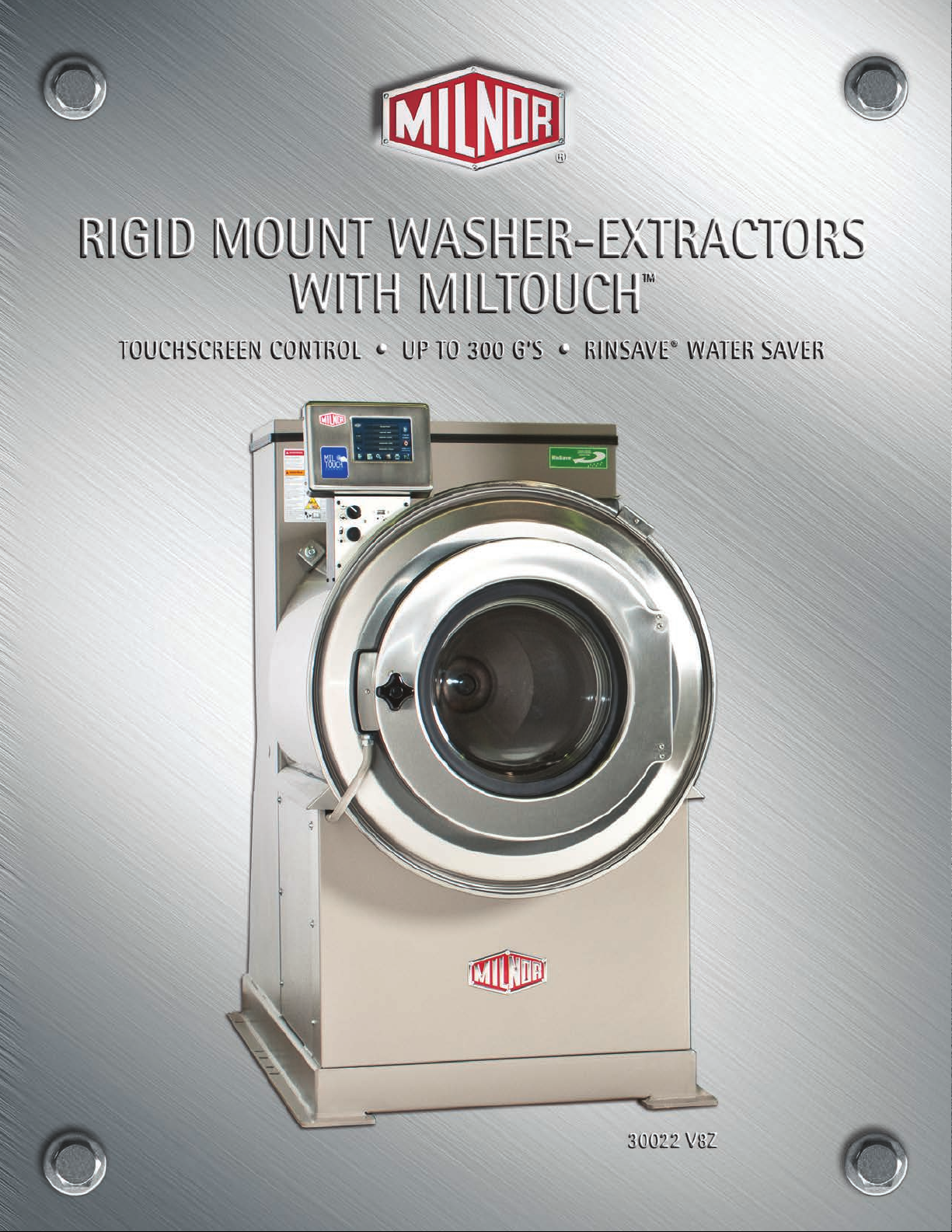

Page 1

Page 2

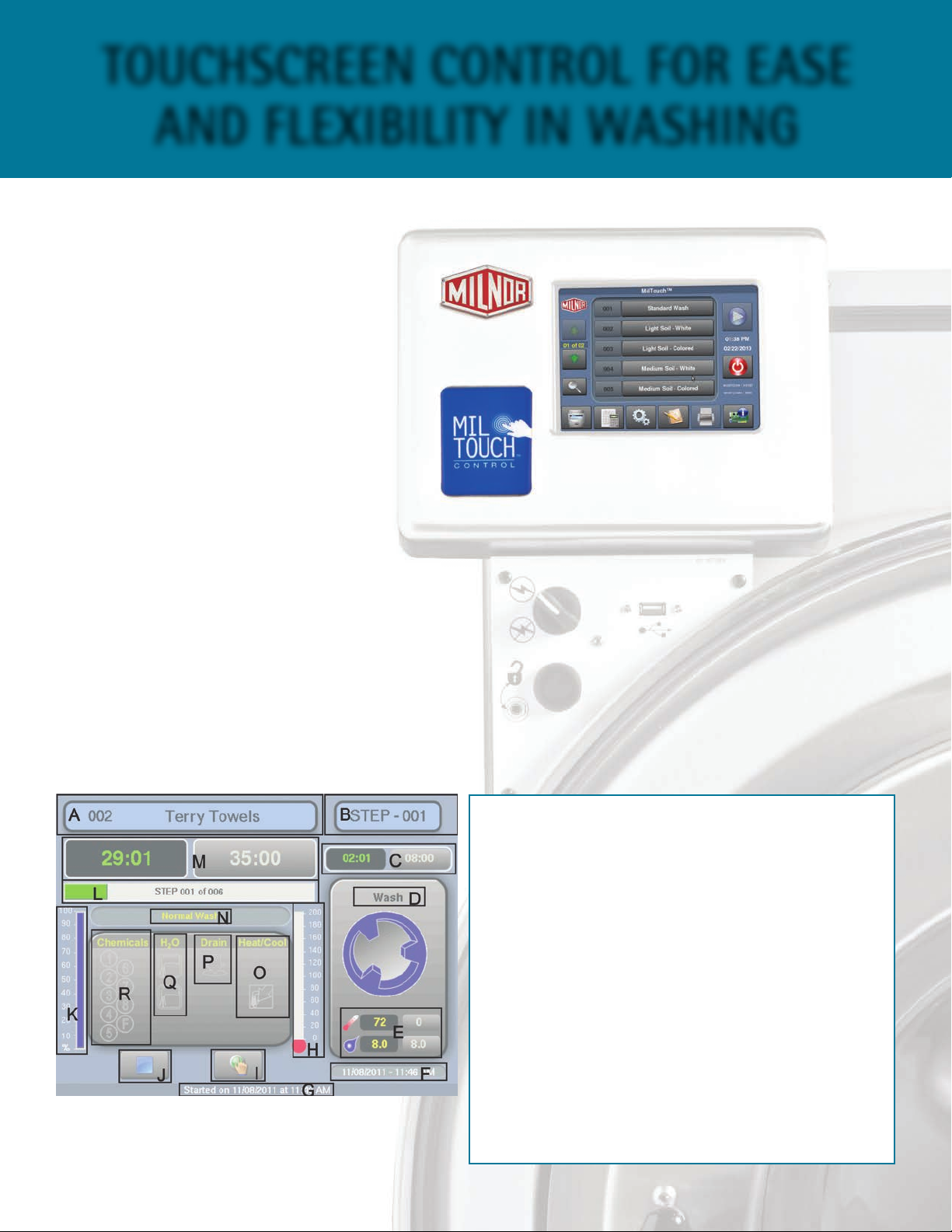

TOUCHSCREEN CONTROL FOR EASE

AND FLEXIBILITY IN WASHING

MILTOUCH™

TOUCHSCREEN

CONTROL

Utilizing resistive touch screen technology and

full VGA resolution, the MilTouch™ control has

a clear and informative display which shows

current machine status info including total

formula time and time elapsed. With complete

programming flexibility, MilTouch™ touchscreen

control formulas can be developed on a PC,

saved to USB external memory and uploaded

with a screen touch. With intuitive fault

diagnosis and relevant troubleshooting

suggestions, the MilTouch™ control streamlines

employee training and eliminates operator guesswork.

WHAT CAN YOU SEE WITH THE MILTOUCH™ CONTROL?

A LOT OF INFORMATION ON ONE EASY-TO-READ SCREEN!

A. Wash Program Number and Name

B. Step Number indicates when the machine will finish

C. Step Time Remaining and Total Step Time

D. The Step Name is programmed by the user

E. Programmed Bath Temperature and Water Level

F. The date and time are recorded in the productivity log files

G. Wash Cycle Start time

H. Bath temperature in a graphic format

I. Manual control allows user to change water levels

J. Pause button allows the user to halt the timer or properly end the formula

K. Bath level indicator

L. Progress bar shows current and total steps

M. Formula Time Remaining and Total Formula Time

N. Step Type displays which of the pre-defined steps is running

O. Steam Valve and Cooldown Valve indicators

To download the MilTouch PC programmer, visit

milnor.com/miltouchprogrammer

P. Drain indicator

Q. Water Valve indicators

R. Chemical Valve indicators

Page 3

STANDARD FEATURES IMPROVE WASH

QUALITY AND PROLONG LINEN LIFE

RINSAVE® WATER SAVER

Milnor’s RinSave® water saver feature is standard on all V-Series

washers (with either E-P Plus or MilTouch™ controls). The

patented software allows for the basket to reach a precise

G-force that “slings” the wash liquor (including water, chemistry,

and soil) out of the goods after a wash step. This feature will

save up to 2 rinses per load and fill/rinse time. Laundries with the

RinSave feature will get more loads per hour to save you money!

