Page 1

type A2USHCPU-S1

User,s Manual

Mitsubishi Programmable Logic Controller

Page 2

SAFETY PRECAUTIONS

(Read these precautions before usi ng.)

When using Mitsubishi equipment, thoroughly read this manual and the associated manuals

introduced in the manual. Also pay careful attention to safety and handle the module properly.

These

and “CAUTION”.

Depending on circumstances, procedures indicated by

results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it whenever necessary. Always

forward it to the end user.

SAFETY PRECAUTIONS classify the safety precautions into two categories: “DANGER”

DANGER

CAUTION

Procedures which may lead to a dangerous condition and cause death or

serious injury if not carried out properly.

Procedures which may lead to a danger ous condition a nd caus e super ficial

to medium injury, or physical da mage only, if not carried out properly.

CAUTION

may also be linked to serious

[DESIGN PRECA UTION S]

!

DANGER

•

Install a safety circuit external to the PC that keeps the entire system safe even when there are

problems with the external power supply or the PC main module. Otherwise, trouble could result

from erroneous output or malfunction.

(1) Configure the following circuits outside the PC: emergency stop circuit, protection circuit,

interlocking circuit for opposite operations such as forward and reverse operations, and

interlocking circuit for machine damage prevention such as upper/lower limit for positioning.

(2) When the PC detects the following problems, it will stop calculation and turn off all output.

•

The power supply module has an over current protection device and over voltage

protection device.

•

The PC CPUs self-diagnostic functions, such as the watchdog timer error, detect problems.

In addition, all output will be turned on when there are problems that the PC CPU cannot

detect, such as in the I/O controller. Build a failsafe circuit exterior to the PC that will make

sure the equipment operates safely at such times.

Refer to the Section 8.1 in this manual for example failsafe circuits.

(3) Output could be left on or off when there is trouble in the output module’s relay or transistor.

So, build an external monitoring circuit that will monitor any single output that could cause

serious trouble.

•

If current over the rating or over-current due to a load short-circuit flows for a long term, it may

cause smoke or fire. Prepare an external safety circuit, such as a fuse.

•

Build a circuit that turns on the external power supply when the PC main module power supply is turned

on. If the external power supply is turned on first, it could result in erroneous output or malfunction.

Page 3

[DESIGN PRECA UTION S]

!

DANGER

Build a circuit that turns on the external power supply after the PLC main module power is turned

•

on.

If the external power supply is turned on first, it could result in accidents due to erroneous

outputs or a malfunction.

When there are communication faulty with the data link, the communication faulty stat ion will

•

enter the following condition. Build an interlock circuit into t he PLC program t hat w ill make sure

the system operates safely by using the communication state information.

Not doing so could result in erroneous output or malfunction.

(1) For the data link data, the data prior t o the communicat ion error will be held.

(2) The MELSECNET (II, /B, /10) remote I/O station will turn all output off.

(3) The MELSECNET/MINI-S3 remote I/O station will hold the output or turn all output off

depending on the E.C. mode setting.

Refer to manuals for corresponding data link system for how to detect the communication faulty

station and the operation status when a communication error occurred.

When configuring a system, do not leave any slots vacant on the base. Should there be any

•

vacant slots, always use a blank cover (A1SG60) or dummy module (A1SG62).

If the cover is not attached, the module's internal parts may be dispersed w hen a short-circuit

test is performed or overcurrent/overvoltage is accidentally applied to the external I/O area.

!

CAUTION

Do not bunch the control wires or communication cable with the main circuit or power wires, or

•

install them close to each other.

They should be installed 100mm (3.94 inch) or more from each other.

Not doing so could result in noise that would cause malfunction.

When controlling items like lamp load, heater or solenoid valve using an out put module, large

•

current (approximately ten times greater than that present in normal circumstances) may flow

when the output is turned OFF

having sufficient rated current.

ON. Take measures such as replacing the module with one

[INSTALLATION PRECAUTIONS]

!

CAUTION

Use the PLC in the environment given in the general specification section of the manual.

•

Using the PLC outside the range of the general specifications may result in electric shock, fire,

or malfunction or may damage or degrade the product.

Before mounting the module, securely insert the projection at the bottom of the module into the

•

fixing hole on the base module.

(The AnS series module must be tightened to the base module at the specified tightening torque.)

An improperly mounted module may result in malfunct ion, failur e, or falling.

Excessive screw tightening may cause falling due to the breakage of the screw or module,

short-circuit, or malfunction.

Page 4

[INSTALLATION PRECAUTIONS]

!

CAUTION

Tighten the screw within the range of specified torque.

•

If the screws are loose, it may result in fallout, short circuits, or malfunctions.

Tightening the screws too far may cause damage to the screw and/or the module, resulting in

fallout, short circuits, or malfunction.

When installing extension cables, be sure that the base unit and the module connectors are

•

installed correctly. After installation, check them for looseness. Poor connections could result in

erroneous input and erroneous output.

Correctly connect the memory card installation connector to the memory card. After installation,

•

make sure that the connection is not loose. A poor connection could result in malfunction.

Do not directly touch the module’s conductive parts or electronic components.

•

Doing so could cause malfunction or failure in the module.

[WIRING PRECAUTIONS]

!

DANGER

Completely turn off the external pow er supply when inst alling or w iring. Not completely tu rning

•

off all power supply could result in electric shock or damage to the product.

When turning on the power or operating the module after installation or wiring work, be sure that

•

the module’s terminal covers are correctly attached. Not attaching t he terminal covers could

result in electric shock.

!

CAUTION

Be sure to ground the FG terminals and LG terminals with a special PLC ground of Type 3 or

•

above. Not doing so could result in electric shock or malfunction.

When wiring in the PLC, check the rated voltage and terminal layout of the wiring, and make

•

sure the wiring is done correctly. Connecting a power supply that differs from the rated voltage

or wiring it incorrectly may cause fire or breakdown.

Do not connect multiple power supply modules in parallel.

•

Doing so could cause overheating, fire, or damage to the power supply module.

Tighten the terminal screws with the specified torque.

•

If the terminal screws are loose, it could result in short circuits, fire, or malfunction.

Tightening the screws too far may cause damage to the screw and/or the module, resulting in

fallout, short circuits, or malfunction.

Take care so that foreign matter such as chips and wiring scraps do not enter the module as it

•

could result in fire, trouble or a malfunction.

External connections shall be crimped or pressure welded with the specified tools, or correctly

•

soldered.

For information regarding the crimping and pressure welding tools, refer to the I/O module’s user

manual. Imperfect connections could result in short circuit, fires, or malfunction.

Page 5

[STARTING A ND MAINTENANCE PRECAUTIONS]

!

DANGER

Do not touch the terminals while power is on. Doing so could cause shock or malfunction.

•

Correctly connect the battery. Also, do not change, disassemble, heat , place in fire, short circuit,

•

or solder the battery.

Mishandling of the battery can cause overheating or cracks which could result in injury and fires.

Make sure to switch all phases of the external power supply off before cleaning or re-tightening

•

screws. If you do not switch off the ext ernal pow er supply , it will cause electr ic shock.

If the screws are loose, it may result in fallout, short circuit, or malfunction. Tightening the

screws too far may cause damages to the screws and/or the module, resulting in fallout, short

circuits, or malfunction.

!

CAUTION

Carefully read manuals and confirm that it is safe enough before performing on-line operations

•

which require to connect peripheral devices to an operating CPU module. (especially w hen

modifying a program, performing forced output, or modifying the operation status.)

Misoperation may damage the module or cause accidents.

Do not disassemble or rebuild the module.

•

It may cause accidents, malfunction, injury, or fire.

When using a cellular phone, keep it 25 cm or more away from the PLC.

•

Otherwise, malfunction may result.

Make sure to switch all phases of the external power supply off before mounting or removing the

•

module. If you do not switch off the exter nal power supply, it w ill cause failure or malfunction of

the module.

[DISPOSAL PRECAUTIONS]

!

Disposing of this product, treat it as industrial wast e.

•

CAUTION

Page 6

Revisions

* The manual number is noted at the lower left of the back cover.

Print Date *Manual Number Revision

Jun. 1997 IB(NA)-66789-A First printing

Jun. 2002

IB(NA)-66789-B

Equivalent to the Japanese version C

Correction

SAFETY PRECAUTIONS, Chapter 1, Section 1.2, Section 2.1, 2.2.1, 2.2.2,

2.2.3, 2.3, Chapter 3, Section 4.1.4, 4.2.2, 4.2.5, Section 5.1, 5.2, Section

6.1.2, 6.1.3, Section 7.1.1, 7.1.5, Section 8.1, Chapter 9, Section 10.3.2,

Appendix 2.1, 2.2, Appendix 4.2

This manual does not imply guarantee or implementation right for industrial ownership or implementation

of other rights. Mitsubishi Electric Corporation is not responsible for industrial ownership problems caused

by use of the contents of this manual.

1997 Mitsubishi Electric Corporation

Page 7

Introduction

Thank you for choosing a Mitsubishi MELSEC-A Series General Purpose Programmable Controller.

Before using your new PC, please read this manual thoroughly to gain an understanding of its functions so

you can use it properly.

Please forward a copy of this manual to the end user.

Table of Contents

About This Manual

1. OVERVIEW 1- 1 to 1- 3

1.1 Features............................................................................................................................................................ 1- 2

1.2 Comparison of Performance and Specifications with A2USCPU(S1)...............................................................1- 3

2. SYSTEM CONFIGURATION 2- 1 to 2- 19

2.1 Overall Configuration ........................................................................................................................................ 2- 1

2.2 Precautions When Configuration the System ................................................................................................... 2- 3

2.2.1 Hardware ............................................................................................................................................... 2- 3

2.2.2 Software package.................................................................................................................................. 2- 5

2.2.3 Precautions when using GPP function software packages and A8PU peripheral devices

which are not compatible with AnU........................................................................................................ 2- 7

2.3 System Equipment............................................................................................................................................ 2- 8

2.4 System Configuration Overview........................................................................................................................2-18

3. GENERAL SPECIFICATION 3- 1

4. CPU MODULE 4-1 to 4- 28

4.1 Performance Specification................................................................................................................................ 4- 1

4.1.1 Overview of operation processing..........................................................................................................4- 3

4.1.2 Operation processing of RUN, STOP, PAUSE, and STEP RUN...........................................................4- 5

4.1.3 Operation processing upon momentary power failure........................................................................... 4- 7

4.1.4 Self-diagnosis........................................................................................................................................4- 8

4.1.5 Device list ..............................................................................................................................................4-10

4.2 Parameter Setting Ranges................................................................................................................................4-11

4.2.1 List of parameter setting range..............................................................................................................4-11

4.2.2 Memory capacity setting (for main program, file register, comment, etc.).............................................4-13

4.2.3 Setting ranges of timer and counter.......................................................................................................4-15

4.2.4 I/O devices.............................................................................................................................................4-17

4.2.5 I/O allocation of special function modules .............................................................................................4-17

4.2.6 MELSECNET/MINI-S3 automatic refresh..............................................................................................4-18

4.3 Function List......................................................................................................................................................4-22

4.4 Precautions When Handling the Module...........................................................................................................4-24

4.5 Name and Setting of Each Part.........................................................................................................................4-25

4.5.1 The name of each part of the A2USHCPU-S1.......................................................................................4-25

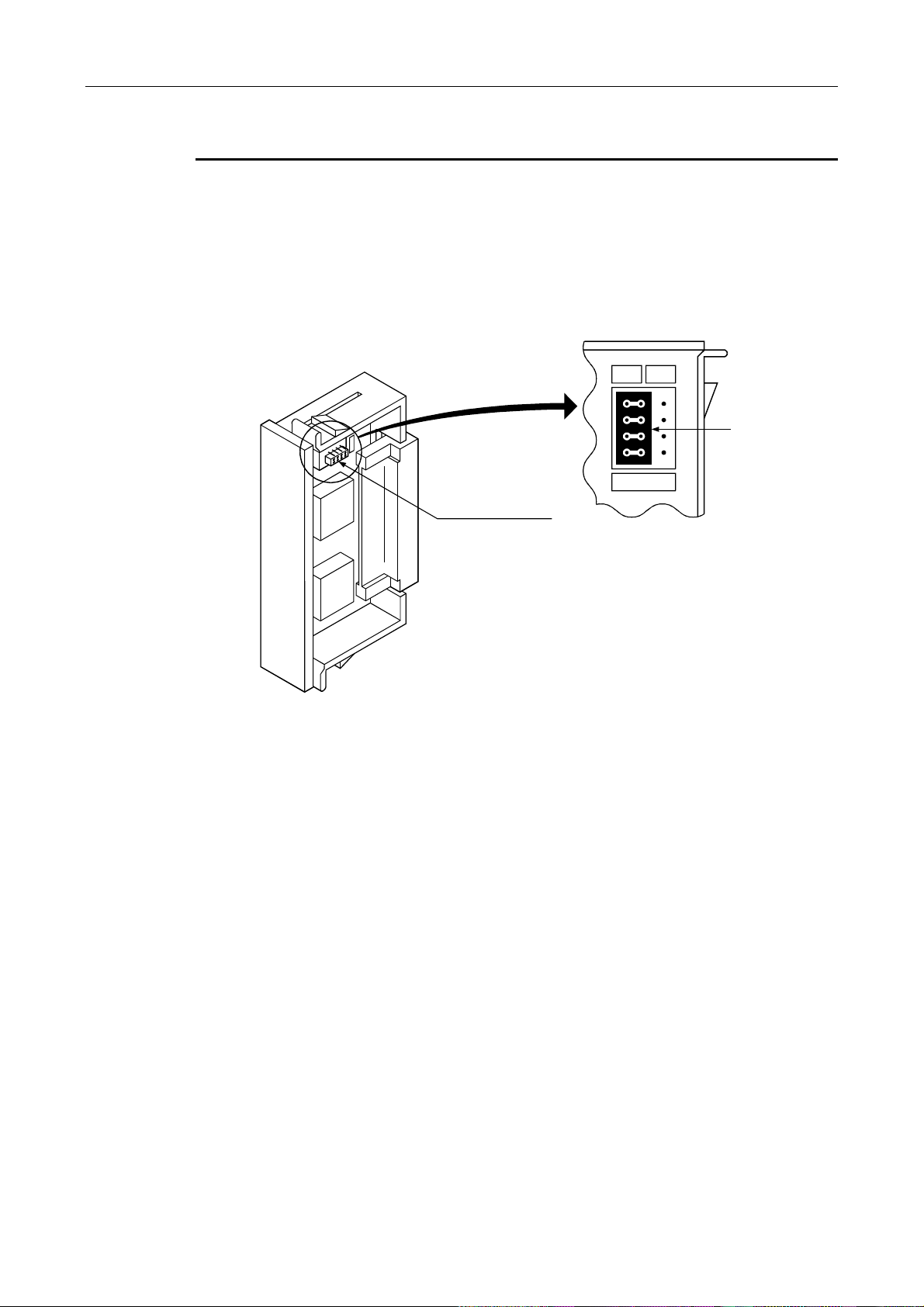

4.5.2 Settings for memory protection switch...................................................................................................4-27

4.5.3 Latch clear operation.............................................................................................................................4-28

5. POWER SUPPLY MODULE 5- 1 to 5- 7

5.1 Specifications.................................................................................................................................................... 5- 1

5.1.1 Selecting a power supply module.......................................................................................................... 5- 4

Page 8

5.2 Name and Setting of Each Part......................................................................................................................... 5- 5

6. BASE UNIT AND EXTENSION CABLE 6- 1 to 6- 7

6.1 Specification...................................................................................................................................................... 6- 1

6.1.1 Base unit specifications.........................................................................................................................6- 1

6.1.2 Extension cable specifications............................................................................................................... 6- 1

6.1.3 Usage standards of extension base units

(A1S52B, A1S55B, A1S58B, A52B, A55B, A58B)...............................................................................6- 2

6.2 Name and Setting of Each Part......................................................................................................................... 6- 6

7. MEMORY CASSETTE AND BATTERY 7- 1 to 7- 5

7.1 Memory Cassette.............................................................................................................................................. 7- 1

7.1.1 Specifications......................................................................................................................................... 7- 1

7.1.2 Precautions when handling the memory cassette.................................................................................7- 1

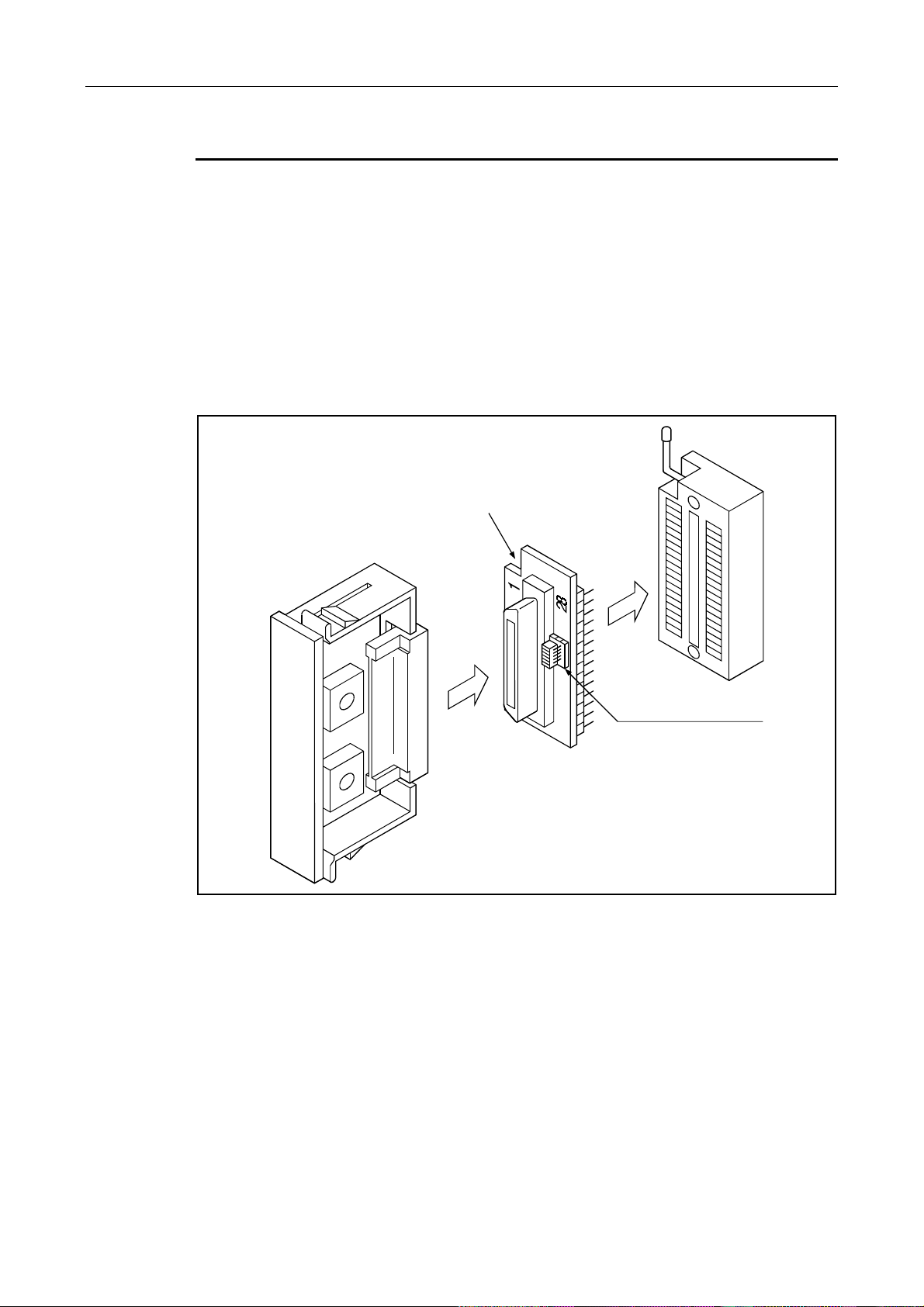

7.1.3 Installation and removal of memory cassette ........................................................................................ 7- 2

7.1.4 Procedure for writing sequence program to A2SMCA-14KP.................................................................7- 3

7.1.5 Memory protection setting of A2SNMCA-30KE.....................................................................................7- 4

7.2 Battery............................................................................................................................................................... 7- 5

7.2.1 Specifications......................................................................................................................................... 7- 5

7.2.2 Precautions when handling.................................................................................................................... 7- 5

7.2.3 Battery installation ................................................................................................................................. 7- 5

