Page 1

Page 2

...

i

0

Precautions Regarding Safety

0

When using your product, please make sure that you have read this manual, as

well

as any related manuals

introduced in this manual, and that careful attention is paid to safety and

correct

handling of the equipment.

Only safety precautions which apply to this specific product have

been

noted here. For precautions pertain-

ing to the PC system, please refer to the User’s Manual provided with the CPU unit.

Safety precautions noted in this section are distinguished by

either

a “Danger” or a “Caution” mark, depend-

ing on the degree of danger involved.

I

Erroneous handling could result in hazardous conditions and could

I

I

I

I

I

I

(BCAUTION?

cause minor or moderately serious injury,

or

could result in dam-

I

age

to

physical property.

Items marked with

ACAUTION

could also cause significant damage or injury, depending on the

circumstances. Precautions marked by either of these signs should be carefully observed and the

contents considered particularly important.

This manual should be stored carefully in a place where

it

is easily accessible when necessary, and

should always

be

passed on to the end user

if

the equipment is transferred to another user.

[Precautions Regarding Design]

@DANGER

~ ~ ~ ~ ~ ~~~~~~~~~~~~~

0 A safety circuit should

be

installed on the exterior of the PC to ensure safe operation of the entire

system even if there is a problem with the external power supply, or if the PC main unit breaks

down.

Erroneous output or operation can result in accidents.

(1)

The circuit configuration on the exterior of the PC should include interlock circuits such

as

an

emergency stop circuit, upper and lower limit position detectors, and other circuits to protect

the machinery from damage.

(2)

A

breakdown in an output unit relay, transistor, or other component could possibly cause the

output to remain on

or

off

inappropriately. The circuit configuration should allow external

monitoring of output signals where serious accidents could possibly occur.

[Precautions When Disposing

of

the Equipment]

/9

CAUTION

0

When disposing of this product,

it

shouM

be

handled through industrial product disposal channels.

Page 3

Page 4

Introduction

,.

.;:

I>

.,

1.

Thank

you

for

purchasing

the MitsubW

tMEtSEC-A

Series

General-Purpose PC.

Before using your product, please

WZhF

manual carefully and ,make..sure.

you';wst@4b

functions

ar@

performance of the A Series sequencer, and that you use it carefulv and prrectly.

'

should the product be transferred to another user, please make sure this manual

is

passed along to the end user

together with the equipment.

.

.-

. .

,

...

.

.

.

.

--.

~

.

..

-

I.

.

.-

-I

1. Overview 1-1

2.

System Configuration

2-1

-2-5

2.1 Overall Configuration

.

..

. , ..

,.

. .

..

. ..

. , .. .. . . . ..

...

.

.

.. ..

.

,

.. ..

.

,

.

..

.

, . ,

...

..

, ,

.. . .. .. .. .. .. .. .. . , .. .. . , .

..

..

. , .

..

..

. , .. .

..

..

...

, . , ,

...

2-1

2.1.1 When Used with a Building-Block CPU

....................

I.....I.....I.....I......I....I.I.....I

,...,.,.,....,

2-1

2.1 .2 When Used with a Compact CPU

.,............,

................................

,.....,

....,.,......,

,....,

,.....,.

2-2

2.1.3 When Used with a Small Building-Block CPU

..........................................

,......

......,.....,

,

2-3

2.2 Applicable Systems

.

. .. .. . . . . . . . , .

. . . . . . . . . , . , .

. . . .

.

,

. . . . . . , . . . . . . , . , . , . , . . . . , . , . . . . .

, ,

. . .

.

, ,

. . . . . . . . . .

. , . . . .

. . . . . . . . .

,

.

. . . . . . . . . . . . . .

.

2-4

2.3 Precautions Concerning the System Configuration

....................................................................

2-5

2.3.1 Precautions Concerning the External Power Supply

.I.....I............I....I.I..........I......I.......I

2-5

2.3.2 Correcting Individual Error in the Linear Scale

...........

.................................

,....,

,.....,......

2-5

C:

+

3. Specifications 3-1 -3-1

0

3.1 General Specifications

.....

.

..

..

. , . . . ..

. .

..

. .. . .

.. ..

.

,

. .. .. . . .. . ..

, ,

.. .. . , . , . .. . , .

..

..

.

,

.. ..

.

,

.. ..

.

.

..

.

,

.

.

,

..

.. . . .

.. . ..

,

.

.. . ..

,

.

.. .. .

.

3-1

3.2 Performance Specifications

,

.

. . . . .

. . . . , .

,

.

. . . . . , . , . . . . , . , .

, . ,

. . . . , .

. . . . . . , .

. . . .

.

. .

. . . . . . . . . . . . . . . . . , . . . . . . . . . . . .

. . . .

. . . . . . . . . . . . . .

.3-2

3.3 Signals Input to and Output from the PC CPU

,............I.I............I.........I......I.............I......I.....,..

3-3

3.3.1 Table of Input and Output Signals

....................

.......

..............,....

,............,

......................

3-3

3.3.2 Functions of Input and Output Signals

...I............I....I..............I.....I......I....I.II....II.....,....

3-4

3.4.1 Buffer Memory Allocation

. .. . , . . . . . . . . . . .

.

, . ,

. . .

.

, , ,

, . ,

, . , . , , ,

, . , , . , . ,

. . , .

, , . ,

.

. , .

, , . ,

. . , . , . . , . , . . , . . . . . . . . . , . . . . . . . . . .

.3-6

3.4.2 An Explanation of the Storage Area

,...,.,

,.....,

......

.................................

..........................

3-7

3.4 Buffer Memory

I....I.I...I.....I.......I.......I....I...................I......I.....,.....,,....,,............,......,............,.....

3-6

r-

-

4. Settinas and Procedures Prior to Omration 4-1 -4-5

,

.'

-1

-

Page 5

4

.4

..

6. Troubleshootinn 6-1

-6-3

Appendices

A-I -A-8

Appendix 1 I Supersonic Linear Scale BTL Specifications

...II......I.I...II......I......I......I..................I..........

A-1

1.1 Supersonic Linear Scale

BTL

Specifications

...,...

.. . , ...

.. . , .

...

.. , .

..,..

..

.....

.. .

..

.. . , .....

..

...... , ...

..

A-1

1.2 Supersonic Linear Scale

BTL

External Dimensions

I......I.......I......I.....II.............I......I.....

A-2

1.3 Orders and Consultation

.I......I......I.......I......I......I.I...II.I....I....I.II...I.I....,.,,.....,,.............,

A-6

Appendix 2. External Dimensions

........................................................................................................

A-8

2.1 A64BTL Supersonic Linear Scale Interface Unit

............................................................

A-8

Page 6

Page 7

\

Page 8

A

2.

System,Configuration

MELSEGA

2.1

Overall

Configuration

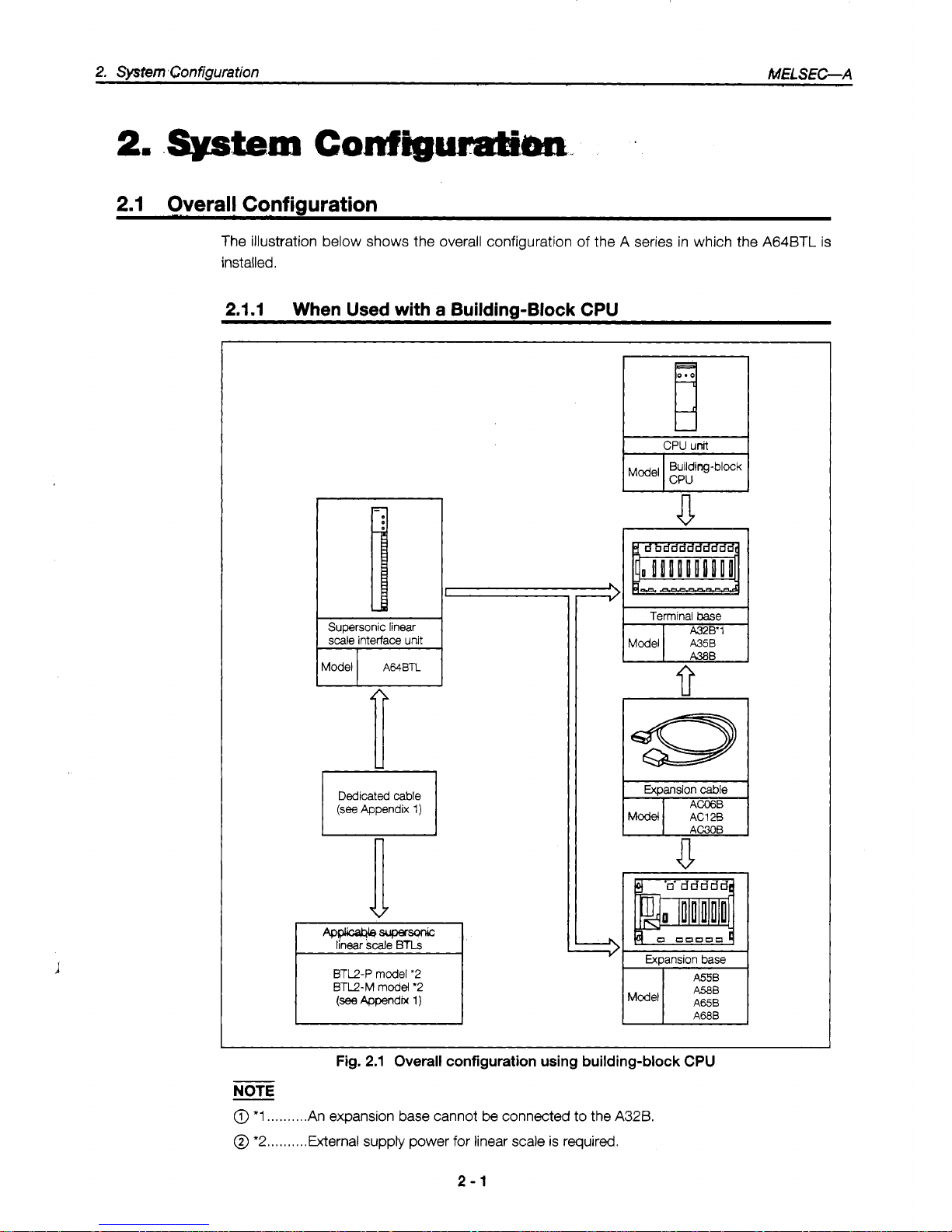

The illustration below shows the overall configuration of the A series in which the A64BTL is

installed.

