Milwaukee Tool 9687-20 User Manual [en, es, fr]

OPERATOR’S MANUAL

HAND OPERATED

LEVER HOIST

Catalog No. Rated Load

9682-20 3/4 Ton

9683-20 (750 Kg)

9684-20

9685-20 1½ Ton

9686-20 (1500 Kg)

9687-20

9688-20

9689-20 3 Ton

9690-20 (3000 Kg)

9691-20

Do not use hoist to lift, support or otherwise transport

people.

To reduce the risk of injury, do not alter or modify the

hoist and only use MILWAUKEE replacement parts.

Alterations or modification of hoist and use of non

MILWAUKEE parts can lead to dangerous operation

and injury.

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATORS

MANUAL.

07/12

SAFETY PRECAUTIONS

Each MILWAUKEE Lever Operated Chain Hoist is built in

accordance with the specifications contained herein and at

he time of manufacture complies with our interpretation of

t

applicable sections of *American Society of Mechanical

Engineers Code (ASME) B30.21 and the *American National

Standards Institute ANSI/ASME HST-3M.

*Copies of this Standard can be obtained from ASME Order

Department, 22 Law Drive, Box 2300, Fairfield, NJ 070072300, U.S.A.

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result in

death or serious injury. To avoid such a potentially

hazardous situation, THE OPERATOR SHALL:

1. NOT operate a malfunctioning or unusually performing

hoist.

2. NOT operate the hoist until you have thoroughly read

and understood this manual.

3. NOT operate a hoist which has been modified without

the manufacturer’s approval or certification to be in

conformity with applicable OSHA regulations.

4. NOT lift or pull more than rated load for the hoist.

5. NOT use damaged hoist or hoist that is Not working

properly.

6. NOT use hoist with twisted, kinked, damaged, or worn

load chain.

7. NOT operate with any lever extension (cheater bar).

8. NOT attempt to “free chain” the hoist while a load is

applied.

9. NOT use the hoist to lift, support, or transport people.

10. NOT lift loads over people and make sure all personnel

remain clear of supported load.

11. NOT attempt to lengthen the load chain or repair dam-

aged load chain.

12. Protect the hoists load chain from weld splatter or other

damaging contaminants.

13. NOT operate a hoist when it is restricted from forming a

straight line from hook to hook in the direction of loading.

14. NOT use load chain as a sling or wrap load chain around

load.

15. NOT apply the load to the tip of the hook or to the

hook latch.

16. NOT apply load unless load chain is properly seated in

the chain wheel(s) or sprocket(s).

17. NOT apply load if bearing prevents equal loading on all

load supporting chains.

18. NOT operate beyond the limits of the load chain travel.

19. NOT leave load supported by the hoist unattended

unless specific precautions have been taken.

20. NOT allow the chain or hook to be used as an electrical

or welding ground.

21. NOT allow the chain or hook to be touched by a live

welding electrode.

22. NOT remove or obscure the warnings on the hoist.

23. NOT operate a hoist which has Not been securely

attached to a suitable support.

24. NOT operate a hoist unless load slings or other approved

single attachments are properly sized and seated in the

hook saddle.

25. NOT lift loads that are Not balanced and the holding action

s Not secure, taking up slack carefully.

i

26. NOT operate a hoist unless all persons are and remain

clear of the supported load.

27. Report malfunctions or unusual performances of a hoist,

after it has been shut down until repaired.

28. NOT operate a hoist on which the safety placards or

decals are missing or illegible.

29. Be familiar with operating controls, procedures and

warnings.

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result in

minor or moderate injury. To avoid such a potentially

hazardous situation, THE OPERATOR SHALL:

1. Maintain a firm footing or be otherwise secured when

operating the hoist.

2. Check brake function by tensioning the hoist prior to

each lift or pulling operation.

3. Use hook latches. Latches are to retain slings, chains, etc.

under slack conditions only.

4. Make sure the hook latches are closed and not supporting

any parts of the load.

5. Make sure the load is free to move and will clear all

obstructions.

6. Avoid swinging the load or hook.

7. Avoid lever “fly-back” by keeping a firm grip on the lever

until operating stroke is completed and lever is at rest.

8. Inspect the hoist regularly, replace damaged or worn

parts, and keep appropriate records of maintenance.

9. Use MILWAUKEE parts when repairing the unit.

10. Lubricate load chain as recommended in this manual.

11. NOT operate except with manual power.

12. NOT permit more than one operator to pull on lever at

the same time. More than one operator is likely to cause

hoist overload.

13. NOT allow your attention to be diverted from operating

the hoist.

14. NOT allow the hoist to be subjected to sharp contact with

other hoists, structures, or objects through misuse.

15. NOT adjust or repair the hoist unless qualified to perform

such adjustments or repairs.

he hoists are intended for general industrial use for

T

moving loads within their load ratings. Prior to

installation and operation, the user should review the

application for abnormal environmental or handling

conditions.

2

SPECIFIC SAFETY RULES - LEVER HOIST

Each MILWAUKEE hand operated lever hoist is built in accordance with the specifications contained herein and at the time of

manufacturer complies with our interpretation of applicable sections of the American Society of Mechanical Engineers (ASME)

Code B30.21 “Manually Lever Operated Hoists” and the Occupation Safety and Health Act (OSHA). Copies of this standard

can be obtained from ASME Order Department, 22 Law Drive, PO Box 2300, Fairfield, NJ 07007-2300, USA.

The safety laws for elevators and for dumbwaiters may specify construction details that are not necessarily incorporated in this

hoist. We recommend the use of equipment that meets state and national safety codes. Milwaukee Electric Tool Corporation

cannot be responsible for applications other than those for which MILWAUKEE equipment is recommended.

. Read ASME B30.21 safety standard for “Manually Lever Operated Hoists” and this manual thoroughly.