8. LOADING AND INSTALLATION 8- 1 to 8- 17

8.1 Concept of Failsafe Circuit................................................................................................................................ 8- 1

8.2 Installation Environment.................................................................................................................................... 8- 5

8.3 Calculation Method of Heat Amount Generated by the PC............................................................................... 8- 5

8.4 Installation of Base Unit.................................................................................................................................... 8- 7

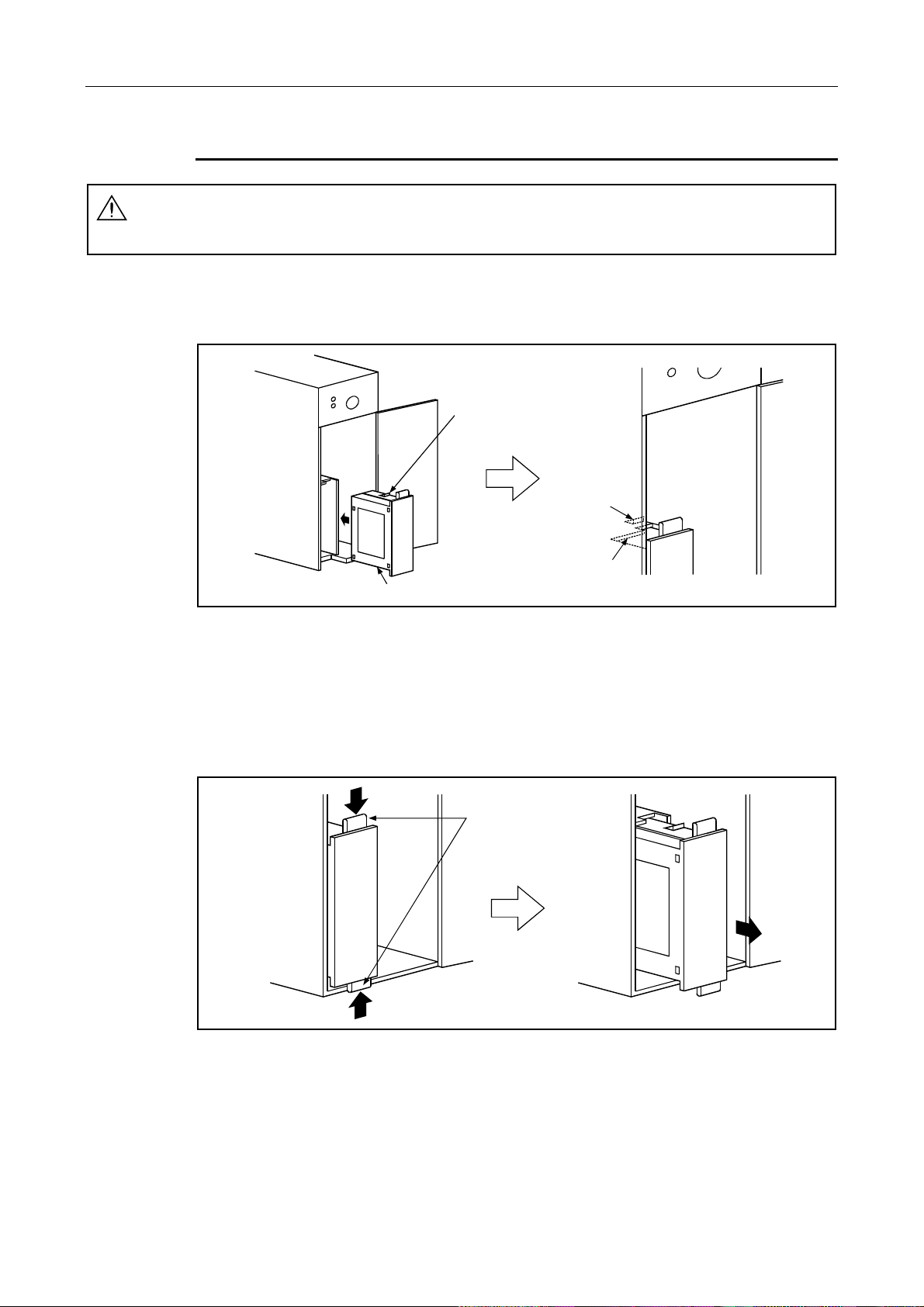

8.4.1 Precautions when installing PC.............................................................................................................8- 7

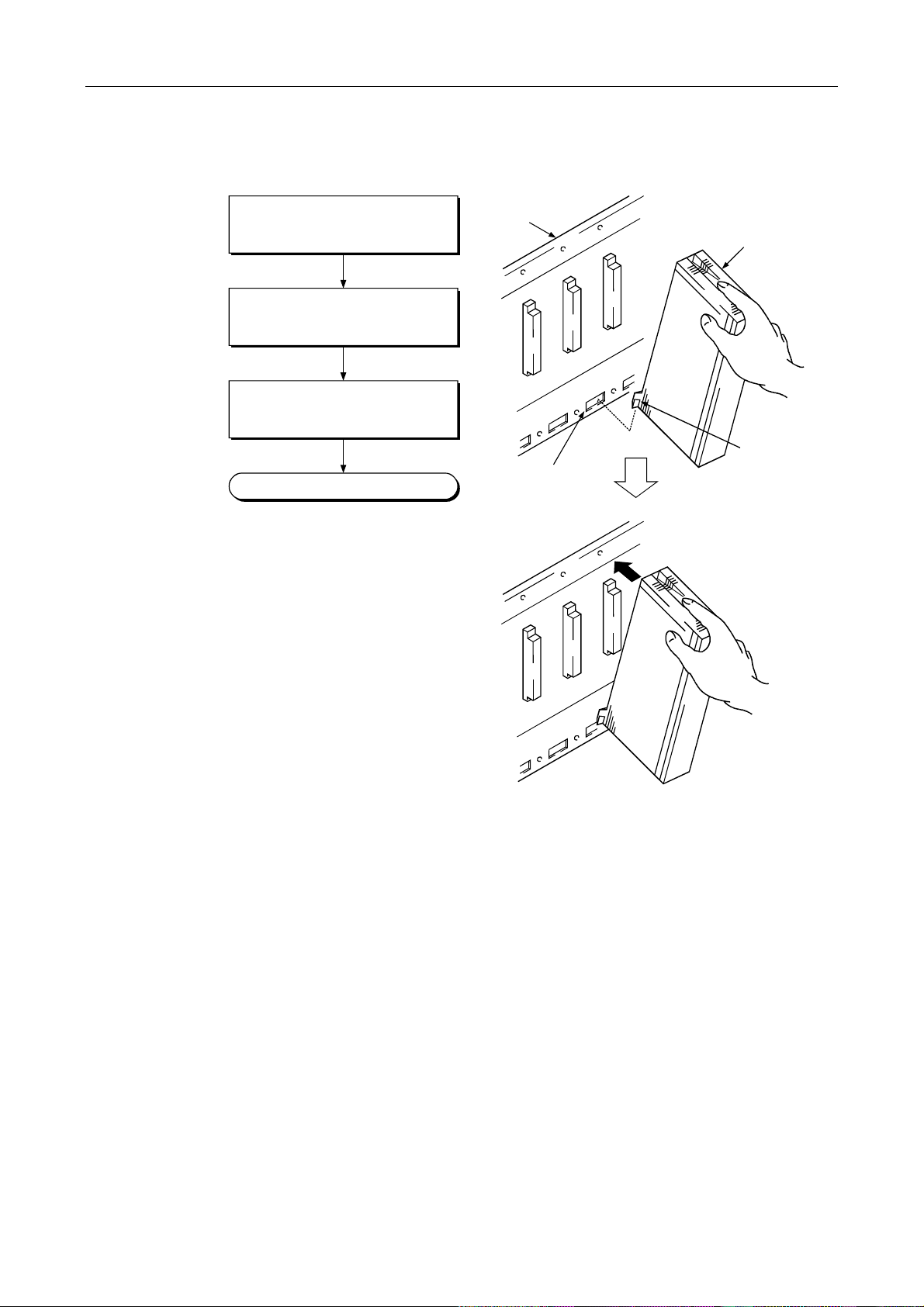

8.4.2 Installation.............................................................................................................................................. 8- 8

8.5 Installation and Removal of the Modules.......................................................................................................... 8- 9

8.6 Installation and Removal of the Dustproof Cover..............................................................................................8-12

8.7 Wiring................................................................................................................................................................8-13

8.7.1 Precautions when wiring........................................................................................................................8-13

8.7.2 Wiring to the module terminals..............................................................................................................8-16

8.8 Precautions When Unfailure Power System (UPS) is Connected ....................................................................8-17

9. EMC DIRECTIVE AND LOW-VOLTAGE INSTRUCTION 9- 1 to 9- 11

9.1 Requirements for Compliance to EMC Directive (89/336/EEC)........................................................................ 9- 1

9.1.1 EMC standards...................................................................................................................................... 9- 1

9.1.2 Installation inside the control cabinet..................................................................................................... 9- 2

9.1.3 Cables.................................................................................................................................................... 9- 3

9.1.4 Power supply module............................................................................................................................. 9- 6

9.1.5 Ferrite core ............................................................................................................................................ 9- 7

9.1.6 Noise filter (power supply line filter)....................................................................................................... 9- 7

9.2 Requirement to Conform to the Low-Voltage Instruction.................................................................................. 9- 8

9.2.1 Standard applied for AnS series............................................................................................................ 9- 8

9.2.2 Precautions when using the AnS series................................................................................................9- 9

9.2.3 Power supply ......................................................................................................................................... 9- 9

9.2.4 Control box.............................................................................................................................................9-10

9.2.5 Module installation.................................................................................................................................9-10

9.2.6 Grounding..............................................................................................................................................9-11

9.2.7 External wiring .......................................................................................................................................9-11

Page 9

10. MAINTENANCE AND INSPECTION 10- 1 to 10- 5

10.1 Routine Inspection............................................................................................................................................10-2

10.2 Periodic Inspection............................................................................................................................................10-3

10.3 Battery Replacement.........................................................................................................................................10-4

10.3.1 Service life of the battery .......................................................................................................................10-4

10.3.2 Battery replacement procedure .............................................................................................................10-5

11. TROUBLESHOOTING 11- 1 to 11- 20

11.1 Fundamentals of Troubleshooting ....................................................................................................................11- 1

11.2 Troubleshooting................................................................................................................................................11- 2

11.2.1 Troubleshooting flowchart......................................................................................................................11- 2

11.2.2 Flowchart for actions when the "POWER" LED is turned OFF..............................................................11- 3

11.2.3 Flowchart for actions when the "RUN" LED is turned OFF....................................................................11- 4

11.2.4 Flowchart for actions when the "RUN" LED is flashing..........................................................................11- 5

11.2.5 Flowchart for actions when the "ERROR" LED is turned ON.................................................................11- 6

11.2.6 Flowchart for actions when the "ERROR" LED is flashing.....................................................................11- 7

11.2.7 Flowchart for actions when the output module's output load does not turn ON.....................................11- 8

11.2.8 Flowchart for actions when the program cannot be written ...................................................................11- 9

11.3 Error Code List..................................................................................................................................................11-10

11.3.1 Procedure to read an error code............................................................................................................11-10

11.3.2 Error code list.........................................................................................................................................11-10

11.4 Possible Troubles with I/O Modules..................................................................................................................11-18

11.4.1 Troubles with the input circuit and the countermeasures ......................................................................11-18

11.4.2 Possible troubles in the output circuit ....................................................................................................11-20

APPENDIX A- 1 to A- 31

Appendix 1 Instruction List....................................................................................................................................... A- 1

Appendix 2 Lists of Special Relays and Special Registers...................................................................................... A- 8

Appendix 2.1 List of special relays.................................................................................................................A- 8

Appendix 2.2 List of special registers.............................................................................................................A-13

Appendix 3 Peripheral Devices................................................................................................................................A-19

Appendix 4 Precautions When the Existing Sequence Programs Are Diverted for the A2USHCPU-S1.................A-20

Appendix 4.1 Instructions with different specifications...................................................................................A-20

Appendix 4.2 Special relays and special registers with different specifications.............................................A-21

Appendix 4.3 Parameter setting.....................................................................................................................A-21

Appendix 4.4 I/O control method....................................................................................................................A-22

Appendix 4.5 Microcomputer program ...........................................................................................................A-23

Appendix 4.6 Processing of the index register...............................................................................................A-23

Appendix 5 External Dimension Diagrams...............................................................................................................A-24

Appendix 5.1 A2USHCPU-S1 module ...........................................................................................................A-24

Appendix 5.2 A1S61PN, A1S62PN and A1S63P power supply modules......................................................A-24

Appendix 5.3 Basic Base Unit........................................................................................................................A-25

Appendix 5.3.1 A1S32B basic base unit................................................................................................A-25

Appendix 5.3.2 A1S33B basic base unit................................................................................................A-25

Appendix 5.3.3 A1S35B basic base unit................................................................................................A-26

Appendix 5.3.4 A1S38B basic base unit................................................................................................A-26

Appendix 5.4 Extension Base unit..................................................................................................................A-27

Appendix 5.4.1 A1S65B extension base unit.........................................................................................A-27

Appendix 5.4.2 A1S68B extension base unit.........................................................................................A-27

Appendix 5.4.3 A1S52B extension base unit.........................................................................................A-28

Appendix 5.4.4 A1S55B extension base unit.........................................................................................A-28

Appendix 5.4.5 A1S58B extension base unit.........................................................................................A-29

Appendix 5.5 Memory Cassette .....................................................................................................................A-29

Page 10

Appendix 5.5.1 A2SMCA- memory cassette.....................................................................................A-29

Appendix 5.5.2 A2SNMCA-30KE memory cassette...............................................................................A-30

Appendix 5.6 A2SWA-28P Memory Write Adapter........................................................................................A-30

Appendix 6 Precautions When Writing Data on a ROM Using PECKER..................................................................A-31

Page 11

About This Manual

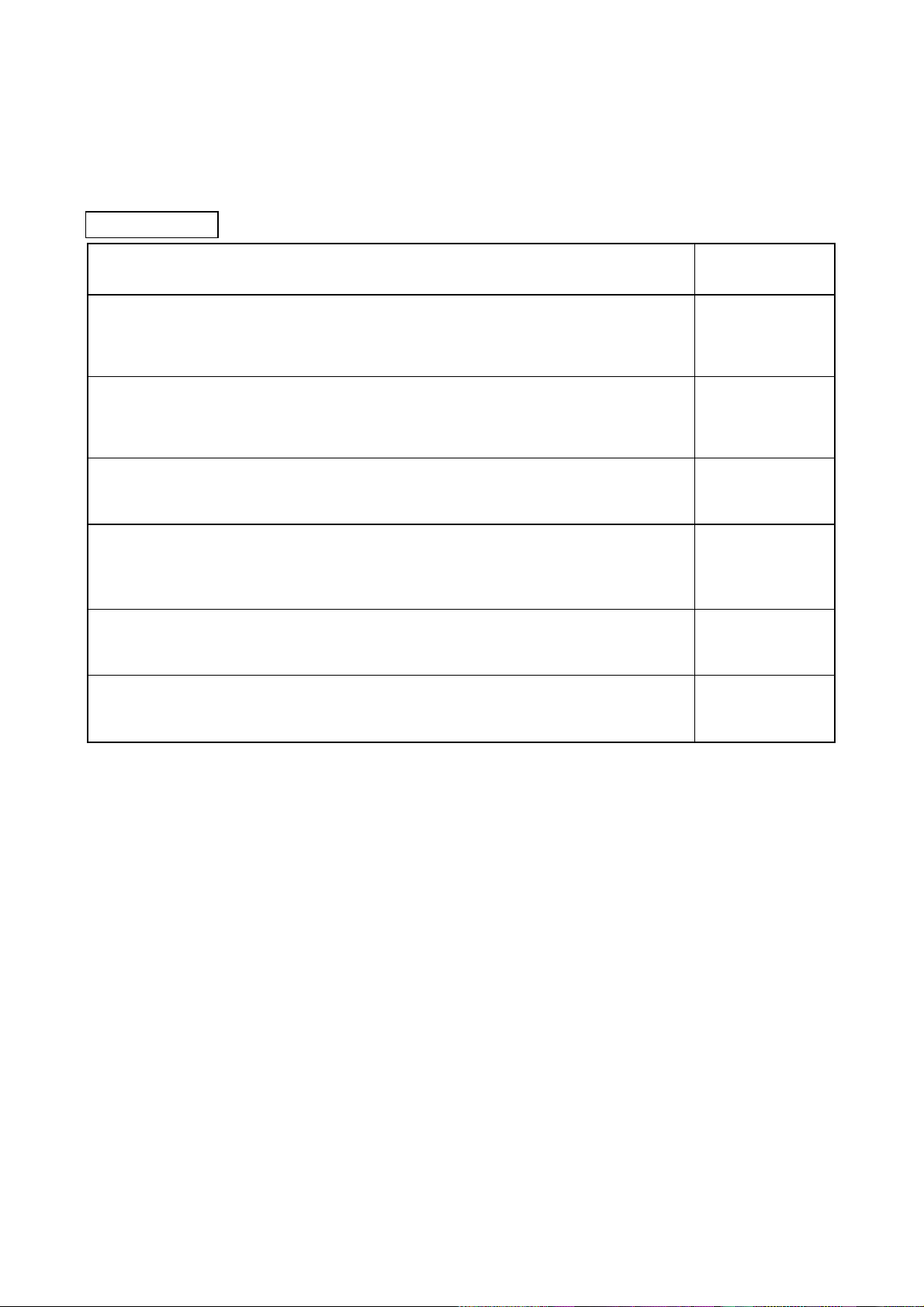

The following table lists manuals regarding this product.

Related Manuals

Manual Name

ACPU Programming Manual (Fundamentals)

Describes programming methods necessary for creating programs, device names, parameters,

program types, memory area configuration, and so on.

(Sold separately)

ACPU Programming Manual (Common Instructions)

Describes how to use the sequence instruction, basic instructions, applied instructions and

microcomputer programs.

(Sold separately)

AnACPU/AnUCPU/QCPU-A (A mode) Programming Manual (Dedicated Instructions)

Describes instructions that have been expanded for A2USHCPU-S1.

(Sold separately)

AnACPU/AnUCPU Programming Manual (AD57 Instructions)

Describes dedicated instructions for A2USHCPU-S1 to control the AD57(S1)/AD58 controller

module.

(Sold separately)

AnACPU/AnUCPU Programming Manual (PID Instructions)

Describes dedicated instructions for A2USHCPU-S1 to perform the PID control.

(Sold separately)

AnS Module type I/O User's Manual

Describes the specification of the compact building block type I/O module.

(Sold separately)

Manual No.

(Model Code)

IB-66249

(13J740)

IB-66250

(13J741)

IB-66251

(13J742)

IB-66257

(13J743)

IB-66258

(13J744)

IB-66541

(13JE81)

Page 12

1. OVERVIEW MELSEC-A

1. OVERVIEW

This User's Manual describes the performance, functions, and handling method of the A2USHCPU-S1

general purpose PC (abbreviated as A2USHCPU-S1 hereafter), as well as the specifications and

handling of the memory cassette, power supply module and the base module.

The A2USHCPU-S1 has higher performance compared with the conventional A2USCPU, with faster

instruction processing speed, increased program size, and so on. Utilize these enhanced capabilities to

operate the A2USHCPU-S1 in the most efficient way.

The instructions used in the sequence programs of the A2USHCPU-S1 are as follows:

•

Sequence instructions........................25 instructions

•

Basic and application instructions ......243 instructions

•

Dedicated instructions........................204 instructions

Refer to Appendix-1 for the complete list of instructions.

The programming modules and software packages have to be compatible with the upgraded A2UCPU,

A2UCPU-S1, A3UCPU, and A4UCPU (abbreviated as AnUCPU hereafter).

When the conventional programming modules and software packages are used, the usable range

varies depending on the model of the CPU (PC model name). --- Refer to Section 2.2.3.

Refer to the list of components in Section 2.3 for various modules which can be used with the

A2USHCPU-S1.

Refer to Section 2.2.1 for the special function modules which have limited range of usable devices.

1-1

Page 13

1. OVERVIEW MELSEC-A

1.1 Features

The A2USHCPU-S1 has the following features when compared with A2USCPU(S1) and A1SCPU:

(1) The program size was greatly increased in the A2USHCPU-S1 to a maximum of 30k steps,

compared with 14k steps of the A2USCPU(S1).

(2) The operation speed (sequence instructions) was substantially improved.

The processing speed of the A2USHCPU-S1 has been improved to 0.09µs/step, compared with

0.2µs/step for the A2USCPU.

