Page 1

Page 2

Page 3

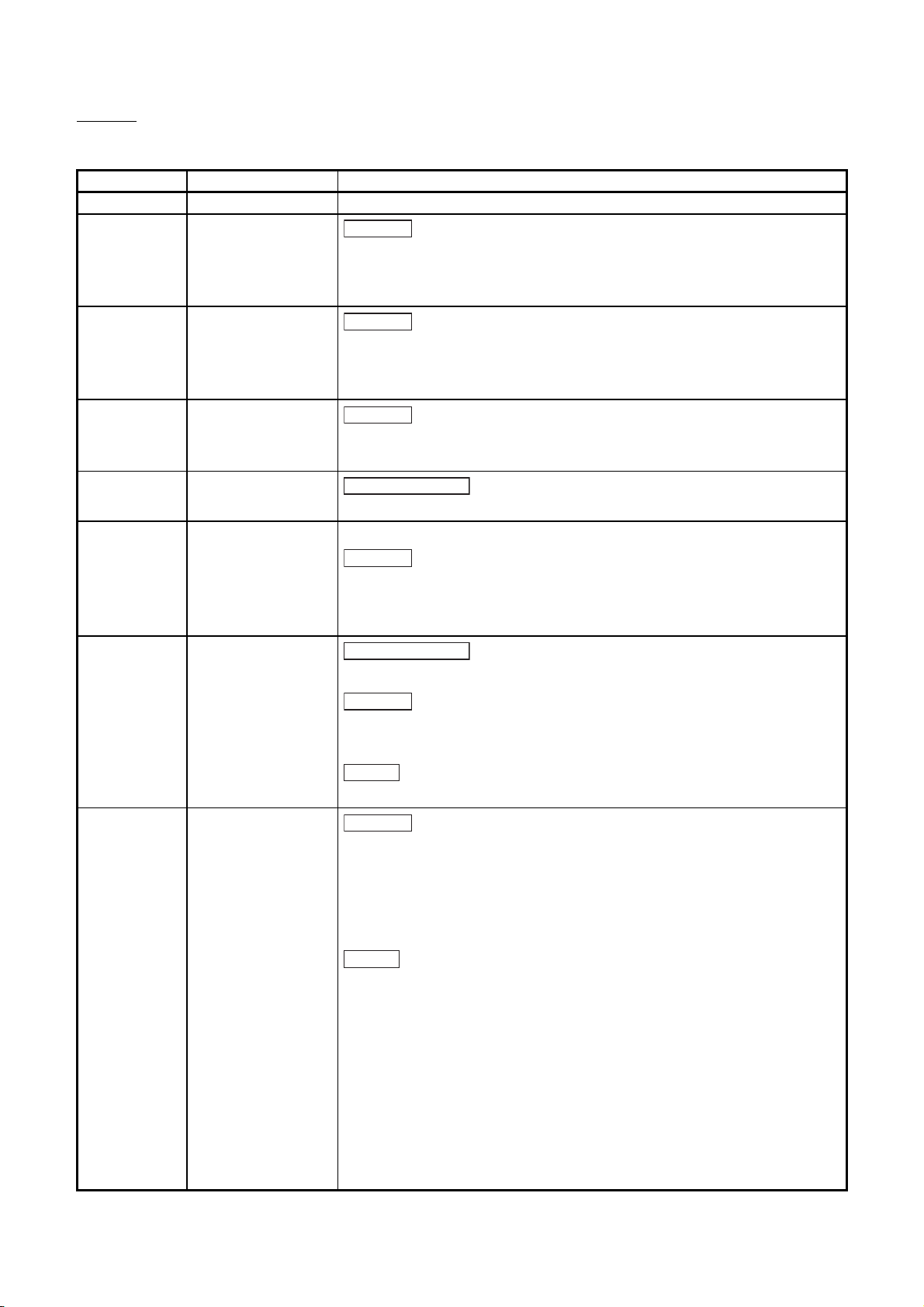

SAFETY PRECAUTIONS

(Be sure to read these instructions before use.)

Before using the product, read this and relevant manuals carefully and handle the product correctly with full

attention to safety.

In this manual, SAFETY PRECAUTIONS are classified into 2 levels: "DANGER" and "CAUTION".

DANGER

CAUTION

Under some circumstances, failure to observe the CAUTION level instructions may also lead to serious

results.

Be sure to observe the instructions of both levels to ensure the safety.

Please keep this manual in a safe place for future reference and also pass this manual on to the end user.

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

Indicates that incorrect handling may cause hazardous conditions, resulting in

medium or slight personal injury or physical damage.

[DESIGN PRECAUTIONS]

DANGER

Create a safety circuit outside the programmable controller to ensure the whole system will operate

safely even if an external power failure or a programmable controller failure occurs.

Otherwise, incorrect output or malfunction may cause an accident.

(1) For an emergency stop circuit, protection circuit and interlock circuit that is designed for

incompatible actions such as forward/reverse rotation or for damage prevention such as the

upper/lower limit setting in positioning, any of them must be created outside the programmable

controller.

Install the emergency stop switch outsid the controlpanel so that workers can operate it easily.

(2) When the programmable controller detects the following error conditions, it stops the operation

and turn off all the outputs.

• The overcurrent protection device or overvoltage protection device of the power supply

module is activated.

• The programmable controller CPU detects an error such as a watchdog timer error by the

self-diagnostics function.

In the case of an error of a part such as an I/O control part that cannot be detected by the

programmable controller CPU, all the outputs may turn on.In order to make all machines

operate safely in such a case, set up a fail-safe circuit or a specific mechanism outside the

programmable controller. For a fail-safe circuit example, refer to "LOADING AND

INSTALLATION" in this manual.

(3) Depending on the failure of the output module's relay or transistor, the output status may remain

ON or OFF incorrectly.

For output signals that may lead to a serious accident, create an external monitoring circuit.

A - 1

Page 4

[DESIGN PRECAUTIONS]

DANGER

If load current more than the rating or overcurrent due to a short circuit in the load has flowed in the

output module for a long time, it may cause a fire and smoke.

as a fuse.

Design a circuit so that the external power will be supplied after power-up of the programmable

controller.

Activating the external power supply prior to the programmable controller may result in an accident

due to incorrect output or malfunction.

For the operation status of each station at a communication error in data link, refer to the respective

data link manual.

The communication error may result in an accident due to incorrect output or malfunction.

When controlling a running programmable controller (data modification) by connecting a peripheral

device to the CPU module or a PC to a special function module, create an interlock circuit on

sequence programs so that the whole system functions safely all the time.

Also, before performing any other controls (e.g. program modification, operating status change

(status control)), read the manual carefully and ensure the safety.

In these controls, especially the one from an external device to a programmable controller in a

remote location, some programmable controller side problem may not be resolved immediately due

to failure of data communications.

To prevent this, create an interlock circuit on sequence programs and establish corrective

procedures for communication failure between the external device and the programmable controller

CPU.

Provide an external safety device such

When setting up the system, do not allow any empty slot on the base unit.

If any slot is left empty, be sure to use a blank cover (A1SG60) or a dummy module (A1SG62) for it.

When using the extension base unit, A1S52B(S1), A1S55B(S1) or A1S58B(S1), attach the included

dustproof cover to the module in slot 0.

Otherwise, internal parts of the module may be flied in the short circuit test or when an overcurrent or

overvoltage is accidentally applied to the external I/O section.

[DESIGN PRECAUTIONS]

CAUTION

Do not install the control lines or communication cables together with the main circuit or power lines,

or bring them close to each other.

Keep a distance of 100mm (3.94inch) or more between them.

Failure to do so may cause malfunctions due to noise.

When an output module is used to control the lamp load, heater, solenoid valve, etc., a large current

(ten times larger than the normal one) may flow at the time that the output status changes from OFF

to ON. Take some preventive measures such as replacing the output module with the one of a

suitable current rating.

A - 2

Page 5

[INSTALLATION PRECAUTIONS]

CAUTION

Use the programmable controller under the environment specified in the user's manual.

Otherwise, it may cause electric shocks, fires, malfunctions, product deterioration or damage.

Insert the module fixing projection into the fixing hole in the base unit and then tighten the module

fixing screw within the specified torque.

When no screw is tightened, even if the module is installed correctly, it may cause malfunctions, a

failure or a drop of the module.

Tightening the screw excessively may damage the screw and/or the module, resulting in a drop of

the module, a short circuit or malfunctions.

Connect the extension cable to the connector of the base unit or module.

Check for incomplete connection after installing it.

Poor electrical contact may cause incorrect inputs and/or outputs.

Insert the memory cassette and fully press it to the memory cassette connector.

Check for incomplete connection after installing it.

Poor electrical contact may cause malfunctions.

Be sure to shut off all phases of the external power supply used by the system before mounting or

removing the module.

Failure to do so may damage the module.

Do not directly touch the conductive part or electronic components of the module.

Doing so may cause malfunctions or a failure of the module.

A - 3

Page 6

[WIRING PRECAUTIONS]

DANGER

Be sure to shut off all phases of the external power supply used by the system before wiring.

Failure to do so may result in an electric shock or damage of the product.

Before energizing and operating the system after wiring, be sure to attach the terminal cover

supplied with the product.

Failure to do so may cause an electric shock.

CAUTION

Ground the FG and LG terminals correctly.

Failure to do so may cause an electric shock or malfunctions.

Wire the module correctly after confirming the rated voltage and terminal layout.

Connecting a power supply of a different voltage rating or incorrect wiring may cause a fire or failure.

Do not connect multiple power supply modules to one module in parallel.

The power supply modules may be heated, resulting in a fire or failure.

Press, crimp or properly solder the connector for external connection with the specified tool.

Incomplete connection may cause a short circuit, fire or malfunctions.

Tighten terminal screws within the specified torque range.

If the screw is too loose, it may cause a short circuit, fire or malfunctions.

Tightening the screw excessively may damage the screw and/or the module, resulting in a drop of

the module, a short circuit or malfunctions.

Carefully prevent foreign matter such as dust or wire chips from entering the module.

Failure to do so may cause a fire, failure or malfunctions.

Install our programmable controller in a control panel for use.

Wire the main power supply to the power supply module installed in a control panel through a

distribution terminal block.

Furthermore, the wiring and replacement of a power supply module have to be performed by a

maintenance worker who acquainted with shock protection.

(For the wiring methods, refer to Section 8.7.)

A - 4

Page 7

[STARTUP AND MAINTENANCE PRECAUTIONS]

DANGER

Do not touch any terminal during power distribution.

Doing so may cause an electric shock.

Properly connect batteries.

Do not charge, disassemble, heat or throw them into the fire and do not make them short-circuited

and soldered.

Incorrect battery handling may cause personal injuries or a fire due to exothermic heat, burst and/or

ignition.

Be sure to shut off all phases of the external power supply used by the system before cleaning or

retightening the terminal screws or module mounting screws.

Failure to do so may result in an electric shock.

If they are too loose, it may cause a short circuit or malfunctions.

Tightening the screw excessively may damage the screw and/or the module, resulting in a drop of

the module, a short circuit or malfunctions.

A - 5

Page 8

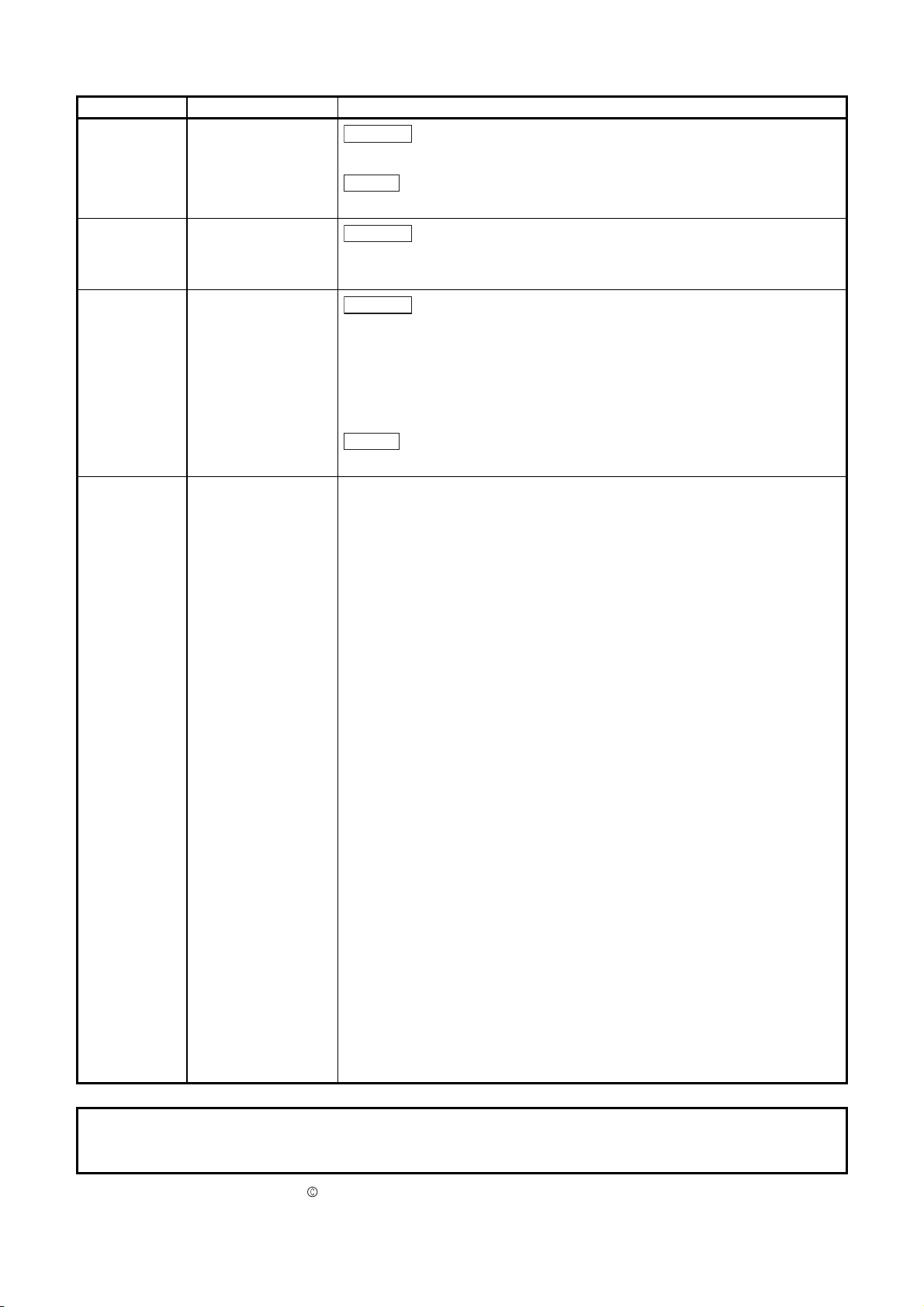

CAUTION

When performing online operations (especially, program modification, forced output or operating

status change) by connecting a peripheral device to the running CPU module, read the manual

carefully and ensure the safety.

