Page 1

PROFIBUS-DP Interface Module

Type AJ71PB92D/A1SJ71PB92D

User,s Manual

Mitsubishi Programmable Logic Controller

Page 2

Page 3

SAFETY PRECAUTIONS

(Read these precautions before using.)

When using Mitsubishi equipment, thoroughly read this manual and the associated manuals introduced

in this manual. Also pay careful attention to safety and handle the module properly.

These precautions apply only to Mitsubishi equipment. Refer to the CPU module user’s manual for a

description of the PLC system safety precautions.

These • SAFETY PRECAUTIONS • classify the safety precautions into two categories: “DANGER” and

“CAUTION”.

DANGER

Procedures which may lead to a dangerous condition and cause death or

serious injury if not carried out properly.

CAUTION

Procedures which may lead to a dangerous condition and cause superficial

to medium injury, or physical damage only, if not carried out properly.

Depending on circumstances, procedures indicated by

CAUTION may also be linked to serious results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it whenever necessary. Always

forward it to the end user.

[DESIGN PRECAUTIONS]

DANGER

z

When a communication error occurs in the PROFIBUS network, the status of the faulty station is as follows.

Configure an interlock circuit in the sequence program using the communication status information (input

X1, buffer memory 2040 to 2079) so that the system can operate safely.

Erroneous outputs and mis-operation could cause accidents.

(1) The input data of the master station maintains the data before abnormality of the communication.

(2) When the master station is down, the output state of each slave station will be in accordance with the

parameter settings.

(3) When any slave station is down, the output state of other slave stations will be in accordance with the

parameter settings of the master station.

z

If a stop error occurs in the CPU module, the communication status is as described below.

(1) Communication with the slave station is stopped.

(2) For the input data received from the slave station, the values at CPU module stop error occurrence are

held.

(3) The output data sent from the AJ71PB92D/A1SJ71PB92D to the slave station are cleared.

CAUTION

z

When the PROFIBUS cable is laid, do not lay it close to main circuits or power lines.

They should be installed 100mm(3.9inch) or more from each other.

Not doing so could result in noise that would cause malfunctioning.

Page 4

[INSTALLATION PRECAUTIONS]

CAUTION

z

Use the module in the environment given in the general specifications of the CPU module’s User’s Manual.

Using the module outside the range of the general specifications may result in electric shock, fire or

malfunctioning, or may damage or degrade the module.

z

Insert the tabs at the bottom of the module into the mounting holes in the base unit before installing the

module. (The AnS series module shall be fastened by screws in the base unit at the specified torque.)

Not installing the module correctly could result in malfunctioning, breakdowns or pieces of the product falling

z

Tighten the fixing screws of the PROFIBUS cable with the specified torque. If the screws are loose, it could

result in malfunction of the module.

z

Do not touch the conductive area or electric parts of the module.

Doing so may cause module malfunctioning or breakdowns.

[WIRING PRECAUTIONS]

CAUTION

z

Switch all phases of the external power supply of the PLC system off before connecting the PROFIBUS

cable. Not doing so could cause failure or malfunctioning of the module.

z

Be careful not to let foreign matter such as filings or wire chips get inside the module. These can cause fire,

breakdowns and malfunctioning.

z

The PROFIBUS cable which is connected to the module must be protected with a duct or secured in

position with clamps.

Unless the cable is thus protected or secured, the module or the cable could be damaged when the cable

swings, moves or it is strained with careless pulls, or it could cause malfunction when the cable contacts

with any undesirable objects.

z

When disconnecting the PROFIBUS cable from the module, do not pull by holding the cable section. To

disconnect the cable, make sure to hold the connector which is coupled with the module. Do not attempt to

pull the cable to disconnect it from the module. It could damage the module or the cable, or cause

malfunction due to a poor contact of the cable.

[STARTING AND MAINTENANCE PRECAUTIONS]

DANGER

z

Switch all phases of the external power supply off before cleaning.

Not doing so could cause electric shock.

Page 5

CAUTION

z

Never disassemble or modify the module.

This may cause breakdowns, malfunctioning, injury and/or fire.

z

Switch all phases of the external power supply off before mounting or removing the module. If you do not

switch off the external power supply, it will cause breakdowns or malfunction of the module.

z

Set the ON/OFF select switch of the terminal resistor before the operation.

If the setting is switched during the operation, network error may occur, or error detection may not be

performed by error.

z

Before handling the module, always touch grounded metal, etc. to discharge static electricity from the

human body.

Failure to do so can cause the module to fail or malfunction.

[OPERATING PRECAUTIONS]

DANGER

z

Do not write data into the "not usable" of the buffer memory of special function modules. Also, do not output

the "not usable" signal as the output signal to a special function module from the PLC CPU. Writing data

into the "not usable area" or outputting an "not usable" signal may cause system malfunctions in the PLC.

CAUTION

z

The online operations conducted for the CPU module being operated (especially when changing data or

operation status), shall be conducted after the manual has been carefully read and a sufficient check of

safety has been conducted.

Operation mistakes could cause breakdowns to or malfunction of the module.

[DISPOSAL PRECAUTIONS]

CAUTION

z

When disposing of this product, treat it as industrial waste.

Page 6

Revisions

* The manual number is noted at the lower left of the back cover.

Print Date *Manual Number Revision

May, 1997 IB (NA)-66773-A First printing

Sep., 1997 IB (NA)-66773-B Correction

Section 2.3, Chapter 3

Addition

Appendix 2

Oct., 1998 IB (NA)-66773-C Model Addition

AJ71PB92D

Correction

SAFTY PRECAUTIONS, Chapter 1, 2, 3, 4, Section 5.1, 5.2, 5.3, 5.5.1,

5.5.2, 5.6, 6.1, Chapter 7, 8, 9

Addition

Appendix 1

Chapter Alteration

Appendix 1 → Appendix 3

Jun., 2000 IB (NA)-66773-D Correction

Chapter 1, Section 2.1, 2.2, 2.3, 2.4, 2.5, 3.1, 3.2, 4.2.1, 4.2.2, 4.3.1, 5.5.1,

Appendix 1

Addition

Section 2.6, 4.4, 4.5, 8.6

Jun., 2003 IB (NA)-66773-E Correction

SAFTY PRECAUTIONS, Section 4.3.2, 6.1, 8.2.1, 8.2.2

Addition

Section 3.3.3, Appendix 2

Apr., 2004 IB (NA)-66773-F Correction

Section 1.2, 3.2, 3.3.3, 4.2.2, 4.3.1, 4.3.2, 4.6, 5.1, 5.3, 6.1, 6.2

Addition

SAFTY PRECAUTIONS, Chapter 9

Aug., 2004 IB (NA)-66773-G Correction

SAFTY PRECAUTIONS, Section 2.2, 3.3.2, 3.3.3, 4.3.2, 5.5.1, Chapter 8,

Section 8.2.2

Japanese Manual Version SH-3330-G

This manual does not imply guarantee or implementation right for industrial ownership or implementation

of other rights. Mitsubishi Electric Corporation is not responsible for industrial ownership problems caused

by use of the contents of this manual.

1998 Mitsubishi Electric Corporation

Page 7

Introduction

Thank you for purchasing the Mitsubishi Programmable Controller MELSEC-A Series.

Before using the equipment, plese read this manual carefully to develop full familiarity with the functions and

performance of the graphic operation terminal you have purchased, so as to ensure correct use.

Please forward a copy of this manual to the end user.

Table of Contents

About This Manual

1. OVERVIEW 1-1 to 1-2

1.1 Software Configuration......................................................................................................................................1- 1

1.2 AJ71PB92D/A1SJ71PB92D Features .............................................................................................................1- 2

2. SYSTEM CONFIGURATION 2-1 to 2-6

2.1 Whole System Configuration ............................................................................................................................2- 1

2.2 System Configuration Example.........................................................................................................................2- 2

2.3 Applicable CPU Modules..................................................................................................................................2- 3

2.4 Installable Base Units .......................................................................................................................................2- 4

2.5 Combining with MELSECNET (II), MELSECNET/B, and MELSECNET/10.......................................................2- 4

2.6 Precautions for Configuring a System ..............................................................................................................2- 5

3. SPECIFICATIONS 3-1 to 3-10

3.1 General Specification........................................................................................................................................3- 1

3.2 Performance Specifications..............................................................................................................................3- 2

3.3 Network Configuration.......................................................................................................................................3- 3

3.3.1 Basic configuration................................................................................................................................3- 3

3.3.2 Applicable configuration.........................................................................................................................3- 4

3.3.3 Number of connectable slaves..............................................................................................................3- 8

4. FUNCTIONS 4-1 to 4-32

4.1 Functions for Exchanging with Slaves..............................................................................................................4- 1

4.1.1 Exchange flow........................................................................................................................................4- 1

4.1.2 Global control functions.........................................................................................................................4- 2

4.2 I/O Signal..........................................................................................................................................................4- 5

4.2.1 I/O signal list..........................................................................................................................................4- 5

4.2.2 I/O signal detail description....................................................................................................................4- 6

4.3 Buffer Memory List............................................................................................................................................4- 9

4.3.1 Buffer memory/configuration..................................................................................................................4- 9

4.3.2 Buffer memory detailed description.......................................................................................................4-10

4.4 While-Run Operation Mode Changing Function...............................................................................................4-30

4.5 AJ71PB92D/A1SJ71PB92D's Remote Parameter Setting Function Using MELSEC ProfiMap

Configuration Software......................................................................................................................................4-31

4.6 E

2

PROM initialization function..........................................................................................................................4-32

5. PROCEDURES BEFORE SYSTEM OPERATION 5-1 to 5-10

5.1 Procedures before Operation............................................................................................................................5- 1

5.1.1 Parameter setting procedure.................................................................................................................5- 2

5.2 Handling Precautions ........................................................................................................................................5- 3

5.3 Part Names and Settings..................................................................................................................................5- 4

Page 8

5.4 Execution Method for Self-diagnosis.................................................................................................................5- 6

5.5 Wiring................................................................................................................................................................5- 7

5.5.1 PROFIBUS cable wiring.........................................................................................................................5- 7

5.5.2 Terminator switch ..................................................................................................................................5- 7

5.5.3 Precautions against wiring.....................................................................................................................5- 8

5.6 Maintenance and Inspection.............................................................................................................................5-10

6. COMMUNICATION TIME 6-1 to 6-4

6.1 Transmission Delay Time When There is One Master Station.........................................................................6- 1

6.2 Transmission Delay Time When There are Multiple Master Stations...............................................................6- 4

7. DDB FILE 7-1 to 7-2

8. PROGRAMMING 8-1 to 8-6

8.1 Initial Program...................................................................................................................................................8- 1

8.2 Data I/O with Slave...........................................................................................................................................8- 2

8.2.1 Normal service mode (MODE switch : No. 0)........................................................................................8- 2

8.2.2 Extend service mode (MODE switch : No. E)........................................................................................8- 3

8.3 Communication Trouble Area and Expansion Communication Trouble Area Clear.........................................8- 4

8.4 Address Information Read................................................................................................................................8- 4

8.5 Global Control...................................................................................................................................................8- 5

8.6 While-Run Operation Mode Changing..............................................................................................................8- 6

9. TROUBLESHOOTING 9-1 to 9-2

APPENDIX A-1 to A-10

Appendix 1 Differences between AJ71PB92D/A1SJ71PB92D Software Versions................................................. A- 1

Appendix 1.1 Differences between A1SJ71PB92D Software Versions...........................................................A- 1

Appendix 1.2 Restrictions on Use of A1SJ71PB92D Software Versions in the Same System....................... A- 2

Appendix 1.3 Differences between AJ71PB92D Software Versions...............................................................A- 2

Appendix 1.4 Restrictions on Use of AJ71PB92D Software Versions in the Same System ...........................A- 2

Appendix 2 Precautions for Replacing AJ71PB92 with A(1S)J71PB92D................................................................A- 3

Appendix 3 Extended Trouble Information of Mitsubishi's Slaves...........................................................................A- 7

Appendix 4 External Dimensions.............................................................................................................................A- 8

Page 9

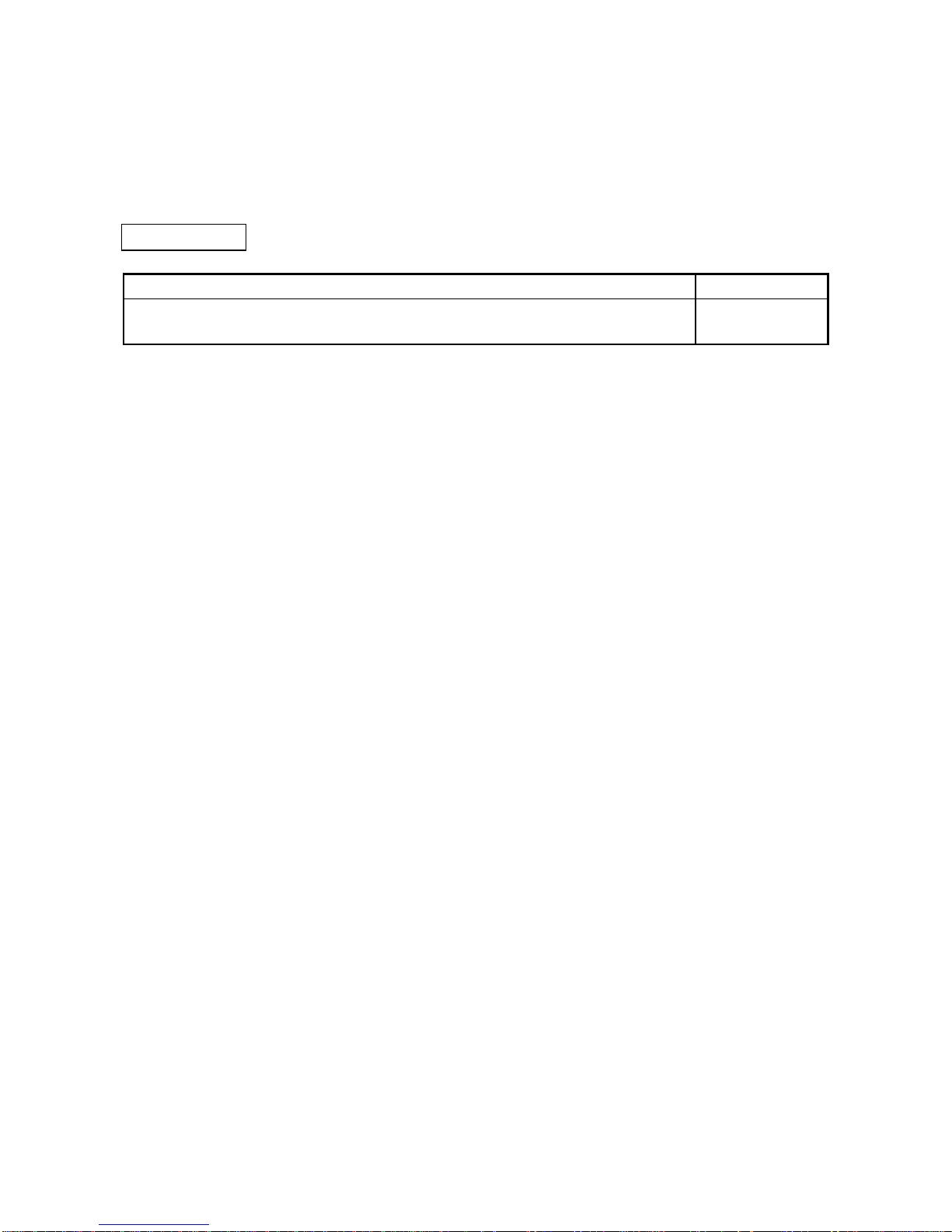

About This Manual

The following are manuals related to this product.

Request for the manuals as needed according to the chart below.