(3) The A2USHCPU-S1 has 256k bytes of built-in RAM memory.

The built-in RAM memory has a capacity of 256k bytes with battery backup.

In addition, an optional memory cassette (EPROM, EEPROM) can be attached.

(4) MELSECNET/10-compatible for fast and large-capacity networking

The MELSECNET/10 network system can be constructed by installing a network module

(A1SJ71LP21, A1SJ71BR11) to the extension base module and setting the network parameters.

It is also compatible with the MELSECNET II system.

(5) The A2USHCPU-S1 has more points for the I/O devices, link devices, and data registers than

those of the A1SCPU.

•

I/O device (X/Y)......8192 points (X/Y0 to 1FFF)

•

Link relay (B) ..........8192 points (B0 to B1FFF)

•

Link register (W).....8192 points (W0 to W1FFF)

•

Data register (D)..... 8192 points (D0 to 8191)

(6) The A2USHCPU-S1 can execute the batch processing of the data communication requests.

•

All of the data communication requests from the A1SJ71UC24-R2, A1SD51S, peripheral

devices, and others, can be processed by single END processing. (Normally, one END

processing processes one communication request.)

•

The batch processing of the data communication requests can be activated by selecting "YES"

on the "END Batch Processing Setup" in the supplementary function setup of the parameter, or

by turning ON the M9029 from the sequence program.

•

Delay of the data transfer to each module will be prevented by using the batch processing of

the data communication requests.

(M9029: When OFF, only one request is processed by one scan.)

(7) The A2USHCPU-S1 can execute the dedicated instructions for the AnA/AnUCPU.

Dedicated instructions for AnA/AnUCPU, AD57 instructions, and PID control instructions can be

executed.

1-2

Page 14

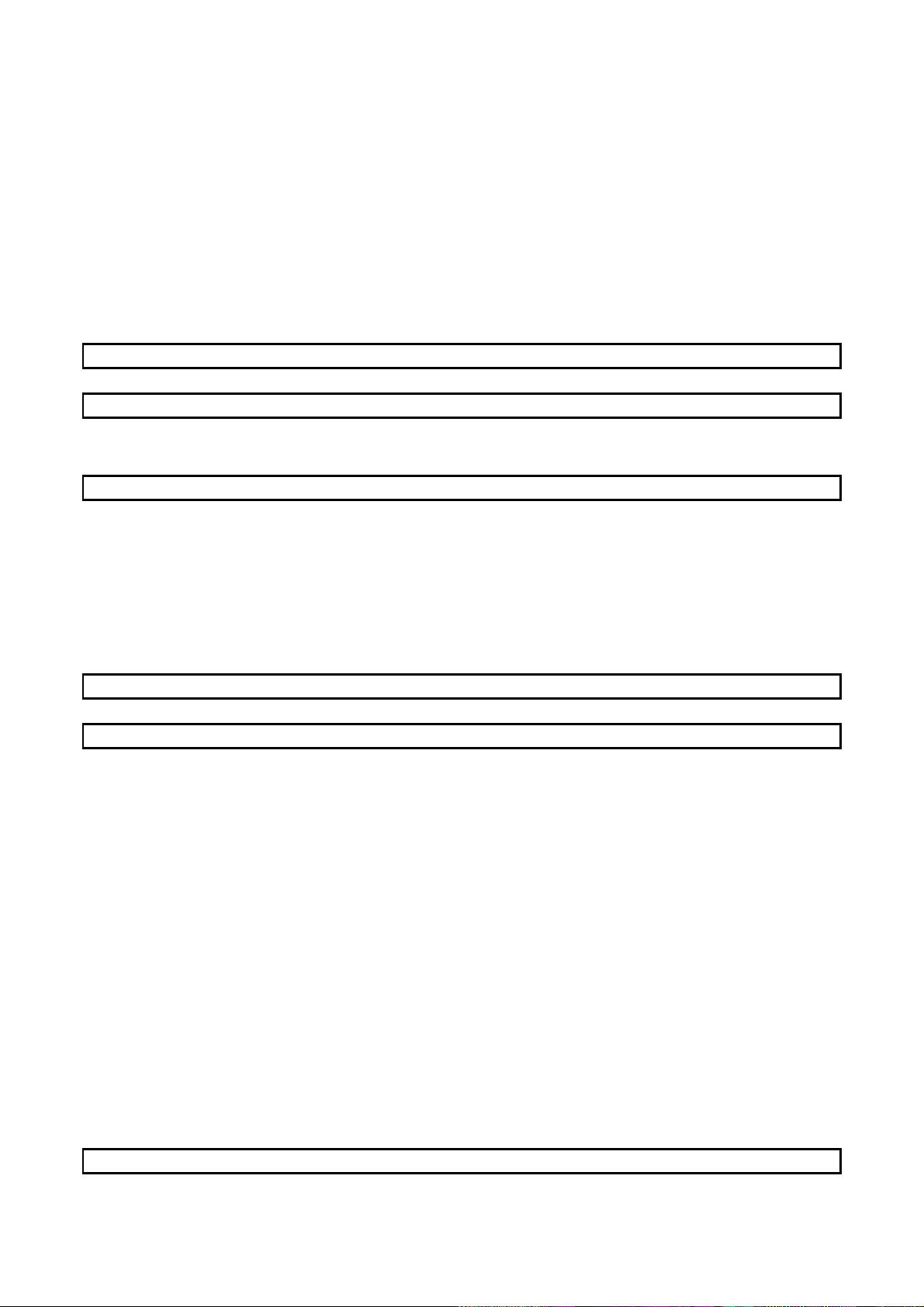

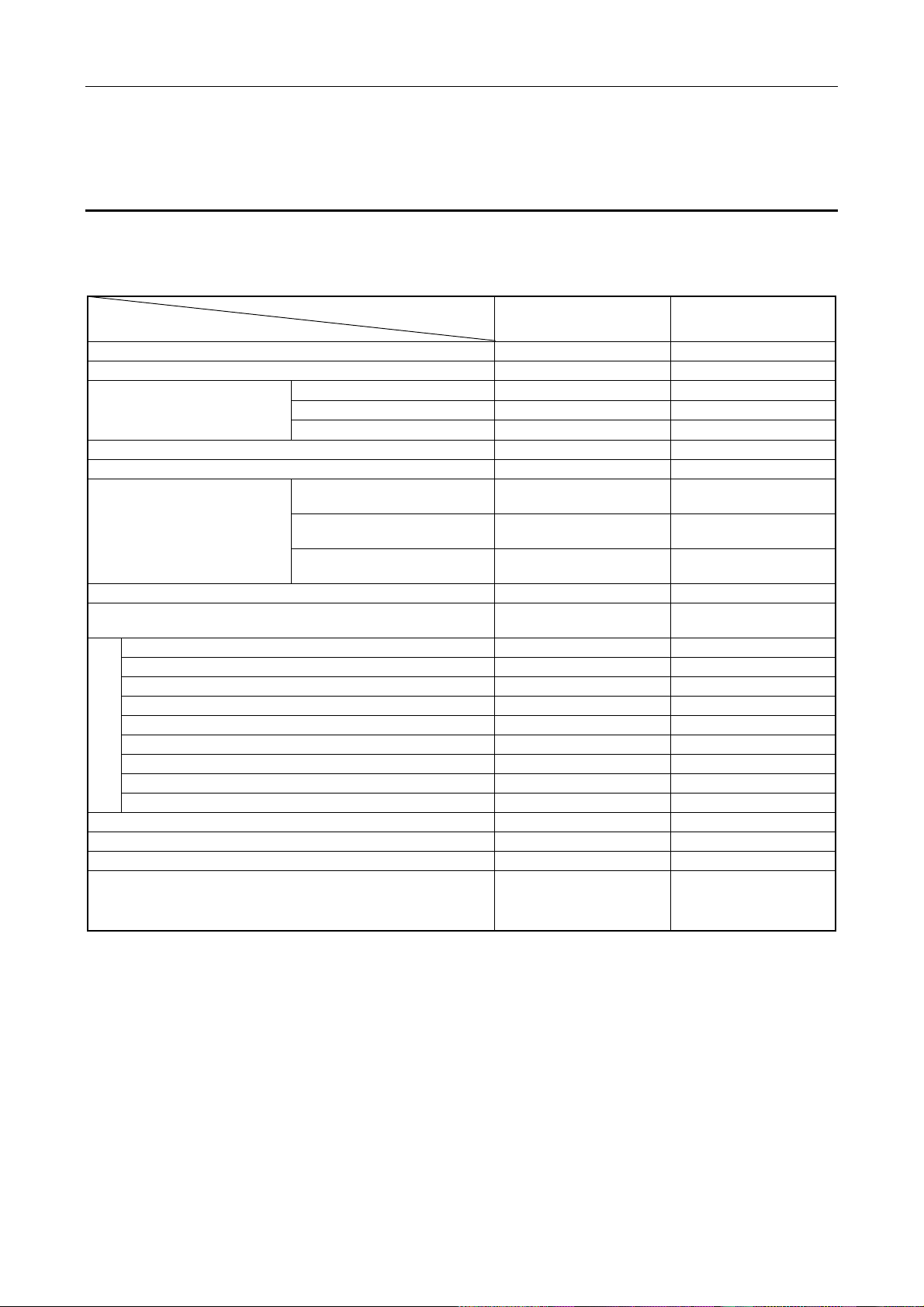

1. OVERVIEW MELSEC-A

1.2 Comparison of Performance and Specifications with

A2USCPU(S1)

The differences in performance and specifications between A2USHCPU-S1 and A2USCPU(S1) are as

follows. Performance and specifications which are not listed here are the same between A2USHCPUS1 and A2USCPU(S1).

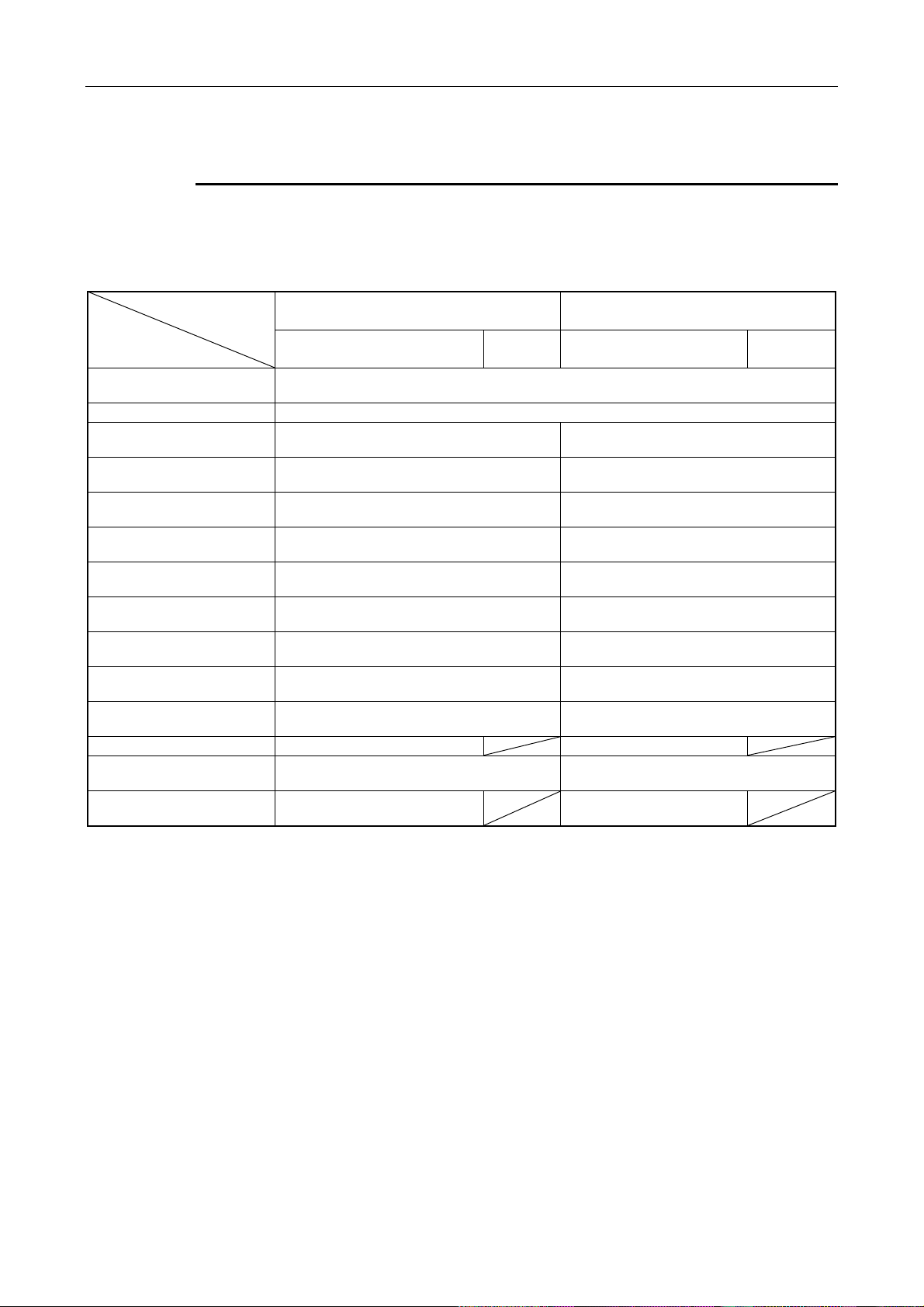

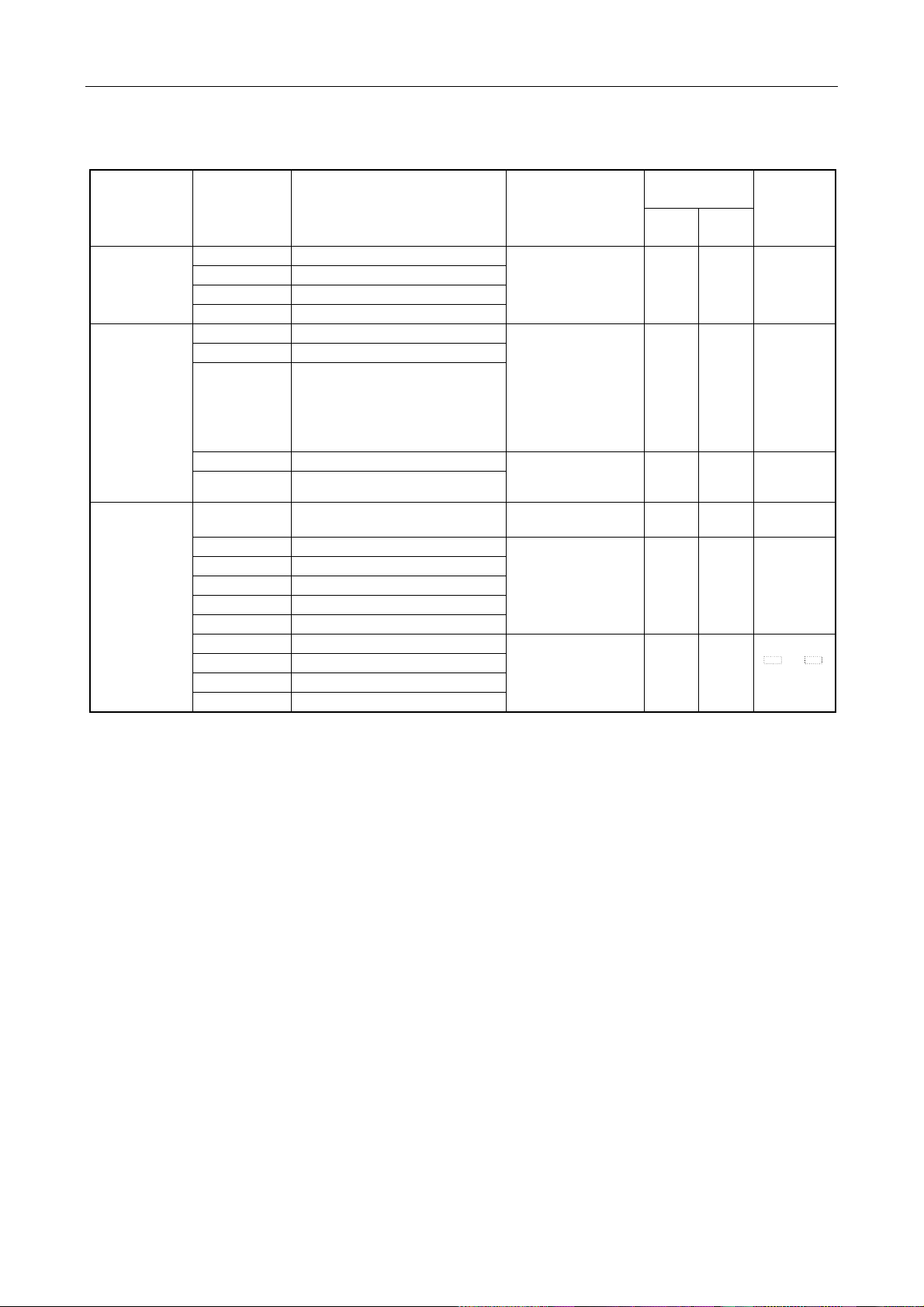

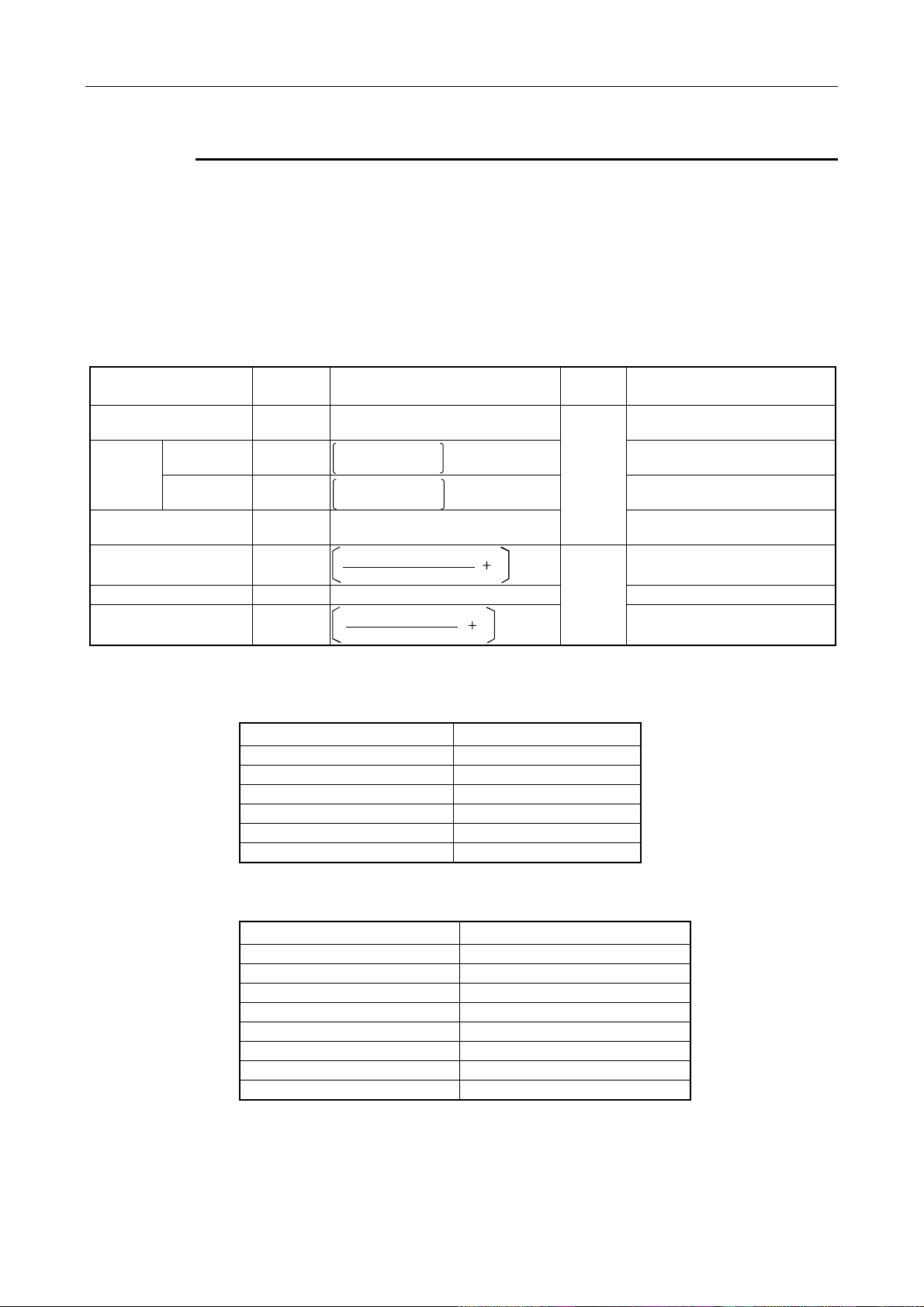

CPU Model

Item

I/O Control method Refresh method Refresh method

Processing speed (Sequence instruction) (µs/step) 0.09 0.2

Sequence instructions

Number of instructions

Constant scan (ms) 10 to 190 10 to 190

Main program capacity A maximum of 30k steps A maximum of 14k steps

Memory capacity and memory

cassette model

Number of I/O device points (points ) 8192 8192

Number of I/O points (points) 1024

Internal relay [M, L, S] (points) 8192 8192

Link relay [B] (points) 8192 8192

Link register [W] (point s ) 8192 8192

Data register [D] (points) 8192 8192

File register [R] (points 8192 8192

Annunciator [F] (points) 2048 2048

Timer [T] (points) 2048 2048

Counter [C] (points) 1024 1024

Number of device points

Index register [V, Z] (points) 14 14

Comment (points) MAX 4032 MAX 4032

Expanded comment (points) MAX 3968 MAX 3968

Watchdog timer set t ing Fixed to 200(ms) Fixed to 200(ms)

Data link

Basic and application instructions 243 243

Dedicated instructions 204 204

Memory capacity

(built-in RAM)

EPROM-type

memory cassette

2

E

PROM-type

memory cassette

*1 When A2USCPU-S1 is used.

