ML-4

INSTRUCTION

BOOK

FOREWORD

Many thanks for your

machine, ML type.

For

use of the machine,

instruction

elegant

chain

fabrics

You can

book.

edge

covering

stitch

whitch

- cotton, wool, rayon,

also

expect many

With

perchasing

please

your

machine

stitch

well

(Over Lock) and a double

become

years'

of MAMMY

read

tricot,

you

with

carefully

can

jersey,

LOCK

this

make an

thick

etc.

enjoyment from your

or

machine which was manufactured with up-to-date

technique and

has

a proud

history

of

its

own.

CONTENTS

00

I

FEATURES

1.

DESCRIPTION

2.

OPERATION

LUBRICATION

3.

THREADING

4.

THREAD

5.

REGULATING

6.

HOW

7.

FINISHING

8.

REGULATING

9.

PRESSE^R

10.

TO

YOUR

THE

CHAIN

THREAD

OPERATE

MACHINE

THE

YOUR

STITCH

FOOT

MACHINE

(Stitching)

TENSION

SEAM

LENGTH

PRESSURE

2

3

4

5

6-10

11

12-13

14

15

16

17

STITCHES

11.

NEEDLE

12.

KNIVES

13.

STITCH

14.

VARIATION

15.

THREADS

SPECIFICATION

16.

CONTENTS

SHIPPING

AND

TROUBLE

AND

OF

AND

IN

CONTAINER

OPERATIONS

ITS

REMEDY

WEIGHT

STITCH

FOR

MODEL

THE

OF

LENGTH

23-24

FABRIC,

ML-4

22

25

26

27

28

MAMMY

LOCK

MACHINE

OPERATING

INSTRUCTIONS

MAINTENANCE

FEATURES

Three

Easily

different

changed

1.

Over

2.

Interlock chainstitching

3.

Safety

Quiet running

Attractive

modern

Guaranteed

stitches

for:

lock stitching

stitching

and

vibrationless

appearance.

for

longer

available

life.

in

one

machine.