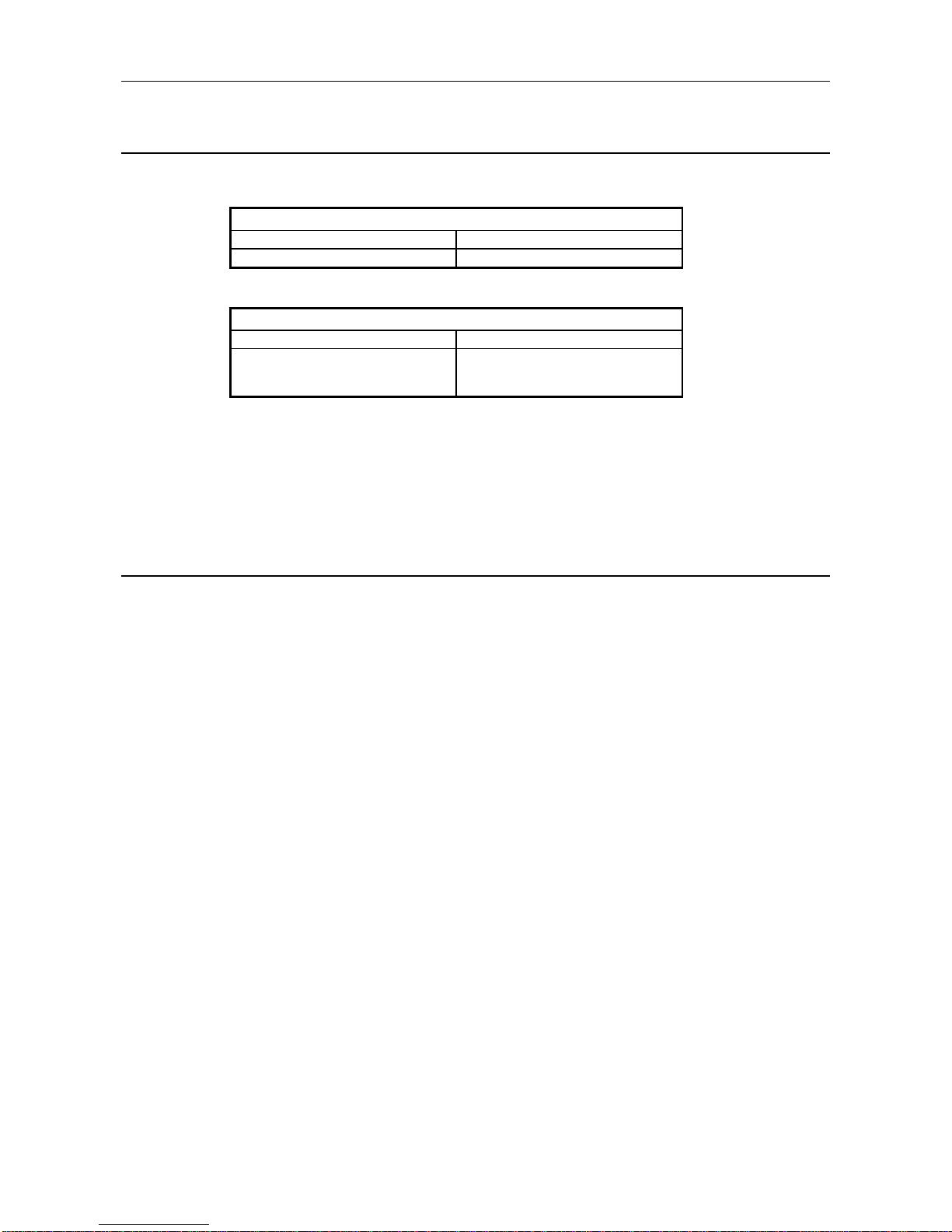

Related Manual

Manual Name Article No.

MELSEC ProfiMap Configuration System for Open Networks Software Manual 65778-B

* Inquiries can be made to :

MITSUBISHI ELECTRIC EUROPE Factory Automation

Gothaer Strasse 8 D-40880 Ratingen Germany

Phone : +49(21 02)486-0

Fax : +49(21 02)486-717

Page 10

1. OVERVIEW MELSEC-A

1-1

1. OVERVIEW

This is the user's manual for the AJ71PB92D/A1SJ71PB92D PROFIBUS-DP interface module

(hereafter abbreviated as " AJ71PB92D/A1SJ71PB92D. When explain separately, however,

abbreviated as AJ71PB92D, A1SJ71PB92D), which is used to connect a MELSEC-A/QnA/Q series

programmable controller to a PROFIBUS-DP network.

The AJ71PB92D/A1SJ71PB92D operates as a master station (class 1) in the PROFIBUS-DP network.

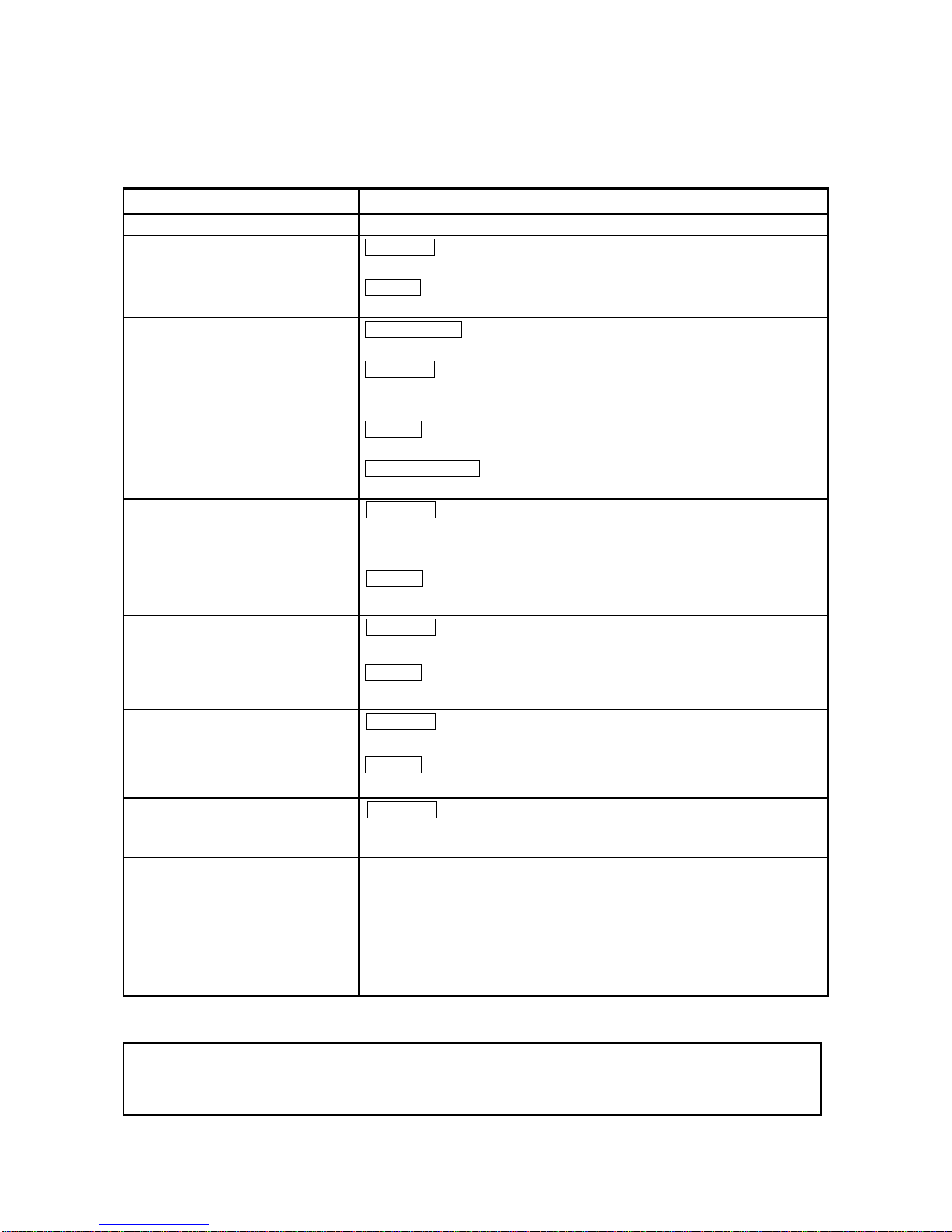

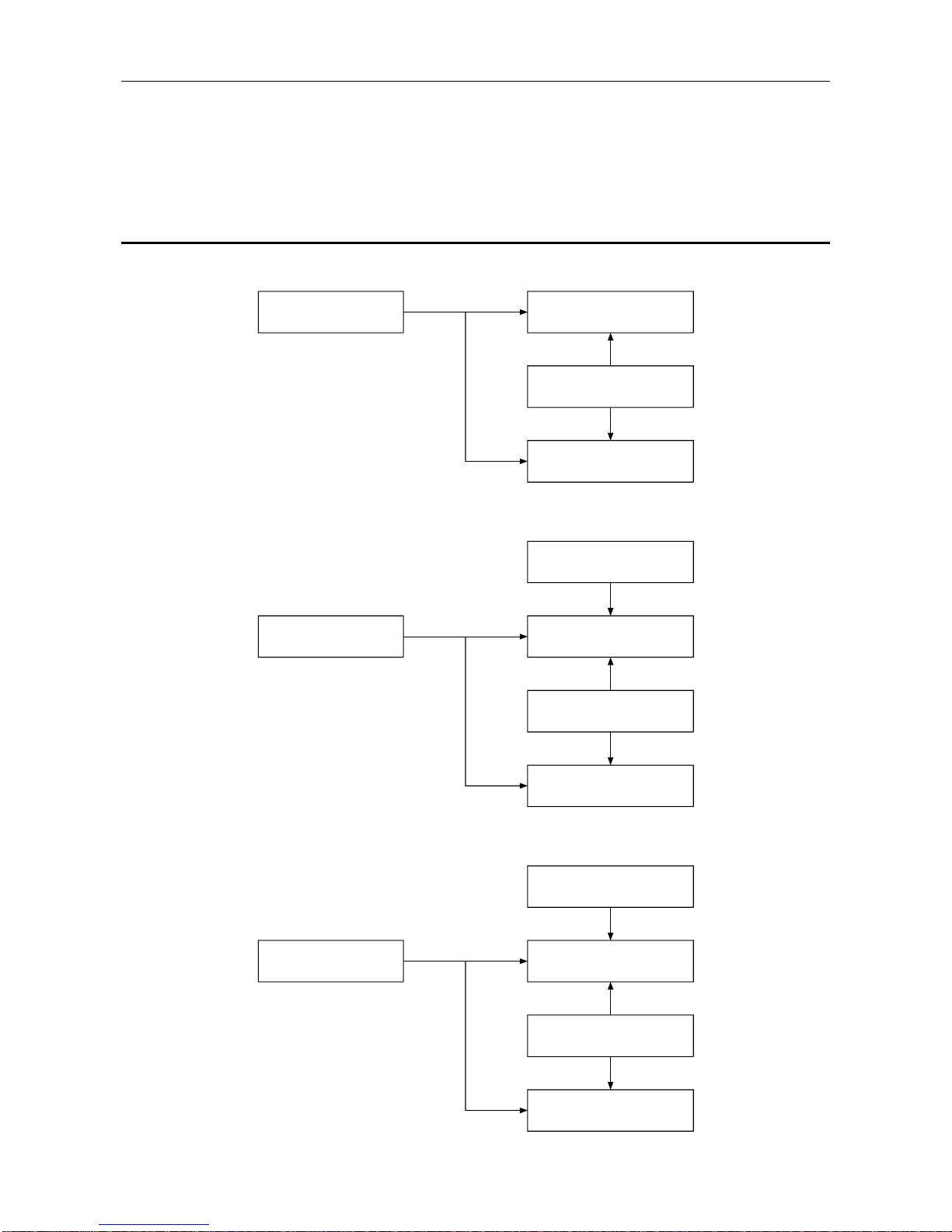

1.1 Software Configuration

FROM/TO

User Interface

Direct Data Link Mapper

FDL

PHY

(DDLM)

empty

FMA1/2

MELSEC A Series PC

Communication using a buffer memory

Portion where master

PCB is installed

Layer 3 to 7

Layer 2 Datalink layer

Layer 1 Physical layer

Portion where slave

PCB is installed

The AJ71PB92D/A1SJ71PB92D has a physical layer, data link layer, DDLM, and user interface that

conform to PROFIBUS-DP, and communicates data with the PLC CPU by using a buffer memory.

The main application of PROFIBUS-DP is networks that execute high-speed communication at the

level of sensors and actuators, and the AJ71PB92D/A1SJ71PB92D has been designed with this in

mind: its functions are mainly related to data I/O with slave stations.

Page 11

1. OVERVIEW MELSEC-A

1-2

1.2 AJ71PB92D/A1SJ71PB92D Features

(1) Operates as a PROFIBUS-DP master (class 1) station.

(2) Makes possible the exchange of input and output data to and from the slave station

without the need to be aware of the PROFIBUS-DP protocol by using I/O signals X/Y and

the buffer memory.

(3) Supports 3M, 6M, 12M [bps] network communication speeds in addition to the 9.6k, 19.2k,

93.75k, 187.5k, 500k, and 1.5M [bps] supported by the AJ71PB92D/A1SJ71PB92D. These

can be selected using a configurator.

(4) Station Nos. from 0 to 125 can be set using the configurator.

(5) Trouble information can be read from the slave station using the I/O signal X/Y and the

buffer memory.

(6) The global control function makes it possible to maintain all slave I/O at the same time. In

addition, this can also be canceled.

(7) The module contains a self-diagnosis function that can be used to test the hardware such

as the internal memory.

Page 12

2. SYSTEM CONFIGURATION MELSEC-A

2-1

2. SYSTEM CONFIGURATION

This section explains system configuration for the AJ71PB92D/A1SJ71PB92D

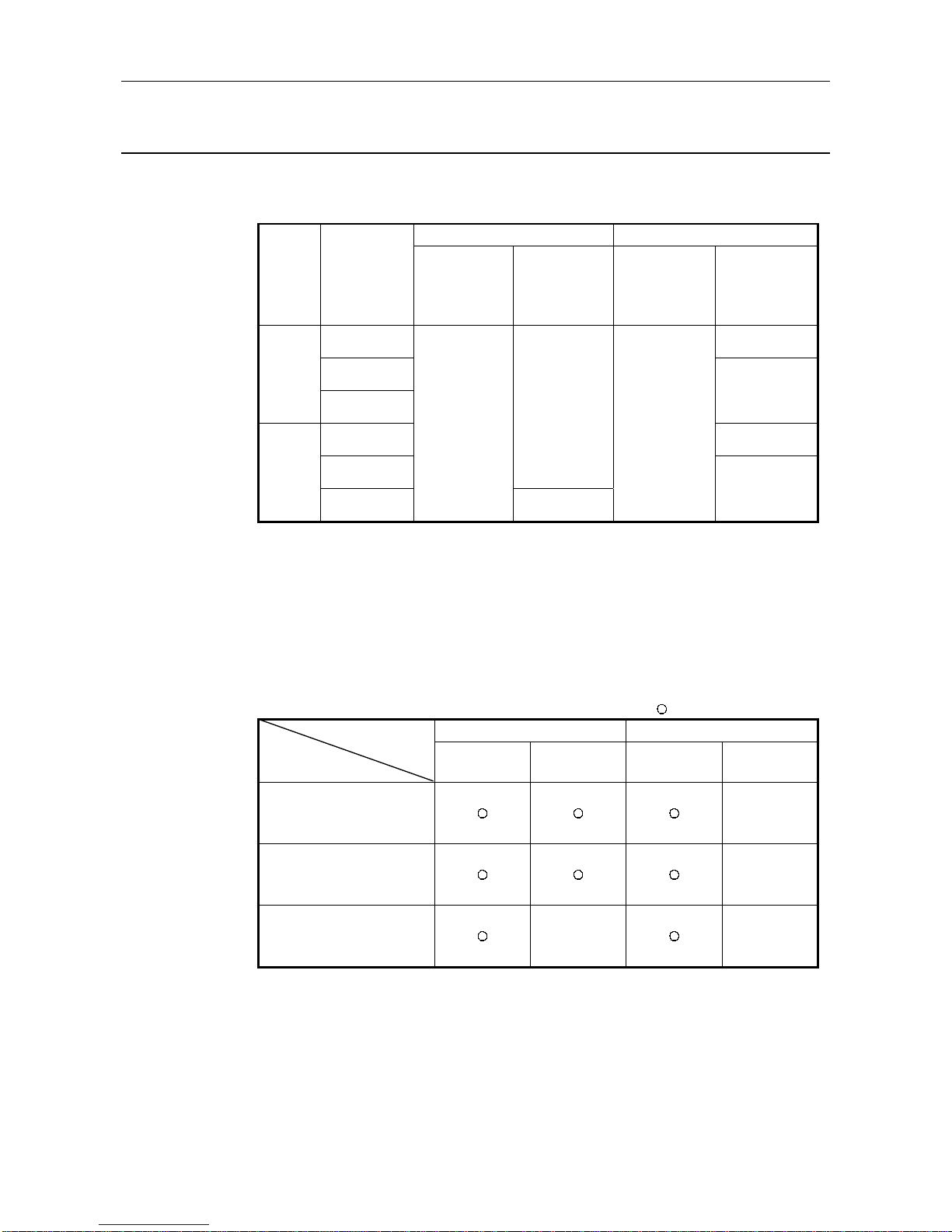

2.1 Whole System Configuration

(1) For the A1SJCPU

A1SJCPU (S3)

