Page 1

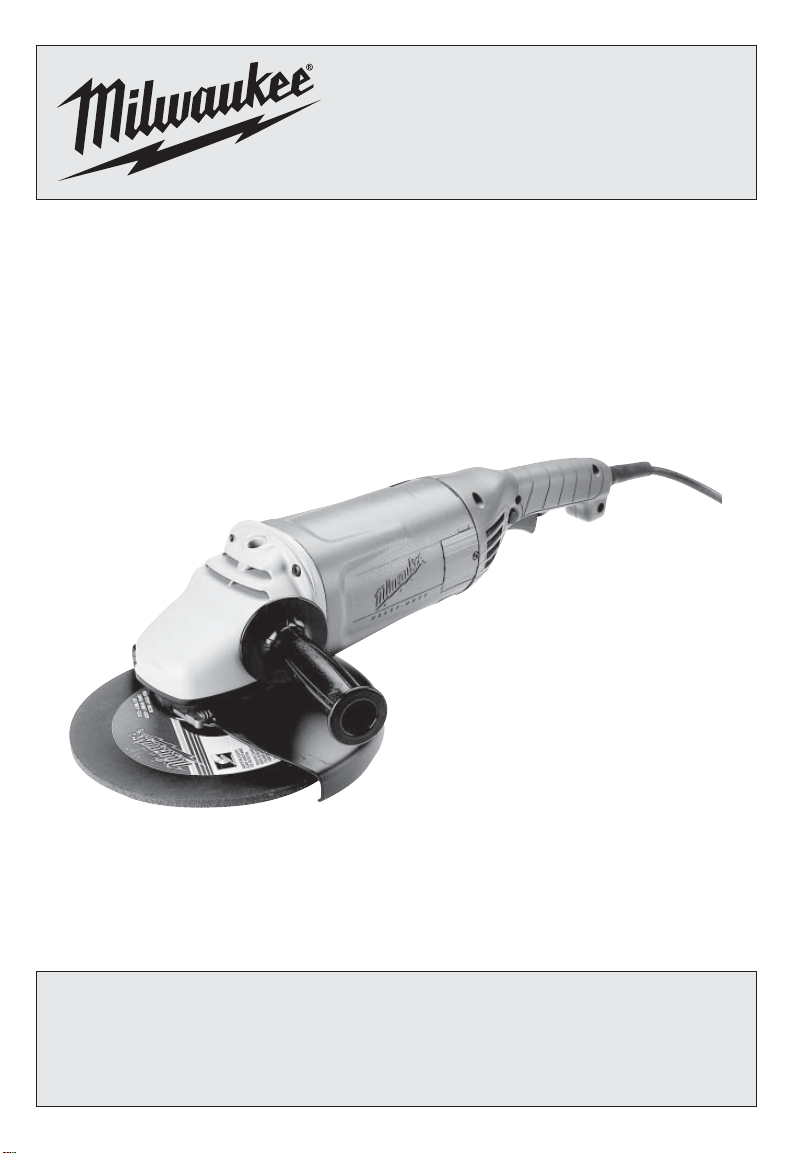

Cat. No.

No de Cat.

6088-30

6088-31

6089-30

6089-31

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

HEAVY-DUTY SANDERS AND GRINDERS

PONCEUSES-RECTIFIEUSES EXTRA ROBUSTES

LIJADORAS Y ESMERILADORAS HEAVY-DUTY

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S

MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN

COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL

MANUAL DEL OPERADOR.

Page 2

2

Page 3

GENERAL POWER TOOL SAFETY WARNINGS

WARNING READ ALL SAFETY WARNINGS AND ALL INSTRUCTIONS. Failure

to follow the warnings and instructions may result in electric shock, fi re and/or serious

injury. Save all warnings and instructions for future reference. The term "power

tool" in the warnings refers to your mains-operated (corded) power tool or battery-operated

(cordless) power tool.

• Keep work area clean and well lit. Cluttered or

WORK AREA SAFETY

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the risk

of electric shock.

• If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the infl uence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your fi nger on the switch or energising power tools

that have the switch on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

• Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such pre-

ventive safety measures reduce the risk of starting

the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

• Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits

etc., in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

SERVICE

• Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

3

Page 4

SPECIFIC SAFETY RULES

Safety Warnings Common for Grinding,

Sanding, Wire Brushing, or Abrasive CuttingOff Operations:

• This power tool is intended to function as

a grinder, sander, wire brushing or cut-off

tool. Read all safety warnings, instructions,

illustrations and specifications provided with

this power tool. Failure to follow all instructions

listed below may result in electric shock, fire and/

or serious injury.

• Operations such as polishing are not

recommended to be performed with this power

tool. Operations for which the power tool was not

designed may create a hazard and cause personal

injury.

• Do not use accessories which are not

specifically designed and recommended by the

tool manufacturer. Just because the accessory

can be attached to your power tool, it does not

assure safe operation.

• The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their RATED SPEED can break and fly apart.

• The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

• The arbour size of wheels, flanges, backing

pads or any other accessory must properly

fit the spindle of the power tool. Accessories

with arbour holes that do not match the mounting

hardware of the power tool will run out of balance,

vibrate excessively and may cause loss of control.

• Do not use a damaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for loose

or cracked wires. If power tool or accessory

is dropped, inspect for damage or install an

undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum

no-load speed for one minute. Damaged

accessories will normally break apart during this

test time.

• Wear personal protective equipment. Depending

on application, use face shield, safety goggles

or safety glasses. As appropriate, wear dust

mask, hearing protectors, gloves and workshop

apron capable of stopping small abrasive or

workpiece fragments. The eye protection must

be capable of stopping flying debris generated

by various operations. The eye protection must

be capable of stopping flying debris generated by

various operations. The dust mask or respirator

must be capable of filtrating particles generated

by your operation. Prolonged exposure to high

intensity noise may cause hearing loss.

• Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of

workpiece or of a broken accessory may fly away and

cause injury beyond immediate area of operation.

• Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact hidden

wiring. Cutting accessory contacting a “live” wire

may make exposed metal parts of the power tool

“live” and could give the operator an electric shock.

• Position the cord clear of the spinning

accessory. If you lose control, the cord may

be cut or snagged and your hand or arm

may be pulled into the spinning accessory.

• Never lay the power tool down until the

accessory has come to a complete stop.

The spinning accessory may grab the surface

and pull the power tool out of your control.

• Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

• Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

• Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

• Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution or shock.

NOTE The above warning does not apply for

power tools specifically designed for use with

a liquid system.

Kickback and Related Warnings

-Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging causes

rapid stalling of the rotating accessory which in turn

causes the uncontrolled power tool to be forced in

the direction opposite of the accessory’s rotation

at the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into

the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump

toward or away from the operator, depending on

direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under

these conditions.

-Kickback is the result of power tool misuse and/

or incorrect operating procedures or conditions

and can be avoided by taking proper precautions

as given below.

• Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up. The

operator can control torque reactions or kickback

forces, if proper precautions are taken.

• Never place your hand near the rotating

accessory. Accessory may kickback over your

hand.

• Do not position your body in the area wherepower tool will move if kickback occurs. Kick-

back will propel the tool in direction opposite to the

wheel’s movement at the point of snagging.

• Use special care when working corners, sharp

4

Page 5

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

• Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent

kickback and loss of control.

Safety Warnings Specific for Grinding and

Abrasive Cutting-Off Operations:

• Use only wheel types that are recommended

for your power tool and the specific guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot be

adequately guarded and are unsafe.

• The guard must be securely attached to the

power tool and positioned for maximum safety,

so the least amount of wheel is exposed

towards the operator. The guard helps to protect

the operator from broken wheel fragments and,

accidental contact with wheel and sparks that could

ignite clothing.

NOTE The above warning may be omitted for

grinders or cut-off grinders with rated capacity of

less than 55 mm.

• Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-off wheel. Abrasive cut-off wheels are

intended for peripheral grinding, side forces applied

to these wheels may cause them to shatter.

• Always use undamaged wheel flanges that are

of correct size and shape for your selected

wheel. Proper wheel flanges support the wheel

thus reducing the possibility of wheel breakage.

Flanges for cut-off wheels may be different from

grinding wheel flanges.

• Do not use worn down wheels from larger power

tools. Wheel intended for larger power tool is not

suitable for the higher speed of a smaller tool and

may burst.

Additional Safety Warnings Specific for Abrasive

Cutting-Off Operations:

• Do not "

• Do not position your body in line with and behind

• When wheel is binding or when interrupting a

• Do not restart the cutting operation in the

jam" the cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut. Overstressing the wheel increases

the loading and susceptibility to twisting or binding

of the wheel in the cut and the possibility of kickback

or wheel breakage.

the rotating wheel. When the wheel, at the point

of operation, is moving away from your body, the

possible kickback may propel the spinning wheel

and the power tool directly at you.

cut for any reason, switch off the power tool

and hold the power tool motionless until the

wheel comes to a complete stop. Never attempt

to remove the cut-off wheel from the cut while

the wheel is in motion otherwise kickback may

occur. Investigate and take corrective action to

eliminate the cause of wheel binding.

workpiece. Let the wheel reach full speed and

carefully reenter the cut. The wheel may bind,

walk up or kickback if the power tool is restarted

in the workpiece.

• Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag under

their own weight. Supports must be placed under

the workpiece near the line of cut and near the

edge of the workpiece on both sides of the wheel.

• Use extra caution when making a “pocket

cut” into existing walls or other blind areas.

The protruding wheel may cut gas or water pipes,

electrical wiring or objects that can cause kickback.

Safety Warnings Specific for Sanding Operations:

• Do not use excessively oversized sanding disc

paper. Follow manufacturers recommendations,

when selecting sanding paper. Larger sanding

paper extending beyond the sanding pad presents

a laceration hazard and may cause snagging,

tearing of the disc or kickback.

Safety Warnings Specific for Wire Brushing

Operations:

• Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive

load to the brush. The wire bristles can easily

penetrate light clothing and/or skin.

• If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire wheel

or brush may expand in diameter due to work load

and centrifugal forces.

Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

• WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and

other masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to fi lter out microscopic particles.