1

2. Do not permit more than one operator to operate lever hoist at one time.

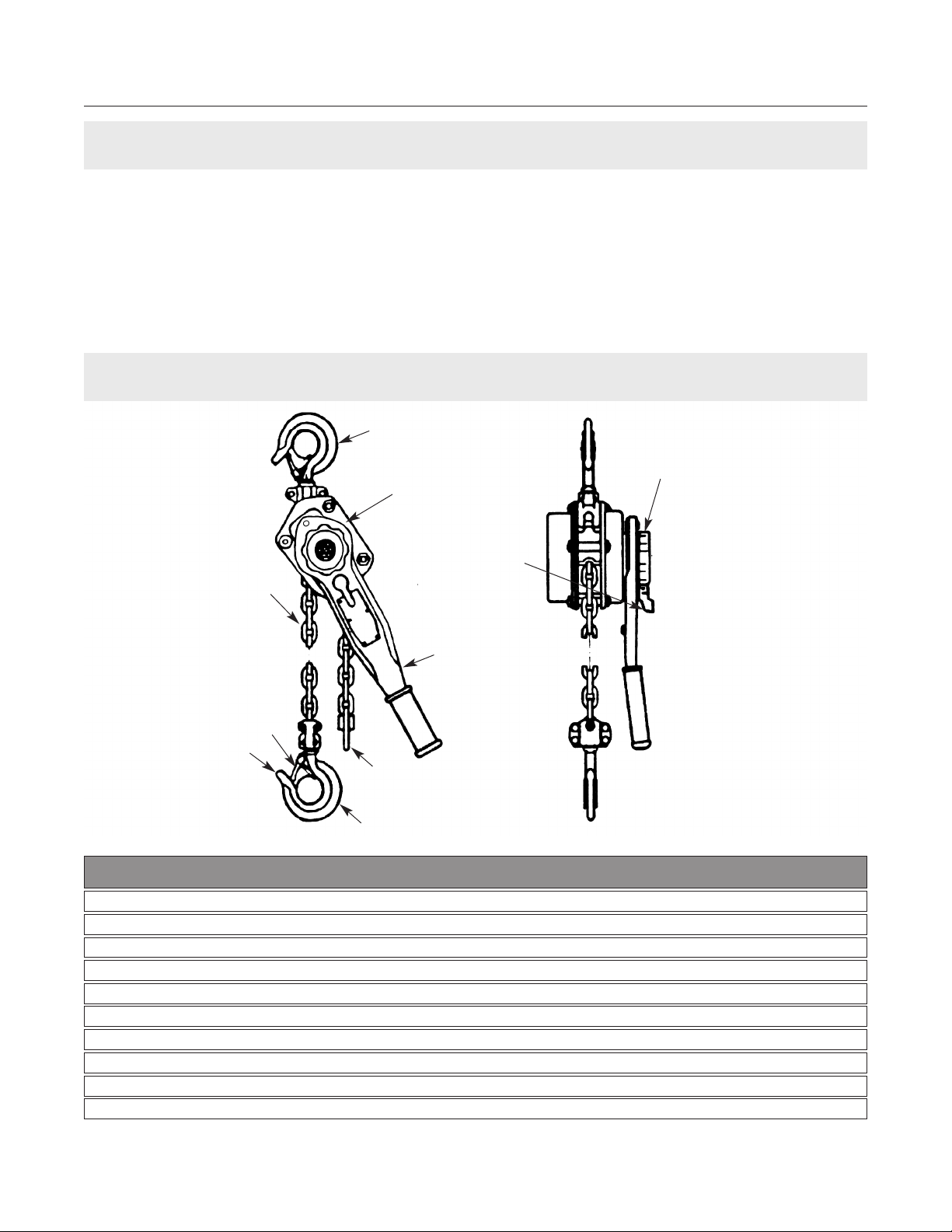

FUNCTIONAL DESCRIPTION

1

3

2

5

4

6

10

9

7

1. Upper Hook

2. Hoist Frame

3. Free Chaining Knob

4. Load Chain

5. Directional Lever

6. Lever

7. End Ring

8. Lower Hook

9. Hook Tip

10. Hook Latch

Table 1 - Specifications

Cata log Capa city Lift

Numb er Tons (Kg) Ft (M)

9682-20 3/4 (750) 5 (1.5)

9683-20 3/4 (750) 10 (3.0)

9684-20 3/4 (750) 20 (6.1)

9685-20 1½ (1,500) 5 (1.5)

9686-20 1½ (1,500) 10 (3.0)

9687-20 1½ (1,500) 20 (6.1)

9688-20 1½ (1,500) 25 (7.6)

9689-20 3 (3,000) 5 (1.5)

9690-20 3 (3,000) 10 (3.0)

9691-20 3 (3,000) 20 (6.1)

8

3

OPERATION

To reduce the risk of injury, carefully check unit for

external damage prior to installation. Do not operate a

damaged or malfunctioning hoist. Do not operate a

hoist with a twisted, kinked, damaged or worn chain.

Operating a unit with obvious external damage may

cause load to drop resulting in personal injury and/or

property damage.

OPERATING INSTRUCTIONS

Before using the MILWAUKEE Lever Hoist, familiarize yourself

with all components of this hoist (See Functional Description).

Always check the hoist for proper operation before use. Under

no circumstances should you operate a malfunctioning hoist.

