Minn kota Ulterra User Manual

™

ULTERRA

BOW-MOUNT TROLLING MOTOR

Owner's Manual

INTRODUCTION

Made by Minn Kota

Johnson Outdoors

Marine Electronics, Inc.

121 Power Drive

Mankato, MN 56001 USA

Trolling Motors

Produced in 2015

SER N O R365 MK123 45

ULTERRA 80/US2/IPLINK-45"_BT

MODEL 1358923

THANK YOU

Thank you for choosing Minn Kota. We believe that you should spend more time fishing and less time positioning your boat. That’s why

we build the smartest, toughest, most intuitive trolling motors on the water. Every aspect of a Minn Kota trolling motor is thought out

and rethought until it’s good enough to bear our name. Countless hours of research and testing provide you the Minn Kota advantage

that can truly take you “Anywhere. Anytime.” We don’t believe in shortcuts. We are Minn Kota. And we are never done helping you

catch more fish.

REGISTRATION

Remember to keep your receipt and immediately register your

trolling motor. A registration card is included with your motor or you

can complete registration on our website at minnkotamotors.com.

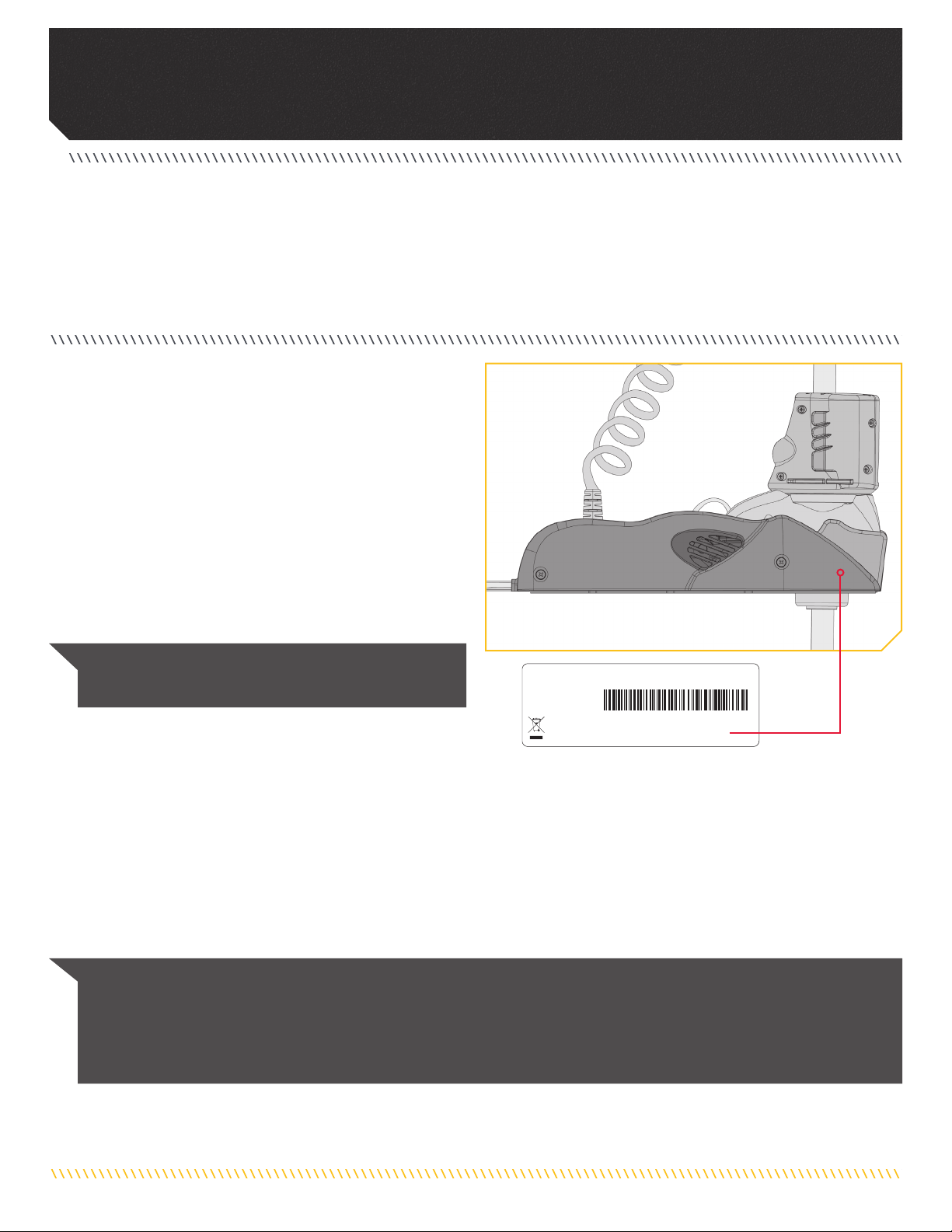

SERIAL NUMBER

Your Minn Kota 11-character serial number is very important.

It helps to determine the specific model and year of manufacture.

When contacting Consumer Service or registering your product, you

will need to know your product’s serial number. We recommend

that you write the serial number down so that you have it available

for future reference.

NOTICE: The serial number on your Ulterra is located

inside the mount near the motor rests.

EXAMPLE

MOTOR INFORMATION (For Consumer Reference Only)

Model: __________________________________________________________________________________________________________________

Serial Number: __________________________________________________________________________________________________________

Purchase Date: __________________________________________________________________________________________________________

Store Where Purchased: ___________________________________________________________________________________________________

NOTICE: Do not return your Minn Kota motor to your retailer. Your retailer is not authorized to repair or replace this unit. You may

obtain service by: calling Minn Kota at (800) 227-6433; returning your motor to the Minn Kota Factory Service Center; sending

or taking your motor to any Minn Kota authorized service center. A list of authorized service centers is available on our website,

at minnkotamotors.com. Please include proof of purchase, serial number and purchase date for warranty service with any of the

above options.

2 | minnkotamotors.com

©2018 Johnson Outdoors Marine Electronics, Inc.

Table Of CONTeNTs

SAFETY CONSIDERATIONS ................................................................................................. 4

WARRANTY ..................................................................................................................... 5

KNOW YOUR BOAT ............................................................................................................ 6

FEATURES ....................................................................................................................... 7

INSTALLATION ................................................................................................................. 8

Installing the Ulterra ................................................................................................... 9

Identifying Trolling Motor Features by their Associated Cables ...................................... 16

Routing Connection Cables ........................................................................................ 16

Feature Overview and Connecting the Cables .............................................................. 18

Built-in MEGA Down Imaging ................................................................................. 18

Universdal Sonar ................................................................................................... 19

i-Pilot Link ............................................................................................................ 21

BATTERY & WIRING INSTALLATION .................................................................................... 23

Boat Rigging & Product Installation ............................................................................ 23

Conductor Gauge and Circuit Breaker Sizing Table ....................................................... 23

Selecting the Correct Batteries ................................................................................... 24

Additional Considerations .......................................................................................... 24

Connecting the Batteries in Series .............................................................................. 25

MOTOR WIRING DIAGRAM ................................................................................................ 27

USING & ADJUSTING THE MOTOR ...................................................................................... 28

Mount Features ........................................................................................................ 28

Installing an External Transducer ............................................................................... 30

Changing the Prop Orientation ................................................................................... 31

Adjusting the Lift Belt .............................................................................................. 34

Greasing the Latch Pin and Power Tilt Motor Shaft ...................................................... 34

Stowing from the Ulterra Motor .................................................................................. 35

Trim/Stow Reset Procedure........................................................................................ 36

Manually Stowing the Ulterra .................................................................................... 37

USING THE FOOT PEDAL .................................................................................................. 41

Controlling Speed & Steering with the Foot Pedal........................................................ 41

Modes ..................................................................................................................... 41

Foot Pedal Operation ................................................................................................ 41

Stowing and Deploying the Motor with the Foot Pedal ................................................. 44

Adjusting the Depth of the Motor (Trim) with the Foot Pedal ........................................ 45

SERVICE & MAINTENANCE ............................................................................................... 46

Propeller Replacement .............................................................................................. 46

General Maintenance ................................................................................................ 47

Troubleshooting ........................................................................................................ 47

Advanced Troubleshooting ......................................................................................... 49

For Further Troubleshooting and Repair ...................................................................... 56

COMPLIANCE STATEMENTS.............................................................................................. 57

PARTS DIAGRAM & PARTS LIST ........................................................................................ 59

©2018 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 3

safeTY CONsIDeRaTIONs

Please thoroughly read the user manual. Follow all instructions and heed all safety and cautionary notices. Use of this motor is only

permitted for persons that have read and understood these user instructions. Minors may use this motor only under adult supervision.

WARNING

You are responsible for the safe and prudent operation of your vessel. We have designed your Minn Kota product to be an accurate

and reliable tool that will enhance boat operation and improve your ability to catch fish. This product does not relieve you from the

responsibility for safe operation of your boat. You must avoid hazards to navigation and always maintain a permanent watch so you can

respond to situations as they develop. You must always be prepared to regain manual control of your boat. Learn to operate your Minn

Kota product in an area free from hazards and obstacles.

WARNING

Never run the motor out of the water, as this may result in injuries from the rotating propeller. The motor should be disconnected from

the power source when it is not in use or is off the water. When connecting the power-supply cables of the motor to the battery, ensure

that they are not kinked or subject to chafe and route them in such a way that persons cannot trip over them. Before using the motor

make sure that the insulation of the power cables is not damaged. Disregarding these safety precautions may result in electric shorts

of battery(s) and/or motor. Always disconnect motor from battery(s) before cleaning or checking the propeller. Avoid submerging the

complete motor as water may enter the lower unit through control head and shaft. If the motor is used while water is present in the

lower unit considerable damage to the motor can occur. This damage will not be covered by warranty.

WARNING

Take care that neither you nor other persons approach the turning propeller too closely, neither with body parts nor with objects.

The motor is powerful and may endanger or injure you or others. While the motor is running watch out for persons swimming and for

floating objects. Persons who lack the ability to run the motor or whose reactions are impaired by alcohol, drugs, medication, or other

substances are not permitted to use this motor. This motor is not suitable for use in strong currents. The constant noise pressure level

of the motor during use is less than 70dB(A). The overall vibration level does not exceed 2,5 m/sec2.

WARNING

When stowing or deploying the motor, keep fingers clear of all hinge and pivot points and all moving parts. In the event of unexpected

operation, remove power leads from the battery.

WARNING

It is recommended to only use Johnson Outdoors approved accessories with your Minn Kota motor. Using non-approved accessories

including to mount or control your motor may cause damage, unexpected motor operation and injury. Be sure to use the product and

approved accessories, including remotes, safely and in the manner directed to avoid accidental or unexpected motor operation. Keep

all factory installed parts in place including motor and accessory covers, enclosures and guards.

4 | minnkotamotors.com

©2018 Johnson Outdoors Marine Electronics, Inc.

WaRRaNTY

WARRANTY ON MINN KOTA FRESHWATER TROLLING MOTORS

Johnson Outdoors Marine Electronics, Inc. (“JOME”) extends the following limited warranty to the original retail purchaser only. Warranty coverage is

not transferable.

Minn Kota Limited Two-Year Warranty on the Entire Product

JOME warrants to the original retail purchaser only that the purchaser’s new Minn Kota freshwater trolling motor will be materially free from defects in

materials and workmanship appearing within two (2) years after the date of purchase. JOME will (at its option) either repair or replace, free of charge,

any parts found by JOME to be defective during the term of this warranty. Such repair, or replacement shall be the sole and exclusive liability of JOME

and the sole and exclusive remedy of the purchaser for breach of this warranty.

Minn Kota Limited Lifetime Warranty on Composite Shaft

JOME warrants to the original retail purchaser only that the composite shaft of the purchaser’s Minn Kota trolling motor will be materially free from

defects in materials and workmanship appearing within the original purchaser’s lifetime. JOME will provide a new composite shaft, free of charge, to

replace any composite shaft found by JOME to be defective during the term of this warranty. Providing a new composite shaft shall be the sole and

exclusive liability of JOME and the sole and exclusive remedy of the purchaser for breach of this warranty; and purchaser shall be responsible for installing,

or for the cost of labor to install, any new composite shaft provided by JOME.

Exclusions & Limitations

This limited warranty does not apply to products that have been used in saltwater or brackish water, commercially or for rental purposes. This limited

warranty does not cover normal wear and tear, blemishes that do not affect the operation of the product, or damage caused by accidents, abuse,

alteration, modifi cation, shipping damages, negligence of the user or misuse, improper or insuffi cient care or maintenance. DAMAGE CAUSED BY THE USE

OF OTHER REPLACEMENT PARTS NOT MEETING THE DESIGN SPECIFICATIONS OF THE ORIGINAL PARTS WILL NOT BE COVERED BY THIS LIMITED WARRANTY. The

cost of normal maintenance or replacement parts which are not in breach of the limited warranty are the responsibility of the purchaser. Prior to using

products, the purchaser shall determine the suitability of the products for the intended use and assumes all related risk and liability. Any assistance

JOME provides to or procures for the purchaser outside the terms, limitations or exclusions of this limited warranty will not constitute a waiver of the

terms, limitations or exclusions, nor will such assistance extend or revive the warranty. JOME will not reimburse the purchaser for any expenses incurred

by the purchaser in repairing, correcting or replacing any defective products or parts, except those incurred with JOME’s prior written permission.

JOME’S AGGREGATE LIABILITY WITH RESPECT TO COVERED PRODUCTS IS LIMITED TO AN AMOUNT EQUAL TO THE PURCHASER’S ORIGINAL PURCHASE PRICE PAID

FOR SUCH PRODUCT.

Minn Kota Service Information

To obtain warranty service in the U.S., the product believed to be defective, and proof of original purchase (including the date of purchase), must be

presented to a Minn Kota Authorized Service Center or to Minn Kota’s factory service center in Mankato, MN. Any charges incurred for service calls,

transportation or shipping/freight to/from the Minn Kota Authorized Service Center or factory, labor to haul out, remove, re-install or re-rig products

removed for warranty service, or any other similar items are the sole and exclusive responsibility of the purchaser. Products purchased outside of the

U.S. must be returned prepaid with proof of purchase (including the date of purchase and serial number) to any Authorized Minn Kota Service Center in

the country of purchase. Warranty service can be arranged by contacting a Minn Kota Authorized Service Center or by contacting the factory at 1-800227-6433 or email service@minnkotamotors.com. Products repaired or replaced will be warranted for the remainder of the original warranty period [or for 90

days from the date of repair or replacement, whichever is longer]. For any product that is returned for warranty service that JOME fi nds to be not covered by or not

in breach of this limited warranty, there will be a billing for services rendered at the prevailing posted labor rate and for a minimum of at least one hour.

NOTICE: Do not return your Minn Kota product to your retailer. Your retailer is not authorized to repair or replace products.

