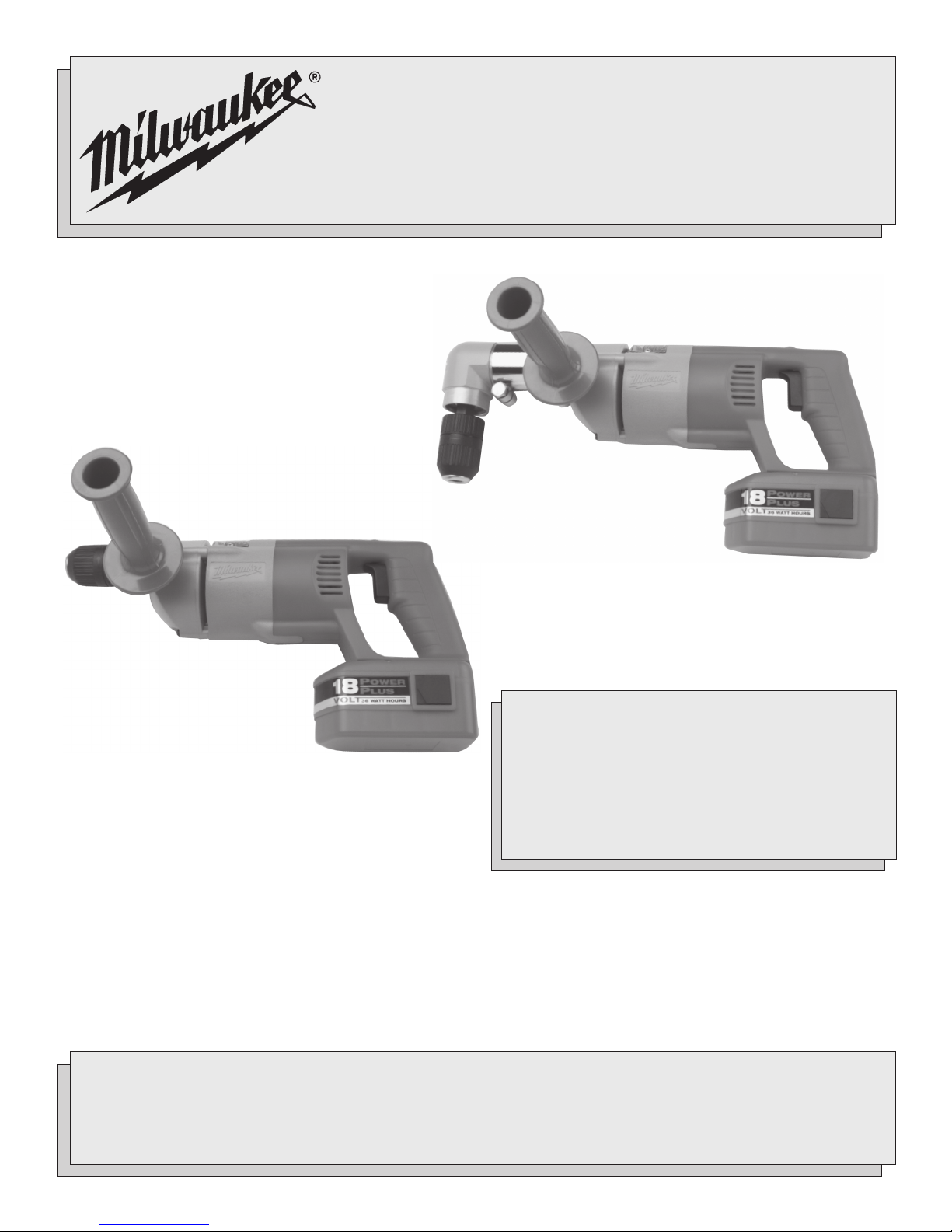

Milwaukee 3109-24, 1109-20 Operator's Manual

Catalog No.

No de Cat.

Catálogo No.

1109-20

3109-24

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

SPECIAL NOTE: New battery packs are not fully charged. Charge

your battery pack before using it for the first time and follow the

charging instructions in your charger manual.

NOTE SPÉCIALE : Les batteries neuves ne sont pas entièrement

chargées. Chargez la batterie avant de vous en servir la première

fois en suivant les instructions de recharge dans le manuel qui

accompagne cet outil.

NOTA ESPECIAL: Las baterías, cuando son nuevas, no están

totalmente cargadas. Cargue su batería antes de usarla por

primera vez y siga las instrucciones de carga que vienen en el

manual de la herramienta.

18 V 1/2" D-HANDLE DRILL AND RIGHT ANGLE DRIVE DRILL

13 mm (1/2") POIGNÉE EN ETRIER ET POIGNÉE COUDEE ANGLE DROIT 18 V

TALADROS DE 13 mm (1/2") CON EMPUNADURA EN "D" CABEZAL PARA

TRANSMISION DE POTENCIA EN ANGULO RECTO DE 18V

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

GENERAL SAFETY RULES — FOR ALL BATTERY OPERATED TOOLS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control. Protect others in the work area from debris such as chips and sparks. Provide

barriers or shields as needed.

ELECTRICAL SAFETY

4. Do not abuse the cord. Never use the cord to carry the tool. Keep

cord away from heat, oil, sharp edges, or moving parts. Replace

damaged cords immediately. Damaged cords may create a fire.

5. A battery operated tool with integral batteries or a separate battery pack must be recharged only with the specified charger for

the battery. A charger that may be suitable for one type of battery

may create a risk of fire when used with another battery.

6. Use battery operated tool only with specifically designated bat-

tery pack. Use of any other batteries may create a risk of fire.

PERSONAL SAFETY

7. Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in serious personal injury.

8. Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in mov-

ing parts.

9. Avoid accidental starting. Be sure switch is in the locked or off

position before inserting battery pack. Carrying tools with your

finger on the switch or inserting the battery pack into a tool with the

switch on invites accidents.

