Mitsubishi Electric A1SJ71DN91, AJ71DN91 User Manual

A1SJ71DN91,

AJ71DN91

User’s manual

_______________________________________________________________________________________________________

SHNA 4004A

REVISIONS

*The manual number is given on the bottom left of the back cover.

Print Date *Manual Number Revision

Oct., 1998 SH (NA) -4004-A First edition

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial

property rights which may occur as a result of using the contents noted in this manual.

© 1998 Mitsubishi Electric Corporation

•• SAFETY PRECAUTIONS ••

(Read these precautions before using.)

When using Mitsubishi equipment, thoroughly read this manual and the associated manuals introduced in this manual.

Also pay careful attention to safety and handle the module properly.

These precautions apply only to Mitsubishi equipment. Refer to the CPU module user's manual for a description of the

PC system safety precautions.

These SAFETY PRECAUTIONS classify the safety precautions into two categories: "DANGER" and "CAUTION".

DANGER

CAUTION

Depending on circumstances, procedures indicated by CAUTION may also be linked to serious results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it whenever necessary.

Always forward it to the end user.

[System Design Precautions]

Procedures which may lead to a dangerous condition and cause death or serious injury if not

carried out properly.

Procedures which may lead to a dangerous condition and cause superficial to medium injury,

or physical damage only, if not carried out properly.

DANGER

• If a communication error occurs in the network of the DeviceNet, the communication error station enters the state

shown below.

(1) The master station (AJ71DN91, A1SJ71DN91) holds the data that was input from a slave station before the

occurrence of a communication error.

(2) Whether the output signal of the slave station goes OFF or is retained depends on the slave station

specifications or the parameter setting at the master station.

Create the interlock circuit on a sequence program which uses the communication state of the slave stations so that

the system operation is secured. At the same time, a safety system must be provided outside the slave station.

CAUTION

• Do not bundle control lines or communication wires together with main circuit or power lines, or lay them close to

these lines.

As a guide, separate these lines by a distance of at least 100 mm, otherwise malfunctions may occur due to noise.

[Cautions on Mounting]

CAUTION

• Use the PC in an environment that conforms to the general specifications in the manual.

Using the PC in environments outside the ranges stated in the general specifications will cause electric shock, fire,

malfunction, or damage to/deterioration of the product.

• Make sure that the module fixing projection on the base of the module is properly engaged in the module fixing hole

in the base unit before mounting the module.(A(1S)J71DN91 must be screwed to the base unit with the specified

torque.)

Failure to mount the module properly will result in malfunction or failure, or in the module falling.

• Do not touch conductive parts or electronic components of the module with your bare hands.

This could cause malfunction or failure of the module.

[Cautions on Wiring]

DANGER

• Switch off all phases of the power supply outside the PC before starting installing or wiring work.

If all phases are not switched off, there will be a danger of electric shock or damage to the product.

CAUTION

• Connect the FG terminal to a dedicated PC ground connection with class 3 grounding or higher.

Failure to do this may result in malfunction.

• Tighten terminal screws to the prescribed torque.

Loose terminal screws can cause shorting and malfunctions.

• Make sure that no foreign matter such as chips or wire offcuts gets inside the module.

It will cause fire, failure, or malfunction.

• The communication cables and power cables connected to the unit must be enclosed in a duct or fixed with clamps.

Failure to do this can result in malfunction due to damage to the unit or cables or defective cable contact caused by

looseness or movement of the cables or accidental pulling on the cables.

• When disconnecting a communication cable and power cable from the unit, do not pull on the cable itself.

If the cable has a connector, pull on the connector to disconnect it from the unit.

If the cable has no connector, loosen the screw where the cable attaches to the unit before disconnecting the cable.

Pulling on a cable while it is connected to the unit can damage the unit or cable, or cause malfunctions due to

defective cable contact.

Always turn off all external power supply phases before touching any terminals.

Failure to do this may result in malfunction.

[Cautions on Startup and Maintenance]

CAUTION

• Always turn off all external power supply phases before touching any terminals.

Failure to do this may result in malfunction.

• Always turn off all external power supply phases before cleaning or tightening the terminal screws.

Failure to do this may result in malfunction.

• Do not disassemble or modify any module.

This will cause failure, malfunction, injuries, or fire.

• Always turn off all external power supply phases before mounting or dismounting the unit.

Failure to do this may result in malfunction or damage to the unit.

[Cautions on Disposal]

CAUTION

• Dispose of this product as industrial waste.

INTRODUCTION

Thank you for purchasing the Mitsubishi MELSEC-A-series.

Before using the equipment, please read the manual carefully to develop full familiarity with the functions and

performance of MELSEC-A-series you have purchased, so as to ensure correct use.

Please forward a copy of this manual to the end user.

CONTENTS

1. OUTLINE 1 – 1 ~ 1 – 8

1.1 Features.........................................................................................................................................1 – 1

1.2 Communication Outline...................................................................................................................1 – 3

1.2.1 Network configuration........................................................................................................1 – 3

1.2.2 Outline of parameter settings.............................................................................................1 – 5

1.2.3 Outline of DN91 - slave station communication...................................................................1 – 5

2. SYSTEM CONFIGURATION 2 – 1 ~ 2 – 6

2.1 Overall Configuration......................................................................................................................2 – 1

2.1.1 Sample system configuration connected with a trunk line....................................................2 – 1

2.1.2 Sample system configuration connected with a drop line.....................................................2 – 1

2.1.3 System configuration with a DeviceNet master unit.............................................................2 – 2

2.2 Applicable Systems ........................................................................................................................2 – 3

2.2.1 Mountable CPUs and number of units................................................................................2 – 3

2.2.2 Important points about the system configuration................................................................. 2 – 4

2.2.3 Operating environment of the configuration software (parameter setting tool)......................2 – 5

2.3 Products Connectable to a Slave Station.........................................................................................2 – 6

3. SPECIFICATIONS 3 – 1 ~ 3 – 26

3.1 General Specifications....................................................................................................................3 – 1

3.2 Performance Specifications .............................................................................................................3 – 2

3.2.1 Maximum transfer distance for thick cable/thin cable combination.......................................3 – 2

3.3 PC CPU I/O Signals........................................................................................................................3 – 3

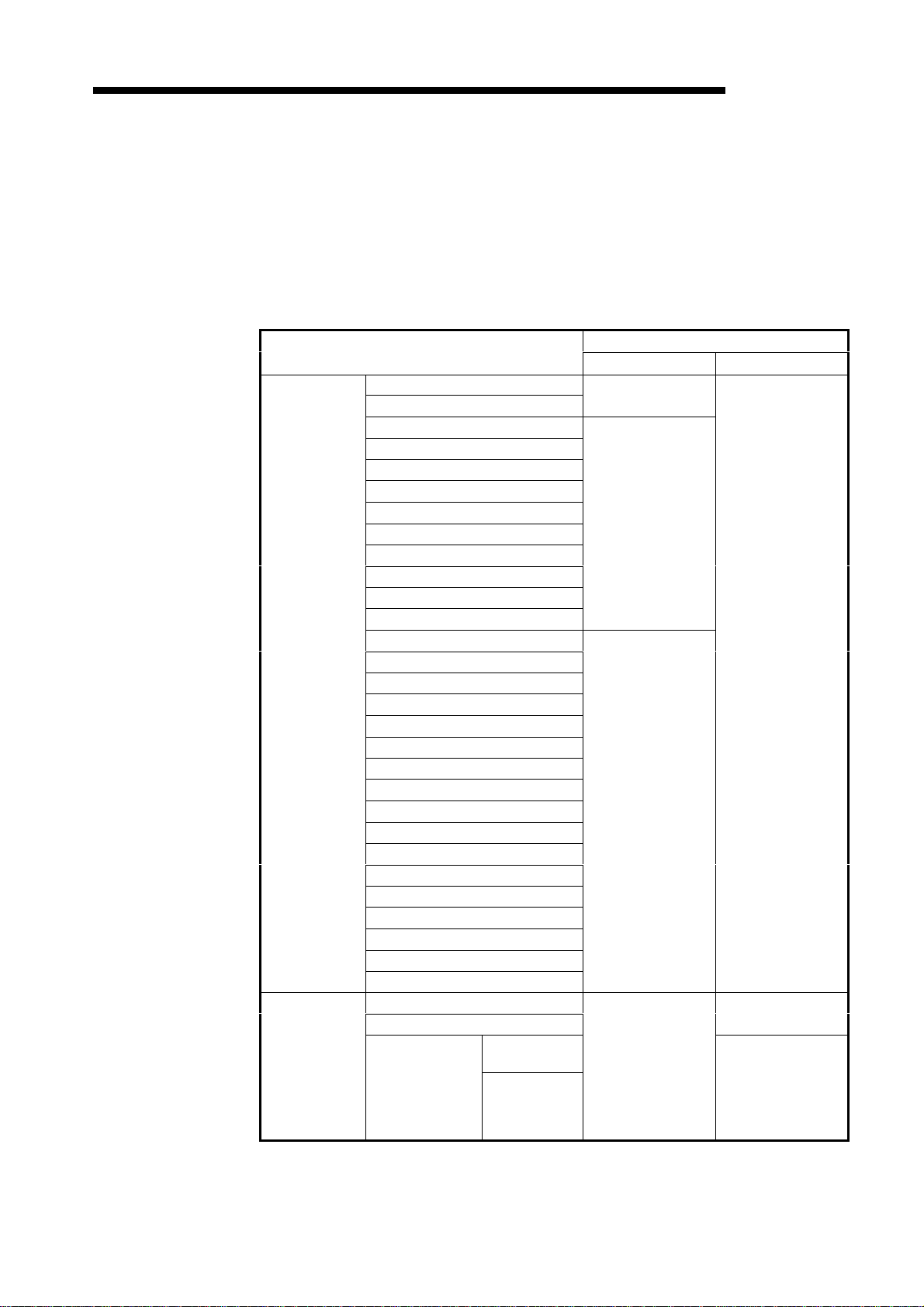

3.3.1 Table of I/O signals............................................................................................................3 – 3

3.3.2 I/O signal details ............................................................................................................... 3 – 5

3.4 Buffer Memory................................................................................................................................3 – 8

3.4.1 Buffer memory table..........................................................................................................3 – 8

3.4.2 Details of the buffer memory..............................................................................................3 – 9

− i −

4. FUNCTIONS 4 – 1 ~ 4 – 5

4.1 I/O Communication Functions .........................................................................................................4 – 1

4.2 Message Communication Functions................................................................................................4 – 3

4.2.1 Get attribute ......................................................................................................................4 – 3

4.2.2 Set attribute......................................................................................................................4 – 4

4.2.3 Read communication error information...............................................................................4 – 5

5. SETTINGS AND PROCEDURES BEFORE OPERATION 5 – 1 ~ 5 – 10

5.1 Settings and Procedures.................................................................................................................5 – 1

5.1.1 DN91 start-up procedure when setting parameters with a sequence program......................5 – 1

5.1.2 DN91 start-up when setting parameters with the configuration software ..............................5 – 2

5.2 Mounting and Installation ................................................................................................................ 5 – 3

5.2.1 Handling instructions.........................................................................................................5 – 3

5.2.2 Installation environment.....................................................................................................5 – 3

5.3 Nomenclature.................................................................................................................................5 – 4

5.4 LED Displays and Indicator Descriptions..........................................................................................5 – 5

5.5 Connecting Communication Cable to DN91.....................................................................................5 – 6

5.6 Instructions for Connecting the Network Power Supply.....................................................................5 – 7

5.6.1 Network power supply unit installation position...................................................................5 – 7

5.6.2 Calculating network power supply unit installation position and current capacity .................. 5 – 8

6. PARAMETER SETTINGS 6 – 1 ~ 6 – 7

6.1 Setting Parameter...........................................................................................................................6 – 1

6.2 Important Points about the Parameter Settings ................................................................................ 6 – 2

6.3 Setting with a Sequence Program ...................................................................................................6 – 2

