mammylock

MANUAL

for

Model

ML-303

MANUAL

FOR

INTRODUCTION

We

thank

you

very

LOCK

This

ML-303

booklet

machine.

contains

maintenanceofthe

which

should

become

use

from

This

machineisdesigned

materials

knit

fabrics

All

machines

ing

carefully

MAMMYLOCK

be usefultoyou

familiar

it.

with

suchaslighttoheavy

beautifully

are

shipped

one

machine

MAMMYOCK

much

for

your

some

notesonthe

buying

ML-303

our

MAMMY-

operations

MAMMYLOCK ML-303 machines,

and

the

should

machine

for

andtoderive

sewingonvarious

help

you

the

kind

weightorwoven

and

firmly.

from

our

by

one,

regularly

so we

factory

hope

and

after

you

forever.

inspect

will use a

and

to

best

of

and

CONTENTS

1.

Name

of parts 1

2. How to run a machine 2

3.

Oiling

4. Threading 5

5. Test

sewing

6. Howto regulatethe thread tensions 9

7. Howtooperate 19

8. Howtoregulate

and the pressure of presser

the

stitch

length

foot

11

9. How to replace the needle 12

10. How to change the upper and lower knives 13

11. How to replacethe carbon brush for the drive motor 15

12. Howtoadjust

13.

The

relation

14. Specifications 17

The

15.

16.