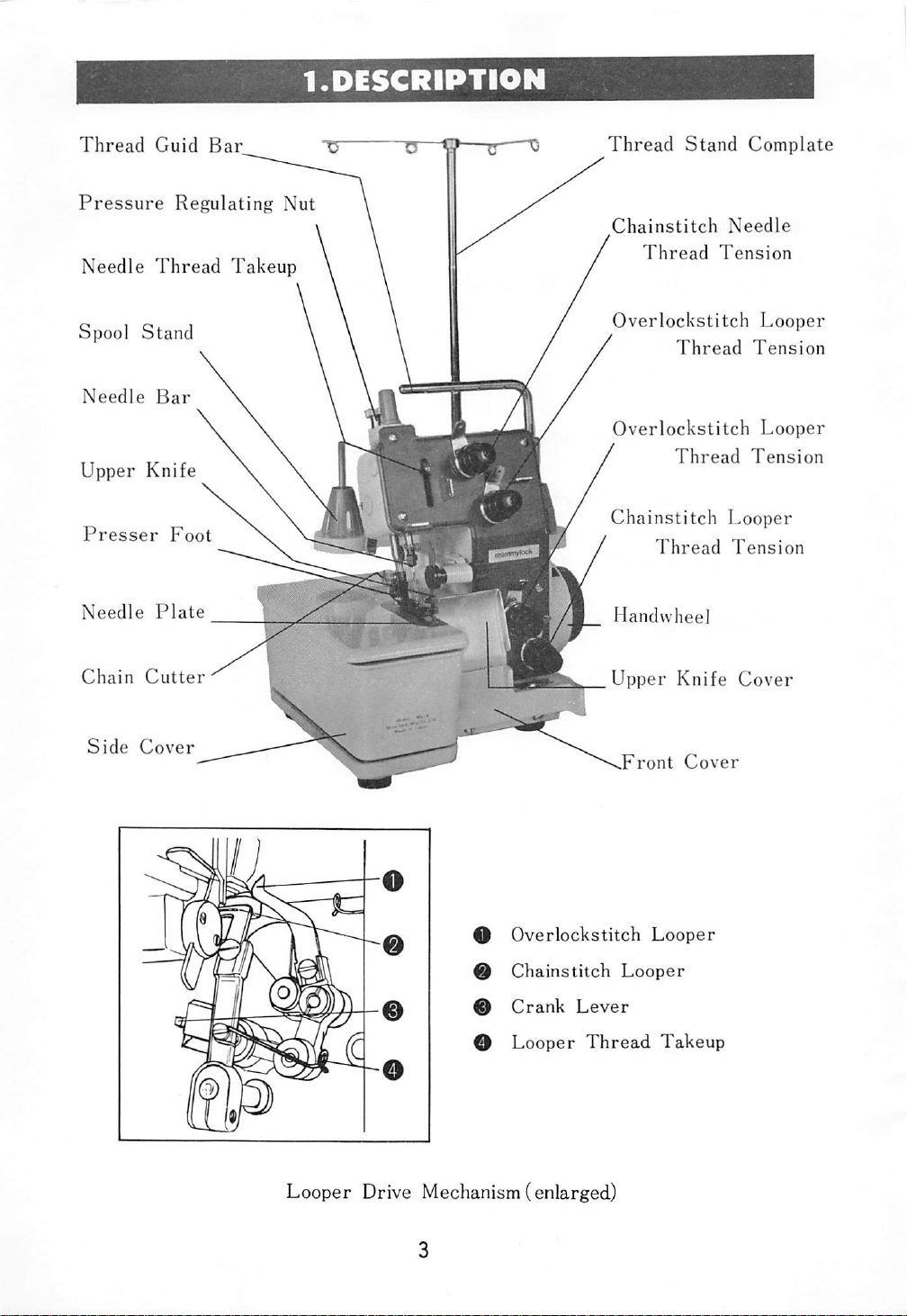

1.DESCRIPTION

Thread

Guid

Pressure

Needle

Spool

Needle

Thread

Stand

Bar

Upper Knife

Presser

Needle

Foot

Plate

Bar

Regulating

Takeup

Nut

Thread

Chainstitch

t

Stand

Thread

Overlockstitch

Thread

Overlockstitch

/

Thread

Chainstitch

Thread

Handvvheel

Complate

Needle

Tension

Looper

Tension

Looper

Tension

Looper

Tension

Chain

Side

Cutter

Cover

O

Overlockstitch

9

Chainstitch

0

O

Crank

Looper

Lever

Thread

Looper Drive Mechanism (enlarged)

Upper

.Front

Looper

Knife

Cover

Looper

Takeup

Cover

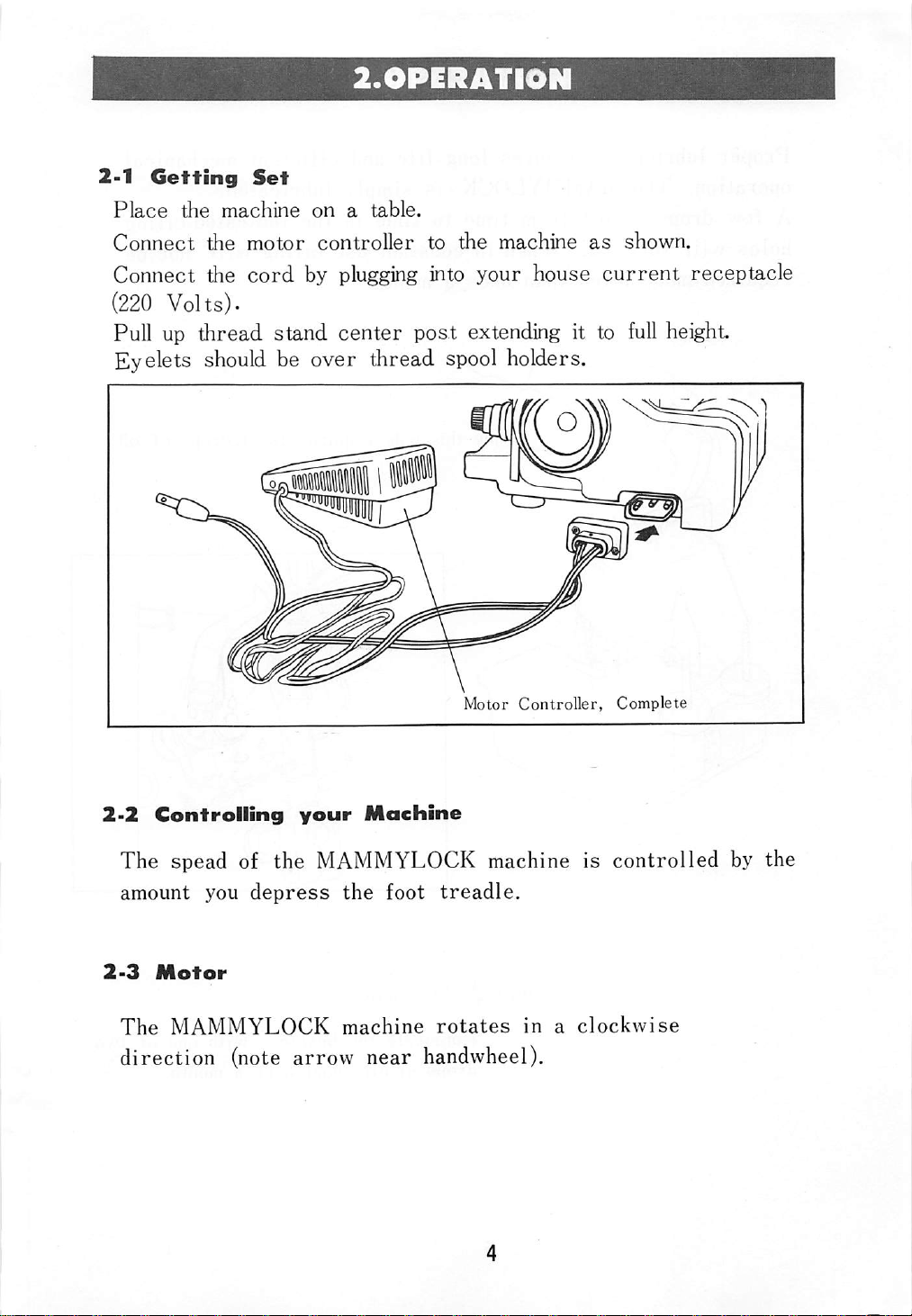

2-1

Getting

2.0PERATI0N

Set

Place

Connect

Connect the

the

machine

the

motor

cord

on

a

table.

