Page 1

AMITSUBISHI

PROGRAMMABLE CONTROLLERS

Page 2

I

Page 3

CONTENTS~

Foreword

Chapter

Chapter

1:

What

How

What Do I Choose

Where

Is

It Difficult

What Can

2:

Central processing unit (CPU Module)

CPU Base Units

Extension Base Units

Power supply modules ............................................................................................ 12

Input modules ......................................................................................................... 13

Output modules

.......................................................................................................

Overview

is

the AIS

Does It Work

&

How

I

AIS

Model No

Model No . AlS32B

Model

Model

Model

Model

Model

Model

Model No . AlS65B

Model

Model

Model

Model

Model

Model No . AlSX20 ..................................................................................... 13

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

of

the

AIS

PLC .......................................................... 2

?

...................................................................................................

?

................................................................................................

?

................................................................................................

Do

I

Install

It

?

..................................................................................

To

Program ?

Use It For

Module Descriptions

......................................................................................

?

..........................................................................................

.........................................................

....................................................................

.

AlSCPU,

AISCPU-S1

..............................................................

......................................................................................................

.....................................................................................

No . AlS33B

No . AlS35B

No

. AlS38B ..................................................................................... 9

.....................................................................................

.....................................................................................

..............................................................................................

No

. AlS52B

No . AlS55B

No

. AlS58B

.....................................................................................

.....................................................................................

.....................................................................................

.....................................................................................

No

. AlS68B

No

.

AlSGIP

No

.

AlS62P

No

. AlS63P

No

.

AlSX10 ..................................................................................... 13

No

. AlSX30

No

. AlSX40 ..................................................................................... 14

No

. AlSX40-S1

No . AlSX40-SZ

No

.

AlSX4l

No

.

AlSX41-SZ

No

. AlSX42

No

. AISX42-SZ

No

.

AlSX71

No

. AlSX80

No

. AlSX80-SI ................................................................................ 15

No

.

AlSX80-SZ

No

. AlSX81

No

.

AlSX81-SZ

.....................................................................................

.....................................................................................

.....................................................................................

.....................................................................................

.....................................................................................

................................................................................

................................................................................

.....................................................................................

................................................................................

.....................................................................................

................................................................................

.....................................................................................

.....................................................................................

................................................................................

.....................................................................................

................................................................................

......................................................................................................

No

.

AlSY10

No

.

AlSY18A ................................................................................... 18

No

. AlSY22

No . AlSY28A

No

. AlSY40

No . AlSY41

No

.

AlSY42

No

. AISYSO

No . AISY6O

No

. A1 SY6OE ................................................................................... 19

No

. AlSY68A ................................................................................... 19

.....................................................................................

.....................................................................................

...................................................................................

.....................................................................................

.....................................................................................

.....................................................................................

.....................................................................................

.....................................................................................

i

2

2

3

3

4

4

5

5

5

8

8

8

9

10

10

10

11

11

11

12

12

12

14

14

14

14

14

15

15

15

15

15

16

16

17

17

18

18

18

18

19

19

19

i

Page 4

‘CONTENTS

..

Model No . AlSY71

No

.

Model

Model

Special function modules ........................................................................................ 21

Model

Model No

Model

Model

Model

Model

Model No

Model

Model

Model

Model No . AlSD71-S2

Model

Model

Model

Model

Model

Model

Model

Model No

Model No

Memory modules

Model

Model No . A1 SMCA-8KE ............................................................................ 27

Model

Extension cables ..................................................................................................... 28

Model

Model

Model

Model No

Model

Terminal block units and cables

Model No

Model

Model

Model

Model No

Model

Model

Model

Model

Model

Model

Model No

Model

Model

Model

Model No

Model No

Model

AlSY80

No

. AlSY81

No

. AlS64AD

. AlS62DA

No

.

AlSJ71C24-R2 .......................................................................... 22

No . AlSJ71C24-R4 .......................................................................... 22

No

.

AlSJ71C24-PRF

No

. AlSD61

. AlS161 ...................................................................................... 23

No

.

AlSJ71T21B ............................................................................. 23

No

. AlSJ71PT32-S3

No

. AlSD70 ..................................................................................... 24

No

. AlSP6O ..................................................................................... 24

No.

AlSH42

No . AlS42X

No

.

AlS42Y

No

.

AlSG6O

No

. AlSG62

No

. AlS62RD3 ................................................................................ 25

. AlS62RD4

.

AlST60

....................................................................................................

No

. AI SMCA-2KE

No

.

A1 SMCA-8KP

No

.

AlSCOlB .................................................................................. 28

No

. AlSC03B

No

. AlSC12B

.

AlSC30B

No . AlSCOSNB

.

A6TBXY36

No . A6TBXY54

No

.

A6TBX70

No . A6TBX36-E

.

A6TBY36-E

No

. A6TBX54-E

No

. A6TBY54-E

No

. A6TBX70-E

No

.

ACOSTB

No

. AClOTB

No

. AC20TB

. AC30TB

No

.

ACSOTB .................................................................................... 31

No

.

ACOSTB-E

No . AClOTB-E ................................................................................. 31

.

AC20TB-E ................................................................................. 32

.

AC30TB-E

No

. ACSOTB-E

.....................................................................................

.....................................................................................

.....................................................................................

..................................................................................

..................................................................................

.......................................................................

.....................................................................................

........................................................................

...............................................................................

.....................................................................................

.....................................................................................

.....................................................................................

....................................................................................

....................................................................................

................................................................................

.....................................................................................

............................................................................

............................................................................

..................................................................................

..................................................................................

..................................................................................

................................................................................

..............................................................................

................................................................................

................................................................................

...................................................................................

...............................................................................

...............................................................................

...............................................................................

...............................................................................

...............................................................................

....................................................................................

....................................................................................

....................................................................................

....................................................................................

.................................................................................

.................................................................................

.................................................................................

20

20

20

21

22

22

23

23

24

24

24

25

25

25

25

26

27

27

27

28

28

28

28

29

29

29

30

30

30

30

30

30

30

31

31

31

31

32

32

Chapter

System selection

3:

System Selection and Configuration .......................................

.....................................................................................................

Step 1

:

Step 2: Output module selection

Input module selection ................................................................... 34

.................................................................

ii

33

33

35

Page 5

Step 3: Special function module selection .................................................. 36

Step 4: Power supply module selection

Step

5:

System configuration

S

System Examples

AI

System Example

System Example 2

System Example 3

System Example

Base unit selection

CONTENTS~

......................................................

..............................................................................................

...........................................................................................

1

4

.........................................................................

.....................................................................................

.....................................................................................

.....................................................................................

.....................................................................................

37

38

39

40

40

41

42

43

Chapter

4:

Installation

Installation environment

Base unit mounting instructions

Mounting the base units on DIN rail

Installation and removal of AIS modules

Installation and removal of dustproof cover

..................................................................................

..........................................................................................

...............................................................................

.........................................................................

................................................................

............................................................. 51

Chapter 5: Wiring .........................................................................................

Wiring instructions for the power supply module

Wiring

Grounding ............................................................................................................... 56

Chapter

Description

Programming language

Numeric value and character representation

Instructions

of

I/O

equipment

6:

Programming

of

internal devices ................................................................................ 58

Inputs X

Outputs Y

Auxiliary relays MI L.

Link relays

Annunciators F

T

Timer

Counter C

Interrupt counters C

Data register D

Link register

File registers R

Accumulator A

Index registers

Nesting N

Pointer

Interrupt pointer

Special relays M

Special registers D

P

..........................................................................................

.............................................................................

......................................................................................................

...................................................................................................

B

...............................................................................................

...................................................................................................... 60

...................................................................................................

W

...................................................................................................

....................................................................................................

S

...............................................................................

...........................................................................................

....................................................................................

...........................................................................................

...........................................................................................

...........................................................................................

............................................................................................

2,

V .................................................................................... 64

I

........................................................................................

.........................................................................................

.....................................................................................

...........................................................................................

Binary (BIN)

Binary coded decimal (BCD)

Hexadecimal (HEX)

ASCI

I

............................................................................................... 74

......................................................................

.................................................................................... 75

......................................................................................................... 76

.............................................................................................................

Explanation of instruction lists

List of sequence instructions

List of basic instructions

List of application instructions ..................................................................... 90

Sequence instruction description

Contact instructionsoperation start, series connection,

parallel connection (LD, LDI, AND, ANI, OR, ORI)

Connection instructionsLadder block series connection and

parallel connection (ANB, ORB)

....................................................................

.......................................................................

.............................................................................

.....................................................

...........................................................

................................................................

.........................

.....................................................

44

44

45

47

49

52

52

55

57

58

58

59

59

60

61

61

62

62

63

63

65

66

66

67

70

73

74

74

77

78

81

83

97

97

100

...

111

Page 6

CONTENTS

Chapter

Building Management

Milling Machine ....................................................................................................... 135

Welding Robot

Winding Machine

Energy Management of Compressor Station

Operation result push. read. pop (MPS. MRD. MPP)

Output instructionsBit device. timer. counter output

Bit device set. reset (SET. RST) .................................................... 109

Edge-triggered differential output (PLS. PLF)

Bit device output reverse (CHK)

Shift instructions. Bit device shift (SFT. SFTP)

Master control instructions. Master control set. reset (MC.

MCR)

.............................................................................................

Termination instructions

Basic instruction descriptions

Application instruction descriptions ............................................................. 133

7:

AIS Application Examples

Other instructions

Comparison operation instructions

Arithmetic operation instructions

BCD/BIN conversion instructions

Data transfer instructions

...........................................................................