contents

Standard

for

incorrect

chartofmaterials

of packing 18

accessories

sewing

and

threads

16

17

^

8

18

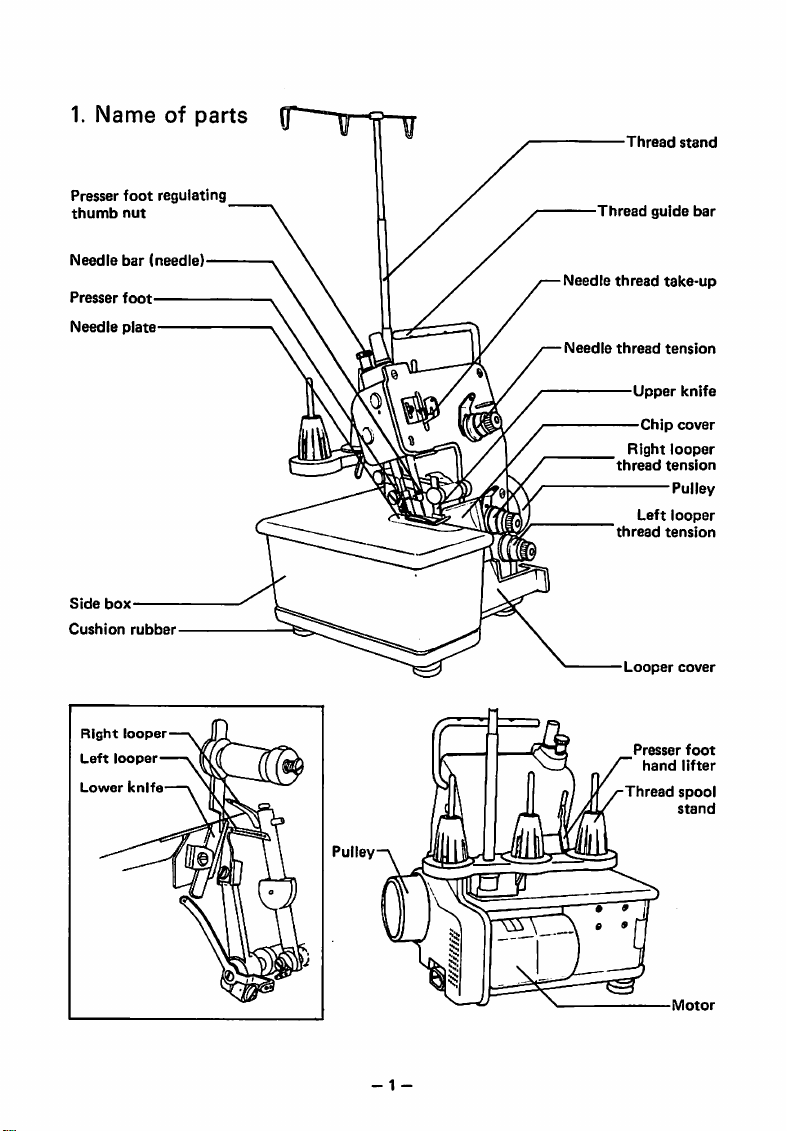

1.

Name

Presser

thumb

Needle

Presser

Needle

Side

Cushion

box

foot

nut

bar

foot

plate

rubber

of

regulating

(needle)

parts

Needle

Needle

Thread

Thread

thread

thread

thread

thread

Looper

stand

guide

take-up

tension

Upper

knife

Chip

cover

Rightlooper

tension

Pulley

Left

looper

tension

cover

bar

Right

Left

Lower

looper—V

looper—V

knife—\

ML

Pulley

- 1 -

Presser

hand

Thread

foot

lifter

spool

stand

Motor

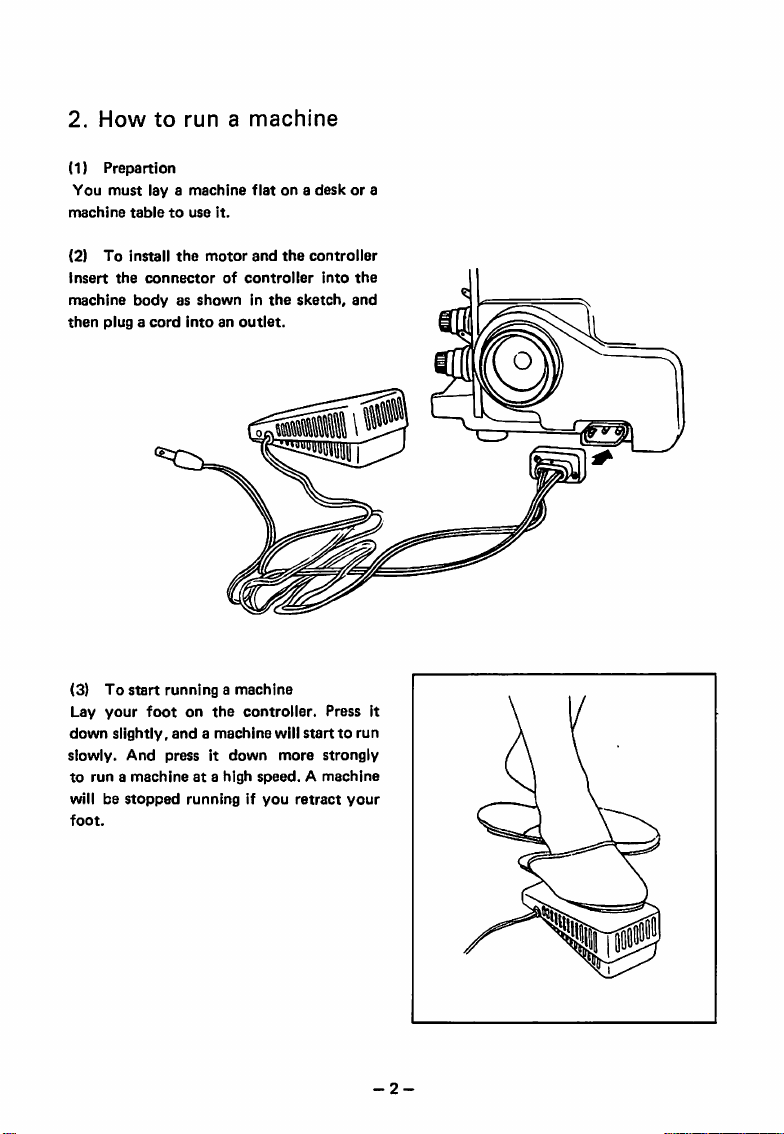

2.