10. Remove adjusting keys or wrenches before turning the tool on.

A wrench or a key that is left attached to a rotating part of the tool

may result in personal injury.

11. Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enable better control of the tool in unexpected situations.

12. Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be used

for appropriate conditions.

TOOL USE AND CARE

13. Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or against

your body is unstable and may lead to loss of control.

14. Do not force tool. Use the correct tool for your application. The

correct tool will do the job better and safer at the rate for which it is

designed.

15. Do not use tool if switch does not turn it on or off. A tool that

cannot be controlled with the switch is dangerous and must be repaired.

16. Disconnect battery pack from tool or place the switch in the

locked or off position before making any adjustments, changing

accessories, or storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

17. Store idle tools out of reach of children and other untrained per-

sons. Tools are dangerous in the hands of untrained users.

18. When battery pack is not in use, keep it away from other metal

objects like: paper clips, coins, keys, nails, screws, or other small

metal objects that can make a connection from one terminal to

another. Shorting the battery terminals together may cause sparks,

burns, or a fire.

19. Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edge are less likely to

bind and are easier to control.

20. Check for misalignment or binding of moving parts, breakage of

parts, and any other condition that may affect the tool’s operation. If damaged, have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools. Do not use a damaged

tool. Tag damaged tools “Do not use” until repaired.

21. Use only accessories that are recommended by the manufac-

turer for your model. Accessories that may be suitable for one tool

may create a risk of injury when used on another tool.

SERVICE

22. Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel may

result in a risk of injury.

23. When servicing a tool, use only identical replacement parts. Fol-

low instructions in the Maintenance section of this manual. Use

of unauthorized parts or failure to follow Maintenance Instructions

may create a risk of shock or injury.

page 2

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a

replacement.

2. Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring. Contact with a

“live” wire will make exposed metal parts of the tool “live” and shock the operator.

3. Keep hands away from all cutting edges and moving parts.

4. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

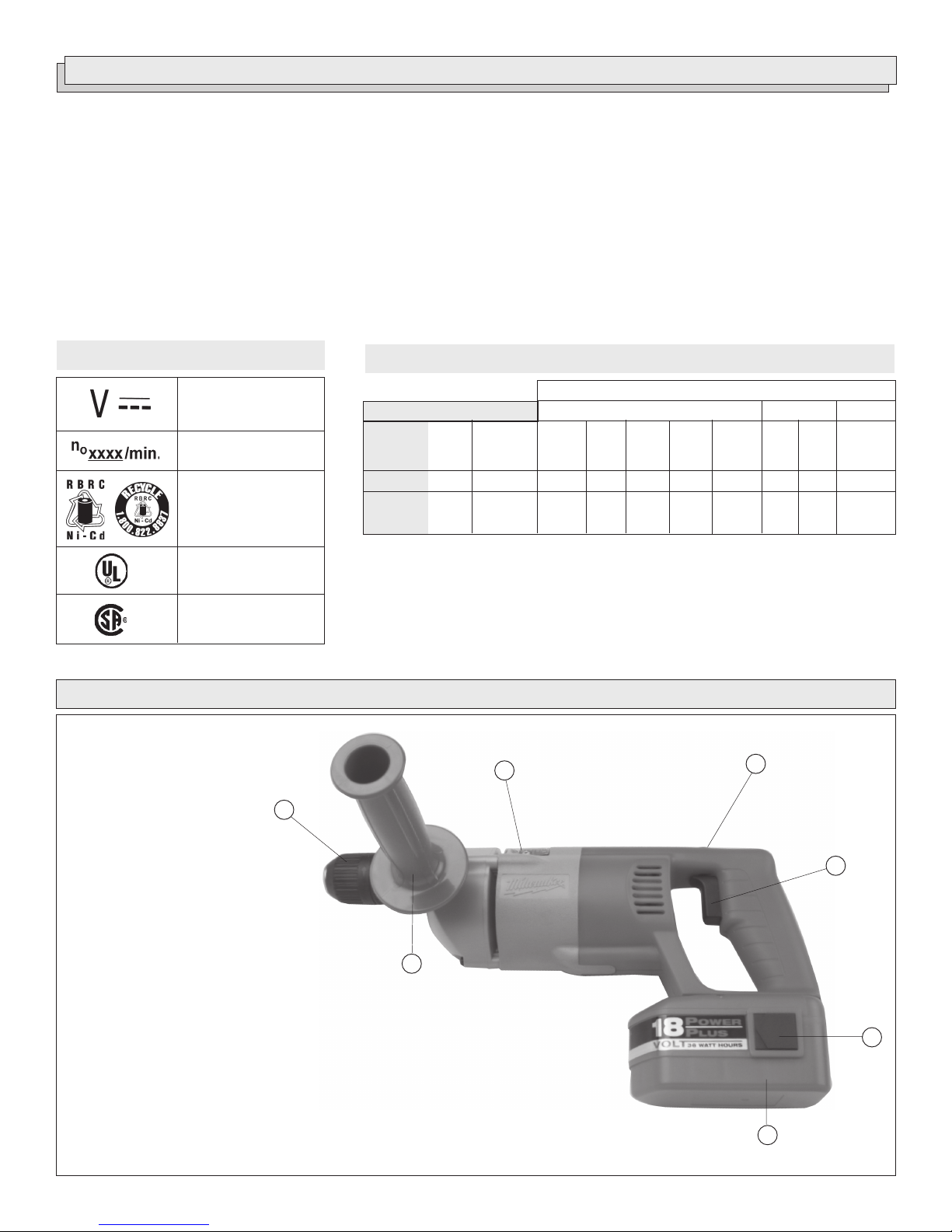

Symbology

Volts Direct Current

No Load Revolutions

per Minute (RPM)

Properly Recycle Nickel

Cadmium Batteries

Cat. No.