2.1.1

When Used with

a

Building-Block CPU

CPU

unit

Terminal

base

fi

A380

FTGFl

Expansion

cable

A4wa4bsuper-

linear

scale

BTLs

BTL2-P model

'2

BTL2-M model

'2

I

Fig.

2.1

Overall

configuration

using

building-block CPU

NOTE

@

*1

..,.......

An expansion base cannot

be

connected

to

the

A32B.

@

*2..

. . . . .

.

..External supply power for linear scale

is

required.

2-1

Page 9

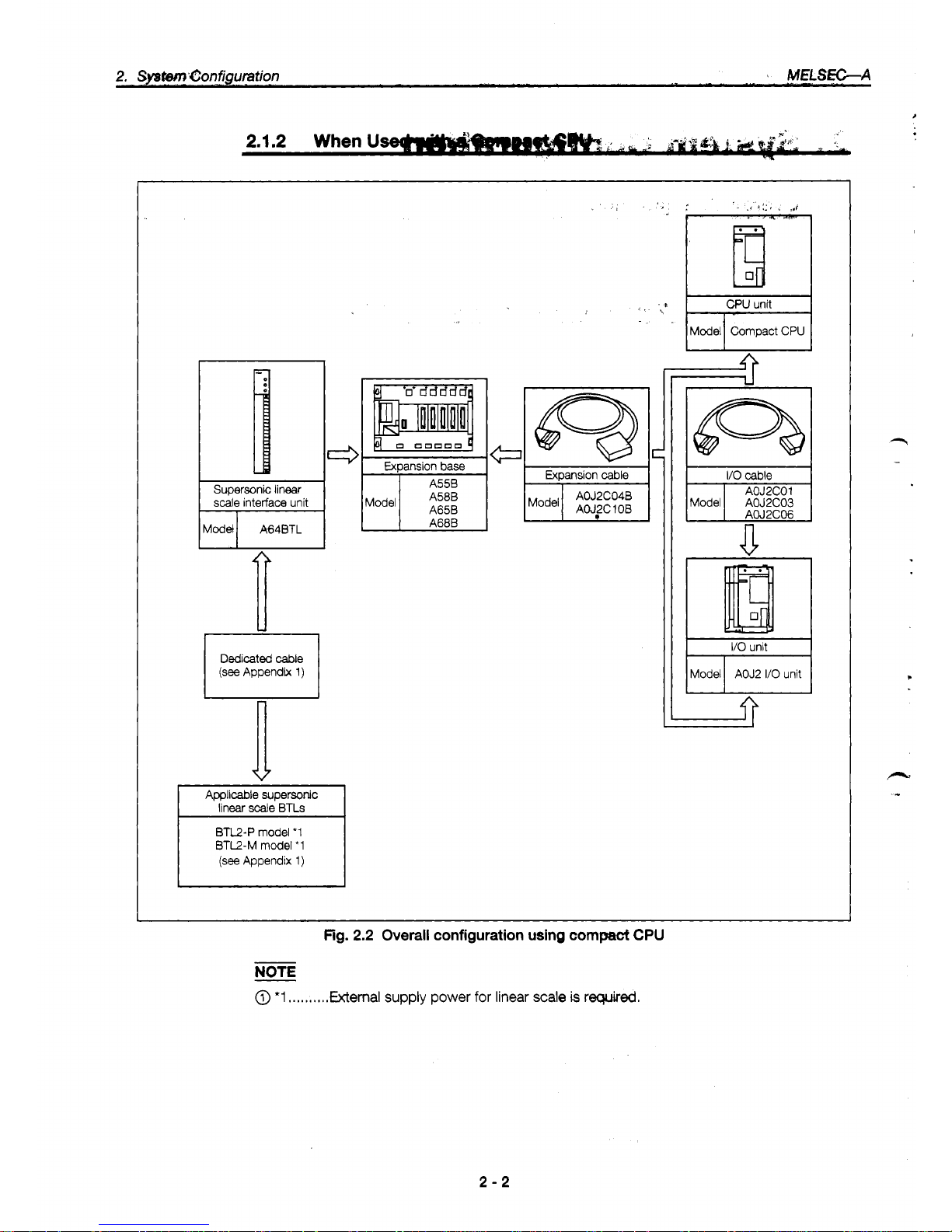

2,

SysmConfiguration

-

,_

MELS-A

Supersonic

linear

scale interface unit

Dedicated

cable

(see

Appendix 1)

a

BTU-P model

'1

BTL2-M model

'1

(see

Appendix

1)

ipJ-

Expansion base

I

bl

AOJZClOB

I

AOJ2C04B

AOJ2COl

t

I10 unit

I

I

Model I AOJ2

I/O

unit

I

Fig.

2.2

Overall

configuration

using

compact

CPU

NOTE

@

*1

.....,,.,.

External supply power

for

linear

scale

is

required.

2-2

Page 10

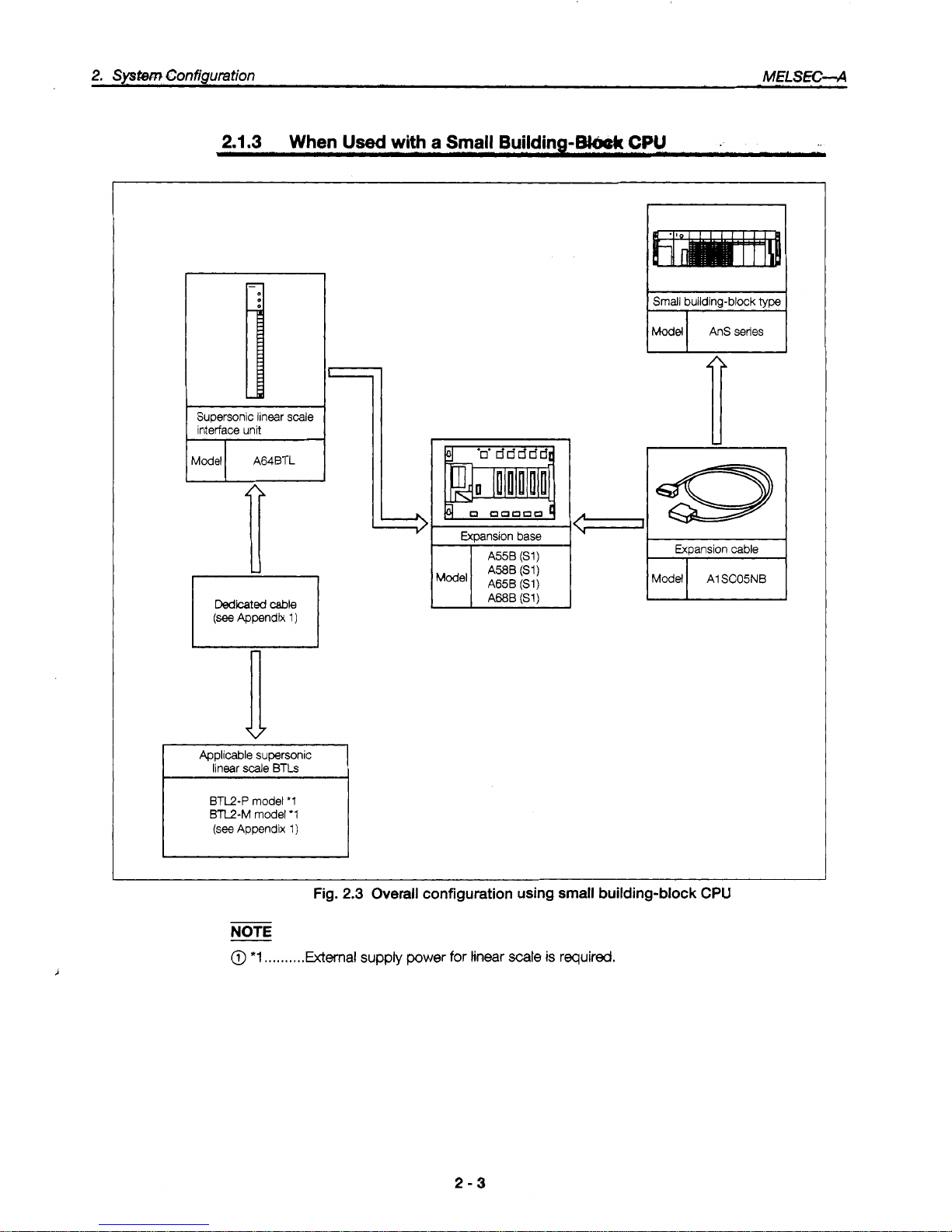

2.1.3

When

Used

with

a

Small

BuAilding-6h&

CPU

I

Supersonic linear scale

interface unit

Model

A64BTL

Applicable supersonic

linear

Scale

BTLs

BTL2-P model

'1

BTL2-M

model

'1

(see

Appendix

1)

L

A55B

(Sl)

A58B

(Sl)

A68B

61)

Small

building-block

type

Expansion cable

Fig.