NOTICE: THERE ARE NO EXPRESS WARRANTIES OTHER THAN THESE LIMITED WARRANTIES. IN NO EVENT SHALL ANY IMPLIED WARRANTIES INCLUDING ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE, EXTEND BEYOND THE DURATION OF THE RELEVANT EXPRESS LIMITED

WARRANTY. IN NO EVENT SHALL JOME BE LIABLE FOR PUNITIVE, INDIRECT, INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES. Without limiting the

foregoing, JOME assumes no responsibility for loss of use of product, loss of time, inconvenience or other damage.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the

above limitations and/or exclusions may not apply to you. This warranty gives you specifi c legal rights and you may also have other legal rights which

vary from state to state.

©2018 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 5

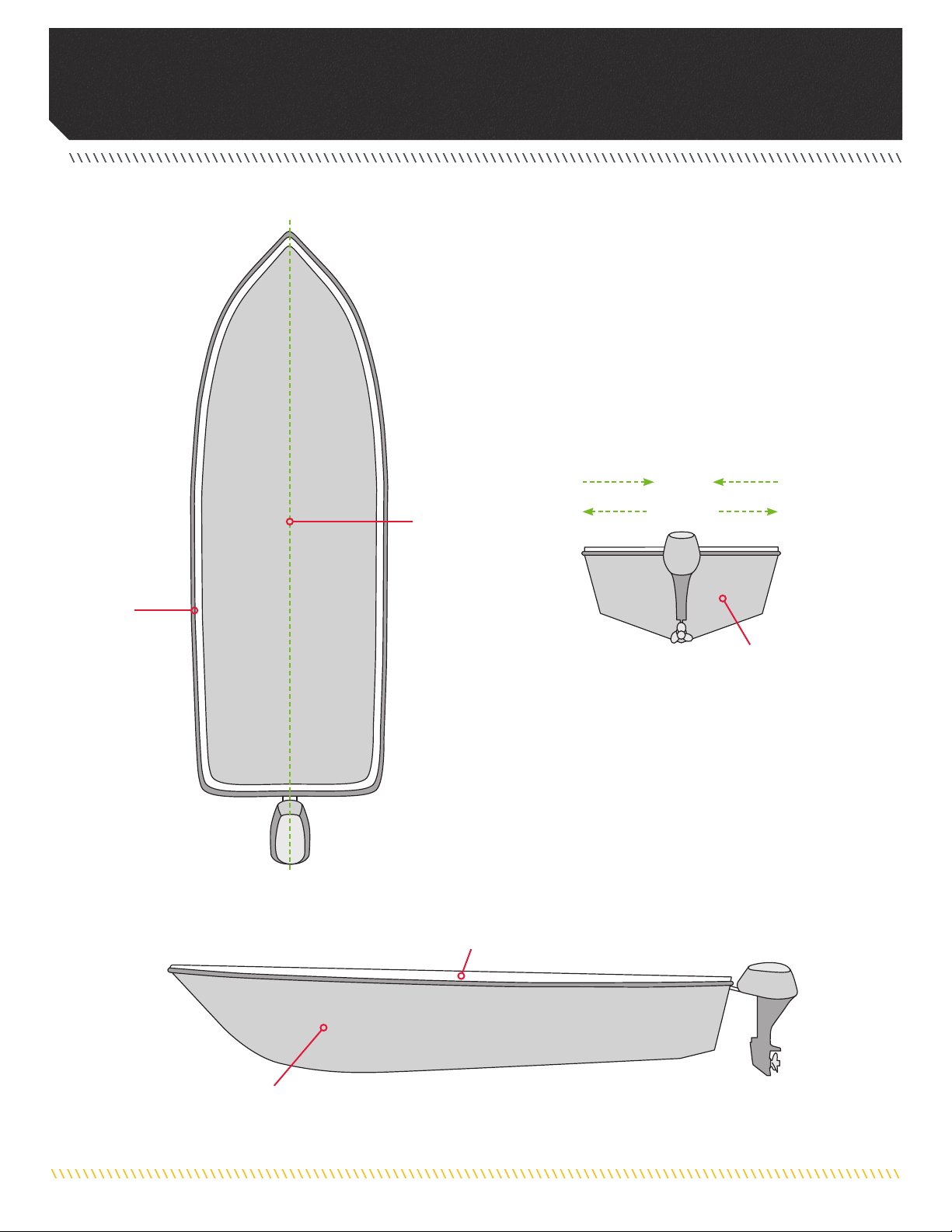

KNOW YOUR bOaT

Bow

Gunwale

Port

Starboard

Keel

Inboard

Outboard

Port Starboard

Transom

Bow

6 | minnkotamotors.com

Stern

Gunwale

Stern

Hull

©2018 Johnson Outdoors Marine Electronics, Inc.

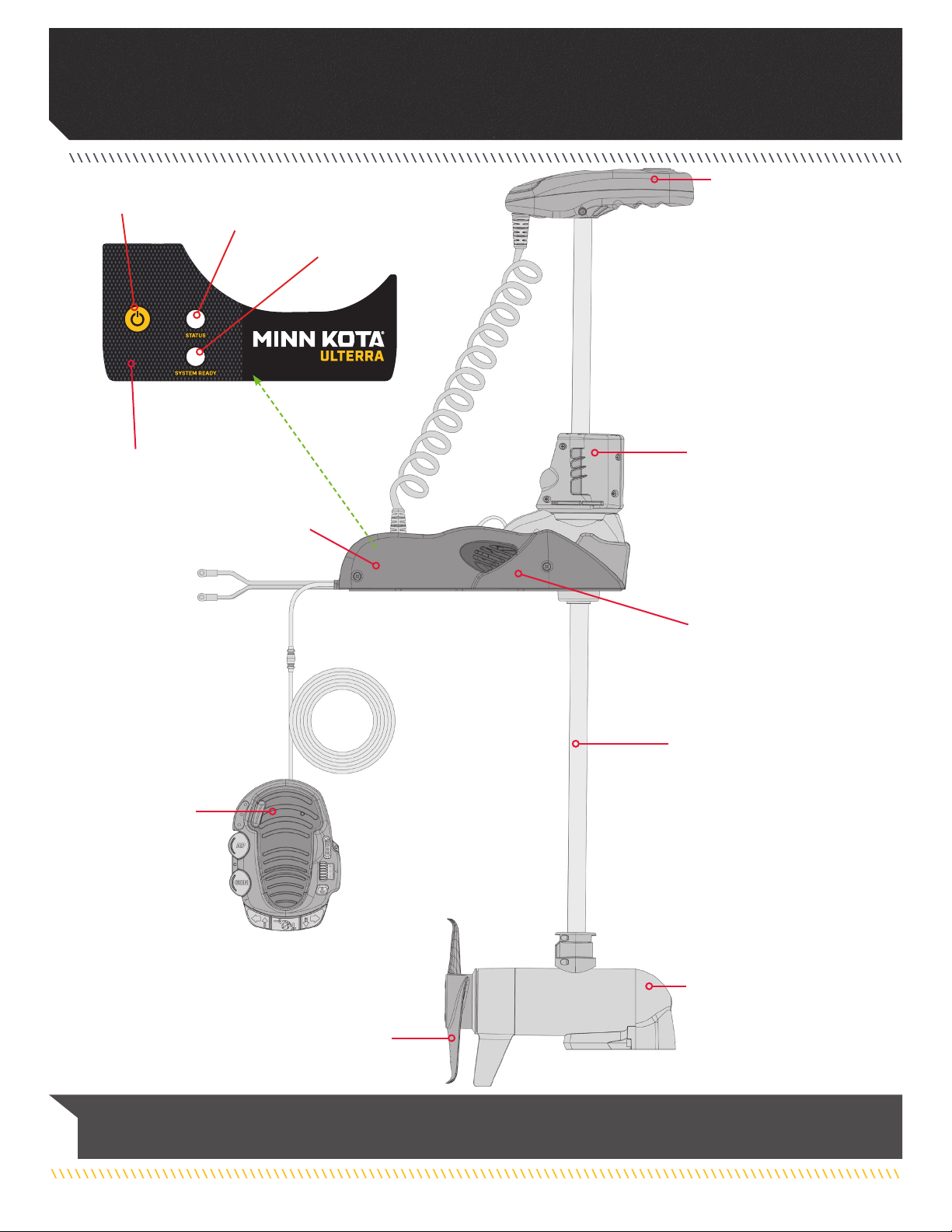

Power Button

feaTURes

Integrated i-Pilot

Control Head

Status Indicator

System Ready Indicator

Indicator Panel

Multi-Function

Foot Pedal

Power Trim

Motor Mount

Auto Stow/Deploy

Lifetime Warranty

Flexible Composite Shaft

Cool Quiet

Power Motor

Weedless Wedge 2 Propeller

NOTICE: Specifications subject to change without notice. This diagram is for reference only and may differ from your actual

motor.

©2018 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 7

INsTallaTION

INSTALLING THE ULTERRA

Your new Ulterra comes with everything you’ll need to directly install it to the boat. This motor can be directly mounted to the boat

or it may be coupled with a Minn Kota quick release bracket for ease of mounting and removal. For installation with a quick release

bracket, refer to the installation instructions provided with the bracket. For compatible quick release mounting bracket, please visit

minnkotamotors.com. To install the motor directly to the boat, please follow the instructions provided in this manual. Please review the

parts list, mounting considerations and tools needed for installation prior to getting started. For additional product support and to locate

your nearest dealer, please visit minnkotamotors.com.

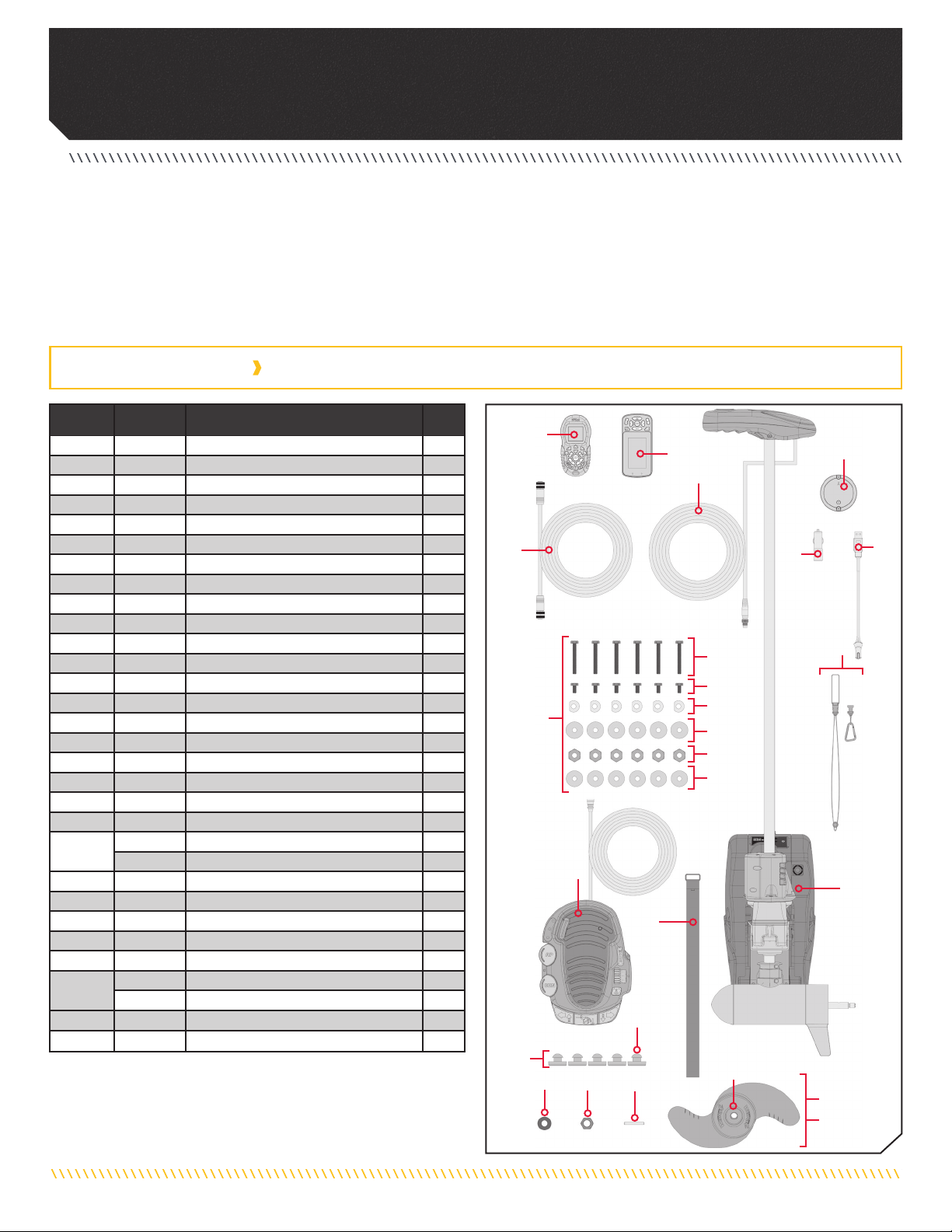

INSTALLATION PARTS LIST

Item /

Assembly

1

AA 2994859 BAG ASY-TERROVA/V2,RUB.BUMPERS 1

2 2325110 PAD, FOOTPEDAL 5

BB 2994917 BAG ASSY, ULTERRA MTG HARDWARE 1

3 2203430 SCREW-1/4-20 X 2.0 HHCS SS 6

4 2203431 SCREW-1/4-20 X 0.5 HHCS SS 6

5 2201725 WASHER-CLIPPED, 1/4", 1.00" OD 6

6 2261713 WASHER-1/4 FLAT 18-8 SS 6

7 2263103 NUT-1/4-20 NYLOCK SS 6

8 2301720 WASHER-MOUNTING - RUBBER 6

9 2203800 STRAP, HOLD DOWN 1

10 2994075

11 2994076 Â REMOTE ASSEMBLY LINK TOUCHSCREEN 1

p

p

12 2390800 t LANYARD, REMOTE W/ CARABINER 1

13 2373241 Â CABLE, USB REMOTE CHARGER LINK 1

14 2375901 Â ADAPTER, USB DC POWER LINK 1

15 2996400 t HEADING SENSOR ASSEMBLY 1

16 490389-1 Â CABLE, ETH (M12-M-M12-F, 30' 1

17

CC 1378132 80# THRUST PROP KIT 1

DD 1378160 112# THRUST PROP KIT 1

18 2262658 PIN-DRIVE 1" X 3/16" S/S 1

19 2091701 WASHER-PROP (LARGE) MAX101 1

20 2093101 NUT-PROP,NYLOC,LG,MX101 3/8 SS 1

21

p

22 2994741 FOOT PEDAL ASSY, ULTERRA 1

p Not shown on Parts Diagram.

✖ This part is included in an assembly and cannot be ordered individually.

t Only available with models factory installed with i-Pilot.

Only available with models factory installed with i-Pilot Link.