......................................................................

.....................................................

................................................................. 118

................................................. 122

....................................................

...................................................

...............................................................

.......................................................

.............................................................................................

MELSECNETIB data link control system application

Positioning control system application

........................................................

...................................

........................................................................................................

Robot control system application ................................................................ 136

....................................................................................................

Analog control system application

..............................................................

...........................................................

Sequence control system application

.......................................................... 138

......................

(OUT)

.............

.................................

..............................

103

106

111

113

114

116

120

121

125

128

130

134

134

134

135

136

137

137

138

Index .............................................................................................................. 139

Page 7

i

I

Foreword

The

programmable logic controller

covered in this manual include unit selection, system configuration, installation,

programming, and application examples.

It is hoped that after reading this, you will have a good understanding of the

PLC system, and be able to set up and use an AIS PLC system without the need

training

details

appropriate you should refer to the relevant user's or programming manual.

AIS

handy manual

or

the study

of

the

AIS

is

designed as a learning aid for use with the MELSEC

(PLC)

and is aimed at the first time

of

individual manuals. However, please note that not all the

PLC

are contained in this handy manual and therefore where

AIS

user. Topics

AIS

AIS

of

1

Page 8

I

OVERVIEW

I

Chapter 1 :

Overview of the AIS

PLC

1

I

IWhat

lHow

is

the

AIS

?

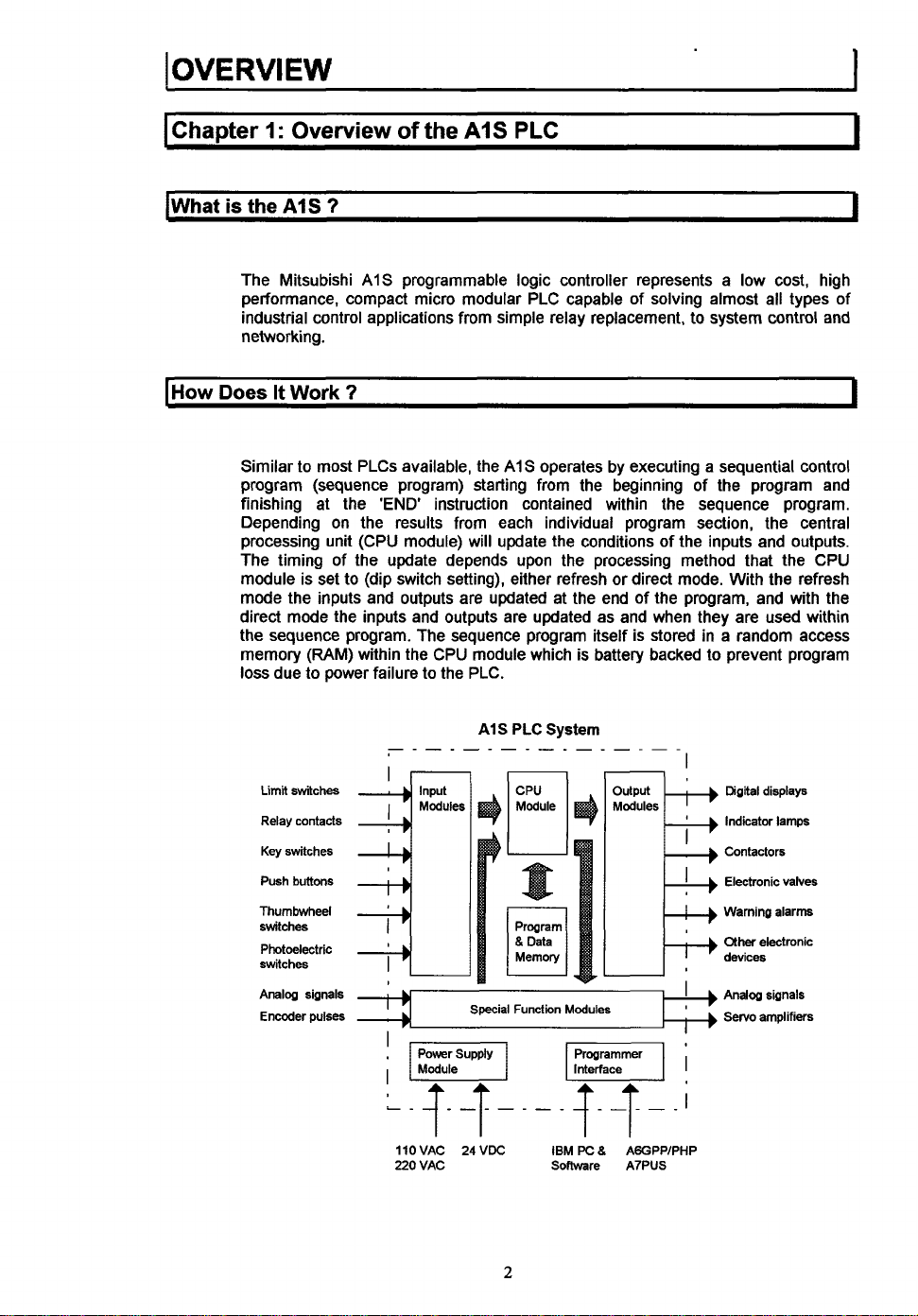

The Mitsubishi

performance, compact micro modular PLC capable of solving almost all types of

industrial control applications from simple relay replacement,

networking.

Does

It

Work

Similar

to

program (sequence program) starting from the beginning of the program and

finishing at the

Depending on the results from each individual program section, the central

processing unit (CPU module) will update the conditions of the inputs and outputs.

The timing of the update depends upon the processing method that the CPU

module is set to (dip switch setting), either refresh or direct mode. With the refresh

mode the inputs and outputs are updated at the end of the program, and with the

direct mode the inputs and outputs are updated as and when they are used within

the sequence program. The sequence program itself is stored in

memory (RAM) within the CPU module which is battery backed to prevent program

loss due to power failure to the PLC.

AIS

programmable logic controller represents a low cost, high

?

most PLCs available, the

'END

instruction contained within the sequence program.

A1S

to system control and

AIS

operates by executing a sequential control

a

random access

PLC

System

I

I

I

Limit

switches

Relay contacts

Key

switches

Push buttons

Thumbwheel

switches

Photoelectric

switches

Analog signals

Encoder

pulses

Input

~

I

,~l

I

L_

s

llOVAC 24VDC IBM

220 VAC Soflware

2

Modules

Programmer

F]i

!X

8

AGGPPIPHP

A7PUS

Digital displays

Indicator lamps

Contactors

Electronic valves

Warning alarm

other

electronic

devices

Servo

amplifiers

Page 9

OVE

RVI

E

w

1

lWhat

(Where

Do

I

Choose

Understandably, when you look at the complete list of different types

output, and special function module available for the AIS, it can seem a difficult

task to choose what you require for your application. But don't worry, the reason for

all the different types of module is

application. All you have

input and output to be used in your application, and select the right type and

number of modules from the list. The only other things to consider then are that you

need a

modules you have selected. Also choose the programming device you want to use

for the creation of your sequence program.

&

How

The AIS

however it can

etc.. is made. Because of its micro modular design it takes up very little space and

can be fixed

back of the base units. Alternatively, the base units can be fixed in to place using

the screw holes provided on each of its corners.

7

so

to do is simply calculate the number

CPU

module, power supply module, and base units to hold all of the

Do

I

Install It

PLC

is primarily designed for installation inside electrical cabinets,

be

on

to

7

installed in other places if adequate protection to dust, water, oil

DIN

rail using the fixing attachments already installed on the

the AIS can be used for all types of

of

different types of

of

input,

I

I

3

Page 10

..

I

OVERVIEW

11s

It

Difficult

To

Program

7

..

.

....

..

. . . . .

....

.

...

.

-

1

I

Like all things that need programming, the

user to be a little difficult to program. However, the sequence programming

language utilized, is designed to make it as easy as possible for you the user

create your own sequence programs without the need of specialized help. In fact,

after a very short time you can become very proficient at writing programs which

can perform the simple or complicated operations required

needs.

Two main types of program construction method are used, both

MELSEC

(List mode) and relay ladder logic (Ladder mode). Each of them can perform the

same tasks, the choice of which one to use is purely dependent on the user's

preference. However the most commonly used method is relay ladder logic (Ladder

mode) because of its graphical representation and simplicity.

A

dedicated sequence programming language, these are; instruction list

AIS

PLC may seem for the first time

to

meet your application

of them using the

to

[What

Can

I

Use

It

For

7

The

A1S

control application. Example applications of where the

link control, positioning control, robot control, analog control, sequence control, data

acquisition, and system monitoring. There are many other types

which the

probably solve it in an easy

is a true general purpose PLC which can be used for almost any type of

A1S

has been used,

so

whatever your control application, the

to

implement,

cost

4

A1S

effective way.

has been used are; data

of

application in

AIS

1

can

Page 11

I

Chanter

2:

AIS

Module Descrintions

I

h

ICentral processing unit (CPU Module)

I

Model

No.

AISCPU. AISCPUSI

The CPU module is the main part of the

]ERROR

ORM

u-=

UlPjUBlsn

system, and can control up

built-in battery backed

function, programming port, operation mode

and key switch control for operation mode. Mounted

in the CPU slot of the CPU base unit, one CPU

module

r

is

required per

to

512

110

points.

