Page 1

®

40-160 LB. WASHER-EXTRACTORS

FLEXIBLE CONTROLS • SIX CAPACITY SIZES

Model 30022 V6J

Page 2

TOP RESULTS.

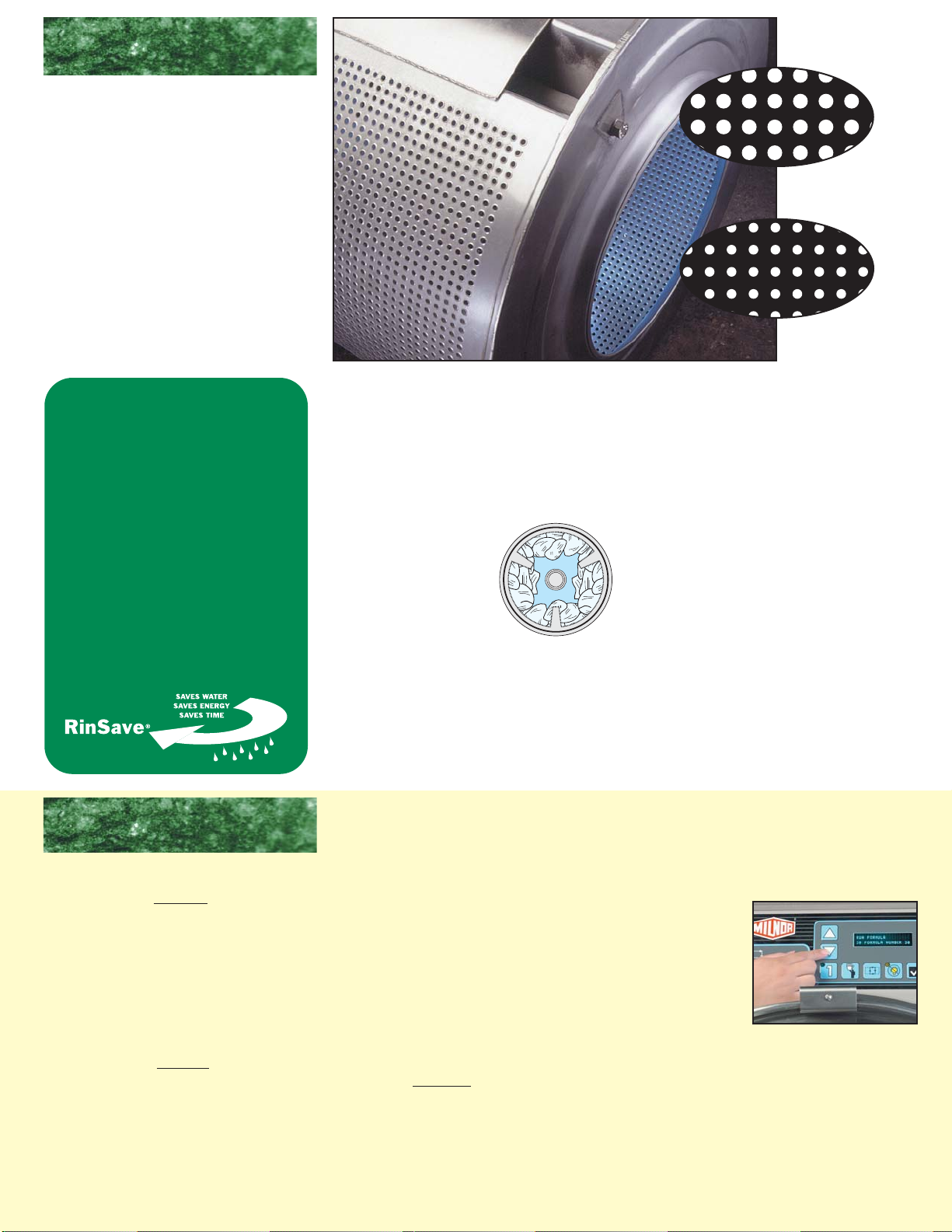

The right cylinder design.

Milnor’s bigger cylinder perforations give:

• Better wash quality (promotes intense

interchange of wash solutions with goods).

• Better rinsing (promotes interchange

of solutions and goods and lets water

drain freely).

