUCTIONS

4

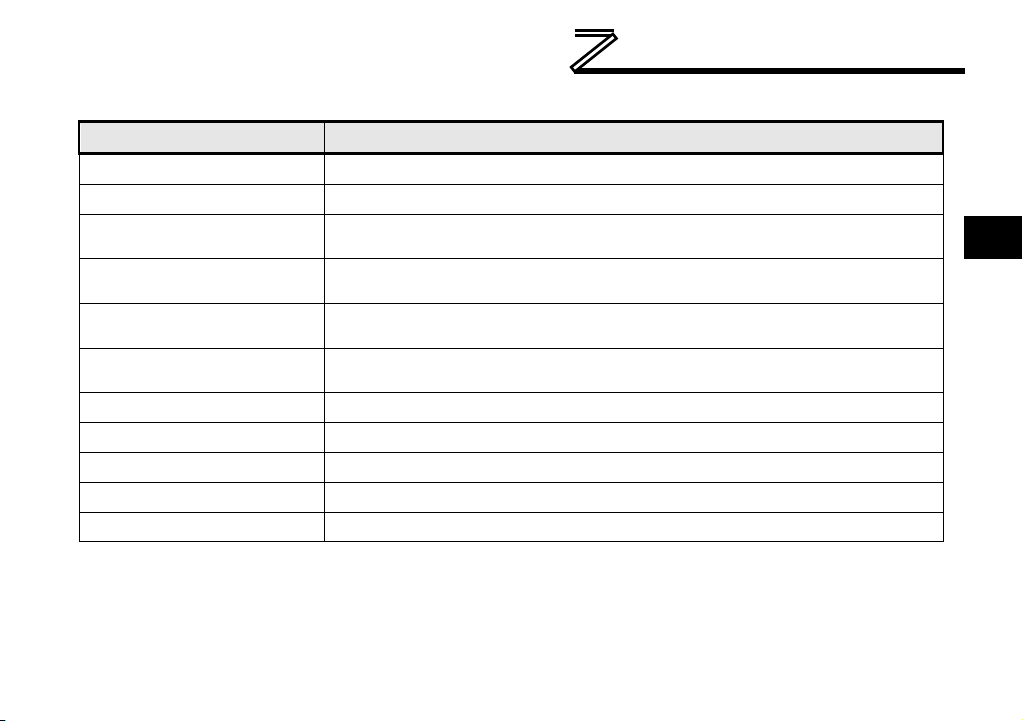

Item

Description

Power Supply

Directly powered by the inverter

Referenced to inverter’s 5V power supply / isolated from inverter

control power common

USB Port

USB 2.0, mini-B 5-pin

Item

Description

Communication Speed

and Duplex

10Mbps half/full, 100Mbps half/full (auto sense optimal speed and

duplex)

Connector Type

RJ-45 Shielded

Cable Length

100m per segment max

Table 2: General Hardware Specifications

Grounding

LED Indicators Module Status, Network Status, 2 x Ethernet Link/Activity

Table 3: Ethernet Hardware Specifications

Number of Ports 2 (internal switch)

Standard IEEE 802.3 10BASE-T/100BASE-TX Ethernet compliant

Auto MDI-X Yes (supports all straight-through and cross-over cables)

Cable Type CAT5-type 8-conductor UTP patch cables

Topologies Star/Tree, Linear/Bus/Daisy-chain, Ring (MRP / DLR)