RAM

memory, real time clock

AIS

system.

AIS

It

LEDs,

b

I

I

PLC

has a

Internal relays

Latch relays (L)

Step relays

(S)

(M)

Internal microcomputer

IO00

points

(MO

to

M999)

1048

points (LlO00 to L2047)

0

points

(default

value)

5

program

can

be

set

to

7K

steps

max.

Page 12

1024 points (BO

256

points

to B3FF)

Specifidins

(W)

(R)

(M)

Number of

points

Specifmtions

2)

(1)

power failure

Counters (C)

Data reaisters (D)

Link registers

Annunciators (F)

File registers

Accumulator (A)

Index registers (V.

Pointers (P)

Interrupt pointers

Special relays

Special data registers (D)

Comments

Self dwnostic functions

Operation mode at time

STOP RUN output mode

Allowable

momentary

Current consumption

(5

VDC)

Weight

of

error

100

msec

$mer dng $me 0 1 to 3276 7

10

msec

timer

setting

time

0

01

100

msec

retentwe

timer

setting

to

to

(RO

131

range 1 to

D1023)

WlO23)

to

4095)

to

M9255)

to

D9255)

batches

setting

parameters)

256

pants

Normal

counter

Interrupt counter setting range 1

1024 points

1024 points

256

Max

2

2 points (V,

256

I

32 points

256

256 points

1

Max

Watchdog error, memory error detection, CPU error

I/O

1

STOP/CONTINUE

Output data

execution

20

04A

0

37 k9/0 81 Ib

(DO

(WO

pants (FO to F255)

4096

polnts

points (AO, AI)

Z)

points (PO to P255)

(IO

to

pants

(M9wo

(woo0

1600

points (set in

error detectmn, battery error detectmn, etc

at

time of STOP restoddata output after operation

msec

to

327 67

time 0 1

32767 (CO

to

32767

of

64

points)

sec

sec

to

(set

3276.7

to

(TO

to

1199)

(T200

to

sec

C255)

in

parameters)

detect~on,

T255)

(set in

Manual Reference No. IB(NA)-66320.

6

A1

SCPU

User's

Manual

Page 13

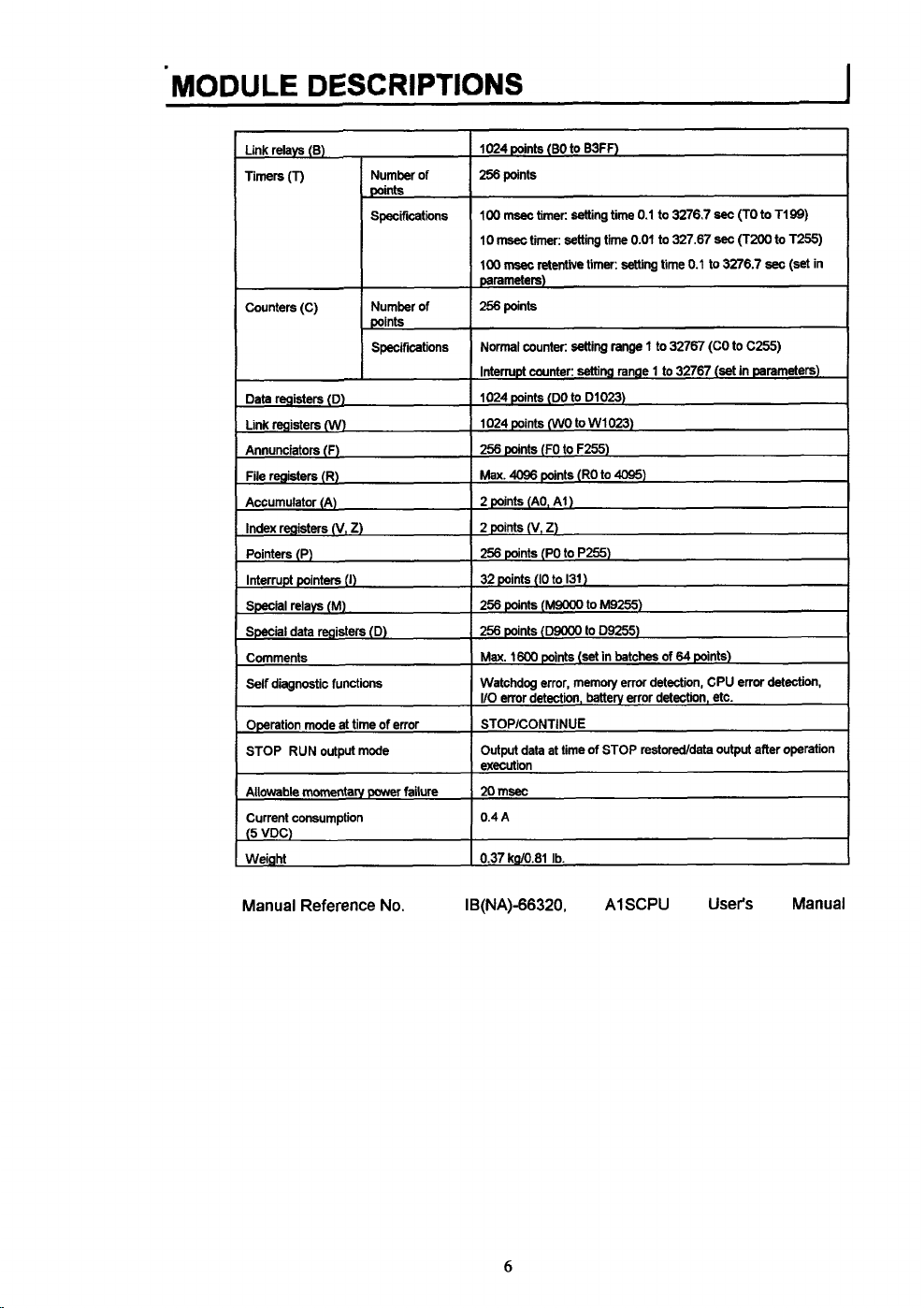

Part identification and setting

of

AISCPU

I

(1)

RUNlSTOP key switch

RUNASTOP: To startlstop running a sequence program

RESET: To reset hardware, and/or reset an error which has occurred during

operation.

LATCH CLEAR: To clear devices in both the latch range and non-latch range which

have been set in parameters.

(2) "RUN LED

ON:

A sequence program operation is being executed with the RUNlSTOP key

switch set in the RUN position.

OFF:

The RUN LED is not lit

the RUNlSTOP key

is

remote PAUSE signal is input.

flashing: The RUN LED flashes if an error causing the sequence operation to stop is

detected by the self-diagnostic functions or the latch clear operation is executed.

if

power

is

not supplied from the power supply module,

in the STOP position, the remote STOP signal is input, or the

(3)

"ERROR LED

ON: The self-diagnostic functions have detected an error.

OFF:

No error has occurred.

Flashing: An annunciator

(4)

RS422 connector

(F)

has been turned ON by the sequence program.

Used for program readhvrite, monitoring, or testing using a peripheral device.

(5)

Cover

Protects the printed circuit board, memory module, connector, battery, etc.

(6)

Module fixing screws

For fixing the module to the CPU base unit.

(7)

Battery

For retaining stored data and programs during power failure.

(8)

Dip switch

Used for switching the

IlO

control method and for setting the memory protect

function.

(9)

Battery connector

For connecting the battery.

(IO)

Memory module installation cover

For installing the optional EPROM and EEPROM memory modules.