A2USHCPU-S1 A2USCPU(S1)

25 25

256k bytes

A2SMCA-14KP A2SMCA-14KP

A2SNMCA-30KE A2SNMCA-30KE

MELSECNET/10 MELSECNET/10

MELSECNET(II) MELSECNET(II)

MELSECNET/B MELSECNET/B

64k bytes

(256k bytes)*1

512

(1024)*1

1-3

Page 15

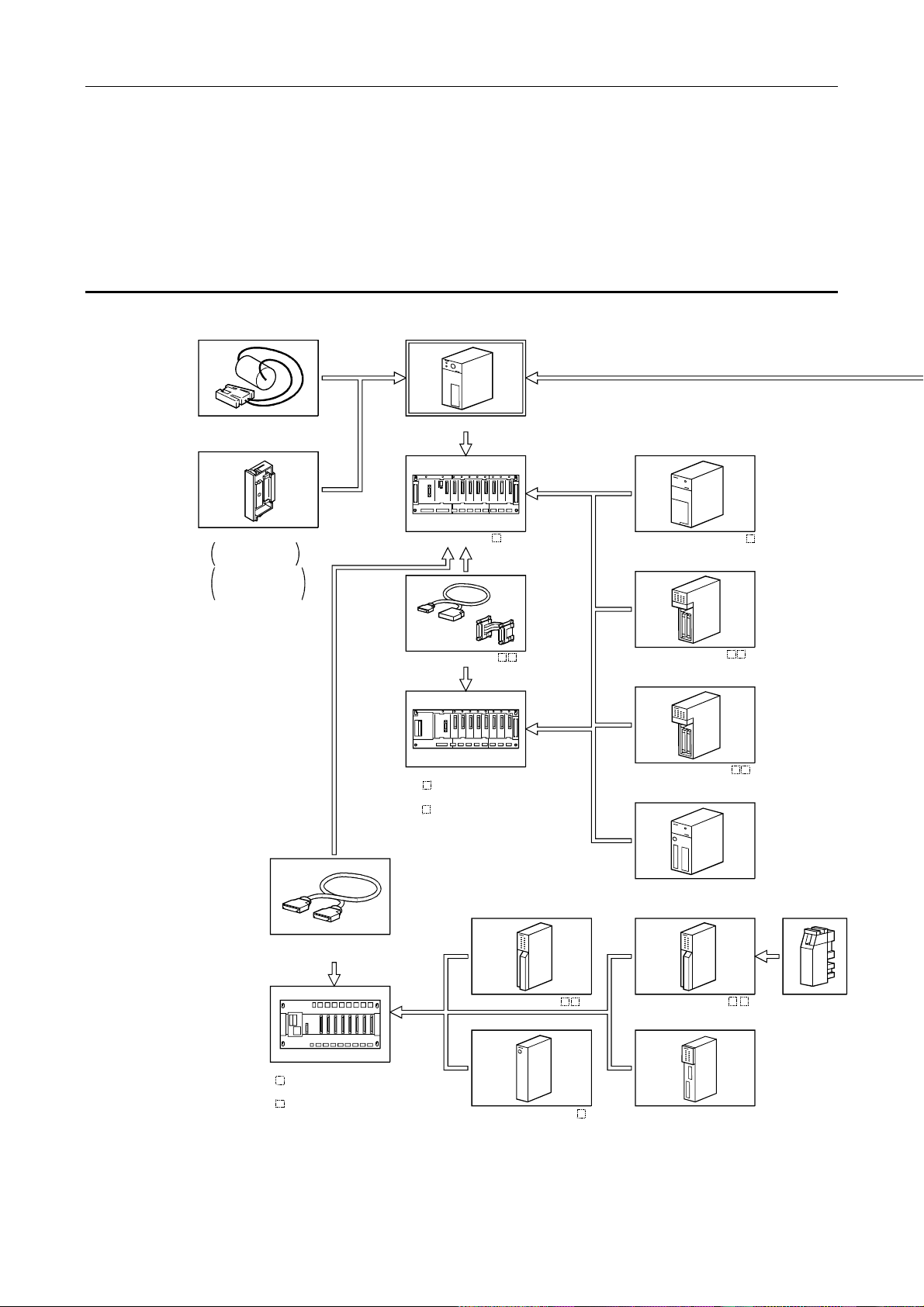

2. SYSTEM CONFIGURATION MELSEC-A

2. SYSTEM CONFIGURATION

The possible system configuration with A2USHCPU-S1, the precautions when the system is

configured, and system components are described.

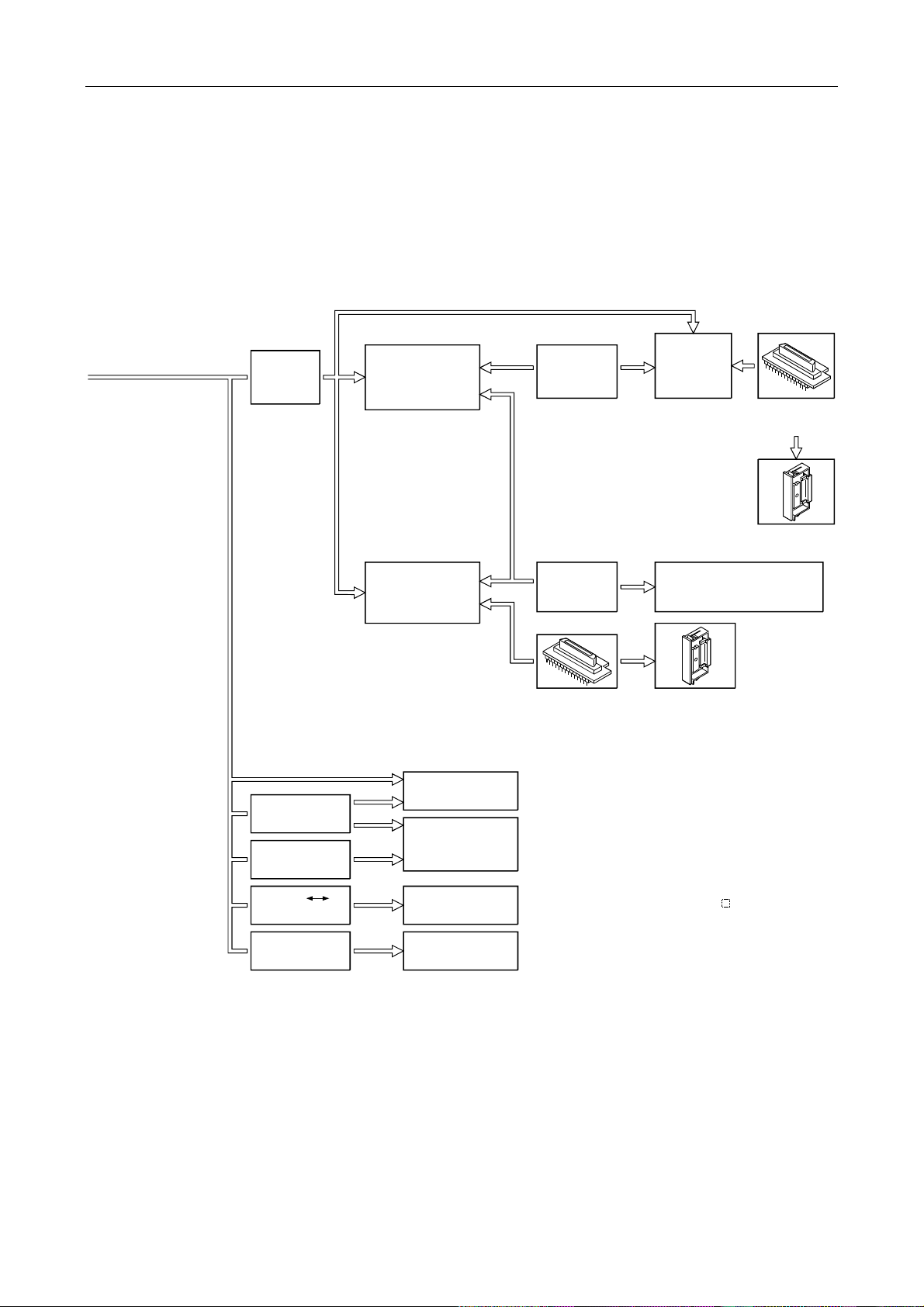

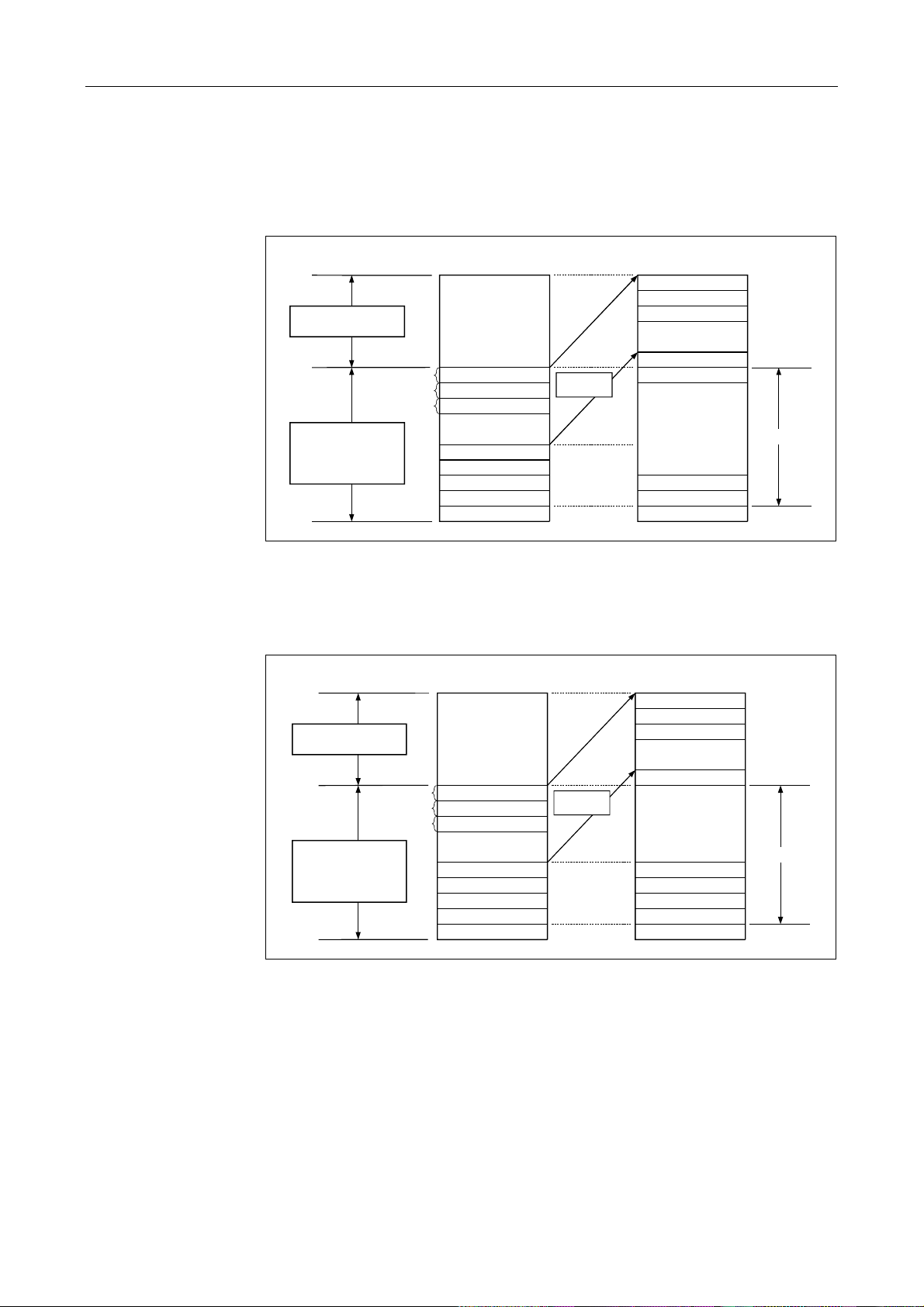

2.1 Overall Configuration

The system configurations of the A2USHCPU-S1 stand-alone system and the peripheral devices are

as follows:

(To peripheral devices)

Battery (A6BAT)

ROM casette

A2SMCA-14KP

with EPROM

A2SMCA-14KE

A2SNMCA-30KE

2

PROM

with E

A2USHCPU-S1

Basic base (A1S3 B)

Extension cable (A1SC B)

Extension base

(A1S5 B)

: without power supply module

(A1S6 B)

: with a power supply module

Power supply module (A1S6 P)

Input module (A1SX )

Output module (A1SY )

Connection cable (A1SCO5NB)

[For building-block type]

Extension base

(A5 B)

: without power supply module

(A6 B)

: with a power supply module

Input module (AX )

Power supply module (A6 P)

2-1

Special function module

Output module (AY )

Special function module

Fuse

Page 16

2. SYSTEM CONFIGURATION MELSEC-A

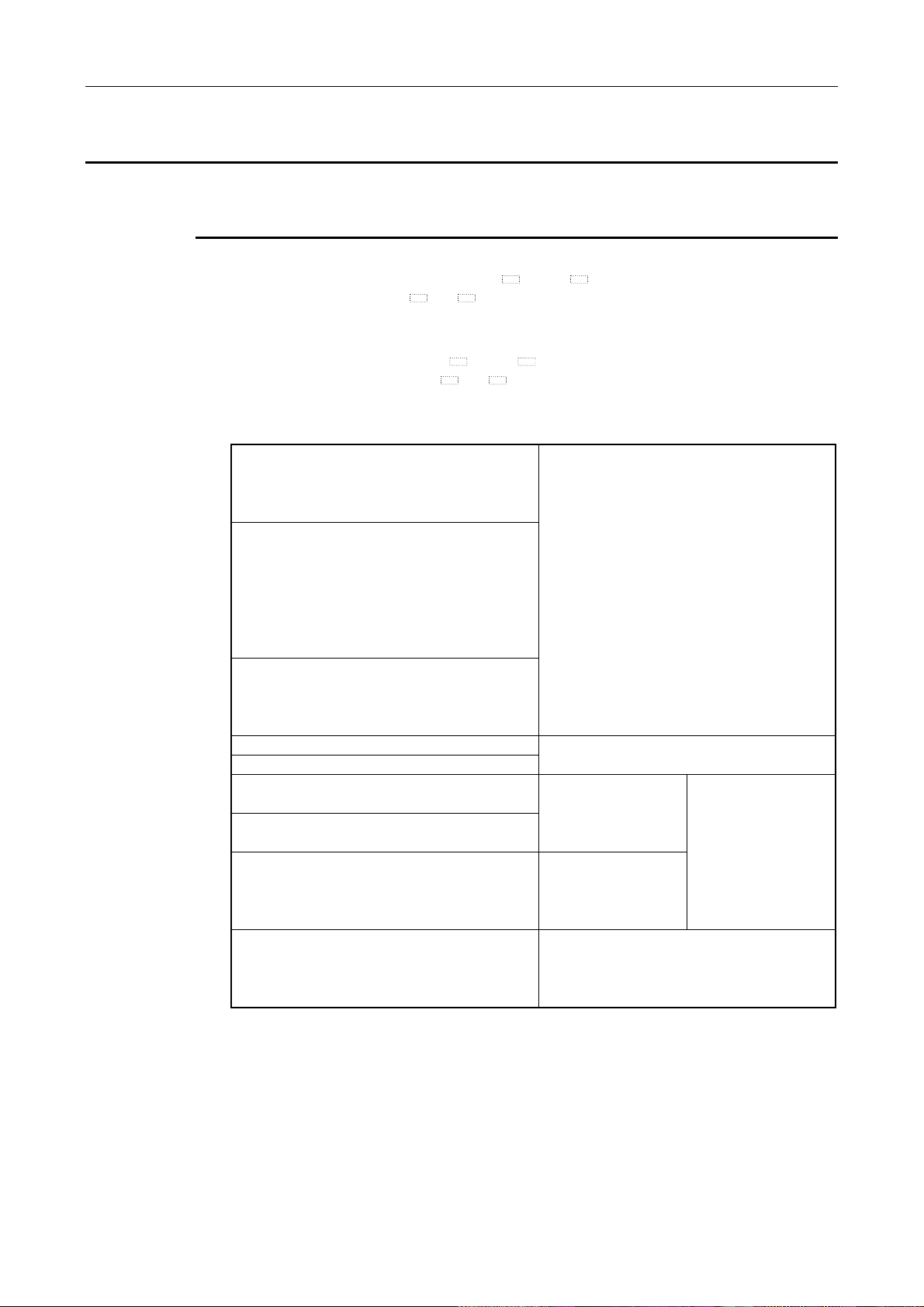

(To A2USHCPU-S1 )

AC30R4

AC300R4

cable

AC30R4-PUS

cable

AC20R4-A8PU

cable

A6PHP

Plasma Hand-held

Graphic Programmer

A6GPP

Intelligent GPP

A7PUS

programming module

A8PU/A8UPU

programming module

AC03R2

cable

AC30R2

cable

EPROM write adapter

(A2SWA-28P)

A6WU

P-ROM writer

module

Printer

(A7NPR-S1, K6PR-K,

general-purpose printer)

ROM cassette

(A2SMCA-14KP)

EPROM write

adapter

(A2SWA-28P)

ROM cassette

(A2SMCA-14KP)

RS-232C

RS-422 converter

AC30R4-PUS

cable

IBM PC/AT or

100% compatible

A6DU-B

data access module

(When a DOS/V personal computer is used, refer to

the system configuration section of the SW IVD-GPPA,

GX Developer Operation Manual.)

2-2

Page 17

2. SYSTEM CONFIGURATION MELSEC-A

2.2 Precautions When Configuring the System

The hardware and software packages which can be used for the A2USHCPU-S1 are described.

2.2.1 Hardware

(1) I/O module

All the building-block-type I/O modules for A

extension base module of A5

B/A6 B.

(2) Special function module

(a) Special function modules for A N and A A can be used by installing them in the

extension base module of A5

B/A6 B.

(b) The special function modules of the following models have a limitation in the number of

installable modules.

AJ71C22-S1 AD51H-S3 *2

AJ71C23-S3 AJ71UC24

AJ71E71-S3 *2

AJ61BT11 (Only when in the intelligent mode.)

A985GOT (Only when the bus connection is used.)

A975GOT (Only when the bus connection is used.)

A970GOT (Only when the bus connection is used.)

A960GOT (Only when the bus connection is used.)

A956WGOT (Only when the bus connection is used.)

A956GOT (Only when the bus connection is used.)

A951GOT

A1SJ71UC24-R2(PRF/R4)

A1SJ71E71-B2-S3(-B5-S3)

A1SD51S A1SD21-S1

A1SJ61BT11(Only when in the intelligent mode.)