Ì Only available with models factory installed with Universal Sonar.

â Only available with models factory installed with Built-in MEGA Down Imaging.

Part # Description Qty.

✖

MOTOR ASSEMBLY 1

t REMOTE ASSEMBLY, IPILOT 1

2397106 t MANUAL, QUICK REF., iPILOT 1.6 1

2397107 Â MANUAL-QUICK REF., iPILOT 3.0 1

2211415 Ì

490507-1 â CABLE, ADP-INT MDI 14 M12-120" *PRE-INSTALLED* 1

2331160 PROP-WW2 (4") w/ADP.RING 1

2341160 PROP-WW2 (4.5) w/ADP.RING 1

2207113 MANUAL, INSTALL GUIDE, ULTERRA 1

CABLE-EXTENSION, PD/AP 110" *PRE-INSTALLED*

10

11

17

16

3

4

BB

1

22

9

2

AA

19 20

18

5

6

7

8

21

14

15

13

12

1

CC

DD

8 | minnkotamotors.com

©2018 Johnson Outdoors Marine Electronics, Inc.

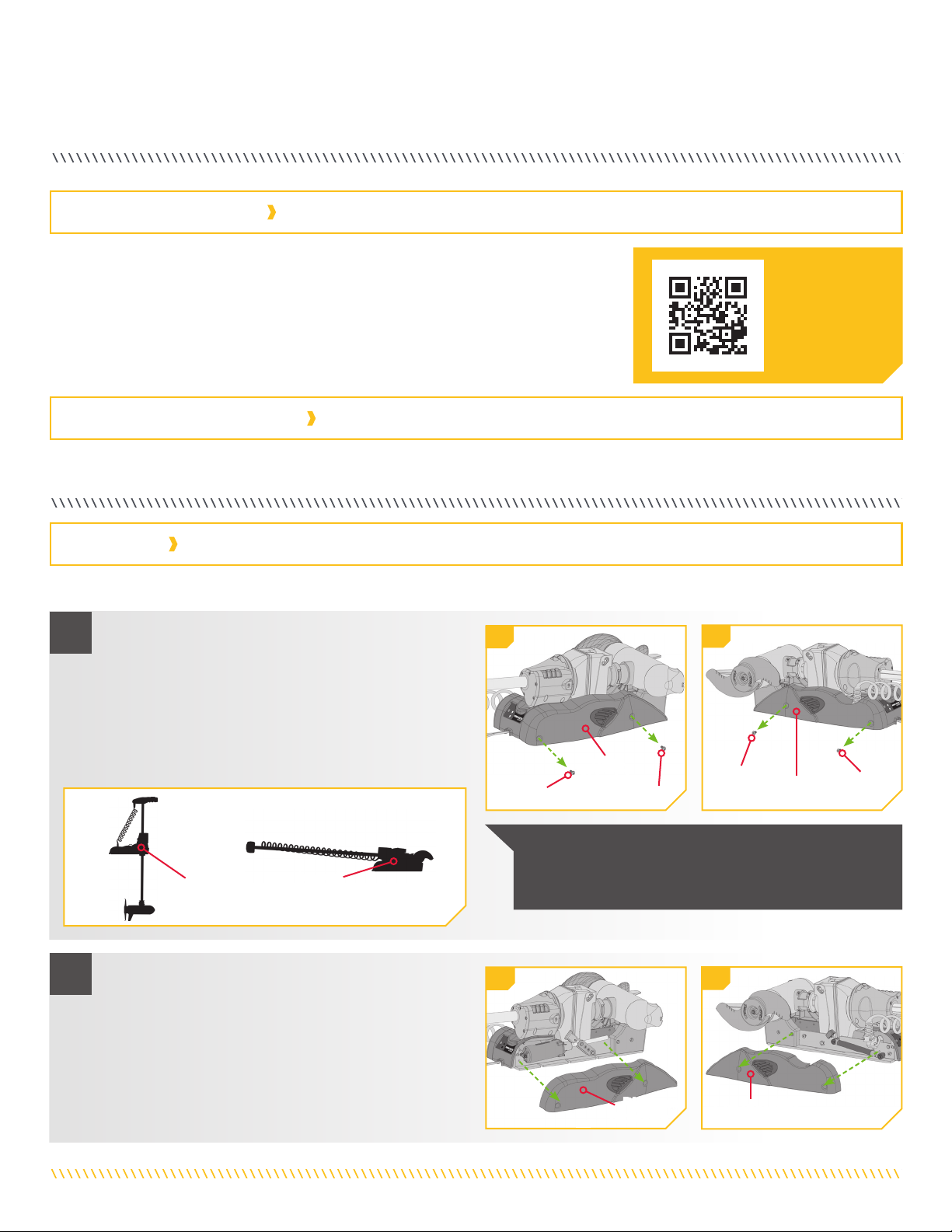

MOUNTING CONSIDERATIONS

It is recommended that the motor be mounted as close to the keel or centerline of the

boat as possible. Make sure the area under the mounting location is clear to drill holes

and install nuts and washers. Make sure the motor rest is positioned far enough beyond

the edge of the boat. The motor must not encounter any obstructions as it is lowered into

the water or raised into the boat when stowed and deployed. Consider a quick release or

adapter bracket with the installation of your motor. To view a list of accessories, please

visit minnkotamotors.com.

TOOLS AND RESOURCES REQUIRED

INSTALLING THE ULTERRA

View accessories

available for your

trolling motor at

minnkotamotors.com.

• #2 Phillips Screwdriver

• #3 Phillips Screwdriver

INSTALLATION

• Drill

• 9/32" Drill Bit

INSTALLING THE ULTERRA

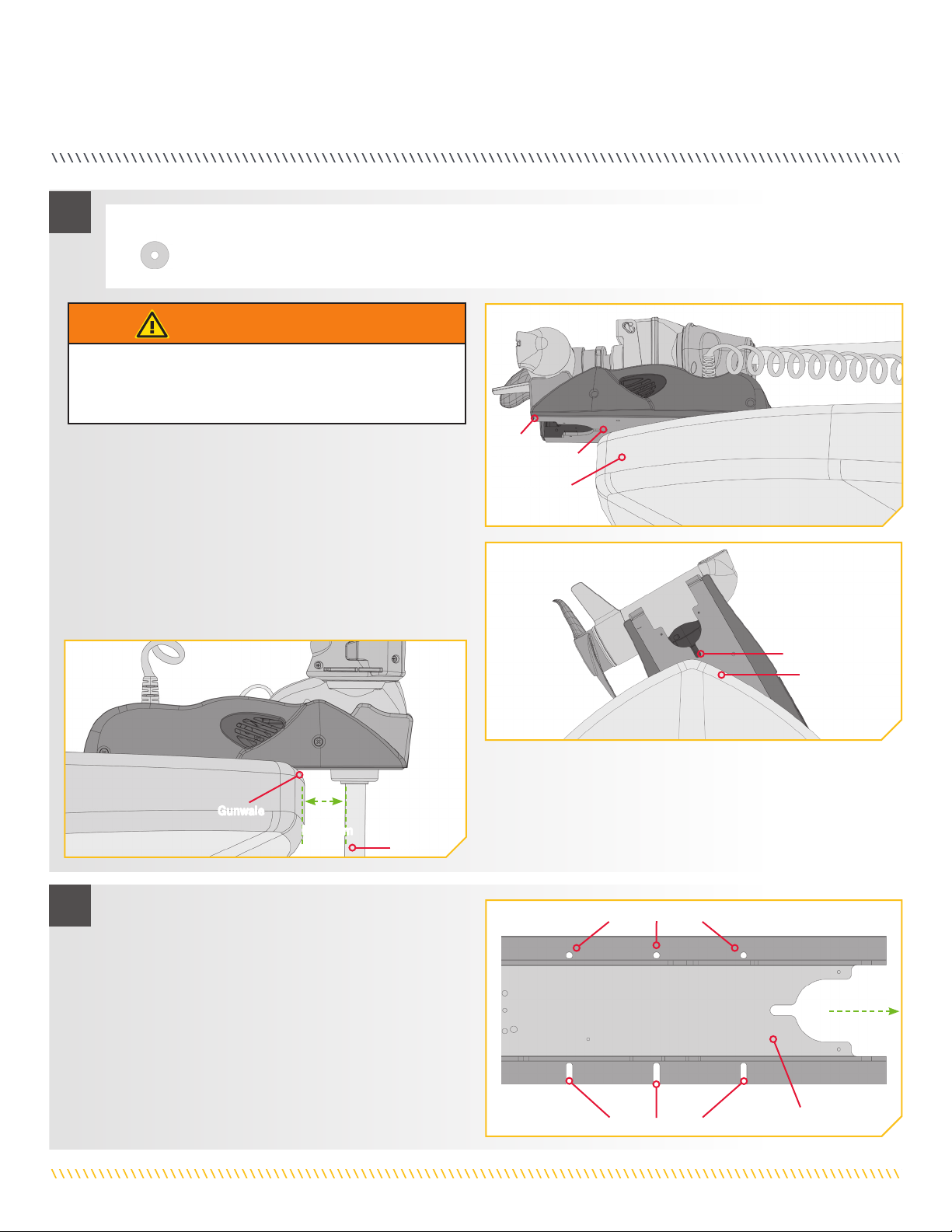

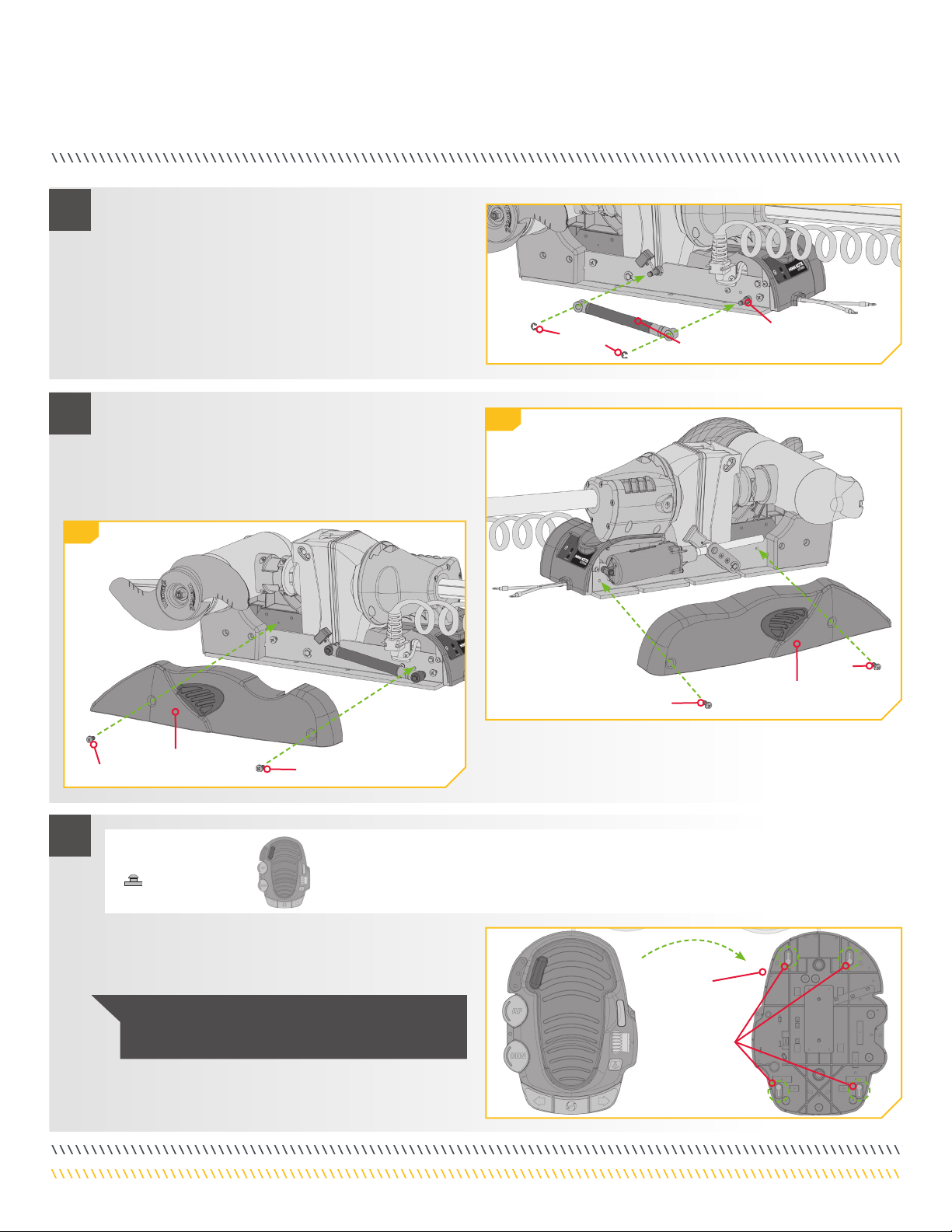

1

a. Place the Motor on an elevated, level surface such

as a workbench or the tailgate of a pickup. The

motor, as removed from the box, should be in the

stowed position.

b. Remove the four sideplate screws using a #3 or #2

Phillips screwdriver. Two of these screws will be

located on each side of the Motor Mount

Deployed

Stowed

• A person to help with

installation

1b

.

Screw

Right

Sideplate

Screw

1b

Screw

Left

Sideplate

Screw

NOTICE: This motor weighs approximately 70 lbs.

We recommend having a second person help with

the installation.

2

©2018 Johnson Outdoors Marine Electronics, Inc.

c. Remove the Right Sideplate to access the

Mounting Slots.

d. Remove the Left Sideplate to access the Mounting

Holes.