7

Page 14

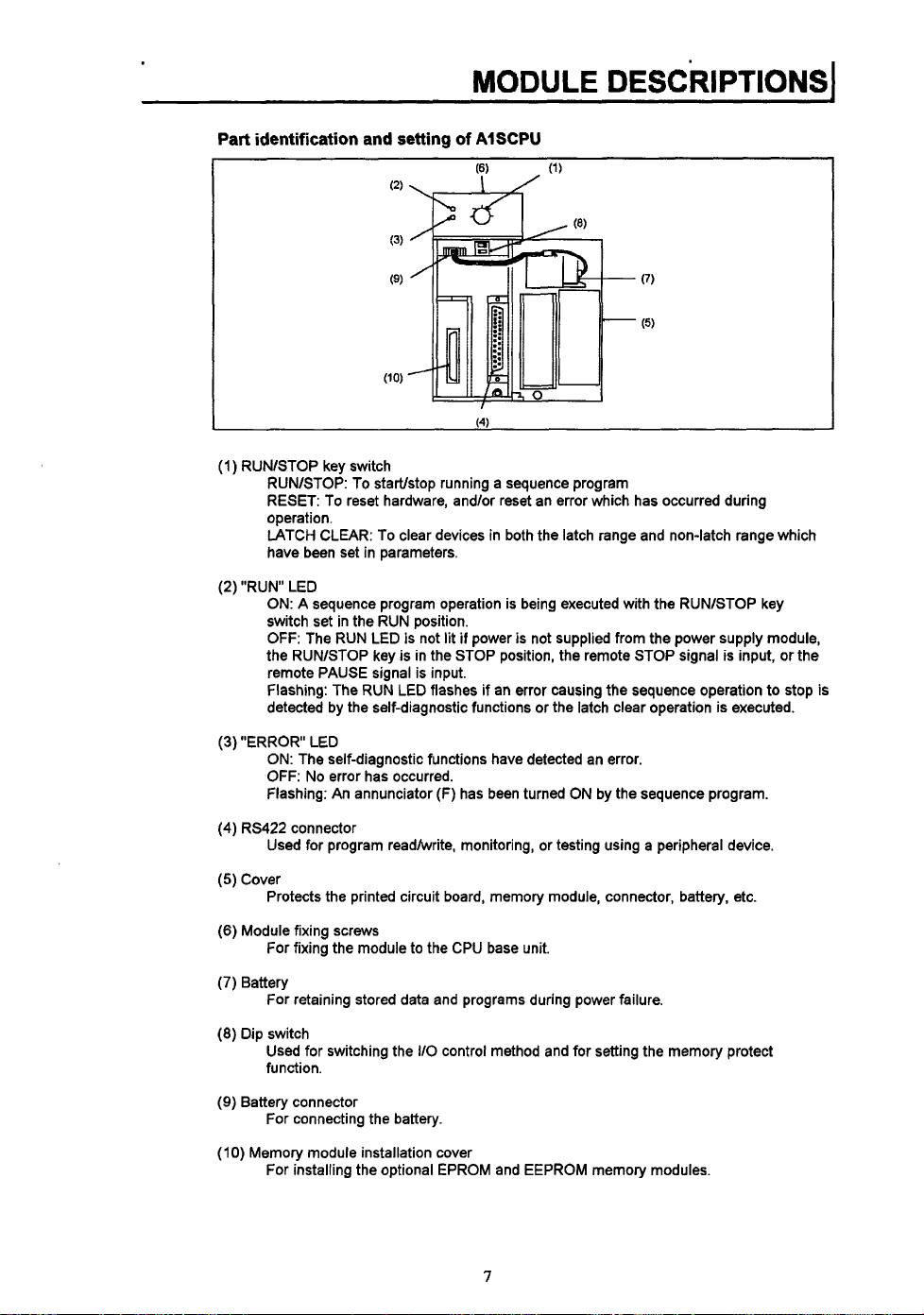

kPU

Base

Units

I

The CPU base units are for mounting the CPU module, 1 power supply module,

and a number of

to the CPU base unit is dependent

the CPU module, each system requires one CPU base unit. Below is a list of the

different CPU base unit models;

I

Model

No.

CPU base unit with spare

External dimensions,

Manual Reference No. IB(NA) 66320, AlSCPU User's Manual

1Model

No.

110

AI 5326

AlS33B

modules. The number

I/O

slots for 2

220

mm x 130 mm x 28 mm (8.66 in x 5.12 in x 1.10

of

I/O

on

the model number

110

modules.

modules that can be mounted

of

the unit selected. Like

in).

on

I

I

CPU base unit with spare 110 slots for

External dimensions, 255 mm

Manual Reference No. IB(NA) 66320, AlSCPU

3

I/O

modules.

x

130 mm x 28 mm (10.04 in x 5.12 in x 1.10 in).

8

User's

Manual

Page 15

I

Model

No.

AlS35B

MODULE DESCRIPTIONS

I

I

CPU base unit with spare

External dimensions, 325

Manual Reference No. IB(NA) 66320, AISCPU User's Manual

I

Model

No.

AlS38B

CPU base unit with spare

External dimensions, 430

Manual Reference No.

110

slots

for

5

I/O

modules.

mm

x

130

mm x 28

110

slots for 8

mm

x

130

mm

IB(NA) 66320, AISCPU User's Manual

I10

modules.

x

28

mm

(12.80 in x 5.12 in x 1.10 in).

mm

(16.93 in x 5.12 in

x

1.10

I

in).

9

Page 16

MODULE

I

Extension Base

The extension base units are for mounting an extra power supply module andlor

extra

110

on the number of

number of

base unit is required. Connection of the extension base unit to the CPU base unit is

made by an extension cable, one extension base unit can be used per system.

The requirement of an extra power supply module is dependent on the total 5 VDC

current consumption of the complete A1S system, if one

extension base with a power supply module slot should be selected. The number of

110

module slots and, if there is a power supply module slot, is dependent upon the

extension base model number. A list of all different AIS extension base units

shown below;

I

Model

No.

DESCRIPTIONS

Units

modules if required. The requirement for the extra 110 modules depends

110

AlS52B

110

slots on the CPU base unit you have selected then

modules you are using on your system, if it exceeds the

is

required then an

one

extension

I

is

I

Extension base unit with spare

External dimensions, 135 mm x 130 mm x 28 mm (5.31 in x 5.12 in x 1.10 in)

Manual Reference No. IB(NA) 66320, AISCPU User's Manual

I

Model

No.

AlS55B

Extension base unit with spare, 110 slots for

External dimensions, 260 mm

Manual Reference

No.

110

slots for 2

x

130 mm

IB(NA) 66320,

x

110

modules.

5

110

modules.

28

mm (10.24 in x 5.12 in x 1.10 in)

AI

SCPU User's Manual

I

10

Page 17

I

Model

No.

A15588

MODULE

DESCRIPTIONS1

I

Extension base unit with spare

External dimensions, 365 mm

Manual Reference No. IB(NA) 66320, AISCPU User's Manual

I

Model

No.

AlS65B

Extension base unit with spare

module slot.

External dimensions, 315 mm x 130 mm x 28 mm (12.40 in x 5.12 in x I

Manual Reference No.

I/O

slots for 8 110

x

130 mm x 28 mm (14.37 in x 5.12 in

110

slots for

IB(NA) 66320, AISCPU

modules.

5

I10

modules and a power supply

User's

Manual

x

1.10

.10 in)

in)

1

I

Model

No.

AlS68B

Extension base unit with spare

module slot.

External dimensions, 420 mm

Manual Reference

No.

110

slots

for 5 110

x

130 mm x 28 mm (16.54 in x 5.12 in x 1.10 in)

IB(NA) 66320, AISCPU

11

modules and a power supply

User's

Manual

I

Page 18

1

I

AIS61P

The power supply modules provide the 5 VDC that is required by the CPU and

modules to function correctly. They are mounted on to the base units in the power

supply module slot, and output the

unit. Input supply voltage to the power supply module is dependent on the model

number selected, below is

I

Model

No.

AISGIP

Power supply module with 110/230 VAC input, and 5 VDC 5 A output.

Manual Reference

I

Model

No.

AlS62P

No.

a

list of all the A1 S power supply modules available:

AlS62P AlS63P

5

VDC they generate to a power rail on the base

IB(NA) 66320, AISCPU User's Manual

I/O

1

I

Power supply module with 11Of230 VAC input, 5 VDC 3 A output, and 24 VDC 0.6

A output

Manual Reference No. IB(NA) 66320, AlSCPU User's Manual

I

Model

Power supply module with 24 VD input, and 5 VDC SA output.

Manual Reference No.

r supply module with 24 VDC input, and

(can

be used for powering relay output modules or input devices etc..)

No.

AlS63P

~~ ~

IB(NA) 66320, AISCPU User's Manual

5

VDC 5 A output.

12

I

Page 19

.. ..

MODULE

DESCRIPTIONS1

t

"'I

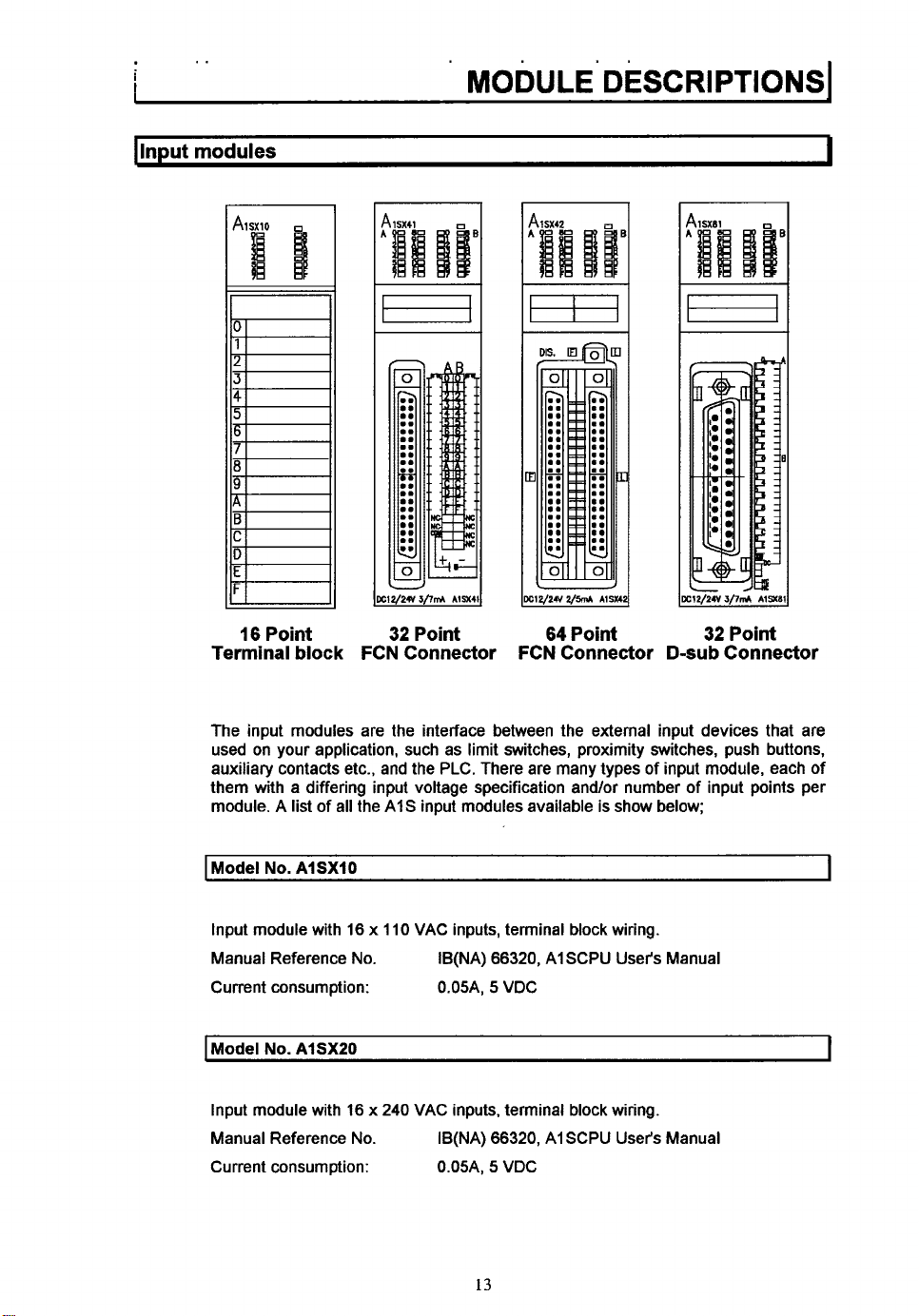

Terminal block

The input modules are the interface between the external input devices that are

used on your application, such as limit switches, proximity switches, push buttons,