controller

to

the

machine

by plugging into your house

(220 Volts)-

Pull up

thread

stand

center

post

extending it to

Eyelets should be over thread spool holders.

Ill

Motor

Controller,

as

shown.

current

full

Complete

receptacle

height

2-2

Controlling

your

Machine

The spead of the MAMMYLOCK machine is controlled by the

amount you

2-3

Motor

The

MAMMYLOCK

direction

depress

(note

arrow

the

foot

treadle.

machine

rotates

near handwheel).

inaclockwise

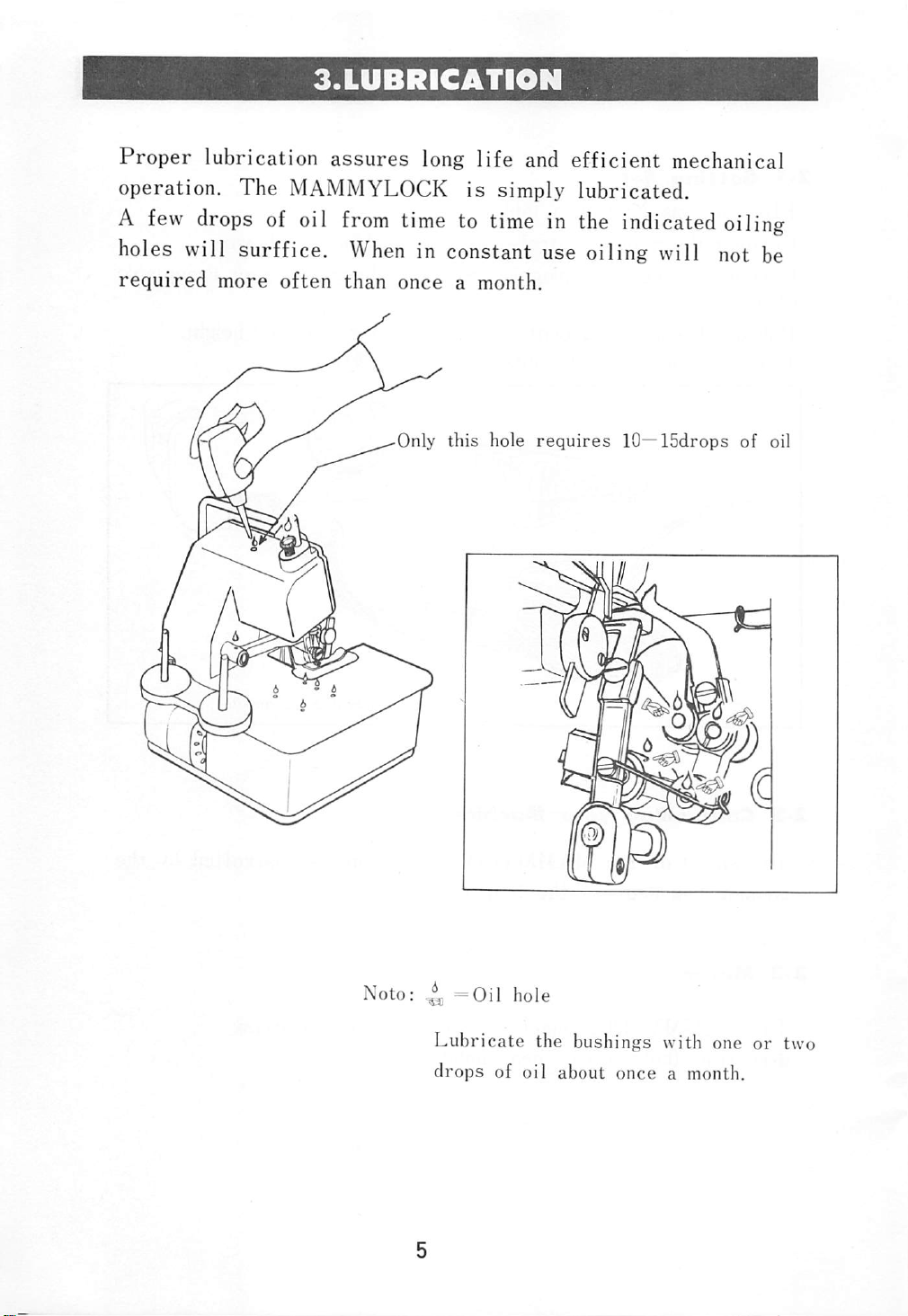

3.LUBRICATIOH

Proper

operation. The MAMMYLOCK

A

few

holes will surffice.