2c

Right

Sideplate

2d

Left Sideplate

minnkotamotors.com | 9

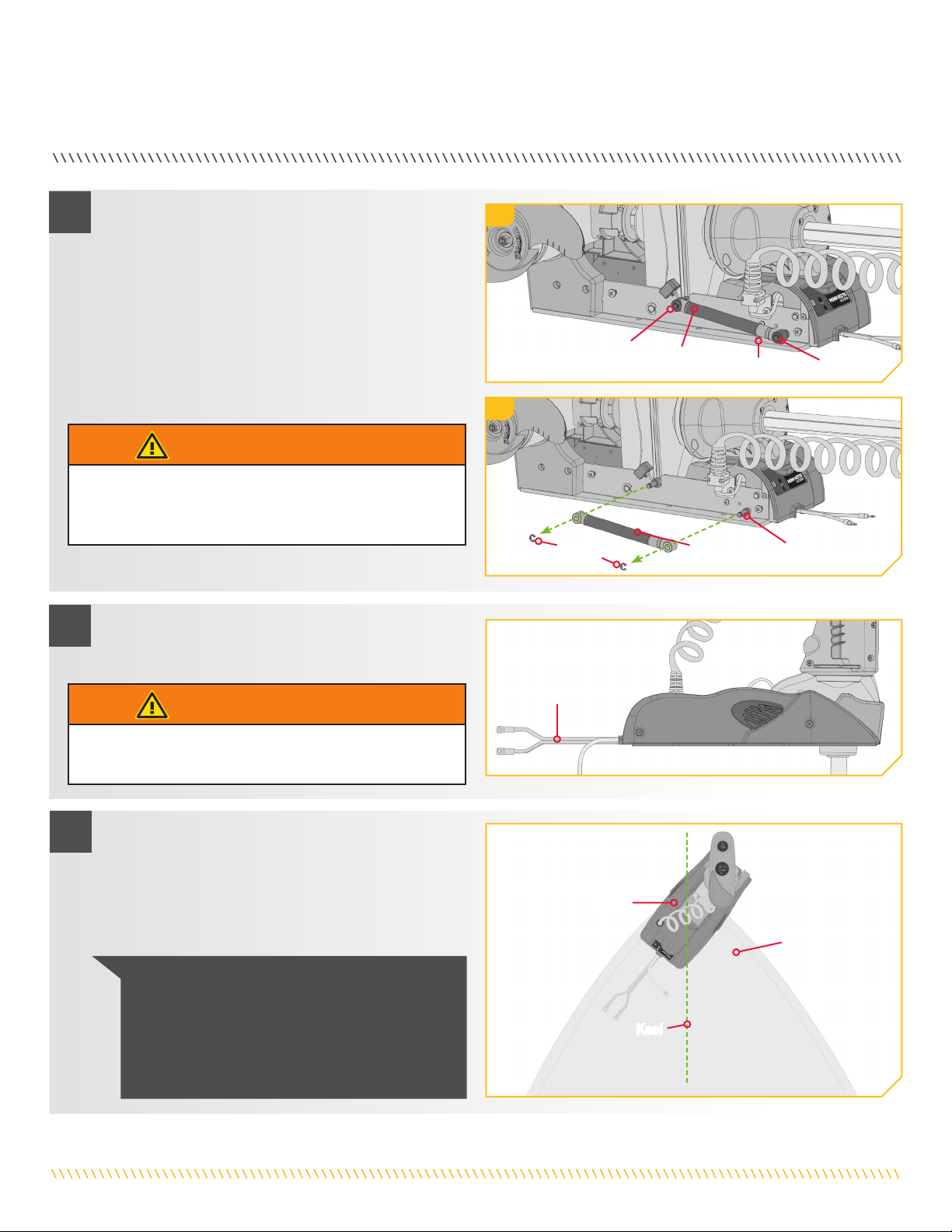

INSTALLING THE ULTERRA

3

e. Under the Left Sideplate, the Extension Damper

obstructs access to the left front Mounting Hole.

f. Using a small Screw Driver, remove the two

5/16" E-clips holding the Extension Damper in

place. Once the E-clips are removed, slide the

Extension Damper off the Damper Pins to expose

the left rear Mounting Hole. Set the two E-clips and

Extension Damper in a safe place so they are not

misplaced before they are reassembled later in the

installation.

WARNING

Do not deploy the motor until it is fully mounted to the boat.

Illustrations are for reference only. Deploying your motor

before it is mounted to the boat may cause injury.

4

g. Make sure the Power Cables from the battery

are disconnected, or that the breaker, if equipped, is

“off”.

3e

3f

E-clips

E-clip

Extension

Damper

Extension

Mounting Hole

Damper

E-clip

Damper Pins

WARNING

Make sure the motor is mounted on a level surface and is not

connected to a power source.

5

h. Place the motor on the bow of the boat. Place the

motor as close to the centerline or keel of the boat

as possible. The motor can be installed on either the

Port or Starboard side of the boat based on personal

preference. Reviewing the mounting considerations

at the beginning of the installation section.

NOTICE: The Emergency Strap (Item #9) is used for

Manually Stowing the Ulterra. The Emergency Strap is

not secured during installation. Store it on your boat

in the event that you would need to manually stow

the motor. To learn how, please refer to the "Manually

Stowing the Ulterra" section of the Owner's Manual.

Power Cables

Mount

Deck of Boat

Keel

10 | minnkotamotors.com

©2018 Johnson Outdoors Marine Electronics, Inc.

INSTALLING THE ULTERRA

6

ITEM(S) NEEDED

#8 x 6

WARNING

Do not deploy the motor until it is fully mounted to the boat.

Illustrations are for reference only. Deploying your motor

before it is mounted to the boat may cause injury.

i. Make sure the slot on the underside of the Base

Extrusion is aligned with the outermost part of

the gunwale of the boat. This will ensure that the

Shaft has a minimum clearance of 1-1/2" when it is

deployed. The lower unit when stowed and deployed

must not encounter any obstructions.

j. Check to be sure that the Motor Mount is level. Use

the Rubber Washers (Item #8) provided to create a

level surface if necessary.

Base

Extrusion

Gunwale

Slot

Slot

Gunwale

Gunwale

7

©2018 Johnson Outdoors Marine Electronics, Inc.

k. It is recommended to mark at least 4 of the 6 holes

in the Base Extrusion to have a minimum of two

bolts on each side that are located the farthest apart.

Ideal installation would allow for 6 bolts to be used,

with a minimum of 4.

l. Make sure the area under the mounting location is

clear to drill holes and install nuts and washers. Drill

through the marked holes using a 9/32"

drill bit.

1-1/2"

Minimum

Shaft

Mounting Holes

Mounting Slots

Bow

Base Extrusion

minnkotamotors.com | 11

INSTALLING THE ULTERRA

8

9

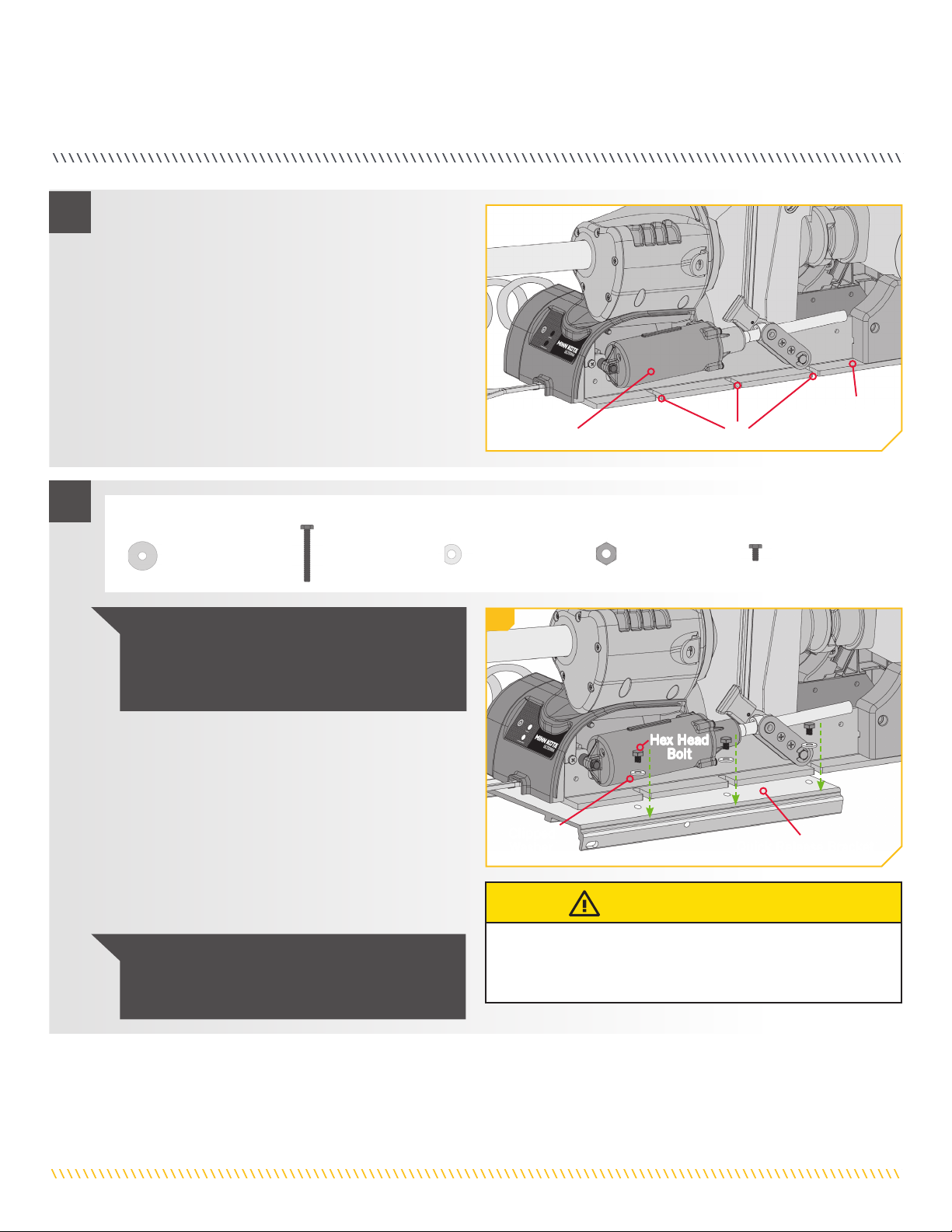

m. Mount the motor to the boat using the provided

hardware. Place the installation hardware for the side

of the Motor where the Power Tilt is located first. This

is the opposite side of the Base Extrusion from where

the Extension Damper was removed. The base of the

Motor where the Power Tilt is located has Mounting

Slots and the side where the Extension Damper is

located has Mounting Holes.

ITEM(S) NEEDED

#6 x 3

#3 x 3

NOTICE: To prevent seizing of the stainless steel

hardware, do not use high speed installation tools.

Wetting the screws or applying an anti-seize may

help prevent seizing.

Base Extrusion

Power Tilt

Mounting Slots

#5 x 3 #7 x 3 #4 x 3

9n

n. If installing with a Quick Release Bracket,

install the motor with the Hex Head Bolts (Item

#4) and Clipped Washers (Item #5). Orientate the

Clipped Washers so that the flat side of the washer

is towards the Base Extrusion. The Bolt should pass

through the Clipped Washer and into a Quick Release

Bracket. Leave at least 1/4" space between the Hex

Head Bolt and Clipped Washer in order to slide the

Base Extrusion under the Clipped Washer and into

place.

NOTICE: The Long Bolts, Flat Washers and Nylock

Nut are not used when installing the Ulterra with a

Quick Release Bracket.

Hex Head

Bolt

Clipped

Washer

Quick Release Bracket

CAUTION

Use extra care to avoid pinching and damaging the sensor wires

that run along side of the Base Extrusion when installing and

tightening the motor mounting bolts.

12 | minnkotamotors.com

©2018 Johnson Outdoors Marine Electronics, Inc.

INSTALLING THE ULTERRA

10

11

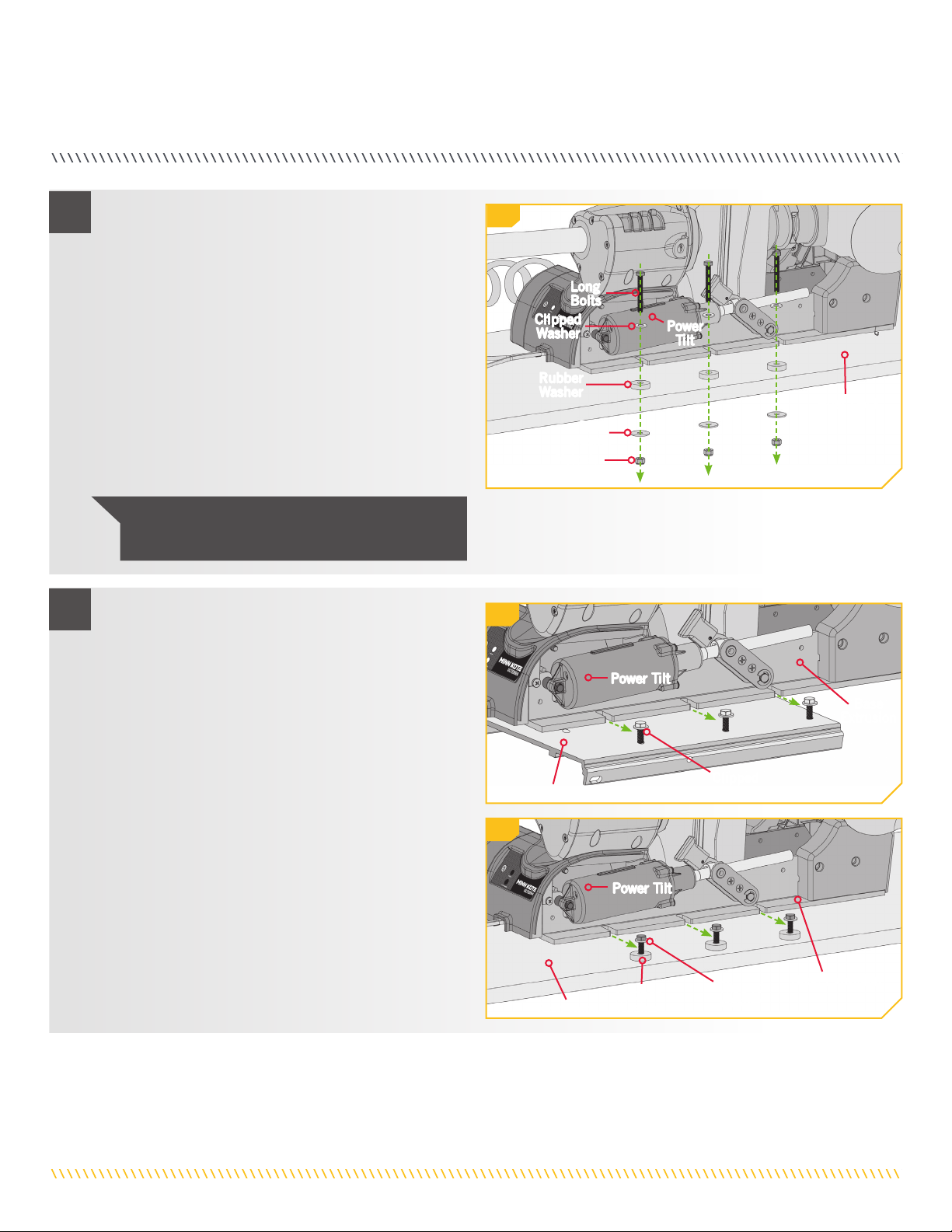

o. If installing directly to the boat deck, install the

motor with the Long Bolts (Item #3), Clipped Washer

(Item #5), Flat Washer (Item #6) and Nylock Nut

(Item #7). Orientate the Clipped Washers so that the

flat side of the washer is towards the Base Extrusion.

The Bolt should pass through the Clipped Washer,

the Rubber Washer and then through the Boat Deck.

The Bolt should be secured by first adding the Flat

Washer (Item #6) to the Bolt and securing with a

Nylock Nut (Item #7). Leave at least 1/4" space

between the Hex Head Bolt and Clipped Washer and

the deck of the boat. This will leave enough space to

slide the Base Extrusion between the Clipped Washer

and Rubber Washer and into place.

