Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

0613-20 LokTor Hammer-Drill

0614-20 LokTor Hammer-Drill

0616-20 LokTor Driver Drill

0622-20 LokTor Driver Drill

0624-20 LokTor Hammer-Drill

14.4 V AND 18 V LOKTOR 1/2" HAMMER-DRILLS & DRIVER DRILLS

MARTEAUX PERFORATEURS ET TOURNEVIS ELECTRIQUES 14,4 V

ET 18 V 13 mm (1/2") LOKTOR

MARTILLOS PERFORADORES Y MARTILLOS TALADRADORES DE

13 mm (1/2") LOKTOR Y 14,4 V Y 18 V

SPECIAL NOTE: New battery packs are not fully charged. Charge your battery pack before using it for the first time and

follow the charging instructions in your charger manual.

NOTE SPÉCIALE: Les batteries neuves ne sont pas entièrement chargées. Chargez la batterie avant de vous en servir la

première fois en suivant les instructions de recharge dans le manuel qui accompagne cet outil.

NOTA ESPECIAL: Las batterias, cuando son nuevas, no están totalmente cargadas. Cargue su bateria antes de usarla

por primera vez siga las instrucciones de carga que vienen en el manuel de la herramienta.

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND

OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET

BIEN COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y

ENTENDER EL MANUAL DEL OPERADOR.

Page 2

GENERAL SAFETY RULES-FOR ALL BATTERY OPERATED TOOLS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and

well lit. Cluttered benches and dark

areas invite accidents.

2. Do not operate power tools in ex-

plosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. Power tools

create sparks which may ignite the

dust or fumes.

3. Keep bystanders, children, and

visitors away while operating a

power tool. Distractions can cause

you to lose control. Protect others in

the work area from debris such as

chips and sparks. Provide barriers or

shields as needed.

ELECTRICAL SAFETY

4. Do not abuse the cord. Never use

the cord to carry the tool. Keep

cord away from heat, oil, sharp

edges, or moving parts. Replace

damaged cords immediately.

Damaged cords may create a fire.

5. A battery operated tool with inte-

gral batteries or a separate

battery pack must be recharged

only with the specified charger

for the battery. A charger that may

be suitable for one type of battery may

create a risk of fire when used with

another battery.

6. Use battery operated tool only

with specifically designated battery pack. Use of any other batteries

may create a risk of fire.

PERSONAL SAFETY

7. Stay alert, watch what you are doing, and use common sense when

operating a power tool. Do not use

tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while

operating power tools may result in

serious personal injury.

8. Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

9. Avoid accidental starting. Be sure

switch is in the locked or off position before inserting battery

pack. Carrying tools with your finger

on the switch or inserting the battery

pack into a tool with the switch on

invites accidents.

10. Remove adjusting keys or

wrenches before turning the tool

on. A wrench or a key that is left at-

tached to a rotating part of the tool

may result in personal injury.

11. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enable better control of the tool in unexpected

situations.

12. Use safety equipment. Always

wear eye protection. Dust mask,

nonskid safety shoes, hard hat, or

hearing protection must be used for

appropriate conditions.

2

Page 3

TOOL USE AND CARE

13. Use clamps or other practical way

to secure and support the workpiece to a stable platform. Holding

the work by hand or against your body

is unstable and may lead to loss of

control.

14. Do not force tool. Use the correct

tool for your application. The correct tool will do the job better and safer

at the rate for which it is designed.

15. Do not use tool if switch does not

turn it on or off. A tool that cannot

be controlled with the switch is dangerous and must be repaired.

16. Disconnect battery pack from tool

or place the switch in the locked

or off position before making any

adjustments, changing accessories, or storing the tool. Such pre-

ventive safety measures reduce the

risk of starting the tool accidentally.

17. Store idle tools out of reach of

children and other untrained persons. Tools are dangerous in the

hands of untrained users.

18. When battery pack is not in use,

keep it away from other metal objects like: paper clips, coins, keys,

nails, screws, or other small

metal objects that can make a

connection from one terminal to

another. Shorting the battery termi-

nals together may cause sparks,

burns, or a fire.

19. Maintain tools with care. Keep cut-

ting tools sharp and clean. Properly maintained tools with sharp cutting edge are less likely to bind and are

easier to control.

20. Check for misalignment or bind-

ing of moving parts, breakage of

parts, and any other condition that

may affect the tool's operation. If

damaged, have the tool serviced

before using. Many accidents are

caused by poorly maintained tools. Do

not use a damaged tool. Tag damaged

tools “Do not use” until repaired.

21. Use only accessories that are rec-

ommended by the manufacturer

for your model. Accessories that

may be suitable for one tool may create a risk of injury when used on another tool.

SERVICE

22. Tool service must be performed

only by qualified repair personnel. Service or maintenance per-

formed by unqualified personnel may

result in a risk of injury.

23. When servicing a tool, use only

identical replacement parts. Follow instructions in the Maintenance section of this manual. Use

of unauthorized parts or failure to follow Maintenance Instructions may create a risk of shock or injury.

3

Page 4

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates. These carry important information. If unreadable

or missing, contact a

2. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area,

and work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

3. Hold tool by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring. Contact with a “live” wire

will make exposed metal parts of the tool “live” and shock the operator.

4. Keep hands away from all cutting edges and moving parts.

5. Wear ear protectors when using the tool for extended periods. Prolonged

exposure to high intensity noise can cause hearing loss.

MILWAUKEE

service facility for a free replacement.

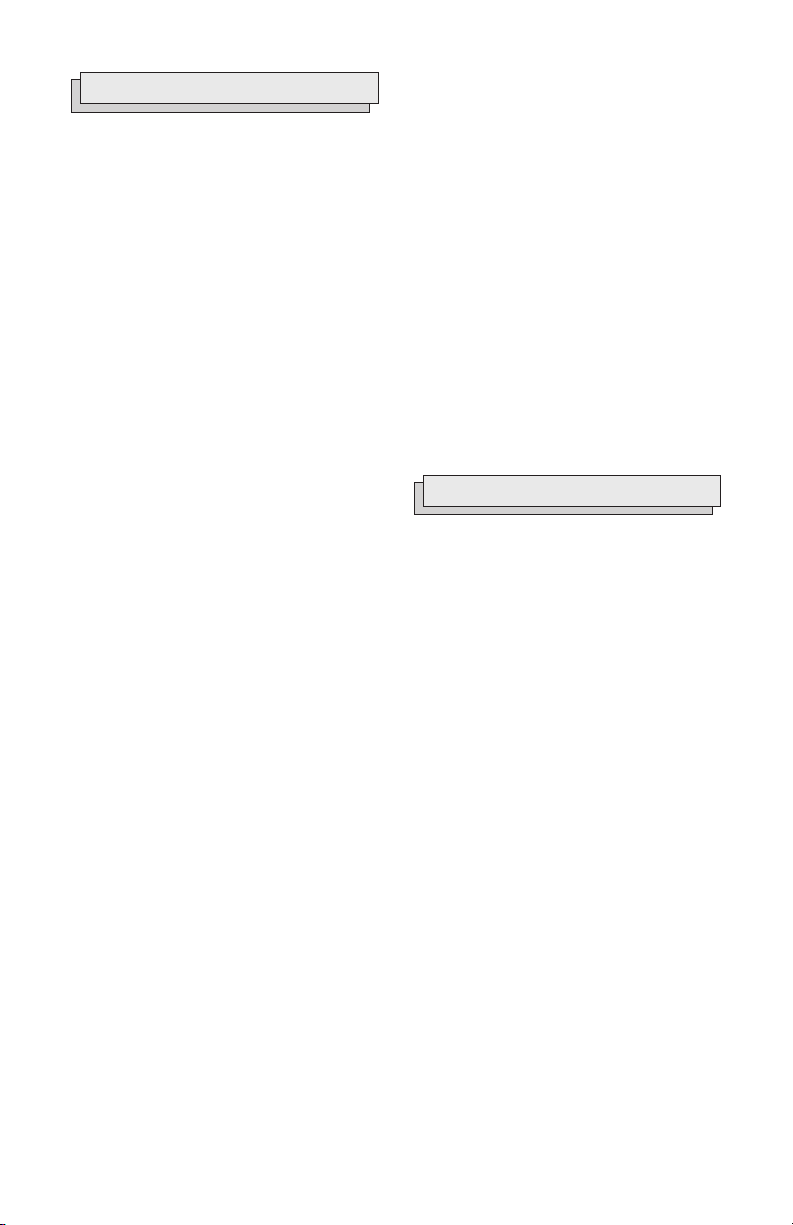

Symbology

Properly Recycle Nickel Cadmium Batteries

Direct Current

Cat. No.

0613-20

0614-20

0616-20

0622-20

0624-20

Underwriters Laboratories, Inc.

No Load Revolutions per Minute (RPM)

Specifications

Volts DC

14.4

14.4

14.4

18

18

No Load RPM

Low 0-500

High 0-1700

Low 0-500

High 0-1700

Low 0-500

High 0-1700

Low 0-500

High 0-1700

Low 0-500

High 0-1700

4

No Load Blows

per Minute

Low 0-7500

High 0-25500

Low 0-7500

High 0-25500

Low 0-7500

High 0-25500

N/A

N/A

Page 5

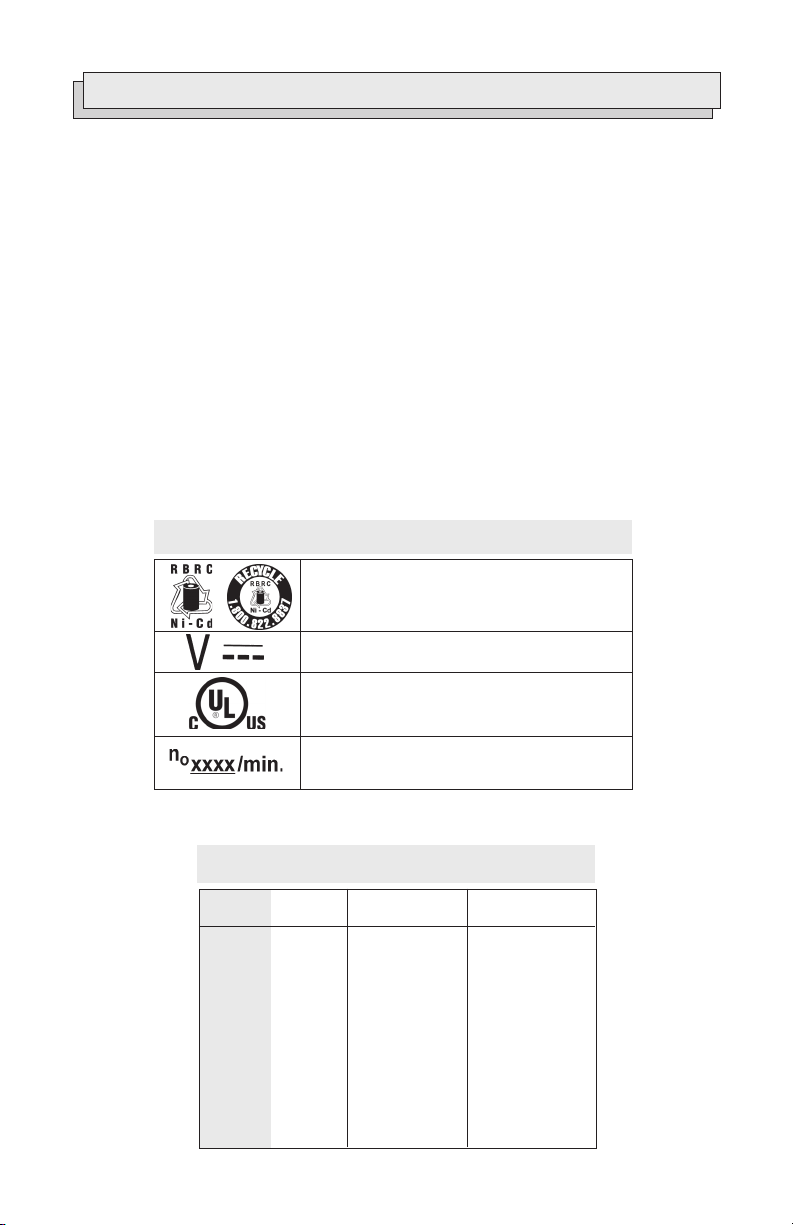

FUNCTIONAL DESCRIPTION

6

1. Speed selector

2. Battery latch

3. Battery pack

4. Trigger

5. Control switch

6. Keyless chuck

7. Side handle

8. Torque selector collar

7

8

1

5

4

2

3

0613-20

0614-20

0616-20

0622-20

0624-20

Steel

1/2"