6.4 Setting Parameters with the Configuration Software (Parameter Setting Tool)...................................6 – 3

6.4.1 Setting configuration..........................................................................................................6 – 3

6.4.2 Setting master parameters ................................................................................................6 – 4

6.4.3 Setting bus parameters ..................................................................................................... 6 – 5

6.4.4 Set the device (slave station) parameters...........................................................................6 – 6

7. PROGRAMMING 7 – 1 ~ 7 – 9

7.1 Important Points about Programming...............................................................................................7 – 1

7.2 System Configuration......................................................................................................................7 – 2

7.3 Setting Parameters with a Sequence Program.................................................................................7 – 4

7.4 I/O Communication with Slave Stations ...........................................................................................7 – 6

7.4.1 Reading slave station I/O data...........................................................................................7 – 6

7.4.2 Writing slave station I/O data.............................................................................................7 – 6

7.5 Message Communication ................................................................................................................7 – 7

7.5.1 Message communication – reading ....................................................................................7 – 7

7.5.2 Message communication – writing ..................................................................................... 7 – 8

7.6 Acquiring Error Information..............................................................................................................7 – 9

− ii −

8. TROUBLESHOOTING 8 – 1 ~ 8 – 12

8.1 Troubleshooting Tables...................................................................................................................8 – 2

8.1.1 Troubleshooting by Symptom Type....................................................................................8 – 2

8.1.2 Problems due to incorrect parameter settings .....................................................................8 – 5

8.2 Troubleshooting Using LED Indications............................................................................................8 – 5

8.2.1 Errors caused by the master unit .......................................................................................8 – 5

8.2.2 Errors caused by incorrect parameter settings or abnormal network....................................8 – 6

8.3 Troubleshooting Using Error Codes.................................................................................................8 – 8

8.3.1 Communication error codes...............................................................................................8 – 8

8.3.2 Execution error codes for message communication..........................................................8 – 11

APPENDICES APP – 1 ~ APP – 4

APPENDIX 1 External View ...............................................................................................................APP – 1

1.1 AJ71DN91.................................................................................................................................APP – 1

1.2 A1SJ71DN91.............................................................................................................................APP – 2

APPENDIX 2 Parameter Setting Sheet ..............................................................................................APP – 3

APPENDIX 3 List of Communication Parameter with Each Maker’s Slave Station................................APP – 4

− iii −

1. OUTLINE

1. OUTLINE

1.1 Features

MELSEC-A

This manual gives information including the specifications and descriptions of parts of the

AJ71DN91/A1SJ71DN91 DeviceNet Master Unit (hereafter AJ71DN91, A1SJ71DN91, or

DN91), which is used in combination with the MELSEC-A/QnA Series PLC CPU.

DN91 is the DeviceNet master station which controls the DeviceNet devices.

See the DeviceNet Specifications (Release 2.0) Volume 1 and Volume 2 for details about the

DeviceNet Specifications.

DeviceNet is a registered trademark of the Open DeviceNet Vendor Association, Inc.

POINT

While it is considered connectable with most commercially available Device-Net

products, we cannot guarantee the connectivity with products of other manufacturers.

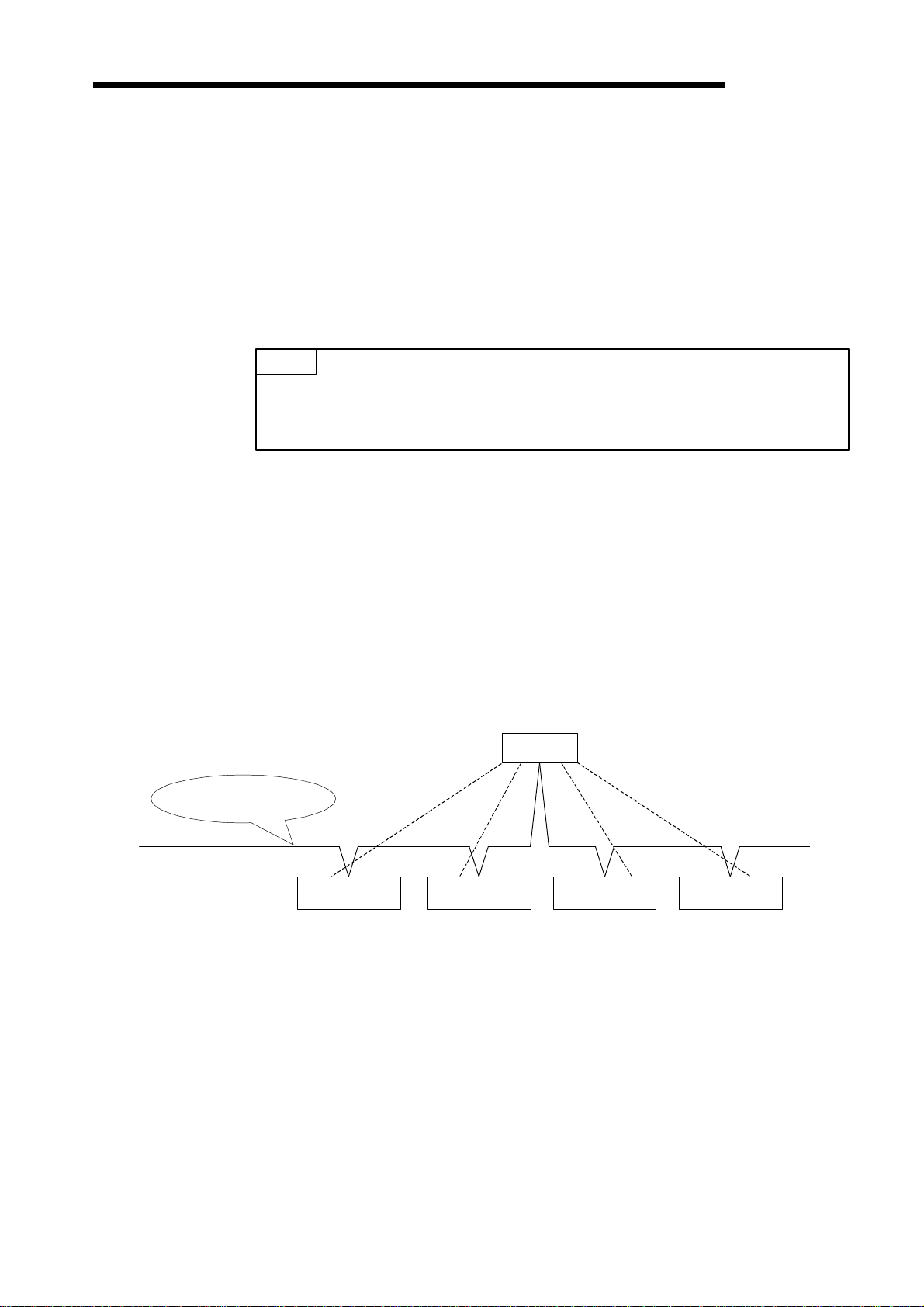

This section describes the features of DN91.

(1) Conforms to the DeviceNet specifications (Release 2.0).

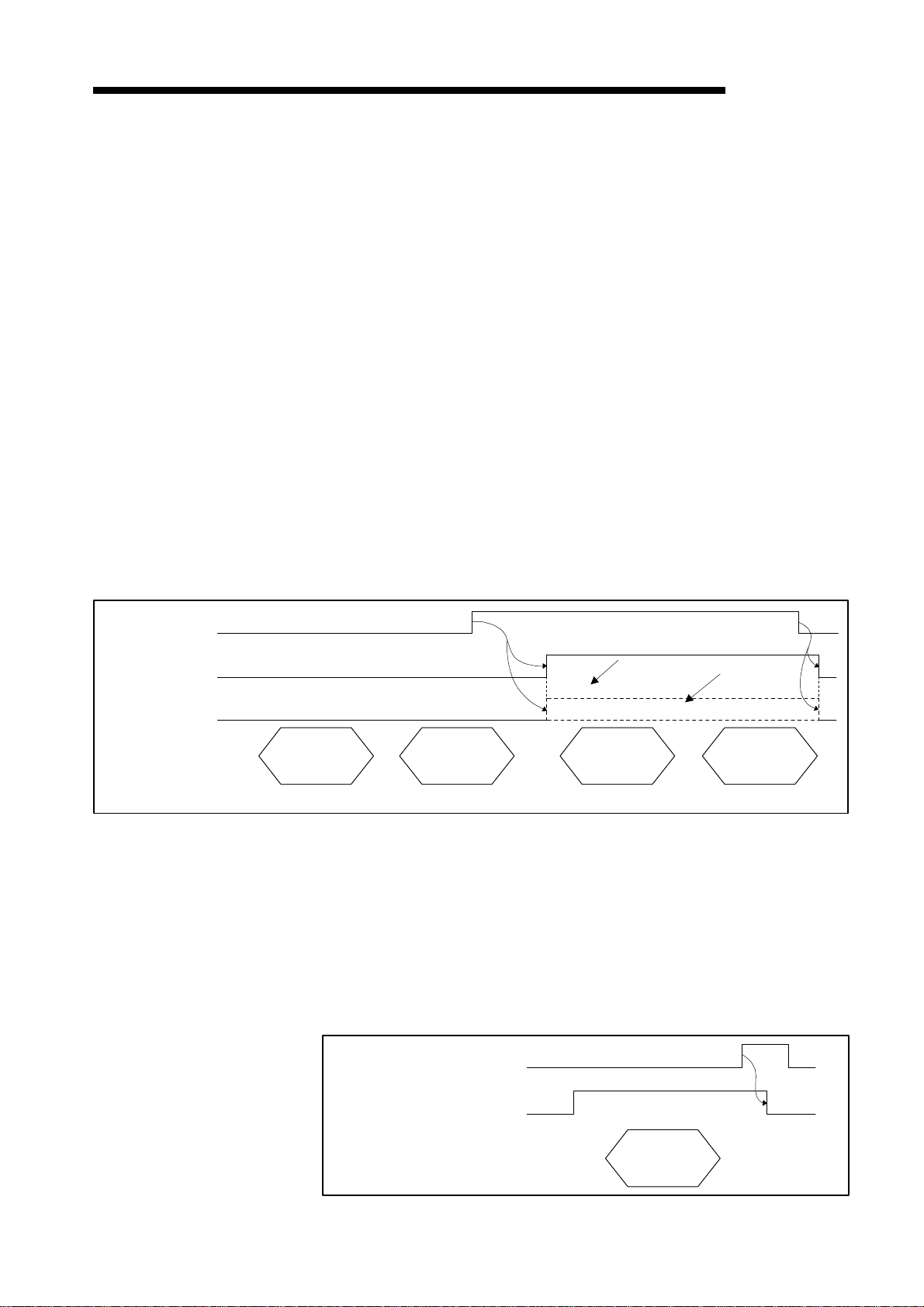

(2) DN91 operates as the DeviceNet master station to permit I/O and message

(3) Each master unit can communicate with up to 63 slave stations.

(4) The communication method for I/O communication can be selected indepen-dently for

DeviceNet network

(5) I/O communication permits communication of 256 bytes of inputs (2048 points) and 256

communications with the DeviceNet slave stations.

each slave station from the following four methods prescribed for DeviceNet: polling, bit

strobe, change of state, and cyclic.

However, only one communication method can be selected for each slave station.

DN91

Polling

Bit strobe

Change of state

Cyclic

Slave station 1 Slave station 2 Slave station 3 Slave station 4

bytes of outputs (2048 points) in the edit mode.

(6) Each message communication can communicate 240-byte message data.

(7) Any of the following two methods may be used to set the DN91 parameters:

• Use TO command of the sequence program to set the parameters.

• Use the configuration software to set the parameters. (Refer to the Section 2.2.3 for

the configuration software.)

1 − 1

1. OUTLINE

MELSEC-A

REMARK

When a network analyzer is connected to monitor the DeviceNet network, DN91 is recognized as a product

of the Hilscher company.