2.3

Overall configuration using

small

building-block

CPU

NOTE

@

*1

,,,.,.,,,.External

supply

power

for

tinear

scale

is

required.

2-3

Page 11

2.2

Applicable

@#a~eaa~

.k

t,~~~~~,Jk,

!~~~;~i

!

,,;..'

il;.;,

.'.

?.*e

,-'.

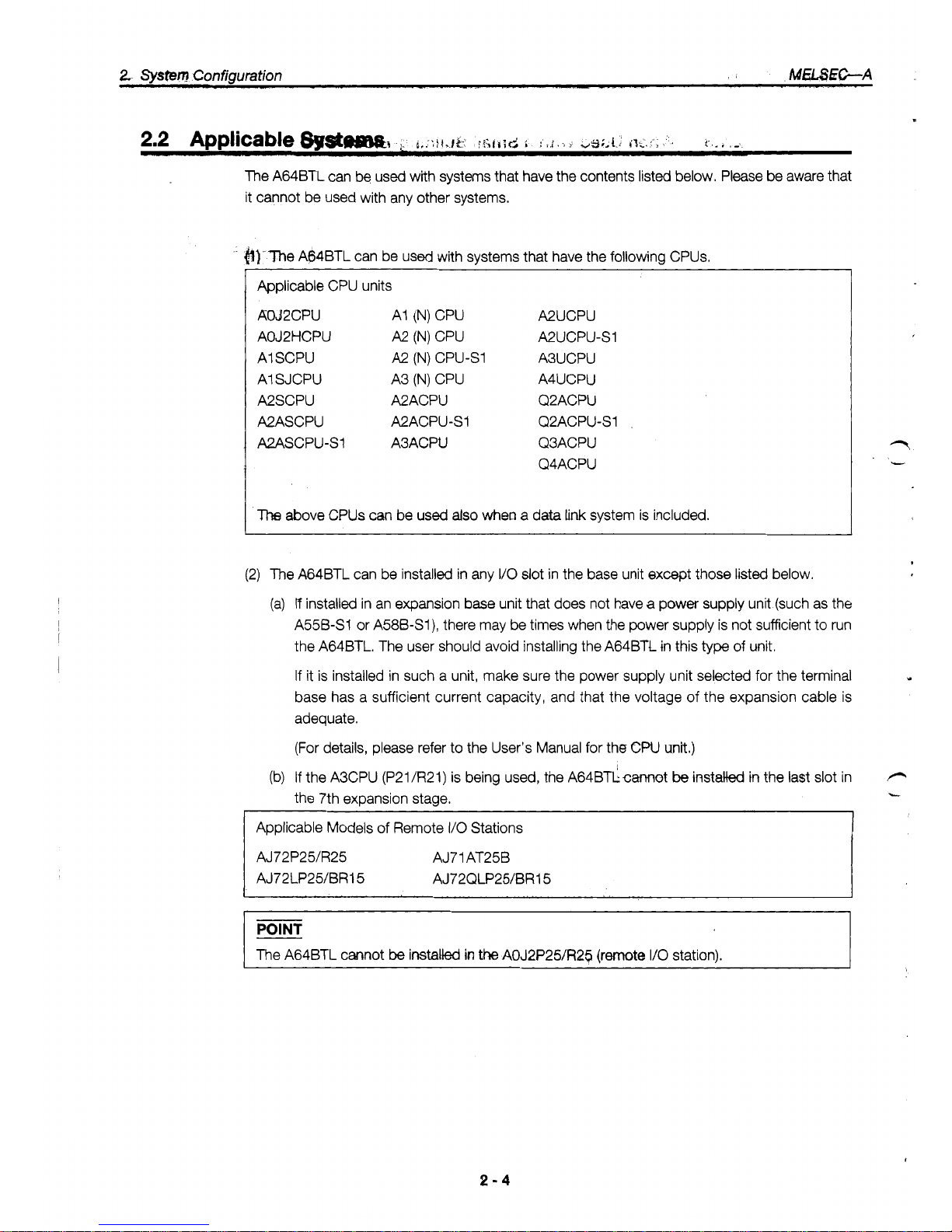

The A64BTL can be used with systems that have the contents listed below, Please be aware that

it cannot be used with any other systems.

&)-The

A64BTL can be used with systems that have the following CPUs.

Applicable CPU units

AOJ2CPU

AI

(N)

CPU

A2UCPU

AOJ2HCPU

A2

(N)

CPU

A2UCPU-s1

AI SCPU

A2

(N)

CPU-S1

A3UCPU

AI SJCPU

A3

(N)

CPU

A4UCPU

A2SCPU A2ACPU

Q2ACPU

A2ASCPU A2ACPU-S1

Q2ACPU-S1

A2ASCPU-SI A3ACPU

Q3ACPU

Q4ACPU

The

above CPUs

can

be used

also

when a data

link

system is included.

(2) The A64BTL can be installed in any

I/O

slot

in the base unit except those listed below.

(a)

If

installed in an expansion base unit that does not have a power supply unit (such as the

A55B-S1 or A58B-S1), there may be times when the power supply is not sufficient to run

the A64BTL. The user should avoid installing the A64BTl in this

type

of

unit.

If

it is installed in such a unit, make sure the power supply unit selected for the terminal

base has a sufficient current capacity, and that the voltage

of

the expansion cable is

adequate.

Y

(For details, please refer to the User's Manual for the

CW

unit.)

(b)

If the A3CPU (P21/R21) is being used, the A64BTLcmot

be

installed

in

the last slot in

P

the 7th expansion stage.

-

Applicable Models of Remote

I/O

Stations

AJ72P25/R25 AJ71AT25B

AJ72LP2UBRl 5 AJ72QLP2WBR15

I

The A64BTL cannot

be

installed

in

the

AOJ2P25/R2$ (remote

110

station).

2-4

Page 12

2.

System

Configuration

-&A

2.3

Precautions Concerning the System Configuration

2.3.1 Precautions Concerning the External Power SUDD~Y

In

order to use the

A64BTL,

an external

24

VDC

power supply is required.

2.3.2 Correcting Individual Error in the Linear Scale

Each linear scale has the correction value for the actual supersonic

speed

stamped on the scale.

Positional measurement can be carried out more accurately if this numeric value is entered in the

buffer memory.

(For

detailed information, please

see

section

3.4.2

(4),

“An Explanation

of

the Storage Area in the

Buffer Memory”.)

2-5

Page 13

c

.

,/

Page 14

3.

SpecifiIcetions

hELSK;-A

3.

