SERVICE MANUAL

Date: 2012/07/12

Table of Contents

Revision history......................................................................................................................................1

A SAFETY AND IMPORTANT WARNING ITEMS............................................................................A-1

1. IMPORTANT NOTICE.................................................................................................................................................A-2

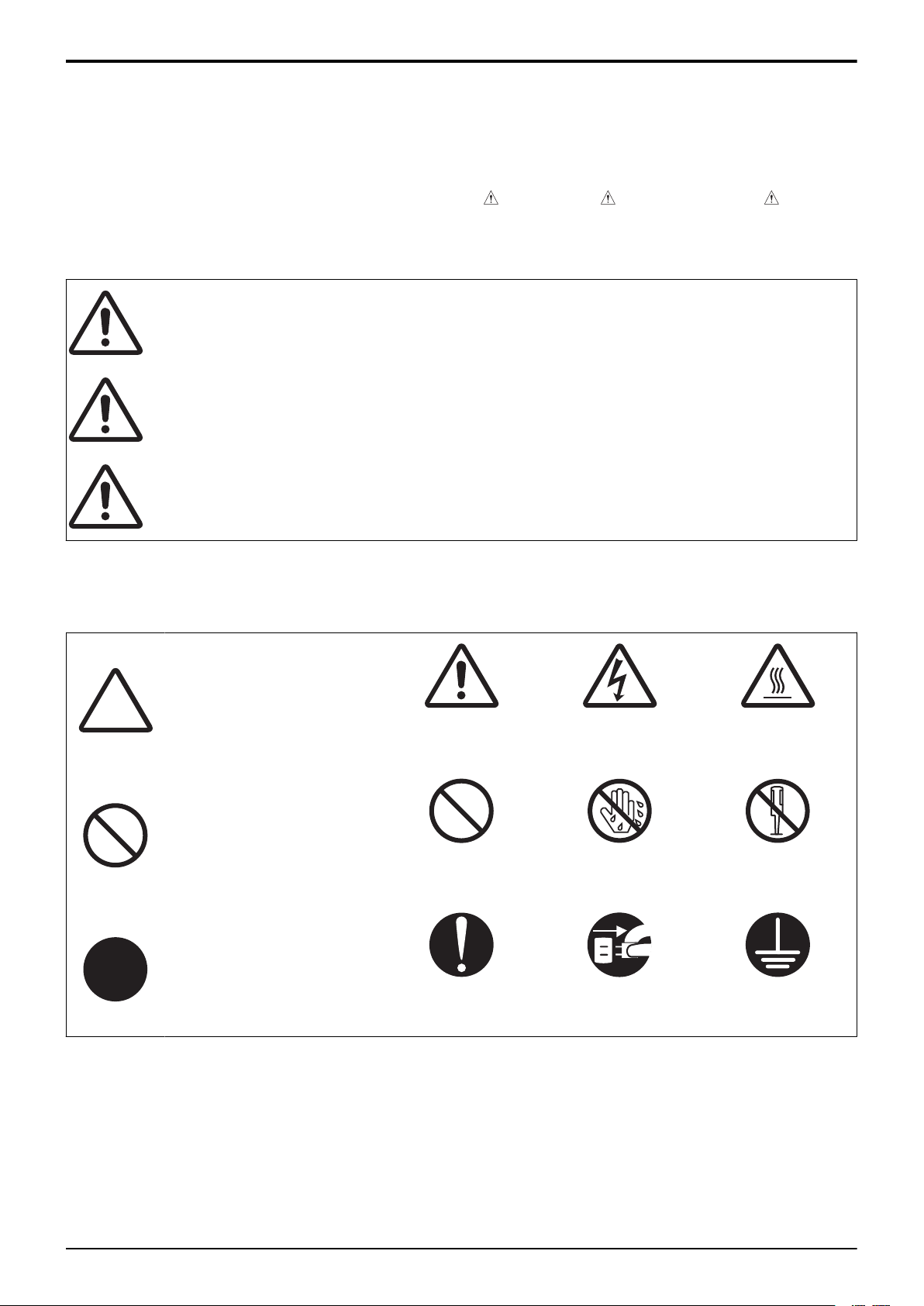

2. DESCRIPTION ITEMS FOR DANGER, WARNING AND CAUTION..........................................................................A-3

2.1 Description items in this Service Manual...................................................................................................................................A-3

2.2 Description items for safety and important warning items.........................................................................................................A-3

3. SAFETY WARNINGS..................................................................................................................................................A-4

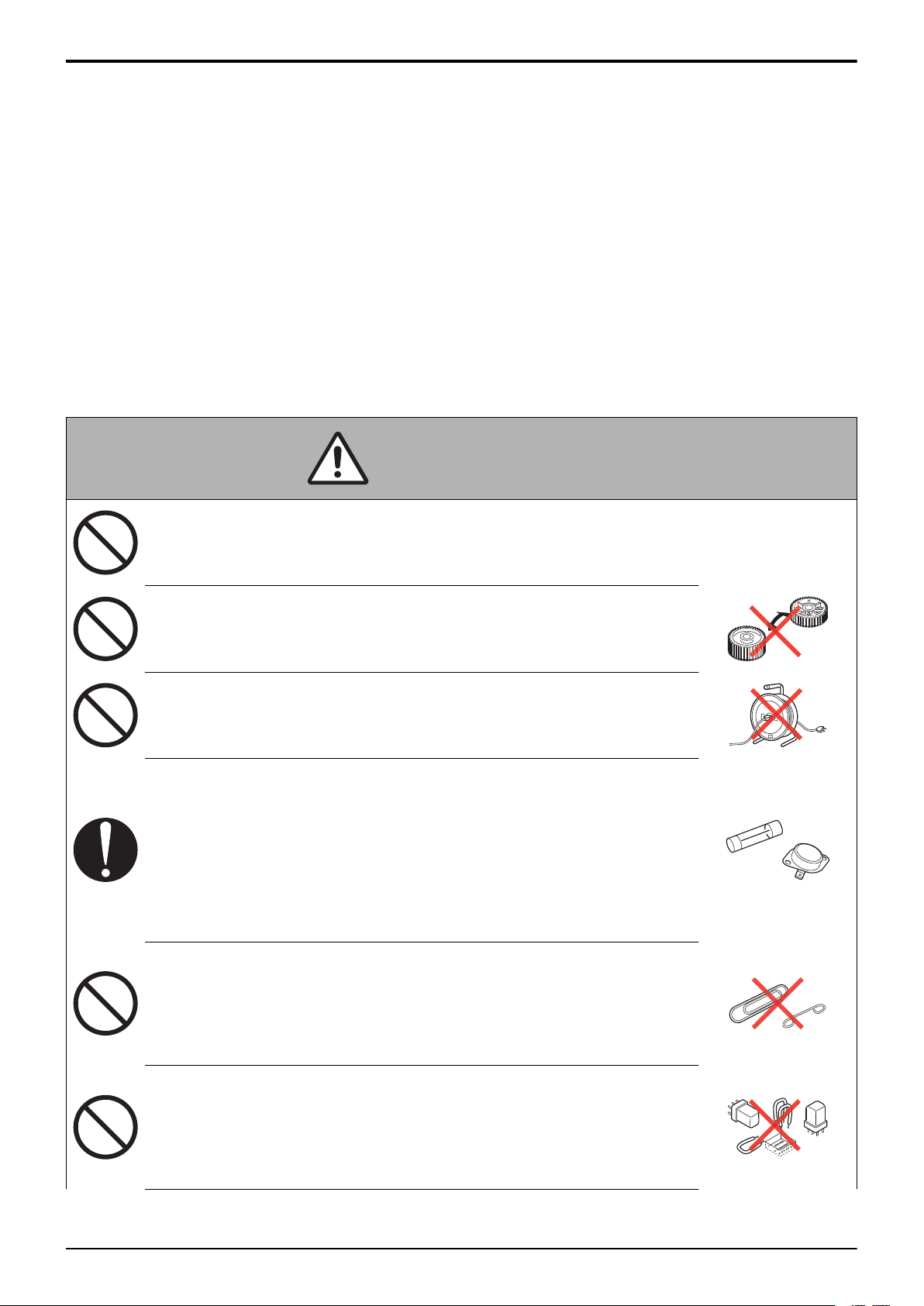

3.1 MODIFICATIONS NOT AUTHORIZED BY KONICA MINOLTA BUSINESS TECHNOLOGIES, INC......................................A-4

3.1.1 Actions requiring special attention...................................................................................................................................A-4