1 − 2

1. OUTLINE

1.2 Communication Outline

1.2.1 Network configuration

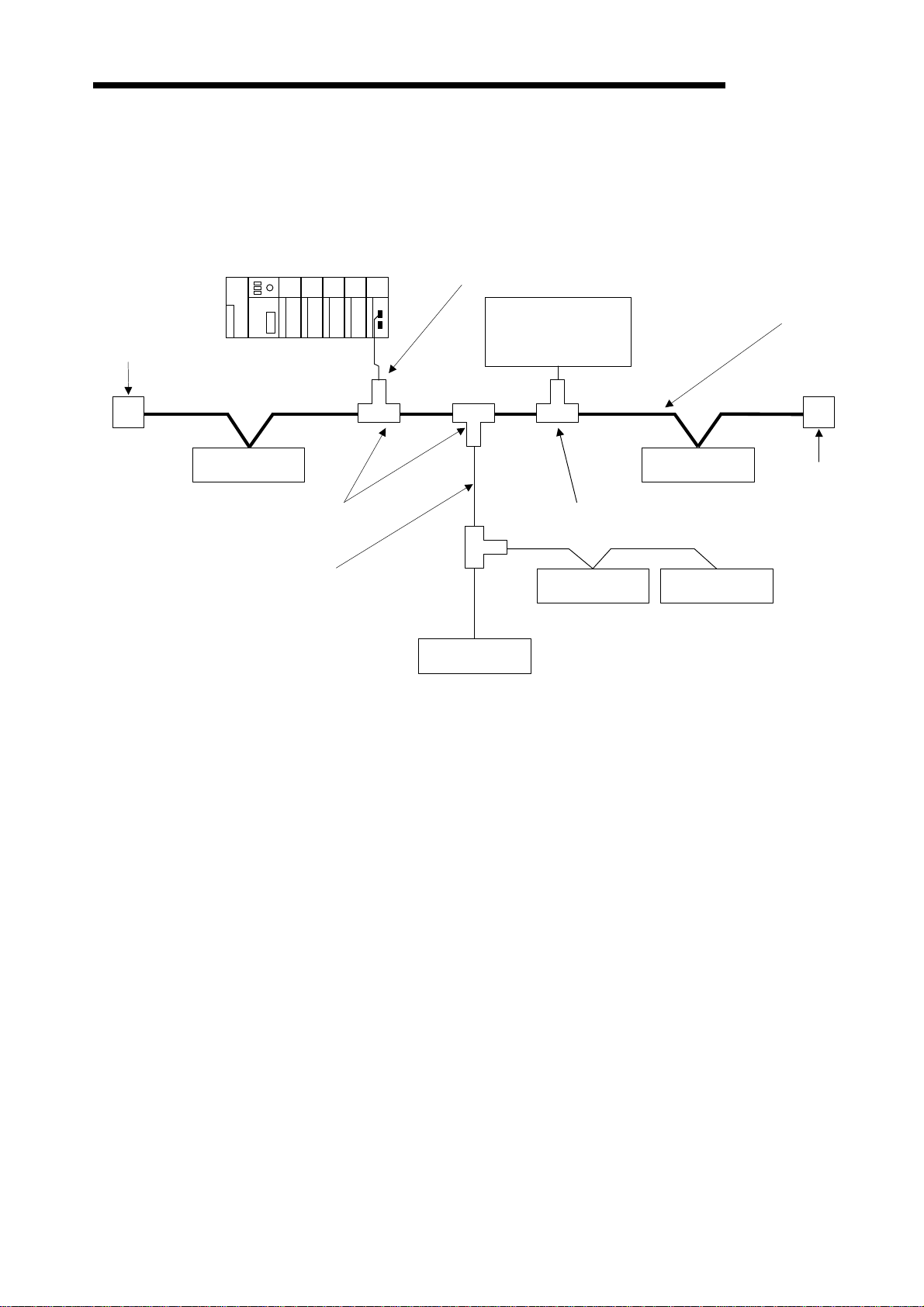

The DN91-based DeviceNet network is configured as shown below.

MELSEC-A

Termination

resistance

Master station

Slave station Slave station

Tap

Drop line (branch)

Drop line

Network power

supply unit

(24 VDC)

Power tap

Slave station Slave station

Slave station

Trunk line

Termination

resistance

1) Up to 64 units can be connected including the master station (DN91) and slave stations.

2) The positions of the master station and slave stations are not fixed. They can be arranged

at any position on the network.

3) The network comprises trunk lines and drop lines.

A termination resistance must be connected to each end of a trunk line.

4) A network power supply must be connected to supply power to the network communication circuits in each station.

1 − 3

1. OUTLINE

MELSEC-A

(1) Network Specifications

This section describes the network specifications of a DeviceNet using DN91.

(a) Communication Speed

The communication speed can be selected as 125, 250, or 500 kbaud using a

sequence program or a configuration software.

The maximum cable length depends on the communication speed. See 3.2

Performance Specifications for details.

(b) Network Power Supply Methods

The following methods are available to supply network power to each station:

1) Connect a dedicated power tap to the trunk line cable and connect a network

power supply unit to it.

2) Supply power from the network power supply unit through network cables to

each station.

REMARK

Contact ODVA or the ODVA Japan office for inquiries about the following devices required for the

DeviceNet network configuration:

• Network power supply unit

• Power tap

• Tap

• Termination resistance

• Cable

Contact Details for ODVA

Open DeviceNet Vender Association, Inc.

Address

8222 Wiles Road, Suite 287, Coral Springs, FL 33067 USA

TEL.305-340-5412 FAX.305-340-5413

ODVA Japan Office

Address

The Japan Chapter of ODVA

Kyoto Research Park 17, Chudoji Minami-Machi, Shimogyo Kyoto 600-8813 Japan

TEL.075-315-9175 FAX.075-315-2898

1 − 4

1. OUTLINE

1.2.2 Outline of parameter settings

Parameter setting is required in advance to communicate with slave stations.

The parameters include DeviceNet communication speed, station number (MAC ID) of DN91,

the number of I/O points of slave stations etc.

They are set in any of the following methods and stored in separate areas of E2PROM inside

DN91.

• Use the sequence program.

• Use the configuration software.

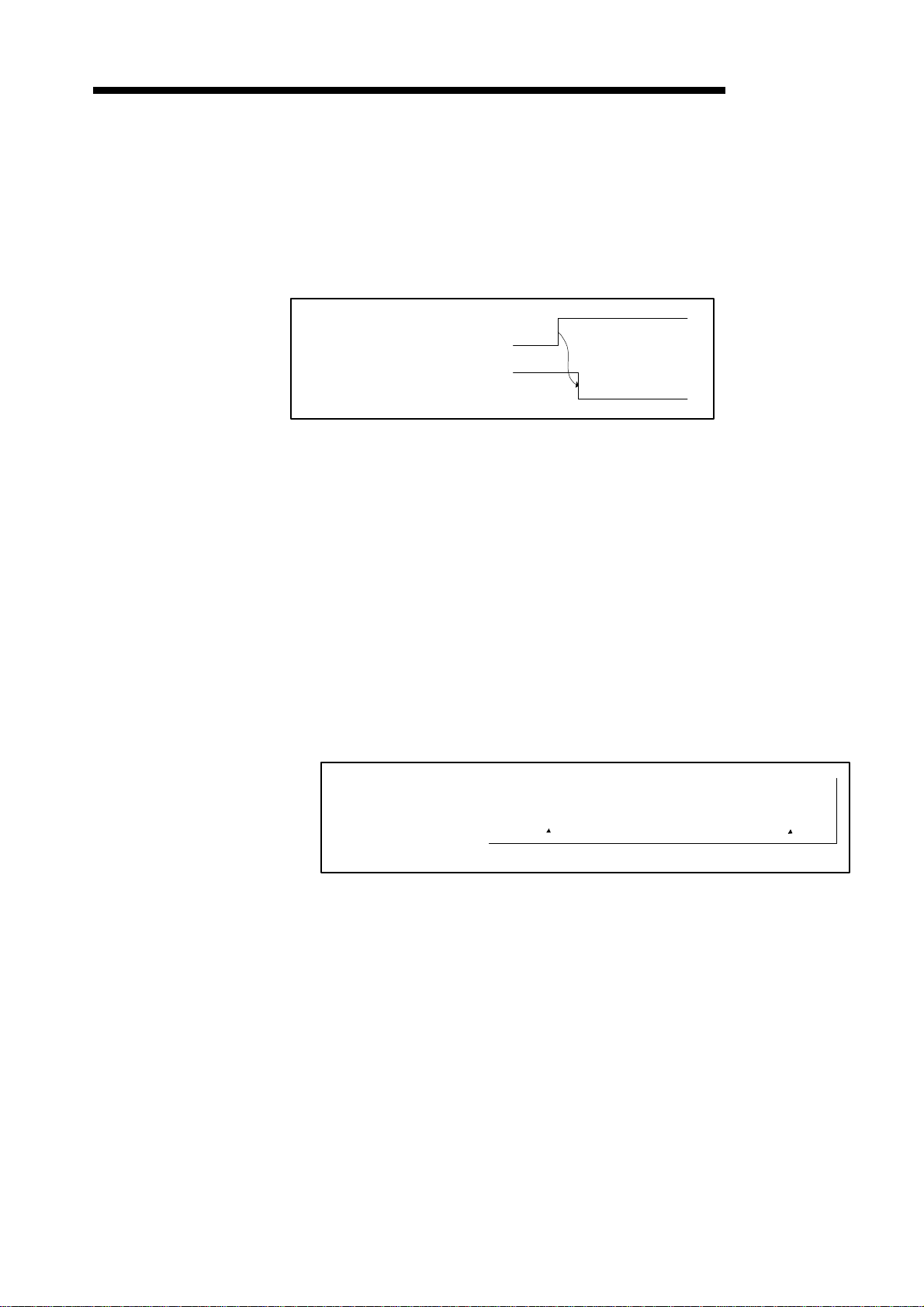

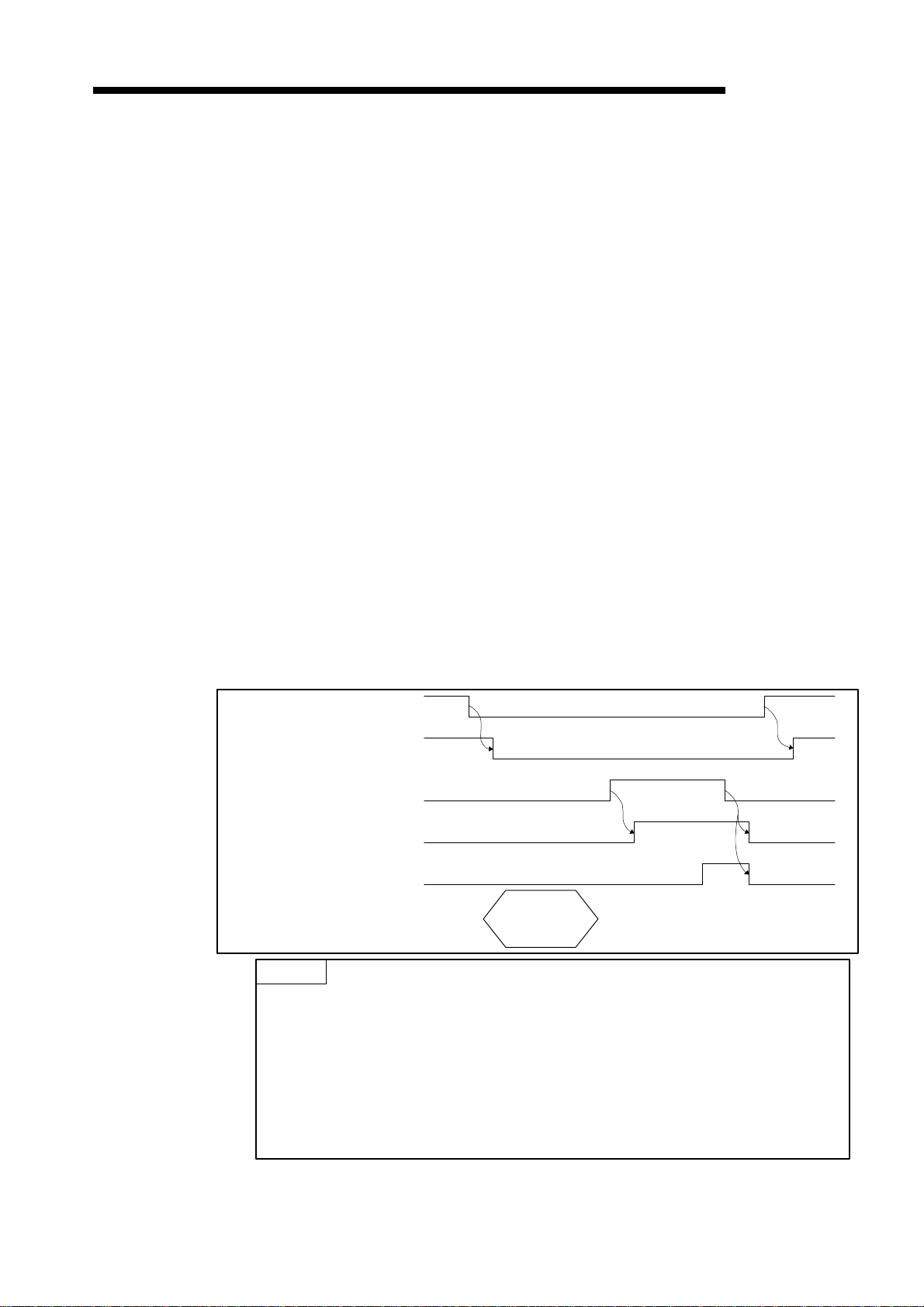

1.2.3 Outline of DN91 - slave station communication

Communication between the DN91 and slave stations is outlined below.

