Milwaukee 4612 Operallng Instructions And Parts List

OPERAllNG INSTRUCTIONS

.

AND PARTS LIST FOR

CATALOG NUMBER

4612

BUL. 54-00-1400

October 1, 1973

MILWAUKEE ELECTRIC TOOL CORP.

I7

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING

INFORMATION AS SHOWN IN THIS LIST:

1. M.E.T.CO. PART NUMBER’

2 The PART NAME 4. The NAME of Item: AC ALTERNATOR

AC ALTERNATOR

3. M.E.T.CO.. CAT. NO. 4612

5. STARTING SERIAL NO. 508 - 1104

DEPENDABLE POWER

MILWAUKEE ELECTRIC TOOL CORPORATION

13135 WEST LISBON ROAD

BROOKFIELD, WISCONSIN 53005

a

Printedin USA-100

Put No. 39639

SB-62651-101

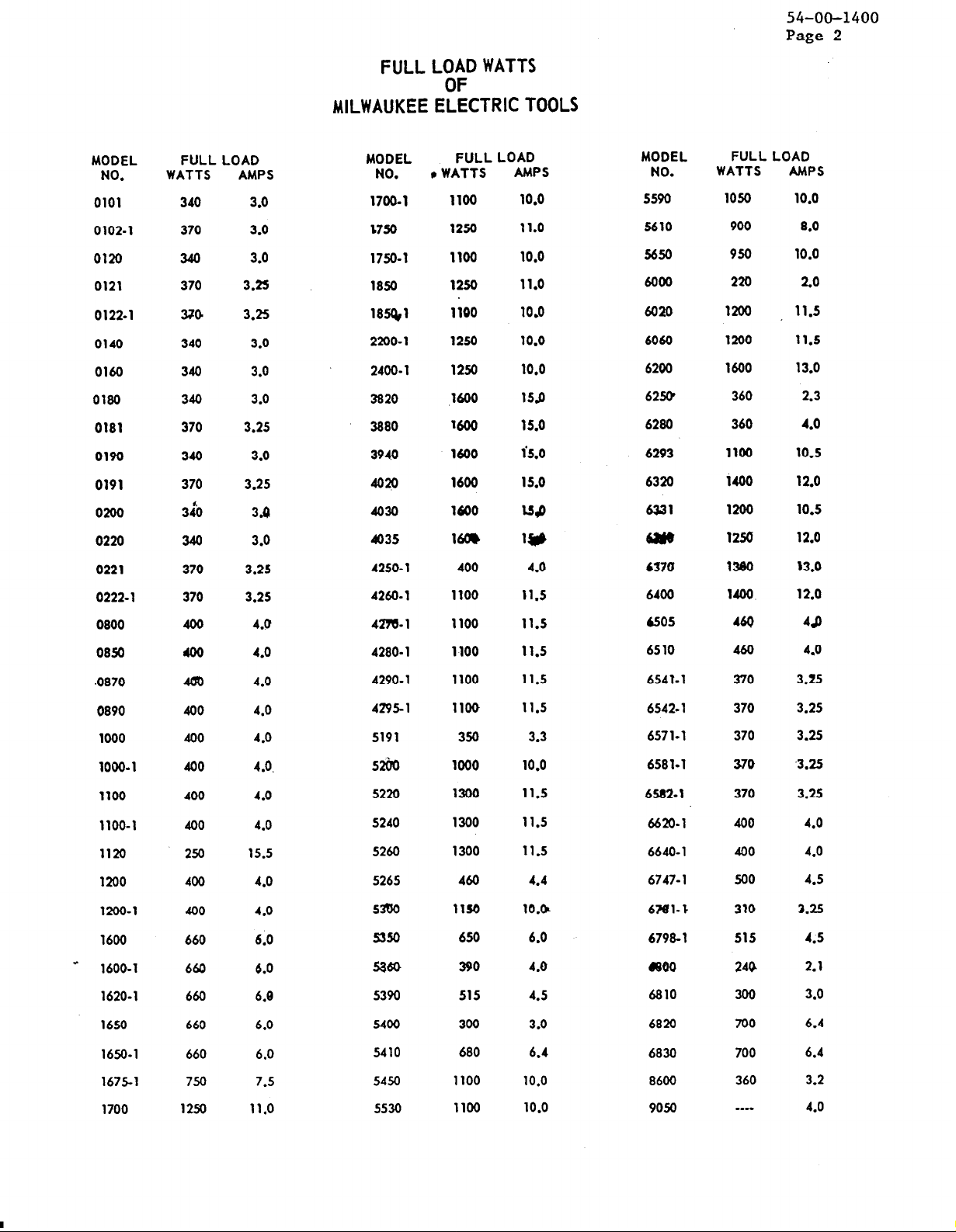

FULL LOAD WATTS

OF

MILWAUKEE ELECTRIC TOOLS

54-00-1400

Page 2

MODEL

NO.

0101

0102-l

0120

0121

0122-l

0140

0160

0180

0181

0190

0191

02OO

0220

0221

0222-l

FULLLOAD

WATTS

340

370

340

370

33th

340

340

340

370

340

370

320

340

370

370

AMPS

3.0

3.0

3.0

3.25

3.25

3.0

3.0

3.0

3.25

3.0

3.25

34

3.0

3.25

3.25

MODEL

NO.