auxiliary contacts etc., and the PLC. There are many types of input module, each of

them with a differing input voltage specification and/or number of input points per

module. A

16

I

Point

list

of all the AIS input modules available

32

Point

FCN Connector

64

Point

FCN Connector

is

show below;

D-sub

Connector

Model

No.

AISXIO

Input module with 16 x 110 VAC inputs, terminal block wiring.

Manual Reference No.

Current consumption: 0.05A,

I

Model

No.

AISXZO

Input module with 16 x

Manual Reference No.

Current consumption: 0.05A,

IB(NA)

66320,

AISCPU User's Manual

5

VDC

240

VAC inputs, terminal block wiring.

66320,

IB(NA)

13

AI SCPU User's Manual

5

VDC

I

I

Page 20

*

. .

. . .

..

MODULE

I

Model

Input module with 16 x 24 VAC or 24 VDC inputs, terminal block wiring.

Manual Reference No.

Current consumption: O.O5A,

I

Model

Input module with 16 x 12 or 24 VDC inputs (sink type), terminal block wiring.

Manual Reference No.

Current consumption: 0.05A,

I

Model

Input module with 16 x 24 VDC high speed inputs (sink type), terminal block wiring.

Manual Reference No.

Current consumption: O.O5A,

..

DESCRIPTIONS

No.

AlSXSO

IB(NA) 66320, A1 SCPU User's Manual

No.

AlSX40

IB(NA) 66320, AISCPU User's Manual

No.

AlSX40-W

IB(NA) 66320, AlSCPU User's Manual

5

5

5

VDC

VDC

VDC

..

..

. ...

.

I

I

I

I

Model

No.

AlSX4052

Input module with 16 x 24 VDC inputs (sink type), terminal block wiring.

Manual Reference No.

Current consumption: 0.05A.

I

Model

No.

AlSX41

Input module with 32 x 12 or 24 VDC inputs (sink type), FCN connector wiring.

Manual Reference No.

Current consumption: 0.08A,

Model

No.

AlSX4lS2

Input module with 32 x 24 VDC inputs (sink type), FCN connector wiring.

Manual Reference No.

Current consumption: O.O8A,

IB(NA) 66320, AlSCPU User's Manual

5

VDC

IB(NA) 66320, A1 SCPU User's Manual

5

VDC

IB(NA) 66320, AlSCPU User's Manual

5

VDC

I

I

I

14

Page 21

MODULE DESCRIPTIONS~

I

Model

No.

AlSX42

Input module with 64 x 12 or 24 VDC inputs (sink type), FCN connector wiring.

Manual Reference No.

Current consumption: 0.09A,

1

Model

No.

AI SX42S2

Input module with 64 x 24 VDC inputs (sink type), FCN connector wiring.

Manual Reference No.

Current consumption: O.O9A,

I

Model

No.

AlSX71

IB(NA) 66320, AISCPU User's Manual

5

VDC

IB(NA) 66320, AlSCPU User's Manual

5

VDC

I

I

I

Input module with 32 x 5

wiring.

Manual Reference No.

Current consumption: O.O75A,

I

Model

No.

AlSX8O

Input module with 16 x 12 or 24 VDC inputs (sink or source type), terminal block

wiring.

Manual Reference No.

Current consumption: O.O5A,

1

Model

No.

AlSX80-W

Input module with 16 x 24 VDC high speed inputs (sink or source type), terminal

block wiring.

Manual Reference No.

Current consumption: 0.05A, 5 VDC

I

Model

N3.

AISX80S2

or 12 VDC inputs (sink or source type), FCN connector

IB(NA) 66320, AISCPU User's Manual

5

VDC

IB(NA) 66320, AISCPU User's Manual

5

VDC

User's

IB(NA) 66320, AISCPU

Manual

i

I

I

Input module with 16 x 24 VDC inputs (sink or source type), terminal block wiring.

Manual Reference No.

Current consumption: 0.05A,

IB(NA) 66320, AISCPU User's Manual

5

VDC

15

Page 22

MODULE

I

Model

DESCRIPTIONS

No.

AlSX81

I

Input module with 32 x 12

wiring.

Manual Reference

Current consumption: 0.08A, 5 VDC

I

Model

No.

Input module with 32 x 24 VDC inputs (sink

Manual Reference

Current consumption: 0.05A, 5 VDC

No.

AlSX81S2

No.

or

24 VDC inputs (sink

IB(NA) 66320, AI SCPU User's Manual

IB(NA) 66320, AISCPU User's Manual

or

source type), D-sub connector

~

or

source type), D-sub connector wiring.

I

16

Page 23

MODULE

DESCRIPTIONS1

I

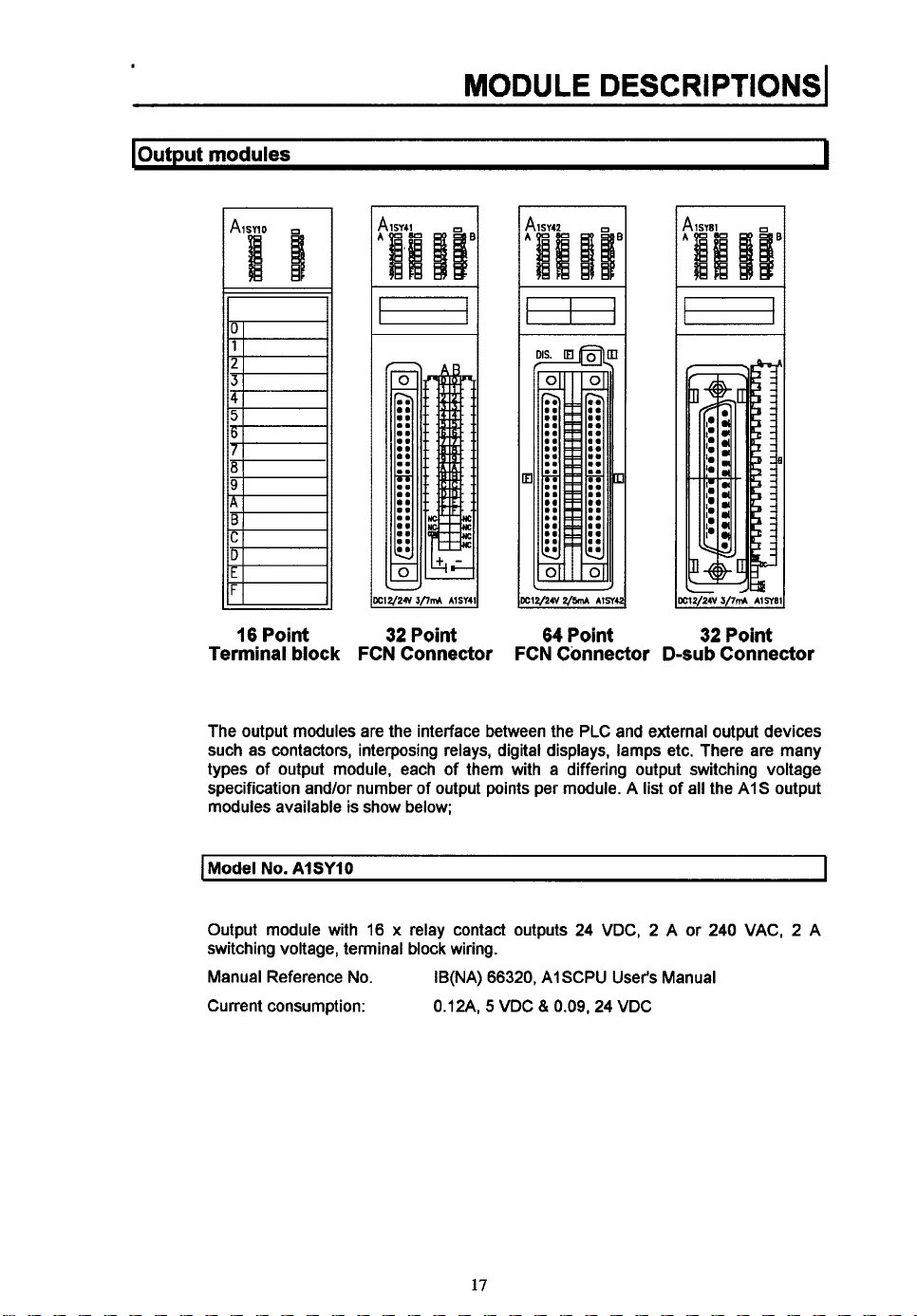

loutnut

modules

16

Point

Terminal

block

32

Point

FCN Connector

3

c12/24v2/m

FCN Connector D-subConnector

64

r1ne

Point

32/21

32

3/7&

Point

AlSY8l

I

The output modules are the interface between the PLC and external output devices

such as contactors, interposing relays, digital displays, lamps etc. There are many

types of output module, each of them with a differing output switching voltage

specification and/or number of output points per module. A list

modules available is show below;

I

Model

No.