NOTICE: The Short Bolts are not used when

installing the Ulterra directly to the boat.

p. Slide the Base Extrusion into place under the Bolts

that were just installed.

q. If installing with a Quick Release Bracket,

the Base Extrusion should slide between the Quick

Release Bracket and the Clipped Washers. Hold the

Clipped Washers up on the Hex Head Bolt, so the

Clipped Washer will sit on top of the Base Extrusion.

10o

11q

Long

Bolts

Clipped

Washer

Rubber

Washer

Washer

Nylock

Nut

Power

Tilt

Boat Deck

Flat

Power Tilt

Base

Extrusion

r. If installing directly to the boat deck, the Base

Extrusion should slide between the Clipped Washer

and the Rubber Washer. Hold the Clipped Washers

up on the Long Bolt, so the Clipped Washer will sit

on top of the Base Extrusion.

©2018 Johnson Outdoors Marine Electronics, Inc.

Quick Release Bracket

11r

Power Tilt

Boat Deck

Rubber

Washer

Clipped

Washer

Clipped

Washer

Base Extrusion

minnkotamotors.com | 13

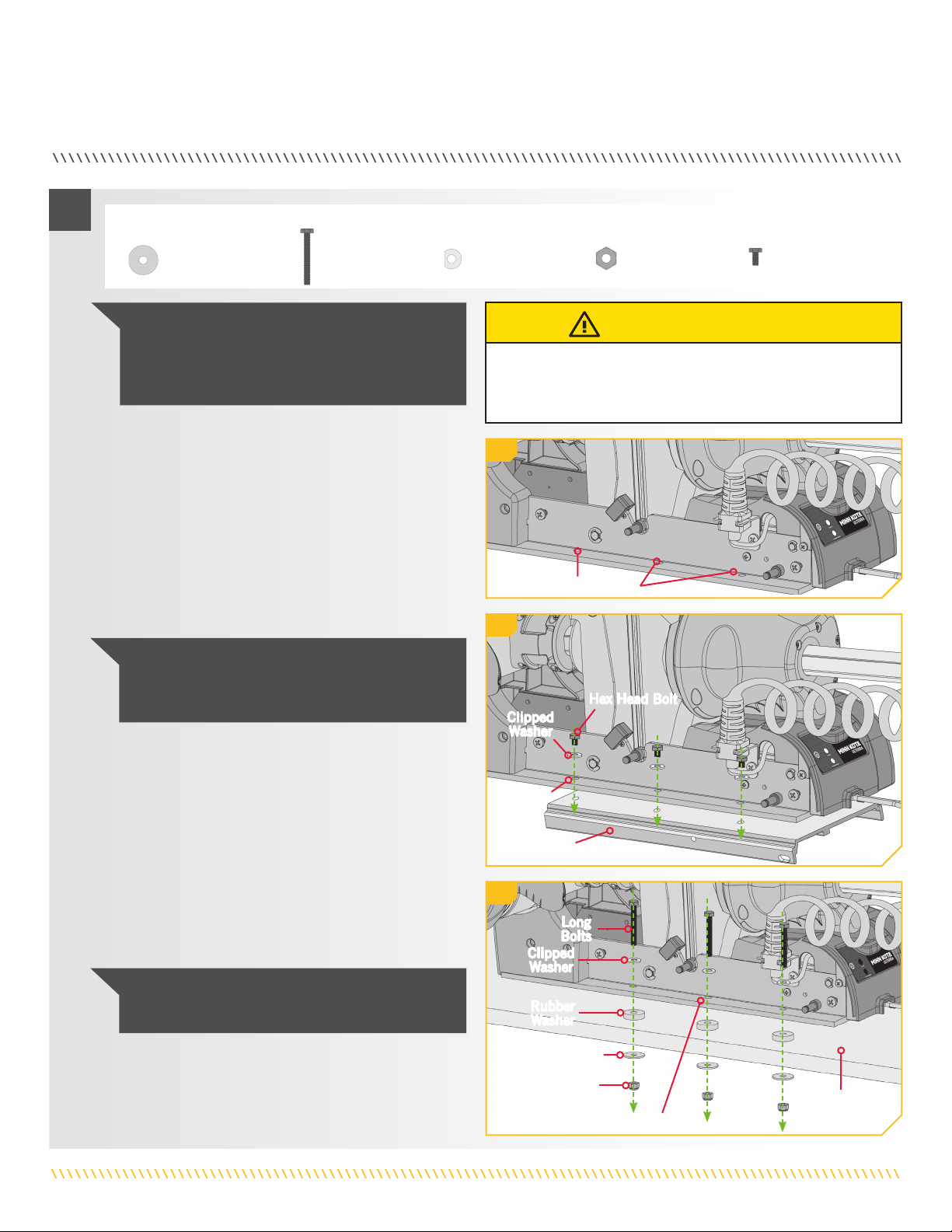

INSTALLING THE ULTERRA

12

ITEM(S) NEEDED

#6 x 3

#3 x 3

NOTICE: To prevent seizing of the stainless steel

hardware, do not use high speed installation tools.

Wetting the screws or applying an anti-seize may

help prevent seizing.

s. Place the hardware on the Damper side of the

mount into the Mounting Holes to secure the Base

Extrusion.

t.

If installing with a Quick Release Bracket,

install the motor with the Hex Head Bolts (Item

#4) and Clipped Washers (Item #5). Orientate the

Clipped Washers so that the flat side of the washer

is towards the Base Extrusion. The Bolt should pass

through the Clipped Washer, Base Extrusion and

into a Quick Release Bracket.

NOTICE: The Long Bolts, Flat Washers and Nylock

Nut are not used when installing the Ulterra with a

Quick Release Bracket.

u.

If installing directly to the boat deck,

install the motor with the Long Bolts (Item #3),

Clipped Washer (Item #5), Flat Washer (Item #6)

and Nylock Nut (Item #7). Orientate the Clipped

Washers so that the flat side of the washer is

towards the Base Extrusion. The Bolt should pass

through the Clipped Washer, the Base Extrusion, the

Rubber Washer and then through the Boat Deck.

The Bolt should be secured by first adding the Flat

Washer (Item #6) and then securing with a Nylock

Nut (Item #7).

NOTICE: The Short Bolts are not used when

installing the Ulterra directly to the boat.

#5 x 3 #7 x 3 #4 x 3

CAUTION

Use extra care to avoid pinching and damaging the sensor wires

that run along side of the Base Extrusion when installing and

tightening the motor mounting bolts.

12s

Mounting Holes

12t

Hex Head Bolt

Clipped

Washer

Mounting

Holes

Quick Release Bracket

12u

Long

Bolts

Clipped

Washer

Rubber

Washer

14 | minnkotamotors.com

Flat

Washer

Nylock

Nut

Boat Deck

Mounting Holes

©2018 Johnson Outdoors Marine Electronics, Inc.

INSTALLING THE ULTERRA

13

14

14x

v. At this point in the installation process the Motor

should be secured to the deck of the boat, and

the Motor can now be reassembled. The Extension

Damper can be slid back in place on the Damper

Pins. This should be done so the shaft on the

Damper is pointing inboard. Reinstall the two 5/16"

E-clips.

w. Replace the Right Sideplate.

x. Replace the Left Sideplate.

y. Replace the four sideplate Screws using a #2 or #3

Phillips Screw Driver.

14w

E-clips

Extension

Damper

Damper Pins

15

Left Sideplate

Screw

Screw

ITEM(S) NEEDED

#18 x 4 #EE x 1

z. Take the Foot Pedal (Item #EE) and turn it over.

Put a Foot Pedal Pad (Item #18) in each of the pad

locations.

NOTICE: The pads are recommended when using

the Foot Pedal on non-carpeted surfaces.

Screw

Foot Pedal

Bottom

Foot Pedal

Pad Placement

Screw

Right Sideplate

©2018 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 15

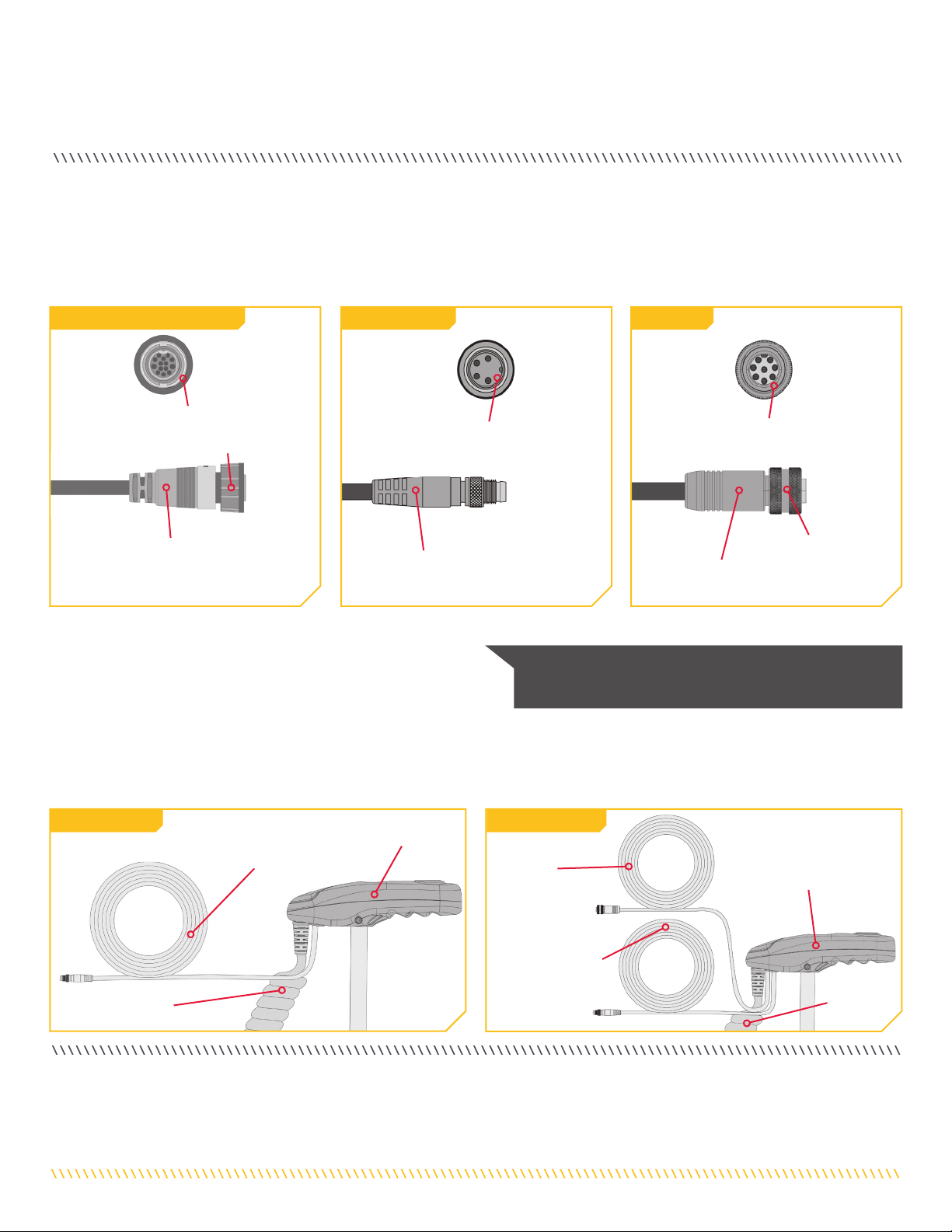

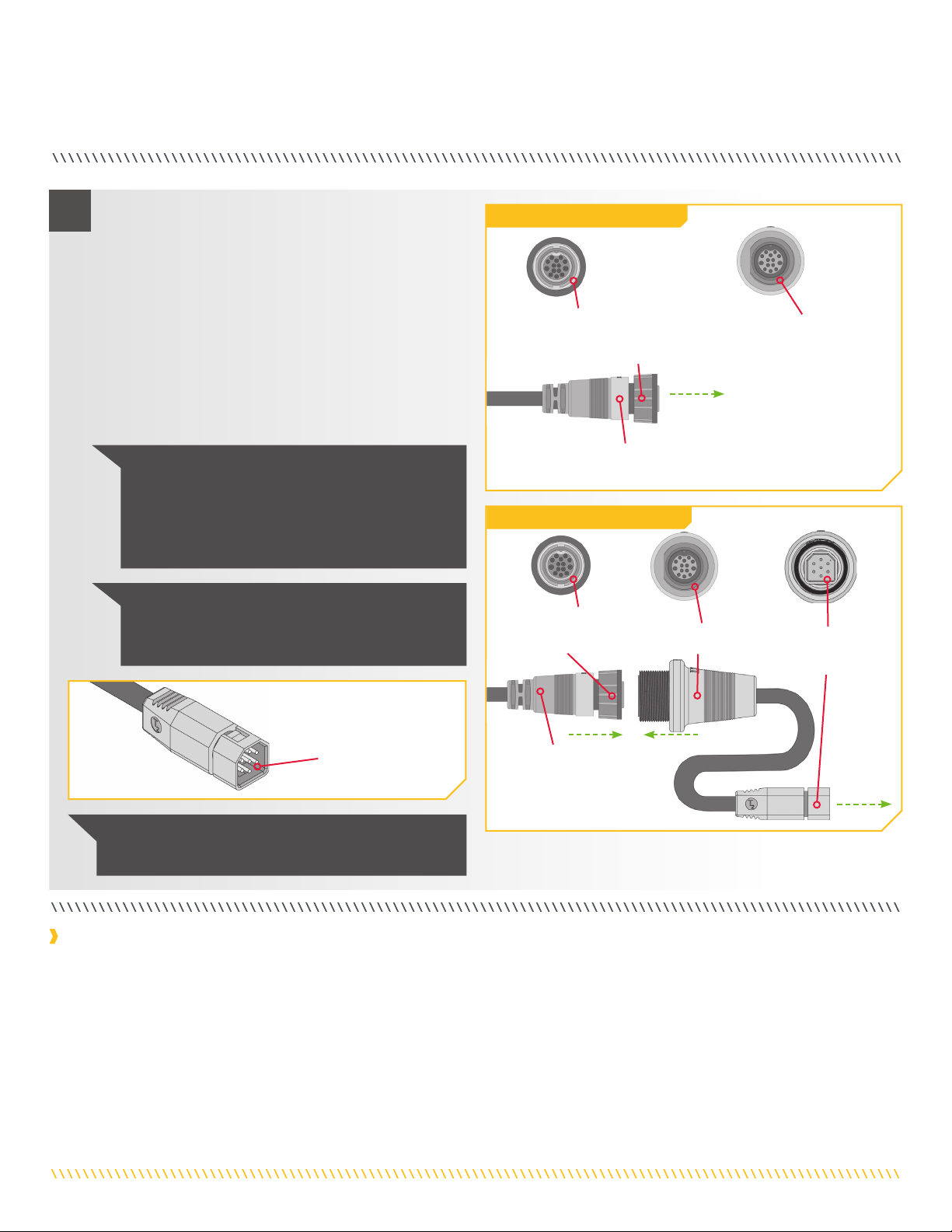

IDENTIFYING TROLLING MOTOR FEATURES BY THEIR ASSOCIATED CABLES

IDENTIFYING TROLLING MOTOR FEATURES BY THEIR ASSOCIATED CABLES

Your trolling motor may be pre-installed with Built-In MEGA Down Imaging OR Universal Sonar, and may include i-Pilot Link. All of these

features require cables to be connected to an output device. These connections are present on the trolling motor and have cables that exit

below the Control Head. To better identify cables present, refer to the diagrams below that detail what the Built-In MEGA Down Imaging,

Universal Sonar, and i-Pilot Link cable connectors look like.

