Milnor 30015, 30020, 30022 Service Manual

Published Manual Number/ECN: MAP30RM1AE/99033N

• Publishing System: TPAS

• Access date: 05/11/2000

• Document ECN's: Latest Available

Service—

30015/30020/30022

Washer-Extractors

PELLERIN MILNOR CORPORATION POST OFFICE BOX 400, KENNER, LOUISIANA 70063-0400, U.S.A.

Please Read

About the Manual Identifying Information on the Cover

The front cover displays pertinent identifying information for this manual. Most important, are

the published manual number (part number) /ECN (date code). Generally, when a replacement

manual is furnished, it will have the same published manual number, but the latest available

ECN. This provides the user with the latest information applicable to his machine. Similarly all

documents comprising the manual will be the latest available as of the date the manual was

printed, even though older ECN dates for those documents may be listed in the table of

contents.

When communicating with the Milnor factory regarding this manual, please also provide the

other identifying information shown on the cover, including the publishing system, access date,

and whether the document ECN’s are the latest available or exact.

References to Yellow Troubleshooting Pages

This manual may contain references to “yellow pages.” Although the pages containing

troubleshooting procedures are no longer printed on yellow paper, troubleshooting instructions, if

any, will be contained in the easily located “Troubleshooting” chapter or section. See the table of

contents.

Trademarks of Pellerin Milnor Corporation

The following, some of which may be used in this manual, are trademarks of Pellerin Milnor

Corporation:

Ampsaver

Autolint

Auto-Purge

®

®

®

Autovac E-P Plus

®

CBW

Dye-Extractor® Hands-Off

Dyextractor® Hydro-Cushion

®

Gear Guardian

Mildata

®

®

®

®

®

Milnet

Milnor

®

Staph-Guard

System 4

Miltrac System 7

Miltron Totaltrol

®

®

®

®

Comments and Suggestions

Help us to improve this manual by sending your comments to:

Pellerin Milnor Corporation

Attn: Technical Publications

P. O. Box 400

Kenner, LA 70063-0400

Fax: (504) 469-1849

Table of Contents

for MAP30RM1AE/99033N

30015/30020/30022 Washer-Extractors

Page Description Document/ECN

1 About This Manual MHP30RM1AE/9541AV

3 Warranty BMP720097/92732A

5 How to Order Parts BMP720097R/72332A

6 Rigid Mount Washer-Extractor Installation & Service Safety MSIN0704AE/9271BV

9 Glossary of Tag Illustrations - M-Style Washer-Extractors MSIUUMTGAE/9449CV

13 Section 1: Service and Maintenance

14 Preventive Maintenance MSSM0705CE/9903AV

17 Fastener Torque Requirements MSSM0101CE/9906AV

36 Description of Single Motor Drive Train MSFD0703AE/9328AV

37 Description of Dual Motor Drive Train MSFD0701BE/9273BV

40 Drive Train Service for all 30015 and 30022 Rigid

Mount Washer-Extractors MSSM0706BE/9273DV

45 Section 2: Drive Assemblies

46 2 Groove Pulleys - Drive Chart (30015 & 30022

S4A, S4G, S4J, S4T) BMP930015/98383V

47 3 Groove Pulleys - Drive Chart (30015 & 30022

S4A, S4G, S4J, S4T) BMP970086/98383V

48 Drive Chart - Rigid Mount Washer-Extractors

(30015M4J, M4G, M4T, M6J, M6G & 30022M5J,

M5G, M5T) BMP910031/98373V

51 Motor Mount Assembly - 30015, 30020 & 30022

Rigid Mount Washer-Extractors BMP920027/93251V

53 Motor Mount - 30015 & 30020 S4A, S4G, S4J, S4T BMP950003/95107V

55 Replacing Main Bearings and Seals on 30015,

30020, 30022Cxx, Kxx, Sxx, and Mxx Models MSSM0708BE/9846AV

63 Section 3: Bearing Assemblies

64 Cylinder + Shell + Bearing + Console Installation

- 30015, 30020 & 30022 Rigid Mount Washer-

Extractors BMP910037/93251V

66 Main Bearing Assembly - 30015C4x, M4x, K5x, S5x BMP910032/96141V

68 Main Bearing Assembly BMP910033/96141V

70 Main Bearing Assembly - 30015M6x BMP910034/95116V

72 Jackshaft Bearing Replacement MSSM0709BE/9273BV

74 Jackshaft Assembly - 30015, 30020, 30022 Rigid

Mount Washer-Extractor BMP910035/93251V

77 Section 4: Shell and Door Assemblies

78 Shellfront Assembly, Conduit & Interlock Installation

- 30015, 30020, & 30022 Rigid Mount Washer-

Extractors BMP920024/93251V

Table of Contents, cont.

Page Description Document/ECN

80 Door Assembly - 30015 & 30020 Rigid Mount

Washer-Extractors BMP920009/94491V

82 Interlock Assembly BMP750046/97341V

85 Section 5: Control and Sensing Devices

86 Replacing and Adjusting the Power Supply MSSM0711AE/9272BV

90 Switch Panel Assembly - 30015, 30020 & 30022

MxG, MxJ, Cxx, K5x BMP880028/96143V

92 About the Coin Counter MSFD0501BE/9273AV

94 Coin Assembly Installation (240V) - 30015, 30020

& 30022 Coin Machines BMP920010/97281V

96 Vibration Safety Switch Adjust MSSMA408BE/9273BV

98 Vibration Safety Switch BMP910038/92343V

99 Section 6: Chemical Supply Devices

100 Liquid Supply Inlet Sidemount BMP940077/94286V

102 Supply Injector and Installation - 30015, 30020,

& 30022 Rigid Mount Washer-Extractors BMP920019/93251V

104 3 Compartment Supply Injector - 30015, 30020,

& 30022 Rigid Mount Washer Extractors BMP770149/96113V

106 Soap Chute & Installation - 30015, 30020, &

30022 Rigid Mount Washer-Extractors BMP920013/93251V

107 Section 7: Water and Steam Piping and

Assemblies

108 Schematic Symbols Key BMP920008/93027V

109 Water/Steam/Drain Schematics - 30015, 30020,

& 30022 Rigid Mount Washer-Extractors BMP920015/96132V

111 Water Inlet & Level Switch Installation & Mounting

Hardware - 30015, 30020, & 30022 Rigid Mount

Washer-Extractors BMP920016/93251V

113 Hays Electric Inlet Valves BMP700710/96081V

115 2-Way Electric Water Valve BMP920029/98443V

117 Universal Actuators & Mounting Hardware for

Watts Ball Valves - New Pivot BMP920005/96067V

120 Air Cylinder for 2" Watts Ball Valves BMP920006/2000133V

122 Watts Ball Valves and Repair Kits BMP920007/96066V

124 Paddlewheel Flow Sensor BMP920025/92662V

126 Steam Installation - 30015, 30020, & 30022 Rigid

Mount Washer-Extractors BMP920021/93251V

128 1/2" & 3/4" Hayes Steam Valves BMP920028/92776V

129 Drain Sump Installation - 30015, 30020, & 30022

Rigid Mount Washer-Extractors BMP920014/93251V

130 Drain Valve Installation - 30015, 30020 & 30022

Rigid Mount Washer-Extractors BMP920020/93251V

132 Electric Drain Valve - 30022 Rigid Mount Washer-

Extractors BMP920017/93251V

Table of Contents, cont.

Page Description Document/ECN

133 Section 8: Pneumatic Piping and Assemblies

134 Pneumatic Schematic - 30015, 30020 & 30022

Rigid Mount Washer-Extractors BMP920018/93251V

135 3 Way Pilot Valves BMP900032/91182V

ABOUT THIS MANUAL

MHP30RM1AE/9541AV (1 of 1)

Scope

—This instruction manual is intended to provide preventive maintenance procedures, service procedures, and mechanical parts identification for all Milnor® 30015, 30020, and 30022 model rigid mount

washer-extractors. Measurements are in commonly used US and metric units unless otherwise noted.

See the appropriate programming, operating, and troubleshooting manual for inform ation on the control

system. See the schematic manual for electrical parts identification and electrical troubleshooting.

Manual Number/Date Code (When To Discard or Save)

—The manual number/date code

is located on the inside front cover, upper right corner just above the manual name. Whenever the manual is

reprinted with new information, part of this number changes. If the date code after the “/” changes , the new

version applies to all machines covered by the old version, but is improved— thus the old version can

be discarded. If the manual number before the “/” changes, the new manual covers only new machines.

Example: Discard MATMODELAE/8739CV when MATMODELAE/8739DV is received (minor improvements). Also, discard MATMODELAE/87

V when MATMODELAE/87

39D

V is received (major im-

46A

provements). But keep MATMODELAE/8746FV when MATMODELBE/8815AV is received, since the

new manual no longer applies to machines originally shipped with the old manual.

Documents and Change Bars

—The individual documents comprising this manual use the same

revision criteria as the manual. Text documents also display change bars. Example: When section

MSOP0599AE/9135BV becomes MSOP0599AE/9135CV, change bars with the letter “C” appear next to all

changes for this revision. For a major rewrite (e.g., MSOP0599AE/92

For Assistance

—Please call:

V), all change bars are deleted.

26A

Trademarks of Pellerin Milnor Corporation

this publication, are trademarks of Pellerin Milnor Corporation:

Ampsaver

Autolint

Auto-Purge

®

®

®

Autovac

®

CBW

Dye-Extractor

Dyextractor

E-P Plus

—The following, some of which may be used in

®

®

®

Hands-Off

Hydro-Cushion

Mildata

®

Gear Guardian

®

®

®

Milnet

Milnor

Miltrac

Miltron

®

®

Staph-Guard

System 4

System 7

Totaltrol

®

®

®

®

3(//(5,10,/125&25325$7,21

/,0,7('67$1'$5':$55$17<

We warrant to the original purchaser that MILNOR machines including electronic

hardware/software (hereafter referred to as “equipment”), will be free from defects in material

and workmanship for a period of one year from the date of shipment from our factory with no

operating hour limitation. This warranty is contingent upon the equipment being installed,

operated and serviced as specified in the operating manual supplied with the equipment, and

operated under normal conditions by competent operators.

Providing we receive written notification of a warranted defect within 30 days of its discovery,

we will – at our option – repair or replace the defective part or parts, FOB our factory. We

retain the right to require inspection of the parts claimed defective in our factory prior to

repairing or replacing same. We will not be responsible, or in any way liable, for unauthorized

repairs or service to our equipment, and this warranty shall be void if the equipment is repaired

or altered in any way without MILNOR’s written consent.

Parts which require routine replacement due to normal wear – such as gaskets, contact points,

brake and clutch linings and similar parts – are not covered by this warranty, nor are parts

damaged by exposure to weather or to chemicals.

We reserve the right to make changes in the design and/or construction of our equipment

(including purchased components) without obligation to change any equipment previously

supplied.