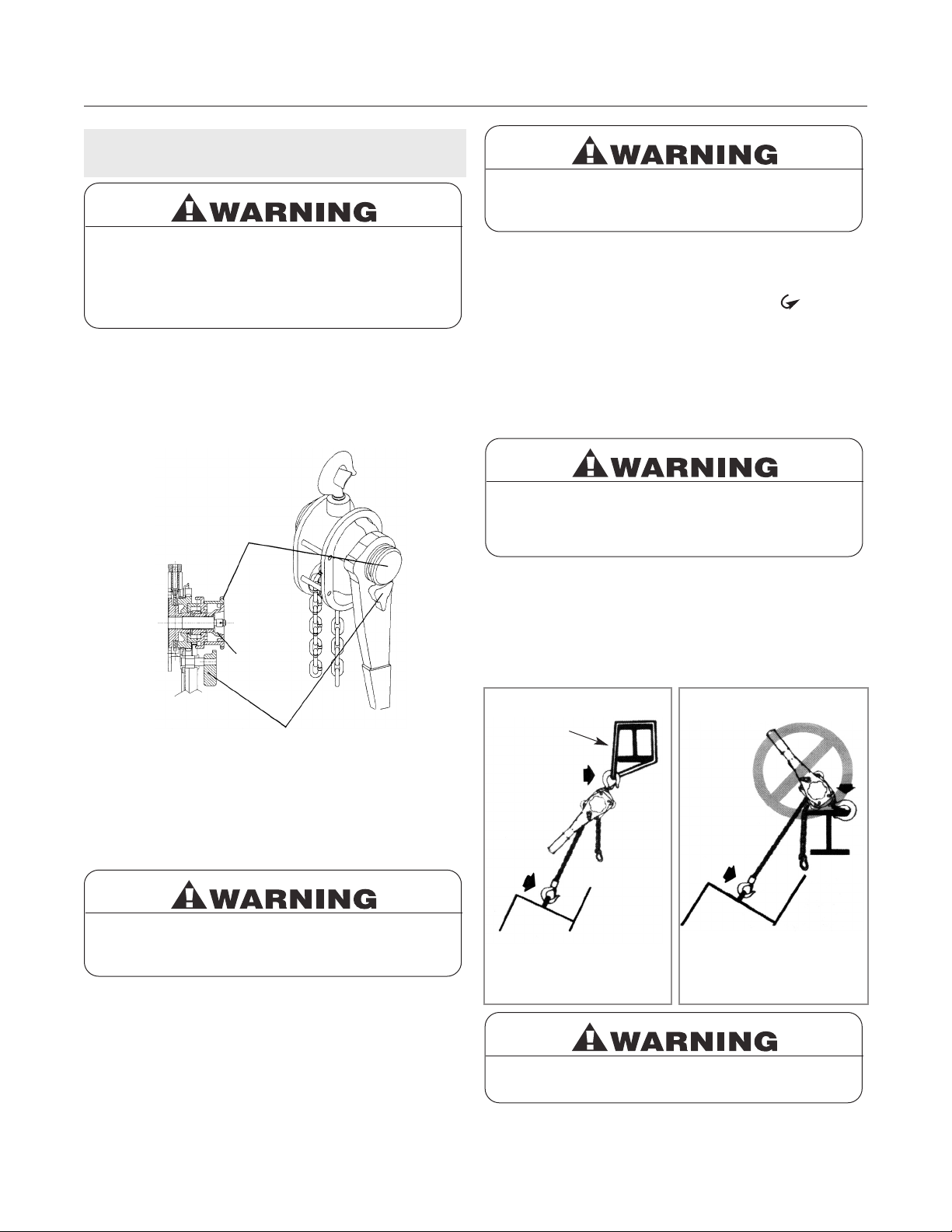

Figure 1

Free

Chaining

Knob

Cam

Guide

To reduce the risk of injury, never pull out or turn the

free chaining knob when the hoist is under load. Pulling

out or turning the free chaining knob with a load

attached will allow the load to release.

To set the hoist to free chaining mode

1. Remove any load from the hoist and move the directions

lever to the (“N”) position.

. Turn the free chaining knob counterclockwise ( ) to

2

disengage the brake and pull on either chain until the lower

hook is at the desired position.

To reset the hoist for load operation

1. To Disengage the free chaining feature, move the directional

lever to the load () or unload position (). Pull the load

chain in either direction to insure the unit is out of the free

chaining mode.

To reduce the risk of injury, rig the hoist in a straight

line hook to hook and keep the frame free to swivel.

If the frame is not free to swivel, the lever pull may

break the frame and cause physical injury and/or loss

of the load.

OPERATING THE LEVER HOIST

The MILWAUKEE Lever Hoist can be used in any position

provided it is rigged to pull in a straight line from hook to hook

(See Figure 2). The frame must always be free to swivel on the

upper hook.

Figure 2

CORRECT

INCORRECT

Directional Lever

Test the operation of the hoist before operating at rated

capacity.

Operate the hoist with no load and then with a light load of

approximately 100 pounds (46Kg) to make sure it operates

properly and that the brake holds the load when the lever is

released.

To reduce the risk of injury, do not lift people or loads

over people.

Do not lift more than the rated load.

Do not use load chain as a sling.

FREE CHAINING

In this mode, the load chain can be pulled through the hoist in

either direction by hand for quick attachment to the load.

Sling

Upper and

lower hooks

in straight

line. Frame

is free to

swivel.

Load

SAFE PULLING ANGLE

Do not allow the frame to touch the load or bear on

any support when in use. This may cause bending of

the hook or frame and cause possible failure.

Not a

straight line

between

upper and

lower hooks.

Frame is not

free to swivel.

Load

DANGEROUS PULLING

ANGLE

4

. Attach the lower hook to the load.

1

2. To take up the slack load chain, follow the instructions

under “Free Chaining”.

OTE: The load chain must feed into the chain guide roller

N

properly. A twisted chain may become damaged in the

liftwheel and cause chain breakage.

When operating in limited spaces, use attachments or

slings to prevent the frame and lever from being obstructed.

3. To lift or tension a load, set the directional lever to the

“LOAD” position and move the lever up and down

repeatedly.

4. To lower or loosen a load, set the directional lever to the

“UNLOAD” position and move the lever up and down

repeatedly.

Malfunctioning of unit, rigging slip or loss of footing

may cause user to slip and result in injury. To avoid

injury, always have a firm and secure footing when

using the MILWAUKEE Lever Hoist.

Do not use an extension on the lever. Exceeding the

rated lever pull or using an extension to lift or pull a

load will overload the hoist.

RECOMMENDED PROCEDURES

1. The hoist must be kept clean to assure proper operation.

Before use, check to be sure the load chain is clean, that

there is no foreign material in the liftwheel area and that

the lever operates freely.