SPECIFICATIONS

15

15

15

15

Spindle

Thread

Size

5/8"-11

5/8"-11

5/8"-11

5/8"-11

Wheel

Size

7"/9"

7"/9"

7"/9"

7"/9"

Cat. No. Amps

6088-30

6088-31

6089-30

6089-31

5

No Load

RPM

120

120

120

120

Page 6

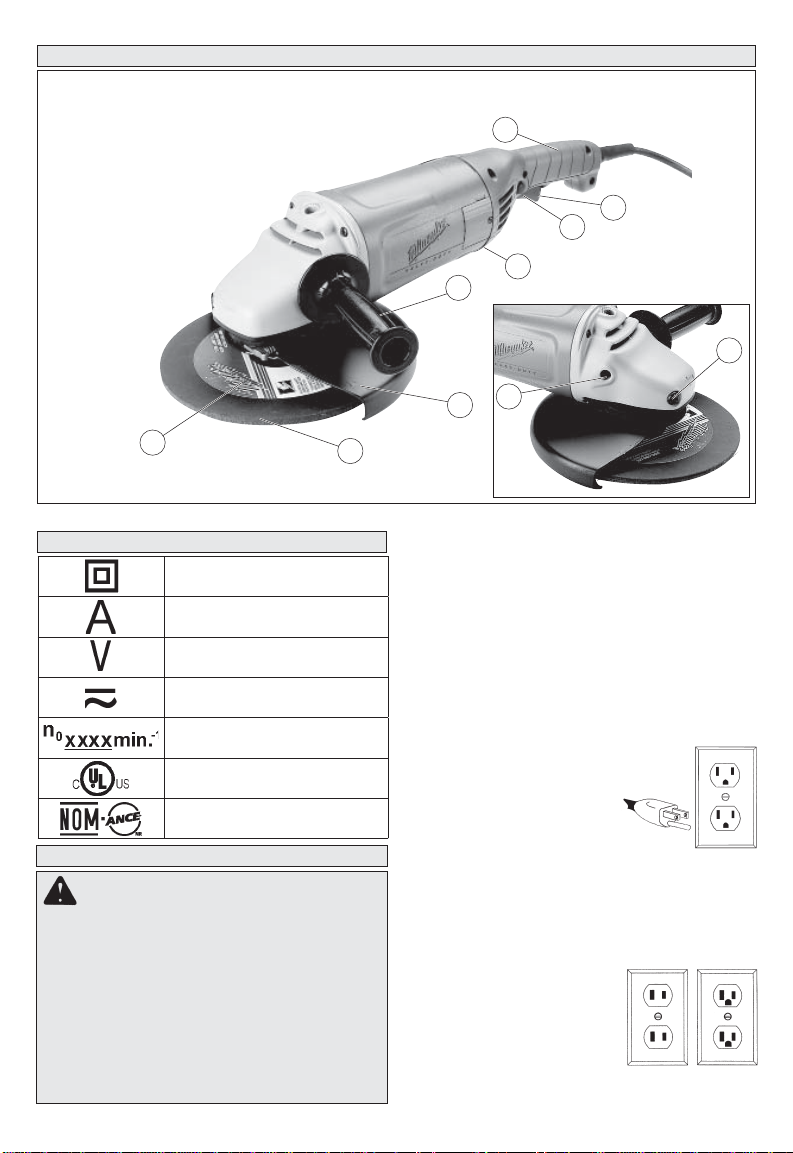

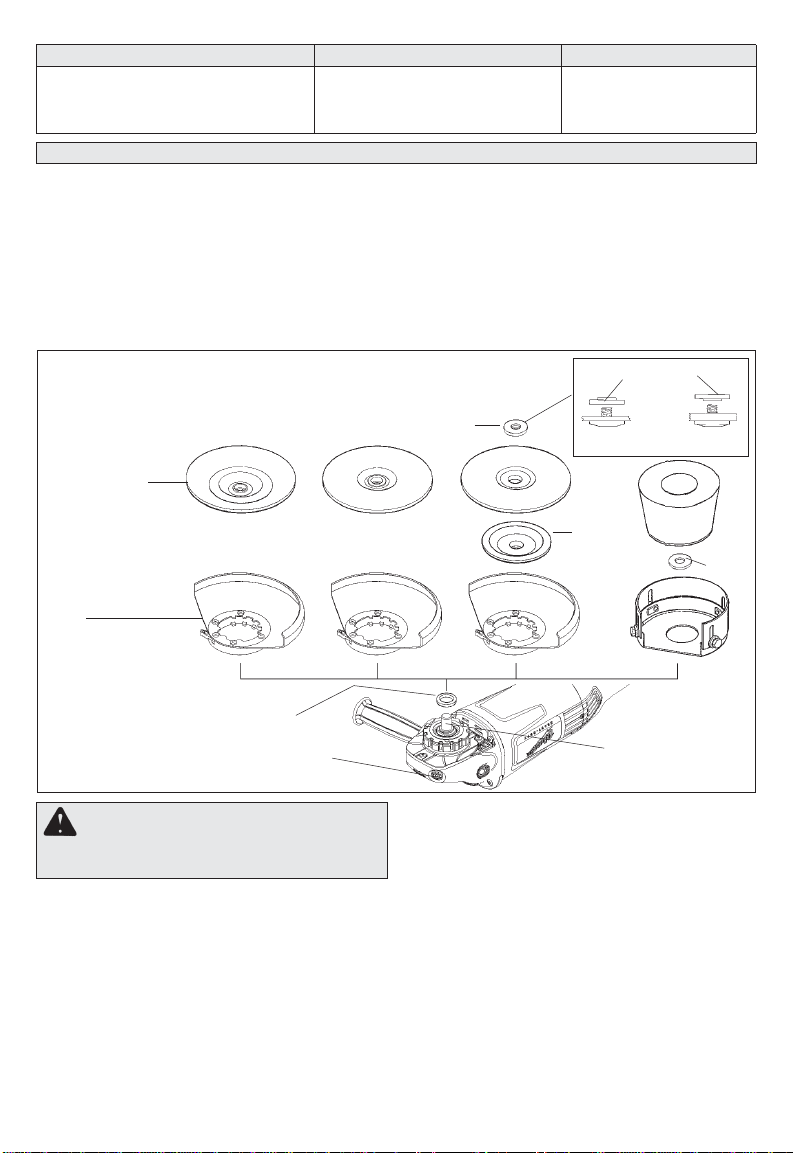

FUNCTIONAL DESCRIPTION

1. Rear handle

2. Trigger

3. Lock-on button (select models)

4. Handle release button (select models)

5. Side handle

6. Wheel guard (select models)

7. Grinding wheel

(select models)

8. Guard adjustment lock lever

(select models)

9. Spindle lock button

10. Side handle socket

8

1

2

3

(on bottom)

4

5

9

10

6

7

5

SYMBOLOGY

Double Insulated

Amperes

Volts

Alternating Current/Direct Current

No Load Revolutions

per Minute (RPM)

Underwriters Laboratories, Inc.

United States and Canada

Mexican Approvals Marking

GROUNDING

WARNING Improperly connecting the

grounding wire can result in the risk of electric shock. Check with a qualifi ed electrician

if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug

provided with the tool. Never remove the

grounding prong from the plug. Do not use

the tool if the cord or plug is damaged. If

damaged, have it repaired by a MILWAUKEE

service facility before use. If the plug will not

fi t the outlet, have a proper outlet installed by

a qualifi ed electrician.

Grounded Tools: Tools with Three Prong Plugs

Tools marked “Grounding Required” have a three

wire cord and three prong grounding plug. The

plug must be connected to a properly grounded

outlet (See Figure A). If the tool should electrically

malfunction or break down, grounding provides a

low resistance path to carry electricity away from

the user, reducing the risk of electric shock.

The grounding prong in the plug is connected

through the green wire inside the cord to the

grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's

grounding system and must never be attached to

an electrically “live” terminal.

Y our tool must be plugged into

an appropriate outlet, properly

installed and grounded in accordance with all codes and

ordinances. The plug and

outlet should look like those

Fig. A

in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do not require

grounding. They have a special double insulation

system which satisfi es OSHA requirements and

complies with the applicable

standards of Underwriters

Laboratories, Inc., the Canadian Standard Association

and the National Electrical

Code. Double Insulated tools

may be used in either of the

120 volt outlets shown in

Fig. B

Fig. C

Figures B and C.

6

Page 7

Grounded tools require a three wire extension

cord. Double insulated tools can use either a two

or three wire extension cord. As the distance from

the supply outlet increases, you must use a heavier

gauge extension cord. Using extension cords with

inadequately sized wire causes a serious drop in

voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the

required minimum wire size.

The smaller the gauge number of the wire, the

greater the capacity of the cord. For example, a 14

gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension

cord to make up the total length, be sure each cord

contains at least the minimum wire size required.

If you are using one extension cord for more than

one tool, add the nameplate amperes and use the

sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be

sure it is marked with the suffi x “W-A” (“W” in Cana-

da) to indicate that it is acceptable for outdoor use.

• Be sure your extension cord is properly wired

and in good electrical condition. Always replace a

damaged extension cord or have it repaired by a

qualifi ed person before using it.

• Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

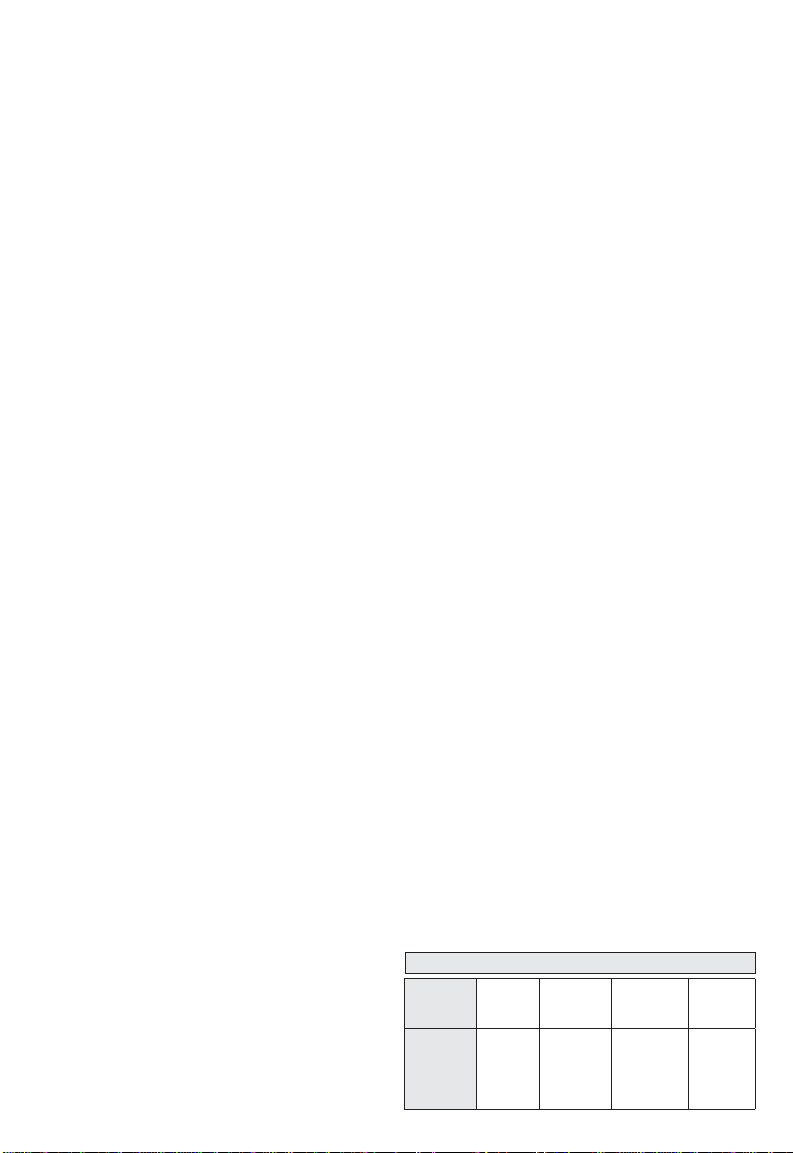

Recommended Minimum Wire Gauge

For Extension Cords*

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

* Based on limiting the line voltage drop to fi ve volts at

150% of the rated amperes.

