Page 1

Page 2

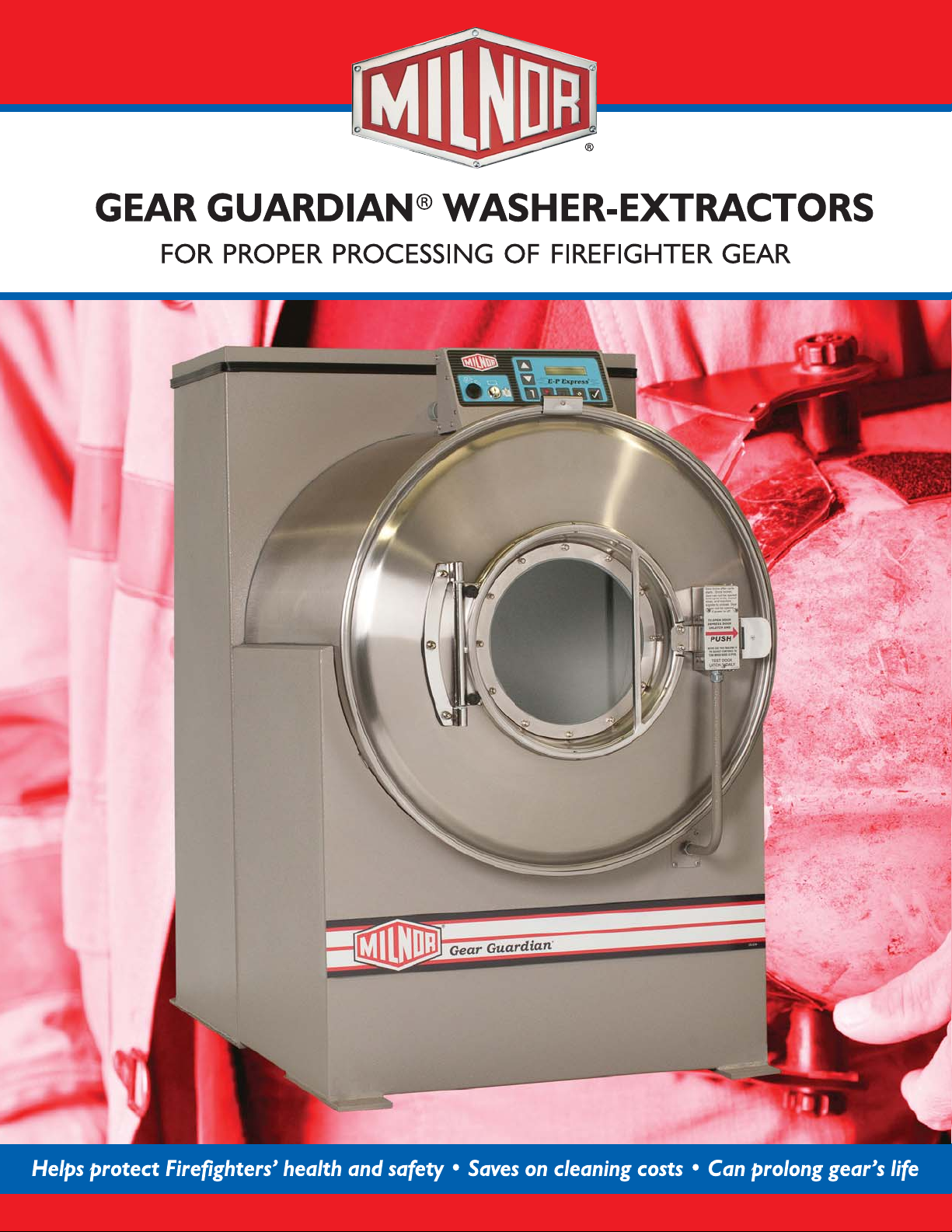

PROTECT FIREFIGHTER GEAR WITH

GEAR GUARDIAN WASHER-EXTRACTORS

Created specifically for firefighter gear

Gear Guardian washer-extractors have 30 different programmable

wash formulas, including 10 pre-programmed strictly for processing

firefighter gear (all 10 can be re-programmed). User-friendly microprocessor controls prompt you through each programming step and

prevent errors. And, all Gear Guardian washer-extractors comply with

NFPA 1851 standards in maintenance and care of protective gear.