1109-20

RAD

3109-24

Tool

No

Load

RPM

0-500

RAD

RPM

- -

Lo 0-335

Hi 0-750

Boring

Specifications

Flat

Hole

Bits

Saw

1-1/2"

1-1/2"

4-1/2"

1-1/2"

3-1/2"

Wood Steel

4"

Auger

Bit

1"

1-1/2"

3/4"

MILWAUKEE

Capacities

Ship

Auger

Selfeed

Bit

Bit

1-1/4"

1-1/2"

1-1/2"

2-9/16"

1"

1"

service facility for a free

Masonry

Hole

Saw

2-5/8"

3"

2"

Carbide

Tipped

Bit

1/2"

1/2"

1/2"

Twist

Drill

1/2"

1/2"

1/2"

Underwriters

Laboratories, Inc.

Canadian Standards

Association

1. Chuck

2. Nameplate

3. Forward/lock/reverse switch

4. Trigger

5. Battery pack release buttons

6. Battery pack

7. Side handle

FUNCTIONAL DESCRIPTION

2

1

7

3

4

5

6

page 3

CHARGING AND USING BATTERY PACK

WARNING!

Charge only

Volt battery packs in chargers. Other types

of batteries may explode causing personal

injury and damage.

Charge your battery pack before using your tool for the first time and

when your tool no longer performs with the power and torque needed for

the job. Full loading capacity of battery pack is only reached after

4 - 5 chargings. Never completely discharge the battery pack. Standard

charging time will vary according to the type of charger you use. The

charging time will also vary depending on the supply voltage and charge

needed. For example, if your battery pack does not require a full charge,

charging time will be less.

FOR SPECIFIC CHARGING INSTRUCTIONS, PLEASE READ THE

CHARGER INSTRUCTION SHEET SUPPLIED WITH YOUR CHARGER.

Battery packs are affected by temperature. Your battery pack will

perform best and have longest life if it is charged when the temperature

is between 60°-80°F (15°-27°C). Do not charge in temperatures below

40°F (5°C) or above 105°F (40°C). Under these conditions, capacity will

be reduced. See “Maintenance”.

MILWAUKEE

12, 14.4 and 18

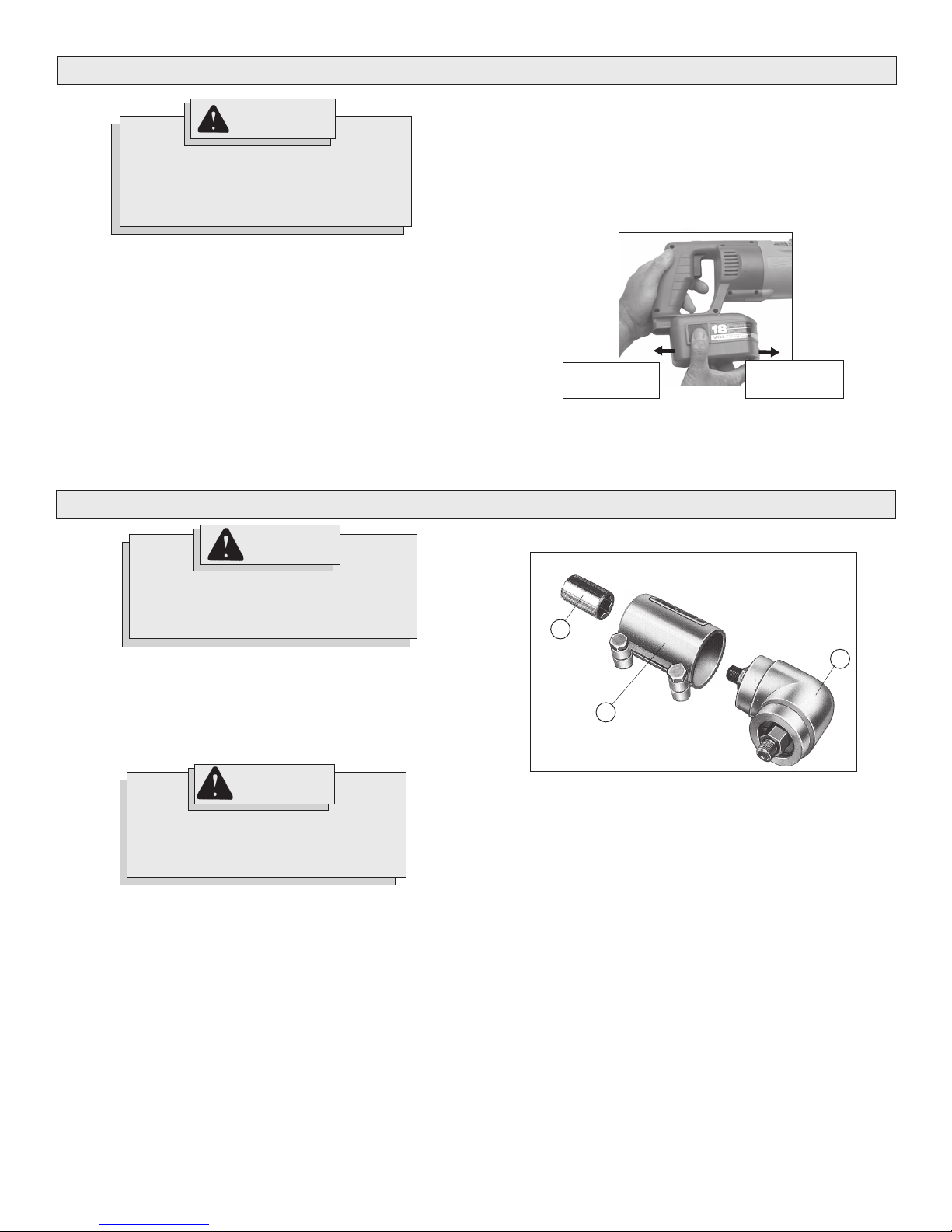

TOOL ASSEMBLY

WARNING!

To reduce the risk of injury, always remove

battery pack before attaching or removing accessories. Use only specifically recommended

accessories. Others may be hazardous.