Incorrect operation will cause mechanical damage or accidents.

Do not disassemble or modify each of modules.

Doing so may cause failure, malfunctions, personal injuries and/or a fire.

When using a wireless communication device such as a mobile phone, keep a distance of 25cm

(9.84inch) or more from the programmable controller in all directions.

Failure to do so may cause malfunctions.

Be sure to shut off all phases of the external power supply used by the system before mounting or

removing the module.

Failure to do so may result in failure or malfunctions of the module.

Do not drop or apply any impact to the battery.

Doing so may damage the battery, resulting in electrolyte spillage inside the battery.

If any impact has been applied, discard the battery and never use it.

Do not mount/remove the module onto/from base unit more than 50 times (IEC61131-2-compliant),

after the first use of the product.

Before handling modules, touch a grounded metal object to discharge the static electricity from the

human body.

Failure to do so may cause failure or malfunctions of the module.

A - 6

Page 9

[DISPOSAL PRECAUTIONS]

CAUTION

When disposing of the product, treat it as an industrial waste.

When disposing of batteries, separate them from other wastes according to the local regulations.

(For details of the battery directive in EU member states, refer to Appendix 6.)

[TRANSPORTATION PRECAUTIONS]

CAUTION

When transporting lithium batteries, make sure to treat them based on the transportation regulations.

(Refer to Appendix 5 for details of the relevant models.)

A - 7

Page 10

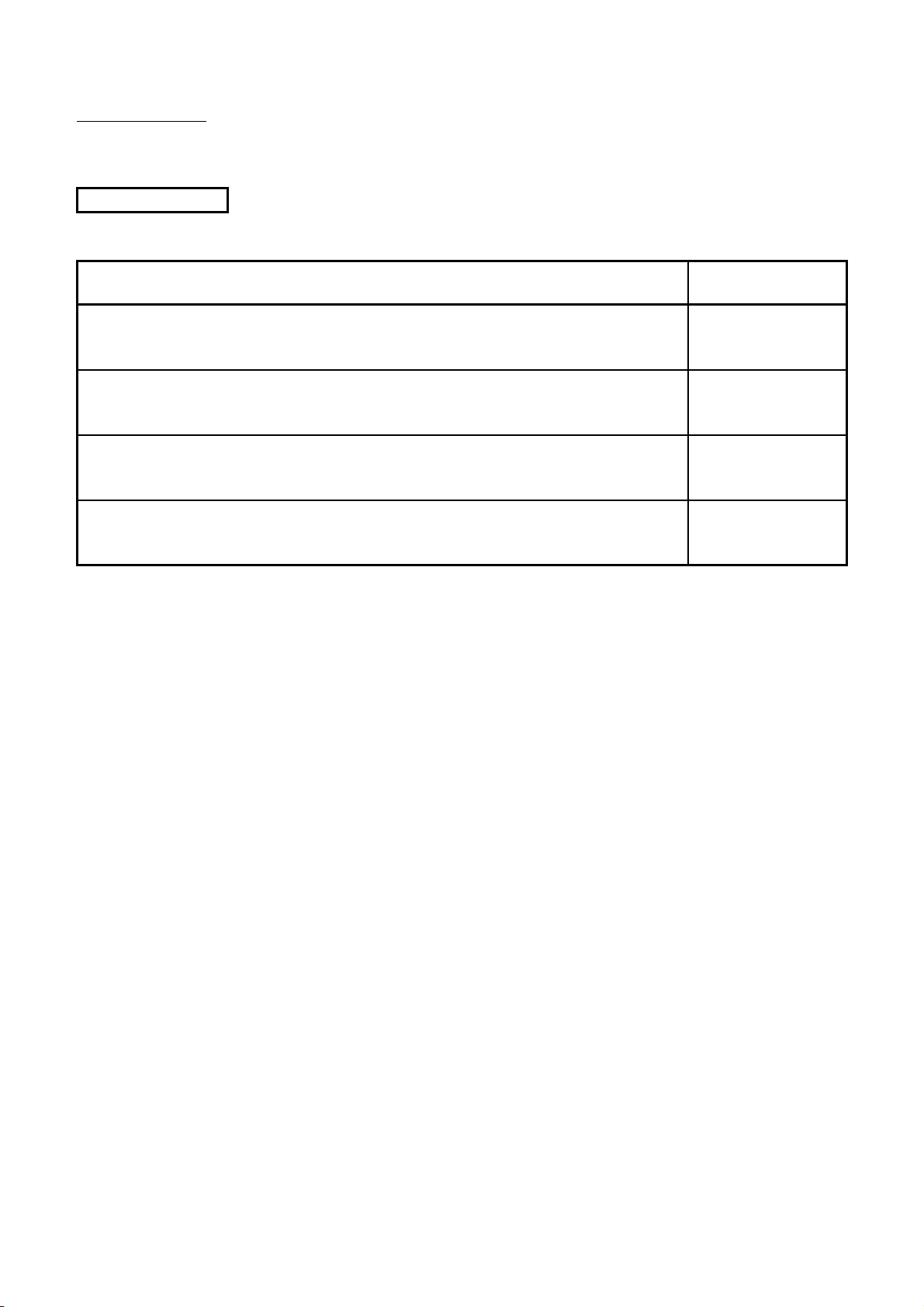

Revision

*The manual number is given on the bottom left of the back cover.

Print Date *Manual Number Revision

May., 1997 IB(NA)66779-A First edition

Nov., 1997 IB(NA)66779-B

Apr., 1998 IB(NA)-66779-C

Aug., 1998 IB(NA)-66779-D

Nov., 1998 IB(NA)-66779-E

Dec., 2002 IB(NA)-66779-F Equivalent to the Japanese version F

Dec., 2003 IB(NA)-66779-G

Correction

Contents, Related manuals, Section 1.1, Section 2.1.1, 2.1.2, Section 2.2, 2.3,

Chapter 3, Section 4.1.6, Section 5.1, 5.2, Section 6.1.2, Section 8.7.1, 8.7.2,

Section 9.1.3, Section 11.3.1, Appendix 1, 1.1, Appendix 3.1, 3.2, Appendix 5.

Correction

SAFETY PRECAUTIONS, Contents, Section 1.1, Section 2.2, 2.3, Section 4.1,

4.1.7, 4.1.8, 4.1.9, 4.4.3, Section 6.1.3, Section 7.1.4, Section 8.7.1, Section

9.2.1, 9.2.2, Section 11.3.1, Appendix 1, 1.1, Appendix 3.1, 3.2, 3.3.3.

Correction

Section 2.2.1, 2.3, Section 4.1, Section 9.1.2.7, 9.1.2.9 Section 11.2.4, Appendix

2.2, 3.3.5

Addition of module

A1SJHCPU-S8

Correction

SAFETY PRECAUTIONS, Section 1.1, 1.2, Section 2.1.1, 2.1.2, 2.2.1, 2.2.2, 2.3,

Chapter 3, Section 4.1.1, 4.1.7, Section 5.1, 5.2, Section 6.1.3, Section 7.1.1,

Section 9.1.4, Chapter 10, Section 11.1.3, Appendix 2.1, 2.2, Appendix 4

Addition of module

A1SY42P

Oct., 2006 IB(NA)-66779-H

Correction

Section 2.2.1, 2.3, Section 7.1.1, 7.1.4, 7.2.1, Section 8.4.1, 8.8, Section 9.1.4,

Section 11.3.1, Appendix 2.1

Addition

Appendix 5

Correction

SAFETY PRECAUTIONS, Section 2.2.1, 2.3, Chapter 3, Section 4.1, 4.1.2, 4.1.3,

4.1.4, 4.1.7, 4.2, 4.3, 4.4.1, 4.4.3, 4.4.4, Section 5.1, 5.2, Section 6.1.2, 6.1.3, 6.2,

Section 7.1.1, 7.1.3, Section 8.1, 8.3, 8.4.1, 8.4.2, 8.5, 8.7.1, 8.7.2, 8.8, Chapter

9, Section 9.1.3, 9.2.6, Chapter 10, Section 10.2, 10.3.2, Section 11.2.8, 11.3.2,

11.4.1, 11.4.2, Appendix 2.1, 2.2, Appendix 4.5.1, WARRANTY

Addition

USER PRECAUTONS, Section 7.2.2, Section 11.2.9, 11.3.1

A - 8

Page 11

Print Date *Manual Number Revision

May, 2007 IB(NA)-66779-I

Jul., 2007 IB(NA)-66779-J

Sep., 2008 IB(NA)-66779-K

Correction

Section 2.3, 8.7.1, 8.7.2, 9.1.3, 9.2.7, 10.3.1, 11.4.2

Addition

Section 9.1.7

Correction

Section 6.2, Appendix 4.4.1, Appendix 4.4.3, Appendix 4.4.4, Appendix 4.4.5,

Appendix 4.4.8, Appendix 4.4.9, Appendix 4.4.10

Correction

SAFETY PRECAUTIONS, Chapter 1, Section 2.2.2, 2.3, 2.4, Chapter 3,

Section 4.1, 4.1.1, 4.1.2, 4.1.3, 4.1.4, 4.1.5, 4.3, 4.4, 5.1, 8.1, 8.2, 8.3, 8.4.1,

8.4.2, 8.7.1, 8.7.2, 8.8, 9.1, 9.1.1, 9.1.2, 9.1.3, 9.2, 9.2.1, 9.2.2, 9.2.3, 9.2.4, 9.2.5,

9.2.6, 9.2.7, Chapter 10, Section 10.3.1, 10.3.2, 11.1, 11.2.3, 11.3, 11.4.1, 11.2.8,

Appendix 1, Appendix2.2

Addition

Appendix 6, Appendix 6.1, Appendix 6.2

Japanese Manual Version SH-3635-L

This manual confers no industrial property rights or any rights of any other kind, nor dose it confer any patent

licenses.Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights

which may occur as a result of using the contents noted in this manual.

1997 MITSUBISHI ELECTRIC CORPORATION

A - 9

Page 12

Introduction

Thank you for purchasing the Mitsubishi programmable logic controller MELSEC-A Series.

Prior to use, please read this manual thoroughly to fully understand the functions.

Please hand in a copy of this manual to the end user.

Table of Contents

1 OVERVIEW 1 - 1 to 1 - 4

1.1 Features ........................................................................................................................................1 - 2

2 SYSTEM CONFIGURATION 2 - 1 to 2 - 30

2.1 Overall Configuration.....................................................................................................................2 - 1

2.1.1 Overall configuration of AnSHCPU .......................................................................................2 - 1

2.1.2 Overall configuration of A1SJHCPU(S8)...............................................................................2 - 3

2.2 Precautions when Configuring the System ...................................................................................2 - 5

2.2.1 Hardware...............................................................................................................................2 - 5

2.2.2 Software package .................................................................................................................2 - 9

2.3 System Equipment ......................................................................................................................2 - 11

2.4 System Configuration Overview ..................................................................................................2 - 26

3 SPECIFICATIONS 3 - 1 to 3 - 1

4 CPU MODULE 4 - 1 to 4 - 29

4.1 Performance Specifications...........................................................................................................4 - 1

4.1.1 Overview of operation processing .........................................................................................4 - 4

4.1.2 Operation processing of RUN, STOP and PAUSE ...............................................................4 - 7

4.1.3 Operation processing upon instantaneous power failure ......................................................4 - 9

4.1.4 Self-diagnostics function .....................................................................................................4 - 10

4.1.5 Device list............................................................................................................................4 - 13

4.2 Parameter Setting Ranges ..........................................................................................................4 - 15

4.2.1 List of parameter setting range ...........................................................................................4 - 15

4.2.2 Memory capacity setting (for main program, file register, comment, etc.) ..........................4 - 17

4.3 Function List ................................................................................................................................4 - 19

4.4 Handling Precautions ..................................................................................................................4 - 21

4.5 Part Names .................................................................................................................................4 - 22

4.5.1 Parts names of the A1SHCPU, A2SHCPU(S1), A1SJHCPU (S8)......................................4 - 22

4.5.2 Setting of I/O control mode switching switch.......................................................................4 - 26

4.5.3 Settings for memory write protect switch ............................................................................4 - 27

4.5.4 Latch clear operation...........................................................................................................4 - 29

5 POWER SUPPLY MODULE 5 - 1 to 5 - 6

5.1 Specifications ................................................................................................................................5 - 1