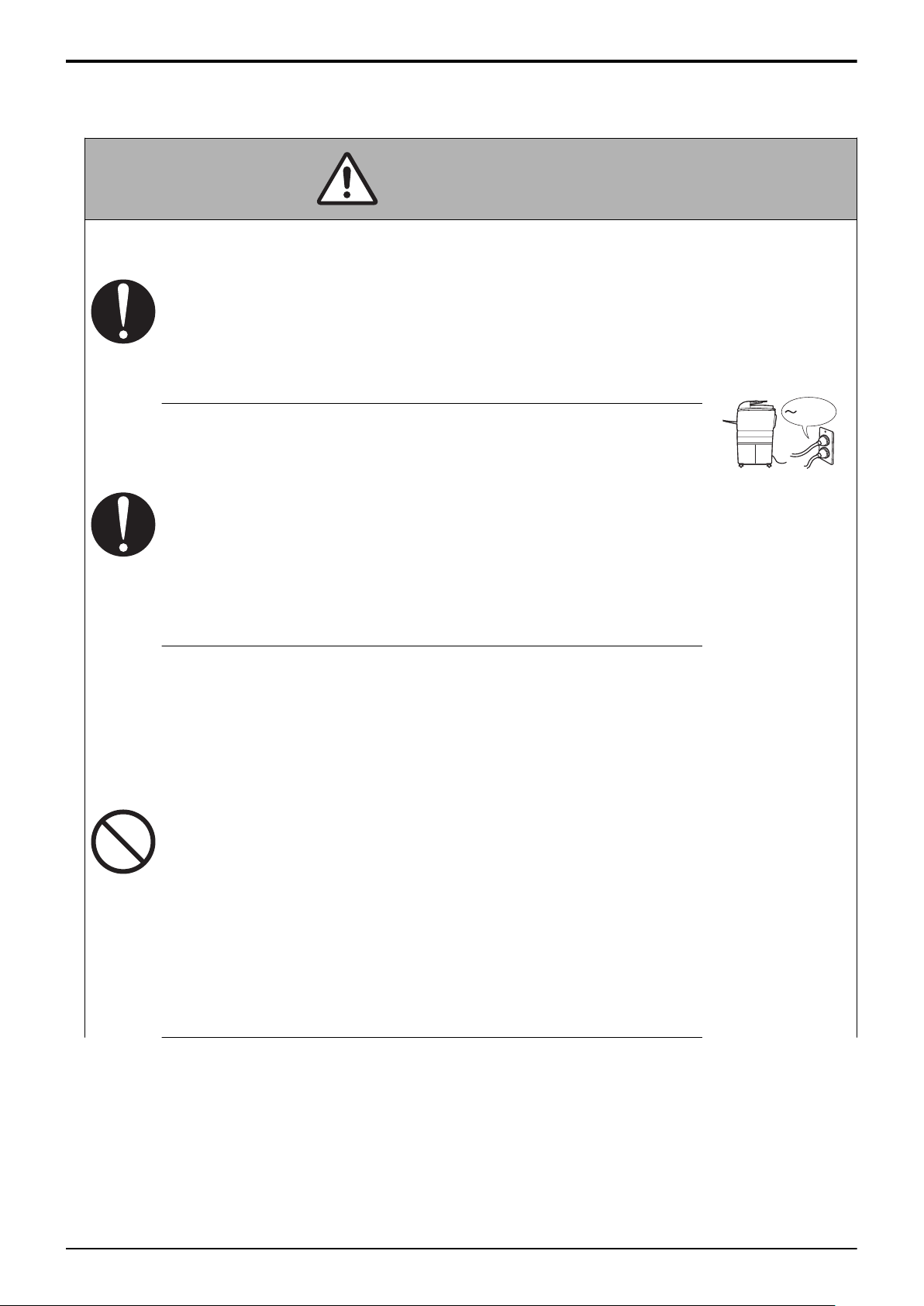

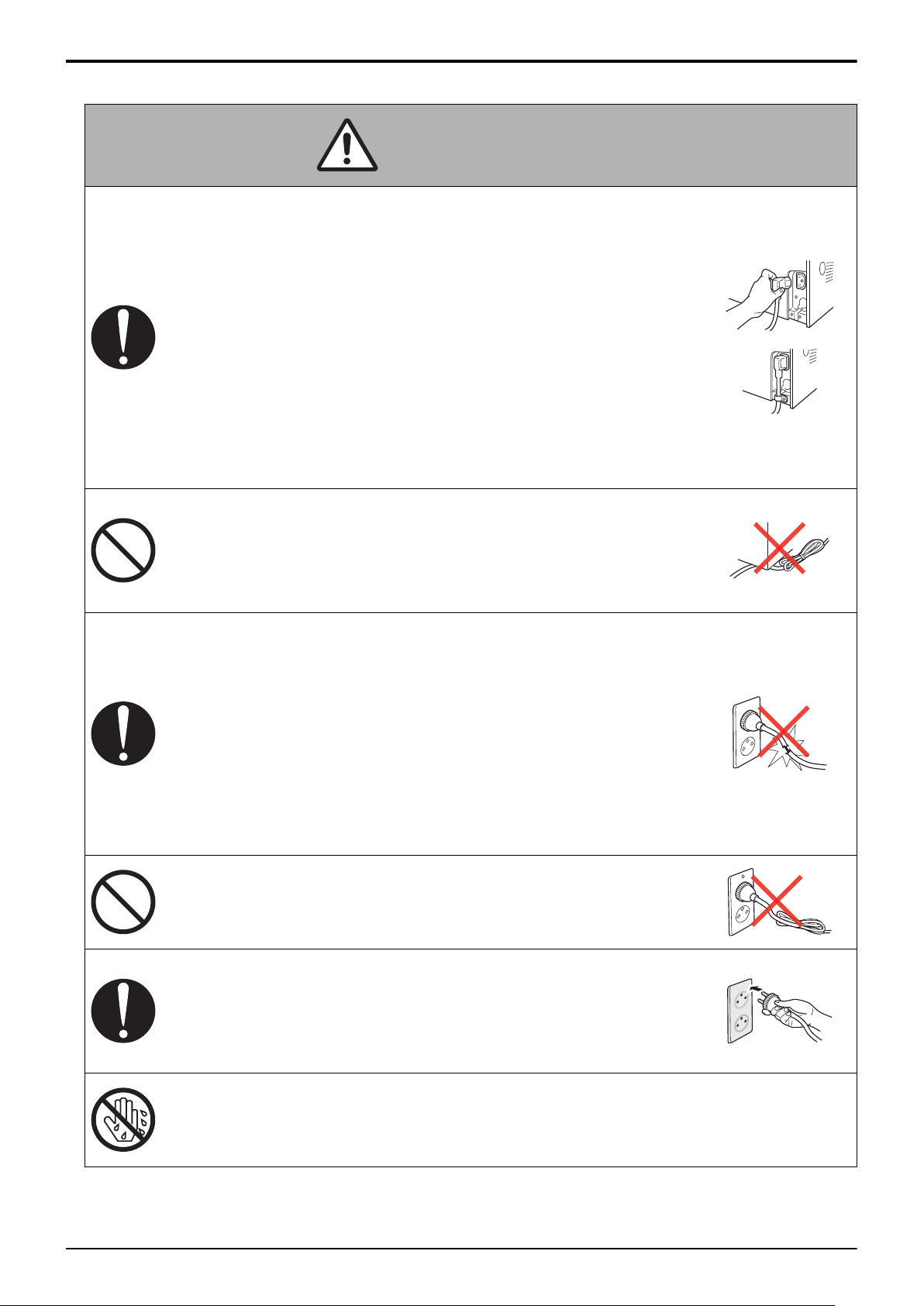

3.2 POWER PLUG SELECTION.....................................................................................................................................................A-5

3.2.1 Power Cord Set or Power Plug.......................................................................................................................................A-5

