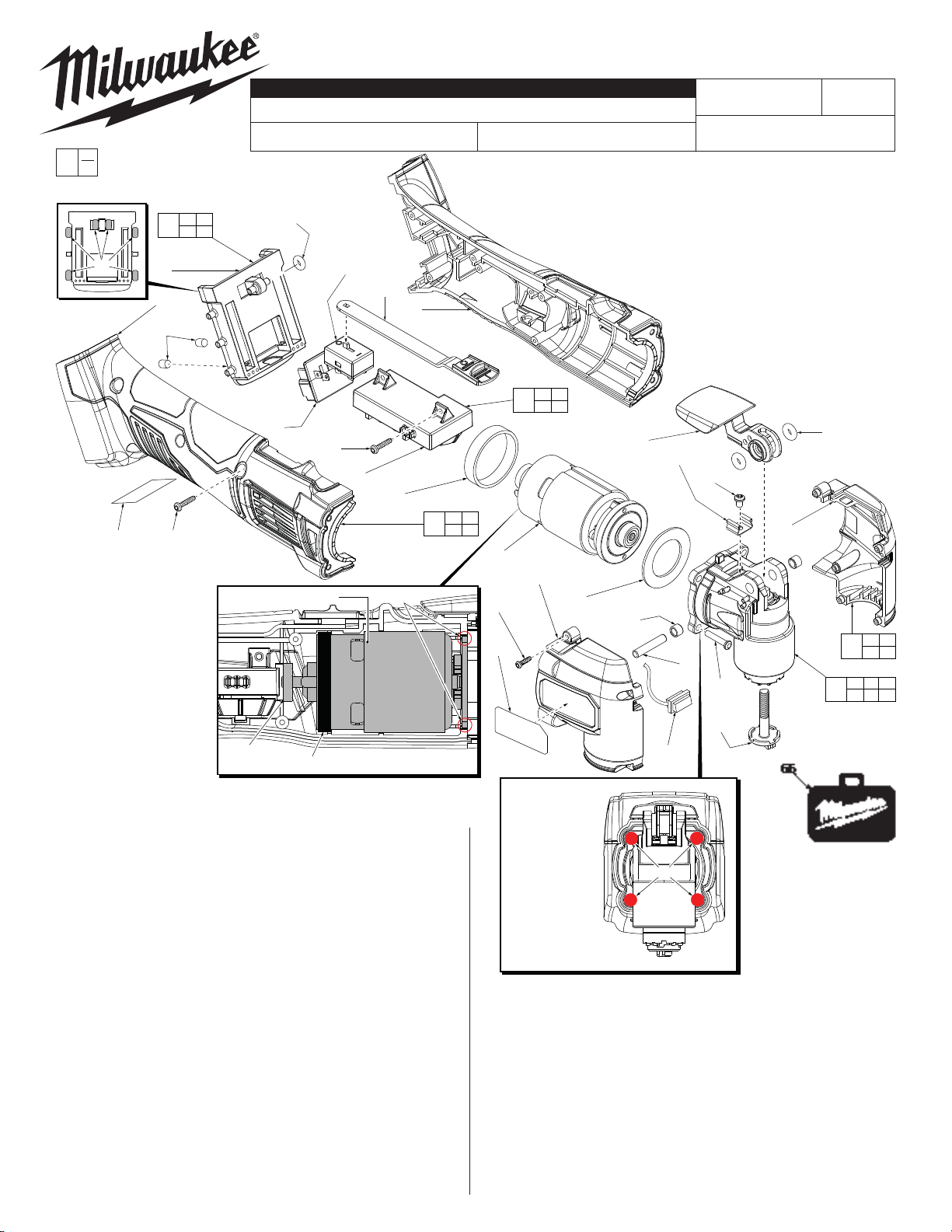

Milwaukee 2626-20 User Manual

EXAMPLE:

00

Component Parts (Small #) Are Included

0

When Ordering The Assembly (Large #).

SERVICE PARTS LIST

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS

M18™ MULTI-TOOL

CATALOG NO. 2626-20

STARTING

SERIAL NO.

F40A

BULLETIN NO.

54-22-2600

REVISED BULLETIN

WIRING INSTRUCTION

See Page Two

DATE

Nov. 2013

12 13

62

14

13

17 16(5x)

When replacing Motor

Assembly #63, be sure to

reuse Motor Band #20.

Place the motor band flush

to the end of the motor

canister as shown. Be sure

not to cover motor vents.

IMPORTANT:

Do not attempt to make

adjustments to the magnet

ring or any other component on the motor assembly.

When reinstalling a motor

assembly, be sure to orient the ‘lobes’ of the motor mount at the 12:00 and

6:00 position prior to placing the motor assembly in Left Rear Handle #2.