1/2"

1/2"

1/2"

1/2"

Flat Bit

1-1/2"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

Capacities

Wood

Auger Bit

1-1/8"

1-1/8"

1-1/8"

1-1/8"

1-1/8"

5

Hole Saw

2-1/8"

2-1/8"

2-1/8"

2-1/8"

2-1/8"

Screws

(dia.)

1/4"

1/4"

1/4"

1/4"

1/4"

Masonry

3/8"

3/8"

N/A

N/A

3/8"

Page 6

CHARGING & USING BATTERY PACKS

WARNING!

Charge only

and 18 Volt battery packs in chargers. Other types of batteries may

explode causing personal injury

and damage.

Charge your battery pack before you use

your tool for the first time and when your

tool no longer performs with the power

and torque needed for the job. Never

completely discharge the battery pack.

Standard charging time will vary according to the type of charger you use. The

charging time will also vary depending on

the supply voltage and charge needed. For

example, if your battery pack does not

require a full charge, charging time will be

less.

FOR SPECIFIC CHARGING INSTRUCTIONS,

PLEASE READ THE CHARGER

OPERATOR'S MANUAL SUPPLIED WITH

YOUR CHARGER.

Battery packs are affected by temperature. Your battery pack will perform best

and have longest life if it is charged when

the temperature is between 60°-80°F (15°27°C). Do not charge in temperatures below 40°F (5°C) or above 105°F (40°C).

Under these conditions, capacity will be

reduced. (See “Maintenance").

MILWAUKEE

12, 14.4

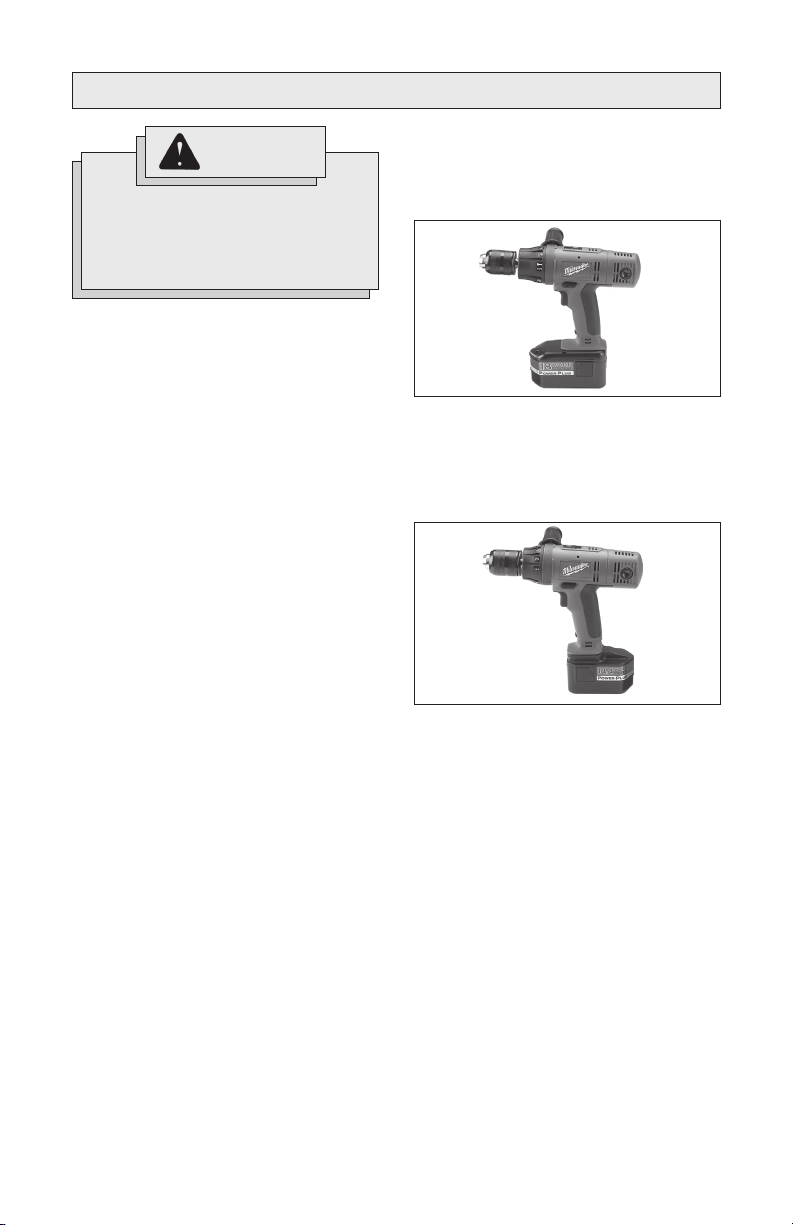

Inserting Battery Pack into Tool

(Fig. 1 & 2)

Battery pack can be inserted into the tool

in two ways.

Fig. 1

1. For working in restricted spaces.

Insert the battery pack from the front

by sliding battery pack into the body of

the tool. Insert the battery pack until

the battery latches lock.

Fig. 2

2. For optimum weight distribution and

balance.

Insert the battery pack from the back

by sliding the battery pack into the body

of the tool. Insert the battery pack until

the battery latches lock.

3. To remove the battery pack, press in

both battery latches and slide the battery pack off of the tool.

6

Page 7

ASSEMBLY

WARNING!

Always lock trigger or remove

battery pack before changing or

removing accessories. Only use

accessories specifically

recommended for this tool.

Others may be hazardous.

WARNING!

To reduce the risk of injury, always

use a side handle when using this

tool. Always brace or hold securely.

OPERATION

WARNING!

To reduce the risk of injury, wear

safety goggles or glasses with

side shields.

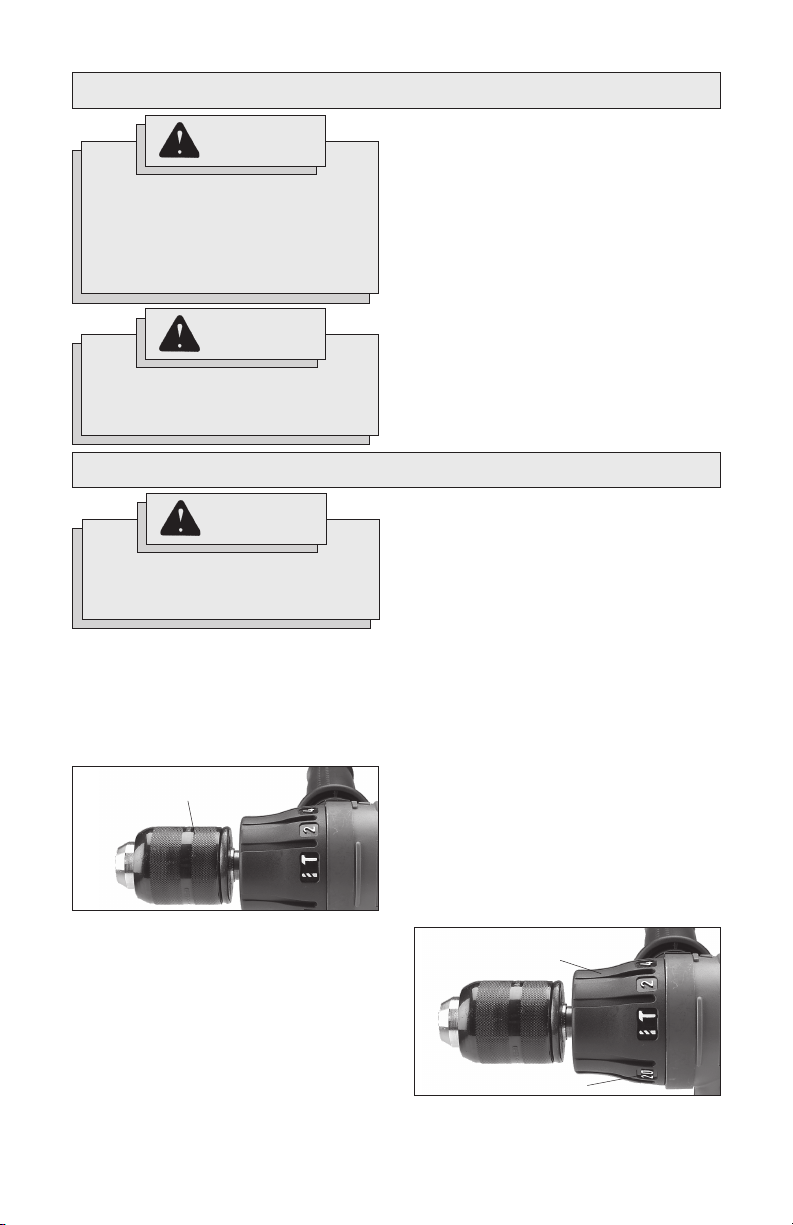

Using Keyless Chucks (Fig. 3)

Your cordless tool is equipped with a spindle

lock. The chuck can be tightened with one

hand, creating higher grip strengths on the bit.

Always remove the battery pack or lock

the trigger before inserting or removing bits.

Fig. 3

1. To open the chuck jaws, turn the sleeve

2. To close the chuck jaws, turn the

Sleeve

in the counterclockwise direction.

When using drill bits, allow the bit to

strike the bottom of the chuck. Center

the bit in the chuck jaws and lift it about

1/16" off of the bottom.

When using screwdriver bits, insert

the bit far enough for the chuck jaws

to grip the hex of the bit.

sleeve in the clockwise direction. The

bit is secure when the chuck makes a

Installing the Side Handle

1. To install the side handle, loosen the

side handle grip until the ring is large

enough to slide over the torque selector collar. The raised rib on the side

handle ring fits inside the groove

around the tool. Rotate the handle to

the desired position and tighten the

side handle until it is secure.

2. To remove the side handle, loosen

the side handle grip until the ring is

large enough to slide off the tool.

ratcheting sound and the sleeve can

not be rotated any further.

3. To remove the bit, turn the sleeve in

the counterclockwise direction.