2. The hoist must always be rigged to lift in a straight line

from hook to hook.

a. Rigging can be defined as the process of lifting and

moving loads using hoists and other mechanical

equipment. Skill acquired through specialized experience

and study is essential to safe rigging operations. For

rigging information, we recommend consulting a

standard text book on the subject.

b. The hoist must always be free to swivel on the upper

hook. Under no condition should the hoist frame be

allowed to bear on any support when in use as this would

cause bending of the hook or frame and damage the unit.

3. When preparing to lift or move a load, be sure that the

attachments to both hooks are firmly seated in the saddles

of the hooks. Avoid off center loading of any kind,

especially loading on the tip of the hook. Observe that the

chain hangs straight (without twist) from upper hook to

lower hook.

4. When lifting, raise the load only enough to clear the floor

or the support, and check to be sure brake will load and

that attachments to the load are firmly seated. Continue

the lift only after you are assured the load is free of all

obstructions.

. Do not load beyond the rated capacity of the hoist. Rated

5

capacity can be achieved with noted force on lever (See

Figure 3). Any greater pull is an indication of either an

overload or an incorrectly maintained unit.

Figure 3

Hois t Force on Lever

Rate d Load to Lift Rat ed Load

Tons (Kg) Poun ds (Kg)

3/4 (750) 33 (15)

½ (1500) 51 (23.1)

1

3 (3000) 77 (34.9)

NOTE: Since force on the lever can easily be applied by one

person, under no circumstances should more than one person

operate the lever hoist. Overloading can cause immediate

failure of some load carrying parts or result in damage causing

future failure at less than rated capacity. When in doubt, use

the next larger capacity MILWAUKEE hoist.

To reduce the risk of injury, do not exceed rated

capacity of the hoist. Doing this may cause the load to

drop resulting in personal injury and/or property

damage.

6. Do not wrap load chain around the load or bring the load

in contact with the hoist. Doing this will result in the loss of

the swivel effect of the hook, which could result in a

twisted chain and a jammed liftwheel. The chain could also

be damaged at the hook.

7. Do not move a load over the heads of other personnel.

Warn personnel of your intention to move a load into their

area. Stand clear of all loads.

8. Do not leave a suspended load unattended.

9. Do not take up the load chain to the point where the chain

stop or lower hook block becomes jammed against the

frame.

10. Do not hold load chain while operating the hoist. Should

the hoist not operate properly, serious injury may occur.

11. Read warnings and instructions on the lever, frame and/or

warning tubes before each use.

12. Do not run the lower hook block into the hoist frame.

Frame and/or chain guide damage may result.

13. Do not operate hoist with other than manual power.

14. Do not use an extension on the lever.

15. Do not use this or any other materials handling equipment

for lifting people.

16. Do not allow the load to bear against the hook latch. The

latch is to prevent detachment of load under slack chain

conditions only.

17. When there is a load on the hoist, do not pull or turn the

free chaining knob. Doing this will allow the load to be

released in a sudden and uncontrolled manner and may

cause injury to you and/or property damage.

5

8. Never operate the hoist when flammable materials or

1

vapors are present. Sharp contact between metal parts

can produce sparks that can cause a fire or explosion.

19. Do not use the hoist when you are tired, distracted or

under the influence of drugs, alcohol or medication,

causing reduced control.

. The latch is secured to the upper and lower hook by a rivet.

2

To remove the latch, it is necessary to remove the head of

the rivet by grinding or drilling. For replacement of the latch

refer to assembly instructions.

3. The pinion shaft and ratchet hub pawl and shaft are under

spring pressure and may fly out of the unit upon

isassembly.

d

FREQUENT INSPECTIONS

To reduce the risk of injury, operate hoist using manual

power only. Power operation may result in structural

damage or premature wear that may cause a part to

break and allow the load to fall.

To reduce the risk of injury, do not allow the load to

bear against the hook latch and/or hook tip. Apply load

to hook bowl or saddle only. Allowing the load to bear

against the hook latch and/or hook tip can result in loss

of load.

MAINTENANCE

Place warning signs and barriers in area when overhead

maintenance is taking place.

MAINTENANCE OF LEVER HOIST AFTER USE

1. After use, set the directional lever to the “UNLOAD” position

and move the lever up and down to disengage the brake.

2. Remove any dirt or dust from the hoist and chain.

3. Lubricate load chain with a light coating of Bar and Chain

Oil such as Lubriplate 10-R

equal lubricant.

4. Store the lever hoist in a dry, clean area.

INSPECTION

To maintain continuous and satisfactory operation, a regular

inspection procedure must be initiated so that worn or

damaged parts can be replaced before they become unsafe.

The intervals of inspection must be determined by the

individual application and must be based upon the type of

service to which the hoist will be subjected. Conduct

inspections only when there is no load on hoist. Place warning

signs and barriers in area when overhead maintenance is

taking place.

The inspection of hoists is divided into two general

classifications designated as “frequent” and “periodic”.

Frequent inspections are performed daily. Periodic inspections

are performed every three (3) months (unless otherwise

specified). Periodic inspections will require partial disassembly

of the hoist (See “Three Point of Caution for Hoist

Disassembly” and “Assembly”).

THREE POINTS OF CAUTION FOR HOIST DISASSEMBLY

Three points of caution are to be observed when

disassembling this tool.

1. Loose rollers are used for the liftwheel bearing on the 3/4

ton (750 Kg), 1½ ton (1 500 Kg) and 3 ton (3 000 Kg) units.

Do not lose these rollers as they may drop from the unit as

various parts are disassembled.

®

(Fiske Bros. Refining Co.) or

These inspections are usually visual examinations by the

operator or other designated personnel. The frequent

inspections are to be performed daily or before each use and

should include the following items:

1. All functional operating mechanisms for maladjustment and

unusual sounds.

2. Hoist braking mechanisms for evidence of slippage.

3. Operation of the directional lever for free movement.

4. Load chain for lubricant, wear, damaged links or foreign

material.

5. Proper reeving of load chain (See “Reeving Load Chain”

under “Maintenance” section).

6. Hooks for damage, cracks, twists, latch engagement and

latch operation.

7. Hoist support for damage.

Any deficiencies noted are to be corrected before the hoist is

returned to service.