5.1.1 Power supply module selection.............................................................................................5 - 4

5.2 Part Names ...................................................................................................................................5 - 5

A - 10

Page 13

6 BASE UNIT AND EXTENSION CABLE 6 - 1 to 6 - 10

6.1 Specifications ................................................................................................................................6 - 1

6.1.1 Base unit specifications.........................................................................................................6 - 1

6.1.2 Extension cable specifications ..............................................................................................6 - 2

6.1.3 Application standards of extension base units (A1S52B(S1), A1S55B(S1), A1S58B(S1), A52B,

A55B, A58B) .........................................................................................................................6 - 3

6.2 Part Names ...................................................................................................................................6 - 7

6.3 Installation and Removal of DIN Rail.............................................................................................6 - 9

7 MEMORY CASSETTE AND BATTERY 7 - 1 to 7 - 8

7.1 Memory Cassette ..........................................................................................................................7 - 1

7.1.1 Specifications ........................................................................................................................7 - 1

7.1.2 Handling precautions ............................................................................................................7 - 2

7.1.3 Installation and removal of memory cassette........................................................................7 - 3

7.1.4 Writing a sequence program to a memory cassette..............................................................7 - 5

7.1.5 Memory protection setting of A2SNMCA-30KE ....................................................................7 - 6

7.2 Battery ...........................................................................................................................................7 - 7

7.2.1 Specifications ........................................................................................................................7 - 7

7.2.2 Handling precautions ............................................................................................................7 - 7

7.2.3 Battery installation.................................................................................................................7 - 8

8 LOADING AND INSTALLATION 8 - 1 to 8 - 23

8.1 Fail-Safe Circuit Concept ..............................................................................................................8 - 1

8.2 Installation Environment ................................................................................................................8 - 6

8.3 Calculation Method of Heat Amount Generated by the PLC .........................................................8 - 7

8.4 Installing the Base Units................................................................................................................8 - 9

8.4.1 Precautions when installing programmable controller...........................................................8 - 9

8.4.2 Installation ...........................................................................................................................8 - 10

8.5 Installation and Removal of the Base Units.................................................................................8 - 11

8.6 Installation and Removal of the Dustproof Cover........................................................................8 - 14

8.7 Wiring ..........................................................................................................................................8 - 16

8.7.1 Wiring instructions...............................................................................................................8 - 16

8.7.2 Wiring to module terminals..................................................................................................8 - 21

8.8 Precautions when Connecting the Uninterruptible Power Supply (UPS) ....................................8 - 23

9 EMC AND LOW VOLTAGE DIRECTIVES 9 - 1 to 9 - 13

9.1 Requirements for Compliance with EMC Directives......................................................................9 - 1

9.1.1 EMC standards .....................................................................................................................9 - 1

9.1.2 Installation instructions for EMC directive .............................................................................9 - 2

9.1.3 Cables ...................................................................................................................................9 - 3

9.1.4 Power supply module............................................................................................................9 - 8

9.1.5 Ferrite core............................................................................................................................9 - 8

9.1.6 Noise filter (power supply line filter) ......................................................................................9 - 9

9.1.7 Power line for external power supply terminal ......................................................................9 - 9

9.2 Requirements for Compliance with Low Voltage Directives........................................................9 - 10

A - 11

Page 14

9.2.1 Standard applied for MELSEC-AnS series programmable controller .................................9 - 10

9.2.2 Precautions when using the MELSEC-AnS series programmable controller......................9 - 10

9.2.3 Power supply.......................................................................................................................9 - 11

9.2.4 Control panel.......................................................................................................................9 - 12

9.2.5 Module installation ..............................................................................................................9 - 13

9.2.6 Grounding ...........................................................................................................................9 - 13

9.2.7 External wiring.....................................................................................................................9 - 13

10 MAINTENANCE AND INSPECTION 10 - 1 to 10 - 8

10.1 Daily Inspection ...........................................................................................................................10 - 2

10.2 Periodic Inspection ......................................................................................................................10 - 3

10.3 Battery Replacement ...................................................................................................................10 - 4

10.3.1 Battery life ...........................................................................................................................10 - 4

10.3.2 Battery replacement procedure...........................................................................................10 - 8

11 TROUBLESHOOTING 11 - 1 to 11 - 22

11.1 Fundamentals of Troubleshooting ...............................................................................................11 - 1

11.2 Troubleshooting...........................................................................................................................11 - 2

11.2.1 Troubleshooting procedure .................................................................................................11 - 2

11.2.2 Flow for actions when the "POWER" LED is turned OFF ...................................................11 - 3

11.2.3 Flow for actions when the "RUN" LED is turned OFF .........................................................11 - 4

11.2.4 Flow for actions when the "RUN" LED is flickering .............................................................11 - 5

11.2.5 Flow for actions when the "ERROR" LED is turned ON......................................................11 - 6

11.2.6 Flow for actions when the "ERROR" LED is flickering ........................................................11 - 7

11.2.7 Flow for actions when the output module's output load does not turn ON ..........................11 - 8

11.2.8 Flow for actions when the program cannot be written.........................................................11 - 9

11.2.9 Flow for actions when the CPU module is not started up .................................................11 - 10

11.3 Error Code List ..........................................................................................................................11 - 11

11.3.1 Procedure to read an error code .......................................................................................11 - 11

11.3.2 AnSHCPU error code list ..................................................................................................11 - 12

11.4 Fault Examples with I/O Modules..............................................................................................11 - 17

11.4.1 Faults with the input circuit and the corrective actions ......................................................11 - 17

11.4.2 Faults in the output circuit .................................................................................................11 - 19

APPENDIX Appendix - 1 to Appendix - 57

Appendix 1 Instruction List .............................................................................................................. App - 1

Appendix 1.1 Precautions for write during RUN of a dedicated instruction .............................. App - 7

Appendix 2 LISTS OF SPECIAL RELAYS AND SPECIAL REGISTERS ...................................... App - 8

Appendix 2.1 List of Special Relays......................................................................................... App - 8

Appendix 2.2 Special Registers ............................................................................................. App - 20

Appendix 3 Precautions when Replacing AnSCPU with AnSHCPU ............................................. App - 39

Appendix 3.1 Differences between A1SHCPU and A1SCPU................................................. App - 39

Appendix 3.2 Differences between A2SHCPU(S1) and A2SCPU .......................................... App - 40

Appendix 3.3 Replacement precautions ................................................................................. App - 40

Appendix 3.3.1 PLC type setting ........................................................................................ App - 40

Appendix 3.3.2 Precautions when performing ROM partition ............................................. App - 40

A - 12

Page 15

Appendix 3.3.3 Precautions when utilizing sequence programs ........................................ App - 41

Appendix 3.3.4 Checking the influence of the increased instruction processing speed on the

system ....................................................................................................... App - 41

Appendix 3.3.5 Handling conventional memory cassettes ................................................. App - 42

Appendix 3.3.6 Replacing the A2SMCA-14KP (when A2SCPU + A2SMCA-14KP has been used)

................................................................................................................... App - 42

Appendix 3.3.7 Restrictions on microcomputer programs .................................................. App - 42

Appendix 4 External Dimensions .................................................................................................. App - 43

Appendix 4.1 CPU module...................................................................................................... App - 43

Appendix 4.1.1 A1SHCPU, A2SHCPU(S1) module ........................................................... App - 43

Appendix 4.1.2 A1SJHCPU module ................................................................................... App - 43

Appendix 4.1.3 A1SJHCPU-S8 module.............................................................................. App - 44

Appendix 4.2 A1S61PN, A1S62PN and A1S63P power supply modules .............................. App - 45

Appendix 4.3 Main base unit................................................................................................... App - 46

Appendix 4.3.1 A1S32B main base unit ............................................................................. App - 46

Appendix 4.3.2 A1S33B main base unit ............................................................................. App - 46

Appendix 4.3.3 A1S35B main base unit ............................................................................. App - 47

Appendix 4.3.4 A1S38B main base unit ............................................................................. App - 47

Appendix 4.4 Extension base unit........................................................................................... App - 48

Appendix 4.4.1 A1S65B extension base unit...................................................................... App - 48

Appendix 4.4.2 A1S68B extension base unit...................................................................... App - 48

Appendix 4.4.3 A1S52B extension base unit...................................................................... App - 49

Appendix 4.4.4 A1S55B extension base unit...................................................................... App - 49

Appendix 4.4.5 A1S58B extension base unit...................................................................... App - 50

Appendix 4.4.6 A1S65B-S1 extension base unit ................................................................ App - 50

Appendix 4.4.7 A1S68B-S1 extension base unit ................................................................ App - 51

Appendix 4.4.8 A1S52B-S1 extension base unit ................................................................ App - 51

Appendix 4.4.9 A1S55B-S1 extension base unit ................................................................ App - 52

Appendix 4.4.10 A1S58B-S1 extension base unit................................................................ App - 52

Appendix 4.5 Memory cassette............................................................................................... App - 53

Appendix 4.5.1 AnSNMCA-[ ] memory cassette ................................................................. App - 53

Appendix 4.6 Memory write adapter ....................................................................................... App - 53

Appendix 4.6.1 A6WA-28P memory write adapter ............................................................. App - 53

Appendix 5 Transportation Precautions ........................................................................................ App - 54

Appendix 5.1 Relevant models ............................................................................................... App - 54

Appendix 5.2 Transportation Guidelines................................................................................. App - 55

Appendix 6 Handling of Batteries and Devices with Built-in Batteries in EU Countries ................ App - 56

Appendix 6.1 Disposal precautions......................................................................................... App - 56

Appendix 6.2 Exportation precautions .................................................................................... App - 57

INDEX Index - 1 to Index - 3

A - 13

Page 16

About This Manual

Related manuals

The following manuals are related to this product.

Manual Name

ACPU/QCPU-A (A mode) Programming Manual (Fundamentals)

Describes programming methods necessary for creating programs, device names, parame-

ters, program types, memory area configuration, and so on. (Sold separately)

ACPU/QCPU-A (A mode) Programming Manual (Common Instructions)

Describes how to use the sequence instruction, basic instructions, applied instructions and

microcomputer programs. (Sold separately)

AnSHCPU/AnACPU/AnUCPU/QCPU-A (A Mode) Programming Manual (Dedicated Instructions)

Describes instructions that have been expanded for AnSHCPU

(Sold separately)

AnS Module type I/O User's Manual

Describes the specification of the compact building block type I/O module.

(Sold separately)

Manual No.

(Model Code)

IB-66249

(13J740)

IB-66250

(13J741)

IB-66251

(13J742)

IB-66541

(13JE81)

A - 14

Page 17

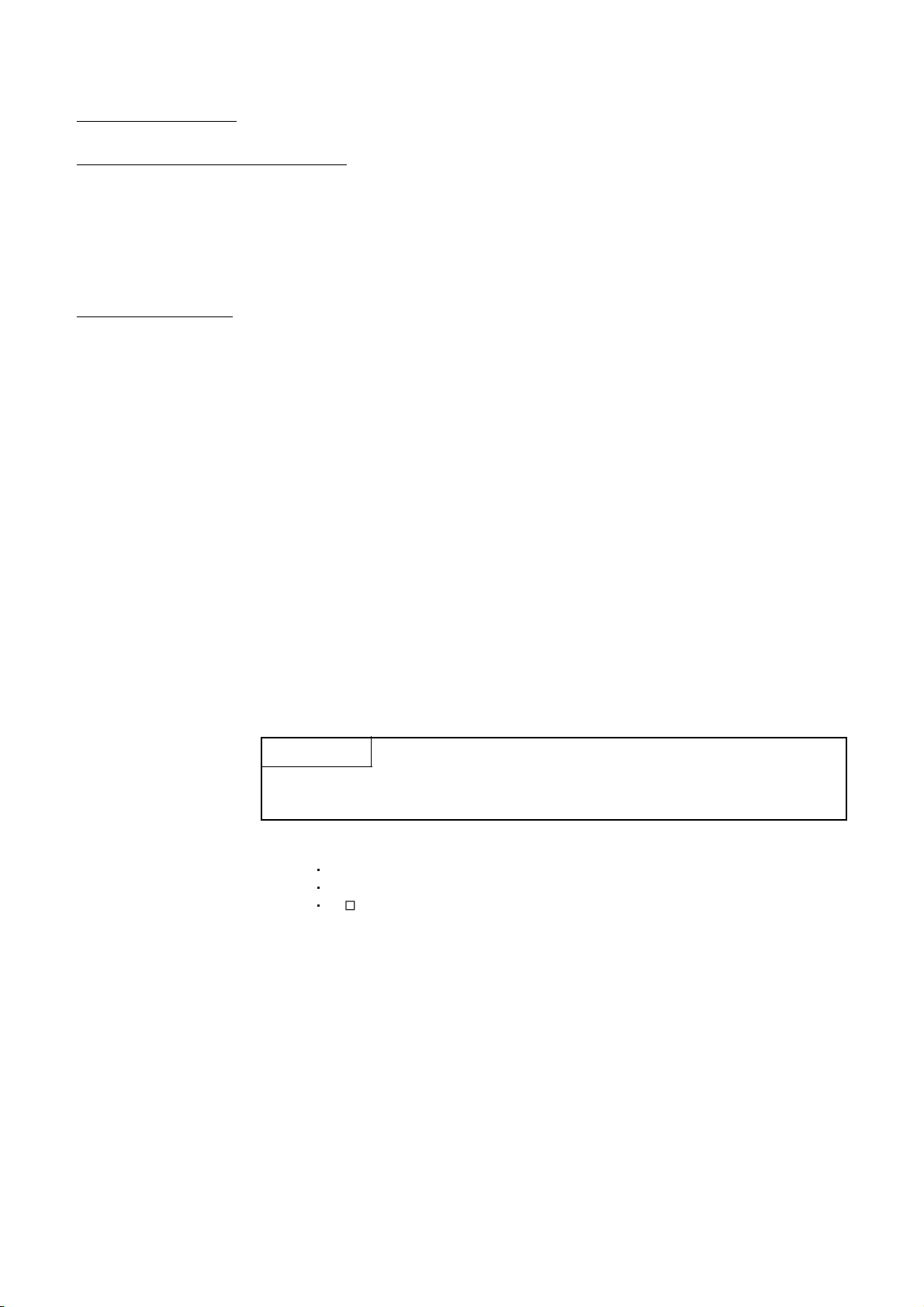

USER PRECAUTIONS

Precautions when using the AnS series

For a new CPU module, which has never used before, the contents of built-in RAM and

device data are undefined.