How

(1)

Prepartion

You

machine

(2)

To

insert

machine

then

plugacord

to

runamachine

must

lay a

machine

tabletouse

install

the

connector

bodyasshownInthe

it.

the

motor

of

intoanoutlet.

flatona

and

the

controller

deskora

controller

sketch,

5*1]

into

the

and

(3)Tostart

Lay

down

slowly.

to

runamachineata high

will be

foot.

your

slightly,

And

stopped

footonthe

runningamachine

controller.

andamachine

pressitdown

speed.Amachine

runningifyou

will

starttorun

more

retract

Press It

strongly

your

-2-

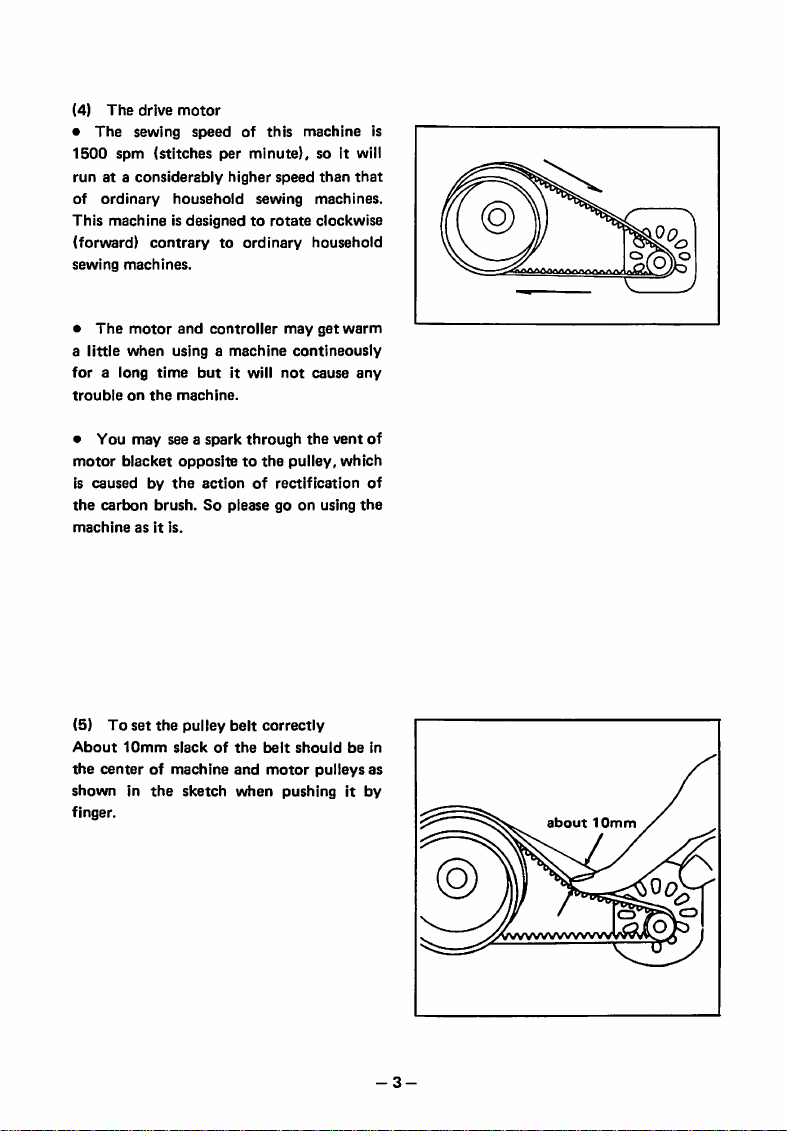

(4)

The

drive

motor

•

The

sewing

speedofthis

1500

spm

(stitches

runata

of

This

(forward)

sewing

•

a

foralong

troubleonthe

considerably

ordinary

machineisdesignedtorotate

household

contrarytoordinary

machines.