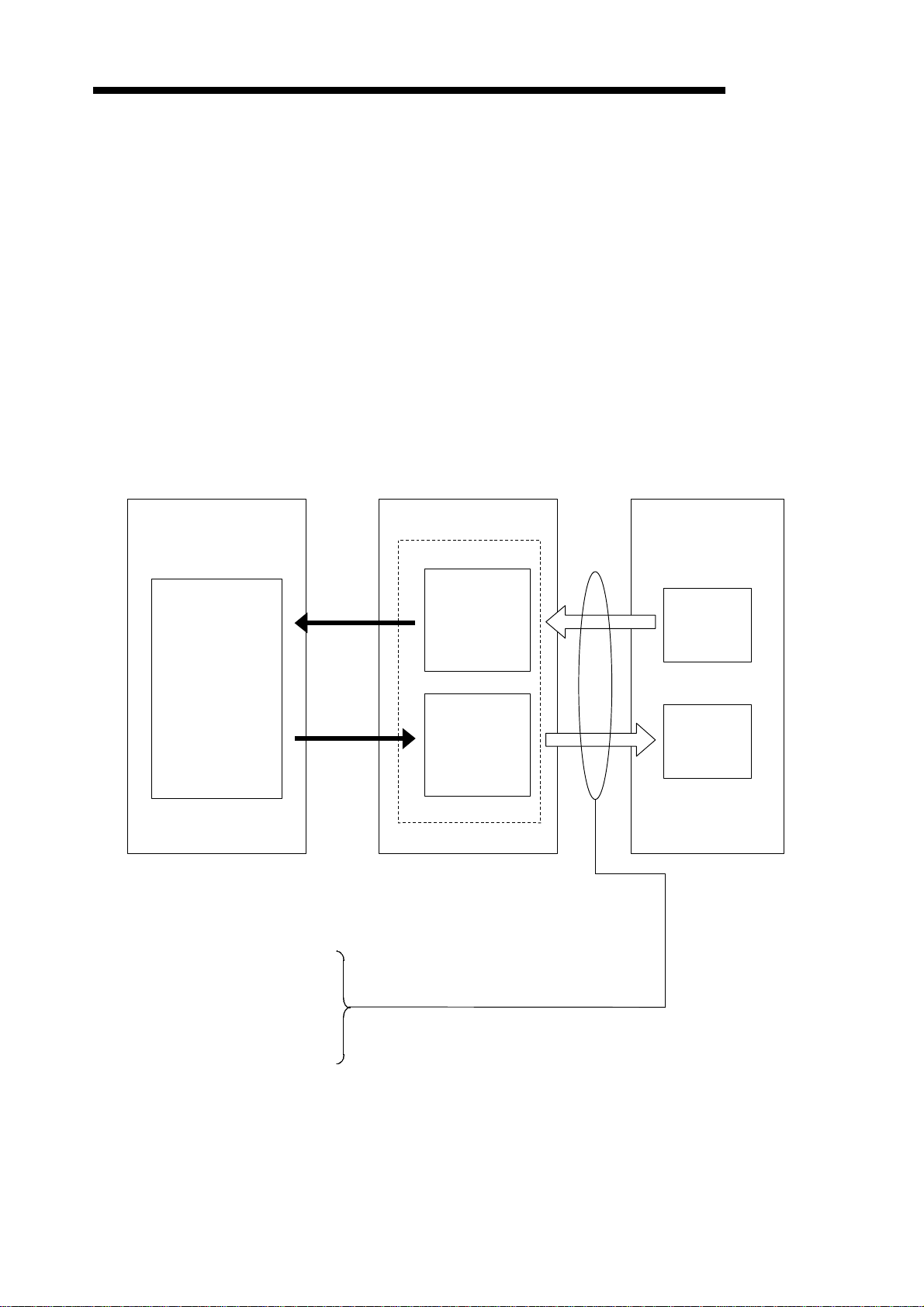

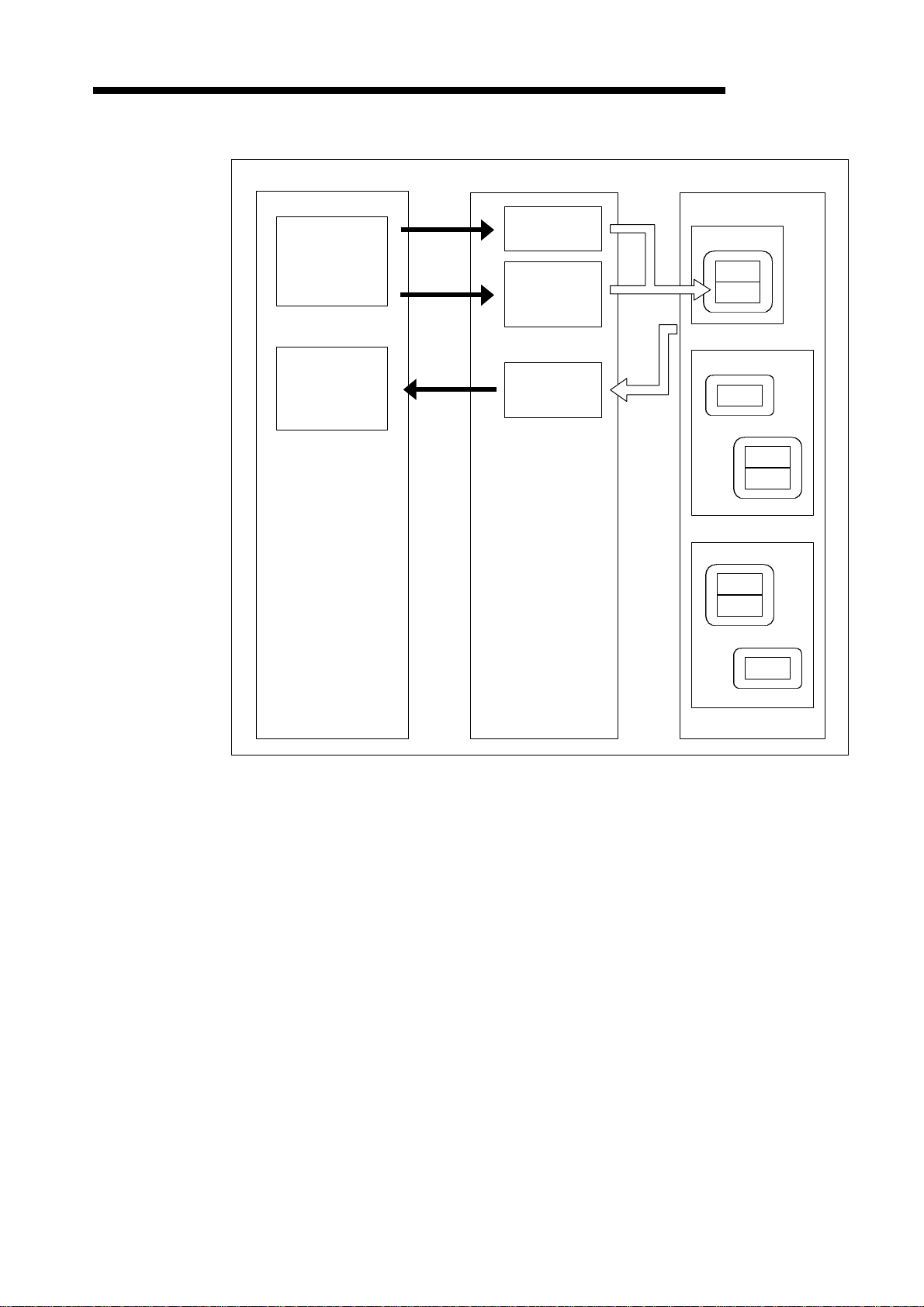

(1) Outline of I/O Communication

I/O communication is a function to communicate I/O data with slave stations.

An outline of I/O communication is shown below.

See 4.1 I/O Communication Functions for details.

Buffer memory

MELSEC-A

Slave stationDN91PLC CPU

Device

FROM

X, Y, M, D, R

TO

Input data area

(Up to 2048

points)

Output data area

(Up to 2048

points)

Input

Output

The following four I/O communication methods are available:

One of these four communication methods can be chosen to match the specification of each slave station.