• Better extraction (allows water to escape

from goods easily, quickly).

Spacious wash cylinders also yield better results.

There’s more room for lift-and-drop action,

and for goods to open up and absorb the

washing solution (and rinse water).

High ribs provide excellent lifting action. They’re

perforated, too (unlike some others), for fast

interchange of goods and water.

RinSave®Water Saver Feature

Save Water

Save Energy

Save Time

The V-Series washer-extractors now

feature RinSave

which eliminates an entire rinse step.

This innovative process allows a precise

high G-force to “sling” the wash liquor

(including water chemistry and soil) out of

the goods after a wash step. Slinging the

wash liquor quickly acts like a rinse. A

large basket open area combined with the

proper and exact G-force is the key to

making RinSave water saver work.

RinSave water saving feature means fewer

cycles and faster turnaround with no

compromise in wash quality. And you

save...save...save...

™

water saver software

Milnor’s cylinder has bigger perforations, allowing water to pass quickly through the goods.

The right speeds.

Efficient inverter drive produces the speeds you

need – normal wash (plus reverse) for shirts and

other cotton goods, gentle wash (plus reverse) for

delicates and polyesters, pre-extract distribution

(helps prevent unbalanced loads), a Rinsave™

speed, and three extract speeds. You get the best

speeds for a wide variety of fabrics.

High-speed extraction is great

for all-cottons. Lower speeds

are available for polyesters

(including 100% poly table

linens). Combined with a big

cylinder (which means a

thinner layer of goods for

water to pass through) and

large perforations, this adds

up to very effective moisture

removal.

ExactXtract™ extraction optimizer control is a

high speed extract option for the 36021V7J,

36026V7J, 42026V6J and the 42030V6J. Unlike

competitive models, the ExactXtract control uses

precision technology to measure physical vibration

of a machine in high extract.

Distribution speed

helps prevent vibration

in extraction.

With this option, after achieving normal high speed

extract (250 Gs for the 36” models and 215 Gs for

the 42” models), ExactXtract control will allow the

machine to continue increasing extraction speed

until 300 Gs is reached, or until a certain vibration

threshold is reached, at which point the extraction

speed will be locked-in.

Competitive brands use the inverter to monitor load

imbalance. If the load is not balanced to spin at the

programmed spin speed, the machine will

redistribute the load. After several unsuccessful

attempts to lower the speed and speed up, the

controller will limit the spin speed. By using the

inverter to limit speed, valuable time is wasted as

the machine cycles through distribution trying to

find the maximum extract speed for the load.

ExactXtract™ high speed control SAVES

VALUABLE TIME by not cycling through

distribution continually to correct an out of balance.

Along with our proper cylinder design and superior

basket open area, it SAVES DRYER ENERGY by

maximizing extract up to 300 Gs.

MILNOR

POPULAR

COMPETITOR

EASIER TO USE.

E-P Plus®microprocessor.

Formulas: Thirty total – all programmable – including

ten pre-programmed specifically for each of eight

markets (see list) … all formulas can be modified to

suit needs … management may choose whether

operator can manually skip to end of existing bath

or extract.

Programming: Simple, two-button programming;

display prompts each step … “help” screen makes it

even easier … create new formulas, add/delete/modify

steps, and/or delete an entire formula – all in one

programming mode … move backward to make

changes, then rapidly forward.

Display: Display uses real words (not codes) to tell

operator what step is underway, what supply is

being injected, time remaining, etc. … also: error

messages, diagnostic information, formula counts.

Supply injection: Any supplies can be injected in

any bath (up to two in one bath) – either with fill, at

level-satisfied, or ten seconds after level and

temperature (with temperature control option) are

achieved … injection duration is programmable, too

(1 to 255 seconds) … five injection signals (includes

connectors for six liquid supply tubes).

Getting the most

from personnel.

Efficient use of labor cuts overtime costs,

prevents delays. And Milnor can help – with

E-P Plus microprocessor formula counters. You

can detect whether employees are running too

many loads on long cycles – which leads to

overtime.

Or too many short cycles – resulting in poor

quality, excessive rewashes, and more overtime.

All Milnor washer-extractors operate

automatically, further enhancing the efficiency

of personnel.

The right formulas.