The

motor

and

controller

little

when

using a

time

butitwill

machine.

per

higher

machine

minute),

speed

sewing

may

not

machine

so it will

than

that

machines.

clockwise

household

get

warm

contineously

cause

any

is

• You may see a

motor

blacket

oppositetothe

is

causedbythe

the

carbon

brush.Sopleasegoon

machineasit

(5)Toset

About

the

centerofmachine

10mm

is.

the

slackofthe

showninthe

finger.

spark

through

pulley,

actionofrectification

pulley

belt

correctly

belt

shouldbein

and

motor

sketch

when

pushingitby

the

using

pulleys

vent

which

the

of

of

as

about

10mm

-3-

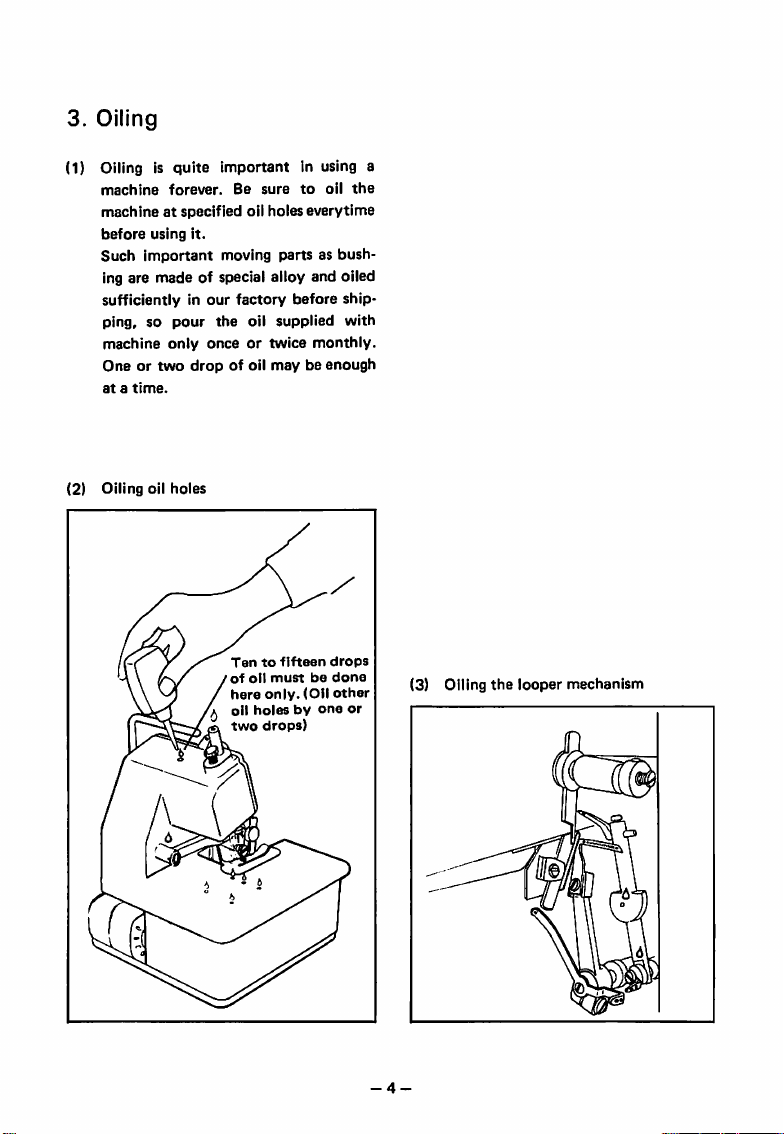

3.

Oiling

(1) Oiling is

machine

machineatspecified

before

Such

quite

forever.

using

it.

important

important in using a

Be

suretooil

oil holes

moving parts as bush

ing are made of special alloy and oiled

sufficiently in

ping, so

machine

Oneortwo

atatime.

