Milwaukee Heavy-Duty Commercial Vacuum User Manual

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

8911

8912

8925

8926

8927

8935

8945

8965

HEAVY-DUTY COMMERCIAL VACUUM

EXTRA ROBUSTE ASPIRATEUR COMMERCIAL

HEAVY-DUTY ASPIRADORA COMMERCIAL

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below, may resultin electric shock, fire and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

To reduce the risk of fire, electric shock or injury:

1. Do not leave appliance when plugged in. Unplug from outlet when not

in use and before servicing.

2. Do not use outdoors or on wet surfaces.

3. Do not allow to be used as a toy. Close attention is necessary when

used by or near children.

4. Use only as described in this manual. Use only manufacturers recommended attachments.

5. Do not use with damaged cord or plug. If appliance is not working as it

should, has been dropped, damaged, left outdoors, or dropped into

water, return it to a service center.

6. Do not pull or carry by cord, use cord as a handle, close a door on cord,

or pull cord around sharp edges or corners. Do not run appliance over

cord. Keep cord away from heated surfaces.

7. Do not unplug by pulling on cord. To unplug grasp the plug not the cord.

8. Do not handle plug or appliance with wet hands.

9. Do not put any object into openings. Do not use with any opening

blocked; keep free of dust, lint, hair, and anything else that may reduce

air flow.

10. Keep hair, loose clothing, fingers, and all parts of body away from

openings and moving parts.

11. Do not pick up anything that is burning or smoking such as cigarettes,

matches, or hot ashes.

12. Do not use without dust bag and filter in place.

13. Turn off all controls before unplugging.

14. Use extra care when cleaning on stairs.

15. Do not use to pick up flammable or combustible liquids such as gasoline

or use in areas where they may be present.

16. Connect to a properly grounded outlet only. See grounding instructions.

17. Vacuum cleaners have motors and other parts that can produce sparks

during normal use. Do not use within 30 feet of areas where explosive

gases may be present (such as gasoline pumps and places where

liquids like paint thinners, cleaners, solvents, etc. are stored).

18. Unplug power cord whenever motor head is removed from tank.

19. Do not use in the presence of explosive liquids or vapors.

20. To reduce the risk of health hazards from vapors or dust, do not vacuum

toxic, carcinogenic or other hazardous materials such as asbestos,

arsenic, barium, berylium, lead, pesticides or other health endangering

materials.

21. Do not use where oxygen or anesthetics are used.

22. Wear electrically insulated footwear, such as rubber boots, when

vacuuming wet material.

23. WARNING! Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

lead from lead-based paint

crystalline silica from bricks and cement and other masonry products,

and

arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specifically designed to filter

out microscopic particles.

Page 2

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE USE.

Symbology

Specifications

Underwriters Laboratories, Inc.

Canadian Standards Association

Hertz

Amps

Volts

Cat.

No.

8911

8912

8925

8926

8927

8935

8945

8965

* For Cat. No. 8927 with onboard outlet:

The entire unit is rated at 12 amps. The vacuum motor is rated at 7

amps. The outlet on the motor head is rated at 5 amps.