required

lubrication

drops

more

of

often

oil

assures

from

When

than

long

time

in constant use oiling will not be

once

Only

life

and

efficient

is

simply lubricated.

to

time

a month.

this

hole

in

requires

m

the

indicated

10—ISdrops

mechanical

oiling

of oil

Noto:

^ =Oil

Lubricate

drops

hole

the bushings with one

of

oil

about

once

a month.

or

two

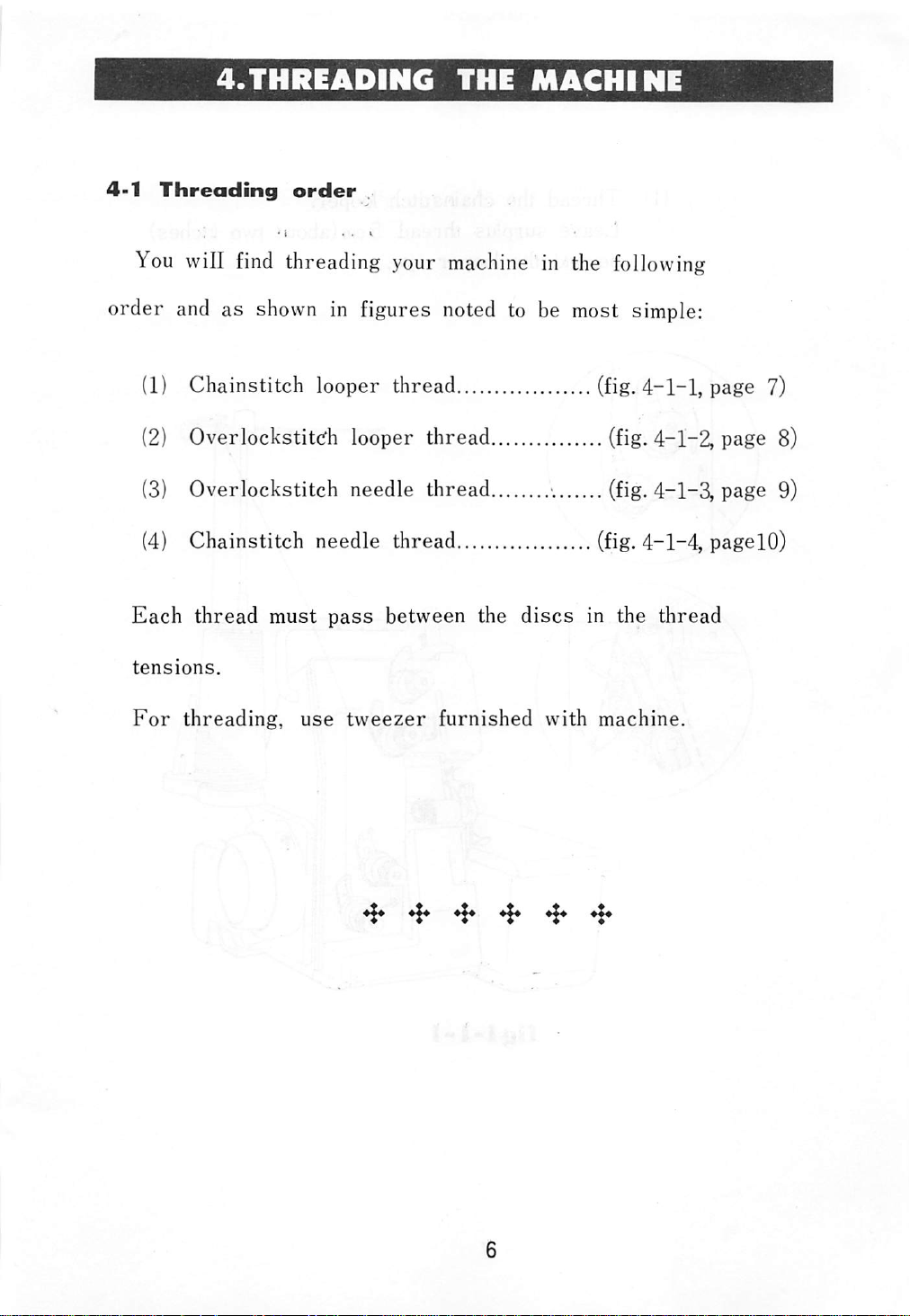

4-1

Threading

You

will

4.THREADING

order

• I K

find

threading your

THE

machine

MACHINE

in the following

order and as

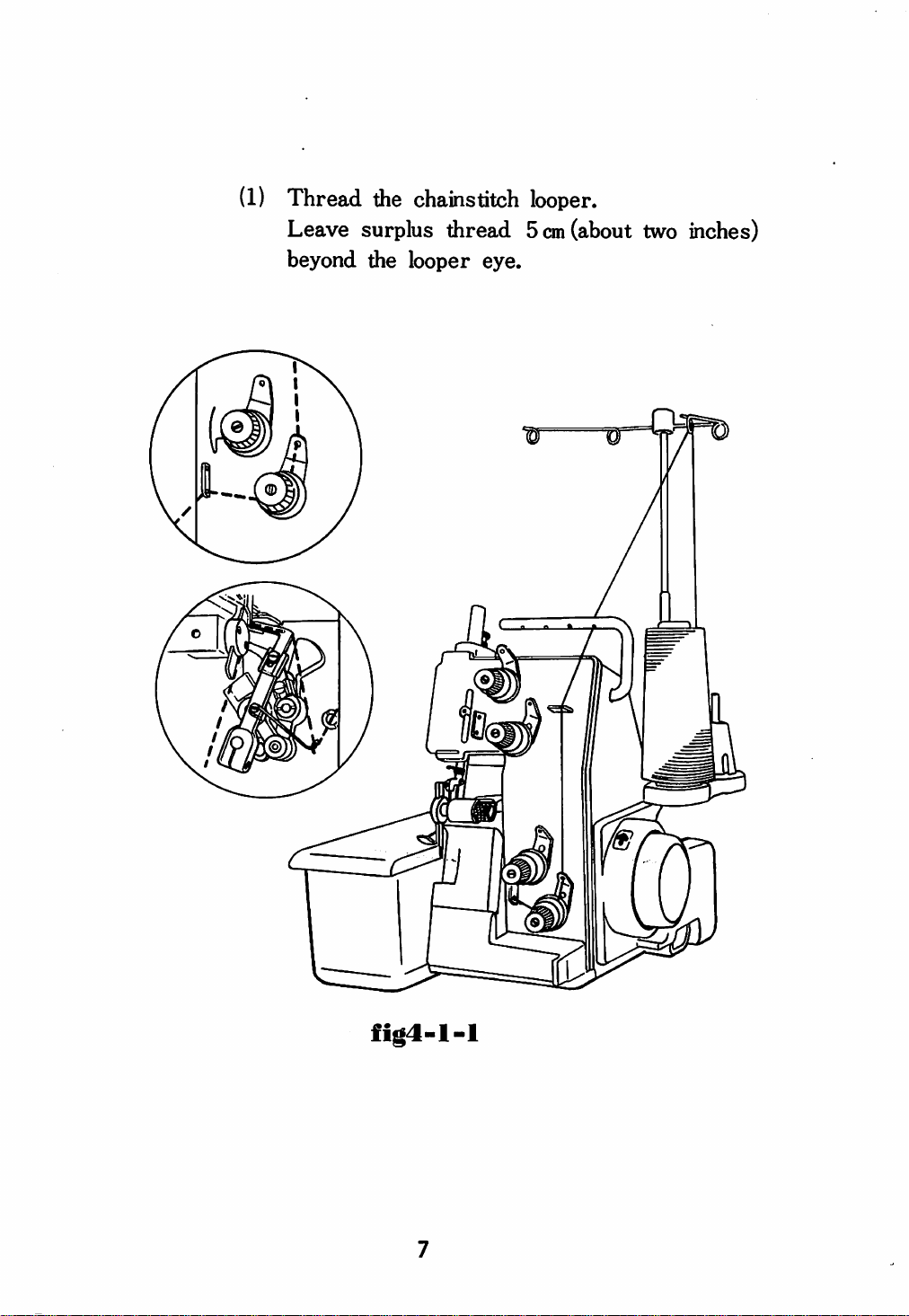

(1)

Chainstitch looper thread (fig.4-1-1, page 7)

(2)

OverIockstit(^h looper thread (fig-4-1-2, page 8)

(3)

Overlockstitch needle thread v (fig.4-1-3, page 9)

(4)

Chainstitch needle thread (fig. 4-1-4, pagelO)

Each

tensions.

For

thread

threading,

shown

must

use

in figures noted to be most simple:

pass

between the

tweezer

furnished

discs

with

in the thread

machine.

aTa aTa

VT

V

•••

^ T V

aT^aTa.

www www

a

www

(1)

Thread the chainstiich looper.

Leave surplus thread 5cm(about two inches)

beyond the looper eye.

fig4-l-l

(2)

Treading the overlockslitch

looper.

Leave surplus thread 5cm(about

2")

beyond

^ / r

looper

eye.

fig4-l-2

8

(3) Threading the overlockstitch needle.

Leave surplus thread 5cm(about2 beyond needle eye.

/

fig4-l-3

For

to

wool

stretch,

or

synthetic thread, usually tending

threading the

thread

tension guide

wire (A) may be unnecessary since less tens

ion is

required

for

the

needle

thread.

(4)

Threading the chainstitch needle thread.

Leave surplus thread 5

cm

(about 2 beyond needle eye.

W

/

fig4-l-4

For

Remark:

It

is recommended to

on Spool

are

used.

Strays

wool

to

stretch,

wire(B)

ion is

when the small

or

synthetic

threading the

may be

required

put

Thread

thread,

thread

unnecessary

for the needle thread.