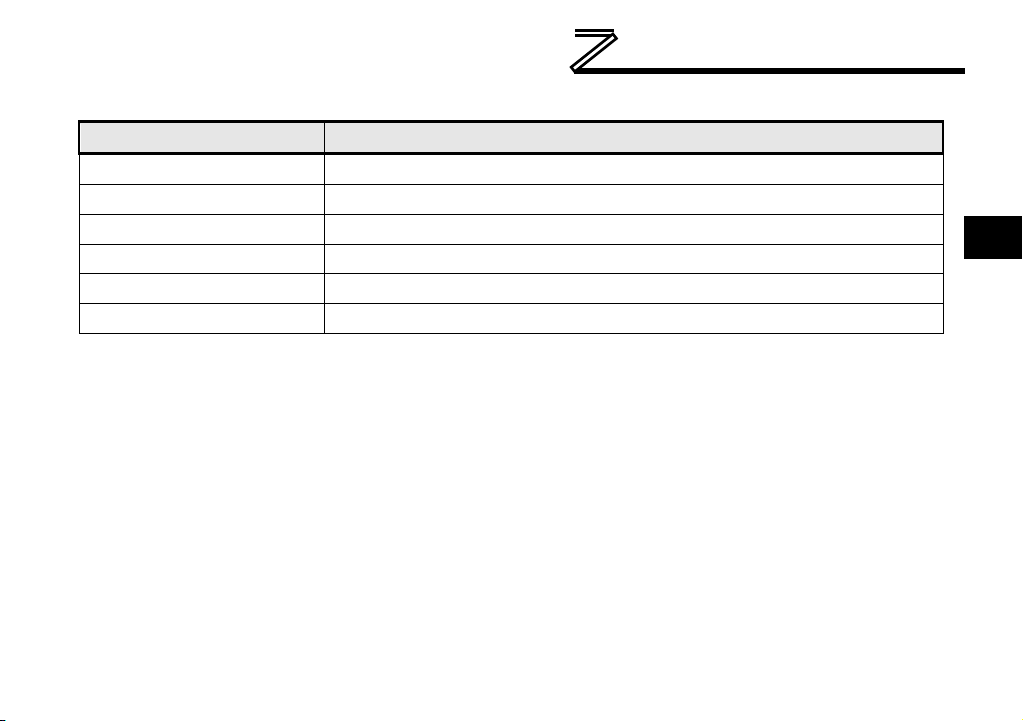

PRE-OPERATION INSTRUCTIONS

5

1

Item

Description

Conformance Class

Class 0, Class 1 (partial), Class 2 (partial)

Read coils (1), Read input status (2), Read multiple registers (3), Read

input registers (4), Diagnostics (8)

Write coil (5), Write single register (6), Force multiple coils (15), Write

multiple registers (16)