PERIODIC INSPECTIONS

These are visual inspections by an appointed and qualified

person or service center who makes records of apparent

external conditions to provide the basis for a continuing

evaluation. The periodic inspections are to be performed every

three (3) months unless otherwise specified in this manual.

Due to the construction of the hoist, it will be necessary to

partially disassemble the unit to perform the periodic

inspections (See “Three Points of Caution for Hoist

Disassembly” and “Assembly”).

The periodic inspections are to include those items listed

under frequent inspections as well as the following:

1. Inspect chain and end connections for excessive wear or

stretch. ---

2. Check for worn, cracked or distorted parts such as lower

hook block, upper hook block, upper hook pin, chain

guide roller, stripper, side plates, gear cover, gears,

bushings, lever, brake cover, free chaining knob, ratchet

hub pawl, cam guide, friction hub and lever ratchet hub.

3. Inspect for wear on the pawl tips, teeth of the ratchet and

pockets of the liftwheel.

4. Check for loose or missing bolts, nuts, pins or rivets.

5. Inspect brake components for worn, glazed or

contaminated friction discs, and scoring of friction hub

and ratchet. Replace friction washers if contaminated,

glazed or if thickness is less than 0.094 in. (2.4 mm).

6. Check for corroded, stretched or broken pawl springs,

ratchet hub pawl spring and pinion spring.

7. Check for free movement of the pawls on the pawl studs.

Apply a thin coat of lubricant to the pawl studs before

reassembling the unit (See “Lubrication” under

“Maintenance” section).

6

. Check for damage to the hooks, hook retaining nuts,

8

collars, pins, welds or rivets used to secure the retaining

members. Dye penetrant, magnetic particle or other

suitable crack detecting inspections should be performed

at least once a year.

9. Check to see if load chain stop is in place and properly

ecured.

s

10. Check for damage of supporting structure.

11. Check for warning labels required by ASME B30.21.

Any deficiencies noted are to be corrected before the hoist is

eturned to service. External conditions may show the need

r

for more detailed inspection which, in turn, may require the

use of nondestructive type testing.

Any parts that are deemed unserviceable are to be replaced

with new parts before the unit is returned to service. It is very

important that the unserviceable parts be destroyed to

prevent possible future use as a repair item.

When the lever hoist is subjected to heavy usage or dusty,

gritty, moist or corrosive conditions, shorter time periods must

be assigned. Inspection must be made of all parts for unusual

wear, corrosion or damage, in addition to those specifically

mentioned above.

HOOK INSPECTION AND MAINTENANCE

Hooks damaged from chemicals, deformations or cracks, or

that have more than a 10 degree twist from the plane of the

unbent hook, excessive opening or seat wear must be

replaced.

Hooks that are opened and allow the latch to disengage the

tip must be replaced.

Any hook that is twisted or has excessive throat opening

indicates abuse or overloading of the unit. As a result, other

components of the hoist could be damaged.

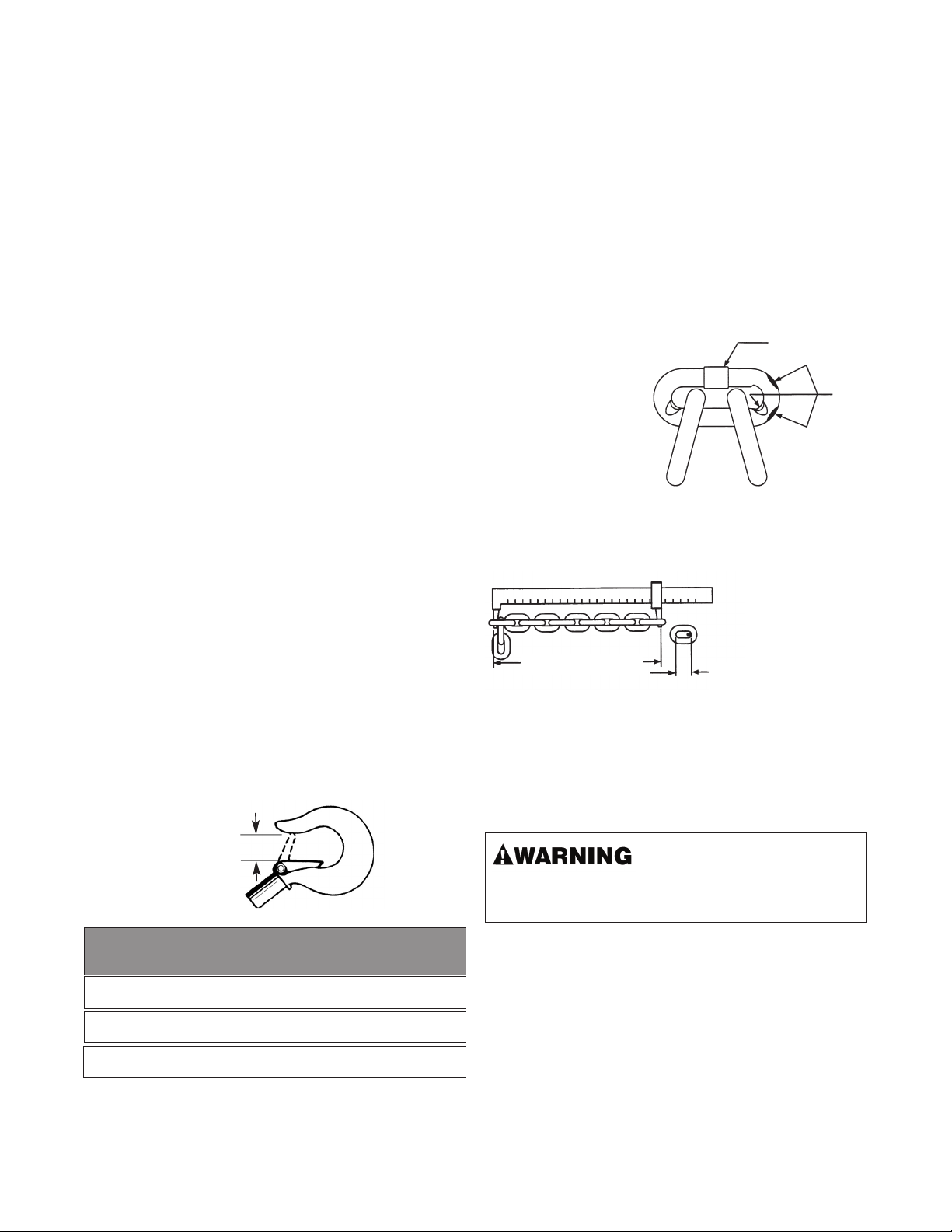

The chart in Figure 4 should be used to determine when the

hook must be replaced. To measure the throat opening,

depress the latch against the hook body (See Figure 4).

