Page 1

PAGE 1 OF 2

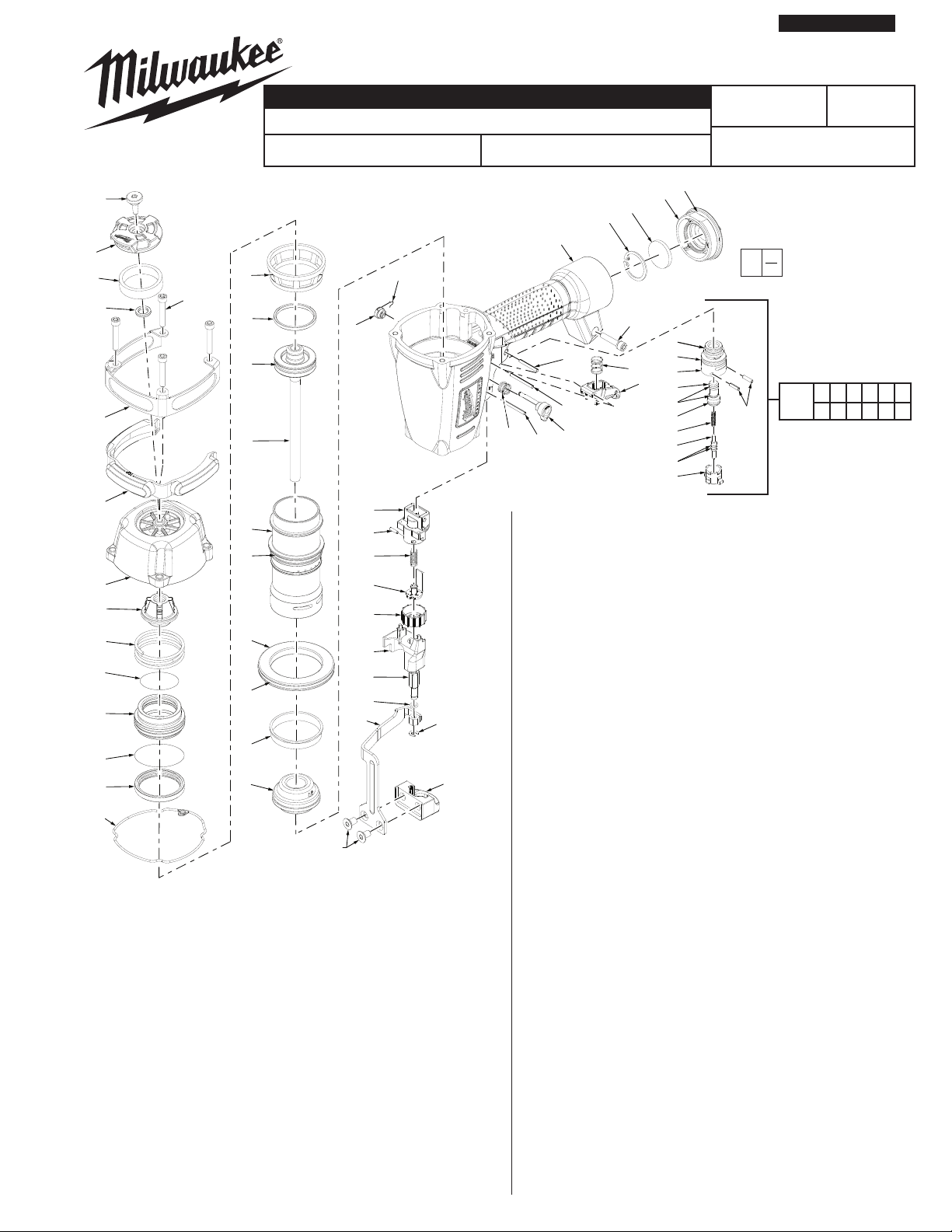

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

93

92

91

90

82

83

84

85

86

87

88

89

26

27

28

29

30

31

32

33

34

35

36

43

37

42

37

39

40

38

106

44

41

45

46

47

48

49

SERVICE PARTS LIST

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS

COIL ROOFING NAILER

CATALOG NO. 7120-21

STARTING

SERIAL NUMBER

A87A

BULLETIN NO.