Number of Connections

8

Max Read Register Size

125 registers

Max Write Register Size

123 registers

TCP Port

502

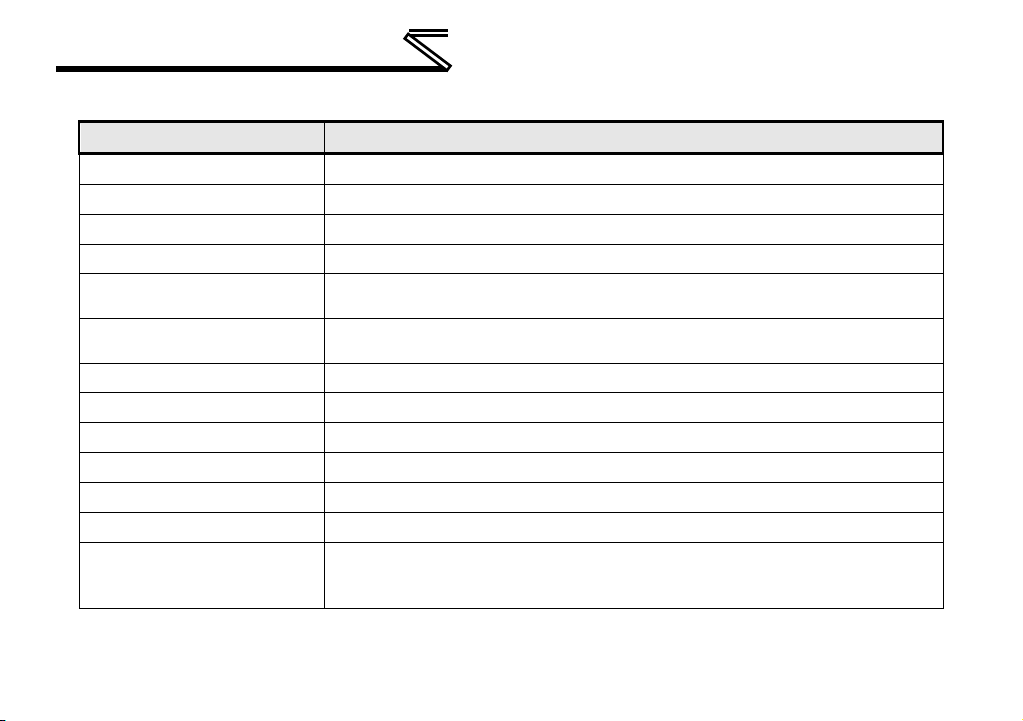

Table 4: Modbus/TCP Server Specifications

Read Function Codes

Write Function Codes

Register Data Type 16-bit integer

Unit (slave) ID Ignored, echoed in response

Response Time Min 160us, Typically less than 1ms

PRE-OPERATION INSTRUCTIONS

6

Item

Description

Conformance Tested

ODVA EtherNet/IP Conformance Test Software Version CT-13

Product Type Code

2 (AC Drive)

AC/DC Drive Profile

Yes

UCMM

Yes

Class 3 (Explicit)

Messaging

Class 1 (Implicit I/O)

Messaging

Number of Connections

16 (Total for both Class 1 and Class 3)

I/O Input Size

Max 32 input words, user configurable

I/O Output Size

Max 32 output words, user configurable

Generic (User

Instances

Table 5: EtherNet/IP Server Specifications

Yes

Yes

Class 1 Unicast T→O

Class 1 Multicast T→O

RPI Min 1ms

Configurable) Assembly

Yes

Yes

100 (input) and 150 (output)

PRE-OPERATION INSTRUCTIONS

7

1

Item

Description

AC/DC Drive Profile

Assembly Instances

Explicit Messaging

Response Time

20 (input) and 70 (output), 21 (input) and 71 (output)

Data Table Read/Write Yes

DLR Device Level Ring Node

Class 1 UDP Port 2222 (0x08AE)

Explicit Messaging Port 44818 (0xAF12)