ANY SALE OR FURNISHING OF ANY EQUIPMENT BY MILNOR IS MADE ONLY UPON

THE EXPRESS UNDERSTANDING THAT MILNOR MAKES NO EXPRESSED OR IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR USE OR

PURPOSE. MILNOR WILL NOT BE RESPONSIBLE FOR ANY COSTS OR DAMAGES

ACTUALLY INCURRED OR REQUIRED AS A RESULT OF: THE FAILURE OF ANY OTHER

PERSON OR ENTITY TO PERFORM ITS RESPONSIBILITIES, FIRE OR OTHER HAZARD,

ACCIDENT, IMPROPER STORAGE, MISUSE, NEGLECT, POWER OR ENVIRONMENTAL

CONTROL MALFUNCTIONS, DAMAGE FROM LIQUIDS, OR ANY OTHER CAUSE BEYOND

THE NORMAL RANGE OF USE. REGARDLESS OF HOW CAUSED, IN NO EVENT SHALL

MILNOR BE LIABLE FOR SPECIAL, INDIRECT, PUNITIVE, LIQUIDATED, OR

CONSEQUENTIAL COSTS OR DAMAGES, OR ANY COSTS OR DAMAGES WHATSOEVER

WHICH EXCEED THE PRICE PAID TO MILNOR FOR THE EQUIPMENT IT SELLS OR

FURNISHES.

WE NEITHER ASSUME, NOR AUTHORIZE ANY EMPLOYEE OR OTHER PERSON TO

ASSUME FOR US, ANY OTHER RESPONSIBILITY AND/OR LIABILITY IN CONNECTION

WITH THE SALE OR FURNISHING OF OUR EQUIPMENT TO ANY BUYER.

BMP720097

92732A

How to order repair parts

Repair parts may be ordered either from the authorized dealer who sold you this

machine, or directly from the MILNOR factory. In most cases, your dealer will

have these parts in stock.

When ordering parts, please be sure to give us the followin g information:

1. Model and serial number of the machine for which the parts are required

2. Part number

3. Name of the part

4. Quantity needed

5. Method of shipment desired

6. In correspondence regarding motors or electrical controls, please include all

nameplate data, including wiring diagram number and the make or

manufacturer of the motor or controls.

All parts will be shipped C.O.D. transportation charges collect on ly.

Please read this manual

It is strongly recommended that you read the installation and operating manual

before attempting to install or operate your machine. We suggest that this manual

be kept in your business office so that it will not become lo st.

PELLERIN MILNOR CORPORATION

32%2;.(11(5/$ 86$

FAX: Administration 504/468-9307, Engineering 504/469-1849, Service 504/469-9777

BMP720097R

72332A

MSIN0704AE/9271BV

ÈRIGID MOUNT WASHER-EXTRACTOR

INSTALLATION AND SERVICE SAFETY

ÊGeneral Safety Requirements

(specific warnings, next page and throughout manual)

Incorrect installation, neglected preventive maintenance, abuse, and/or improper repairs or changes to the

machine can cause unsafe operation and personal injuries, such as multiple fractures, amputations, or death. The

owner or his selected representative ( owner/user) is responsibl e for understanding and ensuring the proper operation

and maintenance of the machine. The owner/user must familiarize himself with the contents of all machine instruction manuals. The owner/user should direct any questions about these instructions to a Milnor® dealer or the Milnor® Service department.

Most regulatory authorities (including OSHA in the USA) hold the owner/user ultimately responsible for

maintaining a safe working environment. Therefore, the owner/user must do the following:

• recognize all foreseeable safety hazards within his facility and take actions to protect his personnel,

equipment, and facility

• require that personnel are familiar with all functional and safety aspects of the machine

• ensure safety devices installed on the machine are in place and properly maintained

• ensure all machine parts and assemblies are properly maintained.

ËLaundry Facility

—Provide a supporting floor that is strong and rigid enough to support--with a reasonable

safety factor and without undue or objectionable deflection--the weight of the fully loaded machine and the forces

transmitted by it during operation. (For washer-extractors, see “ABOUT THE FORCES TRANSMITTED BY MILNOR® WASHER-EXTRACTORS.”) Provide sufficient clearance for machine movement. Provide any safety

guards, fences, restraints, devices, and verbal and/or posted restrictions necessary to prevent personnel, machines,

or other moving machinery from accessing the machine or its path. Provide adequate ventilation to carry away heat

and vapors. Ensure service connections to installed machines meet local and national safety standards, especially

regarding the electrical disconnect (see the National Electric C ode). Prominently pos t safety inform ation, including

signs showing the source of electrical disconnect.

ËPersonnel

—Inform personnel about hazard avoidance and the importance of care and common sense. Provide

personnel with the safety and operating instructions that apply to them. Verify that pers onnel use proper safety and

operating procedures. Verify that that personnel understand and abide by point-of-hazard tags on the machine and

procedure-specific precautions in the instruction manuals.

ËSafety Devices

—Ensure that no one eliminates or disables any s afety device on t he m achine or in t hs facilit y.

Do not allow machine to be used with any missing guard or cover. Service any failing or malfunctioning device

before operating the machine.

ËMaintenance

—Ensure the machine is inspected and serviced in accordance with the norms of good practice and

with the preventive maintenance schedule. Replace belts, pulleys, brake shoes/disks, clutch plates/tires, rollers,

seals, alignment guides, etc. before they are severely worn. Immediately investigate any evidence of impending

failure and make needed repairs (e.g., cylinder, shell, or frame cracks; drive components such as motors, gear boxes,

ÊHazards During Assembly

ELECTROCUTION HAZARD—Contact with high voltage can kill or seriously injure you.

☞ All electrical connections must be made by a competent electrician.

ÊHazards During Servicing and Maintenance

ELECTROCUTION HAZARD—High voltage is present inside electric boxes, motors and many other components. Power switches on machine control panels

disable only control circuit power in certain boxes. You can be killed or seriously injured on contact with high voltage.

☞ Lock OFF and tag out power at the wall disconnect before servicing, except

where specifically instructed otherwise in this manual.

ENTANGLE AND CRUSH HAZARD—Belts and pulleys can entangle and crush

body parts.

☞ Lock OFF and tag out power at the wall disconnect before servicing, except

where specifically instructed otherwise in this manual.

☞ Insure belt guards are in place during service procedures.

B

ÊHazards Requiring Immediate Service

MULTIPLE HAZARDS—Failure to maintain machine in proper working order can result in

fatal or serious injury to operators and/or damage to property. DO NOT permit operation

under any of the following circumstances:

☞ Malfunctioning door interlock mechanism.

☞ Malfunctioning limit switches.

☞ Malfunctioning two hand inching.

☞ Any evidence of cylinder damage.

☞ Missing or removed guards, covers, or side panels.

☞ Malfunctioning tilting components, including but not limited to safety limit switches,

electrical interlocks, and operator controls.

☞ If any of these conditions occur:

• The machine makes a sound like skidding automobile tires as it comes out of extract.

• The wash or drain clutch does not disengage or it reengages during extract.

• V-bel ts jum p off at the start of, during, or at the end of extract.

• A strange whining sound occurs at any time during extract.

B

7\_ccQbi_VDQW9\\ecdbQdY_^c±

=Cdi\UGQcXUb5hdbQSd_bc

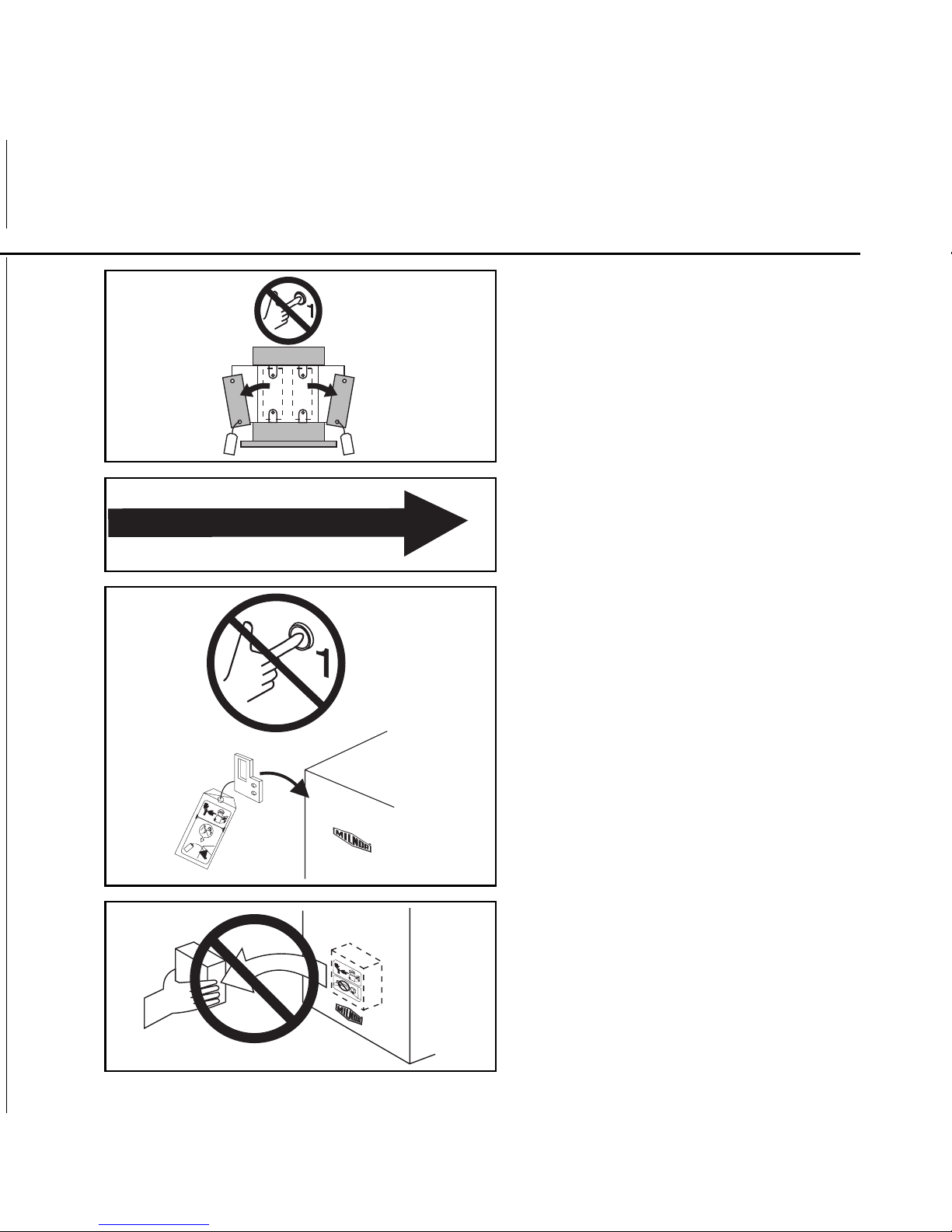

Illustration Explanation Illustration Explanation

Stop! Read the manual first for complete

instructions before continuing.

Do not jack the machine here.

Do not lift the machine here.

<B8DD<C604(##(2E

Use three point or four point lifting as

determined by the lifting eyes furnished. Rig

the load using lifting cables of sufficient size

and length to ensure cables are not

over-stressed.

Do not lift the machine from one corner or one

side edge.

Do not start this machine until the packing

materials, lifting brackets, etc. with this tag

attached or behind this panel are removed.

These materials are painted red. Safety stands

or brackets (also painted red) may be provided

with this machine. Do not discard safety

stands or brackets

This motor or pump should rotate in the

direction of the arrow.

Do not start this machine until the part with

this tag is installed on the machine.

Do not remove this component from the

machine.