54-43-0030

REVISED BULLETIN

WIRING INSTRUCTION

0

EXAMPLE:

0

Component Parts

0

(Small #) Are Included

When Ordering The

Assembly (Large #).

111

DATE

Mar. 2006

26 27 28 29 30 31

32 33 34 35 36 44

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

22 45-36-1655 Cylinder Spacer 1

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

1 05-84-0805 Deflector Bolt 1

2 31-05-0400 Deflector 1

3 43-31-0355 Muffler 1

4 45-88-1720 Deflector Pad 1

5 05-84-0925 Socket Hex Head Screw 5

6 44-66-1355 Wear Plate 1

7 42-38-0370 Wear Pad 1

8 42-92-1425 Top Cap 1

9 45-06-0945 Seal 1

10 40-50-3120 Upper Valve Spring 1

11 34-40-3195 O-Ring 1

12 44-62-0265 Head Valve Piston 1

13 34-40-3245 O-Ring 1

14 42-76-0815 Valve Collar 1

15 45-06-0915 Seal 1

16 44-90-0700 Press Ring 1

17 44-90-0730 Piston Ring 1

18 34-40-3180 O-Ring 1

19 43-12-0255 Driver Assembly 1

20 42-98-0355 Cylinder 1

21 34-40-3135 O-Ring 1

23 34-40-3200 O-Ring 1

24 44-90-0805 Cylinder Ring 1

25 42-38-0315 Bumper 1

26 34-40-3295 O-Ring 1

27 34-40-3300 O-Ring 1

28 42-52-0410 Plunger Cap 1

29 44-70-0250 Valve Plunger 1

30 34-40-3285 O-Ring 2

31 34-40-3280 O-Ring 1

32 40-50-3195 Spring 1

33 44-70-0255 Trigger Valve Plunger 1

34 34-40-3290 O-Ring 2

35 43-64-0150 Trigger Valve Head 1

36 06-65-1465 Spring Pin 2

37 06-65-1440 Spring Pin 2

38 06-65-1425 Spring Pin 1

39 31-92-0200 Trigger Assembly 1

40 40-50-3160 Spring 1

41 44-86-0710 Retainer 1

42 44-10-0650 Selector 1

43 40-50-3095 Selector Spring 1

44 44-90-0825 Ring 1

45 28-50-0805 Tool Body 1

46 44-90-0750 Retaining Ring 1

47 43-31-0370 Filter 1

48 42-92-1355 End Cap 1

49 34-40-3250 O-Ring 1

50 30-61-0200 Nose Piece 1

51 34-40-3165 O-Ring 1

52 34-40-3265 O-Ring 2

53 44-55-0250 Feed Finger 1