Min 160us, Typically less than 1ms

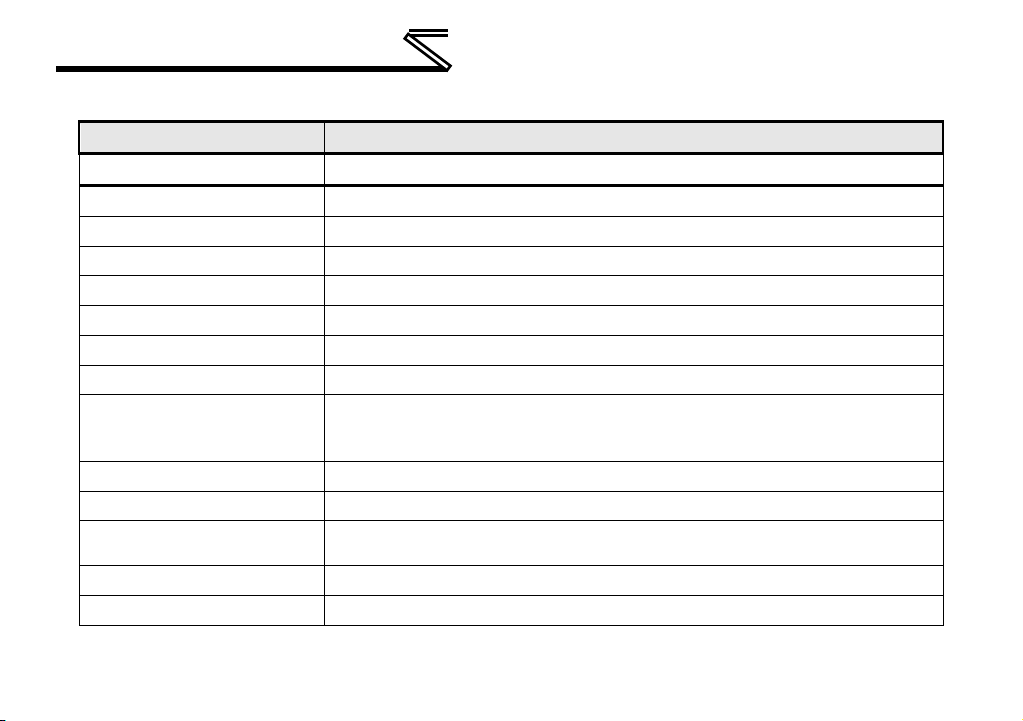

PRE-OPERATION INSTRUCTIONS

8

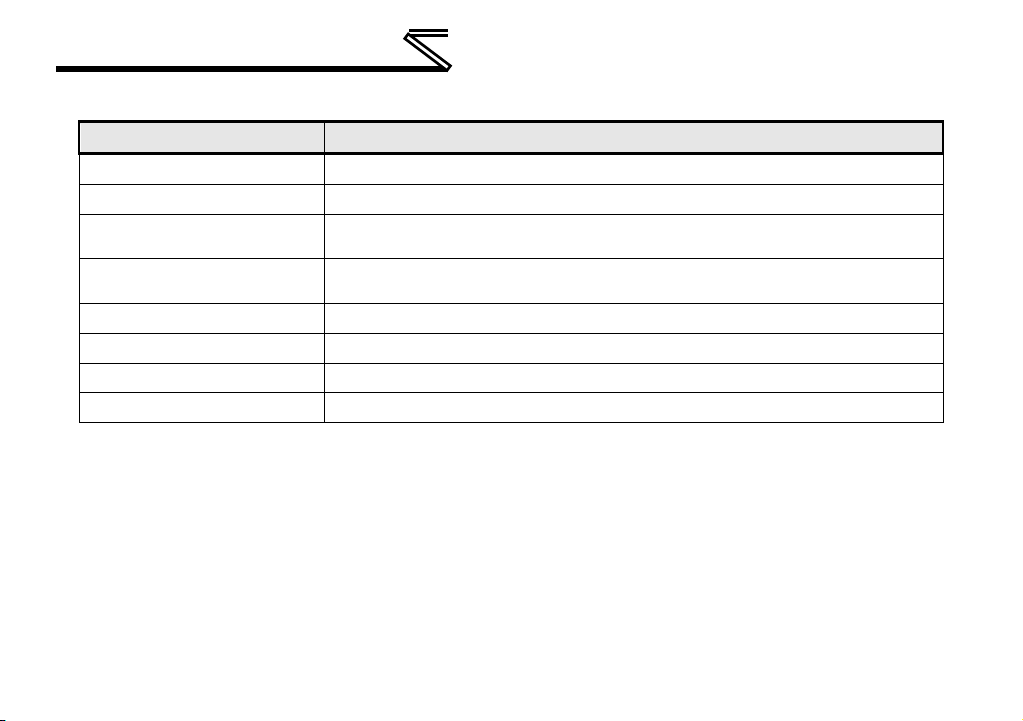

Item

Description

PLC5 Read (DF1 protocol typed read, 0x68),

with three address fields, 0xA2)

PLC5 Write (DF1 protocol typed write, 0x67),

with three address fields, 0xAA)

Logical Binary Addressing

Yes

Max Write Size

240 bytes (120 16-bit Integers)

Table 6: Allen Bradley CSP (PCCC) Server Specifications

Read Services

Write Services

Data Type 16-bit Integer

File Type N (Integer)

Logical ASCII Addressing Yes

Max Read Size 240 bytes (120 16-bit Integers)

PLC5 Word Range Read (DF1 protocol word range read, 0x01),

SLC Read (DF1 protocol protected typed logical read

PLC5 Word Range Read (DF1 protocol word range write, 0x00),

SLC Read (DF1 protocol protected typed logical write

PRE-OPERATION INSTRUCTIONS

9

1

Item

Description

Frame Types

4E (MT), 3E (ST), 1E

Transport Types

TCP/IP, UDP/IP

CPU Model Name Read (0x0101), Device Memory Batch Read

Read (0x0E44), Communication Setting Get (0x0E45)