Make sure to clear the built-in RAM memory (PLC memory all clear) in the CPU module by

peripheral devices and operate latch clear by RUN/STOP key switches.

Precautions for battery

(1) The operation after a battery is unmounted and the programmable controller is stored.

When reoperating after a battery is uncounted and the programmable controller is

stored, the contents of built-in RAM and device data may be undefined.

For this reason, make sure to clear the built-in RAM memory (PLC memory all clear) in

the CPU module by peripheral devices and operate latch clear by RUN/STOP key

switches before start the operation again.

After the built-in RAM clear and latch clear of the CPU module, write the backed-up

memory contents to the CPU module before saving.

(2) The operation after excess of a battery life

If a battery exceeded its guaranteed life is stored and reoperated, the contents of built-in

RAM and device data may be undefined.

For this reason, make sure to clear the built-in RAM memory (PLC memory all clear) in

the CPU module by peripheral devices and operate latch clear by RUN/STOP key

switches before start the operation again.

After the built-in RAM clear and latch clear of the CPU module, write the backed-up

memory contents to the CPU module before saving.

*

*

POINT

Make sure to back up each memory contents before storing the programmable

controller.

* Refer to the following manuals for details of built-in RAM clear (PLC memory all clear) by periph-

eral devices.

GX Developer Operating Manual

A6GPP/A6PHP Operating Manual

SW IVD-GPPA Operating Manual

Refer to Section 4.5 for latch clear operation by RUN/STOP key switch of the CPU module.

A - 15

Page 18

1. OVERVIEW

1 OVERVIEW

This user's manual describes the functions, specification, and handling of the A1SJHCPU

general purpose programmable controller (abbreviated as A1SJHCPU from here on),

A1SJHCPU-S8 general purpose programmable controller (abbreviated as A1SJHCPUS8), A1SHCPU general purpose PLC (abbreviated as A1SHCPU), A2SHCPU general

purpose PLC (abbreviated as A2SHCPU), and A2SHCPU-S1 general purpose PLC

(abbreviated as A2SHCPU-S1).

A1SHCPU and A1SJHCPU are grouped as A1SHCPU, unless there is necessity to

identify each model.

Also, A1SHCPU, A2SHCPU and A2SHCPU-S1 are grouped as AnSHCPU, unless there

is necessity to identify each model.

The AnSHCPU is a compact-type building block programmable controller. The model is

one third the size of the conventional building block type programmable controller, and

allows easy operation in spite of its small size.

Sequence programs that have been created for the existing A0J2CPU, A0J2HCPU and

A NCPU models can be used by changing the CPU module type specification for the

program. Moreover, since modules for use with A NCPU can be used by installing them

on an extension base unit for A NCPU use, it is possible to extend the functions of an

AnSCPU.

This user's manual refers to peripheral devices by using the following abbreviations.

A6GPP, A6PHP, PC/AT (started up with SW IVD-GPPA)

......................................................... Abbreviated as "GPP function".

A7PUS, A8PUE .............................. Abbreviated as "PU".

1 - 1

Page 19

1. OVERVIEW

1.1 Features

(1) High-speed operation processing speed

Compared to the conventional A1SCPU, the A1SHCPU is three times and A2SHCPU

(S1) is four times faster in the operation processing speed, respectively.

Item A1SHCPU A2SHCPU(S1) A1SCPU

Operation processing speed

*1 I/O processing: Refresh and LD instruction

*1

0.33 s 0.25 s 1 s

(2) Addition of new dedicated instructions

The CC-Link dedicated instructions (8 instructions) have been added, making the

operation even easier.

(3) Increased number of I/O device points

The actual number of I/O points is the same as the AnS series, but each CPU has

2048 points (X/Y0 to X/Y7FF) of I/O devices.

The added I/O device can be used as the MELSECNET (/B), MELSECNET/MINI-S3,

or CC-Link.

(4) Increased file register R capacity

The capacity is now max. 8192 points (R0 to R8191), which doubled the AnS series'

4096 points (R0 to R4095).

(5) Increased memory capacity (Increased number of comment points)

The A1SHCPU has 64 k bytes, which doubled the A1SCPU's 32 k bytes.

This increased the number of comment points stored in the CPU module 3648 points

in comparison to the 1600 points in A1SCPU.

(6) Full compatibility with A1S(S1)/A2SCPU(S1)

Because there is full compatibility of the functions and instructions with A1S(S1)/

A2SCPU(S1), all software packages can be used.

In addition, power supply module, base unit, and I/O modules can be used.

(7) Compact size

The appearance of the AnSHCPU system with one power supply module, one CPU,

and eight 16-point I/O modules for use with AnS mounted to the main base unit are:

430mm (16.9in.) (W); 130mm (5.12in.) (H); and 110mm (4.33in.) (D).

(8) Max. 8 k/14 k steps of program

An A1SHCPU allows the creation of a sequence program up to 8k steps, an

A2SHCPU(S1) allows up to 14k steps.

In addition, microcomputer programs and utility programs created by the user can be

used.

1 - 2

Page 20

OVERVIEW1.

(9) SFC language compatible

An AnSCPU contains a microcomputer program area, so an SFC program can be

used.

(10) Two extension connectors, on the right and left sides. (A1SHCPU,A2SHCPU(S1))

In order to facilitate wiring wherever the extension base unit is installed, extension

connectors are provided at both left and right sides of the AnSHCPU and extension

cables that suit the requirements imposed by different mounting locations are

available.

* A1SJHCPU(S8) on the right side only

(11) Use either screws or DIN rail for panel installations

The AnS base unit is provided both with screw holes and, on its rear face, the fixture

for mounting it to a DIN rail.

(12) Easy-to-see terminal block symbol sheet

• A terminal block symbol sheet is attached to the front of AnS I/O modules.

AnSHCPU writes I/O device numbers, connector numbers, etc. on one side of the

sheet.

• Terminal symbols for 16 I/O signals can be written on the other side.

(13) A N, A A-series I/O module and special function module compatible

By connecting an A N, A A-series extension base unit, A N, A A I/O

modules or special function modules can be used.

(14) Same programming environment as other MELSEC-A CPU modules

A sequence program can be created using the peripheral device currently used for

other MELSEC-A CPU modules. For details on the applicable peripheral devices,

refer to Section 2.2 "Precautions when Configuring the System".

1 - 3

Page 21

OVERVIEW1.

MEMO

1 - 4

Page 22

2. SYSTEM CONFIGURATION

2 SYSTEM CONFIGURATION

This chapter describes the applicable system configurations, cautions on configuring a

system, and component devices of the AnSHCPU.

2.1 Overall Configuration

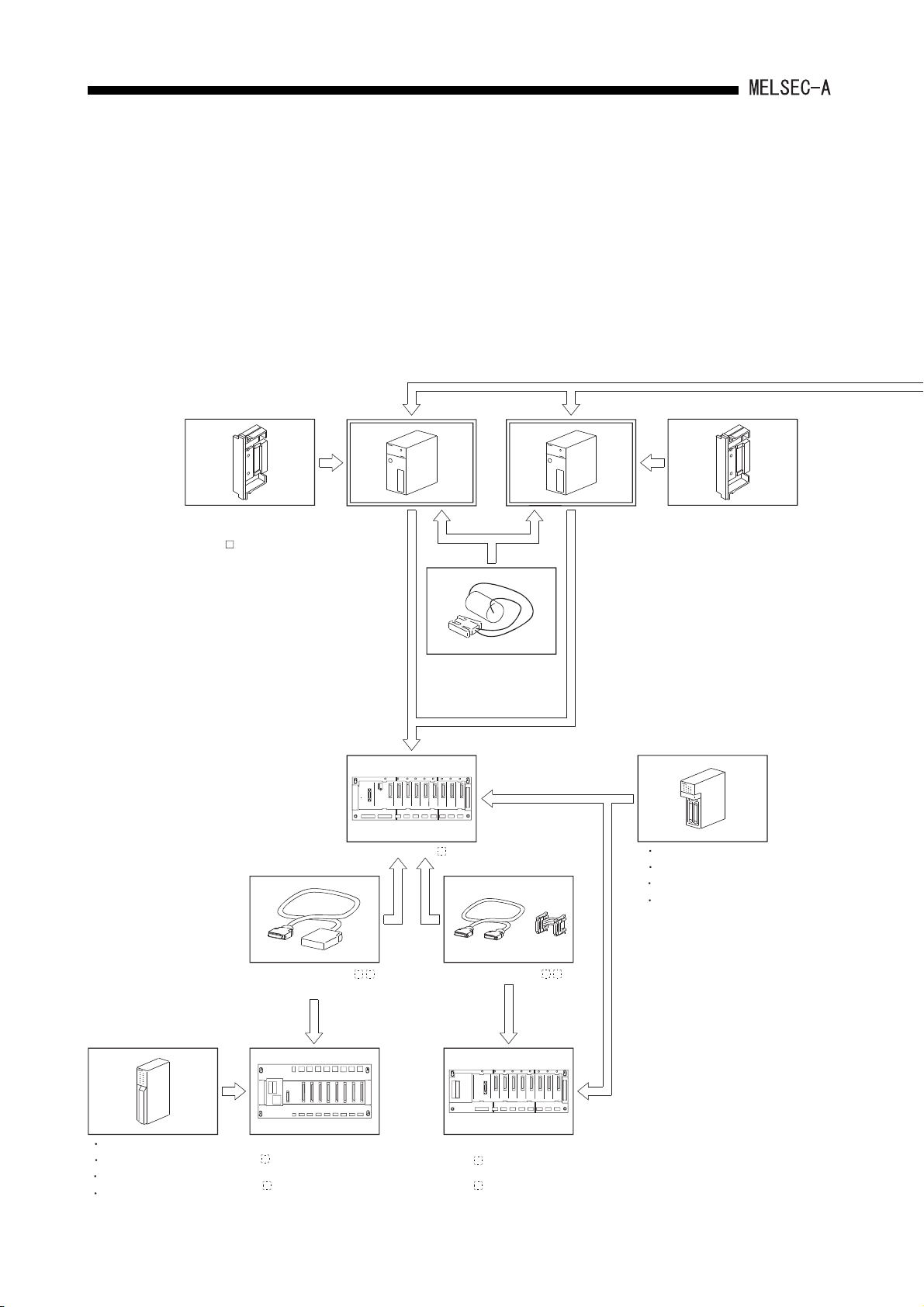

2.1.1 Overall configuration of AnSHCPU

The following figure shows configurations of an AnSHCPU stand-alone system and a

peripheral device.

(To peripheral devices)

ROM cassette

(A1SNMCA-8KP with EP-ROM)

(A1SNMCA- KE with E2PROM)

A1SHCPU

Main base(A1S3 B)

Battery (A6BAT)

A2SHCPU(S1)

ROM cassette

(A2SNMCA-30KE with E PROM)

Power supply module

Input module

Output module

Special function module

2

Power supply module

Input module

Output module

Special function module

Extension cable (A1SC0 NB)

[Building-block type]

Extension base

(A5 B)

: without a power supply module

(A6 B)

: with a power supply module

Extension cable (A1SC NB)

Extension base

(A1S5 B(S1))

: without a power supply module

(A1S6 B(S1))