NOTE: A ratcheting sound may be heard

when the chuck is opened or closed. This

noise is part of the locking feature, and

does not indicate a problem with the chuck's

operation.

Using Clutch (Fig. 4)

This tool has an adjustable clutch for driving different types of screws into different materials. When properly adjusted, the

clutch will slip at a preset torque to prevent driving the screw too deep and to

prevent damage to the screw or tool.

To adjust the clutch, turn the torque selector collar to one of the twenty positions

shown on the collar. The number must line

up with the arrow on top of the tool.

Fig. 4

Torque selector

collar

Position numbers

The torque specifications shown here are

approximate values obtained with a fully

charged battery pack.

7

Page 8

Positions

1 - 5

0614-20 &

0616-20

Torque

0 - 17 in. lbs.

0613-20

Torque

0 - 17 in. lbs.

0622-20 &

0624-20

Torque

0 - 17 in. lbs.

6 - 10

11 - 15

16 - 20

Drill

Low

High

NOTE: Because the above settings are only a guide, use a

piece of scrap material to test the different clutch positions before driving screws into the workpiece.

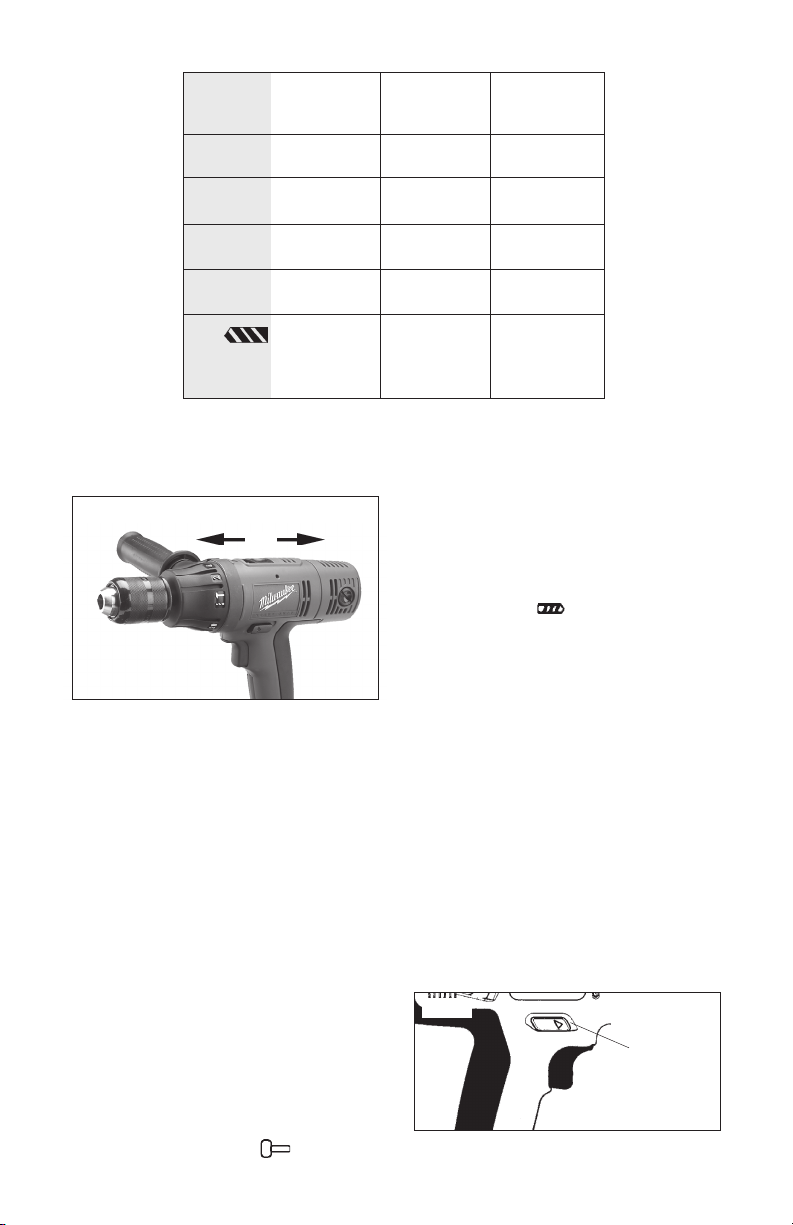

Selecting Speed (Fig. 5)

Fig. 5

The speed selector is on top of the motor

housing. Allow the tool to come to a complete stop before changing speeds. See

“Applications” for recommended speeds

under various conditions.

1. For Low speed (up to 500 RPM), push

the speed selector forward.

2. For High speed (up to 1700 RPM), push

the speed selector back.

Selecting Hammer or Drill Action

(Cat. No. 0613-20, 0614-20, and 0624-20 only)

MILWAUKEE

for two operating modes: drilling with hammering action and drilling only. To set the

operating mode, rotate the torque selector

collar to the desired symbol. A drill or hammer symbol will appear in line with the arrow to indicate operating mode.

1. To use the hammer-drilling mode,

rotate the torque selector collar until

the hammer symbol appears in

Low

Hammer-Drills are designed

21 - 38 in. lbs.

42 - 60 in. lbs.

65 - 85 in. lbs.

460 in. lbs.

160 in. lbs.

High

21 - 38 in. lbs.

42 - 60 in. lbs.

65 - 85 in. lbs.

350 in. lbs

120 in. lbs.

2. To use the drilling only mode, ro-

NOTE: When using carbide bits, do not use

water to settle dust. Do not attempt to drill

through steel reinforcing rods. Both actions will damage the carbide bits.

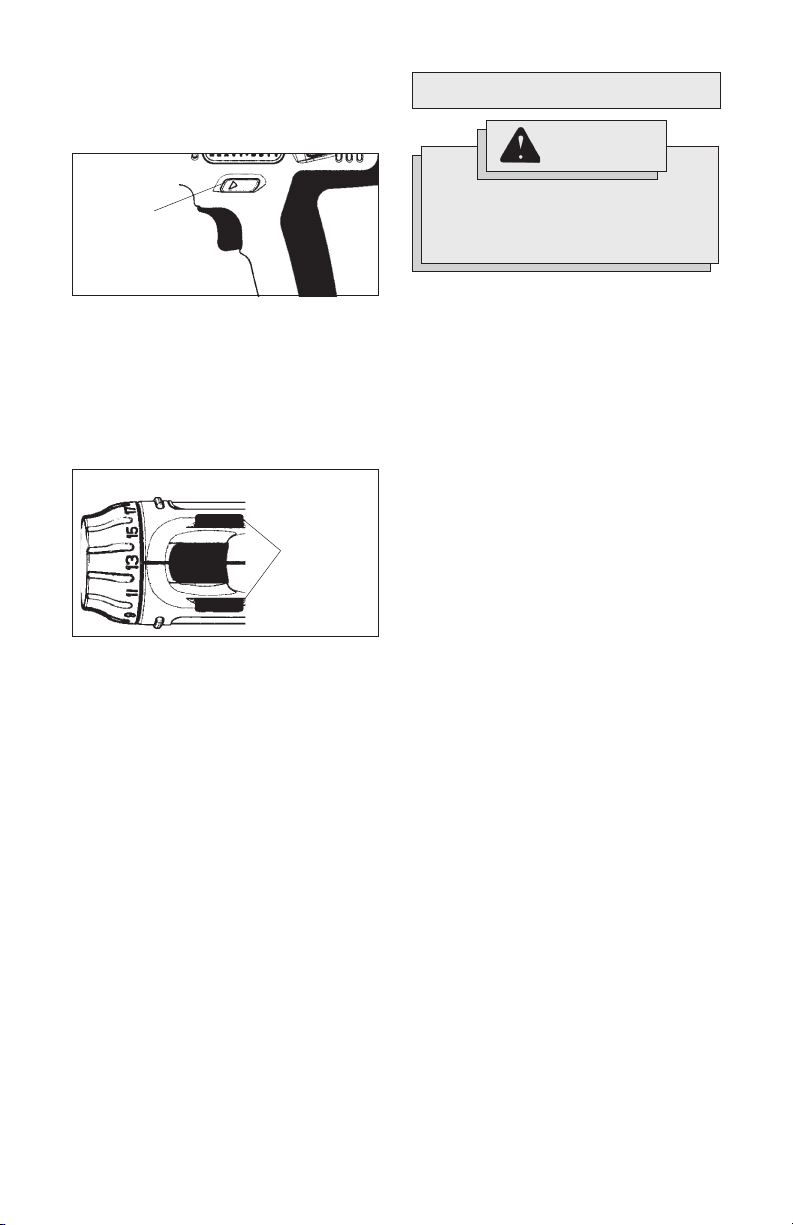

Using Control Switch (Fig. 6, 7 and 8)

The control switch may be set to three

positions: forward, reverse and lock. Due

to a lockout mechanism, the control switch

can only be adjusted when the ON/OFF

switch is not depressed. Always allow the

motor to come to a complete stop before

using the control switch.

For forward (clockwise) rotation, push in

the control switch from the right side of the

tool (Fig. 6). Check the direction of

rotation before use.

Fig. 6

21 - 38 in. lbs.

42 - 60 in. lbs.

65 - 85 in. lbs.

495 in. lbs.

175 in. lbs.

line with the arrow. Apply pressure to

the bit to engage the hammering

mechanism.

tate the torque selector collar until the

drill symbol appears in line with

the arrow.

Push in

for forward

8

Page 9

For reverse (counterclockwise) rotation,

push in the control switch from the left

side of the tool (Fig. 7). Check direction

of rotation before use.

Fig. 7

Push in

for reverse

To lock the trigger, push the control switch

to the center position (Fig. 8). The trigger

will not work while the control switch is in

the center locked position. Always lock the

trigger or remove the battery pack before

performing maintenance, changing accessories, storing the tool and any time the

tool is not in use.

Fig. 8

Push to

center

position to

lock trigger

Starting, Stopping & Controlling

Speed

1. To start the tool, pull the trigger.

2. To stop the tool, release the trigger

and an electric brake stops the tool

instantly.

All models feature variable speed control.

To vary the speed, simply increase or decrease pressure on the trigger. The further

the trigger is pulled, the greater the speed.

Drilling

Set the torque selector collar to the drill

position

Place the bit on the work surface and apply firm pressure before starting. Too much

pressure will slow the bit and reduce drilling efficiency. Too little pressure will cause

the bit to slide over the work area and dull

the point of the bit.

If the tool begins to stall, reduce pressure

slightly to allow the bit to regain speed. If

the bit binds, reverse the motor to free the

bit from the workpiece.

APPLICATIONS

WARNING!

To reduce the risk of electric

shock, check work area for hidden

pipes and wires before drilling or

driving screws.

Drilling in Wood, Composition

Materials and Plastic

When drilling in wood, composition materials and plastic, start the drill slowly, gradually increasing speed as you drill. When

drilling into wood, use wood augers or

twist drill bits. Always use sharp bits.

When using twist drill bits, pull the bit out of

the hole frequently to clear chips from the

bit flutes. To reduce the chance of splintering, back work with a piece of scrap

wood. Select low speeds for plastics with

a low melting point.

Drilling in Metal

When drilling in metal, use high speed steel

twist drills or hole saws. Use a center

punch to start the hole. Lubricate drill bits

with cutting oil when drilling in iron or steel.

Use a coolant when drilling in nonferrous

metals such as copper, brass or aluminum.