(2)

Oiling

only

oil

our

pour

the

onceortwice

drop

holes

factory

oil

supplied

of oil may be

Tentofifteen

of

oil

mustbedone

here

only.

oil

holesbyone

drops)

everytime

before

monthly.

enough

drops

(Oil

ship

with

other

or

the

(3) Oiling

the

looper

mechanism

-4-

4.

Threading

(1)

Notes

•

The

machine do

not

sew if threading

incorrectly. Thread correctly as the following

thread

diagrams.

•

First,

thread

left

looper.

•

Insert

the

thread

between

discs.

• Use a pair of tweezers to

(2)

0

Threading

Thread

left

order

looper

first.

the

thread

tension

easily.

Thread

tension

disc

CautionI

(50mm)ofthread

Draw

about

through

two

inches

the

righ

looper

eye.

-5-

Thread

right

looper

secondly.

*

Caution!

(50mm)ofthread

er

eye.

Draw

about

through

two

the

left

Rightlooper

inches

loop

-6-

thread

Thread

needle lastly.

Needle threed |

*

Caution!

(50mm)ofthread

eye.

Draw

about

through

two

the

Inches

needle

*

01

^ '

~|

[

1r

L

-7-

5.

Test

sewing

CautionI

thread

(D

Put

foot.

(D Hold

left

hand

with

right

you

check

is

obtained.

Do test-sewing

.

a piece of

three

and

hand.