3.3 CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE...................................................................................................A-6

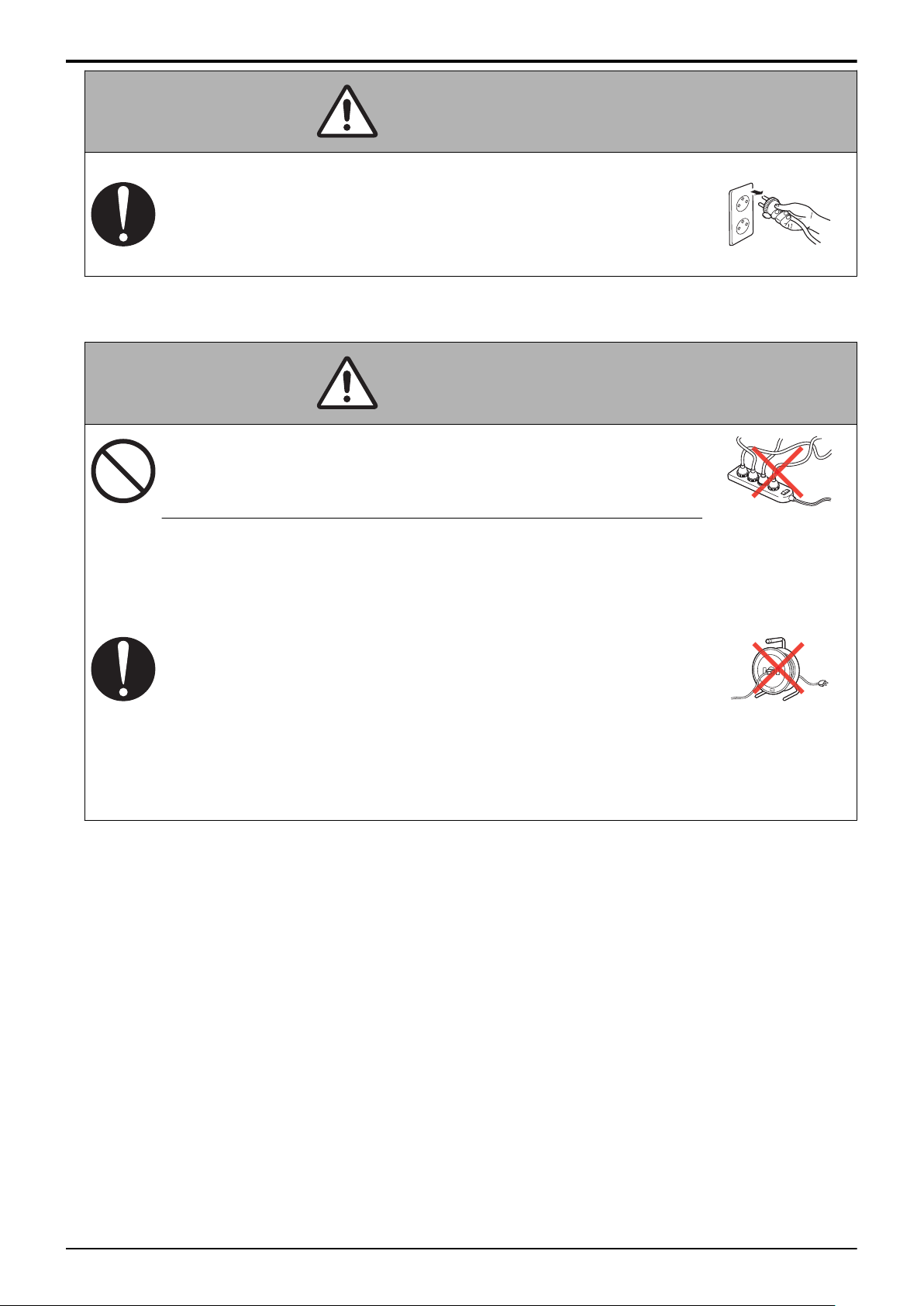

3.3.1 Power Supply..................................................................................................................................................................A-7