3E/4E Frame Write

Function Codes

Device Memory Batch Write (0x1401, Word units), Device Memory

Random Write (0x1402, Word units), IP Address Set (0x0E31)

1E Frame Read Function

Codes

1E Frame Write Function

Codes

Max Read Points

724 points (varies with function code and frame type)

Max Write Points

719 points (varies with function code and frame type)

Data Register (0xA8), Link Register (0xB4), Index Register (0xCC),

File Register (0xAF and 0xB0)

Data Register (0x4420), Link Register (0x5720), File Register (0x5220

and 0x5A52)

Table 7: MELSEC MC Protocol / SLMP Server Specifications

3E/4E Frame Read

Function Codes

Number of Connections 8

3E Device Types

1E Device Types

TCP Port 2009 (Configurable)

(0x0401, Word units), Device Memory Random Read (0x0403, Word

units), Node Search (0x0E30), Device Info Compare (0x0E32), Status

Device Memory Batch Read (0x01, Word units)

Device Memory Batch Write (0x03, Word units)

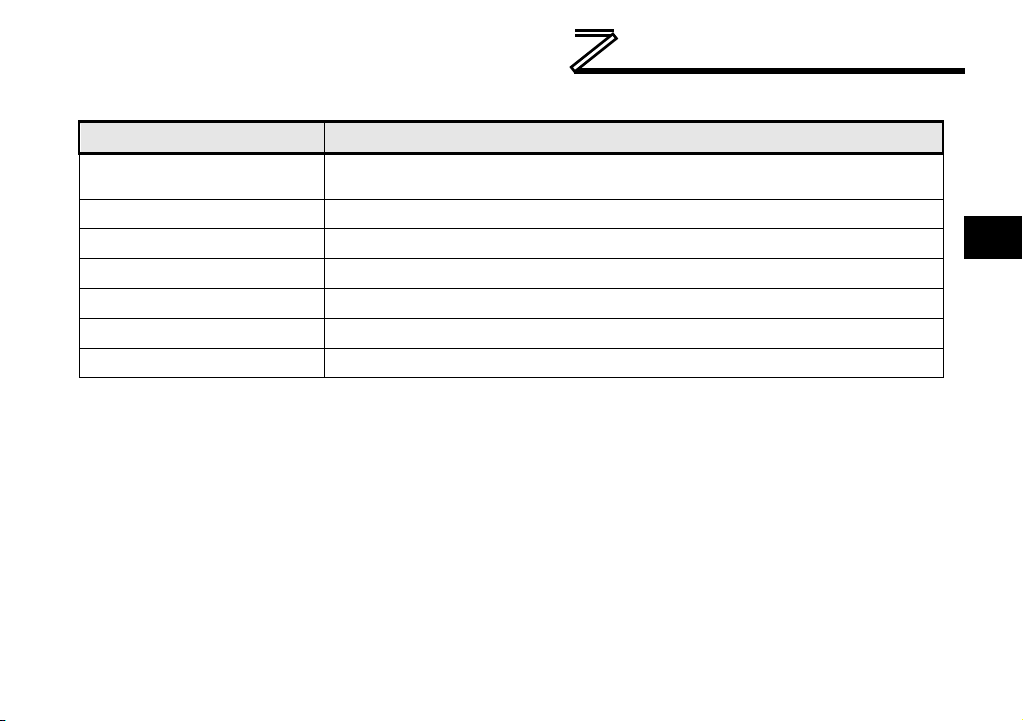

PRE-OPERATION INSTRUCTIONS

10

Item

Description

UDP Port

2009 (Configurable)