that

cloth

threads with your fingers of

turn

the

Starttosew

the

correct

after

under

pulley

stiteh

you

the

-clockwise

slowly

formation

finish

presser

to

after

Pulley

-8-

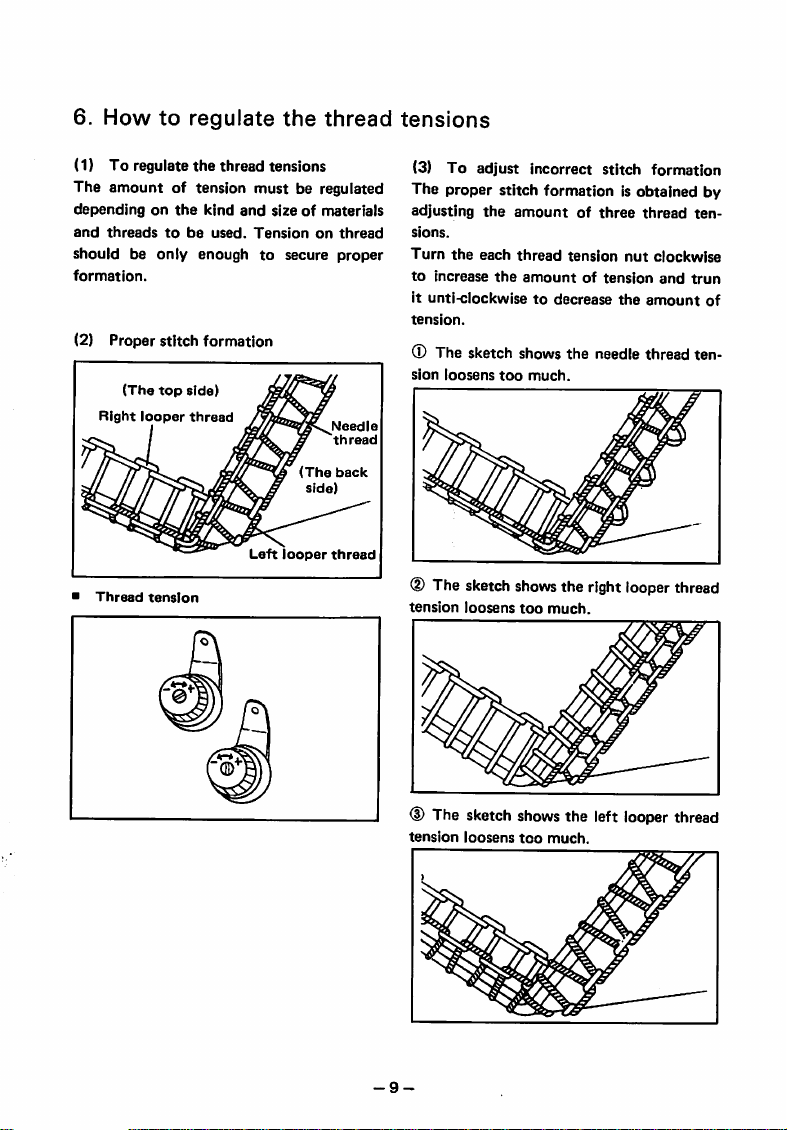

6.

Howtoregulate

the

thread

tensions

(1) To regulate

The

amount

dependingonthe

and

threadstobe

shouldbeonly

formation.

the

thread tensions

of tension

kind

and

used.

enoughtosecure

(2) Proper stitch formation

(The

top

side)

Rightlooper

Thread

thread

Left

tension

must

be regulated

sizeofmaterials

Tensiononthread

proper

Need

thread

(The

back

side)

looper

thread

(3) To adjust incorrect stitch formation

The proper stitch formation is obtained by

adjusting

sions.

Turn

to

it unti-clockwisetodecrease

tension.

the

increase

the

amountofthree

each

thread

the

amountoftension

tension

the

® The sketch shows the needle thread ten

sion

loosens

too

much.

e

The sketch shows the right looper thread

tension

loosens

too

much.

thread

nut

amount

ten

clockwise

and

trun

of

tension

-9-

The sketch shows

loosens

too

the

left looper thread

much.

7.

How

to

operate

•

Put

the

securely

•

Sew

slowly.

• Put

material

and

the

your

under

the

commencetosew.

first

and

second

fingers on

the

presser

foot

stitches

very

material only

enough to guide It as It Isfed automatically.

0

Take

away

the

material

from

the

machine

Run

the

machine

until

about5cmofchanining

obtained

cut

the chaining thread to remain 3 cm

ofItwith

contlneouslyata low

after

the

materialIssewn

the

material

sewn-up.

speed

thread

up.

Then

Is

0

When

the

backtackIsnecessary

Tie a chaining

material.Inthe

fabrics,

thread

materialbyusingacrochet.

insert

into

thread

caseofsewing

back

the

the

stitch

remaining

remained

formation

with

up

chaining

of

the

knit

the

-10-

8.

Howtoregulate

presser

(1)

To

0 Swing

Hold

the

screwdriver

foot

regulate

out

the

pulley imnnovably

supplied

the

side

stitch

covertothe

with

machine.

the

length

with

stitch

your

left.

hand

length

and

loosen

and

the

the

feed regulating

pressure

nut

of

by using a

(2) Move

grooveofthe

obtain

crease

and

(D Tighten

after

(2)

This

medium

it is

presser

weight

The

thumb

Increase

material

material.

the

feed

reguiating

feed

regulatorupand

the

desired

the

stitch

length,

moveitdownward

the

feed regulating

adjusting.

To

reguiate

foot

machineisadjusted

necessarytoreadjust

foot

materials.

pressure

nutasshowninthe

the

pressureofthe

weight

materialsinour

when

sewingoniightorheavy

canberegulatedbyturning

the

pressure

and

decreaseitfor

stitch

move

to

the

for

nutinthe

length.

the

nut

decrease.

nut

for

sewingonthe

factory.

pressureofthe

sketch.

the

heavy

the

light

down

To

upward

secureiy

presser

the

weight

weight

to

in

So

-11-

To

the

the

Increase

pressure

pressure

Feed

nut

Feed

regulating

regulator

Pressure

regulating

thumb

nut

9.