Extension Cord Length

25' 50' 75' 100' 150'

18

18

18

18

18

18

18

16

14

12

18

18

16

14

12

10

18

16

14

12

10

--

16

14

12

10

16

14

12

12

--

--

--

--

--

READ AND SAVE ALL

INSTRUCTIONS FOR FUTURE USE.

ASSEMBLY

WARNING T o reduce the risk of injury ,

always unplug tool before changing or removing accessories. Only use accessories

specifi cally recommended for this tool. Others

may be hazardous.

Removing and Replacing Quik-Lok® Cords

(Select Models)

MILWAUKEE's exclusive Quik-Lok® Cords provide

instant fi eld replacement or substitution.

1. To remove the Quik-Lok® Cord, turn the cord nut

1/4 turn to the left and pull it out.

2. T o replace the Quik-Lok® Cord, align the connector keyways and push the connector in as far as it

will go. Turn the cord nut 1/4 turn to the right to lock.

EXTENSION CORDS

Fig. 1

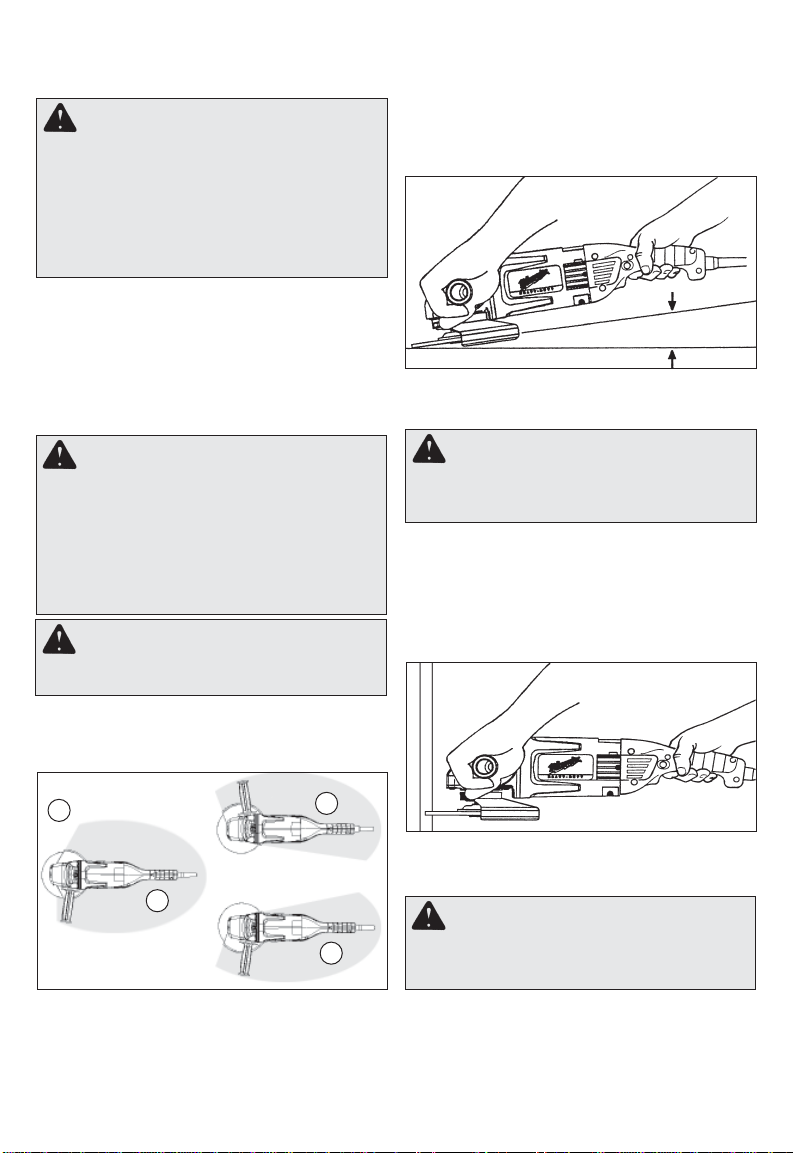

Installing the Side Handle

The side handle may be installed on the top of

the gear case or on either side of gear case for

right or left handed use. Position side handle in

the location which offers best control and guard

protection. For operating zones that provide

maximum protection for the operator, see Fig.

9. To install, thread side handle into side handle

socket on desired side of gear case and tighten

securely.

WARNING To reduce the risk of in-

jury when grinding, ALWAYS use the proper

guard. ALWAYS properly install the guard.

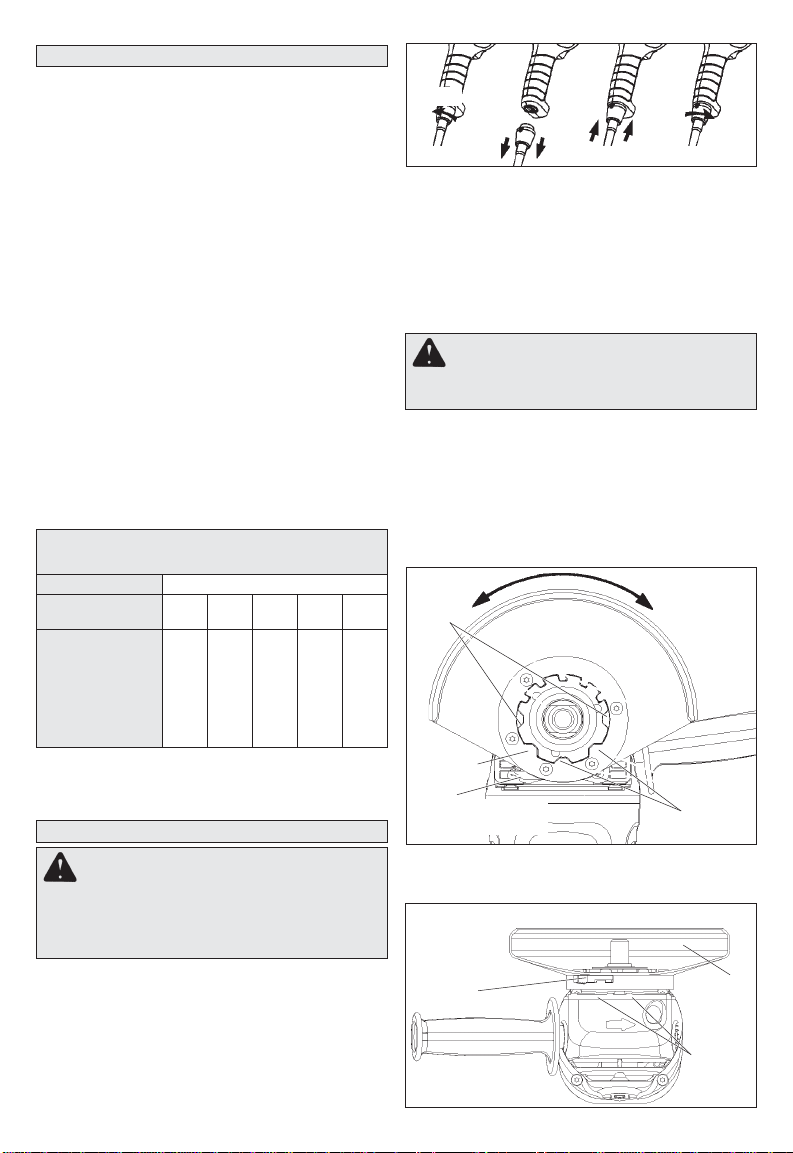

Installing, Adjusting, and Removing the Guard

The guard must be used when using the tool as a

grinder. The guard should be removed when using

tool as a sander.

1. To install the guard, unplug the tool and place

it upside down on a level surface. Remove any

accessories from the spindle.

Line up the tabs with the tab slots (Fig. 2). Then

press the guard down onto the tool.

Fig. 2

Tab slot

Tab slot

Guard adjustment

lock lever

Press in the guard adjustment lock lever and rotate

the guard to one of the detent slots. The lock lever

must engage with one of the detents (Fig. 3).

Fig. 3

Guard adjustment

lock lever

7

Tab slot

Guard

Lock

lever

must

engage

one of

detents

Page 8

Press in the guard adjustment lock lever and ro-

tate the guard to one of the detent slots. The lock

lever must engage with one of the detents (Fig. 3).

2. To adjust the guard, press in the guard adjustment lock lever and rotate the guard to one of

the detents (Fig. 3).

Position the guard in the location which offers

best control and guard protection. For operating

zones that provide maximum protection for the

operator, see Fig. 9.

3. To remove the guard, unplug tool and place it

upside down on a level surface. Remove any

accessories from spindle.

Press in the guard adjustment lock lever and

rotate the guard to line up the tabs with the slots

(Fig. 2). Then lift the guard straight up and away

from the tool.

OPERATION

WARNING T o reduce the risk of injury ,

wear safety goggles or glasses with side shields.