Back the material to prevent binding and

distortion on breakthrough.

Drilling in Masonry

When drilling in masonry, select the

hammer-drill operating mode

(Cat. No. 0613-20, 0614-20, and 0624-20

only). Use high speed carbide-tipped bits.

Drilling soft masonry materials such as cinder block requires little pressure. Hard materials like concrete require more pressure.

A smooth, even flow of dust indicates the

proper drilling rate. Do not let the bit spin in

the hole without cutting. Do not use water

to settle dust or to cool bit. Both actions

will damage the carbide.

9

Page 10

Driving Screws and Nut Running

Drill a pilot hole when driving screws into

thick or hard materials. Set the torque selector collar to the proper position and set

the speed to low. Use the proper style and

size screwdriver bit for the type of screw

you are using.

With the screwdriver bit in the screw, place

the tip of the screw on the workpiece and

apply firm pressure before pulling the trigger. Screws can be removed by reversing

the motor.

Overloading

Continuous overloading may cause permanent damage to tool or battery pack.

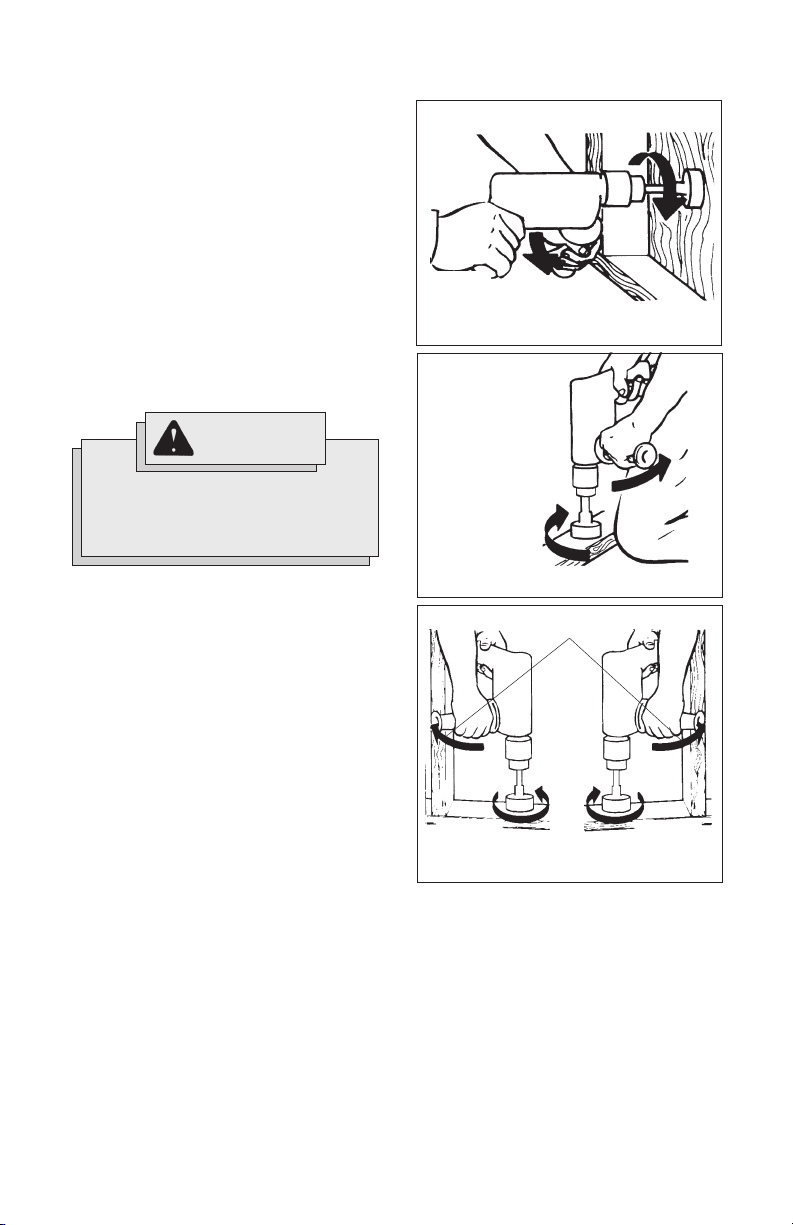

Typical Bracing Methods

Fig. 9

Reaction

Bracing against the floor

Fig. 10

Forward rotation

WARNING!

High rotational force. To reduce

the risk of injury, always hold or

brace securely. Always use side

handle on tools.

Bit Binding

A high rotational force occurs when a bit

binds. If the bit binds, the tool will be forced

in the opposite direction of the bit rotation.

Bits may bind if they are misaligned or when

they are breaking through a hole. Wood

boring bits can also bind if they run into

nails or knots. Be prepared for bit binding

situations.

To reduce the chance of bit binding:

• Use sharp bits. Sharp bits are less

likely to bind when drilling.

• Use the proper bit for the job. There

are bits that are designed for specific

purposes.

• Use caution when drilling pitchy,

knotty, wet or warped material or

when drilling in material that may contain nails.

Forward

rotation

Bracing against your leg

Fig. 11

Reverse rotation

Bracing against a stud

Reaction

Reaction

Forward rotation

10

Page 11

MAINTENANCE

WARNING!

To reduce the risk of injury,

always unplug the charger and

remove the battery pack from

the charger or tool before

performing any maintenance.

Never disassemble the tool,

battery pack or charger. Contact

a

MILWAUKEE

ALL repairs.

Keep your tool, battery pack and charger

in good repair by adopting a regular maintenance program. After six months to one

year, depending on use, return the

tool, battery pack and charger to a

MILWAUKEE

• Lubrication

• Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

• Brush inspection and replacement

• Electrical inspection (battery pack,

charger, motor)

• Testing to assure proper mechanical

and electrical operation

service facility for

service facility for:

Use a

MILWAUKEE

it no longer performs with the power and

torque needed for your application.

Store your battery pack in a cool, dry place.

Do not store it where the temperature may

exceed 120°F (50°C) such as a vehicle or

metal building during the summer. High temperatures will overheat the battery pack,

reducing battery life. If it is stored for several months, the battery pack will gradually lose its charge. One to three cycles of

charging and discharging through normal

use will restore the capacity of the battery

pack. During the life of the battery pack the

operating time between charges becomes

shorter. If the operating time becomes extremely short after a proper charge, the

usable life of the battery pack has been

reached and it should be replaced.

battery pack only until

WARNING!

To reduce the risk of personal

injury and damage, never

immerse your tool, battery pack

or charger in liquid or allow a

liquid to flow inside them.

Maintaining Tool

If the tool does not start or operate at full

power with a fully charged battery pack,

clean the contacts on the battery pack. If

the tool still does not work properly, return

the tool, charger and battery pack, to a

MILWAUKEE

Maintaining Battery Pack

MILWAUKEE

for many years and/or hundreds of cycles

when they are maintained and used according to these instructions.

A battery pack that is stored for six months

without being used will discharge itself.

Batteries discharge at a rate of about 1%

per day. Charge the battery every six

months even if it is unused to maximize

battery life. Do not tape the trigger in the

“ON” position and leave the tool unattended

as this may discharge the battery to a point

where it will no longer be able to recharge.

service facility for repairs.

battery packs will operate

Cleaning

Clean dust and debris from charger and

tool vents. Keep tool handles clean, dry

and free of oil or grease. Use only mild

soap and a damp cloth to clean the tool,

battery pack and charger since certain

cleaning agents and solvents are harmful

to plastics and other insulated parts. Some

of these include gasoline, turpentine, lacquer thinner, paint thinner, clhlorinated

cleaning solvents, ammonia and household

detergents containing ammonia. Never use

flammable or combustible solvents around

tools.

11

Page 12

WARNING!

FIVE YEAR TOOL

LIMITED WARRANTY

To reduce the risk of explosion,

never burn a battery pack even if

it is damaged, dead or

completely discharged.

RBRC Battery Recycling Seals

The RBRC™ Battery Recycling Seals (see

"Symbology") on your tool battery packs indicate that

the recycling of that battery pack with the

Rechargeable Battery Recycling Corporation

(RBRC). At the end of your battery pack's

useful life, return the battery pack to a

MILWAUKEE

or the participating retailer nearest you. For

more information, visit the RBRC web site at

www.rbrc.org.

Disposing of Nickel-Cadmium Battery

Packs

Nickel-Cadmium battery packs are recyclable. Under various state and local laws,

it may be illegal to dispose of this batter

into the municipal waste stream. Dispose

of your battery pack according to federal,

state and local regulations.

Repairs

For repairs, return the tool, battery pack and

charger to the nearest service center listed

on the back cover of this operator's manual.

Battery Pack Warranty

Battery packs for cordless tools are

warranted for one year from the date of

purchase.

MILWAUKEE

Branch Office/Service Center

has arranged for

Every

MILWAUKEE

leaving the factory and is warranted to be

free from defects in material and workmanship.

place (at

out charge, any tool (including battery

chargers) which examination proves to be

defective in material or workmanship from

five (5) years after the date of purchase.

Return the tool and a copy of the purchase

receipt or other proof of purchase to a

MILWAUKEE

MILWAUKEE

MILWAUKEE

port Branch location or

thorized Service Station, freight prepaid

and insured. This warranty does not cover

damage from repairs made or attempted

by other than

sonnel, abuse, normal wear and tear, lack

of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are

warranted for one (1) year from the date

of purchase.

THE REPAIR AND REPLACEMENT REMEDIES

DESCRIBED HEREIN ARE EXCLUSIVE. IN NO

EVENT SHALL

FOR ANY INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING LOSS

OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES, OR

CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR

PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal

rights. You may also have other rights that

vary from state to state and province to

province. In those states that do not allow

the exclusion of implied warranties or limitation of incidental or consequential damages, the above limitations or exclusions

may not apply to you. This warranty applies to the United States, Canada, and

Mexico only.

tool is tested before

will repair or re-

’s discretion), with-

Factory Service/Sales Sup-

MILWAUKEE

MILWAUKEE

authorized per-

MILWAUKEE

Au-

BE LIABLE

12

Page 13

ACCESSORIES

WARNING!

Always remove battery pack before changing or removing accessories. Only use accessories specifically recommended for

this tool. Others may be hazardous.

For a complete listing of accessories refer to your

MILWAUKEE

Electric Tool catalog or go

on-line to www.mil-electric-tool.com. To obtain a catalog, contact your local distributor or

a service center listed on the back cover of this operator’s manual.

1/2" Keyless Chucks

Cat. No. 48-66-1575

Rugged steel housing with rust resistant nickel plated jaws and body.

For cordless drills with 1/2" - 20 thread.

Hammer-Drill Accessory Kit

Cat. No. 48-30-0101

Includes 1/4" socket driver, 6F-7R slotted bit, #1 and #2 Phillips bits, 1/4"

and 3/16" twist bits, and two 1/8" twist bits.

Plastic Carrying Case

Cat. No. 48-55-0930

Side Handle

Cat. No. 49-15-0400

13

Page 14

RÈGLES DE SÉCURITÉ GÉNÉRALES

POUR TOUS LES OUTILS À BATTERIE

AVERTISSEMENT!