How

to

replace

the

needle

•

This

machine

DB X 1ofneedle

•

Generally

determinedbythe

nessorweightofmaterialtobe

Standard

No.9toNo.16ofneedles

®Toremove

Turn

pulley

needle

barIsat

the

needle

driver,

and

downward.

@Toset

At

the

needle

Insertafresh

far

as It will go,

front.

Tighten

securely.

Is designedtouse

whichIsmost

the

sizeofneedle

size of

setting

Is No. 11ofneedle

the

needle

clockwise

Its

highest

clamp

screwbyusingascrew

the

needle

the

needle

bar

beingatIts

needle

with

long

the

clamp

thread

are

also

by

hand

position.

willbewithdrawn

highest

Into

the

needle

groove

of Ittothe

screwinposition

the

popular.

should

and

thick

sewn.

available.

until

Loosen

position.

hole

type

and

the

be

as

Sketchofneedle

Long

groove

(frontofneedle)

Scarfofneedle

(backofneedle)

r

Needle

clamp

screw

-12-

10.

Howtochange

•

When

the

cutting

Caution:

(1)

®Toremove

Loosen

upper

out

@Toset

Push

position

of

the

in

Front

bottomofstoroke,

than

sketch.Inthis

knife

Lastly,

position,

needle

upper

Remove

To

change

the

upper

knife

guide

upperward.

the

the

upper

and

insert

upper

knife

left.

Tighten

position

slightly.

cutting

0.5mm

ciamp

screw

when

the

adjustitsoitcrosses

plateatright

knife

guide

the

the

knife

knife

holder

edgeofupper

—

position,

edgeofknife

the

plug

upper

upper

knife

screw,

holderupto

the

the

upper

should

1.0mm

again

upper

screw

cord

knife

knife

clamp

and

knife

into

with

cutting

knife

extend

as

tighten

securely.

knifeisat

angles.

securely.

the

upper

becomes

from

screw

and

pull

the

its

rightest

the

edge

clamp

knife,atits

not

shown

the

its

the

surface

Tighten

the

the

knife

groove

screw

less

in

the

upper

lowest

the

dull,

outlet,

to

of

and

lower

replace

and

Upper

Needle

knives

withafresh

then

commencetochange

Upper

Upper

knife

knife

plate

oneasfollows.

the

knife

clamp

screw

holder

knife.

Upper

knife

holder

0.5mm—I.Omm

-

13-

(2)

To

replace

(DToremove

Loosen

the

the

lower

the

lower

iower knife

knife

knife

screw

by using a screwdriver,

and

it will be

withdrawn

downward.

(DToset

the

Insertafresh

lower

knife

cutting

edgetothe

Then,

set

even

with

tighten

position

the

securely.

knife

knife

into

holder

from

right.

the

knifesoits

the

surfaceofneedle

lower

knife

the

the

clamp

guide

bottom,

cutting

groove

edge

plate,

screw

with

and

The

guide

groove

knife

screw

holder

of

of

lower

Lower

clamp

knife

is

in

Lower

knife

-14-

11.

How

to

replace

•

The

carbon

brushisoneofarticles

consumption,soexchange

worn-off.

To

catch

the

carbon

1.Tomakeanoise

2.

The

motor

will

not

run

3.Tosparkle

To

1.

Remove

body.

2.

Loosen

3.

Take

the

4.

Insertanew

as

5.

Install

replace

out

carbon

they

the

two

the

were,

the

motorasIt

too

the

brush

brush.

much

carbon

motor

carbon

carbon

and

caps.

set

the

withanew

brush

worn-off

brush

from

the

brush

brush

and

the

capInposition.

was.

carbon

one

machine

spring

its

spring

and

of

if

brush

for

the

drive

Brush

motor

cap

Spring

Carbon

brush

-15-

12.

