Milnor 30022H7J, 30022H8J, 30015T5E, 30015T5J, 30015T5X Service Manual

...

Published Manual Number/ECN: MTRUUS01UU/20020618

• Publishing System: TPAS

• Access date: 06/19/2002

• Document ECN's: Latest Available

Safety Guide - Rigid Washer

Extractors

Guía de seguridad - LavadorExtractora De Base Rígida

PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063-0400, U.S.A.

Please Read

About the Manual Identifying Information on the Cover

The front cover displays pertinent identifying information for this manual. Most important, are

the published manual number (part number) /ECN (date code). Generally, when a replacement

manual is furnished, it will have the same published manual number, but the latest available ECN.

This provides the user with the latest information applicable to his machine. Similarly all

documents comprising the manual will be the latest available as of the date the manual was

printed, even though older ECN dates for those documents may be listed in the table of

contents.

When communicating with the Milnor factory regarding this manual, please also provide the

other identifying information shown on the cover, including the publishing system, access date,

and whether the document ECN’s are the latest available or exact.

References to Yellow Troubleshooting Pages

This manual may contain references to “yellow pages.” Although the pages containing

troubleshooting procedures are no longer printed on yellow paper, troubleshooting instructions, if

any, will be contained in the easily located “Troubleshooting” chapter or section. See the table of

contents.

Trademarks of Pellerin Milnor Corporation

The following, some of which may be used in this manual, are trademarks of Pellerin Milnor

Corporation:

®

Ampsaver

Autolint

®

Auto-Purge

Autovac E-P OneTouch® Mildata

®

CBW

Dye-Extractor® Gear Guardian

Dyextractor® Hands-Off

®

E-P Express® Hydro-Cushion

E-P Plus

®

®

®

®

®

®

Milnet

Milnor

®

Staph-Guard

System 4

Miltrac System 7

Miltron Totaltrol

®

®

®

®

Comments and Suggestions

Help us to improve this manual by sending your comments to:

Pellerin Milnor Corporation

Attn: Technical Publications

P. O. Box 400

Kenner, LA 70063-0400

Fax: (504) 469-1849

Table of Contents

for MTRUUS01UU/20020618

Safety Guide - Rigid Washer Extractors

Page Description Document/ECN

1 Section 1: English

2 Safety Guide - Rigid Washer Extractors MTRUUS01EN/20020618

15 Section 2: Español

16 Guía de seguridad - Lavadora-Extractora De Base Rígida MTRUUS01SP/20020618

Section 1

English

Published Manual Number: MTRUUS01

• Specified Date: 20020618

• As-of Date: 20020618

• Access Date: 20020618

• Depth: detail

• Applicability: RHU RMV RQV

• Language Code: ENG01, Purpose: publication, Format: 1colA

Safety Guide—

Rigid Washer Extractors

PELLERIN MILNOR CORPO RAT ION

POST OFFICE BOX 400, KENNER, LOUISIANA 70063 - 0400, U.S.A.

Applicable Milnor® products by model number:

30022H7J 30022H8J 30015T5E 30015T5J 30015T5X 30015V7J 30022T5E

30022T5J 30022T5X 30022V6J 36026V5J 36026V7J 42026V6J 42026V6W

Table of Contents

Sections Figures, Tables, and Supplements

1. General Safety Requirements—Vital Information

for Management Personnel

1.1. Laundry Facility

1.2. Personnel

1.3. Safety Devices

1.4. Maintenance

(Document BIUUUS02)

Table of Contents

2. The Safety Placards and Their Messages—Vital

Information for All Personnel

2.1. Service Preparations and Entering the Machine

2.2. Electrical and Mechanical Parts

2.3. Linen and the Turning Cylinder

2.4. Heat

2.5. Dangerous Materials

(Document BIUUUS01)