VOUS DEVEZ LIRE ET COMPRENDRE TOUTES

LES INSTRUCTIONS

Le non-respect, même partiel, des instructions ci-après entraîne

un risque de choc électrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

AIRE DE TRAVAIL

1. Veillez à ce que l'aire de travail

soit propre et bien éclairée. Le

désordre et le manque de lumière

favorisent les accidents.

2. N'utilisez pas d'outils électriques

dans une atmosphère explosive,

par exemple en présence de

liquides, de gaz ou de poussières

inflammables. Les outils électriques

créent des étincelles qui pourraient

enflammer les poussières ou les

vapeurs.

3. Tenez à distance les curieux, les

enfants et les visiteurs pendant

que vous travaillez avec un outil

électrique. Ils pourraient vous

distraire et vous faire faire une fausse

manoeuvre. Installez des barrières ou

des écrans protecteurs si nécessaires.

SÉCURITÉ ÉLECTRIQUE

4. Ne maltraitez pas le cordon. Ne

transportez pas l'outil par son

cordon. N'exposez pas le cordon

à la chaleur, à des huiles, à des

arêtes vives ou à des pièces en

mouvement.Remplacez

immédiatement un cordon

endommagé. Un cordon endommagé

peut constituer un risque d'incendie.

5. Un outil à bloc-batterie amovible

ou à batterie intégrée ne doit être

rechargé qu'avec le chargeur

prévu pour la batterie. Un chargeur

qui convient à tel type de batterie peut

présenter un risque d'incendie avec

tel autre type de batterie.

6. N'utilisez un outil qu'avec un

bloc-batterie conçu spécifiquement

pour lui. L'emploi d'un autre

bloc-batterie peut créer un risque

d'incendie.

SÉCURITÉ DES PERSONNES

7. Restez alerte, concentrez-vous

sur votre travail et faites preuve

de jugement. N'utilisez pas un

outil électrique si vous êtes

fatigué ou sous l'influence

de drogues, d'alcool ou de

médicaments. Un instant d'inattention

suffit pour entraîner des blessures

graves.

8. Habillez-vous convenablement.

Ne portez ni vêtements flottants

ni bijoux. Confinez les cheveux

longs. N'approchez jamais les

cheveux, les vêtements ou les

gants des pièces en mouvement.

Des vêtements flottants, des bijoux ou

des cheveux longs risquent d'être

happés par des pièces en mouvement.

9. Méfiez-vous d'un démarrage

accidentel. Avant d'insérer un

bloc-batterie, assurez-vous que

l'interrupteur de l'outil est sur

ARRÊT. Le fait de transporter un outil

avec le doigt sur la détente ou d'insérer

un bloc-batterie alors que l'interrupteur

est en position MARCHE peut mener

tout droit à un accident.

14

Page 15

10. Enlevez les clés de réglage ou de

serrage avant de démarrer l'outil.

Une clé laissée dans une pièce

tournante de l'outil peut provoquer des

blessures.

11. Ne vous penchez pas trop en

avant. Maintenez un bon appui et

restez en équilibre en tout

temps. Un bonne stabilité vous

permet de mieux réagir à une situation

inattendue.

12. Utilisez des accessoires de

sécurité. Portez toujours des lunettes ou une visière. Selon les

conditions, portez aussi un masque

antipoussière, des bottes de sécurité

antidérapantes, un casque protecteur

et/ou un appareil antibruit.

UTILISATION ET ENTRETIEN

DES OUTILS

13. Immobilisez le matériau sur une

surface stable au moyen de

brides ou de toute autre façon

adéquate. Le fait de tenir la pièce

avec la main ou contre votre corps

offre une stabilité insuffisante et peut

amener un dérapage de l'outil.

14. Ne forcez pas l'outil. Utilisez l'outil

approprié à la tâche. L'outil correct

fonctionne mieux et de façon plus

sécuritaire. Respectez aussi la vitesse

de travail qui lui est propre.

15. N'utilisez pas un outil si son

interrupteur est bloqué. Un outil

que vous ne pouvez pas commander

par son interrupteur est dangereux et

doit être réparé.

16. Retirez le bloc-batterie ou mettez

l'interrupteur sur ARRÊT ou en

position verrouillée avant

d'effectuer un réglage, de

changer d'accessoire ou de

ranger l'outil. De telles mesures

préventives réduisent le risque de

démarrage accidentel de l'outil.

17. Rangez les outils hors de la

portée des enfants et d'autres

personnes inexpérimentées. Les

outils sont dangereux dans les mains

d'utilisateurs novices.

18. Lorsque le bloc-batterie n'est pas

en service, tenez-le à l'écart

d'autres objets métalliques

(trombones, pièces de monnaie,

clés, clous, vis, etc.) susceptibles

d'établir un contact électrique entre les deux bornes. La mise en

court-circuit des bornes de la batterie

peut produire des étincelles et

constitue un risque de brûlures ou

d'incendie.

19. Prenez soin de bien entretenir

les outils. Les outils de coupe

doivent être toujours bien

affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien

tranchantes, sont moins susceptibles

de coincer et plus faciles à diriger.

20. Soyez attentif à tout

désalignement ou coincement

des pièces en mouvement, à

tout bris ou à toute autre condition préjudiciable au bon

fonctionnement de l'outil. Si

vous constatez qu'un outil est

endommagé, faites-le réparer

avant de vous en servir. De

nombreux accidents sont causés par

des outils en mauvais état. Fixez-y

une étiquette marquée « Hors

d'usage » jusqu'à ce qu'il soit réparé.

21. N'utilisez que des accessoires

que le fabricant recommande

pour votre modèle d'outil.

Certains accessoires peuvent

convenir à un outil, mais être

dangereux avec un autre.

RÉPARATION

22. La réparation des outils

électriques doit être confiée à un

réparateur qualifié. L'entretien ou

la réparation d'un outil électrique par

un amateur peut avoir des

conséquences graves.

23. Pour la réparation d'un outil,

n'employez que des pièces de

rechange d'origine. Suivez les directives données à la section «

Réparation » de ce manuel. L'emploi

de pièces non autorisées ou le

non-respect des instructions

d'entretien peut créer un risque de

choc électrique ou de blessures.

15

Page 16

RÈGLES DE SÉCURITÉ PARTICULIÈRE

1. Entretenez les étiquettes et marques du fabricant. Les indications qu'elles

contiennent sont précieuses. Si elles deviennent illisibles ou se détachent, faites-les

remplacer gratuitement à un centre de service

2. AVERTISSEMENT! La poussière dégagée par perçage, sciage et autres travaux de

construction contient des substances chimiques reconnues comme pouvant causer

le cancer, des malformations congénitales ou d’autres troubles de reproduction. Voici

quelques exemples de telles substances :

• Le plomb contenu dans la peinture au plomb.

• Le silice cristallin contenu dans la brique, le béton et divers produits de

maçonnerie.

• L’arsenic et le chrome servant au traitement chimique du bois.

Les risques associés à l’exposition à ces substances varient, dépendant de la

fréquence des travaux. Afin de minimiser l’exposition à ces substances chimiques,

assurez-vous de travailler dans un endroit bien aéré et d’utiliser de l’equipement de

sécurité tel un masque antipoussière spécifiquement conçu pour la filtration de

particules microscopiques.

3. Tenez l'outil par ses surfaces de prise isolées pendant toute opération où

l'outil de coupe pourrait venir en contact avec un câblage dissimulé. En cas

de contact avec un conducteur sous tension, les pièces métalliques à découvert de

l'outil transmettraient un choc électrique à l'utilisateur.

4. Tenez les mains à l'écart des arêtes tranchantes et des pièces en

mouvement.

5. Portez un appareil antibruit si vous devez utiliser l'outil pendant une période

prolongée. Une exposition prolongée à un bruit de forte intensité peut entraîner des

lésions de l'ouïe.

MILWAUKEE

accrédité.

Pictographie

Disposez correctement

des batteries au

nickel-cadmium

Tension Courant

Direct

Underwriters

Laboratories, Inc.

Tours-minute á

vide (RPM)

16

Page 17

DESCRIPTION FONCTIONNELLE

6

1. Sélecteur de vitesse

2. Loquet de la pile

3. Bloc de piles

4. Gâchette

5. Commutateur de commande

6. Mandrin sans clé

7. Poignée latérale

8. Collier sélecteur de couple

3

No. de

Cat.

0613-20

0614-20

0616-20

0622-20

0624-20

Volts

CD

14,4

14,4

14,4

18

18

7

8

5

4

Spécifications

Tr/min.

à vide

Bas 0 - 500

Haut 0 - 1 700

Bas 0 - 500

Haut 0 - 1 700

Bas 0 - 500

Haut 0 - 1 700

Bas 0 - 500

Haut 0 - 1 700

Bas 0 - 500

Haut 0 - 1 700

1

2

Coups-

Minute

Bas 0 - 7 500

Haut 0 - 25 500

Bas 0 - 7 500

Haut 0 - 25 500

S/O

S/O

Bas 0 - 7 500

Haut 0 - 25 500

0613-20

0614-20

0616-20

0622-20

0624-20

Acier

13 mm (1/2")

13 mm (1/2")

13 mm (1/2")

13 mm (1/2")

13 mm (1/2")

Mèche

plate

48 mm (1-1/2")

48 mm (1-1/2")

48 mm (1-1/2")

48 mm (1-1/2")

48 mm (1-1/2")

Capacités

Bois

Mèche

hélicoïdale

29 mm (1-1/8")

29 mm (1-1/8")

29 mm (1-1/8")

29 mm (1-1/8")

29 mm (1-1/8")

17

Scie-cloche

54 mm (2-1/8")

54 mm (2-1/8")

54 mm (2-1/8")

54 mm (2-1/8")

54 mm (2-1/8")

Vis

(diam.)

6 mm (1/4")

6 mm (1/4")

6 mm (1/4")

6 mm (1/4")

6 mm (1/4")

Maçonnerie

9,5 mm (3/8")

9,5 mm (3/8")

S/O

S/O

9,5 mm (3/8")

Page 18

MONTAGE DE L'OUTIL

AVERTISSEMENT!

Seules les batteries

de 12V, 14,4V et 18V doivent être

rechargées avec le chargeur de

batterie. D’autres types de batteries pourraient exploser et causer

des dommages et des blessures

corporelles.

Rechargez la batterie avant de vous servir

de l’outil la première fois ou lorsque l’outil

n’offre plus la puissance et le couple

nécessaires au travail à accomplir. Ne

laissez pas la batterie s’épuiser

complètement. La durée normale de recharge est variable selon le type de

chargeur utilisé. Elle peut aussi varier selon

le voltage à la source et la recharge

nécessaire. Par exemple, si la batterie n’a

pas besoin d’une recharge complète, la

durée de recharge sera moindre.

VEUILLEZ CONSULTER LA MANUEL

L’UTILISATEUR QUI ACCOMPAGNE LE

CHARGEUR POUR CONNAÎTRE EN

DÉTAIL LA TECHNIQUE DE

RECHARGE.

Les batteries sont affectées par la

température. La vôtre aura un meilleur

rendement et durera plus longtemps si la

recharge est effectuée à une température

se situant entre 15°-27°C (60°F et 80°F).

Ne procédez pas à une recharge lorsque

la température est inférieure à 5°C (40°F)

ou supérieure à 40°C (105°F), car à ces

températures, la recharge sera moins

efficace. Voir “Maintenance”.