Figure 4

heck to make sure that the latch is not damaged or bent and

C

that it operates properly with sufficient spring pressure. Spring

pressure keeps the latch tight against the tip of the hook and

allows the latch to spring back to the tip when released. If the

latch does not operate properly, It should be replaced.

CHAIN INSPECTION

First clean chain with a non-caustic/ non-acid type solvent

and make a link by link inspection for nicks, gouges, twisted

links, weld spatter, corrosion pits, sitriations (minute parallel

lines), cracks in weld areas, wear and stretching. Chain with

any one of these defects must be replaced.

Slack the portion of the chain that normally passes over the

liftwheel. Examine the

interlink area for the point

of maximum wear

(polishing). Measure and

record the stock diameter

at this point of the link.

Weld

Wear

in

These

Areas

Then measure stock

diameter in the same area

on the link that does not

pass over the liftwheel

(use the link adjacent to

the chain stop for this

Figure 5a - Chain Inspection

purpose). Compare these two measurements. If the stock diameter

of the worn link is 0.010 inches (0.254mm), or more, less than the

stock diameter of the unworn link, the chain must bereplaced.

Vernier Caliper

Also check chain

for stretch using a

vernier caliper as

shown in Figure

5b. Select an

Measure 11 Pitches

Figure 5b - Chain Inspection

unused,

unstretched

One

Pitch

section of chain

(usually at the

loose end) and measure and record the length over 11 chain

links (pitches). Measure and record the same length on a

worn section of chain.

If the result (amount of stretch and wear) is greater than 0.145

inch (3.7 mm), the chain must be replaced.

Use only a “Knife-Edge” caliper to eliminate possibility of

false reading by not measuring full pitch length.

Measure Opening

Hook Throat Opening

Hois t Replace Hook

Rate d Load When Openin g

Tones (Kg) is Greater Than:

3/4 (750) 1¼" (31.8 mm)

1½ (1500) 13/8" (34.9 mm)

3 (3000) 123/32" (43.7 mm)

Using other than Milwaukee supplied load

chain may cause the chain to jam in the

hoist and/or allow the chain to break and

TO AVOID INJURY: Due to size requirements and physical properties,

use only Milwaukee supplied load chain in the Milwaukee Lever Hoist.

the load to drop.

Note that worn chain can be an indication of worn hoist

components. For this reason, the hoist’s frame, stripper, and

liftwheel should be examined for wear and replaced as

necessary when replacing worn chain (See DISASSEMBLY

and ASSEMBLY below).

Also, the load chain is specially heat treated and hardened

and should never be repaired.

IMPORTANT: Do not use replaced chain for other purposes

such as lifting or pulling. Load chain may break suddenly

without visual deformation. For this reason, cut replaced

chain into short lengths to prevent use after disposal.

7

LUBRICATION

Before returning chain to service or after replacing a load

chain, lubricate liberally with Bar and Chain Oil such as

Lubriplate

®

10-R (Fiske Bros, Refining Co.) or equivalent, Be

sure the lubricant reaches the bearing surfaces between the

inks. Remove excess lubricant from chain by wiping with a

l

clean, dry cloth.

To reduce the risk of injury, avoid contact with

lubricants. Handle and dispose of lubricants only as

directed in applicable Material Safety Data Sheets and

in accordance with applicable local, state and federal

regulations.

ASSEMBLY

Particular attention must be given to the following when

assembling the hoist:

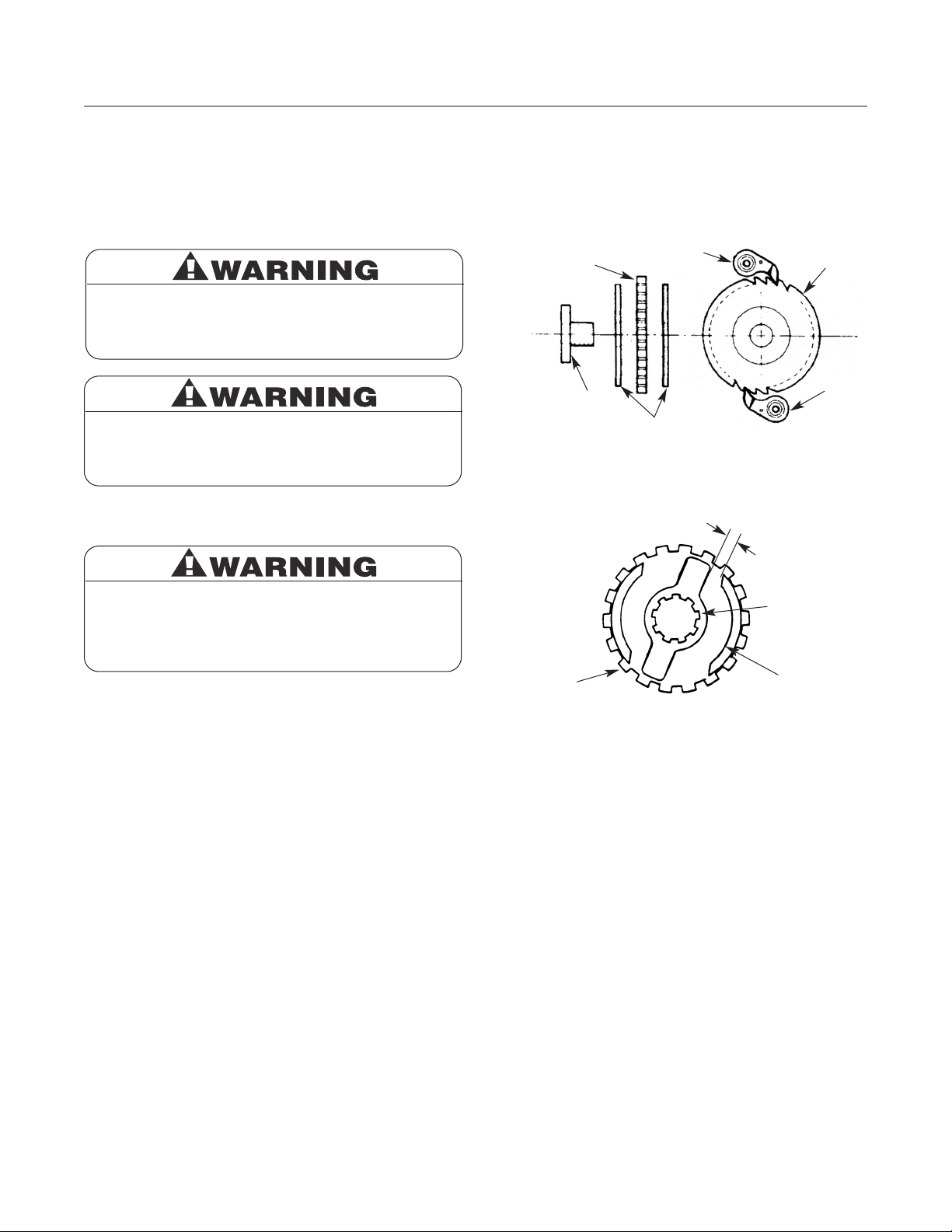

Thread the friction hub onto the pinion shaft and assemble the

riction discs and the ratchet on the friction hub (See Figure 6).

f

Figure 6

Ratchet

Pawl

Ratchet

To reduce the risk of injury, never use used motor oil as

a chain lubricant. Used motor oil contains known

carcinogenic materials. Use only Bar and Chain Oil such

as Lubriplate®10-R or equivalent as a lubricant for the

load chain.

The hoist normally requires no lubrication, except for

periodically lubricating the load chain or when the unit is

disassembled for periodic inspections, cleaning or repairs.

To reduce the risk of injury, do not use any grease or

lubricant on braking surfaces. The brake is designed to

operate dry. Using any grease or lubricant on the

braking surfaces will cause brake slippage and loss of

load control which may result in injury and/or property

damage.

The brake is designed to operate dry. Do not use any grease

or lubricant on the braking surfaces. When lubricating parts

adjacent to the brake, do not use an excessive amount of

lubricant which could seep onto the brake surfaces.

When the hoist is disassembled for periodic inspections,

check the pawl for free movement and apply a light coat of

spray lubricant such as WD-40 (WD-40 Co.) or equivalent, to

the pawl stud. When the hoist is disassembled for cleaning or

repairs, the following locations should be lubricated using

approximately 1 oz. (29.5 ml) per hoist of Extreme Pressure

Grease such as Molykote BR-2-S (Dow Corning Corp.) or

equivalent:

Gears, liftwheel rollers, upper hook pin, rollers of the liftwheel

bearing, inside of chain guide roller, exterior of pinion shaft,

surface of ratchet hub pawl, and surface of cam guide and

gear cover brushings.

NOTE: To assure extra long life and top performance, be sure

to lubricate the various parts of the hoist using the lubricants

specified.

Friction

Hub

Friction

Disc

Pawl

Place the spring over the friction hub and pinion. Place the

brake cover assembly on the frame and thread the lever ratchet

onto the pinion shaft. Firmly seat the lever ratchet and secure

the brake cover assembly to the frame using the four nuts.

Figure 7

Lever

Ratchet

0.094 to 0.312"

(2 to 8 mm)

Check

Washer

Raised

Stop

Place the check washer on the pinion shaft so that there is

0.094 to 0.312 inches (2 to 8 mm) between the edge of the

check washer and the raised stop on the lever ratchet hub

(See Figure 7).

Make sure the directional lever is in the neutral (“N”) position

and the pawl, spring and shaft are in the lever assembly,

attach the lever assembly to the brake cover using the two

locknuts, screw and lockwasher. Place the free chaining knob

on the lever ratchet hub. Place the spacer over the pinion

shaft, thread the brake nut onto the pinion shaft, and firmly

tighten the nut. Back off the nut one to two flats and insert the

cotter pin. Bend the legs of the cotter pin to secure.

When assembling the latch to the hook, the end of the rivet

must be peened over. When peening over rivet, only apply

enough force to form a head to retain the pin. Excessive force

will deform the latch and make the latch inoperable.

When assembling the gears, they must be orientated with the

timing marks aligned (See Figure 8).

8

Figure 8

Timing

Marks

ESTING

T

Prior to initial use, all altered, repaired or used hoists that have

ot been operated for the previous 12 months should be

n

tested by the user for proper operation. Test the unit without a

load and then with a load of 100 pounds (46 Kg) to be sure

that the hoist operates properly and that the brake holds the

load when the lever is released. Then test with a load of 125%

of rated capacity. Hoists in which load sustaining parts have

been replaced should be tested with a load of 125% of rated

capacity by, or under the direction of, an appointed person

and a written report prepared for record purposes.

REEVING LOAD CHAIN

Installing a new length of load chain

To replace the load chain, remove the lower hook block and

chain stop from the chain. Move the directional lever to the

neutral “N” and pull the old chain out of the hoist. Feed a

length of soft wire through one side of the chain guide roller

and over the liftwheel until it comes out on the other side of

the chain guide roller.

Figure 9

Chain guide

roller-Lower

Hook Side

Stripper

Lower

Hook

Block

Chain Welds

Away From

Liftwheel

Liftwheel

Chain Guide

Roller-Chain

Stop Side

Chain Stop-

Position as

Shown

ACCESSORIES

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog. To obtain a catalog,

contact your local distributor.