1) Bit strobe

2) Polling

3) Change of state

4) Cyclic

1 − 5

1. OUTLINE

Message

Message

MELSEC-A

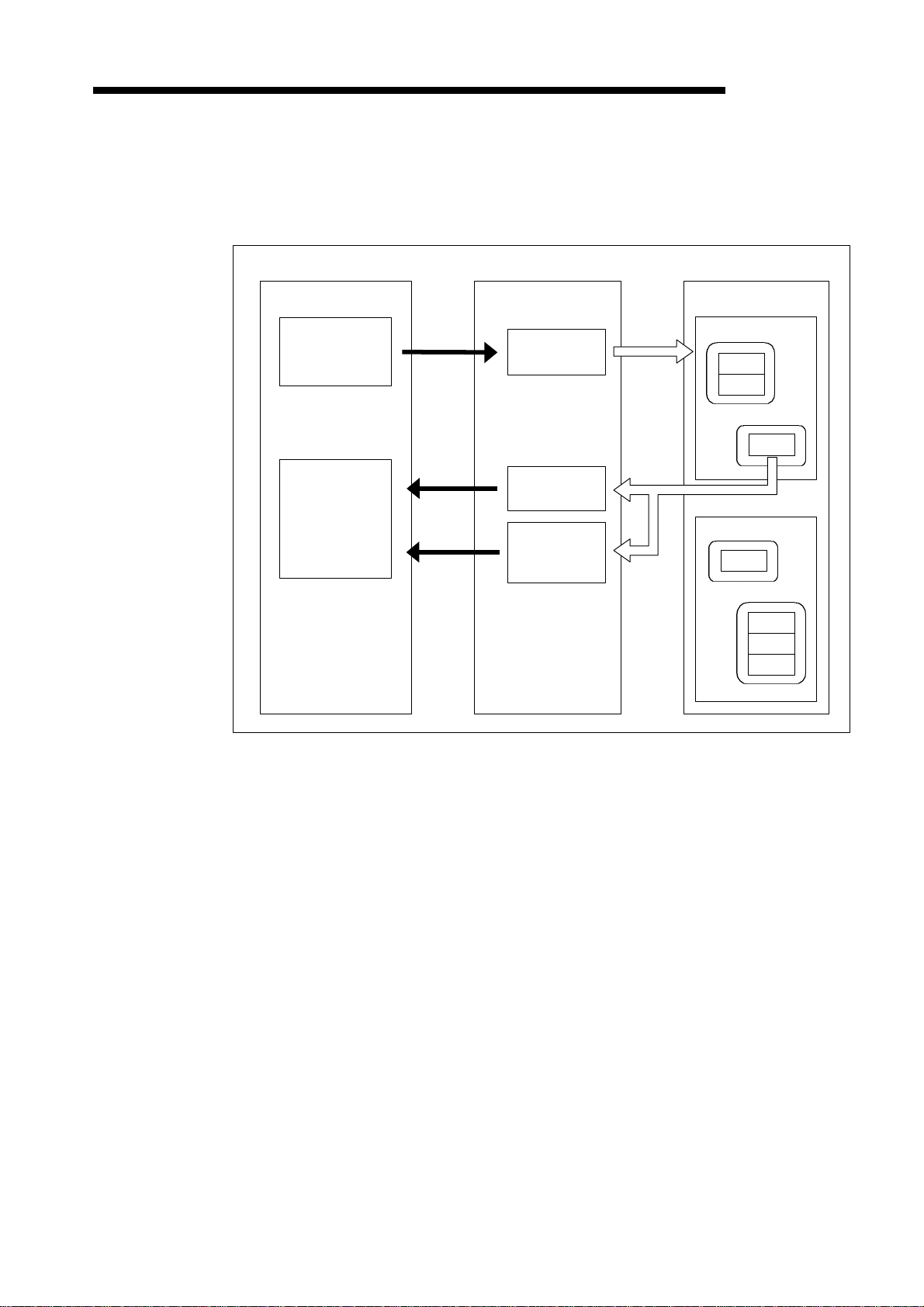

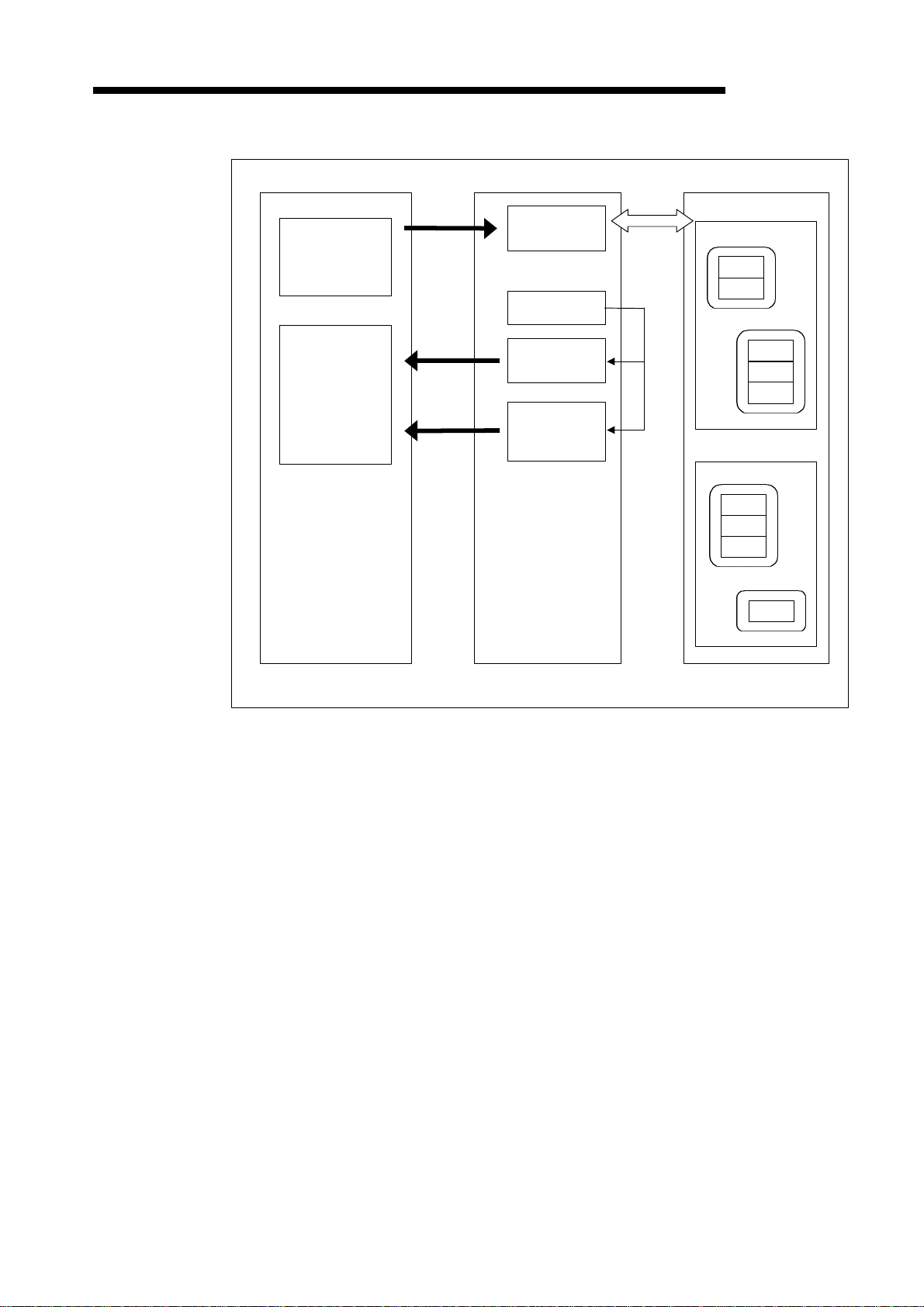

(2) Outline of Message Communication

Message communication is a function to read and write slave station attribute data.

An outline of message communication is shown below. See 4.2 Message Communication

Functions for details.

(a) Reading attributes

Slave stationDN91PLC CPU

Device Class

D, R

Device

D, R

TO

FROM

FROM

communication

command area

Message

communication

result area

communication

data area

(Up to 240 byte)

Instance

Attribute

Attribute

Instance

Attribute

Class

Instance

Attribute

Instance

Attribute

Attribute

Attribute

1 − 6

1. OUTLINE

Message

MELSEC-A

(b) Writing attributes

Slave stationDN91PLC CPU

Device

D, R

Device

D, R

TO

TO

FROM

communication

command area

Message

communication

data area

(Up to 240 byte)

Message

communication

result area

Class

Instance

Attribute

Attribute

Class

Instance

Attribute

Instance

Attribute

Attribute

Class

Instance

Attribute

Attribute

Instance

Attribute

1 − 7

1. OUTLINE

I/O

Device

Device

MELSEC-A

(c) Reading communication error information

D, R

D, R

TO

FROM

FROM

DN91PLC CPU

Message

communication

command area

Slave information

storage area *

Message

communication

result area

Message

communication

data area

(Up to 240 byte)

communi-

cation

Slave station

Class 1

Instance

Attribute

Attribute

Instance

Attribute

Attribute

Attribute

Class

Instance

Attribute

Attribute

Attribute

Instance

Attribute

*: Stores the status of each slave station during I/O communication.

1 − 8

2. SYSTEM CONFIGURATION

2. SYSTEM CONFIGURATION

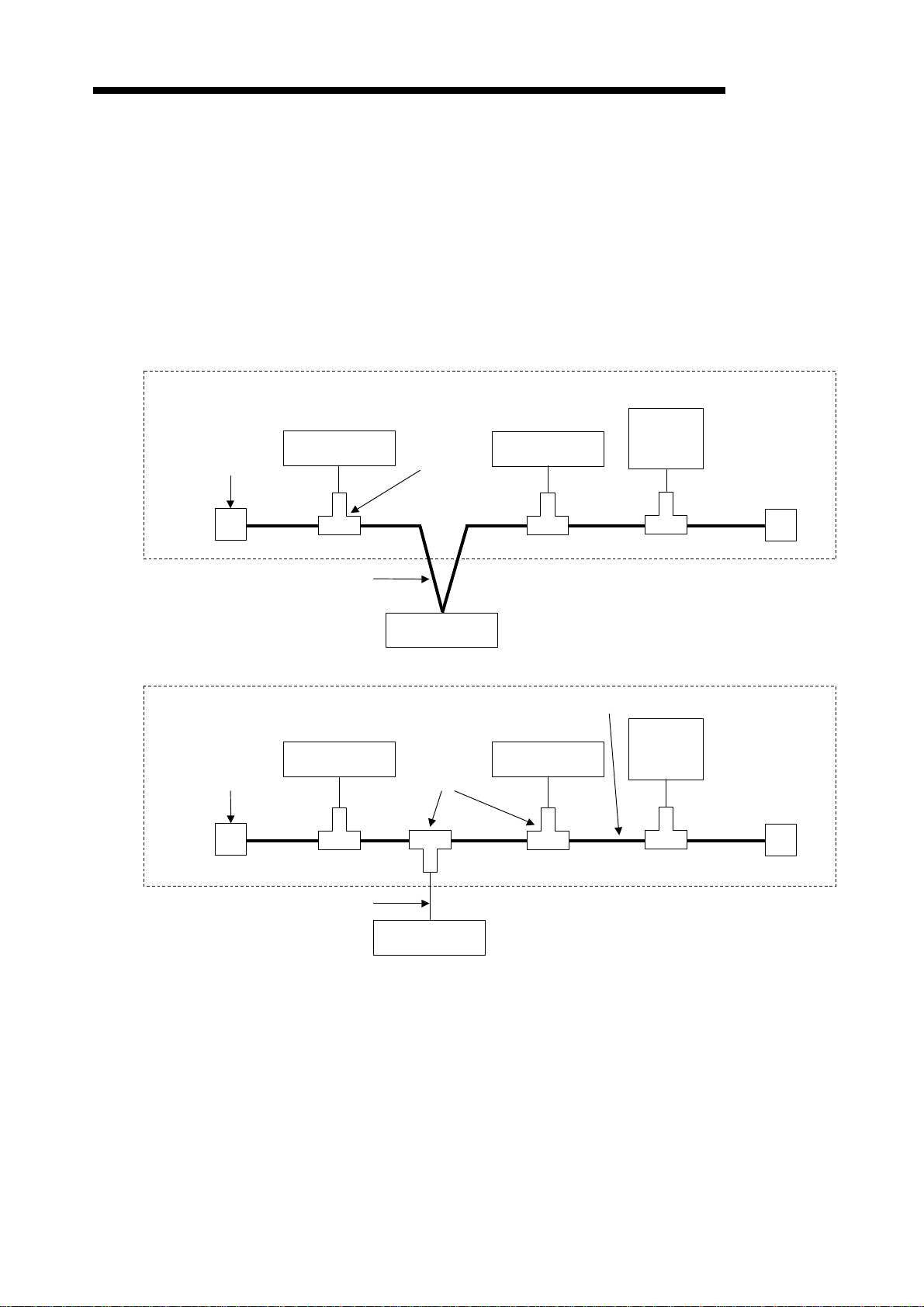

This section describes the system configuration on DeviceNet.

2.1 Overall Configuration

A master station can communicate with up to 63 slave stations.

Each station is connected via a tap on the trunk line or is directly connected to the trunk line.

The system configuration using AJ71DN91/A1SJ71DN91 as the master station is described

below.