AI61(S1)

A1SI61

AJ71AP21 (S3) *2 AJ71AR21 *2

AJ71AT21B *2

A1SJ71AP21 (S3) *2 A1SJ71AR21 *2

A1SJ71AT21B *2

AJ71LP21 AJ71BR11

AJ71LR21 A1SJ71BR11

A1SJ71LP21

A1SJ71LR21

AJ71PT32-S3 (Only when in the extension mode.)

AJ71T32-S3 (Only when in the extension mode.)

A1SJ71PT32-S3 (Only when in the extension mode.)

A1SJ71T32-S3 (Only when in the extension mode.)

*1: Accessible within the device range of A3HCPU.

*2: Accessible within the device range of A3ACPU.

Refer to the user's manual of the corresponding special f unction module for the acc essible device

ranges.

N and A A can be used by installing them to the

A maximum of 6 modules in total can be installed.

Only one module can be installed.

A maximum of 2 modules

in total can be installed.

A maximum of 4 modules

in total can be installed.

A maximum of 4 modules

in total can be installed.

A maximum of 10 modules in total can be installed.

2-3

Page 18

2. SYSTEM CONFIGURATION MELSEC-A

)

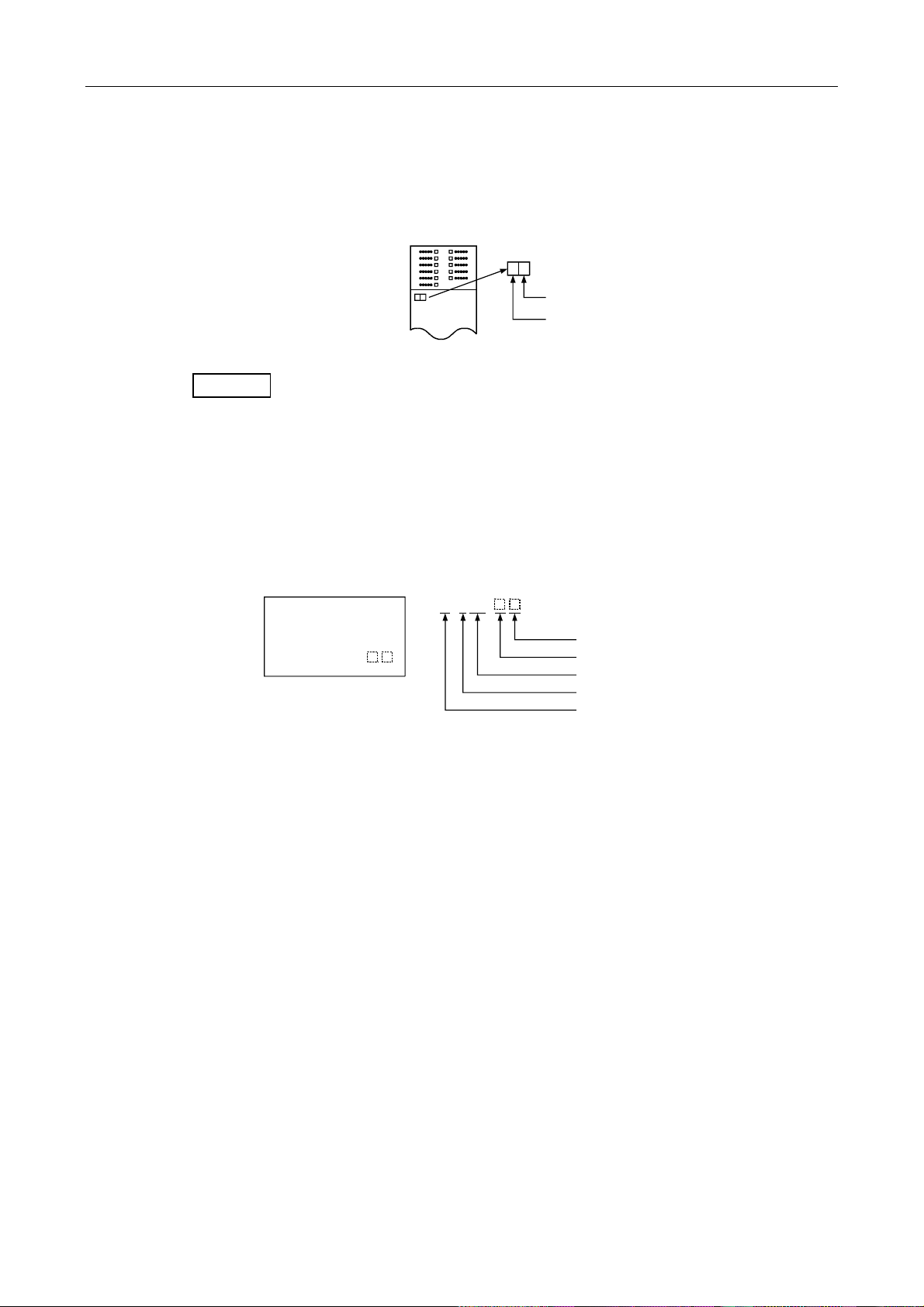

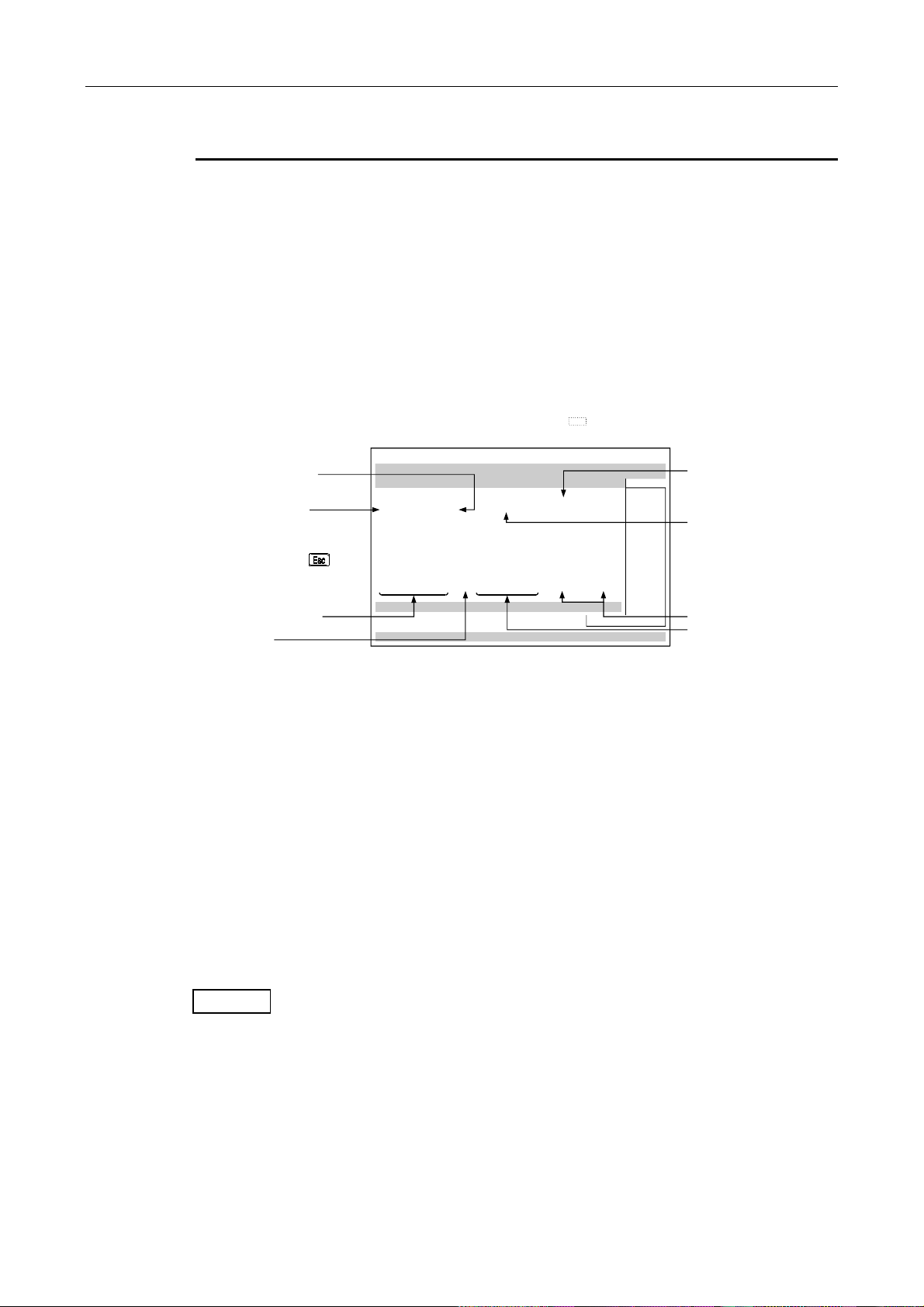

(c) When a remote I/O network is constructed with the MELSECNET/10 network system,

use the A2USHCPU-S1 software of version "A" or later, and the AJ7ILP21/BR11,

A1SJ71LP21/BR11-type network software of version "J" or later.

<Example> For AJ71LP21/BR11:

Software version

Hardware version

Front side of the module

REMARK

The special function modules which cannot be used by the A2USHCPU-S1 are as follows:

AJ71C23

•

AJ71C24 (modules dated before February 1987) • AD51 (modules dated before March 1987)

•

AD57-S2

•

Confirm the manufactured date on the rating plate.

(3) Peripheral devices

(a) Use an A6WU P-ROM writer of the hardware version "E" or later.

<Example> If manufactured date is March 1987:

A6WU

DATE H 703

H 703

Software version

Hardware version

Month

Year (The last digit of the year.

Indicates A3HCPU-compatible.

(b) The A6WU P-ROM writer module cannot be installed as an add-on to be directly attached to

the A2USHCPU-S1.

(c) Among the programming modules (A7PUS, A8PU, A8UPU), only A7PUS is installed as an

add-on.

Other models (A8PU, A8UPU) use only the hand-held method with a cable.

(4) Writing on the ROM for EPROM memory cassettes

An optional A2SWA-28P memory write adapter is required to write on a ROM for the A2SMCA14KP EPROM memory cassette using the A6GPP, A6WU, or ROM writer. (The conventional

A6WA-28P cannot be used.)

(5) Writing while running when operated by E

When "write while running " to the E

2

PROM is executed, the program transfer in progress status is

2

PROM (with A2SNMCA-30KE installed)

displayed on the peripheral device, then the processing for the sequence program is stopped for

approximately two seconds until the transfer finishes to complete the "write while running ".

Because the program processing stops for two seconds, stop the CPU while writing instead of

executing the "write while running " if it affects the operation of the controlled device.

When "A3A" or "A3H" is specified as the PC's model to startup the GPP function software

package which is not AnU-compatible, the "write while running" cannot be executed to the

2

E

PROM.

If "write while running" to the E2PROM is executed, the changed circuit block and any PLF

instruction included in the steps after the instruction will not operate normally.

If the execution condition for the PLF instruction is turned off upon completion of writing, the PLF

instruction is executed.

2-4

Page 19

2. SYSTEM CONFIGURATION MELSEC-A

(6) Writing while in operation by the E2PROM (with A2SNMCA-30KE installed)

(a) When writing a program to the E

2

PROM after the GPP function software package is started

up with the PC's model specified as "A3A" or "A3H", cancel the memory protection of both

the A2USHCPU-S1 main module and the memory cassette for the E2PROM (A2SNMCA30KE) before execution.

(b) The writing of the program cannot be executed from the computer link module or from a

peripheral device connected to other stations on the MELSECNET.

Perform writing of the program from a peripheral device connected to the RS-422 of the

A2USHCPU-S1.

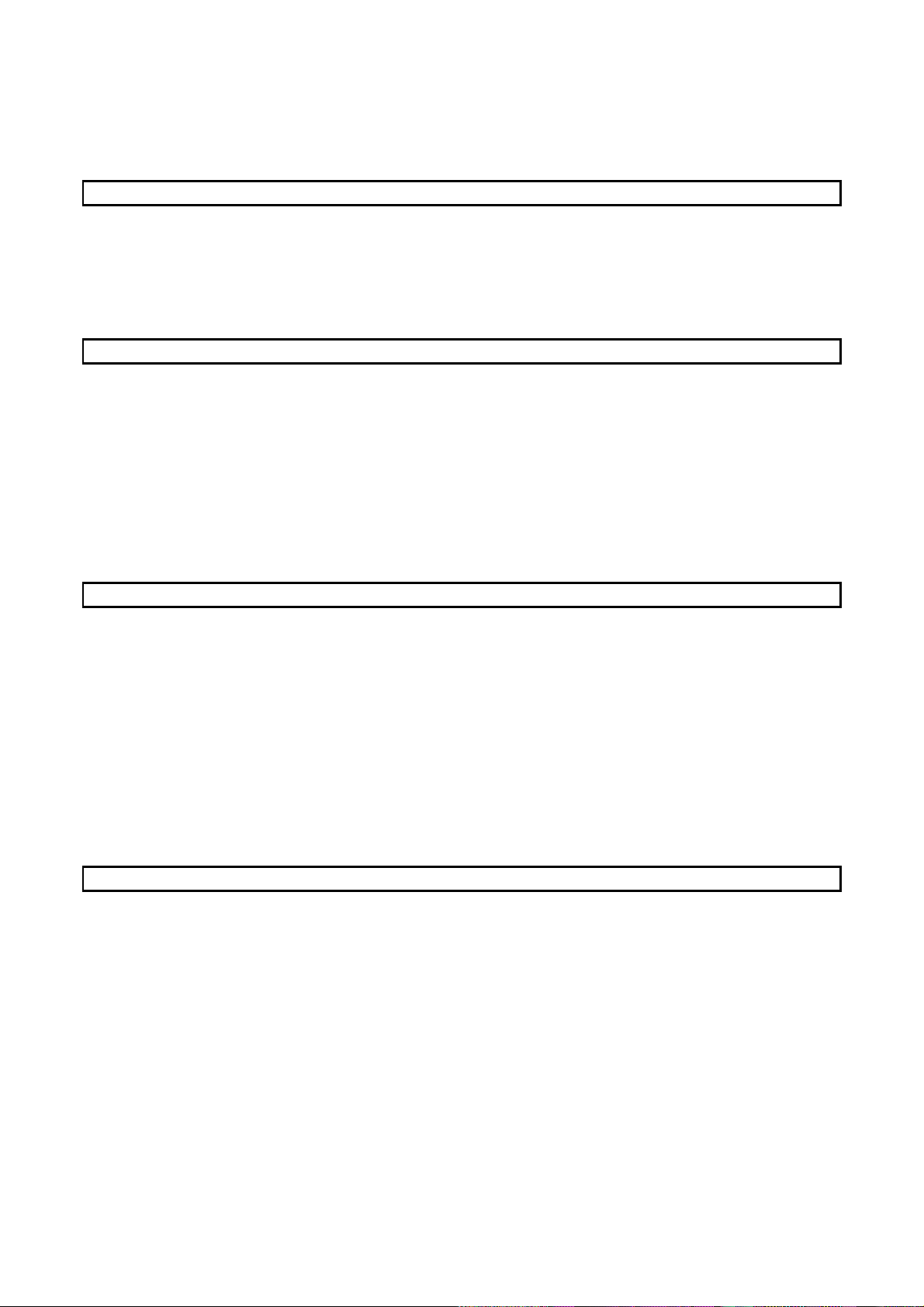

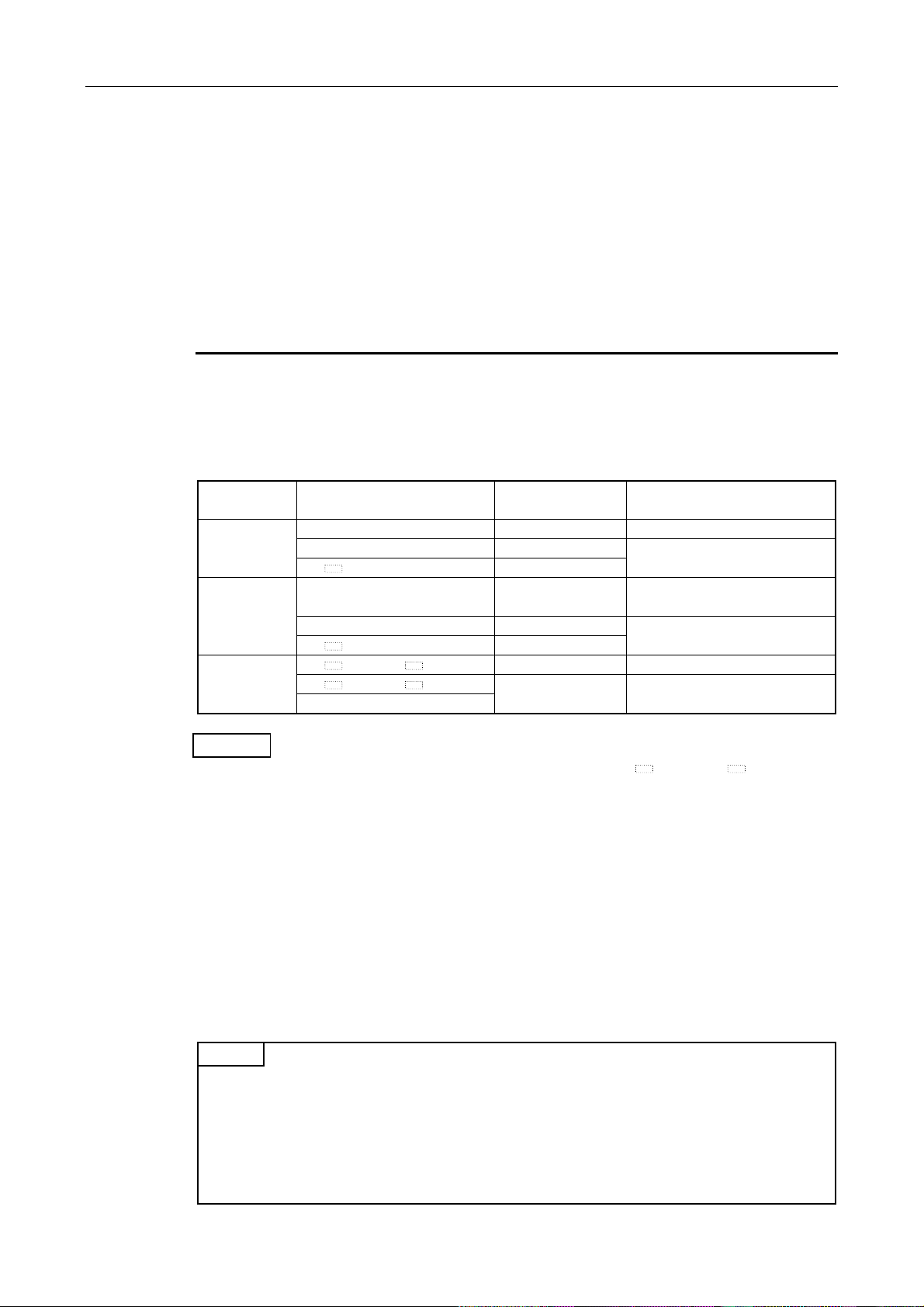

2.2.2 Software package

(1) GPP function software packages and model name setting at the startup

The table below shows the GPP function software packages allowing you to create an

A2USHCPU-S1 program and PLC model settings at startup.

When creating an A2USHCPU-S1 program, if "A2USH-S1" is not available as a PLC model, set

"A3U". If "A3U" is not available, set "A3A". If both "A3U" and "A3A" are not available, set "A3H" .