Extension cable

Extension base unit

A1SJ71PB92D

A1SC[ ]B

A1S6[ ]B(S1)/A1S5[ ]B(S1)

A1SJHCPU

(2) For the compact building block type CPU

Compact building block type

CPU

Extension cable

A1SC[ ]B

Extension base unit

Basic base unit

A1SJ71PB92D

A1S6[ ]B(S1)/A1S5[ ]B(S1)

A1S3[ ]B/A1S38HB

(3) For the building block type CPU

Building block type CPU

Extension cable

AC[ ]B

Extension base unit

Basic base unit

AJ71PB92D

A6[ ]B/A5[ ]B

A3[ ]B/A38HB

Page 13

2. SYSTEM CONFIGURATION MELSEC-A

2-2

(4) For the Q series CPU

Q series CPU

Extension cable

QC[ ]B

Extension base unit

Basic base unit

A1SJ71PB92D

QA1S6[ ]B

Q3[ ]B

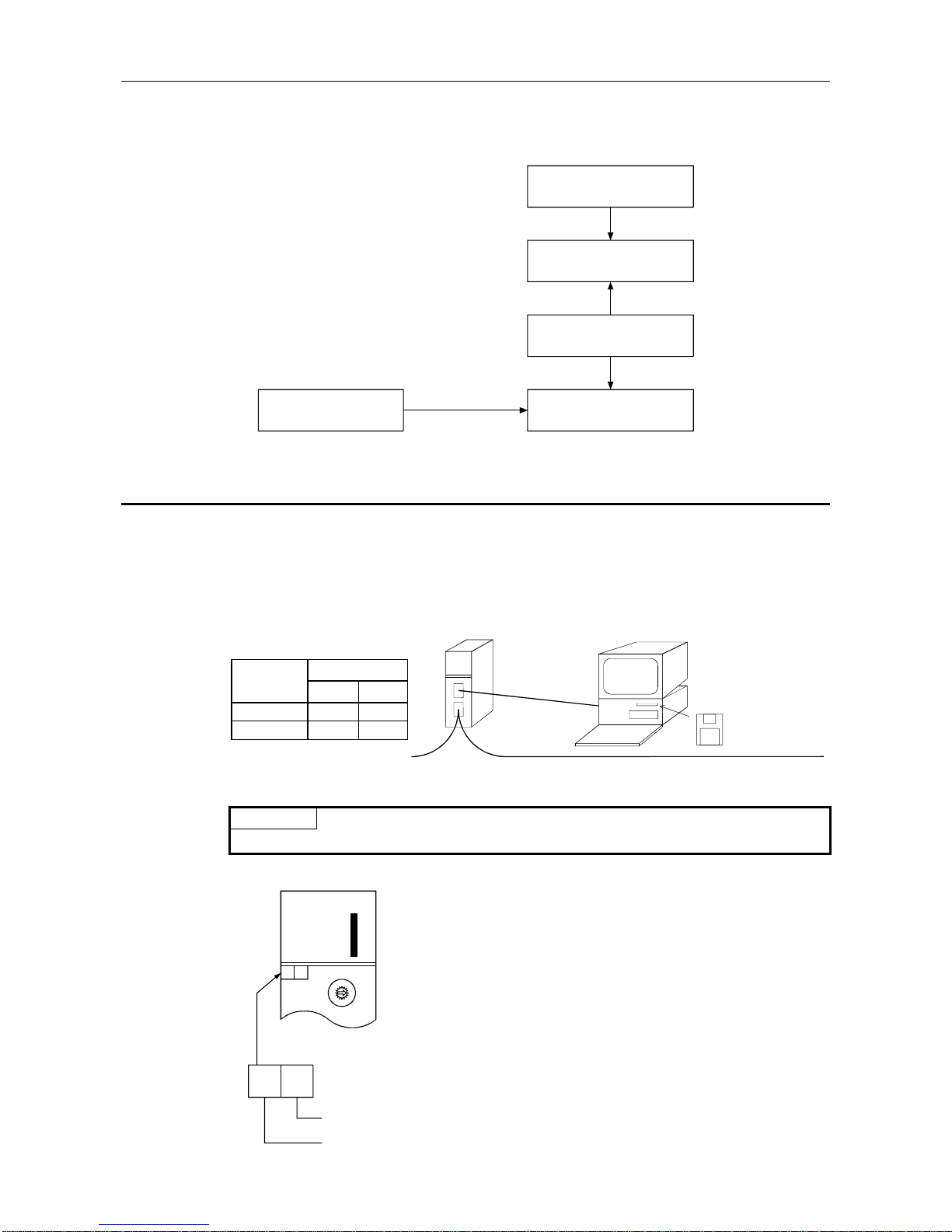

2.2 System Configuration Example

The following describes the A1SJ71PB92D system configuration example.

A communication parameter file is created in Windows using the Configurator software package, this

parameter file can then be down-loaded via an RS-232C cable to the AJ71PB92D/A1SJ71PB92D.

Via RS-232C

AJ71PB92D

A1SJ71PB92D

RS-232C

Personal computer supporting Window s 3.1 or 95

MITSUBISHI ELECTR IC Corp.

MELSEC ProfiMap

(Ver. 3.0 or later)

PROFIBUS network

Point

Refer to "About This Manual" for inquiry for MELSEC ProfiMap.

*: Version confirmation method of AJ71PB92D/A1SJ71PB92D

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

MODE

0:ONLINE 1

1:PRM SET

2:TEST

A1SJ71PB92D

RUN

SD/RD

TOKEN

READY

FROM/TO

PRM SET

RSP ERR.

FAULT

TEST

B6

B5

B4

B3

B2

B1

B0

S

T

.

N

O

.

BG

BG

Software version

Hardware version

E:ONLINE 2

Version

Hardware Software

AJ71PB92D

A or later C or later

A1SJ71PB92D B or later G or later

Model

Page 14

2. SYSTEM CONFIGURATION MELSEC-A

2-3

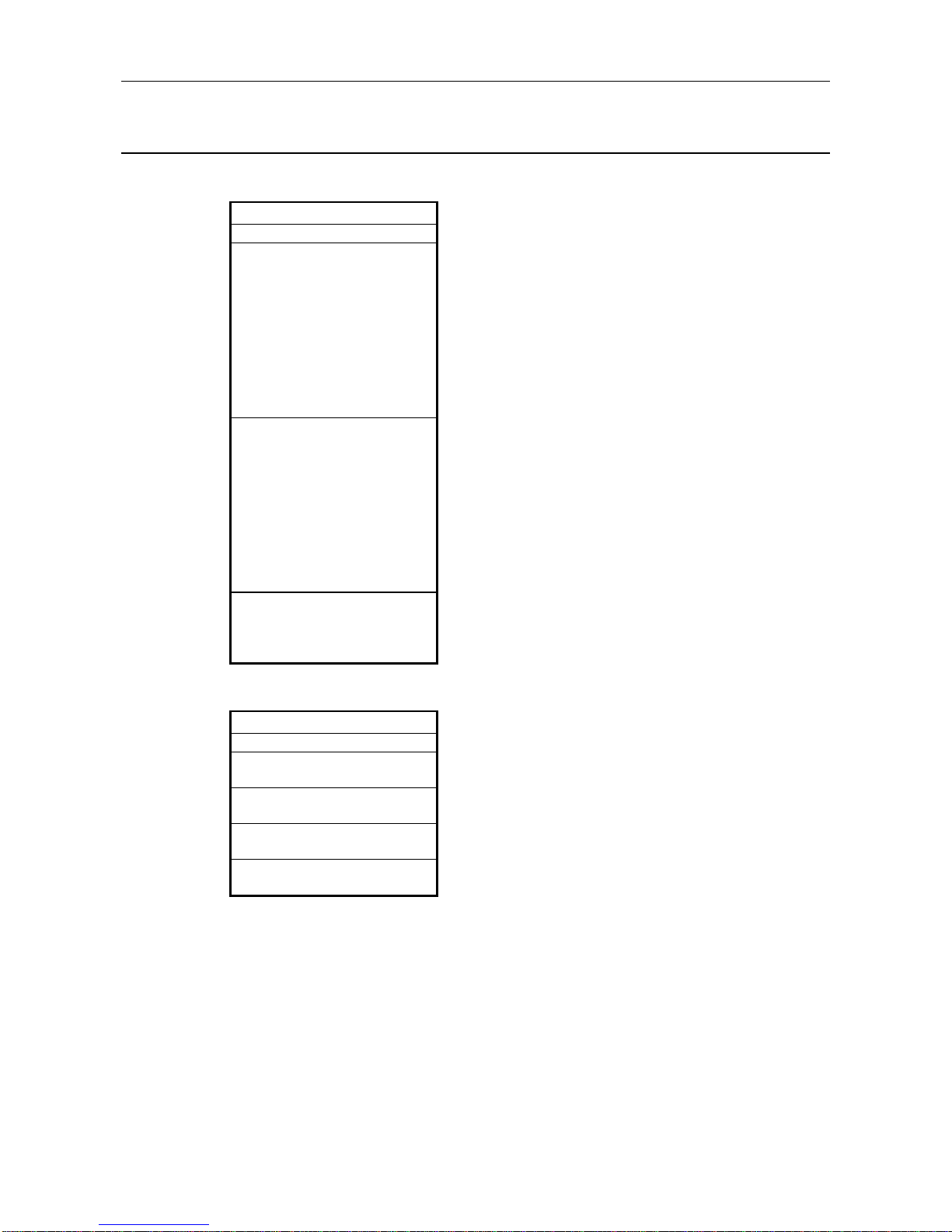

2.3 Applicable CPU Modules

The following table shows the CPUs that the AJ71PB92D/A1SJ71PB92D can use.

(1) AJ71PB92D

Applicable CPU Modules

A1SCPUC24-R2

A1SJHCPU, A1SHCPU,

A2SHCPU, A2SHCPU-S1 ,

A1NCPU, A1NCPUP21,

A1NCPUP21-S3, A1 NCP UR2 1 ,

A2NCPU, A2NCPUP21,

A2NCPUP21-S3, A2 NCP UR2 1 ,

A2NCPU-S1, A2NCPUP2 1 - S 1 ,

A2NCPUP21-S4, A2 NCP UR2 1 ,

A3NCPU, A3NCPUP21,

A3NCPUP21-S3, A3 NCP UR2 1

A2ASCPU, A2ASCPU-S1,

A2ASCPU-S30, A2USHCPU-S1

A2ACPU, A2ACPUP21,

A2ACPUP21-S3, A2ACPUR21,

A2ACPU-S1, A2ACPUP21-S1,

A2ACPUP21-S4, A2ACPUR21,

A3ACPU, A3ACPUP21,

A3ACPUP21-S3, A3ACPUR21,

A2UCPU,A2UCPU-S1,

A3UCPU, A4UCPU

Q2ASCPU, Q2ASCPU-S1,

Q2ASHCPU, Q2ASHCPU- S 1 ,

Q2ACPU, Q2ACPU-S1,

Q3ACPU, Q4ACPU, Q4ARCPU

(2) A1SJ71PB92D

Applicable CPU Modules

A1SCPUC24-R2

A1SJHCPU, A1SHCPU,

A2SHCPU, A2SHCPU-S1

A2ASCPU, A2ASCPU-S1,

A2ASCPU-S30, A2USHCPU-S1

Q2ASCPU, Q2ASCPU-S1,

Q2ASHCPU, Q2ASHCPU- S 1

Q02CPU-A, Q02HCPU-A,

Q06HCPU-A

Page 15

2. SYSTEM CONFIGURATION MELSEC-A

2-4

2.4 Installable Base Units

The base modules that can be installed in the AJ71PB92D/AISJ71PB92D are shown below.

(1) AJ71PB92D

Installable Base Units

Basic base unit Extension base unit

A32B, A32B-S1, A35B, A38B, A38HB A52B, A55B, A58B, A62B, A65B, A68B

(2) A1SJ71PB92D

Installable Base Units

Basic base unit Extension base unit *1

A1S32B, A1S33B, A1S35B, A1S38B,

A1S38HB

A1S52B (S1), A1S55B (S1), A1S58B (S1),

A1S65B (S1), A1S68B (S1),QA1S65B,

QA1S68B

*1: The no power supply module extension base unit A1S5 [ ] B (S1) may not have sufficient power

supply capacity, so use the A1S6 [ ] B (S1) when installing a AJ71PB92D/A1SJ71PB92D in the

extension base unit.

When the A1S5 [ ] B (S1) must be installed, do so after referring to the chapter covering power

supplies in the respective CPU Module User’s Manual.

2.5 Combining with MELSECNET (II) , MELSECNET/B, and

MELSECNET/10

The AJ71PB92D/A1SJ71PB92D can be installed in the MELSECNET (II) and MELSECNET/B master

stations and local stations, and in the MELSECNET/10 control stations and normal stations.

However, the AJ71PB92D/A1SJ71PB92D cannot be installed in the MELSECNET (II),

MELSECNET/B, and MELSECNET/10 remote stations, so be careful.

Page 16

2. SYSTEM CONFIGURATION MELSEC-A

2-5

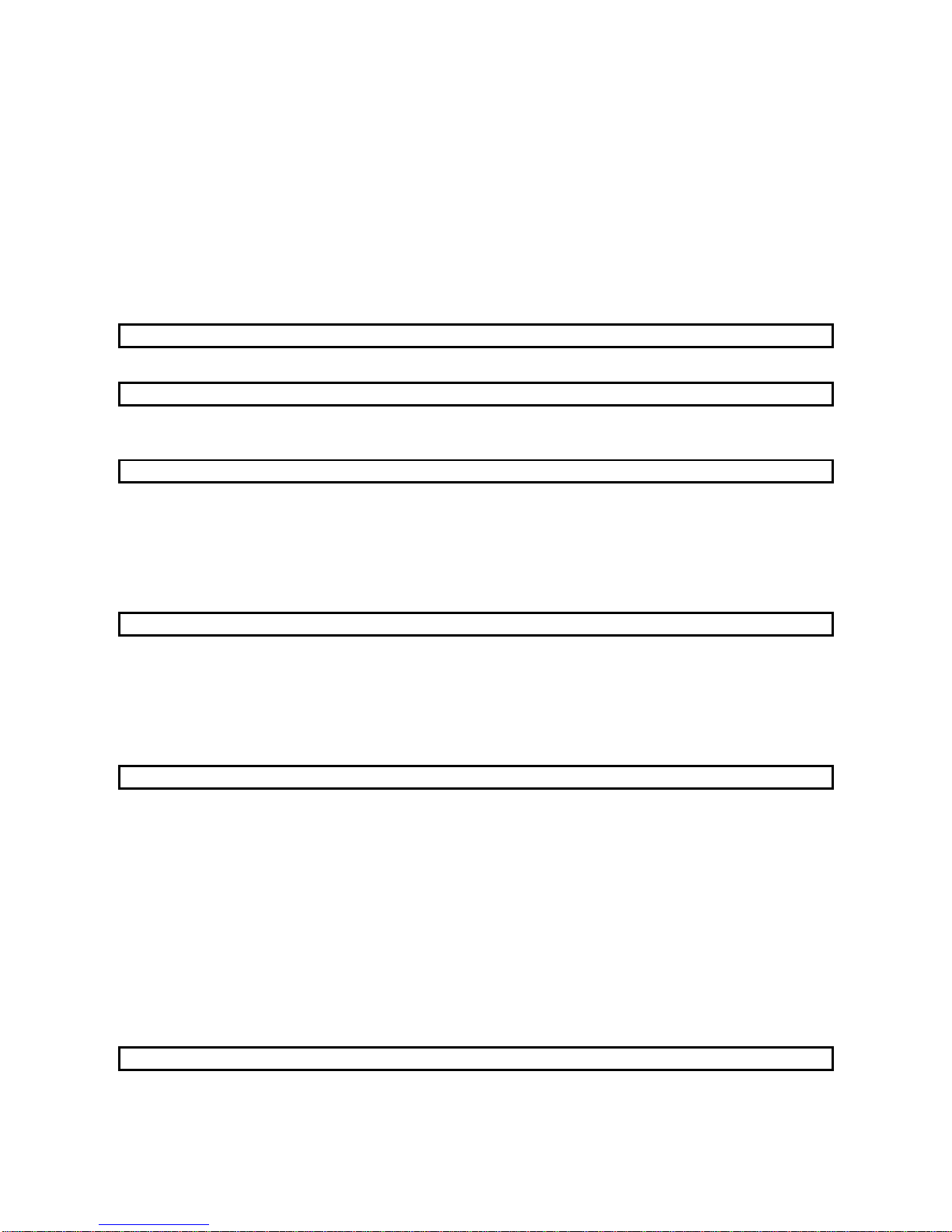

2.6 Precautions for Configuring a System

(1) There are the following restrictions on the AJ71PB92D/A1SJ71PB92D according to the

applied CPU module and used configuration software.