Figure 1: Message About Reading the

Manuals

Figure 2: Message About Utilities and

Residual Energy

Figure 3: Message About Confined Space

Figure 4: Message About Electricity

Figure 5: Message About Moving Parts

Behind Guards and Covers

Figure 6: Message About Grasping Linen

Figure 7: Message About Hot Surfaces

Figure 8: Message About Explosive /

Flammable Materials in Washer

PELLERIN MILNOR CORPORATION

BIUUUS02 (Published) Book specs- Dates: 20020618 / 20020618 / 20020618 Lang: ENG01 Applic: RHU RMV RQV

1. General Safety Requirements—Vital Information for

Management Personnel

Incorrect installation, neglected preventive maintenance, abuse, and/or improper repairs, or

changes to the machine can cause unsafe operation and personal injuries, such as multiple

fractures, amputations, or death. The owner or his selected representative (owner/user) is

responsible for understanding and ensuring the proper operation and maintenance of the machine.

The owner/user must familiarize himself with the contents of all machine instruction manuals.

The owner/user should direct any questions about these instructions to a Milnor® dealer or the

Milnor® Service department.

Most regulatory authorities (including OSHA in the USA and CE in Europe) hold the owner/user

ultimately responsible for maintaining a safe working environment. Therefore, the owner/user

must do or ensure the following:

• recognize all foreseeable safety hazards within his facility and take actions to protect his

personnel, equipment, and facility;

• work equipment is suitable, properly adapted, can be used without risks to health or safety,

and is adequately maintained;

• where specific hazards are likely to be involved, access to the equipment is restricted to those

employees given the task of using it;

• only specifically designated workers carry out repairs, modifications, maintenance, or

servicing;

• information, instruction, and training is provided;

• workers and/or their representatives are consulted.

Work equipment must comply with the requirements listed below. The owner/user must verify

that installation and maintenance of equipment is performed in such a way as to support these

requirements:

• control devices must be visible, identifiable, and marked; be located outside dangerous zones;

and not give rise to a hazard due to unintentional operation;

• control systems must be safe and breakdown/damage must not result in danger;

• work equipment is to be stabilized;

• protection against rupture or disintegration of work equipment;

• guarding, to prevent access to danger zones or to stop movements of dangerous parts before

the danger zones are reached. Guards to be robust; not give rise to any additional hazards; not

be easily removed or rendered inoperative; situated at a sufficient distance from the danger

zone; not restrict view of operating cycle; allow fitting, replacing, or maintenance by

restricting access to relevant area and without removal of guard/protection device;

• suitable lighting for working and maintenance areas;

• maintenance to be possible when work equipment is shut down. If not possible, then

protection measures to be carried out outside danger zones;

• work equipment must be appropriate for preventing the risk of fire or overheating; discharges

of gas, dust, liquid, vapor, other substances; explosion of the equipment or substances in it.

1.1.

Laundry Facility

Provide a supporting floor that is strong and rigid enough to support–with a reasonable safety

factor and without undue or objectionable deflection–the weight of the fully loaded machine and

the forces transmitted by it during operation. Provide sufficient clearance for machine movement.

PELLERIN MILNOR CORPORATION

General Safety Requirements—Vital Information for Management Personnel

Provide any safety guards, fences, restraints, devices, and verbal and/or posted restrictions

necessary to prevent personnel, machines, or other moving machinery from accessing the

machine or its path. Provide adequate ventilation to carry away heat and vapors. Ensure service

connections to installed machines meet local and national safety standards, especially regarding

the electrical disconnect (see the National Electric Code). Prominently post safety information,

including signs showing the source of electrical disconnect.

1.2.

Personnel

Inform personnel about hazard avoidance and the importance of care and common sense. Provide

personnel with the safety and operating instructions that apply to them. Verify that personnel use

proper safety and operating procedures. Verify that personnel understand and abide by the

warnings on the machine and precautions in the instruction manuals.

WARNING 1 : Multiple Hazards

—Careless operator actions can kill or injure personnel,

damage or destroy the machine, damage property, and/or void the warranty.

• Do not tamper with or disable any safety device or operate the machine with a

malfunctioning safety device. Request authorized service.

• Do not operate a damaged or malfunctioning machine. Request authorized service.

• Do not attempt unauthorized servicing, repairs, or modification.