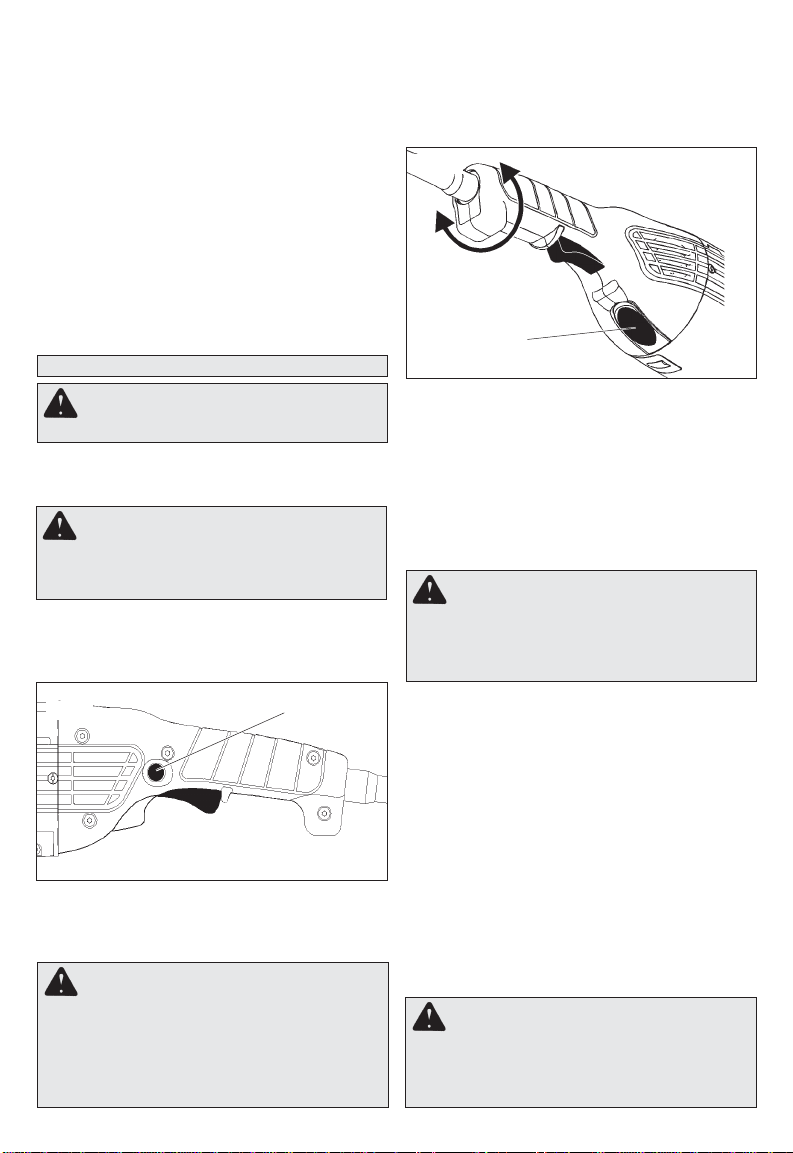

Starting and Stopping the Motor

1. To start the tool, pull the trigger.

2. To stop the tool, release the trigger.

WARNING

or damage to the tool, do not use the spindle

lock button to stop the spindle while the tool

is in use or is coasting after shut-off.

Locking the Trigger

Select Models

The lock button holds the trigger in the ON position

for continuous use.

Fig. 4

1. To lock the trigger on, hold the lock-on button in

while pulling the trigger. Release the trigger.

2. To unlock the trigger, pull the trigger and release.

The lock-on button will pop out.

WARNING

do not operate tool with handle release button pressed in or with handle not locked into

position. If the handle does not lock securely

into position, do not operate tool. Return the

tool to a MILWAUKEE service facility for repair

immediately.

To reduce the risk of injury

Lock-on button

To reduce the risk of injury ,

Adjusting the Rear Handle Position

Select Models

This tool is equipped with an adjustable rear handle.

This feature allows the user to adjust the angle of

the handle to nine positions for optimum operating

positions.

Fig. 5

Handle releas button

(on bottom)

1. Unplug tool.

2. Press and hold the handle release button in

and rotate the rear handle to one of the nine

handle positions. The adjustable handle feature

has detents which allow the handle to snap into

position. Make sure the handle snaps fi rmly into

position and does not rotate.

Position the guard in the location which offers

best control and guard protection. For operating

zones that provide maximum protection for the

operator, see Fig. 9.

WARNING To reduce the risk of

personal injury and damage to the tool, use

ONL Y accessories rated at or above the RPM

listed on the “WARNING” section of the tool's

nameplate.

Sanding Disc and Grinding Wheel Selection

Use sanding discs and grinding wheels that are:

• correct size as written on tool's nameplate

• correct wheel type and grit for the job

• rated at or above the RPM listed in the “WARN-

ING” section on the tool's nameplate

Use backing pads, adapters, and other accessories that are:

•correct size for tool and for sanding disc or grind-

ing wheel

•rated at or above the RPM listed in the “WARN-

ING” section on the tool's nameplate

•the proper accessory for the job

Sanding Disc and Grinding Wheel Material

Sanding discs and grinding wheels are made of

various materials and are designed for different

jobs. Be sure that you choose the proper sanding

disc or grinding wheel for the job you plan to do.

WARNING T o reduce the risk of injury ,

always unplug tool before attaching or remov-

ing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

8

Page 9

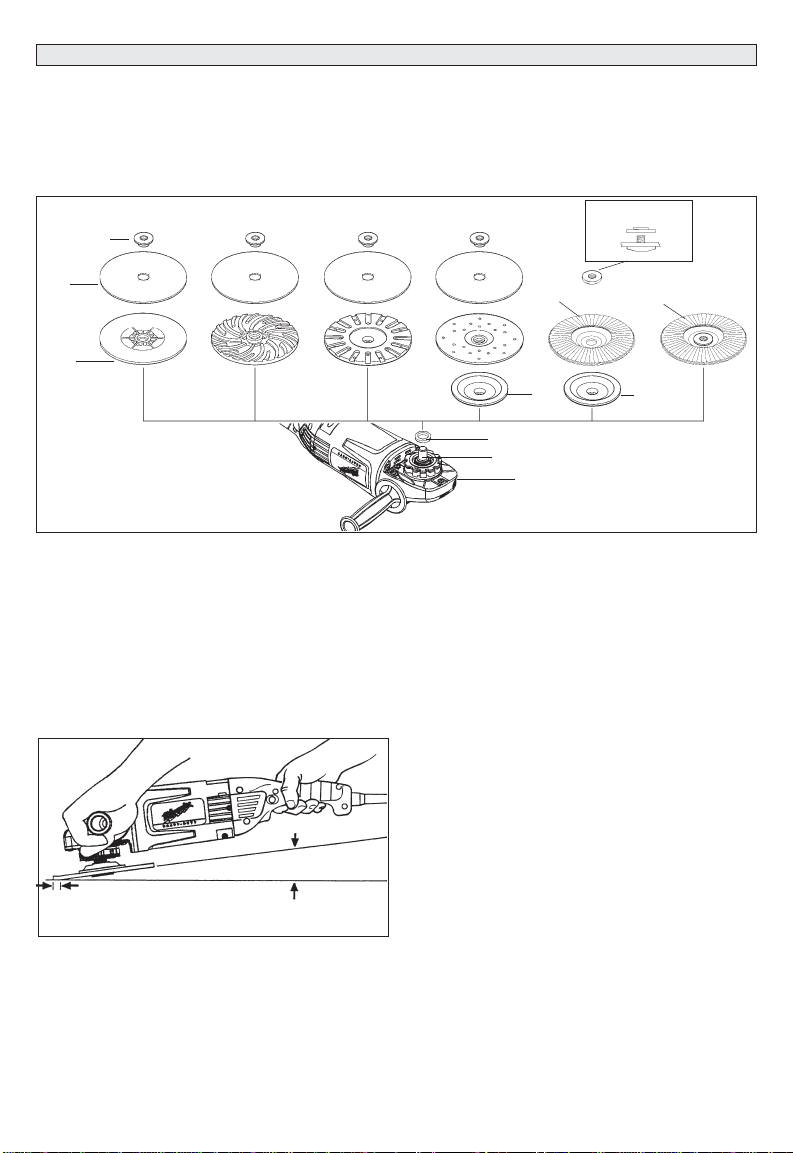

USING SANDING DISCS

Installing Sanding Discs

1. Unplug tool and place it upside down on a level

surface as shown. Remove any accessories from

spindle.

2. Thread nylon washer onto spindle. Attach

backing pad and sanding disc using Fig. 6

to determine type and order of assembly.

Fig. 6

Disc nut

Sanding

disc

B

Backing

pads

A. Polypropylene

B. Spiral

C. Rubber

D. Phenolic

Sanding

1. Use a clamp, vise or other practical means to

hold your work, freeing both hands to control your

tool. Firmly grasp rear handle and side handle

before starting and while tool is in operation.

Allow sanding disc to come to full speed before

beginning to sand.

2. Hold tool at 5° to 15° angle as shown to ensure

proper sanding pressure and control (Fig. 7). T oo

great an angle will result in too much pressure

and could cause excessive wear to the disc and

workpiece. T oo small an angle will reduce control.

Fig. 7

Hold at a 5° to 15° angle

For best results use only

this portion of disc

3. Use long, sweeping, side to side strokes, advancing forward to produce the desired fi nish.

Removing Welds or Hammer Marks

When removing welds or hammer marks, limit

coarse sanding to the immediate area. Use successively fi ner grits to smooth surface.

Cross Sanding

When finishing a surface that has been prepared by a coarse disc or wheel, sand at right

CDA

NOTE: When installing fl ap disc without hub,

position disc nut as shown.

3. To tighten, press the spindle lock button while

turning disc nut clockwise.

4. T o remove sanding disc and backing pad, unplug

tool and reverse procedure.

Disc nut position

Flap disk Flap disk with hub

Rubber

pad

Nylon washer

Spindle

Spindle lock button

Type 27

fl ange

angles to the strokes made by the coarser disc.

Finishing marks left from previous sanding are easily seen and removed for a uniform fi nish. Failure

to cross sand when changing from a coarse disc to

a fi nishing disc may result in deep scratches and

circular marks.

Finishing Metal

Constantly move across the surface. Work faster on

curved surfaces where contact areas are smaller

and pressure is greater. Flat areas may appear at

the end of the stroke when pressure is too heavy.

Ease up on pressure at end of each stroke and

when reversing strokes.

Troubleshooting

Deep scratches and circular marks can result from:

• Using too coarse a grit

• Using a partially glazed disc

• Dirt or loose metal on the workpiece

• Failure to sand across the grain when changing

from coarse to fi nishing discs

Bluish discoloration of metal surface indicates:

• Excessive heat caused by circular motion in a

small area

• Excessive pressure

• Use of worn out or glazed discs

Selecting Sanding Discs & Grit

Refer to the table below to select the correct type

of sanding disc for your job. Generally, use 16, 24

or 36 grit for heavy stock removal; 50, 60 or 80 grit

for medium stock removal and 120 grit for fi nishing.

Always begin with a coarse grit, using successively

fi ner grits to obtain the desired fi nish. See Catalog

for a complete list of MILWAUKEE sanding discs.

9

Page 10

Aluminum Oxide Aluminum Zirconia Bi-Cut Ceramic

For fast cutting, general purpose discs for

most metal jobs. Best for cold-rolled steel,

stainless steel or metals requiring tough, fast

cutting, long lasting abrasives.

Unique grit pattern is arranged in clusters for faster stock removal and cleaning. Ideal for removing paint from cars,

boats, etc. without clogging.

Lasts up to 3 times longer than

aluminum oxide discs. For

general metal working. Ideal

for tough jobs.