Parameter File Write Path Max. I/O Data Length

CPU

Module

Configuration

Software

Via

AJ71PB92D/

A1SJ71PB92D

RS-232C

interface

Via

CPU module

RS-232C/

RS-422

interface

Normal service

mode

Extended

service mode

SW0D5FPROFIMAP

32 bytes each for

input and output

MELSECPROFIMAP 2.0

Q series

CPU

MELSECPROFIMAP 3.0

244 bytes each

for input and

output*1

SW0D5FPROFIMAP

32 bytes each for

input and output

MELSECPROFIMAP 2.0

Write disabled

A/QnA

series

CPU

MELSECPROFIMAP 3.0

Write enabled

Write enabled*1

32 bytes each for

input and output

244 bytes each

for input and

output*1

*1: The software version usable by the AJ71PB92D/A1SJ71PB92D is AJ71PB92D (A or

later) or A1SJ71PB92D (E or later).

When A1SJ71PB92D (software version D or earlier) is used, write is disabled and the

max. data length is 32 bytes each for input and output.

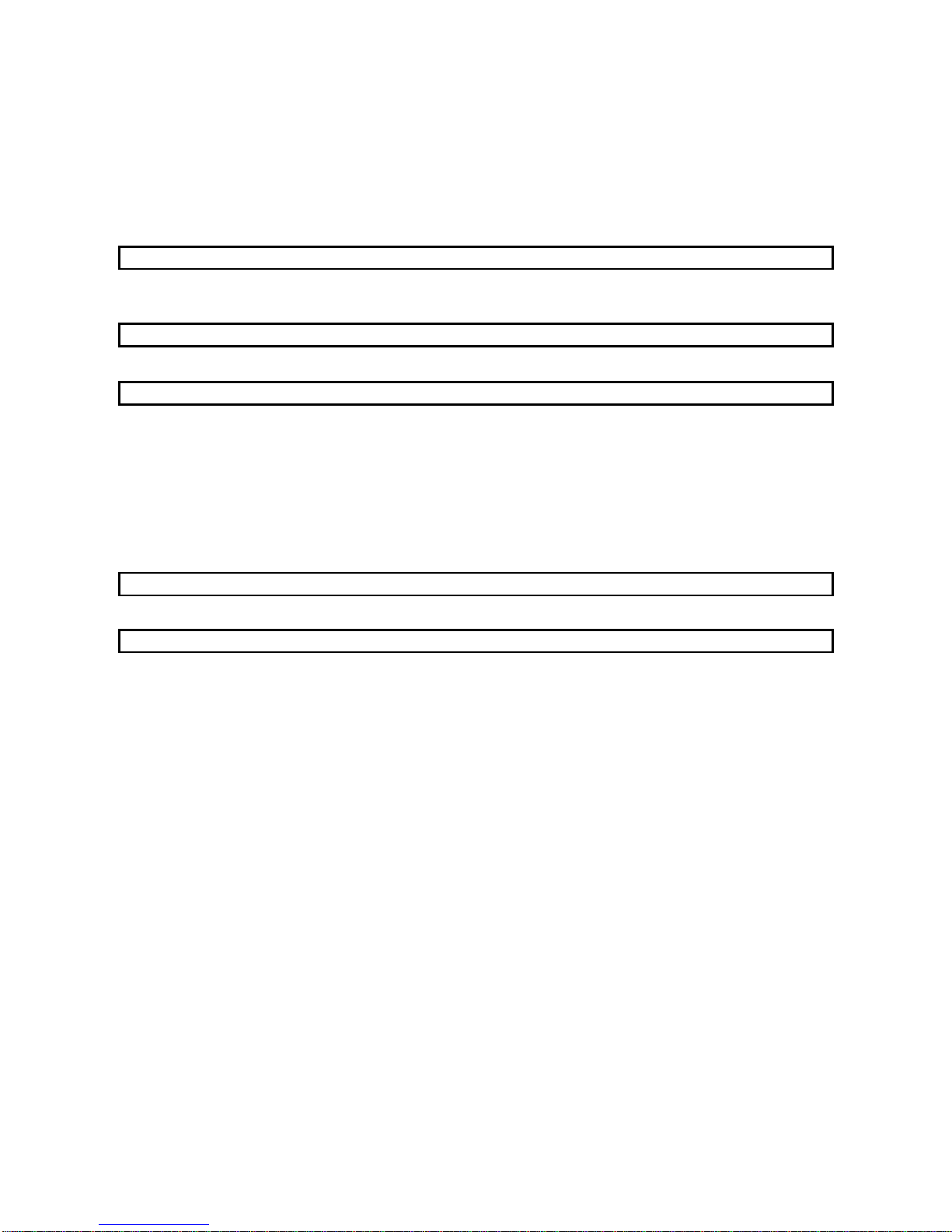

(2) Precautions for using the parameters preset for extended service mode to operate the

module in normal service mode.

The following table gives the operating conditions (conditions per one slave station) for the time

when the parameters preset for the extended service mode are used to operate the

AJ71PB92D/A1SJ71PB92D preset for the normal service mode/extended service mode.

: Operable 5 : Inoperable

Parameter Size Exchange Data LengthOperating Conditi on

AJ71PB92D

A1SJ71PB92D

122 bytes max 244 bytes max 32 bytes max 244 bytes max.

AJ71PB92D software version A

or later and normal service

mode setting

5

A1SJ71PB92D software version

E or later and normal service

mode setting

5

A1SJ71PB92D software version

D or earlier and extended

service mode setting

5 5

(3) In either of the following cases, the AJ71PB92D/A1SJ71PB92D buffer memory must be

accessed by a sequence program when the module ready signal X1D of the

AJ71PB92D/A1SJ71PB92D is ON.

• The operation mode is changed using Y11/X11 in the sequence program.

• Parameter setting is made with ProfiMap connected to other than the RS-232C port of

the AJ71PB92D/A1SJ71PB92D. (For example, parameter setting is made with ProfiMap

connected to the RS-422/RS-232 connector of the CPU module.)

If the buffer memory is accessed with the X1D status ignored, the CPU module may detect

the "SP UNIT DOWN" error, stopping the sequence operation.

Page 17

2. SYSTEM CONFIGURATION MELSEC-A

2-6

(4) Do not make parameter setting via buffer memory and parameter setting from the RS-

232C port of the AJ71PB92D/A1SJ71PB92D at the same time.

If they are made simultaneously, ProfiMap which started parameter write earlier wins the

parameter write right after the operation mode is changed to the parameter setting mode, and

the other ProfiMap cannot perform parameter write and detects an error.

This status will be automatically cleared 15 seconds after completion of parameter write if

parameter write via the CPU module is valid, or 3 seconds after completion of parameter write

if parameter write from RS-232C is valid.

(5) Do not make simultaneous access to the AJ71PB92D/A1SJ71PB92D from multiple

ProfiMap's.

If such access is made, the AJ71PB92D/A1SJ71PB92D may not be accessed properly.

(6) If remote parameter setting is performed from MELSEC ProfiMap to the

AJ71PB92D/A1SJ71PB92D which is making data exchange, note that PROFIBUS data

exchange will stop during parameter setting.

(7) In a system where remote parameter setting is made from MELSEC ProfiMap, do not

execute the mode changing function using the program.

If the mode changing function is executed in the program, an interlock with the remote

parameter setting is not provided and therefore the mode may not be changed.

Page 18

3. SPECIFICATIONS MELSEC-A

3-1

3. SPECIFICATIONS

This section explains the AJ71PB92D/A1SJ71PB92D the general specifications, performance

specifications, and transmission specifications.

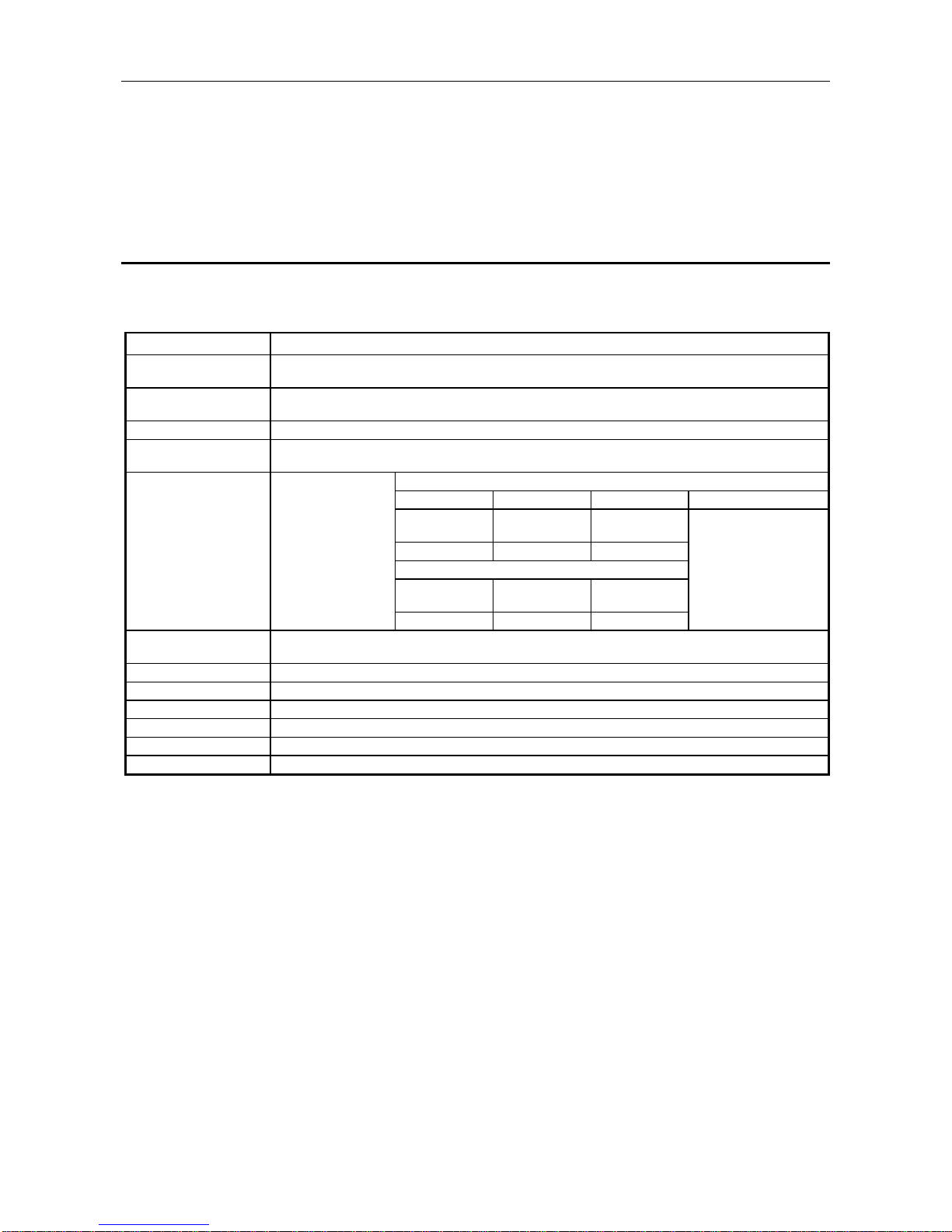

3.1 General Specification

This section explains the AJ71PB92D/A1SJ71PB92D general specifications.

Table 3.1 General Specification

Item Specification

Usage environment

temperature

0 to 55

°

C

Storage environment

temperature

-20 to 75

°

C

Usage environment humidity 10 to 90%RH, No condensation formation

Storage environment

humidity

10 to 90%RH, No condensation formation

When there is intermittent vibration

Frequency Acceleration Amplitude Sweep count

10 to 57Hz —

0.075mm

(0.003in.)

Anti-vibration 57 to 150Hz 9.8m/s

2

—

Where there is continuous vibration

10 to 57Hz —

0.035mm

(0.001in.)

57 to 150Hz 4.9m/s

2

—

Anti-shock

Complies with JIS B3501, IEC61131-2

(147m/s

2

, 3 times in the direction for each of X, Y, Z)

Usage environment No corrosive gas, etc.

Usage altitude 2000m or less

Installation location Inside the control panel

Over voltage category *

1

II or less

Pollution level *

2

2 or less

Cooling method Self cooling

*1 Shows if an estimate has been made for which distribution areas the connections will be done for

the equipment from the public power grid to the equipment installation area inside the

configuration.

Category II applies to equipment that receives its power from fixed facilities. The surge

resistance voltage for equipment rated to 300V is 2500V

*2 Shows the index for inductive matter generation in the environment in which the equipment is

used. Pollution level 2 is for dirt that is non-inductive. However, occasionally inductance can be

generated in the environment by condensation.

Complies with JIS

B3501, IEC61131-2

10 times in each direction

for X, Y, Z (80 minutes)

Page 19

3. SPECIFICATIONS MELSEC-A

3-2

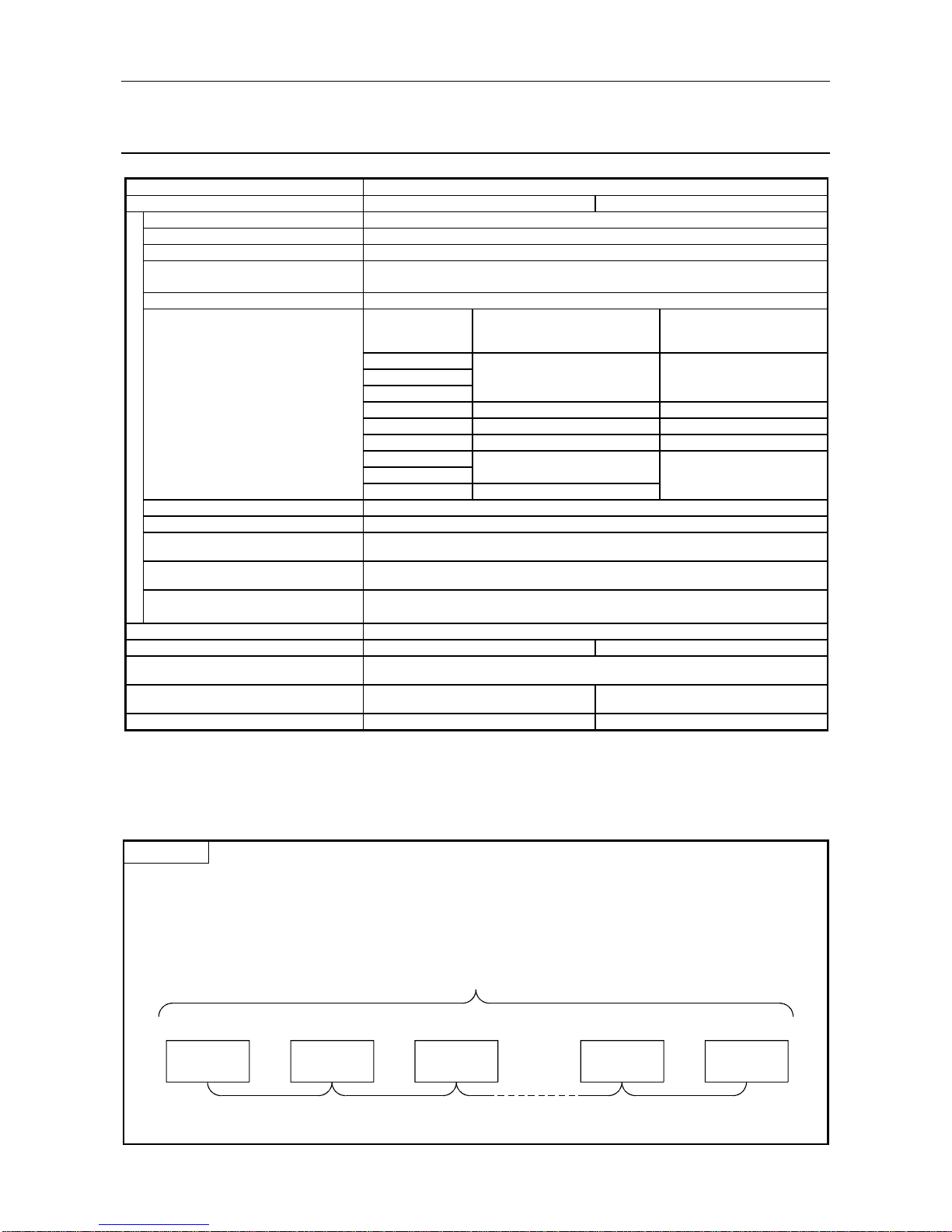

3.2 Performance Specifications

Item Specifications

Model AJ71PB92D A1SJ71PB92D

Electrical standards and characteristic s Complies with EIA-RS485

Medium Shielded twisted cable

Network configuration Bus (however, tree type when a repeater is used)

Data link method • Token passing method (master side)

• Polling method (master/slave side)

Transmission encoding method NRZ

Transmission speed Transmission distance [m/segm ent ]

Maximum transmission distance

when 3 repeaters are used

[m/network]

9.6 [kbps]

19.2 [kbps] 1200 4800

Transmission speed/maximum 93.75 [kbps]

transmission distance *1 *2 187.5 [kbps] 1000 4000

500 [kbps] 400 1600

1.5 [Mbps] 200 800

3 [Mbps]

6 [Mbps] 400

12 [Mbps] 100 *3

Maximum number of repeaters/network 3 units *2

Maximum number of stations/segm ent 32 stations * 3 (See "Point ")

Maximum number of slave stat ions / m as t er

station

60 slaves

Number of connection nodes (number of

repeaters)

32, 62 (1), 92 (2), 126 (3)

Transmittable data

32 bytes/1 station (Normal service mode)

244 bytes/1 station (Extemded service m ode)

Number of occupied I/O 32 points (I/O allocation : special 32 points)

5VDC Internal current consumption 0.54 A 0.56 A

Noise durability, dielectric withstand voltage

insulation resistor

Depending on the AJ71PB92D/A1SJ71PB92D installation system power supply module

specifications. (refer to the CPU Module User's Manual. )

External dimensions

250 mm (9.84 in.)(H) × 37.5 mm (1.48 in.)(W)

× 106 mm (4.17 in.)(D)

130 mm (5.12 in.)(H) × 34.5 mm (1.36 in.)(W)

× 93.6 mm (3.69 in.)(D)

Weight 0.37 kg 0.27 kg

*1 Transmission speed control within +/- 0.3% (PROFIBUS part 1)

*2 Distance that the transmission distance can be expanded by (m/network) using repeaters

Maximum transmission distance (m/network) = (number of repeaters + 1) × transmission distance (m/segment)

*3 The *3 restriction will cease to exist when the system is configured exclusively by the master and slave stations of

the hardware version B or later versions.