Howtoadjust

•

Any

difficult

mainly

causedbymis-adjustment

for

adjustmentIsnot

incorrect

necessary

fundamentally,

sewing

for

this

so

machine.

re-adjusr

The

following

troubles

accordingtonecessities.

are

Trouble

MaterialIsnot

smoothly

NeedleIsbroken

ThreadIsbroken

Skip

stitch

occures

fed

The

pressureofpresser

footistoo

NeadleIsbentorIts

is

damaged.

NeedleIsset

Materialispull

To

thread

ThreadIscaughtonany

obstacle

Thread

tensionIstoo

NeedleIsset

To

use

any

be

specified

NeedleIsbentorIts

Is

damaged

To

set

needle

To

use

any

specified

To

thread

The

pressureofpresser

Is

too

weak

Cause

weak

Incorrectly

out

Incorrectly

inccorectly

needle

not

Incorrectly

needlenoto

Incorrectly

point

strongly

strong

to

point

foot

Turn

the

clockwisetoIncrease

To

change

To

set

Do

not

In

sewing

To

thread

To

checkIfthreadIscaugtonthread

stand

andsoon

See

page9(Howtoregulate

tension)

To

checkIfneedleisset

page

11)

To

use

To

change

To

set

be

To

use

To

thread

To

turn

nut

clockwisetoIncrease

Adjustment

pressure

needle

pushorpull

type

needle

typeDBx 1ofneedle

the

forafresh

correctly

again

properly

DB

forafresh

properly

again

properly

pressure

regulating

x 1

the

needle

(see

out

the

(see

correctly

needle

(see

(see

regulating

thumb

pressure.

page

material

page5to

the

page

page5to

the

pressure

nut

12)

7)

thread

(see

12)

7)

thumb

Proper

stitch

formationIsnot

obtained

Puckering

occures

Insufficient

be

thread

Thread

To

caughtonany

tensions

tensionIstoo

thread

adjustment

Inccorectlytobe

obstacle

of

strong

-16-

To

To

ably

page

To

re-adjust

loosen

when

9)

thread

thread

tensions

thread

tension

sewingonlight

properly

(page5to

(see

nuts

materials

page

consider

7)

9)

(see.

13.

Light

Organdie,

Tafta,

The

relation

Material

weight

Silk,

Fine

suit

materials

toricot,

lining.

chart

of

Cotton

Silk

materials

Thread

No.80—100

No.80-100

and

threads

Stitch

length

3.0mm—4.0mm

Medium

Cotton,

General

Heavy

Tweed,

Denim,

cloth

Knit

Knit

fabrics

14.

Specifications

Sewing

speed

Seam

width

Stitch

length

Presser

foot

Presser

foot

Needle

weight

Tricot,

dress

weight

Coat

Heavy

fabrics

lift

materials

Linen,

materials

materials

cloth.

weight

Cotton

Silk

Cotton

Polyester,

Woolly

No.60—100

No.50-100

No.40—60,

Wooly

nylon

nylon.

Polyester

Silk

No.40—60

1,500

stitches

4.0mm

(standard)

2.0mm—5.0mm

Hinged

Upto5.0mm

Type

DB x

No.

9 —16also

3.0mm—4.0mm

3.0mm—5.0mm

3.0mm—5.0mm

per

minute

l.size

No.11(standard)

available

Numberofthread

Oiling

Machine

Net

head

weight

-17-

3

Manual

253mmx263mmx275mm

10kg

(complete

set

with

motor)

15.

The

1.

Machine

2.

Foot

pedalofcontroller

3.

Manual

4.

Standard

16.

Standard

rnammyiock

contents

head

with

motor

for

MAMMYLOCKML-303

accessories

and

accessories

of

its

packing

box

4MI-

®

Machine

(D

Screwdriver

(D

Tweezers

head

cover

® Thread guide (three pieces)

(D Needle

(D

(7)

(D Brush

-18-

Upper

Oiler

(type

DB x 1, size No. 11)

knife

(contained

for

dusting

with

SOcc oil)

Loading...

Loading...