Stripping

diameter

10

Discs

thread

usually tending

tension guide

since

less

tens

provided

spools

5.THREAD

If the threading of the machine has been perfomed properly,

you will now be on your way to stitching.

This may be confirmed by the following:

(1)

Raise

(2)

Insert a

foot.

(3)

. Lower- the

(4)

Hold

a bit to the left of the stitching line. Pull the

gently and,

wise two or

A

(5)

After

1 inch beyond the

with

presser

the

thread

being

chain

foot

by

lifting the lift lever.

small

needle

piece

presser

of extra

foot.

threads

at

the same time,

three

chain will be produced.

times with your right hand.

certain the thread

inserted

cutter

or

scissors.

in

your

fabric

CHAIN

fabric

left

turn

chain

end

(Stitching)

beneath

hand

the handwheel clock

has been

and

and

cut

the

made

chain

presser

pull

thread

them

sew

6.REGULATING

THREAD

TENSION

Your

thread

stitching

tension.

will be

The

enhanced

tension

by some

required

care

varies

in

properly

with the

type of thread, the number of plies and the type of

number

to page 3

cation

the

Here

stitch

the

of

plies

and

for

of the four (4)

tension

are

nut

clockwise

examples of good stitching.

shows the needle

edge of

the

fabric.

the

the

description

type

thread

and

thread

of

fabric

of

tensions.

to

decrease

stitched

the

To

Observe

and the looper

machine

and

increase

counter-clockwise.

that

thread

size

thread,

Please

note

tension,

the

overlock

joined

setting

and

the

refer

the

lo

turn

at

Fine

chainstitching

Fine

overlockstitching

Regulating

thread

tension continued

When

appear

thread

like

tension is not

the

sketches

properly

below.

The

Increase

the

This

needle

where

is

needle

decrease

appearance

the

the

chainstitch

tension

may

thread

the

too

loose.

thread

tension

looper

regulated the stitching may

needle

the

thread

nut

clockwise.

occur

when

tension is too tight

overlook

Turn

counter-clockwise

the

thread

is

not

nut

clockwise

thread

tension.

thread

tension

the

looper

the

tension.

yet

satisfactory,

is

by

turning

overlockstitch

thread

tension

and

nut

If

increase

''loose''

or

tension

to

the

for

turn

Here

the

nut

increase

turn

thread

the

13

we

have

one

above.

for

the

needle

the

tension.

the

tension

counter-clockwise

looper

thread

the

First

nut

opposite

thread

If

for

tension.

condition to

turn

the

clockwise

necessary,

the

and

tension

and

looper

decrease

7.HOW

TO

OPERATE

YOUR

MACHINE

Operate your

(1) Raise the

(2)

back

Insert

of

so that the

foot. With a little

(3)

(4)

your

presser

Release

on

Depress

seam

the

Note:

machine

presser

the

the

foot.

the

fabric

the

When

the

seams

two or three

stitches

properly made. You will soon

your stitching by varying the

treadle.

machine.

fabric

edge

with

lift

to

treadle

starting

at

in the

following

foot by the lift lever located in the

to

be

sewn

manner:

beneath

of the fabric is

practice

feeding

lever

be

by

started without raising the

and

sewn,

of

the

to

sew,

turning

times

the beginning of the seam

you will be able to

the presser

controller

you

may

the

handwheel

to be certain that your

the

presser

under

the presser

foot

and

start to

wish

learn

pressure

start

will

by

to control

to

begin

hand

are

on the

rest

foot

sew.

(5)

(6)

Guide

Stitch

the fabric as the

about

three or

the fabric. Cut the thread

i

Note:

Hold

are

machine

four

inches

the

sewn

as

shown above when cutting.

about

fabric

feeds

beyond

2

so

it

from

that

forwardL

the

edge

the

edge.

the

of

chains

For

not

best

raveU

8.FINISHING

seam

the

end

following

finish and to

suggestions

THE

assure

SEAM

are

that

made:

your

stitches

will

1.

2.

3.

Knot

thread

Pull

chain

Pull

the

back

and

the

thread

the

stitch

a

smallhook

example a

or

latch

surplus

chain

surplus

back

needle.

the

thread

hand

through

by

using

as

chrochet

tack

for

Safety

stitch

Overlook

stitch

Chain

stitch

9.REGULATING

YOUR

STITCH

LENGTH

Your

^

will

for

This

B for most of your work.

Shold

or

C

stitches

mplished

steps:

(1) Open the side cover.

(2) Holding the handwheel with your

feed regulating screw

furnished.

(3)

Turn

with

For

and for

the regulating thumb nut (B) and line up the scale

the

indicator

longest stitch

shortest

(A)

(C).

set

stitch,

using the screw driver

scale

set

at

at

MAMMYLOCK

come

about 8

is

decrease

to

a good

you

stitches

wish

this

by

right

5

hand, loosen the

(5

stitches

1 (12stitches

you

the

is

the

factory

per

stitch

to

number

easily

following

per

per

machine

set

inch.

length

increase

of

acco

inch),

inch).