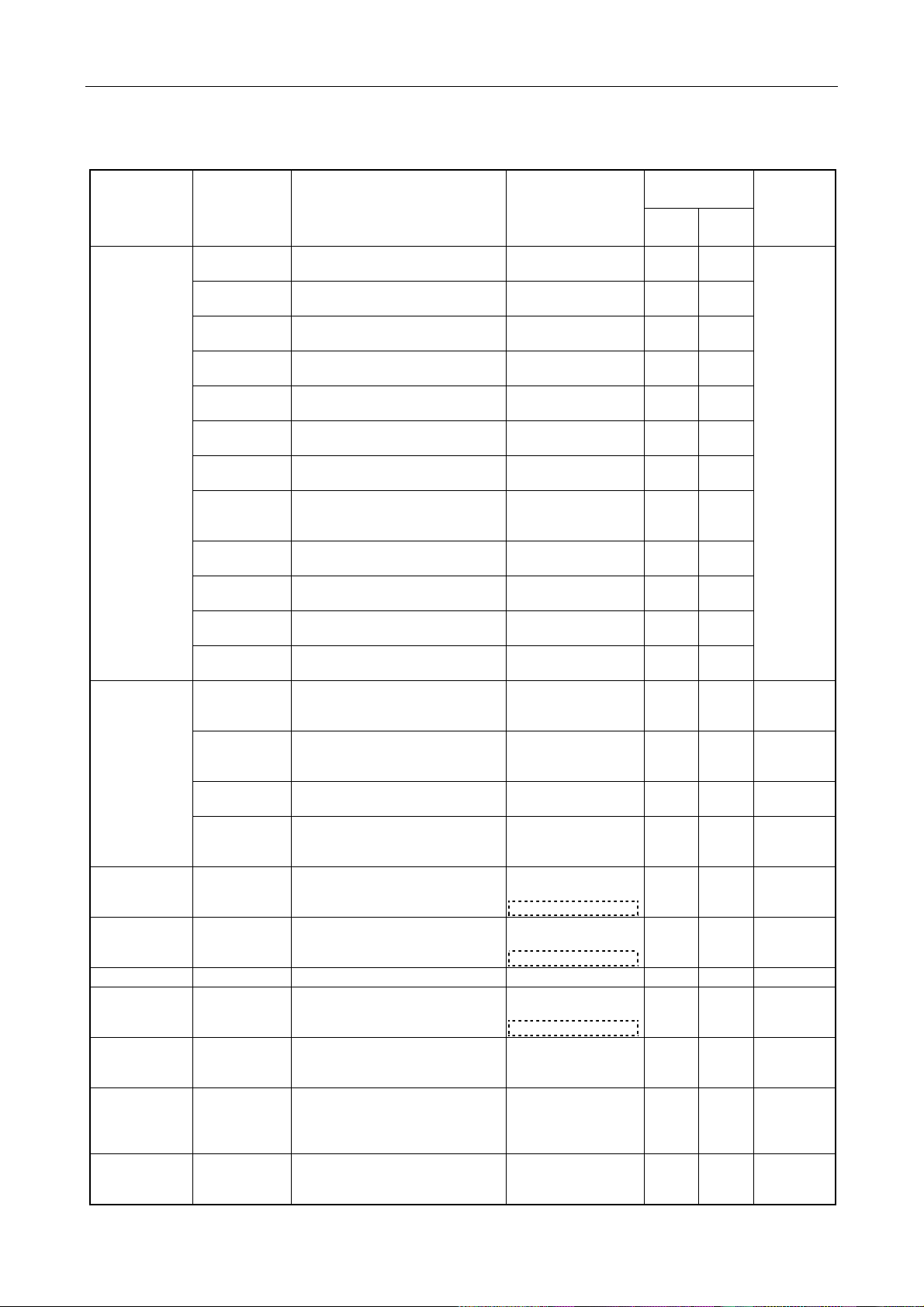

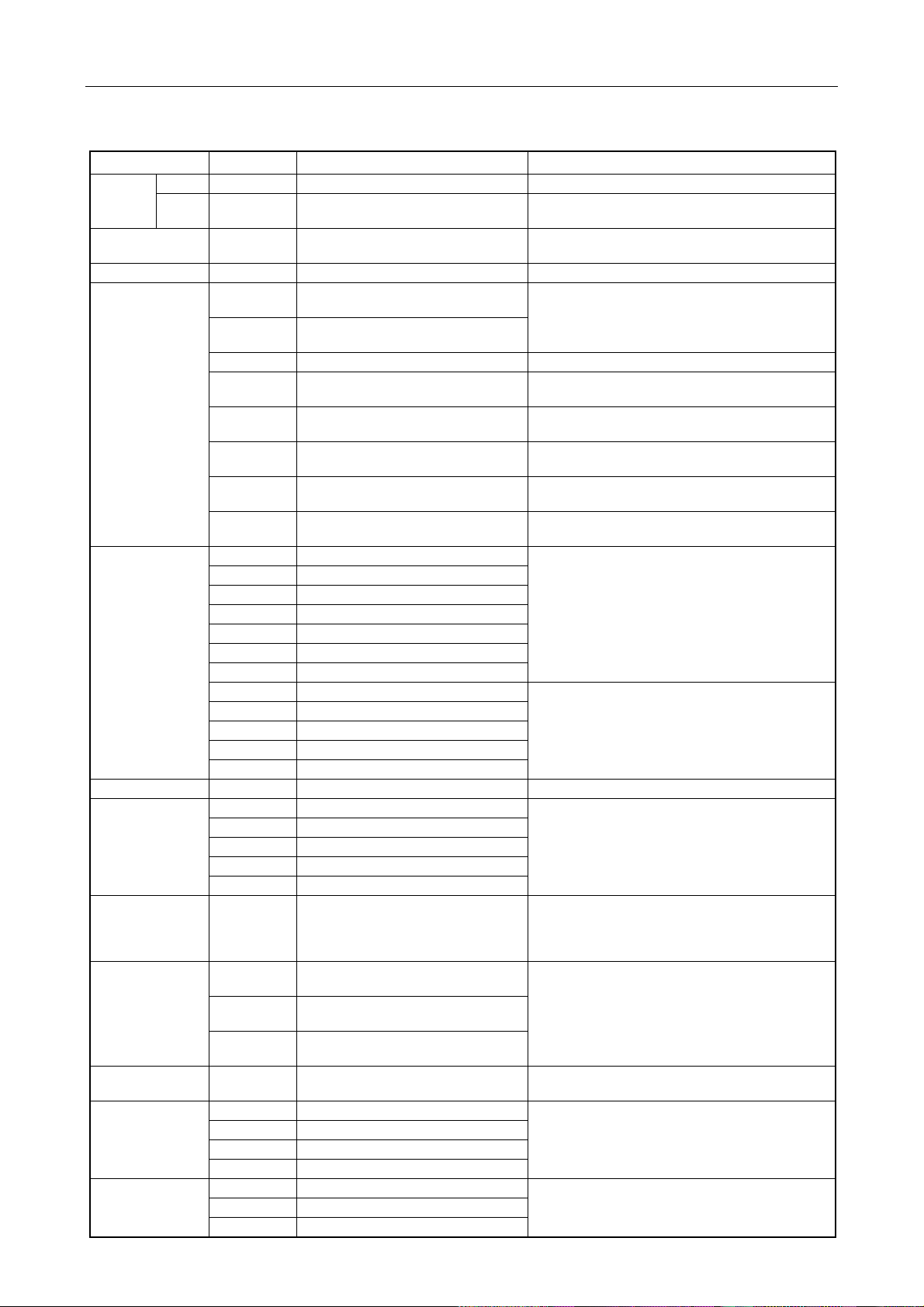

Peripheral

Device

A6PHP

A6GPP

IBM PC/AT

NOTE

1. As the PC's model for the GPP function software package (SW IVD-GPPA; is older than

3) is set to "A3U", attention should be paid to the following:

1) When a LED or LEDC instruction is written, it is not usable but no error will be issued.

2) When a CHG instruction is written, it is not usable, and the error code 13 and detailed error

code 134 will be detected.

3) When a subprogram is set, it is not usable, and the error code 11 and detailed error code

111 will be detected.

2. When the MELSECNET(II), MELSECNET/10 parameters are used up to the maximum of 16k

bytes, program capacity will be limited to 22k steps.

The A2USHCPU-S1 uses the same memory area for the sequence program as that for the

parameters of MELSECNET(II) and MELSECNET/10. Therefore, the remainder in the max. 30k

steps after subtracting the memory area used by the MELSECNET(II) and MELSECNET/10

parameters can be used for the sequence program.

POINT

(1) Old software packages other than SW3-GPPA, SW3GP-GPPA, and SW4GP-GPPA cannot

be used as the software package for system startup for A6GPP/A6PHP.

(2) When a MELSECNET/10 network system is configured with the A2USHCPU-S1, use an

AnU/A2USH-S1-compatible GPP function software package (which contains "A3U" /

"A2USH-S1" in the PC's model name). The network function cannot be set with GPP

function software packages not compatible with AnU (no "A3U" / "A2USH-S1" in the PC's

model name).

Software package for system

SW3GP-GPPA A3H Write on the ROM is not allowed.

SW4GP-GPPA A3A

SW

SW3-GPPA

SW3GP-GPPA

SW4GP-GPPA A3A

SW

SW IVD-GPPA; is 0 to 3 A3U

SW IVD-GPPA; is 4 or later

GX Developer

startup

GP-GPPAU A3U

GP-GPPAU A3U

PC CPU model

setting

A3H Write on the ROM is not allowed.

A2USH-S1

Remarks

2-5

Page 20

2. SYSTEM CONFIGURATION MELSEC-A

(2) Utility package

(a) None of the following utility packages for A6GPP/A6PHP can be used:

•

SW

-AD57P

•

SW -UTLP-FN0

•

•

•

•

•

REMARK

The characters generators and canvas, which are necessary for AD57(S1), are created on the

peripheral device using the SW

-UTLP-FN1 *

SW

SW -UTLP-PID

SW

-SIMA

-UTLP-FD1

SW

SW -SAPA

-AD57P.

POINT

(1) Packages which access the A2USHCPU-S1 by specifying a device in the utility package can

specify only in the device range for A3ACPU or A3HCPU equivalent. (Refer to Section

2.2.3.)

(2) Use an AnU-compatible utility package to use the device range for the A2USHCPU-S1.

(Example: SW1IVD-SAP2, etc.)

The packages marked with * can execute the

same functions using the dedicated instructions.

Refer to AnACPU/AnUCPU Programming

Manual (Dedicated Instruction) for details.

2-6

Page 21

2. SYSTEM CONFIGURATION MELSEC-A

2.2.3 Precautions when using GPP funct ion software packages and A8PU peripheral devices which are not compatibl e with AnU

When the A2USHCPU-S1 is started up using a GPP function software package not compatible

with AnU, A2USH-S1 (the PC model name is "A3A" or "A3H") or from an A8PU peripheral device

(including A7PUS), the usable device range is limited as follows:

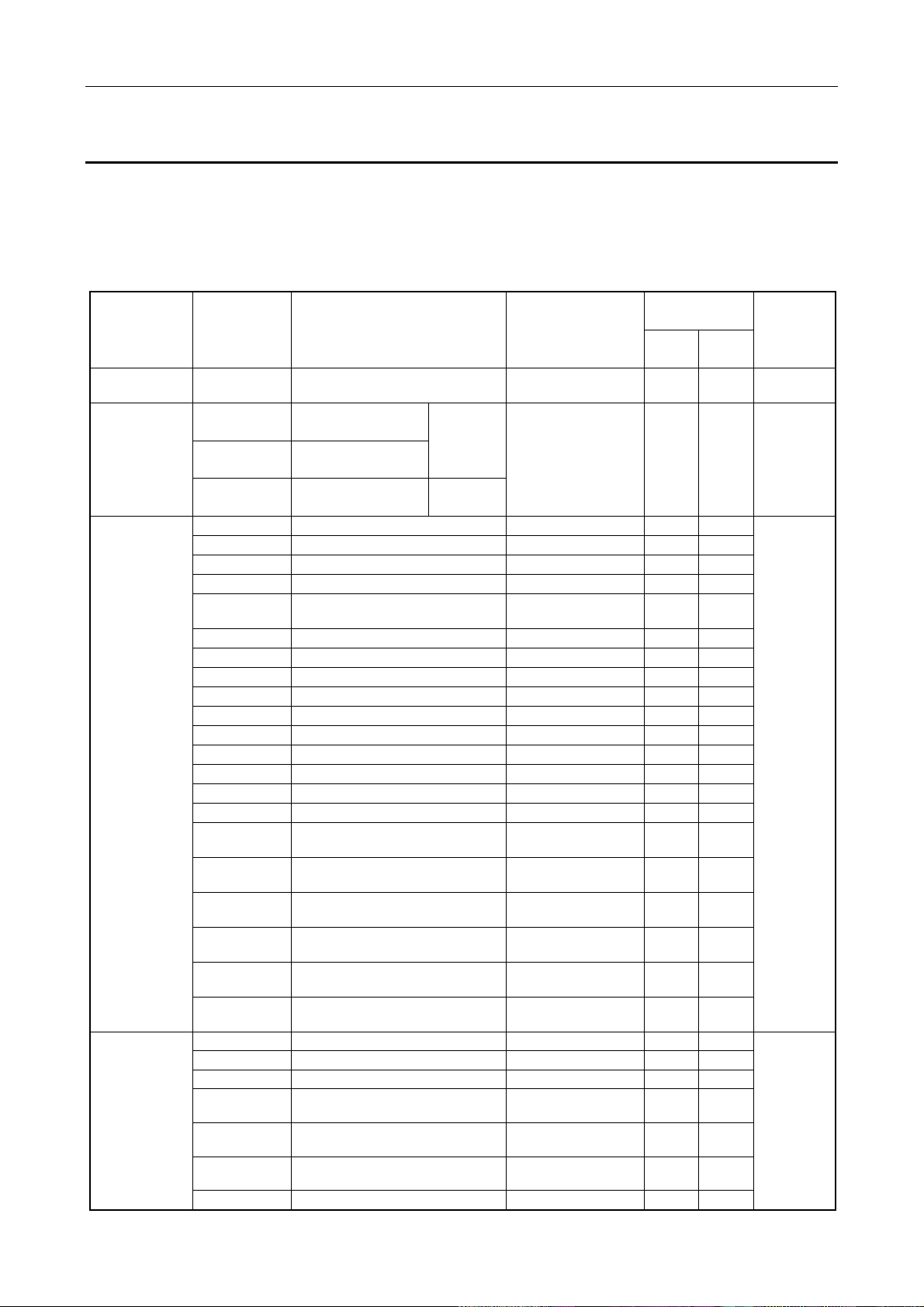

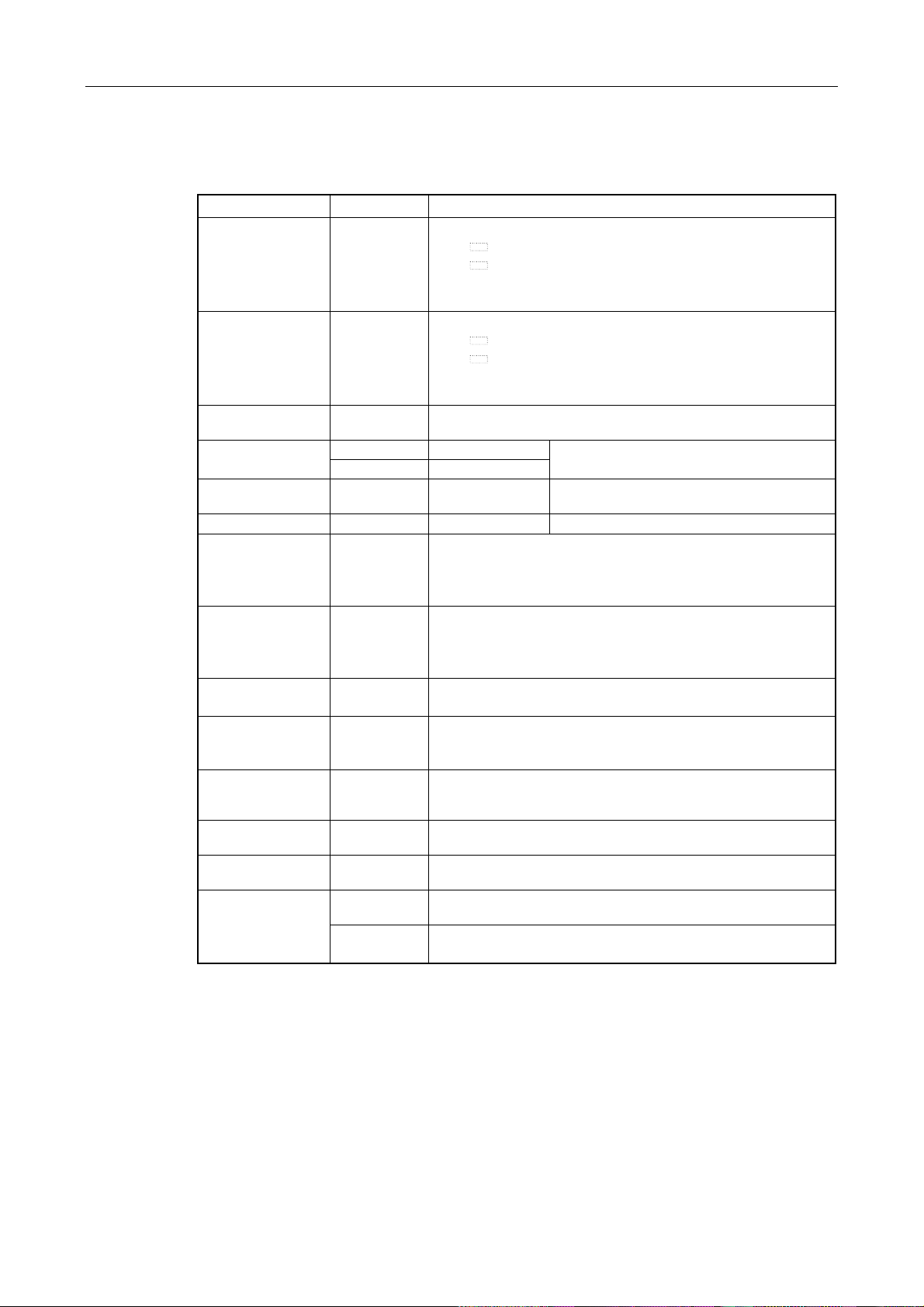

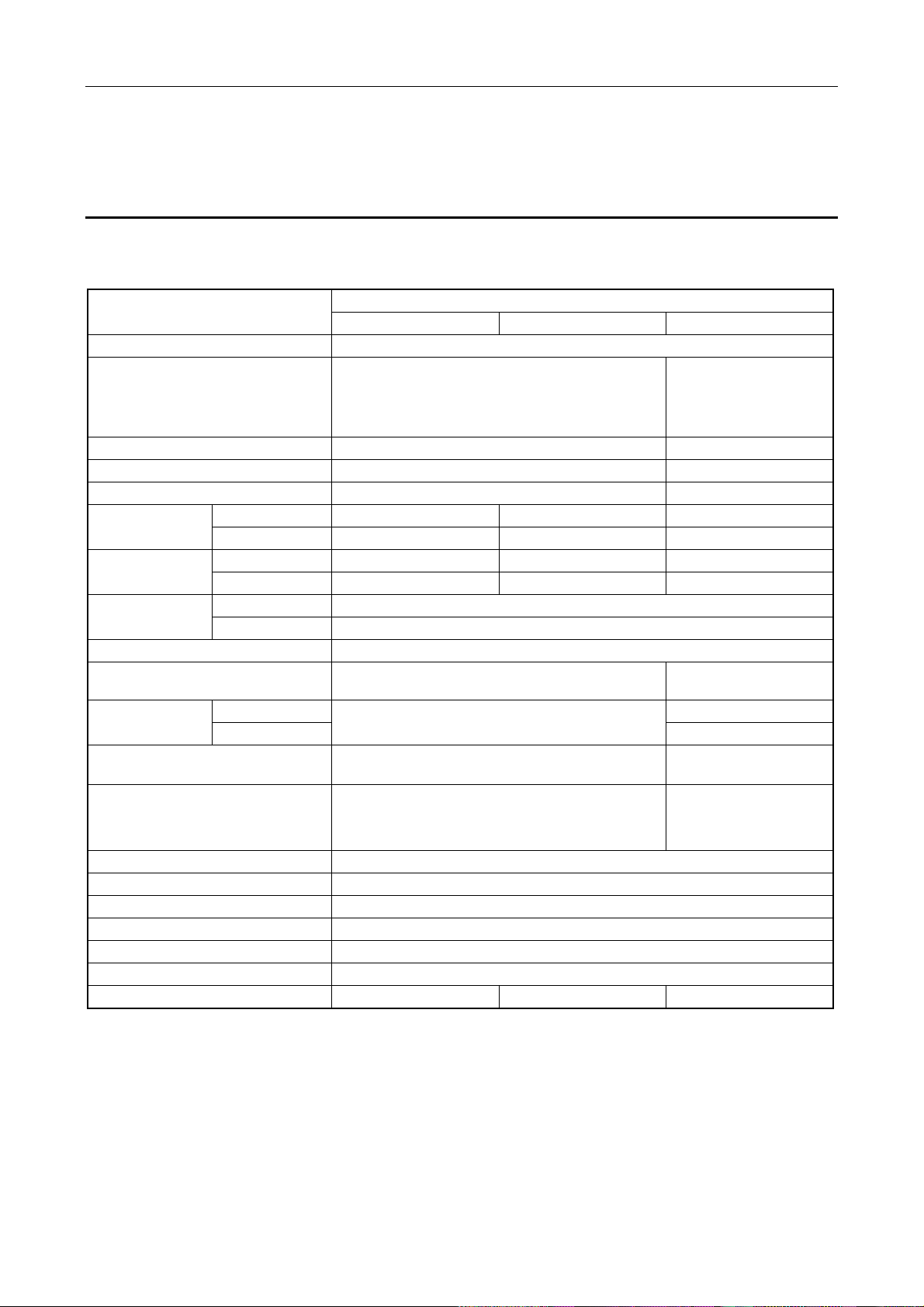

(1) Usable device range

System FD peripher al

Item

Instruction (sequence/basic/

application/dedicated)

Program capacity A maximum of 30k steps can be used for t he m ain program .