MILWAUKEE

Insertion du bloc de piles dans l’outil

(Fig. 1 & 2)

Le bloc de pile peut être inséré de deux

façons.

Fig. 1

1. Pour un travail dans des espaces

restreints.

Insérez le bloc de piles à partir de

l’avant en le faisant glisser dans le

corps de l’outil. Insérez le bloc de piles

jusqu’à ce que son loquet se verrouille.

Fig. 2

2. Pour obtenir le meilleur équilibre et la

meilleure répartition de poids

possibles.

Insérez le bloc de piles à partir de

l’arrière en le faisant glisser dans le

corps de l’outil. Insérez le bloc de piles

jusqu’à ce que son loquet se verrouille.

3. Pour retirer le bloc de piles, enfoncez

les deux loquets de la pile et faites

glisser le bloc hors de l’outil.

18

Page 19

MONTAGE DE L'OUTIL

AVERTISSEMENT!

Il faut toujours retirer la batterie et

verrouiller la détente de l’outil

avant de changer ou d’enlever les

accessoires. L’emploi d’accessoires

autres que ceux qui sont

expressément recommandés

pour cet outil peut comporter des

risques.

AVERTISSEMENT!

Pour minimiser les risques de

blessures corporelles,utilisez

toujours la poignée laterérale

lorsque vous maniez l’outil.

Étayez-la ou maintenez-la

solidement.

MANIEMENT

AVERTISSEMENT!

Pour minimiser les risques de

blessures, portez des lunettes à

coques latérales.

Utilisation de mandrins sans clé (Fig. 3)

Votre outil sans fil est équipé d’un

verrouillage de broche. Le mandrin peut

être serré avec une seule main, ce qui

accroît la force de saisie sur le foret ou la

mèche.

Retirez toujours la pile ou verrouillez la

gâchette avant de monter ou retirer un

accessoire de l’outil.

Fig. 3

Manchon

Installation de la poignée latérale

1. Pour installer la poignée latérale,

desserrez son manche jusqu’à ce que

l’anneau soit suffisamment grand pour

glisser par-dessus le collier sélecteur

de couple. Le nervure surélevée située

sur le côté de l’anneau de la poignée

latérale s’ajuste à l’intérieur de la rainure

autour de l’outil. Faites tourner la

poignée à la position voulue et serrez

la poignée latérale jusqu’à ce qu’elle

soit fixée solidement.

2. Pour enlever la poignée latérale,

desserrez son manche jusqu’à ce que

l’anneau soit suffisamment grand pour

glisser de l’outil.

1. Pour ouvrir les mors du mandrin,

tournez le manchon dans le sens

antihoraire.

Pour monter un foret, engagez-le à

fond dans le mandrin. Centrez le foret

dans les mâchoires du mandrin et

levez-le à environ 2 mm (1/16") du

fond.

Lors de l’utilisation d’embouts de

tournevis, insérez l’embout

suffisamment loin pour que les

mâchoires du mandrin saisissent la

portion hexagonale de l’embout.

2. Pour fermer les mors du mandrin,

tournez le manchon dans le sens

horaire. L’embout est fixé solidement

lorsque le mandrin fait un bruit de

cliquetis et que le manchon ne peut

plus pivoter.

3. Pour enlever l’embout, tournez le

manchon dans le sens antihoraire.

N.B. : Un bruit de cliquetis est normal lors

de l’ouverture ou de la fermeture du mandrin. Ce bruit fait partie de la fonction de

verrouillage et n’indique aucun problème

de fonctionnement du mandrin.

19

Page 20

Utilisation de l’embrayage (Fig. 4)

L’outil est muni d’un embrayage réglable

permettant d’enfoncer différents types de

vis dans plusieurs types de matériaux. Une

fois réglé correctement, l’embrayage

s’engage dans un couple préréglé afin

d’éviter d’enfoncer la vis trop profondément

et d’endommager la vis ou l’outil.

Pour régler l’embrayage, tournez le collier

sélecteur de couple à une des vingt position illustrées sur le collier. Le numéro doit

être aligné avec la flèche située sur le dessus

de l’outil.

Fig. 4

Collier

sélecteur

de couple

Numéros de position

Les spécifications de couples indiquées

ici sont approximatives et sont obtenues

avec un bloc de piles à pleine charge.

0614-20 &

Positions

1 à 5

6 à 10

11 à 15

16 à 20

Perceuse

Faible

Élevée

N.B. : Les réglages ci-dessus ne sont

qu’une approximation, vérifiez les positions

d’embrayage en utilisant un morceau de

rebut avant d’enfoncer des vis dans la

pièce à travailler.

0616-20

Couple

1,9 N•m

2,4 à

4,3 N•m

4,7 à

6,8 N•m

7,3 à

9,6 N•m

52 N•m

18 N•m

0613-20

Couple

0 à

0 à

1,9 N•m

2,4 à

4,3 N•m

4,7 à

6,8 N•m

7,3 à

9,6 N•m

40 N•m

14 N•m

0622-20 &

0624-20

Couple

0 à

1,9 N•m

2,4 à

4,3 N•m

4,7 à

6,8 N•m

7,3 à

9,6 N•m

56 N•m

20 N•m

Sélection de la vitesse (Fig. 5)

Le sélecteur de vitesse est situé à

l’extrémité du boîtier du moteur. Laissez

l’outil arrêter complètement avant de

changer la vitesse. Voir la section « Applications » pour connaître les vitesses

adaptées à différentes conditions.

Fig. 5

1. Pour obtenir une vitesse lente

(jusqu’à 500 tr/min), poussez le

sélecteur de vitesse vers l’avant.

2. Pour obtenir une vitesse rapide

(jusqu’à 1 700 tr/min), poussez le

sélecteur de vitesse vers l’arrière.

Sélection du marteau perforateur de

la perceuse (Pour le no de cat.

0613-20, 0614-20, et 0624-20 seulement)

Les marteaux perforateurs de

sont conçus pour fonctionner sur deux

mode différents : perçage avec martelage

et perçage seulement. Pour régler le mode

de fonctionnement, faites tourner le collier

sélecteur de coupe de perforation-perçage

en face du symbole voulu. Un symbole de

perceuse ou de perforateur sera aligné avec la

flèche pour indiquer le mode de fonctionnement.

1. Pour utiliser le mode perforation-

perçage, faites tourner le collier

sélecteur de coupe jusqu’à ce que le

symbole du perforateur soit aligné

ave la flèche. Appliquez une pression

sur le foret ou la mèche pour engager

le mécanisme de perforation.

2. Pour utiliser le mode perceuse

seulement, faites tourner le collier

sélecteur de coupe jusqu’à ce que le

symbole de perceuse soit aligné

ave la flèche.

N.B. : Lorsque vous utilisez des embouts

au carbone, n’utilisez pas d’eau pour

abattre la poussière. N’essayez pas de

percer des tiges de renforcement d’acier.

Ces deux pratiques endommagent les

embouts au carbone.

Faible

Élevée

MILWAUKEE

20

Page 21

Utilisation du commutateur (Fig. 6, 7,

et 8)

Le commutateur peut être réglé sur trois

positions: marche avant, marche arrière et

verrouillée. En raison d’un mécanisme de

verrouillage, le commutateur ne peut être

réglé que lorsque la commande MARCHE/

ARRÊT n’est pas enfoncée. Toujours

laisser le moteur s’arrêter complètement

avant d’utiliser le commutateur.

Pour une rotation en marche avant (dans

le sens horaire), pousser le commutateur

sur le côté droit de l’outil (Fig. 6). Vérifier la

direction de rotation avant utilisation.

Fig. 6

Pousser pour

la marche

avant

Pour une rotation en marche arrière

(dans le sens anti-horaire), pousser le

commutateur sur le côté gauche de l’outil

(Fig. 7). Vérifier la direction de rota-

tion avant utilisation.

Fig. 7

Pousser pour

la marche

arrière

Pour verrouiller la détente, pousser le

commutateur vers la position centrale

(Fig. 8). La détente ne fonctionne pas tant

que le commutateur est sur la position

verrouillée centrale. Toujours verrouiller la

détente ou déposer la batterie avant

d’effectuer un entretien, de changer

d’accessoire, de remiser l’outil et toutes

les fois que l’outil est inutilisé.

Fig. 8

Pousser

en position

centrale

pour

verrouiller

la détente

Démarrage, arrêt et contrôle de la

vitesse

1. Pour mettre l’outil en marche, appuyez

sur la gâchette.

2. Pour arrêter l’outil, relâchez la gâchette

et le frein électrique arrête l’outil

instantanément.

Tous les modèles sont équipés d’une

commande de vitesse variable. Pour faire

varier la vitesse, il s’agit simplement

d’augmenter ou de diminuer la pression sur

la gâchette. Plus la gâchette est enfoncée,

plus la vitesse est grande.

Perçage

Réglez le collier sélecteur de couple à la

position de perçage.

Placez l’extrémité du foret ou de la mèche

contre la surface de la pièce et appuyez

fermement avant de démarrer. Une

pression trop grande ralentit le foret et

diminue l’efficacité du perçage. Une

pression trop faible fait glisser le foret sur

la surface de la pièce et émèche la pointe

du foret.

Si l’outil commence à bloquer, réduisez

légèrement la vitesse pour permettre au

foret de reprendre de la vitesse. Si le foret

se bloque, inversez le sens de rotation du

moteur pour le libérer de la pièce.

21

Page 22

APPLICATIONS

AVERTISSEMENT!

Pour réduire le risque de

décharge électrique, vérifier avant

de percer ou de visser si l’aire de

travail n’est pas traversée par des

tuyaux dissimulés.

Perçage du bois, des matériaux

synthétiques et du plastique

Lorsque vous percez du bois, des

matériaux synthétiques et du plastique,

démarrez lentement la perceuse et

augmentez graduellement la vitesse à

mesure que vous percez. Lors du perçage

dans le bois, utilisez des mèches ou des

forets hélicoïdaux. Utilisez toujours des

forets ou des mèches bien affûtés.

Lorsque vous utilisez des forets

hélicoïdaux, retirez-les fréquemment du

trou pour enlever les copeaux des

goujures. Afin de réduire les risques

d’éclatement, appuyez la pièce sur un

morceau de bois de rebut. Sélectionnez

des vitesses lentes pour le perçage de

matières plastiques qui ont un point de fusion assez bas.

Perçage dans du métal

Lors du perçage dans du métal, utilisez

des forets hélicoïdaux à haute vitesse en

acier ou des scies-cloches. Utilisez un

centrage au pointeau dans le trou de

départ. Lubrifiez les forets avec de l’huile

de coupe lors du perçage dans le fer ou

l’acier. Utilisez un fluide de refroidissement

lors du perçage de métaux non-ferreux

comme le cuivre, le laiton ou l’aluminium. Calez

le matériau pour éviter un coincement ou une

distorsion lors du débouchage de la coupe.

Perçage de la maçonnerie

Lors du perçage dans la maçonnerie,

sélectionnez le mode marteau perforateur

(No de cat. 0613-20, 0614-20, et 0624-20

seulement). Utilisez des forets à haute

vitesse avec pointe au carbone. Les

matériaux de maçonnerie moins durs,

comme un bloc de cendre, exigent peu de

pression. Les matériaux durs, comme le

béton, exigent plus de pression. Un débit

régulier de poussière indique une bonne

vitesse de perçage. Ne laissez pas le foret

tourner dans le trou sans percer. N’utilisez

pas d’eau pour abattre la poussière ou

refroidir le foret. Ces deux pratiques

endommagent le carbone.