Response Time

Min 160us, Typically less than 1ms

Item

Description

RWw Cyclic Size

Max 32 command words, user configurable

RWr Cyclic Size

Max 32 status words, user configurable

UDP Port

61450

Response Time

Min 160us, Typically less than 1ms

Table 8: CC-Link IE Field Basic Server Specifications

Max Occupied Stations 1

PRE-OPERATION INSTRUCTIONS

11

1

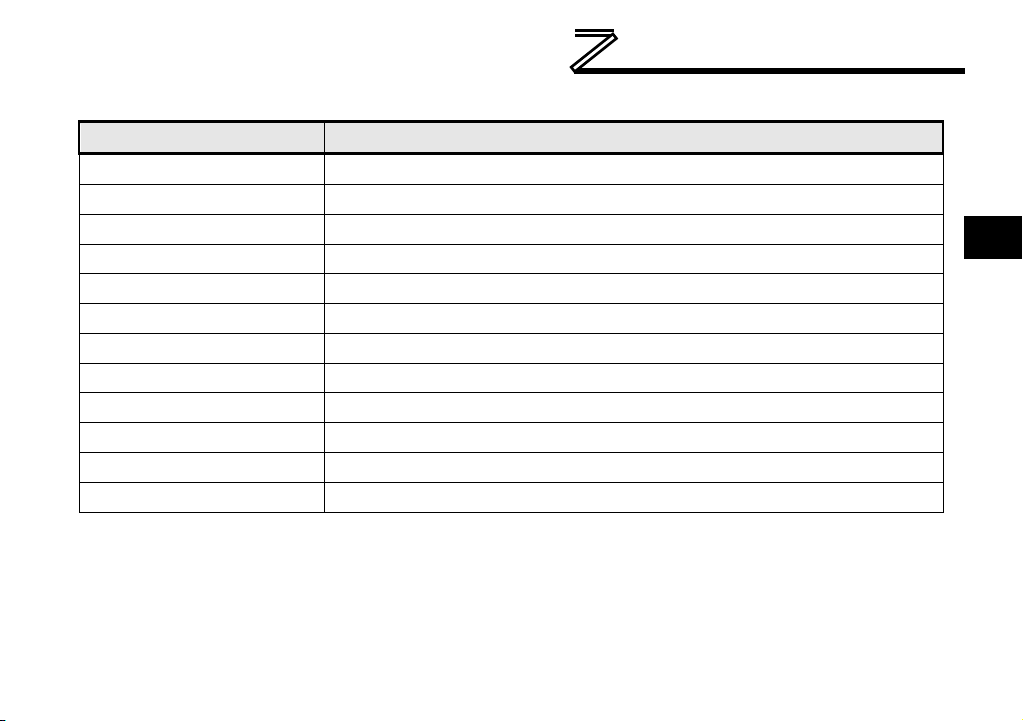

Item

Description

Frame Types

4E (MT), 3E (ST), 1E, Auto-Detect

Transport Types

TCP/IP, UDP/IP

3E/4E Frame Read

Function Codes

3E/4E Frame Write

Function Codes

1E Frame Read Function

Codes

1E Frame Write Function

Codes

Max Read Points

719 points (varies with frame type)