Pre-programmed wash formulas in E-P Plus

models are specifically tailored for each of

eight different markets. They were developed

with the help of laundry chemists. They’re not

common-denominator formulas, as with other

pre-programmed machines. And with the E-P

Plus control, you can modify pre-programed

formulas as needed, and add more.

Why they require less training.

The less judgment a machine calls for, the less

training it takes. And that saves time and money.

Quality is more consistent, too. E-P Plus

microprocessor offers a wide variety of wash

formulas – yet

formula selection is

easy. Formulas

were developed for

specific types of

goods (sheets, for

example). So

workers don’t have

to guess whether

these goods

require “medium”

or “light” soil formulas, as with most other machines.

Automatic supply injection also makes it simple.

Simple, push-button controls

make employees more effective.

Problem solvers.

These machines save time by helping solve

problems. Error messages (such as “door open”)

help prevent production delays. Thorough selfdiagnostics aid in troubleshooting if malfunctions

occur. You can test inputs/outputs without even

removing panels.

Page 3

30022 V6J

60 lbs.

150 Gs

30015 V7J

40 lbs.

200 Gs

RELIABLE.

Make sure you’re getting

an industrial machine.

Get the engineering

expertise that produces

big, durable, industrial

machines like this.

For a machine that stands up to hard use, you

need a true industrial washer-extractor. One built

by a company that knows what industrial

machinery is all about. Most manufacturers star t

from a background of small, appliance-type

machines. They work up from there, based on

what they know. Milnor draws on its long

experience building giant, industrial washerextractors that launder thousands of pounds per

hour. Machines that tolerate not only enormous

workloads, but also multiple shifts. That’s why

used Milnors (if you can find them) are worth so

much more than other brands.

Warranties attest to endurance.

Ask your Milnor dealer about warranties on key

parts of these Milnor machines: Five years on

frame, cylinder and shell; three years on

microprocessor boards; five years on the main

bearing assembly; and three years on nonwearable parts (consult dealer or factory for

details).

42026 V6J

140 lbs.

215 Gs

42030 V6J

160 lbs.

215 Gs

The engineering differences.

Frames are designed to

prevent concentration of

stress in one spot. All

structural components

are tied together for

optimum stress

dispersion. (Next time

you’re at a trade show,

thump a Milnor, and then

do the same with other

brands. You’ll feel and

hear the difference.)

Front and rear bearings are fixed in the same

housing. This prevents damaging misalignment.

Other machines mount their two bearings

independently, with no rigid housing.

MILNOR bearings

aligned in housing.

Milnor’s tapered roller bearings have a large

contact area. This spreads force, contributing

to long life. (Computer-calculated life is well over

20 years!) Milnor bearing design is long proven.

Other companies keep experimenting.

Solid frame withstands

stress (600 RPM model

shown).

COMPETITOR not

secured in housing.

Drive is simple, efficient.

Inverter drive gets

all seven speeds

from only one

single-speed motor.

No idler pulley is

needed. The

energy-efficient

drive also reduces

electric peak load

demand.

Simple drive is

versatile, efficient.

36021 V5J

80 lbs.

150 Gs

36026 V7J

100 lbs.

250 Gs

NOT SHOWN: 36021 V7J / 80 lbs. / 250 Gs

PLUS...

They fit through

standard

doorframes.

To make installation easier

for you, most models* fit

through standard

doorframes, with no need to

remove the jambs. The

30015 and 30022 models

can fit through a 36-inch

doorway. Optional

five-compartment supply

injector can be removed for

passage.

The 36” and 42” models

can fit through a 48-inch

doorframe. Some require

simple removal of

components.

*Standard models.

Microprocessor boards are tested far beyond

electronics industry norms. It’s another reason

why Milnor solid state machines are so reliable.

Painting techniques also contribute to long life.

Surfaces are acid-treated, then electronically

coated with a powder epoxy paint that’s baked-on.

Components are painted before going into the

machine (so even hidden areas are painted for

protection).

Support worldwide

Milnor laundry machinery is sold worldwide by the

most highly regarded dealer network. Dealers not

only provide complete equipment packages, but

also can help with planning an installation and

supply technical support. Ask us for the dealer in

your area.

36026 V5J

100 lbs.

150 Gs

Page 4

Features at a glance.