To reduce the risk of injury, use only specifically

recommended accessories. Others may be hazardous.

Attach the wire to the end of the new chain. Position the chain

so that the first link to enter the chain guide roller will be an

upstanding link and the welds on all upstanding links will be

away from the liftwheel. Pull on the wire until the chain

engages the liftwheel. Turn the free chaining knob, while pulling

on the wire, until the chain comes out of the chain guide roller.

Pull the chain through and remove the wire. Attach the lower

hook block to the chain that is directly below the upper hook.

Attach the chain stop to the other end of the chain.

To reduce the risk of injury, feed load chain between

liftwheel and chain guide before attaching the warning

tubes and end ring. Failure to properly install the load

chain may cause the chain to lift out of the liftwheel

pockets and allow the load to drop.

9

LIMITED WARRANTY - USA AND CANADA

Every MILWAUKEE power tool (including cordless product – tool, battery pack(s) - see separate & distinct CORDLESS BATTERY PACK

LIMITED WARRANTY statements & battery charger and Work Lights*) is warranted to the original purchaser only to be free from

defects in material and workmanship. Subject to certain exceptions, MILWAUKEE will repair or replace any part on an electric power

tool which, after examination, is determined by MILWAUKEE to be defective in material or workmanship for a period of five (5) years*

after the date of purchase unless otherwise noted. Return of the power tool to a MILWAUKEE factory Service Center location or

MILWAUKEE Authorized Service Station, freight prepaid and insured, is required. A copy of the proof of purchase should be included

with the return product. This warranty does not apply to damage that MILWAUKEE determines to be from repairs made or attempted

by anyone other than MILWAUKEE authorized personnel, misuse, alterations, abuse, normal wear and tear, lack of maintenance, or

accidents.

*The warranty period for, Job Site Radios, M12™ Power Port, M18™ Power Source, and Trade Titan™ Industrial Work Carts is one (1)

year from the date of purchase. The warranty period for a LED Work Light and LED Upgrade Bulb is a limited LIFETIME warranty to the

original purchaser only, if during normal use the LED bulb fails the Work Light or Upgrade Bulb will be replaced free of charge.

*This warranty does not cover Air Nailers & Stapler, Airless Paint Sprayer, Cordless Battery Packs, Gasoline Driven Portable Power

Generators, Hand Tools, Hoist – Electric, Lever & Hand Chain, M12™ Heated Jackets, Reconditioned product and Test &

Measurement products. There are separate and distinct warranties available for these products.

Warranty Registration is not necessary to obtain the applicable warranty on a MILWAUKEE power tool product. The manufacturing

date of the product will be used to determine the warranty period if no proof of purchase is provided at the time warranty service is

requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN IS A CONDITION OF THE

CONTRACT FOR THE PURCHASE OF EVERY MILWAUKEE PRODUCT. IF YOU DO NOT AGREE TO THIS CONDITION, YOU

SHOULD NOT PURCHASE THE PRODUCT. IN NO EVENT SHALL MILWAUKEE BE LIABLE FOR ANY INCIDENTAL, SPECIAL,

CONSEQUENTIAL OR PUNITIVE DAMAGES, OR FOR ANY COSTS, ATTORNEY FEES, EXPENSES, LOSSES OR DELAYS ALLEGED

TO BE AS A CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN ANY PRODUCT INCLUDING, BUT NOT LIMITED

TO, ANY CLAIMS FOR LOSS OF PROFITS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY IS

EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES, WRITTEN OR ORAL. TO THE EXTENT PERMITTED BY LAW,

MILWAUKEE DISCLAIMS ANY IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE OR PURPOSE; TO THE EXTENT SUCH DISCLAIMER IS NOT

PERMITTED BY LAW, SUCH IMPLIED WARRANTIES ARE LIMITED TO THE DURATION OF THE APPLICABLE EXPRESS WARRANTY

AS DESCRIBED ABOVE. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU, THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

This warranty applies to product sold in the U.S.A. and Canada only.

Please consult the ‘Service Center Search’ in the Parts & Service section of MILWAUKEE’s website www.milwaukeetool.com or call

1.800.SAWDUST (1.800.729.3878) to locate your nearest service facility for warranty and non-warranty service on a MILWAUKEE

electric power tool.

LIMITED WARRANTY - MEXICO, CENTRAL AMERICA AND CARIBBEAN

TECHTRONIC INDUSTRIES' warranty is for 5 year since the original purchase date.

This warranty card covers any defect in material and workmanship on this Power Tool.

To make this warranty valid, present this warranty card, sealed/stamped by the distributor or store where you purchased the product,

to the Authorized Service Center (ASC). Or, if this card has not been sealed/stamped, present the original proof of purchase to the ASC.

Call toll-free 1 800 832 1949 to find the nearest ASC, for service, parts, accessories or components.

Procedure to make this warranty valid

Take the product to the ASC, along with the warranty card sealed/stamped by the distributor or store where you purchased the

product, and there any faulty piece or component will be replaced without cost for you. We will cover all freight costs relative with this

warranty process.

Exceptions

This warranty is not valid in the following situations:

a) When the product is used in a different manners from the end-user guide or instruction manual.

b) When the conditions of use are not normal.

c) When the product was modified or repaired by people not authorized by TECHTRONIC INDUSTRIES.

Note: If cord set is damaged, it should be replaced by an Authorized Service Center to avoid electric risks.

Model:

Date of Purchase:

Distributor or Store Stamp:

10

SERVICE AND ATTENTION CENTER

Rafael Buelna No.1.

Col. Tezozomoc Mexico, Azcapotzalco D.F.

Ph. 01 800 832 1949

IMPORTED AND COMMERCIALIZED BY:

TECHTRONIC INDUSTRIES MEXICO, .S.A. DE C.V.

Av. Santa Fe 481 piso 6, Col. Curz Manca.

CP 05349, Cuajimalpa, D.F.

Loading...

Loading...