Enfonçage de vis et vissage d’écrou

Percez un trou pilote lorsque vous

enfoncez des vis dans des matériaux épais

ou durs. Réglez le collier sélecteur de

couple à la position correcte et à une

vitesse lente. Utilisez le bon type et la bonne

taille d’embout de tournevis pour le type de

vis utilisé.

Placez un foret pour tournevis dans la vis

et le bout de lavis sur la pièce à travaillez;

appuyez fermement avant d’appuyer sur

la gâchette. Vous pouvez enlever les vis

en inversant le sens de rotation du moteur.

Surcharge

Une surcharge continue peut endommager

l’outil ou le bloc de piles en permanence.

22

Page 23

AVERTISSEMENT!

Haute puissance rotatoire. Afin de

réduire les risques de blessures,

tenez toujours l’outil solidement

et étayez-le fermement. Servezvous toujours de la poignée

latérale lorsque.

Coincement de mèches

Une grande force rotatoire se dégage

lorsqu’une mèche reste coincée dans le

matériau. L’outil est alors projeté dans la direction opposée à la rotation de la mèche.

Les mèches peuvent rester coincées

lorsqu’elles sont mal alignées ou lorsqu’elles

passent au travers du matériau. Les mèches

à bois peuvent aussi rester coincées si elles

viennent en contact avec des clous ou des

noeuds. Prévenez les mouvements de recul

dûs au coincement de la mèche.

Pour minimiser los risques do coincement :

• Employez des mèches bien affûtées. Les

mèches bien affûtées sont moins sujettes

au coincement en cours de perçage.

• Utilisez une mèche appropriée à la

tâche. Il y a des mèches pour chaque

tâche spécifique.

• Soyez prudent lorsque vous percez

dans des matériaux résineux, noueux,

humides, ondulés ou parsemés de clous.

Méthodes d’etayage typiques

Fig. 9

Réaction

Étayage sur le plancher

Fig. 10

Rotation

avant

Étayage contre la jambe

Fig. 11

Rotation avant

Réaction

Réaction

Rotation inverse

23

Rotation avant

Étayage contre un montant

Page 24

MAINTENANCE

AVERTISSEMENT!

Pour minimiser les risques de

blessures corporelles, débranchez

le chargeur et retirez la batterie du

chargeur ou de l’outil avant d’y

effectuer des travaux d’entretien. Ne

démontez jamais l’outil, la batterie ou

le chargeur. Pour toute réparation,

consultez un centre de service

MILWAUKEE

Gardez l’outil, la batterie et le chargeur en

bon état en adoptant un programme

d’entretien ponctuel. Après une période de

six mois à un an, selon l’utilisation, renvoyez

l’outil, la batterie et le chargeur à un centre

de service

services suivants:

• Lubrification

• Inspection et nettoyage de la

mécanique (engrenages, pivots,

coussinets, boîtier etc.)

• Inspection électrique (batterie,

chargeur, moteur)

• Vérification du fonctionnement

électromécanique

Entretien de l’outil

Si l’outil ne démarre pas ou ne fonctionne

pas à pleine puissance alors qu’il est

branché sur une batterie complètement

chargée, nettoyez les points de contact

entre la batterie et l’outil. Si l’outil ne

fonctionne toujours pas correctement,

renvoyez l’outil, le chargeur et la batterie à

un centre de service

accrédité, afinqu’on en effectue la

réparation (voir “Réparations”).

Entretien de la batterie

Les batteries

pour durer plusieurs années et/ou des

milliers de cycles lorsqu’elles sont bien

entretenues et utilisées selon les instructions de ce manuel.

Une batterie qui est rangée durant six mois

perdra sa charge si elle n’est pas utilisée.

Les batteries se déchargent selon un taux

d’environ 1% par jour. Rechargez la

accrédité.

MILWAUKEE

MILWAUKEE

accrédité pour les

MILWAUKEE

sont conçues

batterie tous les six mois, même si elle n’est

pas utilisée, cela prolongera sa durée.

Nemaintenez pas la détente d’interrupteur

à la positon “ON” à l’aide d’un ruban adhésif

et ne laissez pas l’outil sans surveillance

car cela pourrait décharger la batterie0 à

un point tel qu’il deviendra impossible de la

recharger. Employez une batterie

MILWAUKEE

fournira la puissance requise.

Rangez la batterie dans un endroit frais et

sec. Ne la rangez pas dans un endroit où

la température pourrait excéder 120°F

(50°C),dans un véhicule ou une structure

d’acier, l’été par exemple. Les températures

élevées provoquent la surchauffe de la

batterie et en réduisent la durée. Si la

batterie est rangée pour une période de

plusieurs mois, elle perdra graduellement

sa charge. Cependant, après plusieurs

cycles de recharge et de décharge en

période d’utilisation normale, elle retrouvera

sa charge initiale. Avec le temps, les

intervalles entre les recharges de la batterie

deviendront de plus en plus courts.

Lorsque ces intervalles, devenus trop

courts, rendront l’outil inutilisable, il faudra

remplacer la batterie.

Nettoyage

Débarrassez les évents du chargeur et de

l’outil des débris et de la poussière. Gardez

les poignées de l’outil propres, à sec et

exemptes d’huile ou de graisse. Le nettoyage

de l’outil, du chargeur et de la batterie doit se

faire avec un linge humide et un savon doux.

Certains nettoyants tels l’essence, la

térébenthine, lesdiluants à laque ou à

peinture, les solvants chlorés, l’ammoniaque

et les détergents d’usage domestique qui en

contiennent pourraient détériorer le plastique

et l’isolation des pièces. Ne laissez jamais de

solvants inflammables ou combustibles

auprès de l’outil.

aussi longtemps qu’elle

AVERTISSEMENT!

Pour minimiser les risques de

blessures ou de dommages à

l'outil, n'immergez jamais l'outil, la

batterie ou le chargeur et ne laissez

pas de liquide s'y infiltrer.

24

Page 25

AVERTISSEMENT!

Pour minimiser les risques

d’explosion ne faites jamais brûler

une batterie, même si elle est avariée,

âgée ou complètement épuisée.

Sceaux de recyclage pour pile RBRC

Les sceaux de recyclage pour piles

RBRC™ (voir la « Pictographie ») sur la pile

de votre outil, indiquent que

a pris des dispositions avec Rechargeable

Battery Recycling Corporation (RBRC) pour

le recyclage de ce bloc de piles. Lorsque

la vie utile de ce bloc de pile est épuisée,

retournez-le à une succursale ou à un centre de service

détaillant participant le plus près de chez

vous. Pour obtenir plus d’informations,

visitez le site Web RBRC au www.rbrc.org.

Disposition des batteries au nickelcadmium

Les batteries au nickel-cadmium sont

recyclables. En vertu des différents

règlements provinciaux et locaux, il peut être

illégal de disposer d'une batterie par le service d'enfouissement des déchets. Disposez

de votre batterie en conformité de la

réglementation fédérale, provinciale et locale.

Réparations

Pour les réparations, retournez outil,

batterie et chargeur en entier au centreservice le plus près, selon la liste

apparaissant à la derniè page de ce manuel.

Garantie des batteries

Les batteries pour outils sans cordon

sont garanties pour un an à compter de

la date d’achat.

MILWAUKEE

MILWAUKEE

, ou au

GARANTIE LIMITÉE DE

L’OUTIL DE CINQ ANS

Tous les outils

avant de quitter l’usine et sont garantis

exempts de vice de matériau ou de fabrication.

remplacera (à la discrétion de

MILWAUKEE

compris les chargeurs de batterie) dont

l’examen démontre le caractère défectueux

du matériau ou de la fabrication dans les

cinq (5) ans suivant la date d’achat.

Retourner l’outil et une copie de la facture

ou de toute autre preuve d’achat à une

branche Entretien usine/Assistance des

ventes de l’établissement

à un centre d’entretien agréé par

MILWAUKEE

garantie ne couvre pas les dommages

causés par les réparations ou les tentatives

de réparation par quiconque autre que le

personnel agréé par

utilisations abusives, l’usure normale, les

carences d’entretien ou les accidents.

Les batteries, les lampes de poche et les

radios sont garanties pour un (1) an à partir

de la date d’achat.

LES SOLUTIONS DE RÉPARATION ET DE

REMPLACEMENT DÉCRITES PAR LES

PRÉSENTES SONT EXCLUSIVES.

MILWAUKEE

RESPONSABLE, EN AUCUNE

CIRCONSTANCE, DES DOMMAGES

ACCESSOIRES, SPÉCIAUX OU INDIRECTS,

Y COMPRIS LES MANQUES À GAGNER.

CETTE GARANTIE EST EXCLUSIVE ET

REMPLACE TOUTES LES AUTRES

GARANTIES OU CONDITIONS, ÉCRITES OU

ORALES, EXPRESSES OU TACITES DE

QUALITÉ MARCHANDE OU D’ADAPTATION

À UNE UTILISATION OU UNE FIN

PARTICULIÈRE.

Cette garantie vous donne des droits

particuliers. Vous pouvez aussi bénéficier

d’autres droits variant d’un état à un autre

et d’une province à une autre. Dans les

états qui n’autorisent pas les exclusions

de garantie tacite ou la limitation des

dommages accessoires ou indirects, les

limitations ou exclusions ci-dessus peuvent

ne pas s’appliquer. Cette garantie s’applique

aux États-Unis, au Canada et au Mexique

uniquement.

MILWAUKEE

MILWAUKEE

), sans frais, tout outil (y

sont testés

réparera ou

MILWAUKEE

, en port payé et assuré. Cette

MILWAUKEE

NE SAURAIT ÊTRE

ou

, les

25

Page 26

ACCESSOIRES

AVERTISSEMENT!

Il faut toujours retirer la batterie et verrouiller la détente de

l’outil avant de changer ou d’enlever les accessoires. L’emploi

d’accessoires autres que ceux qui sont expressément

recommandés pour cet outil peut comporter des risques.

Pour une liste complète des accessoires, prière de se reporter au catalogue

Electric Tool ou allez en ligne à www.mil-electric-tool.com. Pour obtenir un catalogue, il

suffit de contacter votre distributeur local ou l'un des centres-service énumérés sur la

page de couverture de ce manuel.

Mandrins sans clé de 1/2 po (13 mm)

No de cat. 48-66-1575

Boîtier en acier brut avec mors et corps plaqués au nickel et

résistants à la rouille.

Pour les perceuses sans fil avec filets de 1/2 po - 20

Trousse d’accessoires pour marteau perforateur

No de cat. 48-30-0101

Inclut un enfonce-douille de 1/4 po, un foret rainuré 6F-7R,

des forets Philips no 1 et no 2, des forets hélicoïdaux de 1/4 et

3/16 po et deux forets hélicoïdaux de 1/8 po.

Mallette en plastique

No de cat. 48-55-0930

Poignée latérale

No de cat. 49-15-0400

MILWAUKEE

26

Page 27

INSTRUCCIONES GENERALES DE SEGURIDAD

PARA LAS HERRAMIENTAS A BATERIAS

¡ADVERTENCIA!

LEA Y ENTIENDA TODAS LAS INSTRUCCIONES

El no seguir las instrucciones a continuación puede ocasionar

una descarga eléctrica, incendio y/o lesiones graves.