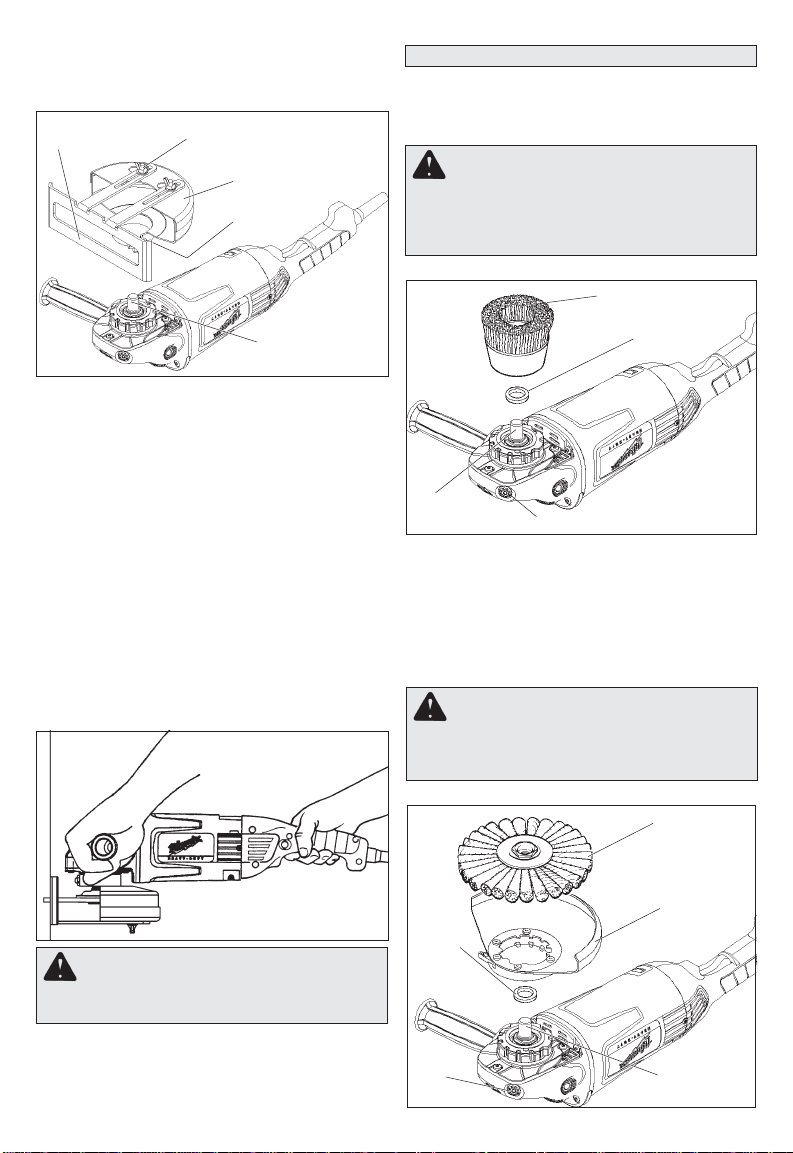

Installing Grinding Wheels

USING GRINDING AND CUT-OFF WHEELS

1. Unplug tool and place it upside down on a level

surface as shown. Remove any accessories from

spindle.

2. Thread nylon washer onto spindle. Attach guard

and grinding wheel using Fig. 8 to determine

type and order of assembly (See Fig. 2 and 3 for

attaching guard). NOTE: When installing Type

27 or Type 29 grinding wheels, position disc nut

according to wheel thickness.

Position the guard in the location which offers

Fig. 8

B

FG

Grinding wheels

A. Type 28 with hub

B. Type 27 with hub

Type 29 with hub

C. Type 27 with fl ange

Type 29 with fl ange

D. Type 11

Guard

E. Type 28

F. Type 27

G. Type 27

H. Type 11

A

E

Nylon washer

Spindle lock button

best control and guard protection. For operating zones that provide maximum protection for

the operator, see Fig. 9. NOTE: When selecting

Type 11 grinding cup wheels, the guard’s skirt

should be adjusted so that no more than 1/8" of

the wheel extends beyond the guard.

3. To tighten, press the spindle lock button while

turning wheel or disc nut clockwise using the

spanner wrench provided.

4. T o remove grinding wheel and guard, unplug tool

and reverse procedure.

Disc nut position

Disc nut

C

1/8" thick or

less wheels

Type 27

fl ange

Spindle

1/4" thick

wheels

D

Type 11

H

B

fl ange

WARNING T o reduce the risk of injury ,

the operator should be instructed in the use,

care and protection of grinding wheels.

Care of Grinding & Cut-Off Wheels

Grinding and cut-off wheels should be protected from:

• wetness and extreme humidity

• any type of solvent

• extreme changes in temperature

• dropping and bumping

Grinding and cut-off wheels should bestored:

• in an organized way so wheels can be removed

without disturbing or damaging other wheels

• with their safety information

Grinding and cut-off wheels should NOT be:

• dropped

• rolled

• bumped

If any wheel is dropped, rolled, bumped, subjected

to extreme changes in temperature, or has come

into contact with solvents or wetness, discard wheel

immediately.

Troubleshooting

Deep scratches and circular marks can result from:

• Uneven pressure

• Using a partially glazed wheel - especially on

aluminum applications

• Dirt or loose metal on the workpiece

• Failure to constantly move across surface

Bluish discoloration of metal surface indicates:

• Excessive heat caused by circular motion in a

small area

• Excessive pressure

• Use of worn out or glazed wheels

Inspecting Wheels

Always handle wheels carefully to avoid damage.

10

Page 11

Before installing any wheel, always inspect it for

cracks. If wheel is cracked, discard it to prevent

others from using it.

WARNING Only use wheels with Maxi-

mum Safe Operating Speed rated at or above

the RPM listed on the “WARNING” section

of the tool's nameplate. This speed is based

on the strength of the wheel, allowing for a

reasonable measure of safety. It is not meant

to imply a best or most effi cient operating

speed. Do not exceed the Maximum Safe

Operating Speed.

Selecting Wheels

Grinding is the cutting action of thousands of abrasive grains on the face of a grinding wheel. When

grinding metals such as steel and iron, choose an

aluminum oxide grinding wheel. Select a silicon

carbide grinding wheel for stone and concrete. Use

cotton reinforced wheels for non-ferrous metals.

Type 27 reinforced 1/8" cut-off wheels are suited for

small cut-off and shallow notching operations only .

3. Firmly grasp rear handle and side handle before

starting and while using tool. Allow wheel to come

to full speed before starting to grind.

4. When grinding, hold tool at a 5o to 15o angle as

shown, using constant pressure for a uniform

fi nish (Fig. 10). Too great an angle causes too

much pressure on small areas which may gouge

or burn work surface.

Fig. 10

Hold at a 5° to 15° angle

5. Control pressure and surface contact between

wheel and workpiece. T oo much pressure slows

cutting speed.

WARNING To reduce the risk of injury

when grinding:

• ALW A YS hold the tool fi rmly with both hands

using the handles provided; before and during grinding

• NEVER allow the wheel to bind

• NEVER use a wheel that has been dropped

• NEVER bang grinding wheel onto work

• NEVER grind without proper safety equipment

WARNING To reduce the risk of injury

when grinding, AL WA YS use the proper guard.

ALWAYS properly install the guard.

Grinding

1. Depending on your job, position the guard to

provide maximum protection for the operator

(Fig. 9).

Fig. 9

1

Operator's Zones

1

2. If you have just installed a grinding wheel or are

just beginning a period of work, test the wheel

by letting it spin for one minute before applying

it to the workpiece.

NOTE: Out-of-balance wheels can mar work-

piece, damage the tool, and cause stress to

wheel that may cause wheel failure.

1

1

WARNING A Type 27 guard must be

installed when using a Type 27 cut-off wheel to

provide maximum protection for the operator

if the wheel should break.

Using Type 27 Cut-Off Wheels

Type 27 cut-off wheels are only suited for small

cut-off and shallow notching operations.

1. Firmly grasp rear handle and side handle before

starting and while using tool. Allow wheel to come

to full speed before starting.

2. When using a cut-off wheel, hold tool as shown,

using only the edge of the wheel (Fig. 11).

Fig. 11

3. Control pressure and surface contact between

wheel and workpiece. T oo much pressure slows

cutting speed.

WARNING A Type 1 guard must be

installed when using a Type 1 cut-off wheel to

provide maximum protection for the operator

if the wheel should break.

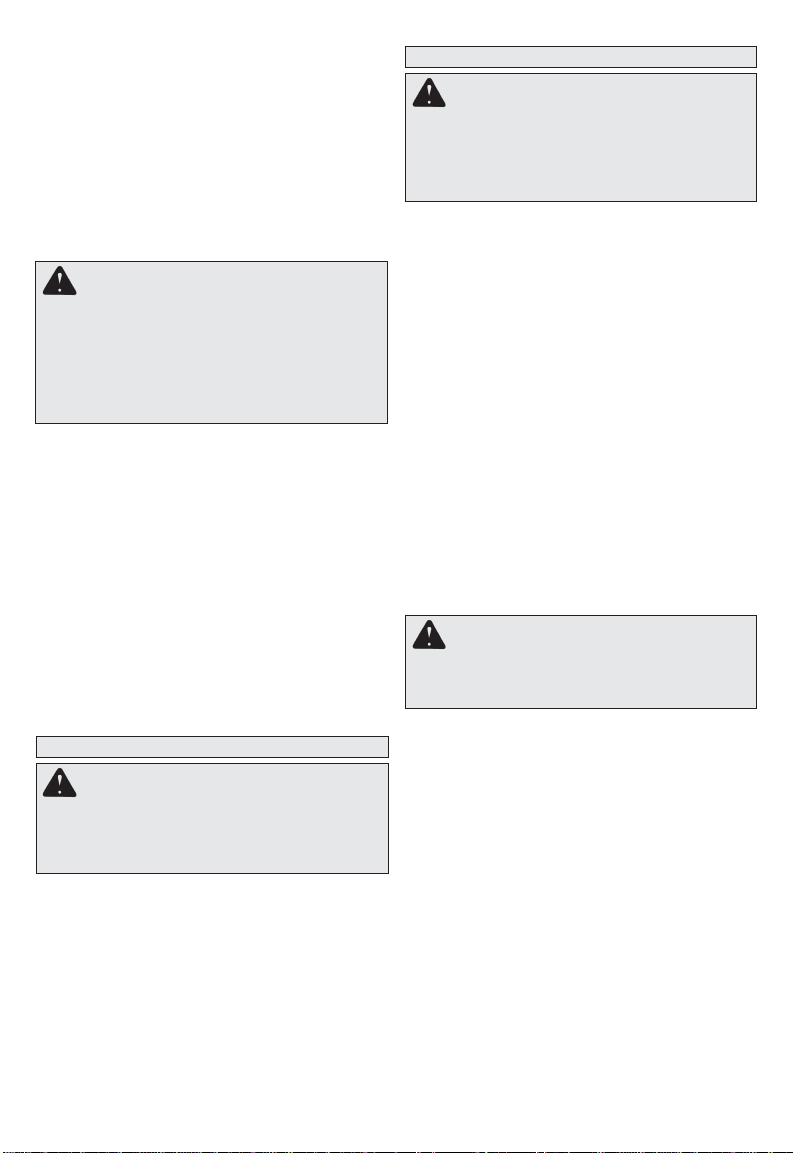

Installing and Removing Type 1 Guard Assembly and Adjusting Shoe

1. Unplug tool and place it upside down on a level

surface. Remove any accessories from spindle.