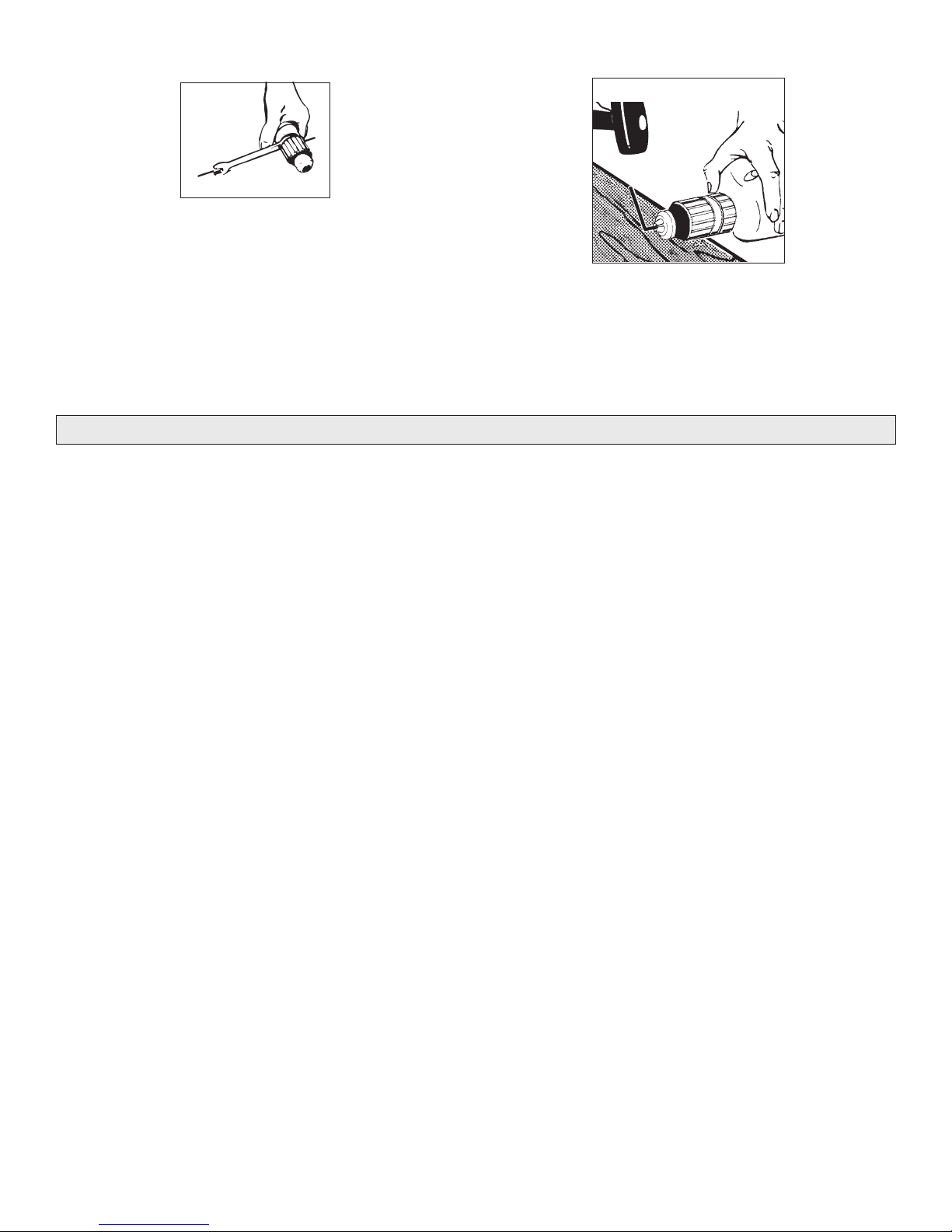

Removing Battery Pack from Tool (Fig. 1)

Push in the release buttons and remove the battery pack.

Inserting Battery Pack into Tool (Fig. 1 )

To insert the battery pack into the tool, push in the release buttons and

slide it into the body of the tool (Fig 1).

Fig. 1

Inserting a

battery pack

Attaching Right Angle Drive to a Drill (Fig. 2)

Fig. 2

Removing a

battery pack

1

Installing Side Handle

A side handle has been supplied with your tool. It can be

attached to the gear case on either side of the drill. Because of the high

torque of this drill, the side handle must always be used when operating

the drill. To attach the side handle, screw the threaded end of the side

handle into the hole on the drill's gear case.

WARNING!

To reduce the risk of injury, always use a

side handle when using this tool. This tool

operates with high torque. Always brace or

hold the tool securely.

Ring Clamp Side Handle For Right Angle Drive Unit

A ring clamp side handle is supplied with Right Angle Drive Units. This

handle clamps onto the Right Angle Drive Unit and swivels 360° to be

locked tight in any position. When using the Right Angle Drive Unit, do

not use the side handle. When using the D-Handle Drill without the Right

Angle Drive Unit, do not clamp the ring clamp side handle to the front of

the gear case; instead, use the side handle.

3

2

1. Remove the chuck from the drill following instructions (see “Removing

the Chuck from the Drill”). Slip the double hex coupling (1) over the

hex on the drill spindle.

Loosen the clamping screws on the clamping sleeve (2) and slip the

sleeve onto the drill collar.

2. Slide the right angle drill head (3) into the other side of the sleeve

and turn the drive head slightly in either direction so the hexagonal

hole in the coupling engages the hexagonal portion of the spindle.

NOTE: Attaching the drill chuck to the side designated “low” reduces

the speed by 1/3, or 33%. Attaching the drill chuck to the opposite

side of the right angle drill head increases the speed by 1/2, or 50%.