Point

*3 When using 12Mbps transmission speed, restriction of the cable length and the number of connector stations

described below is necessary.

1) Minimum length of the cable between stations is greater than or equal to one meter.

2) Maximum number of the connection stations are smaller than or equal to 11.

Master Slave Slave Slave Slave

2)

1)1) 1)

100

Transmission specification

s

Page 20

3. SPECIFICATIONS MELSEC-A

3-3

3.3 Network Configuration

3.3.1 Basic configuration

1) Equipment types

• Class 1 master

• Configurator

• Slave

• Repeater

2) Number of units that can be connected to the entire network (when repeaters are used)

Master+slave ≤ 126 units

3) Number that can be connected for 1 segment

Master+slave+repeaters ≤ 32 units

4) Communications can be conducted via a maximum of 3 repeaters from an arbitrary master or

arbitrary slave to an arbitrary master or arbitrary slave (Not 3 units in the entire network).

5) The maximum number of slaves that can be connected to 1 AJ71PB92D/A1SJ71PB92D is 60

stations.

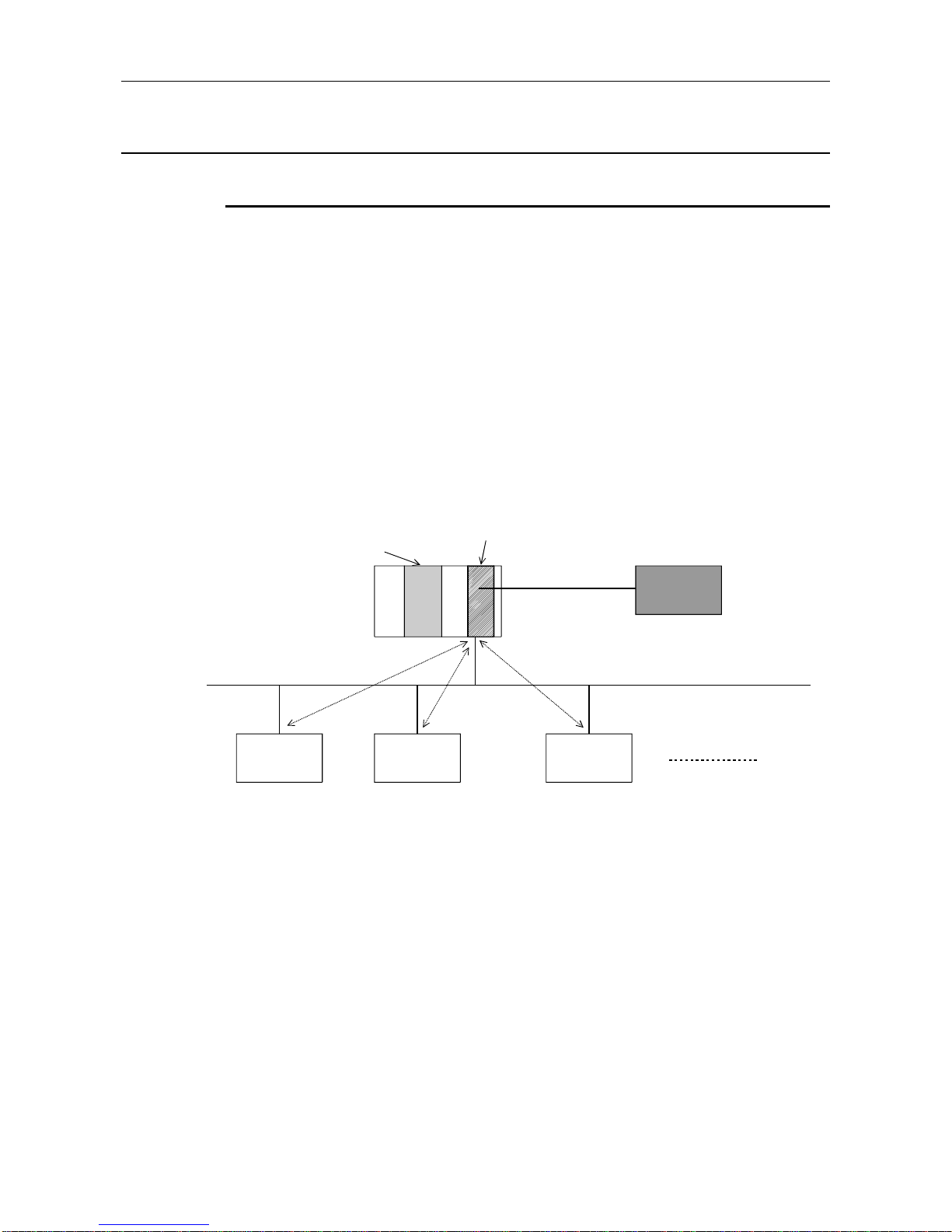

CPU module

Master (class 1)

AJ71PB92D

A1SJ71PB92D

Configurator

Slave Slave Slave

• The PROFIBUS-DP cable is provided by the user.

Page 21

3. SPECIFICATIONS MELSEC-A

3-4

3.3.2 Applicable configuration

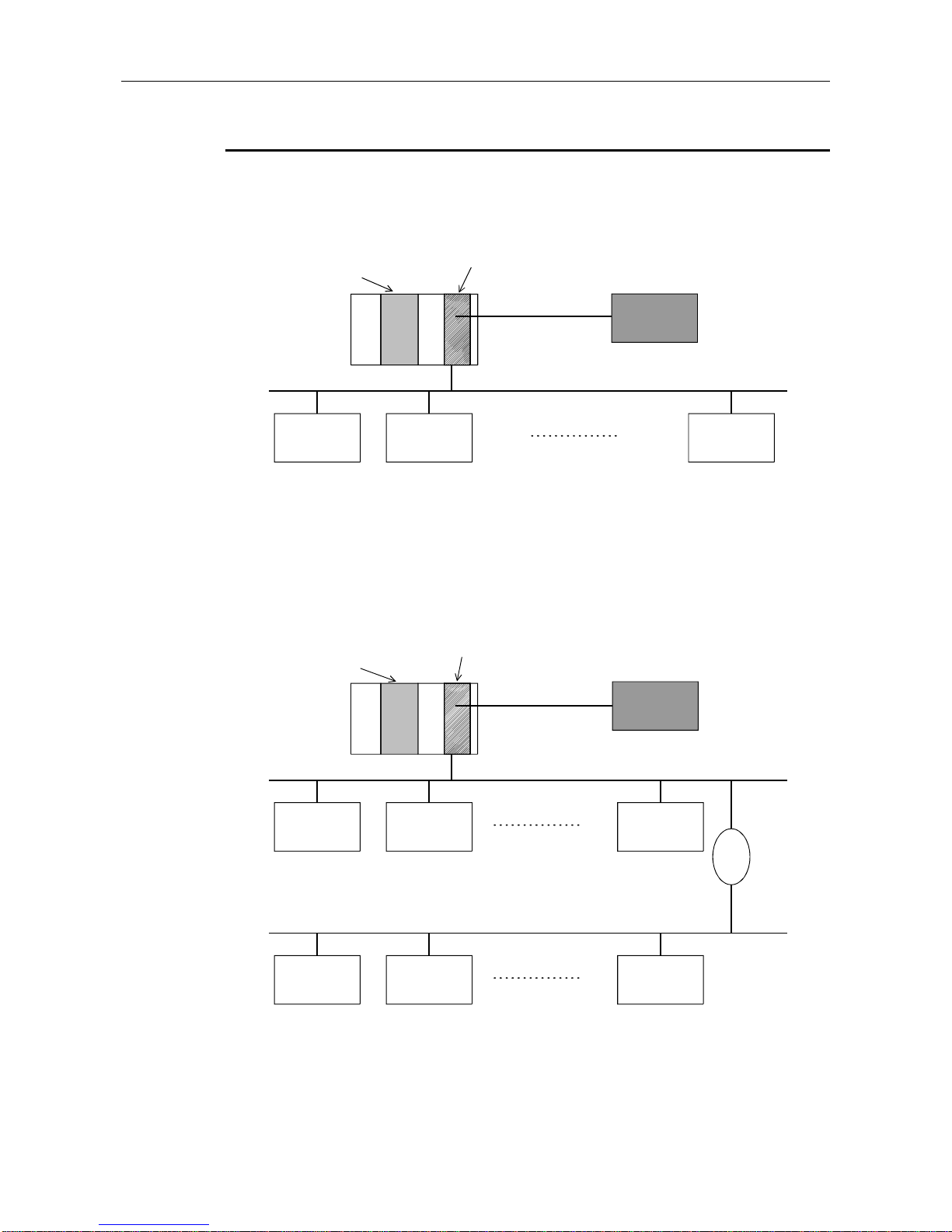

1) When 1 master (class 1) station is connected

Master (class 1)

AJ71PB92D

A1SJ71PB92D

CPU mlodule

Configurator

Slave

Slave Slave

Station No. 1 Station No. 2 Station No. 31

*: A maximum of 32 stations can be connected to 1 segment.

2) When 1 master (class 1) station and 1 repeater are connected

Master (class 1)

AJ71PB92D

A1SJ71PB92D

CPU module

Configurator

Slave

Station No. 1

Slave

Station No. 2

Slave

Station No. 30

Slave

Station No. 31

Slave

Station No. 32

Slave

Station No. 60

Repeater

*: In the above configuration a maximum of 60 slaves can be connected.

Page 22

3. SPECIFICATIONS MELSEC-A

3-5

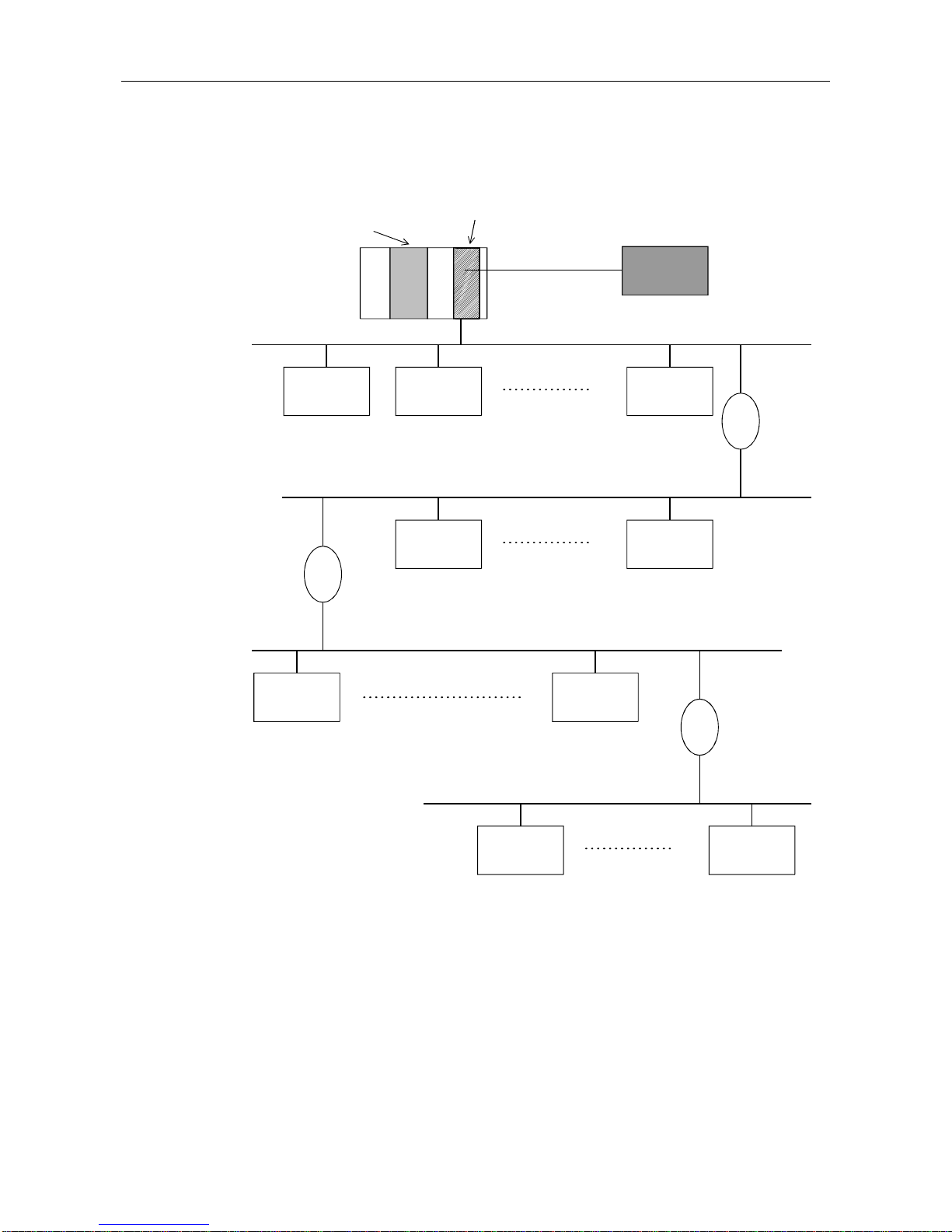

3) When 1 master (class 1) station and 3 repeaters are connected

Master (class 1)

AJ71PB92D

A1SJ71PB92D

CPU module

Configurator

Slave

Station No. 19

Slave

Station No. 35

Slave

Station No. 36

Slave

Station No. 44

Slave

Station No. 45

Slave

Station No. 60

Slave

Station No. 1

Slave

Station No. 2

Slave

Station No. 18

Repeater

Repeater

Repeater

*: In the above configuration a maximum of 60 slaves can be connected. The difference between

this configuration and the one in 2) is that the possible communication distance can be

extended.