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

1 --------------- Front Housing - Left 1

2 --------------- Rear Handle - Left 1

3 44-10-0225 Quick Release Lever 1

4 05-88-0045 M4 x 0.7 x 8mm Pan Hd. Taptite Phillips Scr 1

5 42-70-0510 Clip 1

6 34-40-0077 Rubber O-Ring 2

7 42-40-0125 Nylon Bushing 2

9 45-24-1030 Switch Slide 1

10 --------------- On-Off Switch 1

11 --------------- Terminal Block 1

12 44-66-0392 Terminal Block Plate 1

13 43-86-0005 Rubber Isolators 6

14 45-30-1000 Silicone Slug 2

15 --------------- LED Assembly 1

16 06-82-1080 M3 x 14mm Pan Hd. Plastite T-10 Screw 7

17 10-20-2743 Warning Label 1

18 --------------- PCBA 1

20 42-16-0450 Motor Band (Rubber) 1

22 --------------- Rear Handle - Right 1

29 45-88-0088 Washer 1

31 44-60-0605 5.0 x 26mm Pin 1

32 --------------- Front Housing - Right 1

33 06-82-2385 M2.6 x 14mm Pan Hd. Plastite T-8 Screw 5

34 12-20-2638 Service Nameplate 1

12

22

14

13(6x)

10

9

11

16(2x)

18

20

Motor Assembly #63 Lobes

Magnet

Ring Motor Band #20

2

60

10 11

61

15 18

3

5

4

2 16

17 22

63

32

33

(5x)