AlSYlO

Output module with

switching voltage, terminal block wiring.

Manual Reference No.

Current consumption:

16 x relay contact outputs

IB(NA)

66320,

AISCPU User's Manual

5

WDC

81

0.12A,

0.09,24

24

WDC, 2 A or

WDC

of

all the AIS output

240

WAC, 2 A

I

17

Page 24

I

Model

No.

AlSY18A

Output module with 8 x independent relay contact outputs 24 VDC, 2 A or 240 VAC,

2 A switching voltage, terminal block wiring.

Manual Reference No.

Current consumption:

Model

No.

AlSY22

Output module with 16 x triaciSSR outputs 100-240 VAC, 0.6 A switching voltage,

terminal block wiring.

Manual Reference No.

Current consumption:

I

Model

No.

AlSY28A

Output module with 8 x independent triadSSR outputs 100-240 VAC, 1 A switching

voltage, terminal block wiring.

Manual Reference No.

Current consumption:

IB(NA) 66320, A1 SCPU User's Manual

&

0.24A, 5 VDC

IB(NA) 66320, AlSCPU User's Manual

0.27A, 5 VDC

IB(NA) 66320, AI SCPU User's Manual

0.1 lA, 5 VDC

O.O75A, 24 VDC

&

O.O04A, 200 VAC

I

I

I

[Model

I

No.

AlSY40

Output module

switching voltage, terminal block wiring.

Manual Reference No.

Current consumption:

Model

No.

Output module with 32 x transistor outputs (sink type) 12 or 24 VDC, 0.1 A

switching voltage, FCN connector wiring.

Manual Reference

Current consumption:

with

AlSY41

16 x transistor outputs (sink type) 12

IB(NA) 66320, AlSCPU User's Manual

No.

0.27A, 5

IB(NA) 66320, AlSCPU User's Manual

0.50A, 5 VDC

18

VDC

& 0.016A. 24 VDC

&

O.O16A, 24 VDC

or

24 VDC, 0.1 A

I

I

Page 25

I

Model

No.

AlSY42

I

Output module with

switching voltage, FCN connector wiring.

Manual Reference No.

Current consumption:

I

Model

No.

AlSY50

Output module with 16 x transistor outputs (sink type) 12 or 24 VDC,

switching voltage, terminal block wiring.

Manual Reference No.

Current consumption:

I

Model

No.

AISYGO

Output module with

voltage, terminal block wiring.

Manual Reference No.

Current consumption:

I

Model

No.

AISYGOE

64

x

transistor outputs (sink type) 12 or 24 VDC, 0.1

IB(NA) 66320, AISCPU User's Manual

5

0.93A,

IB(NA) 66320, AISCPU User's Manual

0.12A,

~

16

x

transistor outputs (sink type) 24 VDC, 2 A switching

IB(NA) 66320, AISCPU User's Manual

0.12A,

VDC 8 0.016A, 24 VDC

5

VDC & 0.12A, 24 VDC

5

VDC &

O.O15A,

24 VDC

0.5

A

I

A

I

I

Output module with 16 x transistor outputs (source type) 5 or 12 or 24 VDC, 1 A

switching voltage, terminal block wiring.

Manual Reference No.

Current consumption:

I

Model

No.

AlSY68A

Output module with 8 x independent transistor outputs (sink or source type) 5 or 12

or 24 or 48 VDC, 2 A switching voltage, terminal block wiring.

Manual Reference No.

Current consumption: 0.13A,

IB(NA) 66320, AISCPU User's Manual

5

0.20A,

IB(NA) 66320, AISCPU User's Manual

VDC & 0.01A, 24 VDC

5

WDC

19

I

Page 26

MODULE

I

Model

No.

Output module with 32 x transistor outputs (sink type) 5 or 12 VDC, 16 mA

switching voltage, FCN connector wiring.

Manual Reference No.

Current consumption:

I

Model

No.

DESCRIPTIONS

AISY71

IB(NA) 66320, AI SCPU User's Manual

5

0.40A,

AISYIO

I

VDC & O.I5A, 24 VDC

I

Output module with 16 x transistor outputs (source type) 12 or 24 VDC,

switching voltage, terminal block wiring.

Manual Reference No.

Current consumption:

I

Model

No.

AISYII

Output module with 32 x transistor outputs (source type) 12 or 24 VDC,

switching voltage, D-sub connector wiring.

Manual Reference

Current consumption:

No.

IB(NA) 66320, AISCPU User's Manual

5

0.12A,

IB(NA) 66320, AISCPU User's Manual

0.50A,

VDC & O.O4A, 24 VDC

5

VDC & O.O16A, 24 VDC

-

0.8

0.1

A

-1

A

20

Page 27

!.

I

..

MODULE

DESCRIPTIONSI

ISpecial

function

a

A1 S62DA

Analog

modules

Output

A1 SD61

High Speed

Counter

A1 SJ71 T21

MELSECNET/B

B

I

AlSJTl C24-R2

Computer Link

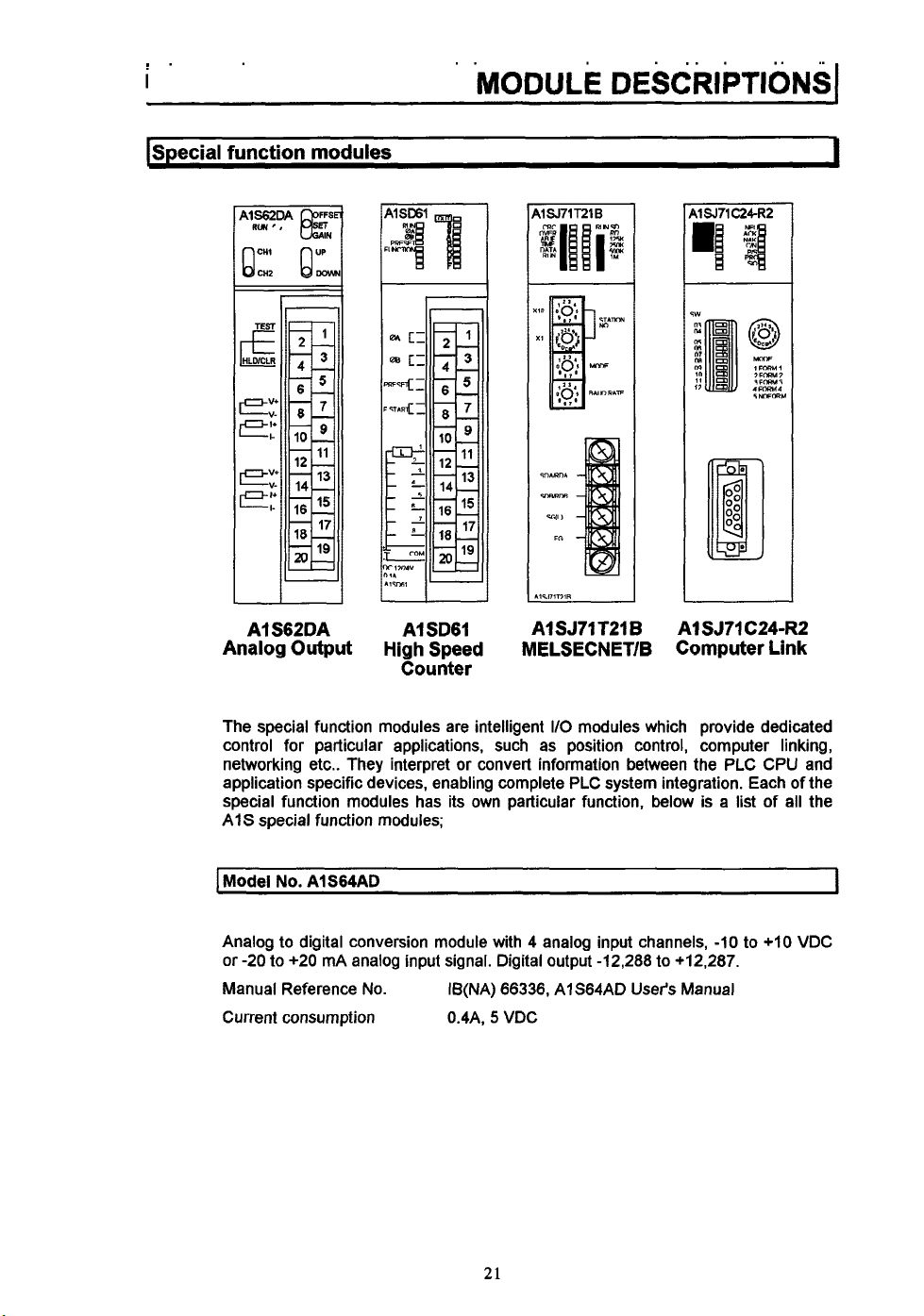

The special function modules are intelligent

control for particular applications, such as position control, computer linking,

networking etc.. They interpret or convert information between the PLC CPU and

application specific devices, enabling complete PLC system integration. Each of the

special function modules has its own particular function, below is a list of all the

AIS special function modules;

I

Model No.