Page 23

3. SPECIFICATIONS MELSEC-A

3-6

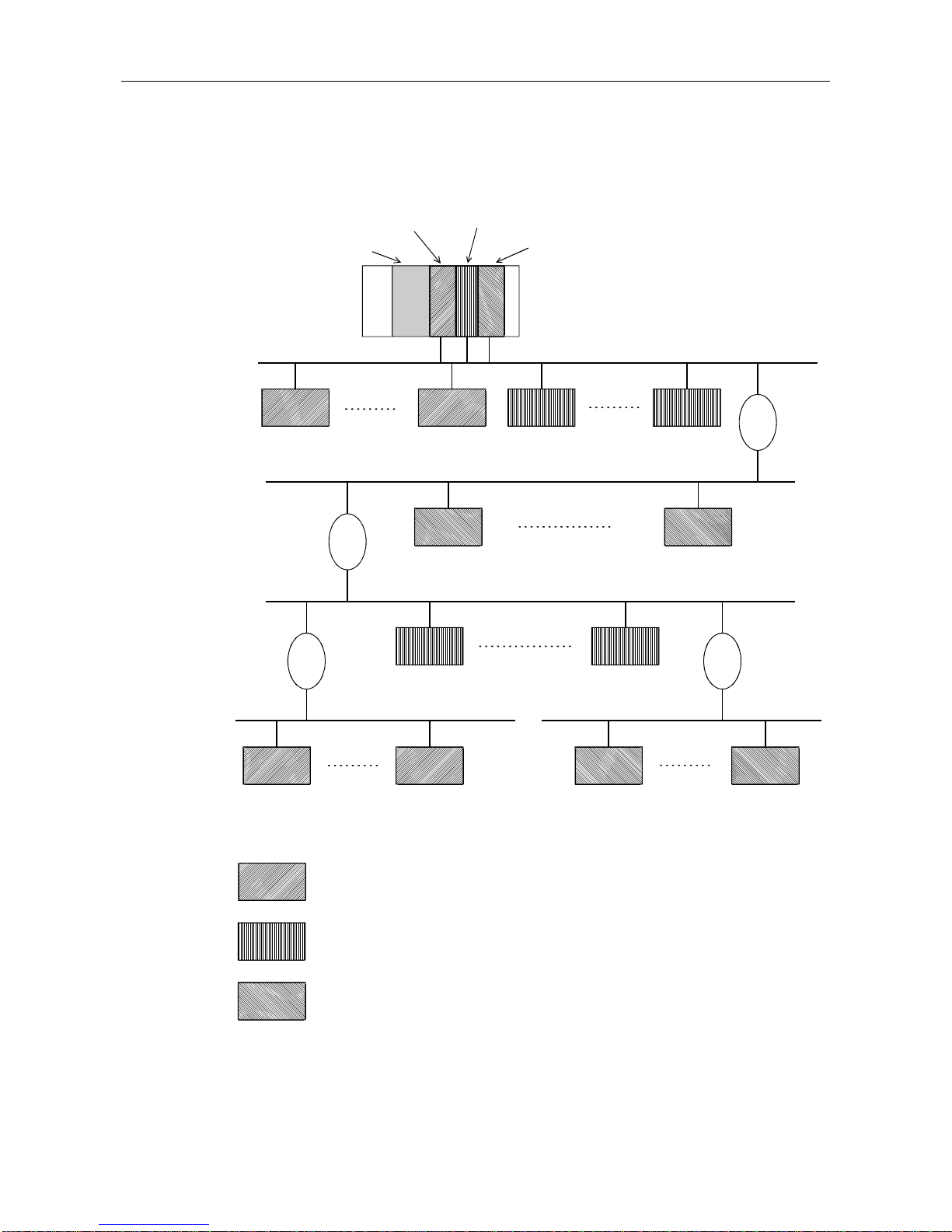

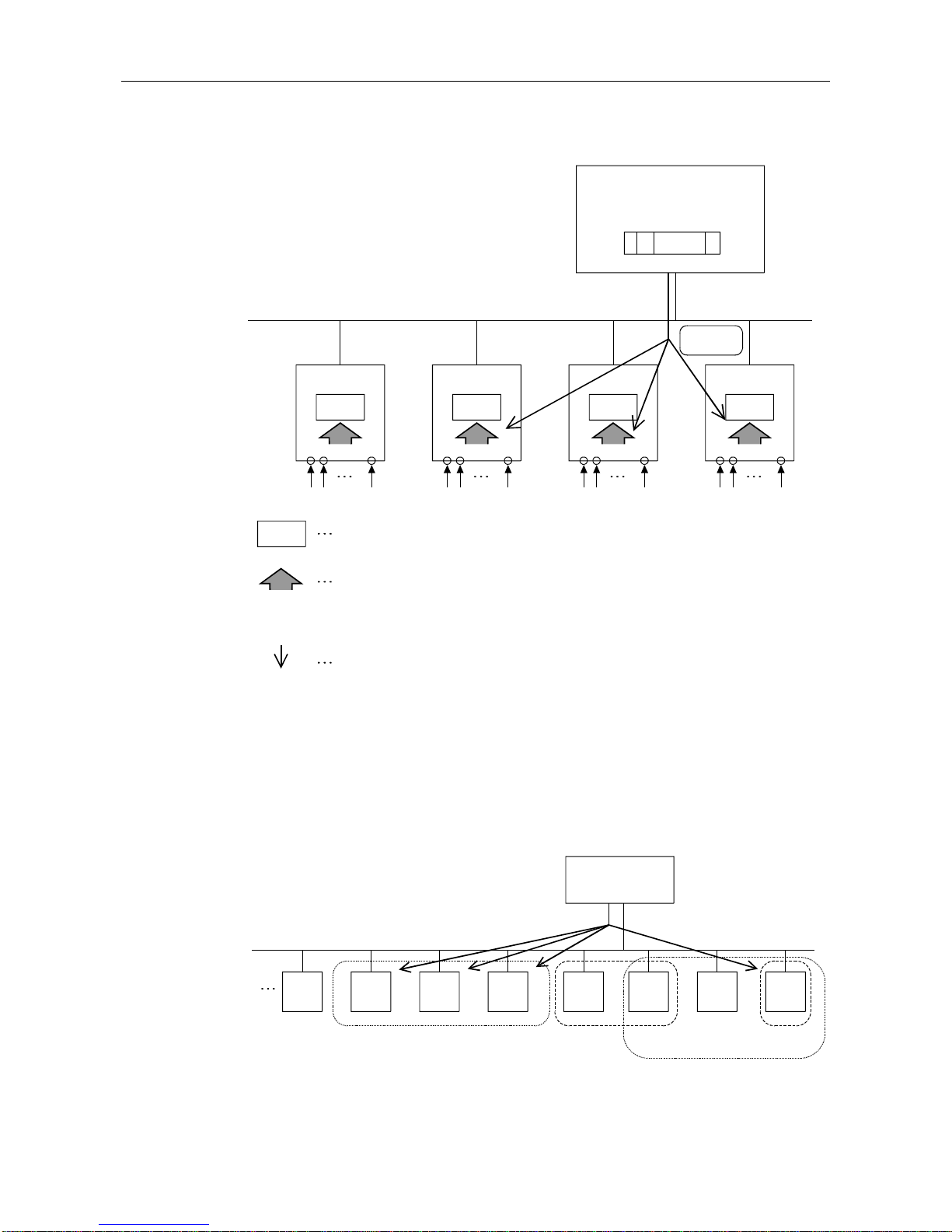

4) When 126 master (class 1) and slave stations are connected

(When 60 or more slaves are connected)

CPU module

Slave

Station No. 1

Slave

Station No. 19

Slave

Station No. 56

Slave

Station No. 57

Slave

Station No. 85

Slave

Station No. 86

Slave

Station No. 107

Slave

Station No. 108

Slave

Station No. 123

Slave

Station No. 14

Slave

Station No. 15

Slave

Station No. 18

Repeater

Repeater

Repeater

1st master

(class 1)

2nd master

(class 1)

3rd master

(class 1)

: This slave is controlled by t he 1st master (class 1).

: This slave is controlled by t he 2nd master (class 1).

: This slave is controlled by t he 3rd master (class 1).

Repeater

*: In the above configuration a maximum of 123 slave stations can be connected.

Page 24

3. SPECIFICATIONS MELSEC-A

3-7

Point

In configurations that use multiple master stations (multimaster configuration), when reconnecting

a cable after disconnecting a PROFIBUS cable for 1 master that is exchanging data at a low baud

rate, the communications of the master for which the cable is not disconnected could stop and

the slave output could be turned off. To prevent this, the master PROFIBUS cable must be

secured with a screw.

In addition, there is a high possibility that the above phenomena can be avoided if care is taken

with the following points when configuring a system.

(1) Set the slave watchdog timer setting value to larger than (T

T

r × G)/BR. However,

TTr : Target token rotation time (Unit: Bit Time)

G : Gap update factor

BR : Baud rate (Unit: bps)

(2) Use a high baud rate.

(3) The HSA (Highest Station Address) value is made to match the maximum station No. that is

actually connected.

Page 25

3. SPECIFICATIONS MELSEC-A

3-8

3.3.3 Number of connectable slaves

Please calculate the number of the slave which can be connected under the following

(1) and (2) conditions.

(1) Restrictions on maximum data length of slave station error

information

The maximum data length of the slave station error information that the

AJ71PB92D/A1SJ71PB92D can receive varies with the minimum station number

and maximum station number of the slave stations set in the parameters, and can

be calculated using the following expression.

Maximum data length of acceptable error information [bytes] = Min

12600

N - 10

, 244

N = Min((a - b + 1) 5, 300)

a: Maximum station number of slave station

b: Minimum station number of slave station

: Min(a, b) = A or B, whichever is smaller

If the maximum data length (Max_Diag_Data_Len) of the error information

described in the GSD file of a slave station is greater than the value calculated by

the above expression, normal communication may not be made with that slave

station.

If normal communication cannot be made, try the following methods:

(a) Set the station numbers of the slave stations with no unused numbers in

between.

(b) Make setting on the slave station side to shorten the maximum data length of

the error information. (If possible)

(c) Using two or more AJ71PB92D/A1SJ71PB92D, reduce the number of slave

stations per module.

(2) Restrictions on parameter data length of slav e stati on

The parameter size which can be set in AJ71PB92D/A1SJ71PB92D should meet

the following formula.

Note that the system construction which does not meet the following formula

causes the error of 1302

H

.

5 +

i = 1

n

(number of parameter blocks of each slave station) 128

n = number of slave stations

(number of parameter blocks of each slave station) = sum total of the numbers of parameter

blocks calculated by each slave station

Page 26

3. SPECIFICATIONS MELSEC-A

3-9

The number of parameter blocks for each station is decided by the parameter size

of the station as follows.

Parameter size of each

slave station

Number of blocks of each

slave station

246 bytes or less 1 block

247 to 480 bytes 4 blocks

481 to 720 bytes 5 blocks

721 to 762 bytes 6 blocks

Calculate the parameter size of each slave station using the following formula.

Parameter size of each slave station = 31 + (User_Param data length)

+ (configuration data length) +

(a) User_Param data length

The value of User_Prm_Data usage on the screen displayed when Select

Modules is selected on the slave station setting screen of GX ConfiguratorDP.

(b) Configuration data length

The value differs depending on the slave station type as shown below.

1) Module type slave station

Sum of the number of Module set values, which are described in the

GSD file of the slave station, of the modules registered to the [slot]

Installed Module list.

SD file descriptio n

Module="1 Word In,con word" 0x50

Module="1 Word Out,con word" 0x60

Number of set values is "1"

Number of set values is "1"

Configuration

data length is

"2".

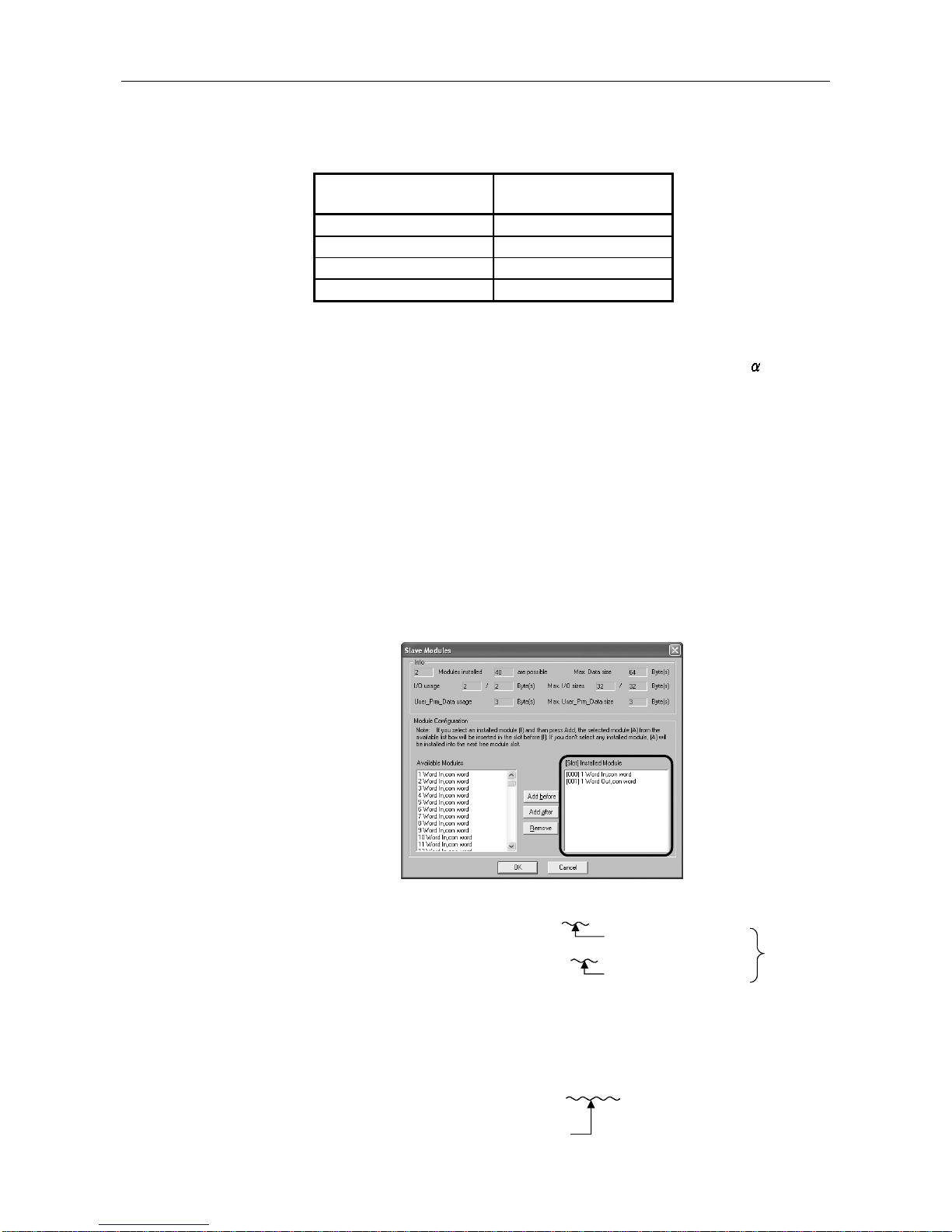

(Example) [slot] Installed Module registration status of GX Configurator-DP

2) Block type slave station

Number of Module set values described in the GSD file of the slave

station.

(Example) GSD file description

Module="1 Byte Out,3 Byte In" 0x20,0x12

As the number of set values

is "2", the configuration data

len

g

th is "2".

Page 27

3. SPECIFICATIONS MELSEC-A

3-10

(c)

(constant)

= 2 : When the slave station has only input or output

= 4 : When the slave station has both input and output

(example)

When the system is constructed using only the stave stations with 520 bytes

parameter, AJ71PB92D/A1SJ71PB92D can be connected up to the following

number of the slave stations.

When the parameter size is 520 bytes, the number of the parameter block is five.

5 + (5

n) 128 : n = number of slaves

n = 24.6

128 - 5

5

n = 24

The calculation mentioned above tells that AJ71PB92D/A1SJ71PB92D can be

connected up to 24 slave stations.

Therefore, when 25 slave stations or more are set by the parameter,

AJ71PB92D/A1SJ71PB92D detects the error of 1302

H

.