2. Loosen the guard screw and slip the guard over

the spindle.

Position the guard in the location which offers

11

Page 12

best control and guard protection. For operating

zones that provide maximum protection for the

operator, see Fig. 9. Tighten the guard screw

securely.

Fig. 12

Adjusting shoe

Carriage bolt and wingnut

Guard

Guard screw

USING WIRE BRUSHES

Selecting Wire Brushes

Wire brushes are useful for removing rust, scale,

burrs, weld slag, etc. A wide variety of wire brushes

are available for many applications.

WARNING Everyone in the area must

wear protective clothing and safety goggles

or face shields. Fatigued wires and residue

will fl y off the brush with considerable force,

causing the potential for serious injuries.

Installing Wire Cup Brushes

Fig. 14

Wire cup brush

Spindle

3. To adjust the guard, unplug the tool, loosen the

guard screw, rotate the guard to the desired

position and retighten the guard screw.

4. To remove the adjusting shoe, loosen the wing

nuts, slide the shoe over to the access holes

and lift out. To install the adjusting shoe, insert

the head of the carriage bolts into guard access

holes and slide the shoe over to the far edge of

slots. Adjust shoe to desired position and tighten

wing nuts securely.

5. To remove the guard, unplug the tool, remove

the accessories and reverse the procedure.

Using Type 1 Cut-Off Wheels

1. Firmly grasp rear handle and side handle before

starting and while using tool. Allow wheel to come

to full speed before starting.

2. When using a cut-off wheel, hold tool as shown,

using only the edge of the wheel (Fig. 13).

3. Control pressure and surface contact between

wheel and workpiece. Too much pressure slows

cutting speed.

Fig. 13

Nylon washer

Spindle

Spindle lock button

1. Unplug tool and place it upside down on a level

surface. Remove any accessories from spindle.

NOTE: Never use a guard with a wire cup brush.

2. Thread nylon washer onto spindle. Attach wire

cup brush onto spindle.

3. Press the spindle lock button while tightening

brush with a wrench (not provided with tool).

4. To remove wire cup brush, unplug tool and

reverse procedure.

WARNING Because the wires on wire

wheel brushes are directed towards the operator, a Type 27 guard must be used to protect

the operator when fatigued wires break.

Installing Wire Wheel Brushes

Fig. 15

Nylon

washer

Wire wheel brush

Guard

WARNING T o reduce the risk of injury ,

never use a Type 1 cut-off wheel for surface

grinding.

12

Spindle

lock

button

Spindle

Page 13

1. Unplug tool and place it upside down on a level

surface. Remove any accessories from spindle.

2. Thread nylon washer onto spindle. Attach guard

and wire wheel brush onto spindle (see Fig. 2

and 3 for attaching guard).

Position the guard in the location which offers

best control and guard protection. For operating

zones that provide maximum protection for the

operator, see Fig. 9.

3. Press the spindle lock button while tightening

brush with a wrench (not provided with tool).

4. To remove wire wheel brush and guard, unplug

tool and reverse procedure.

WARNING Never exceed Maximum

Safe Operating Speed of the brush. Do not use

a damaged brush or one which is functioning

improperly (throwing wires, out-of-balance,

etc.). These conditions increase the possibility of further brush failure and possible

injury. Discard and replace damaged brushes

immediately.

Using Wire Brushes

1. Do not wear loose clothing when using wire

brushes. The wires may catch on loose clothing

and pull the clothing into the moving parts.

2. Firmly grasp rear handle and side handle before

starting and while using tool. Always test the wire

brush for balance and loose or damaged wires

by running tool at no load speed for at least one

minute before applying it to your work.

3. When applying brush to work, avoid using too

much pressure. This causes over-bending of

wires and heat build-up resulting in premature wire

breakage, rapid dulling and reduced brush life.

Instead of using more pressure, try a wire

wheel brush with more aggressive cutting action (increased wire size, decreased wire length

or different brush type, i.e. knot type instead of

crimped wire type).

ACCESSORIES

WARNING To reduce the risk of injury ,

always unplug the tool before attaching or

removing accessories. Use only specifi cally

recommended accessories. Others may be

hazardous.

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go on-line

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or a service center.

MAINTENANCE

WARNING T o reduce the risk of injury,

always unplug your tool before performing

any maintenance. Never disassemble the tool

or try to do any rewiring on the tool’s electrical

system. Contact a MILW AUKEE service facility

for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the

general condition of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounting, broken parts and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use a

damaged tool. Tag damaged tools “DO NOT USE”

until repaired (see “Repairs”).

Under normal conditions, relubrication is not necessary until the motor brushes need to be replaced.

After six months to one year, depending on use,

return your tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears, spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• T esting to assure proper mechanical and electrical

operation

WARNING T o reduce the risk of injury,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to fl ow inside the tool.

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your

tool since certain cleaning agents and solvents

are harmful to plastics and other insulated parts.

Some of these include: gasoline, turpentine, lacquer

thinner, paint thinner , chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the

nearest service center.

13

Page 14

LIMITED WARRANTY - USA AND CANADA

Every MILWAUKEE power tool (including cordless product – tool, battery pack(s) - see separate & distinct

CORDLESS BATTERY PACK LIMITED WARRANTY statements & battery charger and Work Lights*) is warranted to the original purchaser only to be free from defects in material and workmanship. Subject to certain

exceptions, MILWAUKEE will repair or replace any part on an electric power tool which, after examination,

is determined by MILWAUKEE to be defective in material or workmanship for a period of fi ve (5) years* after

the date of purchase unless otherwise noted. Return of the power tool to a MILWAUKEE factory Service

Center location or MILWAUKEE Authorized Service Station, freight prepaid and insured, is required. A copy

of the proof of purchase should be included with the return product. This warranty does not apply to damage that MILWAUKEE determines to be from repairs made or attempted by anyone other than MILWAUKEE

authorized personnel, misuse, alterations, abuse, normal wear and tear, lack of maintenance, or accidents.

*The warranty period for, Job Site Radios, M12™ Power Port, M18™ Power Source, and T rade T itan™ Industrial Work Carts is one (1) year from the date of purchase. The warranty period for a LED Work Light and LED

Upgrade Bulb is a limited LIFETIME warranty to the original purchaser only, if during normal use the LED bulb

fails the Work Light or Upgrade Bulb will be replaced free of charge.

*This warranty does not cover Air Nailers & Stapler , Airless Paint Sprayer , Cordless Battery Packs, Gasoline Driven

Portable Power Generators, Hand T ools, Hoist – Electric, Lever & Hand Chain, M12™ Heated Jackets, Reconditioned

product and T est & Measurement products. There are separate and distinct warranties available for these products.

Warranty Registration is not necessary to obtain the applicable warranty on a MILWAUKEE power tool product.

The manufacturing date of the product will be used to determine the warranty period if no proof of purchase is

provided at the time warranty service is requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN IS

A CONDITION OF THE CONTRACT FOR THE PURCHASE OF EVERY MILWAUKEE PRODUCT. IF YOU

DO NOT AGREE TO THIS CONDITION, YOU SHOULD NOT PURCHASE THE PRODUCT. IN NO EVENT

SHALL MILWAUKEE BE LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL OR PUNITIVE

DAMAGES, OR FOR ANY COSTS, ATTORNEY FEES, EXPENSES, LOSSES OR DELAYS ALLEGED TO

BE AS A CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN ANY PRODUCT INCLUDING, BUT NOT LIMITED TO, ANY CLAIMS FOR LOSS OF PROFITS. SOME STATES DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHER EXPRESS WARRANTIES, WRITTEN OR ORAL. TO THE EXTENT PERMITTED BY

LAW, MILWAUKEE DISCLAIMS ANY IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE OR PURPOSE;

TO THE EXTENT SUCH DISCLAIMER IS NOT PERMITTED BY LAW, SUCH IMPLIED WARRANTIES ARE

LIMITED TO THE DURATION OF THE APPLICABLE EXPRESS WARRANTY AS DESCRIBED ABOVE.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO

THE ABOVE LIMITATION MAY NOT APPLY TO YOU, THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

This warranty applies to product sold in the U.S.A. and Canada only.

Please consult the ‘Service Center Search’ in the Parts & Service section of MILWAUKEE’s website

www.milwaukeetool.com or call 1.800.SAWDUST (1.800.729.3878) to locate your nearest service facility for

warranty and non-warranty service on a Milwaukee electric power tool.

LIMITED WARRANTY - MEXICO, CENTRAL AMERICA AND CARIBBEAN

TECHTRONIC INDUSTRIES' warranty is for 5 year since the original purchase date.

This warranty card covers any defect in material and workmanship on this Power Tool.

To make this warranty valid, present this warranty card, sealed/stamped by the distributor or store where you

purchased the product, to the Authorized Service Center (ASC). Or, if this card has not been sealed/stamped,

present the original proof of purchase to the ASC.

Call toll-free 1 800 832 1949 to fi nd the nearest ASC, for service, parts, accessories or components.

Procedure to make this warranty valid

Take the product to the ASC, along with the warranty card sealed/stamped by the distributor or store where

you purchased the product, and there any faulty piece or component will be replaced without cost for you. We

will cover all freight costs relative with this warranty process.

Exceptions

This warranty is not valid in the following situations:

a) When the product is used in a different manners from the end-user guide or instruction manual.

b) When the conditions of use are not normal.

c) When the product was modifi ed or repaired by people not authorized by TECHTRONIC INDUSTRIES.

Note: If cord set is damaged, it should be replaced by an Authorized Service Center to avoid electric risks.

SERVICE AND ATTENTION CENTER

Model:

Rafael Buelna No.1.

Col. Tezozomoc Mexico, Azcapotzalco D.F.

Date of Purchase:

Ph. 01 800 832 1949

Distributor or Store Stamp:

IMPORTED AND COMMERCIALIZED BY:

TECHTRONIC INDUSTRIES MEXICO, .S.A. DE C.V.

Av. Santa Fe 481 piso 6, Col. Curz Manca.

CP 05349, Cuajimalpa, D.F.

14

Page 15

RÈGLES DE SÉCURITÉ GÉNÉRALES RELATIVES AUX

OUTILS ÉLECTRIQUES

AVERTISSEMENT LIRE TOUTES LES RÈGLES ET INSTRUCTIONS DE SÉCURITÉ.

un incendie ou des blessures graves. Conserver les règles et les instructions à des

Ne pas suivre l’ensemble des règles et instructions peut entraîner une électrocution,

fi ns de référence ultérieure. Le terme «outil électrique» fi gurant dans les avertissements ci-

dessous renvoie à l’outil électrique à alimentation par le réseau (à cordon) ou par batterie (sans fi l).

SÉCURITÉ DU LIEU DE TRA VAIL

• Maintenir la zone de travail propre et bien

éclairée. Les zones encombrées ou mal éclairées

sont favorables aux accidents.