Scan to see

cost savings

SAFE CHEMICAL INJECTION

Chemicals are injected in

the rear of the machine

(unlike certain brands where

chemicals are injected near

the front of the machine at

eyelevel). Chemicals are diluted

and flushed into the sump of

the washer-extractor so that

raw chemical does not come

in direct contact with the

linen or the stainless steel. The

metal lip prevents corrosion,

which prolongs the life of your

Milnor washer-extractor.

30022 V8Z chemical

inlet shown

SUPERIOR

CYLINDER

DESIGN

Milnor’s tall rib

construction and

precise cylinder

speeds combine to

provide excellent MAF – Mechanical Action Factor –

ensuring goods get clean the first time, reducing timeconsuming and costly rewashes.

CONTINUOUSLY

WELDED FRAME

Milnor frames are designed to

prevent concentration of stress

in one spot and all structural

components are tied together

for optimum stress dispersion.

This proven structural integrity

means your machines will last longer.

30022 V8Z frame shown

EXTRACTION OPTIMIZER

ExactXtract® extraction optimizer monitors physical

vibration of the machine allowing the machine to safely

reach final extraction speeds up to 300Gs. This utility

saving feature is standard on the following models:

36021 V7Z, 36026 V7Z, 42026 V6Z, and 42030 V6Z.

EFFICIENT MOTOREXACTXTRACT®

A NEMA Premium® efficient

inverter-driven motor

reaches maximum

extraction speed more

gradually and efficiently,

reducing peak electricity

amperage draw compared to

multi-speed motor machines.

NEMA Premium® is a registered

trademark of Baldor Electric Company.

Page 4

Milnor’s V-Series washer-extractors with

the MilTouch™ control are available in

five capacities, ranging from 60-160 lbs.

(27-72 kg). The continuously welded frame,

intelligent control, and standard RinSave®

water saver, make these washer-extractors

42026 V6Z 36021 V5Z

ideal for any commercial laundry.

SPECIFICATIONS

30022 V8Z 36021 V5Z 36021 V7Z 36026 V5Z 36026 V7Z 42026 V6Z 42030 V6Z

CAPACITY–LBS. (KG)* 60 (27) 80 (36) 80 (36) 100 (45) 100 (45) 140 (64) 160 (72)

CYLINDER DIAMETER–INS. (MM) 30 (762) 36 (914) 36 (914) 36 (914) 36 (914) 42 (1066) 42 (1066)

CYLINDER DEPTH–INS. (MM) 22 (559) 21 (533) 21 (533) 26 (660) 26 (660) 26 (660) 30 (762)

CYLINDER VOLUME–CU. FT. (L) 9 (225) 12.37 (350) 12.37 (350) 15.3 (433) 15.3 (433) 20.8 (590) 24 (679)

DOOR OPENING–INS. (MM) 15.5 (394) 18 (457) 18 (457) 18 (457) 18 (457) 20 (508) 20 (508)

OVERALL WIDTH–INS. (MM) 34.5 (876) 47.88 (1216) 52.63 (1337) 47.88 (1216) 52.63 (1337) 52.25 (1327) 52.25 (1327)

OVERALL DEPTH–INS. (MM) 56.5 (1436) 53 (1346) 67.19 (1706) 58 (1473) 72.19 (1833) 75.88 (1927) 79.81 (2028)

OVERALL HEIGHT–INS. (MM) 58.68 (1491) 67 (1702) 69 (1753) 67 (1702) 69 (1753) 69.63 (1768) 69.63 (1768)

MOTOR–HP (KW) 5 (3.72) 5 (3.72) 10 (7.45) 5 (3.42) 10 (7.45) 10 (7.45) 15 (11.19)

WASH SPEEDS–RPM 10-44 25-45 25-45 25-45 25-45 25-41 25-41

DISTRIBUTION SPEED–RPM 65 65 65 65 65 65 65

EXTRACTION SPEED–RPM 200-840 200-550 200-700 200-550 200-710 200-710 200-710

EXTRACTION G FORCE 300 150 300 150 300 300 300

INLET VALVE–INS. (MM) 0.75 (19) 0.75 (19) 0.75 (19) 0.75 (19) 0.75 (19) 1.25 (31) 1.25 (31)

DRAIN VALVE–INS. (MM) 3 (76) 3 (76) 3 (76) 3 (76) 3 (76) 3 (76) 3 (76)

APPROX. NET WEIGHT–LBS. (KG) 1,056 (479) 1,340 (607) 2,384 (1081) 1,452 (658) 2,270 (1029) 2,400 (1088) 2,476 (1123)

*Depending on soil content and density of goods. Specifications and appearance subject to change without notice. Contact factory for acoustics data.

Printed in the U.S.A.

© Pellerin Milnor Corporation

Brochure B22SL13001/13144

Pellerin Milnor Corporation

P.O. Box 400, Kenner, LA, 70063-0400 USA

Phone: 504.712.7656 • 800.469.8780

Fax: 504.468.3094

Email: milnorinfo@milnor.com

www.milnor.com

Loading...

Loading...