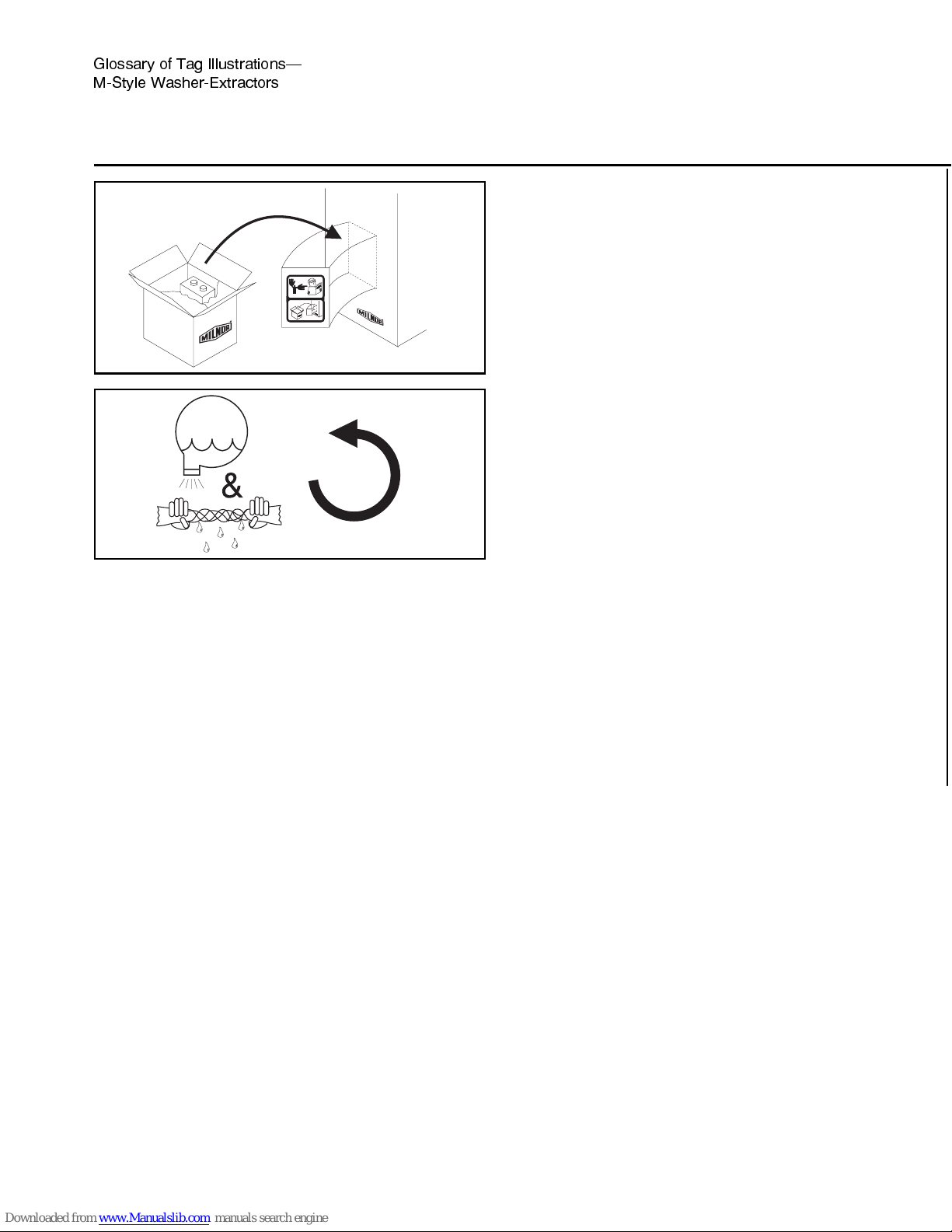

Illustration Explanation Illustration Explanation

Install the appropriate part here before

operating the machine.

During drain and extract, the cylinder must

rotate counterclockwise when viewed from

here.

7\_ccQbi _V DQW 9\\ecdbQdY_^c±

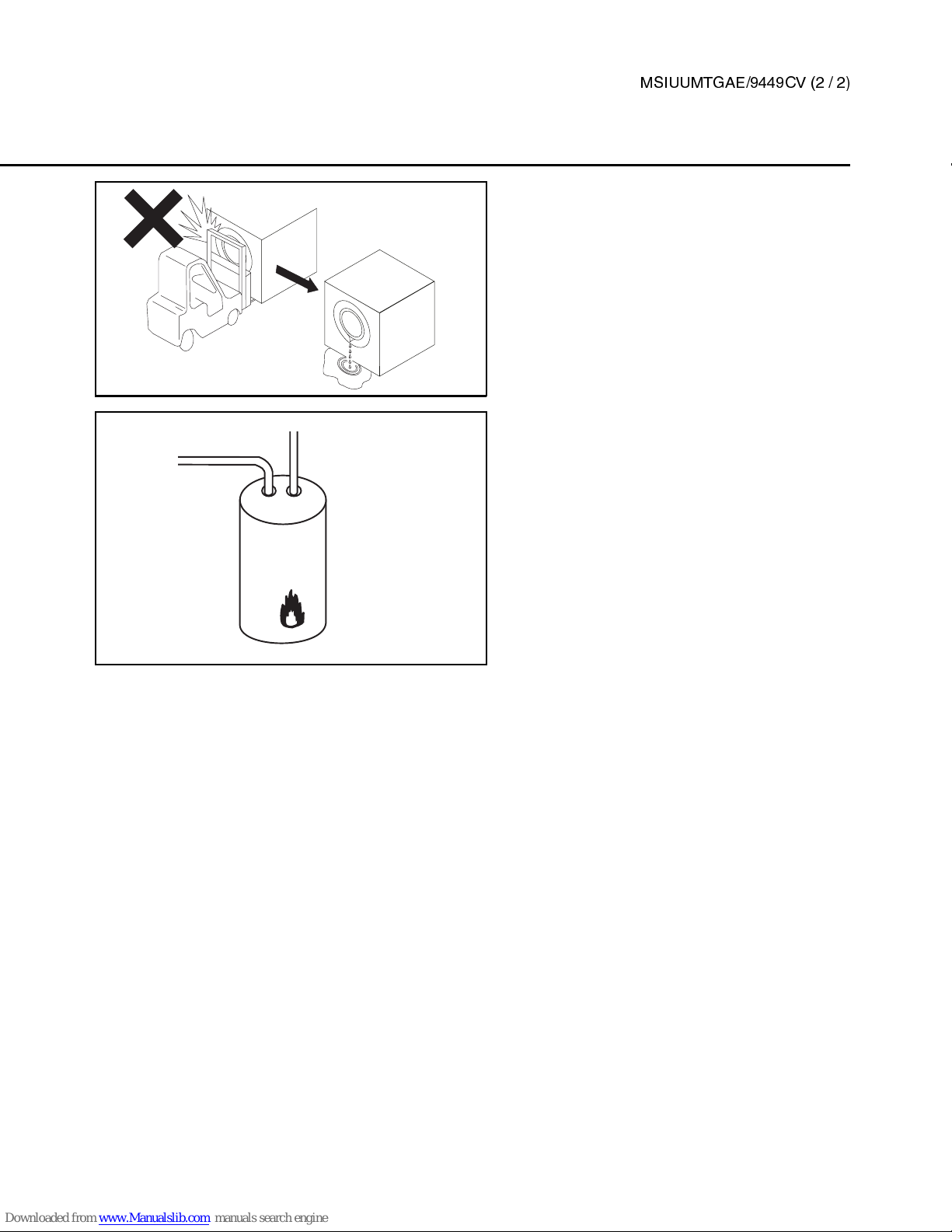

=Cdi\U GQcXUb5hdbQSd_bc =C9EE=D715)$$)3F " "

Do not strike shell front of washer-extractors

during fork lifting. Striking shell front will

cause door to leak.

This is the hot water inlet.

Section 1

Service and Maintenance

MSSM0705CE/9903AV

ÈPREVENTIVE MAINTENANCE

As required by the warranty, to ensure safe operation, and to achieve optimum performance and service life

from Milnor® washer-extractors, the schedules, instructions, and precautions herein must be strictly followed.

ÏPreventive Maintenance Schedule

Component Procedure Frequency Info. Source

Door interlock

(coin machines)

Test functioning for safe operation. daily MSOP0512AE in

Operating and

Troubleshooting

Manual

Electronic coin counter

(coin machines)

Test functioning for safe operation. monthly

Main bearing housing Change lubricant. Check rear bolt

tightness and adjust if necessary.

every four months this section

(see FIGURE 1)

Foundation bolts Check bolt tightness and wear.

Adjust or replace if necessary. every four months

dimensional

drawing

(see NOTE 1 )

Drive train Check belt tension and wear. Check

pulleys and other drive components

for wear. Replace if necessary.

every four months

MSSM0706BE

(see NOTE 1 )

3/5 Compartment

Supply injector

(if so equipped)

Inspect and clean strainers in water

valves, and each compartment. If rust is

detected, carefully clean it away once

each week.

every four months

BMP770149

BMP920019

(see NOTE 2)

Steam strainer

(if so equipped)

Inspect and clean strainer. every four months BMP920015

(see NOTE 2)

NOTE 1: See Table of Contents for information not in this section.

NOTE 2: Drawings apply only to 30015Mxx, and Sxx; 30020Mxx; 30022Mxx, and Sxx models.

ÊMain Bearing Housing Preventive Maintenance

ELECTROCUTION HAZARD—High voltage is present inside electric boxes, motors, and many other components. Power switches on machine disable only

control circuit power in certain boxes. You can be killed or seriously injured on

contact with high voltage.

☞ Lock OFF and tag out power at the wall disconnect before servicing.

ENTANGLE AND CRUSH HAZARD—Belts and pulleys can entangle and crush

body parts.

☞ Lock OFF and tag out power at the wall disconnect before servicing, except

where specifically instructed otherwise in this section.

☞ Permit only qualified maintenance personnel to perform these procedures.

ËLubrication Procedures

—See the appropriate main bearing assembly drawing (if provi ded) during this

procedure (see Table of Contents).

1. Remove the console top by prying out the four plugs from each corner on the top of the machine and remov-

ing the four bolts. Remove the belt guard.

2. Remove the drain plug on the bottom of the main bearing housing and allow the bearing housing to drain

completely. Inspect the leak-off, drained oil, and magnetic drain plug for water and/or metal particles. Water

and/or metal particles can indicate worn or damaged seals and bearings. See “REPLACING MAIN BEARINGS AND SEALS,” if provided (see Table of Contents). Install the drain plug.

3. Locate the two 1/2" plastic tubes secured to the frame. Clean the surrounding area and remove the cork

stoppers from each.

MALFUNCTION HAZARD—Oil spilled on components may cause machine malfunction.

☞ Refill bearing housing carefully.

MACHINE DAMAGE HAZARD—Mixing incompatible lubricants will result in severe machine damage.

☞ DO NOT mix different base lubricants.

☞ Before using a non-specified lubricant, consult the lubricant manufacturer

to determine compatibility.

4. Strictly following lubrication specifications, refill the bearing housing. After refilling the bearing housing,

reinstall the cork stoppers and clean any excess lubricant from the machine.

