Milnor 50050 User Manual

The right sizes

These dryers can be used with washer-extractors or with CBW® tunnel washers.

Basket volumes available are 56.8 cu. ft. (1608 L), 108 cu. ft. (3058 L),

119 cu. ft. (3373 L) and 200 cu. ft. (5663 L). They’re ideal for loads ranging

from 110 lbs. (50 kg) to 550 lbs. (250 kg).

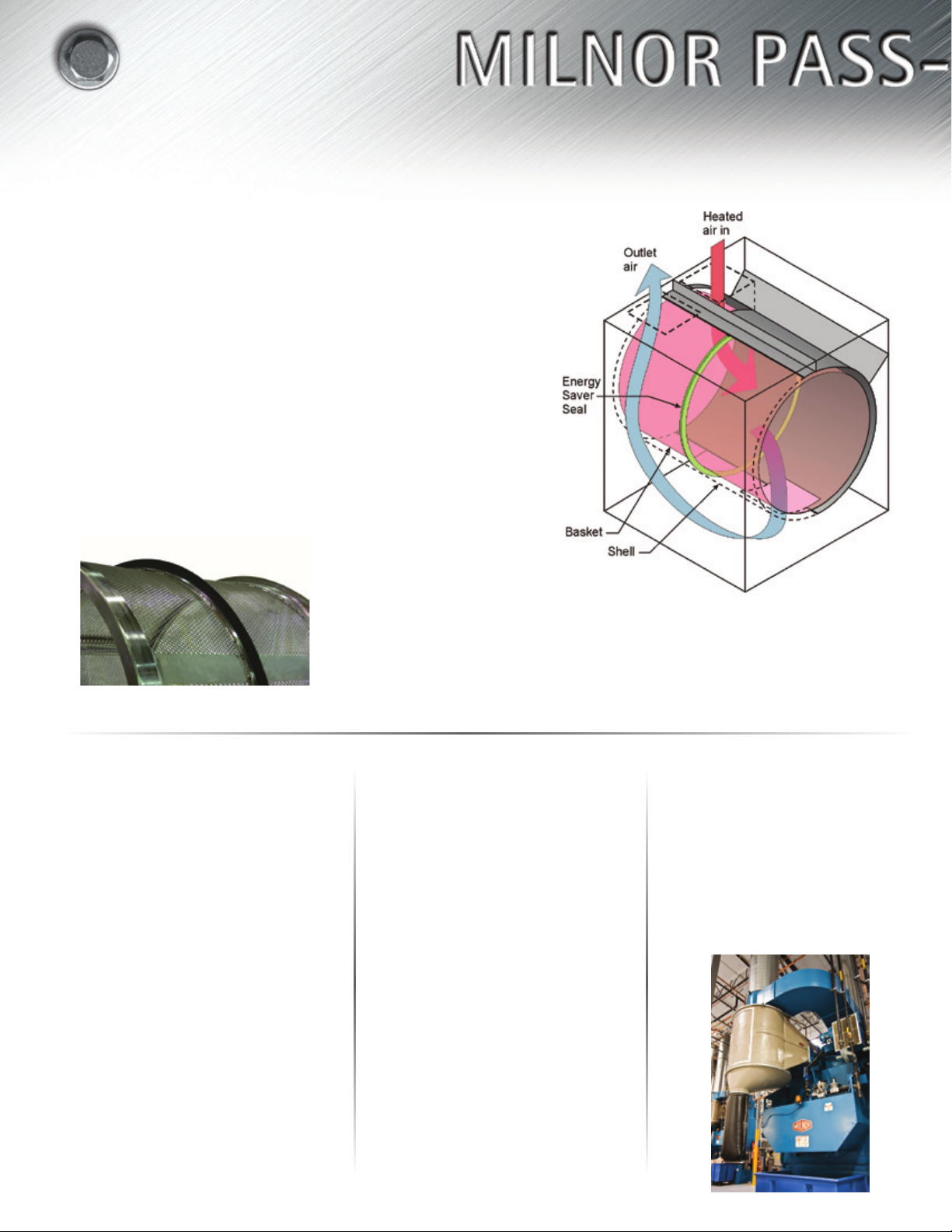

Why they save time and energy

• Goods circulate freely – as they dry, they move to the upper end; 56.8 – 200 cu. ft.

(1608 – 5663 L) cylinder enhances movement of hot air through the load.

• Huge open area – with about 65% of the perforated side sheet open, hot air ows

easily through the basket.

• Unique Energy Saver Seal™ – keeps air owing through the goods, without

escaping around the outside of the basket.

• Fixed tilt – places the heaviest goods, which are wettest, nearest heat entry.

• Fast unloading – no need to wait for mechanized tilting or operator attention, as

the basket is always tilted toward the unload end.

Milnor maintains proper hot

airflow with a low-friction seal

that rides on a polished band.

Efficiency is long-term

Most dryers are efficient when new. Milnor dryers

stay that way. This is possible because the seal is

placed circumferentially, not front-to-back as with

competitive dryers. Because competitive seals are

abraded by the reverse side of the basket perforations

– the “cheese grater” effect – they tend to wear out

quickly. This lets air escape around the outside of the

basket, wasting energy and time.

Insulation helps prevent heat loss, too (and improves

the work environment).

They boost productivity

Fast cycles mean more output. And so does fast

turnaround from one load to another. Milnor

conveyors and shuttles allow automated loading

when the dryer is ready, without operator

attention. This minimizes delays. Or, if you

prefer, sling loading can be employed (the

xed tilt helps goods fall to the back). Gravity

unloading is automatic, without an attendant,

and there are no delays for hydraulic tilting.

Pass-through design is ideal for streamlined

workow.

Unique air path means a Milnor dryer gets

the most efficient use of hot air. These design

features are not found on other dryers.

Optional Recirculation

available

Exhaust air recirculation option redirects heated

exhaust air during the rst part of the cycle to

warm up the incoming fresh air, saving up to 10%

or more of the heat energy.

Loading...

Loading...