Built-In MEGA Down Imaging Universal Sonar i-Pilot Link

Fourteen Pin Connector

Locking Collar

Built-In MEGA

Down Imaging from

Control Head

If one connection below the Control Head is present, the motor may be equipped with:

1. i-Pilot and Universal Sonar,

2. i-Pilot and Built-in MEGA Down Imaging,

3. ONLY Universal Sonar, or

4. ONLY Built-in MEGA Down Imaging.

If two connections below the Control Head are present, the motor may be equipped with either:

1. i-Pilot Link and Universal Sonar or

2. i-Pilot Link and Built-in MEGA Down Imaging

One Connection Two Connections

Built-in MEGA

Down Imaging or

Universal Sonar

Universal Sonar

Control Head

Control Head

Four Pin Connector

Cable from

NOTICE: The i-Pilot system does not have an external

wired connection.

i-Pilot

Link

Eight Pin Connector

Locking Collar

i-Pilot Link Ethernet Cable

from Control Head

Control Head

Built-in MEGA

Down Imaging or

Universal Sonar

Coil Cord

Coil Cord

ROUTING CONNECTION CABLES

Please follow these instructions for routing any and all of the cables present for any of the pre-installed features that may come with your

trolling motor. This routing should be followed whether there are one or two connection cables present. If you are unsure of the cables

present, please review the “Identifying Trolling Motor Features By Their Associated Cables” section of these Installation Instructions.

16 | minnkotamotors.com

©2018 Johnson Outdoors Marine Electronics, Inc.

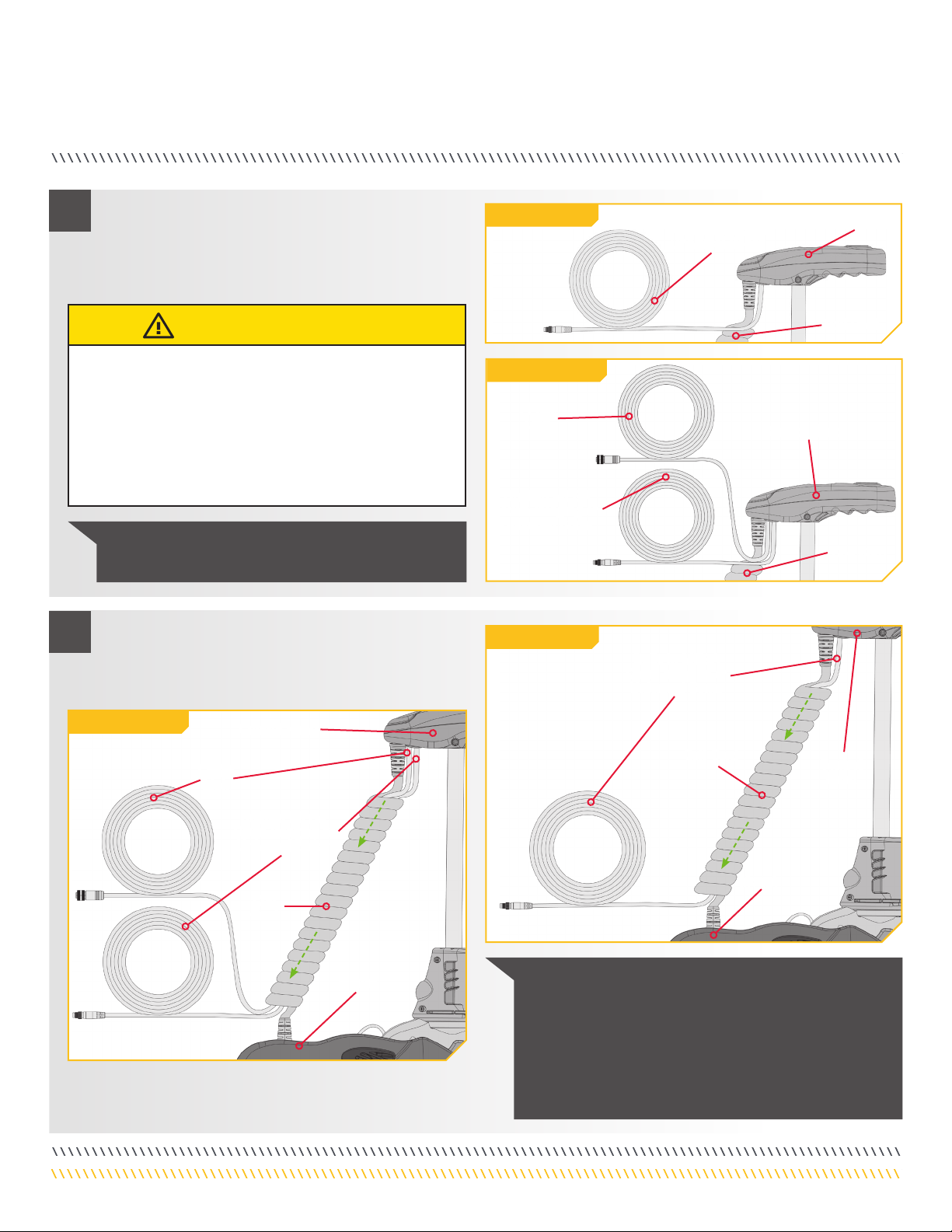

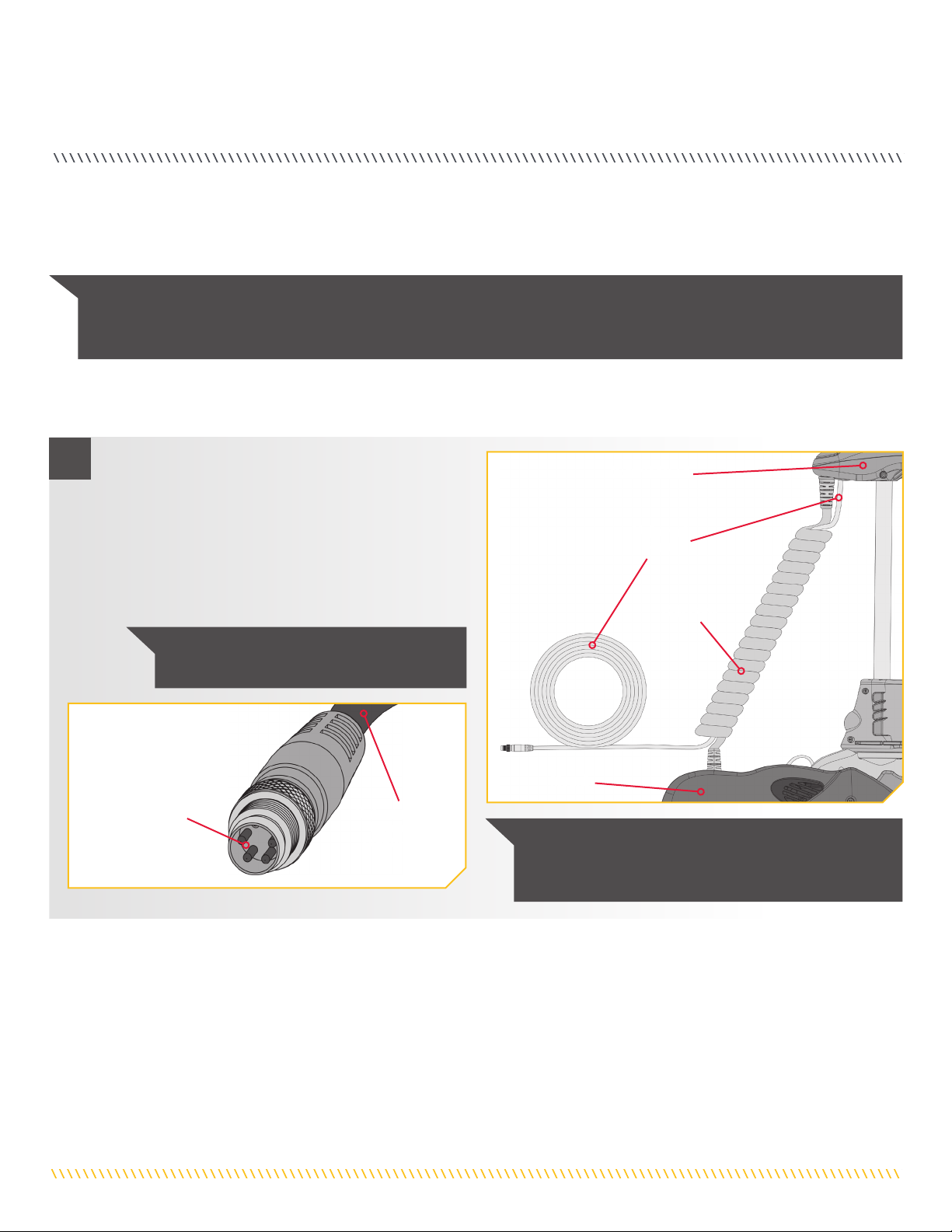

ROUTING CONNECTION CABLES

1

a. Place the motor in the deployed position.

b. Locate the Built-in MEGA Down Imaging, i-Pilot Link

and/or Universal Sonar cable(s), at the base of the

Control Head.

CAUTION

Not following the recommended wire routing for the Built-in

MEGA Down Imaging, i-Pilot Link and/or Universal Sonar

cable(s), if equipped, may cause damage to the product and

void your product warranty. Route cables away from pinch

points or other areas that may cause them to bend in sharp

angles. Routing the cables in any way other than directed may

cause damage to the cables by being pinched or severed.

NOTICE: Universal Sonar connector shown for

illustration purposes.

2

c. The cable(s) should be fed all the way through the

Coil Cord. It/they should exit the Coil Cord at the

bottom of the Coil Cord, where it connects to the

Mount.

One Connection

Two Connections

i-Pilot

Link

Built-in MEGA

Down Imaging or

Universal Sonar

One Connection

Built-in MEGA

Down Imaging or

Universal Sonar

Built-in MEGA

Down Imaging or

Universal Sonar

Control Head

Coil Cord

Control Head

Coil Cord

Two Connections

Control Head

i-Pilot

Link

Built-in MEGA

Down Imaging or

Universal Sonar

Coil

Cord

Mount

Coil Cord

Mount

Control

Head

NOTICE: After the cable(s) exit(s) the Coil Cord, it/they

should be routed through an established routing system on

the boat, in an area with minimal interference. Power cables

or other elements that may produce interference for the sonar

signals. Inspect the selected route carefully to ensure that

there are no sharp edges, obstacles, or obstructions that may

damage the cables.

©2018 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 17

FEATURE OVERVIEW AND CONNECTING THE CABLES

FEATURE OVERVIEW AND CONNECTING THE CABLES

The cable(s) from the Control Head for each feature installed on the trolling motor is connected to an output device separately. Once the

features that may be installed are identified, follow the instructions below to ensure the cables are connected correctly.

Built-In MEGA Down Imaging

Built-In MEGA Down Imaging delivers nearly 3X the output of standard Side Imaging®, and takes fishfinding into the megahertz frequency

for the very first time. The Minn Kota flagship families of trolling motors, including Ultrex, Ulterra, Terrova, and Fortrex, now include

Built-In MEGA Down Imaging sonar, the clearest imaging available only from Humminbird. With Humminbird MEGA imaging sonar built

right into the trolling motor, you now have a crystal clear view of what’s directly beneath the boat, without having to manage all of the

cables that come with external transducers. The Built-In MEGA DI transducer is only available on new models equipped from the factory

and cannot be added to an existing trolling motor.

The Built-in MEGA DI transducer will provide both MEGA Down Imaging and 2D CHIRP Digital Sonar to select Humminbird models. All

Built-In MEGA DI trolling motors, will come “Solix Ready” out of the box. An adapter cable accessory (MKR-MDI-1 1852085 or MKRMDI-2 1852086) is available for purchase that will allow the connection of any compatible Humminbird Helix fish finder. The MKR-MDI-1

is used on Helix 8, 9, 10 and 12 models. The MKR-MDI-2 is used for Humminbird Helix 7 models only. See the Built-In MEGA Down

Imaging Compatibility chart online.

NOTICE: You can only view MEGA Down Imaging with a MEGA DI or MEGA SI HELIX G2N or G3N Series model and a required

adapter, or with any SOLIX Series model. The built-in transducer cannot supply MEGA Down Imaging to Humminbird models that do

not already have the capability. f you have a G2/G2N or a G3/G3N HELIX that is not a MEGA SI or MEGA DI model, you will still get

2D CHIRP Digital Sonar from the transducer. Built-In MEGA DI is not supported by HELIX G1 models or other brands of fish finders.

1

a. Place the motor in the deployed position.

b. The Built-In MEGA Down Imaging connector from the

Control Head is a 14 pin connector. Built-In MEGA

Down Imaging may be installed on its own, or in

conjunction with an i-Pilot or i-Pilot Link system. It will

never be installed with Universal Sonar. Locate and

identify the correct connection for Built-in MEGA Down

Imaging cable(s), at the base of the Control Head.

i-Pilot

Link

Built-in MEGA

Down Imaging

Control

Coil

Cord

NOTICE: Built-in MEGA Down Imaging is

always paired with either i-Pilot or i-Pilot Link

on Terrova, Ulterra and Ultrex motors. It may be

pre-installed on a Fortrex motor without other

features that require external connections.

Mount

Head

Fourteen Pin

Built-in MEGA Down

Imaging cable from

Control Head

18 | minnkotamotors.com

Connector

NOTICE: Critical cable routing for 60" and 72" motors with

i-Pilot Link and Built-in MEGA Down Imaging. Accessory

Cables must exit the Coil Cord leaving three or more open

coils between where the cables exit and the motor base; as

assembled by the factory. Routing the cables in any other

manner will not allow the motor to stow properly.

©2018 Johnson Outdoors Marine Electronics, Inc.