Specifications

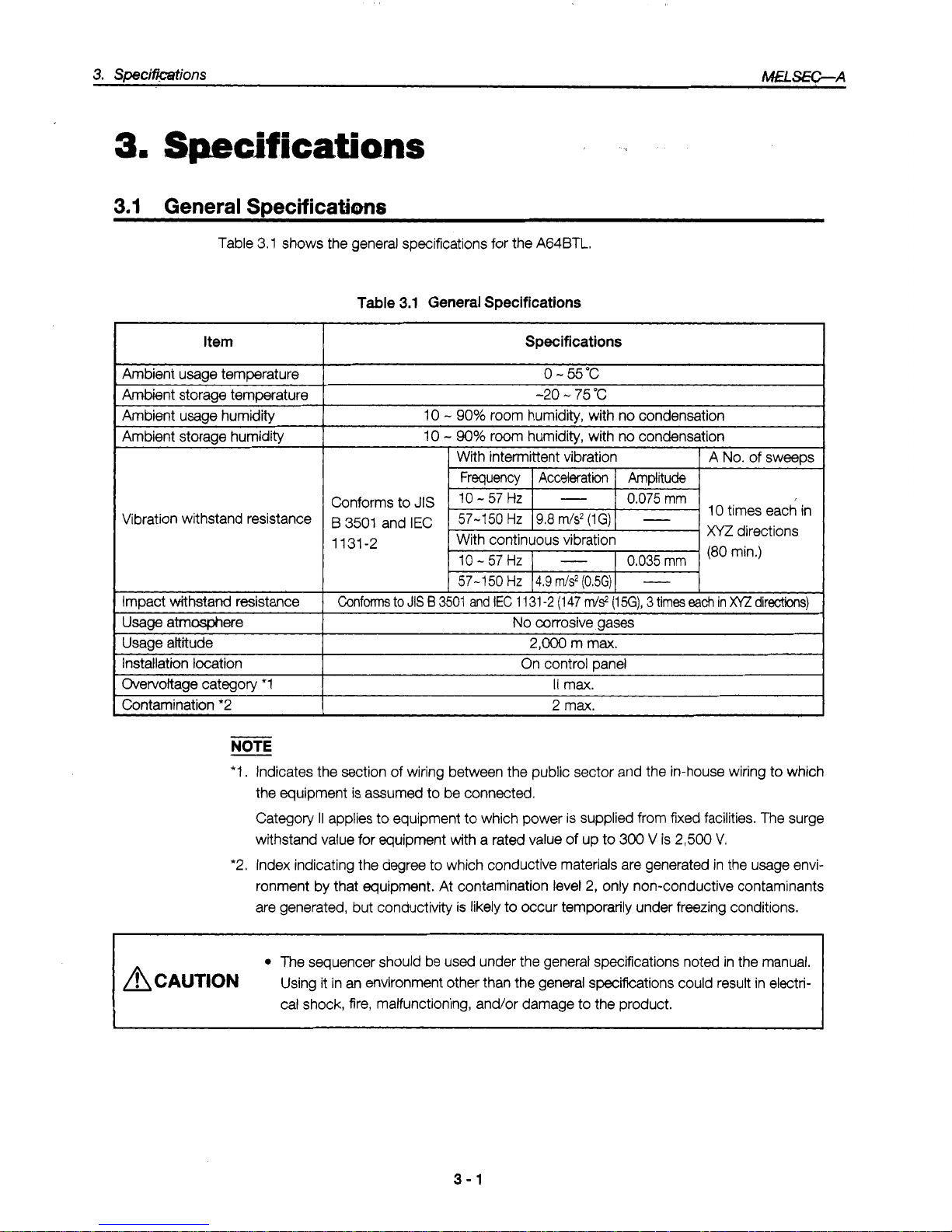

Table 3.1 shows the general specifications for the A64BTL.

Item

Table

3.1

General Specifications

Specifications

0

-

55°C

I

-20 - 75

"C

10

-

90%

room humidity, with no condensation

I

Ambient storage humiditv

I

Vibration withstand resistance

Impact

withstand

resistance

10

-

90%

room humidity, with

IX)

condensation

With intermittent vibration

Frequency

I

Acceleration I Amplitude

A

No.

of sweeps

Conforms to

JIS

0.075

mm

B

3501

and

IEC

1131-2

10

-

57 HZ

0.035

mm

I

I

57-1

50

Hz 14.9

m/s2

(0.5G)

I

-

Confm

to

JIS

B

3501

and

IEC

1

131

-2

(1

47

rrJs2

(1

5G),

3

times

ea&

in

x/z

directions)

Usage atmmere

Usage altitude

Installation location

Overvoltage category

*1

No

corrosive gases

I

~~

2,000

m max.

On control Dane1

I1

max.

I

I

Contamination *2

NOTE

2

max.

I

*I.

Indicates the section of wiring between the public sector and the in-house wiring to which

the equipment is assumed

to

be connected.

Category

II

applies to equipment to which power is supplied from fixed facilities.

The

surge

withstand value for equipment with a rated value of up to

300

V

is

2,500

V.

*2. Index indicating the degree to which conductive materials are generated in the usage envi-

ronment by that equipment. At contamination level

2,

only non-conductive contaminants

are generated, but conductivity is likely to occur temporarily under freezing conditions.

The

sequencer should be used under the general Specifications noted in the manual.

A

CAUTION

Using it in an environment other than the general specifcations could result in electrical shock, fire, malfunctioning, and/or damage to the product.

3-1

Page 15

Table 3.2 shows the performance specifications for the A64BTL.

I

Item

Specifications

No. of

I/O

points allocated

0.025

Resolution (*3)

Position

’

.

4channels

No. of channels

32 points

(VO

assignments: 32 special function unit points)

Measurement range

0.OOO

’-

3550.000

mm

(‘7)