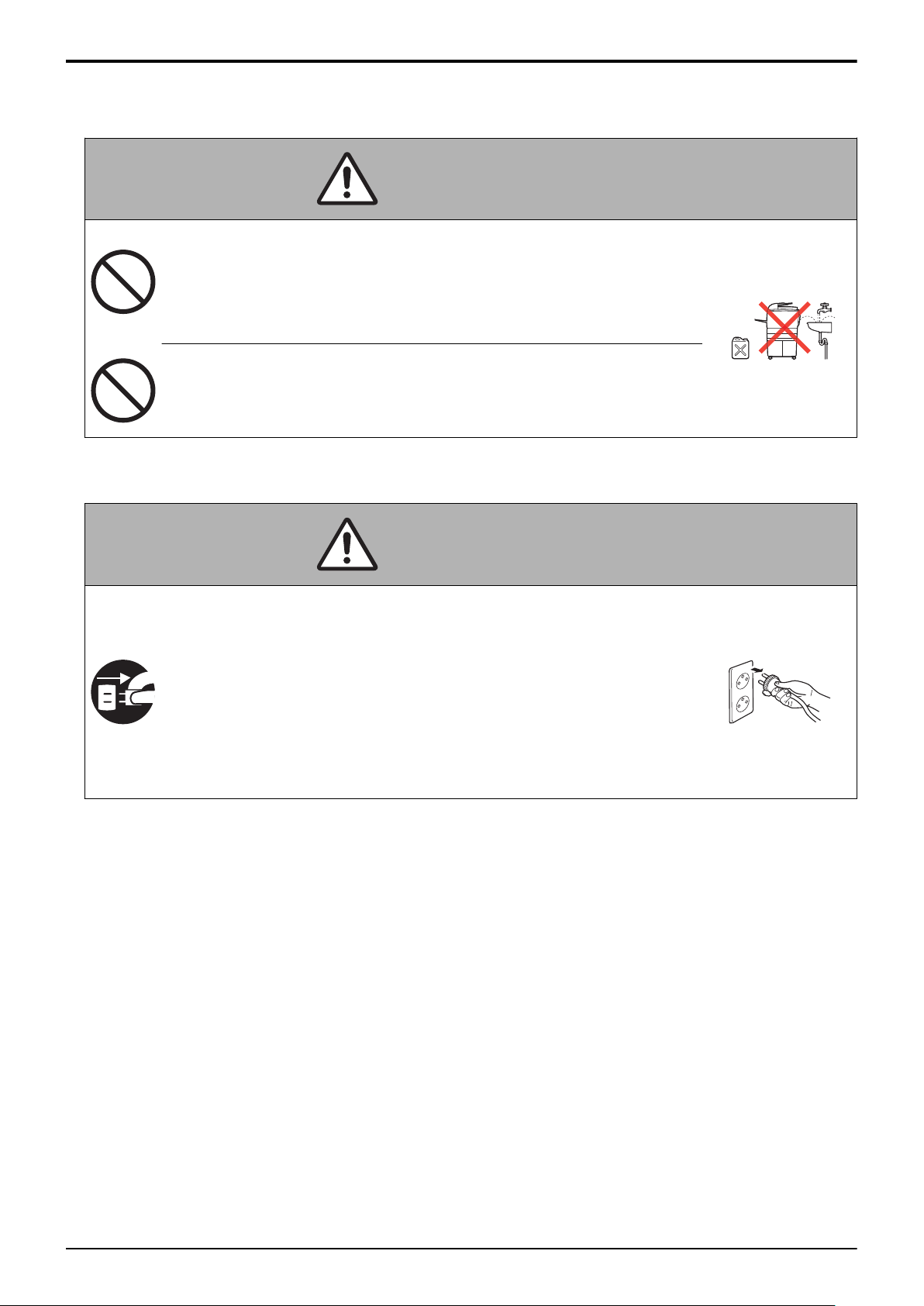

3.3.2 Installation Requirements..............................................................................................................................................A-11

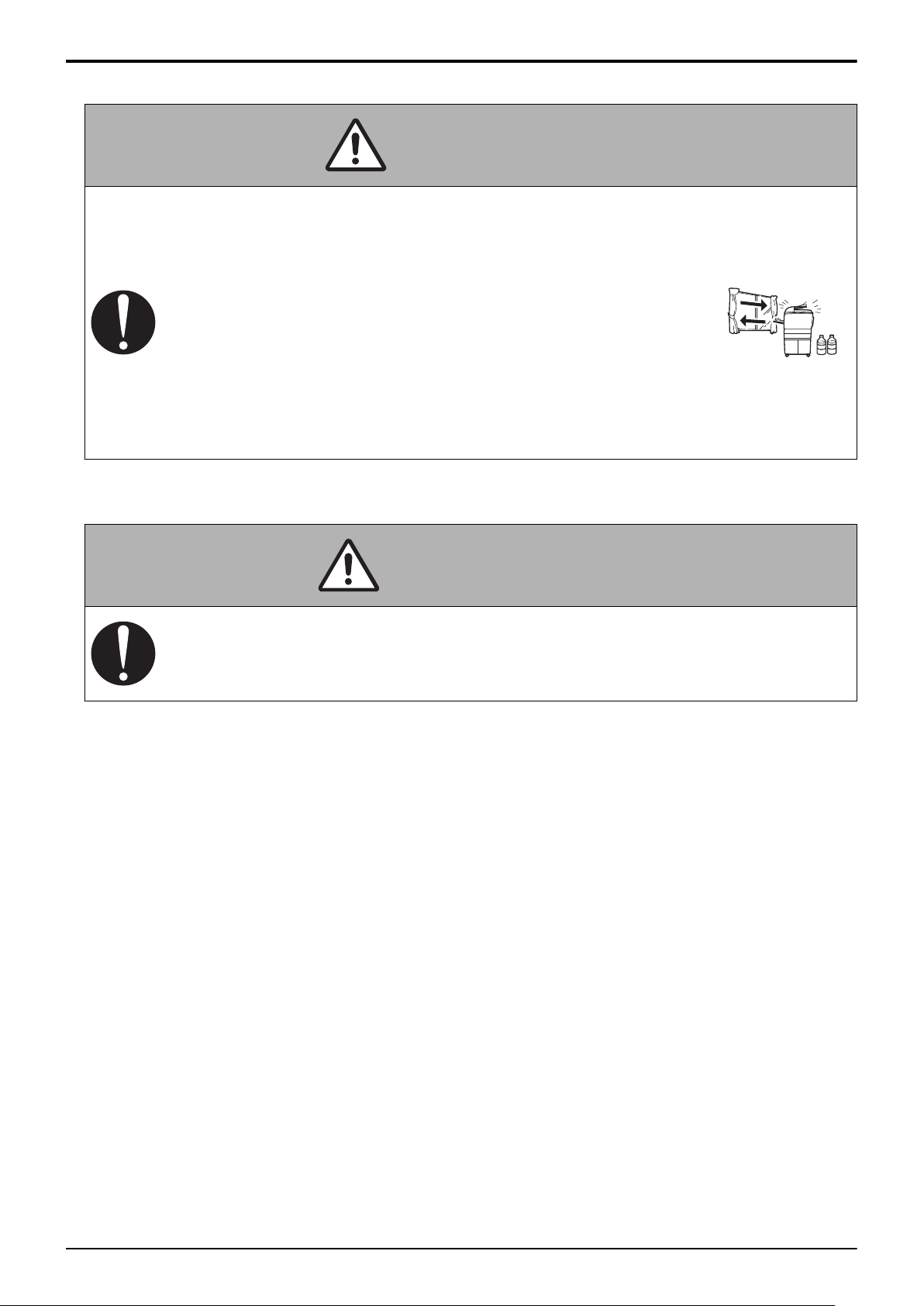

3.3.3 After Service..................................................................................................................................................................A-13

3.4 FUSE.......................................................................................................................................................................................A-18

3.5 Used Batteries Precautions.....................................................................................................................................................A-19

3.5.1 ALL Areas......................................................................................................................................................................A-19

3.5.2 Germany........................................................................................................................................................................A-19

3.5.3 France...........................................................................................................................................................................A-19

3.5.4 Denmark........................................................................................................................................................................A-19

3.5.5 Finland, Sweden............................................................................................................................................................A-19

3.5.6 Norway..........................................................................................................................................................................A-19

3.6 Laser Safety............................................................................................................................................................................A-20

3.6.1 Laser Safety..................................................................................................................................................................A-20

3.6.2 Internal Laser Radiation................................................................................................................................................A-20

3.6.3 Laser Safety Label........................................................................................................................................................A-24

3.6.4 Laser Caution Label......................................................................................................................................................A-24

3.6.5 PRECAUTIONS FOR HANDLING THE LASER EQUIPMENT.....................................................................................A-24

4. WARNING INDICATIONS ON THE MACHINE.........................................................................................................A-26

4.1 Warning indications inside the machine..................................................................................................................................A-26

4.2 Warning indications on the boards..........................................................................................................................................A-27

5. MEASURES TO TAKE IN CASE OF AN ACCIDENT...............................................................................................A-28

B NOTATION OF THE CONTENTS..................................................................................................B-1

1. NOTATION OF THE CONTENTS...............................................................................................................................B-1

1.1 Product name............................................................................................................................................................................B-1

1.2 Brand name...............................................................................................................................................................................B-1