54 05-84-0915 Bolt Assembly 4

55 44-62-0260 Feed Piston 1

56 44-60-1905 Feed Piston Pin 1

82 43-56-0865 Work Contact Element Guide 1

83 06-65-1405 Spring Pin 1

84 40-50-3050 Adjustment Spring 1

85 42-36-1970 Contact Bracket B 1

86 43-98-0755 Depth Adjustment Knob 1

87 42-92-1500 Work Contact Element Cover 1

88 44-94-0580 Adjustment Rod Assembly 1

89 34-40-3170 O-Ring 1

90 42-36-1985 Contact Element Bracket 1

91 44-90-0770 E-Ring 1

92 42-36-1960 Contact Element Bracket A 1

93 05-85-0050 Flat Head Hex Bolt 2

MILWAUKEE ELECTRIC TOOL CORPORATION

13135 W. Lisbon Road, Brookfield, WI 53005

Drwg.2

Page 2

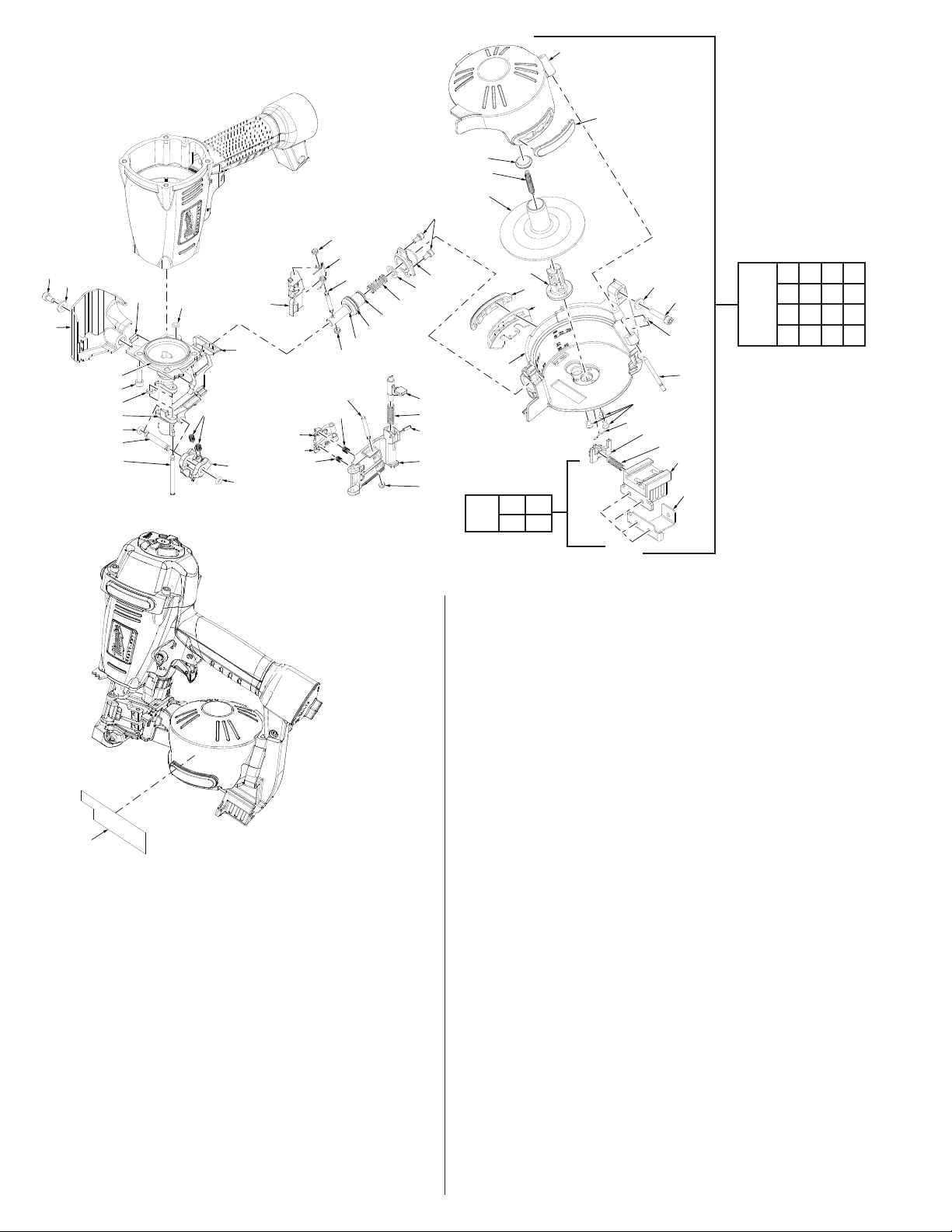

94 95 96 97

115

52

54

58

50

77

76

74

80

79

78

69

68

65

66

67

72

71

73

70

58

68

75

77

100

103

107

108

109

110

102

106

79

94

81

51

50

58

59

60

55

61

62

63

101

105

104

99

53

58

57

56

64

96

97

98

95

104

98 99 100 101

112

102 103 104 105

107 108 109 110

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

57 40-50-3005 Feed Finger Spring 1

58 44-86-0705 Retainer Ring 1

59 34-40-3235 O-Ring 1

60 34-40-3205 O-Ring 1

61 40-50-3085 Feed Piston Spring 1

62 42-38-0345 Feed Bumper 1

63 42-92-1415 Feed Piston Cap 1

64 05-84-0820 Bolt Assembly 2

65 44-55-0260 First Stopper Finger 1

66 44-55-0255 Second Stopper Finger 1

67 40-50-3010 Spring 1

68 40-50-3080 Stopper Finger Spring 1

69 44-60-1895 Nail Stop Pin 1

70 42-92-1410 Door 1

71 40-50-3015 Latch Spring 1

72 44-20-0860 Door Latch 1

73 06-65-1415 Spring Pin 1

74 44-50-0205 Door Shaft Pin 1

75 43-56-0890 Guide Block 1

76 44-60-1860 Fixed Pin 1

77 34-40-3190 O-Ring 2

107 108

113

109 110

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

78 42-92-1480 Work Contact Element Cover 1