Analog to digital conversion module with 4 analog input channels,

or

-20 to +20 mA analog input signal. Digital output -12,288 to +12,287.

Manual Reference

Current consumption 0.4A,

AlS64AD

No.

IB(NA) 66336, AlS64AD User's Manual

5

21

VDC

I/O

modules which provide dedicated

-10

to +IO VDC

I

Page 28

MODULE

I

Model

No.

Digital to analog conversion module with 2 analog output channels, -1 0 to +10 VDC

0

to +20 mA analog output signal. Digital input -12,000 to +12,000.

or

Manual Reference No.

Current consumption OBA,

I

Model

No.

RS232C computer link module with 1 RS232C communication port. Full or half

duplex transmission, 4 protocol modes, no-protocol mode, bi-directional mode, and

protocol switching function.

Manual Reference No.

Current consumption

I

Model

No.

RS422/485 computer link module with 1 RS42Z485 communication port. Full or

half duplex transmission, 4 protocol modes, no-protocol mode, bi-directional mode,

protocol switching function, and multidrop capability.

Manual Reference No.

Current consumption O.lA,

DESCRIPTIONS

AlS62DA

IB(NA) 66335, AlS62DA User's Manual

5

VDC

AlSJllC24-RZ

IB(NA) 66270, A1 SJ71 C24-RZPRF User's Manual

O.IA,

5

VDC

AlSJ71C24R4

IB(NA) 66364, AlSJ7lC24-R4 User's Manual

5

VDC

I

I

I

I

I

Model

No.

AISJ71C24-PRF

RS232C printer module with 1 RS232C communication port. Full or half duplex

transmission, 31 variable and 400 fixed message storage, with messages up to

characters long.

Manual Reference No.

Current consumption

IB(NA) 66270, A1 SJ71 C24-R2/PRF User's Manual

O.lA,

5 VDC

22

I

80

Page 29

I

Model

No.

AISD61

MODULE

DESCRIPTIONS~

I

High speed counter module with 1 single or bi-phase input channel. Maximum

count speed

outputs, ring counter function, limit switch function, hold function, and sampling

function.

Manual Reference No.

Current consumption 0.35A,

I

Model

High

speed

points. Minimum input pulse length

Manual Reference No.

Current consumption 0.057A,

I

Model

MELSECNET/B data link system interface module. Connects on

network linking up to 32

speed up to

Manual Reference No.

Current consumption 0.66A,

50

KHz, 32 bit signed binary count range, 8 comparison transistor

IB(NA) 66337, AISD61 User's Manual

5

VDC

No.

AIS161

interrupt module with 16 x 12 or 24 VDC high speed interrupt input

0.5

ms, rising edge or falling edge interrupts.

IB(NA) 66396, AIS161 User's Manual

5

VDC

No.

AlSJ71 T21

1

Mbaud, and

B

AIS

PLCs, twisted pair cable connection, transmission

1

K byte link points per station.

IB(NA) 66339, AI SJ71 T21 B User's Manual

5

VDC

to

MELSECNET/B

I

I

I

Model

No.

AlSJ71PT32-W

MELSECNET/MINI-S3 remote

remote I/O points, twisted pair or plastic fiber optic connection, transmission speed

1.5 Mbaud, allows connection of

series inverters.

Manual Reference No.

Current consumption 0.0.35A,

I/O

network master module. Controls up to

F

and

FX

series PLCs, A2C

IB(NA) 66368, A1 SJ71 PT32-S3 User's Manual

5

VDC

23

I/O

modules, and

512

I

Z

Page 30

MODULE

I

Model

Single axis positioning module with one analog output channel. 32 bit signed binary

positioning range, 1 to 400,000 PLSlSec positioning speed, zeroing and jogging

functions.

Manual Reference No. IB(NA) 66367, AlSD70 User's Manual

Current consumption 0.3A,

I

Model

DESCRIPTIONS

No.

AISD7O

No.

AlSD71S2

5

VDC

8

024,

+15 VDC & 0.02A

1

-1 5 VDC

I

Two axis positioning module with

16,252,928. 10 to 200,000 PLSlSec positioning speed, zeroing, M-code, backlash,

compensation, and jogging functions.

Manual Reference No.

Current consumption

Model

No.

AISPGO

Pulse catch module with 16 x 24 VDC pulse input points. Pulse catch or normal

input function, minimum pulse width

Manual Reference No.

Current consumption 0.055A,

I

Model

No.

AlSH42

Combined input and output module with 32 x 12 or 24 VDC input points, and 32 x

transistor outputs (sink type) 12 or 24 VDC switching voltage. Inputs and outputs

FCN connector wiring.

Manual Reference No.

Current consumption

two

pulse output channels. Positioning range 1 to

IB(NA) 66399, AlSD7142 User's Manual

0.8A,

5

VDC &0.05A, 4.75 to 26.4 VDC

0.5

ms.

IB(NA) 66398, AlSP6O User's Manual

5

VDC

IB(NA) 66320, AlSCPU User's Manual

5

VDC & 0.008,24 VDC

0.5A,

I

I

I

Model

No.

AlS42X

Dynamic input module with 16 x 12 or 24 VDC input points. Input points can be

automatically multiplexed for 16 or 32 or 48 or 64 points by switch selection.

Manual Reference No.

Current consumption 0.08A,

IB(NA) 66320, AlSCPU User's Manual

5

VDC

24

I

Page 31

Model

No.

AIS42Y

MODULE

DESCRIPTIONS

I

I

Dynamic output module with 16 x transistor outputs (sink type) 12

switching voltage. Output points can

or

64 points by switch selection.

Manual Reference No.

Current consumption

I

Model

No.

AISG6O

I/O

slot blanking module for filling unused I/O slots on the base units.

Manual Reference No. IB(NA) 66320, AISCPU User's Manual

Current consumption None

I

Model

No.

AlSG62

Dummy I/O point module for reservation of I/O points for future additions to the

PLC system. 16

Manual Reference No.

Current consumption None

Model

No.

or

32

AlS62RD3

or

48

of

be

automatically multiplexed for 16

IB(NA) 66320, AISCPU User's Manual

O.IA,

5

VDC & 0.008A 24 VDC

64

110

points can be reserved by switch setting.

IB(NA) 66320, AISCPU User's Manual

or

24 VDC

or

32 or 48

I

I

I

3 wire temperature sensor input module with two sensor input channels. Compatible

with 3 wire PTIOO temperature sensors, 16 or 32 bit binary sensing value, and wire

breakage detection.

Manual Reference No.

Current consumption 0.54A, 5 VDC

I

Model

No.

AlS62RD4

4 wire temperature sensor input module with two sensor input channels. Compatible

with 4 wire PT100 temperature sensors, 16 or 32 bit binary sensing value, and wire

breakage detection.

Manual Reference No.

Current consumption 0.44A,

IB(NA) 66338, AIS62RD3/4 User's Manual

IB(NA) 66338, AlS62RD3/4 User's Manual

5

VDC

25

I

Page 32

..

..

MODULE

I

Model

.

..

DESCRIPTIONS

No.

AlST6O

...

......

_.

I

Timer module with 8 analog timers. Timer range

accuracy.

IB(NA)

66397,

Manual Reference

Current consumption

No.

0.055A, 5 VDC

AIST6O

0.1

to

000

User's Manual

seconds with a

+/-

2%

26

Page 33

..

MODULE

DESCRIPTIONS1

pmofmodules

I

Model

No.

EEPROM memory module with a capacity

Manual Reference No. IB(NA)

I

Model

No.

EEPROM memory module with a capacity

Manual Reference

AlSMCA-2KE

AlSMCA-8KE

No.

The memory modules allow EEPROMs and EPROMs

to be used for program storage, in addition to the

memory in the CPU module.

of

8k

bytes

(2k

steps).

66320,

AlSCPU User's Manual

of

32k

bytes

(8k

steps).

IB(NA)

66320,

AISCPU User's Manual

RAM

I

I

I

t

Model

No.

AlSMCA-8KP

EPROM memory module with a capacity of

Manual Reference No.

IB(NA)

66320.

27

8k

bytes

(2k

steps).

AISCPU User's Manual

I

Page 34

..

1

MODULE

I

Extension

cables

*.

DESCRIPTIONS

..

I

I

I

The extension cables are for connecting the

extension base units

Different cable lengths are available according

the model number. A list of the AIS extension

cables is shown below;

I

Model

No.

AlSCOlB

Extension base to CPU base,

Manual Reference No.

I

Model No. AlSC03B

Extension base to CPU base,

Manual Reference No. IB(NA)

I

Model

No.

AlSClZB

Extension base to CPU base,

Manual Reference No.

5.5

cm long.

IB(NA)

33

cm long.

120

IB(NA)

66320,

66320,

cm long.

66320,

to the CPU base units.

to

1

AISCPU User's Manual

I

AISCPU User's Manual

I

AISCPU User's Manual

I

Model

No.

AlSCJOB

Extension base to CPU base,

Manual Reference No.

I

Model No. AlSCOBNB

AnN extension base to AIS CPU base,

Manual Reference No, IB(NA)

300

IB(NA)

cm long.