2.1.1 A typical system configuration that connects with a trunk line

Termination

resistance

Slave station

Tap

Slave station

MELSEC-A

Slave stations: max. 63

stations

Power

supply: 24

VDC

Trunk line

Master station

DeviceNet master unit

AJ71DN91/A1SJ71DN91

2.1.2 A typical system configuration that connects with a drop line

Termination

resistance

Tap

Drop line

Master station

Slave stationSlave station

DeviceNet master unit

AJ71DN91/A1SJ71DN91

Trunk line

Slave stations: max. 63

stations

Power

supply: 24

VDC

2 − 1

2. SYSTEM CONFIGURATION

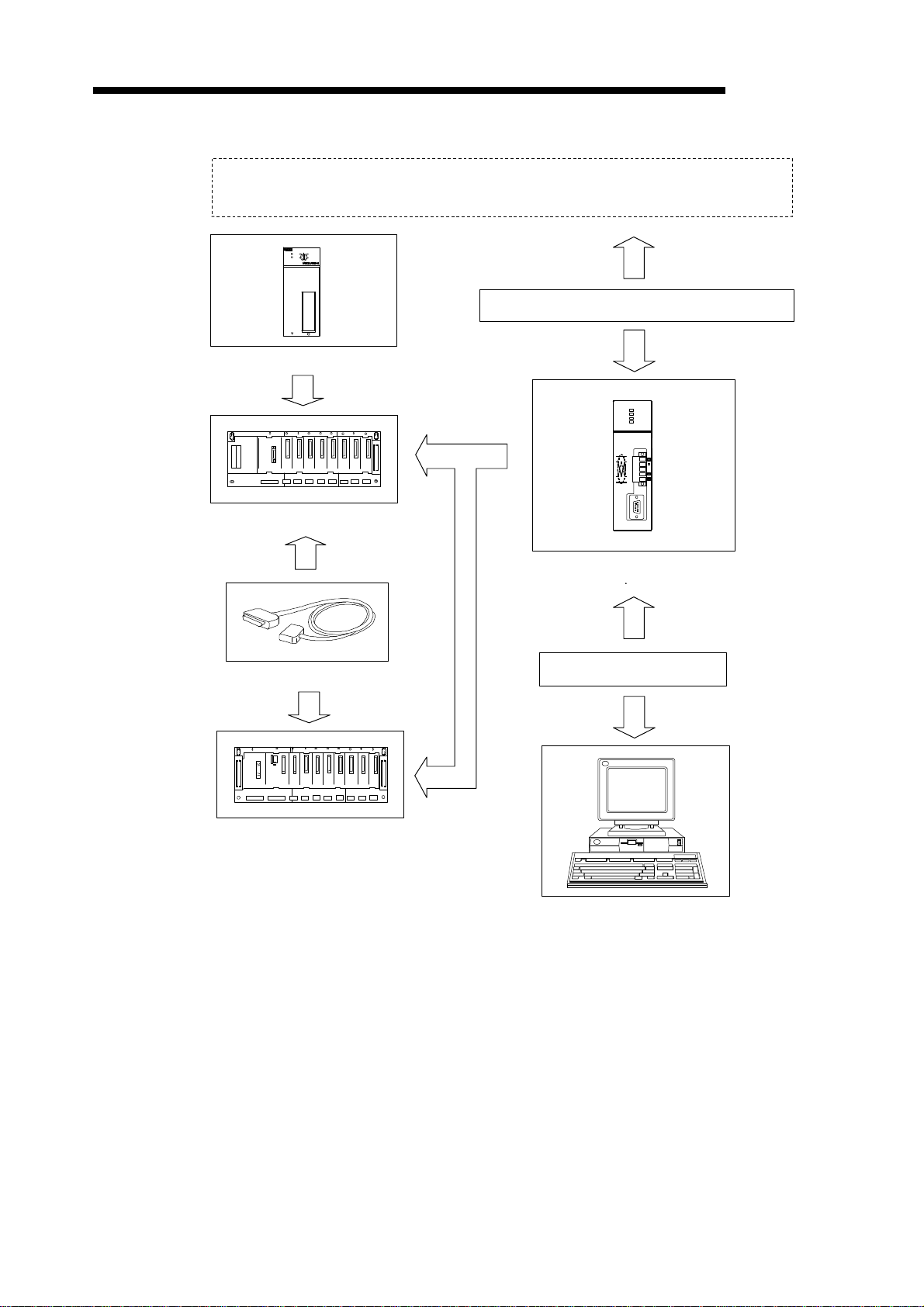

2.1.3 System configuration with a DeviceNet master unit

DeviceNet network

A

CPU

S1

STOP

RUN

L.CLR

RUN

ERROR

RESETRESET

CPU

PULL

PLC CPU

Trunk line or drop line

A1SJ71DN91

RUN

L.RUN

MS

NS

DeviceNet

MELSEC-A

Main base

Extension Cable

Extension base

RS-232-C

DeviceNet master unit

AJ71DN91 A1SJ71DN91

RS-232C cross-cable

Configuration unit (*)

*: PC/AT-compatible computer + configuration software

2 − 2

2. SYSTEM CONFIGURATION

2.2 Applicable Systems

This section describes important points regarding which CPU units can be used and the

system configuration.

2.2.1 Mountable CPUs and number of units

Table 2.1 shows which PLC CPUs can be mounted and the number of units.

Mounting Position

A0J2CPU

A0J2HCPU

A1SCPU(S1)

A1SHCPU

A1SJCPU(S3)

A1SJHCPU(S8)

A1SCPUC24-R2

A2SCPU(S1)

A2SHCPU(S1)

A2ASCPU(S1/S30)

Q2ASCPU(S1)

Q2ASHCPU(S1)

A1CPU

A2CPU(S1)

PLC CPU

Data link and

network

A3CPU

A1NCPU

A2NCPU(S1)

A3NCPU

A3MCPU

A3HCPU

A2ACPU(S1)

A3ACPU

A2UCPU(S1)

A3UCPU

A4UCPU

Q2ACPU(S1)

Q3ACPU

Q4ACPU

Q4ARCPU

MELSECNET remote I/O station

MELSECNET/B remote I/O station

MELSECNET/10

remote I/O station

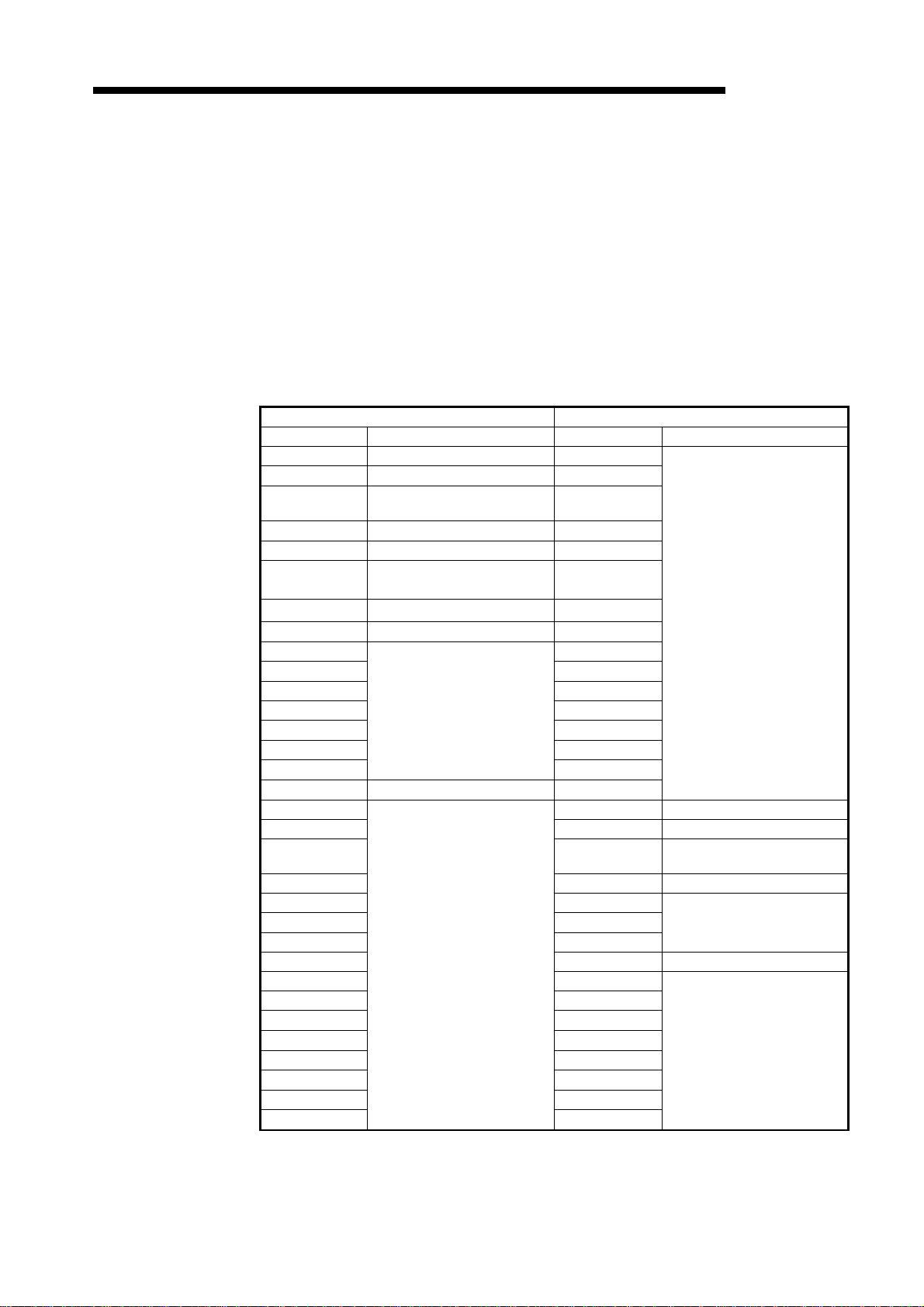

Table 2.1 Mountable CPUs and Number of Units

Number of Mountable Units

A1SJ71DN91 AJ71DN91

Cannot be used

No restriction

Cannot be used

AJ72LP25

AJ72BR15

A1SJ72QLP25

AJ72QLP25

A1SJ72QBR15

AJ72QBR15

Cannot be used

MELSEC-A

No restriction

Cannot be used

No restriction

2 − 3

2. SYSTEM CONFIGURATION

2.2.2 Important points about the system configuration

This section gives some important points about configuration of a DeviceNet network system.

(1) Maximum Number of Units

Units up to the number of CPU I/Os may be installed. The DN91 uses 32 I/O points and

one slot.

(2) Applicable Base Units

The DN91 can be mounted in any main base unit or extension base unit slot, with the

following exceptions.

(a) Avoid mounting the DN91 in an extension base unit with no power supply (A5 B,

A1S5 B extension base unit) as the power supply capacity may be insufficient.

If the DN91 is mounted in this type of unit, select the power supply unit and

extension cable with due consideration to the current capacity of the power supply

unit and the voltage drop in the extension cable.

See the user's manual of your PLC CPU for details.

(b) The DN91 cannot be mounted in the final slot of the A3CPU(P21/R21) expansion

7th stage.

MELSEC-A

(3) Not Mountable in MELSECNET(II), MELSECNET/B Remote I/O Station

DN91 cannot be mounted in a MELSECNET(II), MELSECNET/B remote I/O station.

(4) Cautions When Connecting Wiring

To avoid noise interference, separate DeviceNet communication cables, power cables,

and I/O unit signal cables.

(5) No Remote Operation from Another Node

It is not enabled to read, write, or monitor the sequence program of the PLC CPU, which

contains the DN91, and the data of slave stations via nodes on the DeviceNet.

2 − 4

2. SYSTEM CONFIGURATION

2.2.3 Operating environment of the configuration software (parameter setting tool)

This section describes the operating environment when setting DN91 parameters with the

configuration software.

The configuration software is a peripheral device which installs the following configuration

software in a personal computer to allocate communication data for each slave station to the

DeviceNet master station.

(1) Configuration Software

SyCon Ver. 2.0.6.2 or later (Include DLL file Ver. 2.5.0.1 or later.)