AC

120

120

120

120

120

120

120

120

Amps

7.5

9.2

9.2

9.2

12*

7.5

9.2

6.2

FUNCTIONAL DESCRIPTION

1

For

Materials

Wet or Dry

Wet or Dry

Wet or Dry

Wet or Dry

Wet or Dry

Wet or Dry

Wet or Dry

Wet or Dry

Tank

Capacity

Gallons

11

11

15

21

21

6

no tank

10

Air Flow

Cubic Feet

per Minute

8

94

92

92

92

94

94

92

133

Sealed

Suction

in Water

84

130

130

130

84

84

130

49

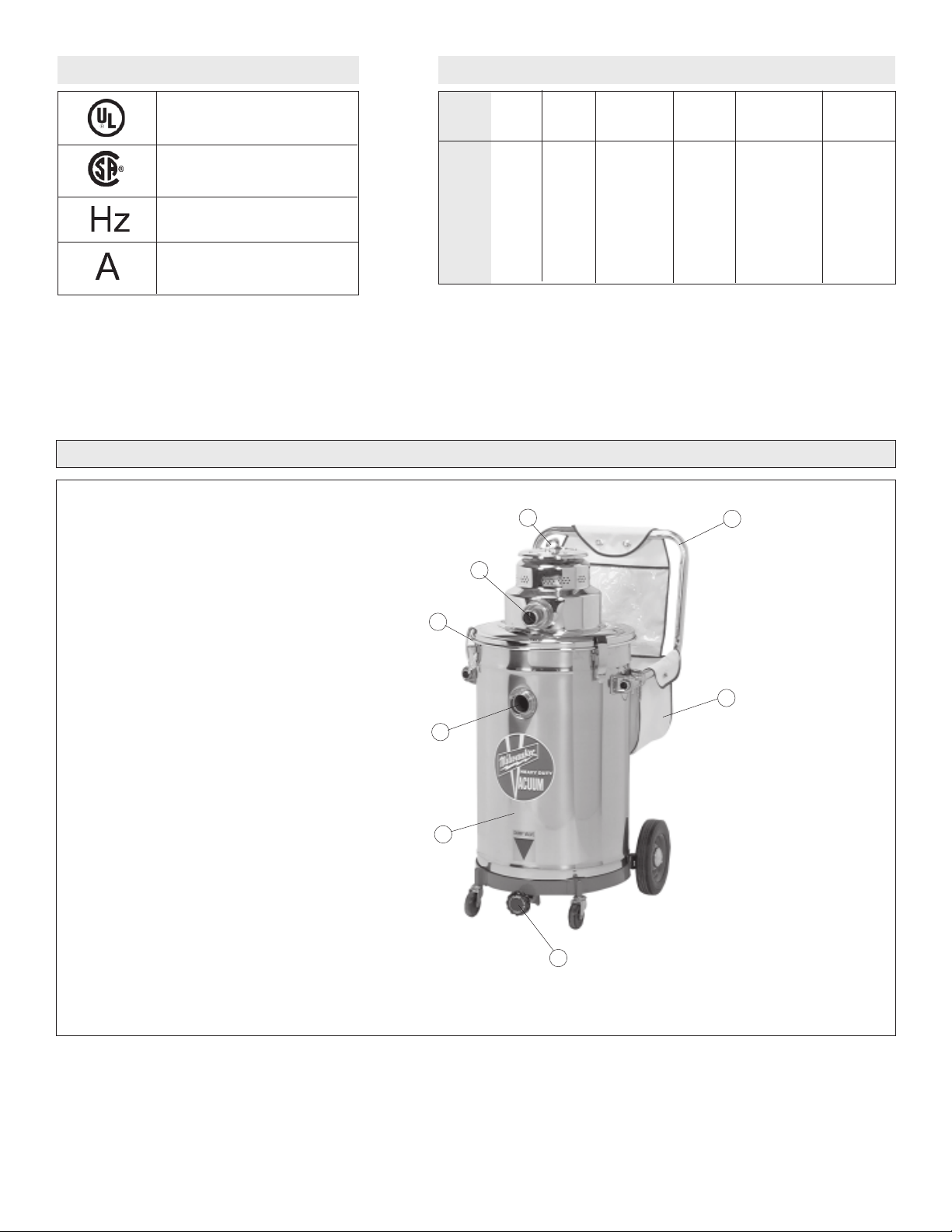

1. Motor head handle

2. Exhaust port

3. Tank latch

4. Intake port

5. Tank

6. Drain valve

7. Accessory storage pouch

8. Handle

2

3

7

4

5

6

Page 3

GROUNDING

WARNING!

Improperly connecting the grounding wire can result in the

risk of electric shock. Check with a qualified electrician if you

are in doubt as to whether the outlet is properly grounded.