Pre-programmed wash formulas

get you started quickly:

1. Light soil turnouts

2. Heavy soil turnouts/gloves

3. Light soil moisture barriers

4. Heavy soil moisture barriers

5. Oil-contaminated gear

6. Brush gear

7. Hoods/suspenders

8. Truck towels

9. Stationwear

10. Sheets/pillow cases

Easy Operation

Anyone can operate a MILNOR Gear Guardian washer-extractor.

Formula choices are clear. Just pick the right formula and press the

start button. Then full automation takes over. The machine also keeps

you informed by displaying information, including what function is

underway and how much formula time remains. Any trouble with the

machine? Check troubleshooting messages to minimize downtime.

Control protects turnouts by not allowing gear to tumble during fill.

And automatic supply injection means no attention is needed while

the machine is washing.

Helps avoid vibration

A special load distribution speed – before extraction – prevents bulky

gear from creating an imbalance inside the cylinder. This helps avoid

vibration during the extraction. Besides saving time (since you don’t

have to stop the machine to manually correct the load), less vibration

means longer machine life.

Distribution speed also protects gear by preventing tumbling action

while water is draining from the cylinder.

Rugged Construction

Firefighters with bulky, heavy turnouts can be rough on a machine –

but not a Gear Guardian washer-extractor. It’s built for long service

under tough conditions – by the most respected name in commercial

laundry machinery.

Features include continuous (rather than spot) welding, large tapered

roller bearings, with a triple shaft seal to shield bearings from water on

most models, heavy gauge console materials, and heavy-duty motors.