(2) Operating Environment of the Configuration Software

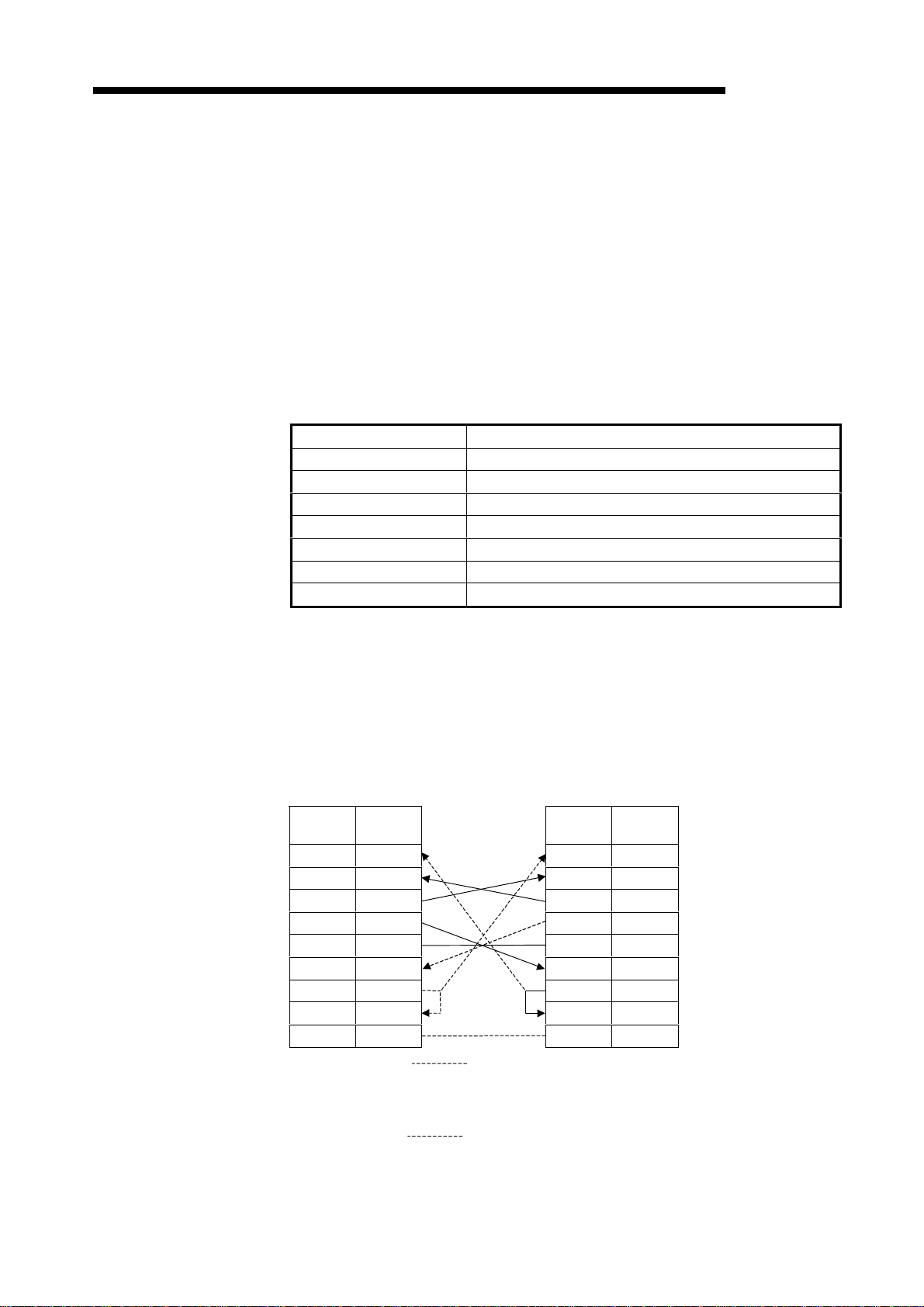

The operating environment is shown below.

Table 2.2 Operating Environment

Item Environment

Personal computer PC/AT compatible personal computer

CPU Intel 486 processor, or above

OS Windows95, WindowsNT3.51, WindowsNT4.0 *

Free disk space 10 Mbyte min.

RAM 16 Mbyte min.

Display resolution 800 x 600 dot, min.

External storage CD-ROM drive (for installation only)

MELSEC-A

*: Registered trademark of Microsoft Corporation.

(3) RS-232C Cross-cable

The wiring connections of the RS-232C cross-cable which links the PC/AT-compatible

personal computer and DN91 are shown below.

A(1S)D53DN15Dsub

female connector

(9 pin)

Signal

Name

1 1 DCD

RD 2 2 RxD

SD 3 3 TxD

DTR 4 4 DTR

SG 5 5 GND

6 6 DSR

RS 7 7 RTS

CS 8 8 CTS

9 9 RI

Pin

Number

not connected

PC/AT-compatible

PC Dsub female

connectors

(9 pin)

Pin

Number

Signal

Name

• Shielded cable is recommended.

• Connection of is recommended to eliminate directionality.

2 − 5

2. SYSTEM CONFIGURATION

REMARK

Configurator suppliers are listed below.

• USA

Synergetic Micro Systems, Inc.

2506 Wisconsin Ave.

Downers Grove, IL USA 60515

TEL: +1-630-434-1770

FAX: +1-630-434-1987

• Germany

Hilscher Gesellschaft füE Systemautomation GmbH

Rheinstrasse 78

D-65795 Hattersheim

Germany

TEL: +49-6190-9907-0

FAX: +49-6190-9907-50

• Japanese Agent

NPS Ltd.

4F Shinjuku No. 7 Hayama Building

1-36-2 Shinjuku

Shinjuku-ku

Tokyo

TEL: 03-3226-8110

FAX: 03-3226-8113

MELSEC-A

2.3 Products Connectable to a Slave Station

While it is considered connectable with most commercially available DeviceNet products, we

cannot guarantee the connectivity with products of other manufa-cturers.

2 − 6

3. SPECIFICATIONS

3. SPECIFICATIONS

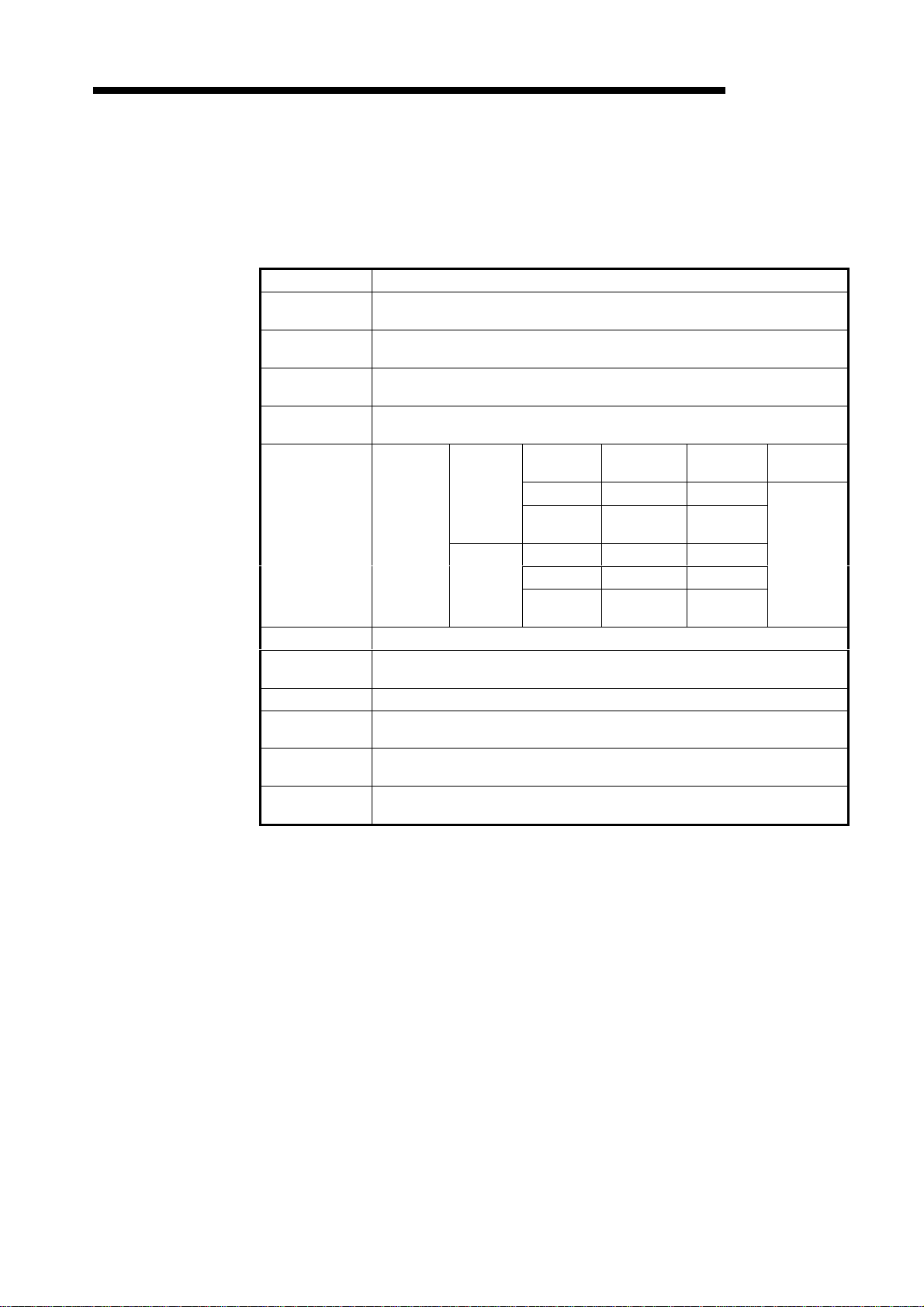

3.1 General Specifications

Table 3.1 shows the general specifications of the DN91.

Operating ambient

temperature

Operating ambient

humidity

Storage ambient

temperature

Storage ambient

humidity

Vibration

resistance

Shock resistance Conforming to JIS B 3501, IEC 1131-2 (147 m/s2 {15G}, 3 times in 3 directions)

Operating

environment

Operating altitude 2000 m max.

Installation

position

Over-voltage

category

Degree of

contamination

Table 3.1 General Specifications

Item Specification

0 to 55 °C

10 to 90 %RH, no condensation

- 20 to 75 °C

10 to 90 %RH, no condensation

Frequency Acceleration Amplitude

Intermittent

Conforming

to JIS

B3501,

IEC1131-2

*3

*1

*2

vibrations

Continuous

vibrations

10 to 57 Hz 0.075 mm

57 to 150 Hz

Frequency Acceleration Amplitude

10 to 57 Hz 0.035 mm

57 to 150 Hz

No corrosive gas

In control box

9.8 m/s

{1G}

4.9 m/s

{0.5G}

II max.

2 max.

MELSEC-A

Number of

Sweeps

2

2

10 in X, Y,

and Z

directions

(80 minutes)

*1: Indicates the position of the distribution board to which the device is assumed to be connected

between the public power network and the position of the machine in the factory.

Category II is applicable to devices supplied by power from fixed plant.

For devices rated up to 300 V, surge-voltage resistance is 2500 V.

*2: Indicator showing the degree of generation of conducting material in the device operating

environment.

A degree of contamination of 2 indicates that only non-conducting contamination occurs. However,

temporary conductivity may arise in this environment due to accidental condensation.