1700-l

175o

1750-l

1850

185Q,l

2200-l

2400-l

3820

3880

3940

4om

4o3o

4035

4250-l

4260.1

FULLLOAD

*WATTS

1100

125o

1100

1250

1100

1250 10.0

1250

1600

1600 15.0

1600 is.0

1600

l&O

16a+

400

1100

AMPS

10.0

11.0

10.0

11.0

10.0

10.0

15P

15.0

w

lrp

4.0

11.5

MODEL

NO.

5590

5610

565o

6000

6020

6oM)

6200

625O'

6280

6293

6320

6331

637U

6400

FULLLOAD

WATTS

1050

900

950

220

1200

lmo

1600

360

360

1100

1400

12OO

1250

MO

Moo

-AMPS

10.0

8.0

10.0

2.0

11.5

11.5

13.0

2.3

4.0

10.5

12.0

10.5

12.0

13.0

12.0

c

0800

0850

.0870

0890

1000

1000-l

1100

1100-l

1120

lmo

1200-l

1600

1600-l

1620-l

1650

165Q-1

1675-1

1700

400

4oo

4al

400

400

a00

400

400

250 15.5

400

400

660

660

660

660

660

750

1250

4.0

4.0

4.0

4.0

4.0

4.0.

4.0

4.0

4.0

4.0

6.0

6.0

6.0

6.0

6.0

7.5

11.0

427u.l

4280-l

4290-l

4295-l

5191

52ho

5220

5240

5260

5265

53uo

535o

5360

5390

5400

5410

5450

5530

1100 11.5

1100 11.5

1100 11.5

1100

350

loo0 10.0

1300

1300

1300 11.5

460

1150

650

390

515

300

680

1100

1100 10.0

11.5

3.3

11.5

11.5

4.4

1O.b

6.0

4.0

4.5

3.0

6.4

10.0

6505

6510

6541-1

6542-l

6571-1

6581.1

6582-l

66x)-1

6640-l

6747-l

6?81-1

6798-l

#BOO

6810

6820

6830

8600

9050

460

460

370

370

370

370

370

400

400

MO

310

515

24Q

300

700

700

360

-_-s

4a

4.0

3.25

3.25

3.25

,3.25

3.25

4.0

4.0

4.5

3.25

4.5

2.1

3.0

6.4

6.4

3.2

4.0

54-00-1400

Page 3

RULES FOR SAFE OPERATION

1. Gasoline engines give off deadly carbon monoxide. Never run a gasoline engine in the basement

or other areas in a building.

2. This alternator has an air cooled engine which

must have good circulation of air.

3. Gasoline engines should not be stored or operated

in holds of boats or ships.

4. Check the local code as to the laws governing

storing gasoline in confined areas.

5. Never fill a gasoline engine in the dark or when

the engine is hot.

6. Check the oil every time you fill the gas tank or

every 5 hours.

7. Under no condition should the gasoline engine

be hooked up to any pressure fuel pump (auto,

tractor or auxiliary line).

8. Always check wattage requirements on labeled

motors and appliances before attempting to oper-

ate.

9. If an extension cord is necessary, always use as

short a length as possilbe. The longer the cord the

greater the voltage drop resulting in less power

applied to the tube.

10. The load should be applied to the alternator

after it has reached its operating speed. Never start

alternator with load.

11. Engine speed is preset at the factory. If this

speed is incorrectly readjusted by the customer,

serious damage may be incurred in the tools or W

pliances connected to the alternator.

ALTERNATOR

3099 WATT - Manual Start

TYPE: Revolving field four pole, single phase,

115/230 volt at 26/13 amps. 60 cycle, drip

proof design.

ROTOR: Laminated electrical steel, pressed on

shaft, sintered brass collection rings. Windings are

precision semi-automatic wound.

STATOR: Laminated electrical steel pressed into

steel stator band. Precision wound, automatic tied

coils, pressed end returns.

BEARINGS: Life Time sealed ball bearings running

in a steel bearing insert.

VARNISH: Class “H” Westinghouse double dip

7 hr. cure cycle.

INSULATION: Modified class “H” insulating sys-

tem, DMD liners, heavy polythermaleze wire insu-

lation. Dacron tie tape, modified fiber wedges.

COOLING: Centrifugal blower directly connected

to the rotor shaft.

COLOR: Metco Red

INSTALLING & OPERATING

1. ( ) Uncrate and inspect for shipping damage.

2. ( ) Ventilation: Adequate ventilation must be

provided ror safe, efficient operation.

3. ( ) Fill engine with 32 oz. of oil.

CAUTION

This product has been engineered and manufactured.

W_ provide trouble free operation, if proper-

ly cared for and used within its rated specifications.

Always use care when operating or repairing this

alternator, lethal voltages are present and the same

caution should be exercised as is used with’ the

electrical wiring in your home. Follow a regular

maintenance and service schedule to provide efficient and safe operation.

ENGINE

SPECIFICATIONS

TYPE: 4 cycle, L head, single cylinder, 3% ” bore,

2-7/8” stroke, 27.66 cu. in. displacement, 12 H.P.

COOLING: Pressure Air Cooled

GOVERNOR: Mechanical Type Preset

IGNITION: Flywheel Magneto

STARTING: Rope

3lL SYSTEM: Splash Lube 32 Oz.

FUEL TANK: 1 gallon capacity

Note: To Order An Exact Replacemen

t Engine, Order From M.E.T.O.

NOTE: Oil weight Recommendations

Summer -SAE 30 M.S.

Winter - cNv20 M.S.

4, ( ) Fill fuel tank, with regular or low-leaded

gasoline.

MAINTENANCE

1. Periodically

hours) inspect

(approximately every 290 operating

the alternator brushes and clean the

slip rings.

Part No. 43-20-4010

Loading...

Loading...