ÏLubrication Specifications

Component Lubricant/Type Amount of Lubricant

Main bearing

housing

Any high quality SAE 30, 40, or 50 (ISO 100, 140,

or 220) single weight heavy duty motor oil,

non-detergent if available

22 ounces (623.7 grams)

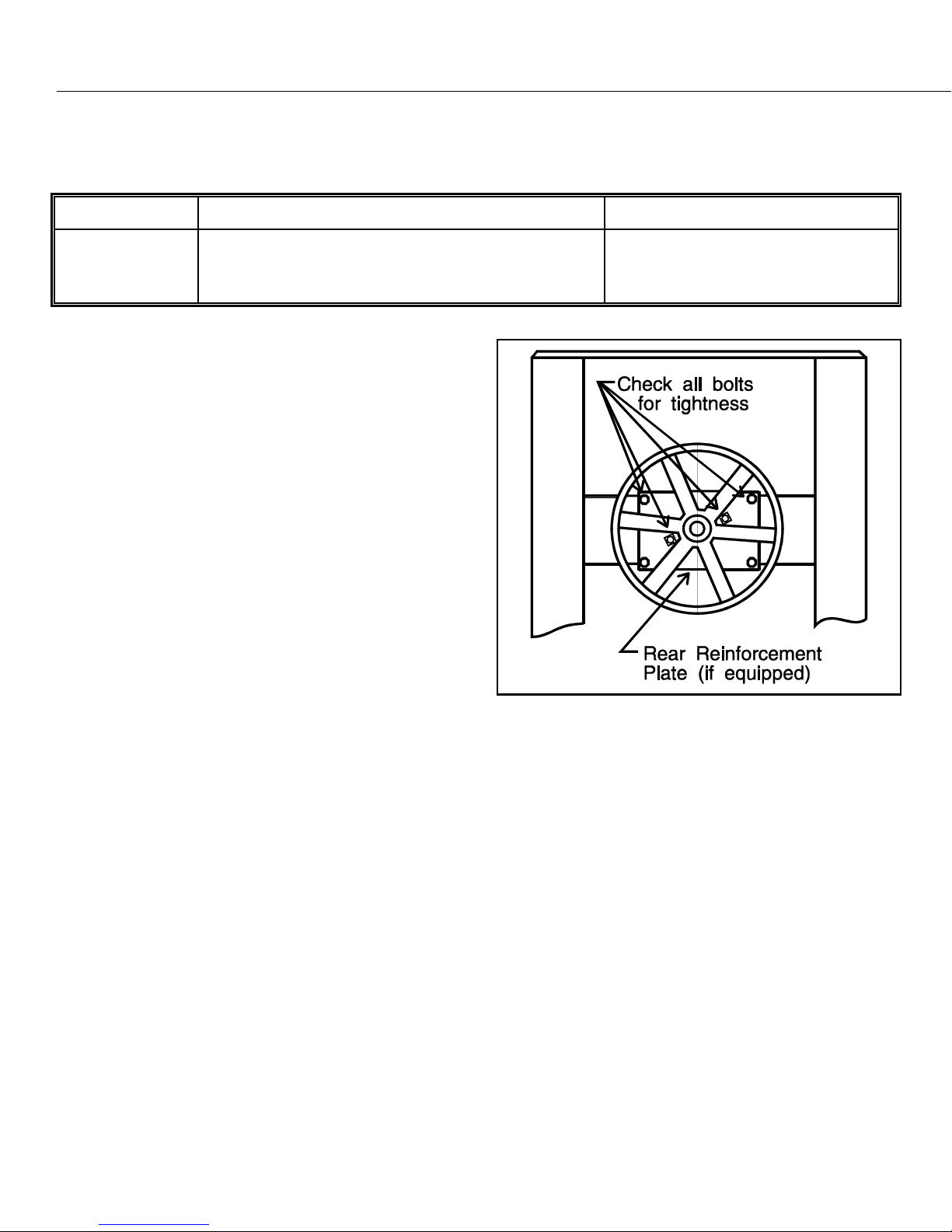

ËBolt Inspection

Check the main bearing support bolts for tightnes s as

shown in FIGURE 1.

ÎFIGURE 1

(MSSM0705CE)

ÎMain Bearing Housing

Bolt Locations

MSSM0101CE/9 90 6A V (1of 19 )

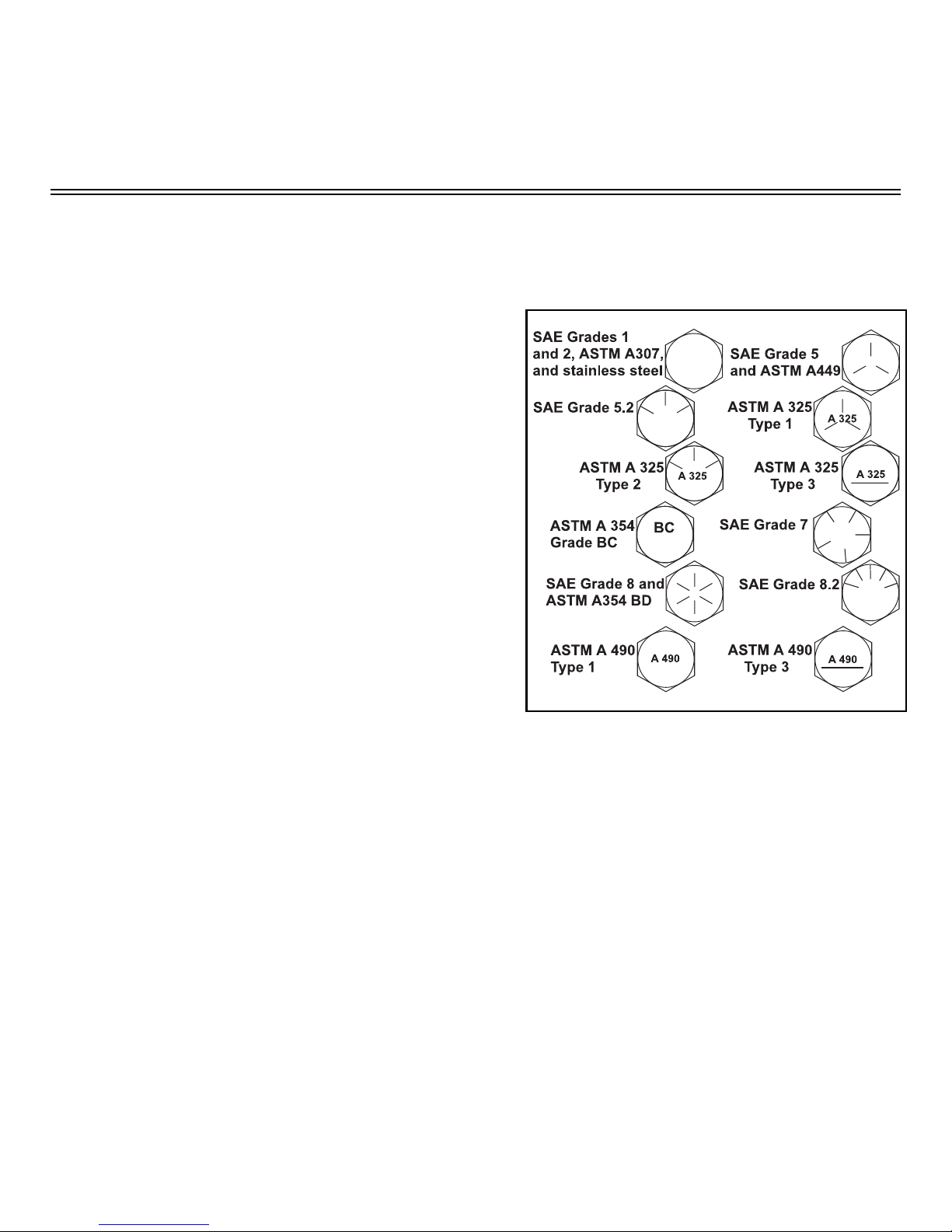

ÈFASTENER TORQUE REQUIREMENTS

The specifications in this section apply to 1/4 inch and larger Unified National fine and coarse fasteners used on

Milnor® machines. This information is to be used only when torque specifications are not stated in the installation

or service instructions.

When tightening applicable fastener, abide by the follow-

ing precautions:

1. Always use new fasteners. Replace bolts, nuts, flat wash-

ers, and lock washers in the order shown on the parts

drawing.

2. Unless otherwise specified, use:

• Loctite® 271 threadlocker or equivalent for bearing

housing mounting bolts from one half to one inch in di-

ameter.

• Loctite® 277 threadlocker or equivalent for bearing

housing mounting bolts of one inch diameter or larger.

• Loctite® 242 threadlocker for all other fasteners

requiring thread locking compound.

3. Use a torque wrench to assure proper tightness.

4. Never lubricate fasteners. The values specified herein are

maximum recommended torques and are calculated from

published ASTM and SAE data. Actual allowable torques

are application dependent and can vary for many reasons,

(joint types, gaskets, etc.). Use these values as a guide.

5. Although FIGURE 1 depicts hex head bolts, the table applies to all head types.

ÎFIGURE 1

ÎFastener Grade Markings

(MSSM0101CE)

ÊFasteners and Threadlocker

ËHow Fasteners Loosen

bly. With the fastener at the proper torque, 85% of the tightening torque is absorbed in the threads and under the

fastener head. The remaining 15% provides t he fricti on t hat prevents the t hread from sl ippi ng. When thi s frict ion is

overcome (by bending, thermal expansion, internal pressures, functional loads, or impact) the thread slips and loosens. Although higher torques reduce the likelihood of thread slippage, if slippage occurs, the threads unwind and

the fastener loosens. Once thread slippage begins, vibration increases the rate of loosening.

ËPreventing Loosening

cation of a threadlocking compound. Threadlocker provides lubrication during assembly, then hardens to seal the

threads against corrosion and provide resistance to thread slippage.

—Standard threaded fasteners are manufactured with a clearance fit for easy assem-

—The most effective way to prevent loosening of threaded parts is by proper appli-

MSSM0101CE/9906AV (2 of 19)

ÊApplying Threadlocker

NOTE: The following threadlocker information and

illustrations are excerpts from the Loctite® User’s

Guide and are used with permission.

For maximum strength, threadlocker must fill the thread

voids completely, as shown in FIGURE 2. Organic or petroleum solvent will remove excess uncured adhesive from

joints. Consult information below for the specific fastener application.