informa-

I

~amdnu

timma

I

2ms

t

tion

Normal

Accuracy

~~~ ~~

k2

x

Resolution mm

(*4)

Comparison ranae

+5

x

Resolution -2

x

Resolution mm

Noise weight

24-bit binarv (to 3rd decimal place

x

lo00 times)

1

Comparison results

I

Contact point operation:

Output when dog ON address

I

counter value < dog

OFF

address

External

(4 points

x

1 dog) / 1

channel

No.

of

comparison output points

output

Transistor output (source type)

12/24 VDC, 0.1 N1 point, 2

Nl

common, fuse: 3.2

Nl

common

Comparison output

(Response time)

OFF

+

ON: 4.8 ms max.

(‘2)

ON

+

OFF:

4.8 ms max.

(resistance

load)

I

-$~?~~~~~)~i~~~

BTL

1

P

and M types (switchable using setting pins)

-

See

Section

4.3,

@

I

~~ ~ ~

Noise withstand volume

%-mint terminal base Connection terminals

500

VAC grounding to

all

DC external terminals for 1 minute Voltage withstand resistance

Noise vdtage 1500 Vp-p

I

Amlicabk

cable

size

1

0.75

-

2 mm2

(amiicable

tiahtenina toraue: 7

ka-cm)

I

Applicable crimp terminals

0.5 kg

Weight

1.05

A

Internal current consumption (DCSV)

V1. 25-3, V1. 25-YS3A, V2-S3, V2-YS3A

-

-

External dimensions (mm)

1

250

(H)

x

37.5

(w) x 131

(D)

(*1) The A64BTL can

be

set

so

that the position information output for any position within the

linear scale measurement range is

0.

r2) This is the time between when the linear

scale

pointer strrives

at

the specified external output

position and the external output is output.

(*3)

The

resotution

is

formulated and it

is

changed by actual supersonic

speed

correction value as follows.

Resolution

=

0.025

x

actual supersonic ,speed correction value

2850

(mm)

(*4)

Theaccwa~y

described in this section is the

accuracy

only

for A64BTL.

POINT

Noise withstand volume

The rated noise voltage is applied by a noise simulator, with a noise width of

1

ps

and a noise

frequency of 25

-

60

Hz.

h

i,

.

-.

i

L.

3-2

Page 16

3.

Specifications

MfcSEC-A

3.3

Sianals

hut

to

and

Outout

from

the

PC

CPU

3.3.1

Table

of

Input

and Output

Signals

The signals input to and output from the PC CPU

of

the A64BTL are as shown below.

(1) The A64BTL uses 32 input points and 32 output points for transmitting data to and from the

PC CPU.

(2) The input and output signals have the following meaning:

(a) Device

X:

Input signals from the A64BTL to the PC CPU

(b) Device Y: Output signals from the PC CPU to the A64BTL

(3) Table 3.3 shows the signals when the A64BTL has been installed in

I/O

Slot 0 of the terminal

base unit.

Table

3.3

I/O

signals

Signal

Direction:

A64BTL

+

CPU

I

Sisnal

Direction:

CPU

+

A64BTL

1

r

tt

kvice No.

Sianal

Name

I

Device

No

Signal Name

X00

x01

WDT error flag

YO0

External output

0-3

enabled flag

External output 4-7 enabled flag

External output 8-B enabled flag

External output C-F enabled flag YOC

Error flag YOD

Can’t be used

x02

X03

X04

X05

X06

Interlock signals for RFRP and

RTOP instructions when A64BTL is

used

for

remote

I/O

station

CH.

1 dimmed wiling detection

flag

1

CH.

2

disccxlrtected

wirina

detection

Raa

YOF X07

CH.

3

disconnected wiring detection flag

I

Y10

CH.

4

disconnected wiring detection flag

I

Y11

Forced output mode instruction

CH.

1

external output enabled

CH. 2 external output enabled

X08

x09

XOA

xi

c

CH. 3 external owbut enabled

CH. 4 external output enabled

Error reset

Can’t be used ODen Y16

CH.

1

zero point correction setting

CH. 2 zero point correction setting

CH. 3 zero point correction setting

CH. 4 zero point correction setting

X1 D

X1

F

Interlock signals for RFRP

and

RTOP instructions when A64BTL

is

used for remote

I/O

station

Y1

F

Can’t be used

IMPORTANT

YO0 - YOC and Y1 B - Y1 F are used for the system, and are not available to the user.

If they are used (turned

ON/OFF)

by the sequence program, the function of the A64BTL

cannot

be

guaranteed.

X00

-

X1 F and YO0 - Y1 F of the same numbers cannot be used as internal relays.

Page 17

3.

SpeMaations

MHd3ZC-A

This sections explains the ON/OFF timing. conditions, and other information pertaining to the

~..

signals input to and output

from

the

sequiKlWCPU!:

._,....

.....

,.

.

WDT

(watchdog

timer)

em

flag

WOO)

This is turned ON if a watchdog timer error is determined to have occurred by the A64BTL

self-diagnosis function. If this happens, all output from the A64BTL to external equipment

(Channels 1

-

4) is tumed OFF.

If

X00

goes

ON,

there is a problem with the AWBTL hardware.

External output enabled flags

(X01

-

XO4)

When Y11 - Y14 (Ch. 1 - 4 external output enable flags) go

ON,

the ON/OFF position data is

read, and comparison processing is enabled. Following this, X01

-

X04 (external output

0

-

F

enabled flags) go ON.

Error flag

(X05)

This goes ON

if

one

of

the errors described in Ch-apter 6 occurs. The X05 flag can

be

turned

L

OFF

by

cancelling

the

cause of the error and turning

ON

Y15

@or

reset signal).

Disconnected wiring detection flags

(X06

-

XO9)

These go ON

if

one of the four channels

(CH.

1

-

4)

has

not

been wired or

has

been discon-

nected, or

if

24 VDC is not being supplied on the linear

scale

side.

They go OFF automatically

when the problem has been corrected.

Forced

output

mode instruction

(Y10)

Turning on the forced output mode instruction signal initiates the forced output mode and

outputs the values in the forced output data area (address

78)

in the buffer memory to an

external destination.

POINT

Before using the forced output mode, all of the external output enabled signals should be

turned OFF.

tf

any

of

the external output enabled signals are ON, the forced output mode is

ignored.

If

Y10

is turned ON and a forced output is initiated, external output enabled signals will be

ignored even if they

go

ON, and the forced output mode will continue to be effective.

(6)

External output enabled (Y1 1 - Y14)

Turning ON an extemal output enabled signal initiates comparison processing

of

the compari-

son data for CH.

1 - CH. 4 and the counter value, and outputs the results to an external

destination.

Y1

1

.................

CH. 1 extemal output enable

Y12

.................

CH. 2 external output enable

Y13

.................

CH. 3 external output enable

Y14

.................

CH. 4 external output enable

3-4

Page 18

3.

Speifmtions

IWfLSEC-A

(a) The comparison processing is run when

Y11 - Y14

are ON.

To

determine

M.ljming

at

which

the pr&essing is carried out, the last START/STOP input signal during the

2

msec

of the

INT

output signal cycle is used as the measured value,

and

the measured value is compared with

the set

value.

The results of the comparison are output within

2.8

ms

after INT signal

is

output.

External output

maledsignal

of

-ant

I

channel (Yl1

-

Y14)

2ms

INT output

Operation

enabled

Signal output

IM

to linear scale

START/STOP

upt

Signal input

STOP START

to linear

scale

Counted

dunng

this Interval

(measured

value)

External

output

LroN

Within

2.8

ms

(b)

Up to 4 ON/OFF position data can be compared to one measured value, and the results

output to an external destination.

(c) Turning OFF an external output enabled signal

(Y1

1

-

Y14)

during output

of

data to an

external destination causes the corresponding external output to go

off

as well.

(7)

Emr reset

(Y15)

Turning

ON

the error

reset

signal

('Y15)

turns

OFF

the error flag

(X05)

for

the

A64BTL

error and clears to error

code stored

in

the error code area (address

9)

of

the buffer memory, writing

"0

to

that address instead.

Enor flag

(X05)

(Turned

ONDFF

by

system)

Enor

reset

(Y15)

Fumed

ON/OFF by user program)

Buffer

memory address

9

(8)

Zero point correction setting

(Y17

-

Yl

A)

To

correct the zero point, move the linear scale pointer to the position to be used as the

zero

point, and turn on whichever setting

(Y17 - Y1

A)

corresponds to the linear scale. This com-

pletes correction of the zero point. (Always make sure

Y10

and all external output enable

signals are turned OFF.)

Pointer

U

0

Position

to

be

USA

for

zero

mint

correction

MAX

1-

Linear scale measurement range

-4

NOTE

Of

the setting value data for the four ON/OFF positions,

if

the ON position data

of

any

one

data

element is a higher value than the

Off

position data (error), no comparison processing can

be

carried out for that measured value. If there are no errors in the setting value data for the

ON/

OFF positions

of

any

of

the other channels, however, comparison processing can be contin-

ued.

3-5

Page 19

3.

Specifidations

M€l!3&C-A

.

3.4.1

Buffer

Memow

Allocation

The A64BTL has a buffer memory for storing data being sent to and received from the

CPU

(this

buffer memory does not have battery backup).

This

section described the buffer memory alloca-

tion and the data configuration.

When the system is booted, the buffer memory access instruction should always

be

issued through

the sequence program. (When the power supply is turned

off.

the values for data written to this

buffer memory return to the initial values.)

befautt valw Read

-

inabled

-

inabled

inabled

-

Write

-

Disable

-

Disable

Disable'

-

Detailed

Information

Address

(decimal)

0

1

Input

CH. 1 measured value

Input CH. 2 measured value

h

i

n

L

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

0

Section 3.4.2 (1)

Input CH. 3 measured value

Input

CH. 4 measured value

External

output

status

Error

code

0

Section 3.4.2 (2)

Section 3.4.2

(3)

0

28500 inabled Enabla Section 3.4.2 (4)

ON

position data for output

0

OFF position data for output 0

l.

7