*3: JIS (Japanese Industrial Standard)

3 − 1

3. SPECIFICATIONS

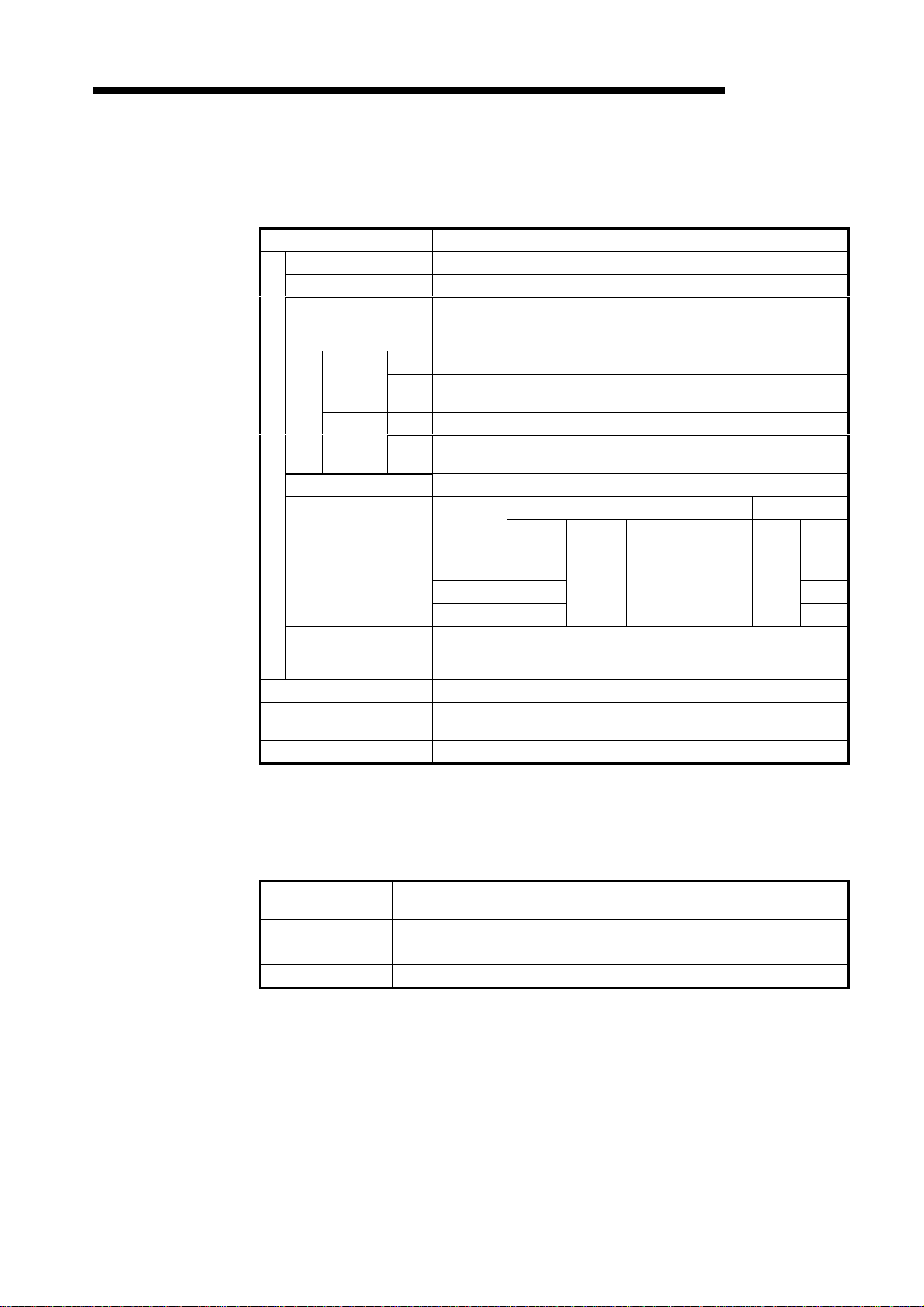

3.2 Performance Specifications

Table 3.2 shows the general specifications of the DN91.

By node type Group 2 dedicated client

Settable station numbers 0 to 63

Maximum number of

slave stations to

communicate with

Communication speed Select 125 kbaud, 250 kbaud, or 500 kbaud

Communication specification

Max. cable length *

Amperage consumption

(mA) required on the

network

Number of occupied I/Os Special 32 points

Internal current consumption

at 5 VDC (A)

Product weight (kg) A1SJ71DN91: 0.23, AJ71DN91: 0.43

Table 3.2 Performance Specifications

Item Specification

I/O

communication

volume

Message

communication

Communication data

Send 2048 points (256 bytes)

Re-

ceive

Send 240 bytes

Re-

ceive

Communi-

cation

Speed

125 kbaud 500 m 156 m

250 kbaud 250 m 78 m

500 kbaud 100 m

Trunk Line Max. Transfer Distance Drop Line

Thick

Cable

2048 points (256 bytes)

Thin

Cable

100 m See 3.2.1 6 m

63

240 bytes

Thick Cable/Thin

Cable Combination

26.5

0.24

MELSEC-A

Max. Total

39 m

*: See the DeviceNet Specifications (Release 2.0) Volume 1 and Volume 2 for details about the

maximum cable lengths.

3.2.1 Maximum transfer distance of a trunk line that contains both thick and thin cables

This section shows the maximum transfer distances for thick cable/thin cable com-binations.

Communication

Speed

125 kbaud (Thick cable length + 5) x thin cable length ≤ 500 m

250 kbaud (Thick cable length + 2.5) x thin cable length ≤ 250 m

500 kbaud Thick cable length x thin cable length ≤ 100 m

Trunk Line Max. Transfer Distance with a Thick Cable/Thin Cable

Combination

3 − 2

3. SPECIFICATIONS

3.3 PLC CPU I/O Signals

This section describes the I/O signals for the DN91 PLC CPU.

3.3.1 Table of I/O signals

Table 3.3 shows the table of DN91 I/O signals.

The letter "n" in the table represents the leading I/O number of DN91. It is determin-ed by the

position installed and the unit installed before DN91.

<Example> If the DN91 head I/O number is "X/Y30"

Input Number Signal Name Output Number Signal Name

MELSEC-A

Xn0 to X(n+1)F → X30 to X4F

Yn0 to Y(n+1)F → Y30 to Y4F

Table 3.3 Table of I/O Signals

DN91 →→ PLC CPU PLC CPU →→ DN91

Xn0 Watchdog timer error Yn0

Xn1 Refreshing Yn1

Xn2

Xn3 Error set signal Yn3

Xn4 Slave down signal Yn4

Xn5

Xn6 Parameter being set Yn6

Xn7 Parameter setting complete Yn7

Xn8 Yn8

Xn9 Yn9

XnA YnA

XnB YnB

XnC YnC

XnD YnD

XnE

XnF Unit ready YnF

X(n+1)0 Y(n+1)0 Unusable

X(n+1)1 Y(n+1)1 Refresh request

X(n+1)2 Y(n+1)2

X(n+1)3 Y(n+1)3 Error reset request

X(n+1)4 Y(n+1)4

X(n+1)5 Y(n+1)5

X(n+1)6 Y(n+1)6

X(n+1)7 Y(n+1)7 Parameter set request

X(n+1)8 Y(n+1)8

X(n+1)9 Y(n+1)9

X(n+1)A Y(n+1)A

X(n+1)B Y(n+1)B

X(n+1)C Y(n+1)C

X(n+1)D Y(n+1)D

X(n+1)E Y(n+1)E

X(n+1)F

Message communication

complete

Message communication error

signal

Unusable

Unusable

Yn2

Yn5

Unusable

YnE

Message communication

request

Unusable

Unusable

Y(n+1)F

3 − 3

3. SPECIFICATIONS

Important

MELSEC-A

The output signals designated as "unusable" in Table 3.3 are reserved for system use

and are not available to the user. Normal operation cannot be guaranteed if the user

operates one of these output signals (that is, turns the signal ON or OFF).

3 − 4

3. SPECIFICATIONS

3.3.2 I/O signal details

This section explains the I/O signal ON/OFF timing and conditions.

(1) Watchdog timer error: Xn0

(2) Refreshing: Xn1, Refresh request: Y(n+1)1

MELSEC-A

Turns ON if an error occurs in DN91.

OFF: Unit normal

ON: Unit abnormal

Watchdog timer error (Xn0)

Unit ready (XnF)

These signals determine whether the data in the input data area and output data area of

the buffer memory is used to refresh the network.

Refresh is conducted if the status of the master communication status area in buffer

memory is "operation in progress."

(a) To start the data refresh, turn ON refresh request (Y(n+1)1) with a sequen-ce

program.

(b) When refresh request (Y(n+1)1) is turned ON, the refresh operation starts and

refreshing (Xn1) turns ON automatically.

(c) To stop the data refresh, turn OFF refresh request Y(n+1)1 with a sequen-ce

program.

(d) The data refreshing is interrupted with "Refreshing" signal (Xn1) turned OFF

automatically and "OFF" or 0 data transmitted to all slave stations.

Refreshing the input data area still continues.

Refresh request (Y(n+1)1)

Refreshing (Xn1)

3 − 5

3. SPECIFICATIONS

(3) Message communication complete : Xn2

MELSEC-A

Message communication error signal : Xn5

Message communication request : Y(n+1)2

These signals are used for message communication. Message communication is

conducted if the status of the master communication status area in buffer memory is

"operation in progress."

(a) Follow the procedure below to conduct message communication.

1) Write the message communication data to the message communication

command area in buffer memory.

2) Turn ON message communication request (Y(n+1)2) with a sequence program.

(Set the interval of turning ON the message communication request at 100 ms

or over.)

(b) The message communication completes with the results written onto the "Message

communication results" area, and the message communication complete (Xn2)

turns ON.

(c) Check the results of the message communication through the message

communication error signal (Xn5).

Message communication

request (Y(n+1)2)

Message communication

complete (Xn2)

Message communication

error signal (Xn5)

FROM/TO

(d) After reading the communication data with FROM command, the sequence program

is used to turn OFF the message communication request (Y(n+1)2).

The message communication complete (Xn2) and message communication error

signal (Xn5) automatically turns OFF.

Write message

communication

command (TO

instruction)

Error involved

Write message

communication

data (TO

instruction)

(For data send only) (For data receive only)

Read message

communication

results (FROM

instruction)

No error

Read message

communication

data (FROM

instruction)

(4) Error set signal: Xn3, Error reset request: Y(n+1)3

These signals are used to notify an error and reset error codes.

(a) If an error occurs, error information is stored in the error information area in buffer

memory and the error set signal (Xn3) turns ON.

The error set signal automatically turns OFF when the cause of the error is

removed.

(b) Once the cause of error is removed, turning ON the error-resetting request

(Y(n+1)3) with the sequence program clears the error code set on the "error

information" area.

Error reset request (Y(n+1)3)

Error set signal (Xn3)

FROM/TO

3 − 6

Read error

information (FROM

instruction)

3. SPECIFICATIONS

(5) Slave down signal: Xn4

(6) Parameter-being-set : Xn6

MELSEC-A

This signal indicates whether any slave station has stopped communication.

(a) This signal turns ON if any slave station for which parameters are set stops

communication.

OFF : All stations communicating normally

ON : Abnormal communication at a station

Which station has stopped communication can be confirmed from the station

communication status area at addresses 01BCH to 01BFH of the buffer memory.

(b) This signal automatically turns OFF when the slave station communication restarts.

Parameter set complete : Xn7

Parameter set request : Y(n+1)7

These signals are used to set parameters with a sequence program. Set the parameters

when the refreshing (Xn1) signal is OFF.

(a) Follow the procedure below to write parameters.

1) Write the parameters to the parameter set area in buffer memory.

2) Turn on parameter set request (Y(n+1)7) with a sequence program.

(b) Once the write request is received and the parameter analysis completes normally,

parameter-writing action gets executed with the parameter-being-set (Xn6) turned

ON.

(c) Parameter set complete (Xn7) automatically turns ON when the parameter write

operation is complete. Communication with other slave stations is disabled while

parameters are being set.

Parameter set complete (Xn7) automatically turns OFF when parameter set request

(Y(n+1)7) turns OFF.

Refresh request (Y(n+1)1)

Refreshing (Xn1)

Parameter set request (Y(n+1)7)

Parameter being set (Xn6)

Parameter set complete (Xn7)

TO instruction

POINTS

(1) If refreshing (Xn1) is ON when parameter set request (Y(n+1)7) turns ON,

parameter set complete (Xn7) does not turn ON. First, turn OFF refresh request

(Y(n+1)1) and confirm that refreshing (Xn1) is OFF before turning parameter set

request (Y(n+1)7) OFF and back ON.

(2) If parameter set request (Y(n+1)7) is ON when refresh request (Y(n+1)1) turns ON,

refreshing (Xn1) does not turn ON. First, turn OFF parameter set request

(Y(n+1)7), then reset refresh request (Y(n+1)1) and turn it back ON.

Write parameter

data

3 − 7

Loading...

Loading...