79 45-88-1760 Flat Washer 1

80 05-84-0895 Bolt, M5 x 0.8-08 1

81 44-26-0100 Magnet 1

94 44-60-1885 Pin 2

95 42-38-0355 Magazine Cover 1

96 43-78-0165 Spring Base A 1

97 40-50-3040 Pull Spring 1

98 45-36-1660 Spacer 1

99 44-55-0265 Nail Tray Adjustor 1

100 05-78-0815 Tap Bolt 3

101 42-98-0375 Magazine Base 1

102 34-40-3130 O-Ring 1

103 44-86-0715 Spring Retainer 1

104 42-38-0365 Magazine Wear Pad B 2

105 42-98-0380 Magazine Wear Pad A 1

106 05-84-0845 Bolt Assembly 1

107 44-66-1335 Positional Plate 1

108 40-50-3055 Work Contact Element Spring 1

109 44-66-1330 Adjusting Plate A 1

110 44-66-1325 Adjusting Plate B 1

111 31-94-0110 Trigger Valve Assembly 1

112 45-24-0020 Magazine Coil Assembly 1

113 43-56-0565 Shingle Guide Assembly 1

115 12-98-0310 Service Nameplate/Warning Label 1

14-70-0140 Overhaul Kit (Not Shown) 1

14-70-0160 Driver Maintenance Kit (Not Shown) 1

Page 3

BULLETIN NO. 54-43-0030 Mar. 2006

Disassembly:

1, 2, 3, 4, 8 Remove bolt (1) from top cap (8) using a 4 mm hex key and remove assembly (2, 3, 4)

5, 8 Remove four screws (5) from top cap (8) using a 4 mm hex key.

PAGE 2 OF 2

8, 9, 10, 11, 12,

13, 14

16, 17, 18, 19, 20,

21, 22, 23, 24,

25, 45

20, 22, 23, 24 Remove cylinder ring (24) from cylinder (20) prior to removing cylinder spacer assembly (22, 23).

45,50,79, 106,112 Remove screw (106) and washer (79) from tool body (45) to lift magazine coil assembly (112) o nose piece (50).

37, 38, 39, 40, 41,

42, 43, 44, 45, 111

Reassembly:

50, 63, 64 Apply Blue Loctite®, 242, onto threads of screws (64) prior to installing feed piston cap (63) onto nose assembly (50).

50, 78, 80 Apply Blue Loctite® onto threads of screw (80) prior to installing work contact element cover (78) onto nose assembly (50).