Do not modify the plug provided with the tool. Never remove

the grounding prong from the plug. Do not use the tool if the

cord or plug is damaged. If damaged, have it repaired by a

MILWAUKEE service facility before use. If the plug will not fit

the outlet, have a proper outlet installed by a qualified

electrician.

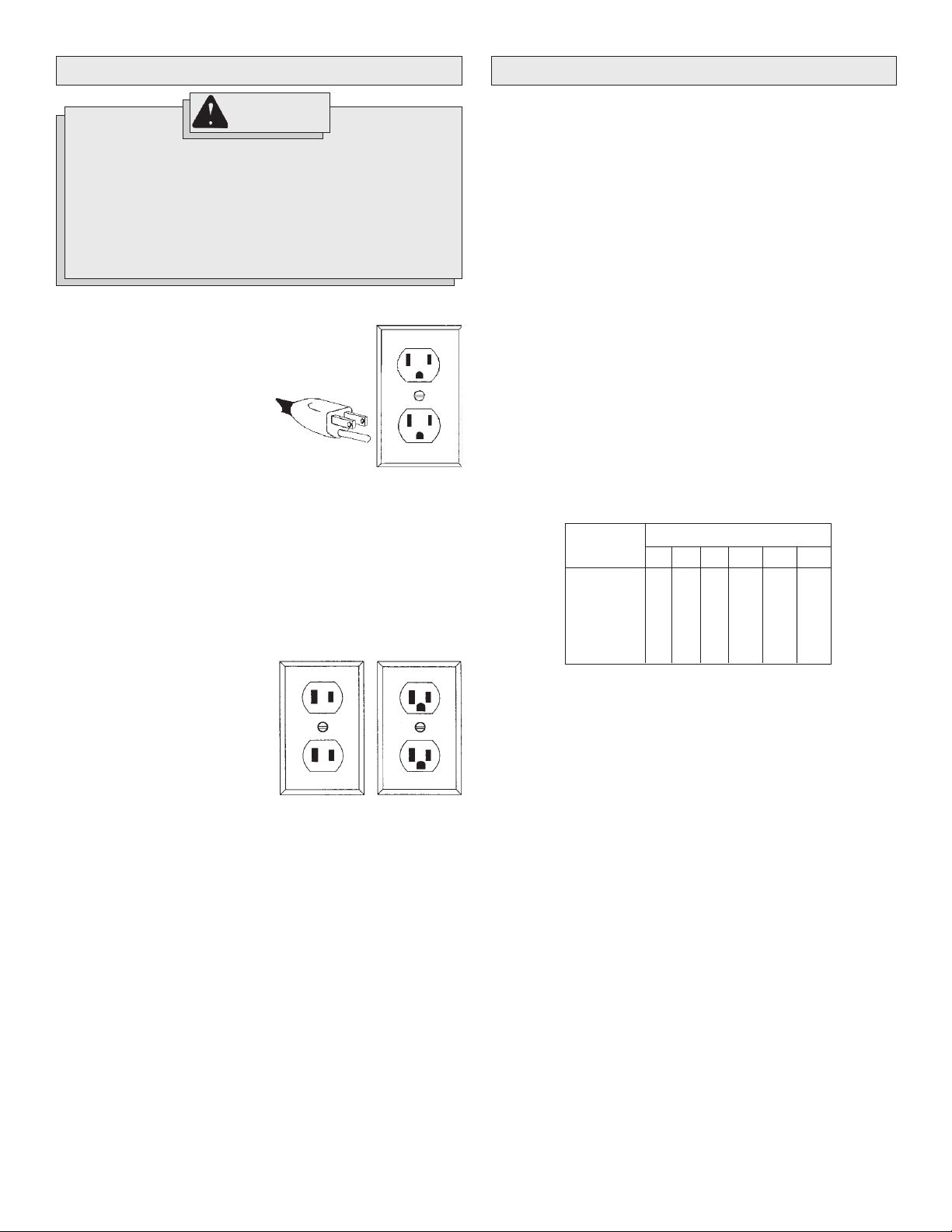

Grounded Tools:

Tools with Three Prong Plugs

Tools marked Grounding Required

have a three wire cord and three

prong grounding plug. The plug must

be connected to a properly grounded

outlet (See Figure A). If the tool should

electrically malfunction or break

down, grounding provides a low resistance path to carry electricity

away from the user, reducing the risk

of electric shock.