FEATURE OVERVIEW AND CONNECTING THE CABLES

2

c. When installing with a Solix, the Built-In MEGA

Down Imaging cable can be plugged directly into

the Solix fish finder. Plug the Built-in MEGA Down

Imaging cable into the corresponding connection on

the Solix fish finder.

d. When installing with a Helix, first attach the Adapter

Cable and then plug the Adapter Cable into the

Helix fish finder. The Adapter Cable will only have

one connection that is keyed on the back of the

Helix fish finder. Plug the Adapter Cable into the

only matching keyed connection.

NOTICE: Check for compatibility or any required

adapter cables online at minnkotamotors.com. The

cable from the trolling motor can be extended with a

10’ Extension Cable #720081-1 or the 30’ Extension

Cable #720081-2 found at humminbird.com.

NOTICE: If any cables need to be routed, please

follow the guidelines in the Routing Connection

Cables section of these installation instructions.

Humminbird Solix Fish Finder

Fourteen Pin Connector

Locking Collar

Built-In MEGA Down Imaging

from Trolling Motor

Humminbird Helix Fish Finder

Fourteen Pin Connector

Locking Collar

Adapter Cable

(Helix ONLY)

Solix Fish Finder

Connection

Plug directly into

Solix Fish Finder

Adapter

Cable Keyed

Connection

Keyed Adapter Cable

for Helix Fish Finder

Built-In MEGA

Down Imaging from

Trolling Motor

Plug into

Helix Fish

Finder

NOTICE: The connectors are keyed to prevent

reversed installation.

Universal Sonar

Your trolling motor may be pre-installed with a Universal Sonar transducer system. Universal Sonar is a 2D sonar transducer with a

temperature sensor that is integrated into the lower unit of the trolling motor. It has an operating frequency of 83/200 kHz. Connecting

this transducer to a compatible fish finder gives you a 2D sonar view of what is happening directly below your trolling motor. The

integrated design protects the transducer from underwater hazards, and prevents tangles and damage to the transducer cables.

All Universal Sonar motors are equipped with an internal bonding wire, incorrect rigging will cause sonar interference and can damage

your trolling motor, electronics and other boat accessories. To minimize trolling motor interference, ensure that the fish finder and trolling

motor are powered by separate batteries. Please refer to the Battery & Wiring Installation and Motor Wiring Diagram sections of this

manual for correct rigging instructions.

©2018 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 19

FEATURE OVERVIEW AND CONNECTING THE CABLES

The Universal Sonar Cables are shielded to minimize interference. To protect this shielding the cables should not be pulled tight against

sharp angles or hard objects. If using cable ties, do not over-tighten. Any excess cable should be bundled in a loose loop of no less than

4” in diameter. In certain situations, air bubbles may adhere to the surface of the Universal Sonar transducer, and effect the performance.

If this happens simply wipe the surface of the transducer with your finger.

NOTICE: Universal Sonar does not support imaging screens that require higher frequencies such as 455 kHz or 800 kHz (Down

Imaging, Side Imaging, etc.). Down Imaging (DI) specific units are not compatible with Universal Sonar. See compatibility chart

for a list of compatible fish finders at minnkotamotors.com.

The connector for Universal Sonar exits the trolling motor below the Control Head and consists of a 4 pin plug. An adapter cable (MKRUS2) that is sold separately is required for all installations. For a current list of compatible fish finders and the correct adapter cable, or

more information on Universal Sonar, please visit minnkotamotors.com.

1

a. Place the motor in the deployed position.

b. Locate the Universal Sonar, if equipped, at the base

of the Mount.

c. Locate the Universal Sonar four pin connector at

the end of Universal Sonar Extension Cable. The

connector is black with a stainless steel threaded

locking collar.

NOTICE: Your fish finder should be turned

off until this procedure is complete.

Four Pin

Connector

Universal Sonar

Cable from

Control Head

Control Head

Universal

Sonar

Coil Cord

Mount

NOTICE: If the cable length does not reach the desired

fish finder installation location, a 14.5’ extension cable is

available (MKR-US2-11) (sold separately).

20 | minnkotamotors.com

©2018 Johnson Outdoors Marine Electronics, Inc.

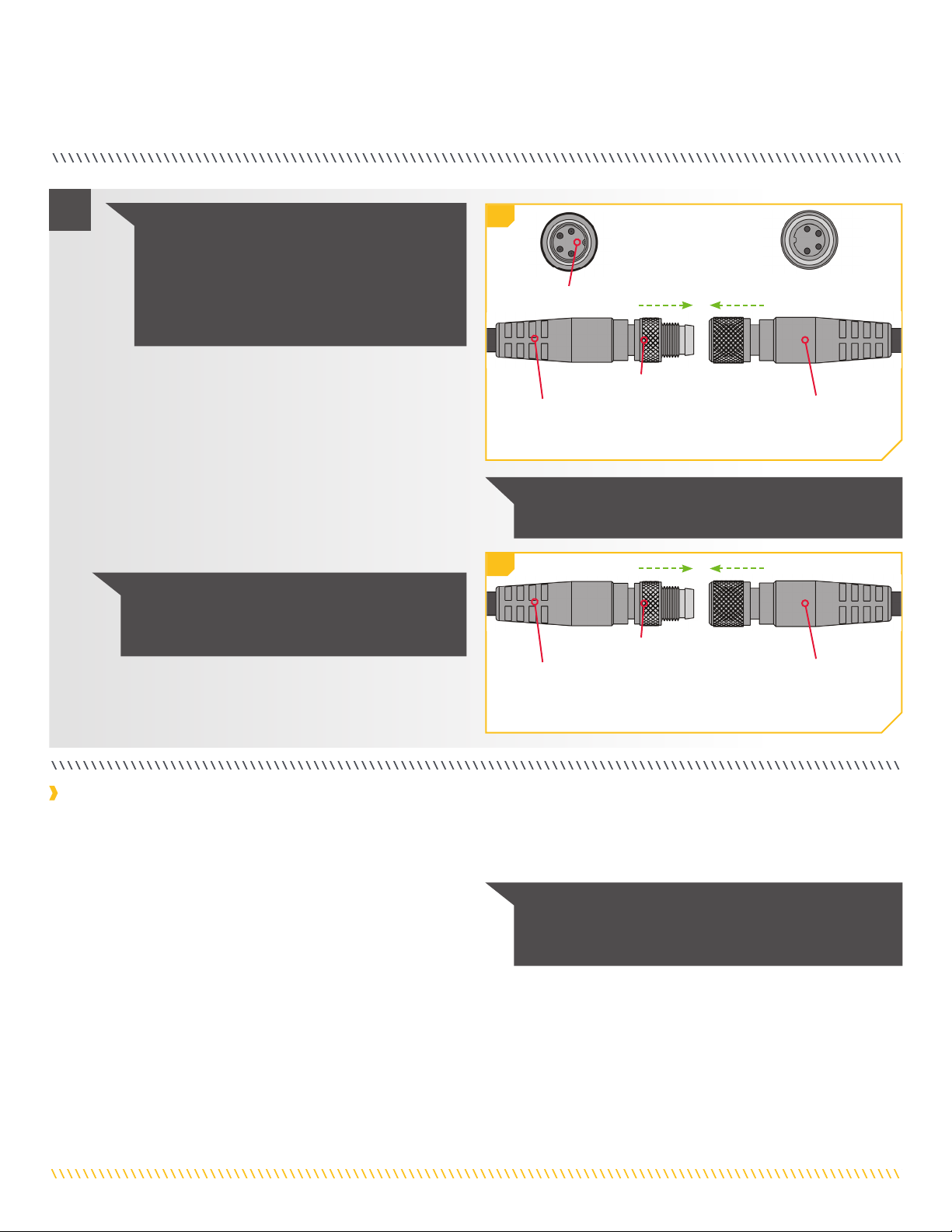

FEATURE OVERVIEW AND CONNECTING THE CABLES

2

NOTICE: The Universal Sonar Cable may not be

long enough to reach the fish finder. If the cable

length does not reach the desired fish finder

installation location, a 14.5’ extension cable is

available to purchase. Minn Kota recommends

using the MKR-US2-11.

d. Take the Universal Sonar Extension Cable, if needed,

and attach it to the Universal Sonar Cable exiting

the Control Head. Firmly push the plug together and

twist the locking collar until it is snug.

e. Install the Universal Sonar Cable that exists the

Control Head or the Universal Sonar Extension

Cable (if used) to the appropriate Universal Sonar

Adapter Cable. Install the Adapter Cable to your fish

finder. Refer to your fish finder manual for complete

installation instructions.

NOTICE: If any cables need to be routed, please

follow the guidelines in the Routing Connection

Cables section of these installation instructions.

2d

Four Pin Connector

Locking Collar

Universal Sonar

Cable from

Control Head

Universal Sonar

Extension Cable

NOTICE: The connectors are keyed to prevent reversed

installation.

2e

Locking Collar

Universal Sonar Cable from

Control Head OR Universal

Sonar Extension Cable

Universal Sonar

Adapter Cable to

fish finder

i-Pilot Link

i-Pilot Link allows your Minn Kota trolling motor and Humminbird to communicate with each other to change the way you fish. i-Pilot Link

delivers a large array of GPS capabilities including controlling speed, steering, Spot-Lock, and the ability to record and retrace paths on

the water, all at your fingertips. To learn more about the GPS capabilities available with your i-Pilot Link navigation system, please refer to

the Owner’s Manual by visiting minnkotamotors.com.

The i-Pilot Link remote and controller make up the i-Pilot Link

navigation system. The i-Pilot Link remote comes paired to the

controller from the factory. The i-Pilot Link controller contains a

very sensitive compass and is where all GPS satellite and i-Pilot Link remote signals are received. The i-Pilot Link controller is

contained in the trolling motor Control Head and is connected to a fish finder from a connection cable that exits the Control Head.

The Ethernet cable for the i-Pilot Link system has an 8 pin connector. The i-Pilot Link system can be connected directly to the Humminbird

or to the Humminbird Ethernet Switch (optional). If you purchase an Ethernet Switch, install it using the instructions included in the

Ethernet Installation Guide. The Ethernet Extension Cable is optional for your installation. To purchase Ethernet switches, Ethernet cables,

and extension cables, visit the web site humminbird.com or call Humminbird Customer Service at 1-800-633-1468. Depending on the

shape of the Ethernet port on your Humminbird fish finder, an additional ethernet adapter cable (Ethernet Adaptor Cable AS EC QDE

#720074-1 for Helix fish finders) may be required for the installation. Refer to your fish finder operations manual or see the i-Pilot Link

Compatibility Chart on our web site with a list of all compatible Humminbird Units and SC Cards.

©2018 Johnson Outdoors Marine Electronics, Inc.

NOTICE: The i-Pilot Link system needs an external wired

connection. The i-Pilot system does not need an external

wired connection.