1.3 Paper feed direction..................................................................................................................................................................B-1

C PRODUCT SPECIFICATIONS......................................................................................................C-1

1. bizhub 235/215/195.....................................................................................................................................................C-1

1.1 Type..........................................................................................................................................................................................C-1

1.2 Functions...................................................................................................................................................................................C-1

1.3 Paper.........................................................................................................................................................................................C-2

1.4 Materials....................................................................................................................................................................................C-2

1.5 Print volume..............................................................................................................................................................................C-2

1.5.1 bizhub 215.......................................................................................................................................................................C-2

1.5.2 bizhub 195.......................................................................................................................................................................C-2

1.6 Machine specifications..............................................................................................................................................................C-2

1.7 Operating environment..............................................................................................................................................................C-3

1.8 Print function.............................................................................................................................................................................C-3

1.9 Scan function.............................................................................................................................................................................C-3

2. AD-509........................................................................................................................................................................C-4

2.1 Type..........................................................................................................................................................................................C-4

2.2 Paper type.................................................................................................................................................................................C-4

2.3 Machine specifications..............................................................................................................................................................C-4

2.4 Operating environment..............................................................................................................................................................C-4

3. DF-625........................................................................................................................................................................C-5

3.1 Type..........................................................................................................................................................................................C-5

3.2 Functions...................................................................................................................................................................................C-5

3.3 Paper type.................................................................................................................................................................................C-5

3.4 Paper feed prohibited originals..................................................................................................................................................C-5

3.5 Paper feed not guaranteed originals.........................................................................................................................................C-5

3.6 Mixed original feed chart...........................................................................................................................................................C-6

i

3.7 Machine specifications..............................................................................................................................................................C-6

3.8 Operating...................................................................................................................................................................................C-6

4. MB-505........................................................................................................................................................................C-7

4.1 Paper.........................................................................................................................................................................................C-7

4.2 Machine specifications..............................................................................................................................................................C-7

4.3 Operating environment..............................................................................................................................................................C-7

5. PF-507........................................................................................................................................................................C-8

5.1 Type..........................................................................................................................................................................................C-8

5.2 Paper type.................................................................................................................................................................................C-8

5.3 Machine specifications..............................................................................................................................................................C-8

5.4 Operating environment..............................................................................................................................................................C-8

6. FK-510........................................................................................................................................................................C-9

D OVERALL COMPOSITION............................................................................................................D-1

1. SYSTEM CONFIGURATION......................................................................................................................................D-1

2. CROSS SECTIONAL VIEW........................................................................................................................................D-2

3. PAPER PATH.............................................................................................................................................................D-3

4. OVERALL CONFIGRATION.......................................................................................................................................D-4

4.1 Control Block Diagram..............................................................................................................................................................D-4

4.2 Image creation process ............................................................................................................................................................D-4

E SERVICE TOOL.............................................................................................................................E-1

1. Service material list.....................................................................................................................................................E-1

2. CE tool list...................................................................................................................................................................E-2

F MAINTENANCE..............................................................................................................................F-1

1. Concept of periodical maintenance.............................................................................................................................F-1

1.1 Concept of periodical maintenance...........................................................................................................................................F-1

1.2 bizhub 235/215/195...................................................................................................................................................................F-1

1.2.1 Periodical maintenance 1 (Total counter; every 55,000 counts).....................................................................................F-1

1.2.2 Periodical maintenance 2 (PM counter; every 165,000 counts)......................................................................................F-1

1.2.3 Periodical maintenance 3 (SUPPLIES counter; every 165,000 counts)..........................................................................F-1

1.3 Option........................................................................................................................................................................................F-1

1.3.1 Reverse automatic document feeder (DF-625)...............................................................................................................F-1

1.3.2 Paper feeder unit (PF-507)..............................................................................................................................................F-1

1.3.3 Multi bypass tray (MB-505)..............................................................................................................................................F-2

2. PERIODICAL MAINTENANCE ITEMS........................................................................................................................F-3

2.1 Periodical replacement parts list................................................................................................................................................F-3

2.1.1 Periodical replacement parts list......................................................................................................................................F-3

2.1.2 bizhub 235/215/195.........................................................................................................................................................F-3

2.1.3 Option..............................................................................................................................................................................F-3

2.2 Periodical cleaning parts list......................................................................................................................................................F-3

2.2.1 bizhub 235/215/195.........................................................................................................................................................F-3

2.2.2 Option..............................................................................................................................................................................F-4

2.3 Concept of parts life...................................................................................................................................................................F-4

2.3.1 Life value of consumables and parts...............................................................................................................................F-4

2.3.2 Conditions for life specifications values...........................................................................................................................F-4

3. PERIODICAL MAINTENANCE PROCEDURE bizhub 235/215/195...........................................................................F-5

3.1 Processing section.....................................................................................................................................................................F-5

3.1.1 Replacing the developer..................................................................................................................................................F-5

3.1.2 Replacing the drum.........................................................................................................................................................F-7

3.1.3 Replacing the drum charge corona assy.........................................................................................................................F-8

3.1.4 Replacing the cleaning blade..........................................................................................................................................F-9

3.1.5 Application of toner..........................................................................................................................................................F-9

3.1.6 Replacing the toner bottle..............................................................................................................................................F-10

3.1.7 Cleaning of the Ds collars..............................................................................................................................................F-11

3.1.8 Cleaning of the drum separator fingers.........................................................................................................................F-12

3.1.9 Cleaning of the developer scattering prevention plate..................................................................................................F-12

3.1.10 Replacing the imaging unit..........................................................................................................................................F-14

3.2 Conveyance section................................................................................................................................................................F-14

3.2.1 Cleaning of the registration roller...................................................................................................................................F-14

3.2.2 Cleaning of the pre-image transfer guide plate.............................................................................................................F-14

3.3 Fusing section..........................................................................................................................................................................F-16

3.3.1 Replacing the fusing unit...............................................................................................................................................F-16

3.4 Paper feed section...................................................................................................................................................................F-17

3.4.1 Replacing the tray 1 feed roller......................................................................................................................................F-17

3.4.2 Replacing the tray 1 separation pad..............................................................................................................................F-18

3.5 Conveyance section................................................................................................................................................................F-18

ii

3.5.1 Replacing the transfer roller unit....................................................................................................................................F-18

4. PERIODICAL MAINTENANCE PROCEDURE DF-625.............................................................................................F-19

4.1 Paper feed section (DF-625)...................................................................................................................................................F-19

4.1.1 Replacing the separation roller (DF-625)......................................................................................................................F-19

4.1.2 Cleaning of the pick-up roller/feed roller/separation roller (DF-625)..............................................................................F-20

4.1.3 Cleaning of the document transport sensor (DF-625)...................................................................................................F-21

4.2 Conveyance section (DF-625).................................................................................................................................................F-21

4.2.1 Cleaning of the roller and rolls (DF-625).......................................................................................................................F-21

4.3 Scanning section (DF-625)......................................................................................................................................................F-22

4.3.1 Cleaning of the scanning guide (DF-625)......................................................................................................................F-22

5. PERIODICAL MAINTENANCE PROCEDURE PF-507.............................................................................................F-24

5.1 Paper feed section (PF-507)....................................................................................................................................................F-24

5.1.1 Replacing the feed roller (PF-507)................................................................................................................................F-24

6. PERIODICAL MAINTENANCE PROCEDURE MB-505............................................................................................F-25