(4)

After obtaining proper stitch length, tighten screw (A).

(5)

Close

the

side

cover.

The

presser

weight

Should

pressure

10.PRESSER

foot

pressure

fabric.

you wish to

regulating

This

should

increase

nut

clockwise

FOOT

is

set

cover

or

PRESSURE

at

the

most

decrease

for

greater

factory

of

your

pressure,

for

medium

requirements.

turn

pressure;

the

counter-clockwise

the

more

seam,

pressure

the

less

increase

decrease

than

for

less

pressure

required

pressure.

is

required.

to

feed

Ordinarily,

the

material.

Do

the

not

thinner

use

any

Pressure

regulating

nut

11.STITCHES

AND

OPERATIONS

11-1

1

11-2

Safety

Chainstitch

Stitch

By using all four

sews

For

with

Safety

threading,

threads,

Stitch.

refer

to pages

Operation: Sleeve setting

General

Representative items:

the machine

Seaming

shirts,

dresses,

jackets,

6^10.

blouses,

slacks,

etc.

Threads

used

for

chainstitch

are

the

chainstitch needle and looper threads

only.

For

threading,

Operation:

Please

note

refer

General

fabrics

that

for

to pages 7, 10.

seaming on

or

jersey

chainstitching

knitted

the

overlook looper (see fig.ll~2-2 ) should be

disengaged and the overlook needle should

be removed. The upper knife (see fig.11-

2-1)

fabric

engaged

desired.

should be disengaged if trimming the

is

not

where

required;

trimming

it may be

the

fabric

left

is

11—2

Chainstitch

continued

11-2-1

11-2-2

Upper

m

figl

Overiockstitch

knife

1-2-1

iooper

To

disengage

disengage

the

Open the

Turn

the

position.

Pushing the upper knife to right

by finger,

clamp thumb

sketch. Cutting edge is to

the

the overiockstitch looper:

upper

front

the

handwheel by

needle

back

of

knife:

bar

turn

nut

the

cover.

hand

is

at

its

lowest

the upper knife

as

per

the

machine.

until

figl

1-2-2

Open the side

At

needle

turn

up the

that

it

is

cover.

bar* s

''V

released

lowest

position

shape pin so

from

the

groove in the bushing collar.

19

11-2-3

Cloth

gauge

plate

-

furnished

with

machine

Open

Pull

front

upward

the front cover.

front

/

Move

cover

cover.

to

in

to

remove

Insert

plate

side.

the

upper

knife

cover

the cloth gauge plate in the

of

the

Close

upper

both

knife

covers.

cover.

from

20

11-3

Overlockstitching

Threads

and

For

Operation:

Representative

Before

(1)

used

looper

threading,

for overlockstitching

threads.

refer

to

pages

Overedging, serging,

items:

dresses,

operation confirm the followings:

The'''V'' shape pin is in the groove of the bushing

collar and the overlockstitch looper is driving.

(2) The upper knife is properly

(3)

The

upper knife

cover

are

the overlock needle

8~9.

blouses,

set

to trim.

is fixed in the

slacks,

front

etc.

cover.

12.NEEDLE

12-1

Heedles

© o

required

Needle enlarged

Groove

The

following

MAMMYLOCK

System:

DBXl

needles

TEXI

—for

machine:

or

woolen

Size; #14 is standard

12-2

(1)

How

Turn

highest

to

replace

the

position.

handwheel

(2) Loosen the needle clamp

thdrawn

machine.

(3)

Insert

hole facing

scarf

(4)

Tighten the needle clamp

downward.

a new needle as

the

long

to the

rear.

are

available

DBX1(TEX1

for

use

—Standard

in

fabric, cotton fabric, etc.)

needles

by

Use

thread

See

(available

hand

screw

the

far

as it will go into the needle

groove

sketch

screw

in

#11-#16)

until

the

needle

and the needle can be wi

screw

driver

to

Needle

the

enlarged.

loosened.

the

bar

furnished

front

is

at

and

its

with

the

13.KNIVES

13-1

Hi

:e

the

upper

knife

m

Loosen

withdrawn

Insertanew

down

left.

Turn

est

Slide

the

upper

upward-

knife in the holder with the tang (tongue)

and

to

the

Lightly affix it

the

handwheel

position.

the

knife up

knife clamp

rear.

with

until

or

down

The

the

the

so

screw

cutting

clamp

knife

that

and

the

edge will be to

screw.

holder

the

is

front

ting edge overlaps the lower (fixed)knife by

Tighten

the

clamp

screw

securely.

knife

at

of

the

1/32".

its

can

be

the

low

cut

13-2

How

(1)

Loosen the lower knife clamp screw and the knife can

be

to

replace

withdrawn

the

downward.

lower

knife

(2)

Insert

is

a new knife in the

same

level

with

the

holder

needle

plate

until

top

its

(3) Tighten the clamp

24

cutting

surface.

screw

edge

securely.

14.