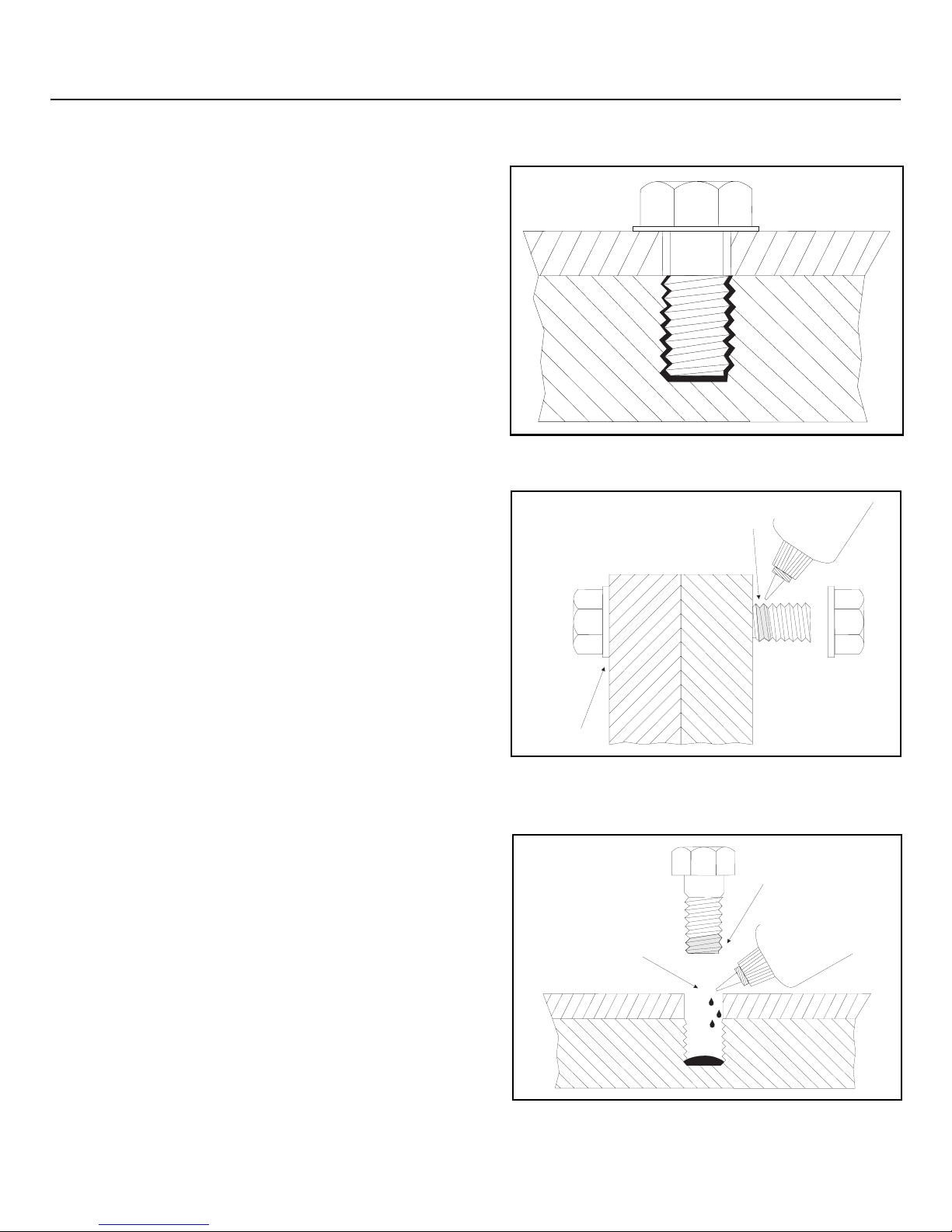

ËBolts and Nuts

—See FIGURE 3.

1. Clean all threads (bolt and nut) with cleaning solvent.

2. Spray all threads with Loctite® Primer N. Allow to dry.

3. Insert bolt into through hole assembly.

4. Apply several drops of threadlocker onto bolt engage-

ment area.

5. Assemble and tighten nut to correct torque for the

threadlocker.

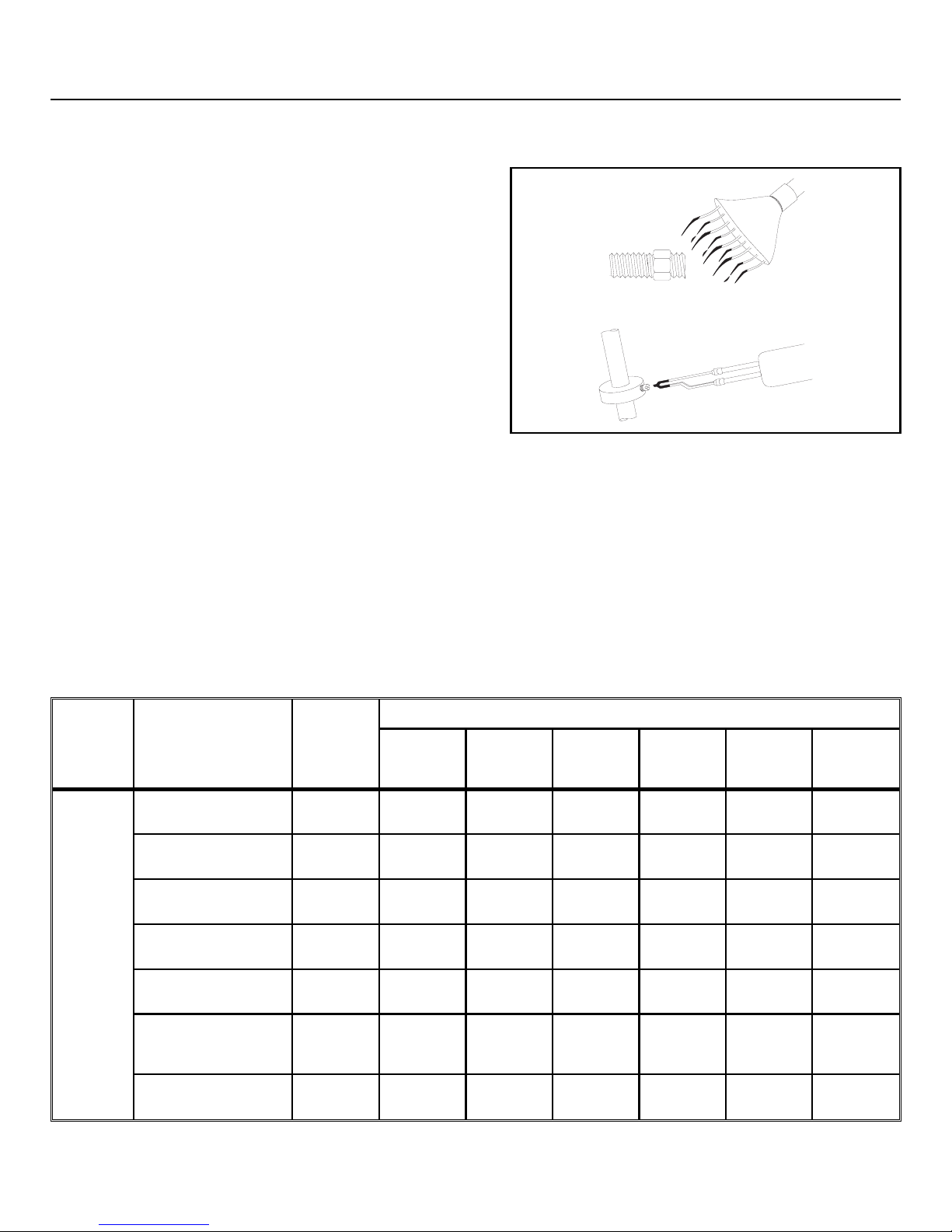

ËBlind Holes

—See FIGURE 4.

1. Clean all threads (bolt and nut) with cleaning solvent.

2. Spray all threads with Loctite® Primer N. Allow to dry.

3. Squirt several drops down female threads into bottom of

hole.

4. Apply several drops to bolt.

Not here

ÎFIGURE 2

(MSSM0101CE)

ÎCorrect Threadlocker Use

Apply here

ÎFIGURE 3

(MSSM0101CE)

ÎApplying Threadlocker to

Through Hole

Onto

threads

5. Tighten to correct torque for the threadlocker.

Onto

threads

ÎFIGURE 4

(MSSM0101CE)

ÎApplying Threadlocker to Blind Holes

FASTENER TORQUE REQUIREMENTS MSSM0101CE/9906AV (3 of 19)

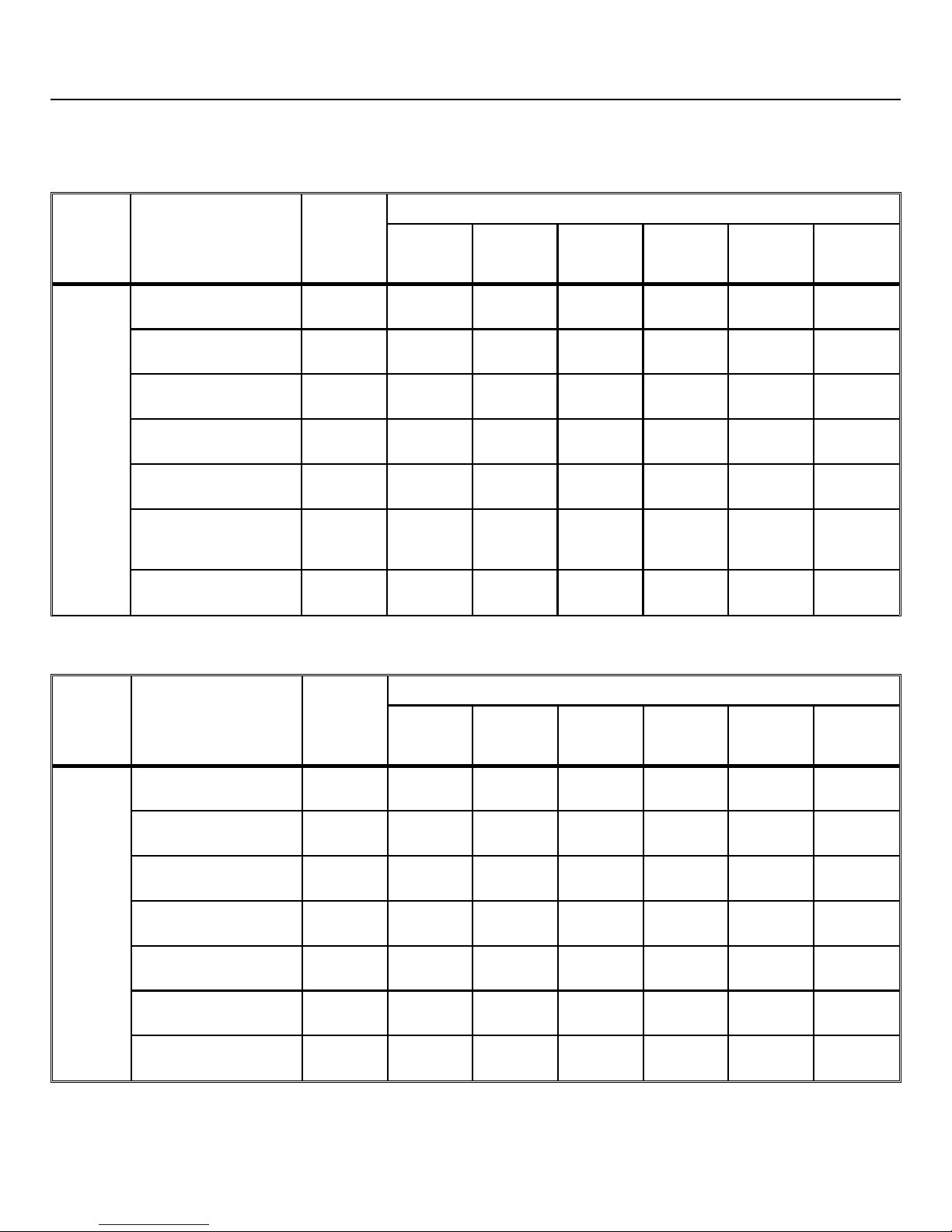

ËRemoving Fasteners

High strength threadlockers like Loctite® 271 (or equivalent)

may be weakened by heating to at least 500o F (260o C) as

follows.