minnkotamotors.com | 21

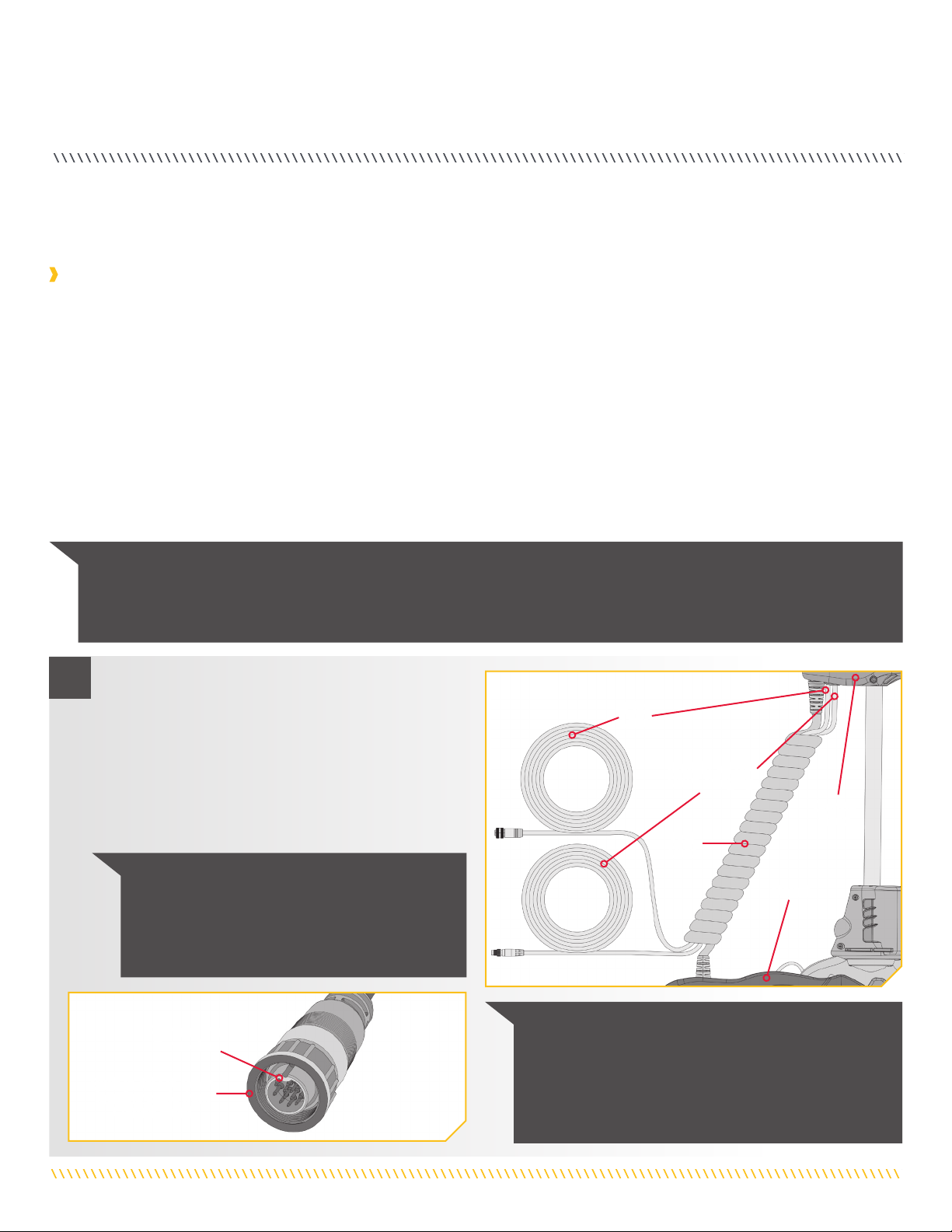

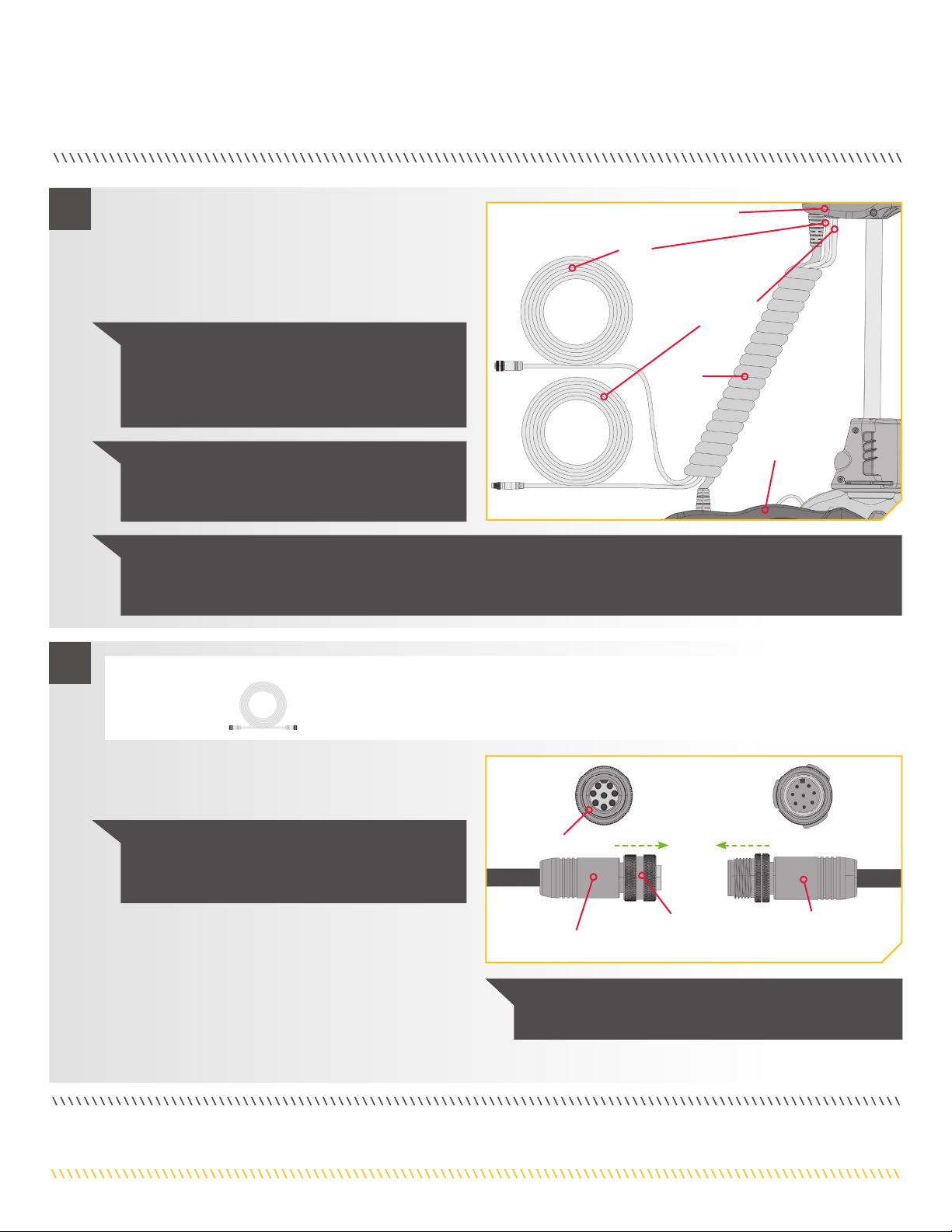

FEATURE OVERVIEW AND CONNECTING THE CABLES

1

a. Place the motor in the deployed position.

b. The i-Pilot Link connector from the Control Head is

an 8 pin connector. Locate and identify the correct

connection for i-Pilot Link, at the base of the Control

Head.

Control Head

i-Pilot

Link

Built-in MEGA

Down Imaging or

Universal Sonar

NOTICE: i-Pilot Link will be paired with either

Built-in MEGA Down Imaging or Universal Sonar

on Ultrex, Ulterra or Terrova. i-Pilot Link is not a

feature offered on Fortrex motors.

NOTICE: Paired with a Universal Sonar connector

for illustration purposes. A Built-in MEGA Down

Imaging connector may be present instead.

Coil

Cord

Mount

NOTICE: Critical cable routing for 60" and 72" motors with i-Pilot Link and Built-in MEGA Down Imaging. Accessory Cables

must exit the Coil Cord leaving three or more open coils between where the cables exit and the motor base; as assembled by the

factory. Routing the cables in any other manner will not allow the motor to stow properly.

2

ITEM(S) NEEDED

#16 x 1

c. If necessary, to reach the installed fish finder, take the

i-Pilot Link Ethernet Cable (Item #16) and attach it to

the i-Pilot Link cable exiting the Control Head.

NOTICE: If any cables need to be routed, please

follow the guidelines in the Routing Connection

Cables section of these installation instructions.

d. Install the i-Pilot Link Ethernet Cable directly into

the Humminbird fish finder, or refer to your fish

finder installation manual for complete installation

instructions. If an Adapter Cable is needed (Ethernet

Adaptor Cable AS EC QDE for Helix fish finders),

install it on the end of the i-Pilot Link Ethernet Cable

and refer to your fish finder installation manual for

complete installation instructions.

Eight Pin

Connector

Locking Collar

i-Pilot Link Ethernet

Cable from Control Head

i-Pilot Link Ethernet

Extension Cable OR

Ethernet Extension Cable

NOTICE: The connectors are keyed to prevent reversed

installation.

22 | minnkotamotors.com

©2018 Johnson Outdoors Marine Electronics, Inc.

baTTeRY & WIRINg INsTallaTION

BOAT RIGGING & PRODUCT INSTALLATION

For safety and compliance reasons, we recommend that you follow American Boat and Yacht Council (ABYC) standards when rigging

your boat. Altering boat wiring should be completed by a qualifi ed marine technician. The following specifi cations are for general

guidelines only:

CAUTION

These guidelines apply to general rigging to support your Minn Kota motor. Powering multiple motors or additional electrical devices

from the same power circuit may impact the recommended conductor gauge and circuit breaker size. If you are using wire longer than

that provided with your unit, follow the conductor gauge and circuit breaker sizing table below. If your wire extension length is more

than 25 feet, we recommend that you contact a qualifi ed marine technician.

CAUTION

An over-current protection device (circuit breaker or fuse) must be used. Coast Guard requirements dictate that each ungrounded

current-carrying conductor must be protected by a manually reset, trip-free circuit breaker or fuse. The type (voltage and current rating)

of the fuse or circuit breaker must be sized accordingly to the trolling motor used. The table below gives recommended guidelines for

circuit breaker sizing.

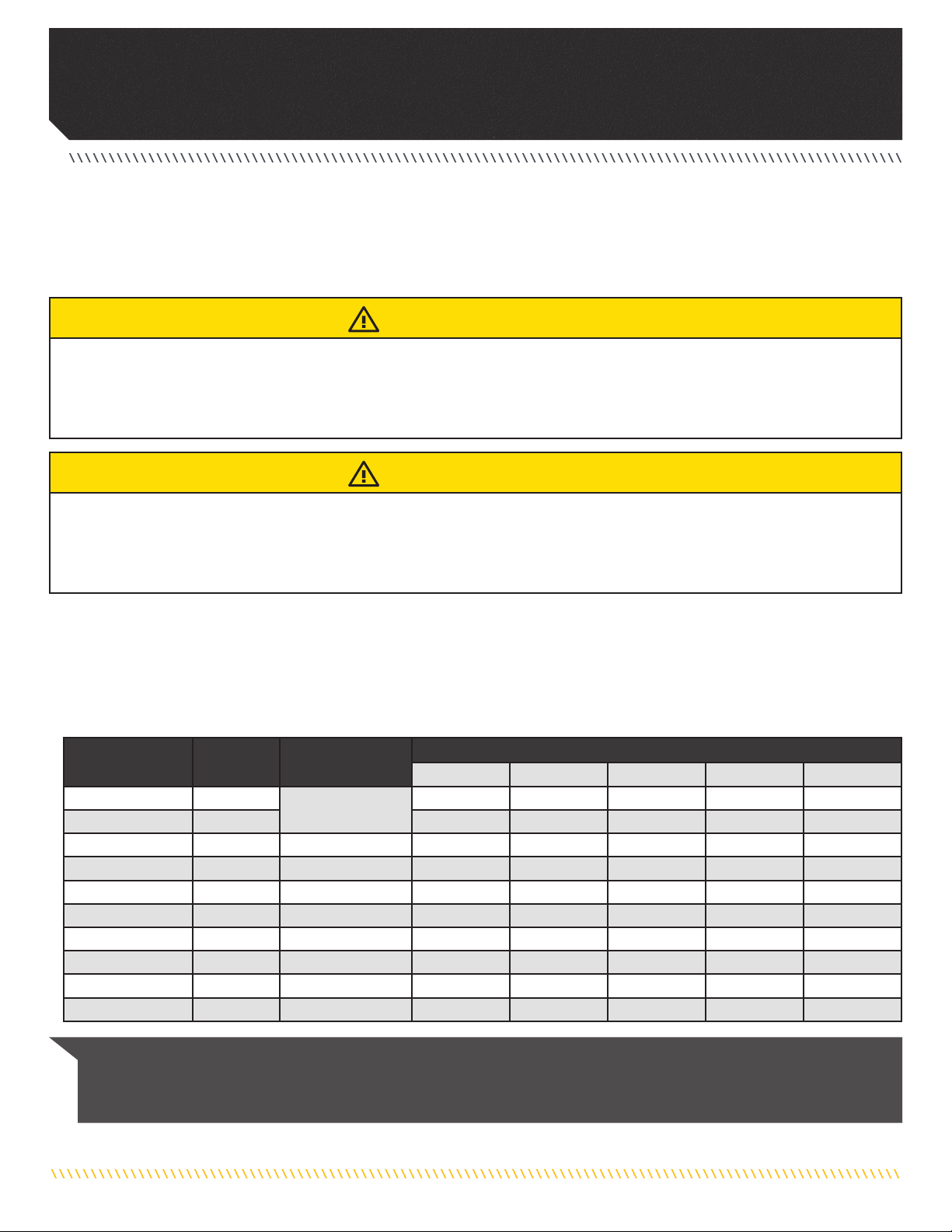

CONDUCTOR GAUGE AND CIRCUIT BREAKER SIZING TABLE

This conductor and circuit breaker sizing table is only valid for the following assumptions:

1. No more than 2 conductors are bundled together inside of a sheath or conduit outside of engine spaces.

2. Each conductor has 105° C temp rated insulation.

3. No more than 5% voltage drop allowed at full motor power based on published product power requirements.

Motor Thrust / Model

30 lb. 30

40 lb., 45 lb. 42 10 AWG 8 AWG 6 AWG 4 AWG 4 AWG

50 lb., 55 lb. 50 60 Amp @ 12 VDC 8 AWG 6 AWG 4 AWG 4 AWG 2 AWG

70 lb. 42 50 Amp @ 24 VDC 10 AWG 10 AWG 8 AWG 8 AWG 6 AWG

80 lb. 56 60 Amp @ 24 VDC 8 AWG 8 AWG 8 AWG 6 AWG 6 AWG

101 lb. 46 50 Amp @ 36 VDC 8 AWG 8 AWG 8 AWG 8 AWG 8 AWG

Engine Mount 101 50 60 Amp @ 36 VDC 8 AWG 8 AWG 8 AWG 8 AWG 8 AWG

112 lb. 52 60 Amp @ 36 VDC 8 AWG 8 AWG 8 AWG 8 AWG 8 AWG

Engine Mount 160 116 (2) x 60 Amp @ 24 VDC 6 AWG 6 AWG 4 AWG 2 AWG 2 AWG

E-Drive 40 50 Amp @ 48 VDC 10 AWG 10 AWG 10 AWG 10 AWG 10 AWG

Max

Amp Draw

Circuit Breaker

50 Amp @ 12 VDC

5 feet 10 feet 15 feet 20 feet 25 feet

10 AWG 10 AWG 8 AWG 6 AWG 4 AWG

NOTICE: Wire Extension Length refers to the distance from the batteries to the trolling motor leads. Consult website for

available thrust options. Maximum Amp Draw values only occur intermittently during select conditions and should not be used

as continuous amp load ratings.

Wire Extension Length

Reference

United States Code of Federal Regulations: 33 CFR 183 – Boats and Associated Equipment ABYC E-11: AC and DC Electrical Systems on Boats

©2018 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 23

SELECTING THE CORRECT BATTERIES

SELECTING THE CORRECT BATTERIES

The motor will operate with any lead acid, deep cycle marine 12 volt battery/batteries. For best results, use a deep cycle, marine

battery with at least a 105 amp-hour rating. Maintain battery at full charge. Proper care will ensure having battery power when you

need it, and will significantly improve the battery life. Failure to recharge lead-acid batteries (within 12-24 hours) is the leading cause

of premature battery failure. Use a multi-stage charger to avoid overcharging. We offer a wide selection of chargers to fit your charging

needs. If you are using a crank battery to start a gasoline outboard, we recommend that you use a separate deep cycle marine battery/

batteries for your Minn Kota trolling motor. For more information on battery selection and rigging, please visit minnkotamotors.com.

WARNING

Never connect the (+) and the (–) terminals of the same battery together. Take care that no metal object can fall onto the battery and

short the terminals. This would immediately lead to a short and extreme fire danger.

CAUTION

Refer to “Conductor Gauge and Circuit Breaker Sizing Table” in the previous section to find the appropriate circuit breaker or fuse for

your motor. For motors requiring a 60-amp breaker, the Minn Kota MKR-19 60-amp circuit breaker is recommended.

CAUTION

Please read the following information before connecting your motor to your batteries in order to avoid damaging your motor and/or

voiding your warranty.

ADDITIONAL CONSIDERATIONS

Using Alternator Chargers

Your Minn Kota trolling motor may be designed with an internal bonding wire to reduce sonar interference. Most alternator charging

systems do not account for this bonding wire, and connect the negative posts of the trolling motor batteries to the negative posts of

the crank/starting battery. These external connections can damage connected electronics and the electrical system of your trolling

motor, voiding your warranty. Review your charger’s manual carefully or consult the manufacturer prior to use to ensure your charger is

compatible.

Minn Kota recommends using Minn Kota brand chargers to recharge the batteries connected to your Minn Kota trolling motor, as they

have been engineered to work with motors that include a bonding wire.

Additional Accessories Connected to Trolling Motor Batteries

Significant damage to your Minn Kota motor, your boat electronics, and your boat can occur if incorrect connections are made between

your trolling motor batteries and other battery systems. Minn Kota recommends using an exclusive battery system for your trolling

motor. Where possible, accessories should be connected to a separate battery system. Radios and sonar units should not be connected

to any trolling motor battery systems as interference from the trolling motor is unavoidable. If connecting any additional accessories to

any trolling motor battery system, or making connections between the trolling motor batteries and other battery systems on the boat, be

sure to carefully observe the information below.

The negative (-) connection must be connected to the negative terminal of the same battery that the trolling motor negative lead

connects to. In the diagrams below this battery is labeled “Low Side” Battery. Connecting to any other trolling motor battery will input

24 | minnkotamotors.com

©2018 Johnson Outdoors Marine Electronics, Inc.

Loading...

Loading...