6.1 Paper feed section (MB-505)...................................................................................................................................................F-25

6.1.1 Replacing the feed roller (MB-505)................................................................................................................................F-25

6.1.2 Replacing the separation roller assy (MB-505).............................................................................................................F-26

G DISASSEMBLING/REASSEMBLING............................................................................................G-1

1. Disassembly/adjustment prohibited items...................................................................................................................G-1

1.1 Disassembly/adjustment prohibited items.................................................................................................................................G-1

1.1.1 Paint-locked screws........................................................................................................................................................G-1

1.1.2 Red-painted screws........................................................................................................................................................G-1

1.1.3 Variable resistors on board.............................................................................................................................................G-1

1.1.4 Removal of PWBs...........................................................................................................................................................G-1

1.1.5 Warnings for disassembly...............................................................................................................................................G-2

1.1.6 Precautions/warnings during setup or transportation......................................................................................................G-2

1.2 Units from which removing is prohibited...................................................................................................................................G-3

1.2.1 PH unit............................................................................................................................................................................G-3

1.2.2 Fusing unit......................................................................................................................................................................G-3

2. bizhub 235/215/195....................................................................................................................................................G-4

2.1 Disassembly/reassembly parts list............................................................................................................................................G-4

2.1.1 Exterior parts...................................................................................................................................................................G-4

2.1.2 Units................................................................................................................................................................................G-4

2.1.3 Boards.............................................................................................................................................................................G-4

2.1.4 Others.............................................................................................................................................................................G-4

2.2 Disassembly/reassembly procedure (Exterior parts)................................................................................................................G-4

2.2.1 Front door.......................................................................................................................................................................G-4

2.2.2 Front cover......................................................................................................................................................................G-5

2.2.3 Left cover........................................................................................................................................................................G-5

2.2.4 Right rear cover..............................................................................................................................................................G-5

2.2.5 Right lower cover............................................................................................................................................................G-6

2.2.6 Rear cover......................................................................................................................................................................G-6

2.2.7 Scanner right cover.........................................................................................................................................................G-6

2.2.8 Paper exit rear cover.......................................................................................................................................................G-6

2.2.9 Paper exit tray (left) / Paper exit tray (right)....................................................................................................................G-7

2.2.10 Control panel left cover.................................................................................................................................................G-7

2.2.11 Control panel.................................................................................................................................................................G-7

2.2.12 Original glass assy........................................................................................................................................................G-8

2.3 Disassembly/reassembly procedure (Units)..............................................................................................................................G-9

2.3.1 Tray 1..............................................................................................................................................................................G-9

2.3.2 PH unit..........................................................................................................................................................................G-10

2.3.3 CIS module (CIS)..........................................................................................................................................................G-11

2.3.4 Scanner unit..................................................................................................................................................................G-12

2.3.5 Paper exit unit...............................................................................................................................................................G-13

2.4 Disassembly/reassembly procedure (Boards)........................................................................................................................G-14

2.4.1 MFP board (MFPB).......................................................................................................................................................G-14

2.4.2 High voltage unit (HV1).................................................................................................................................................G-15

2.4.3 DC power supply (DCPU).............................................................................................................................................G-15

2.4.4 BB Module board (BBMB).............................................................................................................................................G-16

2.5 Disassembly/reassembly procedure (Others).........................................................................................................................G-16

2.5.1 Ozone filter....................................................................................................................................................................G-16

2.5.2 Main motor (M1)............................................................................................................................................................G-16

2.5.3 Toner supply motor (M2)...............................................................................................................................................G-17

2.5.4 Scanner motor (M3)......................................................................................................................................................G-17

2.5.5 Switchback motor (M4).................................................................................................................................................G-18

2.5.6 Fusing cooling fan motor (FM1)....................................................................................................................................G-19

2.5.7 Registration clutch (CL1)..............................................................................................................................................G-19

2.5.8 Tray1 paper feed clutch (CL2)......................................................................................................................................G-19

iii

2.5.9 Temperature/humidity sensor (TEM/HUM)...................................................................................................................G-20

2.5.10 Inch/metric sensor (PS6) assy (Asia Pacific only)......................................................................................................G-20

3. Option.......................................................................................................................................................................G-22

3.1 Disassembly/reassembly parts list..........................................................................................................................................G-22

3.1.1 DF-625..........................................................................................................................................................................G-22

3.1.2 PF-507..........................................................................................................................................................................G-22

3.1.3 MB-505.........................................................................................................................................................................G-22

3.1.4 AD-509..........................................................................................................................................................................G-22

3.1.5 FK-510..........................................................................................................................................................................G-22

3.1.6 IC-209/NC-504..............................................................................................................................................................G-22

3.1.7 MC-504.........................................................................................................................................................................G-22

3.2 Disassembly/reassembly procedure(DF-625).........................................................................................................................G-23

3.2.1 Upper cover (DF-625)...................................................................................................................................................G-23

3.2.2 Front cover (DF-625)....................................................................................................................................................G-23

3.2.3 Rear cover (DF-625).....................................................................................................................................................G-24

3.2.4 Original paper set tray (DF-625)...................................................................................................................................G-24

3.2.5 Reverse Automatic Document Feeder (DF-625)..........................................................................................................G-25

3.2.6 Upper door assy (DF-625)............................................................................................................................................G-26

3.2.7 Document conveyance unit (DF-625)...........................................................................................................................G-27

3.2.8 DF control board (DFCB) (DF-625)...............................................................................................................................G-28

3.2.9 Feed roller/Pick-up roller (DF-625)...............................................................................................................................G-28

3.2.10 DF motor (M1) (DF-625).............................................................................................................................................G-29

3.2.11 Document feed clutch (CL1) (DF-625)........................................................................................................................G-30

3.2.12 Document registration clutch (CL2) (DF-625).............................................................................................................G-30

3.2.13 Switchback clutch (CL3) (DF-625)..............................................................................................................................G-30

3.3 Disassembly/reassembly procedure (PF-507)........................................................................................................................G-31

3.3.1 Tray (PF-507)................................................................................................................................................................G-31

3.3.2 Rear cover (PF-507).....................................................................................................................................................G-31

3.3.3 Paper Feeder Unit (PF-507).........................................................................................................................................G-32

3.3.4 PF drive board (PFDB) (PF-507)..................................................................................................................................G-34

3.3.5 Paper size detect switch (S1) (PF-507)........................................................................................................................G-34

3.3.6 Paper feed solenoid (SD1) (PF-507)............................................................................................................................G-35

3.4 Disassembly/reassembly procedure (MB-505).......................................................................................................................G-36

3.4.1 Multi Bypass Tray (MB-505).........................................................................................................................................G-36

3.4.2 Bypass paper feed clutch (CL1) (MB-505)....................................................................................................................G-36

3.4.3 Bypass pick-up solenoid (SD1) (MB-505).....................................................................................................................G-37

3.5 Disassembly/reassembly procedure (AD-509)........................................................................................................................G-38

3.5.1 Right cover (AD-509)....................................................................................................................................................G-38

3.5.2 Automatic Duplex Unit (AD-509)...................................................................................................................................G-38

3.5.3 AD drive board (ADDB) (AD-509).................................................................................................................................G-39

3.5.4 AD motor (M1) (AD-509)...............................................................................................................................................G-39

3.5.5 Cooling fan motor (FM2) (AD-509)...............................................................................................................................G-39

3.6 Disassembly/reassembly procedure (FK-510)........................................................................................................................G-40