1. Apply localized heat to fastener as shown in FIGURE 5.

2. Disassemble while hot. Once disassembled, the cured ad-

hesive can be removed with Loctite® Gasket Remover

#790 (or equivalent).

Nominal

bolt size

Grade

Designation and

Standard

1/4 - 20 SAE Grade 1

ASTM A307

SAE Grade 2 4.1

ÎRemoving High Strength Threadlocker

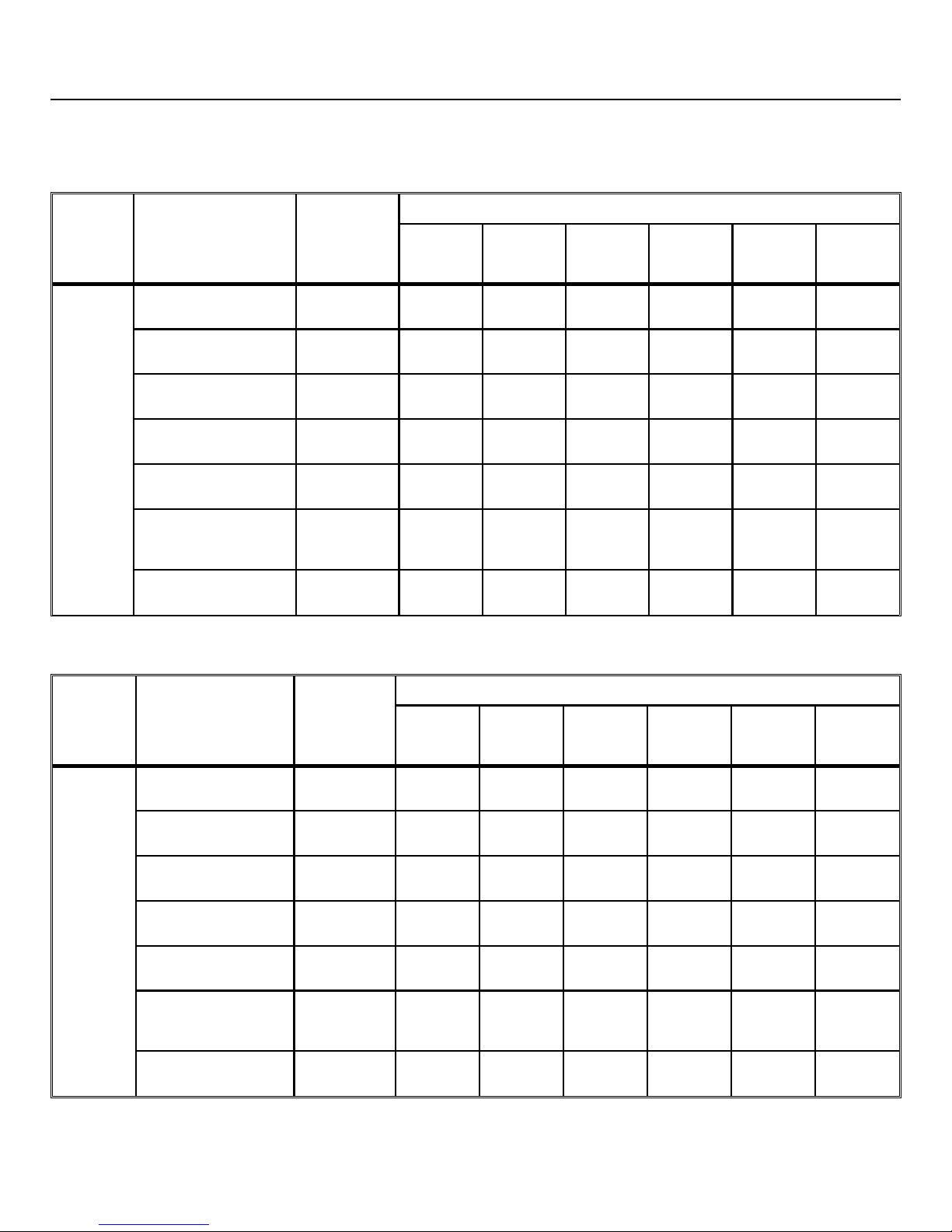

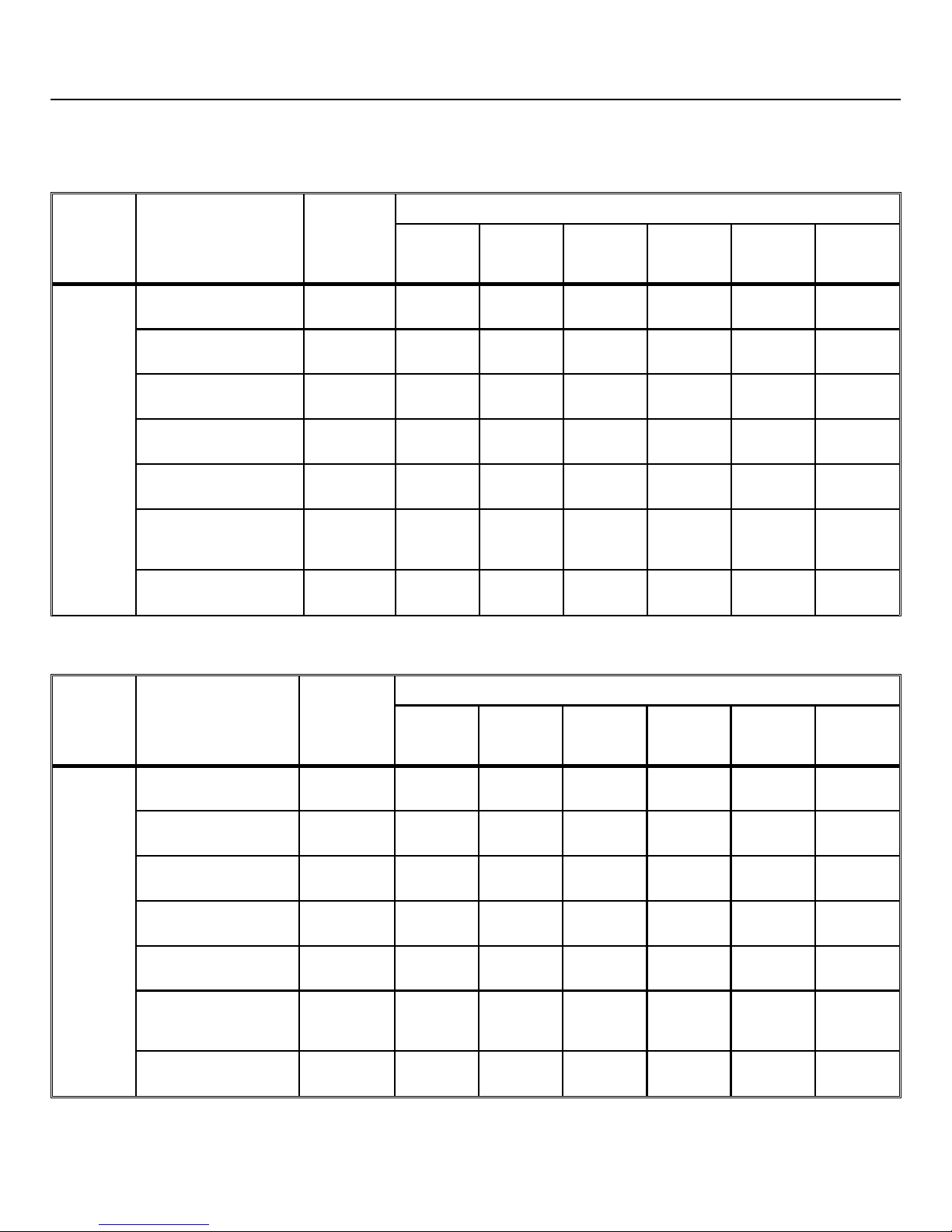

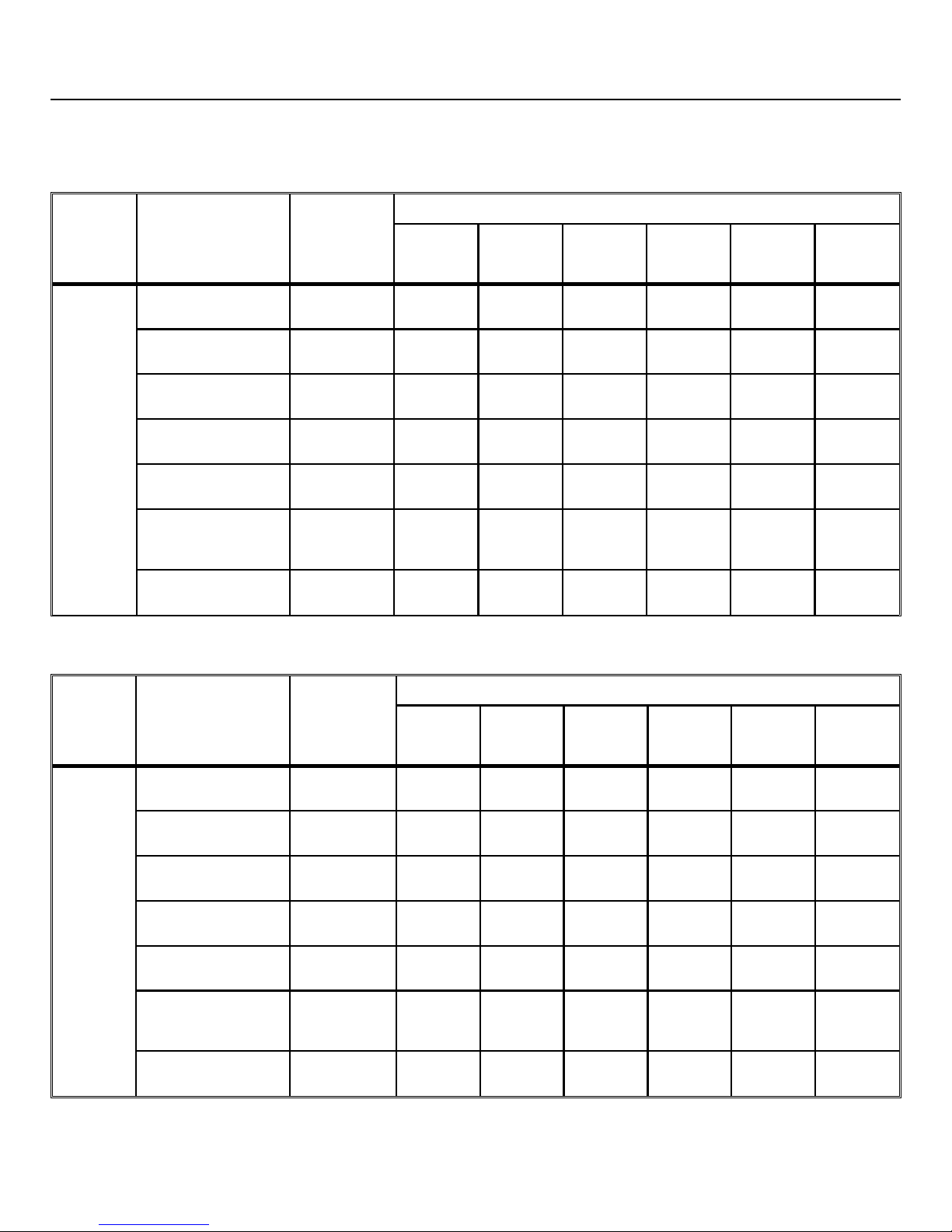

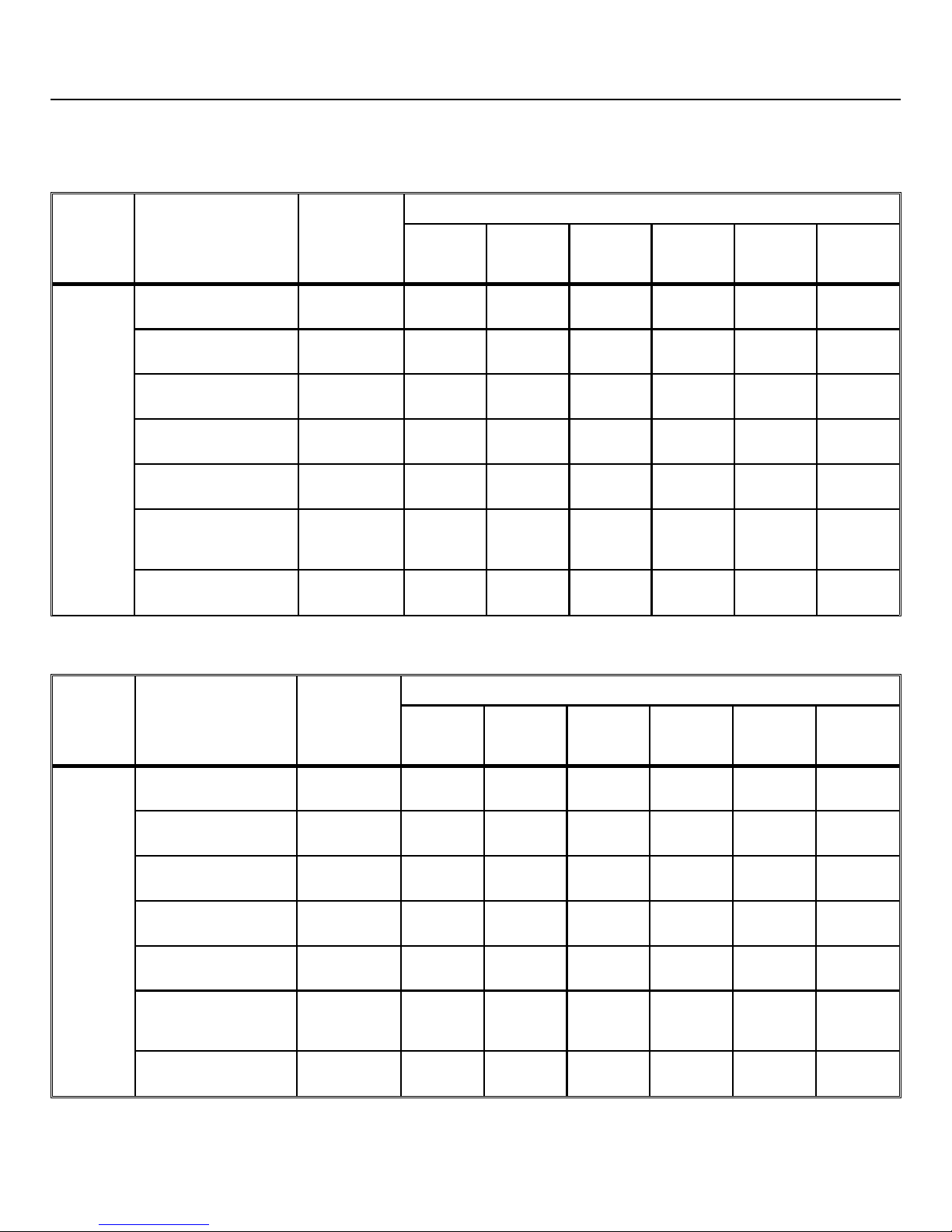

ÏCarbon Steel Fasteners

Ï

All values in foot pounds and (Newton meters)

Zinc or

Cadmium

Plated

2.5

(3.39)

(5.56)

If instructions call for :

Loctite

222 or

Loctite

242

262

3.0

(4.06)

4.9

(6.64)

3.3

(4.47)

5.5

(7.45)

Loctite

271

3.6

(4.88)

6.0

(8.13)

ÎFIGURE 5

Loctite

272

4.6

(6.23)

7.7

(10.44)

(MSSM0101CE)

Loctite

277

4.3

(5.83)

7.1

(9.63)

Bare

3.3

(4.47)

5.5

(7.46)

SAE Grade 4 4.8

(6.50)

SAE Grade 5

ASTM A449

(8.54)

SAE Grade 7 7.9

(10.7)

SAE Grade 8

ASTM A354 Grade

(12.0)

BD

ASTM A354 Grade

BC

(10.7)

6.3

8.9

7.9

5.8

(7.86)

7.6

(10.3)

9.4

(12.7)

10.7

(14.5)

9.4

(12.7)

6.4

(8.67)

8.4

(11.38)

10.5

(14.23)

11.9

(16.13)

10.5

(14.23)

7.0

(9.49)

9.3

(12.60)

11.5

(15.59)

13.1

(17.76)

11.5

(15.59)

9.0

(12.20)

11.8

(15.99)

14.7

(19.93)

16.6

(22.50)

14.7

(19.93)

8.3

(11.25)

11.0

(14.91)

13.6

(18.44)

15.4

(20.88)

13.6

(18.44)

6.4

(8.67)

8.4

(11.39)

10.5

(14.23)

11.9

(16.13)

10.5

(14.23)

MSSM0101CE/9906AV (4 of 19)

Ï

All values in foot pounds and (Newton meters)

Nominal bolt

Grade Designation

and Standard

size

1/4 - 28 SAE Grade 1

ASTM A307

SAE Grade 2 4.7

SAE Grade 4 5.5

SAE Grade 5

ASTM A449

SAE Grade 7 8.9

SAE Grade 8

ASTM A354 Grade

BD

ASTM A354 Grade

BC

Zinc or

If instructions call for :

Cadmium

Plated

Loctite

222 or

Loctite

242

Loctite

271

Loctite

272

Loctite

277

Bare

262

2.8

(3.80)

(6.37)

(7.46)

7.3

(9.90)

(12.07)

10.2

(13.83)

3.4

(4.61)

5.6

(7.60)

6.6

(8.95)

8.7

(11.80)

10.7

(14.50)

12.2

(16.54)

3.8

(5.15)

6.3

(8.54)

7.3

(9.90)

9.7

(13.15)

11.9

(16.13)

13.6

(18.44)

4.1

(5.56)

6.9

(9.36)

8.1

(10.98)

10.7

(14.50)

13.1

(17.76)

15.0

(20.34)

5.3

(7.18)

8.8

(11.93)

10.3

(13.96)

13.6

(18.44)

16.6

(22.51)

19.0

(25.76)

4.9

(6.64)

8.1

(10.98)

9.5

(12.88)

12.6

(17.08)

15.4

(20.88)

17.7

(23.99)

3.8

(5.15)

6.3

(8.54)

7.3

(9.90)

9.7

(13.15)

11.9

(16.13)

13.6

(18.44)

———————

Nominal

bolt size

Grade Designation