GUARDE ESTAS INSTRUCCIONES

AREA DE TRABAJO

1. Mantenga el área de trabajo limpia

e iluminada. Las mesas de trabajo

desordenadas y las áreas con poca

iluminación propician los accidentes.

2. No opere las herramientas con

motor en ambientes explosivos,

tales como los ambientes

con líquidos, gases o polvo

inflamables. Las herramientas con

motor producen chispas que pueden

inflamar el polvo o los gases.

3. Mantenga a las personas alejadas

mientras esté utilizando una

herramienta con motor. Las

distracciones pueden causar la

pérdida del control de la herramienta.

Proteja a las demás personas en el

área de trabajo contra escombros,

tales como astillas y chispas. Instale

barreras si se necesitan.

SEGURIDAD ELECTRICA

4. No utilice los cordones de manera

inadecuada. Nunca transporte la

herramienta por el cordón.

Mantenga el cordón alejado del

calor, aceite, bordes afilados

o partes en movimiento.

Sustituya los cordones dañados

inmediatemente. Los cordones

dañados pueden causar un incendio.

5. Una herramienta con baterías

incorporadas o con una batería

separada debe ser recargada

solamente con el cargador

específico para este tipo de

batería. Un cargador que es apropiado

para un tipo de batería puede producir

riesgo de incendio si se usa con otra

batería.

Use la herramienta a batería

6.

solamente con la batería

especificamente designada para

ella. El uso de cualquier otro tipo de

batería puede producir riesgo de

incendio.

SEGURIDAD PERSONAL

7. Ponga mucha atención, fíjese en

lo que hace y use su sentido

común al operar una herramienta

con motor. No use la herramienta

cuando esté cansado o bajo la

influencia del alcohol, drogas o

medicamentos. Descuidarse por

sólo un momento cuando se esté

utilizando la herramienta, puede

resultar en lesiones graves.

8. Vístase apropiadamente. No lleve

ropa o joyas sueltas. Mantenga el

pelo largo recogido. Mantenga el

cabello, la ropa y los guantes

alejados de las partes en

movibles. Las ropas sueltas, las

joyas, o el cabello largo pueden

engancharse en las partes movibles.

9. Evite el encendido accidental de

la herramienta. Asegúrese que el

gatillo esté bloqueado o apagado

antes de insertar la batería. Llevar

la herramienta con el dedo sobre el

gatillo o insertar la batería en una

herramienta con el gatillo encendido,

aumenta el riesgo de accidentes.

10. Saque las llaves antes de

encender la herramienta. Una llave

sujeta a una parte en movimiento puede

causar lesiones.

27

Page 28

11. No se aleje demasiado del mate-

rial de trabajo. Siempre mantenga

el equilibrio. El equilibrio correcto

permite el mejor control de la

herramienta durante situaciones

inesperadas.

12. Utilice el equipo de seguridad.

Siempre utilice la protección para

los ojos. Se debe usar una máscara

contra el polvo, zapatos de seguridad

antidelizantes, casco y protector para

los oidos, cuando las condiciones así

lo requieran.

USO Y MANTENIMIENTO DE

LA HERRAMIENTA

13. Utilice abrazaderas u otra manera

práctica para sujetar y apoyar el

material en una plataforma

estable. Tener el material en la mano

o contra el cuerpo es inestable y puede

causar la pérdida del control.

14. No fuerce la herramienta. Utilice

la herramienta apropiada para la

aplicación. La herramienta realizará

el trabajo de manera más eficaz y

segura, si la opera a la velocidad

apropiada.

15. Si el gatillo no enciende o apaga

la herramienta, no utilice la

herramienta. Una herramienta que

no se puede controlar con el gatillo es

peligrosa y debe ser reparada.

16. Desconecte la batería de la

herramienta o coloque el gatillo

en la posición de bloqueo o

apagado antes de realizar un

ajuste, cambiar accesorios o

almacenar la herramienta. Tales

medidas preventivas de seguridad

reducen el riesgo de encender la

herramienta accidentalmente.

17. Almacene las herramientas que

no se estén usando fuera del

alcance de los niños y de personas que no estén capacitadas. Es

peligroso permitir a los usuarios utilizar

las herramientas, si no están

capacitados previamente.

18. Cuando la herramienta no esté en

uso, manténgala alejada de otros

objetos metálicos tales como

clips, moneda, llaves, clavos, tor-

nillos u otro objetos pequeños

metálicos que pueden realizar

una conexión desde un terminal

a otro. Hacer un cortocircuito de los

terminales de la batería, puede producir

chispas, quemaduras o un incendio.

19. Mantenga las herramientas en

buenas condiciones. Las

herramientas cortadoras deben

mantenerse afiladas y limpias. Esto

reduce el riesgo de que la herramienta

se atasque y facilita el control de la

misma.

20. Verique que las partes en

movimiento estén alineadas y no

estén atascadas. También debe

verificarse que las partes no

estén rotas o tengan cualquier

otra condición que pueda afectar

el funcionamiento de la

herramienta. Si está dañada, se

debe reparar la herramienta antes de utilizarla. Muchos accidentes

se deben al mantenimiento incorrecto

de la herramienta. No utilice una

herramienta dañada. Colóquele una

etiqueta que diga “No Debe Usarse”

hasta que sea reparada.

21. Utilice solamente los accesorios

recomendados por el fabricante

para ese modelo. Los accesorios

que son apropiados para una

herramienta pueden aumentar el riesgo

de lesiones cuando se usan con otra

herramienta.

SERVICIO

22. El servicio de mantenimiento

debe ser realizado solamente por

personal técnico debidamente

capacitado. El servicio o

mantenimiento realizado por personal

no calificado puede aumentar el riesgo

de lesiones.

23. Cuando realice el servicio de

mantenimiento, utilice solamente

repuestos idénticos. Siga las

instrucciones en la sección de

mantenimiento de este manual.

El uso de partes no autorizadas o el

incumplimiento de las instrucciones de

mantenimiento puede aumentar el

riesgo de descarga eléctrica o

lesiones.

28

Page 29

REGLAS ESPECIFICAS DE SEGURIDAD

1. Guarde las etiquetas y placas de especificaciones. Estas tienen información

importante. Si son ilegibles o si no se pueden encontrar, póngase en contacto con un

centro de servicio de

2. ¡ADVERTENCIA! Algunas partículas de polvo resultantes del lijado mecánico, aserrado,

esmerilado, taladrado y otras actividades relacionadas a la construcción, contienen

sustancias químicas que se saben ocasionan cáncer, defectos congénitos u otros

daños al aparato reproductivo. A continuación se citan algunos ejemplos de tales

sustancias químicas:

• plomo proveniente de pinturas con base de plomo

• sílice cristalino proveniente de ladrillos, cemento y otros productos de albañilería y

• arsénico y cromo provenientes de madera químicamente tratada.

El riesgo que usted sufre debido a la exposición varía dependiendo de la frecuencia

con la que usted realiza estas tareas. Para reducir la exposición a estas sustancias

químicas: trabaje en un área bien ventilada, y utilice equipo de seguridad aprobado

como, por ejemplo, máscaras contra el polvo que hayan sido específicamente

diseñadas para filtrar partículas microscópicas.

3. Tome la herramienta por la superficie de agarre con aislado, mientras

realice una operación en que la herramienta cortadora pueda tener contacto

con alambres escondidos. El contacto de una herramienta con un alambre

electrificado conectará las partes metálicas expuestas de la herramienta y dará una

descarga al usuario.

4. Mantenga las manos alejadas de todos los bordes cortadores y partes en

movimiento.

5. Al emplear la herramienta durante períodos prolongados utilice protectores

para los oídos. La exposición prolongada al ruido de alta intensidad puede causar

sordera.

MILWAUKEE

para una refacción gratis.

Simbología

Baterías de niquel

cadmio correctamente

recicladas

Volts corriente

directa

Underwriters

Laboratories, Inc.

Revoluciones por

minuto sin carga (RPM)

Cat. No.

0613-20

0614-20

0616-20

0622-20

0624-20

29

Especificaciones

Volts cd

14,4

14,4

14,4

18

18

rpm

Baja 0-500

Alta 0-1700

Baja 0-500

Alta 0-1700

Baja 0-500

Alta 0-1700

Baja 0-500

Alta 0-1700

Baja 0-500

Alta 0-1700

Impactos

Per Minute

Baja 0-7500

Alta 0-25500

Baja 0-7500

Alta 0-25500

N/A

N/A

Baja 0-7500

Alta 0-25500

Page 30

DESCRIPCION FUNCIONAL

7

6

1. Interruptor de selección de velocidad

2. Seguro de la batería

3. Batería

4. Gatillo

5. Interruptor de control

6. Mandril sin chaveta

7. Mango Lateral

8. Collar del selector de par torsor

3

8

1

5

4

2

0613-20

0614-20

0616-20

0622-20

0624-20

Acero

13 mm (1/2")

13 mm (1/2")

13 mm (1/2")

13 mm (1/2")

13 mm (1/2")

Broca Plana

48 mm (1-1/2")

48 mm (1-1/2")

48 mm (1-1/2")

48 mm (1-1/2")

48 mm (1-1/2")

Capacidades

Madera

Broca de

Berbiquí

29 mm (1-1/8")

29 mm (1-1/8")

29 mm (1-1/8")

29 mm (1-1/8")

29 mm (1-1/8")

Broca Hueca

30

Cilíndrica

de Bordes

54 mm (2-1/8")

54 mm (2-1/8")

54 mm (2-1/8")

54 mm (2-1/8")

54 mm (2-1/8")

Tornillos

(diam.)

6 mm (1/4")

6 mm (1/4")

6 mm (1/4")

6 mm (1/4")

6 mm (1/4")

Concreto

9,5 mm (3/8")

9,5 mm (3/8")

N/A

N/A

9,5 mm (3/8")

Page 31

USO Y CARGA DE LA BATERIA

¡ADVERTENCIA!

Cargue solamente las baterías

MILWAUKEE

en cargadores. Otros tipos de

baterías pueden explotar y causar

lesiones personales y daños.

Cargue su batería antes de usar su

herramienta po primera vez o cuando la

misma no opera ya con el poder y torque

necesario para la aplicación. Nunca

permita que la batería se descargue por

completo. El tiempo estándar de cargado

variará dependiendo del voltaje en el

tomacorriente y de la carga que necesita

la batería. Por ejemplo, si su batería no

requiere una carga completa, el tiempo

para cargarla será menor.

Las baterías pueden ser afectadas por la

temperatura. Su batería se desempeñará

mejor y tendrá una vida mas larga si se le

carga donde la temperatura sea entre 15°27°C (60-80°F). No cargue cuando la

temperatura está por debajo de 5°C (40°F)

o por encima de 40°C (105°F). Si lo hace

en estas condiciones, reducirá la

capacidad. Vea “Mantenimiento”.

de 12 V, 14,4 V y 18 V

Cómo insertar la batería en la

herramienta (Fig. 1 y 2)

La batería se puede insertar en la

herramienta de dos maneras.

Fig. 1

1. Cuando se trabaja en espacios

limitados.

Inserte la batería desde la parte frontal deslizándola en el cuerpo de la

herramienta. Inserte la batería hasta

que los seguros de la misma queden

trabados.

Fig. 2