3.6.1 FAX board (FAXB) (FK-510).........................................................................................................................................G-40

3.6.2 FAX control panel (FK-510)..........................................................................................................................................G-40

3.6.3 Speaker (FK-510).........................................................................................................................................................G-40

3.7 Disassembly/reassembly procedure (IC-209/NC-504)............................................................................................................G-41

3.7.1 PCL/NIC board (PNICB)/NIC board (NICB) (IC-209/NC-504)......................................................................................G-41

3.8 Disassembly/reassembly procedure (MC-504).......................................................................................................................G-41

3.8.1 Mechanical Counter (MC-504)......................................................................................................................................G-41

H CLEANING/LUBRICATION...........................................................................................................H-1

1. bizhub235/215/195......................................................................................................................................................H-1

1.1 Cleaning parts list......................................................................................................................................................................H-1

1.2 Cleaning procedure...................................................................................................................................................................H-1

1.2.1 Tray 1 feed roller.............................................................................................................................................................H-1

1.2.2 Tray 1 separation pad.....................................................................................................................................................H-1

1.2.3 Original glass .................................................................................................................................................................H-1

2. Option..........................................................................................................................................................................H-2

2.1 Cleaning parts list......................................................................................................................................................................H-2

2.1.1 PF-507............................................................................................................................................................................H-2

2.1.2 AD-509............................................................................................................................................................................H-2

2.1.3 MB-505............................................................................................................................................................................H-2

2.2 Cleaning procedure (PF-507)....................................................................................................................................................H-2

2.2.1 Feed roller.......................................................................................................................................................................H-2

2.2.2 Vertical transport roller/roll..............................................................................................................................................H-2

2.3 Cleaning procedure (AD-509)...................................................................................................................................................H-2

2.3.1 Automatic duplex unit transport roller/roll........................................................................................................................H-2

2.3.2 Switchback section transport roller/roll............................................................................................................................H-3

2.3.3 Automatic duplex unit ventilation section........................................................................................................................H-3

iv

2.4 Cleaning procedure (MB-505)...................................................................................................................................................H-3

2.4.1 Separation roller..............................................................................................................................................................H-3

2.4.2 Feed roller.......................................................................................................................................................................H-4

I ADJUSTMENT/SETTING.................................................................................................................I-1

1. HOW TO USE THE ADJUSTMENT/SETTING SECTION............................................................................................I-1

1.1 Outline.........................................................................................................................................................................................I-1

1.2 Advance checks..........................................................................................................................................................................I-1

2. UTILITY MODE.............................................................................................................................................................I-2

2.1 List of utility mode.......................................................................................................................................................................I-2

2.2 Starting/Exiting............................................................................................................................................................................I-4

2.2.1 Starting procedure............................................................................................................................................................I-4

2.2.2 Exiting procedure..............................................................................................................................................................I-4

2.3 MACHINE SETTING...................................................................................................................................................................I-4

2.3.1 AUTO PANEL RESET......................................................................................................................................................I-4

2.3.2 SLEEP MODE..................................................................................................................................................................I-4

2.3.3 AUTO SHUT TIME...........................................................................................................................................................I-4

2.3.4 DENSITY (ADF)................................................................................................................................................................I-5

2.3.5 DENSITY (BOOK)............................................................................................................................................................I-5

2.3.6 PRINT DENSITY..............................................................................................................................................................I-5

2.3.7 LCD CONTRAST..............................................................................................................................................................I-5

2.3.8 KEY SPEED SETTING.....................................................................................................................................................I-5

2.3.9 LANGUAGE......................................................................................................................................................................I-6

2.3.10 BUZZER VOLUME.........................................................................................................................................................I-6

2.3.11 INITIAL MODE................................................................................................................................................................I-9

2.3.12 SCAN THRESHOLD.......................................................................................................................................................I-9

2.4 PAPER SOURCE SETUP........................................................................................................................................................I-10

2.4.1 TRAY1............................................................................................................................................................................I-10

2.4.2 TRAY2/TRAY3/TRAY4/TRAY5......................................................................................................................................I-10

2.5 CUSTOM SIZE MEMORY........................................................................................................................................................I-10

2.5.1 CUSTOME SIZE MEMORY............................................................................................................................................I-10

2.6 DRUM DEHUMIDIFY................................................................................................................................................................I-11

2.6.1 Use.................................................................................................................................................................................I-11

2.6.2 Step................................................................................................................................................................................I-11

2.7 ADMIN. MANAGEMENT...........................................................................................................................................................I-11

2.7.1 ADMINISTRATOR NO....................................................................................................................................................I-11

2.7.2 DISPLAY AUTO SHUT...................................................................................................................................................I-11

2.7.3 SLEEP SHIFT.................................................................................................................................................................I-11

2.7.4 ACCOUNT TRACK.........................................................................................................................................................I-11

2.7.5 REMOTE MONITOR......................................................................................................................................................I-12

2.7.6 NETWORK SETTING - IP ADDRESS SETTING...........................................................................................................I-13

2.7.7 NETWORK SETTING - IPv6..........................................................................................................................................I-14

2.7.8 NETWORK SETTING - DNS CONFIG...........................................................................................................................I-15

2.7.9 NETWORK SETTING - WEB SETTING.........................................................................................................................I-15

2.7.10 NETWORK SETTING - LPD SETTING........................................................................................................................I-15

2.7.11 NETWORK SETTING - SLP SETTING........................................................................................................................I-15

2.7.12 NETWORK SETTING - SNMP SETTING.....................................................................................................................I-15

2.7.13 NETWORK SETTING - AUTO GET TIME....................................................................................................................I-15

2.7.14 E-MAIL SETTING 1......................................................................................................................................................I-16

2.7.15 E-MAIL SETTING 2......................................................................................................................................................I-18

2.7.16 LDAP SETTING............................................................................................................................................................I-20

2.7.17 COMM. SETTING.........................................................................................................................................................I-22

2.7.18 USER SETTING...........................................................................................................................................................I-23

2.7.19 SCAN TO USB.............................................................................................................................................................I-24

2.8 COPY SETTING 1....................................................................................................................................................................I-24

2.8.1 PAPER PRIORITY..........................................................................................................................................................I-24

2.8.2 QUALITY PRIORITY......................................................................................................................................................I-24

2.8.3 DENSITY PRIORITY......................................................................................................................................................I-25

2.8.4 DENSITY LEVEL............................................................................................................................................................I-25

2.8.5 DUPLEX PRIORITY.......................................................................................................................................................I-25

2.8.6 OUTPUT BIND POS.......................................................................................................................................................I-25

2.8.7 ORIG.BINDING POS......................................................................................................................................................I-25

2.8.8 BINDING POSITION.......................................................................................................................................................I-26

2.8.9 MARGIN SETTING.........................................................................................................................................................I-26

2.8.10 ERASE SETTING.........................................................................................................................................................I-26

2.8.11 SMALL ORIGINAL........................................................................................................................................................I-26

2.9 COPY SETTING 2....................................................................................................................................................................I-26

2.9.1 COPY PRIORITY............................................................................................................................................................I-26

2.9.2 OUTPUT PRIORITY.......................................................................................................................................................I-27

2.9.3 CRISSCROSS MODE....................................................................................................................................................I-27

v

2.9.4 4IN1 COPY ORDER.......................................................................................................................................................I-27

2.9.5 MIXED ORIGINAL..........................................................................................................................................................I-27

2.9.6 ORIG. DIRECTION.........................................................................................................................................................I-27