STITCH

TROUBLE

AND

ITS

REMEDY

Stitch

Machine

properly feed

trouble

does

not

Cause

Presser

ssure

suspected

foot

on the

pre-

material to be material too light.

1.

Frequent

breakage

needle

Frequent thread

breakage

Skip

stitching

Needle

needle point

2.

Bad

3. Pulling the

badly

1. Wrong

2.

Thread

3.

Too

tension

4.

Bad

5. Using

needle

1.

Needle

dle point

2.

Incorrect

setting

3.

Using

needle

4.

Wrong

5.

Too

of

the

6.

Using

stretchy

bent

needle

tight

needle

incorrect

incorrect

threading

weak

presser

material

woolen

or

breakage

setting

material

threading

knots

thread

setting

bent

or

breakage

needle

pressure

foot

yarn-

thread

nee

on

Turn

thumb

increase

material.

the

screw

Replace

new

needle.

Reset

Do

not

by

hands

Re-thread

See

page

Pull

knot

Get

appropriate

See

page

Reset

See

page

Use

specified

See

page

Replace

Reset

See

page

Use

specified

See

page

Re-thread

See

page q~]q

Turn

thumb

increase

material.

the

Releace

tension

See

page

Remedy

pressure

clockwise

pressure

Do

gradually.

the

bad

the

needle

pull

the

during

correctly.

6—10

through.

12-13

the needle

22

needle

22

with new

the needle

22

needle.

22

correctly

pressure

screw

clockwise

pressure

thread

guide

wires.

g-io

regulating

on

the

needle

correctly.

material

operation.

tension.

correctly.

needle.

correctly.

regulating

on

the

caught in

and

with

sewn

and

Get

Bad

stitching

Puckering

Bad

thread

1,

Too

tensions

2.

Wrong

threads

something

tight

threading

affected

tensions

thread

or

by

irregular

appropriate

See

page |2~13

When

decrease

as

much

still

stitch.

Re-thread

See

page

sewing

thread

as

correctly.

6-10

possible

tensions.

light

tensions

fabrics

and

15.VARIATION

OF

WEIGHT

OF

FABRIC,

Weight

of

fabric

Light

Medium

Heavy

THREADS

Type

of

fabric

Organdies, light

traffeta,

etc.

Cotton,

satin,

etc.

Tweed,

fabrics,

heavy

fabrics,

linings, silk,

tricot,

dress

outerwear

fabrics,

overcoat

denim,

etc.

tricots,

linen,

AND

STITCH

Operation

Chainstitch

Overlook

stitch

Chainstitch

Overlook

stitch

Chainstitch

Overlook

stitch

LENGTH

Threads

Cotton#80~

Silk

Cotton

Silk

Cotton

Silk

Cotton

Silk

Cotton

Silk

Tetlon,

Cotton

Silk

Tetlon,

#80-#100

#80-#100

#80-#100

# 60—# 100

#50-#100

# 60— # 100

#50-#100

#40—

#40-

Woolen

#40—

#40-

Woolen

# 100

#60

#60

yarn

#60

#60

yarn

Stitches

per

inch

12-8

8-6

12-8

8-6

12-6

8-5

Knitted

fabrics

Chainstitch

Overlook

stitch

Cotton

Silk

Tetlon,

Woolen

available

very

thin

looper

#40—

#30-

Woolen

yarn,

to

thread

thread

use

#50

#40

yarn

tetlon

in

12-6

8-5

26

16.SPECIFICATION

FOR

MODEL

ML-4

Overlook seam width

Needle gauge

Stitch

Maximum

capacity

Needle

VT

Number

Size

per

used

1 <•

of

of

machine

inch

sewing capacity

.1

threads

1 A

4mm

(Standard)

(S/IG'')

3mm(l/8'0

2~

5mm(12st/in—5

5mm(3/16'0

TEX

1 #14

/!•

4 (four) ^ ^

253mm

263 (10

275 (10

\

(10")

(Standard)

- Length

3/8'0

7/8'0

_

Width

_ Height

st/in)

CONTENTS

IN

THE

SHIPPING

CONTAINER

Content

(1)

(2)

(3)

(4)

of a shipping

Sewing Machine with

container:

Motor

Controller, complete 1

Operator

Accessories

containing:

Screw

Allen

Needles

Upper Knife,

Tweezers

Cleaning

Oiler(contain 50cc oil) 1

Detachable Cloth Gauge

Welt

Welt

Thread

Driver

Screw

Type;

Guide

Guide

s

instruction

box

book 1

Driver for Needle Clamp 1

TExi

spare

Brush

Screw

Stripping

Size;

#14

Plate

Disc 4

10

1

1

1

1

1

1

1

1

Packing

A

attachments

Weight

Weight

Measurement

case

containing1set

Net:

15.0kg

of machine:

of

Carrying

and

accessories.

Gross:

11.0kg

Case:

of

machine

3.5kg

17.0kg

including

machine

and

standard

MIMA

SEWING

MACHINE

CO.,

LTD.

MIMASEIKI

CO.,

LTD.

Osaka,

Japan.

Loading...

Loading...