90, 92, 93 Apply Red Loctite® onto threads of screws (93) when securing contact element bracket (90) to contact element bracket A

37, 38, 45, 111 Reinstall trigger valve assembly (111) into tool body (45) by aligning the grooves in the valve assembly with the two holes for

Using a 1/8 in. punch, gently push valve assembly (9, 10, 11, 12, 13, and 14) out of top cap (8) through the holes in the cover.

Remove press ring (16) from top of cylinder (20), turn tool body (45) over and tap outside edge of tool body against a piece of

wood to separate assembly (17-25) from tool body.

Remove trigger valve assembly (111) from tool body (45) by placing a 3/32 in. (2.5mm) punch inside half-moon slot of retainer

(41) and gently tapping shaft of selector (42). Remove spring (43), retainer (41), and ring (44). Remove trigger and spring (39,40)

from tool body and push pins (37, 38) out of tool body (45) just far enough to remove valve assembly. Note: Once pins (37, 38)

have been moved, trigger valve assembly (111) can be gently pushed out of the tool body from the inside handle area of the

tool body using a at blade screwdriver.

Note: Use service xture #61-60-0005 to move spring pins (42, 43), or use a 1/8" punch.

(92).

spring pins (37, 38). Drive spring pins into tool body until they are ush with the casting surface.

Use service xture #61-60-0005 to reinstall pins (37, 38).

39, 40, 41, 42, 43,

44, 45

20, 21, 22, 23 Install o-ring (21) onto cylinder (20) prior to installing cylinder spacer assembly (22, 23).

20, 22, 23, 24 Install cylinder ring (24) onto cylinder (20) only after cylinder ring assembly (22, 23) have been installed.

17, 18, 19, 20, 21,

22, 23, 24, 25,

45, 50

8, 16, 20 Install press ring (16) onto top of cylinder (20) with wide edge facing toward top cap (8).

2, 6, 7 Install bumper band pad (7) into bumper band (6) with the word ‘TOP’ facing toward deector (2).

47, 48 Install smooth side of lter (47) toward end cap (48).

1, 8 Apply Blue Loctite® onto threads of screw (1) if removed from top cap (8).

Reinstall selection lever assembly (41, 42, 43, 44,) and trigger assembly (39, 40) by doing the following.

• Place spring (43) onto shaft of selection lever (42)

• Position spring (40) and trigger (39) over plunger of trigger valve assembly (111)

• Insert selection lever assembly (42, 43) into tool body (45) and align half-moon slot of retainer (41) with half-moon

shaft of selection lever (42) and snap retainer assembly (41, 44) onto the shaft

Note: Large anged end of cylinder ring (24) must facing the top of cylinder (20) when installed.

Install preassembled driver assembly (17, 18, and 19) into preassembled cylinder assembly (20, 21, 22, 23, 24, and 25) and

install assembled components into tool body (45). Note: Orientation of driver assembly (19) must match orientation in nose

assembly (50).

Page 4

Lubrication:

Type I Grease 49-08-7100

Clean all parts with a dry clean cloth.

8, 9, 10, 11, 12,

13, 14,

18, 17, 19 Coat o-ring (18) and piston ring (17) prior to installing into groove of driver assembly (19).

20, 21, 22, 23, 24 Coat cylinder o-ring (21), cylinder spacer (22), o-ring (23) and cylinder ring (24) prior to installing onto cylinder (20).

26, 27 28, 29, 30,

31, 32, 33, 34,

35, 36

50, 55, 56, 57, 59,

60, 61, 62

Place a thin coating of grease into internal bore of top cap (8), coat parts (9-14) and reassemble in order shown.

Coat all parts of the trigger valve assembly if being replaced individually. Components cleaned in any type of solvent or

water solution will require new lubrication. Note: A new trigger valve assembly will be pre-lubricated and will not require any

additional lubrication.

Place a thin coating of grease into pocket of feed piston located on nose (50). Once pocket area has been coated, coat

additional components (55, 56, 57, 59, 60, 61, and 62).

Loading...

Loading...