and Standard

5/16 - 18 SAE Grade 1

ASTM A307

SAE Grade 2 8.5

SAE Grade 4 10.0

SAE Grade 5

ASTM A449

SAE Grade 7 16.1

SAE Grade 8 ASTM

A354 Grade BD

ASTM A354 Grade

BC

Ï

All values in foot pounds and (Newton meters)

Zinc or

If instructions call for :

Cadmium

Plated

Loctite

222

Loctite

242

Loctite

271

or262

5.1

(6.91)

(11.52)

(13.56)

13.0

(17.63)

(21.83)

18.5

(25.08)

16.1

(21.83)

6.2

(8.40)

10.2

(13.83)

12.0

(16.27)

15.6

(21.15)

19.3

(26.17)

22.1

(29.96)

19.3

(26.17)

6.8

(9.22)

11.3

(15.32)

13.3

(18.03)

17.4

(23.60)

21.5

(29.15)

24.6

(33.35)

21.5

(29.15)

7.5

(10.17)

12.5

(16.95)

14.6

(19.79)

19.1

(25.90)

23.6

(31.99)

27.1

(36.74)

23.6

(31.99)

Loctite

272

9.6

(13.02)

15.9

(21.56)

18.6

(25.22)

24.3

(32.95)

30.1

(40.81)

34.5

(46.78)

30.1

(40.81)

Loctite

277

8.9

(12.07)

14.7

(19.93)

17.3

(23.46)

22.6

(30.64)

27.9

(37.83)

32.0

(43.39)

27.9

(37.83)

Bare

6.8

(9.22)

11.3

(15.32)

13.3

(18.03)

17.4

(23.60)

21.5

(29.15)

24.6

(33.35)

21.5

(29.15)

FASTENER TORQUE REQUIREMENTS MSSM0101CE/9906AV (5 of 19)

Ï

All values in foot pounds and (Newton meters)

Nominal

bolt size

Grade Designation

and Standard

5/16 - 24 SAE Grade 1

ASTM A307

SAE Grade 2 9.4

SAE Grade 4 11.0

SAE Grade 5

ASTM A449

SAE Grade 7 17.9

SAE Grade 8

ASTM A354 Grade

BD

ASTM A354 Grade

BC

Zinc

If instructions call for :

orCadmium

Plated

Loctite

222 or

Loctite

242

Loctite

271

Loctite

272

Loctite

277

Bare

262

5.6

(7.59)

(12.74)

(14.91)

14.4

(19.52)

(24.27)

20.4

(27.66)

6.7

(9.08)

11.3

(15.32)

13.2

(17.90)

17.2

(23.32)

21.4

(29.01)

24.4

(33.08)

7.4

(10.03)

12.5

(16.94)

14.6

(19.79)

19.1

(25.90)

23.8

(32.27)

27.1

(36.74)

8.2

(11.12)

13.8

(18.71)

16.1

(21.83)

21.1

(28.60)

26.2

(35.52)

29.9

(40.54)

10.4

(14.10)

17.5

(23.73)

20.5

(27.79)

26.8

(36.35)

33.4

(45.28)

38.0

(51.52)

9.6

(13.01)

16.3

(22.09)

19.0

(25.76)

24.9

(33.76)

31.0

(42.03)

35.3

(47.86)

(10.03)

12.5

(16.94)

14.6

(19.79)

19.1

(25.90)

23.8

(32.27)

27.1

(36.74)

— ——————

7.4

Nominal

bolt size

Grade

Designation and

Standard

3/8 - 16 SAE Grade 1

ASTM A307

SAE Grade 2 14.9

SAE Grade 4 17.8

SAE Grade 5

ASTM A449

SAE Grade 7 28.7

SAE Grade 8

ASTM A354

Grade BD

ASTM A354

Grade BC

Ï

All values in foot pounds and (Newton meters)

Zinc or

If instructions call for :

Cadmium

Plated

Loctite

222 or

Loctite

242

Loctite

271

262

9.0

(12.20)

(20.20)

(24.13)

23.2

(31.45)