I/O device points (X/Y)

M, L, S relay M/L/S0 to 8191 can be used.

Link relay (B)

Timer (T) T0 to T2047 can be used.

Counter (C) C0 to C1023 can be used.

Data register (D)

Link register (W)

Annunciator (F) F0 to F2047 can be used.

Index register (V, Z) V, V1 to V6, Z, and Z1 to Z6 can be used.

Expanded comment A maximum of 3968 points Unusable

Latch (power failure

compensation) range

I/O assignment

device

Number of I/O occupied points and

the module model can be registered.

(1) The device range other than listed above is the same as that of A2USHCPU-S1.

(2) Refer to the operation manual of each peripheral device for available functions.

AnACPU-compatible m odule A3HCPU-compatible module

Modules whose PC mode l for

system FD startup is "A3A"

X/Y0 to 7FF can be used.

(X/Y800 to 1FFF cannot be used.)

B0 to BFFF can be used

(B1000 to B1FFF cannot be used.)

D0 to D6143 can be used.

(D6144 to D8191 cannot be used.)

W0 to WFFF can be us e d .

(W1000 to W 1FFF cannot be used.)

The device range shown above can be latched. The device range shown above can be latched.

A8PU

All instructions can be used.

Modules whose PC mode l for

system FD startup is "A3H"

X/Y0 to 7FF can be used.

(X/Y800 to 1FFF cannot be used.)

M/L/S0 to 2047 can be used.

(M/L/S2048 to 8191 cannot be used.)

B0 to B3FF can be used.

(B400 to B1FFF cannot be used.)

T0 to T255 can be used.

(T256 to T2047 cannot be used.)

C0 to C255 can be used.

(C256 to C1023 cannot be used.)

D0 to D1023 can be used.

(D1024 to D8191 cannot be used.)

W0 to W 3FF can be used.

(W400 to W 1FFF cannot be used.)

F0 to F255 can be used.

(F256 to F2047 cannot be used.)

V and Z can be used.

1

to V6 and Z1 to Z6 cannot be used.)

(V

Number of I/O occupied points

can be registered.

A7PUS

2-7

Page 22

2. SYSTEM CONFIGURATION MELSEC-A

2.3 System Equipment

Various components of each module and peripheral device which can be used by the A2USHCPU-S1

are listed.

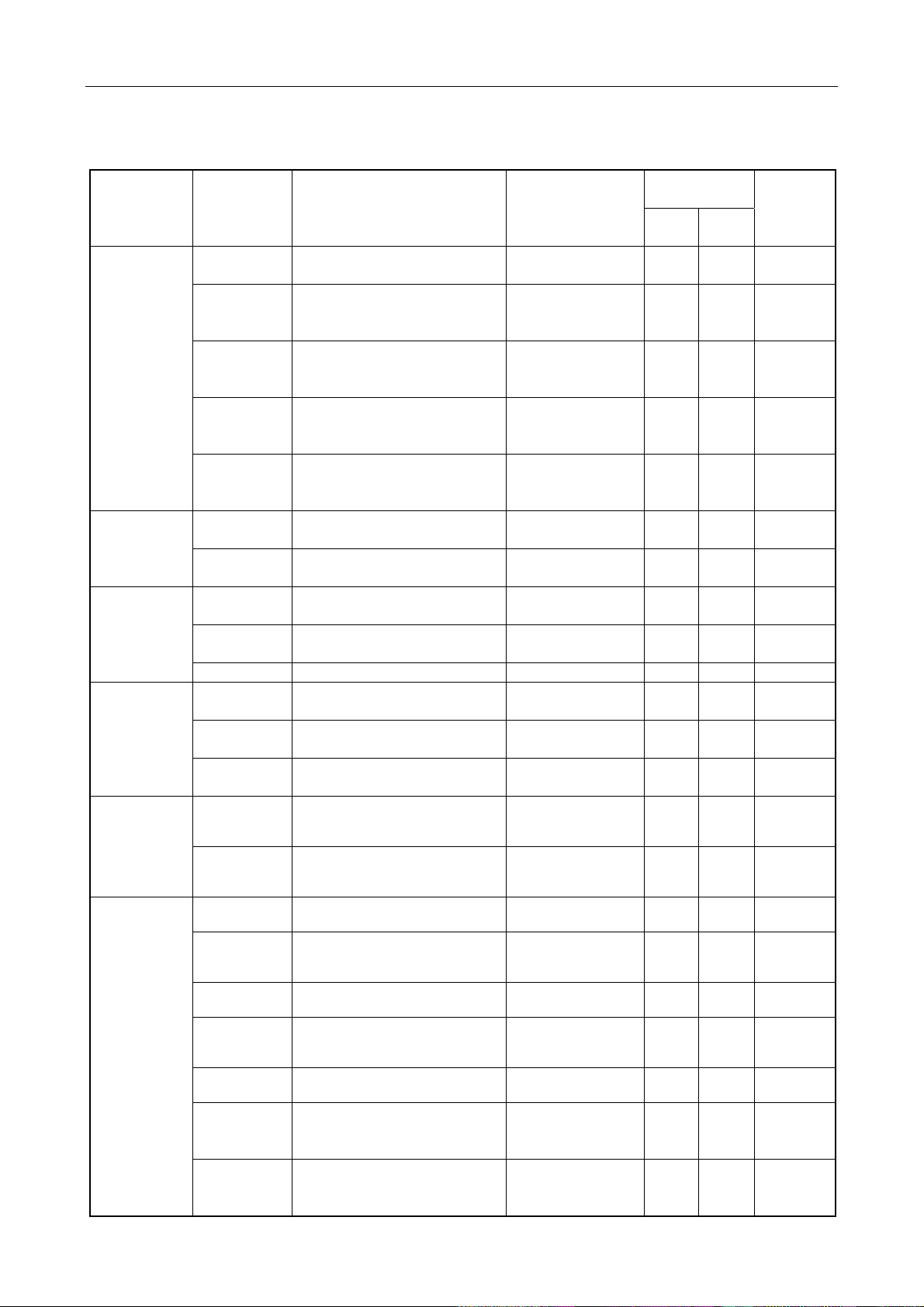

(1) Modules dedicated to A1S

Item Model Description

CPU module A2USHCPU-S1

A1S61PN 5VDC, 5A

Power supply

module

Input module

Output module

A1S62PN 5VDC, 3A/24VDC, 0.6A

A1S63P 5VDC, 5A 24VDC input

A1SX10 16-point 100 to 120 VAC input module 16 [16 input points] 0.05

A1SX10EU 16-point 100 to 120 VAC input module 16 [16 input points] 0.05

A1SX20 16-point 200 to 240 VAC input module 16 [16 input points] 0.05

A1SX20EU 16-point 200 to 240 VAC input module 16 [16 input points] 0.05

A1SX30

A1SX40 16-point 12/24VDC input module 16 [16 input points] 0.05

A1SX40-S1 16-point 24VDC input module 16 [16 input points] 0.05

A1SX40-S2 16-point 24VDC input module 16 [16 input points] 0.05

A1SX41 32-point 12/24VDC input module 32 [32 input points] 0.08

A1SX41-S1 32-point 24VDC input module 32 [32 input points] 0.12

A1SX41-S2 32-point 24VDC input module 32 [32 input points] 0.08

A1SX42 64-point 12/24VDC input module 64 [64 input points] 0.09

A1SX42-S1 64-point 24VDC input module 64 [64 input points] 0.16

A1SX42-S2 64-point 24VDC input module 64 [64 input points] 0.09

A1SX71 32-point 5/12/24VDC input module 32 [32 input points] 0.075

A1SX80

A1SX80-S1

A1SX80-S2

A1SX81

A1SX81-S2

A1SX82-S1

A1SY10 16-point relay contact output module (2A) 16 [16 output points] 0.12 0.09

A1SY10EU 16-point relay contact output module (2A) 16 [16 output points] 0.12 0.09

A1SY14EU 12-point relay contact output module (2A) 16 [16 output points] 0.12 0.10

A1SY18A

A1SY18AEU

A1SY22 16-point Triac output module (0.6A) 16 [16 output points] 0.27

A1SY28EU 8-point Triac output module (0.6A) 16 [16 output points] 0.27

1024 real I/O points, 256k bytes memory

capacity

16-point 12/24VDC, 12/24VAC input

module

16-point 12/24VDC sink/source input

module

16-point 24VDC sink/source input

module

16-point 24VDC sink/source input

module

32-point 12/24VDC sink/source input

module

32-point 24VDC sink/source input

module

64-point 24VDC sink/source input

module

8-point relay contact output module (2A)

for independent contacts

8-point relay contact output module (2A)

for independent contacts

100/200VAC

input

Number of occupied

points (points)

[I/O alloc a t ion module

type]

0.32

16 [16 input points] 0.05

16 [16 input points] 0.05

16 [16 input points] 0.05

16 [16 input points] 0.05

32 [32 input points] 0.08

32 [32 input points] 0.08

64 [64 input points] 0.16

16 [16 output points] 0.24 0.075

16 [16 output points] 0.24 0.075

Current

consumption

5VDC

(A)

24VDC

(220VAC)

(A)

0.002

Remark

Built-in

RAM memory

Installed in the

power supply

slot of the

basic base

module and

expansion

base module.

2-8

Page 23

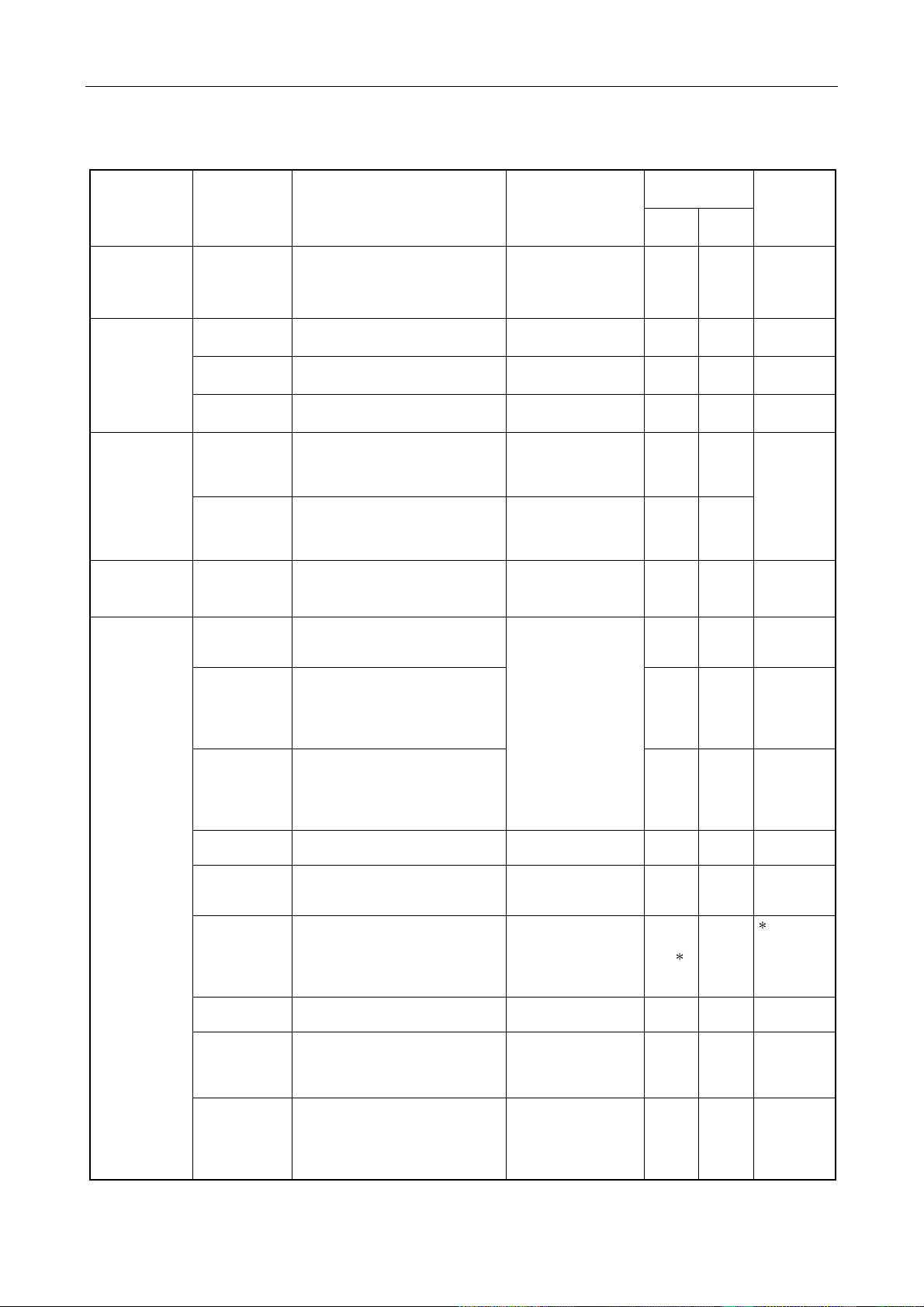

2. SYSTEM CONFIGURATION MELSEC-A

Number of occupied

Item Model Description

A1SY28A

A1SY40

A1SY41

A1SY42

A1SY50

A1SY60

Output module

I/O hybrid module

Dynamic input

module

Dynamic output

module

Blank cover A1SG60 Dust-proof cover for unused slot 16 [Empty]

Dummy module A1SG62

Pulse catch

module

Analog timer

module

Interrupt module A1SI61

A1SY60E

A1SY68A

A1SY71

A1SY80

A1SY81

A1SY82

A1SH42

A1SH42-S1

A1SX48Y18

A1SX48Y58

A1S42X

A1S42Y

A1SP60

A1ST60

8-point Triac output module (1A)

All points independent

16-point 12/24VDC transistor output

module(0.1A) sink type

32-point 12/24VDC transistor output

module(0.1A) sink type

64-point 12/24VDC transistor output

module(0.1A) sink type

16-point 12/24VDC transistor output

module(0.5A) sink type

16-point 24VDC transistor output

module(2A) sink type

16-point 5/12/24VDC transistor output

module(2A) source type

8-point 5/12/24/48VDC transistor output

module (2A) sink/source type

All points independent

32-point 5/12VDC transistor output

module(0.016A) sink type

16-point 12/24VDC transistor output

module(0.8A) source type

32-point 12/24VDC transistor output

module(0.1A) source type

64-point 12/24VDC transistor output

module(0.1A) source type

32-point 12/24VDC input module

32-point 12/24VDC transistor output

module(0.1A) sink type

32-point 24VDC input module

32-point 24VDC transistor output

module(0.1A) sink type

8-point 24VDC input module

8-point relay contact output module (2A)

8-point 24VDC input module

8-point 12/24VDC transistor output

module (0.5A)

16/32/48/64 points

12/24VDC dynamic input module

16/32/48/64 points

12/24VDC dynamic output module

16-point, 32-point, 48-point, or 64-point

selectable module

16-point input module for short ON-time

pulse input

(pulse with a minimum of 0.5ms)

8-point analog timer module whose

timer setting value can be changed f or

different volumes (0.1 to 1.0s, 1 to 10s,

10 to 60s, 60 to 600s)

Interrupt module for specifying the

interrupt program (16-point interrupt

input)

points (points)

[I/O alloc a t ion module

type]

16 [16 output points] 0.13

16 [16 output points] 0.27 0.008

32 [32 output points] 0.50 0.016

64 [64 output points] 0.93 0.008

16 [16 output points] 0.12 0.06

16 [16 output points] 0.12 0.015

16 [16 output points] 0.20 0.01

16 [16 output points] 0.11

32 [32 output points] 0.40 0.15

16 [16 output points] 0.12 0.02

32 [32 output points] 0.50 0.016

64 [64 output points] 0.93 0.008

32 [32 output points] 0.50 0.008

32 [32 output points] 0.50 0.008

16 [16 output points] 0.085 0.045

16 [16 output points] 0.06 0.06

Specified number of

points [Input

specified number of points]

Specified number of

points [Output

specified number of points]

Specified number of

points [Input

specified number of points]

16 [16 output points] 0.055

16 [16 output points] 0.055

32 [32 special points] 0.057

Current

consumption

5VDC

0.08

0.10 0.008

(A)

24VDC

(A)

Remark

2-9

Page 24

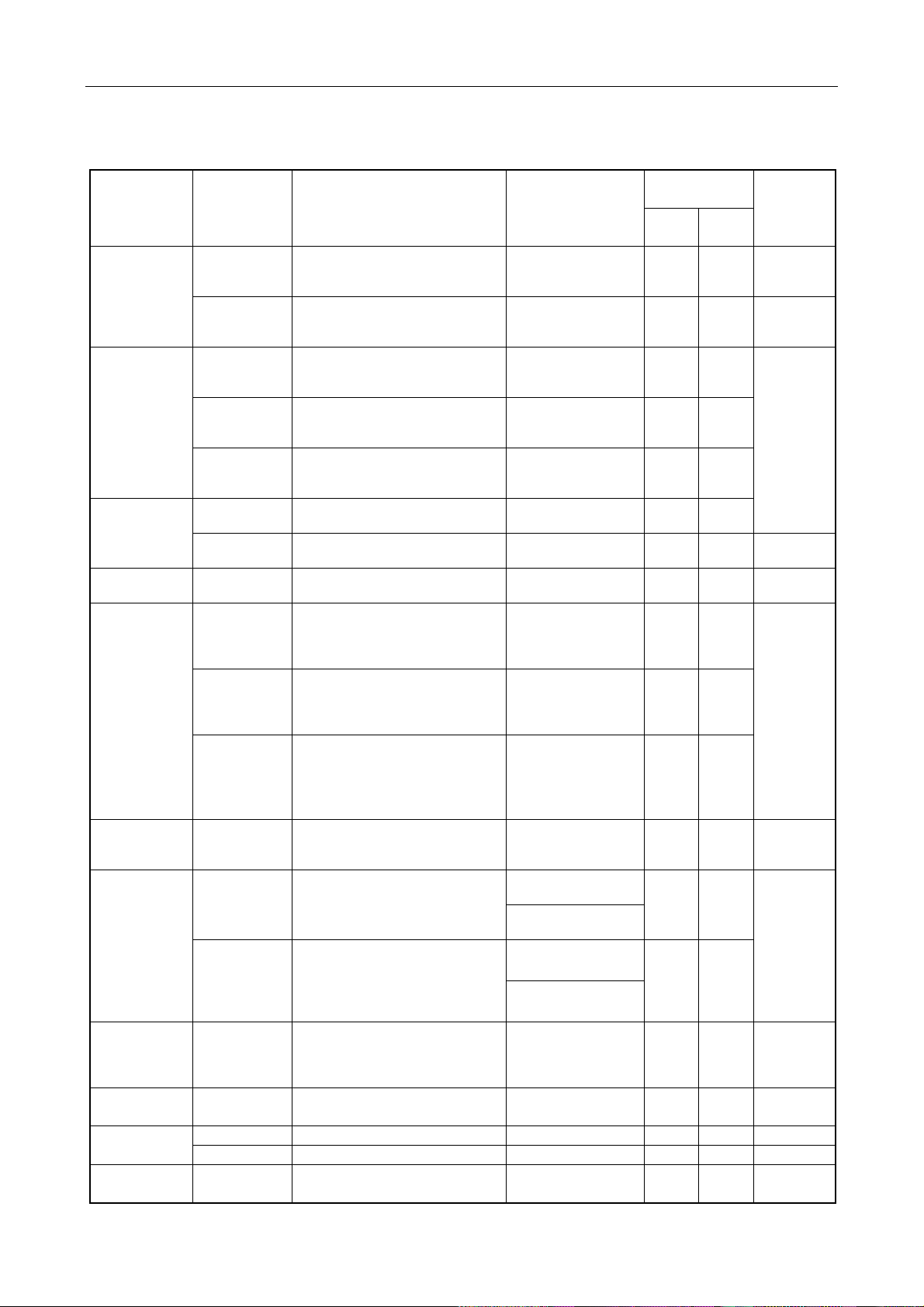

2. SYSTEM CONFIGURATION MELSEC-A

Item Model Description

32-bit signed binary

50kBPS, 1 channel

24-bit signed binary, 2 channels

100kPPS, DC input

Transistor output (sink type)

24-bit signed binary, 2 channels

200kPPS, difference input

Transistor output (sink type)

24-bit signed binary, 2 channels

200kPPS, difference input

Transistor output (sink type)

24-bit signed binary, 2 channels

100kPPS, DC input

Transistor output (source type)

4 to 20mA/0 to 10V

4 analog channels

4 to 20mA/0 to 10V

8 analog channels

For Pt100 (3-wire type) connection

2 channels of temperature input

For Pt100 (4-wire type) connection

2 channels of temperature input

4 to 20mA/0 to 10V

2 analog output channels

-10 to 10V input

Analog output, 8 channels

4 to 20mA input

Analog output, 8 channels

Analog input, 2 channels, simple loop

control is allowed.