3. When assembled, turn the right angle head to the desired position

and tighten the clamping screws to secure the unit. Thread the chuck

onto the right angle drive spindle and install the chuck screw.

page 4

Removing the Chuck from the Right Angle Drive Unit (Fig. 3)

Removing the Chuck from the Drill (Fig. 4)

Fig. 3

The chuck can be removed from the right angle drive unit in the same

manner it is removed from the drill; however, ALWAYS REMOVE RIGHT

ANGLE DRIVE FROM THE DRILL BEFORE ATTEMPTING TO LOOSEN

THE CHUCK. This will prevent damaging the drill's gearing. Use the open

end wrench provided to hold the right angle drive spindle before attempting to loosen the chuck.

APPLICATIONS

Selecting Bits

When selecting a bit, use the right type for your job. For best performance, always use sharp bits.

Drilling

1. Before drilling, be sure the workpiece is clamped securely. Use backing material to prevent damage to the workpiece during breakthrough.

2. When starting a hole, place the drill bit on the work surface and

apply firm pressure. Begin drilling at a slow speed, gradually increasing the speed as you drill.

3. Always apply pressure in line with the bit. Use enough pressure to

keep the drill biting, but do not push hard enough to stall the motor.

4. Reduce pressure and ease the bit through the last part of the hole.

While the tool is still running, pull the bit out of the hole to prevent

jamming.

Drilling in Wood, Composition Materials and Plastic

When drilling in wood, composition materials and plastic, start the drill

slowly, gradually increasing speed as you drill. When drilling into wood,

use wood augers or twist drill bits. Always use sharp bits. When using

twist drill bits, pull the bit out of the hole frequently to clear chips from the

bit flutes. To reduce the chance of splintering, back work with a piece of

scrap wood. Select low speeds for plastics with a low melting point.

Fig. 4

1. To remove the left-hand screw inside the chuck, remove the battery

pack from the tool and open the chuck jaws. Insert a T-handle hex

key into the screw inside the chuck. Turn the T-handle hex key and

remove the screw. Save the screw for installing your new chuck.

2. To remove chuck: Tighten a large hex key into the chuck. Place the

chuck on a workbench as shown. Strike the hex key with a soft-headed

mallet to loosen the chuck. Remove the chuck by hand.

Drilling in Metal

When drilling in metal, use high speed steel twist drills or hole saws. Use

a center punch to start the hole. Lubricate drill bits with cutting oil when

drilling in iron or steel. Use a coolant when drilling in nonferrous metals

such as copper, brass or aluminum. Back the material to prevent binding

and distortion on breakthrough.

Drilling in Masonry

When drilling in masonry, use high speed carbide-tipped bits. Drilling soft

masonry materials such as cinder block requires little pressure. Hard

materials like concrete require more pressure. A smooth, even flow of

dust indicates the proper drilling rate. Do not let the bit spin in the hole

without cutting. Do not use water to settle dust or to cool bit. Both actions

will damage the carbide.

Driving Screws

When driving screws, use the proper screwdriver bit for your job. After

drilling pilot and shank holes, start the screw slowly and increase the

speed as driving progresses. Set the screw by slowing to a stop. Do not

run screws down at excessive speeds. To remove screws, reverse the

motor.

page 5

OPERATION

WARNING!

To reduce the risk of injury, wear safety goggles

or glasses with side shields.

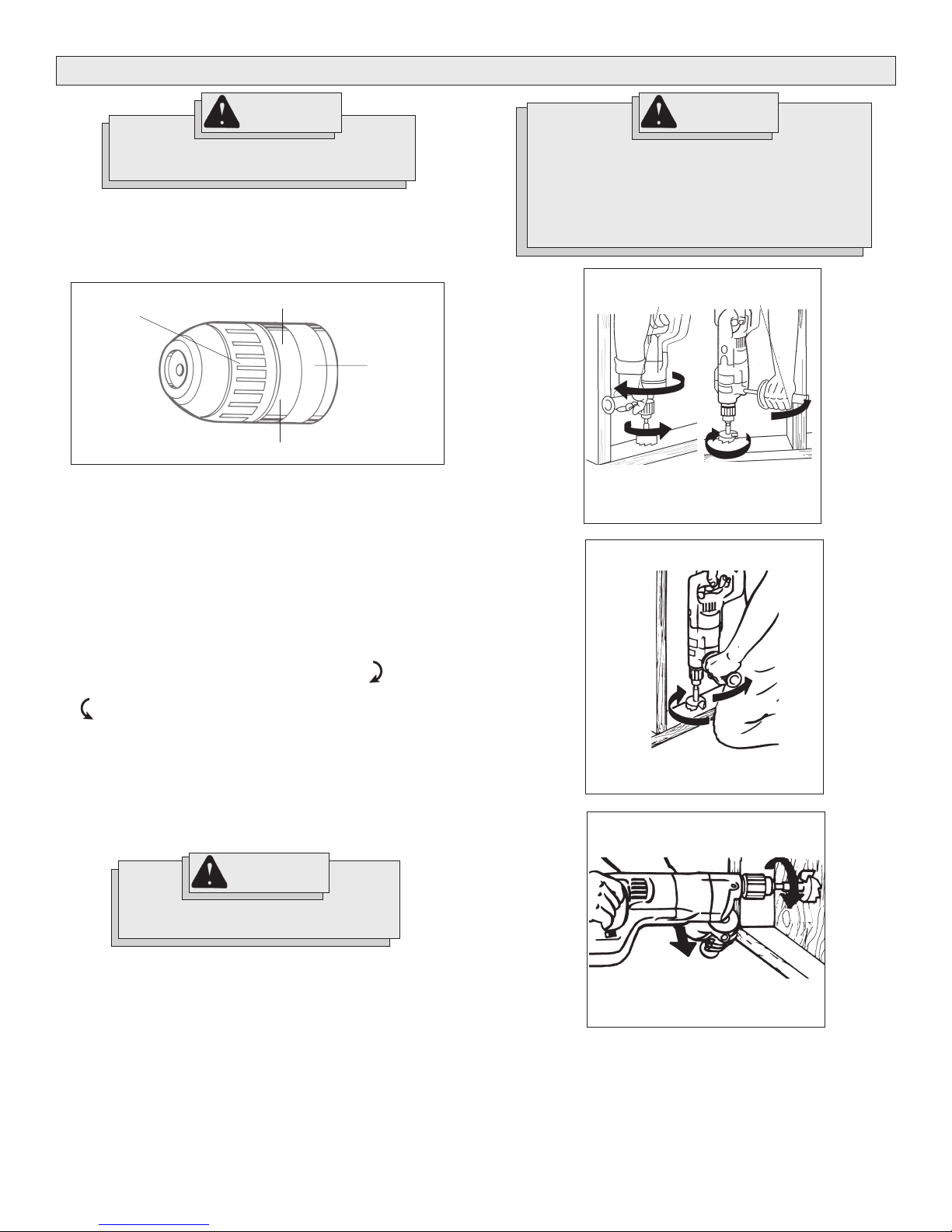

Using keyless chucks (Fig. 5)