(38.91)

32.7

(44.33)

28.7

(38.91)

10.8

(14.64)

17.9

(24.27)

21.3

(28.88)

27.8

(37.69)

34.4

(46.64)

39.2

(53.15)

34.4

(46.64)

12.0

(16.27)

19.9

(26.98)

23.7

(32.13)

30.9

(41.89)

38.2

(51.79)

43.6

(59.11)

38.2

(51.79)

13.1

(17.76)

21.9

(29.69)

26.0

(35.25)

34.0

(46.09)

42.0

(56.94)

48.0

(65.08)

42.0

(56.94)

Loctite

272

16.7

(22.64)

27.9

(37.83)

33.1

(44.87)

43.3

(58.70)

53.5

(72.54)

61.0

(82.70)

53.5

(72.54)

Loctite

277

15.5

(21.01)

25.9

(35.11)

30.8

(41.76)

40.2

(54.50)

49.7

(67.39)

56.7

(76.87)

49.7

(67.39)

Bare

12.0

(16.27)

19.9

(26.98)

23.7

(32.13)

30.9

(41.89)

38.2

(51.79)

43.6

(59.11)

38.2

(51.79)

MSSM0101CE/9906AV (6 of 19)

Ï

All values in foot pounds and (Newton meters)

Nominal

bolt size

Grade Designation

and Standard

3/8 - 24 SAE Grade 1

ASTM A307

SAE Grade 2 16.9

SAE Grade 4 20.0

SAE Grade 5

ASTM A449

SAE Grade 7 32.3

SAE Grade 8

ASTM A354 Grade

BD

ASTM A354 Grade

BC

Zinc or

If instructions call for :

Cadmium

Plated

Loctite

222 or

Loctite

242

Loctite

271

Loctite

272

Loctite

277

Bare

262

10.2

(13.83)

(22.91)

(27.11)

26.2

(35.52)

(43.79)

36.9

(50.02)

12.2

(16.54)

20.3

(27.52)

24.0

(32.54)

31.4

(42.57)

38.8

(52.60)

44.3

(60.06)

13.6

(18.44)

22.5

(30.52)

26.7

(36.20)

34.9

(47.32)

43.1

(58.44)

49.2

(66.70)

15.0

(20.33)

24.8

(33.62)

29.4

(39.86)

38.4

(52.06)

47.4

(64.26)

54.1

(73.35)

19.0

(25.76)

31.5

(42.70)

37.4

(50.70)

48.9

(66.30)

60.4

(81.89)

68.9

(93.41)

17.7

(24.00)

29.3

(39.73)

34.7

(47.04)

45.4

(61.55)

56.1

(76.06)

64.0

(86.77)

13.6

(18.44)

22.5

(30.50)

26.7

(36.20)

34.9

(47.32)

43.1

(58.43)

49.2

(66.70)

— ——————

Nominal

bolt size

Grade Designation

and Standard

7/16 - 14 SAE Grade 1

ASTM A307

SAE Grade 2 24.0

SAE Grade 4 28.3

SAE Grade 5

ASTM A449

SAE Grade 7 45.9

SAE Grade 8

ASTM A354 Grade

BD

ASTM A354 Grade

BC

Ï

All values in foot pounds and (Newton meters)

Zinc or

If instructions call for :

CadmiumPlated

Loctite

222 or

Loctite

242

Loctite

271

262

14.0

(18.98)

(32.54)

(38.37)

37.1

(50.30)

(62.23)

52.5

(71.18)

45.7

(61.96)

17.0

(23.04)

28.8

(39.05)

34.0

(46.10)

44.5

(60.33)

55.1

(74.70)

63.0

(85.41)

54.9

(74.43)

19.14

(25.95)

32.0

(43.39)

37.7

(51.11)

49.5

(67.11)

61.3

(83.11)

70.0

(94.90)

61.0

(82.70)

21.0

(28.47)

35.2

(47.72)

41.5

(56.27)

54.4

(73.76)

67.4

(91.38)

77.0

(104.40)

67.1

(90.97)

Loctite

272

27.0

(36.60)

44.8

(60.74)

52.8

(71.59)

69.3

(93.96)

85.8

(116.33)

98.0

(132.87)

85.4

(115.79)

Loctite

277

25.0

(33.89)

41.6

(56.40)

49.1

(66.57)

64.3

(87.18)

79.6

(107.92)

91.0

(123.38)

79.3

(107.52)

Bare

19.0

(25.76)

32.0

(43.39)

37.7

(51.11)

49.5

(67.11)

61.3

(83.11)

70.0

(94.90)

61.0

(82.70)

FASTENER TORQUE REQUIREMENTS MSSM0101CE/9906AV (7 of 19)

Ï

All values in foot pounds and (Newton meters)

Nominal

bolt size

Grade

Designation and

Standard

7/16 - 20 SAE Grade 1

ASTM A307

SAE Grade 2 26.9

SAE Grade 4 31.6

SAE Grade 5

ASTM A449

SAE Grade 7 51.3

SAE Grade 8

ASTM A354

Grade BD

ASTM A354

Grade BC

Zinc or

If instructions call for :

Cadmium

Plated

Loctite

222 or

Loctite

242

Loctite

271

Loctite

272

Loctite

277

Bare

262

16.0

(21.70)

(36.48)

(42.84)

41.4

(56.13)

(69.55)

58.2

(78.90)

19.2

(26.03)

32.2

(43.66)

37.9

(51.39)

49.7

(67.38)

61.5

(83.38)

69.9

(94.77)

21.3

(28.88)

35.8

(48.54)

42.1

(57.08)

55.2

(74.84)

68.4

(92.74)

77.7

(105.35)

23.5

(31.86)

39.4

(53.42)

46.3

(62.77)

60.8

(82.43)

75.2

(101.96)

85.4

(115.78)

29.9

(40.54)

50.1

(67.93)

59.0

(79.99)

77.3

(104.80)

95.7

(129.75)

108.7

(147.37)

27.7

(37.56)

46.6

(63.18)

54.7

(74.16)

71.8

(97.35)

88.9

(120.53)

101.0

(136.94)

(28.88)

(48.54)

(57.08)

(74.84)

(92.74)

(105.35)

— ——————

21.3

35.8

42.1

55.2

68.4

77.7

Nominal

bolt size

Grade

Designation and

Standard

1/2 - 13 SAE Grade 1

ASTM A307

SAE Grade 2 36.6

SAE Grade 4 43.1

SAE Grade 5

ASTM A449

SAE Grade 7 69.8

SAE Grade 8

ASTM A354

Grade BD

ASTM A354

Grade BC

Ï

All values in foot pounds and (Newton meters)

Zinc or

If instructions call for :

Cadmium

Plated

Loctite

222

Loctite

242

Loctite

271

or262

22.0

(29.83)

(49.62)

(58.44)

56.7

(76.87)

(94.64)

79.7

(108.05)

69.8

(94.64)

26.0

(35.25)

43.9

(59.52)

51.8

(70.23)

68.1

(92.33)

83.8

(113.62)

95.6

(129.62)

83.8

(113.62)

29.38

(39.83)

48.8

(66.16)

57.5

(77.96)

75.6

(102.5)

93.1

(126.23)

106.3

(144.12)

93.1

(126.23)

32.0

(43.39)

53.6

(72.67)

63.3

(85.82)

83.2

(112.80)

102.4

(138.84)

116.9

(158.50)

102.4

(138.84)

Loctite

272

41.0

(55.59)

68.3

(92.60)

80.5

(109.14)

105.9

(143.58)

130.4

(176.80)

148.8

(201.75)

130.4

(176.80)

Loctite

277

38.0

(51.52)

63.4

(85.96)

74.8

(101.42)

98.3

(133.27)

121.1

(164.19)

138.1

(187.24)

121.1

(164.19)

Bare

29.0

(39.32)

48.8

(66.16)

57.5

(77.96)

75.6

(102.50)

93.1

(126.23)

106.3

(144.12)

93.1

(126.23)

MSSM0101CE/9906AV (8 of 19)

Ï

All values in foot pounds and (Newton meters)

Nominal

bolt size

Standard and

Grade Designation

1/2 - 20 SAE Grade 1

ASTM A307

SAE Grade 2 41.3

SAE Grade 4 48.8

SAE Grade 5

ASTM A449

SAE Grade 7 78.8

SAE Grade 8

ASTM A354 Grade

BD

ASTM A354 Grade

BC

Zinc or

If instructions call for :

Cadmium

Plated

Loctite

222 or

Loctite

242

Loctite

271

Loctite

272

Loctite

277

Bare

262

24.8

(33.62)

(56.00)

(66.16)

63.8

(86.50)

(106.84)

90.0

(122.02)

29.8

(40.40)

49.5

(67.11)

58.5

(79.32)

76.5

(103.72)

94.5

(128.12)

108.0

(146.43)

33.1

(44.88)

55.0

(74.57)

65.0

(88.13)

85.0

(115.24)

105.0

(142.36)

120.0

(162.70)

36.4

(49.35)

60.5

(82.02)

71.5

(96.94)

93.5

(126.77)

115.5

(156.60)

132.0

(179.00)

46.4

(62.91)

77.0

(104.40)

91.0

(123.38)

119.0

(161.34)

147.0

(199.30)

168.0

(277.78)

43.1

(58.44)

71.5

(96.94)

84.5

(114.57)

110.5

(149.82)

136.5

(185.07)

156.0

(211.51)

(44.88)

(74.57)

(88.13)

(115.24)

(142.36)

(162.70)

— ——————

33.1

55.0

65.0

85.0

105.0

120.0

Nominal

bolt size

Grade Designation

and Standard

9/16 - 12 SAE Grade 1

ASTM A307

SAE Grade 2 52.7

SAE Grade 4 62.2

SAE Grade 5

ASTM A449

SAE Grade 7 100.7

SAE Grade 8

ASTM A354 Grade

BD

ASTM A354 Grade

BC

Ï

All values in foot pounds and (Newton meters)

Zinc or

If instructions call for :

Cadmium

Plated

Loctite

222

Loctite

242

Loctite

271

or 262

32.0

(43.39)

(71.45)

(84.33)

81.7

(110.77)

(136.53)

115.0

(155.92)

100.7

(136.53)

38.0

(51.52)

63.3

(85.82)

74.7

(101.28)

98.1

(133.00)

120.9

(163.92)

138.0

(187.10)

120.9

(163.92)

42.19

(57.20)

70.3

(95.31)

83.0

(112.53)

109.0

(147.78)

134.3

(182.09)

153.3

(207.85)

134.3

(182.09)

46.0

(62.37)

77.3

(104.80)

91.3

(123.79)

119.9

(162.56)

147.7

(200.25)

168.6

(228.59)

147.7

(200.25)

Loctite

272

59.0

(80.00)

98.4

(133.41)

116.2

(157.55)

152.6

(206.90)

188.0

(254.89)

214.6

(290.96)

188.0

(254.89)

Loctite

Bare

277

55.0

(74.57)42(56.94)

91.4

(123.92)

107.9

(146.30)

141.7

(192.17)

174.6

(236.73)

199.3

(270.21)

174.6

(236.73)

70.3

(95.31)

83.0

(112.53)

109.0

(147.78)

134.3

(182.09)

153.3

(207.85)

134.3

(182.09)

Loading...

Loading...