• Ne pas utiliser d’outil électrique dans une atmosphère explosive, telle qu’en en présence

de liquides, de gaz ou de poussières infl am-

mables. Les outils électriques génèrent des

étincelles qui peuvent enfl ammer les poussières

ou les fumées.

• Tenir les enfants et les personnes non autorisées à l’écart pendant le fonctionnement

d’un outil électrique. Un manque d’attention de

l’opérateur risque de lui faire perdre le contrôle de

l’outil.

SÉCURITÉ ÉLECTRIQUE

• La fi che de l’outil électrique doit correspondre

à la prise d’alimentation. Ne jamais modifi er la

fi che d’une manière quelconque. Ne pas utiliser d’adaptateur avec les outils électriques mis

à la terre (à la masse). Des fi ches non modifi ées

et des prises d’alimentation assorties réduisent le

risque de choc électrique.

• Éviter tout contact corporel avec des surfaces

reliées à la masse ou à la terre telles que

tuyaux, radiateurs, cuisinières et réfrigérateurs. Un risque de choc électrique plus élevé

existe si le corps est relié à la masse ou à la terre.

• Ne pas exposer les outils électriques à la pluie ou

à l’humidité. Le risque de choc électrique augmente

si de l’eau s’infi ltre dans un outil électrique.

• Prendre soin du cordon. Ne jamais utiliser le

cordon pour transporter, tirer ou débrancher

l’outil électrique. Tenir le cordon à l’écart de la

chaleur, des huiles, des arêtes coupantes ou

des pièces en mouvement. Un cordon endom-

magé ou emmêlé présente un risque accru de

choc électrique.

• Se procurer un cordon d’alimentation approprié en cas d’utilisation d’un outil électrique à

l’extérieur. L’utilisation d’un cordon d’alimentation

pour usage extérieur réduit le risque de choc

électrique.

• S’il est nécessaire d’utiliser l’outil électrique

dans un endroit humide, installer un appareil

à courant résiduel (RCD). L’utilisation d’un RCD

réduit le risque de décharge électrique.

SÉCURITÉ INDIVIDUELLE

• Être sur ses gardes, être attentif et faire preuve

de bon sens en utilisant un outil électrique. Ne

pas utiliser un outil électrique en cas de fatigue

ou sous l’infl uence de drogues, d’alcool ou

de médicaments. Un instant d’inattention lors

de l’utilisation d’un outil électrique peut entraîner

des blessures graves.

• Porter l’équipement de protection requis.

Toujours porter une protection oculaire. Selon

les conditions, porter aussi un masque antipoussières, des bottes de sécurité antidérapantes,

un casque protecteur ou une protection auditive

afi n de réduire les blessures.

• Empêcher les démarrages accidentels.

S’assurer que la gâchette est en position

d’arrêt avant de brancher l’outil à une source

de courant, d’insérer la batterie, de le ramasser

ou de le transporter. Le fait de transporter

l’outil en gardant le doigt sur la gâchette ou de le

brancher lorsque la gâchette est en position de

marche favorise les accidents.

• Retirer toute clé de réglage avant de mettre

l’outil sous tension. Une clé laissée attachée sur

une pièce mobile de l’outil électrique peut entraîner

des blessures.

• Ne pas travailler à bout de bras. Bien garder

un bon équilibre à tout instant. Ceci permet de

mieux préserver la maîtrise de l’outil électrique

dans des situations imprévues.

• Porter des vêtements adéquats. Ne pas porter

de vêtements amples ni de bijoux. Ne pas approcher les cheveux, vêtements et gants des

pièces en mouvement. Les vêtements amples,

les bijoux ou les cheveux longs risquent d’être

happés par les pièces en mouvement.

• Si des dispositifs sont prévus pour l’extraction

et la récupération des poussières, vérifier

qu’ils sont connectés et utilisés correctement.

L’utilisation de ces dispositifs peut réduire les

risques liés aux poussières.

UTILISATION ET ENTRETIEN

DE L’OUTIL ÉLECTRIQUE

• Ne pas forcer l’outil électrique. Utiliser l’outil

électrique approprié à l’application considérée.

L’outil électrique adapté au projet considéré produira de meilleurs résultats, dans des conditions

de sécurité meilleures, à la vitesse pour laquelle

il a été conçu.

• Ne pas utiliser l’outil électrique si le commutateur ne le met pas sous ou hors tension. Tout

outil électrique dont le commutateur de marchearrêt est inopérant est dangereux et doit être

réparé.

• Débrancher la fi che de la prise d’alimentation

et/ou la batterie de l’outil électrique avant

d’effectuer des réglages, de changer

d’accessoires ou de ranger l’outil. De telles

mesures de sécurité préventive réduisent le risque

de mettre l’outil en marche accidentellement.

• Ranger les outils électriques inutilisés hors

de la portée des enfants et ne pas laisser des

personnes qui connaissent mal les outils électriques ou ces instructions utiliser ces outils. Les

15

Page 16

outils électriques sont dangereux dans les mains

d’utilisateurs non formés à leur usage.

• Entretien des outils électriques. S’assurer de

l’absence de tout désalignement ou de grippage des pièces mobiles, de toute rupture de

pièce ou de toute autre condition qui pourrait affecter le bon fonctionnement de l’outil

électrique. En cas de dommages, faire réparer

l’outil avant de l’utiliser de nouveau. Les outils

électriques mal entretenus sont à la source de

nombreux accidents.

• Garder les outils de coupe affûtés et propres.

Les outils de coupe correctement entretenus et

bien affûtés risquent moins de se gripper et sont

plus faciles à manier.

• Utiliser l’outil électrique, les accessoires, les

grains etc. conformément à ces instructions

en tenant compte des conditions de travail

et de la tâche à effectuer. L’utilisation de cet

outil électrique pour effectuer une opération pour

laquelle il n’est pas conçu peut occasionner une

situation dangereuse.

ENTRETIEN

• Faire effectuer l’entretien de l’outil électrique

par un technicien qualifi é qui n’utilisera que

des pièces de rechange identiques. La sécurité

d’utilisation de l’outil en sera préservée.

RÈGLES DE SÉCURITÉ

SPÉCIFIQUES

Règles de sécurité générales pour le meulage

des pièces, le nettoyage à l’aide d’une brosse

métallique ou le découpage à l’abrasif :

•Cet outil électrique est conçu pour servir

de meuleuse, ponceuse, brosse métallique

ou d’outil à tronçonner. Consulter tous les

avertissements et toutes les instructions, les

illustrations et les précisions fournis avec cet

outil électrique. Ne pas suivre l’ensemble des

instructions décrites ci-dessous peut entraîner une

électrocution, un incendie ou des blessures graves.

•Il n’est pas recommandé d’utiliser cet outil

électrique pour polir des pièces. Le fait d’utiliser

l’outil pour effectuer des tâches pour lesquelles

il n’est pas conçu peut présenter du danger et

entraîner des blessures.

•Ne pas utiliser des accessoires qui ne sont pas

spécialement conçus et recommandés par le

fabricant. Le simple fait qu’un accessoire peut

s’ajuster sur l’outil électrique ne signifi e pas qu’il

peut être utilisé en toute sécurité.

•La vitesse nominale de l’accessoire doit au moins

être égale à la vitesse maximale indiquée sur l’outil

électrique. Les accessoires qui sont utilisés à une

vitesse supérieure à leur VITESSE NOMINALE

peuvent se briser et se détacher.

•Le diamètre extérieur et l’épaisseur de l’accessoire

doivent être conformes à la capacité de l’outil

électrique. Il est impossible d’envelopper ou

de contrôler adéquatement un accessoire de

dimension inappropriée.

La taille de l’arbre des meules, des brides, des

plateaux porte-disque ou de tout autre accessoire

doit convenir parfaitement à la broche de l’outil

électrique. Si les accessoires utilisés sont dotés

d’alésages centraux qui ne conviennent pas à la

pièce de montage de l’outil, ils se déstabiliseront,

vibreront de façon excessive et pourront causer

une perte de contrôle.

•Ne pas utiliser un accessoire endommagé.

Inspecter l’accessoire avant chaque utilisation

afi n de s’assurer que les meules, par exemple,

sont exemptes d’ébréchures et de fi ssures, que

le plateau porte-disque est exempt de fi ssures

et qu’il n’est pas usé de façon excessive, et

que la brosse métallique ne comprend pas de

fi ls détachés ou craquelés. Si l’outil électrique

ou l’accessoire est échappé, s’assurer

qu’il n’est pas endommagé ou installer un

autre accessoire. Après avoir effectué cette

opération, se tenir à distance de l’accessoire

en rotation et faire fonctionner l’outil à sa

vitesse à vide maximale pendant une minute.

S’assurer que personne ne se tient à proximité

de l’outil. Les accessoires endommagés se brisent

généralement lors de cette vérifi cation.

•Porter de l’équipement de protection individuelle. Selon le type d’opération, porter un

masque de protection ou des lunettes de

sécurité. Au besoin, porter également un masque anti-poussières, un protecteur d’oreille,

des gants et un tablier d’atelier résistant aux

petits fragments abrasifs ou aux fragments

provenant des pièces à travailler. La protection oculaire utilisée doit résister aux débris

projetés lors des différentes opérations. La

protection oculaire utilisée doit résister aux débris

projetés lors des différentes opérations. Le masque anti-poussières et le masque fi ltrant doivent

fi ltrer les particules produites lors de l’opération.

Une exposition prolongée à un bruit fort peut

entraîner une perte auditive.

•S’assurer que personne ne se tient à proximité

du lieu de travail. Toute personne qui entre sur

le lieu de travail doit porter l’équipement de

protection individuelle requis. Des fragments

provenant de la pièce à travailler ou d’un accessoire

brisé peuvent être projetés et causer des blessures,

même à des personnes se tenant à une certaine

distance du lieu de travail immédiat.

•Lorsque l’outil est utilisé pour un travail risquant

de mettre l’accessoire de coupe en contact

avec des fi ls électriques cachés, le tenir par les

surfaces de prise isolées uniquement. Le contact

d’un accessoire de coupe avec un fi l sous tension

« électrifi e » les pièces métalliques exposées de

l’outil et peut électrocuter l’utilisateur.

•Tenir le cordon loin de l’accessoire en rotation.

En cas de perte de contrôle, le cordon peut être

coupé ou accroché, et la main ou le bras de

l’utilisateur risquent d’entrer en contact avec

l’accessoire en rotation.

•Ne jamais déposer l’outil électrique avant l’arrêt

complet de l’accessoire. L’accessoire en rotation

peut attraper la surface et occasionner une perte

de contrôle.

•Ne jamais laisser l’outil électrique fonctionner

en le transportant à ses côtés. L’accessoire en

rotation peut s’accrocher accidentellement aux

vêtements et entrer en contact avec l’utilisateur.

16

Page 17

•Nettoyer régulièrement les évents d’aération

de l’outil électrique. Le ventilateur du moteur

aspire la poussière dans le logement et crée une

accumulation excessive de métal fritté, ce qui peut

causer un danger électrique.