Analog output, 1 channel

Analog input, 4 channels, simple loop

control is allowed.

Analog output, 2 channels

Thermocouple input - transistor input, 4

channels

Thermocouple input - transistor input, 4

channels

With disconnection det ec t ion f unction

Platinum resistance temperature sens or

input - transistor input, 4 channels

Platinum resistance temperature sens or

input - transistor input, 4 channels

With disconnection det ec t ion f unction

Thermocouple input - transistor output

(overheat cooling), 2 channels

Thermocouple input - transistor output

(overheat cooling), 2 channels

With disconnection det ec t ion f unction

Platinum resistance temperature sens or

input - transistor output (heat cooling), 2

channels

High-speed

counter module

A/D converter

module

Temperature/

digital converter

module

D/A converter

module

Analog I/O module

Temperature

regulating module

A1SD61

A1SD62

A1SD62D

A1SD62D-S1

A1SD62E

A1S64AD

A1S68AD

A1S62RD3N

A1S62RD4N

A1S68TD Thermocouple input, 8 channels 32 [32 special points] 0.32

A1S62DA

A1S68DAV

A1S68DAI

A1S63ADA

A1S66ADA

A1S64TCTT-S1

A1S64TCTTBWS1

A1S64TCRT-S1

A1S64TCRTBWS1

A1S62TCTT-S2

A1S62TCTTBWS2

A1S62TCRT-S2

Number of occupied

points (points)

[I/O alloc a t ion module

type]

32 [32 special points] 0.35

32 [32 special points] 0.1

32 [32 special points] 0.25

32 [32 special points] 0.27

32 [32 special points] 0.1

32 [32 special points] 0.4

32 [32 special points] 0.4

32 [32 special points] 0.49

32 [32 special points] 0.39

32 [32 special points] 0.8

32 [32 special points] 0.65

32 [32 special points] 0.85

32 [32 special points] 0.8

32 [32 special points] 0.21 0.16

32 [32 special points] 0.33

32 [32 special points] 0.42

32 [32 special points] 0.33

32 [32 special points] 0.42

32 [32 special points] 0.19

32 [32 special points] 0.28

32 [32 special points] 0.19

2-10

Current

consumption

5VDC

24VDC

(A)

(A)

Remark

Page 25

2. SYSTEM CONFIGURATION MELSEC-A

Item Model Description

Platinum resistance temperature sens or

Temperature

regulating module

Computer link

module

Ethernet interface

module

Intelligent

communication

module

Positioning module

A1S62TCRTBWS2

A1SJ71UC24-R2

A1SJ71UC24PRF

A1SJ71UC24-R4

A1SJ71E71N-B2 10 Base 2 (for Cheapernet) 32 [32 special points] 0.64

A1SJ71E71N-B5T 10 Base 5 (for Ethernet), 10 Base T 32 [32 special points] 0.42

A1SD51S

A1SD70

A1SD71-S2

A1SD71-S7

A1SD75P1-S3

A1SD75P2-S3

A1SD75P3-S3

A1SD75M1

A1SD75M2

A1SD75M3

input - transistor output (heat cooling), 2

channels

With disconnection det ec t ion f unction

Computer link function

RS-232C, 1 channel

Computer link function, printer function

RS-232C, 1 channel

Computer link function, multidrop link

function RS-422/RS-485, 1 channel

BASIC (interpreter/compiler)

RS-232C, 2 channels

RS-422/485, 1 channel

Analog voltage output (0 to ±10V) for 1-

axis positioning control, speed

control, and speed-positioning control.

For positioning control, speed control,

and speed-positioning control.

Pulse train output, 2-axis (independent,

2-axis simultaneous, linear

interpolation

For positioning control, setting for

manual pulse output speed can be

changed.

Pulse train output, 2-axis (independent,

2-axis simultaneous, linear interpolation)

For positioning control, pulse output, 1axis

For positioning control, pulse output, 2axis (independent, 2-axis simultaneous,

linear interpolation, circular interpolation)

For positioning control, pulse output, 3axis (independent, 3-axis simultaneous,

2-axis linear interpolation, 2-axis circular

interpolation)

For positioning control, digital output, for

MR-H-B/MR-J-B/MR-J2-B, 1-axis SSCNET

For positioning control, digital output, for

MR-H-B/MR-J-B/MR-J2-B, 2-axis SSCNET

(independent, 2-axis simultaneous,

linear interpolation, circular interpolation)

For positioning control, digital output, for

MR-H-B/MR-J-B/MR-J2-B, 3-axis SSCNET

(independent, 3-axis simultaneous, 2axis linear interpolation, 2-axis circular

interpolation)

Number of occupied

points (points)

[I/O alloc a t ion module

type]

32 [32 special points] 0.28

32 [32 special points] 0.1

32 [32 special points] 0.1

32 [32 special points] 0.1

32 [32 special points] 0.4

48 [First half: 16 empty

points]

[Second half: 32 special

points]

32 [32 special points] 0.7

32 [32 special points] 0.7

32 [32 special points] 0.7

32 [32 special points] 0.7

32 [32 special points] 0.7

32 [32 special points] 0.7

Current

consumption

5VDC

24VDC

(A)

0.3

0.8

0.8

(A)

Remark

Only AnACPUequivalent

device range

accessibleFil

e register and

program

read/write

disabled.

When

differential

driver is

connected

: 0.78

2-11

Page 26

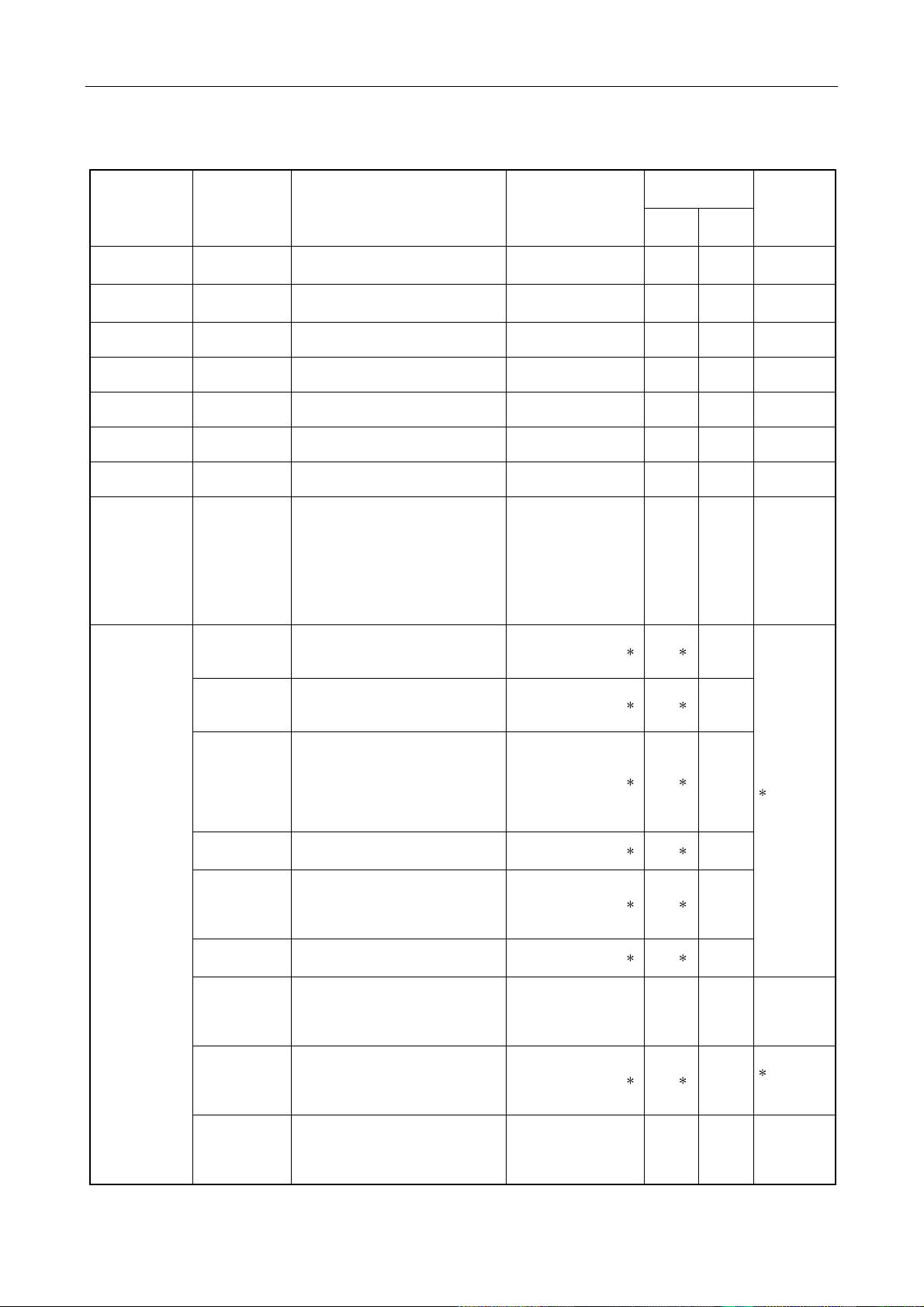

2. SYSTEM CONFIGURATION MELSEC-A

Item Model Description

ID interface module

ID interface

module

MELSECNET(II)

data link module

MELSECNET/B

data link module

B/NET data link

module

MELSECNET/10

data link module

CC-Link system

master module

MELSECNET

/MINI-S3 master

module

MELSECNET-I/O

LINK master

module

S-LINK interface

module

JEMANET (JPCN-

1) interface module

DeviceNet

interface module

A1SD35ID1

A1SD35ID2

A1SJ71AP21

A1SJ71AP21-S3

A1SJ71AR21

A1SJ71AT21B

A1SJ72T25B

A1SJ71B62-S3

A1SJ71LP21

A1SJ71BR11

A1SJ71LR21

A1SJ61BT11

A1SJ71PT32-S3

A1SJ71T32-S3

A1SJ51T64

A1SJ71SL92N

A1SJ71J92-S3 JEMANET (JPCN-1) master module 32 [32 special points] 0.40

A1SJ72J95 JEMANET (JPCN-1) slave module 32 [32 special points] 0.40

A1SJ71DN91

One reader/writer module can be

connected.

ID interface module

Two reader/writer modules can be

connected.

For the master and local stations of

MELSECNET(II) data link system (for

the optical fiber cable)

For the master and local stations of

MELSECNET(II) data link system (for

the GI-type optical fiber cable)

For the master and local stations of

MELSECNET(II) data link system (for

the coaxial cable)

For the master and local stations of

MELSECNET/B data link system

For the remote I/O station of

MELSECNET/B data link system

Master module for B/NET

For the control, master, and normal

stations of the MELSECNET/10 data link

module system (For the dual loop SItype optical fiber cable)

For the control, master, and normal

stations of the MELSECNET/10 data

link module system (For the single bus

coaxial cable)

For the control, master, and normal

stations of the MELSECNET/10 data

link module system (For the single bus

coaxial cable)

(For the coaxial cable dual loop)

For the master and local stations of the

CC-Link data link system(For the twisted

pair shield cable only.)

For MELSECNET/MINI-S3 master

stations (max. 64 stations). Performs

remote I/O and remote terminal control

of a total of 512 I/O points.

MELSECNET/MINI-S3 master station

Performs remote I/O and remote

terminal control of a maximum 64

stations and a total of 512 I/O

points.(For the twisted pair cable only.)

MELSECNET-I/O LINK master station.

Controls I/O LINK remote I/O module of

a maximum of 64 stations and a total of

128 I/O points.

Master module for S-LINK

I/O total 128 points

Master module for DeviceNet

I/O total 4096 points

Number of occupied

points (points)

[I/O alloc a t ion module

Expanded mode 48 [48

Expanded mode 48 [48

type]

32 [32 special points] 0.25 0.17

32 [32 special points] 0.25 0.33

32 [32 special points] 0.33

32 [32 special points] 0.33

32 [32 special points] 0.8

32 [32 special points] 0.66

0.3

32 [32 special points] 0.08

32 [32 special points] 0.65

32 [32 special points] 0.80

32 [32 special points] 1.14

32 [32 special points] 0.40

I/O dedicated mode 32

[32 special points]

special points]

I/O dedicated mode 32

[32 special points]

special points]

64 [64 output points] 0.115 0.09

32 [32 special points] 0.20

32 [32 special points] 0.24

Current

consumption

5VDC

0.35

0.30

24VDC

(A)

(A)

Remark

Access is

allowed within

the device

range of the

A3ACPU.

Accessible

only within

MELSECNET

(II) range

2-12

Page 27

2. SYSTEM CONFIGURATION MELSEC-A

Item Model Description

PROFIBUS-DP

slave module

AS-I interface

module

Modem interface

module

Paging interface

module

Position detection

module

PC easier

monitoring module

Memory card

interface module

Simulation module A6SIM-X64Y64

Graphic operation

terminal

A1SJPB93D

A1SJ71AS92

A1SJ71CMO-S3 Modem interface module 32 [32 special points] 0.26

A1SD21-S1 Paging interface module 32 [32 special points] 0.14

A1S62LS Absolute position detection module 32 [32 special points] 0.55

A1SS91 PC easier monitoring module 32 [32 special points] 0.08

A1SD59J-S2 Memory card interface module 32 [32 special points] 0.05

A985GOT

A975GOT

A970GOT

A960GOT

A956GOT

A956WGOT

A953GOT

A951GOT

A950GOT

Slave module for PROFIBUS-DP

I/O data total 192 words

Master module for AS-I

I/O total 496 points

An I/O simulation unit used connected to

the base module. Debugging can be

executed without connecting the I/O

module to the base module.

Use an expansion cable of the AnS

series between the basic base module

of the AnS series and the A6SIMX64Y64.

Large-size graphic operation terminal

256 colors, TFT color, 800 × 600 dots,

high intensity

Large-size graphic operation terminal

256 colors, TFT color, 640 × 480 dots,

high intensity

Large-size graphic operation terminal

16 colors, TFT color, 640 × 480 dots,

high intensity/16 colors, TFT color, 640

480 dots, wide viewing angle/8 colors,

×

STN color, 640 × 480 dots/2 colors, STN

monochrome, 640 × 480 dots

Large-size graphic operation terminal

2 colors, EL, 640 × 400 dots

Medium-size graphic operation terminal

8 colors, STN color, 320 × 240 dots/STN

monochrome, 320 × 240 dots/256

colors, TFT color, 320 × 240 dots

Medium-size graphic operation terminal

256 colors, TFT color, 480 × 234 dots

Medium-size graphic operation terminal

8 colors, STN color, 320 × 240 dots/STN

monochrome, 320 × 240 dots/256

colors, TFT color, 320 × 240 dots

Medium-size graphic operation terminal

8 colors, STN color, 320 × 240 dots/STN

monochrome, 320 × 240 dots/256

colors, TFT color, 320 × 240 dots

Medium-size graphic operation terminal

8 colors, STN color, 320 × 240 dots/STN

monochrome, 320 × 240 dots/256

colors, TFT color, 320 × 240 dots

Number of occupied

points (points)

[I/O alloc a t ion module

32 [32 special points] 0.22

32 [32 special points] 0.22

32 [32 special points]

32 [32 special points]

32 [32 special points] 0.22

32 [32 special points] 0.22

32 [32 special points] 0.22

type]

32 [32 special points] 0.36

32 [32 special points] 0.15

64 [64 input points]

64 [64 output points]

Current

consumption

5VDC

(A)

TYP. 0.3

(when all

points

“ON”.)

0.22

0.22

24VDC

(A)

Remark

When bus connected

For RS-232C

connected

only

When bus connected

For RS-422

connected

only

2-13

Page 28

2. SYSTEM CONFIGURATION MELSEC-A

Item Model Description

A1S32B 2 I/O module can be installed.

Basic base unit

Extension base

unit

Extension cable

A1S33B 3 I/O module can be installed.

A1S35B 5 I/O module can be installed.

A1S38B 8 I/O module can be installed.

A1S52B 2 I/O module can be installed.

A1S55B 5 I/O module can be installed.

A1S58B 8 I/O module can be installed.

A1S65B 5 I/O module can be installed.

A1S68B 8 I/O module can be installed.

A1SC01B 55mm (2.17 in.) long flat cable

A1SC03B 330mm (13 in.) long

A1SC07B 700mm (27.56 in.) long

A1SC12B 1200mm (47.24 in.) long

A1SC30B 3000mm (118.11 in.) long

A1SC60B 6000mm (236.22 in.)long

A1SC05NB 450mm (17.72 in.)long

A1SC07NB 700mm (27.56 in.) long

A1SC30NB 3000mm (118.11 in.) long

A1SC50NB 5000mm (196.86 in.) long

Number of occupied

points (points)

[I/O alloc a t ion module

type]

Current

consumption

5VDC

(A)

24VDC

(A)

Remark

Extension

connector on

the right and

left side each.

The power

supply module

cannot be

installed.

(Power is

supplied from

the basic base

module.)

The power

supply module

is required.

For extension

towards right.

Connection

cable for the

extension

base module.

Cable for the

N, A A

A

extension

base module.

2-14

Page 29

2. SYSTEM CONFIGURATION MELSEC-A

Item Model Contents Applicable models

Memory

cassette

EPROM

E

Memory write adapter A2SWA-28P

Battery A6BAT IC-RAM memory backup Installed in the A2USHCPU-S1 main module

Connector/terminal

block converter unit

Cable for the

connector/terminal

block converter unit

Relay terminal unit A6TE2-16SRN For the sink-type output m odule A1SY41, A1SY42, A1SH42(S1)

Cable for connecting

the relay terminal unit

Terminal block cover

for the A1S I/O

module and the

special module

Insulation

displacement terminal

block adapter

Terminal block

adapter

40-pin connector

37-pin D-sub

connector

A2SMCA-14KP With a 14k-step EPROM (direct connection) A2SWA-28P is required

2

PROM

A2SNMCA30KE

A6TBXY36

A6TBXY54

With a 30k-step E

PROM (direct

connection)

Adapter for the memory cassette

attachment connector/28-pin EPROM

For the sink-type input module and sinktype output module. (standard type)

For the sink-type input module and sinktype output module. (2-wire type)

Direct writing to and reading from a peripheral device is

feasible.

Used for the ROM writing of A2SMCA-I4KP

A1SX41(S1/S2), A1SX42(S1/S2), A1SY41, A1SY42,

A1SY82, A1SH42(S1)

2

A6TBX70 For the sink-type input module. (3-wire type) A1SX41(S1/S2), A1SX42(S1/S2), A1SH42(S1)

A6TBX36-E

A6TBY36-E

A6TBX54-E

A6TBY54-E

A6TBX70-E

For the source-type input module. (standard

type)

For the source-type output module.

(standard type)

For the source-type input module. (2-wire

type)

For the source-type output module. (2-wire

type)

For the source-type input module. (3-wire

type)

A1SX81(S2), A1SX71, A1SX82-S1

A1SY81, A1SY82

A1SX81(S2), A1SX71, A1SX82-S1

A1SY81, A1SY82

A1SX81(S2), A1SX71, A1SX82-S1

AC05TB 0.5m (1.64 ft.) for the source module

AC10TB 1m (3.28 ft.) for the source module

AC20TB 2m (6.56 ft.) for the source module

AC30TB 3m (9.84 ft.) for the source module

AC50TB 5m (16.40 ft.) for the source module

A6TBXY36

A6TBXY54

A6TBX70