For best performance, always use sharp, clean bits and be sure the chuck

jaws are clean. Dirt particles may cause the bit to line up improperly. Do

not use bits larger than the maximum recommended capacity for the drill

because gear damage or motor overloading may result.

Fig. 5

Sleeve

1. Remove the battery pack from the tool. To open the chuck jaws, turn

the sleeve in the direction marked RELEASE.

2. Allow the bit to strike the bottom of the chuck and center the bit in the

chuck jaws.

To close the chuck jaws, hold the collar while turning the sleeve in

the direction marked GRIP. Tighten securely. Insert battery pack on

the tool.

3. To remove the bit, hold the collar while turning the sleeve in the direction marked RELEASE.

RELEASE

Collar

GRIP

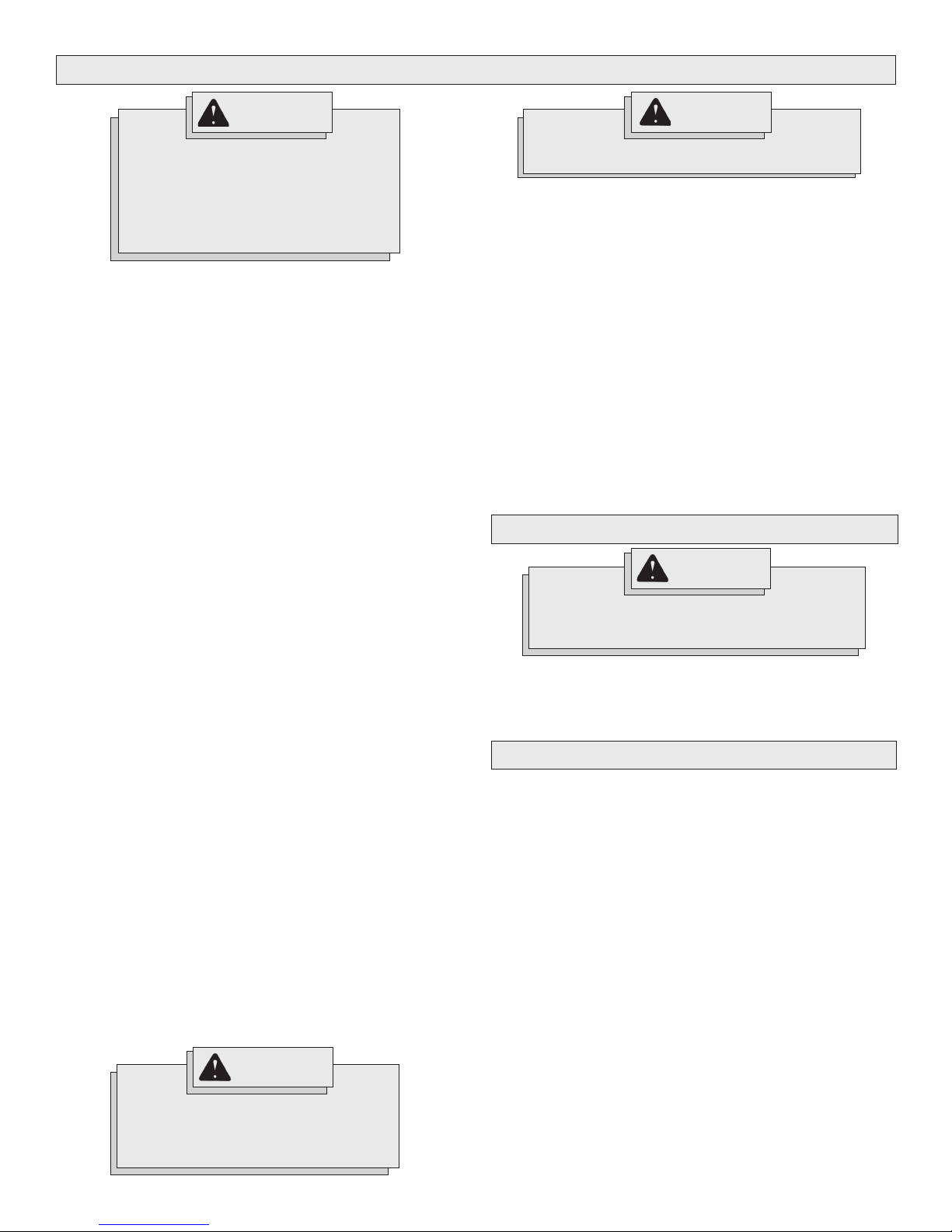

WARNING!

To reduce the risk of personal injury, hold the tool

securely. Brace tools with side handles as shown

(Fig. 6, 7 & 8). If the bit binds, the tool will be forced

in the opposite direction. Bits may bind if they are

misaligned or when breaking through a hole. Wood

boring bits can also bind if they run into nails or

knots.

Fig. 6

Reaction

Reverse

rotation

Bracing against a stud

Fig. 7

Reaction

Forward

rotation

Using forward/lock/reverse switch

1. For forward (clockwise) rotation, push the switch to .

2. For reverse (counterclockwise) rotation, push the switch to

. Although an interlock prevents reversing the tool while the motor

is running, allow it to come to a full stop before reversing.