66320,

45

66320,

28

1

AISCPU User's Manual

I

cm long.

AlSCPU User's Manual

Page 35

..

i

..

MODULE

DESCRIPTIONS1

(Terminal

Remote terminal block units for use with connector wiring type input and output

modules. Connected

many types of terminal block unit with a differing number of terminal points and/or

compatible with different

There are

modules, and the other for use with source type input/output modules. Below is a

list of the

block

units and cables

32

Point

D-sub Connector

two

types

AIS

terminal block units and cables available

36

Point Terminal

Block

D-sub Connector

to

the

110

modules using a terminal block cable. There are

110

modules.

of

terminal block cable, one for use with sink type inputloutput

1

1

Model

No.

A6TBXY36

36 point terminal block unit for use with sink type input and output modules,

AlSX41(S2), AlSX42(S2), AlSY41, AISY42,

Manual Reference

I

Model

No.

54

point terminal block unit for use with sink type input and output modules,

A1 SX41 (S2), AI SX42(S2), AI SY41, AlSY42,

Manual Reference

No.

A6TBXY54

No.

No

manual, specification sheet No. 88

No

manual, specification sheet

29

or

AlSH42.

or

Ai SH42.

No.

88

I

I

Page 36

MODULE

I

Model

70

point terminal block unit for use with sink type input modules,

AlSX42(S2),

Manual Reference

I

Model

DESCRIPTIONS

No.

A6TBX70

or

AlSH42.

No.

A6TBX36-E

No.

No

manual, specification sheet

No.

AlSX41(S2),

88

I

I

I

I

36 point terminal block unit for use with source type input module,

Manual Reference

1

Model

No.

36

point terminal block unit for use with source type output module,

Manual Reference

I

Model

No.

54

point terminal block unit for use with source type input module,

Manual Reference

I

Model

No.

54

point terminal block unit for use with source type output module,

Manual Reference

I

Model

No.

No.

A6TBY36-E

No.

A6TBX54-E

No.

A6TBY54-E

No.

A6TBX70-E

No

manual, specification sheet

No manual, specification sheet

No

manual, specification sheet

No

manual, specification sheet

AlSX81(S2).

No.

88

AISY81.

No.

88

AlSX81(S2).

No.

88

AlSY81.

No.

88

I

I

I

1

70

point terminal block unit for use with source type input module,

Manual Reference

I

Model

No.

Terminal block unit cable for use with sink type terminal block units and input/output

modules,

Manual Reference

0.5

ACOBTB

m long.

No.

No.

No

manual, specification sheet

No

manual, specification sheet

30

A1 SX81 (S2).

No.

88

No.

88

I

Page 37

..

.

I

MODULE

DESCRIPTIONS1

.I

[Model

I

I

No.

ACIOTB

Terminal block unit cable for use with sink type terminal block units and inputloutput

modules,

Manual Reference

Model

Terminal block unit cable for use with sink type terminal block units and inputloutput

modules,

Manual Reference

Model

Terminal block unit cable for use with sink type terminal block units and inputloutput

modules,

Manual Reference

Model

1

m long.

No.

ACZOTB

2 m long.

No.

AClOTB

3

m long.

No.

AC50TB

No.

No.

No.

No

manual, specification sheet

No

manual, specification sheet

No

manual, specification sheet

No.

No.88

No.

88

88

1

I

I

I

Terminal block unit cable for use with sink type terminal block units and inputloutput

modules,

Manual Reference

I

Model

Terminal block unit cable for use with source type terminal block units and

inputloutput modules,

Manual Reference

I

Model

Terminal block unit cable for use with source type terminal block units and

inputloutput modules, 1 m long.

Manual Reference

5

m long.

No.

ACOCTB-E

No.

ACIOTB-E

No.

No.

No.

0.5

No

m long.

No

No

manual, specification sheet

manual, specification sheet

manual, specification sheet

No.

88

No.

88

No.

88

I

I

31

Page 38

..

MODULE

I

Model

DESCRIPTIONS

No.

ACZOTB-E

..

I

Terminal block unit cable for use with source type terminal block units and

inputloutput modules,

Manual Reference

Model

No.

ACSOTB-E

Terminal block unit cable for use with source type terminal block units and

inputloutput modules,

Manual Reference

I

Model

No.

ACSOTB-E

Term-inal block unit cable for use with source type terminal block units and

inputloutput modules,

Manual Reference

No.

No.

No.

2

m long.

3

m long.

5

m long.

No manual, specification sheet

No

manual, specification sheet

No

manual, specification sheet

No.

No.

No.

88

88

88

I

I

32

Page 39

I

Chapter

SELECTION

3:

System Selection and Configuration

AND

CONFIGURATION^

I

Jsystem selection

AIS

system selection may seem to be a difficult task with

of modules and accessories to choose from, as can be seen in chapter

it

can be made easy by following the five steps outlined in this chapter. Follow them

carefully and you will be able

application requirements.

to

match the

AIS

so

many different types

PLC

system exactly to your

2.

However,

I

33

Page 40

'SELECTION

I

Step

1:

Input module selection

AND

CONFIGURATION

I

12124 VDC

Sink or source

inputtype

?

16pOW

1

Sink

or

16,320r64

point modules

?

+

source Model number:

inputtype?

.

64 point Model number:

'

Sink

€4

point

Sink Model number:

16 point

t

Sink

L

Sink

source

Sink

L

r

Source

-

Source

-

Model number:

I

AlSX41

L

c

AlSX81

c

Model number.

AlSX42

h

I

Model number:

J

Model number.

\

1

1

1

4

Start

DC

inputs

AC, DC or

TTL

AC inputs

L

i

I

inputs

?

I

t

24

16 point

220

16 point

7-

Source

High

speed

inputtype

7

TTL

inputs

Sin k/source

32

point Model number:

VAC

11OVAC

16

24,110 or

220 V inputs

VAC

point

L

?

v

I

34

AlSX40S2

AlSXBOSl

Model number:

AlSXBOS2

U

Model number:

Model number:

Model number:

Page 41

I

Step

SELECTION

2:

Output module selection

AND

CONFIGURATION^

I

16

point

Ah

0.1,0.5

or 2 A

outputcurrent?

12I24VDC

1Zi24VDC

L

v

-

2A

24 VDC

0.1 A

Model number:

AlSY40

b

t

Model number:

AISYSO

I

*

Model number:

AISY6O

b

*

I

1

4

1

I

start

+

Transistor,

relay, Mac or

TTL outputs

Reky+

TTL

L

r

? Trk

7

32

point Sinkkource

1A

Independent

commons

Independent Model number:

commons

I

?

?

8point

0.6 A

100-240 VAC

16

point

2A

24VDC,lW240VAC

24 VDC,100-240 VAC

16

point Model number:

AlSY71

AlSY28A

AlSY22

-

AI SY18A

AISYIO

35

Page 42

-SELECTION

I

Step 3: Special function

AND

CONFIGURATION

module

selection

I

start

-

AID,

QIA

conversion

7r

No

TI

No

NetworKmg

I I

YeS

?

L

r

Yes

L

?

-

RemoteUOor

masterilocal

AID

or

QIA

conversion

7

1

?

Remote

L

v

Model number:

Model number:

VO

Model number:

r

Masterllocal Model number:

P

A1

SJ71T21

B

36

Model number:

Model number:

Model number:

4

wire

Model number:

Page 43

I

Step

SELECTION

4:

Power supply

module

AND

selection

CONFIGURATION^

I

Stad

-

vohge

?

r

Model number:

t-

\r

No

Model number:

Note:

1.

If

an AlS62P power supply unit has been selected, then ensure that the DC 5V

current consumption

does not exceed 3A.

power supply module should be selected, and an external power supply should

be used for the DC 24V that is required.

If

an AlS65B or AlS68B extension base are used, then an additional power

2.

supply module is required.

of

all the modules being powered by this power supply

If

the current consumption

is

above 3A, then an AIS61P

31

Page 44

:SELECTION

I

Step

5:

Base unit selection

AND

CONFIGURATION

I

.

b

Calculate the number

VO

slots

required.

More than

2

slots

requked

t

yes

3

More than

slots

required

t

yes

-

More than

5

slots

required

More than

8

slots

required

t

yes

I

More than

slots required

10

I

UO

UO

UO

VO

?

?

?

?

UO

?

of

No

L

v

No

L

r

No

L

r

t

Is

the total DC

r

consumption greaterthan

the power suppfy

5V

current

OP

?

I

T

r

Model number:

Model number:

AlS300

+

tY~

Is

More than

slots

required

t

13

yes

UO

?

the total

r

consumption greaterthan

the power supply O/P

Isthe total

consumption greater than

the power supply

38

!X

DC

I

5V

YeS

w

YeS

current

current

OIP

r

?

Model number:

(AlS65B

'L

r

?

L

Model number:

J

Page 45

SELECTION

AND

CONFIGURATION^

lsystem

configuration

After selecting all of the components for your AIS system, it is then necessary

configure the system and assign input/output numbers for each of the modules you

have chosen.

First of all each of the modules in your system must be allocated

either the CPU or extension base unit. So write in the model numbers of the

modules you have selected against the slot number where you want to locate them

on the base units selected. A good idea when doing this is to keep all the input

modules, output modules and special function modules together in groups, this

it

makes

When you have allocated an

to

range from

A,

base unit. From the module in slot 0 the numbers follow on consecutively through

all the modules on the CPU base unit and then on to the modules in the extension