Page 28

4. FUNCTIONS MELSEC-A

4-1

4. FUNCTIONS

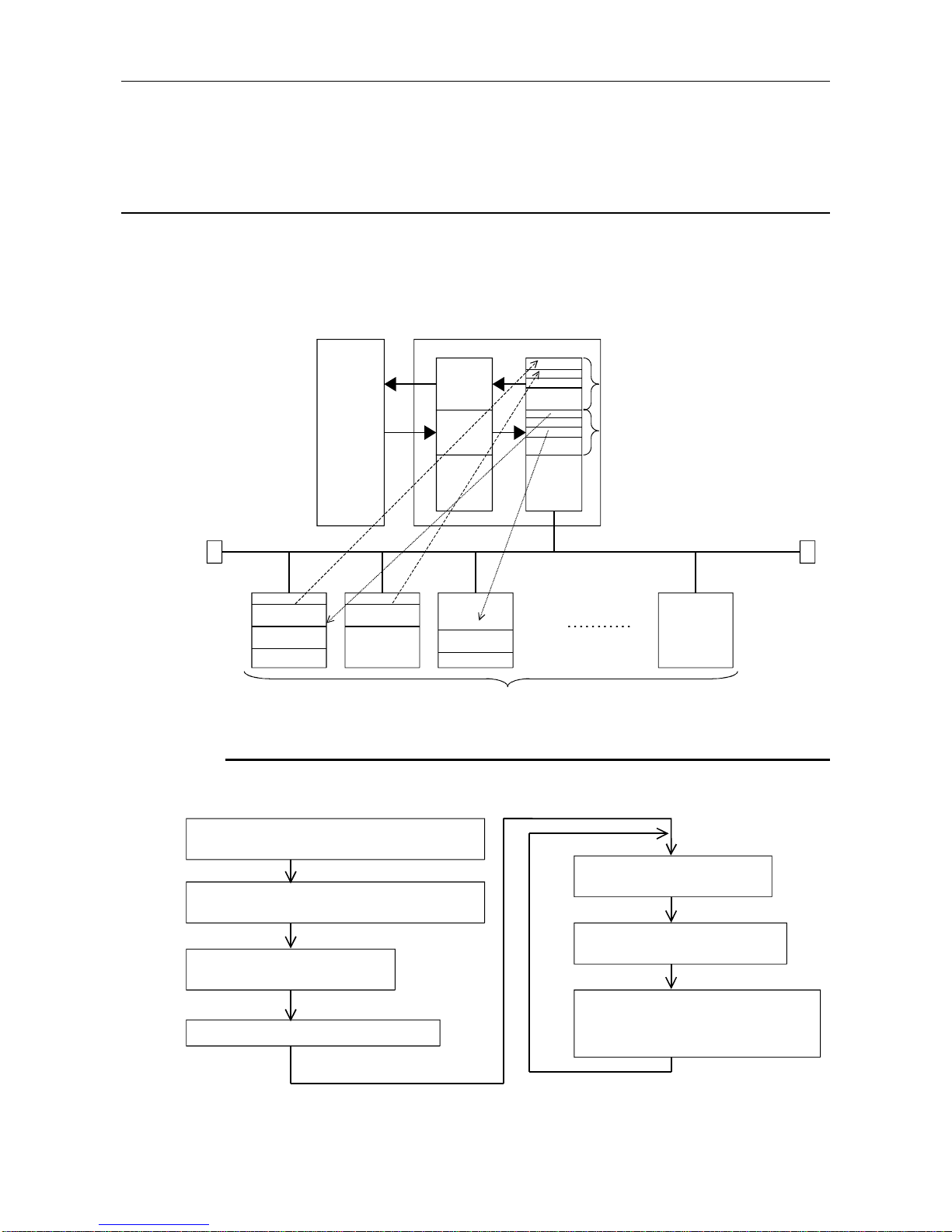

4.1 Functions for Exchanging with Slaves

The main function in the AJ71PB92D/A1SJ71BP92D is for exchanging I/O data with slave stations

connected to the PROFIBUS-DP network. The method used for this exchange is to read/write the I/O

image in the buffer memory using FROM/TO instructions.

A schematic drawing of this exchange function is as follows.

CPU module

AJ71PB92D/

A1SJ71PB92D

(Class 1 master)

FROM

TO

Buffer memory

Input

image

Output

image

Input

image

Output

image

Input image Input image

Output image

Output image

PROFIBUS-DP network

Slave stati on

4.1.1 Exchange flow

The I/O data exchange flow with slave station is shown below.

* The buffer memory refresh with the FROM/TO instructions is conducted asynchronously.

Set the slave troubl e in fo rm ation cancel area.

(Setting is unnecessary if the default value can be left

unchanged.)

Communication trouble area type selection

(This setting is unnecessary if the default value can

be left unchange d.)

Write the initial OUTPUT dat a value in

the output area.

Turn ON the exchange start request signal (Y00).

Check that the exchange start/end

signal (X00) is ON.

Read the input dat a from the input area

using the FROM instruction.

Write the OUTPUT data in the output area in the

buffer memory using the TO instruction.

Page 29

4. FUNCTIONS MELSEC-A

4-2

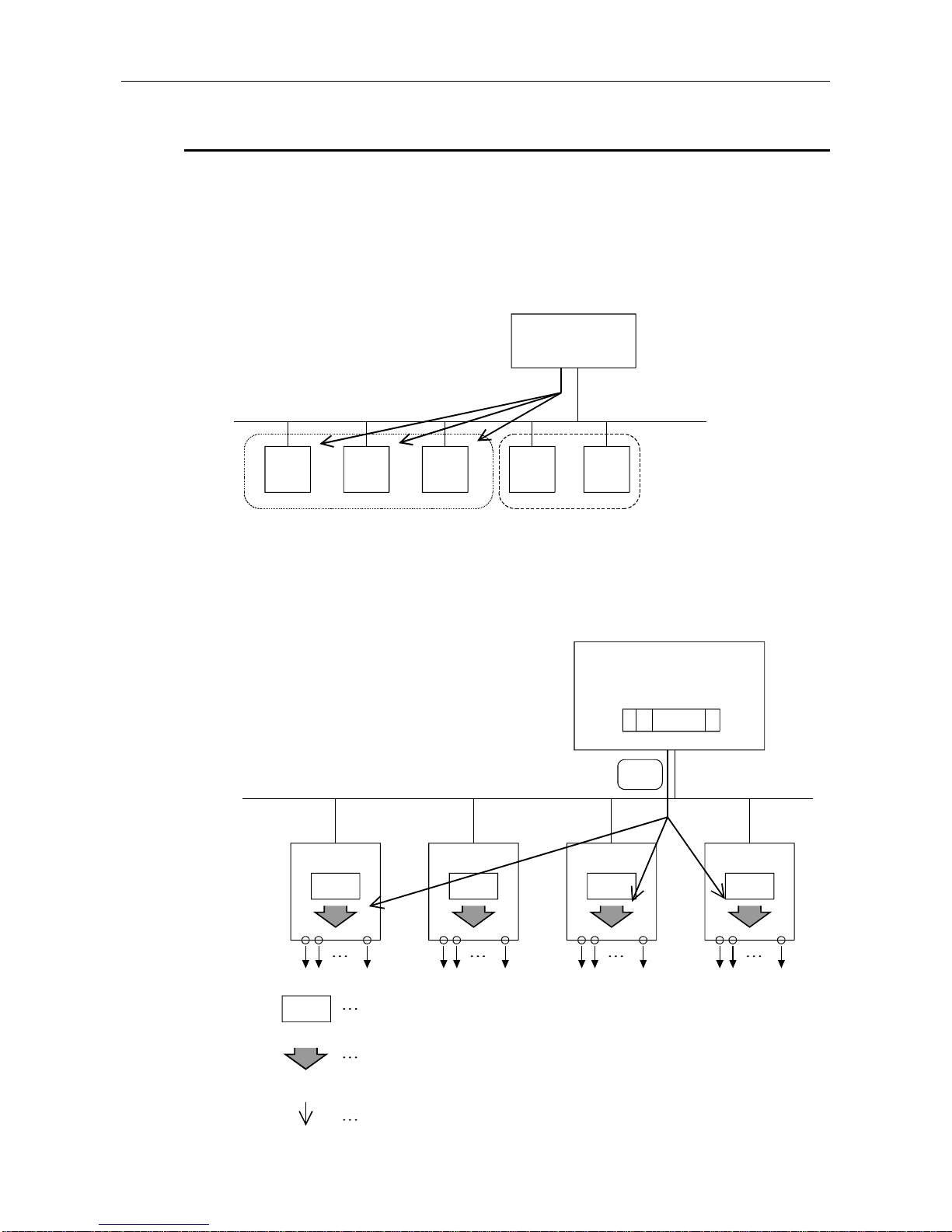

4.1.2 Global control functions

Global control contains the four functions of SYNC, UNSYNC, FREEZE, and UNFREEZE, which are

functions that are used to maintain/cancel slave I/O for which multicast communication is conducted at

the same time.

The slaves that execute the global control function are those located in one or more groups of the

eight groups. The group No. of the group containing the slaves is set by the configurator. In the

AJ71PB92D/A1SJ71PB92D the group can be arbitrary specified and the global control commands

transmitted using multicast communication. This makes is possible to select a slave and conduct

global control.

Master

PROFIBUS-DP network

Group 1

Group 5

The global control function is executed using X, Y, and FROM/TO instructions from the sequence

program.

(1) Service SYNC, UNSYNC

Master

(SYNC transmission to group 1)

Output data

SYNC

(Group 1) (Group 2)

(Group 1)

(Group 1)

Slave 1 Slave 2 Slave 3 Slave n

Output image memory: Data is always refreshed using polling.

<During UNSYNC execution/default>The output image memory value is output unchanged

(normal condition)

<During SYNC execut ion>The output image memory value is only output once during the

SYNC service timing.

Service SYNC (issued in the same group)

Page 30

4. FUNCTIONS MELSEC-A

4-3

(2) Service FREEZE, UNFREEZE

(Group 8)

Slave 1

(Group 3)

Slave 2

(Group 3)

Slave 3

(Group 3)

Slave n

Master

(FREEZE transmission to group 3)

Input data

FREEZE

Input image memory: The data is always refreshed by polling.

<during FREEZE cancel/default>The actual input is input to the input memory unchanged

(normal condition)

<during FREEZE execute>The actual input is input once into the input image memory at the FREEZE

service timing.

Service FREEZE (issued within the same group)

(3) Group selection

• The number of groups is from 1 to 8 if with a total of 8 groups.

• The slave can exist in arbitrary group of the 8 groups. They can also exist in multiple groups.

(The configurator specifies in which group which slaves exist.)

• Multiple groups can be arbitrarily selected from the sequence program and global control

executed.

• When selecting group 0 and transmitting the service is transmitted to all slave stations.

Master

(transmitted to

groups 1 and 2)

PROFIBU S-DP network

Slave

Group 1

Group 5

Group 2

Group 8

Page 31

4. FUNCTIONS MELSEC-A

4-4

(4) Procedure for issuing a global service.

Sequence

program

A1SJ71PB92D Slave

TO global control area

Turn on the global co ntr o l

request signal (Y04).

Turn on the global co ntr o l

end signal (X04).

Time

Global control service

AJ71PB92D

Page 32

4. FUNCTIONS MELSEC-A

4-5

4.2 I/O Signal

4.2.1 I/O signal list

The I/O signal configuration used in the AJ71PB92D/A1SJ71PB92D and the data communications

with the PLC CPU are described below.

Signal direction: AJ71PB92D/A1SJ71PB92D

→→→→

PLC CPU Signal direct ion: PLC CPU

→→→→

AJ71PB92D/A1SJ71PB92D

Device No. Description Device No. Description

X00 Exchange start end signal Y00 Exchange start request signal

X01 Communication trouble detection signal Y01 Communication trouble det ec t ion s ignal res et

X02 Communication trouble area clear end signal Y02 Communication trouble area clear request signal

X03 Not usable Y03 Communication trouble area t ype selec tion

X04 Global control end signal Y04 Global control request signal

X05 Global control error end

X06

…

……

…

X0C

Not usable

Y05

……

…………

……

Y0C

Not usable

X0D W at c hdog t im er error s ignal Y0D St art up reques t s ignal

X0E

X0F

Not usable

X10 Operation mode signal

Y0E

…

……

…

Y10

Not usable

X11 Operation mode change completion signal Y11 Operation mode change request signal

X12

…

……

…

X1A

Not usable

X1B Communication READY signal

X1C Not usable

X1D Module READY signal

X1E to X1F

Not usable

Y12

…

……

……

……

……

……

……

……

……

……

……

……

…

Y1F

Not usable

Point

If a device which is not usable is accidentally turned on and off in the sequence program, it

cannot guarantee as the AJ71PB92D/A1SJ71PB92D function.

Page 33

4. FUNCTIONS MELSEC-A

4-6

4.2.2 I/O signal detail description

(1) Exchange start request signal (Y00), exchange start end signal (X00)

(a) After the exchange start request signal (Y00) is turned on by the sequence program the

exchange start end signal (X00) is turned on when cyclic exchange starts.

(b) The exchange start end signal (X00) turns off in either of the following cases.

• When the exchange start request signal (Y00) is turned off

• When the parameters are written from the configurator to the AJ71PB92D/A1SJ71PB92D

Exchange start request sign al (Y00)

Exchange start end signal (X00)

Exchange start

request

Exchange start end

Maximum 200 ms

Exchange

(c) An interlock is used for FROM/TO of the I/O data.

(d) Before the exchange start request signal is turned on the output data initial value must be

written to the buffer memory.

(2) Communication trouble detection signal (X01), communication trouble detection signal

reset (Y01)

(a) The communication trouble detection signal (X01) is turned on when a communication

trouble occurs. At the same time the RSP ERR.'s LED turns on. At this time the error code

and detailed data are stored in the buffer memory communication trouble area.

(b) The communication trouble detection signal (X01) is turned off when the communication

trouble detection signal reset signal (Y01) is turned on from the sequence program or when

communication failure is all resolved. At this time, the RSP ERR. LED is turned off.

(c) The communication trouble detection signal reset (Y01) is turned off by the sequence

program after it has been confirmed that the communication trouble detection signal (X01)

has been turned off.

(d) The following sequence is used.

Communication trouble detection signal reset (Y01)

Communication trouble detection signal (X01)

Trouble detection

Trouble detection reset

FROM

The error code is read from the buffer memory to the PLC CPU.

FROM/TO

Page 34

4. FUNCTIONS MELSEC-A

4-7

(3) Communication trouble area clear request (Y02), communication trouble area clear end

(X02)

(a) The communication trouble area clear request (Y02) is turned on by the sequence program

when all of the communication trouble areas and extension trouble areas are cleared.

(b) The communication trouble clear end signal (X02) is turned on after all of the communication

trouble area and extension trouble areas are cleared by turning on the communication

trouble area clear request signal (Y02).

(c) The communication trouble area clear request (Y02) is turned off by the sequence program

after it has been confirmed that the communication trouble area clear end signal (X02) has

been turned on.

(e) When the communication trouble area clear request signal (Y02) is turned off the

communication trouble area clear end signal is turned off.

(d) A sequence like the one below is used.

Communication trouble area clear request (Y02)

Communication troublev area clear end (X02)

Clear request

Clear end

(4) Global control request signal (Y04), global control end signal (X04)

(a) The global control end signal (X04) is turned on after service processing has ended when

the global control request signal (Y04) is turned on by the sequence program.

(b) The global control request signal (Y04) is turned off by the sequence program after it has

been confirmed that the global control service end signal (X04) has turned on.

(c) When the global control request signal (Y04) is turned off the global control end signal (X04)

turns off.

(d) The global control request signal (Y04) cannot be received if the exchange starting (X00) is

not on. If Y04 is turned on when X00 is off then both X04 and X05 will turn on.

(e) A sequence like the one below is used.

Global control request

X00

Global control end

TO

Output data write

Exchange start end signal (X00)

Global control request signal (Y04)

Global control end signal (X04)

(5) Global control error end signal (X05)

(a) If global control is requested when exchange start (X00) is not on then global control error

end (X05) and the global control service end signal (X04) will turn on at the same time.

(b) The slave I/O is not held/deleted when the global control error end signal (X05) is on.

Global control request

Global control end

Global control error end

Global control request signal (Y04)

Global control end signal (X04)

Global control error end signal (X05)

Page 35

4. FUNCTIONS MELSEC-A

4-8

(6) Watchdog timer error end (X0D)

(a) This turns on when a Watchdog timer error occurs.

(b) This will not turn off until the module is reset or its power supply is turned off and on.

(7) Operation mode signal (X10)

Indicates whether the current operation mode is the parameter setting mode or not.

ON: Parameter setting mode

OFF: Normal service mode/extended service mode

(8) Operation mode change request signal (Y11), operation mode change completion signal

(X11)

Used to change the operation mode without resetting the CPU module.

This function is valid only when a start is made with the mode setting switch in the 0, 1 or E

position.

(a) Operation mode change request signal (Y11)

OFF¨ON: Requests the operation mode to be switched to the one specified in the

operation mode change request area (address 2255/8CFh) of the buffer memory.

ON¨OFF: Turns off X11.

(b) Operation mode change completion signal (X11)

Turns on when the result is stored into the operation mode change result area (address

2256/8D0h) of the buffer memory. This signal also turns on on normal or abnormal

completion of an operation mode change.

This signal turns off when Y11 turns from ON to OFF.

(9) Communication READY signal (X1B)

(a) This is turned on when the station enters the exchange start possible state after the

AJ71PB92D/A1SJ71PB92D has started up and the module READY signal (X1D) has turned

on. (Only during the normal transmission mode.)

(b) This turns off when a exchange continuation impossible error occurs.

(c) The exchange start request signal (Y00) is used as an interlock when turned on by the

sequence program.