• Choice of capacities: 40 lbs., 60 lbs., 80 lbs., 100 lbs.,

140 lbs. or 160 lbs.

• Seven speeds for processing a variety of goods.

• Simple and efficient single-motor, inverter drive.

• RinSave

• E-P Plus control (30 programmable formulas)

is easy-to-use.

• Microprocessor offers formulas pre-programmed for

specific markets, self-diagnostics, formula counter.

• Large diameter cylinders deliver excellent lift-and-drop

action. Volumes range from 6.14 cu. ft. to 24 cu. ft.

®

water saver saves water, energy, and time.

• Cylinder sides have large perforations.

• High, perforated ribs.

• Liquid soap connectors standard.

• Solid-plate steel frame (stress is spread evenly).

• Tapered roller bearings aligned in rigid housing.

• Triple water seals protect bearings.

• Five-year limited warranty on frame, cylinder, and shell.

Three-year limited warranty on non-wearable parts

(consult dealer or factory for details).

• Microprocessor boards tested far beyond industry norm.

• Most models fit through standard doorways.

Specifications

30015 30022 36021 36021 36026 36026 42026 42030

V7J V6J V5J V7J V5J V7J V6J V6J

Maximum capacity - 40 60 80 80 100 100 140 160

lbs. (kg)+ (18) (27) (36) (36) (45) (45) (63) (72)

Cylinder diameter 30x15 30x22 36x21 36x21 36x26 36x26 42x26 42x30

x depth - ins. (mm) (762x381) (762x559) (914x533) (914x533) (914x660) (914x660) (1067x660) (1067x762)

Gross cylinder 6.14 9 12.37 12.37 15.3 15.3 20.8 24.0

vol. - cu. ft. (L) (174) (255) (350) (350) (433.7) (433.7) (590.3) (679)

Motor - HP 5 5 7.5 7.5 10 10 10 10

(kW) (3.72) (3.72) (5.59) (5.59) (7.45) (7.45) (7.45) (7.45)

Wash 1 - RPM* 38 38 33 33 33 33 33 33

Wash 2 - RPM* 43 43 43 43 43 43 40 40

Distrib. speed - RPM* 65 65 65 65 65 65 60 60

Extract 1 - RPM* 542 420 385 495 385 495 425 425

Extract 2 - RPM* 663 485 470 605 470 605 512 512

Max. extract 685 600 542 700 542 700 600 600

speed - RPM* 766♦ 766♦ 710♦ 710♦

Max. G forces - 200 150 150 250 150 250 215 215

Max. G force with N/A N/A N/A 300 N/A 300 300 300

ExactXtract™ control

Drain valve - ins. 3 3 3 3 3 3 3 3

Inlet valve - ins. 0.75 0.75 0.75 0.75 0.75 0.75 1.25 1.25

(mm) (19.1) (19.1) (19.1) (19.1) (19.1) (19.1) (32) (32)

Overall width - ins. 34.5 34.5 43.38 51 43.38 51 52.25 52.25

(mm) ** (876) (876) (1102) (1295) (1102) (1295) (1327) (1327)

Overall depth - ins. 45.75 52.25 53 67.19 58 72.19 76.38 80.31

(mm) ** (1162) (1327) (1346) (1706) (1473) (1833) (1939) (2041)

Overall height - 54 54 67 69 67 69 69.63 69.63

ins. (mm) ** (1372) (1372) (1702) (1753) (1702) (1753) (1768) (1768)

Approx. net 844 909 1,340 2,384 1,452 2,270 2,400 2,476

weight - lbs. (kg) (383) (412) (608) (1081) (658) (1030) (1088) (1124)

(76) (76) (76) (76) (76) (76) (76) (76)

+Depending on density and soil content of goods. *Approximate. **Standard accessories. Specifications and appearance subject to change without notice.

♦with optional ExactXtract™ extraction optimizer control

Pellerin Milnor Corporation

P.O. Box 400, Kenner, LA 70063-0400 USA

504/712-7656

800/469-8780

Fax: 504/468-3094

®

E-mail: mktg@milnor.com

http://www.milnor.com

Printed in U.S.A.

© Pellerin Milnor Corporation

Class 5-1 Brochure B22SL00002/10473

Loading...

Loading...