: with a power supply module

2 - 1

Page 23

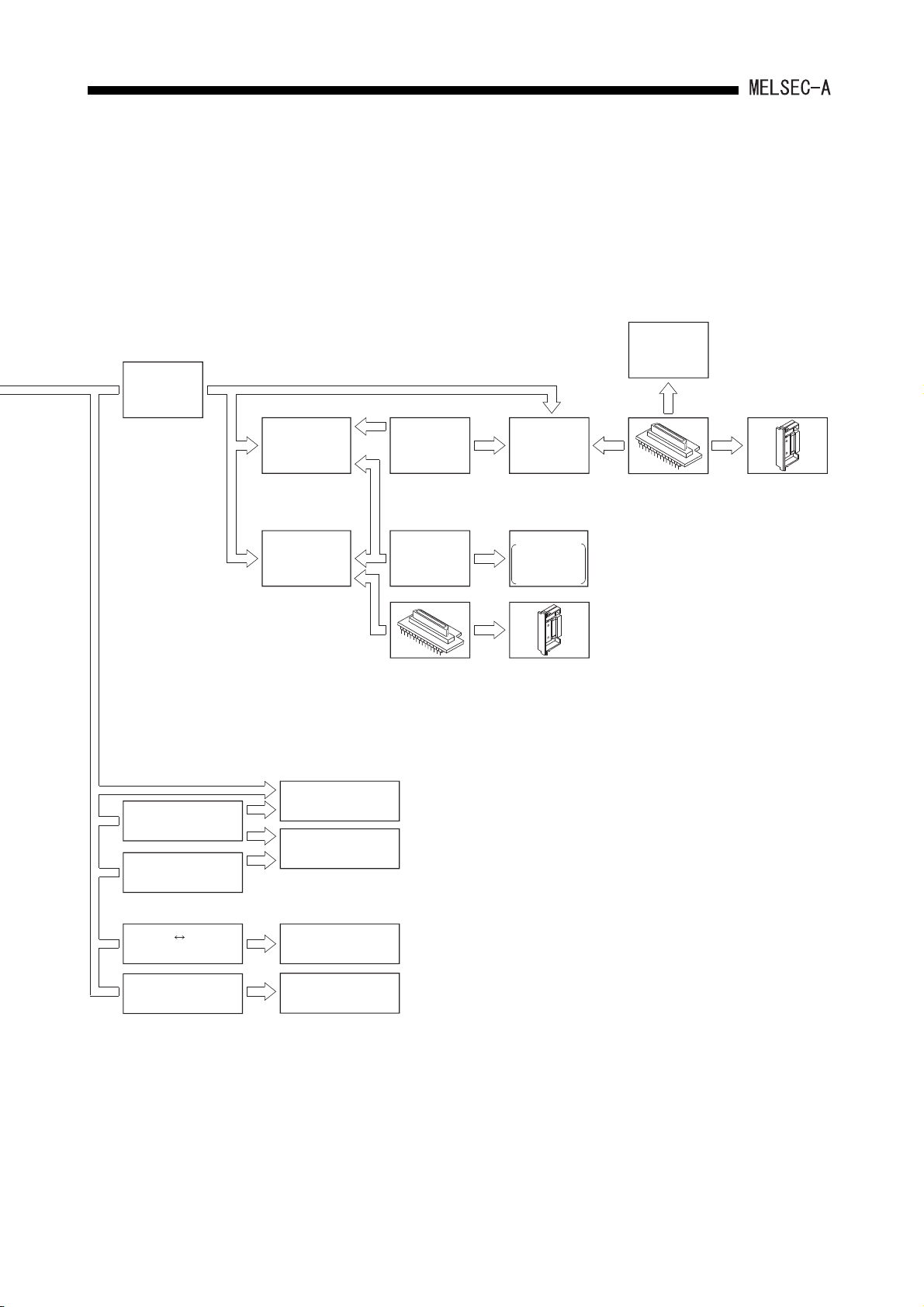

SYSTEM CONFIGURATION2.

To CPU module

AC30R4

AC300R4

cable

AC30R4-PUS

cable

AC20R4-A8PU

cable

A6PHP

Plasma hand-held

graphic programmer

A6GPP intelligent

GPP

A7PUS

programming unit

A8PUE

programming unit

AC03WU

cable

AC30R2

cable

EP-ROM write adapter

(A6WA-28P)

A6WU

P-ROM writer

module

Printer

A7NPR-S1,

K6PR-K,

Generalpurpose printer

ROM cassette

(A1SNMCA-8KP)

ROM writer

*

EP-ROM write adapter

(A6WA-28P)

ROM cassette

(A1SNMCA-8KP)

RS-232C RS-422

converter

AC30R4-PUS

cable

IBM-PC/AT-compatible

personal computer

A6DU-B

data access module

2 - 2

Page 24

SYSTEM CONFIGURATION2.

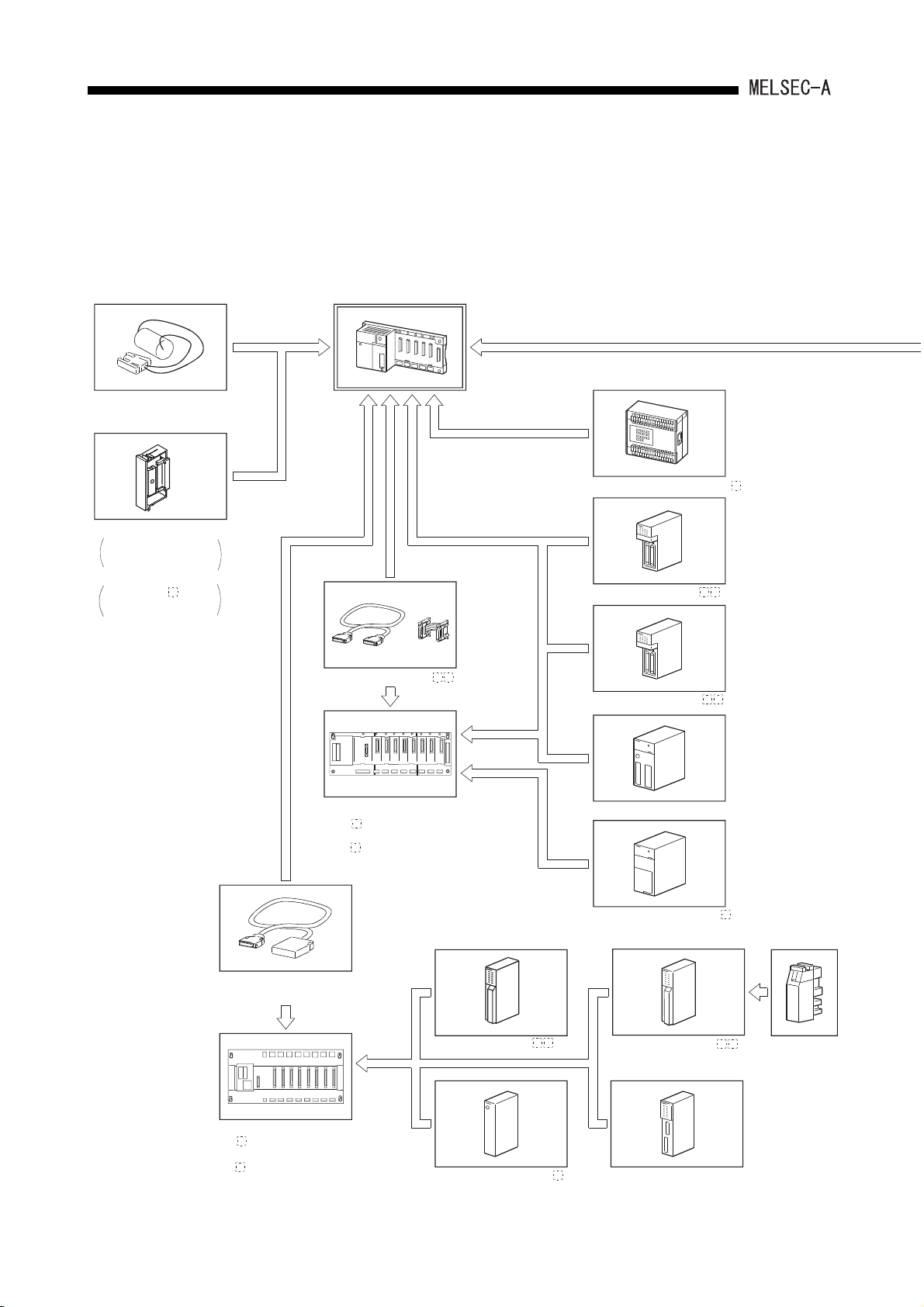

2.1.2 Overall configuration of A1SJHCPU(S8)

The following figure shows configurations of a A1SJHCPU(S8) stand-alone system and

peripheral device.

A1SJHCPU(S8)

Battery (A6BAT)

(To peripheral device)

Thin type I/O module (A1SJ-56 )

ROM cassette

A1SNMCA-8KP

with EP-ROM

A1SNMCA- KE

2

with E PROM

Extension cable (A1SC B)

Extension base

(A1S5 B(S1))

:Without a power supply module

(A1S6 B(S1))

:With a power supply module

Extension cable (A1SC05NB)

[Building block type]

Input module (A1SX )

Output module (A1SY )

Special function module

Power supply module (A1S6 P)

Extension base

(A5 B)

:Without a power supply module

(A6 B)

:With a power supply module

Input module (AX )

Power supply module (A6 P)

2 - 3

Output module (AY )

Special function module

Fuse

Page 25

SYSTEM CONFIGURATION2.

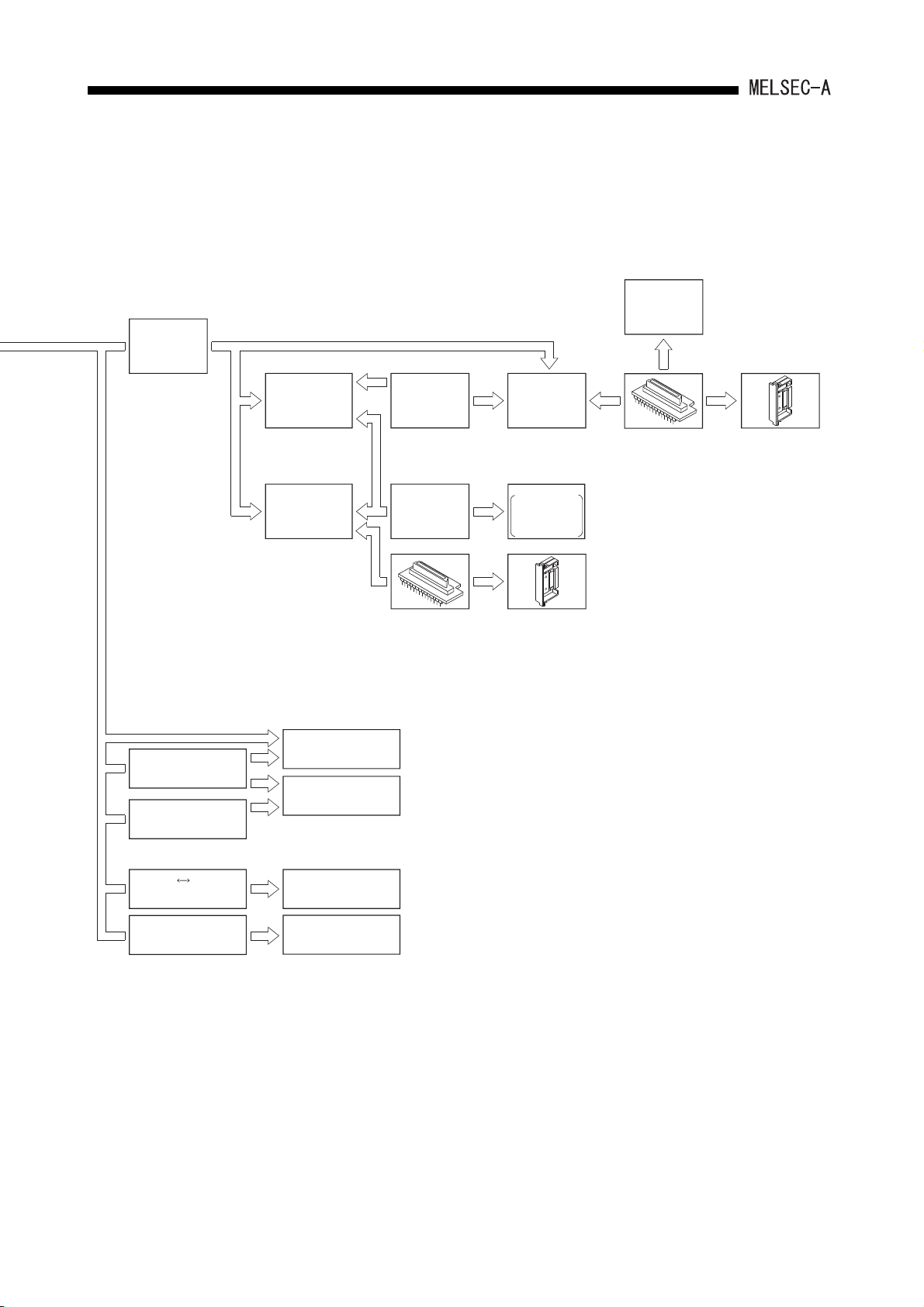

(To A1SJHCPU(S8))

AC30R4

AC300R4

cable

AC30R4-PUS

cable

AC20R4-A8PU

cable

A6PHP

Plasma hand-held

graphic programmer

A6GPP

intelligent GPP

A7PUS

programming module

A8PUE

programming module

AC03WU

cable

AC30R2

cable

EP-ROM write adapter

(A6WA-28P)

A6WU

P-ROM writer

module

Printer

A7NPR-S1,

K6PR-K,

general-purpose

printer

ROM cassette

(A1SNMCA-8KP)

ROM writer

EP-ROM write

adapter

(A6WA-28P)

*

ROM cassette

(A1SNMCA-8KP)

RS-232C RS-422

conerter

AC30R4-PUS

cable

*1, *2

IBM PC/AT or

100% compatible

A6DU-B

data access module

*1:

Refer to SW0IX-GPPAE Software

Package Operating Manual or the

MELSEC-MEDOC Operating Manual for

connectable cables and devices.

*2:

IBM is a registered trademark of the

International Buisiness Machines Corporation.

2 - 4

Page 26

2. SYSTEM CONFIGURATION

2.2 Precautions when Configuring the System

The hardware and software packages which can be used for the CPU module are

described.

2.2.1 Hardware

(1) I/O module

All the building-block-type I/O modules for A N and A A can be used by installing

them to the extension base module of A5 B/A6 B.

2 - 5

Page 27

SYSTEM CONFIGURATION2.

(2) Special function module

(a) Special function modules for A N and A A can be used by installing them in

the extension base of A5 B/A6 B.

(b) Installation count of the following modules are limited of the special function

modules.

AD51H-S3

AJ71UC24

AJ71E71N-B5

AJ71C23-S3

AJ61BT11 (Only when the intelligent mode is used.)

GOT-A900 Series (Only when the bus connection is

*1

used.)

GOT1000 Series (Only when the bus connection is

*1

used.)