3E Device Types

Any

1E Device Types

Any

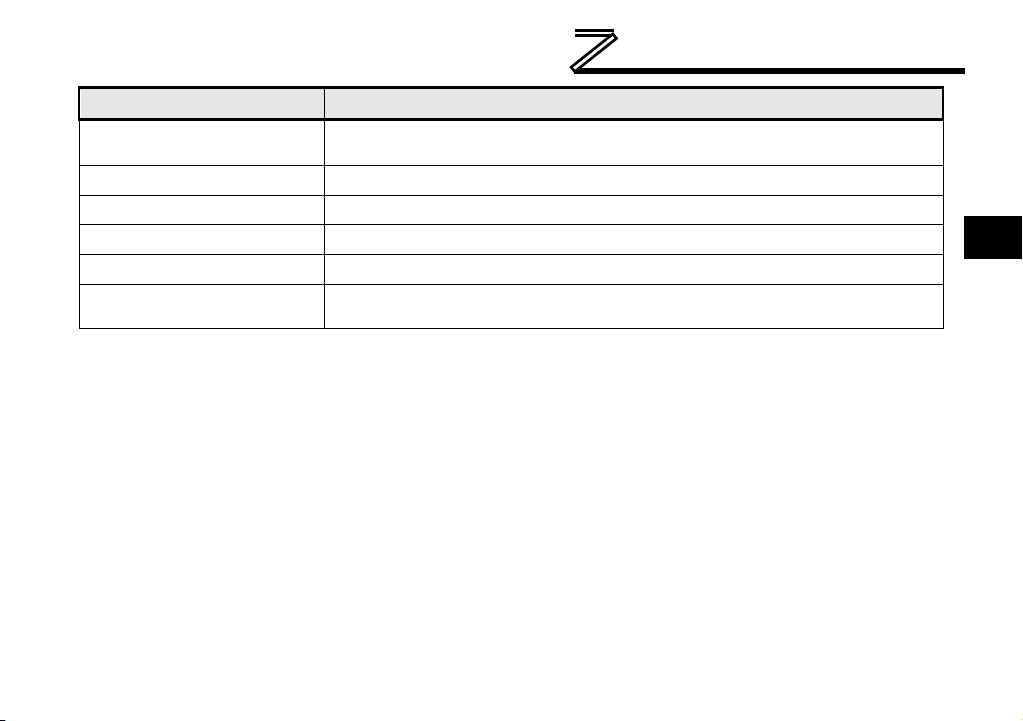

Table 9: MELSEC MC Protocol Client Specifications

Device Memory Batch Read (0x0401, Word units)

Device Memory Batch Write (0x1401, Word units)

Device Memory Batch Read (0x01, Word units)

Device Memory Batch Write (0x03, Word units)

Number of Connections 8

Max Write Points 719 points (varies with frame type)

PRE-OPERATION INSTRUCTIONS

12

Item

Description

Frame Types

4E (MT), 3E (ST), Auto-Detect

Transport Types

TCP/IP, UDP/IP

3E/4E Frame Read

Function Codes

3E/4E Frame Write

Function Codes

Number of Connections

8

Max Read Points

719 points (varies with frame type)

Table 10: SLMP Client Specifications

Device Memory Batch Read (0x0401, Word units)

Device Memory Batch Write (0x1401, Word units)

Max Write Points 719 points (varies with frame type)

3E Device Types Any

PRE-OPERATION INSTRUCTIONS

13

1

Item

Description

Protocol Level

RT (real-time)

RT Conformance Class

Class B

Netload Class

III

I/O Cycle Time

Min 1ms

I/O Input Size

Max 32 input words, user configurable

I/O Output Size

Max 32 output words, user configurable

MRP

Media Redundancy Protocol Client

I&M

I&M0

Number of Controllers

Allows access to only 1 controller

Table 11: PROFINET IO Specifications

DCP Discovery, set station name, set IP address

LLDP Yes

Alarms Plug, Pull

PRE-OPERATION INSTRUCTIONS

14

Item

Description

BACnet IP

Annex J

Protocol Revision

2

Standard Device Profile

(Annex L)

ReadProperty-B (DS-RP-B), ReadPropertyMultiple-B (DS-RPM-B),

Dynamic object Binding-B (DM-DOB-B)

Analog Output, Analog Input, Analog Value, Binary Output, Binary

Value

Priority Array

Yes

Table 12: BACnet/IP Server Specifications

BACnet Application Specific Controller (B-ASC)

BACnet Interoperability

Building Blocks (BIBB)

Segmentation Not supported

Max APDU Length 1444 bytes

Character Sets ANSI X3.4

Object Types

UDP Port 47808 (0xBAC0, configurable)