Locking the trigger

To lock the trigger, slide the trigger lock switch until the “locked” symbol is

visible. The trigger will not work while the switch is in the locked position.

Always lock the trigger and remove the battery pack before performing

maintenance and changing accessories. Lock the trigger when storing

the tool and when the tool is not in use.

WARNING!

To reduce the risk of injury, keep hands

away from the bit and all moving parts.

Starting, stopping and controlling speed

1. To start the tool, pull the trigger.

2. To vary the drilling speed, increase or decrease pressure on the

trigger. The further the trigger is pulled, the greater the speed.

3. To stop the tool, release the trigger.

Forward

rotation

Bracing against your leg

Fig. 8

Reaction

Bracing against the floor

Reaction

Forward

rotation

page 6

MAINTENANCE

WARNING!

To reduce the risk of personal injury,

always unplug the charger and remove the

battery pack from the charger or tool

before performing any maintenance. Never

disassemble the tool, battery pack or

charger. Contact a

facility for ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good repair by adopting a

regular maintenance program. After six months to one year, depending

on use, return the tool, battery pack and charger to a

vice facility for:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears, spindles,

bearings, housing, etc.)

• Electrical inspection (battery pack, charger, motor)

• Testing to assure proper mechanical and electrical operation

If the tool does not start or operate at full power with a fully charged

battery pack, clean the contacts on the battery pack. If the tool still does

not work properly, return the tool, charger and battery pack to a

MILWAUKEE

Maintaining Battery Pack

MILWAUKEE

of cycles when they are maintained and used according to these instructions.

A battery pack that is stored for six months without being used will discharge itself. Batteries discharge at a rate of about 1% per day. Charge

the battery every six months even if it is unused to maximize battery life.

Do not tape the trigger in the “ON” position and leave the tool unattended

as this may discharge the battery to a point where it will no longer be able

to recharge. Use a

forms with the power and torque needed for your application.

Store your battery pack in a cool, dry place. Do not store it where the

temperature may exceed 120°F (50°C) such as in a vehicle or metal building during the summer. High temperatures will overheat the battery pack,

reducing battery life. If it is stored for several months, the battery pack

will gradually lose its charge. One to three cycles of charging and discharging through normal use will restore the capacity of the battery pack.

During the life of the battery pack, the operating time between charges

becomes shorter. If the operating time becomes extremely short after a

proper charge, the usable life of the battery pack has been reached and

it should be replaced.

Cleaning

Clean dust and debris from charger and tool vents. Keep tool handles

clean, dry and free of oil or grease. Use only mild soap and a damp cloth

to clean the tool, battery pack and charger since certain cleaning agents

and solvents are harmful to plastics and other insulated parts. Some of

these include gasoline, turpentine, lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia and household detergents containing

ammonia. Never use flammable or combustible solvents around tools.

service facility for repairs.

battery packs will operate for many years and/or hundreds

MILWAUKEE

MILWAUKEE

battery pack only until it no longer per-

service

MILWAUKEE

ser-

WARNING!

To reduce the risk of personal injury and

damage, never immerse your tool, battery

pack or charger in liquid or allow a liquid to

flow inside them.

WARNING!

To reduce the risk of explosion, never burn a battery pack

even if it is damaged, dead or completely discharged.

RBRC Battery Recycling Seals

The RBRC™ Battery Recycling Seals (see "Symbology") on your tool battery packs indicate that

battery pack with the Rechargeable Battery Recycling Corporation (RBRC).

At the end of your battery pack's useful life, return the battery pack to a

MILWAUKEE

est you. For more information, visit the RBRC web site at www.rbrc.org.

Disposing of Nickel-Cadmium Battery Packs

Nickel-Cadmium battery packs are recyclable. Under various state and

local laws, it may be illegal to dispose of this battery into the municipal

waste stream. Dispose of your battery pack according to federal, state

and local regulations.

Repairs

For repairs, return the tool, battery pack and charger to the nearest service center listed on the back cover of this operator's manual.

Battery Pack Warranty

Battery packs for cordless tools are warranted for one year from the date

of purchase.

Branch Office/Service Center or the participating retailer near-

MILWAUKEE

has arranged for the recycling of that

ACCESSORIES

WARNING!

Always remove battery pack before changing or removing accessories. Only use accessories specifically recommended for this tool. Others may be hazardous.

For a complete listing of accessories refer to your

Tool catalog or go on-line to www.mil-electric-tool.com. To obtain a catalog, contact your local distributor or a service center listed on the back

cover of this operator’s manual.

MILWAUKEE

Electric

FIVE YEAR TOOL LIMITED WARRANTY

Every

MILWAUKEE

ranted to be free from defects in material and workmanship.

will repair or replace (at

tool (including battery chargers) which examination proves to be defective in material or workmanship from five (5) years after the date of

purchase. Return the tool and a copy of the purchase receipt or other

proof of purchase to a

Branch location or

paid and insured. This warranty does not cover damage from repairs

made or attempted by other than

abuse, normal wear and tear, lack of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are warranted for one (1) year

from the date of purchase.

THE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN ARE

EXCLUSIVE. IN NO EVENT SHALL

INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, OR CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal rights. You may also have other

rights that vary from state to state and province to province. In those

states that do not allow the exclusion of implied warranties or limitation

of incidental or consequential damages, the above limitations or exclusions may not apply to you. This warranty applies to the United States,

Canada, and Mexico only.

tool is tested before leaving the factory and is war-

MILWAUKEE

MILWAUKEE

MILWAUKEE

MILWAUKEE

’s discretion), without charge, any

Factory Service/Sales Support

Authorized Service Station, freight pre-

MILWAUKEE

MILWAUKEE

authorized personnel,

BE LIABLE FOR ANY

page 7

RÈGLES DE SÉCURITÉ GÉNÉRALES POUR TOUS LES OUTILS À BATTERIE

AVERTISSEMENT!