(10) Module READY signal (X1D)

(a) This is turned on when the AJ71PB92D/A1SJ71PB92D is started up.

Therefore, it is turned on regardless of the operation mode.

(b) This is turned of when the AJ71PB92D/A1SJ71PB92D goes down.

(11) Communication trouble area type selection (Y03)

(a) This is used to select the communication trouble area type (ring type or fixed type).

(b) This is turned off when ring type is selected and on when fixed type is selected.

(c) This signal becomes valid when the exchange start or communication trouble area clear

request (Y02) is on.

Communication trouble area

type selection (Y03)

Fixed type

selection

Ring type selection

Initial type

(Becomes valid)

Exchange start or communication

trouble area clear request (Y02) on

(12) Restart request signal (Y0D)

(a) When the AJ71PB92D/A1SJ71PB92D goes down for some reason (when the FAULT LED

turns on and X1D is off) then turning Y0D from off to on to off again will make it possible to

restart the AJ71PB92D/A1SJ71PB92D.

(b) The same state will be entered if after start up the power supply is turned off and then on

again.

Page 36

4. FUNCTIONS MELSEC-A

4-9

4.3 Buffer Memory List

4.3.1 Buffer memory/configuration

The configuration of the buffer memory used to receive and send data with the AJ71PB92D/

A1SJ71PB92D and the PLC CPU is described below.

Buffer memory address

(decimal/hexadecimal)

0/

959/

0h

3BFh

Input area

(Description)

This is the area that stores the input data from the slave.

960/

1919/

3C0h

77Fh

Output area

(Description)

This is the area that stores the output data to the slave.

1920/

2039/

780h

7F7h

Address information area

(Description)

This is the area that shows the slave address and I/O data length.

2040/

2079/

7F8h

81Fh

Communication trouble area

(Description)

This is the area that shows the trouble information that occurred during communication.

2080/ 820h Slave error information cancel area

(Description)

This is the area that sets the data that masks the slave trouble information.

2081/ 821h Global control area

(Description)

This is the global control function hold/cancel selection area.

2082/ 822h Not usable

2083/ 823h Time out time setting area (Closed to users because this is a debugging function.)

(Description)

This is used to set the time out time when an exchange start/stop is executed.

2084/ 824h Trouble no information time setting area

(Description)

This is used to set the time that does not inform the communication trouble after the exchange start.

2085/

2095/

825h

82Fh

Not usable

2096/

2110/

830h

83Eh

Expansion communication trouble area

(Description)

This area shows the expansion information of the trouble information which is occurred during the

communication.

2111/ 83Fh Not usable

2112/ 840h Slave status area

(Description)

2116/ 844h This is the area that shows the status information of each slave.

2117/

2127/

845h

84Fh

Not usable

2128/

2247/

850h

8C7h

Input/Output start address area (Extended service mode only)

(Description)

This is the area that shows the addresses to start the input area and output area of each slave.

2248/

2253/

8C8h

8CDh

Not usable

2254/ 8CEh Current operation mode

(Description)

This area indicates the operation mode of the AJ71PB92D/A1SJ71PB92D when it has started up.

2255/ 8CFh Operation mode change request area

(Description)

In this area, set the operation mode of the AJ71PB92D/A1SJ71PB92D which you want to choose.

2256/ 8D0h Operation mode change result area

(Description)

This area indicates the execution result of the operation mode change request.

2257/

3775/

8D1h

EBFh

Not usable

Point

Don't read and write to the buffer memory which is not usable.

If you perform it, it cannot guarantee as the AJ71PB92D/A1SJ71PB92D function.

Page 37

4. FUNCTIONS MELSEC-A

4-10

4.3.2 Buffer memory detailed description

(1) INPUT area

Either normal service mode or extended service mode can be selected via the mode switch on

the main unit.

(a) Normal service mode (MODE switch : No. 0)

This is the area that stores the input data from the slave station.

This area is fixed to an allocation of 32 bytes (16 words) per station for a total of 60 stations

worth. This input area configuration is as follows.

Example : When the input data length for the first station is set to 29 bytes and that for the

second station to 32 bytes

Address

Address

1st station input data

2nd station input data

n th station input data

60th station input data

1st station 2nd byte

1st station 4th byte

1st station 1st byte

1st station 3rd byte

1st station 29th byte

b15

b0

2nd station 2nd byte

2nd station 4th byte

2nd station 1st byte

2nd station 3rd byte

2nd station 30th byte

2nd station 32nd byte

2nd station 29th byte

2nd station 31st byte

b15

b0

(Upper byte)

(Lower byte)

: Free area (00h)

*1: Since the data area is fixed to 32 bytes,

all unused areas will become free.

*1

*1

0/0h

15/Fh

16/10h

31/1Fh

944/3B0h

959/3BFh

0/0h

1/1h

14/Eh

15/Fh

16/10h

17/11h

30/1Eh

31/Fh

Point

The input data of the slave station, which was disabled from communication during normal

communication and whose corresponding bit of the communication status area*1 turned ON (1),

is not stored into the input area of the AJ71PB92D/A1SJ71PB92D.

In the input area of the corresponding slave station, the data before communication failure is

held.

*1: Indicates the area of buffer memory addresses 2113 (841

H

) to 2116 (844H) in the slave status

area.

Page 38

4. FUNCTIONS MELSEC-A

4-11

(b) Extended service mode (MODE switch : No. E)

This is the area that stores the input data from the slave station.

In this area, the data length (in byte units) for each station is assigned in variable length

according to the parameter file set in the configurator software package.

The data length can be set in the range of 0 to 244 bytes.

Number of stations that can be set will vary in the range of 1 to 60, depending on the

specified data length. For example, seven stations can be set if the data length for each

station is 244 bytes, and 60 stations if the data length is 32 bytes.

Example : When the input data length for the first station is set to 23 bytes and that for the

second station to 7 bytes

Address

Address

0/0h

11/Bh

12/Ch

1st station input data

2nd station input data

n th station input data

60th station input data

1st station 2nd byte

1st station 4th byte

1st station 1st byte

1st station 3rd byte

1st station 22nd byte

1st station 21st byte

1st station 23rd byte

0/0h

10/Ah

11/Bh

2nd station 2nd byte

2nd station 4th byte

2nd station 1st byte

2nd station 3rd byte

12/Ch

13/Dh

2nd station 6th byte

2nd station 5th byte

2nd station 7th byte

14/Eh

15/Fh

1/1h

15/Fh

b15

b0

*2

b15

b0

(Upper byte)

(Lower byte)

: Free area (00h)

*2: When the data lenghth is set to an odd number

of bytes, the last upper byte becomes a free area

and data for the next station is assugned from

the next address.

Point

The input data of the slave station, which was disabled from communication during normal

communication and whose corresponding bit of the communication status area*1 turned ON (1),

is not stored into the input area of the AJ71PB92D/A1SJ71PB92D.

In the input area of the corresponding slave station, the data before communication failure is

held.

*1: Indicates the area of buffer memory addresses 2113 (841

H

) to 2116 (844H) in the slave status

area.

Page 39

4. FUNCTIONS MELSEC-A

4-12

(2) OUTPUT area

Either normal service mode or extended service mode can be selected via the mode switch on

the main unit.

(a) Normal service mode (MODE Switch : No. 0)

This is the area that stores the output data to the slave station.

This area is fixed to an allocation of 32 bytes (16 words) per station for a total of 60 stations

worth. This output area configuration is as follows.

Example : When the output data length for the first station is set to 1 bytes and that for the

second station to 3 bytes

Address

Address

960/3C0h

975/3CFh

976/3D0h

991/3DFh

1904/770h

1919/77Fh

1st station output data

2nd station output data

n th station output data

60th station output data

1st station 1st byte

b15

b0

960/3C0h

961/3C1h

974/3CEh

975/3CFh

2nd station 2nd byte 2nd station 1st byte

2nd station 3rd byte

976/3D0h

977/3D1h

991/3DFh

b15

b0

(Upper byte)

(Lower byte)

: Free area (00h)

*1: Since the data area is fixed to 32 bytes,

all unused areas will become free.

*1

*1

(b) Extended service mode (MODE switch : No. E)

This is the area that stores the output data to the slave station.

In this area, the data length (in byte units) for each station is assigned in variable length

according to the parameter file set in the configurator software package.

The data length can be set in the range of 0 to 244 bytes.

Number of stations that can be set will vary in the range of 1 to 60, depending on the

specified data length. For example, seven stations can be set if the data length for each

station is 244 bytes, and 60 stations if the data length is 32 bytes.

Example : When the output data length for the first station is set to 19 bytes and that for the

second station to 5 bytes

Address

Address

1st station output data

2nd station output data

n th station output data

60th station output data

1st station 2nd byte

1st station 4th byte

1st station 1st byte

1st station 3rd byte

1st station 18th byte

1st station 17th byte

1st station 19th byte

2nd station 2nd byte

2nd station 4th byte

2nd station 1st byte

2nd station 3rd byte

2nd station 5th byte

b15

b0

*2

b15

b0

: Free area (00h)

*2: When the data lenghth is set to an odd number

of bytes, the last upper byte becomes a free area

and data for the next station is assugned from

the next address.

(Upper byte)

(Lower byte)

960/3C0h

968/3C8h

969/3C9h

970/3CAh

971/3CBh

972/3CCh

961/3C1h

960/3C0h

969/3C9h

970/3CAh

972/3CCh

Page 40

4. FUNCTIONS MELSEC-A

4-13

(3) Address information area

This area shows the station address, input byte length, and output byte length for each slave

station. This allocation is set by the configurator. The station addresses for the 1st through the

60th stations are stored in the order of registration in the configurator. (Station addresses: 1 to

126, do not need to be sequential numbers.)

The address information area configuration is shown below. For details refer to Section 4.3.2 (4).

Address

1920/780h

1921/781h

1922/782h

1923/783h

2036/7F4h

2037/7F5h

2038/7F6h

2039/7F7h

Station address of 1st station

1st station input byte length 1st station output byte length

Station address of n station

n th station input byte length n th station output byte length

Station address of 59th station

59th station input byte length 59th station output byte length

Station address of 60th station

60th station input byte length 60th station output byte length

2nd station input byte length

2nd station output byte length

Station address of 2nd station

(a) The station address of unallocated stations is FFFFh, and the I/O byte is FFh.

(b) When the I/O byte length of allocated stations is 0, a 0 is stored for the byte length.

(c) The n does not show the station address but represents a number (the nth number) used for

the input/output area.

Page 41

4. FUNCTIONS MELSEC-A

4-14

(4) Example address information area, INPUT area, and OUTPUT area

The AJ71PB92D/A1SJ71PB92D reads the slave station address and I/O byte length set by the

parameter file which is set by the configurator and stores these in the buffer memory address

information area.

With the AJ71PB92D/A1SJ71PB92D, I/O areas are assigned to each slave station based on the

I/O byte length information in the address information area, and each I/O data will be stored in the

corresponding buffer memory area.

Example : At extended service mode

Address

Address information area

1920

1921

1922

1923

5

: Vacant area

CPU module

AJ71PB92D

A1SJ71PB92D

Slave

Slave

PROFIBUS-DP

network

Station address : 10

Input data length : 7 byte

Output data length : 5 byte

963/3C3h

Address

1st station 2nd input byte

INPUT/OUTPUT area

0/0h

1/1h

2/2h

959/3BFh

9600/3C0h

961/3C1h

1919/77Fh

IN P UT

OUTPUT

1st station1st input byte

3/3h

4/4h

5/5h

6/6h

1st station 3rd input byte

2nd station 2nd input byte

2nd station 1st input byte

2nd station 4th inp ut byte

2nd station 6th inp u t byte

2nd station 3rd input byte

2nd station 5th input byte

2nd station 7th input byte

2nd station 2nd output byte 2nd station 1st output byte

2nd station 4th output byte 2nd station 3rd output byte

2nd station 5th output byte

b15

b0

b15

b0

*

1

0

*

3

3

*

2

10

57

962/3C2h

*4

Station address : 5

Input data length : 3 byte

Output data length : 0 byte

*1: Station address (FFFFh if not assigned)

*2: Input byte length (FFh if not assigned)

*3: Output byte length (FFh if not assigned)

*1, *2 and *3 are also set in a reserved station.

(The free areas in the INPUT area

are initialized with [00h].)

*4: Since output from the first station has a byte length of 0,

no area is allocated in the OUTPUT area.

Page 42

4. FUNCTIONS MELSEC-A

4-15

(5) Communication trouble area

When some kind of trouble occurs during communication the AJ71PB92D/A1SJ71PB92D stores

the contents of the trouble in this area. Fixed type or ring type can be selected for this area by

turning the communication trouble area type selection (Y03) on or off (refer to Section 4.2.2 (9)).

As shown in the following diagram, a total of 8 pieces of trouble information that consist of the

trouble code, detailed data length, and detailed data can be stored in the basic configuration

regardless of whether for fixed or ring data.

Ring type data is stored in order from the header with the header always being the latest trouble

information.

With fixed type data, when 8 pieces of trouble information are stored the areas 2 to 8 (data 1 to 7)

are fixed, so when the next new trouble occurs only header area 1 (data 8) is updated.

All trouble information for either type can be cleared by turning on the communication trouble

area clear request signal (Y02). When the communication trouble detection signal reset signal

(Y01) is on, the contents of the communication trouble area are held though the communication

trouble detection signal (X01) turns off.

The communication trouble area is configured as shown below.

(a) Communication trouble area configuration

Address

2040/7F8h

2044/7FCh

2045/7FDh

2049/801h

2050/802h

2054/806h

2075/81Bh

2079/81Fh

Trouble information area 1

Trouble information area 2

Trouble information area 3

Trouble information area 8

2040/7F8h

2041/7F9h

2042/7FAh

2043/7FBh

2044/7FCh

Error code (refer to the next page.)

Detailed data length (0 to 3)

Detailed data 1

Detailed data 2

Detailed data 3

Data 1

Ring type

Fixed type

Trouble

information area 1

Trouble

information area 2

Trouble

information area 1

Trouble

information area 2

Trouble

information area 8

Trouble

information area 8

Data 2 Data 9Data 8

Data 1

Data 2

Data 1

Data 1

Data 7

Data 1

Data 8

Data 7

Data 1

Data 8

Data 2

Data 9

Data 7

Data 1

Address

Page 43

4. FUNCTIONS MELSEC-A

4-16

(b) Error codes

The error codes are shown below.

Error Data Detailed data CommuniCode length

123

cation state

0200h (c)

Ref.

(c)

Ref.

(c)

Ref.

(c)

Ref.

(c) Ref. (c) Ref.

1121h 1 03h

The slave address specified in the parameter is t he

same as that of the master. This error occurs

immediately after the power supply is turned on or

the CPU is reset. Even though this error is

occurring, if the exchange start (Y00) is on then

error of error code 3000h will occur, the FAULT

LED will turn on, and operation will stop.

×

1300h 2 Contents

ref.

Contents

ref.

Not even 1 active slave station is set in the

parameter. When this error occ urs t he det ailed

data is set to:

Detailed data 1: Number of slaves set in t he

parameter.

Detailed data 2: Number of active slav es s et in

the parameter.

This error occurs immediately after the power

supply is turned on or the CPU is reset. Even

though this error is occurring, if the exchange start

(Y00) is on then error of error code 3000h will

occur, the FAULT LED will turn on, and operation

will stop.

×

1) Set 1 or more active

slaves in the

parameter.

2) When the FAULT

LED is turned on,

reset is enabled by

turning OFF

→ON→

OFF the Y0D

3000h 1 Ignored

1) When the above errors 1300h or 1121h have

occurred before this error:

Refer to errors 1300h, 1121h above.

2) Otherwise

An unexpected error has occurred.

×

For 1)

Refer to the above

1300h, 1121h

errors.

For 2)

Contact the nearest

Mitsubishi Electric

branch office or

dealer.

×: Exchange stops after the error occurs. : Exchange continues.

User processingDescription

Page 44

4. FUNCTIONS MELSEC-A

4-17

(c) When the trouble code = 0200h

For a slave trouble information occurrence (error code = 0200h), the slave trouble

information is stored in the detailed data. The communication trouble area configuration for

this case is shown below. In addition, the expansion communication trouble information is

stored in buffer memory 2096 to 2110 for only the latest trouble information of the error code

= 0200h trouble information. For information regarding the expansion communication trouble

information refer to Section 4.3.2 (6).

Error code = slave trouble information occurrenc e

Detailed data length = 3

Detailed data 1 Master address (*1) Slave address (* 2)

Detailed data 2 Trouble information

Detailed data 3 Slave ID (*3)

*1 The station address of the master station that controls the slave station in which this trouble

information occurred is stored. However, FFh is stored when the trouble information shows

the exchange with the slave is failed.