0

Mled Enabla Section 3.4.2

(5)

ON

position data

for

output F

74

75

76

77

78

79

80

After the power

supply has been

in the E'PROM,

and remains in the

OFF position data for output

F

0

inabled

inabled

-

-

Enable

Enabla

-

-

Disable1

Section 3.4.2

(6)

Section 3.4.2

(7)

_--.

___.

CH. 1

zero

point correction data

0

inabled Section 3.4.2

(8)

0

@I.

4

zero

point correction

data

I

3-6

Page 20

3.

Speciftdations

MELS€G-A

3.4.2

An

Explanation

of

the

Storage

Area

(1)

Input channel measurement

values

The measured values for the supersonic linear scale BTF pointer are stored in addresses

0

-

7. Measured values are carried to three decimal places and multiplied by

1000.

(Example) A value of 125.371 mm will be entered as

“1

25371

”.

(2)

External output status

The results

of

a comparison between the measured values for CH.

1

-

4

and the specified

ON/OFF positions are entered as the output status.

The table below shows the relation between the various measured values and the ON/OFF

position data when compared.

I

CH. 1 measured value

I

ON/OFF Dositions for outtsut

0 - 3

I

I

CH. 2 measured value

I

ON/OFF Dositions for outDut

4 - 7

I

~~ ~ ~~~ ~

CH. 3 measured value

ON/OFF positions for output C

-

F CH.

4

measured value

ON/OFF positions for output

8

-

B

Comparison results

measured values

ON

position data

I

for

CH,

1 - 4

<

OFF position data

...............

a value

of

“1”

is entered.

measured values

ON position data

>

for

CH,

1

-

4

or

measured

2

OFF position data

for

CH.

1

-

4

...............

a value of

“0”

is entered.

POINT

With the A64BTL, measured values (counter values) are sampled at 2-msec intervals. The

measured values are then compared to the specified ON/OFF position data and the results

output.

Consequently, no external output status

is

output for movements occurring with a 2-msec

interval.

3-7

Page 21

.

(Example) The measumIvaluefor,CH. 1 is

comparxtb~faur

WOFF positions shown below.

.

i*

14,15

16,17

18,19

20,21

22,23

24,25

26,27

28,29

Address (decimal)

Measured

valueafter

2

mSec

1

(m~d

value

ON

position

data

for

OFF

position

data for

;

I

ON position data for

OFF position data for

:

ON position data for

for address 0, input

CH.

1)

Address 8

-

Because measured value is within

comparison range, output 0 is

ON

(1)

ON

position

j

OFF

position

1-1

output

1

-

Because measured value is within

comparison range, output

1

is

ON

(1)

OUtDUt

2

-

OFF position data for

ON position data for

-

Because measured value is not within

comparison range, output 2 is OFF (0)

OFF position data for

L

-

Because measured value is not within

comparison range, output 3 is OFF

(0)

J

7

6

5

4

3

2

1olRPlrtO

0011

FEDCBASB

I

I

I

I I I

I

I

I

The

output statuses

for

the comparison results are also entered

in

outputs

4

-

F.

NOTE

If

it

is

not necessary to set all four of the ON/OFF positions, errors can be avoided by entering

the same values for the ON/OFF position data of outputs which do not need to be set.

(Example) If ON/OFF settings are not needed for CH.

1-2

ON position for CH.

1-0 : 10 mm / OFF position

for

CH.

1-0:

40

mm

ON Dosition for CH.

1-1

:

30

mm / OFF oosition for CH.

1-1

:

60

mm

I

ON

position for CH.

1-2

:

50

mm

/

OFF position for

CH. 1-2:

50

mm

I

ON position for CH.

1-3

:

50

mm / OFF position for CH.

1-3:

100

mm

F

(3)

Error codes

Turning ON the error flag

(X05)

enters an error code in address 9 of the buffer memory.

(Normally,

0

is entered in this address.)

For detailed information on error codes, please refer to Chapter

6.

(4)

Actual supersonic speed correction values

Actual supersonic speed correction values are used to correct solid differences between actual supersonic speed values on the supersonic linear scale BTL, in order to obtain more

precise measurements. Values which are entered should always be created by rounding off

the fraction of the value displayed on the linear scale

(see

Appendix

1.2)

and multiplying the

value by

IO.

Page 22

3.

Specifications

AdEiSEC-A

(a) The measured values are created

by

carrying out position correction based on these

values. (When not setting, the measured values are created by carrying

out

position cor-

rection with default values.)

(b) Values higher than “28999” should

not

be

set for the actual supersonic

speed.

Please be

aware that no error is displayed even if a value outside of the allowable range is entered.

Address (decimal)

A

CH.

1

actual supersontc

speed correction value

speed

correction value

I

speed

correction value

I

(5) ON/OFF

position

data

for

outputs

0

-

F

Because these values are compared with the measured values input

for

CH.

1

-

4 and are

written when Y11

-

Y14 (external output enabled signals) are turned

ON,

they should be

specified before Y11

-

Y14 are turned

ON.

(a) The setting range for

ON/OFF

position data is from

-1

6777.21 6 - 16777.21 5 mm, but the

values written to the buffer memory should be multiplied by 1000.

(Example) 123.456

+

123456

(b) The setting range should consist

of

two

words.

Address (decimal)

OFF

position data

for output 0

I

ON

position data for

19 output

1

CH.l

3-9

Page 23

3.

SpcifkWions

MELSEC-A

(6)

Output

data

for

forced

outputs

Wherl the forced output mode instruction

(Yl

0)

is turned

ON,

16-point external output is

carried out based on the output data.

(Example)

If

the output data is 01 11

H:

7654321

Of the outputs

0

-

F,

only outputs

4,

8,

and F are turned on.

(7)

Zero point correction value clear

CH.

To

clear the zero point correction value data for CH.

1 - 4,

stored in the E2PROM, write the

channel number (1

-

4)

to which the linear scale to be cleared is connected.

If

a value

of

“5”

is entered, the zero point correction values for all

of

the channels are cleared

to zero.

(a)

No

values

other

than

1

-

5 should

be

written,

as

other

values

will cause an error.

(b)

When the zero point correction values have been cleared to zero, a value of

“0”

is written

to address K79. The zero clear processing is not carried

Out

if

a value of

“0”

is written.

-

..

To

clear CH. 1 to zero

+

Write “1

’I,

To

clear

CH.

2

to zero

+

Write

“2”.

To

clear CH. 3 to zero

+

Write

“3”.

To

clear CH. 4 to zero

+

Write

“4”.

To

clear

all

of

the channels to zero

+

Write

“5”.

t

(8)

Zero point correction data

The zero point correction data is written to the E’PROM by turning

ON

the zero point correc-

tion settings (Yl7

-

Yl

A).

The values for the positions at which zero point correction was

carried out are also written from the

E’PROM

to addresses

80 - 87

in the buffer memory.

F.

POINT

If

an error occurs during the zero point correction processing and the error continues to occur

even after it has been corrected several times, there is a problem with the hardware.

If

this

happens, the unit should be replaced.

3

-

10

I

Page 24

4.

Settings

and

Procedures

Prior

to

Operation

MfLSEC-A

Operation

This section describes what to do

to

get

ready for

option,

as

well

as precautions concerning

handling of the equipment, names

of

parts, and the various functions.

4.1

Preparing for Operation

Fig.

4.1.

shows

the process

used

to prepare

for

0peratk.m.

For each channel, install the short-circuit

arm

that matches

the

type

(P

or

M)

of

linear

scak

which

has

been

connected.

.

.

Unit

instanation

Install

the

A64BlL

in

the specified

slot.

Connect the

24

VDC

power suppty for the external output

circuit

to

the

A64BTL.

wng

Wire the

A64Bl-L

and the peripheral equipment.

Wire the power supply for the

linear

scale.

I

Pregremmingandda4ugging

Create and check the sequence program

to

control the

A64El-L.

1

End

..

. .

See Section

4.3

Fig.

4.1

Preparation procedure

4-1

Page 25

Page 26

4.

Settings

and

Procedures Prior

to

Operation

A4fLSEC-A

4.3

Names

of

Parts

Names

of

A64BTL

Parts

+

Jo.

Signal and Appearance

@

1

"RUN" LED

I

@

"ST1 -ST4" LED

@

I

"OUT" LED

Linear scale signal wire

@

External output terminal

@

connection terminal

"FUSE" LED

@I

BTL

type selection pin

@

Supersonic linear scale

Power supply input terminal

@

Contents

This LED indicates the operation status of the A64BTL.

Lighted:

Operating normally

Not lighted:

Power is not being supplied to the A64BTL.

A

WDT error has occurred in the A64BTL.

A hardware problem has occurred with the A64BTL.

The CPU has detected an error and stopped the operation.

When START/STOP signals are received from the various channels, the corre-

sponding LED lights. The brightness varies depending on the length of the

linear scale measurement. (The LED is brighter for a long measurement and

dimmer for a short measurement.)

This LED lights when the output

is

ON as a resutt of comparison processing of

the measured values from the various channels.

These are used to read the linear scale signals from the various channels.

The results of the comparison between the measured value and the ON/OFF

position data are output as an output signal.

These are the input terminals for the external power supply (24 VDC). They are

also used to output external output signals.

Short-circuit arms are installed here to match the type (P or

M)

of linear scale

connected to the various channels.

This

is

the fuse for external supply power (DC24V). This LEO lights when the

fuse

is blowed by over current or when the wiring is not connected for external

supply power.

4-3

Page 27

4.

S&€h@and Procedures Prior to Operation

W8EC-A

4.4

Wiring

..

,I

,:

,

!