VOUS DEVEZ LIRE ET COMPRENDRE TOUTES LES INSTRUCTIONS.

Le non-respect, même partiel, des instructions ci-après entraîne un risque de choc

électrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

AIRE DE TRAVAIL

1. Veillez à ce que l'aire de travail soit propre et bien éclairée. Le

désordre et le manque de lumière favorisent les accidents.

2. N'utilisez pas d'outils électriques dans une atmosphère explo-

sive, par exemple en présence de liquides, de gaz ou de

poussières inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les poussières ou les vapeurs.

3. Tenez à distance les curieux, les enfants et les visiteurs pendant

que vous travaillez avec un outil électrique. Ils pourraient vous

distraire et vous faire faire une fausse manoeuvre. Installez des

barrières ou des écrans protecteurs si nécessaires.

SÉCURITÉ ÉLECTRIQUE

4. Ne maltraitez pas le cordon. Ne transportez pas l'outil par son

cordon. N'exposez pas le cordon à la chaleur, à des huiles, à

des arêtes vives ou à des pièces en mouvement. Remplacez

immédiatement un cordon endommagé. Un cordon endommagé

peut constituer un risque d'incendie.

5. Un outil à bloc-batterie amovible ou à batterie intégrée ne doit

être rechargé qu'avec le chargeur prévu pour la batterie. Un

chargeur qui convient à tel type de batterie peut présenter un risque

d'incendie avec tel autre type de batterie.

6. N'utilisez un outil qu'avec un bloc-batterie conçu spécifiquement

pour lui. L'emploi d'un autre bloc-batterie peut créer un risque

d'incendie.

SÉCURITÉ DES PERSONNES

7. Restez alerte, concentrez-vous sur votre travail et faites preuve

de jugement. N'utilisez pas un outil électrique si vous êtes fatigué

ou sous l'influence de drogues, d'alcool ou de médicaments. Un

instant d'inattention suffit pour entraîner des blessures graves.

8. Habillez-vous convenablement. Ne portez ni vêtements flottants

ni bijoux. Confinez les cheveux longs. N'approchez jamais les

cheveux, les vêtements ou les gants des pièces en mouvement.

Des vêtements flottants, des bijoux ou des cheveux longs risquent

d'être happés par des pièces en mouvement.

9. Méfiez-vous d'un démarrage accidentel. Avant d'insérer un

bloc-batterie, assurez-vous que l'interrupteur de l'outil est sur

ARRÊT. Le fait de transporter un outil avec le doigt sur la détente ou

d'insérer un bloc-batterie alors que l'interrupteur est en position

MARCHE peut mener tout droit à un accident.

10. Enlevez les clés de réglage ou de serrage avant de démarrer

l'outil. Une clé laissée dans une pièce tournante de l'outil peut

provoquer des blessures.

11. Ne vous penchez pas trop en avant. Maintenez un bon appui et

restez en équilibre en tout temps. Un bonne stabilité vous permet

de mieux réagir à une situation inattendue.

12. Utilisez des accessoires de sécurité. Portez toujours des lunettes

ou une visière. Selon les conditions, portez aussi un masque

antipoussière, des bottes de sécurité antidérapantes, un casque

protecteur et/ou un appareil antibruit.

13. Immobilisez le matériau sur une surface stable au moyen

debrides ou de toute autre façon adéquate. Le fait de tenir la pièce

avec la main ou contre votre corps offre une stabilité insuffisante et

peut amener un dérapage de l'outil.

UTILISATION ET ENTRETIEN DES OUTILS

14. Ne forcez pas l'outil. Utilisez l'outil approprié à la tâche. L'outil

correct fonctionne mieux et de façon plus sécuritaire. Respectez aussi

la vitesse de travail qui lui est propre.

15. N'utilisez pas un outil si son interrupteur est bloqué. Un outil que

vous ne pouvez pas commander par son interrupteur est dangereux

et doit être réparé.

16. Retirez le bloc-batterie ou mettez l'interrupteur sur ARRÊT ou

en position verrouillée avant d'effectuer un réglage, de changer

d'accessoire ou de ranger l'outil. De telles mesures préventives

réduisent le risque de démarrage accidentel de l'outil.

17. Rangez les outils hors de la portée des enfants et d'autres

personnes inexpérimentées. Les outils sont dangereux dans les

mains d'utilisateurs novices.

18. Lorsque le bloc-batterie n'est pas en service, tenez-le à l'écart

d'autres objets métalliques (trombones, pièces de monnaie, clés,

clous, vis, etc.) susceptibles d'établir un contact électrique entre les deux bornes. La mise en court-circuit des bornes de la batterie

peut produire des étincelles et constitue un risque de brûlures ou

d'incendie.

19. Prenez soin de bien entretenir les outils. Les outils de coupe

doivent être toujours bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger.

20. Soyez attentif à tout désalignement ou coincement des pièces

en mouvement, à tout bris ou à toute autre condition préjudiciable

au bon fonctionnement de l'outil. Si vous constatez qu'un outil

est endommagé, faites-le réparer avant de vous en servir. De

nombreux accidents sont causés par des outils en mauvais état. Fixezy une étiquette marquée « Hors d'usage » jusqu'à ce qu'il soit réparé.

21. N'utilisez que des accessoires que le fabricant recommande pour

votre modèle d'outil. Certains accessoires peuvent convenir à un

outil, mais être dangereux avec un autre.

RÉPARATION

22. La réparation des outils électriques doit être confiée à un

réparateur qualifié. L'entretien ou la réparation d'un outil électrique

par un amateur peut avoir des conséquences graves.

23. Pour la réparation d'un outil, n'employez que des pièces de

rechange d'origine. Suivez les directives données à la section «

Réparation » de ce manuel. L'emploi de pièces non autorisées ou

le non-respect des instructions d'entretien peut créer un risque de

choc électrique ou de blessures.

page 8

Loading...

Loading...