•Ne pas faire fonctionner l’outil électrique à

proximité de matériaux infl ammables. Les

étincelles peuvent enfl ammer ces matériaux.

•Ne pas utiliser d’accessoires qui nécessitent

des liquides de refroidissement. L’utilisation

d’eau ou d’un autre liquide de refroidissement peut

entraîner une électrocution ou un choc électrique.

REMARQUE L’avertissement ci-dessus

ne s’applique pas aux outils électriques

spécifi quement conçus pour être utilisés avec

un système de liquide.

rebonds et avertissements connexes

- au pincement ou à l’accrochage de la meule, du

plateau porte-disque, de la brosse ou de tout

autre accessoire en rotation. Un pincement ou

un accrochage provoque le blocage immédiat de

l’accessoire en rotation qui, à son tour, entraîne

l’outil incontrôlé dans le sens opposé à la rotation

de l’accessoire, à l’endroit du coincement.

- Par exemple, si une meule abrasive est accrochée

ou pincée par la pièce à travailler, le rebord de la

meule qui entre dans le point de pincement peut

s’enfoncer dans la surface du matériau, éjectant la

meule ou la faisant rebondir. La meule peut sauter

vers l’utilisateur ou loin de lui, selon le sens du

mouvement de la meule au point de pincement.

Dans ces conditions d’utilisation, les meules

abrasives peuvent également se briser.

- Un rebond est attribuable à une mauvaise utilisation

de l’outil ou au non-respect des procédures ou des

conditions d’utilisation. Pour empêcher les rebonds,

respecter les directives décrites ci-dessous.

• T enir fermement l’outil électrique et placer le corps

et les mains de manière à pouvoir résister aux

rebonds. Toujours utiliser la poignée auxiliaire,

s’il y en a une, pour assurer un contrôle optimal

en cas de rebond ou de réaction de couple lors

du démarrage de l’outil. L’utilisateur peut contrôler

les rebonds et les réactions de couple s’il respecte

les directives prescrites.

•Ne jamais placer les mains à proximité de

l’accessoire en rotation. En cas de rebond,

l’accessoire peut dévier sur celles-ci.

•Ne pas positionner le corps à l’endroit où

sera entraîné l’outil électrique si un rebond se

produit. Un rebond entraînera l’outil dans le sens

opposé au mouvement de la meule, à l’endroit de

l’accrochage.

•Faire preuve d’une extrême prudence au

moment d’utiliser l’outil sur des coins ou

des rebords tranchants. Les coins, les rebords

tranchants et les surfaces qui tressautent ont

tendance à s’accrocher à la pièce en rotation et

à causer une perte de contrôle ou des rebonds.

•Ne pas fi xer une lame de sculpteur pour scie à

chaîne ou une lame de scie dentée. Ces deux

types de lame occasionnent de nombreux rebonds

et des pertes de contrôle fréquentes.

Règles de sécurité spécifi ques pour le meulage

des pièces et le découpage à l’abrasif :

•Utiliser seulement les types de meule recommandés

pour cet outil électrique et le garde-meule

spécialement conçu pour la meule utilisée. Il est

impossible d’envelopper de façon adéquate et

sécuritaire les meules qui ne sont pas spécialement

conçues pour l’outil électrique.

•Le garde-meule doit être fi xé solidement à l’outil

électrique et positionné de manière à garantir une

sécurité optimale; il importe donc de diriger le moins

possible la meule vers l’utilisateur. La garde aide à

protéger l’opérateur des fragments de meule brisés

et d’un contact accidentel avec la meule ainsi que

des étincelles pouvant enfl ammer les vêtements.

REMARQUE L’avertissement ci-dessus peur

être ignoré pour les meuleuses ou meules de

tronçonnage d’une capacité nominale inférieure

à 55 mm.

•Utiliser seulement les meules pour effectuer

des opérations pour lesquelles elles sont

conçues. Par exemple : ne pas meuler avec

le côté d’une meule à tronçonner. Seule la

périphérie des meules à tronçonner abrasives doit

être utilisée pour le meulage. Le fait d’appliquer

une force latérale sur ces meules peut provoquer

leur éclatement.

•Toujours utiliser des brides de meule non

endommagées de formes et de dimensions

convenables pour la meule choisie. Les brides

de meule adéquates soutiennent la meule, ce qui

minimise les risques de bris de celle-ci. Les brides

de meules à tronçonner peuvent différer des brides

de meules standards.

•Ne pas utiliser de meules usées qui proviennent

d’outils électriques de plus grandes dimensions.

Les meules conçues pour des outils électriques de

plus grandes dimensions ne conviennent pas à

la vitesse plus élevée des outils de plus petites

dimension et peuvent éclater.

Règles de sécurité supplémentaires spécifi ques

pour le découpage à l’abrasif :

•S’assurer que la meule à tronçonner ne se coince

pas et éviter d’appliquer trop de pression. Ne

pas régler la meule à une profondeur de coupe

excessive. Le fait d’appliquer trop de pression

sur la meule augmente la charge, la tendance de

la meule à se tordre ou à se coincer pendant la

coupe, ainsi que les risques de rebond ou de bris

de la meule.

• Ne pas se tenir vis-à-vis de la meule en rotation

ou derrière celle-ci. Pendant l’opération, lorsque la

meule s’éloigne de l’utilisateur, un rebond pouvant

projeter la meule en rotation et l’outil électrique

directement vers l’utilisateur peut se produire.

•Si la meule se coince ou si l’opération de coupe est

interrompue pour une raison quelconque, éteindre

l’outil électrique et le maintenir immobile jusqu’à ce

que la meule s’arrête complètement. Ne jamais

essayer de retirer la meule à tronçonner de la

coupe quand la meule est en mouvement, car

ceci pourrait provoquer un rebond. Déterminer

et éliminer la cause du blocage de la meule.

•Ne pas remettre en marche l’outil si celui-ci est

dans la pièce à travailler. Permettre à la meule

d’atteindre sa vitesse maximale puis la réinsérer

dans le trait de coupe avec précaution. La meule

risque de se coincer, de se soulever ou de rebondir

17

Page 18

si cette précaution n’est pas prise.

•Soutenir les panneaux ainsi que toute pièce à

travailler surdimensionnée afi n de minimiser les

risques de pincement et de rebond de la meule.

Les pièces à travailler de grandes dimensions

ont tendance à fl échir sous leur propre poids. Il

importe donc de disposer des supports sous la

pièce à travailler, près du trait de coupe ainsi que

du rebord de la pièce à travailler, des deux côtés

de la meule.

•Redoubler de prudence lors de la découpe

d’évidements dans des cloisons existantes

ou autres endroits sans visibilité arrière. La

meule sortante peut couper les conduites d’eau ou

de gaz, le câblage électrique, ainsi que tout autre

objet pouvant provoquer un rebond.

Règles de sécurité spécifi ques pour le ponçage :

•Ne pas utiliser un papier pour disque abrasif

surdimensionné. Suivre les recommandations

du fabricant au moment de choisir le papier

abrasif. Un papier abrasif qui excède la surface

du disque de ponçage présente un danger de

lacération et peut s’accrocher, se déchirer, ou

entraîner un rebond.

Règles de sécurité spécifi ques pour le brossage

métallique :

•Porter une attention particulière à la brosse

métallique, dont les poils peuvent être projetés

même pendant une opération régulière. Éviter

de surcharger les poils en appuyant sur la

brosse de manière excessive. Les poils de la

brosse métallique peuvent pénétrer facilement

dans les vêtements léger ou la peau.

•S’il est recommandé d’installer un dispositif

protecteur pour utiliser une brosse métallique,

s’assurer qu’il n’entre pas en contact avec la brosse.

Le diamètre de la brosse métallique peut augmenter

en raison de la charge et de la force centrifuge.

• Entretenez les étiquettes et marqies di fabri-

cant. Les indications qu'elles contiennent sont

précieuses. Si elles deviennent illisibles ou se

détachent, faites-les remplacer gratuitement à un

centre de service MILWAUKEE accrédité.

• AVERTISSEMENT: La poussière degage par

perçage, sclage, perçage et autres travaux de

construction contient des substances chimiques

reconnues comme pouvant causer le cancer, des

malformations congénitales ou d’autres troubles

de reproduction. Voici quelques exemples de telles

substances :

• Le plomb contenu dans la peinture au plomb.

• Le silice cristallin contenu dans la brique,

le béton et divers produits de maçonnerie.

• L’arsenic et le chrome servant au traitement

chimique du bois.

Les risque associés à l’exposition à ces substanc-

es varient, dépendant de la fréquence des travaux.

Afi n de minimiser l’exposition à ces substances

chimiques, assurez-vous de travailler dans un

endroit bien aéré et d’utiliser de l’equipement

de sécurité tel un masque antipoussière spécifi quement conçu pour la fi ltration de particules

microscopiques.

SPÉCIFICATIONS

No de

Cat.

6088-30

6088-31

6089-30

6089-31

Volts A

120

CA/CD

120

CA/CD

120

CA/CD

120

CA/CD

T/Min.

Dimension

à vide

6 000

15

6 000

15

6 000

15

6 000

15

Pivot

5/8"-11

5/8"-11

5/8"-11

5/8"-11

Dimension

Meule

178/229 mm

7"/9"

178/229 mm

7"/9"

178/229 mm

7"/9"

178/229 mm

7"/9"

CORDONS DE RALLONGE

Si l’emploi d’un cordon de rallonge est nécessaire,

un cordon à trois fi ls doit être employé pour les

outils mis à la terre. Pour les outils à double isolation, on peut employer indifféremment un cordon

de rallonge à deux ou trois fi ls. Plus la longueur

du cordron entre l’outil et la prise de courant est

grande, plus le calibre du cordon doit être élevé.

L’utilisation d’un cordon de rallonge incorrectement

calibré entraîne une chute de voltage résultant en

une perte de puissance qui risque de détériorer

l’outil. Reportez-vous au tableau ci-contre pour

déterminer le calibre minimum du cordon. Moins

le calibre du fi l est élevé, plus sa conductivité est

bonne. Par exemple, un cordon de calibre 14 a une

meilleure conductivité qu’un cordon de calibre 16.

Lorsque vous utilisez plus d’une rallonge pour couvrir la distance, assurez-vous que chaque cordon

possède le calibre minimum requis. Si vous utilisez

un seul cordon pour brancher plusieurs outils, additionnez le chiffre d’intensité (ampères) inscrit sur

la fi che signalétique de chaque outil pour obtenir le

calibre minimal requis pour le cordon.

Directives pour l’emploi des cordons de rallonge

• Si vous utilisez une rallonge à l’extérieur, assurez-

vous qu’elle est marquée des sigles « W-A » (« W »

au Canada) indiquant qu’elle est adéquate pour

usage extérieur.

• Assurez-vous que le cordon de rallonge est correctement câblé et en bonne condition. Remplacez