This section describes precautidns

whiCh,shcxM

be

followed when wiring the AWBTL, as well as

how the A64BTL

is'

wired

to

peripheral equipment.

4.4.1

Precautions Concerning Wiring

In order to take full advantage

of

the many functions of the A64BTL and assure high reliability of

the system,

it

is important to make sure the external wiring minimizes the effects

of

noise as much

as possible.

The following precautions should be observed when connecting the wiring.

(1)

Separate cables should be used for connecting the AC and the external output signals of the

A64BfL, and for the 24 VDC input. Steps should

be

taken to protect against surges and

inductance on the AC side.

(2)

Single-point grounding should be used for the shielding on shielded wires and shielded cables.

&,

P

ACAUT~ON

Control cables and communications cables should not be bundled with main circuits

and power cables, and should

be

kept well separated.

As

a

rule, cables should be separated by at least

100

mm, to prevent faulty operation

because

of

noise interference.

4.4.2

Wirina

the

A64BTL

and

per^^

(1)

Fig. 4.2 shows an example

of

how the A64BTL should be wired to peripheral equipment.

_.

I

Linear

scale

External

power

supply

(DC15V

or

DC

24V)

External

power

supply

Fig.

4.2

Wiring

the

A64BTL

and

peripheral

equipment

4-4

Page 28

4.

Settings and Procedures Prior

to

Operation

i.

-+-A

.*

'4

+

ACAUTION

The

SLD

terminal should always be grounded using a Class 3 or higher ground used

for the

PC

alone, and not shared with other equipment.

4.4.3

Connecting

an

External

Power

Supply

to

the

A64BTl

The following shows how to connect an external power supply to the

AMBTL.

(1)

In order to prevent electromagnetic inductance noise and other noise interference, twistedpair wiring should be used for connections.

A64BTL

1

I

Ir

I

u

DC24V(-)

Fig.

4.3

Connecting the

A64BTL

to an external power supply

4-5

Page 29

*

Page 30

5.

Programming

MELS&C-A

Programming

This section describes the programming method used with the

A64BTL.

5.1

Programming Procedures

Fig.

5.1

shows the procedure by which a program

is

created when reading and writing data

between the

CPU

and

A64BTL.

Program creation

Y11 - Y14 all

off

I

Create a program to write actual

To

find the corrected values, the

fractional segments of the numeric

supersonic speed correction values. value stamDed on the namedate

of the tin& scale are rounded

off,

and the value is multiplied

by

10.

When the defauk values for all

of the channels are

"28500"

position data for each

of

the channels.

I

1

Yes (Run)

I

Move pointer

to

position

zero point

r

I

No

(Not run)

Y11 - Y14

turned ON

I

Turn

ON

Y17-Y1P

corresponding to

linear

scale,

to

conclude

correction.

I

Y11

-Y

'1 4 turned ON

I

J

tl0

urned ON

Fig.

5.1

Programming procedure

~ ~~~~~

5-1

Page 31

5.2

Programming Examples

This example shows a program which first writes the actual supersonic

speed

correction values of

the various linear scales as initial values, then writes the set values for the ON/OFF positions of

each of the channels and begins comparing the values.

~heprscesses

for

forced

output,

clearing

the

zero

point oc;;fP;ection

vah

to

&,

And

zero

pdnt

correction set are also

shown,

as

related programs.

.a'

?.

1

Conditions for

Sam~li?

Proararn

I

(1)

System configuration

woo

x20

//

W1F X5F

.........

y60

Y9F

1

I

I/O

numbers

(2)

Contents of initial

settinge

(a) Actual supersonic speed correction values

........................................

CH. 1 : 28000

CH.

2:

27000

(b)

Set

values

for ON/OFF positions

............................

ON position for output

0:

1200

OFF position for output

0:

1600

(3)

Devices used by the user

(a) Command for writing ON/OFF position data for output

0

-

3

...........................

X21

(b)

Command for writing forced output data

..........................................................

X25

(d) Registers for storing

CH.

1 and

CH.

2 actual supersonic speed

correction values

.........................................................................................

DO,

Dl

(e) Registers for storing ON/OFF position data for output

0

...........................

D4

-

D7

(9) Register for storing clear CH, CH. 1 zero point correction value

.......................

072

(c) Command for clearing CH.

1

zero point correction value

.................................

X2A

n

(f)

Register for storing output data from forced output

.........................................

D68

5-2

Page 32

5.

Pquamming

MELSEC-A

1

1

Setting of initial actual

supersonic

speed

correction values;

writing of CH. 1 and 2

_c

f

<

M9036

(

Ahrays

ON

)

II

[

SCJ

P1

X00

IY

K

AI

[

MW

28000

DO

-

-

CH.1 corrected value

i

of 28000 is written to

DO

[

MOV

27000

DI

- -

CH.2 corrected value

of 27000 is written to

Dl

K

[TO

o

10

w

KI

--

Valueof Doiswitten

HK

to address

10

HK

TO 0 11 Dl

-

-

Value of

DO

is written

to address 11

Writing

of

ON/OFF

position data for

Outputs

0

-

3

(CH.l)

PI

Forced output reset

[

TOP

0

78 0

HK K

K

K1

+---

Forced output data clear

[

DMOVP 1200 D4

+-

-

ON

position data of

stored in

D4

and D5

1200

for output 0 is

[

DMOVP

1600

~6

E.

-

-

OFF position data of

1600

for output 0 is

stored in

D6

and D7

[DTOP 0 14 D4

K2

>-.--DataforD4-D7is

K

HK

written to addresses

14

-

17

/

Setting of

bN/OFF

posiGm-

11-3

Y10

IY

AI

--

CH.1

external output

en&

Yi?

ylL

Reading of ON/OFF position data for outputs

4

-

F

(CH.2-CH.4) is done in the same way

as apove.

-,

x00

x25

I,

?'-

,y

[

K

[MOVP 0 KlYll

D68>b---Datatotumonmtyoutputs

[MOVP 0111

+---All outputs enable clear

+----Data for

D68

is written

[Top 0

78

D68

K1

0,

4,

and

8

is

written

to

D68

r

Writing of output data

for forced output

-

H

7

L

HK

.

to address 78

Y11 Y12 Y13 Y14

t

IY

IY

IY

1Y

[SET

YIO

l-*-

-

-

Forced output is

implemented

T

0

5-3

Page 33

Zero point comtion

for CH. 1 is

set

value

for

CH.

1

is

cleared

(+)

Error detection circuit

Error detection

r

I

*I

X00

X26

--Forcedoutput reset

--All

outputs enable clear

Y10

Y11 Y12

Y13Y14

IY

IY

IY

IY

IY

AI

--CH.l is set

Zero point correction for

__

x00

x[:;

*

set in the-same way as-above.

GGjGZerot

correction for

CH.

2 -

cH.

4

is

[

RST

K

-4

-

-Forced

output

reset

[MOVP

0

KlY11

--AI

outputsenableclear

I[MW

1"

D72

4

--clear

zm

CH.

pointaxrecfionvalue

is

set

for CH.1

i

Wlre breakage

HK

Zero point correction value

for CH.1 is cleared

__

x00 x:-;

Error detection

Error code

is

read

to

D80

A

L

BCD

D80

X2E

Y40

K

-

Error

reset

K

=

11

D80

1-[

RST

=

12

D80

1-[

RST

K

K2

Y50

4

Error code is displayed

yll

41

When ON/OFF position data

setting is mistaken, external

coirespouding

CH.is cleared

ouput

enable for

y15

1

reset

Y40

Error detection clear

I-[MOVP

X06

I

GH.1

wire breakage

<Y41

>-I

CH.l wire breakage detection

K2Y504

Error code display clear

I-

Wire breakage detection for CH.2-CH.4

is

programed

in

the Same way

-j

as*F.

f

k

5-4

Page 34

6.

Tmhbshooting

MELSEC-A

This section describes the contents

of

errors which may occur while using the A64BTL, and the

appropriate troubleshooting measures that should be taken.

6.1

Table

of

Error

Codes

This section shows the A64BTL error codes. If the A64BTL detects an error,

X05

goes ON, and

the error code is written to address 9 in the buffer memory.

Table

6.1

Error

Codes

Cause

(ERXWcsQ

Normal

00

ON

positions for outputs

0

-

3

OFF positions for outputs

0

-

3

ON

positions for outputs 4

-

7

If

ON

position data > OFF

PO-

OFF

positions for outputs

4

-

7

sition data

"

ON

positions for outputs

8

-

B

OFF positions for outputs

8

-

B

ON positions for outputs C

-

F

OFF positions for outputs

C - F

13

Data other than 1

-

5 was written to address 79.

14

An instruction was written to an address outside the allowable

area (addresses 10

-

79).

20

10

11

12

The zero point correction value for CH. 1 was not written cor-

rectly to the E2PROM, or the value could not be cleared to zero.

The zero point correction value for CH.

2

was not written correctly to the E2PROM, or the value could not be cleared to zero.

The zero point correction value for CH. 3 was not written correctly to the'E2PROM, or the value could not

be

cleared to zero.

The zero point correction value for

CH.

4 was not written cor-

rectly to the E2PROM, or the value could not be cleared to zero.

40

41

42

43

NOTE

Solution

Check the specified numeric

value and correct it.

Check the sequence program

and

correcf

it.

Write the zero point correction

value again.

Each time an error occurs, the most recent error code is set. Errors can be reset (the error

code cleared) by turning Y15 on through the PC CPU.

If an error

is

not reset, the last error code set will remain even if all of the data entered is

correct.

6-1

Page 35

6.2

Troubleshooting

This section explains simple troubleshooting procedures which can be

carried

out while using the

A64BTL.

For items relating to the sequencer CPU unit, please refer to the User's Manual

for

the sequencer

CPU being used.

7

START

'

"ST1

"

-

"STC

LED

is

not kghted.

.

..

.

<

tmn connected?

>

Has linear scale power supply

/

Check the rated voltage for the linear

YES

I

"OUT" LED does not light at all

when linear scale pointer is moved.

-

for

each channel a higher

value than the OFF

YES

Check

the

set

numeric

value,

and

write

the

correct

value to the buffer memory.

CPU unit breakdown