A1SJ71UC24-R2(PRF/R4)

A1SJ71E71N-B2

A1SJ71E71N-B5T

A1SD51S A1SD21-S1

A1SJ61BT11 (Only when the intelligent mode is

used.)

AI61(S1)

A1SI61

AJ71AP21(S3)

AJ71AT21B

A1SJ71AP21(S3)

A1SJ71AT21B

AJ71LP21(G/GE)

AJ71LR21

AJ71C22-S1

AJ71E71N-B2

AJ71E71N-T

AD22-S1

AJ71AR21

A1SJ71AR21

AJ71BR11

Up to 2 modules in total can be installed.

Only one module can be installed.

Only one module can be installed.

A1SJ71LP21(GE)

A1SJ71LR21

AJ71PT32-S3 (Only when the extension mode is

used.)

AJ71T32-S3 (Only when the extension mode is

used.)

A1SJ71PT32-S3 (Only when the extension mode is

used.)

A1SJ71T32-S3 (Only when the extension mode is

used.)

*1 Refer to the following manual for the GOT model names.

GOT-A900 Series User's Manual (GT Work2 Version2/GT Designer2 Version2 Compatible

Connection System Manual)

GOT1000 Series Connection Manual

A1SJ71BR11

2 - 6

Only one module can be installed.

Page 28

SYSTEM CONFIGURATION2.

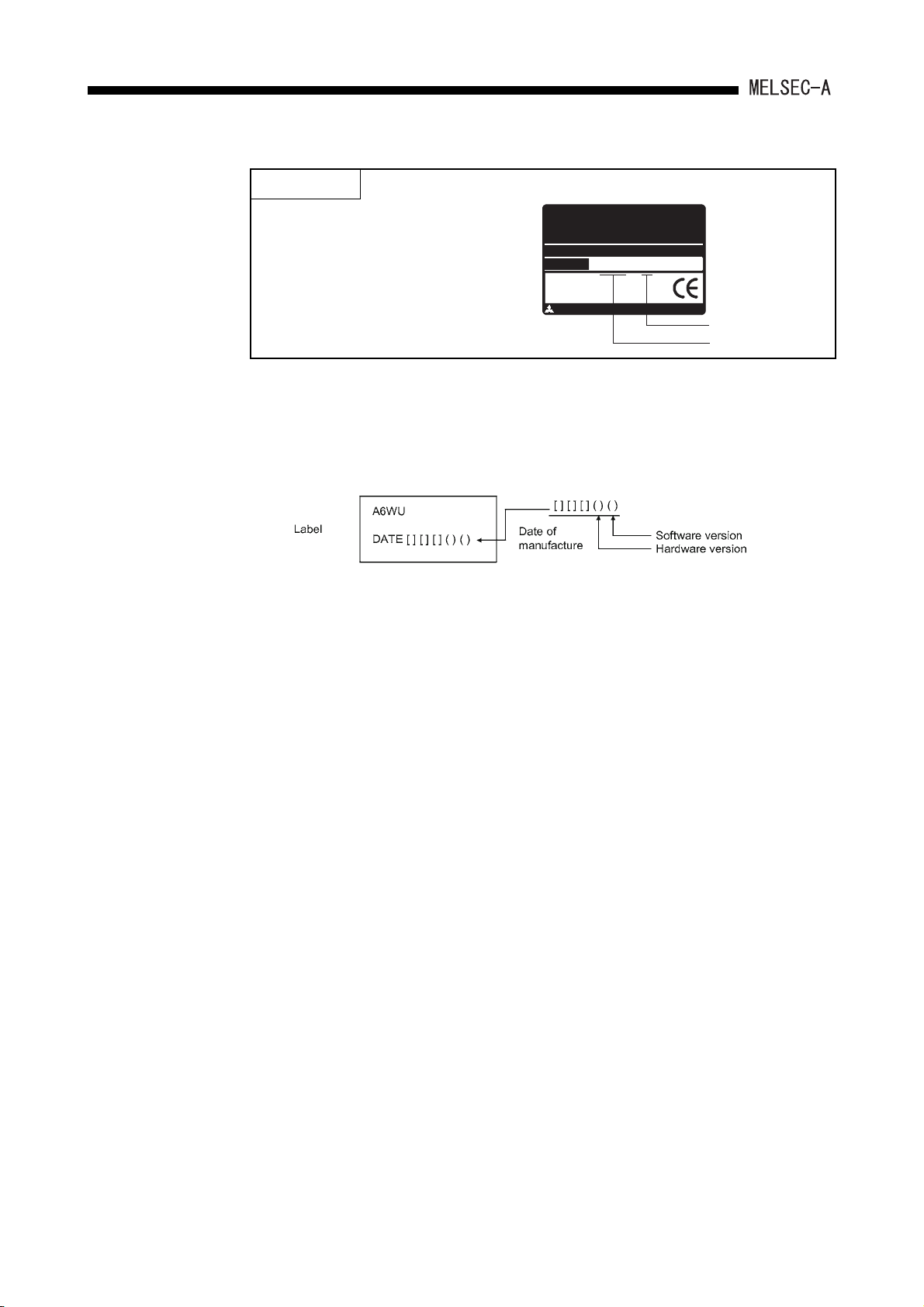

POINT

When the dedicated instruction for

the CC-Link is used, use the master

module marked "9707 B" or later in

MITSUB ISHI

CPU UNIT

MODEL

A2USHCPU-S1

MAX 30kSTEP

DATE

9707 B

the DATE column of the rated plate.

MITSUBISHI ELECTRIC

BD992D008H38

Function version

Date of manufacture

(3) Peripheral device

(a) Precautions when using an A6WU P-ROM writer

1) When using an A1SHCPU

Use an A6WU P-ROM writer module whose software version is E or later.

(b) The A6WU P-ROM writer module cannot be installed with add-on system, which

is installed directly in the AnSHCPU.

Only hand-held system, which is installed using cables, is possible.

(c) Among the programming modules (A7PUS and A8PUE), only the A7PUS can be

installed with add-on system.

Other models (A8PUE) can be installed with hand-held system, which is

connected with cables.

2 - 7

Page 29

SYSTEM CONFIGURATION2.

(4) EP-ROM memory cassette ROM partition

Partitioning the EP-ROM memory cassette with an A6GPP (SW4GP-GPPA)/A6WU

requires a memory write adapter (optional).

The following shows the valid combinations of memory cassette and memory write

adapter:

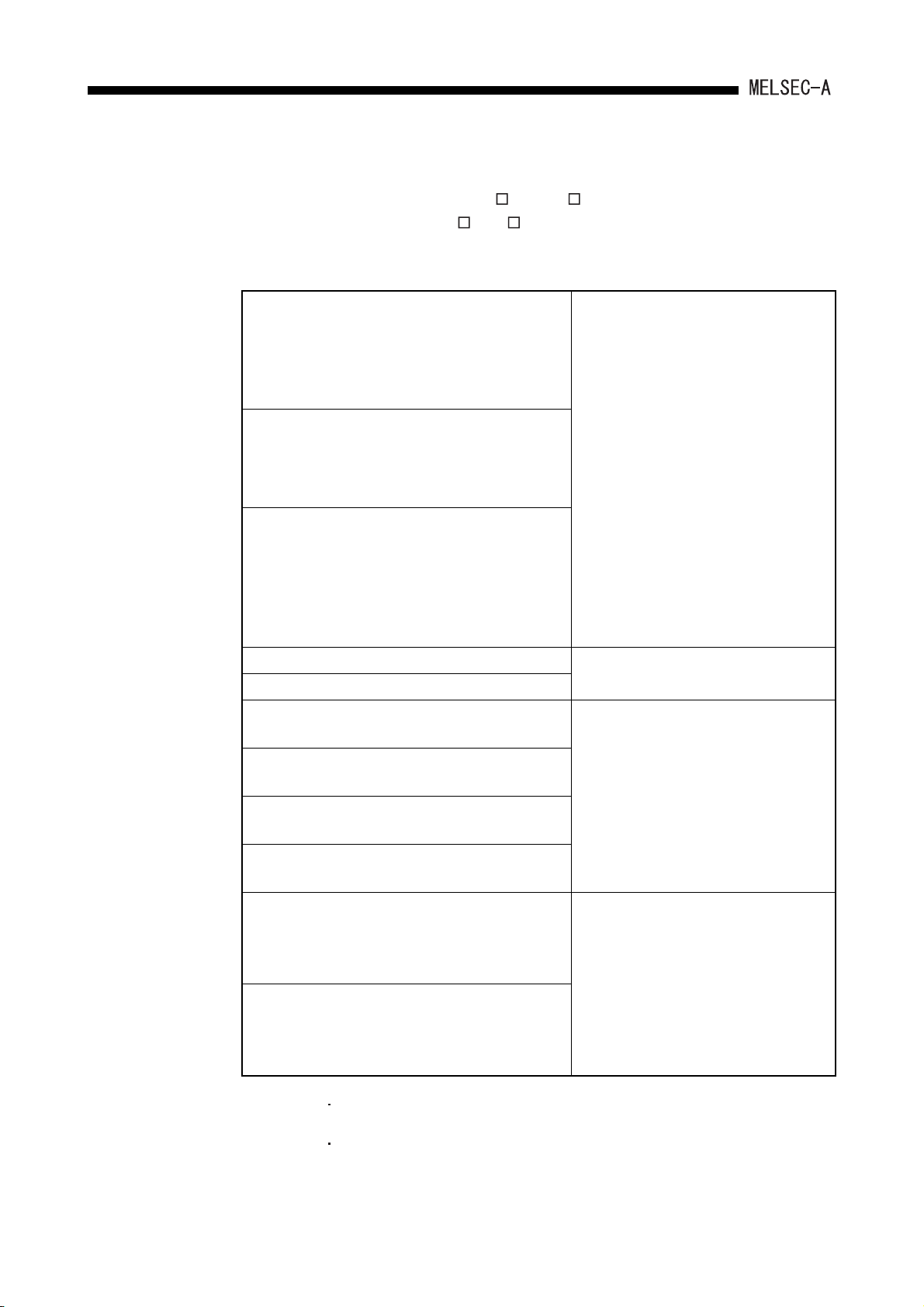

CPU Model

A1SHCPU A1SNMCA-8KP 32k bytes

A1SJHCPU(S8) A1SNMCA-8KP 32k bytes

(5) Program write during operation with E

(a) When an operation is executed using an E

Memory Cassette

Model Capacity

2

PROM

Memory Write Adapter Model

A6WA-28P

2

PROM, write during RUN is not

possible. If write during RUN is executed, the following messages are displayed

on the peripheral devices:

For SW3GP-GPPA: "PLC COMMUNICATIONS ERROR : ERROR

CODE = 19"

For SW0RX-GPPA: "PLC COMMUNICATIONS ERROR :ERROR

CODE = 19"

For A7PUS: "PLC NOT RESPOND"

(b) The writing of the program cannot be executed from the computer link module or

from a peripheral device connected to other stations on the MELSECNET.

Write programs from peripheral devices connected to the AnSHCPU's RS-422.