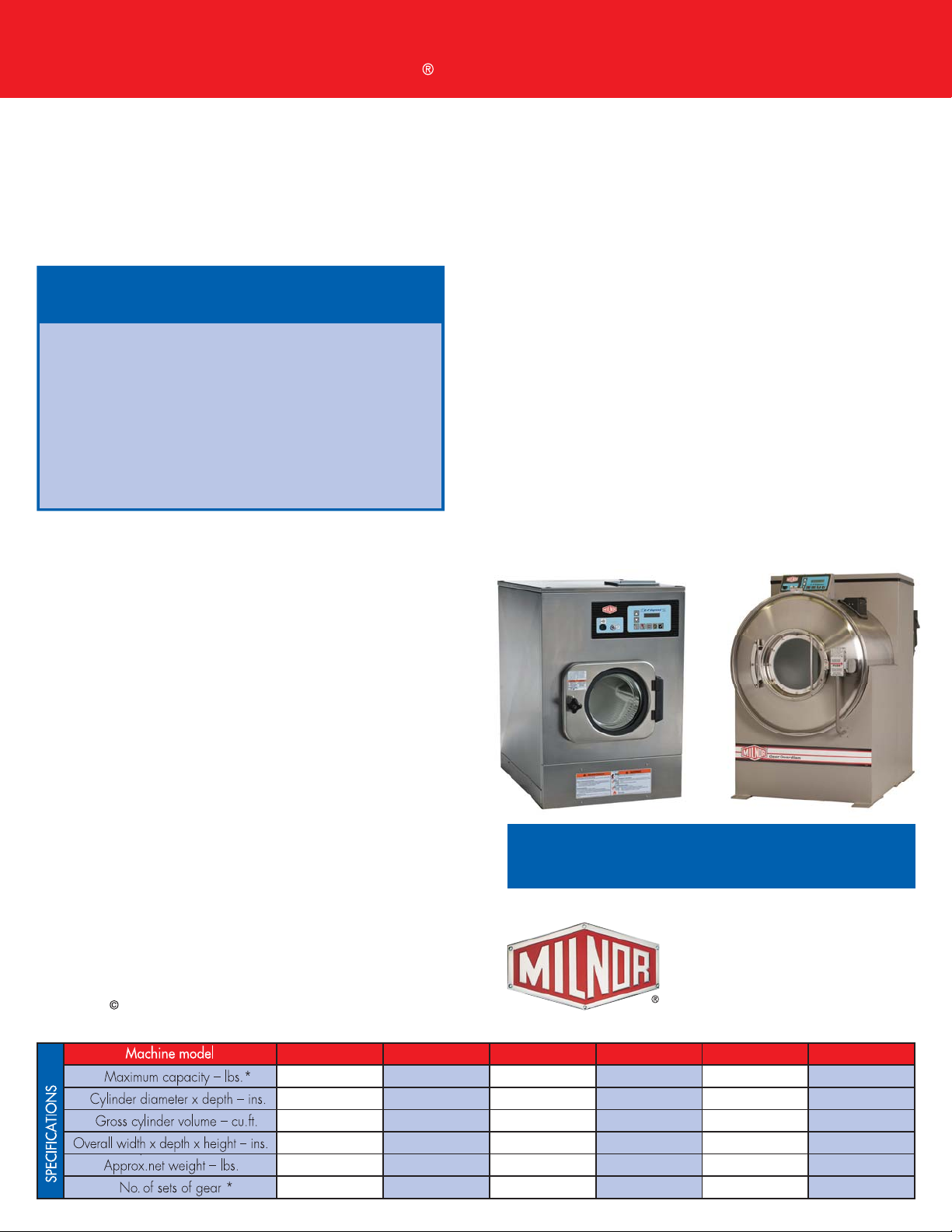

A choice in sizes

Gear Guardian washer-extractors are available from 35 lb. to 100 lb.

capacities. The size you choose depends on the amount of gear you

need to process within a given timeframe.

Roomy wash cylinders

Firefighting gear is bulky, so the spacious Gear Guardian cylinder

is essential for a fast, commercial-quality wash. Big ribs lift and drop

gear to help remove heavy soil. The large cylinder cuts processing time

and you can launder more gear per load.

Speeds processing

Heavily-soiled firefighting gear needs effective rinsing. Intermediate

extractions “sling” water and chemicals from gear prior to the next

rinse. So, gear gets cleaner faster! Gear Guardian washer-extractors

have the unique ability to allow as many intermediate extractions as

you need, since they use continuous duty (rather than intermittent

duty) motors. Low extract speeds are used with MILNOR Gear

Guardian machines to better protect turnout gear. High spin cycles

can damage these valuable goods.

Pellerin Milnor Corporation Printed in U.S.A.

B22SL91032/12266

MWR16X5 30015T5X & V7J MWR18X4 30022T5X & V6J 36021 V5J 36026 V5J

35 40 45 60 80 100

23 x 18 30 x 15 28 x 18 30 x 22 36 x 21 36 x 26

4.3 6.14 6.4 9 12.37 15.3

29 x 42 x 42.38 34.5 x 45.75 x 54 34.45 x 47.63 x 52.63 34.5 x 52.25 x 54 43.38 x 53 x 67 43.38 x 58 x 67

495 740 & 844 760 895 & 909 1240 1310

1 to 2 2 to 3 3 4 to 5 6 to 7 8 to 9

*Depending on density and soil content of goods. For complete technical information, please request bid specifications. Specifications and appearance subject to change without notice.

35 1b. model 60 1b. model

Budget models, too! If you’re on a tight budget, T-series machines

and cabinet models are available with lower extraction rates.

PELLERIN MILNOR CORPORATION

P.O. BOX 400 - Kenner, LA 70063

504/467-9591

Fax: 504/468-3094

Email: milnorinfo@milnor.com

www.milnor.com

Loading...

Loading...