• Do not use the machine in any manner contrary to the factory instructions.

• Use the machine only for its customary and intended purpose.

• Understand the consequences of operating manually.

1.3.

Safety Devices

Ensure that no one eliminates or disables any safety device on the machine or in the facility. Do

not allow machine to be used with any missing guard, cover, panel or door. Service any failing or

malfunctioning device before operating the machine.

DANGER 2 : Entangle and Sever Hazards

—Cylinder door interlock—Operating the

machine with a malfunctioning door interlock can permit opening the door when the cylinder is

turning and/or starting the cycle with the door open, exposing the turning cylinder.

• Do not operate the machine with any evidence of damage or malfunction.

WARNING 3 : Multiple Hazards

—Operating the machine with an inoperative safety device

can kill or injure personnel, damage or destroy the machine, damage property, and/or void the

warranty.

• Do not tamper with or disable any safety device or operate the machine with a

malfunctioning safety device. Request authorized service.

WARNING 4 : Electrocution and Electrical Burn Hazards

Operating the machine with any electric box door unlocked can expose high voltage conductors

inside the box.

• Do not unlock or open electric box doors.

WARNING 5 : Entangle and Crush Hazards

machine with any guard, cover, or panel removed exposes moving components.

• Do not remove guards, covers, or panels.

PELLERIN MILNOR CORPORATION

—Electric box doors—

—Guards, covers, and panels—Operating the

1.4.

Maintenance

Ensure the machine is inspected and serviced in accordance with the norms of good practice and

with the preventive maintenance schedule. Replace belts, pulleys, brake shoes/disks, clutch

plates/tires, rollers, seals, alignment guides, etc. before they are severely worn. Immediately

investigate any evidence of impending failure and make needed repairs (e.g., cylinder, shell, or

frame cracks; drive components such as motors, gear boxes, bearings, etc., whining, grinding,

smoking, or becoming abnormally hot; bending or cracking of cylinder, shell, frame, etc.; leaking

seals, hoses, valves, etc.) Do not permit service or maintenance by unqualified personnel.

WARNING 6 : Multiple Hazards

—Operating a damaged machine can kill or injure

personnel, further damage or destroy the machine, damage property, and/or void the warranty.

• Do not operate a damaged or malfunctioning machine. Request authorized service.

WARNING 7 : Explosion Hazards

—Cylinder—A damaged cylinder can rip apart during

extraction, puncturing the shell and discharging metal fragments at high speed.

• Do not operate the machine with any evidence of damage or malfunction.

CAUTION 8 : Explosion Hazards

—Clutch and speed switch (multiple motor machines)—A

damaged clutch or speed switch can permit the low speed motor to engage during extract. This

will over-speed the motor and pulleys and can cause them to rip apart, discharging metal

fragments at high speed.

• Stop the machine immediately if any of these conditions occur: • abnormal whining sound

during extract • skidding sound as extract ends • clutches remain engaged or re-engage

during extract

— End of BIUUUS02 —

PELLERIN MILNOR CORPORATION

BIUUUS01 (Published) Book specs- Dates: 20020618 / 20020618 / 20020618 Lang: ENG01 Applic: RHU RMV RQV

2. The Safety Placards and Their Messages—Vital Information for

All Personnel

Safety placards are affixed to your Milnor® machine at the appropriate locations. These advise

personnel of hazards that can result from improper use or maintenance. The safety placards help

to ensure a safe work environment and, as with any other machine component, must be properly

maintained.

They must be replaced immediately, if lost or damaged.

documentation identifying the placards, their locations on the machine, and their replacement part

numbers.