Response Time Min 160us, Typical less than 1ms

WriteProperty-B (DW-WP-B), Dynamic Device Binding-B (DM-DDB-B),

Input, Binary Value, Multi-state Output, Multi-state Input, Multi-state

PRE-OPERATION INSTRUCTIONS

15

1

Item

Description

Unbuffered Reports

Yes, writeable

GOOSE

Type 1, data set writeable

Dynamic Data Sets

Yes, maximum of 10 data sets

Generic Status Objects

100 MV (Measured Value integers)

Generic Control Objects

100 APC (Controllable Analog Process Value integers)

Authentication

None/Password, configurable

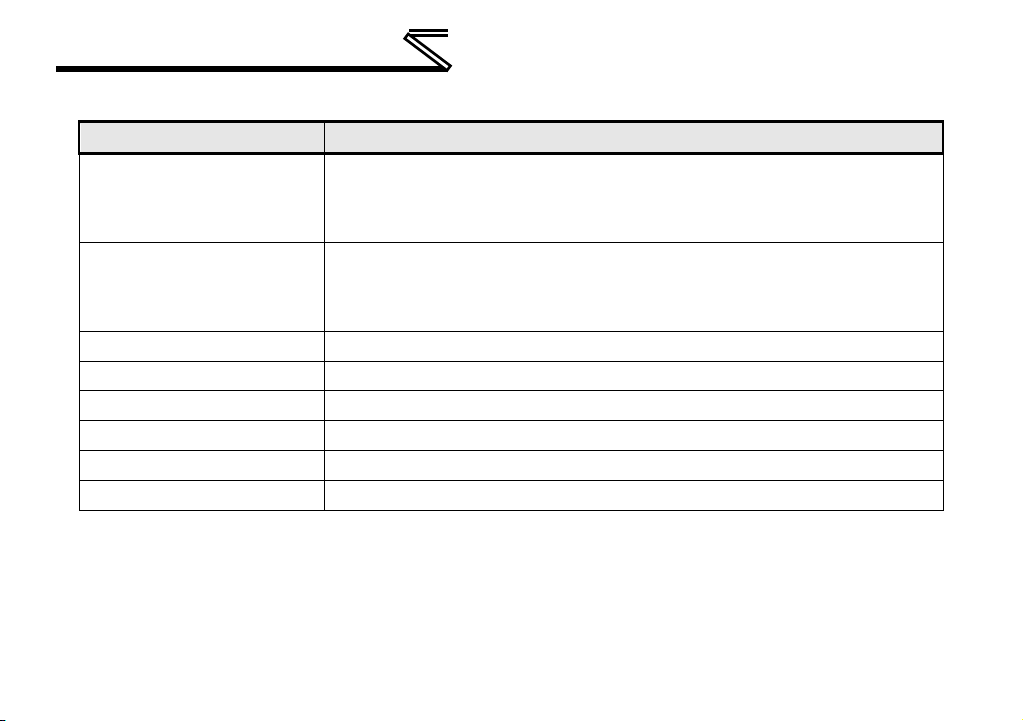

Table 13: IEC 61850 Server Specifications

PRE-OPERATION INSTRUCTIONS

16

Item

Description

Conformance Tested

EtherCAT ET9400 Conformance Test Tool V1.20.80

Source Code

Beckhoff ET9300 EtherCAT Slave Source Code (SSC) V5.10

Slave Controller

Equivalent to Beckhoff ET1100

Process I/O Transmit Size

Max 32 transmit words, user configurable

Process I/O Receive Size

Max 32 receive words, user configurable

Operating Modes

FreeRun/SM-Synchron, DC-Synchron

FreeRun Cycle Time

Min 1ms

Fieldbus Memory

(FMMU)

Sync Managers (SM)

8 max

CoE Complete Access

Support

CoE SDO Info Support

Yes

Distributed Clocks SYNC0/1

Table 14: EtherCAT Slave Specifications

Management Unit

Mailbox CoE

Latency 700ns end-to-end

8 max

Yes

PRE-OPERATION INSTRUCTIONS

17

1

Item

Specification

Indoors, less than 1000m above sea level, do not expose to direct

sunlight or corrosive / explosive gasses

Relative Humidity

20% ∼ 90% (without condensation)

Cooling Method

Self-cooled

RoHS (Lead free)

Yes

Operating Environment

Table 15: Environmental Specifications

Operating Temperature

Storage Temperature

Vibration

-10 ∼ +50°C (+14 ∼ +122°F)

-40 ∼ +85°C (-40 ∼ +185°F)

5.9m/s2 (0.6G) or less (10 ∼ 55Hz)

Loading...

Loading...