34

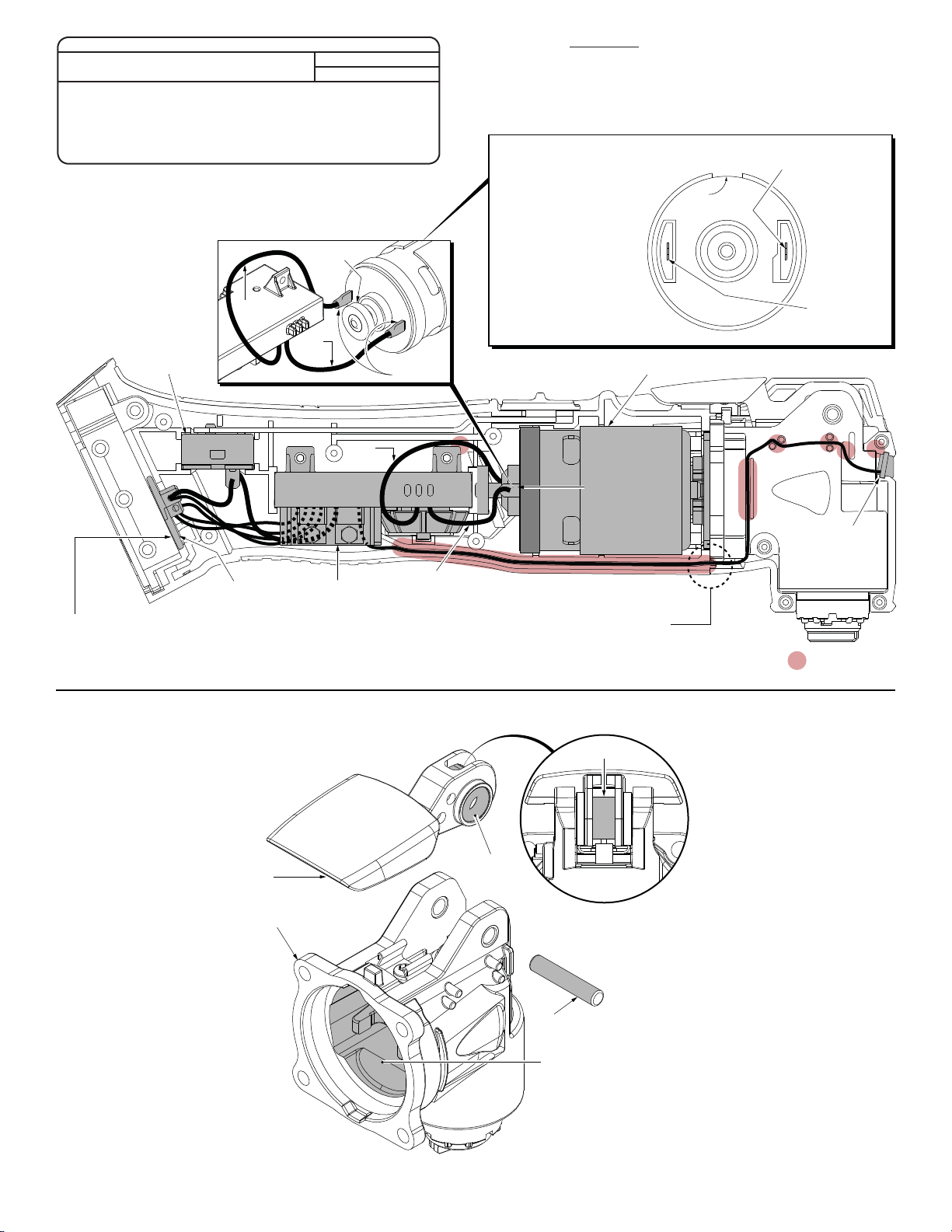

Alternate the

tightening pattern

for gearcase

screws #42 as

shown.

Seat torque to

be 19.5 in/lbs

(21.5 kg/cm)

Order is 1,2,3,4

than 1,2,3,4 again

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

42 05-88-0400 M4 x 20mm Fillister Hd. T-20 Screw 4

47 06-75-0025 Blade/Backing Pad Screw 1

60 31-44-1055 Rear Handle Assembly 1

61 14-20-2626 Switch/Electronics Assembly 1

62 14-67-0130 Terminal Block Plate Assembly 1

63 14-50-0705 Motor Assembly 1

64 14-38-2000 Front Housing Assembly 1

65 14-29-2626 Gearcase Assembly 1

66 48-55-3500 Carrying Case 1

29

7(2x)

31

42

(4x)

47

15

1

4

MILWAUKEE ELECTRIC TOOL CORPORATION

3

42

2

13135 W. Lisbon Road, Brookfi eld, WI 53005

1

6(2x)

64

65

1 32

33 34

3 4 5

6 7 31

Drwg. 3

SEAT TORQUE

FIG. PART NO. WHERE USED (KG/CM) (IN/LBS)

4 05-88-0045 Gearcase (Top) / Clip 13±2 11.5±1.5

16 06-82-1080 Rear Handle - Right 10±2 8.5±1.5

16 06-82-1080 PCBA 10±2 8.5±1.5

33 06-82-2385 Front Housing - Right 7±1 6±1

42 05-88-0400 Gearcase (Front) 21.5±2 18.5±1.5

NOTE:

Route the blue wire (from the PCBA to the negative motor terminal)

behind the PCBA screw lobe. Be sure to tuck the blue wire down

into the rear handle as much as possible, away from the magnet

ring of the motor assembly.

It is recommended to use

heat shrink tubing over the

soldered wires / motor

terminals as shown.

SCREW TORQUE SPECIFICATIONS

Magnet

Ring

Blue Wire

Red

On-Off

Switch

Wire

+

Heat Shrink

Tubing

Blue

Wire

It is recommended to hand tighten Rear Handle Screws #16, PCBA

Screws #16 and Front Housing Screws #33 to prevent over tightening.

Exercise caution when tightening screws if a cordless driver drill is used.

Proper orientation of the

Motor Assembly #63 is

with the slot in the motor

canister to the top at the

12:00 position.

This rear view of the motor

assembly is shown without

the rubber motor band #20

in place so the slot at the

top could be seen.

Motor Assembly

Positive Motor

Terminal

Positive motor terminal is surrounded

by a plastic ledging with a step

Slot

in it. Connect red

wire from PCBA

to this terminal.

+

terminal has

Connect blue

wire from PCBA

to this terminal.

The plastic

around the

negative

no step.

ledging

Terminal

Block

NOTE:

Terminal Block #11 must be

installed at the same time into

Terminal Block Plate #12.

LUBRICATION NOTES:

Use Type 'J' Grease,

No. 49-08-4220

When servicing, remove 90-95%

of the existing grease prior to installing Type “J”. Original grease

maybe similar in color but not

compatible with “J”.

PCBA

Place a light coating of grease on the

metal cam portion of the Quick Release

Lever #3 prior to installing on the

Gearcase Assembly #65.

3

65

Red Wire

Before securing the Right Rear Handle #22

and the Right Front Housing #32, be sure that

the LED wires are tucked completely down in

the wire trap. Be careful not to pinch the LED

wires in the area where the rear handles, front

housings and gearcase meet.

LED

= WIRE TRAPS

or GUIDES

Place a light coating of grease on the

O-Rings #6 (both sides) prior to installing

Metal Cam

6

Front View of #3

Quick Release Lever

Place a light coating of

grease on Metal Pin #31

prior to installing in the

Gearcase Assembly #65.

31

in the Quick Release Lever #3.

Fill the inside cavity of

Gearcase Assembly #65

with approximately .35oz.

(10g) of grease.

Loading...

Loading...