The grounding prong in the plug is connected through the green wire

inside the cord to the grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's grounding system and

must never be attached to an electrically live terminal.

Your tool must be plugged into an appropriate outlet, properly installed

and grounded in accordance with all codes and ordinances. The plug

and outlet should look like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked Double Insulated do

not require grounding. They have a

special double insulation system

which satisfies OSHA requirements

and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard

Association and the National Electrical Code. Double Insulated tools may

be used in either of the 120 volt outlets shown in Figures B and C.

Fig. A

Fig. B

Fig. C

EXTENSION CORDS

Grounded tools require a three wire extension cord. Double insulated

tools can use either a two or three wire extension cord. As the distance

from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a

serious drop in voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the

total length, be sure each cord contains at least the minimum wire size

required. If you are using one extension cord for more than one tool, add

the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

If you are using an extension cord outdoors, be sure it is marked with

the suffix W-A (W in Canada) to indicate that it is acceptable for

outdoor use.

Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it repaired by a qualified person before using it.

Protect your extension cords from sharp objects, excessive heat and

damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to five

volts at 150% of the rated amperes.

for Extension Cords*

25'

0 - 5

5.1 - 8

16

16

14

12

10

Extension Cord Length

100'

50'

16

16

14

12

10

75'

16

14

12

10

10

14

12

10

10

150'

12

10

--

--

--

--

200'

12

--

--

--

--

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE USE.