2.9.7 BOOK SEPARATION.....................................................................................................................................................I-28

2.9.8 STAMP...........................................................................................................................................................................I-28

2.9.9 PAGE FORMAT..............................................................................................................................................................I-28

2.9.10 DATE & TIME FORMAT...............................................................................................................................................I-28

2.10 DIAL REGISTRATION............................................................................................................................................................I-28

2.10.1 ONE-TOUCH DIAL.......................................................................................................................................................I-28

2.10.2 SPEED DIAL.................................................................................................................................................................I-29

2.10.3 GROUP DIAL................................................................................................................................................................I-29

2.10.4 PROGRAM DIAL..........................................................................................................................................................I-29

2.11 FAX REGISTRATION.............................................................................................................................................................I-29

2.11.1 MAILBOX......................................................................................................................................................................I-29

2.11.2 RELAY BOX.................................................................................................................................................................I-30

2.12 FAX TX OPERATION.............................................................................................................................................................I-30

2.12.1 DENSITY LEVEL..........................................................................................................................................................I-30

2.12.2 QUALITY PRIORITY....................................................................................................................................................I-30

2.12.3 DEFAULT TX................................................................................................................................................................I-30

2.12.4 HEADER.......................................................................................................................................................................I-31

2.12.5 CONFIRM FAX NO.......................................................................................................................................................I-31

2.13 FAX RX OPERATION.............................................................................................................................................................I-31

2.13.1 MEMORY RX MODE....................................................................................................................................................I-31

2.13.2 NO. of RINGS...............................................................................................................................................................I-31

2.13.3 REDUCTION RX..........................................................................................................................................................I-31

2.13.4 RX PRINT.....................................................................................................................................................................I-38

2.13.5 RX MODE.....................................................................................................................................................................I-38

2.13.6 FORWARD...................................................................................................................................................................I-38

2.13.7 FOOTER.......................................................................................................................................................................I-38

2.13.8 SELECT TRAY.............................................................................................................................................................I-39

2.13.9 CLOSED NETWORK....................................................................................................................................................I-39

2.14 REPORTING...........................................................................................................................................................................I-39

2.14.1 ACTIVITY REPORT......................................................................................................................................................I-40

2.14.2 RESERVATION REPORT............................................................................................................................................I-40

2.14.3 TX RESULT REPORT..................................................................................................................................................I-40

2.14.4 RX RESULT REPORT..................................................................................................................................................I-40

2.15 SCAN SETTING.....................................................................................................................................................................I-40

2.15.1 RESOLUTION..............................................................................................................................................................I-40

2.15.2 IMAGE FORMAT..........................................................................................................................................................I-40

2.15.3 BW CODING METHOD................................................................................................................................................I-41

2.15.4 COLOR SETTING........................................................................................................................................................I-41

3. ADJUSTMENT ITEM LIST.........................................................................................................................................I-42

4. SERVICE MODE........................................................................................................................................................I-45

4.1 List of SERVICE MODE............................................................................................................................................................I-45

4.2 Starting/Exiting..........................................................................................................................................................................I-47

4.2.1 Starting procedure..........................................................................................................................................................I-47

4.2.2 Exiting procedure............................................................................................................................................................I-47

4.2.3 Changing the setting value in SERVICE MODE functions.............................................................................................I-47

4.3 SERVICE'S CHOICE................................................................................................................................................................I-47

4.3.1 MARKETING AREA........................................................................................................................................................I-47

4.3.2 SHIPMENT.....................................................................................................................................................................I-48

4.3.3 ENABLE AUTO SHUT....................................................................................................................................................I-48

4.3.4 MAINTENANCE COUNT................................................................................................................................................I-48

4.3.5 IU LIFE STOP MODE.....................................................................................................................................................I-48

4.3.6 ID ADJUST.....................................................................................................................................................................I-49

4.3.7 VG ADJUST....................................................................................................................................................................I-49

4.3.8 TRANSFER (PLAIN).......................................................................................................................................................I-49

4.3.9 TRANSFER (RECYCLE)................................................................................................................................................I-49

4.3.10 TRANSFER (CARD1)...................................................................................................................................................I-49

4.3.11 TRANSFER (CARD2)...................................................................................................................................................I-50

4.3.12 TRANSFER (OHP).......................................................................................................................................................I-50

4.3.13 TRANSFER (ENV.).......................................................................................................................................................I-50

4.3.14 TRANSFER (PLAIN-D).................................................................................................................................................I-50

4.3.15 TRANSFER (RECY.-D)................................................................................................................................................I-50

4.3.16 TRANSFER (CARD1-D)...............................................................................................................................................I-50

4.3.17 TRANSFER (CARD2-D)...............................................................................................................................................I-51

4.3.18 FUSER TEMP. (PLAIN)................................................................................................................................................I-51

4.3.19 FUSER TEMP. (CARD1)..............................................................................................................................................I-51

4.3.20 FUSER TEMP. (CARD2)..............................................................................................................................................I-52

4.3.21 FUSER TEMP. (OHP)..................................................................................................................................................I-52

vi

4.3.22 FUSER TEMP. (ENV.)..................................................................................................................................................I-52

4.3.23 LEADING EDGE...........................................................................................................................................................I-52

4.3.24 TRAILING EDGE..........................................................................................................................................................I-53

4.3.25 VERTICAL EDGE.........................................................................................................................................................I-53

4.3.26 LOOP Ad. (TRAY1)......................................................................................................................................................I-54

4.3.27 LOOP Ad. (TRAY2-5)...................................................................................................................................................I-54

4.3.28 LOOP Ad. (DUPLEX)....................................................................................................................................................I-54

4.3.29 LOOP Ad. (BYPASS)....................................................................................................................................................I-55

4.3.30 FLS PAPER SIZE.........................................................................................................................................................I-55

4.3.31 FLS/LEGAL CHANGE..................................................................................................................................................I-55

4.3.32 TX SPEED....................................................................................................................................................................I-55

4.3.33 RX SPEED....................................................................................................................................................................I-55

4.3.34 TX LEVEL.....................................................................................................................................................................I-56

4.3.35 DTMF LEVEL................................................................................................................................................................I-56

4.3.36 CNG LEVEL..................................................................................................................................................................I-56

4.3.37 CED LEVEL..................................................................................................................................................................I-56

4.3.38 ECM MODE..................................................................................................................................................................I-56

4.3.39 CODING SCHEME.......................................................................................................................................................I-57

4.3.40 VOIP.............................................................................................................................................................................I-57

4.3.41 REPORT DESTINATION..............................................................................................................................................I-57

4.3.42 TONER EMPTY REPORT............................................................................................................................................I-58

4.3.43 IU LIFE REPORT..........................................................................................................................................................I-58

4.3.44 MAINTENANCE REPORT............................................................................................................................................I-58

4.3.45 PROTOCOL REPORT..................................................................................................................................................I-58

4.3.46 CIS APS SIZE...............................................................................................................................................................I-58

4.3.47 GDI TIMEOUT..............................................................................................................................................................I-59

4.3.48 ERASER INSTALL.......................................................................................................................................................I-59

4.3.49 SUCTION FAN.............................................................................................................................................................I-59

4.3.50 LANGUAGE GROUP....................................................................................................................................................I-60

4.3.51 HV B(AC) CLK..............................................................................................................................................................I-60

4.3.52 PH STANBY MODE......................................................................................................................................................I-60

4.4 ADJUST....................................................................................................................................................................................I-60