CPU unit normal

Note the detailed mtents

of

the

1

YES

H

problem

and

then please return the

product

to

our nearest Sales agency

I

Connection

cable

or branch offce.

I

Connection cables normal

n

....

Please

contact Nihon Balluff for

assistance.

6-2

Page 36

6.

Troubleshootino

,,

h4ELSEC-A

6.2.2

Measured Value

does

not Match Set Value

-

START

Write the numeric value stamped on

1

to

the buffer memory.

the nameplate of each of the scales

NO

c

Set the

type

for each channel,

with the short-circuit arm.

NO

error code table been

Eliminate the error codes in address

9 of the buffer memory.

Please contact Nihon Balluff

for assistance.

If

the problem cannot be solved by following the troubleshooting procedures, there may be a

problem with the unit hardware. Please describe the problem to your nearest sales agency or

branch office and request assistance.

6-3

Page 37

MEMO-

Page 38

Apwudix

1.

Swrsonic

Linear

Scale

BTL

Soecifications

1.1

Supersonic Linear Scale

BTL

Specificati~~s~

This

Section

describes

Scale specifications

of

the supersoo~ Scale BTL (made by BALLUFF

of

Germany) used with- the

A64BTL.

.

..

.

Procedure for orderina scales:

BTL2-P1 -0750-B-S32

-rT

000

TT

1-

T

T

@@@a

0

BALLUFF supersonic linear scale

@

Series 2

@

Interfaces

STARTETOP,

RS-485

P = Falling edge

M

=

Rising edge (without rod type)

@

Power supply voltage

1

=24VDCf

10%

2

=

f

15 VDC f 2%

(M

type only)

@

Nominal length

of

scale:

See

NOTE

(2)

GJ

Shapes

P

=

Profile type

F

=

Profile type with slide pointer

B

=

Rod

twe flanae attachment screw

M18 x 1.5

-

Connectors (scale side)

0.75

mm2

(shielded cable)

Applicable cables

BKS-S32-00

or BKS-S33-00

Z

=

Rod

type flange attachment screw

3/4-16UNF

Connections

,,

S32 = Connector connection, S32 type

KA05

=

Cable connection, cable length

5

rn

(cable connection models are available

only in rod

type

configurations)

NOTE

(1)

When ordering the supersonic linear scale, in addition to specifying the model

of

scale,

instructions must also be included concerning the

type

of pointer and the connector for

the scale to be used (both ordered separately).

(2)

The

following nominal lengths are available

far

the

scales

indicated under

*l

above:

0700,0150,

(0200),

0225,0250,0300, (0320, 0340,03&;0360,

0400,0450,

0500,

m,

0750,

1000,1250,

1500, 1750, 2000,

2250,

25&,2750,3000,

(3200),

3250,

3550

Items which are underlined are applicable only to profile models and models with slide

pointers. Items in parentheses are available only in rod type models.

Page 39

Page 40

Connection shafts

(ordered separately)

The

LS

dimension can

be

specified in mrn units.

LG

c

LS

,

24

9

B

Securing nut

M5

DIN934

I""

Rod

'INm8

Connection

cable

DIN71

802

Provided

as

accessory

with

pointer

Procedure for ordering Connection shaft BYI-GrIi3-T-T

connection shaft

BALLUFF supersonic linear scale

Connection shaft

External dimentions size,

10

mm

Material

A

=

Aluminum

A-3

Page 41

Nut

M18

x

1.5

The cable should

be

a

shielded

cable measuring

7

x

0.25 mm'.

L

size

(m)

(nominal length)

M18

screw type

L

size

(inch) (nominal

length) UNF

screw

type

320

60

72

-.

-_

Pointer

(ordered separately)

BTL-P-1013-4R BTL-P-I

01

3-4s BTL-P-1012-4R

a

I

0

32

032

cl

3

a

1-

22.5

b

Scale connector

(ordered separately)

r

61

The same connector

is

used

for profile type and rod type models.

The connector made by the German firm Binder should be

used.

R-4

Page 42

Appendjces

MELSEC-A

Location

of

actual supersonic

speed

correction value stamp

Nameplate

/

correction

value

Nameplate

A-5

Page 43

1.3

Orders and Consultation

.

To order the supersonic linear scale BTL, or to request further information, please contact one of

the locations listed below.

Germany.

.a

Gebhd

BaM~i-I

&

Co.

Gartenstrak.21-25.:.

..

D-73765 Neuhausen/FiIcfer

:.

,

Postfach 1 1 60

D-73761 Ne&au&Filder

Phone

(0

71 58) 1 73-0

Fax

(0

71 58)

50

10

Telex 7 23 392

wortd

Headqrr,a*

Gebhard

Balluff

GmbH

8t

Co.

joints

captitals

to following

8

commnies.

Austria

a

Gebhard Balluff GmbH

&

Co.'-

''

-'

Niederlassung Osten-eich

IndustriestraOe

B

16

A-2345 Brunn am Gebirge

Phone

(0

22

36) 3 25 21

-0

Telex 7 91 66

Fax

(0

22 36) 3 25 21 46

P

Brazil

ED

BALLUFF CONTROLES

6LETRICOS Itda.

Avenida do Cursino, 2462

cep: 04132

-

Jardim da Saude

BR-Sao Paulo

Phone (01 1) 2 75 62 77

Telex 1 157 482

Fax

(0

11) 5 78 68

55

JaDan

a

NlHON BALLUFF Comp., Ltd.

2491 Koya Ogawa-machi

Hiki-gun

J-Saitama, 355-03

Phone (04

93)

73

27

23

Fax

(04

93) 74 49 59

Singapore

63

BALLUFF ASIA Pte. Ltd.

BLK 1004 Toa Payoh Ind. Park

Lorong 8,

#

03-1489

SGP-Singapore 1231

Phone2524384

Fax 2 52 90 60

Czech Republic

@

Switzerland

@

BALLUFF CZ, s.r.0.

BALLUFF Sensortechnik AG

Nad Ond rejovem 81 8/20

Riedstr. 6

CZ- 140

00

Praha 4

CH-8953 Dietikon

Phone

/

Fax

Phone (01) 7 40 87 20

(02) 43 20 31,43 60 23

Fax

(01)

7 40 87 05

Hunaaria

(H'>

Balluff Elektronika KFT

Marketing lroda

Vihar u. 22

H-1221 Budapest

Phone

(1)

2 26 23 95

Telex 2 25 740

Fax

(1)

2 26 23 95

USNCanada

BALLUFF Inc.

81 25 Holton Drive

P.0.Box 937

USA-Florence,

Kentucky 4 10 42-0937

Phone (606) 727-2200

1-800-543-8390

F~x

(606) 727-4823

Representatives

Argentine

0

Nortecnica S.R.L.

Av. Francisco Beiro 4541

141

9

Capital Federal

Argentina

Phone (01)

5

03 35

05

Fax (01)

5

03

41 32

Australia

Erwin

Sick

Optik Electronic

Pty.

Ltd.

Heidelberg Road 899

AUS-lvanhoe, Victoria 3079

Phone (03) 4 97 41

00

Fax (03) 4 97 11 87

Belgium

a

MULTITECHNIC n.

v.

Leuvensesteenweg 262

B-1800

Vilvoorde

Phone (02) 2 52 14

50

Fax (02) 2 52 49 59

Bulgaria

@

lwan Dotschowsky

Boul. lskarsko Chauss6e 12

BG- 1 592 Sofia

Phone (2) 79 30

01

Fax (2) 79 37 40

China

eRc3

Balluff South China

Service Center

Dept. of Applied Physics

Shanghai Jiao Tong Univ.

Hua Shan Road 1954

PR-200030 Shanghai

Phone

(0

21) 4 71 49 36

Fax

(0

21) 4 71 49

36

Denmark

G3

Sick Optic-Electronic

A/S

Datavej 52

DK-3460 Birkerad

Phone

45

82 64

00

Fax 45 82 64 01

Finland

@

Murrelektronik Oy

Siltamaenkatu 35

SF-1

5300 Lahti

Phone (18) 7 56 41 88

Fax (18)

7

56 41 87

t

1

A-6

Page 44

France

a

BALLUFF Autoflation

*'

'*

2 Rue du Vallon

F-94440 Marolles en Brie

Phone

(1)

45.6923

32

Fax (1) 45 99 22 99

Great Britain

G9

Muttiswitch

Balluff

UK

The

Old

Mill-Technical Studio

Finney

Lane

GB-Cheadle,

Cheshire

SK

8 3

DQ

Phone (01

61)

4

37

12

34/5/6

Fax

(01

61)

4

36

14

35

Honq Kong

@

CCL SYSTEMS

FAR EAST LIMITED

14/F., Tai Po

Corn.

Centre,

152 Kwong Fuk Road,

Tai Po, N.T., Hong Kong.

Phone6566323

Fax (852) 6 51 68

08

India

@

BALLUFF India

21

0,

Arjun Centre

Govandi Station Road

Govandi,

IND-Bombay 400 088

Phone

(0

22)

5 56

80

97

Fax

(0

22) 5 56

08

71

Indonesia

a

ELMECON

Automatic Control

Equipments

(I.

Gajah Mada No. 218/i

RI-Jakarta-Indonesia

Phone (021) 63 01 36

Fax (021) 6 49

50

89

/

Iran

@

Iran Technical Supply Co.

3rd Floor, No. 141 Sohrevardi

Shomali Ave

IR-Teheran

Phone (021) 86 37 31

Fax (021) 86 95 37

Israel

0

Ancitech Ltd.

21,

Haorgim St. Unit 21

Industrial Zone

IL-Holon 58857

Phone (03)

5

56 83 51

Fax (03)

5

56 92 78

Italy

a

"Sick

italiana S.p.A.

Corso Giambone 63

I-IO1 3,4,TwJ04

P~(O11)3

120444

Telex 2 20 298

Fax

(011) 3 17 01 40

Korea

69

Hankuk Sangsa Co.

Sungjee Heights

Ill

Bldg. 3F.

642-6, Yuksam dong

Kangnam-ku

Seoul 135-080, Korea

Phone (02)

5

64 96 92/3

Fax (02)

5

64 96 94

Croatia

63

Elma-Femm

Sime Devicica 6/4

Hrvatska

CRO-41000 Zagreb

Phone

(0

41) 3 35-9 85

Fax

(0

41) 3 35-9 85

Malaysia

Sumber Engineering (M)

SDN.BHD.,

No:

2 Lorong

SS

136 A,

Subang Jaya Indust. Estate

MAL-47500 Petaling Jaya

Selangor

Phone (03) 53 42 27

Fax (03) 7 33 42 39

Mexico

Freda S.A.de C.V.

Apartado Postal No. 13 48,

Col.

Centro,

Delg. Cuauhtemoc

5

de Mayo No. 32-413

MEX-06000 Mexico D.F.

phone

(5)

5

21

21

&,5

12

74

84,

521

11

09,5124942,521 6280,

Fa~(5)521-7821 /521-4691

Netherlands

@

Vierpool

BV.

lndustrieweg 2

NL-3606 AS Maarssen

Phone

(0

34 65) 9

45

11

Telex 76 186

Fax

(0

34 65) 7 40

55

Norway

CFj)

Sick Optic Electronic AS

Baerumsveien 383

Postboks 160

N-1346 Gjettum

Phone

(0

67) 56 75

00

Fax

(0

67) 56 66 10

Pohnd

ELTRON

elktronic

s.

c.

"

UI.

Szewska 3

PL-5p-053

w=w+

Phone

@714

44

25

32.

.

Fax (071) 44 11 41

Portugal

a

LA2P, Lda.

Rua Amirante Sousa Dias,

Loja

D - Nova Oeiras

P-2780 Oeiras

Phone (1 1) 442 26 08,

442 26 58

Fax (1 1) 442 28 08

Sweden

BALLUFF Svenska

Uektronik AB

Per Mkanssons vag

lndustrihotellet

Byggnad A, Port 8

Phone (04 13) 1 30 65

Fax

(04

13) 1 06 89

Spain

a

ELION S.A.

Farell

5

E-0801 4 Barcelona

Phone

(03)

4 31 61 11

Telex

5

2 734

Fax

(03)

4 31 18

00

S-24122 EsIOV

South Africa

0

Retron cc

P.O. Box 39448

ZA-Bramley, 201 8

Phone (1 1) 7 86

05

53

Fax

(1

1) 4 40 82 75

Taiwan

caDaan€I€mccorp.

6F-5, NO. 63, Sec. 2

Chang

An

East Road

Taipei, Taiwan, R.O.C.

Phone (02)

5 08

23 31

Fax (02)

5

08

47 44

Thailand

Compomax Company Limited

9/17 Thana Arcade

Ekamai Road

(Sukhumvit 63)

THA-10110 Bangkok

Phone (02) 3 91 -27 94

Fax

(02)

3

81 17

10

Jurw

MEGA

TEKNIK'EL€KIRIK

Okcumusa Menevse Han

w.

No,

64/14

TR-80020 Karakoy Istanbul

Phone(O2

12)254

1699

Fax (02 12) 2 54 53 19

A-7

Page 45

Amendices

MEiSEC-A

.2.1

lW4BTL

Sum

Linear

Scale

Interface

Unit

PCB

A64BTL

RUN

y-

FUSE

2

ST2

:

ST1

’

ST3

ST4

OUT

A

B

C

E

F-

I.

37.5

4

A-8

7

Page 46

Loading...

Loading...