Page 4

MONTAGE DE LOUTIL

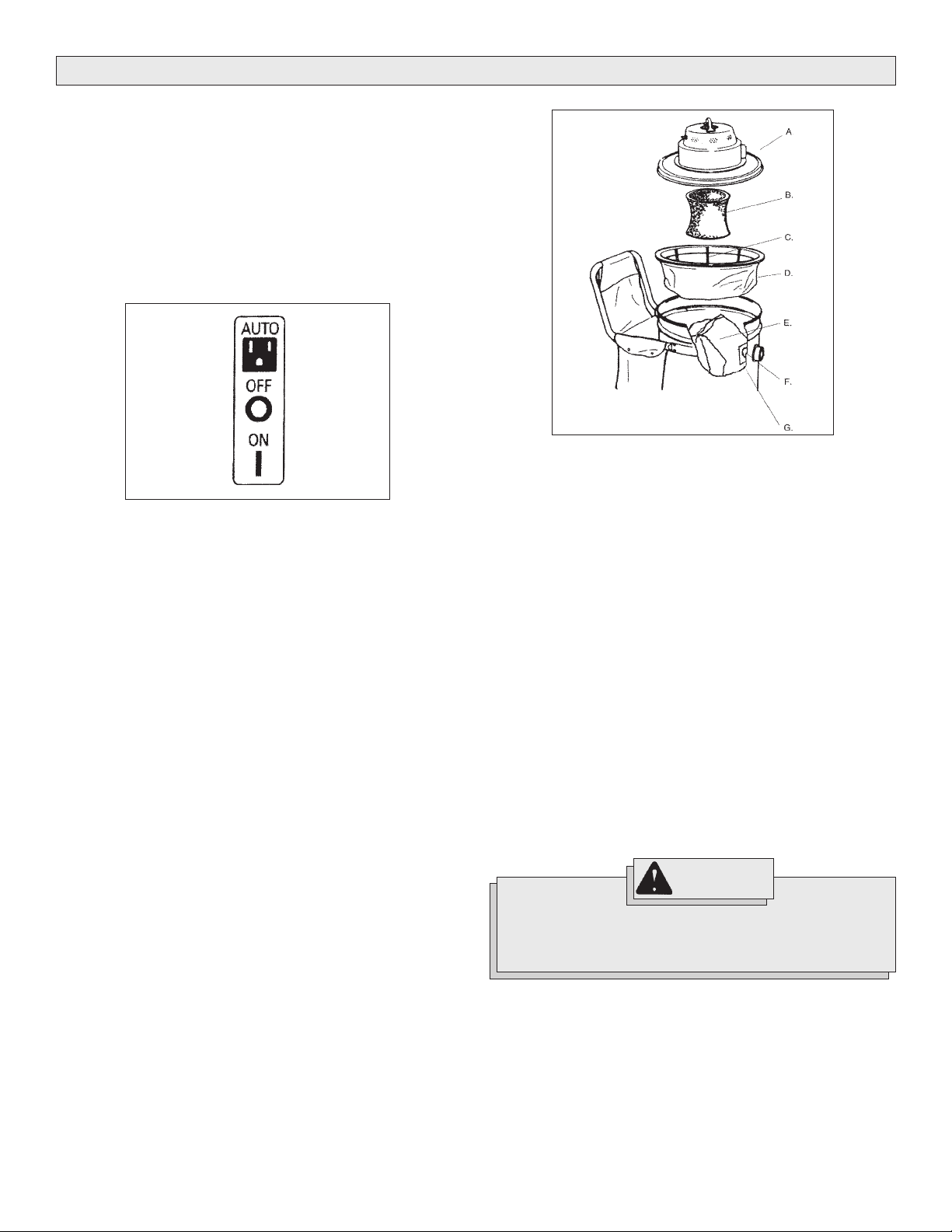

Starting and Stopping Vacuum Cleaner

To turn on the vacuum cleaner, set the ON/OFF switch to the ON position.

To turn off the vacuum cleaner, set the ON/OFF switch to the OFF position.

For Cat. No. 8927:

To turn on the vacuum cleaner, set the AUTO/ON/OFF switch to the ON

position.

To turn off the vacuum cleaner, set the AUTO/ON/OFF switch to the OFF

position.

To set the vacuum cleaner to turn on or off automatically buy using a tool

plugged into the outlet on the motor head, set the AUTO/ON/OFF switch

to the AUTO position (Fig. 1).

Fig. 1

Cat. No. 8927 has a circut breaker that protects the vacuum cleaner. To

reset the circut breaker, push in the circut breaker.

Using the Vacuum Cleaner To Pick Up Dry Materials:

Make sure that the tank is dry before using the vacuum cleaner to pick up

dry materials. If the vacuum cleaner tank is wet, run the vacuum cleaner

for about 5 minutes (without picking up anything) to dry the inside of the

tank.

Installing Filters (Fig. 2)

1. Remove motor head (A) and set aside.

Caution: Use care when handling motor head. Dropping motor head

may cause permanent damage.

2. If you are using Cat. No. 8965, place foam filter sleeve (B) over float

value cage.

3. Install only one of the following filters:

If you plan to vacuum dry material into a filter bag, expand the paper

filter bag (E) and fit cardboard collar (G) onto the intake tube (F) as far

as possible.

If you plan to vacuum medium fine to coarse, sharp dry material directly

into the tank without a filter bag, fit a dacron filter onto the cloth filter

assembly (C and D).

If you plan to vacuum extremely fine material directly into the tank

without a filter bag, fit a paper filter onto the tank.