2 - 8

Page 30

2. SYSTEM CONFIGURATION

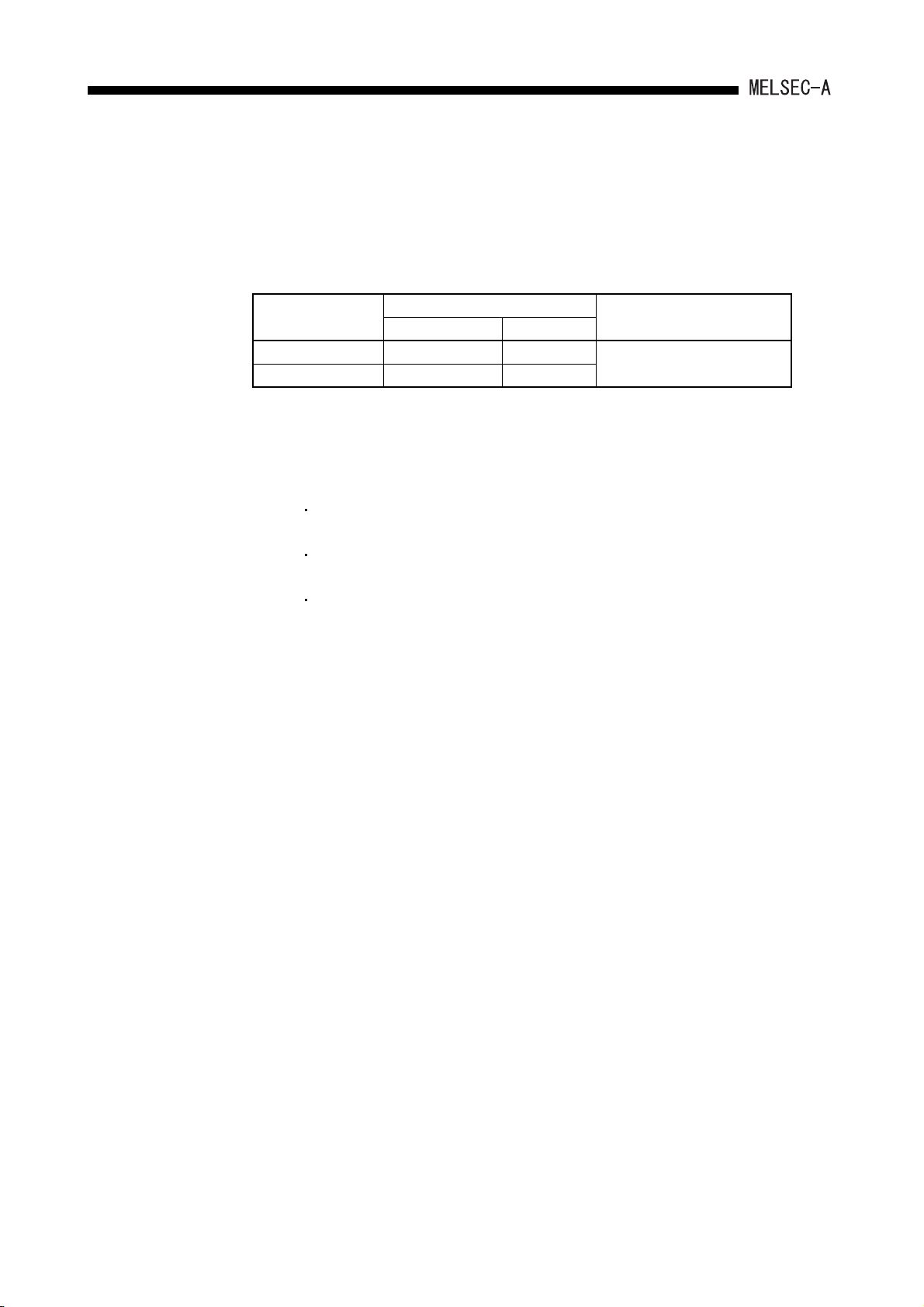

2.2.2 Software package

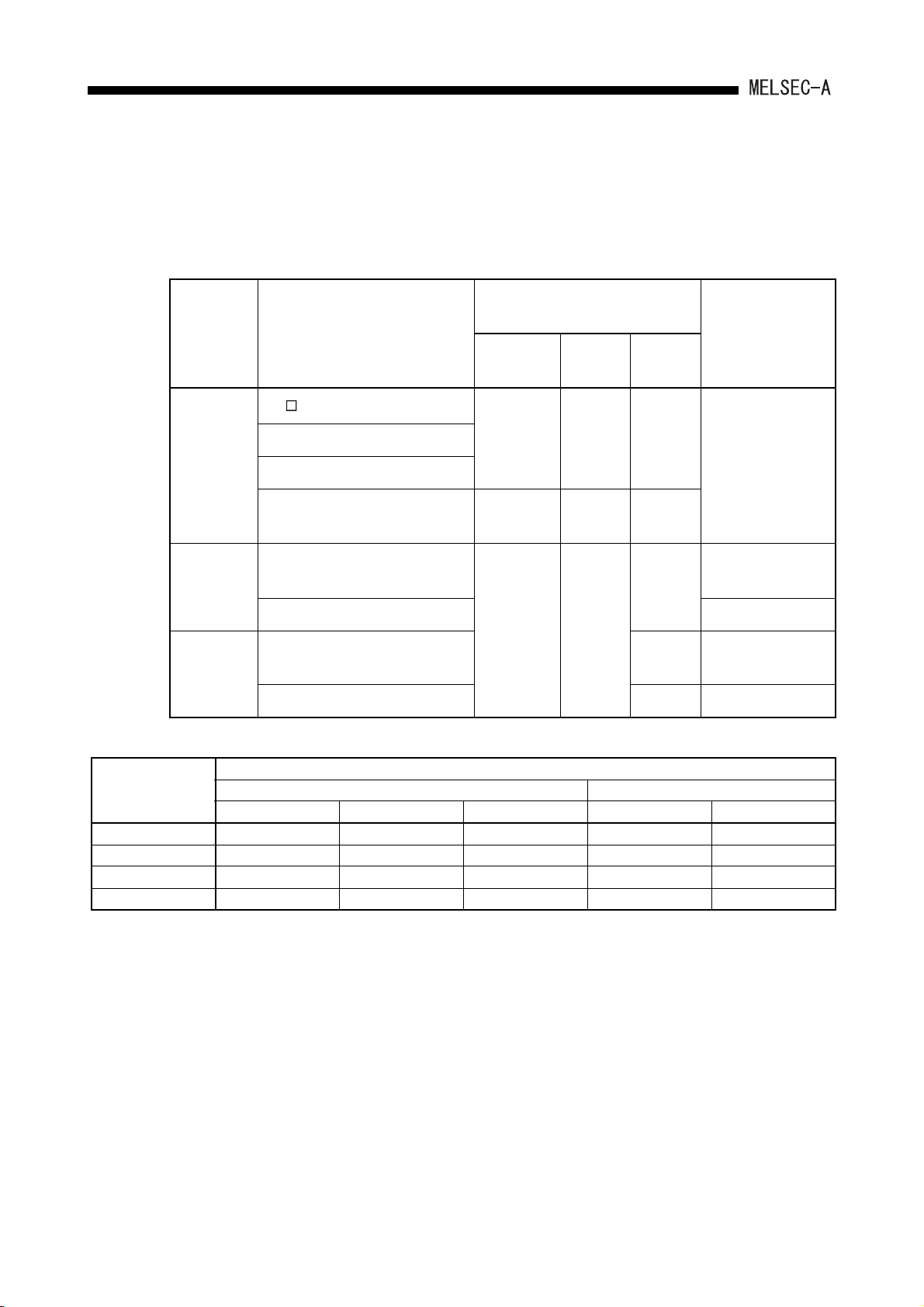

(1) GPP function software packages and model name setting at the start-up

(a) For AnSHCPU start-up, use the PLC model "A3".

(b) Perform the PLC type setting as shown below when using conventional

peripheral devices.

Peripheral

Device

Software Package for System

Start-u p

Programmable controller CPU

Model for Set-up

A1SJH

/A1SH

A2SH A2SH-S1

Remark

IBM PC/AT

SW IVD-GPPA

MELSEC MEDOC

*

A3

*

A3 A3

MELSEC MEDOC plus

A1SJH/

A1SH

A2SH A2SH-S1

A3

Writing on the ROM

is not allowed.

A6PHP

GX Developer

SW3GP-GPPA

SW4GP-GPPA

A3* A3

A6GPP SW3-GPPA

SW3GP-GPPA

A3

Writing on the ROM

is not allowed.

SW4GP-GPPA

*Select the model names according to the software package versions as shown below:

Model Name

Type

Select "A0J2H" Select "A1S" Select "A1SH" Select "A3" Select "A1SH"

SW4GP-GPPA Q or earlier R or later All versions

SW3RXV-GPPA 30D or earlier 40E or later 30D or earlier 40E or later

SW3NX-GPPA 60G or earlier 70H or later 60G or earlier 70H or later

SW3IVD-GPPA 60G or earlier 70H or later 60G or earlier 70H or later

For ROM Writing For Programming

2 - 9

Page 31

SYSTEM CONFIGURATION2.

POINT

(1) Old software packages other than SW3-GPPA, SW3GP-GPPA, and SW4GP-

GPPA cannot be used as the software package for system start-up for

A6GPP/A6PHP.

(2) Take caution when using a software version that selects "A0J2H" or "A1S" for

ROM writing, since the file register area of 8k points is reduced to 4k points.

To measure this, use a software package for which A1SJH/A1SH can be

selected.

(2) Utility package

(a) The following shows the applicable utility packages:

SW0GHP-UTLPC-FN1 SW0GHP-UTLPC-PID SW0GHP-UTLP-FD1

SW0GHP-UTLPC-FN0 SW0C-UTLP-FN0 SW1GP-AD57P

SW0-AD57P

[1] Select "A3CPU" when a SW0GHP-UTLPC-FN1 or a SW0GHP-UTLP-

FD1 is started up.

[2] If both a SW1GP-AD57P and another utility package are used in

combination, specify "AD57P-COM" as the file name.

(b) The following shows the inapplicable utility package model:

SW0-SAPA(MELSAP)

2 - 10

Page 32

2. SYSTEM CONFIGURATION

2.3 System Equipment

The following shows the system equipment (modules and peripheral devices) that can be

used in an AnS system.

(1) AnS series modules

Product Name Model Name Description

Number of I/O points: 256, memory capacity: 64k

bytes,

Number of I/O slots: 5

Number of I/O points: 256, memory capacity: 64k

bytes,

Number of I/O slots: 8

Number of I/O points: 256, memory capacity: 64k

bytes,

Number of I/O points: 512, memory capacity: 256k

bytes

bytes

CPU module

Power supply

module

A1SJHCPU

A1SJHCPU

(S8)

A1SHCPU

A2SHCPU

A2SHCPU-S1Number of I/O points: 1024, memory capacity: 192k

A1S61PN 5VDC, 5A

A1S62PN 5VDC, 3A/24VDC, 0.6A

A1S63P 5VDC, 5A 24VDC input

100/200VAC

input

Number of occupied points

(points)

[I/O Assignment

Module Type]

–0.30–

–0.30–

–0.30–

–0.40–

–0.40–

–––

Current

Consumption

5VDC(A) 24VDC(A)

Remark

Built-in RAM

memory

Installed in the

power supply slot

of the main base

and extension

base.

2 - 11

Page 33

SYSTEM CONFIGURATION2.

Product Name Model Name Description

A1SX10 16-point 100 to 120 VAC input module 16 [16 input points] 0.05 –

A1SX10EU 16-point 100 to 120VAC input module 16 [16 input points] 0.05 –

A1SX20 16-point 200 to 240VAC input module 16 [16 input points] 0.05 –

A1SX20EU 16-point 200 to 240VAC input module 16 [16 input points] 0.05 –

A1SX30 16-point 12/24VDC, 12/24VAC input module 16 [16 input points] 0.05 –

A1SX40 16-point 12/24VDC input module 16 [16 input points] 0.05 –

A1SX40-S1 16-point 24VDC input module 16 [16 input points] 0.05 –

A1SX40-S2 16-point 24VDC input module 16 [16 input points] 0.05 –

A1SX41 32-point 12/24VDC input module 32 [32 input points] 0.08 –

A1SX41-S1 32-point 24VDC input module 32 [32 input points] 0.12 –

Input module

A1SX41-S2 32-point 24VDC input module 32 [32 input points] 0.08 –

A1SX42 64-point 12/24VDC input module 64 [64 input points] 0.09 –

A1SX42-S1 64-point 24VDC input module 64 [64 input points] 0.16 –

Number of occupied points

(points)

[I/O Assignment

Module Type]

Current

Consumption

5VDC(A) 24VDC(A)

Remark

A1SX42-S2 64-point 24VDC input module 64 [64 input points] 0.09 –

A1SX71 32-point 5/12/24VDC input module 32 [32 input points] 0.075 –

A1SX80 16-point 12/24VDC sink/source input module 16 [16 input points] 0.05 –

A1SX80-S1 16-point 24VDC sink/source input module 16 [16 input points] 0.05 –

A1SX80-S2 16-point 24VDC sink/source input module 16 [16 input points] 0.05 –

A1SX81 32-point 12/24VDC sink/source input module 16 [16 input points] 0.08 –

A1SX81-S2 32-point 24VDC sink/source input module 32 [32 input points] 0.08 –

A1SX82-S1 64-point 24VDC sink/source input module 32 [32 input points] 0.16 –

*1:0.08A is shown on the rating plate of the module.

2 - 12

Page 34

SYSTEM CONFIGURATION2.

Product Name Model Name Description

A1SY10 16-point relay contact output module (2A) 16 [16 output points] 0.12 0.09

A1SY10EU 16-point relay contact output module (2A) 16 [16 output points] 0.12 0.10

A1SY14EU 12-point relay contact output module (2A) 16 [16 output points] 0.12 0.10

A1SY18A

A1SY18AEU

A1SY22 16-point triac output module (0.6A) 16 [16 output points] 0.27

A1SY28A

A1SY40

A1SY40P

A1SY41

8-point relay contact output module (2A) for

independent contacts

8-point relay contact output module (2A) for

independent contacts

8-point triac output module (1A)

All points independent

16-point 12/24VDC transistor output module

(0.1A) sink type

16-point 12/24VDC transistor output module (0.1A)

sink type

32-point 12/24VDC transistor output module

(0.1A) sink type

Number of occupied points

(points)

[I/O Assignment

Module Type]

16 [16 output points] 0.24 0.075

16 [16 output points] 0.24 0.075

16 [16 output points] 0.13 –

16 [16 output points] 0.27 0.008

16 [16 output points]

32 [32 output points] 0.50 0.008

Current

Consumption

5VDC(A) 24VDC(A)

(200VAC)

0.002

*2

0.079

0.011

Remark

Output module

A1SY41P

A1SY42

A1SY50

A1SY60

A1SY60E

A1SY68A

A1SY71

A1SY80

A1SY81

A1SY82

32-point 12/24VDC transistor output module (0.1A)

sink type

64-point 12/24VDC transistor output module

(0.1A) sink type

16-point 12/24VDC transistor output module

(0.5A) sink type

16-point 24VDC transistor output module

(2A) sink type

16-point 12/24VDC transistor output module

(2A) source type

8-point 5/12/24/48VDC

transistor output module (2A) sink/source type

All points independent

32-point 5/12VDC transistor output module

(0.016A) sink type

16-point 12/24VDC transistor output module

(0.8A) source type

32-point 12/24VDC transistor output module

(0.1A) source type

64-point 12/24VDC transistor output module

(0.1A) source type

*3

32 [32 output points]

64 [64 output points] 0.93 0.008

16 [16 output points] 0.12 0.06

16 [16 output points] 0.12 0.015

16 [16 output points] 0.20 0.01

16 [16 output points] 0.11 –

32 [32 output points] 0.40 0.15

16 [16 output points] 0.12 0.02

32 [32 output points] 0.50 0.008

64 [64 output points] 0.93 0.008

0.141

0.012

*2:0.08A is shown on the rating plate of the module.

*3:0.15A is shown on the rating plate of the module.

2 - 13

Page 35

SYSTEM CONFIGURATION2.