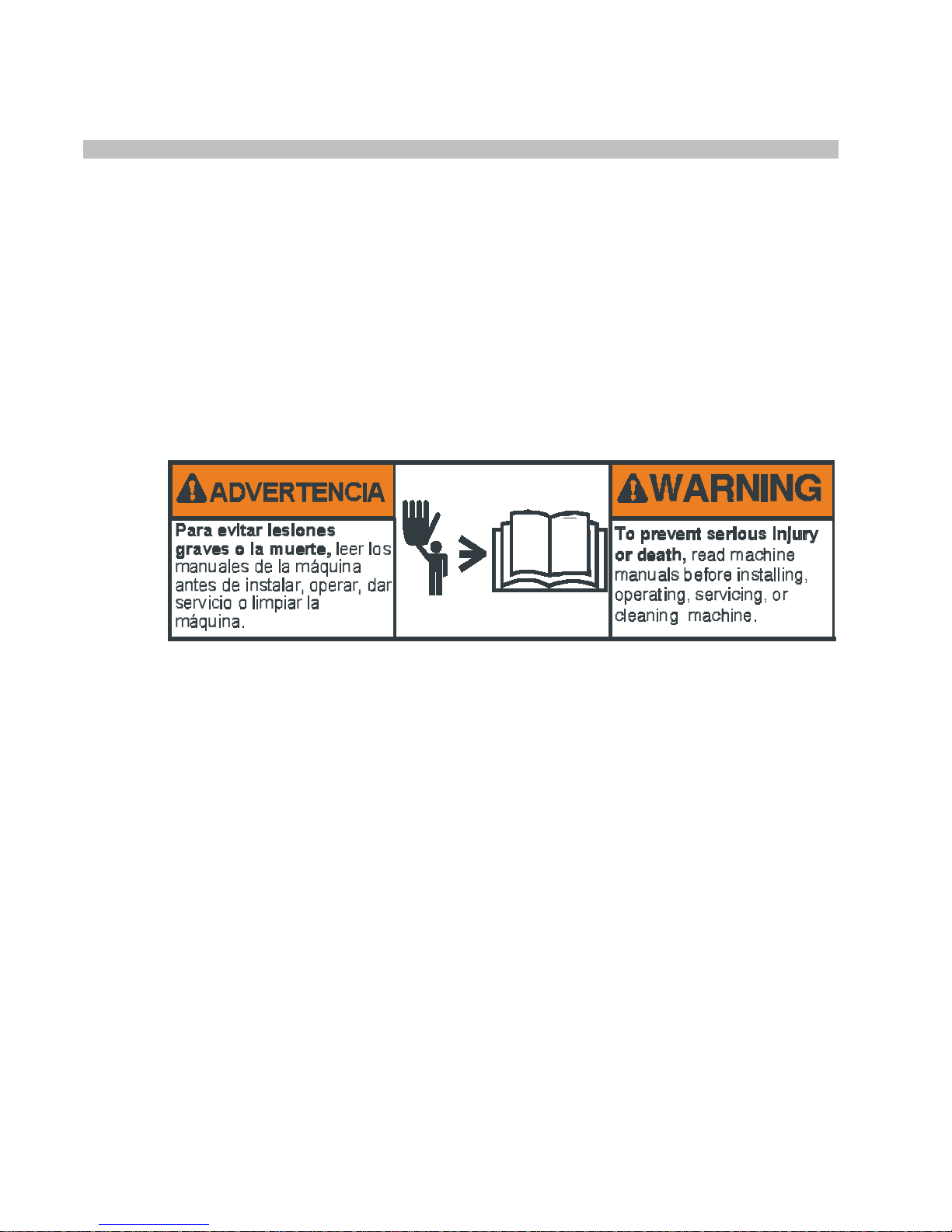

The placarded message shown in Figure 1 reminds personnel to read the manuals first. This safety

manual explains the placarded messages in more detail. The various user manuals may also

contain detailed information regarding hazards addressed by the placards. If you are not clear

about a hazard, review all applicable manuals. If you are still unsure, consult your supervisor.

Figure 1: Message About Reading the Manuals

Placards must be kept clean so that the pictorials and wording are not obscured.

A parts page is provided in the

The other messages conveyed by the safety placards address hazards in general terms and remind

personnel to stop and think before performing certain actions. A placard may contain more than

one message. The following provides more specific information regarding each message and its

associated hazard(s). Each placarded message is shown first, followed by more detailed

information.

PELLERIN MILNOR CORPORATION

Loading...

Loading...