4. Attach cloth filter (D) to filter frame (D).

5. Set filter frame and cloth filter assembly (C and D) onto tank.

6. Replace motor head and snap down tank latches.

Fig. 2

Changing Paper Filter Bag and Cleaning Cloth Filter

1. Remove motor head and set aside.

2. Clean the cloth filter each time the tank is emptied by shaking off loose

material and brushing the filter with a soft bristle brush. Do not wash

cloth filter with water. Washing can shrink the filter and damage the

gasket.

3. Pull bag out of the tank using care not the tear bag on intake tube. Seal

bag with cardboard flaps and discard.

Using the Vacuum Cleaner To Collect Dust Created By Tools:

Many tools (such as sanders) are designed so they can be used with

vacuum cleaners. The vaccum cleaners collect the dust that these tools

create before it gets into the air or onto the floor. Vacuum cleaners with

the AUTO setting are ideal for collecting dust because they can be set up

to turn on and off automatically using the tools AUTO/ON/OFF switch.

Vacuum cleaners without an AUTO setting can still collect dust. The

operator will simply have to turn the vacuum on and off.

Using a Vacuum Cleaner without an Automatic Switch as a Dust

Collection Device for a Tool

1. Connect vaccum hose to the tools dust collection port.

2. Turn on the vacuum cleaner.

3. Turn on tool.

WARNING!

To reduce the risk of fire, electric shock, injury, and damage

to the tool: Do not plug any tool or appliance rated over 5 amps

into the outlet on the vacuum cleaner. Check nameplate on

the tool for the amp rating.

Using a Vacuum Cleaner with an Automatic Switch as a Dust

Collection Device for a Tool

1. Connect vacuum hose to the tool.

2. Plug the tool into the electrical outlet on the vacuum cleaners motor

head.

3. Set the AUTO/ON/OFF switch to the AUTO position.

4. Turn on the tool and the vacuum cleaner will start automatically

within a few seconds.

Page 5

Using the Vacuum Cleaner To Pick Up Wet Materials:

WARNING!

To reduce the risk of electric shock, DO NOT pick up wet

materials unless the vacuum cleaner is properly set up to

pick up wet materials.

A float valve shuts off suction when the tank is full. Be sure the float is

clean and moves freely in the float cage to ensure that the float valve

works (Figs. 3 & 4).

Fig. 3

Float cage

Removing Liquid from the Vacuum Tank on Vacuum Cleaners

with Drain Valves

1. Center drain valve over floor drain.

2. Open drain valve.

For Cat. No. 8925, open drain valve by turning the drain valve handle

counter clockwise. To closedrain valve trun clockwise.

For Cat. No. 8924, 8926 and 8927, open drain valve by pulling up on the

handle. To close push down on handle.

3. Drain.

4. Rinse, dry tank and close drain valve.

Removing Liquid from the Vacuum Tank on Vacuum Cleaners

without Drain Valves

1. Remove motorhead and wet adapter and set aside.

2. Block wheels.

3. Carefully dump contents into floor drain.

4. Rinse and dry tank.

Do not store vacuum cleaner with liquid in tank. Run the vacuum for

about 5 minutes without picking up anything to dry the inside of the tank.

Float

WARNING!

If the float is clean, moves freely and the suction does not

shut off when the tank is filled (you will be able to see water

in the exhaust port), send the motorhead to the nearest

MILWUAKEE service facility for repair.

Cat. No. 8965 does not need a wet adapter for picking up wet materials.

The safety valve is already built in to the 8965 vaccum cleaner. Do not

remove the foam filter sleeve. It is designed to be used with both wet and

dry materials.

Installing Wet Adapter (Fig. 4)

1. Remove motorhead and set aside.

2. Set wet adapter into tank.

3. Replace motorhead and snap down tank latches.

Fig. 4

WARNING!

To reduce the risk of injury: wear saftey glasses and a dust

mask when using the vacuum cleaner as a blower.

Using the Vacuum as a Blower

1. Attached hose exhaust port on the motorhead.

2. Attach the appropriate accessory to the hose.

3. Turn the vacuum on.

Page 6

Float

cage

Float

Loading...

Loading...