Product Name Model Name Description

32-point 12/24VDC input module

I/O hybrid

module

Dynamic input

module

A1SH42

A1SH42P

A1SH42-S1

A1SH42P-S1

A1SX48Y18

A1SX48Y58

A1S42X

32-point 12/24VDC transistor output module

(0.1A) sink type

32-point 12/24VDC input module

32-point 12/24VDC transistor output module

(0.1A) sink type

32-point 24VDC input module

32-point 12/24VDC transistor output module

(0.1A) sink type

32-point 24VDC input module

32-point 12/24VDC transistor output module

(0.1A) sink type

8-point 24VDC input module

8-point relay contact output module (2A)

8-point 24VDC input module

8-point 12/24VDC transistor output module (0.5A)

16/32/48/64 points

12/24VDC dynamic input module

Number of occupied points

(points)

[I/O Assignment

Module Type]

32 [32 output points] 0.50 0.008

32 [32 output points] 0.13 0.012

32 [32 output points] 0.50 0.008

32 [32 output points] 0.13 0.012

16 [16 output points]

16 [16 output points] 0.06 0.06

Specified number of points

[Input

Specified number of points

Current

Consumption

5VDC(A) 24VDC(A)

*4

0.085

0.08 –

]

0.045

Remark

Dynamic output

module

*4:0.09A is shown on the rating plate of the module.

A1S42Y

16/32/48/64 points

12/24VDC dynamic output module

Specified number of points

[Output

Specified number of points

0.18 0.055

]

2 - 14

Page 36

SYSTEM CONFIGURATION2.

Number of occupied points

Product Name Model Name Description

Blank cover A1SG60 Dust-proof cover for unused slot 16 [Empty] – –

Specified number of points

[Input

Specified number of points

16 [16 output points]

16 [16 output points]

32

32

32

Dummy module A1SG62

Pulse catch

module

Analog timer

module

Interrupt

module

A1SP60

A1ST60

A1SI61

A1SD61

A1SD62

16-point, 32-point, 48-point, 64-point selectable

module

Short ON-time pulse input module

(pulse with a minimum of 0.5ms) 16 input points

A module whose timer setting value can be

changed for different volumes (0.1 to 1.0s1 to

10s10 to 60s60 to 600s)

Analog timer 8 points

Interrupt module for specifying the interrupt

program

(16-point interrupt input)

32-bit signed binary

50kPPS, 1 channel

24-bit signed binary, 2 channel

100kPPS, DC input,

transistor output (sink type)

(points)

[I/O Assignment

Module Type]

[32 special

points]

[32 special

points]

[32 special

points]

Current

Consumption

5VDC(A) 24VDC(A)

––

]

*5

0.055

*5

0.055

*5

0.057

0.35 –

0.1 –

Remark

–

–

–

High-speed

counter module

A/D converter

module

D/A converter

module

Analog I/O

module

A1SD62D

A1SD62D-S1

A1SD62E

A1S64AD

A1S68AD

A1S62DA

A1S68DAV

A1S68DAI

A1S63ADA

A1S66ADA

24-bit signed binary, 2 channel

200kPPS, difference input,

transistor output (sink type)

24-bit signed binary, 2 channel

200kPPS, difference input,

transistor output (sink type)

24-bit signed binary, 2 channel

100kPPS, DC input,

transistor output (source type)

4 to 20mA/0 to 10V

4 analog channels

4 to 20mA/0 to 10V

8 analog channels

4 to 20mA/0 to 10V

2 analog output channels

-10 to 10V input

8 analog output channels

4 to 20mA input

8 analog output channels

Analog input, 2 channels, simple loop control is

allowed

1 analog output channels

Analog input, 4 channels, simple loop control is

allowed

2 analog output channels

32

32

32

32

32

32

32

32

32

64

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[64 special

points]

0.25 –

0.27 –

0.1 –

0.4 –

0.4 –

0.8 –

0.65 –

0.85 –

0.8 –

0.21 0.16

*5:0.06A is shown on the rating plate of the module.

2 - 15

Page 37

SYSTEM CONFIGURATION2.

Product Name Model Name Description

For connecting to Pt100 (3-wire)

Temperature input, 2 channels

For connecting to Pt100 (4-wire)

Temperature input, 2 channels

Transistor output, thermocouple input

2 channels/modules

PID control: ON/OFF pulse

Transistor output, thermocouple input

2 channels/modules

PID control: ON/OFF pulse, wire breakage

detection function

Transistor output, platinum temperature-mesuring

resistor input

2 channels/modules

PID control: ON/OFF pulse

Transistor output, platinum temperature-mesuring

resistor input

2 channels/modules

PID control: ON/OFF pulse, wire breakage

detection function

Transistor output, thermocouple input

4 channels/modules

PID control: ON/OFF pulse or 2 positioning control

Temperature

regulating

module

A1S62RD3

A1S62RD4

A1S68TD Thermocouple input, 8 channels 32

A1S62TCTTS2

A1S62TCTT

BW-S2

A1S62TCRTS2

A1S62TCRT

BW-S2

A1S64TCTTS1

Number of occupied points

(points)

[I/O Assignment

Module Type]

32

32

32

32

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

Current

Consumption

5VDC(A) 24VDC(A)

0.49 –

0.39 –

0.32 –

0.19 –

0.28 –

0.19 –

0.28 –

0.33 –

Remark

A1S64TCTT

BW-S1

A1S64TCRTS1

A1S64TCRT

BW-S1

A1S64TCTR

T

A1S64TCTR

TBW

Transistor output, thermocouple input

4 channels/modules

PID control: ON/OFF pulse or 2 positioning control

Heater wire breakage detection function

Transistor output, thermocouple input

4 channels/modules

PID control: ON/OFF pulse or 2 positioning control

Transistor output, thermocouple input

4 channels/modules

PID control: ON/OFF pulse or 2 positioning control

Heater wire breakage detection function

Transistor output, thermocouple/platinum

temperature-mesuring resistor input.

4 channels/modules

PID control: ON/OFF pulse or 2 positioning

control

Transistor output, thermocouple/platinum

temperature-mesuring resistor input.

4 channels/modules

PID control: ON/OFF pulse or 2 positioning

control

Heater break detection function

32

32

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

0.42 –

0.33 –

0.42 –

0.33 –

0.39 –

2 - 16

Page 38

SYSTEM CONFIGURATION2.

Product Name Model Name Description

Computer link

module

Ethernet

interface

module

Intelligent

communication

module

A1SJ71UC24

-R2

A1SJ71UC24

-PRF

A1SJ71UC24

-R4

A1SJ71E71N

3-T

A1SJ71E71N

-T

A1SJ71E71N

-B2

A1SJ71E71N

-B5

A1SD51S

Computer link function RS-232C, 1 channel 32

Computer link function, printer function

RS-232C, 1 channel

Computer link function, multidrop link function

RS-422/RS-485, 1 channel

10 Base-T 32

10 Base-T 32

10 Base 2 (for Cheapernet) 32

10 Base 5 (for Ethernet) 32

BASIC (interpreter/compiler)

RS-232C, 2 channels

RS-422/RS-485, 1 channel

Number of occupied points

(points)

[I/O Assignment

Module Type]

[32 special

points]

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

Current

Consumption

5VDC(A) 24VDC(A)

0.1 –

0.1 –

0.1 –

0.69 –

0.56 –

0.66 –

0.57 –

0.4 –

Remark

Accessible within

the AnACPU

device range

Positioning

module

ID

interface

module

A1SD70

A1SD75P1S3

A1SD75P2S3

A1SD75P3S3

A1SD75M1

A1SD75M2

A1SD75M3

A1SD35ID1

A1SD35ID2

1 axis positioning control, speed control, analog

voltage output for speed-positioning control 0 to

10V)

For positioning control, pulse output, 1 axis 32

For positioning control, pulse output, 2 axes (2-axis

simultaneous, linear interpolation, circular

interpolation)

For positioning control, pulse output, 3 axes

(Independent, 3-axis simultaneous, linear

interpolation, circular interpolation)

For positioning control, digital output, for MR-H-B/

MR-J-B/MR-J2-B, 1-axis SSCNET

For positioning control, digital output, for MR-H-B/

MR-J-B/MR-J2-B, 2-axis SSCNET (independent, 2axis simultaneous, linear interpolation, circular

interpolation)

For positioning control, digital output, for MR-H-B/

MR-J-B/MR-J2-B, 3-axis SSCNET (independent, 3axis simultaneous, 2-axis linear interpolation, 2-axis

circular interpolation)

ID interface module

One reader/writer modules can be connected.

ID interface module

Two reader/writer modules can be connected.

48

First half

Second

32

32

32

32

32

32

32

16 empty points

half

32 special points

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

0.3 –

0.7 –

0.7 –

*

0.7

0.7 –

0.7 –

0.7 –

0.25 0.17

0.25 0.33

–

* When different

driver is

connected: 0.78A

2 - 17

Page 39

SYSTEM CONFIGURATION2.

Product Name Model Name Description

For the master and local stations of

MELSECNET(II)

data link

module

MELSECNET/B

data link

module

B/NET

interface

module

A1SJ71AP21

A1SJ71AP21

-S3

A1SJ71AR21

A1SJ71AT21BFor the master and local stations of MELSECNET/

A1SJ72T25B

A1SJ71B62S3

A1SJ71LP21

MELSECNET(II) data link system (for the optical

fiber cable)

For the master and local stations of

MELSECNET(II) data link

(for the GI-type optical fiber cable)

For the master and local stations of

MELSECNET(II) data link system (for the coaxial

cable)

B data link system

For the remote I/O station of

MELSECNET/B data link system

Master module for B/NET 32

For the control, master, and normal stations of the

MELSECNET/10 data link module system

(For the coaxial cable dual loop)

Number of occupied points

(points)

[I/O Assignment

Module Type]

32

32

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

–0.3–

[32 special

points]

[32 special

points]

Current

Consumption

5VDC(A) 24VDC(A)

0.33 –

0.33 –

0.8 –

0.66 –

0.08 –

0.65 –

Remark

Access is allowed

within the device

range of the

AnACPU.

MELSECNET/

10 data link

module

CC-Link system

master module

MELSECNET/

MINI-S3 master

module

MELSECNETI/O LINK

master module

S-LINK

interface

module

A1SJ71LP21

GE

A1SJ71BR11

A1SJ71LR21

A1SJ61BT11

A1SJ71PT32

-S3

A1SJ51T64

A1SJ71SL92NMaster module for S-LINK

For the control, master, and normal stations of the

MELSECNET/10 data link module system

(For the GI-type optical fiber cable dual loop)

For the control, master, and normal stations of the

MELSECNET/10 data link module system

(For the single bus coaxial cable)

For the control, master, and normal stations of the

MELSECNET/10 data link module system

(For the coaxial cable dual loop)

For the master and local stations of the CC-Link

data link system

(For the twisted pair shield cable only)

For MELSECNET/MINI-S3 master stations (max.

64 stations). Performs remote I/O and remote

terminal control of a total of 512 I/O points.

MELSECNET-I/O LINK master station.Controls I/O

LINK remote I/O module of a maximum of 16

stations and a total of 128 I/O points.

I/O total 128 points

32

32

32

32

I/O mode

[32 special points]

Expanded mode

48 [48 special points]

64

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[64 special

points]

[32 special

points]

0.65 –

0.80 –

1.14 –

0.40 –

0.35 –

0.115 0.09

0.20 –

AS-I interface

module

Positioning

detection

module

*6:0.06A is shown on the rating plate of the module.

A1SJ71AS92

A1S62LS Absolute positioning detection module 32

Master module for AS-I

I/O total 496 points

2 - 18

32

[32 special

points]

[32 special

points]

0.15 –

0.55 –

Page 40

SYSTEM CONFIGURATION2.

Product Name Model Name Description

PC easier

monitoring

module

Memory card

interface

module

Simulation

module

PROFIBUS

interface

module

Device Net

interface

module

A1SS91 PC easier monitoring module 16

A1SD59J-S2 Memory card interface module 32

An I/O simulation unit used connected to the base

module.Debugging can be executed without

A6SIMX64Y64

A1SJ71PB92

D

A1SJ71PB96

F

A1SJ71DN91 Device net master module 32

connecting the I/O module to the base module.Use

an expansion cable of the AnS series between the

main base of the AnS series and the A6SIM-

X64Y64.

PROFIBUS-DPmaster module 32

PROFIBUS-FMS interface module 32

Number of occupied points

(points)

[I/O Assignment

Module Type]

[16 special

points]

[32 special

points]

64

64

[64 input points]

[64 output points]

[32 special

points]

[32 special

points]

[32 special

points]

Current

Consumption

5VDC(A) 24VDC(A)

0.08 –

0.05 –

TYP. 0.3

(When

all points

ON)

0.56 –

0.56 –

0.24 –

–

Remark

The current consumption

describes in

connecting

A1SD59J-MIF.

MODBUS

interface

module

A1SJ71UC24

-R2-S2

A1SJ71UC24

-R4-S2

RS-232Ctype MODBUS interface module 32

RS-422/485type MODBUS interface module 32

[32 special

points]

[32 special

points]

0.1 –

0.1 –

2 - 19

Page 41

SYSTEM CONFIGURATION2.

Product Name Model Name Description

A985GOT

A975GOT

A970GOT

A960GOT

A956GOT

A956WGOT

Graphic

operation

terminal

A953GOT

Large-size graphic operation terminal

256 colors, TFT color, 800 600 dots, high intensity

Large-size graphic operation terminal

256 colors, TFT color, 640 480 dots, high intensity

Large-size graphic operation terminal

16 colors, TFT color, 640 480 dots, high intensity/

16 colors, TFT color, 640 480 dots, wide viewing